Quenching lift for bearing ring

A bearing ring and elevator technology, which is applied to lifting frames, quenching devices, lifting devices, etc., can solve the problem of uneven hardness, and achieve the effects of improving hardness uniformity, fast stringing speed, and fast stringing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

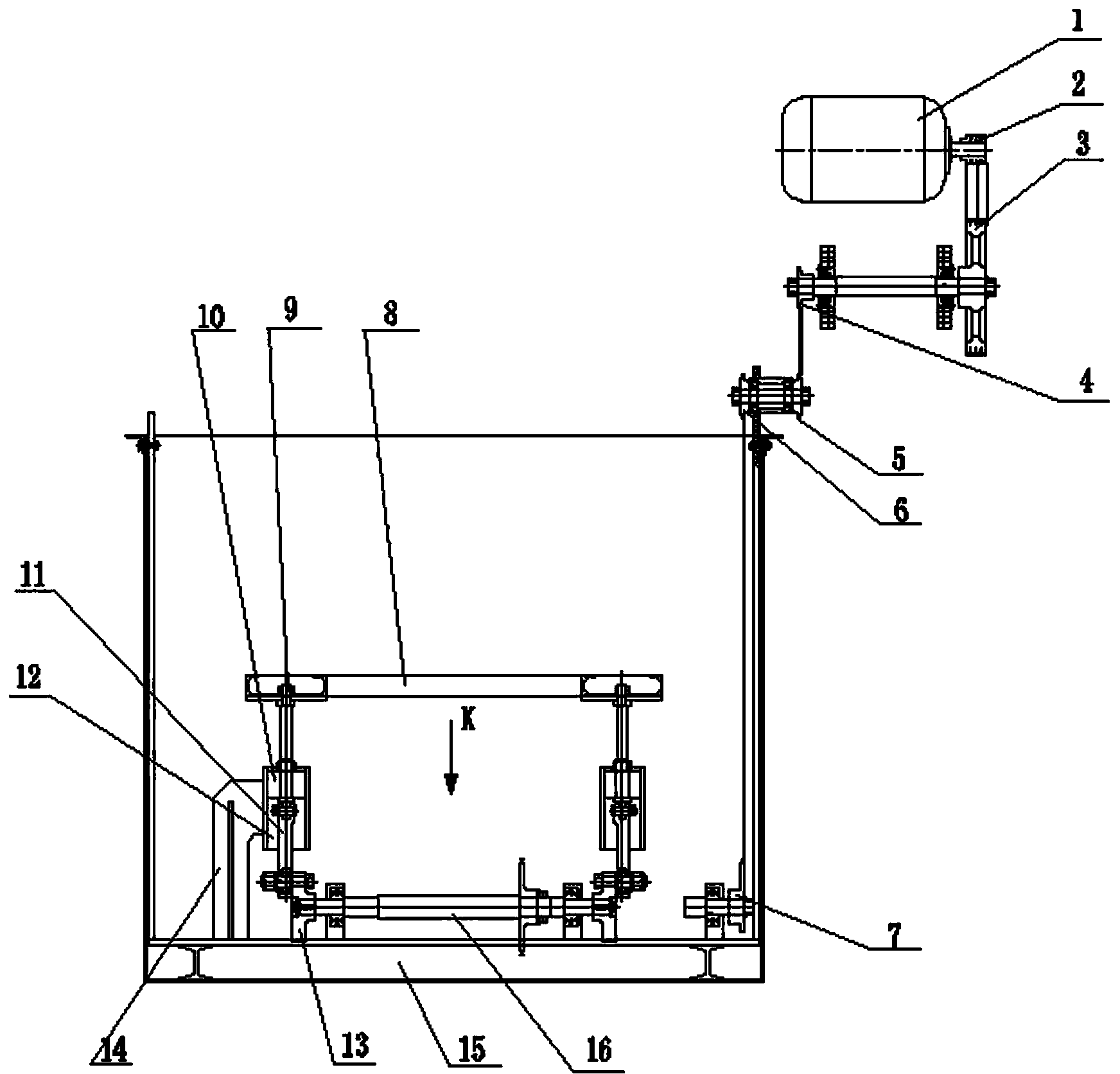

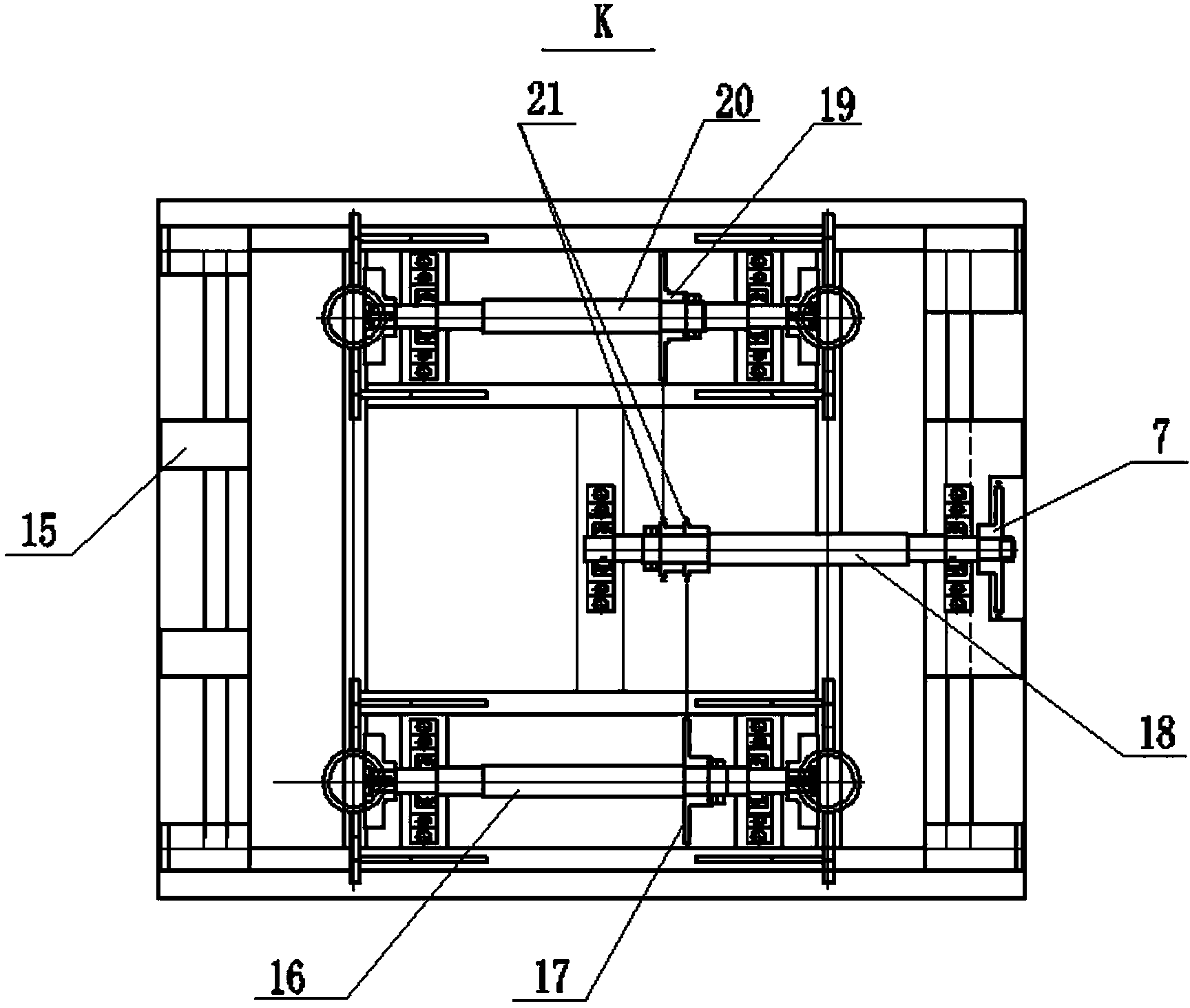

[0009] Bearing ring quenching and cooling elevator, including motor 1, frame 15, workbench 8,

[0010] Crank linkage mechanism, power transmission mechanism. Motor 1 is Y160M2-8 5.5kw motor n=720 / min. The 8-pole motor is decelerated by 4 stages. The speed of the motor is further adjusted by frequency converter, so that the lifting frequency can be adjusted according to the wall thickness of the workpiece. The power transmission mechanism includes a motor pulley 2 , a large pulley 3 , a transmission shaft 18 , a first main shaft 20 , and a second main shaft 16 . Motor pulley 2 adopts V-belt pulley A type 3 groove φ80, large pulley φ400. The transmission shaft 18 is equipped with a large passive sprocket 7 and the same two driving sprockets 21 respectively. The transmission shaft 18 is supported on the frame 15 with bearings at both ends, and the first main shaft sprocket 19 is installed on the first main shaft 20. , the second main shaft 16 is equipped with the second main sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com