Calendaring roller shell and manufacturing method thereof

A manufacturing method and calender roll technology, which is applied in the field of metallurgical rolls, can solve the problems of calender roll failure, shallow hardened layer, and difficult control of paper thickness, and achieve high uniformity of alloy structure, good mechanical properties, and high uniformity of hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment )

[0019] The manufacturing method of the calender roll sleeve of the present embodiment has the following steps:

[0020] ①Prepare blank roll.

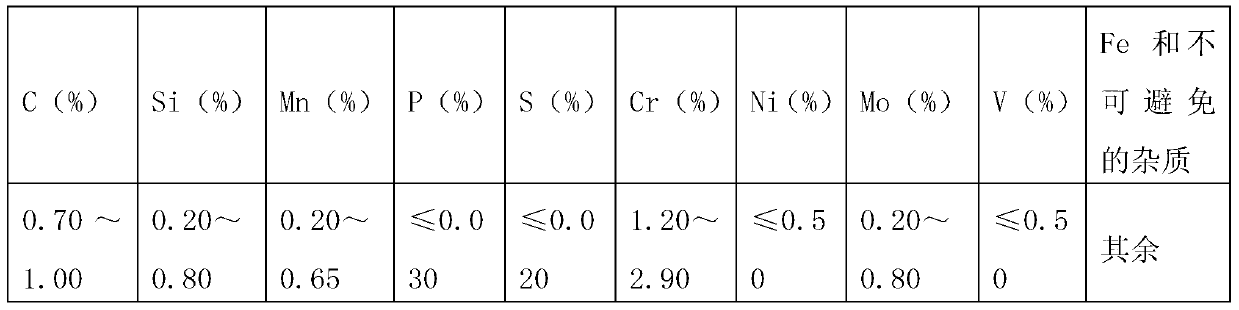

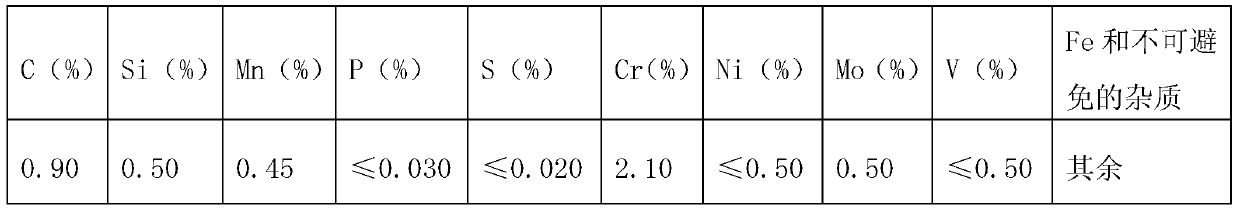

[0021] The billet roll is made of MC2B forged steel, and its chemical composition and weight percentage are shown in Table 2.

[0022] Table 2

[0023]

[0024] .

[0025] ② Quenching and tempering treatment.

[0026] Heat the forged billet roll to 860-880°C as a whole, oil quenching after sufficient heat preservation, and high-temperature tempering at 600-630°C after quenching.

[0027] Quenching and tempering treatment can not only ensure the good rigidity of the non-use layer inside the roller sleeve, and will not cause the risk of later use due to the high pressure of the roller sleeve, but also improve the hardness and uniformity of the used layer after surface quenching, and reduce the later surface. Quenching deformation.

[0028] After quenching and tempering, the blank roll is hollowed out to obtain a hollow blank roll....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com