Highly-polished prehardened die steel, and preparation method thereof

A preparation process and pre-hardening technology, which is applied in the field of alloy steel, can solve the problems of strict polishing process requirements, many mold manufacturing processes, and increased manufacturing costs, and achieve high polishing performance, good polishing performance, and the effect of improving grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

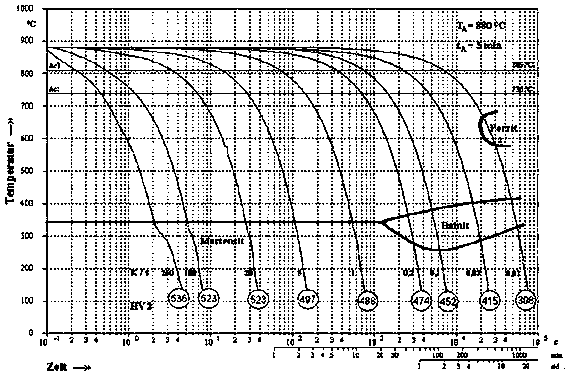

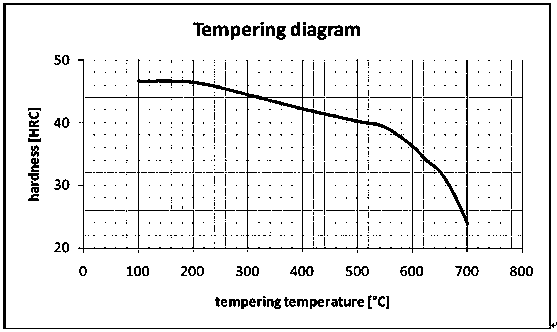

Method used

Image

Examples

Embodiment

[0026] In this embodiment, the components and mass percentages of the highly polished pre-hardened mold steel are as follows: C0.25%, Si 0.15%, Mn 1.60%, Cr 1.70%, Ni 0.90%, Mo 0.50%, V 0.07%, P 0.012%, S 0.002%, Nb 0.03%, Fe balance.

[0027] Adopt the material in this embodiment to produce the technological process and the step of high polished pre-hardened die steel as follows:

[0028] (1) Smelting: According to the composition and mass percentage of high-polished pre-hardened mold steel, batching, electric arc furnace smelting and refining, then vacuum degassing and casting, and finally demoulding and hot delivery to forging heating furnace;

[0029] (2) High-temperature diffusion heat treatment: the steel ingot is heated in stages in the forging furnace, that is, isothermal at 600°C, 800°C, and 1100°C respectively, and finally heated to 1180-1250°C, and the holding time is 10-20 hours after reaching the uniform temperature ;

[0030] (3) Forging hot processing: Cool th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com