Heat treatment method for improving hardness uniformity of roller body of support roller of forged steel

A heat treatment method and technology of uniform hardness, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of low hardness uniformity of backup rolls, improve accident resistance, improve roll body hardness uniformity, and shorten holding time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

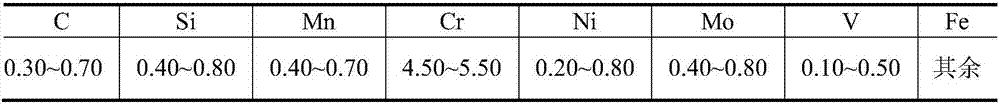

[0057] The size and main technical requirements of the back-up rolls for cold-acid rolling in a steel plant are as follows:

[0058]

[0059] The existing differential temperature heat treatment is carried out on the above-mentioned support roller, and the hardness test results are as follows:

[0060]

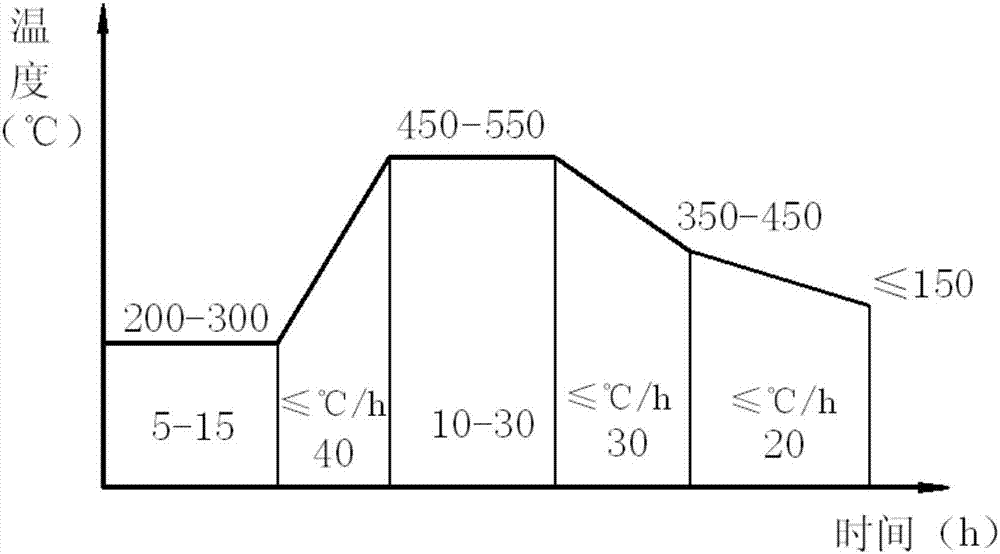

[0061] According to the above requirements, the hardness uniformity of the roll body needs to be improved to meet the technical requirements. The specific heat treatment process is as follows:

[0062] 1) First, apply a temperature measuring thermocouple (2 in total) on the shoulder of the back-up roll body and the middle of the roll body to monitor the temperature of the back-up roll workpiece during heat treatment.

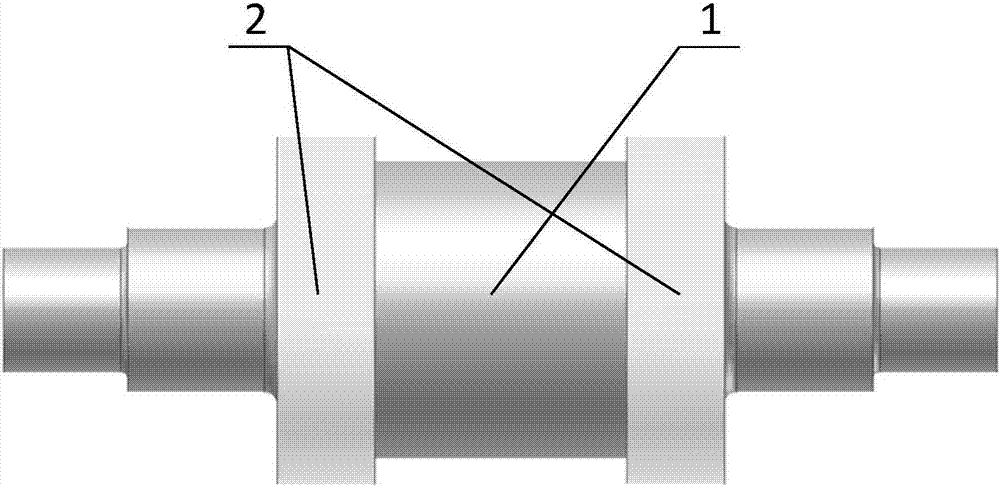

[0063] 2) if figure 2 As shown, the high temperature resistant asbestos felt with a thickness of 80mm and a width of 350mm is glued and wrapped on the shoulder of the roller body, the main purpose is to reduce the temperature rise rate of the shoulder of t...

Embodiment 2

[0069] The size and main technical requirements of a galvanized back-up roll in a steel plant are as follows:

[0070]

[0071] The existing differential temperature heat treatment is carried out on the above-mentioned support roller, and the hardness test results are as follows:

[0072]

[0073] According to the above requirements, the hardness uniformity of the roll body needs to be improved to meet the technical requirements. The specific heat treatment process is as follows:

[0074] 1) First, apply a temperature measuring thermocouple (total 2) on the upper and lower shoulders of the back-up roll body and in the middle of the roll body to monitor the temperature of the back-up roll workpiece during heat treatment.

[0075] 2) if figure 2 As shown, the high temperature resistant asbestos felt with a thickness of 100mm and a width of 300mm is glued and wrapped on the shoulder of the roller body; the main purpose is to reduce the temperature rise rate of the shoulde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com