Rolling technology and heat treatment method of pre-hardening type plastic die steel

A technology of plastic mold steel and heat treatment method, which is applied in the field of metallurgy, can solve problems such as easy cracking, and achieve the effects of improving hardness uniformity, large market prospects, and enriching variety structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

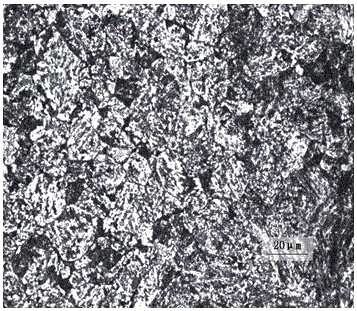

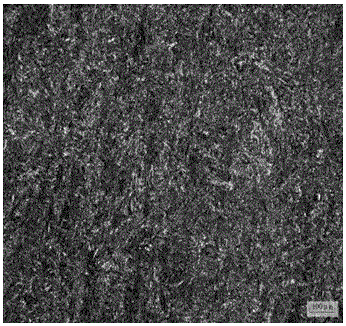

Image

Examples

Embodiment 1

[0036] Embodiment 1: Rolling process and heat treatment embodiment of LGP20 series:

[0037] The chemical composition of LGP20 series is as follows:

[0038] Chemical composition of LGP20

[0039]

[0040] For LGP20 series blanks, the soaking temperature is controlled at 1200-1250°C, the final rolling temperature is 930-980°C, air-cooled to 380-420°C and then slowly cooled to room temperature; normalized at 890°C, air-cooled to room temperature and then 560-580 ℃ tempering treatment.

[0041] The temperature of the billet in the heating section 1 and 2 of the heating furnace is 1240°C and 1110°C respectively, and the temperature in the soaking section is 1230°C. After the furnace time reaches 258min, the steel is tapped, and the tapping temperature is 1186°C.

[0042] Rolling control conditions: 6 passes of rough rolling, the pass reductions are 18mm, 18mm, 15mm, 26mm, 26mm, 25mm, rolling with a large reduction, and the billet thickness is 82mm; There are 4 passes, the pas...

Embodiment 2

[0048] Embodiment 2: to the rolling process of LG2311 series and heat treatment embodiment:

[0049] Chemical composition of LG2311

[0050]

[0051] The temperature of the billet in the heating section 1 and 2 of the heating furnace is 1230°C and 1109°C respectively, and the temperature in the soaking section is 1228°C. After the furnace time reaches 274min, the steel is tapped, and the tapping temperature is 1181°C.

[0052] Rolling control situation: rough rolling and finish rolling were rolled for 9 passes, of which 5 passes were used for rough rolling, and the pass reductions were 10, 11, 27, 27, 25 respectively. The billet thickness is 120mm; the finishing rolling pass is 4 passes, the pass reductions are 9, 5, 4, 2 respectively, and the finished product specification is 100mm.

[0053] Normalizing control: temperature 870±10°C; time in furnace=2min / mm×thickness+20min (holding time), air cooling.

[0054]

[0055] Tempering control situation: the corresponding te...

Embodiment 3

[0061] Embodiment 3: to the rolling process of LG718 series and heat treatment embodiment:

[0062] Chemical composition of LG718 billet

[0063]

[0064] The temperature of the billet in the heating section 1 and 2 of the heating furnace is 1241°C and 1100°C respectively, and the temperature in the soaking section is 1236°C. After the furnace time reaches 284min, the steel is tapped, and the tapping temperature is 1186°C.

[0065] Control of rolling passes: rough rolling and finish rolling are rolled for 9 passes, of which 7 passes are rough rolled, and the reductions in the last three passes of rough rolling are 28, 27, and 25 respectively, and rolling with large reductions is adopted. The rolled product specification is 36mm.

[0066] Normalizing control: temperature 870±10°C; furnace time=2.5min / mm×thickness+25min (holding time), air cooling.

[0067]

[0068] Tempering control situation: the corresponding tempering temperature has been formulated for different har...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com