Intelligent paperboard printing method

A printing method and cardboard technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of lowering industrial production automation standards, affecting the quality of pattern forming, ink penetration and diffusion, etc., to avoid rigid impact, protect devices, improve The effect of the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

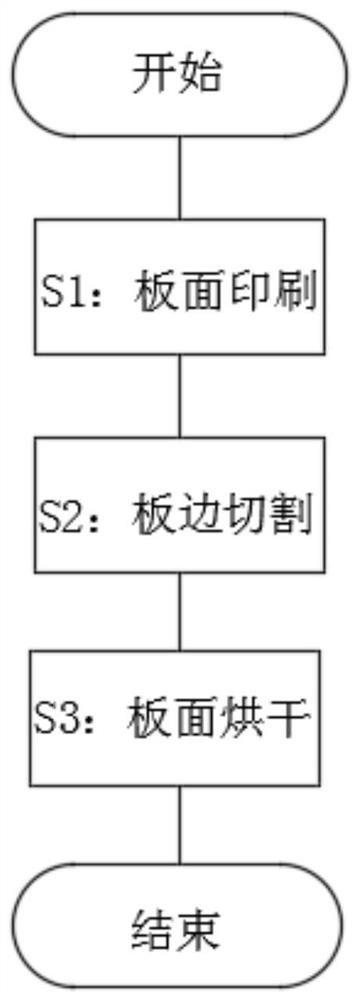

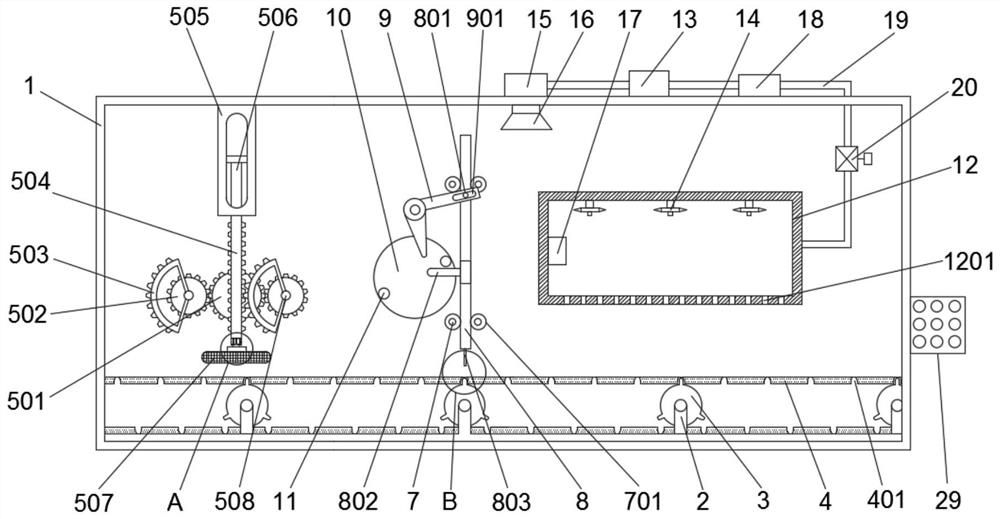

[0040] Example: such as Figure 1-10 Shown, a kind of intelligent cardboard printing method comprises the steps:

[0041] S1. Plate surface printing: put the cardboard on the transmission plate, start the first motor, the cardboard moves from left to right with the transmission plate, control the second motor to work, and drive the tooth plate to move down by controlling the left sector gear to mesh with the tooth plate , press down the printing plate to print on the surface of the cardboard;

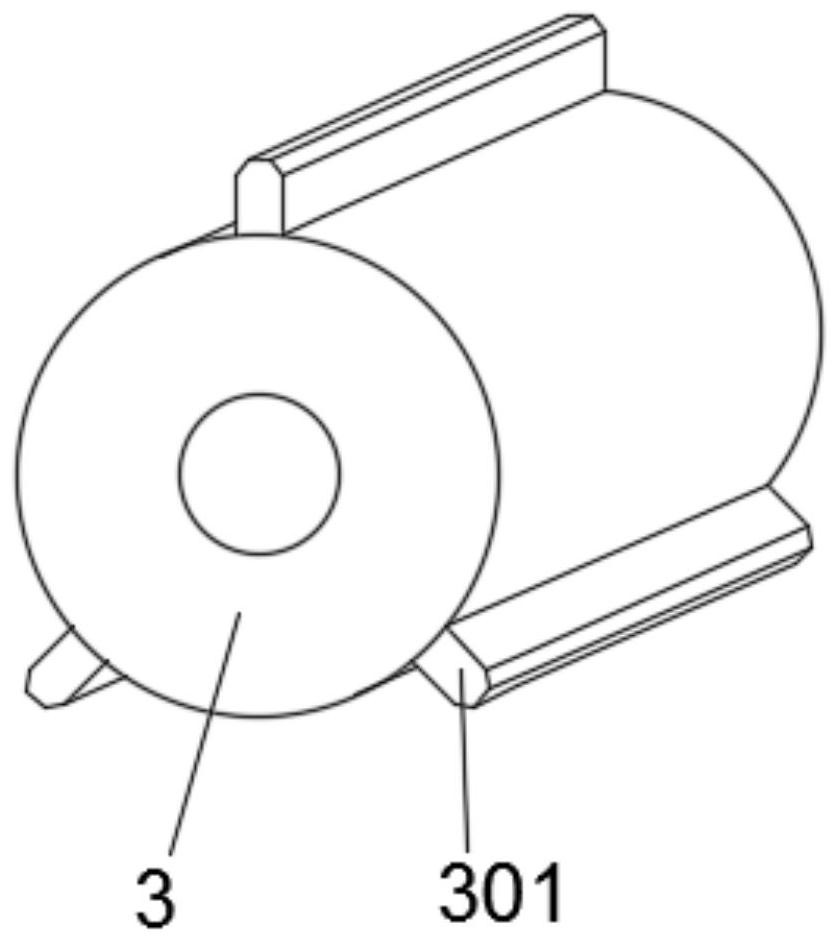

[0042] S2. Board edge cutting: the printed cardboard is conveyed to the bottom of the cutting device under the drive of the transmission plate, the second motor drives the second pulley to rotate through the first pulley, the turntable drives the first short column to rotate, and the first short column Press down the connecting rod, so that the moving rod drives the cutter to move downward, and the cutter passes through the cutting groove under the cardboard and cooperates with the cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com