Working roller of copper foil rolling machine

A technology of work rolls and rolling mills, applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems of immature copper foil rolling technology, copper foil products not yet available in the market, small size of work rolls, etc., to achieve Ensure the uniformity of high hardness, shrink the thickness, and improve the hardness of the roll surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

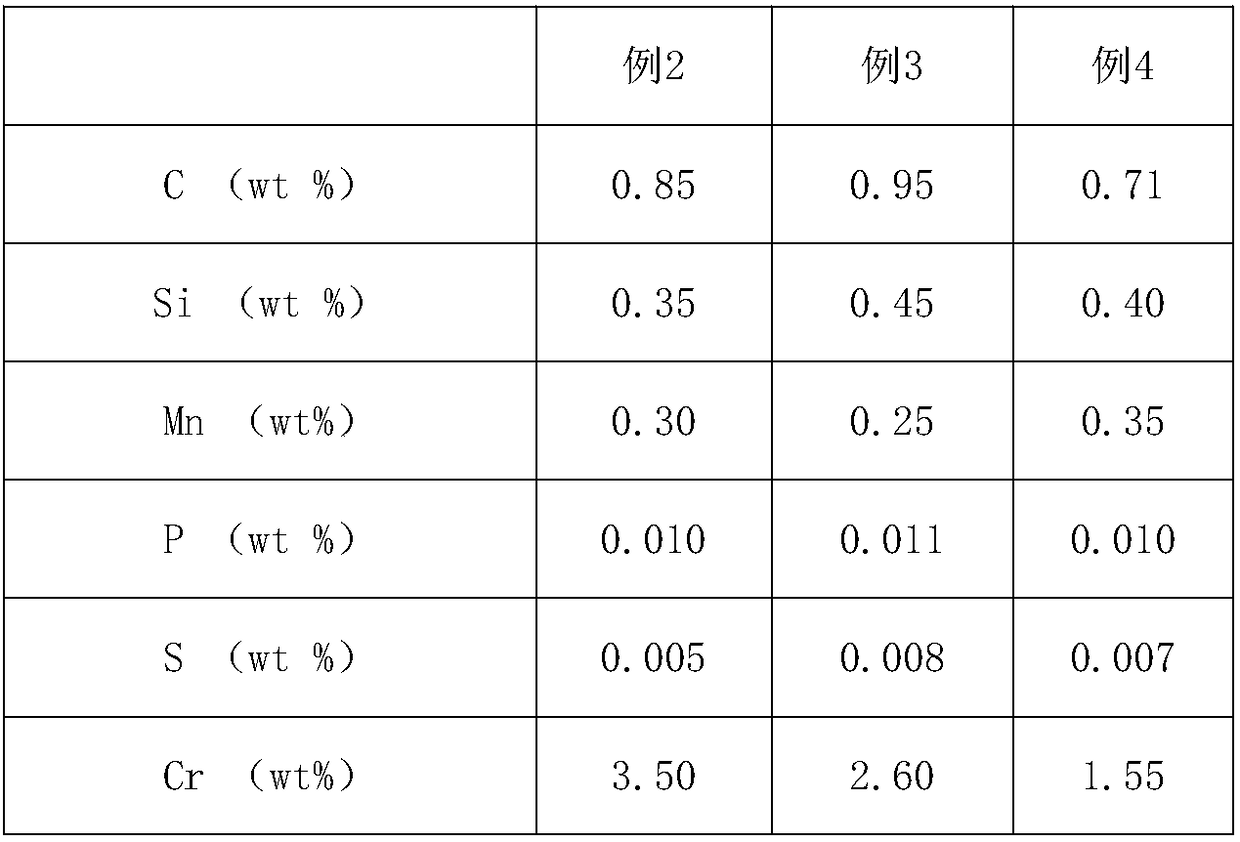

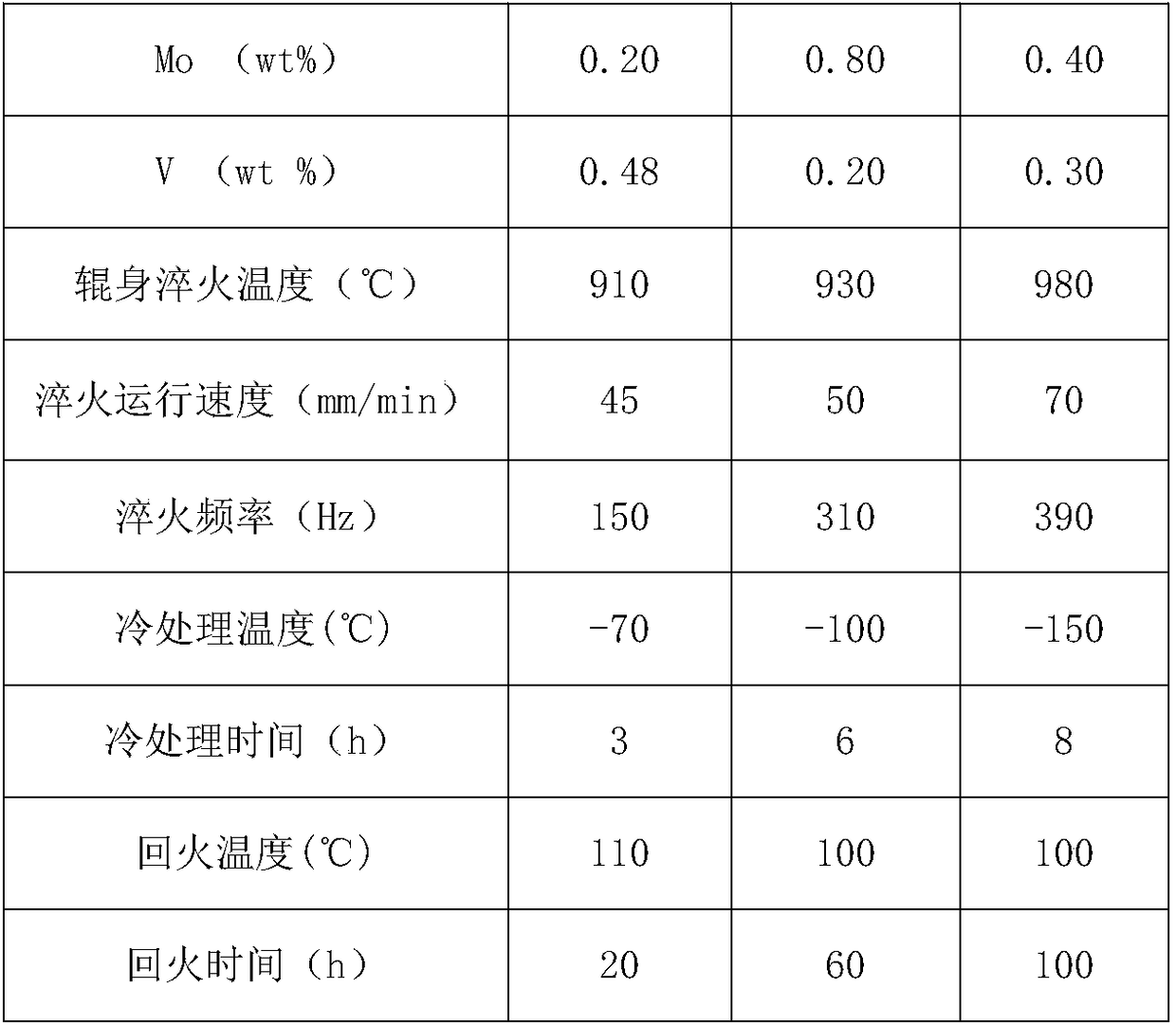

[0019] The preparation steps of the work roll are as follows:

[0020] Steel is first refined, and steel billets are manufactured to make the chemical composition and content of the steel reach the required range, and the cold-rolled billet is manufactured by conventional production technology. Cast the electrode, then anneal the electrode ingot, melt and cast the electrode ingot into an electroslag ingot, and finally test it. After the composition is qualified, the electroslag ingot is heated, forged into a forging billet, heat treated for the forging billet, and finally turned (rough turning ), after passing the inspection, carry out quenching and tempering treatment (preparation heat), the quenching and tempering treatment is carried out in a resistance furnace, the heating temperature is 850-880°C, and the holding time is 6-8h;

[0021] Then induction hardening is carried out. The heating temperature during induction hardening is 910-980°C, the quenching speed is 50-100mm / ...

Embodiment 1

[0023] A work roll of a copper foil rolling mill, the slenderness ratio of the work roll is 17, the material of the work roll is 9Cr2Mo, the chemical composition and the weight percentage of each composition are C 0.91%, Si 0.35%, Mn 0.30%, Cr1. 98%, Mo 0.32%, Ni0.04%, P 0.01%, S 0.01%, and the rest are Fe and unavoidable impurities.

[0024] The preparation steps of the work roll are as follows:

[0025] Steel is first refined, and steel billets are manufactured to make the chemical composition and content of the steel reach the required range, and the cold-rolled billet is manufactured by conventional production technology. Cast the electrode, then anneal the electrode ingot, melt and cast the electrode ingot into an electroslag ingot, and finally test it. After the composition is qualified, the electroslag ingot is heated, forged into a forging billet, heat treated for the forging billet, and finally turned (rough turning ), after passing the inspection, carry out quenchin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com