Heat treatment method for large high-speed steel cold-rolled work roll

A technology of cold-rolled work rolls and heat treatment methods, which is applied in the field of heat treatment, can solve the problems of restricting the production and popularization of large-scale high-speed steel cold rolls, affecting the safe production of large-scale forged high-speed steel rolls, and difficult to obtain high roll body hardness. The effect of avoiding destructive failure, outstanding roughness retention ability, and satisfactory surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

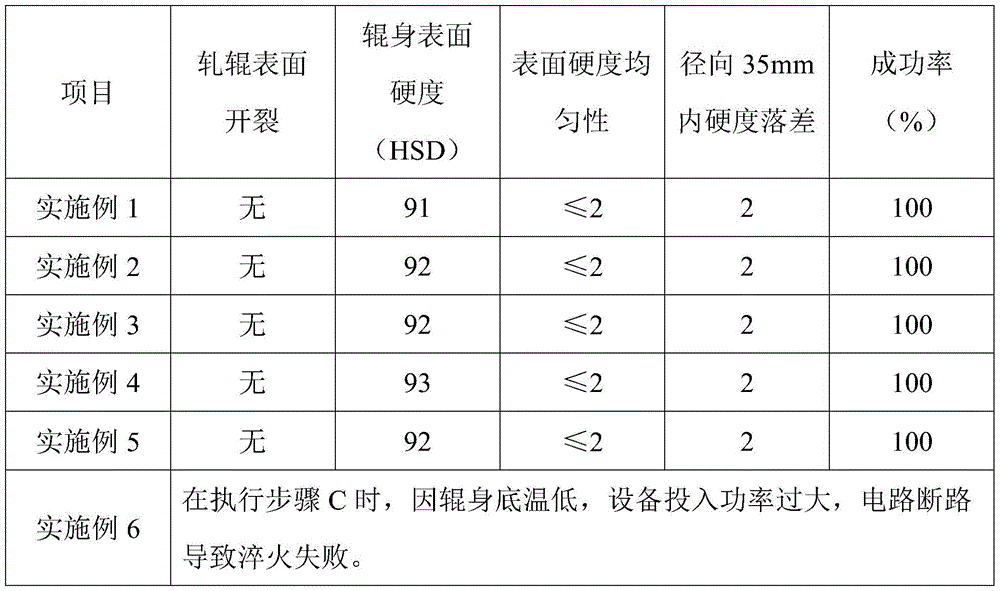

Examples

Embodiment 1

[0024] A heat treatment method for large-scale high-speed steel cold-rolled work rolls, the requirements of the work rolls are as follows:

[0025] Roll diameter:

[0026] Roll body hardness requirement: 90~95HSD;

[0027] Working layer thickness requirement: ≥33mm;

[0028] Roll material: forged high-speed steel, using electric furnace + ladle refining + electroslag remelting to produce steel ingots, the steel ingots are heated and forged according to process requirements to make roll forging blanks.

[0029] The heat treatment method includes preliminary treatment, preheat treatment and final heat treatment, and the steps are as follows:

[0030] 1. Preparatory treatment: Preliminary treatment is carried out on the high-speed steel cold-roll forging billet according to the requirements, and it is machined to the required size according to the drawing requirements;

[0031] 2. Preheating treatment:

[0032] A. Overall low-temperature preheating: Preheat the pre-treated ...

Embodiment 2

[0040] The difference between this embodiment and Embodiment 1 is: the preheating and holding temperature in step A is 350°C, and the holding time is 20h.

Embodiment 3

[0042] The difference between this embodiment and Embodiment 1 is: in step B, the temperature of the roll exiting the induction coil is 750°C; the roll continues to move upwards, and air cools for 20 minutes after exiting the induction coil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com