Stirring head power supply-assisted composite double-shaft friction stir welding method

A friction welding and biaxial stirring technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of low welding speed, wear of stirring head, and bulky equipment, etc., to improve welding speed, increase strength, reduce Effects of Welding Defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

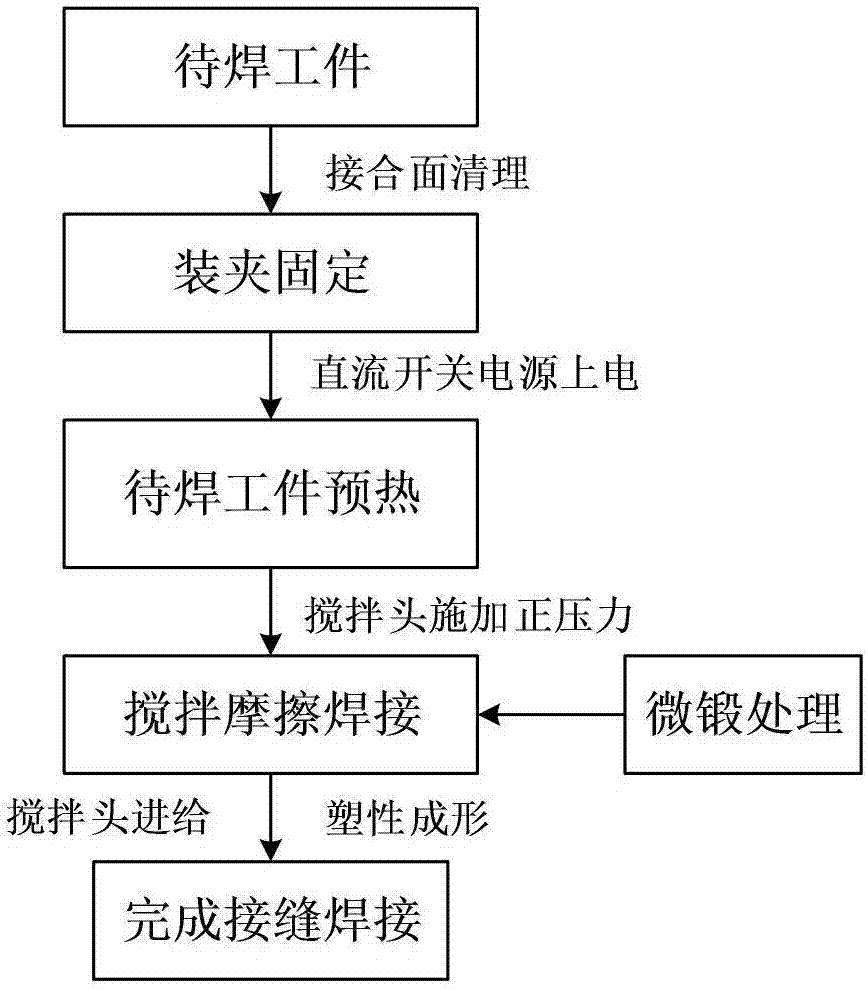

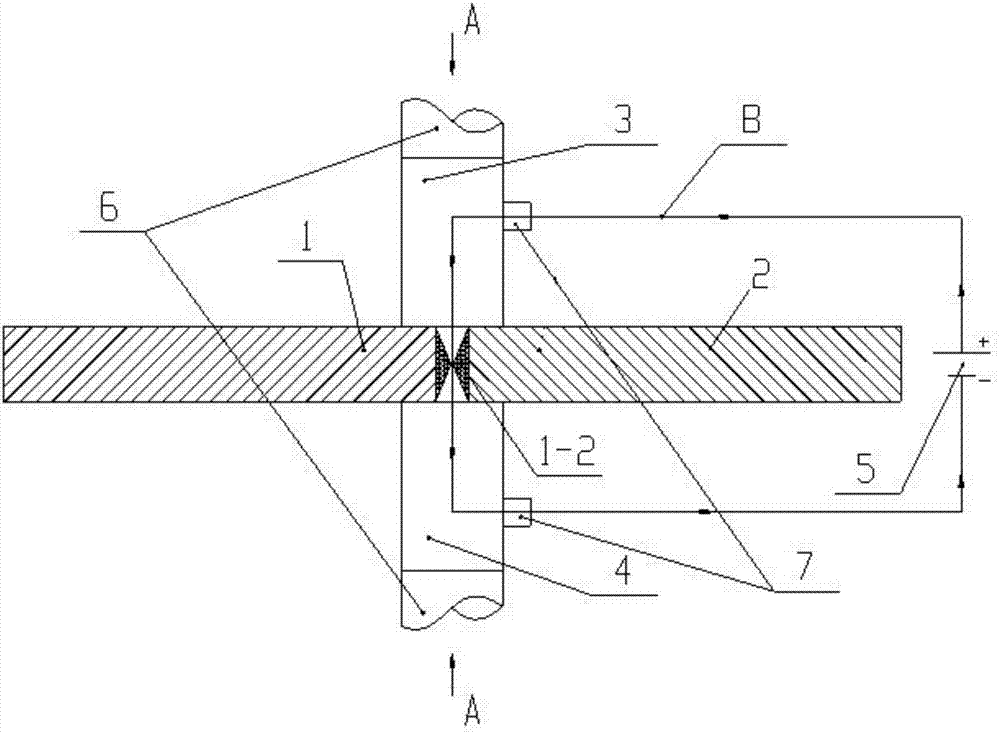

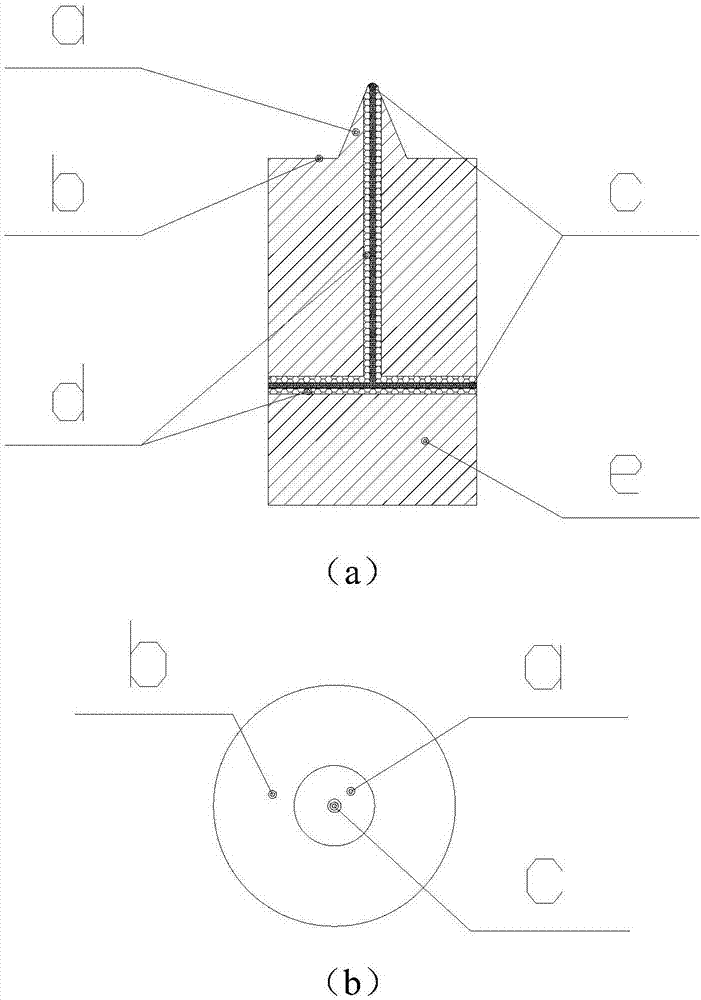

[0020] refer to figure 1 , figure 2 , image 3 and Figure 4 , a composite biaxial friction stir welding method powered by a stirring head, comprising the following steps:

[0021] 1) Clamping and fixing the first workpiece 1 to be welded and the second workpiece 2 to be welded on the welding workbench, the seam gap between the first workpiece 1 to be welded and the second workpiece 2 to be welded is 0-0.6mm; The welding workbench and workpiece fixture need to be insulated to prevent the danger of equipment leakage; before clamping, it is necessary to clean the joint surface of the first workpiece 1 to be welded and the second workpiece 2 to be welded to remove oil. Remove oxide film;

[0022] 2) The first workpiece 1 to be welded, the second workpiece 2 to be welded, the first stirring head 3, and the second stirring head 4 are connected by the first stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com