Adjustable high-frequency vibration assisted electromagnetic forming device and method

A high-frequency vibration, electromagnetic forming technology, applied in the direction of improving energy efficiency and process efficiency, can solve the problems of workpiece deformation, difficulty in forming depth to meet requirements, low amplitude, etc., to achieve uniform current, reduce yield strength and flow. Stress, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below through specific embodiments.

[0036] A certain intensity of vibration can effectively reduce the flow stress and deformation resistance of the metal material, increase the elongation, and significantly change the forming properties of the material, which helps to enter the plastic stage earlier and reduce the energy required for the forming of the workpiece. Combined with electromagnetic forming technology, it is expected to greatly improve the forming limit and forming quality of materials, effectively solve the problems of difficult deformation and unsatisfactory forming depth, and provide a promising new way for the forming and manufacturing of lightweight materials.

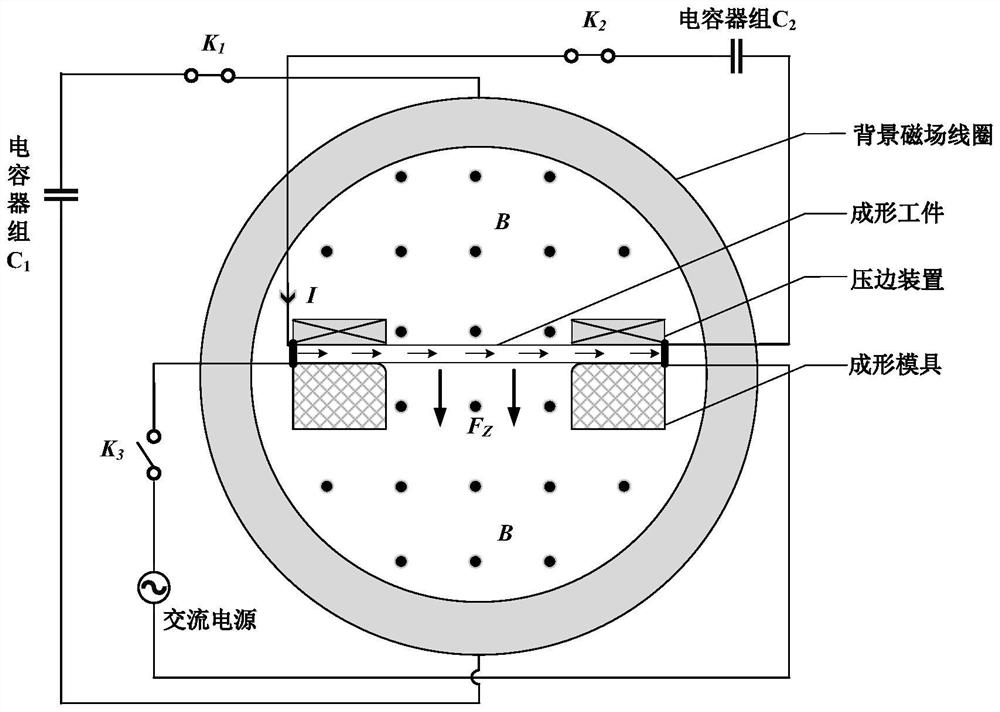

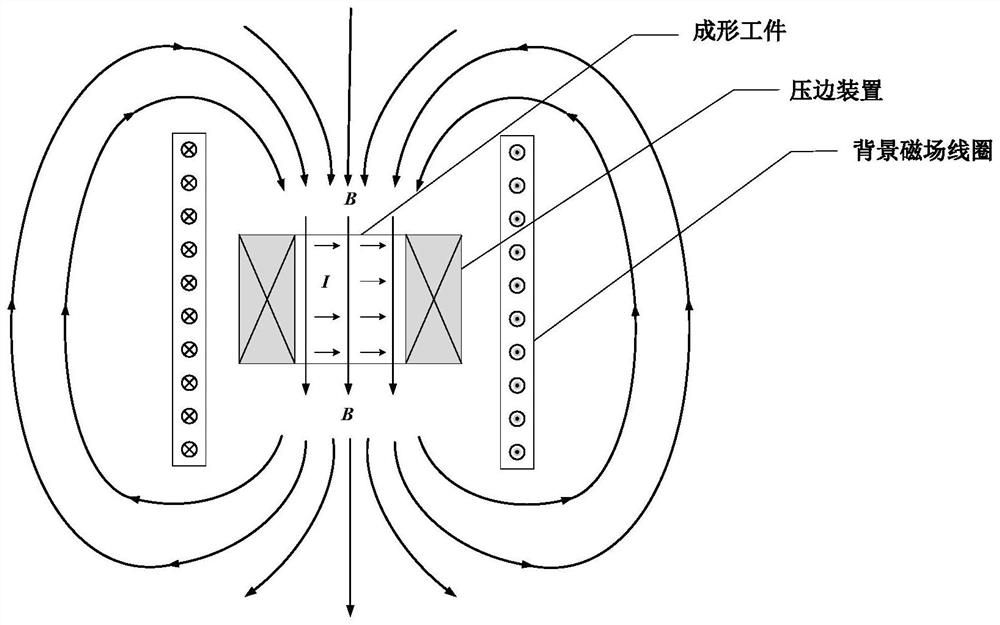

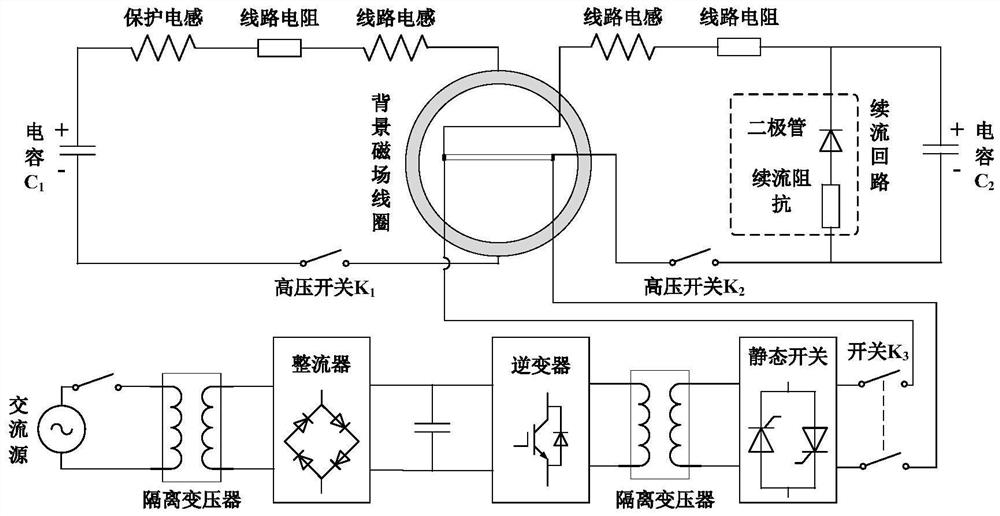

[0037] In this embodiment, the present invention is applied to the sheet metal forming process. figure 1 The overall schematic diagram of the electromagnetic forming device assisted by adjustable high-frequency vibration.

[0038] like Figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com