Patents

Literature

78results about How to "Improve hardness uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Economical non-quenched and non-tempered micro-alloyed plastic die steel plate and making method thereof

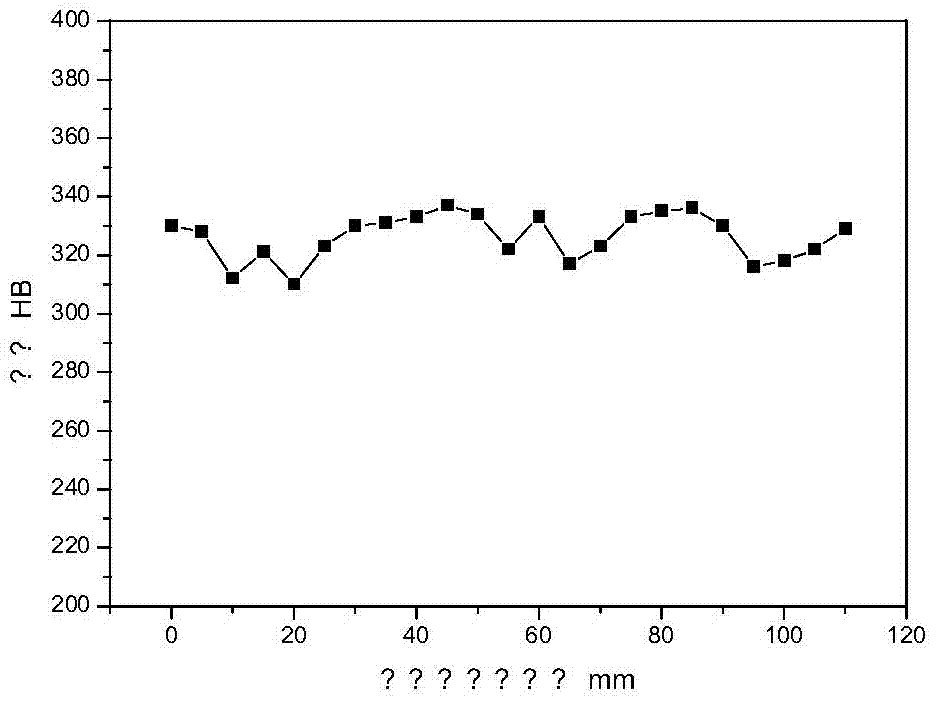

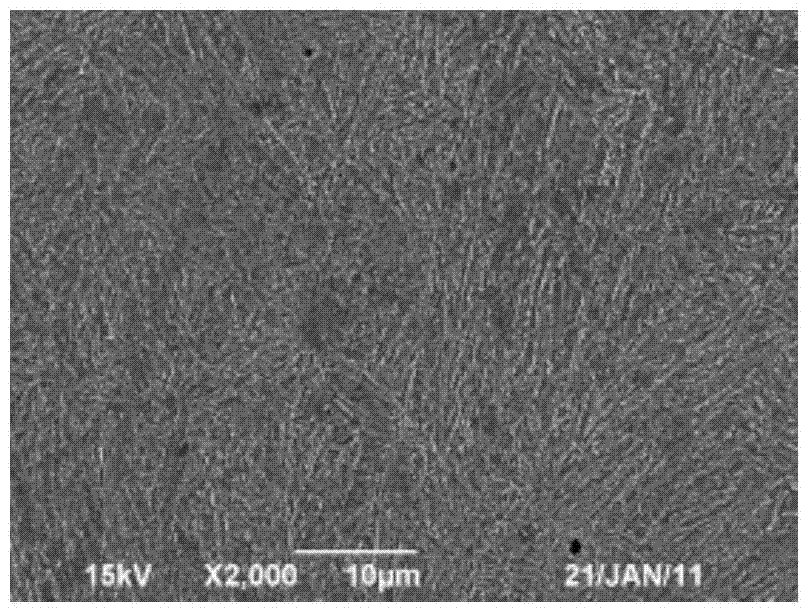

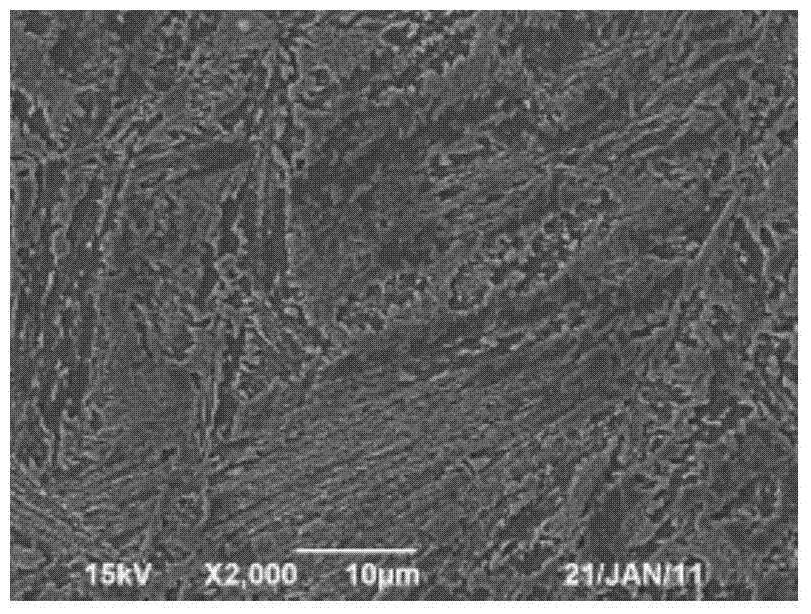

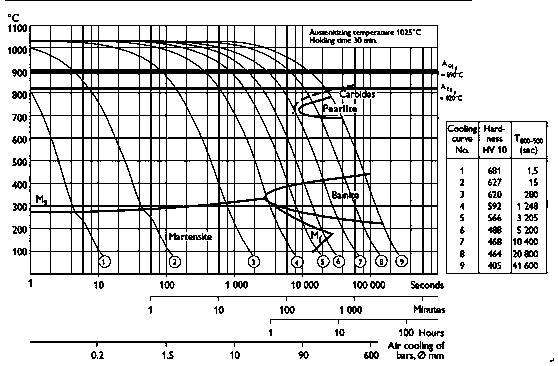

The invention discloses an economical non-quenched and non-tempered micro-alloyed plastic die steel plate and a making method thereof. The economical non-quenched and non-tempered micro-alloyed plastic die steel plate comprises 0.32-0.40wt% of C, 0.20-0.50wt% of Si, 1.00-1.50wt% of Mn, 1.20-1.70wt% of Cr, 0.20wt% or less of Mo, 0.0025wt% or less of B, 0.03wt% or less of Ti, 0.03wt% or less of Nb, and the balance Fe. The making method comprises the following steps: carrying out converter smelting, LF+RH refining and continuous slab casting; heating the obtained slab at 1200-1230DEG C, carrying out precision rolling at 900-950DEG C, and carrying out finishing rolling at 870-920DEG C; carrying out controlled cooling after the steel plate rolling; and tempering the steel plate obtained after the controlled rolling and controlled cooling at 550-600DEG C to obtain the finished pre-hardened plastic die steel plate having a bainite structure. The yield strength, the normal temperature impact toughness and the cross section hardness of the steel plate are above 800MPa, above 20J and 310-350HB respectively. The making method is suitable for the production of pre-hardened plastic die steel plates with the specification of below 120mm from 320mm continuous casting blanks.

Owner:NANJING IRON & STEEL CO LTD +1

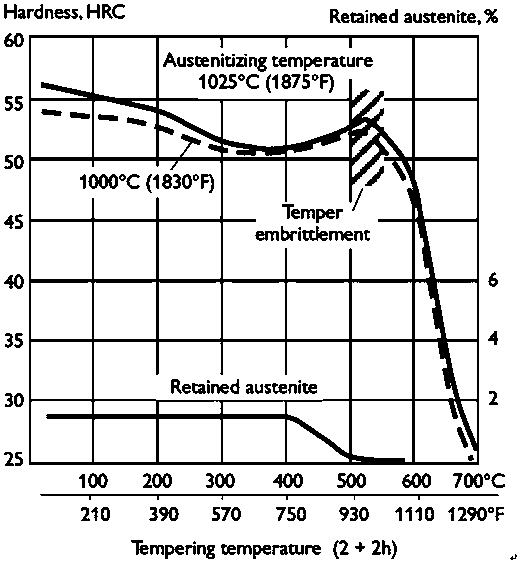

High-performance hot-working die steel for large die-casting die and manufacturing technology of high-performance hot-working die steel

The invention relates to high-performance hot-working die steel for a large die-casting die and a manufacturing technology of the high-performance hot-working die steel. The high-performance hot-working die steel is prepared from, by mass, 0.20%-0.30% of C, smaller than or equal to 0.40% of Si, 0.30%-0.60% of Mn, 4.10%-4.50% of Cr, 2.10%-2.30% of Mo, 0.10%-0.20% of W, 0.40%-0.80% of V, smaller than 0.01% of P, smaller than 0.005% of S, 0.02%-0.04% of Nb and the balance Fe. The manufacturing method of the die steel comprises the following manufacturing process that material mixing, smelting andcasting are conducted, and then electroslag remelting is conducted; high-temperature diffusion heat treatment is conducted, multi-directional forging hot working is conducted, and cooling controllingafter forging is conducted; secondary carbide refining heat treatment and isothermal annealing treatment are conducted; and finally quenching and tempering heat treatment is conducted. The hot-working die steel has the advantages that the hardenability, the heat stability, the impact toughness and the thermal fatigue property are superior to those of H13 steel, the hot-working die steel can be machined into a single large die-casting die with the weight reaching 5 tons or above, and the good using performance is achieved.

Owner:ZHANGJIAGANG CITY GUANGDA MACHINERY FORGING

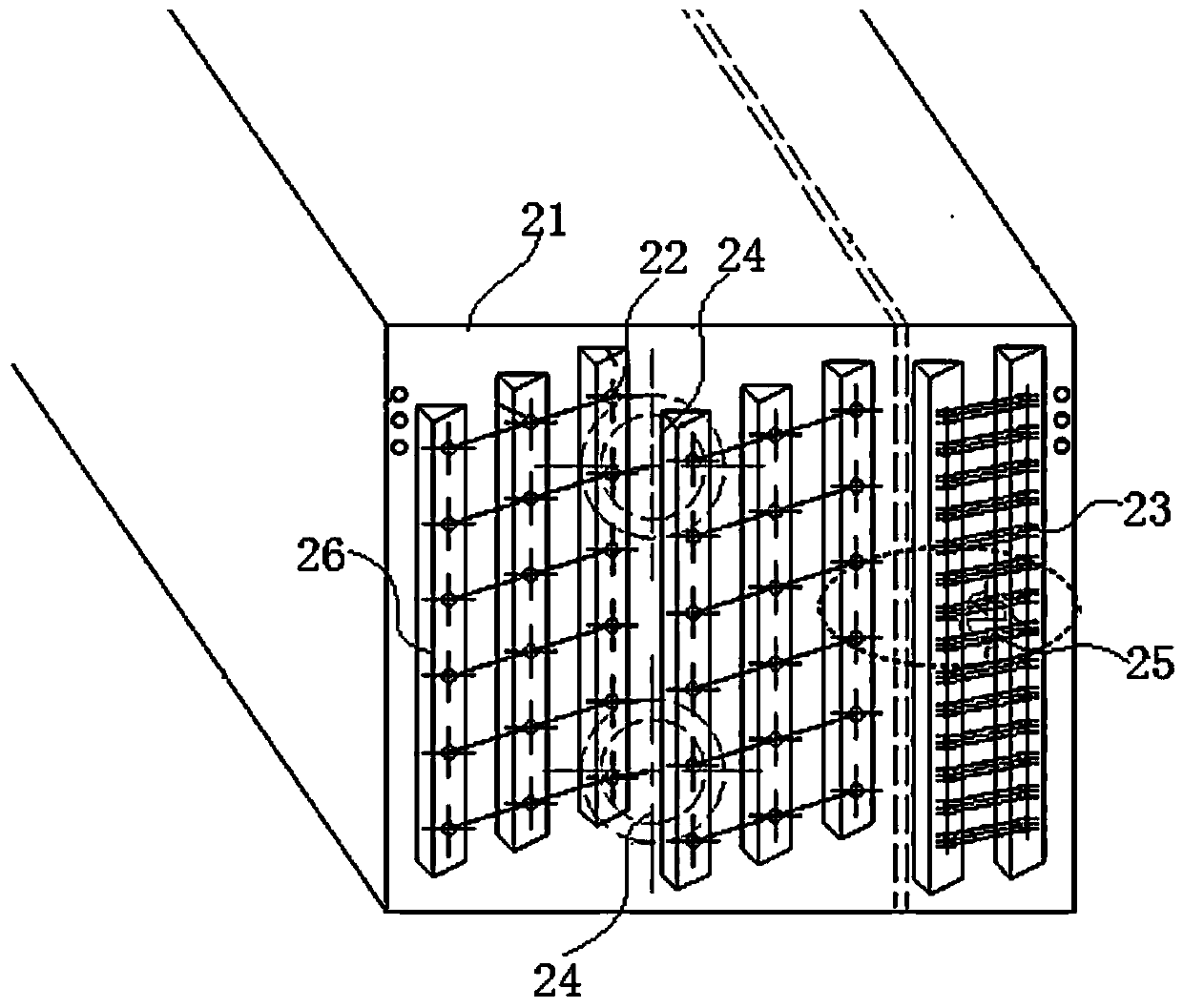

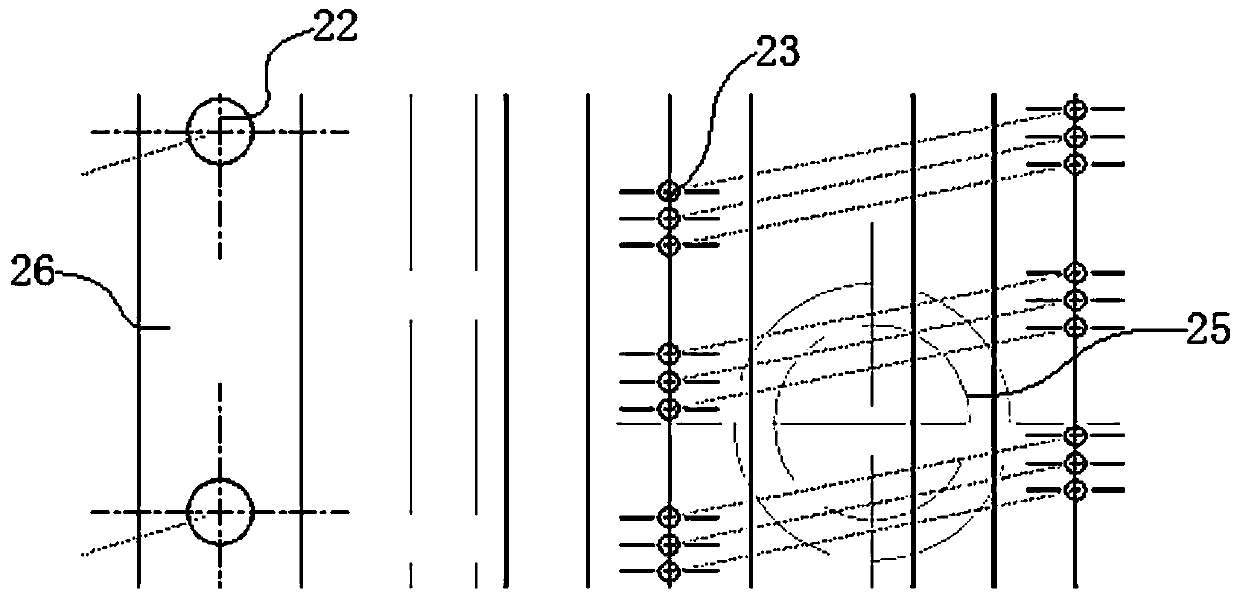

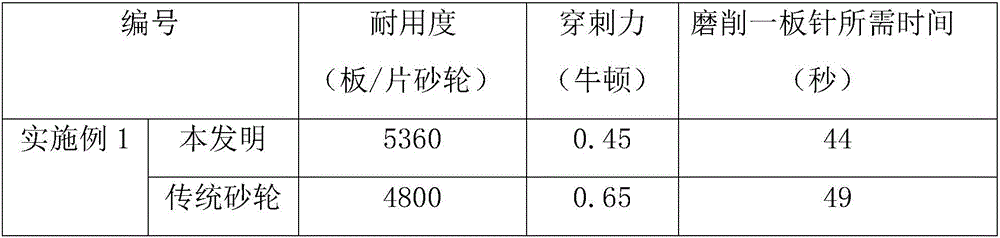

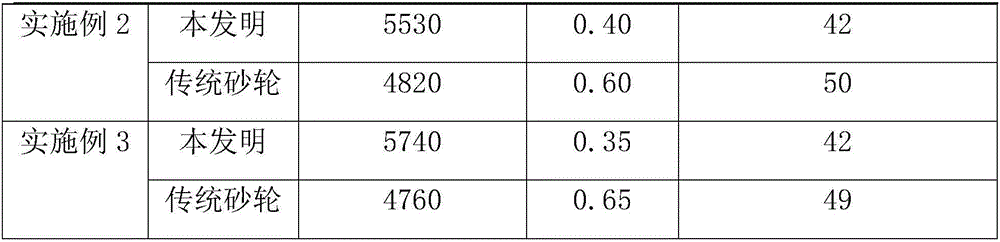

Large-standard high-speed resin heavy duty grinding wheel for grinding steel billet

ActiveCN104625978AHigh tensile and flexural strengthImprove the lubrication effectAbrasion apparatusGrinding devicesFiberMaximum diameter

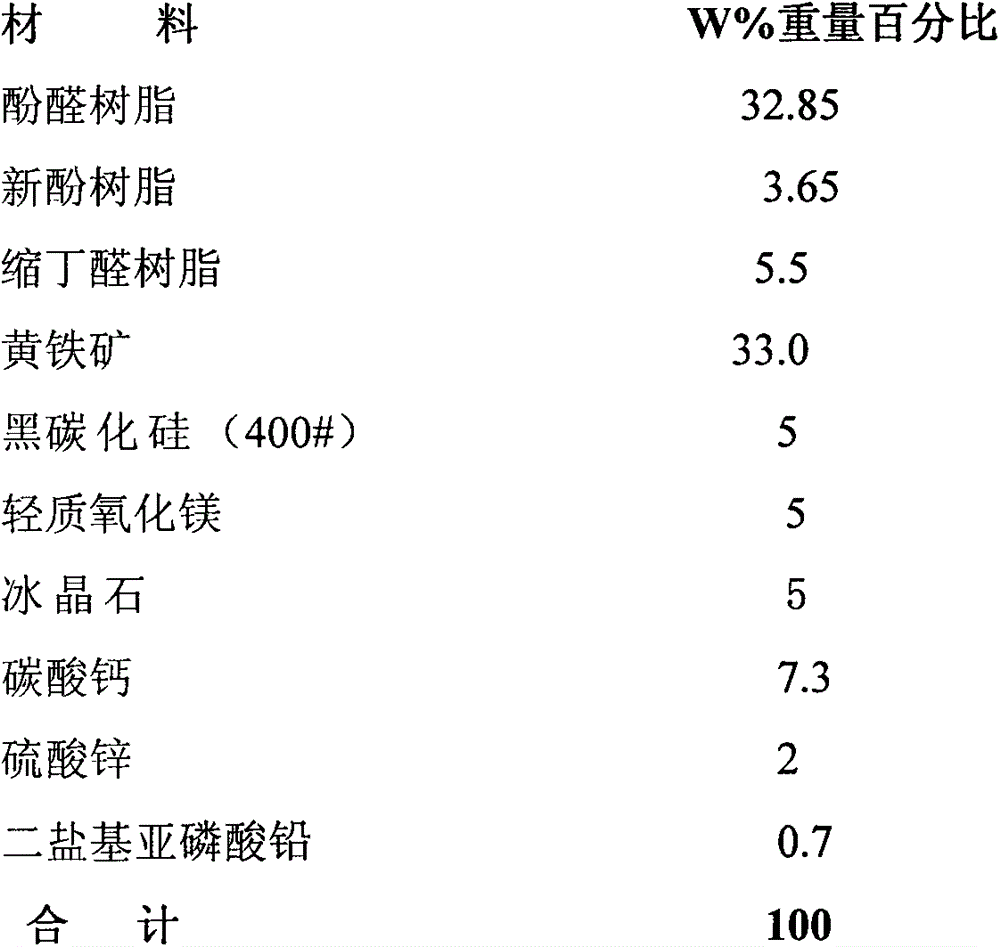

The preparation method for the large-standard high-speed resin heavy duty grinding wheel for grinding a steel billet comprises the steps that a dedicated binding agent for a high-performance modified high polymer matrix phenolic resin grinding wheel is prepared by using phenolic resin, xylok resin, butyral resin, iron pyrite, cryolite, light magnesium oxide, barite, 400 # carborundum and calcium carbonate, dedicated formulas for a grinding layer and a core layer are separately designed by using grinding materials such as fused alumina zirconia, aluminium oxide sintered corundum, black silicon carbide, furfural, dibutyl ester, fibers and steel rings, and the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is prepared by adopting a dual-phase reinforced composite technology and structure. According to the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet, the linear velocity is equal or greater than 90 m / s to 120 m / s, the maximum diameter is 925 mm, the thickness is 125 mm, and the tensile and breaking strength and the grinding efficiency of the grinding wheel are greatly improved. When the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is under heavy duty, the adaptability of the condition of grinding range is wide, and the linear velocity is high. The grinding efficiency reaches a thickness of 1 cm at a time, the problems that an existing grinding wheel cannot adapt to a steel billet, and the heavy duty grinding of steel is difficult are solved well, and the increasing development requirements of the iron and steel industry are met.

Owner:江苏华东砂轮有限公司

Boron microalloyed die steel and preparation process thereof

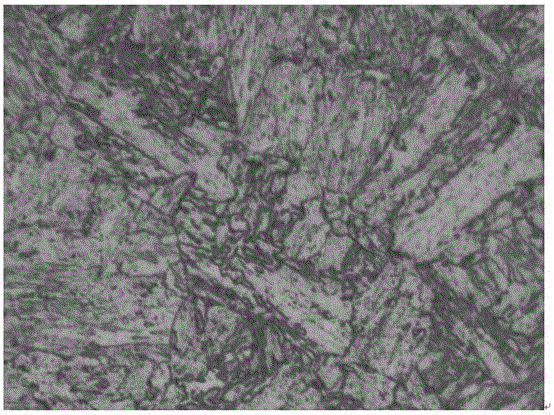

The invention relates to boron microalloyed die steel and a preparation process thereof and belongs to the technical field of alloy steel preparation processes. The main alloy elements in alloy chemical components of the die steel comprise, by mass, 0-0.20% of C, 0-0.20% of Si, 1.20-1.60 of Mn, 1.10-1.50% of Cr, 0-0.30% of Ni, 0.20-0.35% of Mo, 0-0.10% of V, less than 0.015% of P, less than 0.005% of S, 0.005-0.01% of B, and the balance Fe. The preparation process of the steel includes the following steps of conducting burdening, smelting, casting and hot delivery; conducting high temperature diffusion heat treatment, multi-directional forging hot working and post-forging hydrogen diffusion tempering treatment; and finally conducting quenching-and-tempering heat treatment so as to obtain a tempered martensite structure with the hardness being 32-38 HRC. The boron microalloyed die steel and the preparation process thereof have the advantages that the prepared die steel has low cost, high hardenability, high hardness, high polishing performance and high skin grain etching performance.

Owner:RUGAO HONGMAO HEAVY FORGING

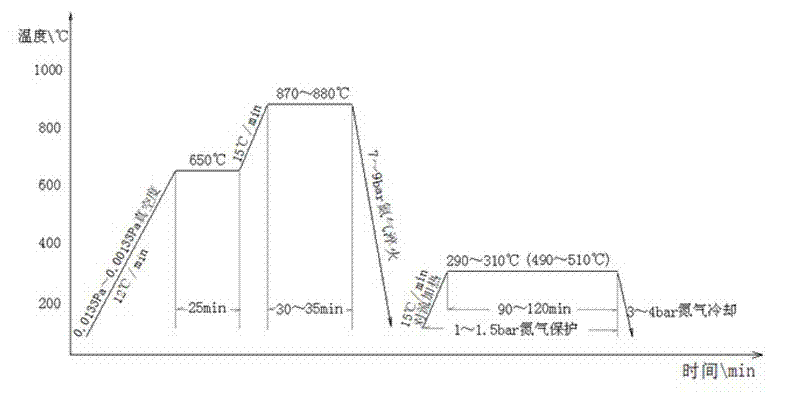

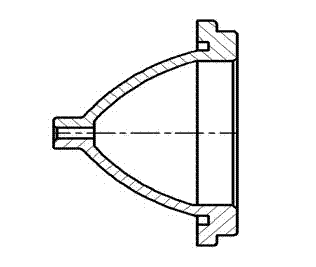

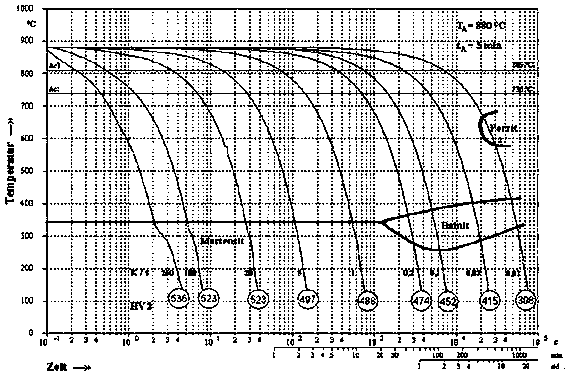

High-strength steel thin-wall piece vacuum thermal treatment process

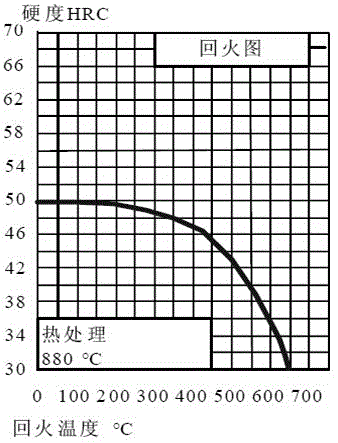

InactiveCN102560037AHeating evenlyNo decarbonizationFurnace typesHeat treatment furnacesCounter flowHardness

The invention discloses a high-strength steel thin-wall piece vacuum thermal treatment process, which comprises vacuum quenching and vacuum tempering, wherein the vacuum quenching comprises the following specific steps of: heating to 650 DEG C at the vacuum degree between 1.33*10<-4> Pa and 1.33*10<-2> Pa; preserving heat for 25 minutes; heating to 870-880 DEG C; preserving heat for 30-35 minutes; charging 7-9 bar of high-purity nitrogen gas into a furnace for performing air pressure quenching; and cooling to 50-60 DEG C; and vacuum tempering comprises the following specific steps of: performing counter-flow heating to a tempering temperature under the protection of 1-1.5 bar of high-purity nitrogen gas; preserving heat for 1.5-2 hours; charging 3-4 bar of high-purity nitrogen gas into the furnace for performing air pressure cooling; and cooling to a low temperature for discharging. A high-strength steel thin-wall piece vacuum thermal treatment surface has the advantages of freeness from oxidation and decarburization, high size precision, uniform hardness, high strength and low cost.

Owner:HENAN BEIFANG HONGYANG IND

Prehardening plastic die steel plate and manufacture method thereof

The invention relates to a prehardening plastic die steel plate and a manufacture method thereof. The steel plate comprises, by weight, C 0.28 to 0.40, Si 0.20 to 0.80, Mn 0.60 to 1.0, Cr 1.40 to 2.2, Mo 0.30 to 0.50, P no more than 0.030, S no more than 0.030, Al 0.01 to 0.08, Ti 0.01 to 0.05 and B 0.0010 to 0.0050, with the balance being Fe and unavoidable impurities. The manufacture method comprises a first step of smelting, that is, carrying out tapping and casting when components in liquid steel meet requirements so as to obtain steel ingots, a second step of hot rolling, that is, rolling the steel ingots into steel plates with a thickness of 60 to 200 mm, a width of 300 to 1500 and a length of 2000 to 8000 mm, a third step of cooling, that is, cooling the steel plates to a temperature below 550 DEG C, wherein, slow cooling time is no less than 24 hours, and a fourth step of tempering, that is, arranging the steel plates in a tempering furnace for tempering at a temperature of 400 to 600 DEG C, carrying out insulation for 4 to 12 hours, taking the steel plates out of the tempering furnace and cooling the steel plates to room temperature in the air. The difference of surface hardness of prehardening plastic die steel plates manufactured in the invention is within 20 HB.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Highly-polished prehardened die steel, and preparation method thereof

The invention relates to a highly-polished prehardened die steel, and a preparation method thereof. The highly-polished prehardened die steel is composed of, by mass, 0.21 to 0.25% of C, Si<=0.30%, 1.40 to 2.00% of Mn, 1.30 to 1.70% of Cr, 0.60 to 1.00% of Ni, 0.40 to 0.60% of Mo, V<=0.10%, P<0.015%, S<0.005%, 0.02 to 0.04% of Nb, and the balance Fe. The preparation method comprises following steps: material blending, smelting, casting, and hot charging; high temperature diffusion heat treatment, multi-directional forging heat processing, after-forging heat treatment, and sawing; and hardeningand tempering heat treatment. The hardness of the obtained tempered martensite structure ranges from 38 to 42HRC. The advantages of the highly-polished prehardened die steel are that: cost is low, hardenability and hardness are high, and polishing properties and cleavage line etching performance are excellent.

Owner:ZHANGJIAGANG CITY GUANGDA MACHINERY FORGING

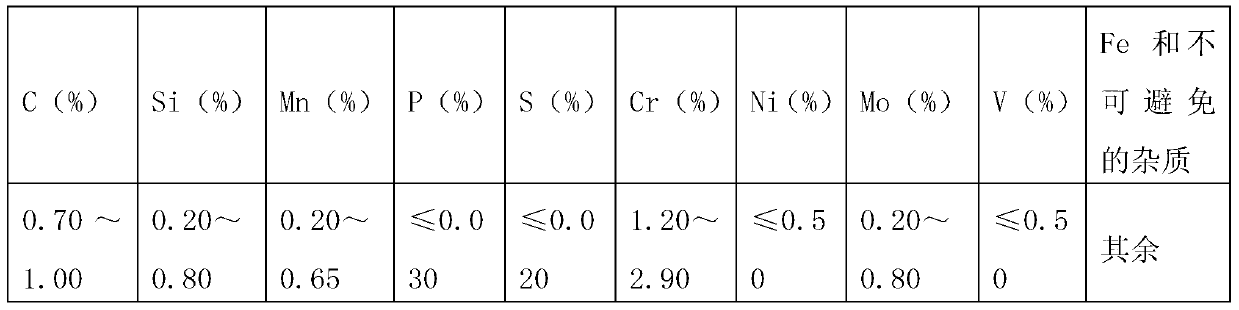

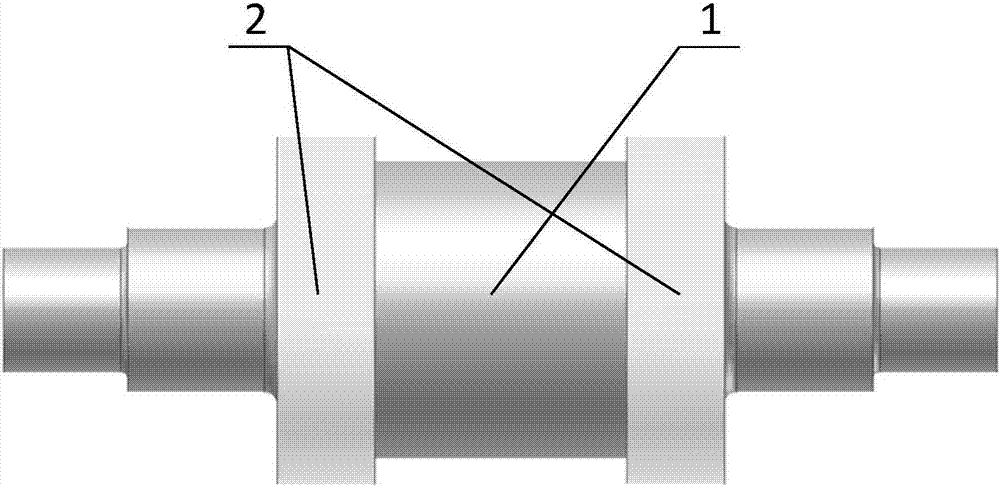

Bearing roller of 4200 mm or above wide and thick plate rolling mill and manufacturing process of bearing roller

ActiveCN108277443AReduced risk of fatigue spallingHigh hardnessRollsMetal rolling arrangementsImpurityChromium

The invention relates to a bearing roller of a 4200 mm or above wide and thick plate rolling mill and a manufacturing process of the bearing roller, and belongs to the technical field of forging. Thebearing roller comprises, by mass percent, 0.50 to 0.65% of C, 0.17 to 0.50% of Si, 0.80 to 2.0% of Mn, 0.30 to 0.70% of Ni, 1.60 to 2.5% of Cr, 0.30 to 1.00% of Mo, 0.10 to 0.35% of V, not larger than 0.020% of P, not larger than 0.010% of S, not larger than 0.15% of Cu, not large than 1.0 ppm of H, and the balance iron and inevitable impurities. The carton content of a new material of the super-huge type forged steel bearing roller is low, alloy elements of chromium, nickel and vanadium are added, the microstructure comprises bainite and pearlite, the strength and toughness of the material are improved, the solidification segregation of a large steel ingot is reduced, the comprehensive performance is good, and the service life is long.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

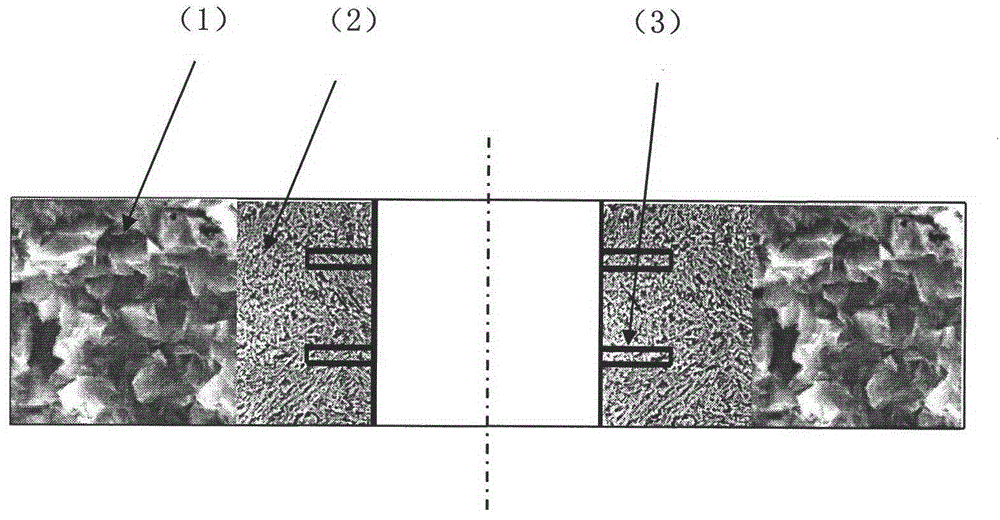

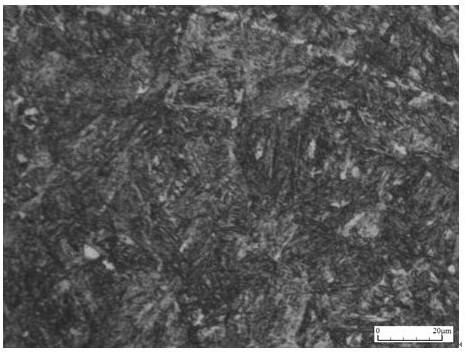

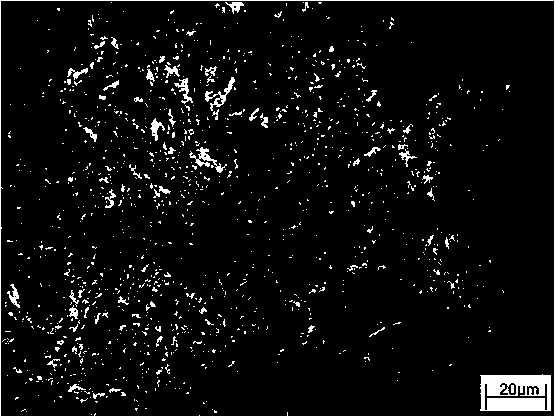

High-uniformity and high-polishing type plastic mould steel ZW636 and preparation method thereof

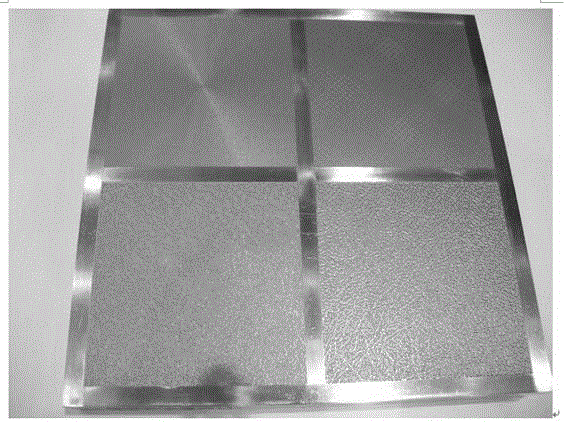

The invention relates to high-uniformity and high-polishing type plastic mould steel ZW636 and a preparation method thereof. The plastic mould steel particularly comprises the following components inpercentage by mass: 0.20 to 0.30 percent of C, 0.10 to 0.40 percent of Si, 1.20 to 1.60 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.005 percent, 1.20 to 1.80 percent of Cr, 0.90 to 1.20 percent of Ni, 0.48 to 0.70 percent of Mo, 0.08 to 0.15 percent of V, 0.015 to 0.030 percent of Als, less than or equal to 0.25 percent of Cu, O of less than or equal to 12 ppm,N of 60 to 100 ppm, H of less than or equal to 1.5 ppm and the balance of Fe and unavoidable impurities. Through the specific preparation method, the plastic mould steel has the following characteristics: (1) the tissue is uniform, the grain crystal is small, the tissue rating is less than or equal to level 4, and the grain size is more than level 6; (2) the hardness is uniform and the hardness uniformity of the same section is less than or equal to 3 HRC; and (3) the high-uniformity and high-polishing type plastic mould steel ZW636 has high polishing property and can be polished to 8000 meshes, and the polishing rate is 95 percent.

Owner:唐山志威科技有限公司

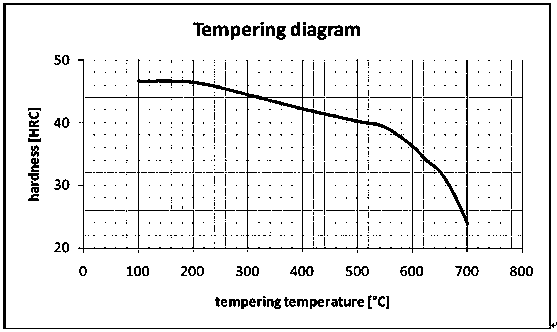

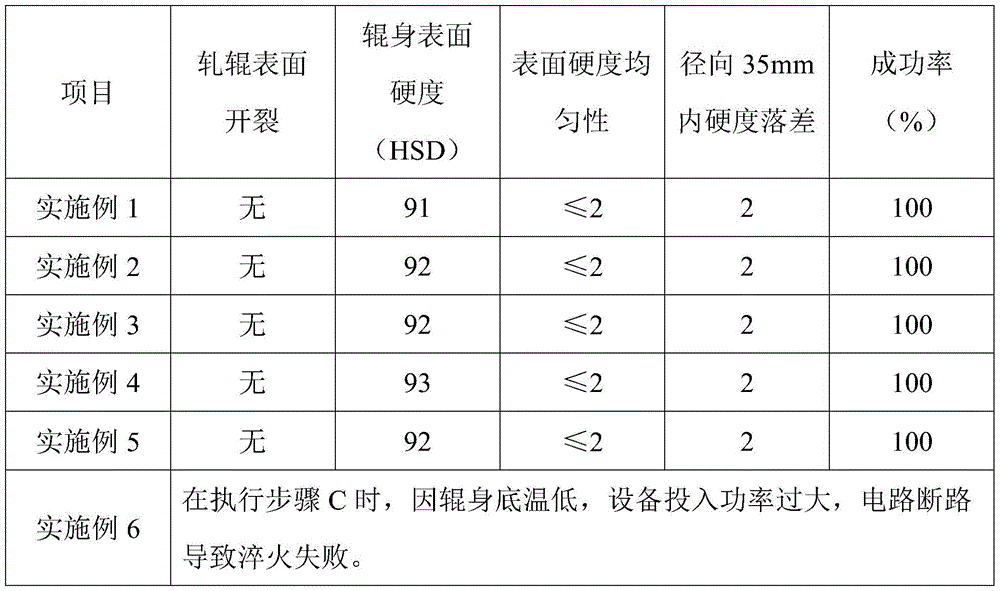

Heat treatment method for large high-speed steel cold-rolled work roll

ActiveCN105483354AImprove heat treatment success rateHigh hardnessIncreasing energy efficiencyFurnace typesWork rollTreatment success

The invention discloses a heat treatment method for a large high-speed steel cold-rolled work roll, and belongs to the technical field of heat treatment. The heat treatment method comprises pretreatment, preheat treatment and finish heat treatment. The preheat treatment comprises integral low-temperature preheat and continuous induction heating preheat. During continuous induction heating preheat, the temperature of the roll when the roll gets out of an induction coil is required to be 600-750 DEG C, the roll continues to move upwards, air cooling is conducted for 15-35 min after the roll gets out of the induction coil, and finish heat treatment is conducted. The heat treatment method is different from a conventional continuous induction quenching manner, the roll body continuous induction preheat treatment step is added on the basis of conventional integral preheat, and the heat treatment success rate of the large high-speed steel roll can be greatly increased. Meanwhile, cold treatment is added after first-time tempering of the roll is conducted, a roll body has hardness of 90 HSD or more after finish heat treatment of the high-speed steel cold-rolled work roll is conducted, and the technology requirement of a cold-rolled steel plate can be completely met.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Steel for high-strength, high-toughness and high-wear-resistance steel ball and preparing method of steel

ActiveCN110846586AImprove hardenabilityImprove the hardness of the heartFurnace typesHeat treatment furnacesIngotSteel ball

The invention discloses steel for a high-strength, high-toughness and high-wear-resistance steel ball and a preparing method of the steel, and belongs to the technical field of steel for wear-resistant steel balls. The problems that the strength and toughness of existing steel for wear-resistant steel balls cannot meet requirements at the same time, and uniformity is poor are solved. The steel forthe wear-resistant steel ball comprises, by mass, 0.60-0.70% of C, 1.50-1.80% of Si, 0.92-1.2% of Mn, 1.30-2.00% of Cr, 0.01-0.20% of Mo, 0.25-0.60% of Ni, 0.01-0.05% of Al, 0.05-0.10% of Cu, 0.01-0.20% of V, less than or equal to 0.03% of S, 0.01-0.02% of P and the balance Fe and inevitable trace impurities, wherein the sum of Mo and V is greater than or equal to 0.08%. The preparing method includes the following steps of performing smelting to obtain molten steel, performing casting to obtain a cast ingot, forging the cast ingot to obtain a steel blank, and performing quenching and annealing treatment on the steel blank or quenching and partitioning treatment on the steel blank. The steel for the high-strength, high-toughness and high-wear-resistance steel ball is high in strength, toughness and uniformity and wide in application range.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

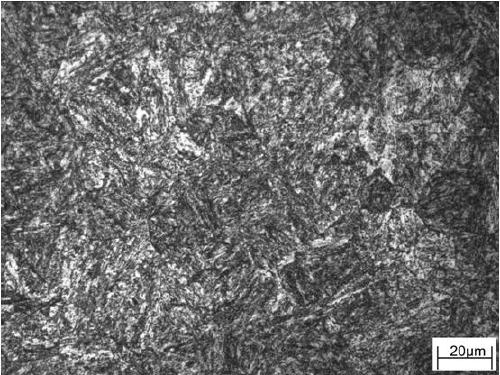

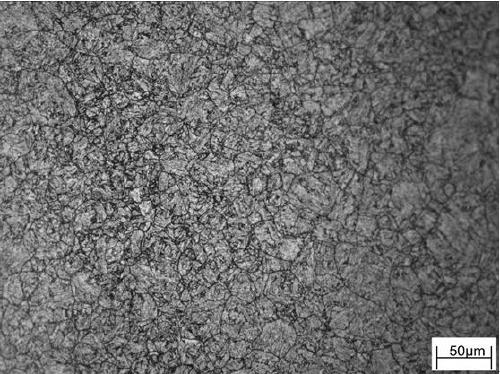

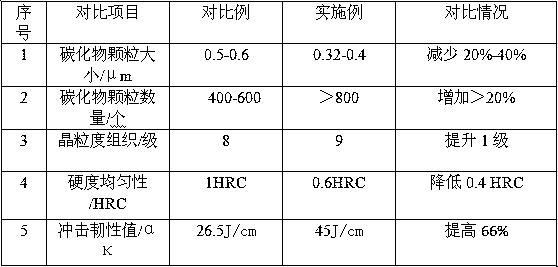

Hot processing technology method for bearing steel parts

ActiveCN109536689ARefine grain sizeRefined grain sizeHeat treatment process controlQuenching agentsOptimal controlCarbide

The invention relates to a hot processing technology method for bearing steel parts. The hot processing technology method for the bearing steel parts comprises the steps of forging a blank, cooling after forging, keeping warm, spheroidizing annealing, quenching and tempering after machining. Through optimal control on the cooperation in the multiple steps, the carbide particles in the manufacturedbearing steel parts are fine, the quantity of the carbide particles is more, and the grain size can be further improved, so that the strength, the impact toughness, the hardness uniformity and the service life of the parts can be improved, the overall performance of the bearing steel parts is improved extensively, and the hot processing technology method for the bearing steel parts can meet the use performance requirement on bearing steel under the working condition of high temperature in the field such as bearings, and is suitable for popularization and application.

Owner:LUOYANG BEARING RES INST CO LTD

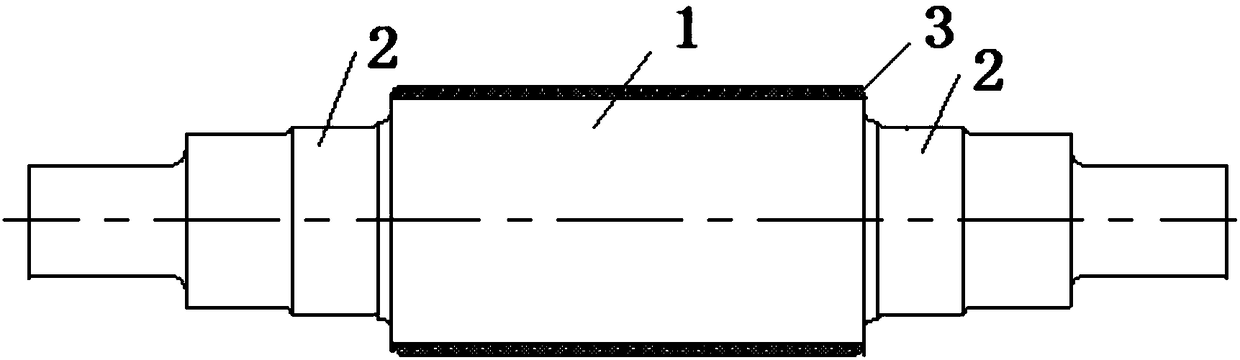

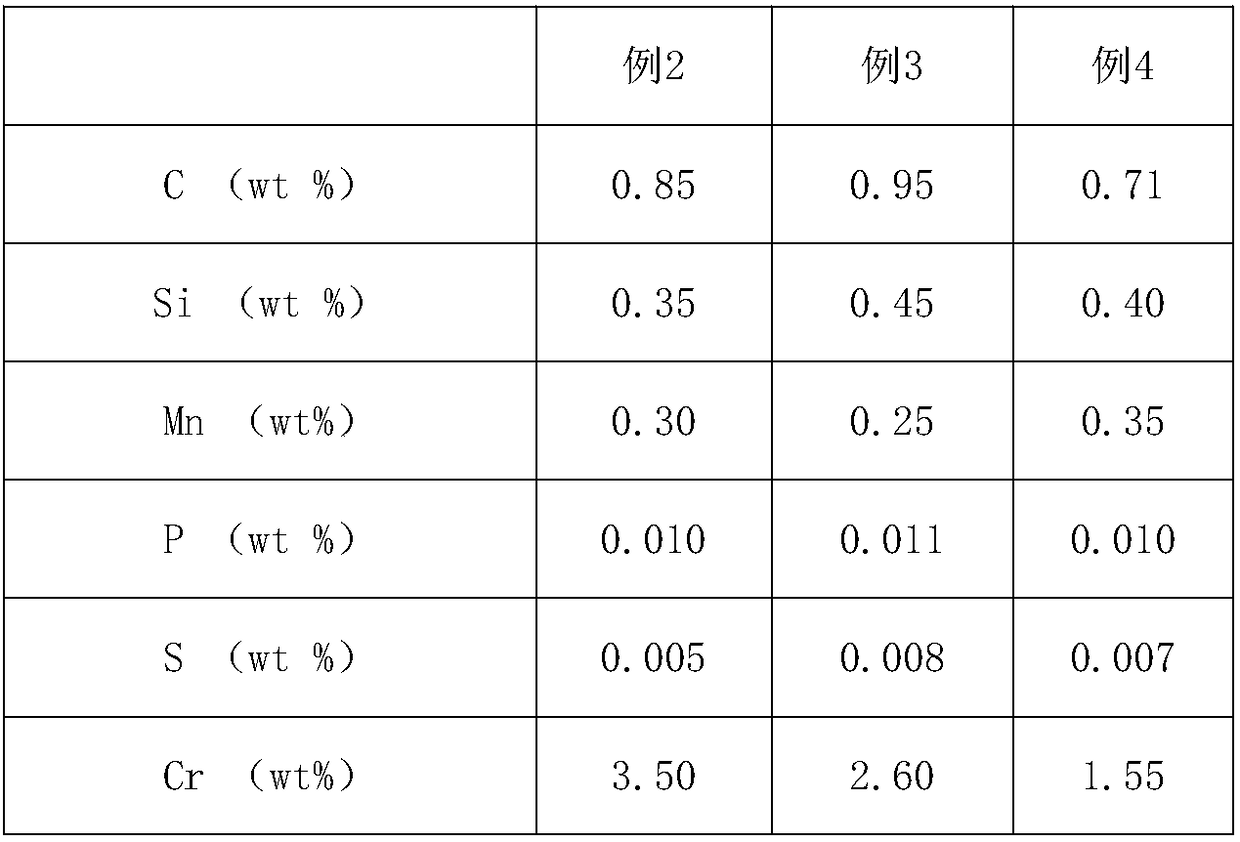

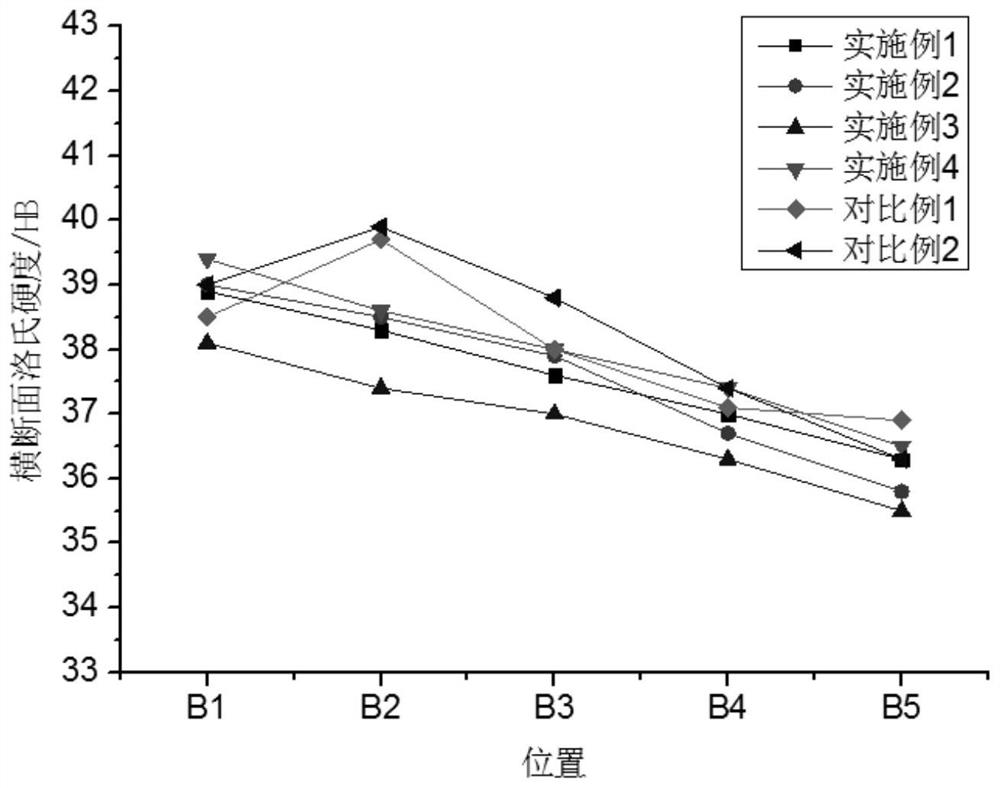

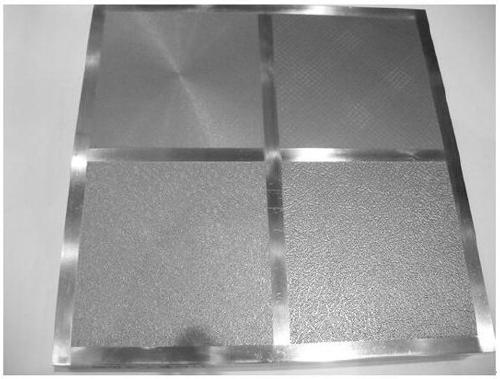

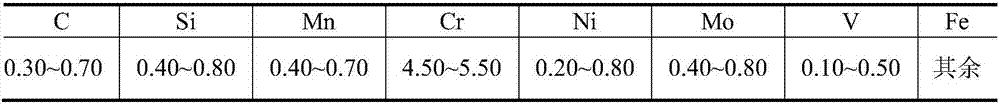

Working roller of copper foil rolling machine

InactiveCN108220775AHigh hardnessImprove hardness uniformityFurnace typesRollsChemical compositionStrip mill

The invention discloses a working roller of a copper foil rolling machine and belongs to the field of preparation of rollers. The working roller is prepared from the following chemical components in percentage by weight: 0.7 to 1.0 percent of C, 0.2 to 1.0 percent of Si, 0.1 to 0.6 percent of Mn, 1.5 to 3.5 percent of Cr, 0.1 to 0.8 percent of Mo, less than or equal to 0.6 percent of Ni, less thanor equal to 0.5 percent of V, less than or equal to 0.02 percent of P and less than or equal to 0.02 percent of S. The working roller disclosed by the invention has the advantages of high hardness and high hardness uniformity; the thickness of a rolled copper foil can reach 10mu m or lower.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

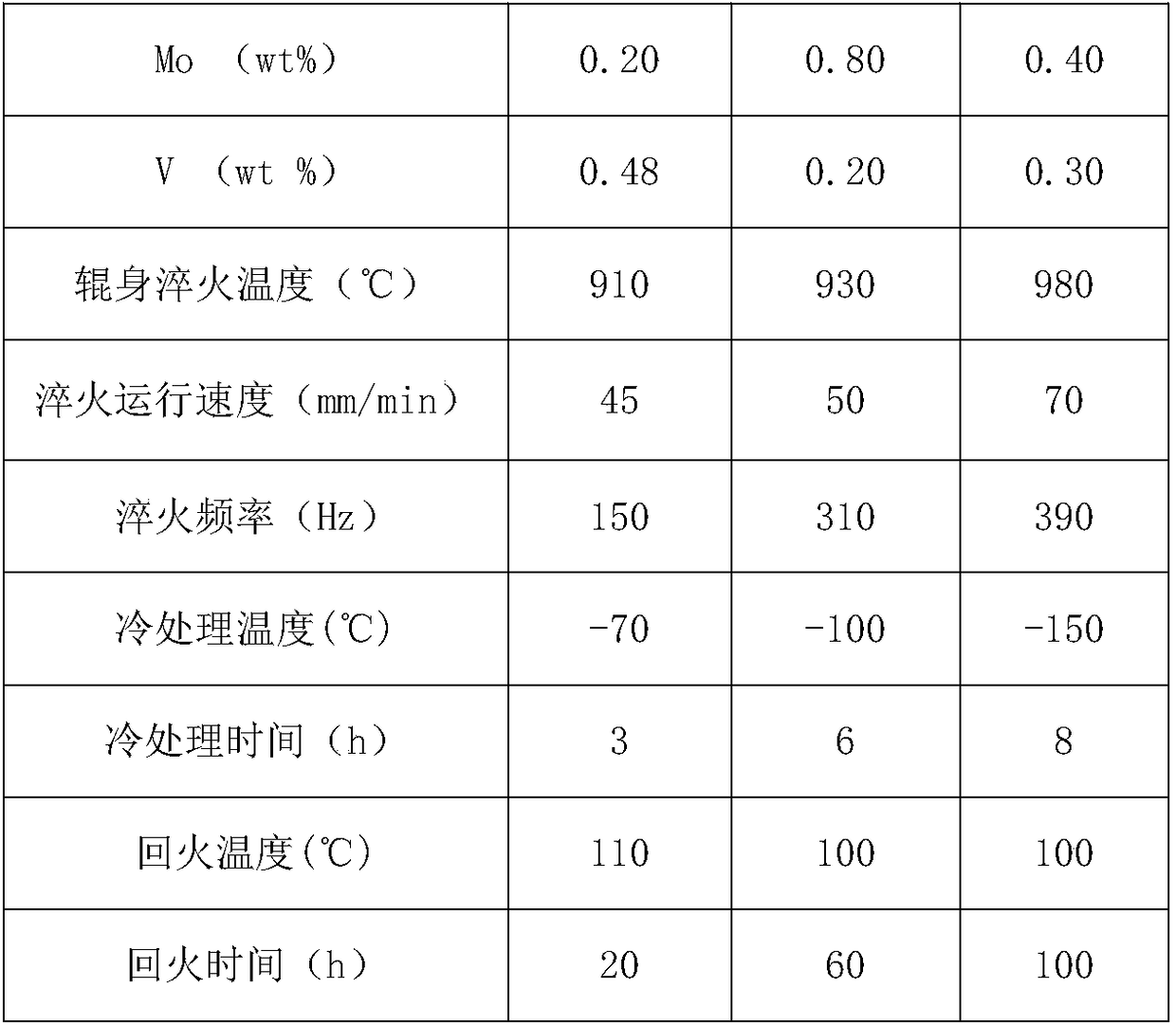

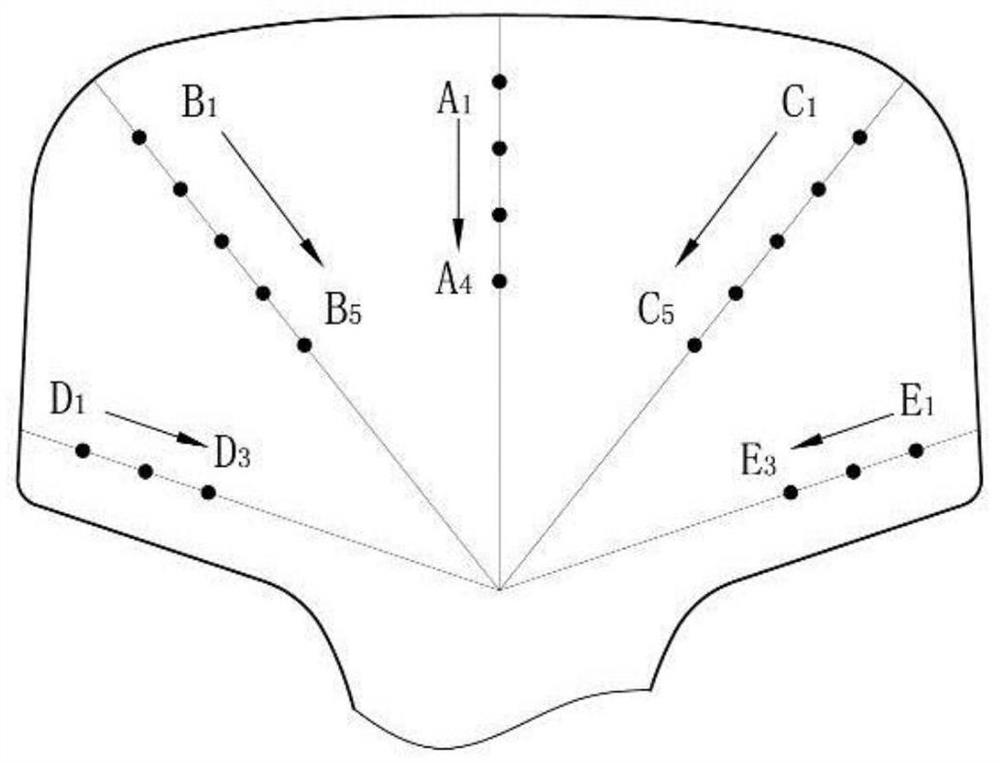

Method for improving hardness uniformity of cross section of heat-treated steel rail head

ActiveCN111961810AImprove hardness uniformityAchieve dynamic balanceQuenching agentsThermodynamicsFree cooling

The invention relates to a method for improving hardness uniformity of a cross section of a heat-treated steel rail head. The method comprises the following steps that the starting cooling temperatureof the heat-treated steel rail head is 740-820 DEG C, a dynamic staged accelerated cooling process is adopted, and the cooling speed and the cooling time of five cooling stages of the heat-treated steel rail head are sequentially as follows that the cooling speed is less than or equal to 9 DEG C / s, and cooling time is 8-12s; the cooling speed is less than or equal to 3 DEG C / s, and the cooling time is 3s; the cooling speed is less than or equal to 6 DEG C / s, and the cooling time is 30-40s; the cooling speed is less than or equal to 2 DEG C / s, and the cooling is carried out to 300-380 DEG C; and the natural cooling is carried out to room temperature. In the cooling stage, the cooling speed difference between adjacent stages is less than and equal to 6 DEG C / s. The cooling stage and the initial time of the heat-treated rail bottom are the same as those of the heat-treated rail head, and the cooling speed of each stage of the heat-treated rail bottom is 60-70% of that of the corresponding stage of the heat-treated rail head. The method is simple and high in operability, and the Rockwell hardness distribution uniformity of the cross section of the heat-treated steel rail head is remarkably improved.

Owner:WUHAN UNIV OF SCI & TECH

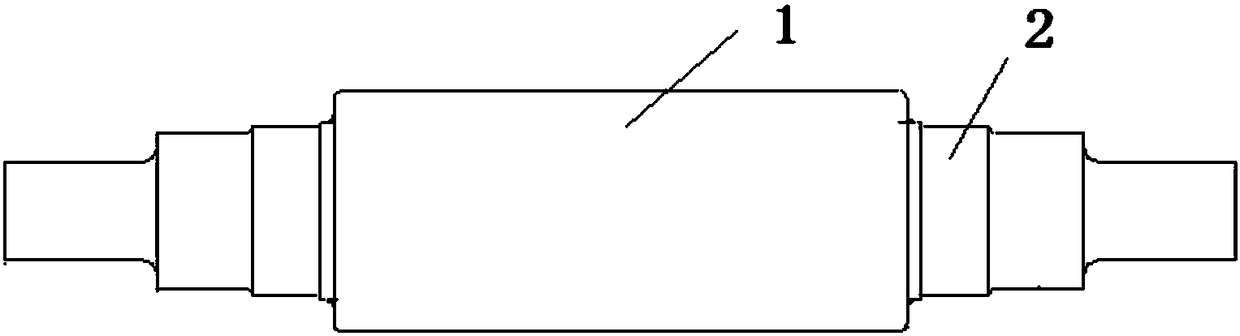

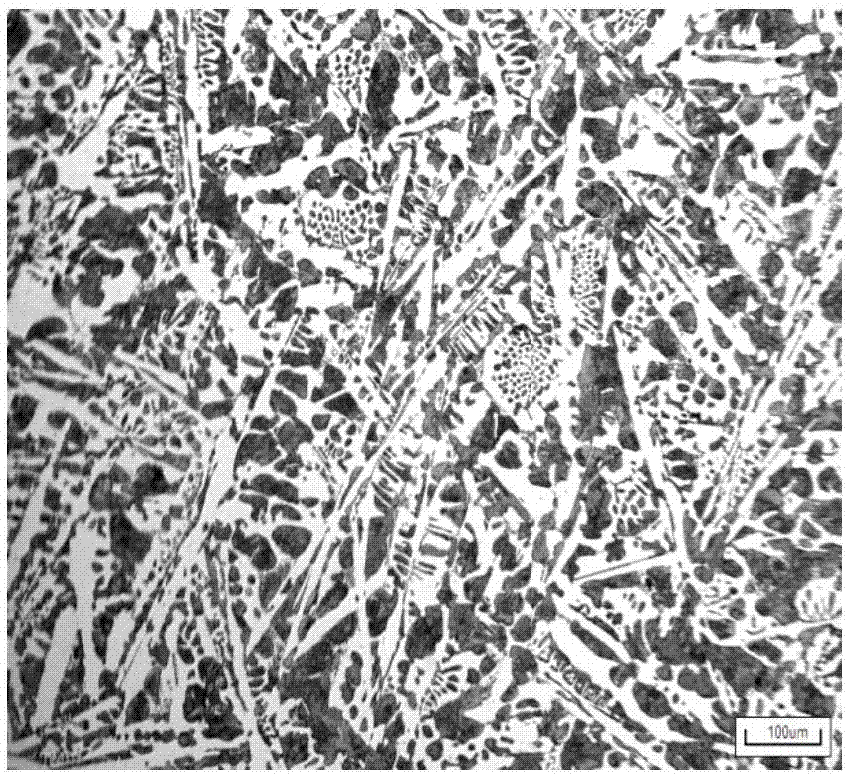

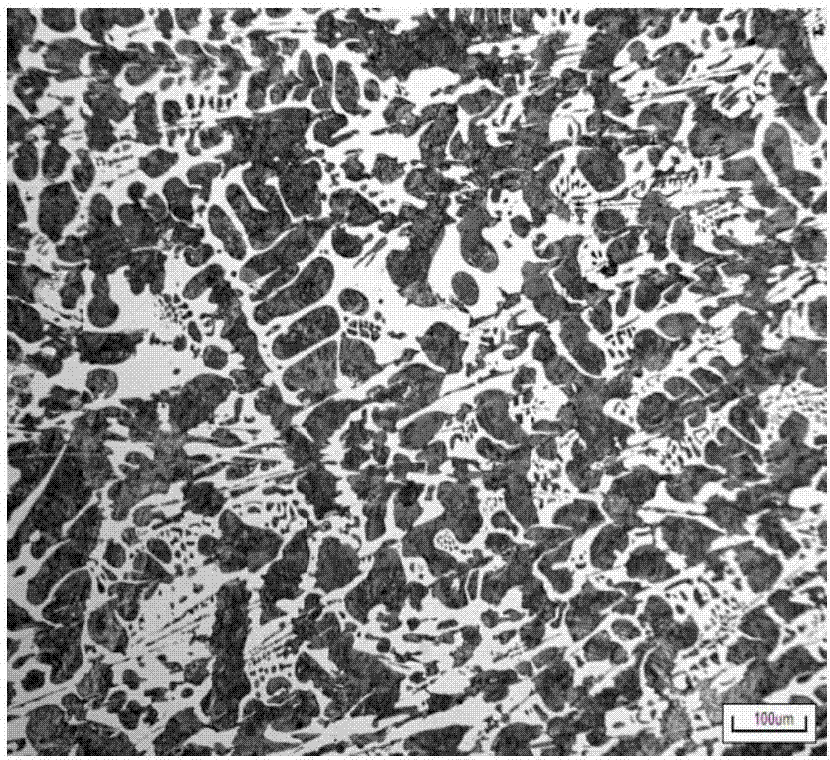

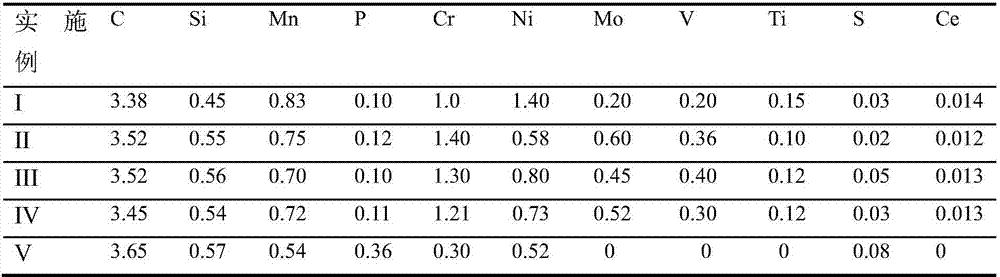

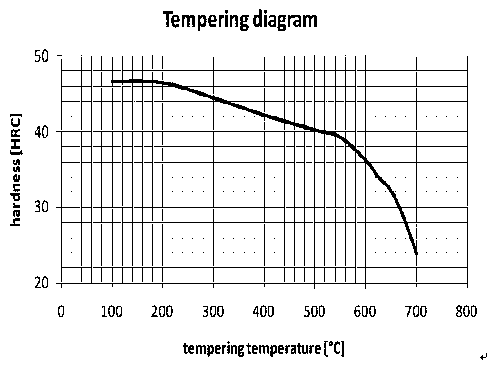

Low-alloy composite roller and manufacturing method thereof

InactiveCN107574359AImprove toughnessImprove hardness uniformityFurnace typesRollsAlloy compositeHardness

The invention discloses a low-alloy composite roller and a manufacturing method of the low-alloy composite roller. The composite roller comprises an outer white cast iron layer and an inner grey castiron layer. The outer white cast iron layer is prepared from, by mass, 3.0-3.60% of C, 0.50-1.0% of Si, 0.50-1.0% of Mn, 0.50-1.50% of Cr, 0.50-1.50% of Ni, 0.20-1.0% of Mo, 0.10-0.80% of V, 0.10-0.30% of Ti, 0.10-0.30% of Ce, P with the content less than 0.15%, S with the content less than 0.10% and the balance Fe. The inner grey cast iron layer is prepared from, by mass, 3.0-3.5% of C, 1.5-2.5%of Si, 0.5-1.0% of Mn and the balance Fe. The toughness and hardness uniformity of the roller can be improved, the hardness of the composite roller is larger than 53HRC, and the wear resistance of theroller is effectively improved.

Owner:HUBEI GOLD STANDARD GENERAL ROLLER

Large-thickness wear-resisting steel plate based on NQT process and having good -40 DEG C low-temperature toughness and preparing method

ActiveCN110157987AEnsure the uniformity of mechanical properties in the thickness directionImprove hardenabilityChemical compositionHardness

The invention discloses a large-thickness wear-resisting steel plate with good low-temperature toughness and a preparing method. The steel plate comprises, by weight percent, 0.16 to 0.18% of C, 0.20to 0.30% of Si, 1.15 to 1.30% of Mn, not larger than 0.010% of P, not larger than 0.002% of S, 0.010 to 0.020% of Nb, 0 to 0.05% of Cu, 0.40 to 0.60% of Cr, 0.45 to 0.60% of Mo, 0.95 to 1.20% of Ni, 0.025 to 0.040% of V, 0.001 to 0.0025% of B, larger than or equal to 0.060% of Alt, 0.002 to 0.004% of Ca, and the balance Fe and trace impurities. The hardenability index of steel is larger than or equal to 140, the wear-resisting index is larger than or equal to 0.59, the steel plate thicknesses ranges from 80 to 100 mm, the NQT process is adopted, the large-thickness wear-resisting steel plate with good -40 DEG C low-temperature toughness is excellent in mechanical property, the steel plate surface hardness ranges from 330 HBW to 380 HBW, the hardness average value in the thickness directionis not lower than the surface hardness by 90%, and -40 DEG C impact energy at the 1 / 4 thickness is 60 to 80 J.

Owner:贝斯山钢(山东)钢板有限公司 +1

Copper-containing high-polishing pre-hardening plastic die steel and manufacturing process thereof

The invention relates to a copper-containing high-polishing pre-hardening plastic die steel and a manufacturing process thereof. The alloy chemical components of the die steel are mainly composed of the alloy elements of, in percentage by mass, less than or equal to 0.10% of C, less than or equal to 0.30% of Si, 0.20-0.40% of Mn, less than or equal to 0.30% of Cr, less than or equal to 0.20% of Mo, less than or equal to 0.10% of V, less than 0.015% of P, less than 0.005% of S, 1.60-2.00% of Ni, 0.40-0.70% of Al, 0.40-0.70% of Cu and the balance Fe; and the hot-work die steel is subjected to material preparing, smelting, casting, and then electroslag remelting; the die steel is subjected to high-temperature diffusion heat treatment, then multi-directional forging thermal processing and post-forging heat treatment; then the die steel is subjected to hydrogen diffusion annealing and pre-hardening treatment; and finally, the die steel is subjected to aging heat treatment. The die steel hasthe advantages that the hot-work die steel has the high polishing performance and the low alloy cost.

Owner:RUGAO HONGMAO HEAVY FORGING

Calendaring roller shell and manufacturing method thereof

ActiveCN103343474AImprove mechanical propertiesWear resistanceCalendersIncreasing energy efficiencyHardnessQuenching

The invention discloses a calendaring roller shell and a manufacturing method of the calendaring roller shell. The calendaring roller shell is made of forged steel. The manufacturing method of the calendaring roller shell comprises the steps of roller blank preparation, thermal refining, surface quenching treatment, tempering treatment and final machining treatment. A line-frequency induction quenching method is adopted by surface quenching treatment. The quenching temperature is 890 DEG C-910 DEG C, the heating width of a line-frequency induction ring is 80mm-100mm, and the walking speed of the line-frequency induction ring is 0.8mm / s-1.2mm / s. According to the calendaring roller shell, cast iron is replaced by the forged steel and a special surface quenching technology is combined, so that the hardness of the surface of the finally machined calendaring roller shell reaches 82 HSD-88HSD, the uniformity of hardness is equal to or smaller than 3HSD, the depth of a surface quenching layer reaches 15mm-20mm, and the service life reaches over 20 years.

Owner:BAOSTEEL ROLL SCI & TECH

Heating processing technology for tooth punching and tempering on open large gear

ActiveCN102605160AQuality assuranceLight in massFurnace typesHeat treatment furnacesGear wheelQuenching

The invention discloses a heating processing technology for tooth punching and tempering on an open large gear. The heating processing technology comprises the following steps: before tempering heating process, performing coarse tooth punching on the open large gear, and uniformly reserving allowances on tooth thickness and diameter according to the diameter of the open large gear; putting the open large gear into a furnace by virtue of a lifting appliance, and then performing the heating process for tooth punching and tempering on the open large gear; when reaching the holding time, hanging the open large gear into a quenching tank so as to be subjected to oil cooling, wherein the precooling time ranges from 3 minutes to 8 minutes, the temperature of the large gear wheel ranges from 760 DEG C to 790 DEG C when the large gear enters oil, the oil cooling time ranges from 60 minutes to 90 minutes per 100mm (which means the thickness of the rim wall of the gear), and the oil outlet temperature ranges from 260 DEG C to 300 DEG C; and after quenching, performing tempering process on the open gear, and cooling the open gear to 250+ / -10 DEG C at a cooling speed of 40 DEG C to 60 DEG C per hour, and air-cooling after discharging. According to the invention, the hardness uniformity of the open large gear subjected to the heating process is enhanced, the hardness attenuation gradient of the open large gear subjected to the heating process is reduced, the deformation of the open large gear in subsequent processing is reduced, and the quality of the open large gear is improved wholly.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Preprocessing technology for processing integral key shaft

InactiveCN1598003AImprove processing qualityImprove uniformityFurnace typesIncreasing energy efficiencyProcess qualityGranularity

The invention realtes to a preprocessing technology for processing integral key shaft, accomplished by the following steps: induction annealing area of integral key shaft using electromagnetic induction to be heated to above A[C3] over 50-80 degree for incubation of 1-2 hours, namely slowly cooling to 300 degree in asbestos drum and then air colling to narmal temperature. The surface hardness can be greatly decreased by surface induction annealing treatment, at the same time the uniformity of hardness is increased and the grain can be refined (grain size 8), and the uniformity of structure can be advanced, therefore the processability of integral key shaft can be greatly improved, the process quality thereof can be advanced, the tool life is increased by more than 5 times, the processing cost is saved, and the production effciency and economy benefit can also be obviously generated. Compared with modulator procedure, the said technology saves proscessing cost and greatly increases production timeefficiency.

Owner:WANXIANG QIANCHAO TRANSMISSION SHAFT

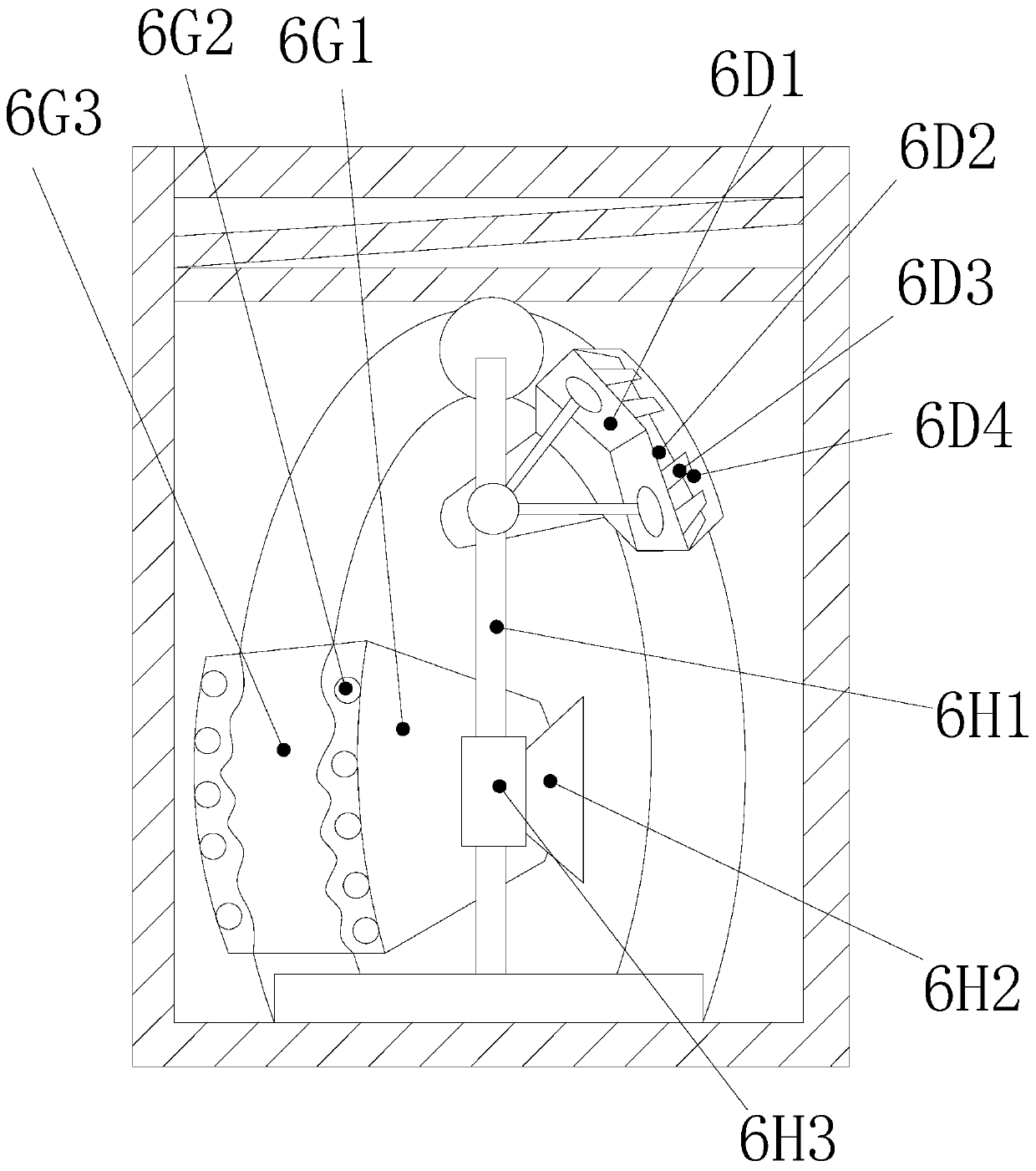

Method for stirring welding pool in process of welding and electromagnetic pendulum device

InactiveCN101596637AImprove hardness uniformityGuaranteed pass rateArc welding apparatusMelting tankMetal impurities

The invention relates to the welding processing field, disclosing a method for stirring a welding pool in the process of welding and an electromagnetic pendulum device. The method comprises the following steps: the electromagnetic pendulum device is installed at the position of a welding gun; after a electromagnetic coil power supply of the electromagnetic pendulum device is connected, the magnetic field with a certain direction is generated around a magnetic rod, under the action of the magnetic field, the electric arc generated by the welding gun oscillates and stirs the welding pool to ensure the evenness of metal impurities. The electromagnetic pendulum device comprises the electromagnetic coil, the magnetic rod and a magnetic pendulum shield; wherein, the electromagnetic coil winds the periphery of the magnetic rod, and the magnetic pendulum shield is arranged outside the electromagnetic coil. The method in the invention improves the uniformity of hardness of work pieces and ensures the quality of the surfacing layers on the surfaces of the work pieces, thus ensuring the qualification rate of repaired work pieces.

Owner:CHENGDU HANYAN TECH

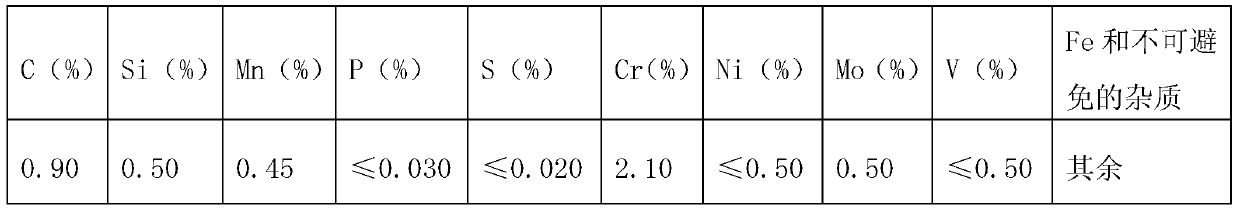

High-toughness plastic die steel and production method thereof

The invention relates to the field of steel for dies, in particular to high-toughness plastic die steel and a production method thereof. The die steel comprises the chemical components of, by mass, 0.55-0.75% of C, 2.00-3.50% of Mn, 0.45-0.50% of Mo, 2.00-3.00% of Cr, 0.40-0.60% of Sr, 0.80-1.20% of Ni, 0.02-0.04% of S, 0.20-0.30% of V, 0.004% of Ca and the balance Fe and unavoidable impurities. The production method comprises the following steps of plate blank heating, rolling, steel plate slow cooling, normalizing treatment and tempering heat treatment. By controlling rolling and the normalizing process, crystal particles are greatly refined, the hardness uniformity is high, the impact toughness is high, the free-cutting effect is obvious, the performance is stable, and the toughness ishigh.

Owner:莫祖勇

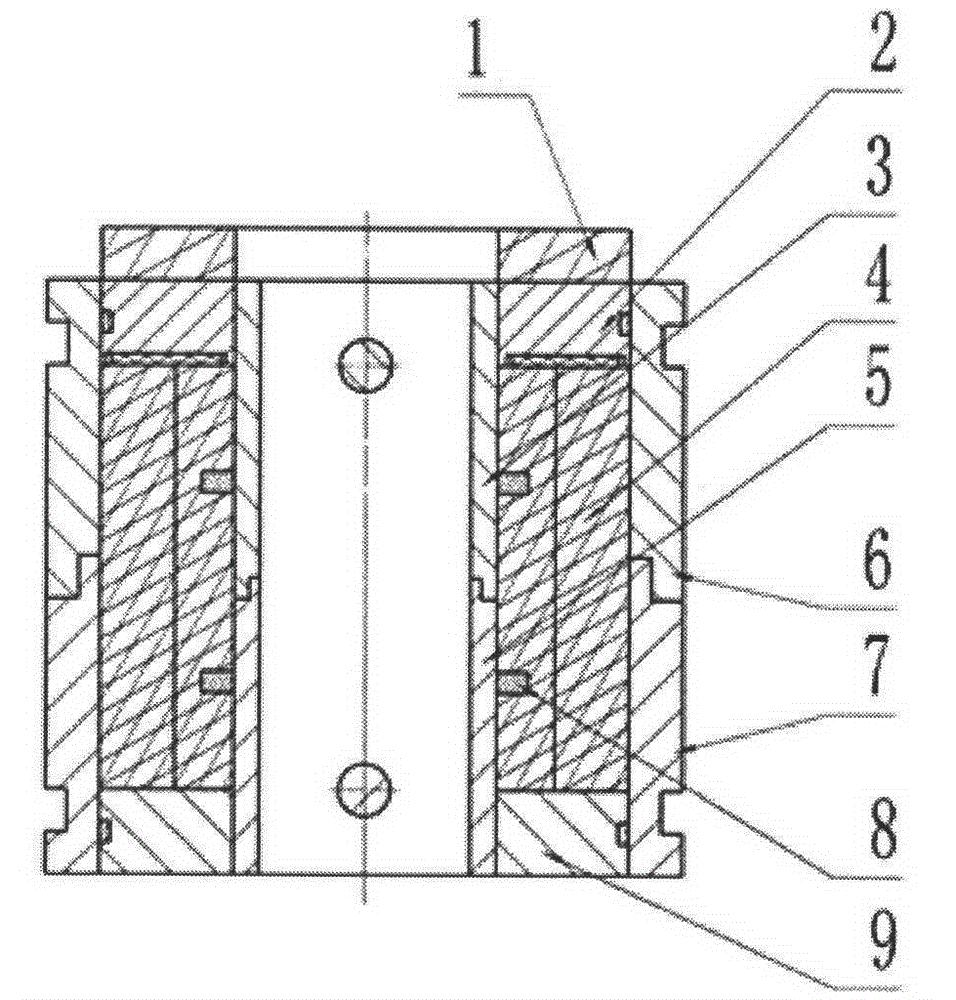

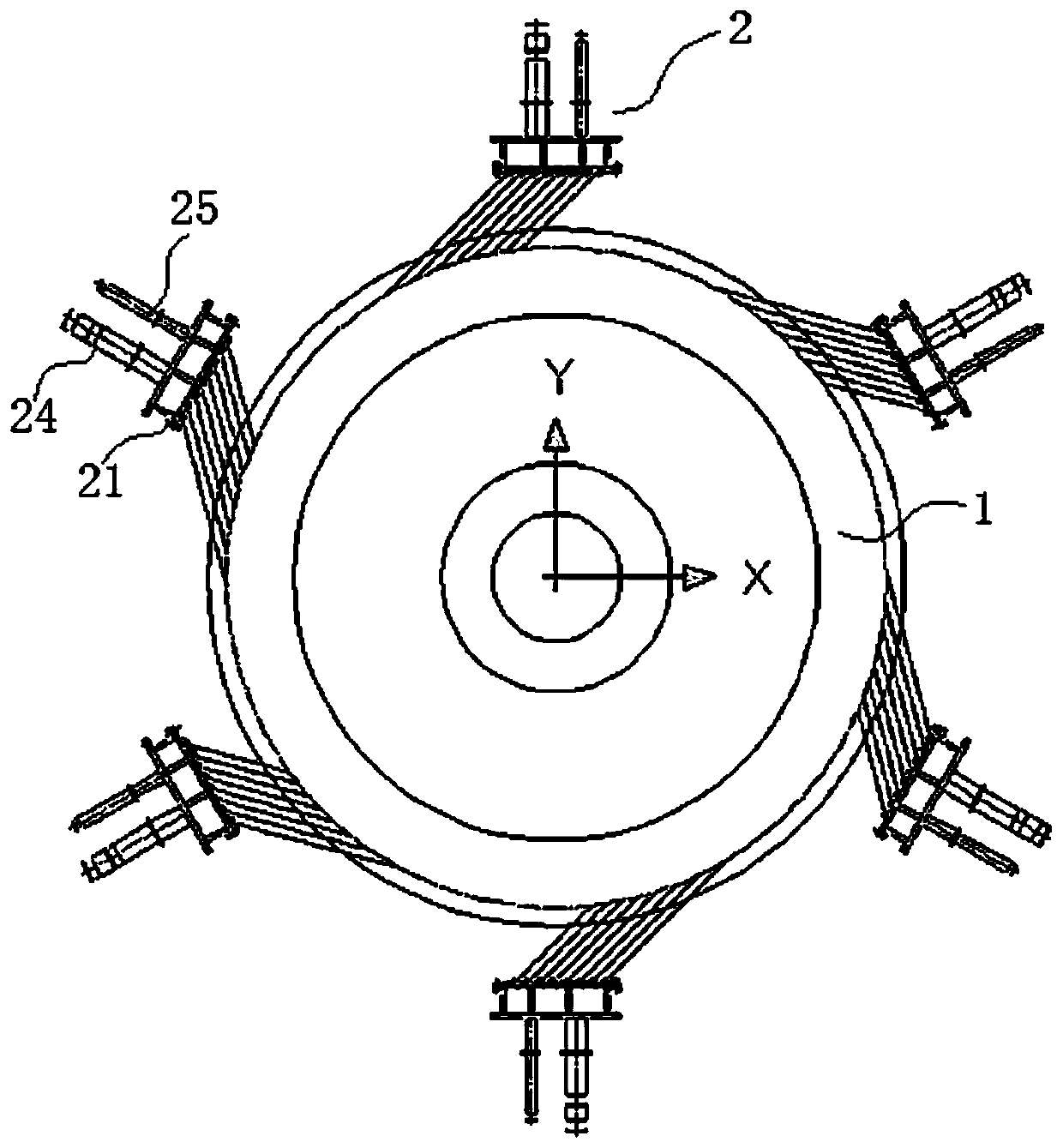

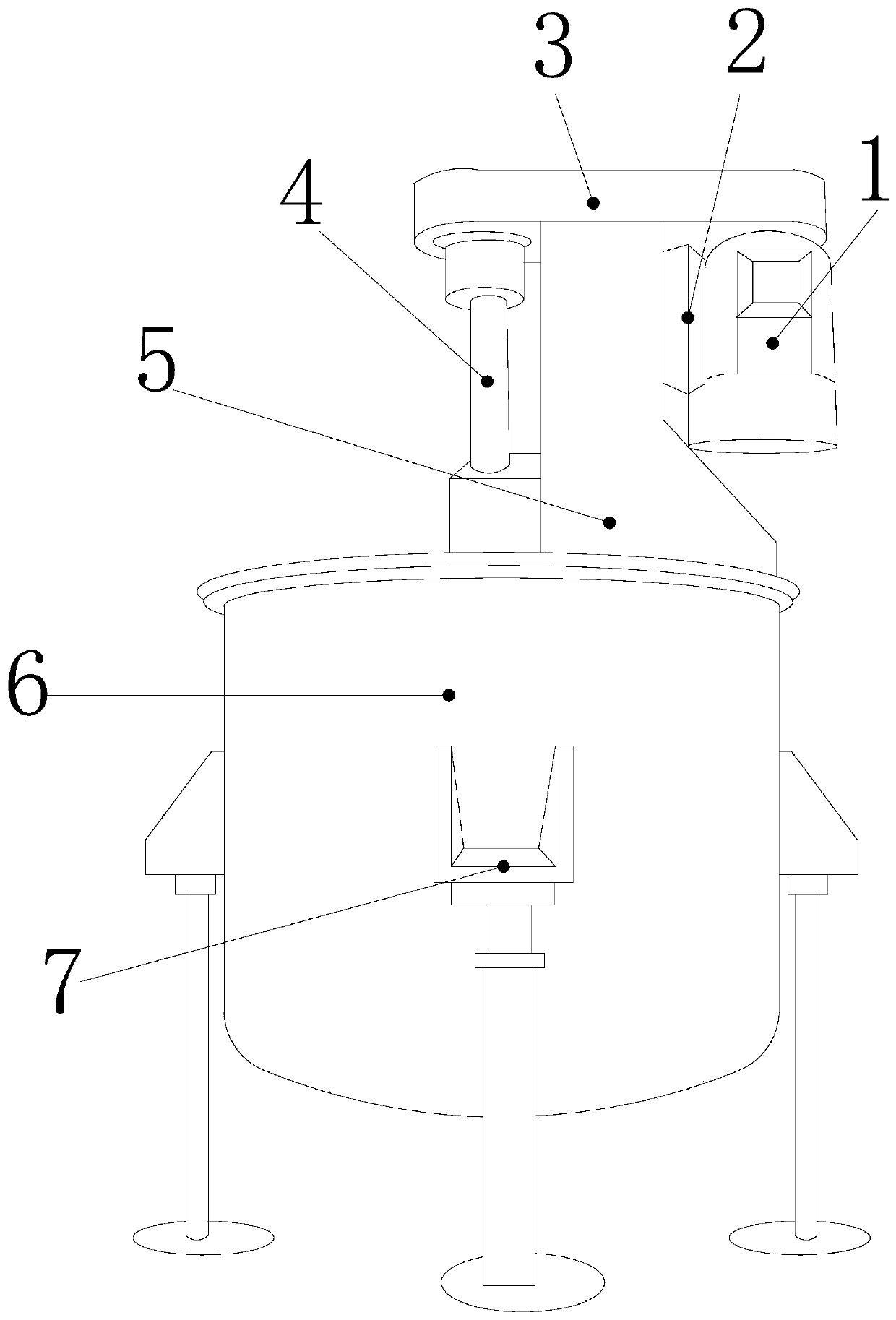

Train wheel cooling device and method and preparation method

PendingCN110777241AAdjust the spray volumeImprove cooling uniformityFurnace typesHeat treatment furnacesControl theoryMechanical engineering

The invention discloses a train wheel cooling device and method and a preparation method, and belongs to the technical field of train wheels. The device comprises a quenching table and a plurality ofspray guns which are uniformly arranged in the circumferential direction of the quenching table, and each spray gun comprises a water outlet panel and a water inlet branch pipe. Large and small spraying holes which are different in diameter are formed in the water outlet panels, wherein outlet water from the small spraying holes is separately controlled by a branch pipe, the large spray holes aredivided into the upper large spray holes and the lower large spray holes, and outlet water from the upper large spray holes and outlet water from the lower large spray holes are controlled by different branch pipes. According to the train wheel cooling device, the intensity of the cooling water jetted to the train wheels can be easily adjusted, and the uniformity of cooling, in the radial direction and in the axial direction, of wheel rims is improved. The cooling method is used for cooling of heat treatment of the train wheels by using the cooling device when the train wheels are prepared, the hardness uniformity of the wheel rims is effectively enhanced, and the using performance of the train wheels is improved. The preparation method is used for cooling of the heat treatment of the train wheels in the process of preparation using the cooling method, and the train wheels which are high in wheel rim hardness uniformity can be prepared.

Owner:MAANSHAN IRON & STEEL CO LTD

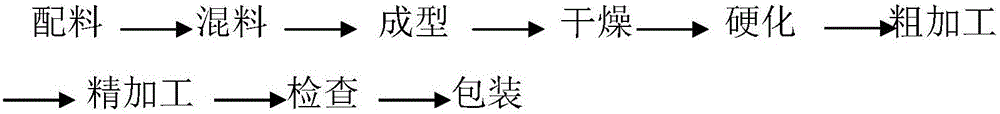

Medical grinding wheel for grinding insulin needles and manufacturing method thereof

InactiveCN105856080AImprove the finishReduce grinding scratchesAbrasion apparatusGrinding devicesOxideZinc

The invention particularly relates to a medical grinding wheel for grinding insulin needles and a manufacturing method thereof. The medical grinding wheel for grinding the insulin needles is characterized in that raw material components of the medical grinding wheel include, by weight, 60-65% of silicon carbide, 10-18% of micropowder-grade ceramic corundum, 8-12% of modified resin, 5-15% of glass beads, 1-4% of cryolite powder and 1-4% of zinc oxide, and the cryolite powder and the zinc oxide serve as filling agents. Micropowder-grade ceramic corundum abrasive materials can conduct self-sharpening at the nanoscale size during the grinding process, and micro grinding edges are exposed continuously, so that the cutting depth can be increased, and the grinding efficiency can be improved. Poor grinding faces caused by smoothed and blunted abrasive particles can be avoided through the micro grinding edges exposed continuously. During production of the grinding wheel, water pressure pads are adopted in the diameter direction and the thickness direction of the grinding wheel, and the balance performance and structure uniformity of the grinding wheel are improved by 50% more than the specified value of the national standard.

Owner:QINGDAO SISA ABRASIVES CO LTD

Quenching lift for bearing ring

ActiveCN103848371AFix frequent damageSolve the hardnessGearingLifting framesDrive shaftAgricultural engineering

The invention discloses a quenching lift for a bearing ring. The quenching lift comprises a motor, a frame, a workbench, a crank connecting rod mechanism and a power transmission mechanism. A transmission shaft of the power transmission mechanism is supported on the frame through bearings on two ends, and a first spindle and a second spindle are respectively arranged on two sides of the transmission shaft. A motor belt pulley is connected to a big belt pulley through a belt, a drive chain wheel on the big belt pulley shaft is connected to a driven chain wheel through a chain, the driven chain wheel drives an intermediate chain wheel, the intermediate chain wheel is connected to a large driven chain wheel on the transmission shaft through the chain, and two same drive chain wheels on the transmission shaft are respectively connected to a first spindle chain wheel and a second spindle chain wheel through the chain. Cranks of the crank connecting mechanism are respectively arranged on two ends of the first spindle and the second spindle, a cylinder sleeve and the frame are fixed through a support plate, and a piston in the cylinder sleeve is connected to the workbench through a vertical shaft of the workbench. According to the quenching lift for the bearing ring, the quenching hardness uniformity is improved by 2-3 HRC, the problems of uneven hardness and soft spots during quenching of the bearing ring are completely solved, the quenching efficiency is high, and the product quality is stable.

Owner:DALIAN GRANDWAY BEARING

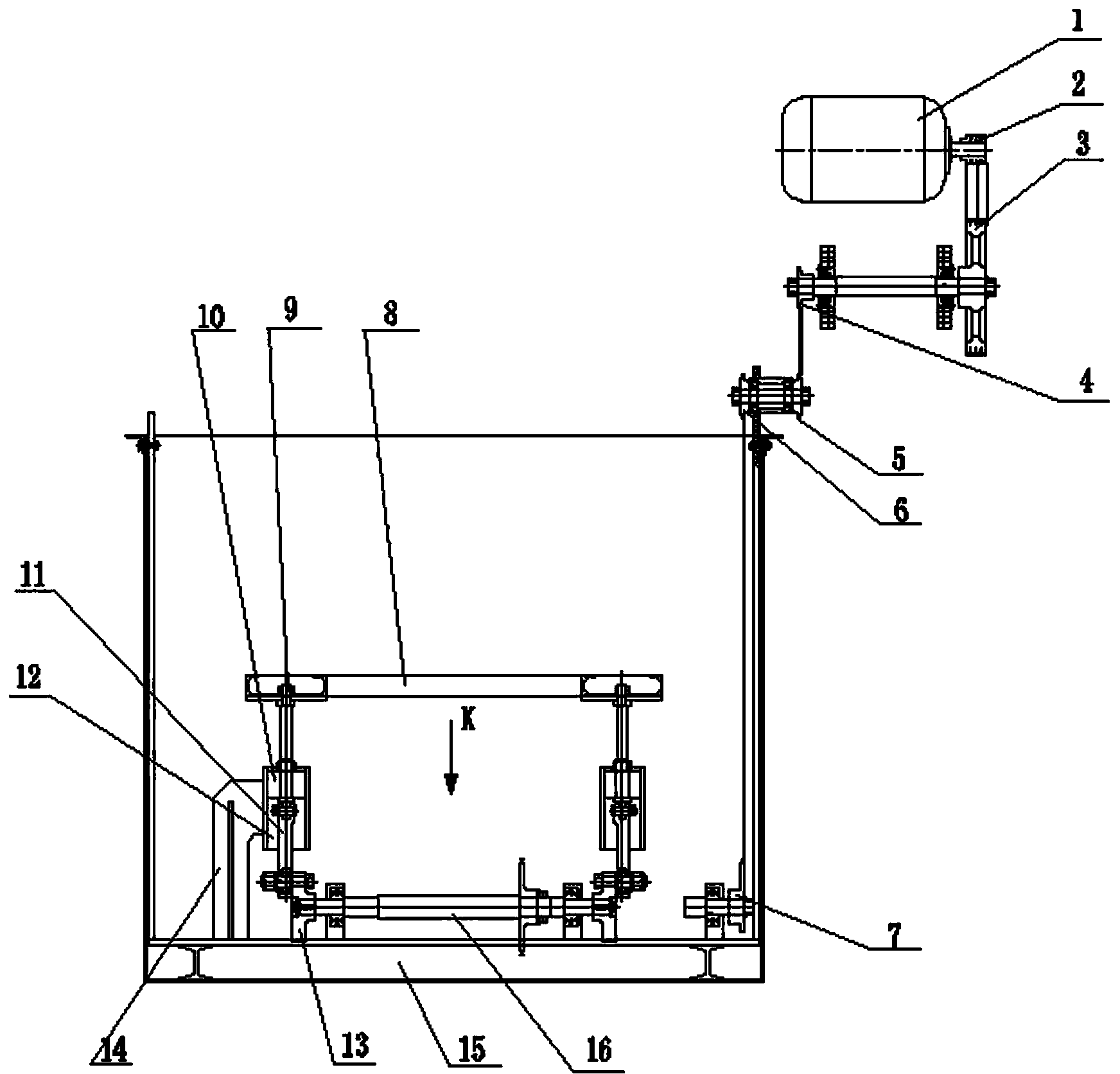

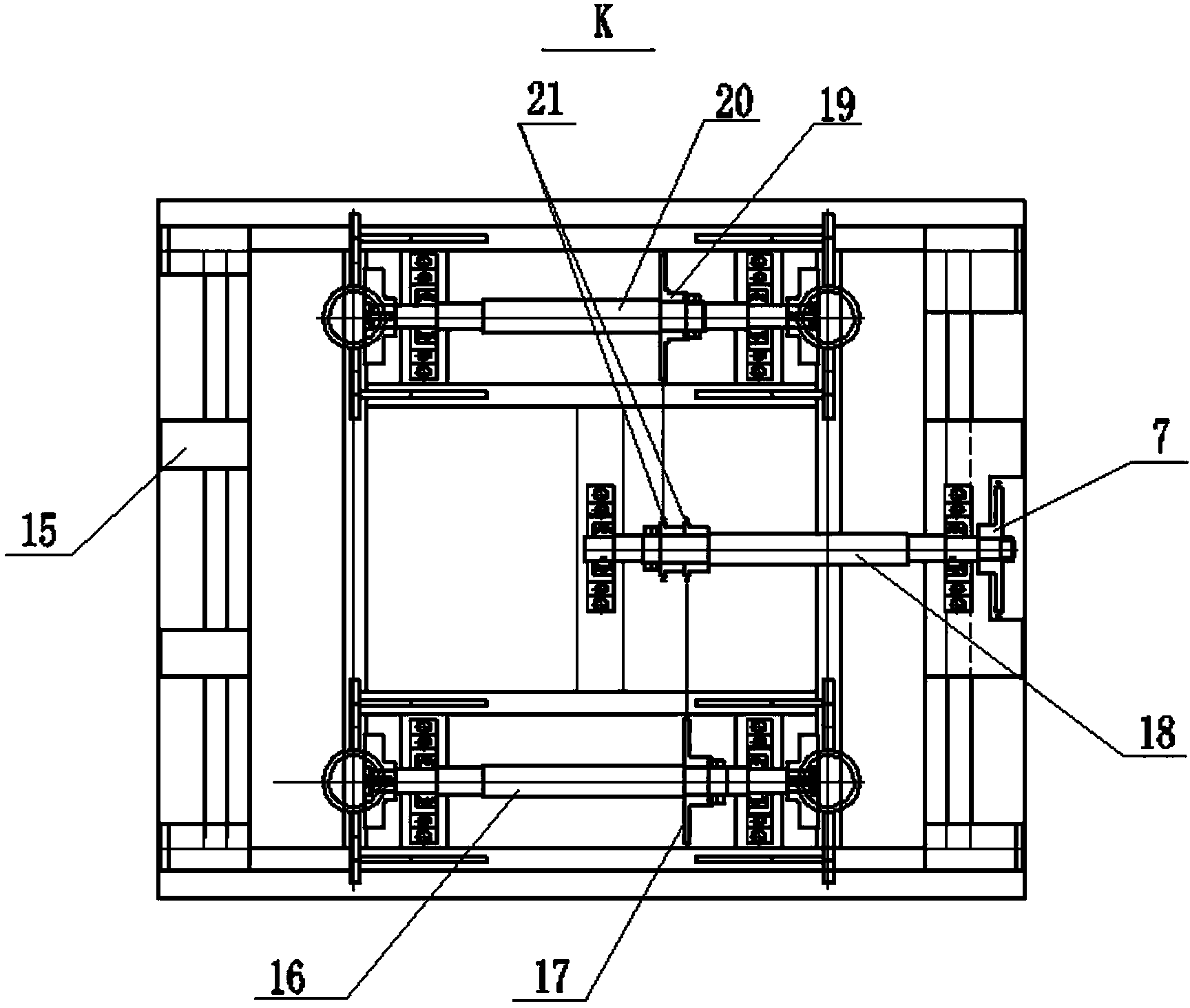

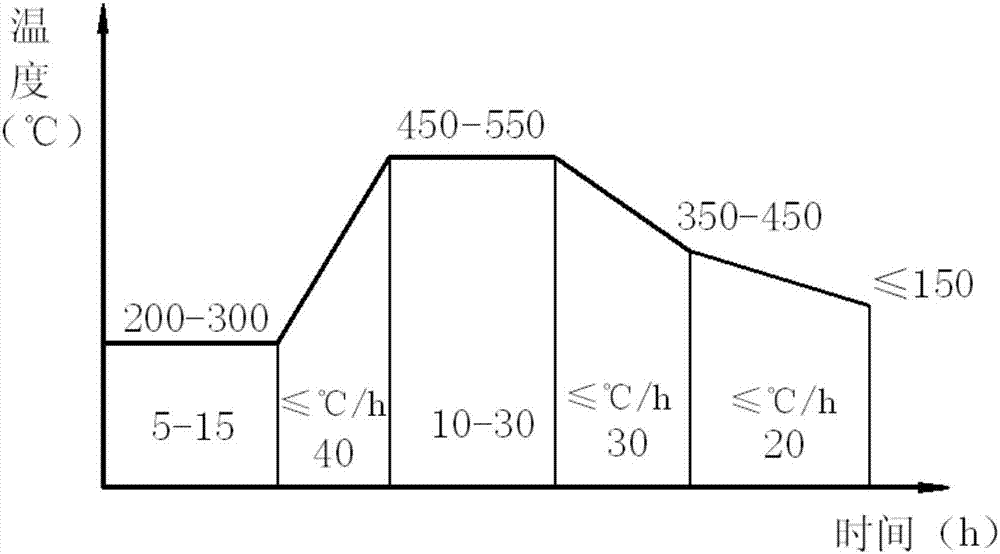

Heat treatment method for improving hardness uniformity of roller body of support roller of forged steel

ActiveCN106893812AImprove hardness uniformityMeet technical requirementsFurnace typesHeat treatment furnacesFurnace temperatureQuality level

The invention relates to a heat treatment method for improving the hardness uniformity of a roller body of a support roller of forged steel. The heat treatment method comprises the steps that the temperature of the support roller is kept for 5-15 hours at the furnace temperature of 200-300 DEG C; the furnace temperature rises to 450-550 DEG C at the temperature rising speed smaller than or equal to 40 DEG C / h, and the temperature is kept for 10-30 hours; the furnace temperature drops to 350-450 DEG C at the cooling speed smaller than or equal to 30 DEG C / h; the furnace temperature drops to 150 DEG C below at the cooling speed smaller than or equal to 20 DEG C / h; and the support roller is taken out from a medium-low temperature tempering furnace and is cooled to the normal temperature in the air. By the adoption of the heat treatment method, the support roller can meet the requirements that the hardness of the roller body ranges from 60 HSD to 78 HSD and the uniformity of hardness delta HSD is smaller than or equal to 4, and the quality level of the support roller of the forged steel is increased.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

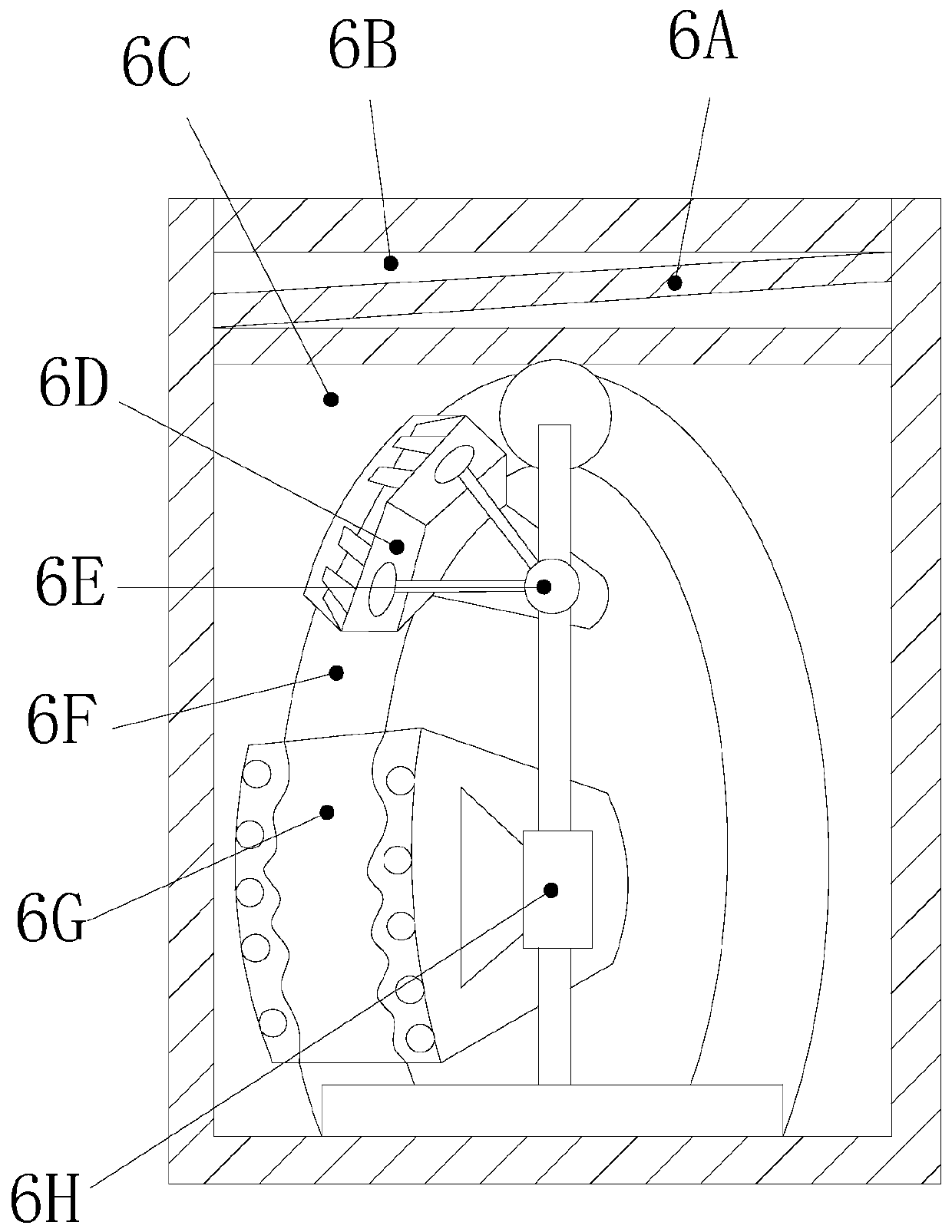

Double-ring differential centrifugal pressure vacuum pouring system with enhanced ceramic density

InactiveCN110666929AImprove hardness uniformityImprove finished product qualityCeramic shaping apparatusVacuum castingElectric machine

The invention discloses a double-ring differential centrifugal pressure vacuum casting system with enhanced ceramic density. The double-ring differential centrifugal pressure vacuum casting system with the enhanced ceramic density structurally comprises a shaft-driven motor, a power distribution block, a gear top cover seat, a rotating shaft column rod, a side frame support arm, a sliding frame pouring tank and lug fixing columns. According to the double-ring differential centrifugal pressure vacuum casting system, the cooperation of the rotating shaft column rod and the sliding frame pouringtank can be realized, the fine machining effect of an upper arc top sliding ring and a lower arc top sliding ring is achieved, and the effect of disturbance cooling and sweeping after pouring is formed; thickening stirring is carried out on the consistency of the clay through a display panel slide sheet and a corrugated liner plate, the slow pulling traction overall clay forms a transverse extension laying, and the clay molecular density at the early stage of the ceramic casting is ensured to be uniform, so that the compactness and smoothness of post-forming of the ceramic are optimized; and the polishing effect of the sliding rings as well as the vibration isolating operation enable the hardness uniformity after ceramic casting cooling is extremely high, the falling-resistant strength isimproved, the sliding-drawing leveling effect is formed for the concave-convex groove surface inside, the quality of the ceramic finished product is high, the processing and crushing probability is low, the cost is saved, and the forming efficiency is improved.

Owner:南安市波彼电子商务有限公司

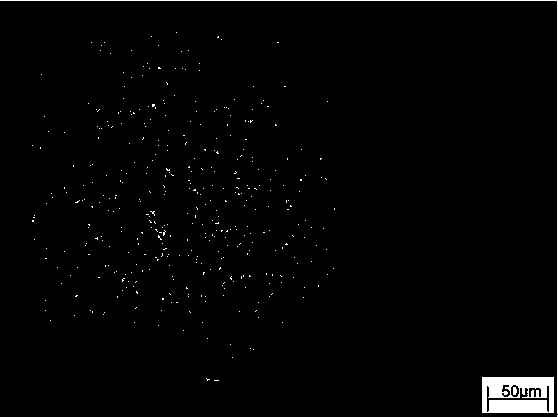

A kind of high uniformity and high polishing type plastic mold steel ZW636 and preparation method thereof

The invention relates to high-uniformity and high-polishing type plastic mould steel ZW636 and a preparation method thereof. The plastic mould steel particularly comprises the following components inpercentage by mass: 0.20 to 0.30 percent of C, 0.10 to 0.40 percent of Si, 1.20 to 1.60 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.005 percent, 1.20 to 1.80 percent of Cr, 0.90 to 1.20 percent of Ni, 0.48 to 0.70 percent of Mo, 0.08 to 0.15 percent of V, 0.015 to 0.030 percent of Als, less than or equal to 0.25 percent of Cu, O of less than or equal to 12 ppm,N of 60 to 100 ppm, H of less than or equal to 1.5 ppm and the balance of Fe and unavoidable impurities. Through the specific preparation method, the plastic mould steel has the following characteristics: (1) the tissue is uniform, the grain crystal is small, the tissue rating is less than or equal to level 4, and the grain size is more than level 6; (2) the hardness is uniform and the hardness uniformity of the same section is less than or equal to 3 HRC; and (3) the high-uniformity and high-polishing type plastic mould steel ZW636 has high polishing property and can be polished to 8000 meshes, and the polishing rate is 95 percent.

Owner:唐山志威科技有限公司

Differential-temperature heat treating method for roller

ActiveCN105296735AImprove hardness uniformityGood heart tissueFurnace typesHeat treatment furnacesHardnessHigh velocity

The invention discloses a differential-temperature heat treating method for a roller, and relates to the technical field of heat treating. The differential-temperature heat treating method includes the steps of a technological preparation stage, a preheating stage, a differential-temperature preheating stage, a high-speed temperature rising stage and a high-temperature heat preservation stage. According to the differential-temperature heat treating method, the preheating temperature is low and is 480 DEG C to 500 DEG C, the constant temperature before high-speed temperature rising is 800 DEG C to 850 DEG C, a stage-type temperature rising mode is adopted for the high-speed temperature rising stage, three temperature rising nodes exist, heat preservation is carried out for two minutes every time one temperature node is achieved, high-temperature heat preservation is divided two stages, and the heat preservation time and the temperature of the two stages are different. The roller prepared with the heat treating method has high hardness evenness and the good core microstructure, energy consumption of heat treatment can be reduced, and the production cost of an enterprise can be reduced.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Heat treatment method of ultra-large bearing ring

InactiveCN102220472AImprove hardness uniformityReduce consumptionFurnace typesHeat treatment furnacesWater basedRoom temperature

The invention relates to a heat treatment method of an ultra-large bearing ring, which comprises the step of quenching treatment: heating to 800-830 DEG C according to the effective thickness of the ultra-large bearing ring made of GCr15SiMn steel, keeping the temperature for 0.7-1.0 minute per millimeter of the effective thickness, then quenching in ZHY-101 quenching liquid, cooling to 50-120 DEG C, taking out of the quenching liquid and air-cooling to a room temperature; and heating to 180-250 DEG C for quenching and keeping the temperature for 6-12 hours. According to the heat treatment method, as water-based quenching is adopted, the mechanical properties are significantly better than those of oil quenching, the hardness and the uniformity of the hardness of the ultra-large bearing ring are improved greatly, and the insufficient quenching hardness of a rolling path and an inner diameter in traditional oil quenching is overcome. A water base is used for replacing an oil product, the consumption amount of the water base is significantly lower than the consumption amount of oil, the water-based quenching time is short, electrical energy is saved, and the water-based quenching liquid costs lower than the oil, so that the heat treatment cost of a bearing is greatly reduced. By adopting the heat treatment method, oil smoke, harmful volatile matters and fire hidden trouble can be avoided during the water-based quenching process.

Owner:瓦房店东旭非标准轴承集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com