Patents

Literature

101results about How to "Lower yield stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modification of pb-free solder alloy compositions to improve interlayer dielectric delamination in silicon devices and electromigration resistance in solder joints

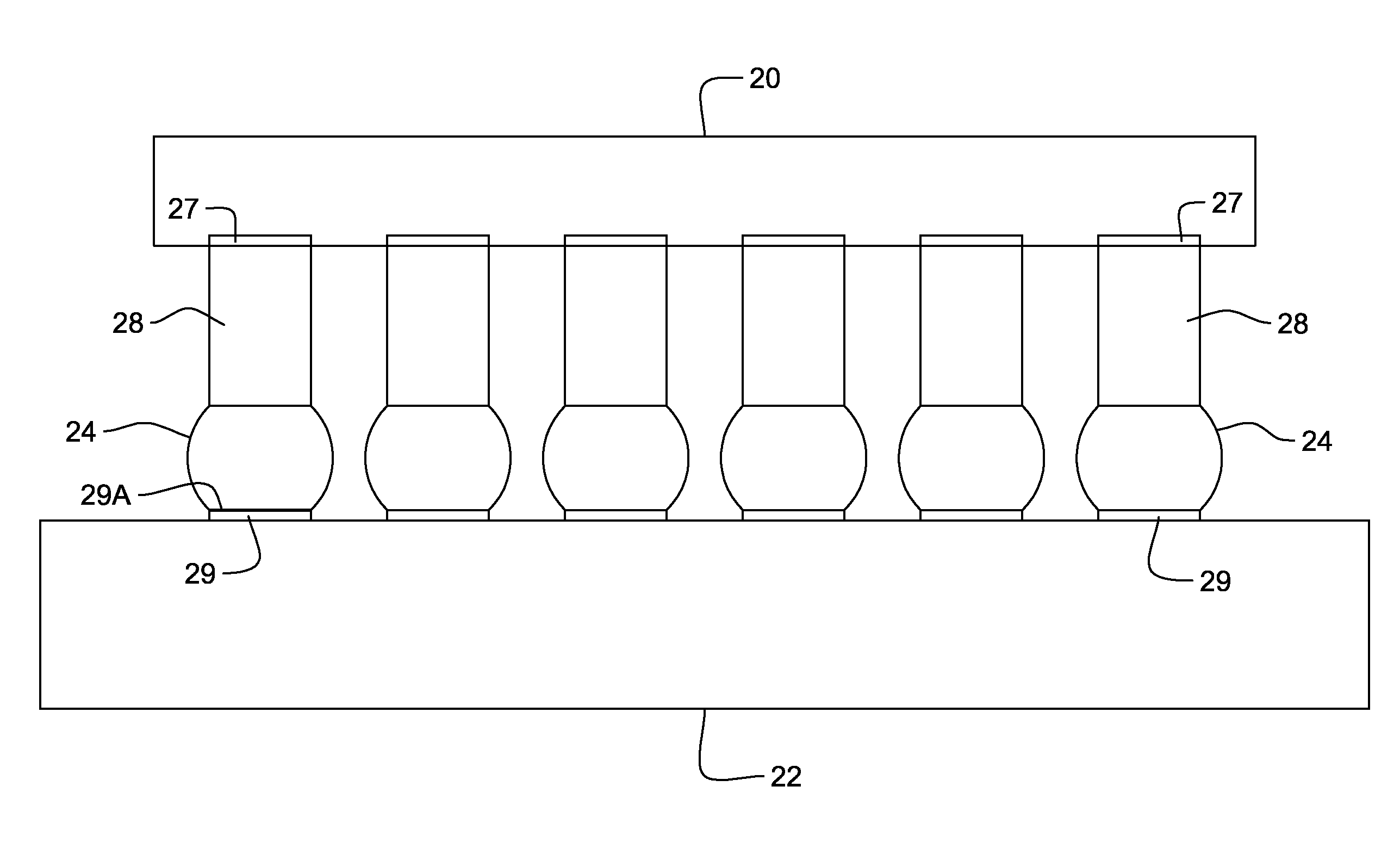

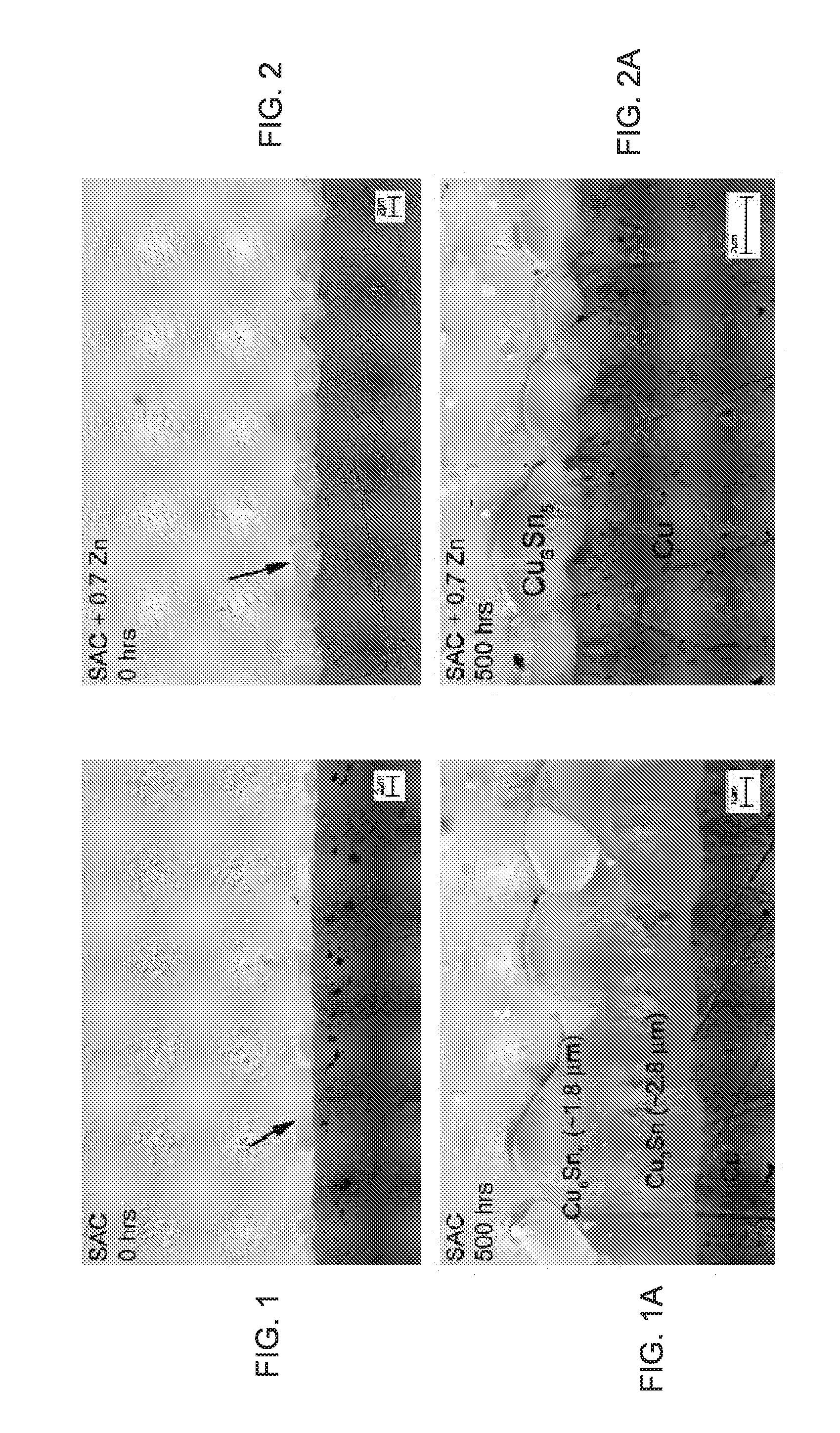

InactiveUS20090197114A1Good mechanical integrityImprove reliabilitySolid-state devicesPrinted circuit manufactureDielectricSilicon

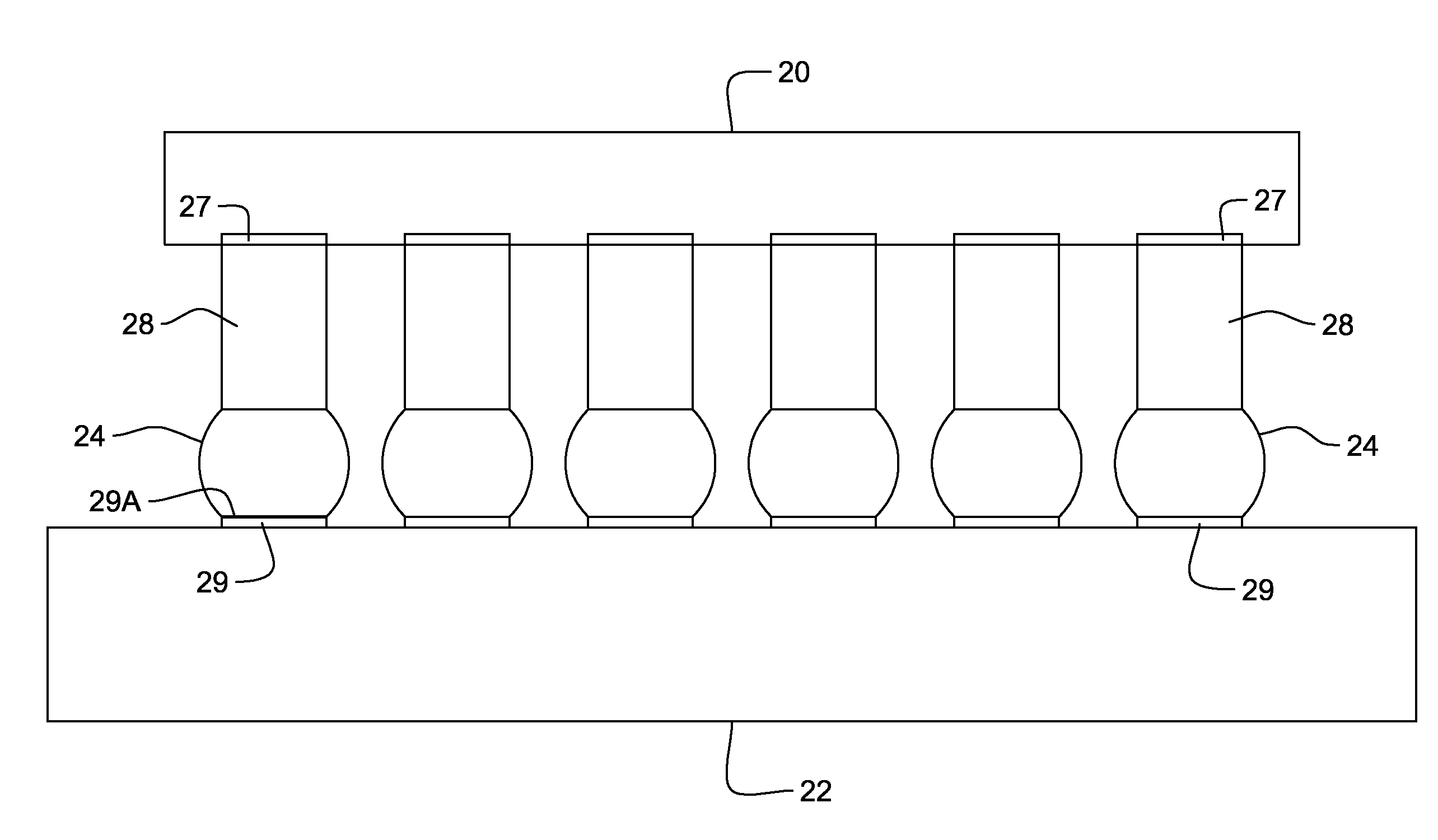

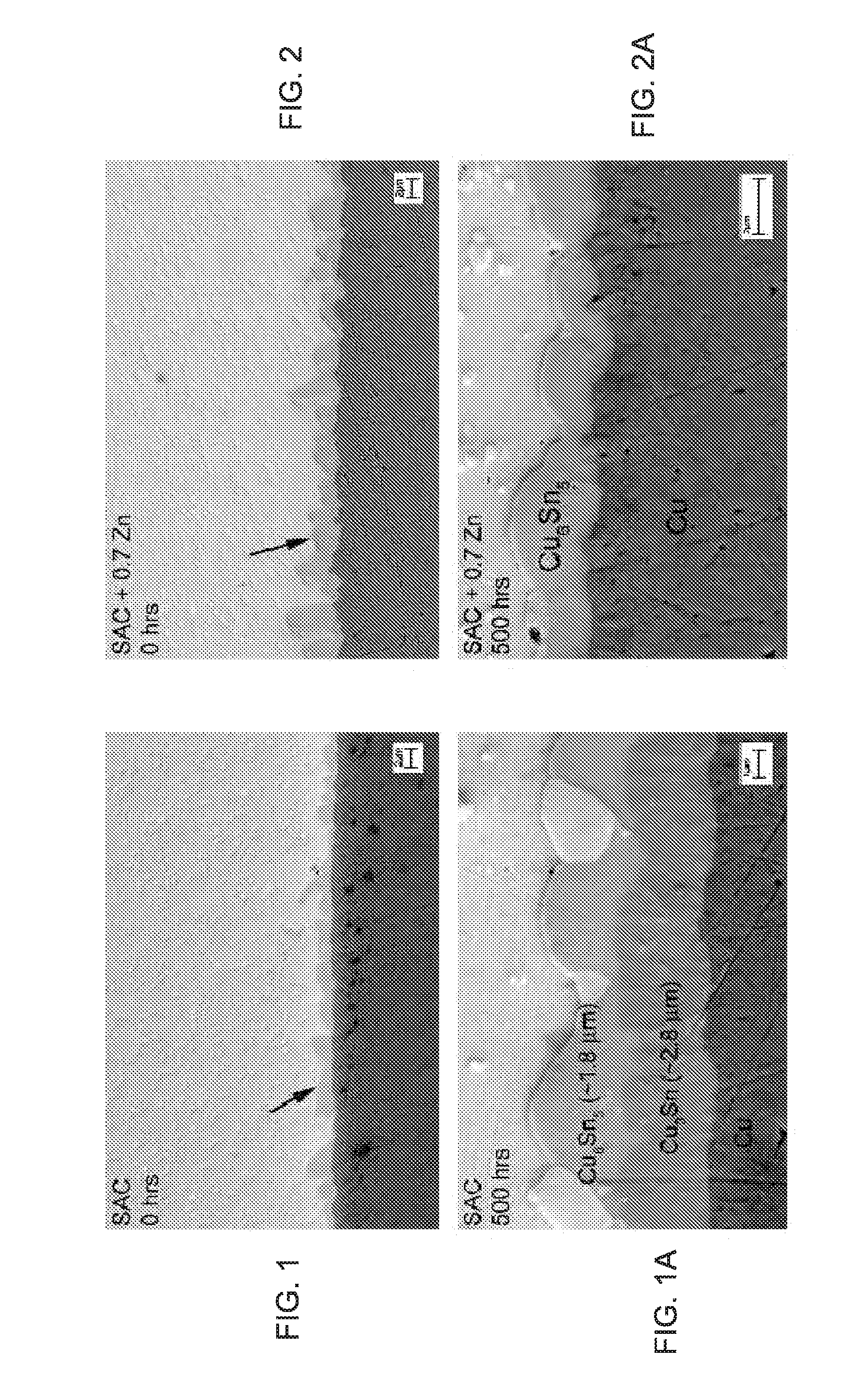

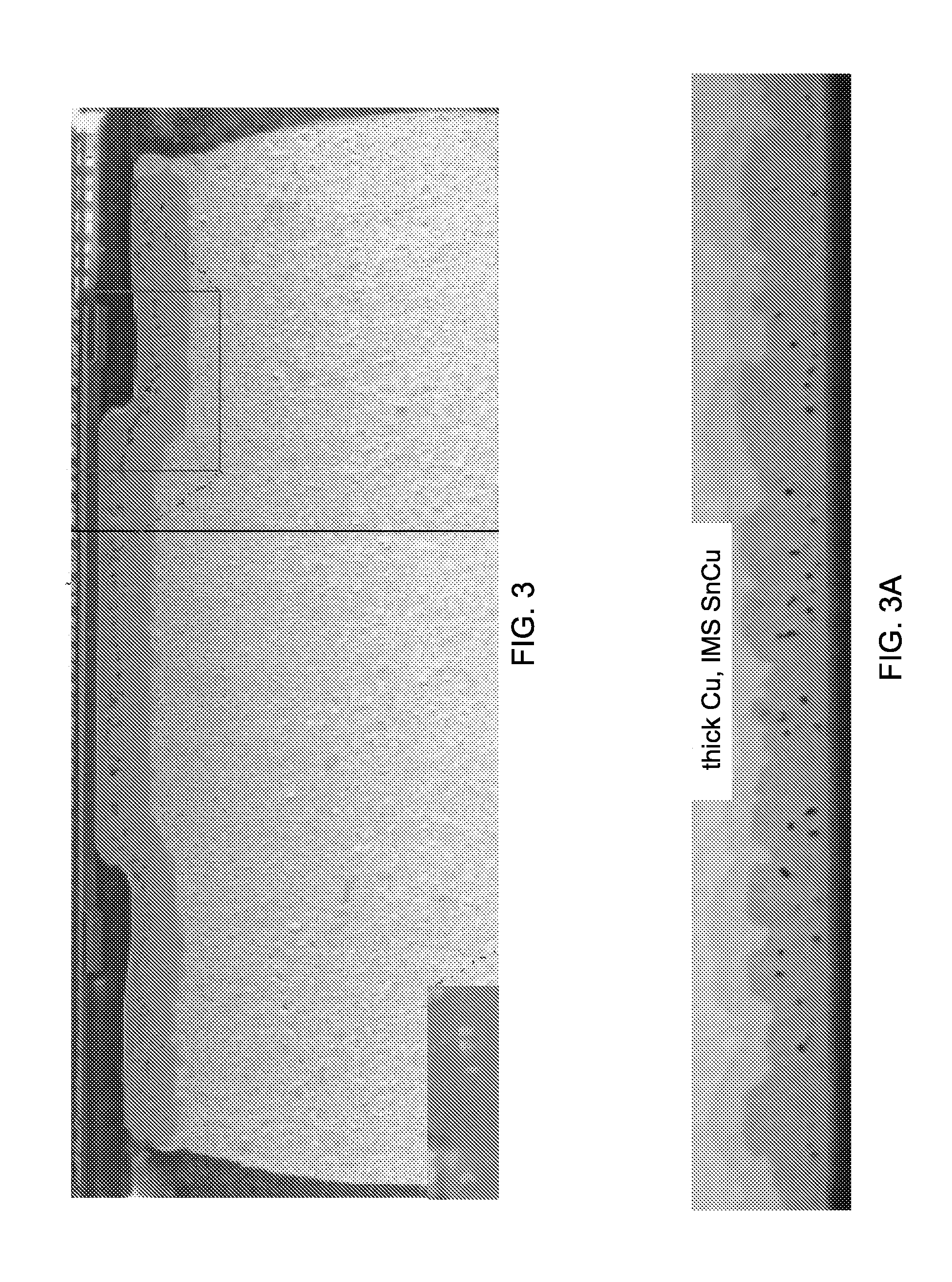

A solder joint comprising a solder capture pad on a substrate having a circuit; and a lead free solder selected from the group comprising Sn—Ag—Cu solder and Sn—Ag solder adhered to the solder capture pad; the solder selected from the group comprising between 0.1 to 2.0% by weight Sb or Bi, and 0.5 to 3.0% Ag. Formation of voids at an interface between the solder and the solder capture pad is suppressed, by including Zn. Interlayer dielectric delamination is suppressed, and electromigration characteristics are greatly improved. Methods for forming solder joints using the solders.

Owner:SHIH YUAN +5

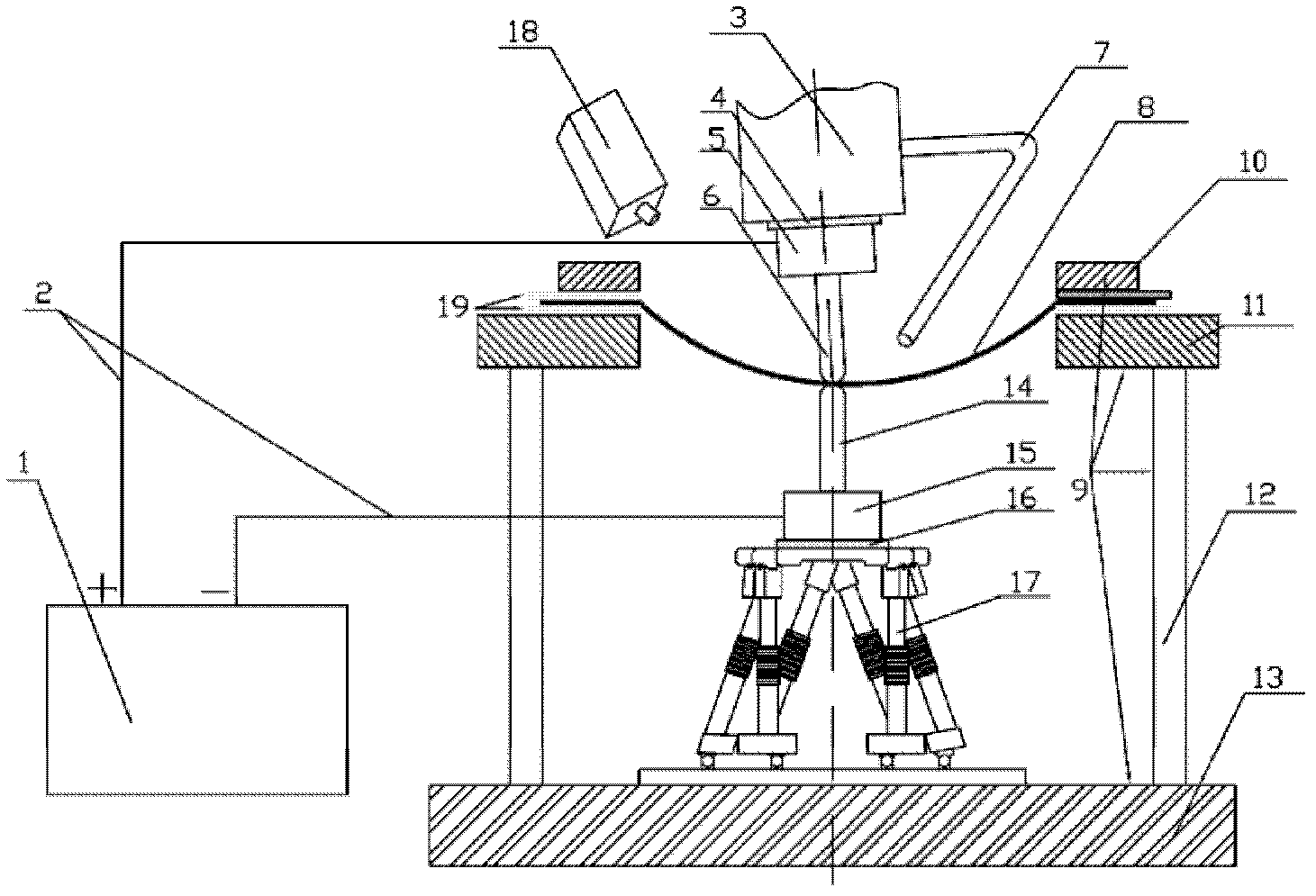

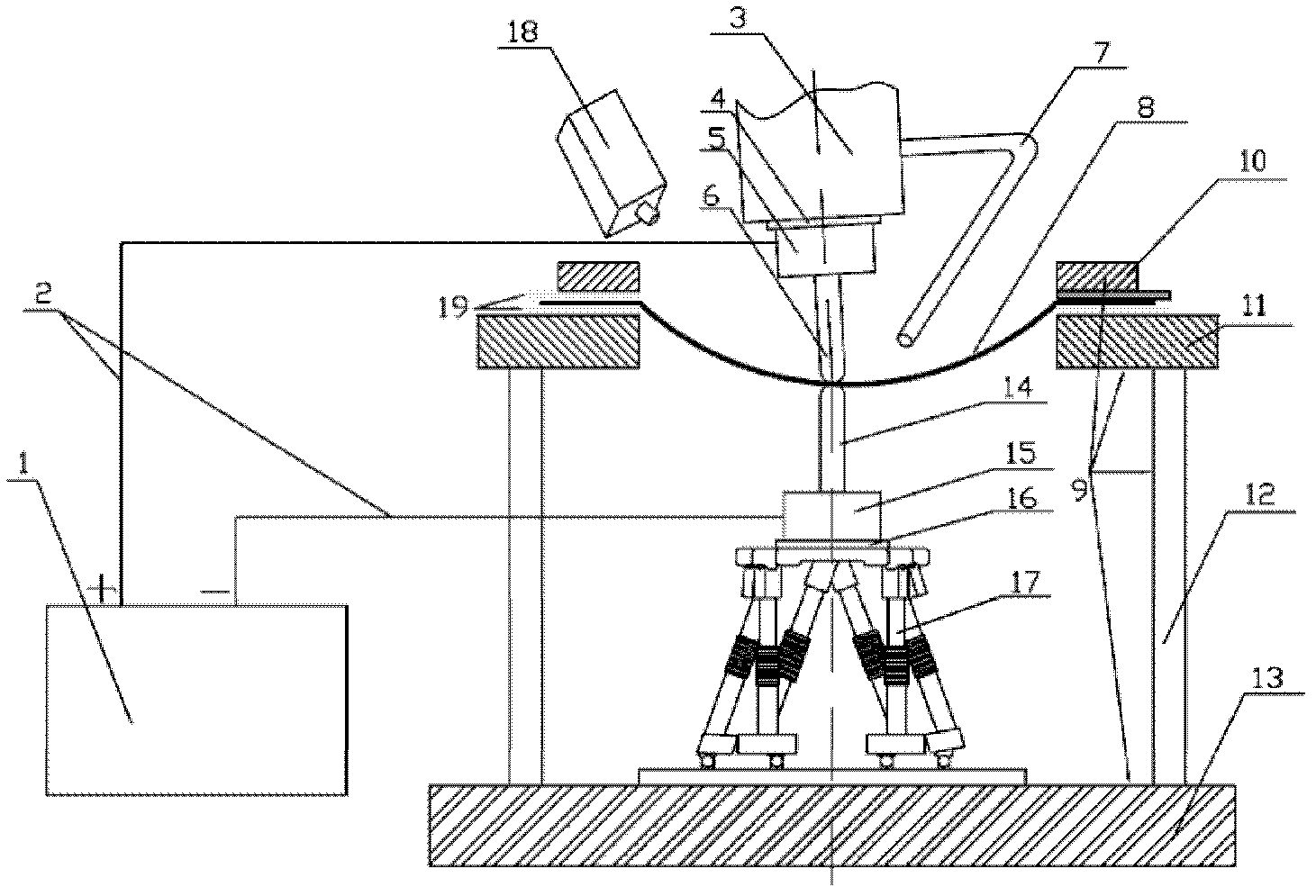

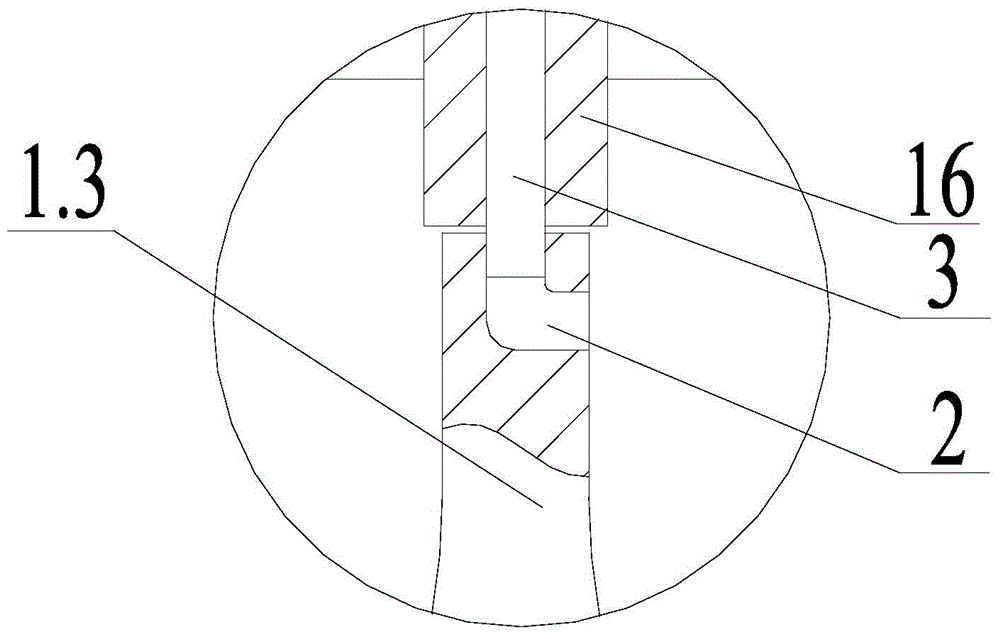

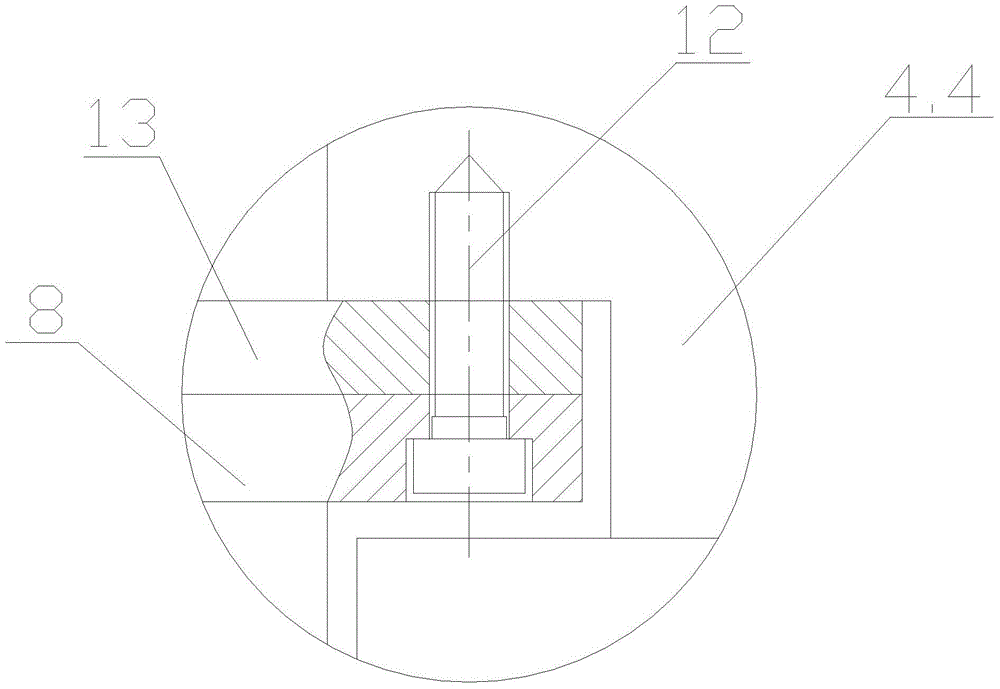

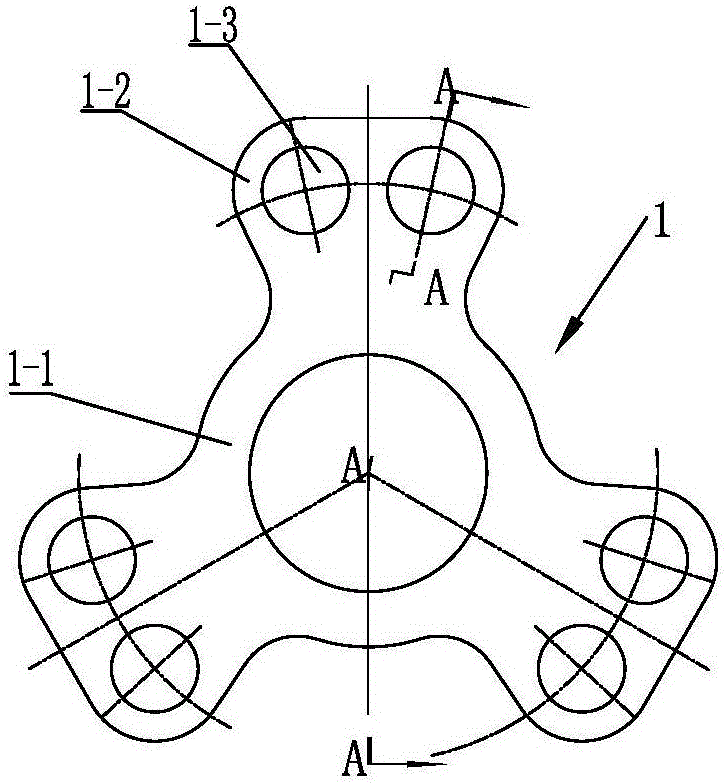

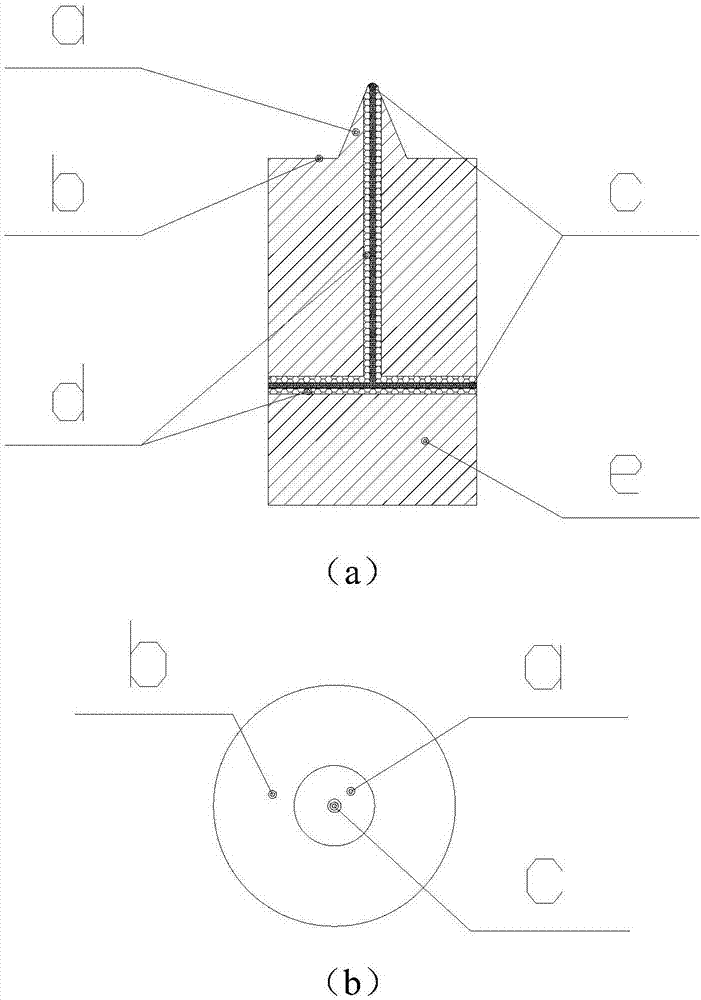

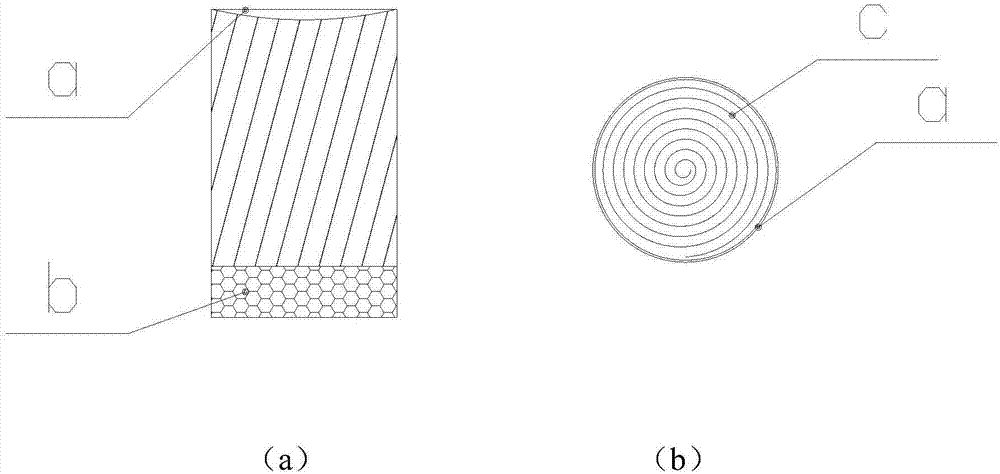

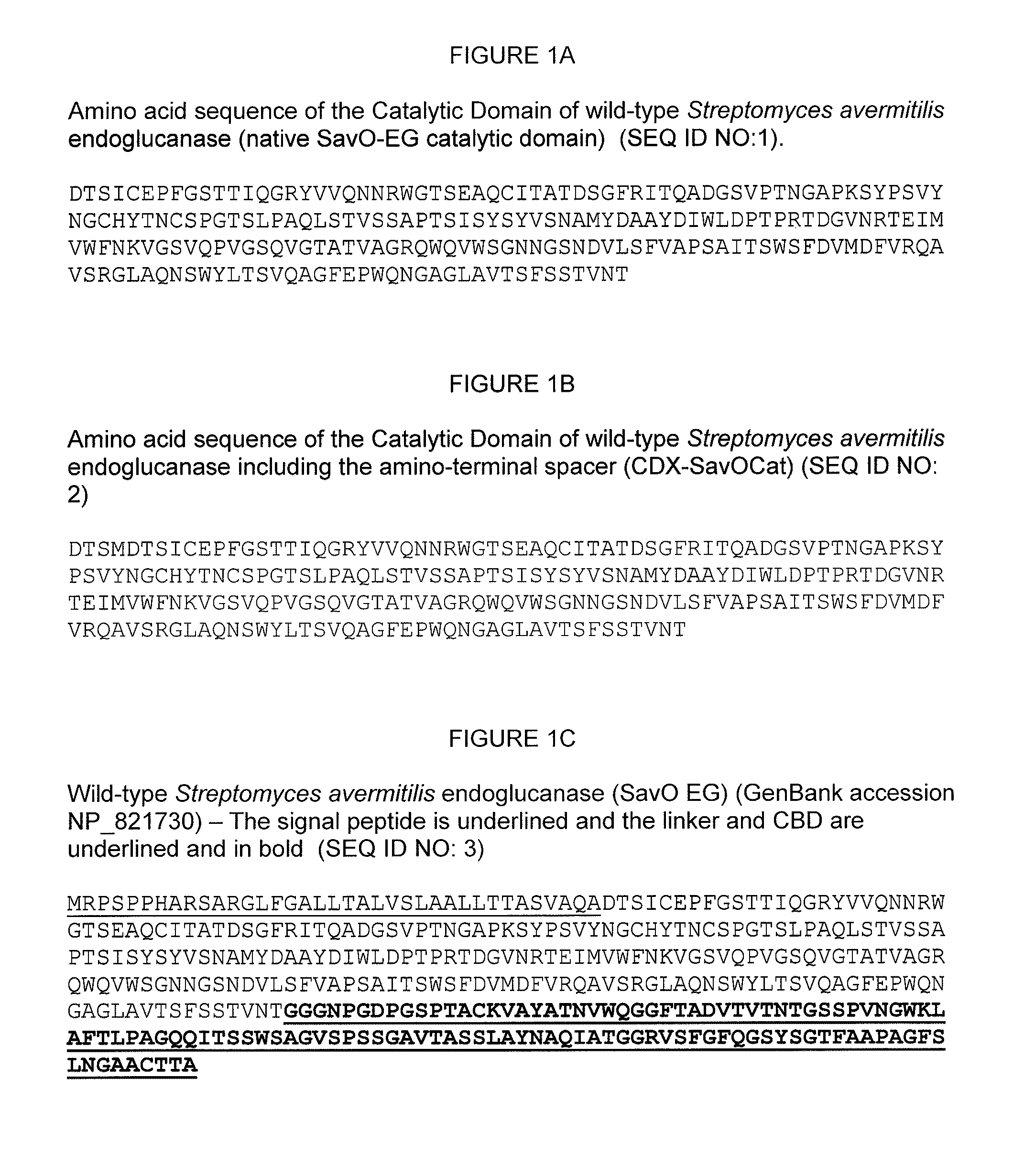

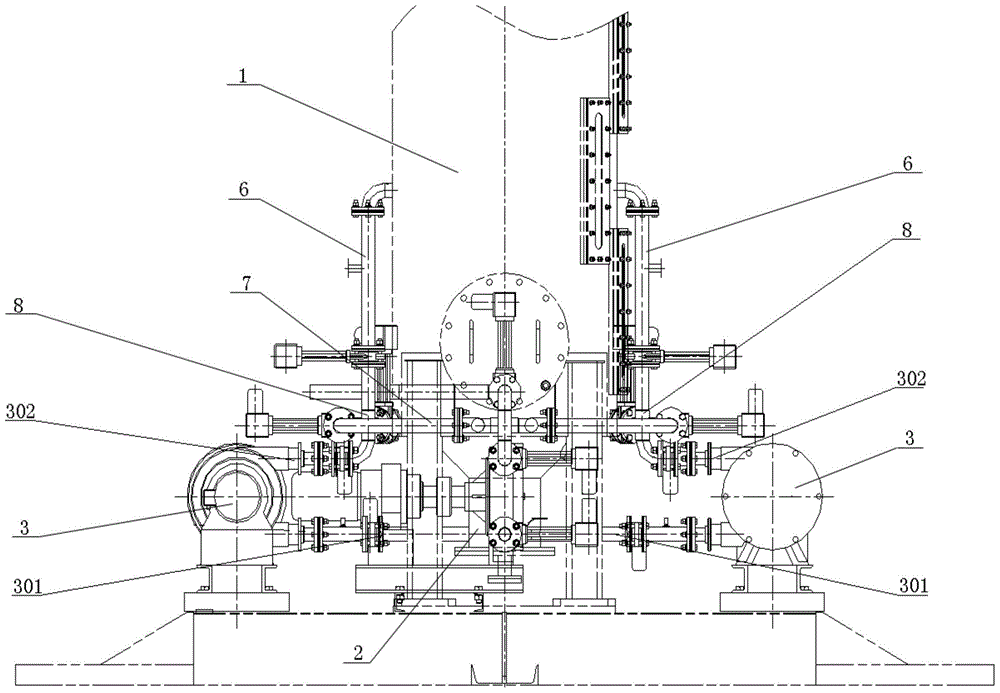

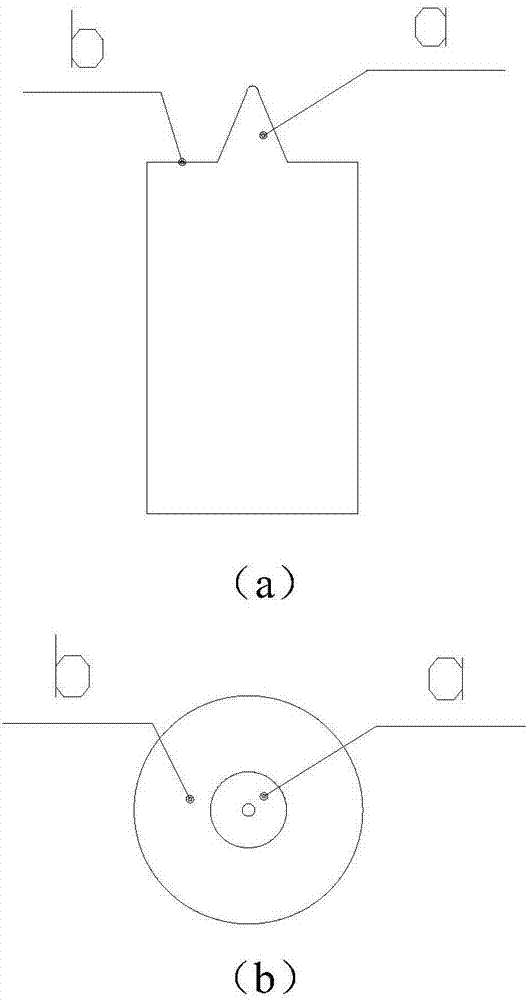

Electroplastic incremental forming device and method for plates

ActiveCN102527830ALower yield stressHigh geometric accuracyMetal-working feeding devicesPositioning devicesNumerical controlHigh energy

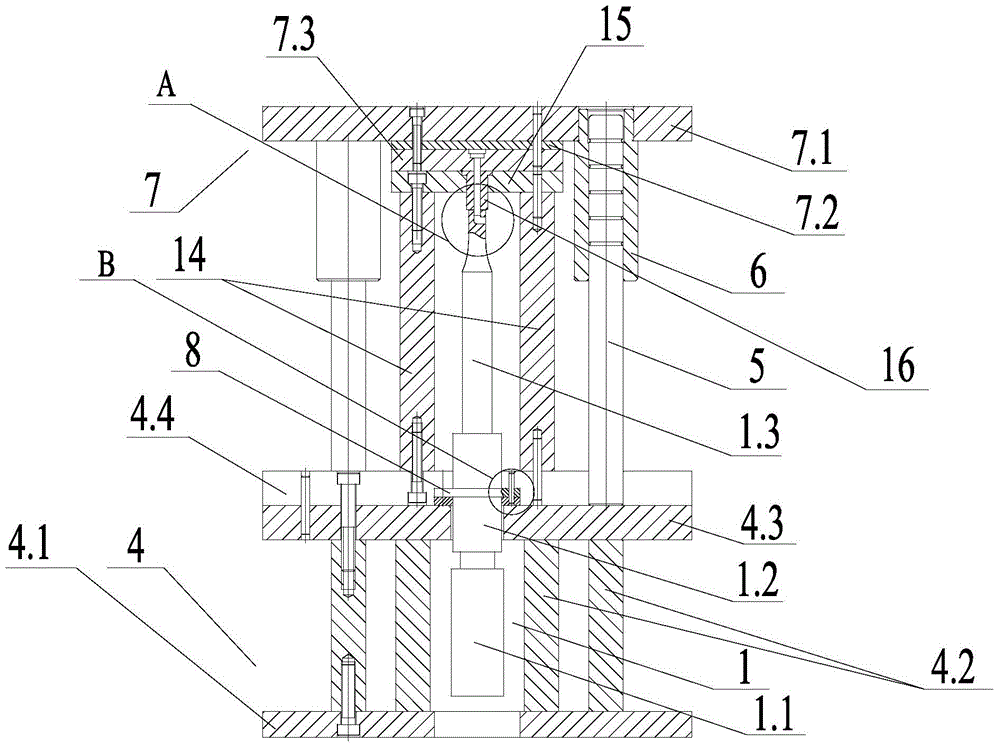

The invention relates to an electroplastic incremental forming device and an electroplastic incremental forming method for plates. The device comprises a five-axis numerical control forming machine tool, a six-axis parallel robot machining system, a plate forming clamp, a high energy pulse power supply, an infrared thermometer, and a compressed air cooling system embedded in the machine tool, wherein an upper forming pressing head is arranged at the tail end of a spindle of the five-axis numerical control forming machine tool; the six-axis parallel robot machining system is arranged on a working table of the machine tool; the top of the six-axis parallel robot machining system is provided with a lower forming pressing head; the plate forming clamp is fixed on the working table of the machine tool; positive and negative poles of the high energy pulse power supply are connected with the upper forming pressing head and the lower forming pressing head through high current-carrying conductors respectively so as to form a current loop among the high energy pulse power supply, the upper forming pressing head, the lower forming pressing head and the plates; a camera of the infrared thermometer is aligned with a central area of each plate; and the compressed air cooling system is aligned with a forming area of each plate. Compared with the prior art, the invention has the advantages of high efficiency, energy conservation, high machining precision, high surface quality and the like.

Owner:SHANGHAI JIAO TONG UNIV

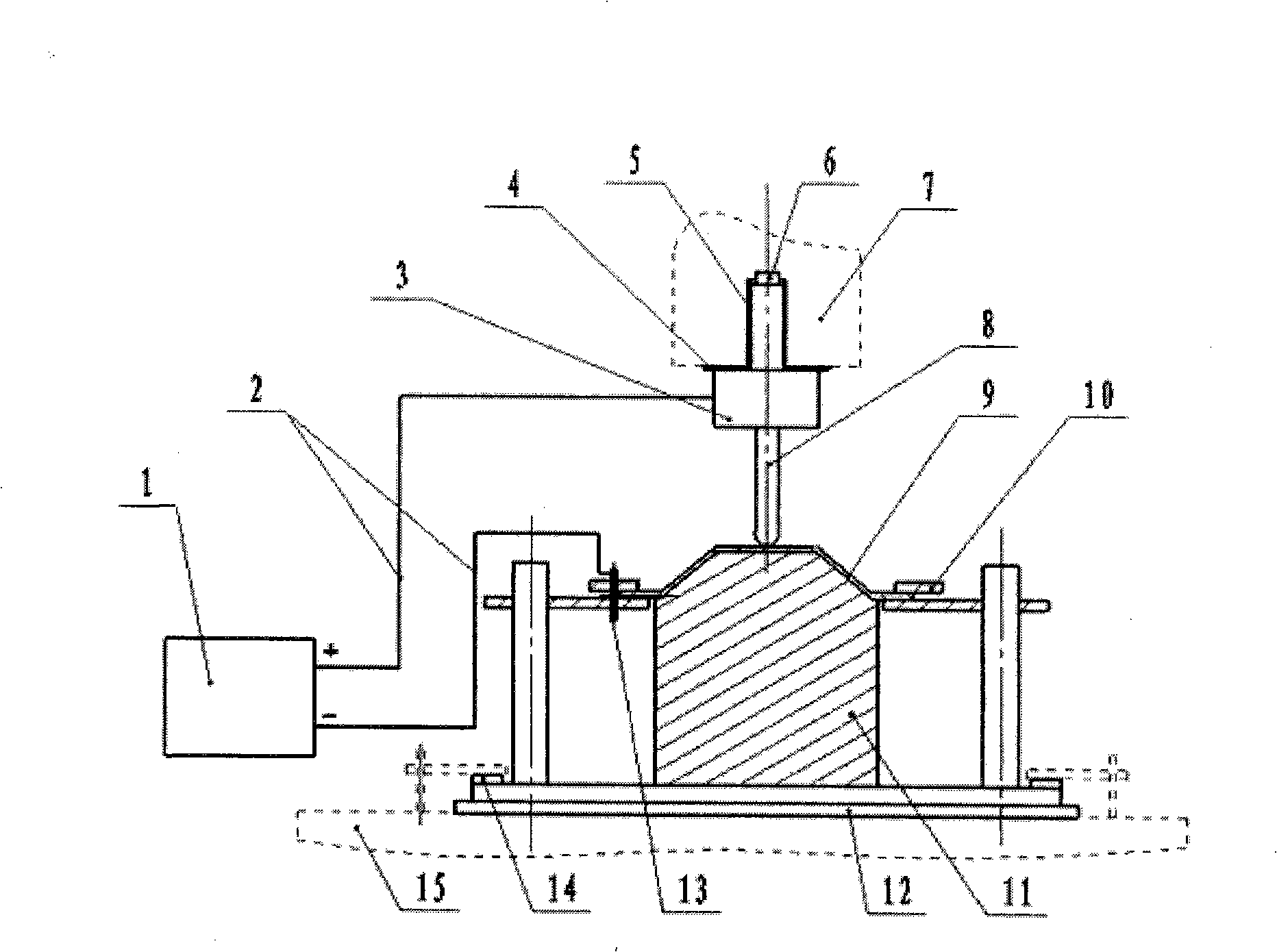

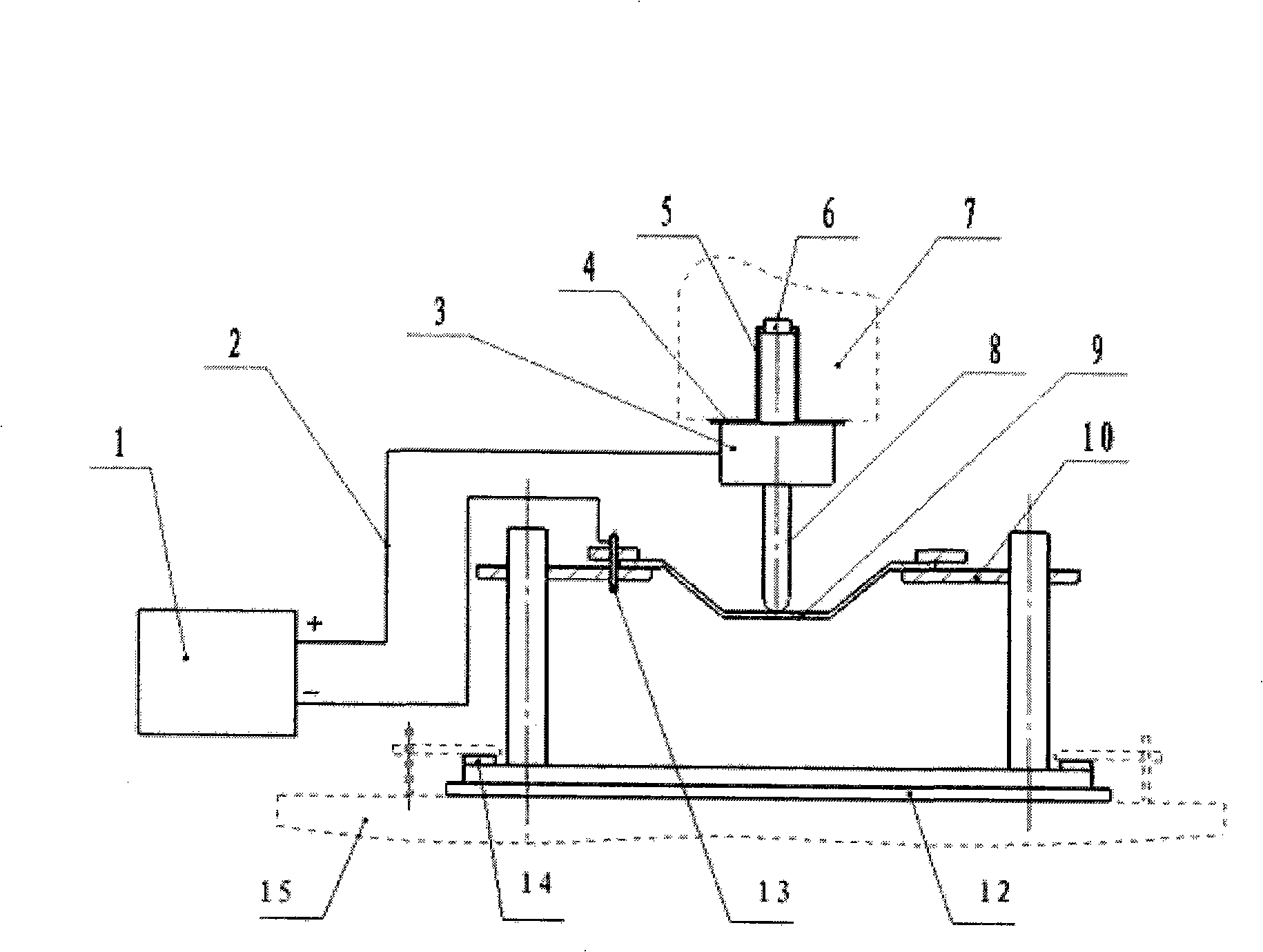

Electrical heating numerical control incremental forming processing method and device for plate

The invention relates to a device and a method of the electrical heating numerical control incremental forming processing of a sheet metal and belongs to the technical field of the sheet metal incremental forming processing. The key points of the device and the method lie in that a large current-carrying wire is used for forming an auxiliary power supply, a forming pressure head, a forming clamp and the sheet metal into a current loop; the power supply provides a low-voltage large current to cause the materials in a processing area to generate joule heat and to be softened in the sheet metal processing and forming so as to ensure the smooth implementation of the incremental forming processing. The heating method is fast in temperature rising, convenient in control and low in price, thus solving the problem that other heating methods are complex to control, improving the processing precision and being favorable for forming complex parts. At the same time, the method is suitable for the incremental processing of sheet metals such as the titanium magnesium sheet metal, and the like, which are hard to be plastically formed at normal temperature.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

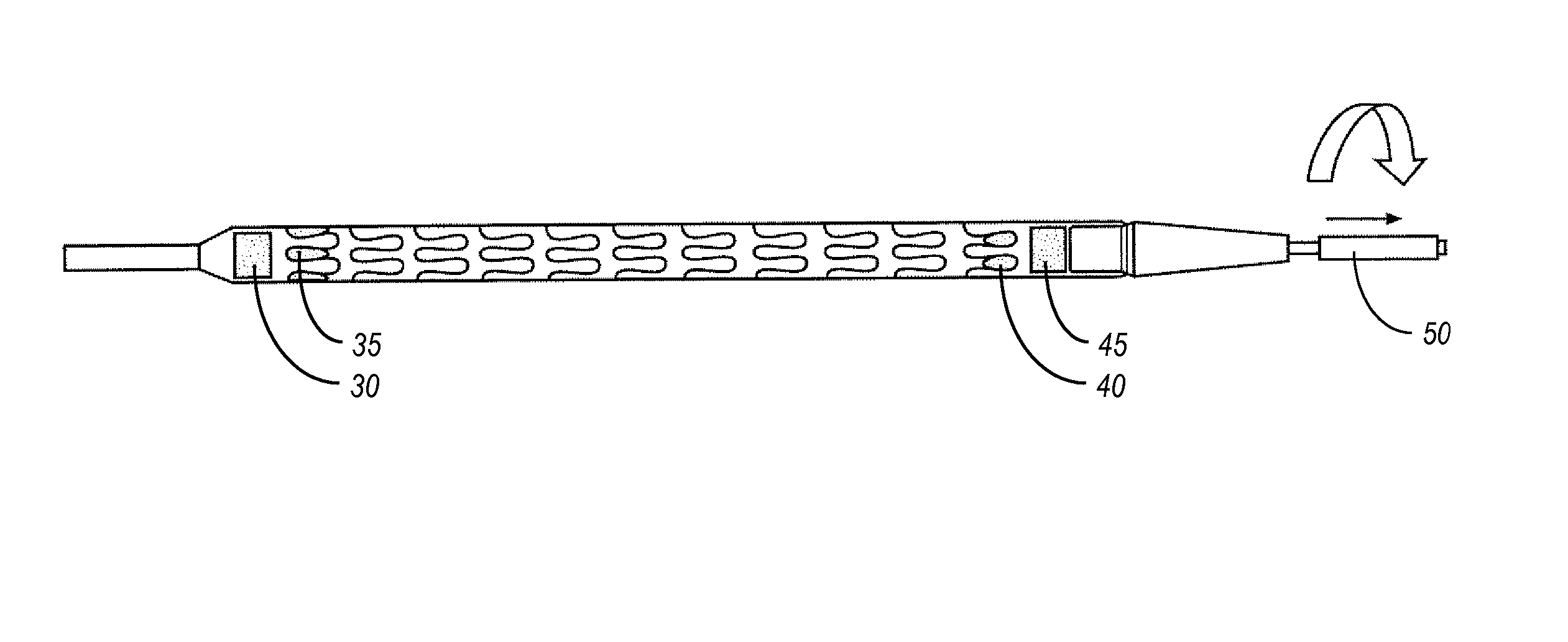

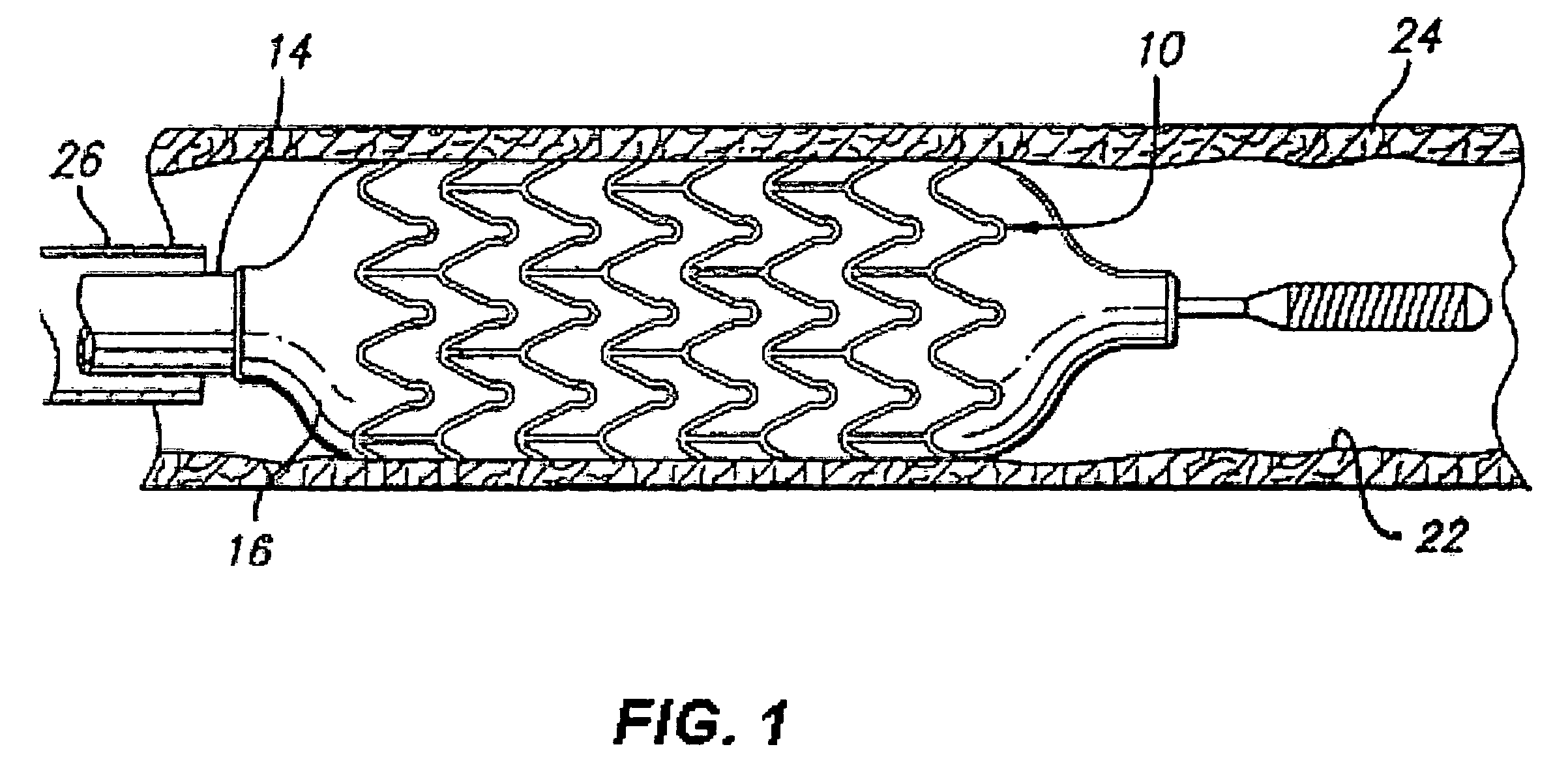

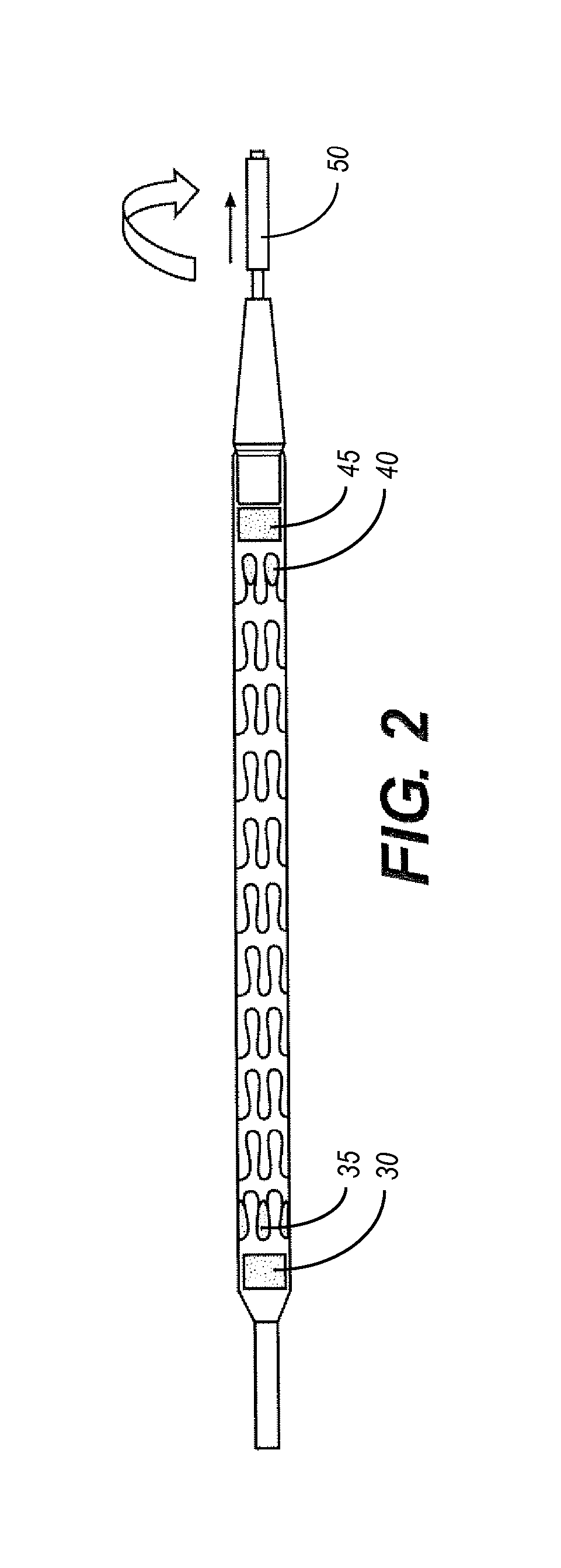

Radiopaque markers and medical devices comprising binary alloys of titanium

There is disclosed medical devices, such as stents, guidewires and embolic filters, comprising a binary alloy of titanium and one binary element selected from platinum, palladium, rhodium, and gold. There is also disclosed a radiopaque marker comprising the disclosed binary alloy, as well as medical devices having the radiopaque marker attached thereto. Methods of attaching the radiopaque marker to the medical devices, such as by welding, are also disclosure also disclosed.

Owner:ABBOTT LAB INC

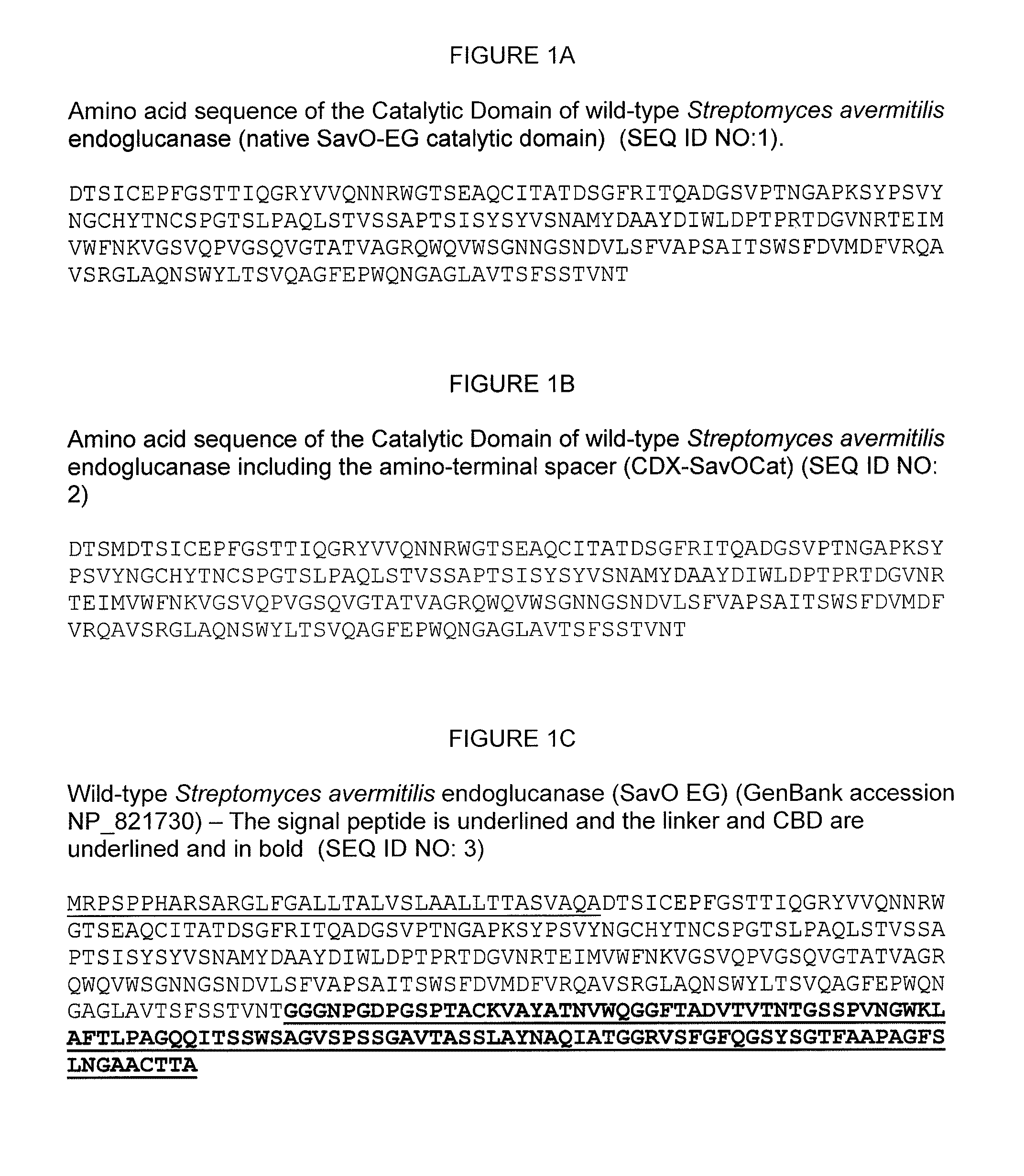

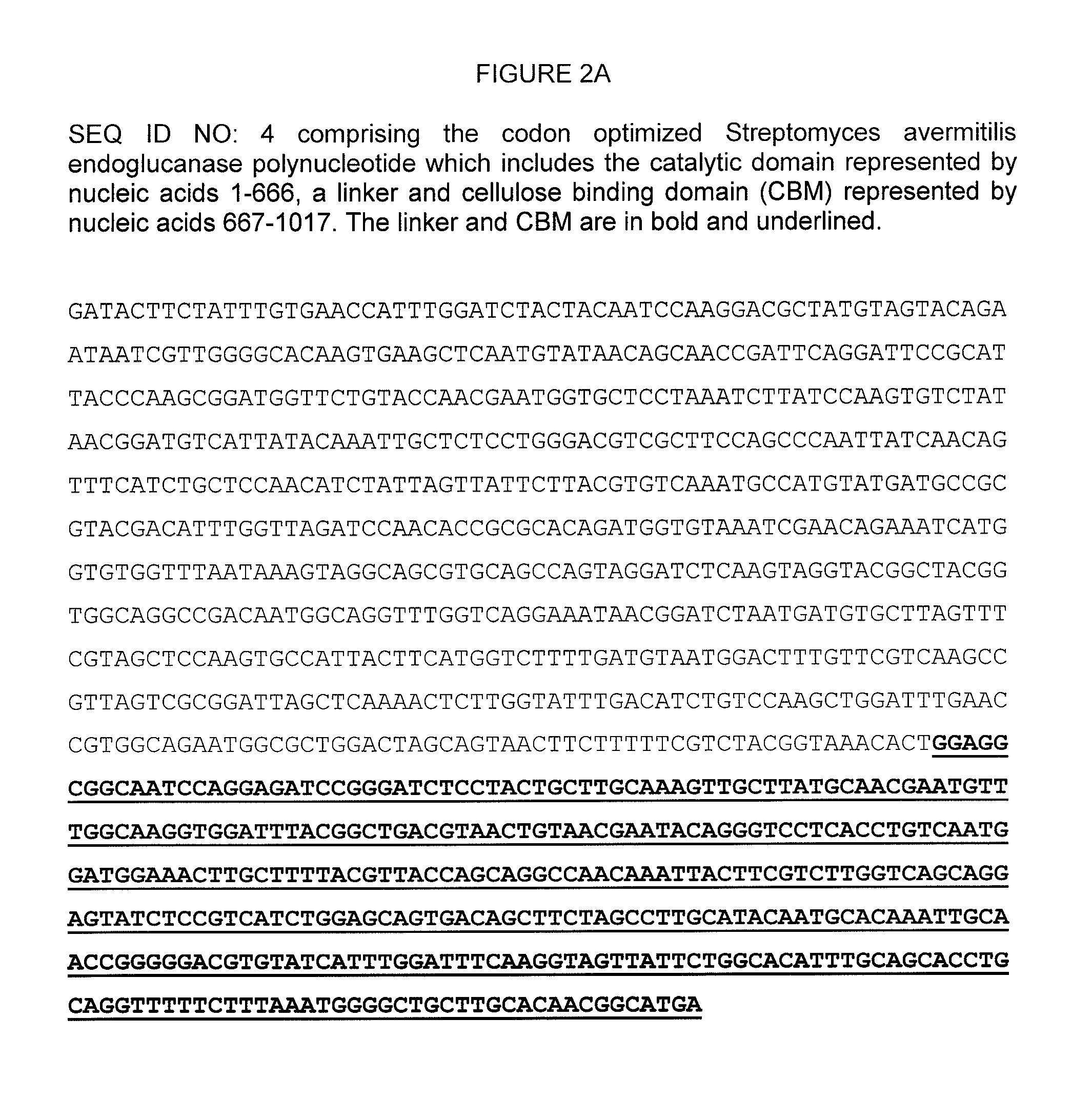

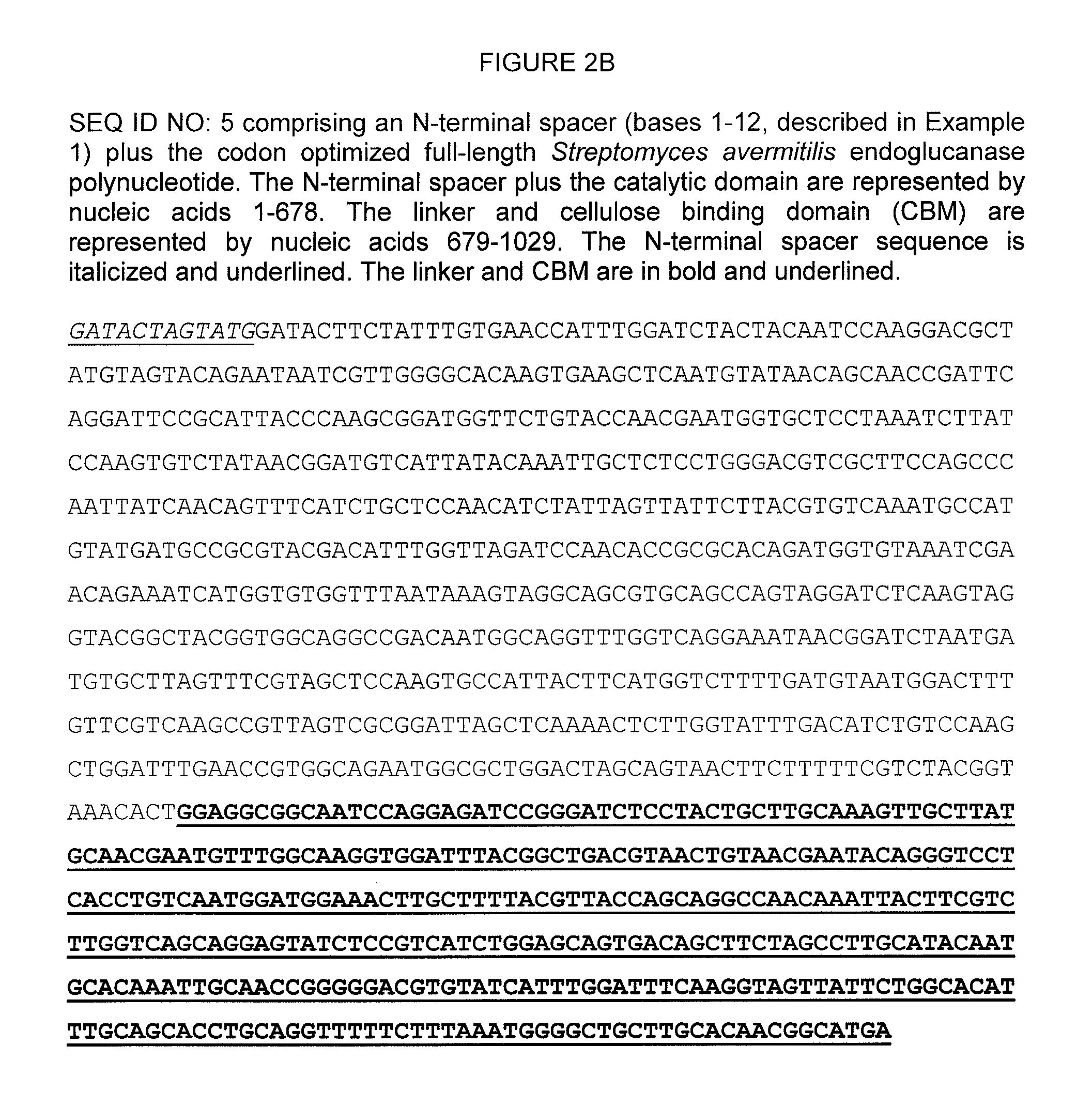

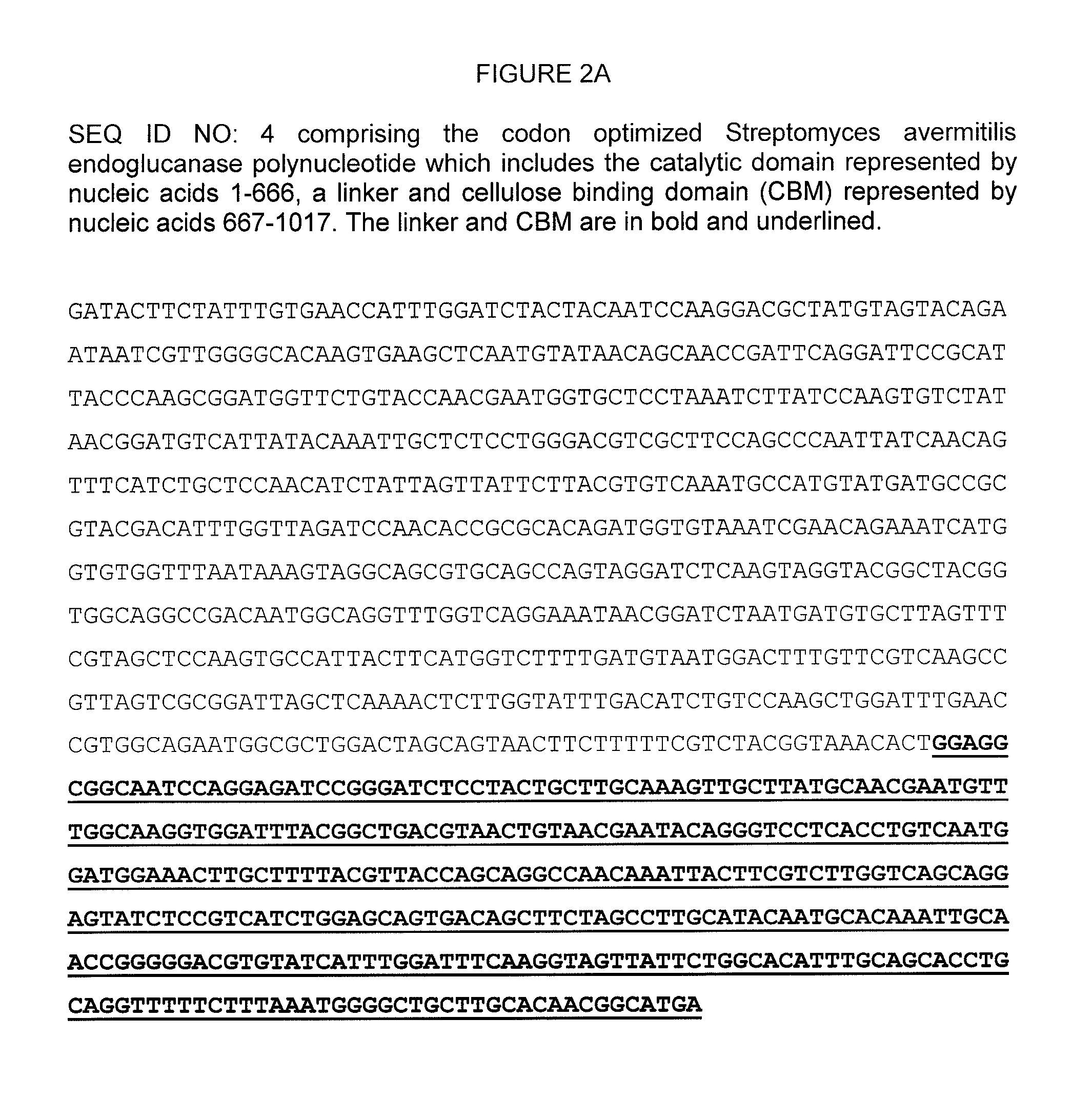

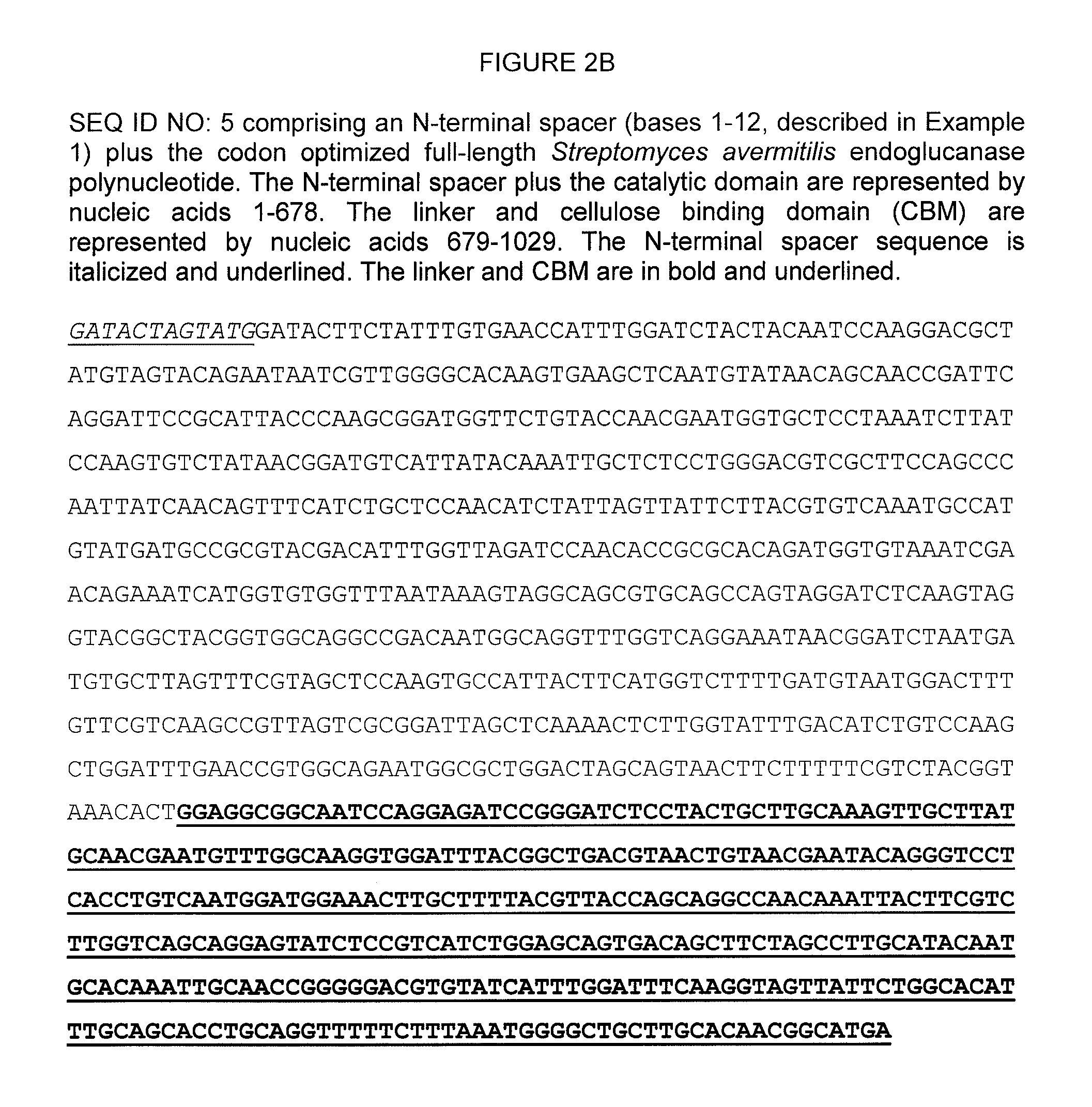

Endoglucanases

ActiveUS20100267089A1Saccharification of cellulosic feedstockLower yield stressPolypeptide with localisation/targeting motifSugar derivativesGlucanaseWild type

Owner:CODEXIS INC

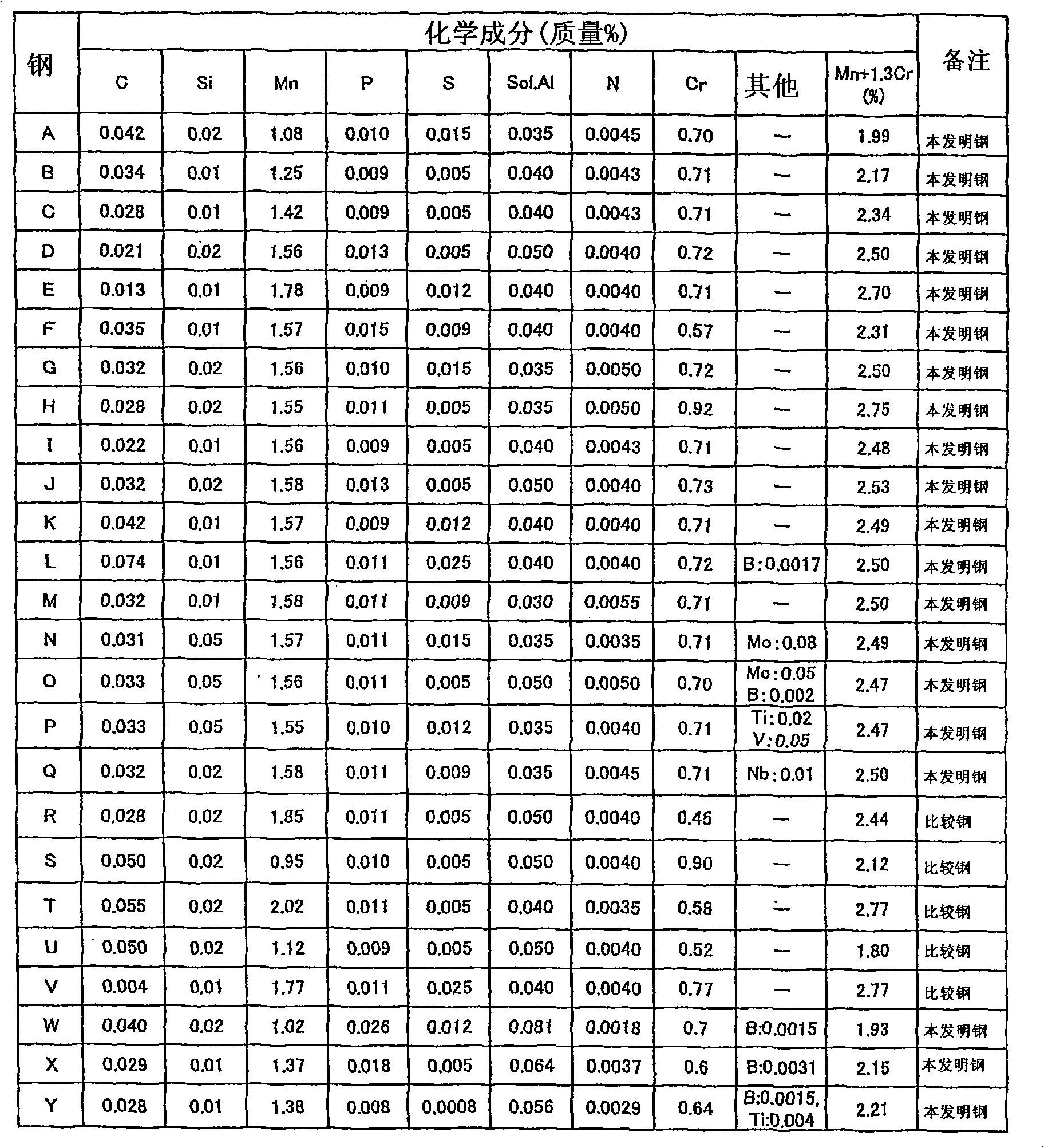

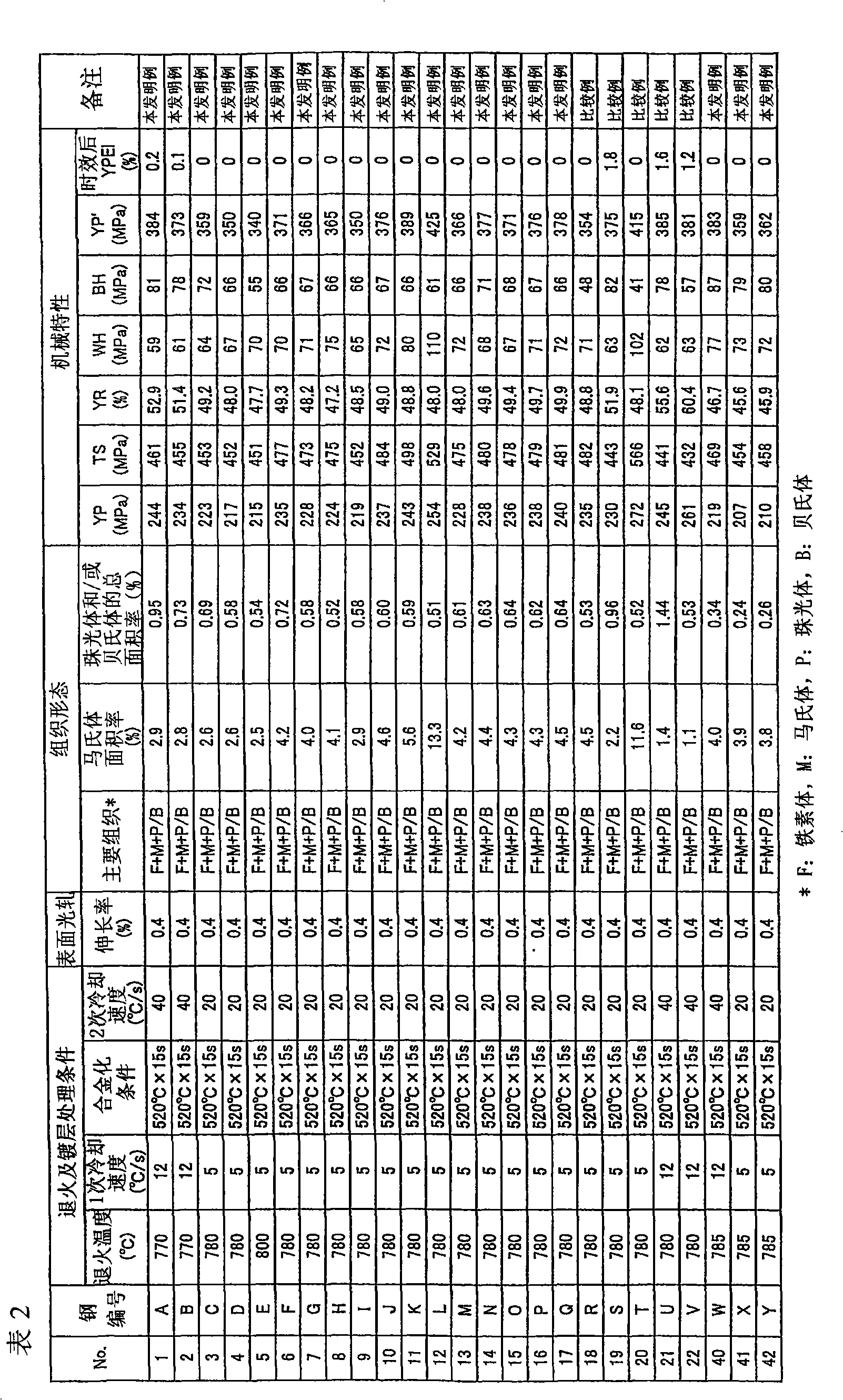

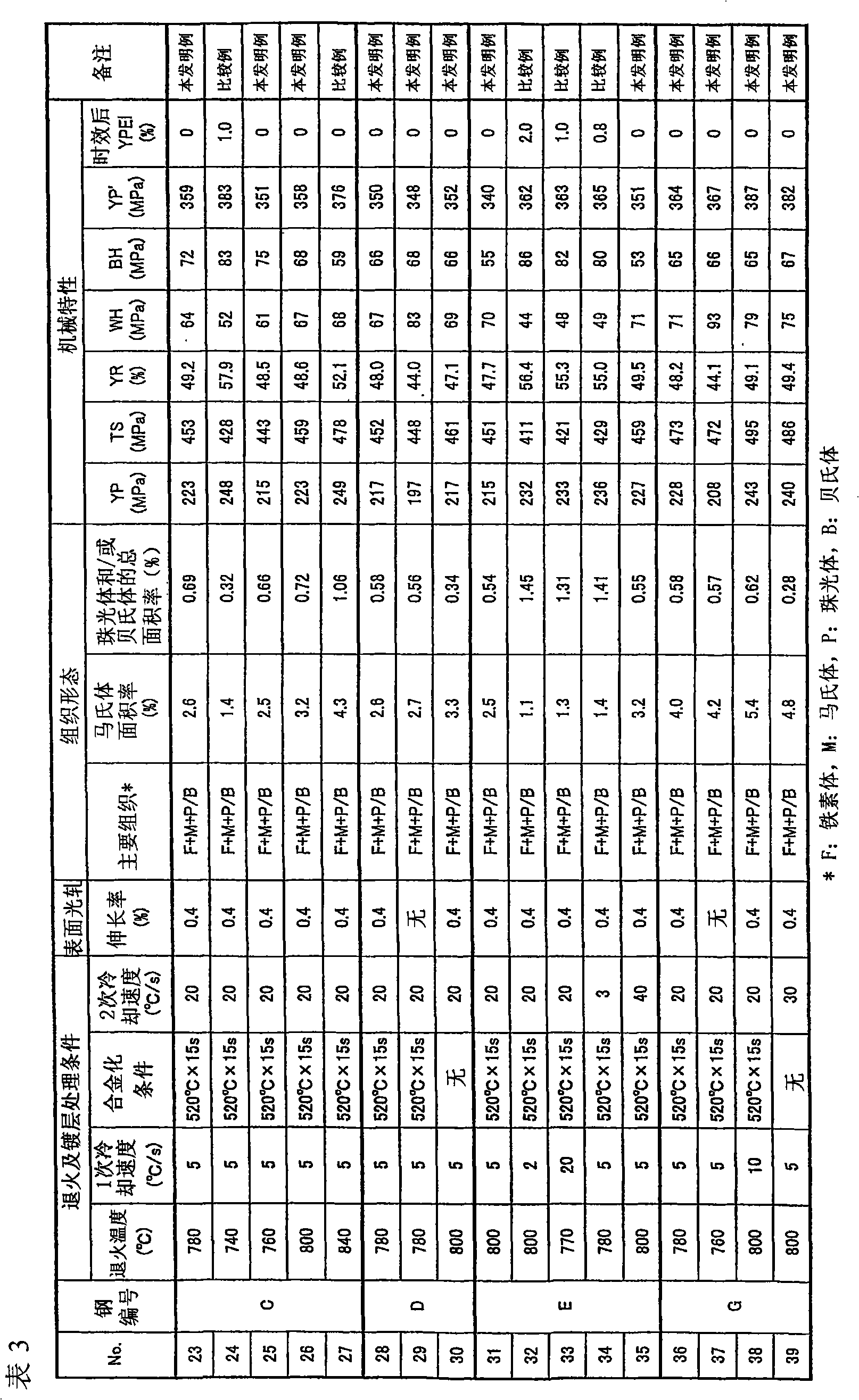

High-strength hot-dip galvanized steel sheet and process for producing the same

ActiveCN101688277ALower yield stressAchieve lightweightHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

A high-strength hot-dip galvanized steel sheet that even on the premise of ordinary CGL heat cycle, has a low yield stress and excels in resistance to natural aging and baking hardenability without reliance on the use of expensive Mo; and a process for producing the same. The constituent composition thereof comprises 0.01 to less than 0.08% C, 0.2% or less Si, more than 1.0 to 1.8% Mn, 0.10% or less P, 0.03% or less S, 0.1% or less Al, 0.008% or less N and more than 0.5% Cr so that the relationship 1.9=Mn(mass%)+1.3Cr(mass%)=2.8 is satisfied and comprising the balance iron and unavoidable impurities. The structure thereof has a ferrite phase and a martensite phase of 2 to 15% area ratio, and the cumulative area ratio of pearlite phase and / or bainite phase is 1.0% or less. In the productionof this hot-dip galvanized steel sheet, the temperature and cooling rate are controlled during the annealing / plating operation subsequent to cold rolling.

Owner:JFE STEEL CORP

Viscosity reducible radiation curable resin composition

InactiveUS20060231982A1Improve photostabilityImprove stabilityCoatings3-dimensional image productionShear rateChemistry

The invention relates to a viscosity reducible radiation curable composition comprising at least one radiation curable component and a filler, wherein the composition has the properties i) a yield stress value of <1100 Pa, ii) a viscosity (at a shear rate of 1 sec−1) between 1 and 1500 Pa·sec, and iii) a filler settling speed less than 0.3 mm / day.

Owner:DSM IP ASSETS BV

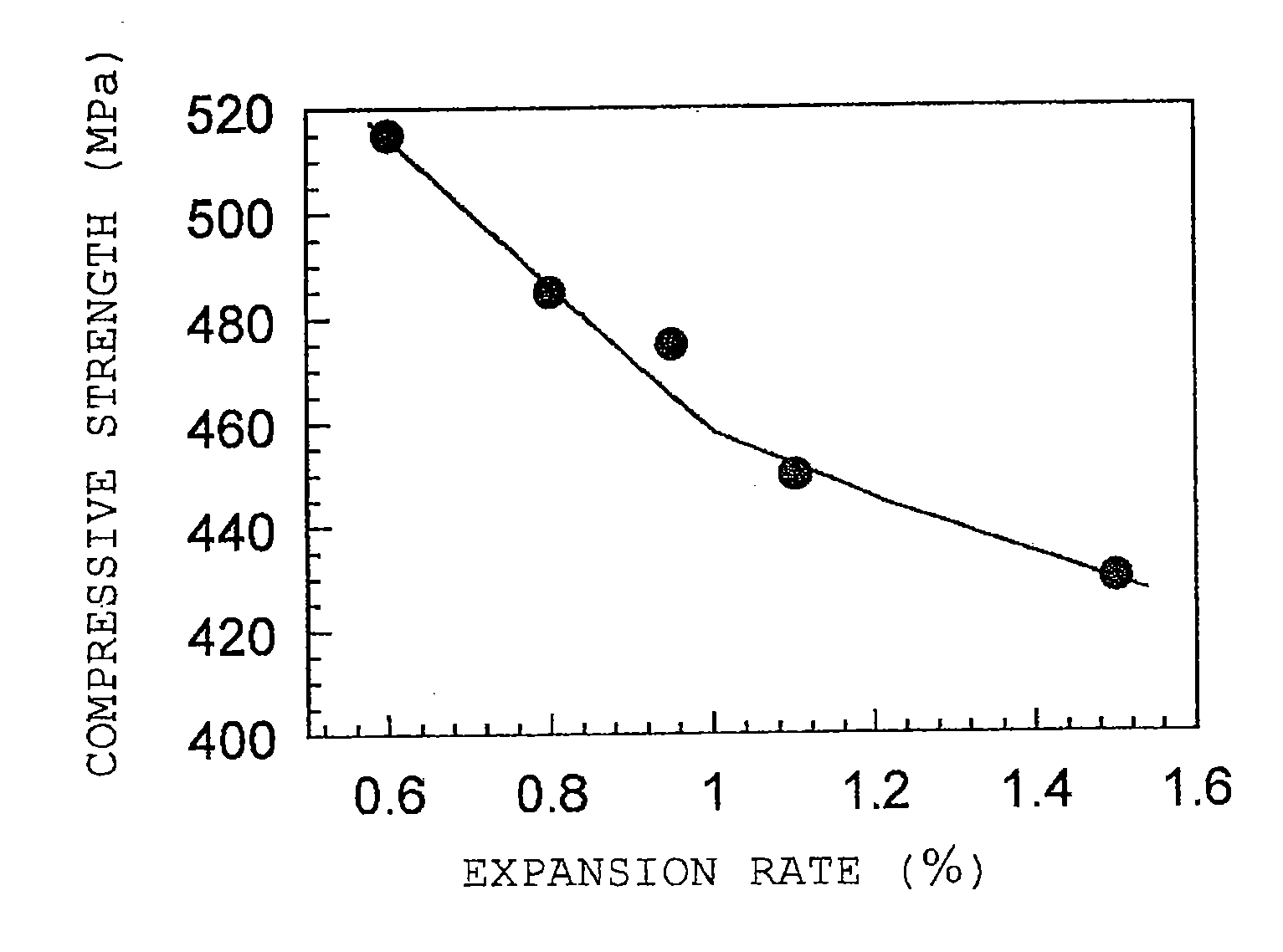

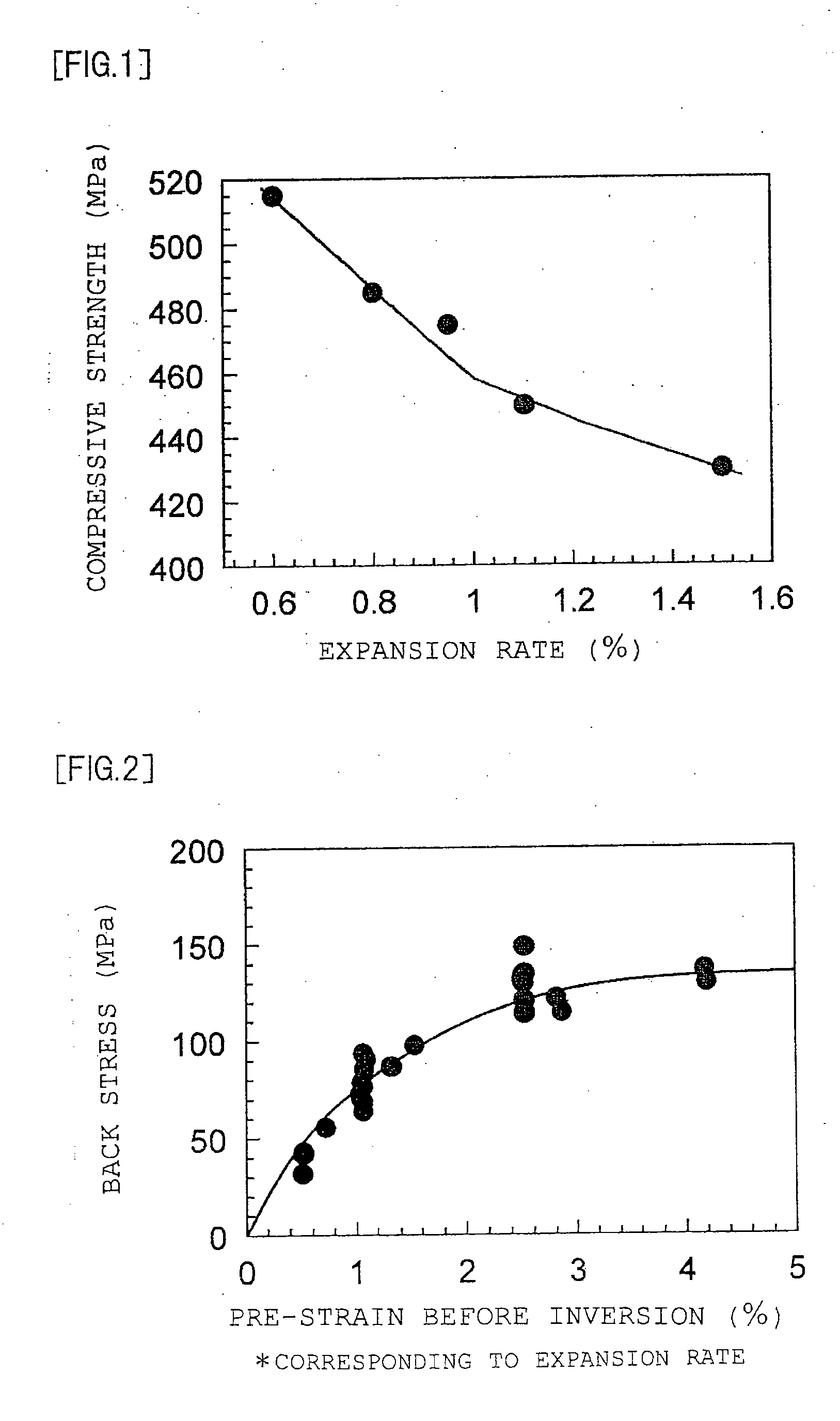

Welded steel pipe for linepipe having high compressive strength and high fracture toughness and manufacturing method thereof

InactiveUS20120305122A1High compressive strengthGood fracture toughnessArc welding apparatusFurnace typesSteel platesHigh fracture

Provided are a steel pipe for a linepipe having a heavy wall thickness and excellent fracture toughness in a base material, and methods of producing the same. A welded heat affected zone is achieved by suppressing lowering of yield stress caused by a Bauschinger effect by optimizing the metal microstructure of a steel plate. A steel pipe has a composition which contains by mass % 0.03 to 0.08% C, 0.10% or less Si, 1.00 to 2.00% Mn, 0.010% or less P, 0.0030% or less S, 0.06% or less Al, 0.005 to 0.020% Nb, 0.005 to 0.025% Ti, 0.0010 to 0.0060% N, and Fe and unavoidable impurities as a balance. Ti(%) / N(%) is a value which falls within a range of 2 to 4, and a Ceq value is 0.30 or more.

Owner:JFE STEEL CORP

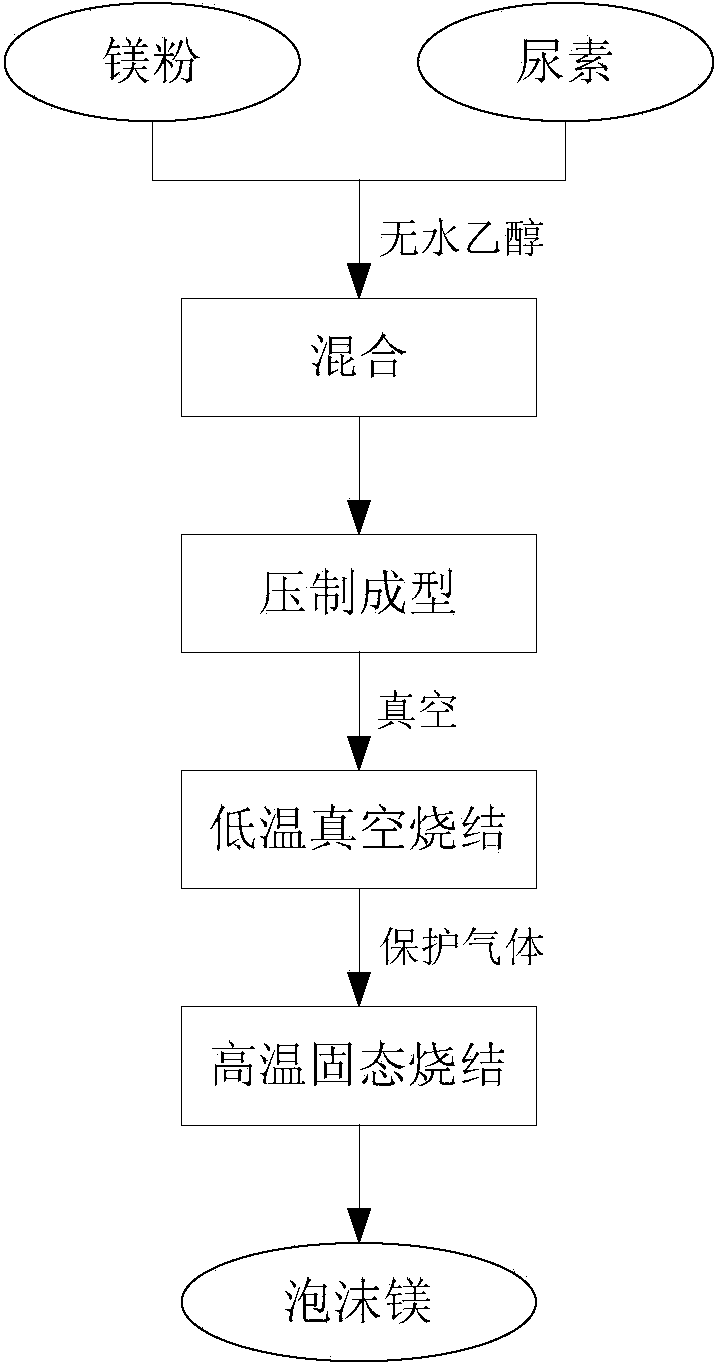

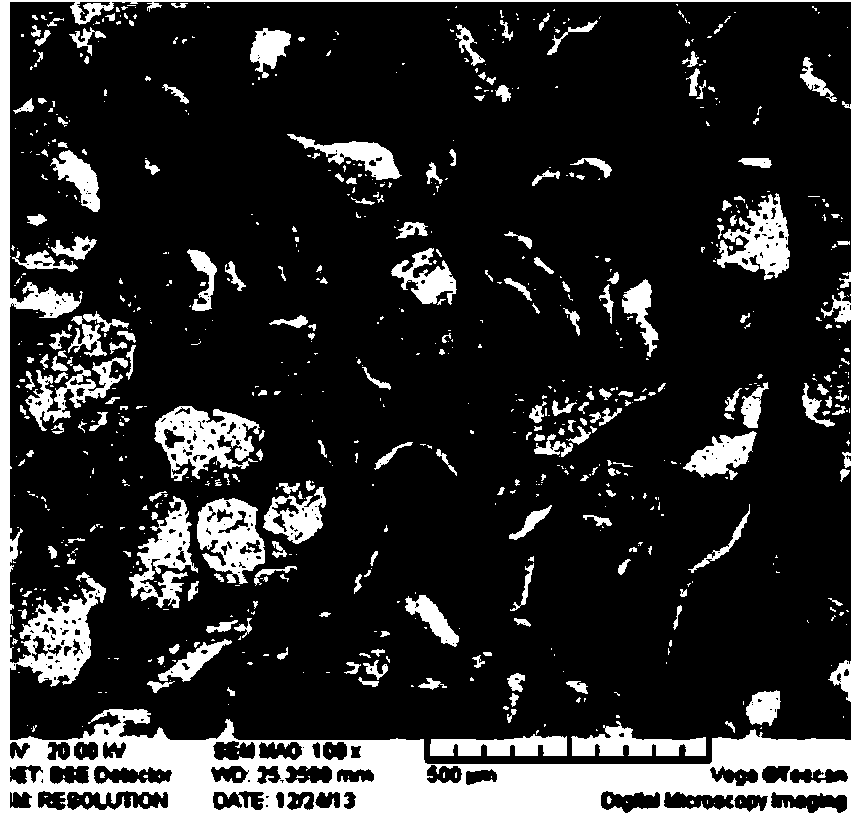

Method for preparing foamed magnesium used as buffering energy absorption material

The invention discloses a method for preparing foamed magnesium used as a buffering energy absorption material. According to the method, the powder metallurgy pore-forming agent technology is adopted, urea and magnesium powder are used for preparing the foamed magnesium through the compounding and mixing step, the compression molding step and the sintering step, the urea is used as a pore-forming agent, and absolute ethyl alcohol is used as a binder; as a result, the pore structure of the material is more uniform, the performance of the obtained foamed magnesium material is improved, substances which pollute the environment cannot be produced after the urea and the absolute ethyl alcohol are removed at a high temperature, and the material cost is low; moreover, the two-section type sintering process is adopted, so that consumption of energy is reduced, preparation cost is lowered, and benefit is increased. The foamed magnesium prepared through the method has low yield stress and a wide stress platform, meets the requirement for a good buffering energy absorption material, can be well applied to a vehicle damper and the like to serve as the buffering energy absorption material, provides a novel technological approach for preparation of a material of a high-performance buffer and has very good application prospect.

Owner:CHONGQING UNIV

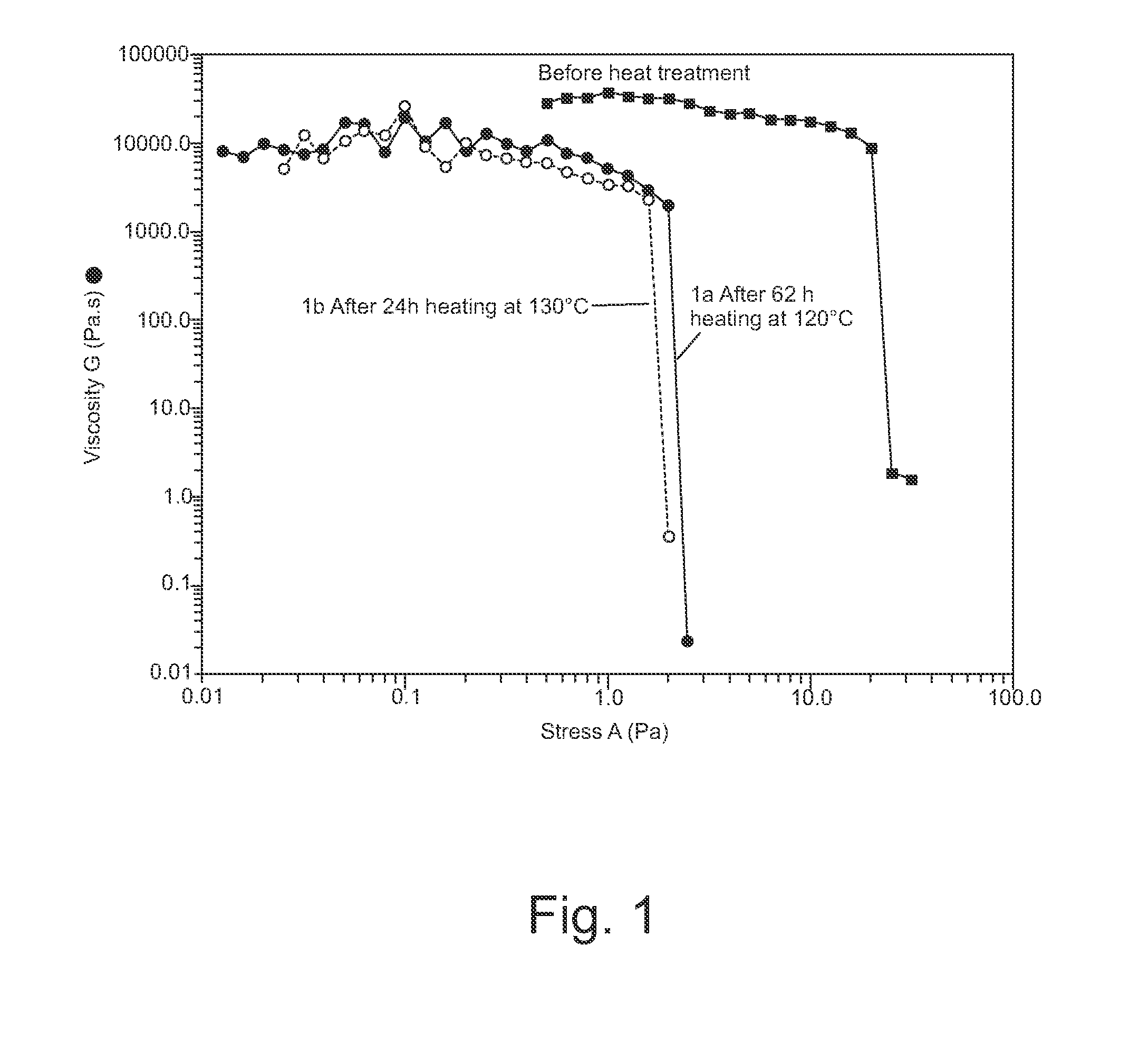

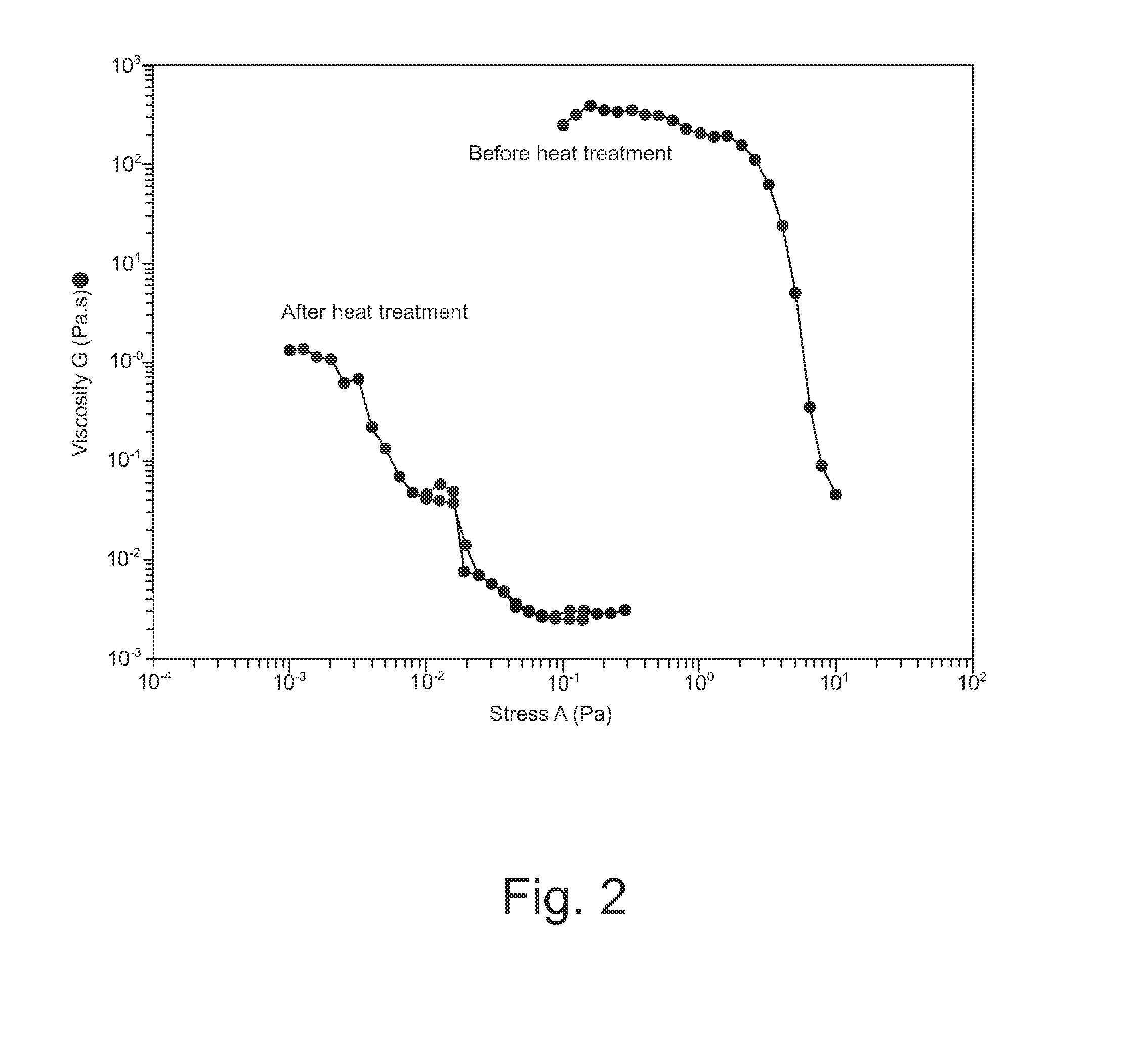

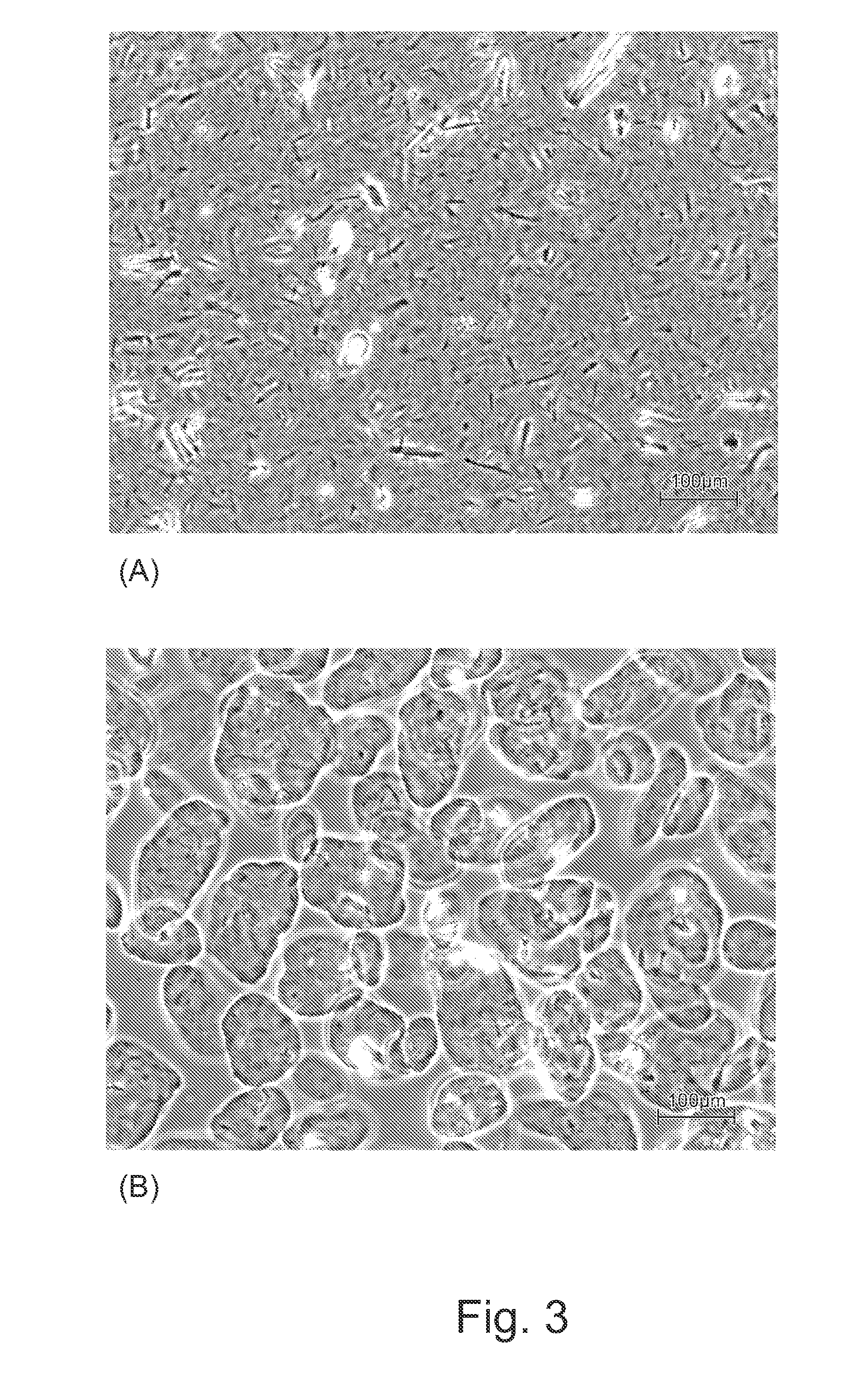

Method of modifying nanofibrillar cellulose composition

ActiveUS20160176989A1Low viscosityLower yield stressSpecial paperPaper after-treatmentCelluloseFiber

The invention relates to a method for modifying nanofibrillar cellulose composition, comprising—preparing fibrous dispersion of ionically charged nanofibrillar cellulose (NFC), and—applying heat treatment at a temperature of at least 90° C. to the fibrous dispersion until the viscosity of NFC starts to decrease. The viscosity of the heat-treated NFC is reversible by applying shear forces to the NFC.

Owner:UPM-KYMMENE OYJ

High-strength cold-rolled steel sheet, high-strength plated steel sheet, and methods for their manufacture

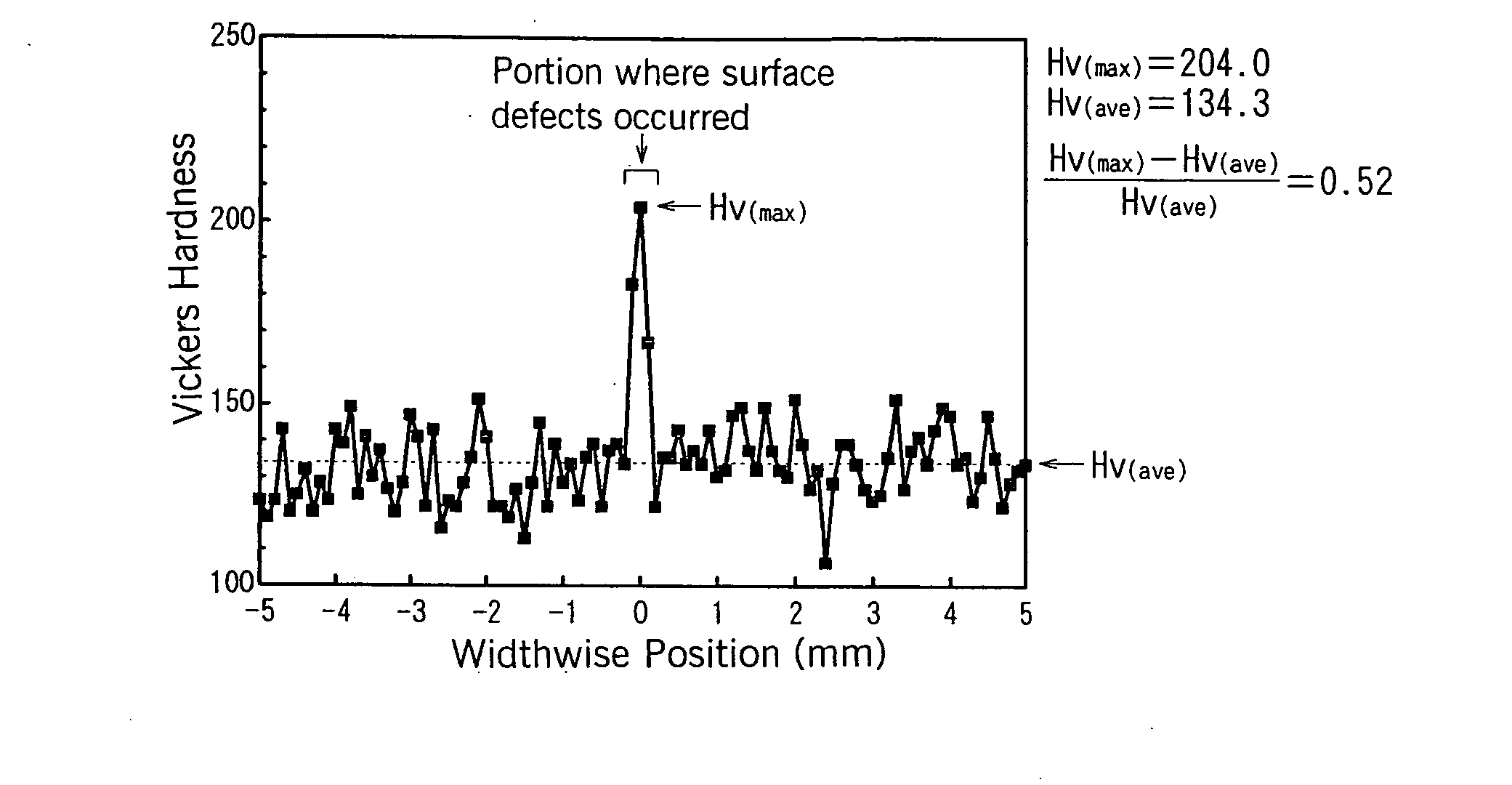

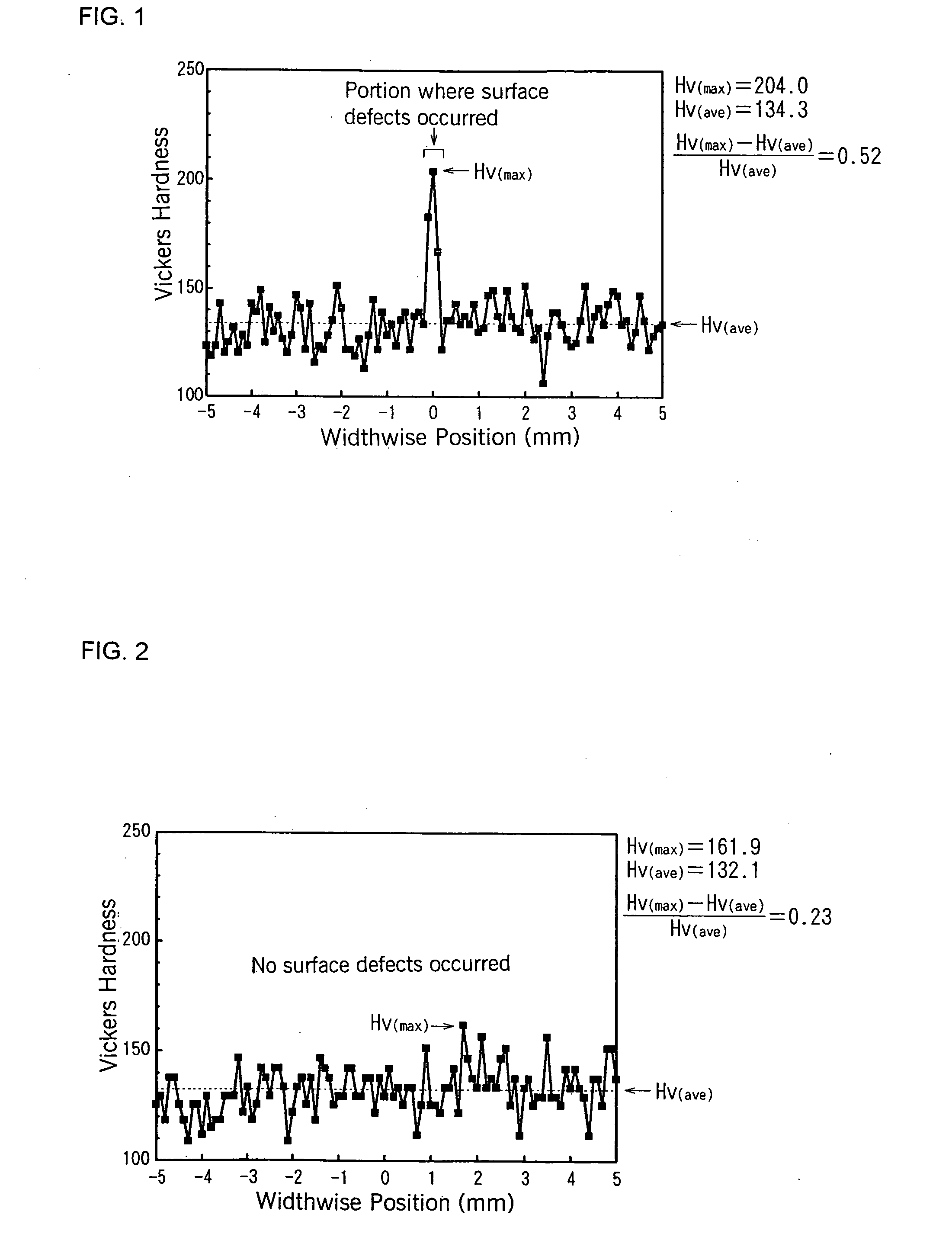

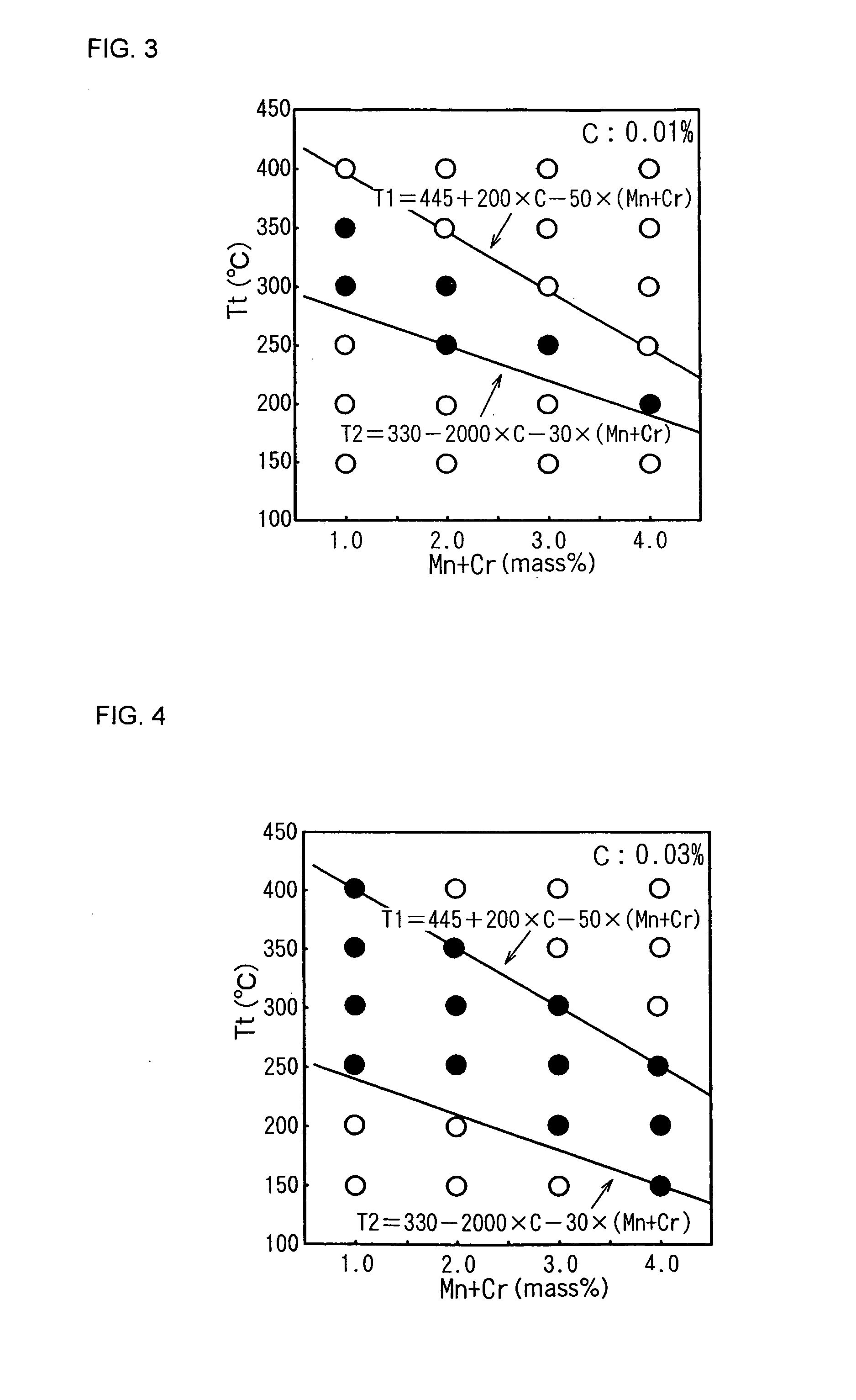

InactiveUS20080202638A1Sufficient formabilityNot develop surface defectHot-dipping/immersion processesFurnace typesRoom temperatureHigh intensity

A high-strength cold-rolled steel sheet providing a product with a good surface condition after press forming, having excellent bake hardenability and anti room temperature aging property, and having a dual phase structure with a tensile strength of at least 340 MPa is provided.A high-strength cold-rolled steel sheet has a structure comprising a main phase which is a ferrite and a secondary phase which is a low temperature transformation product including a martensite and has a hardness distribution of the ferrite phase in an arbitrary cross section having a length of 10 mm in the widthwise direction of the sheet which satisfies the relationship prescribed by (Hv(max)−Hv(ave))<0.5×(Hv(ave). Hv(max) is the maximum Vickers hardness of ferrite grains in a region at a distance of from (⅛)t to (¼)t in the thickness direction from the surface when the thickness of the high-strength cold-rolled steel sheet is t, and Hv(ave) is the average Vickers hardness of ferrite grains in this region.

Owner:SUMITOMO METAL IND LTD

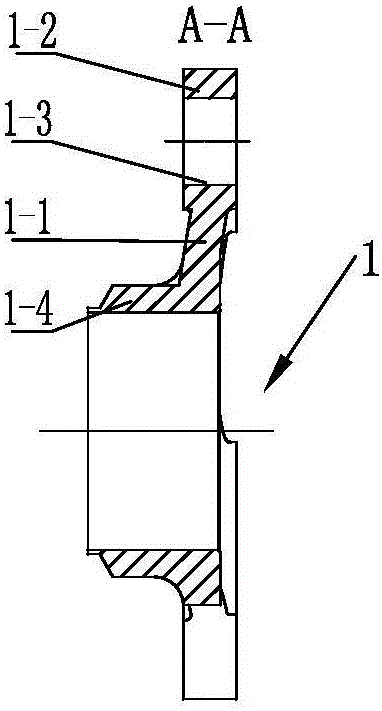

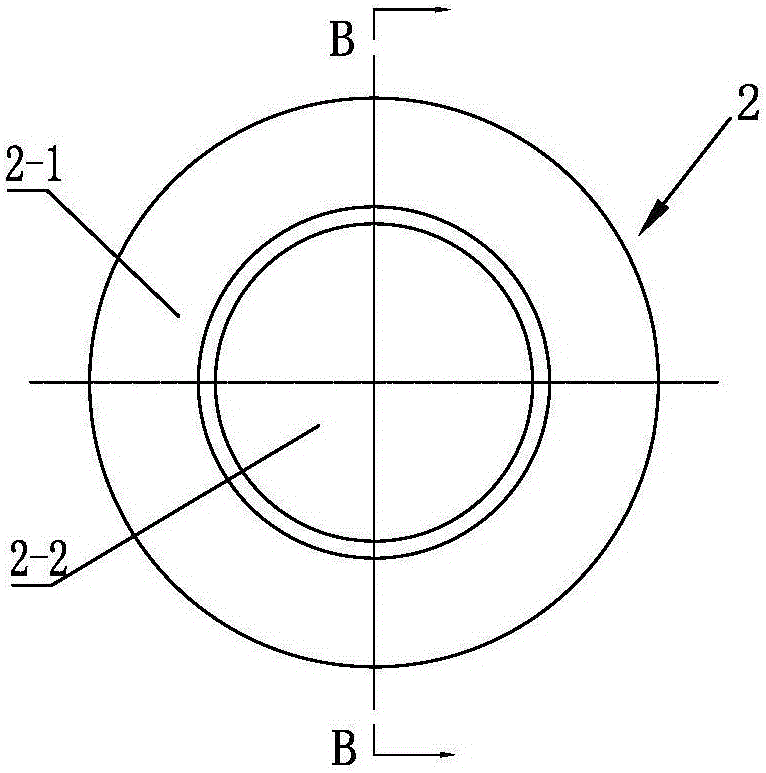

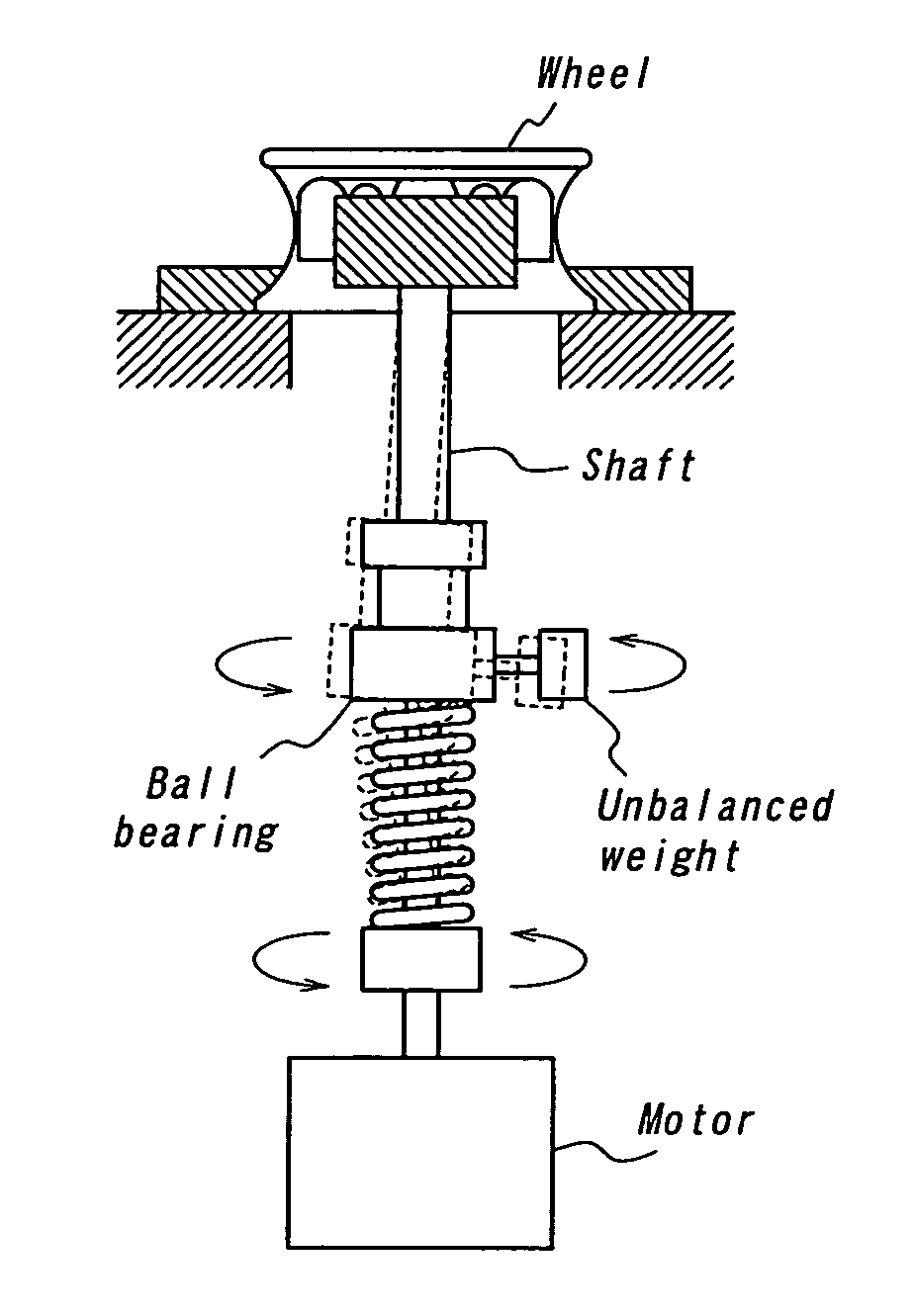

Ultrasonic wave vibration equal channel angular extrusion combined mold

ActiveCN104307910ALower yield stressHigh fillingExtrusion diesMechanical vibrations separationFlow stressEqual channel angular extrusion

The invention discloses an ultrasonic wave vibration equal channel angular extrusion combined mold. An ultrasonic wave vibration system is fixed on a mold base in the vertical direction; an L-shaped concave mold hole is formed in the output end of the ultrasonic wave vibration system; the feeding direction of the concave mold hole is parallel to the ultrasonic wave vibration direction; the discharge direction of the concave mold hole is perpendicular to the ultrasonic wave vibration direction; guide columns are uniformly arranged on the mold base; guide sleeves which relatively move in match with the guide columns are arranged on the guide columns; the guide sleeves are fixed on a top base of the mold; a convex mold is also fixed on the top base of the mold; a plurality of material guide sleeve support rods are uniformly fixed on the mold base; material guide sleeve fixing plates are fixed on the tops of the material guide sleeve support rods; material guide sleeves in match with the convex mold are fixed on the material guide fixing plates; the material guide sleeves are positioned above the convex mold hole; gaps are formed between the material guide sleeves and the concave mold hole. The ultrasonic wave vibration system and an equal channel angular extrusion mold are reasonably combined to form the ultrasonic wave vibration equal channel angular extrusion combined mold, so that both the yield stress and the flowing stress of a material are reduced, and crystal grains of the material are refined, and the comprehensive mechanical property of the material is improved.

Owner:JIANGHAN UNIVERSITY

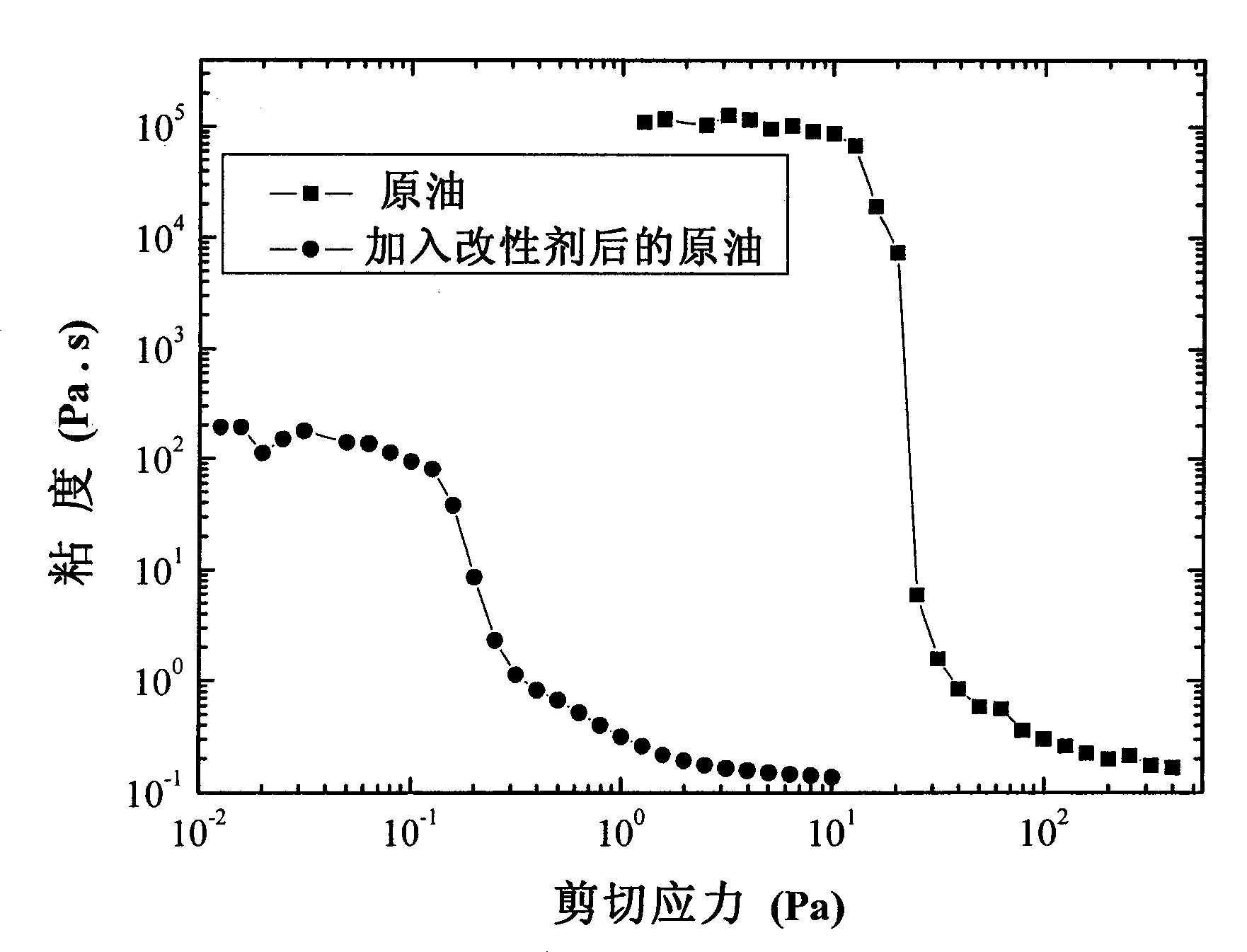

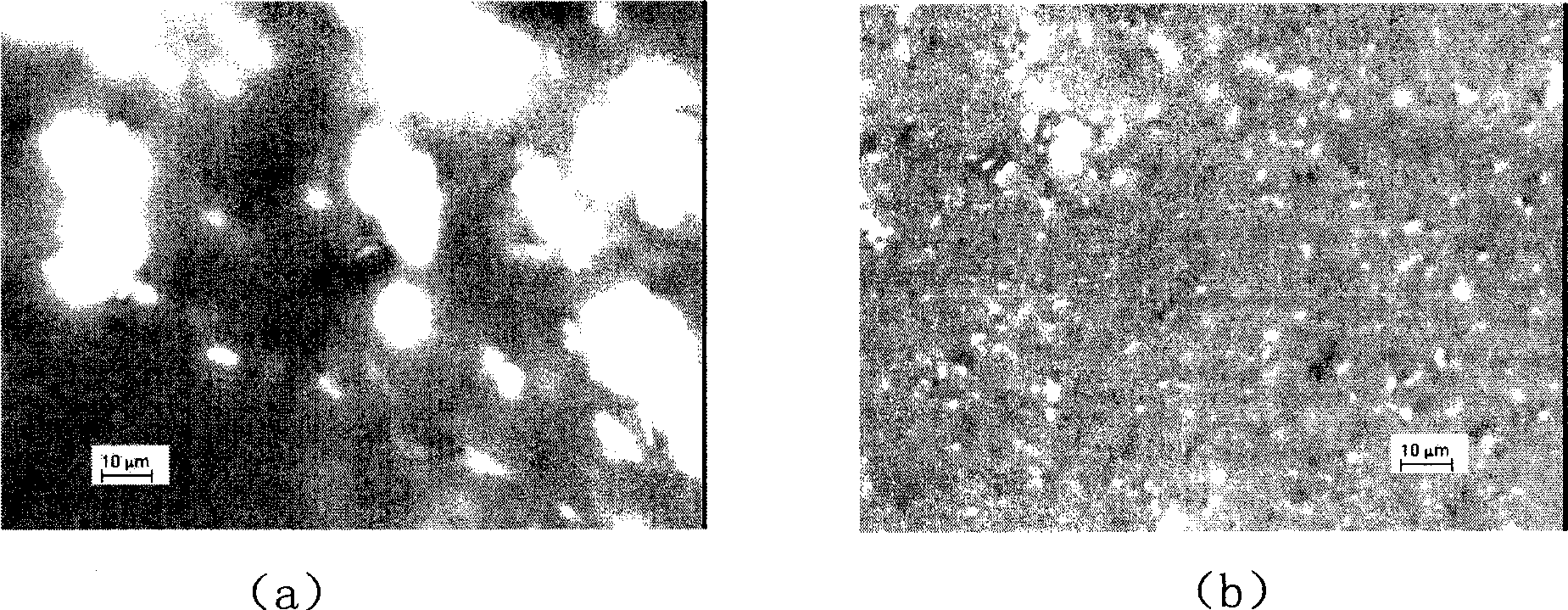

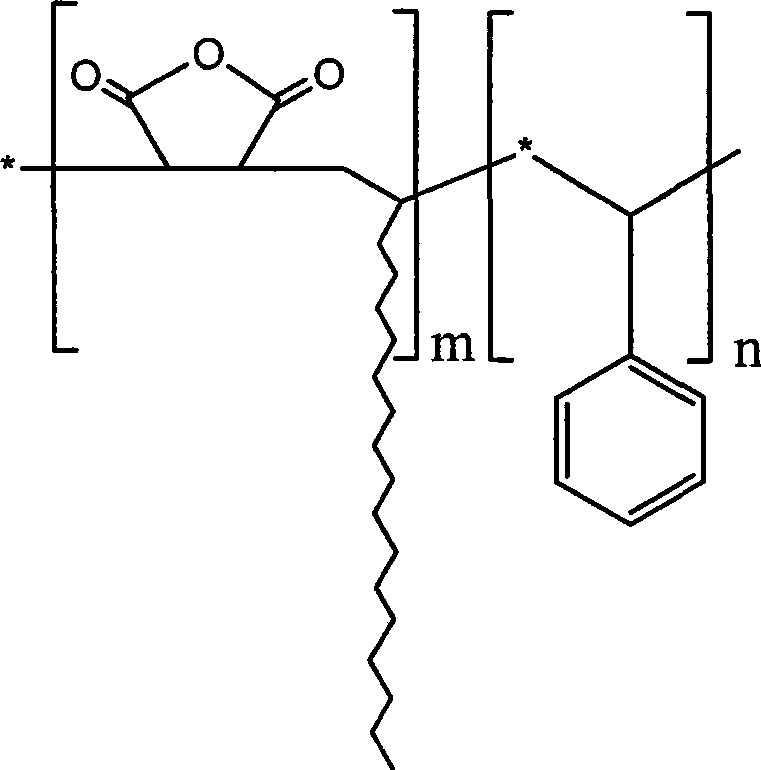

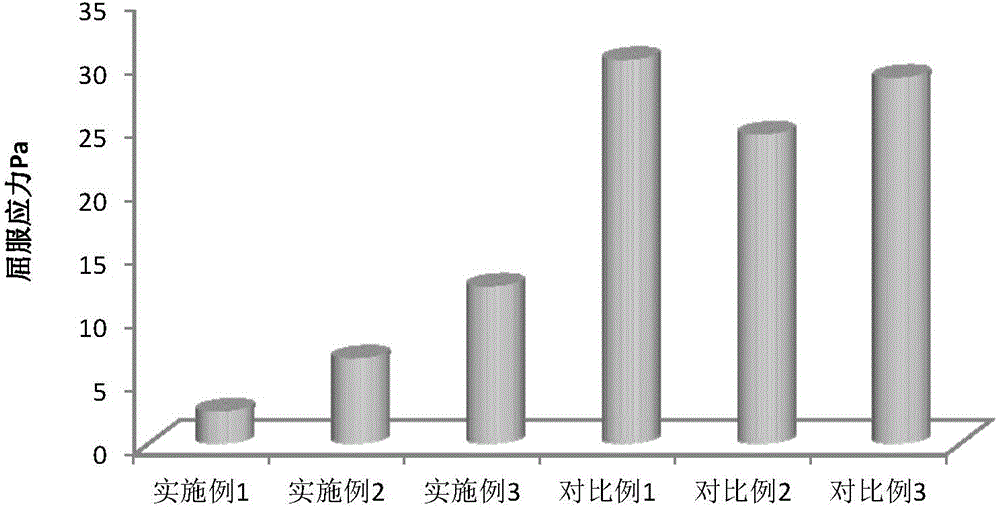

Three-element comb type copolymer, preparation method and application thereof

The invention relates to a three-element comb type copolymer, a preparation method and application thereof. The preparation method comprises two steps: firstly, copolymerizing alpha-olefin and maleic anhydride monomer by a method of free radical polymerization, adding styrene monomer into the mixture in the polymerizing process to obtain a three-element copolymer of the alpha-olefin, the maleic anhydride and the styrene; and then, adding primary alcohol or primary amine to react with estolide, and obtaining the three-element comb type copolymer which not only contains a nonpolar alkyl lateral chain, but also contains polar carboxylic acid and aromatic group. The hydrophobic degree and size of polarity of the three-element comb type copolymer and the content of the aromatic group in the copolymer can be adjusted respectively by adjusting the alkyl length of the alpha-olefin, the primary alcohol or the primary amine, changing the dosage of the primary alcohol or the primary amine, and changing feed time and dosage of the styrene monomer. Experiment results prove that after the three-element comb type copolymer is added in a plurality of kinds of crude oil, stress yield of the crude oil is significantly reduced at low temperature, wax-crystal dimension is reduced, and the effects of pour point depression and viscosity reduction are obvious.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for forging workblank of transmission disc of locomotive

ActiveCN105834348ASave placement timeLower yield stressMetal-working apparatusWheelsManufacturing cost reductionHeating furnace

The invention relates to a method for forging a workblank of a transmission disc of a locomotive. A selected raw material is cut into a blank according to weight; the blank is placed into a heating furnace to be heated to 1100 DEG C to 1180 DEG C; the heated blank is placed into a lower mold cavity of a pre-forging lower die to be positioned, the blank is forged to enable a material of the blank to flow in a pre-forging mold cavity of a pre-forging upper die and the pre-forging mold cavity of the pre-forging lower die in the free upsetting radial direction, and a molded pre-forging piece forms a corresponding thinning part at a protrusion bridge part and correspondingly forms a thickening part at the position of a cavity; the pre-forging piece is turned over to be placed into the mold cavity of the pre-forging lower die to be automatically positioned, the pre-forging piece is forged to enable the material of the pre-forging piece to flow in finish-forging mold cavities of a finish-forging upper die and a finish-forging lower die in the radial direction, and a molded finish-forging piece outwards extends along a disc body to form three uniformly-distributed lug parts and a shaft sleeve located at the middle portion of the disc body; and parting-line flashes of the finish-forging piece are cut off, connecting skin is punched away, and the workblank of the forging piece is prepared. By means of the method, the manufacturing cost is reduced, the production efficiency is improved, the complete streamline of a material of the transmission disc product of the locomotive can be kept, and the transmission disc of the locomotive has the excellent overall performance.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Ultra-high-performance anti-impact anti-abrasion concrete

InactiveCN111233390AGuaranteed internal compactnessImprove corrosion resistanceSilica fumeDefoaming Agents

The invention relates to ultra-high-performance anti-impact anti-abrasion concrete. Cement, microbeads and silica fume are used as cementing materials; aggregate and ultrafine aggregate are added to perfect the grain composition; nanometer ultrafine silicon dioxide, fibers, a water reducing agent, a defoaming agent, a regulating agent, a coagulation accelerator and a retarder are added to be usedas functional auxiliary agents. The concrete can be used for building or repairing parts with impact abrasion damage in hydraulic structures, can also be used for engineering parts with structure impact damage needing to be repaired, and has good construction performance, mechanical performance and impact abrasion resistance.

Owner:CNBM ZHONGYAN TECH

Modification of pb-free solder alloy compositions to improve interlayer dielectric delamination in silicon devices and electromigration resistance in solder joints

InactiveUS20090197103A1Good mechanical integrityImprove reliabilitySolid-state devicesPrinted circuit manufactureDielectricSilicon

A solder joint comprising a solder capture pad on a substrate having a circuit; and a lead free solder selected from the group comprising Sn—Ag—Cu solder and Sn—Ag solder adhered to the solder capture pad; the solder selected from the group comprising between 0.1 to 2.0% by weight Sb or Bi, and 0.5 to 3.0% Ag. Formation of voids at an interface between the solder and the solder capture pad is suppressed, by including Zn. Interlayer dielectric delamination is suppressed, and electromigration characteristics are greatly improved. Methods for forming solder joints using the solders.

Owner:SHIH YUAN +5

Child toothpaste composition

ActiveCN104905987APseudoplasticThixotropicCosmetic preparationsToilet preparationsToothpasteVeterinary medicine

The invention discloses child toothpaste composition. The child toothpaste composition comprises, by weight, 0.1-5 percent of thickener, 0.5-4 percent of solubilizer, 1-60 percent of humectant, 10-90 percent of water, 0.1-2 percent of essence and the balance other components. Abrasives are not added into the child toothpaste composition, and toothpaste body is transparent, generates a little or nearly no foam, is easy to extrude and brush, so that friction to the surfaces of teeth is reduced. The child toothpaste composition is high in safety with the pH range being 5.5-7.5, and can be used as training toothpaste for children at the age of 2-6.

Owner:GUANGZHOU LIBY

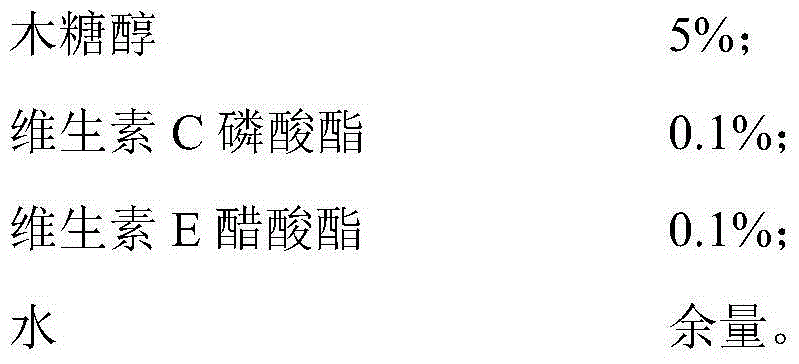

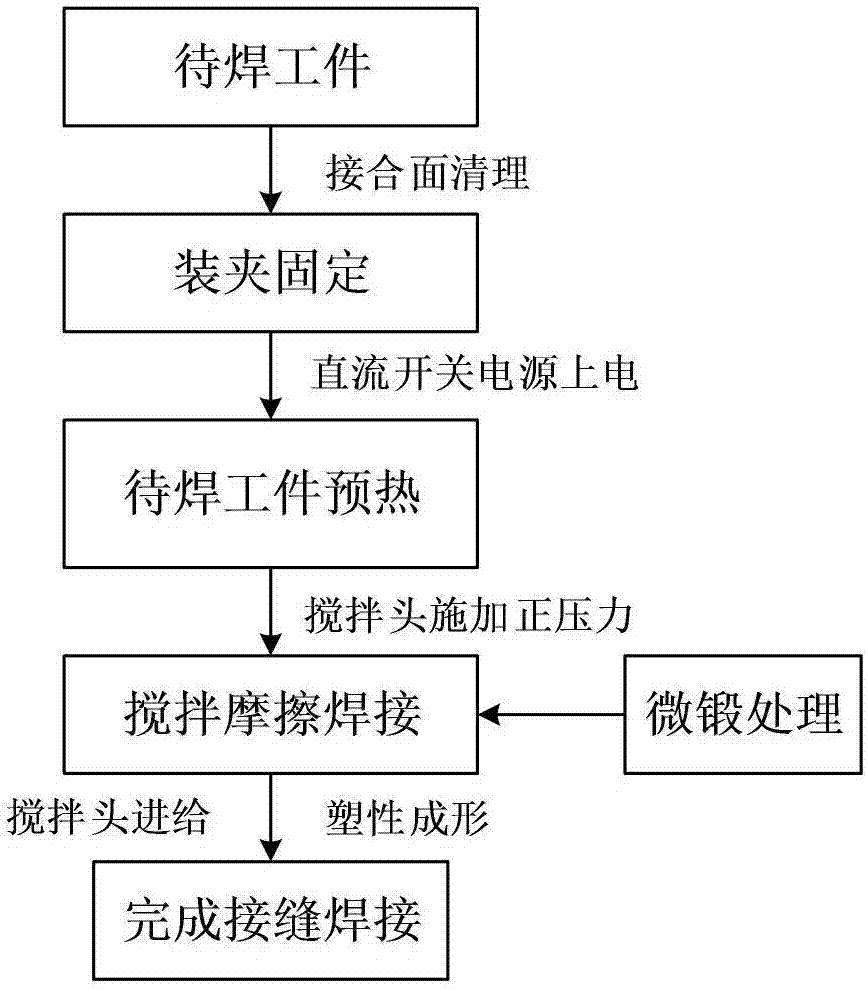

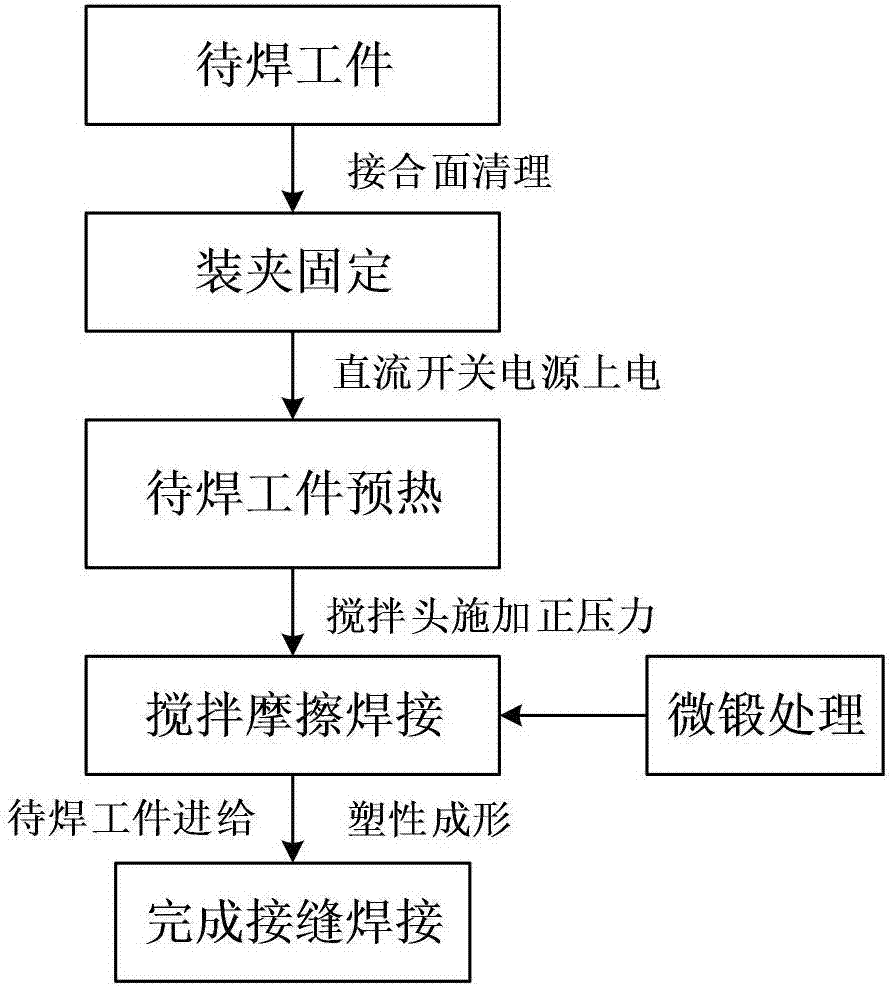

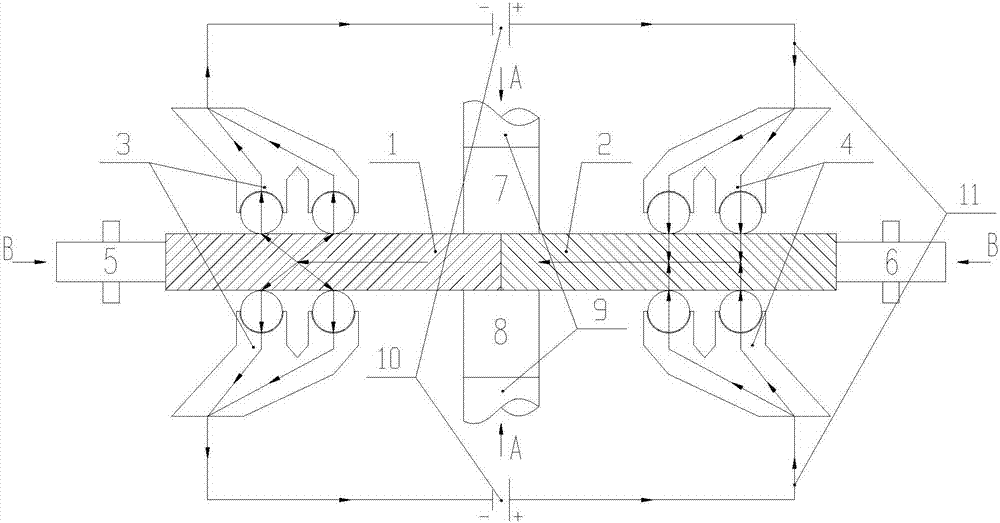

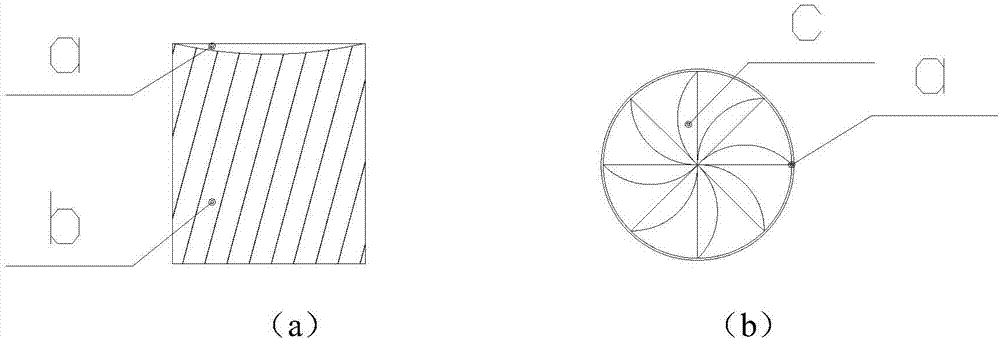

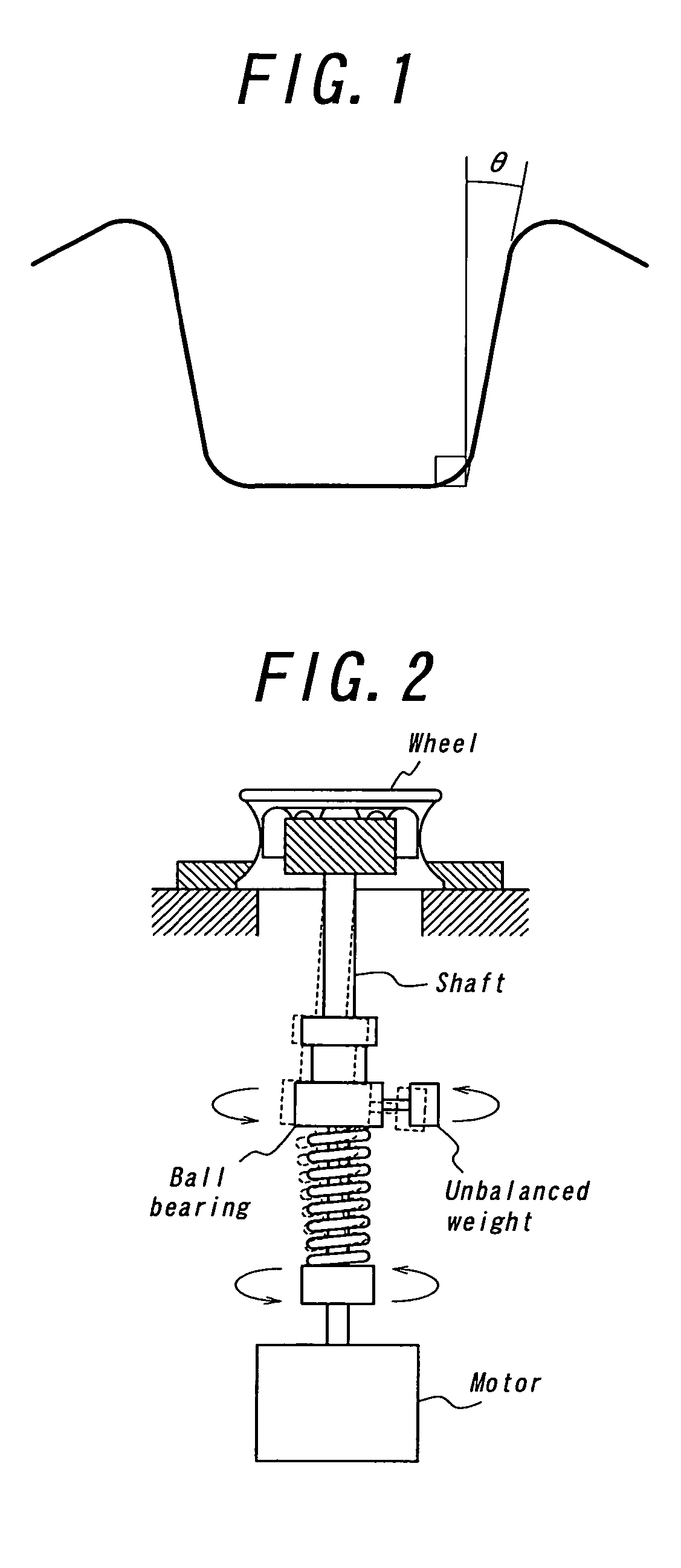

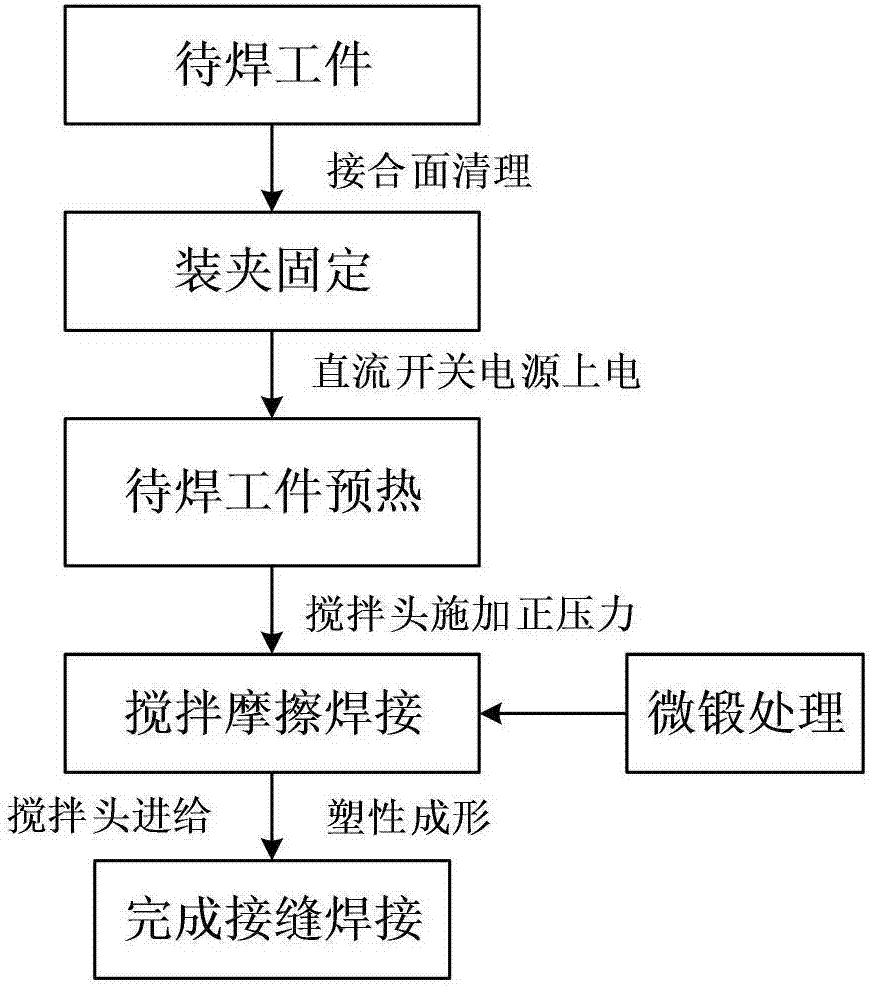

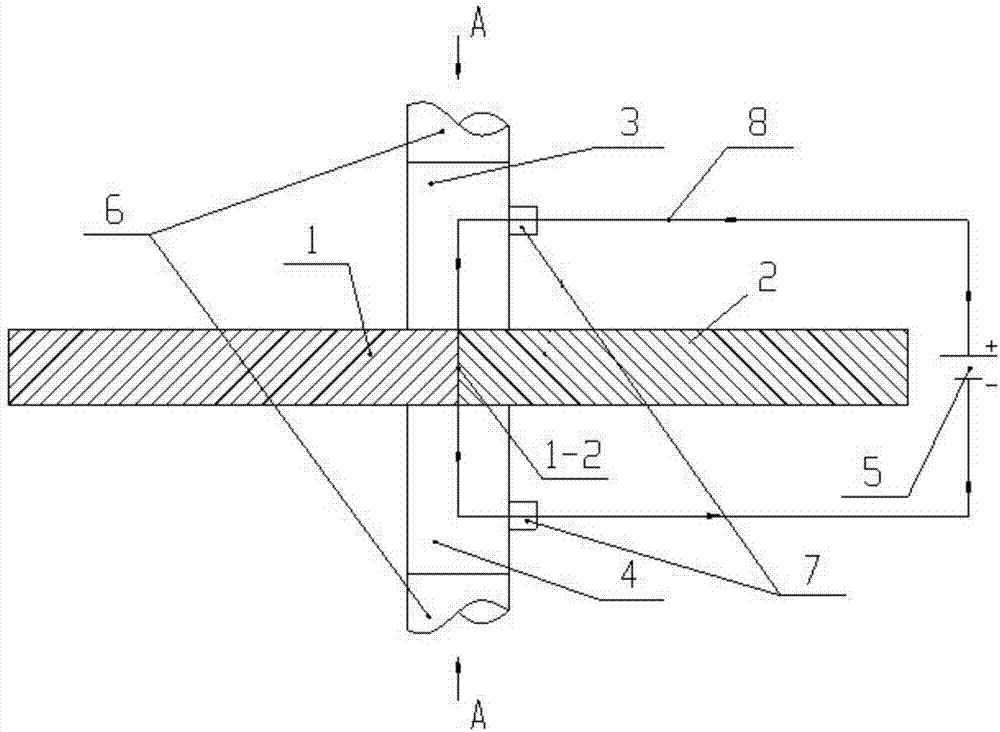

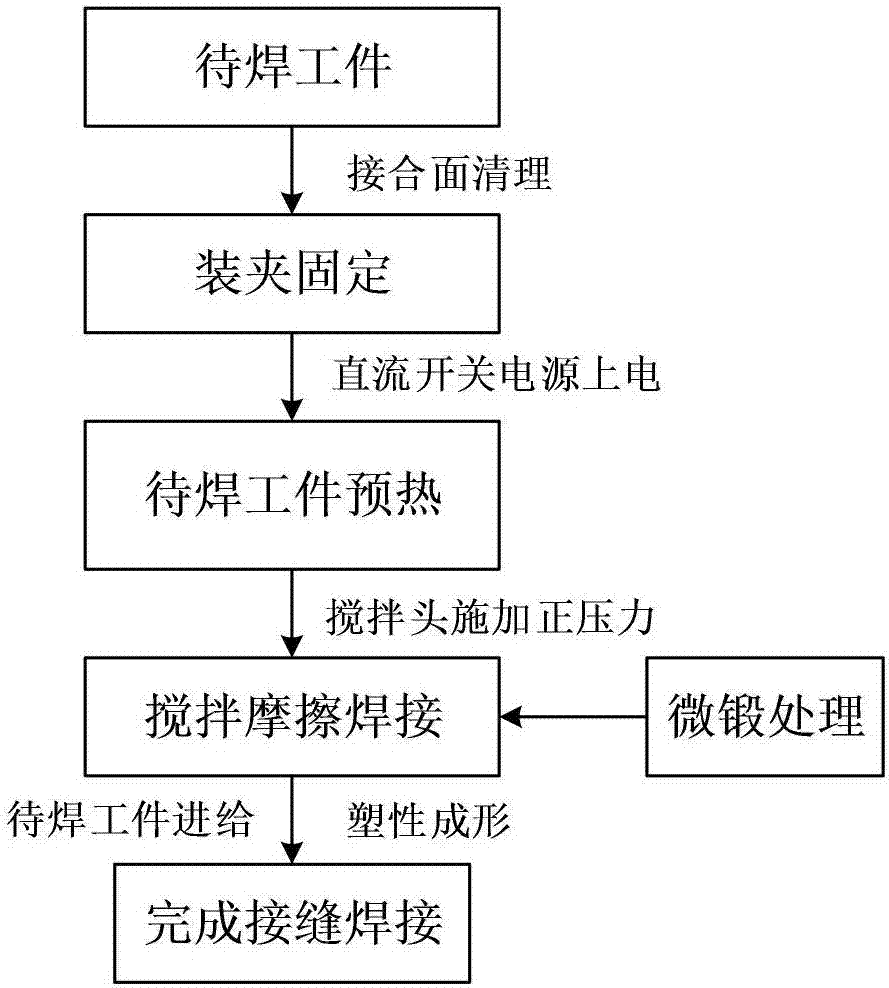

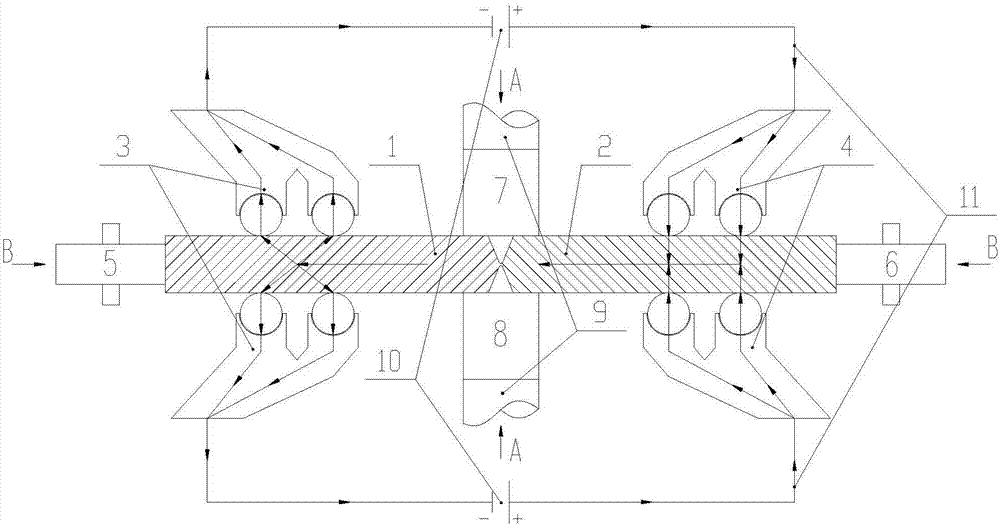

Stirring head power supply-assisted composite double-shaft friction stir welding method

ActiveCN107199394ARefined grain structureQuality improvementNon-electric welding apparatusMetallic materialsWelding defect

The invention discloses a stirring head power supply-assisted composite double-shaft friction stir welding method. The method comprises the steps that stirring friction heads are adopted as electrodes of a resistor heat source, high-density currents are provided for the interior of a to-be-welded workpiece through a direct-current switch power supply, and the resistor-assisted heat source is provided for the stirring heads rotating at a high speed in the friction stir welding process; the stirring heads rotating at the high speed are inserted into the two sides of a joint, and upsetting pressure is exerted to metal at the joint through a shaft shoulder, so that the metal material at the joint is softened; the metal structure at the joint achieves a plasticizing state under the stirring effect through the stirring heads, and meanwhile micro-forging treatment is conducted on the plasticized metal by adopting an ultrasonic vibration exciter, so that metal structure crystalline grains at the joint are refined; the stirring heads do forward feeding motion in the direction of the joint, a cavity formed after a stirring needle moves is continuously filled with the plasticized metal under the stirring and extruding effect of the stirring heads, and the plasticized metal is gradually cooled and solidified to form a welding joint. According to the method, wear of the stirring heads is reduced, the welding thickness is increased, the welding speed is increased, and welding defects are reduced.

Owner:XI AN JIAOTONG UNIV

Process for Improving the Rheological Properties of an Aqueous Dispersion

ActiveUS20140080945A1Lower yield stressHigh energyWaste water treatment from quariesCosmetic preparationsSynthetic materialsAnionic polymers

A process for improving the rheological properties of an aqueous dispersion comprising adding a rheology modifier to the aqueous dispersion, and then adding a water soluble synthetic polymer flocculant to the aqueous dispersion. The rheology modifier may be selected from the group consisting of natural polymers, semi-natural polymers, synthetic materials and combinations thereof. The water soluble synthetic polymer flocculant may be selected from the group consisting of water soluble anionic polymers, cationic polymers, amphoteric polymers, nonionic polymers, and combinations thereof.

Owner:SOLENIS TECH CAYMAN

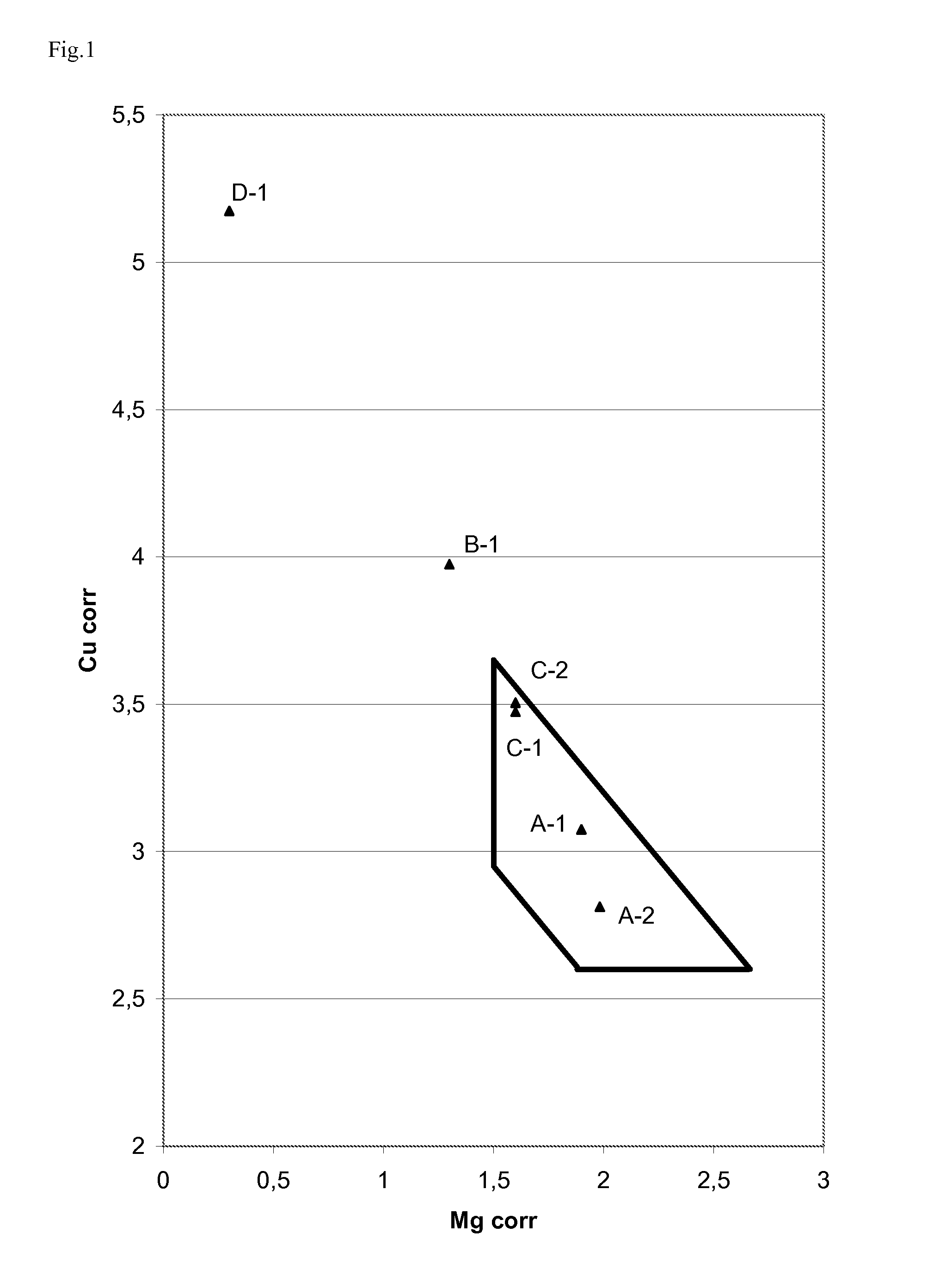

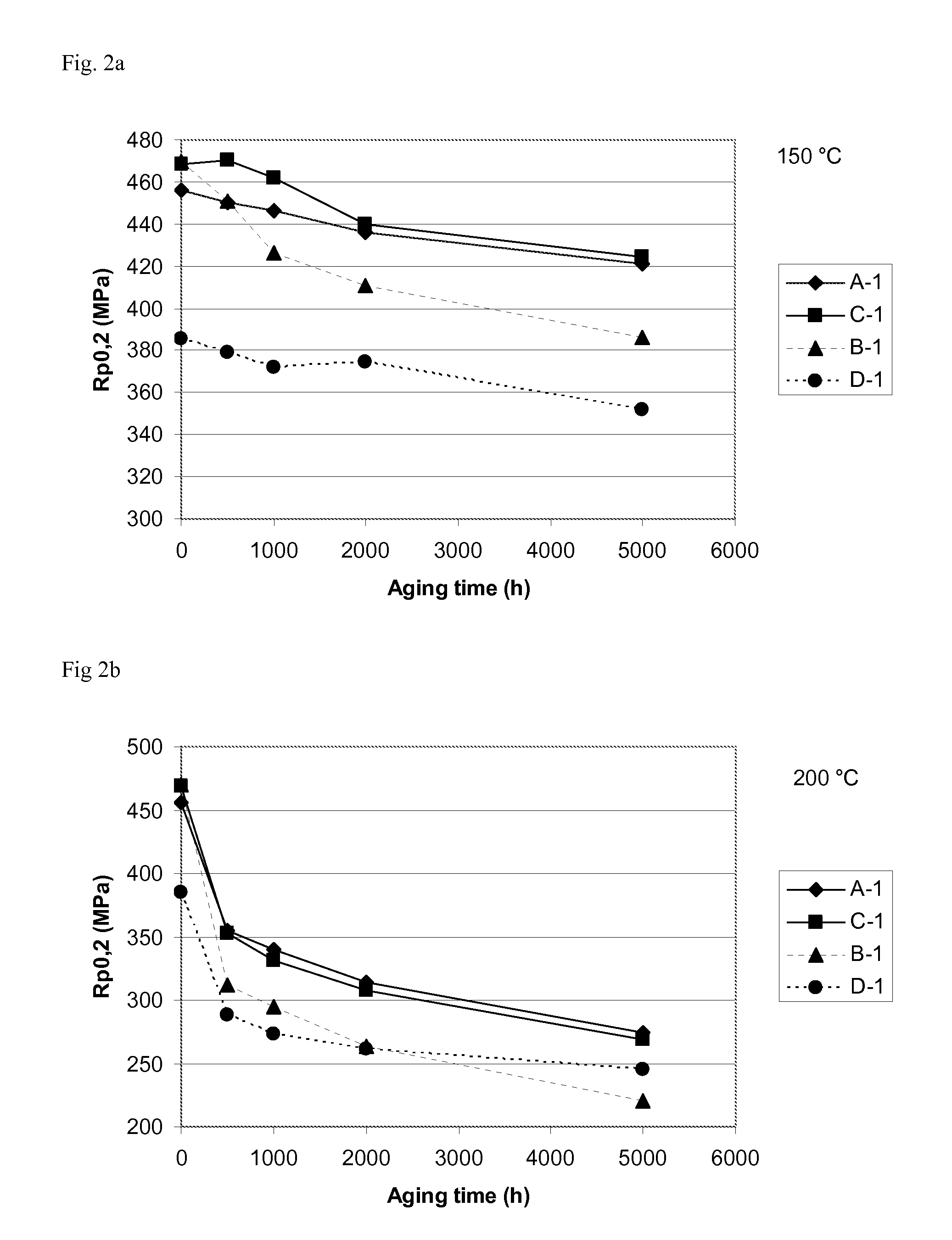

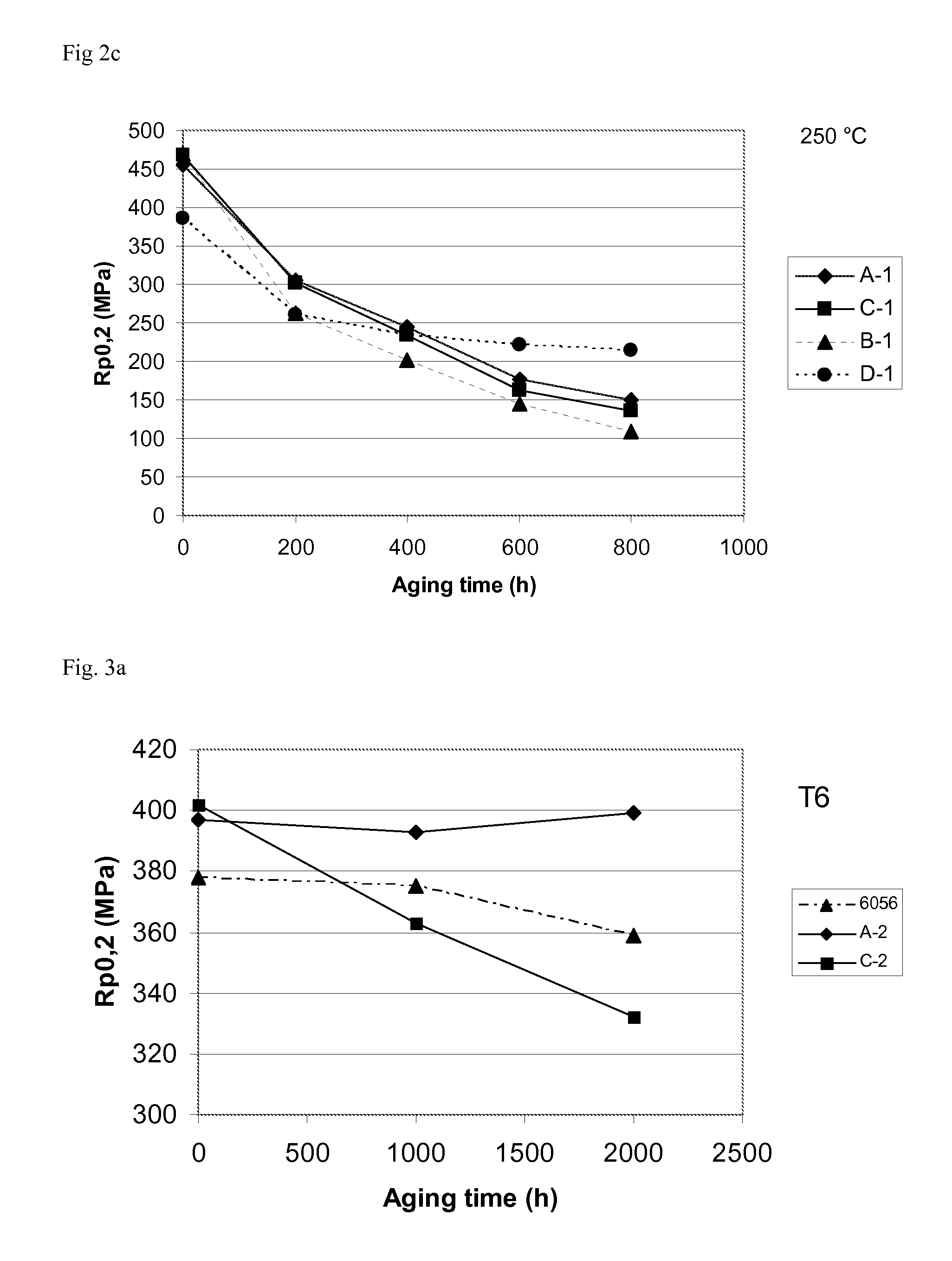

High-temperature efficient aluminum copper magnesium alloys

The disclosure provides for wrought products made of Al—Cu—Mg aluminum alloy composed as follows, as a percentage by weight, Cucorr: 2.6-3.7; Mgcorr: 1.5-2.6, Mn: 0.2-0.5; Zr: ≦0.16; Ti: 0.01-0.15; Cr≦0.25; Si≦0.2; Fe≦0.2; other elements <0.05 the rest aluminum; with Cucorr>−0.9 (Mgcorr)+4.3 and Cucorr<−0.9 (Mgcorr)+5.0; where Cucorr═Cu−0.74 (Mn−0.2)−2.28 Fe and Mgcorr═Mg 1.73 (Si−0.05) for Si≧0.05 and Mgcorr═Mg for Si<0.05 and their manufacturing process.

Owner:CONSTELLIUM ISSOIRE

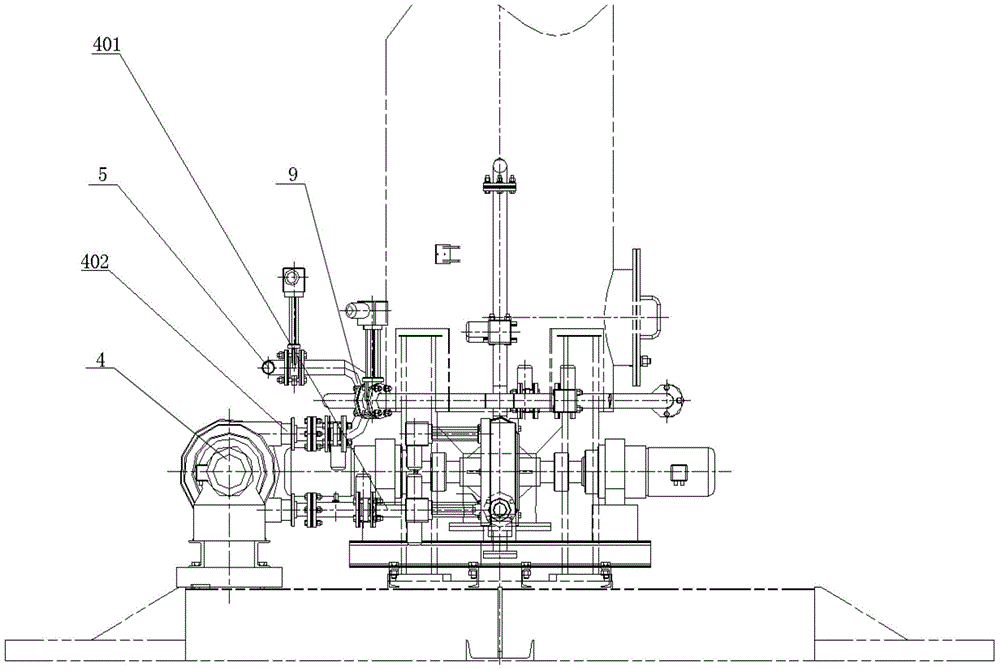

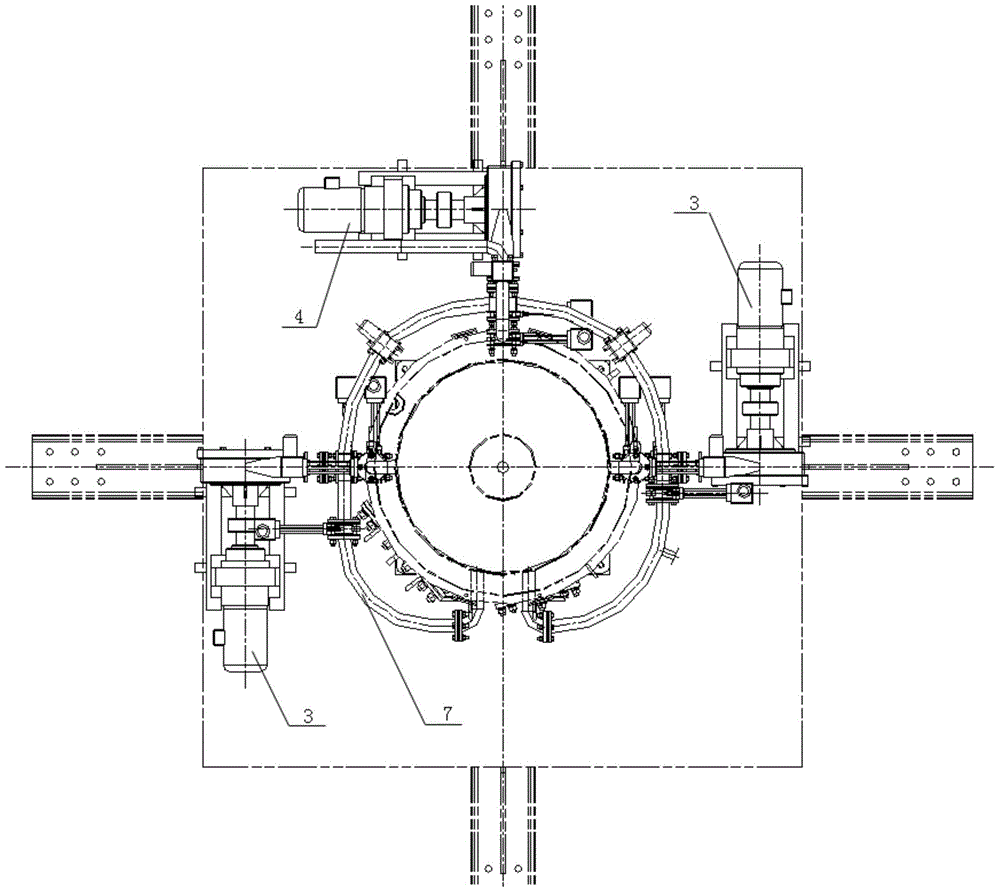

Heat source auxiliary compound double-axis needleless dynamic friction stir welding method

ActiveCN107150166ARefined grain structureQuality improvementNon-electric welding apparatusFriction weldingHigh density

The invention discloses a heat source auxiliary compound double-axis needleless dynamic friction stir welding method. Positive and negative electrode dynamic clamping heads and a guide pretightening wheel are adopted to finish clamping of workpieces to be welded; a direct-current switch power supply is used for providing high-density current into the workpieces to be welded; metals in joints of the workpieces to be welded are preheated; stirring heads rotating at high speed are pressed in two sides of the joints; positive pressure is applied to the metals in the joints through shaft shoulders, so that the metal materials in the joints are softened; the stirring heads rotating at high speed enable the metal structures in the joints to achieve a plastified state under the friction stirring effect; meanwhile, a ultrasonic exciter is adopted to finely forge the plastified metals; the workpieces to be welded are forwards fed along with a welding worktable in the directions of the joints; and the plastified metals are continuously filled in a cavity formed after movement of the stirring head under the stirring and extruding effects of the stirring heads, and are gradually cooled to condense as final welding lines. The method relieves the wear of the stirring heads, increases the welding thickness, accelerates the welding speed, and reduces the welding defects.

Owner:XI AN JIAOTONG UNIV

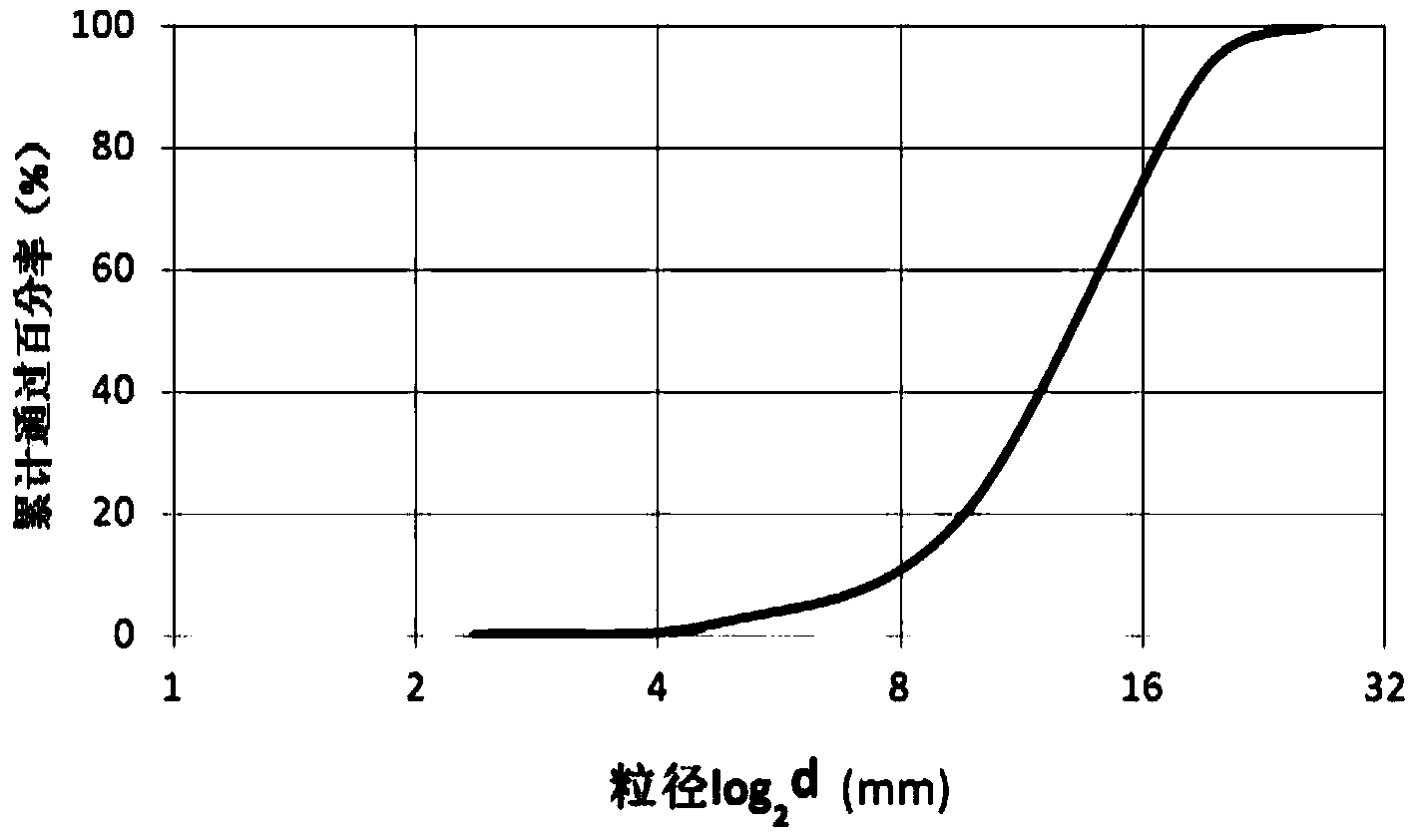

Underwater dispersion-resistant porous concrete with large particle size and preparation method thereof

InactiveCN103936355AHigh strengthImprove early strengthSolid waste managementMass ratioCrushed stone

The invention discloses underwater dispersion-resistant porous concrete with a large particle size. The underwater dispersion-resistant porous concrete comprises the following raw materials: aggregate, cement, mineral admixture, water and a thickener, wherein a mass ratio of the sum of the cement and the mineral admixture to the aggregate is 0.19-0.23; the mineral admixture is micron silicon powder and nano calcium carbonate, wherein the micron silicon powder accounts for 0%-10% of the cement, and the nano calcium carbonate accounts for 0%-1% of the cement; the thickener accounts for 2%-4.5% of the sum of the cement and the mineral admixture; the aggregate is graded aggregate with the particle size of 5mm-20mm; and water accounts for 0.25-0.35 of the sum of the cement and the mineral admixture. The invention further discloses a preparation method of the concrete. The concrete has underwater dispersion-resistant self-leveling property and is not isolated under vibration and underwater environment, and uniform in hole structure uniformity. As a pile body material, the underwater dispersion-resistant porous concrete can realize rapid pulling of a sleeve during vibration immersed tube method construction, generates little disturbance on soil around the pile and does not have pile breakage and hole shrinkage; moreover, the underwater dispersion-resistant porous concrete has good anti-blocking ability.

Owner:SHANDONG UNIV

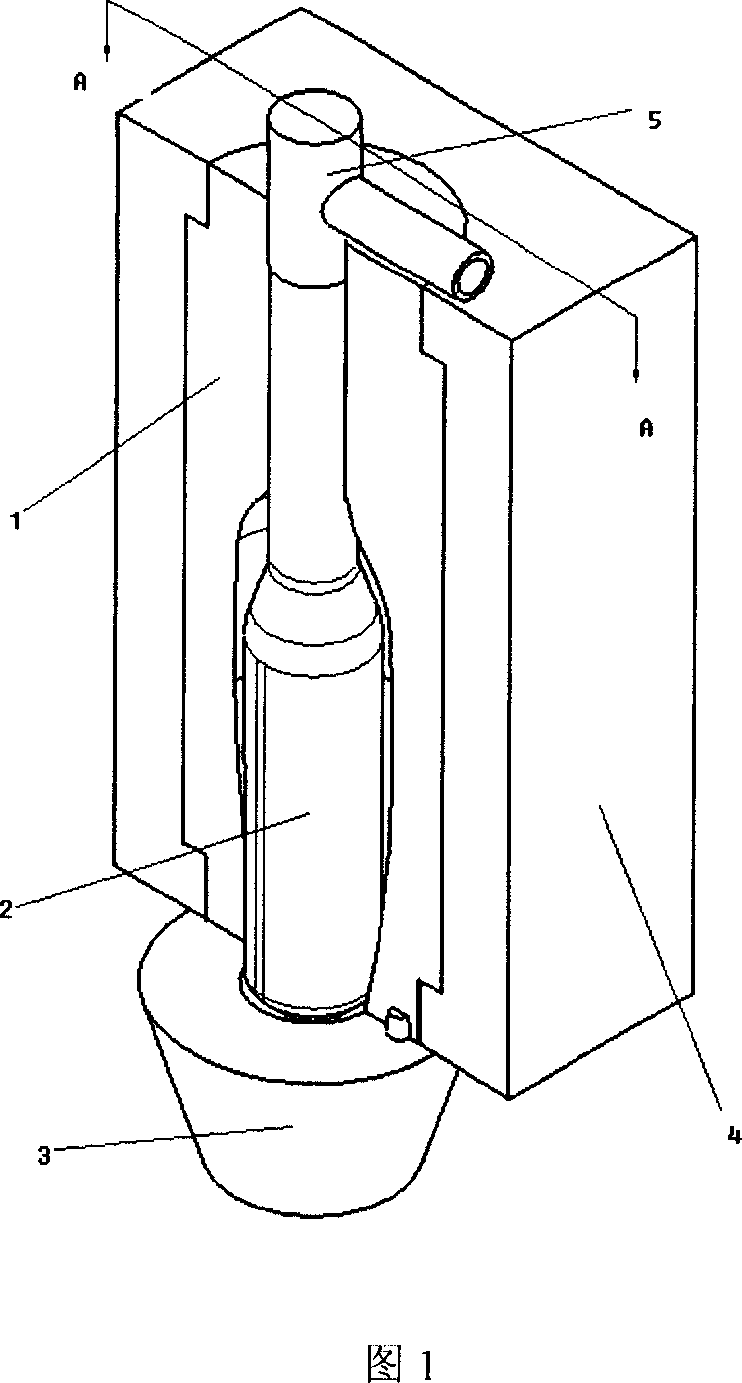

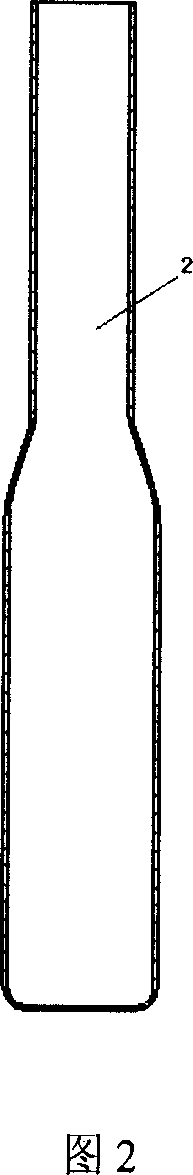

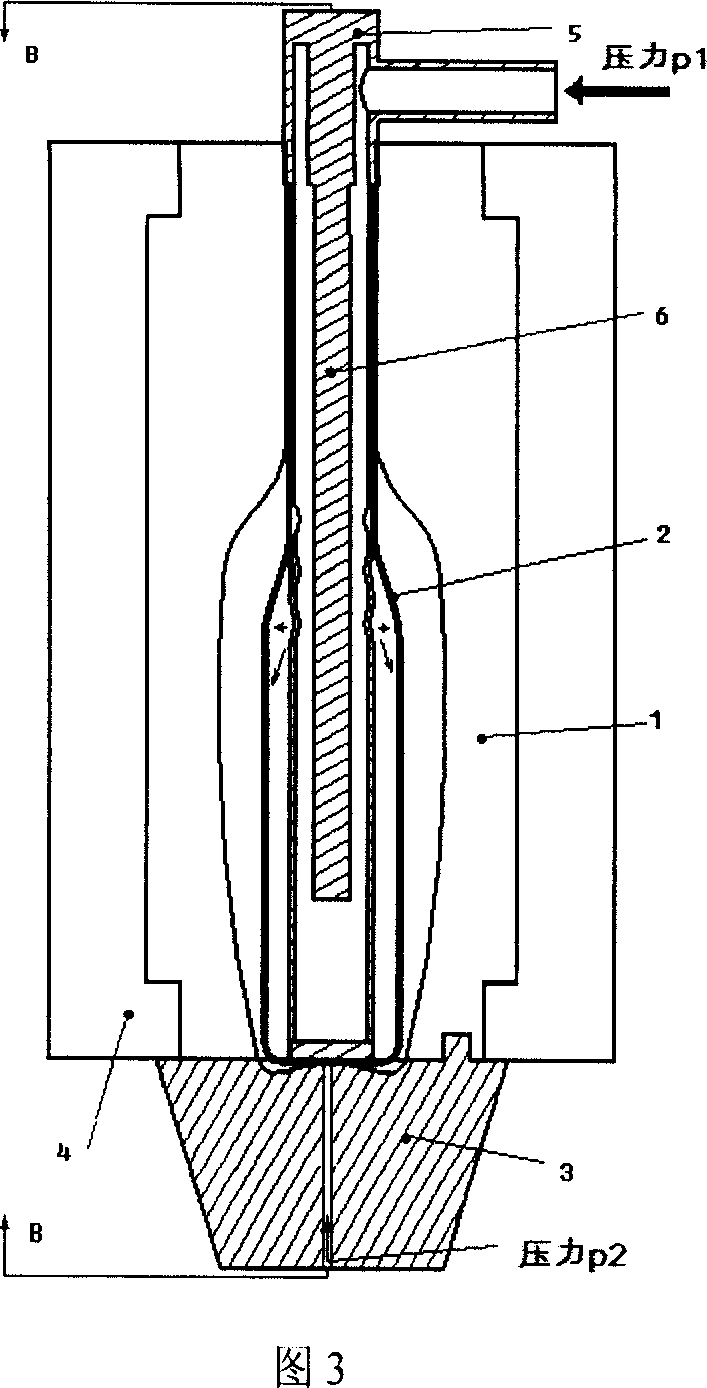

Hot pressure blowing method of forming metal bottle

The hot pressing and blowing process for forming metal bottle is to form metal bottle with high pressure inside a closed mold on the principle that at high temperature, metal material has lowered yield stress and raised plasticity. The forming machine consists of mold seat, side molds, bottom mold, pressure conducting duct and heater. The hot pressing and blowing process for forming metal bottle includes: fixing the bottle blank inside the mold cavity with sealed pressure conducting duct; heating the bottle blank with the heater to the forming temperature and intruding pressure gas into the bottle blank for the bottle blank to be formed into the required shape. The process of the present invention is suitable for forming various kinds of metal containers, including complicated ones, and the formed metal container has homogeneous wall thickness and smooth transition.

Owner:谢靖佳

High tensile hot rolled steel sheet excellent in shape freezing property and endurance fatigue characteristics after forming

InactiveUS7347902B2Improve fatigue durabilityExcellent shape fixabilityFurnace typesHeat treatment furnacesHigh intensityUltimate tensile strength

According to the invention, a high-strength hot rolled steel sheet having an excellent shape fixability as hot-rolled and an excellent fatigue durability after the forming, excellent weldability and phosphatability and a tensile strength of not less than 590 MPa level can be obtained by comprising C: not less than 0.02 mass % but not more than 0.2 mass %, Si: not less than 0.5 mass % but not more than 2.0 mass %, Mn: not less than 1.0 mass % but not more than 3.0 mass %, Al: not less than 0.01 mass % but not more than 0.1 mass %, N: not less than 0.002 mass % but not more than 0.006 mass %, P: not more than 0.03 mass %, S: not more than 0.01 mass % and solid-soluted (C+N): not less than 0.0010 mass % and the reminder being Fe and inevitable impurities, and having a steel structure that a primary phase is ferrite and a secondary phase is martensite phase of 5-30 % at a volume ratio and a total of both is not less than 95 % as a volume ratio, and further having an average crystal grain size of ferrite of not more than 8 μm.

Owner:JFE STEEL CORP

Resistor heat source-assisted composite double-shaft needle-free friction stir welding method

ActiveCN107199395ARefined grain structureQuality improvementNon-electric welding apparatusNeedle freeMetallic materials

The invention discloses a resistor heat source-assisted composite double-shaft needle-free friction stir welding method. The method comprises the steps that stirring friction heads are adopted as electrodes of a resistor heat source, high-density currents are provided for the interior of a to-be-welded workpiece through a direct-current switch power supply, and the resistor-assisted heat source is provided for the stirring heads in the friction stir welding process; the stirring heads rotating at a high speed are inserted into the two sides of a joint, and upsetting pressure is exerted to metal at the joint through a shaft shoulder, so that the metal material at the joint is softened; the metal structure at the joint achieves a plasticizing state under the stirring effect through the stirring heads rotating at the high speed, and meanwhile micro-forging treatment is conducted on the plasticized metal by adopting an ultrasonic vibration exciter, so that metal structure crystalline grains at the joint are refined; the stirring heads do feeding motion in the direction of the joint, a cavity formed after a stirring needle moves is continuously filled with the plasticized metal under the stirring and extruding effect of the stirring heads, and the plasticized metal is gradually cooled and solidified to form a final welding joint. According to the method, the life of the stirring heads is prolonged, the welding thickness is increased, the welding speed is increased, and welding defects are reduced.

Owner:XI AN JIAOTONG UNIV

Endoglucanases

ActiveUS8088608B2Saccharification of cellulosic feedstockLower yield stressPolypeptide with localisation/targeting motifSugar derivativesGlucanaseWild type

Owner:CODEXIS INC

Green alkali-activated material for repair and protection and preparation method thereof

The invention relates to a green alkali-activated material for repair and protection. The green alkali-activated material is composed of 55%-70% of an alkali-activated active matter, 0-20% of concretewaste slurry powder, 1%-2% of a reinforcing component, 6%-10% of an alkali activator, 1.5%-2% of a water reducing component and the balance water, and the total mass of the green alkali-activated material is 100%. The material is high in early strength, high in fluidity and suitable for construction. Specifically, the concrete waste slurry powder can provide part of excitation alkalinity requiredby an early reaction, aluminosilicate in the waste residue powder has potential alkali-activated active matters, and has a good way of absorbing mixing plant waste residues. The fluidity of a geopolymer can be improved by doping the fly ash and silica fume, the yield stress of the slurry is reduced, and the fluidity required by repair and protection is met. The ultra-dispersed nano reinforcing material is doped, so that the filling effect can be achieved in the alkali-activated reaction process, the dissolution of aluminosilicate minerals is promoted, and the mechanical properties of the alkali-activated material are improved. The green alkali-activated material for repair and protection is low in cost and environmentally friendly, and has high promotable value.

Owner:HUNAN CSCEC5B CONCRETE +1

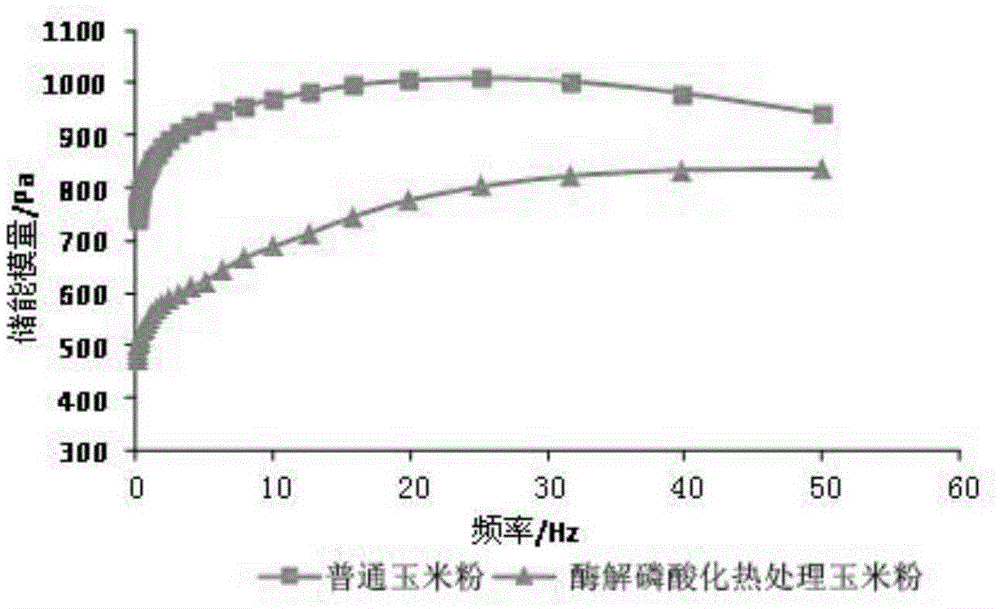

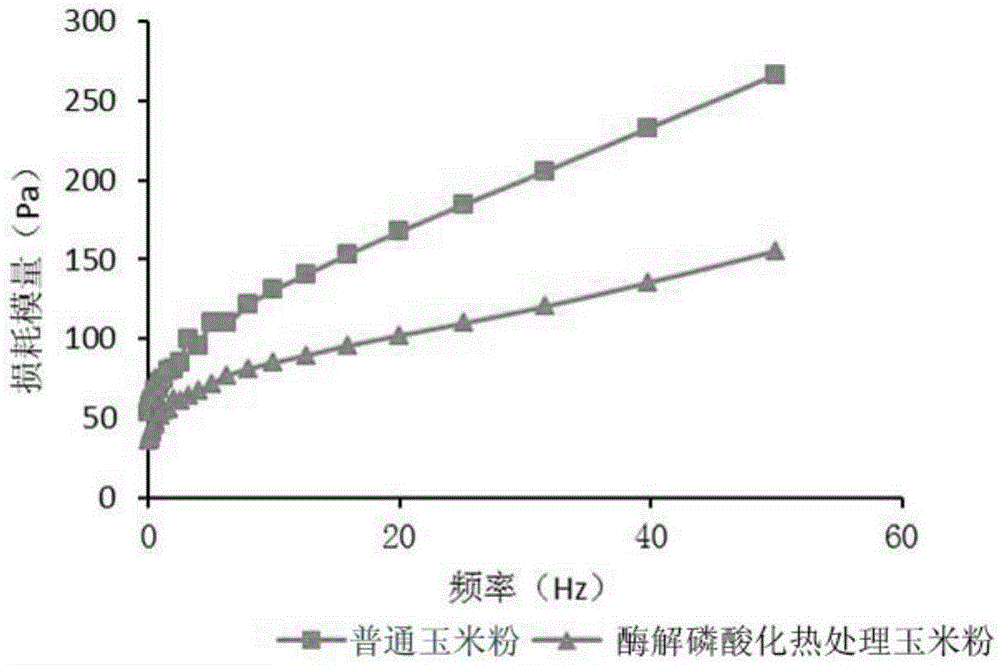

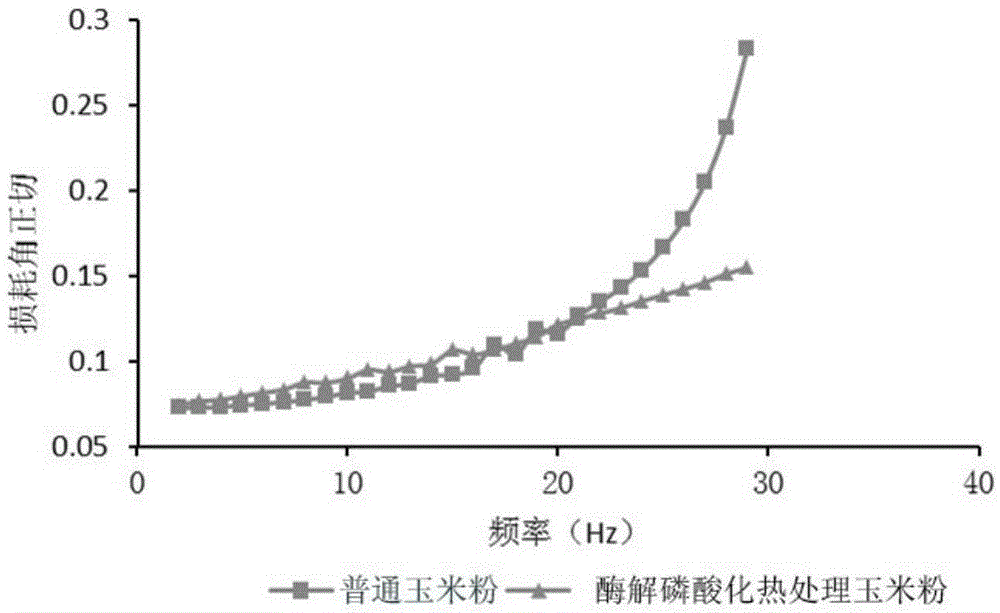

Enzymolysis, phosphorylation and heat treatment method for corn flour

PendingCN105410632AAmino acid content is not reducedRetain nutritional valueFood scienceNeutral proteasePhosphate

The present invention relates to an enzymolysis, phosphorylation and heat treatment method for corn flour. The selected corn flour is fully mixed with water to form a paste-like viscous fluid, neutral protease is added into the paste-like viscous fluid for enzymolysis, then the mixture is heated to inactivate the enzyme, and enzyme inactivated liquid mixture is frozen, dried and pulverized to obtain the enzymatic corn flour. Phosphate esterification reagents are fully and evenly mixed with the enzymatic corn flour, and the mixture is sealed, dried and then placed in a drying oven for heating reaction. The neutral protease and phosphate esterification reagents are used to conduct enzymolysis and chemical modification on the corn flour, lifting the binding of protein to starch granules for degrading the protein into small molecules and releasing organic nutrient substances (starch, polysaccharides, peptides, etc.); wherein the amino acid content remains unchanged to retain the nutritional value, shortcomings of the corn flour, such as poor viscoelasticity, flexibility, etc., are improved since the corn flour itself contains no mucedin. The finished products are exquisite and smooth in taste, relatively suitable for traditional corn food processing.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Thickener and bottom flow circulating system thereof

ActiveCN104941262ALower yield stressLow viscositySedimentation settling tanksCirculating pumpWaste management

The invention discloses a bottom flow circulating system of a thickener. The bottom flow circulating system comprises a thickening pool, a bottom flow cylinder arranged at the bottom of the thickening pool, a bottom flow circulating pump and a bottom flow discharge pump, wherein the inlet I of the bottom flow circulating pump is connected with the bottom flow cylinder, the outlet I of the bottom flow circulating pump is connected with the thickening pool; and the inlet II of the bottom flow discharge pump is connected with the bottom flow cylinder and the outlet II of the bottom flow discharge pump is connected with a slurry discharging pipeline. According to the bottom flow circulating system of the thickener, through the action of the bottom flow circulating pump, ore slurry flows out from the inside of the bottom flow cylinder to the bottom flow circulating pump and flows back to the thickening pool from the bottom flow circulating pump; the process is repeated again and again, so that the ore slurry at the bottom of the thickener can be forcefully circulated and the occurrence of rake pressing or sticking of the thickener can be effectively prevented; thus the thickener with the bottom flow circulating system has both preparation and storage functions; and besides, the ore slurry of a qualified concentration can be smoothly discharged through the slurry discharging pipeline. The invention further discloses the thickener comprising the bottom flow circulating system.

Owner:FENY +1

Chuck power supply auxiliary compound double-axis dynamic friction stir welding method

ActiveCN107150167ARefined grain structureQuality improvementNon-electric welding apparatusPositive pressureMetallic materials

The invention discloses a chuck power supply auxiliary compound double-axis dynamic friction stir welding method. Positive and negative electrode dynamic clamping heads and a guide pretightening wheel are adopted to finish clamping of workpieces to be welded; a direct-current switch power supply is used for providing high-density current into the workpieces to be welded; metals in joints of the workpieces to be welded are preheated; stirring heads rotating at high speed are inserted in two sides of the joints; positive pressure is applied to the metals in the joints through shaft shoulders, so that the metal materials in the joints are softened; the stirring heads enable the metal structures in the joints to achieve a plastified state under the stirring effect; meanwhile, a ultrasonic exciter is adopted to finely forge the plastified metals, so that grains of the metal structures in the joints are refined; the workpieces to be welded are fed along with a welding worktable in the directions of the joints; and the plastified metals are continuously filled in a cavity formed after movement of stirring needles under the stirring and extruding effects of the stirring heads, and are gradually cooled to condense as welding lines. The method relieves the wear of the stirring heads, increases the welding thickness, accelerates the welding speed, and reduces the welding defects.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com