Patents

Literature

220results about How to "Avoid Rigid Impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

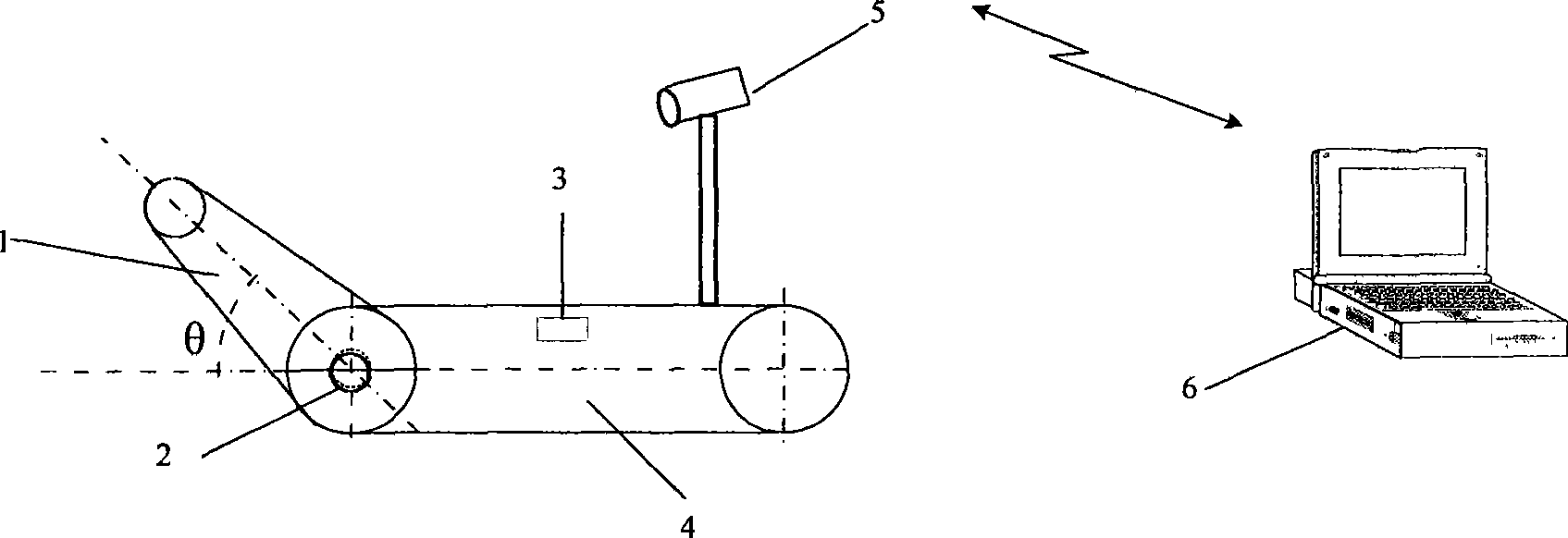

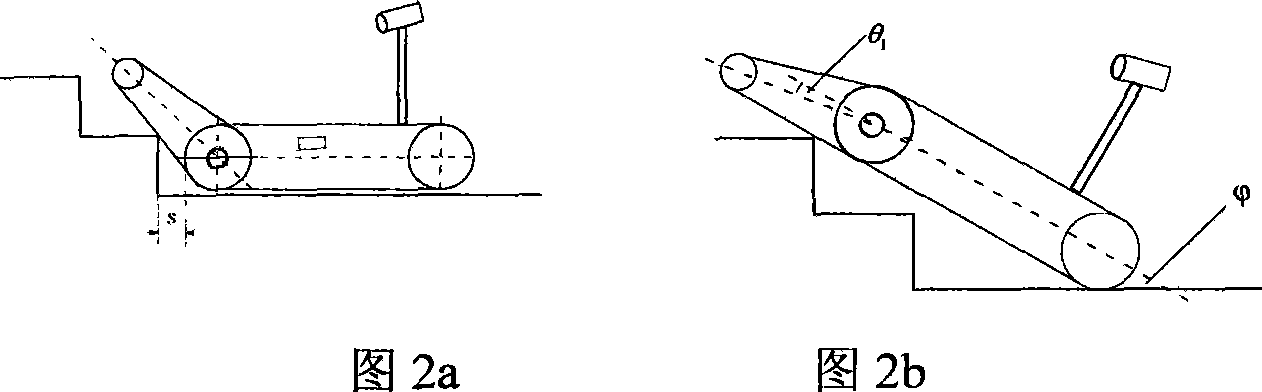

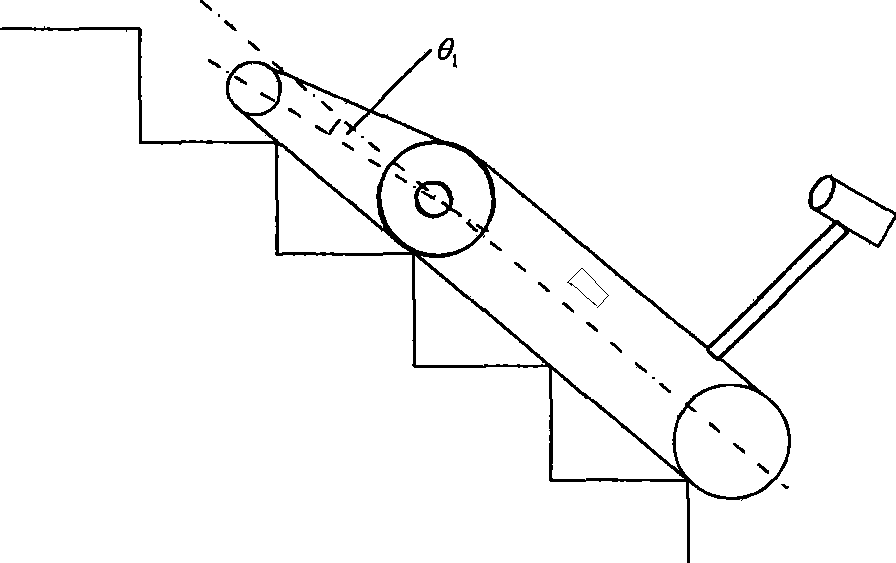

Stairs climbing control method for crawler moving robot with guide arm

InactiveCN101486360ANo overturningSmooth and reliable climbingEndless track vehiclesRotational axisControl theory

The invention relates to a stair-climbing method for a crawler-type mobile robot with guide arms, which is characterized by comprising the following steps: step one: the robot moves near the stair, the guide arms rotate downward; the robot is lifted after being contacted with the stair step and climbs the stair forward; when an ultrasonic and infrared distance-measuring sensor on the robot measures that the distance between the robot and the object at the front is larger than the width of the stair step and judges that the robot climbs to the top of the stair, the robot can stop climbing; step two: the guide arms rotate downward till the front ends of the guide arms are contacted with the ground; when the rotating shafts of the guide arms generate torque M which is larger than the set value, the guide arms stop rotating, the robot climbs upward continuously, the guide arms are separated from the ground with the climbing of the robot, the torque M disappears and the robot stops climbing; step three: the step two is repeated, a two-dimensional attitude sensor measures that the inclined angle Phi between the body and the horizontal plane is reduced with the climbing of the robot, and when the robot climbs continuously till the inclined angle Phi is not reduced, the robot stops climbing, the guide arms rotate backward and stop rotating when the inclined angle Theta between the guide arms and the body is 45 degrees.

Owner:JIANGSU CHENGCHAO LIMITED OF ALUMINUM IND +1

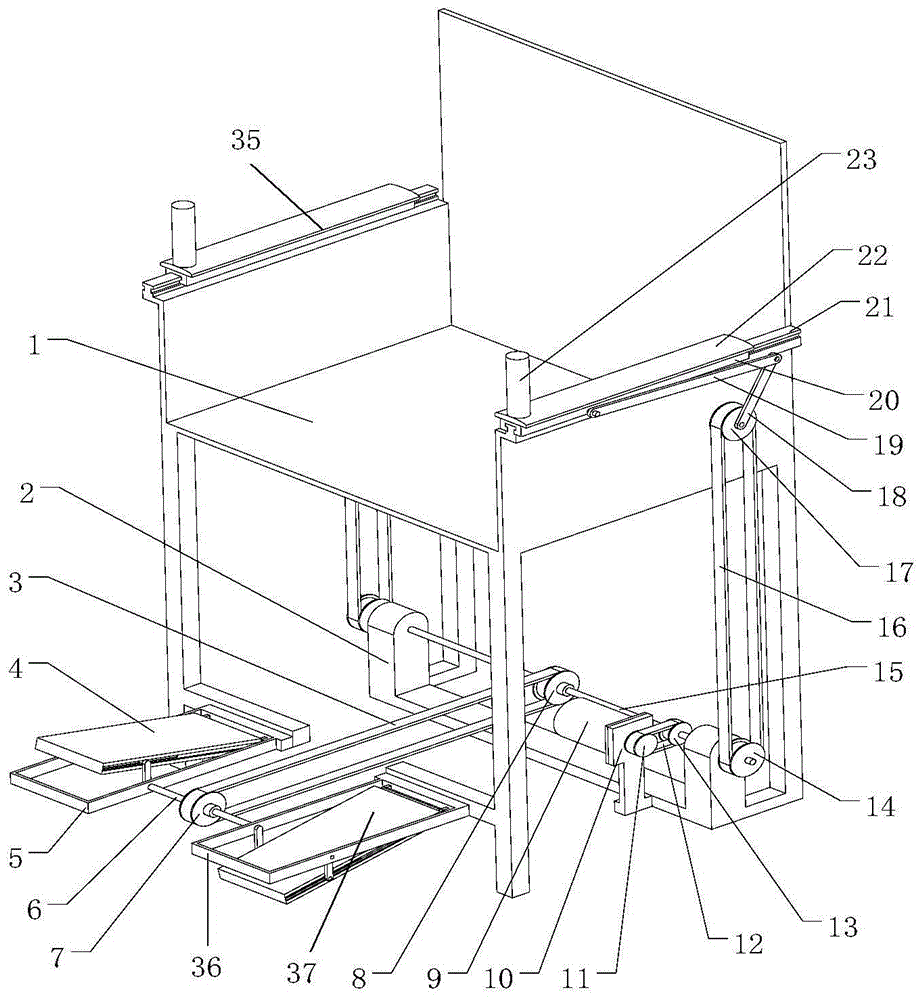

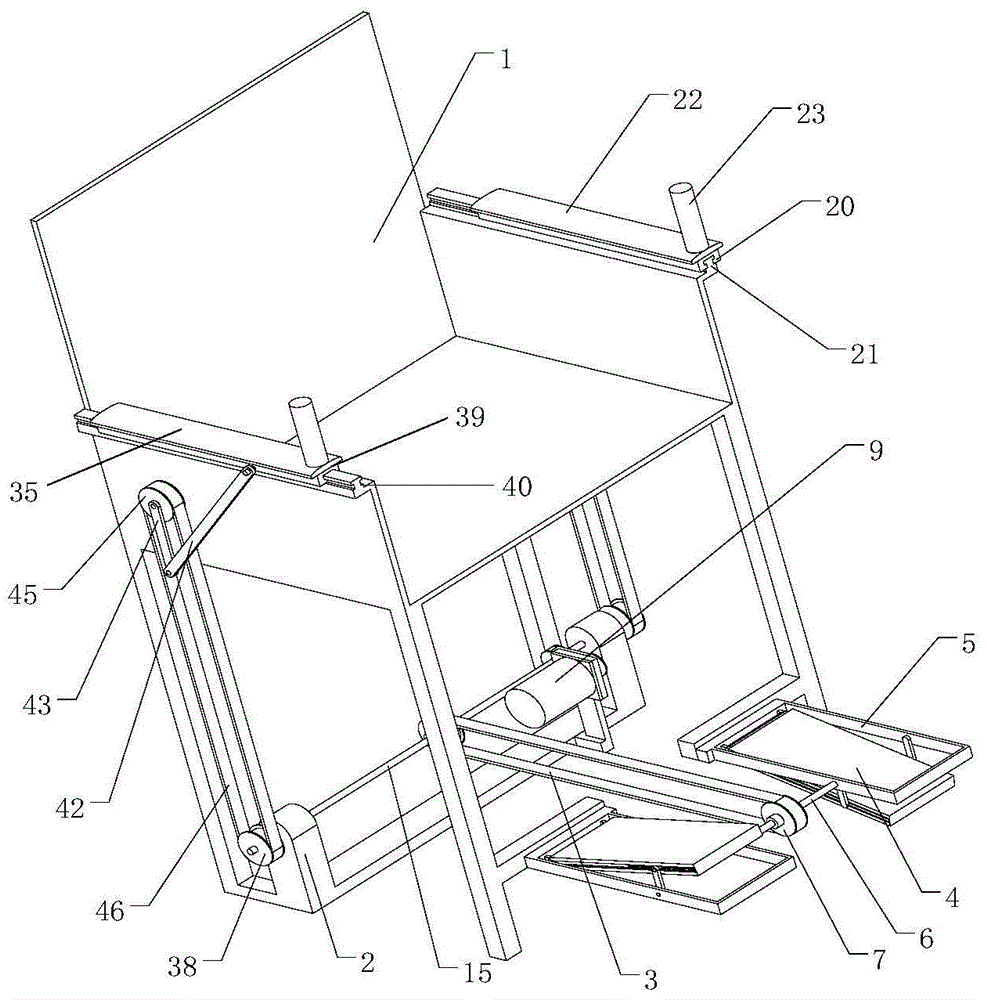

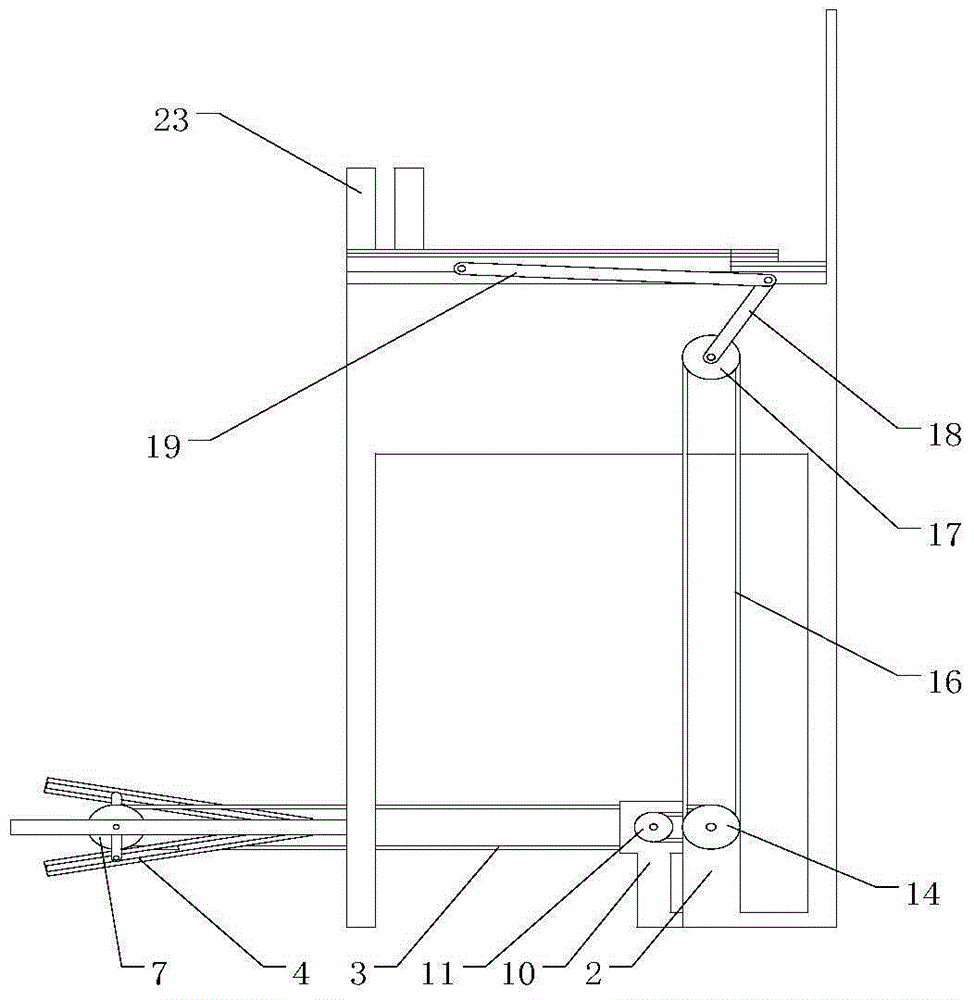

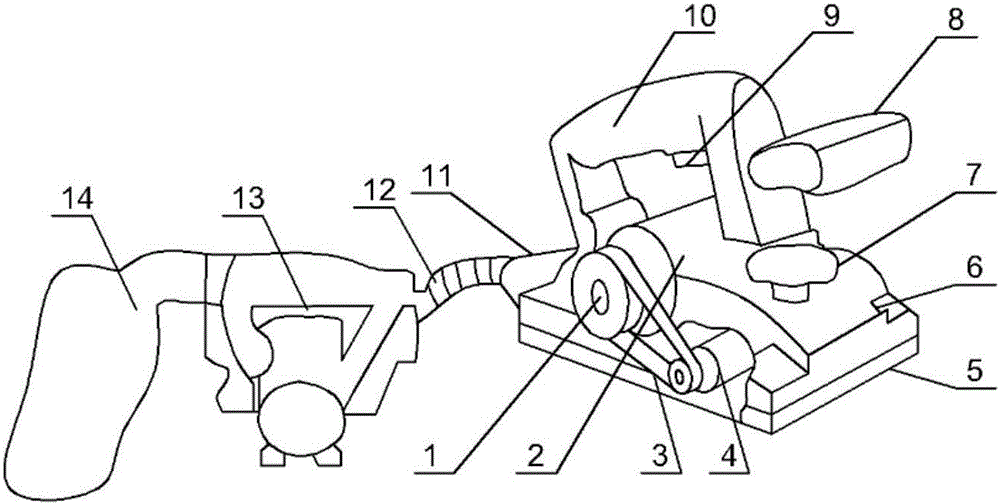

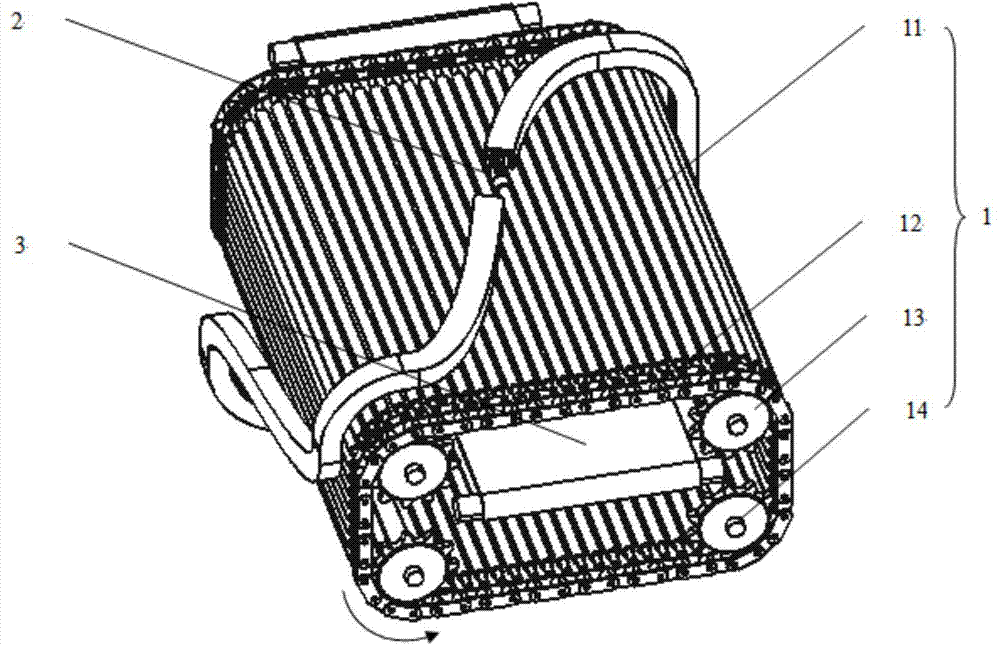

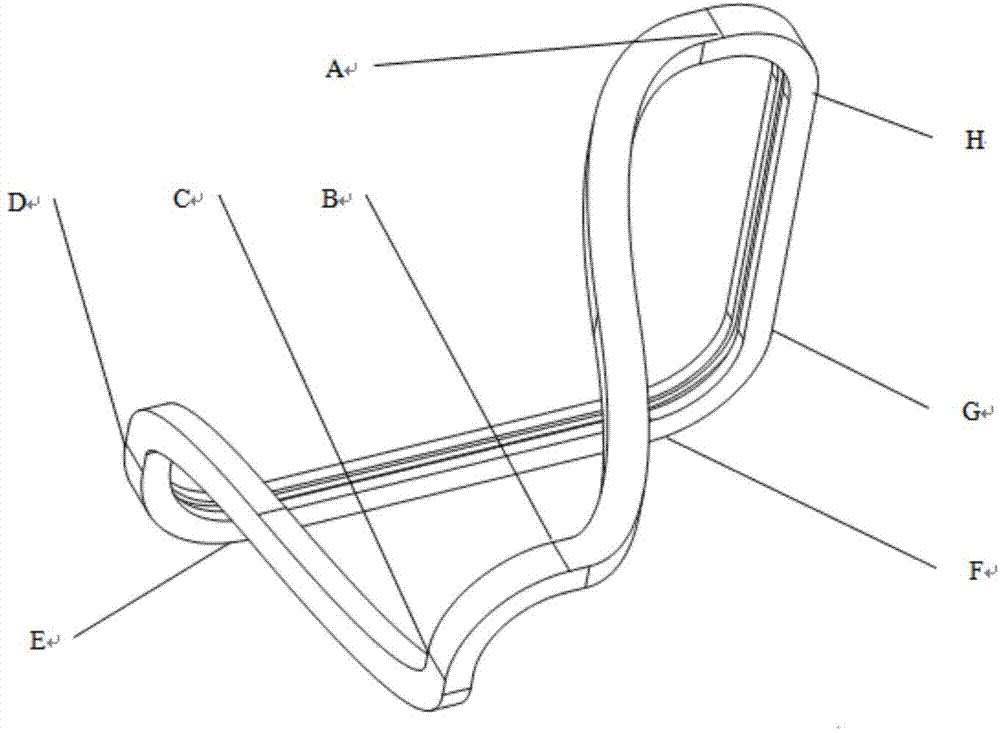

Rehabilitation chair for upper limbs and lower limbs

The invention provides a rehabilitation chair for the upper limbs and the lower limbs. The rehabilitation chair comprises a chair frame, a motor, a lower-limb rehabilitation mechanism and an upper-limb rehabilitation mechanism, wherein the lower-limb rehabilitation mechanism comprises a motor, belt wheels, belts, a transmission shaft, pedal plates, a crankshaft assembly and sliding blocks and the like; the upper-limb rehabilitation mechanism comprises belt wheels, belts, cranks, connecting rods, sliding blocks, sliding rails and a handle and the like; the motor drives the transmission shaft by a belt-wheel transmission mechanism; the belt wheels are arranged at the middle part of the transmission shaft and drive the crankshaft to rotate by belt transmission; the rotation of the crankshaft drives the pedal plates to do certain-angle pitching movement around the installing axis of the top end so as to drive the lower limbs to do rehabilitation movement; and the two ends of the transmission shaft are respectively provided with the belt wheels to drive a belt transmission mechanism and drive the cranks to rotate; the connecting rods drive the sliding blocks to do reciprocating linear movement along the sliding rails; hand-held plates and the handle are fixed on the sliding blocks so as to drive the upper limbs to do reciprocating rehabilitation movement. The rehabilitation chair provided by the invention has the advantages that the structure is simple, the use is convenient, and the simultaneous rehabilitation function of the upper limbs and the lower limbs is realized by a single power source, so that the rehabilitation chair is suitable for being promoted and applied.

Owner:HARBIN ENG UNIV

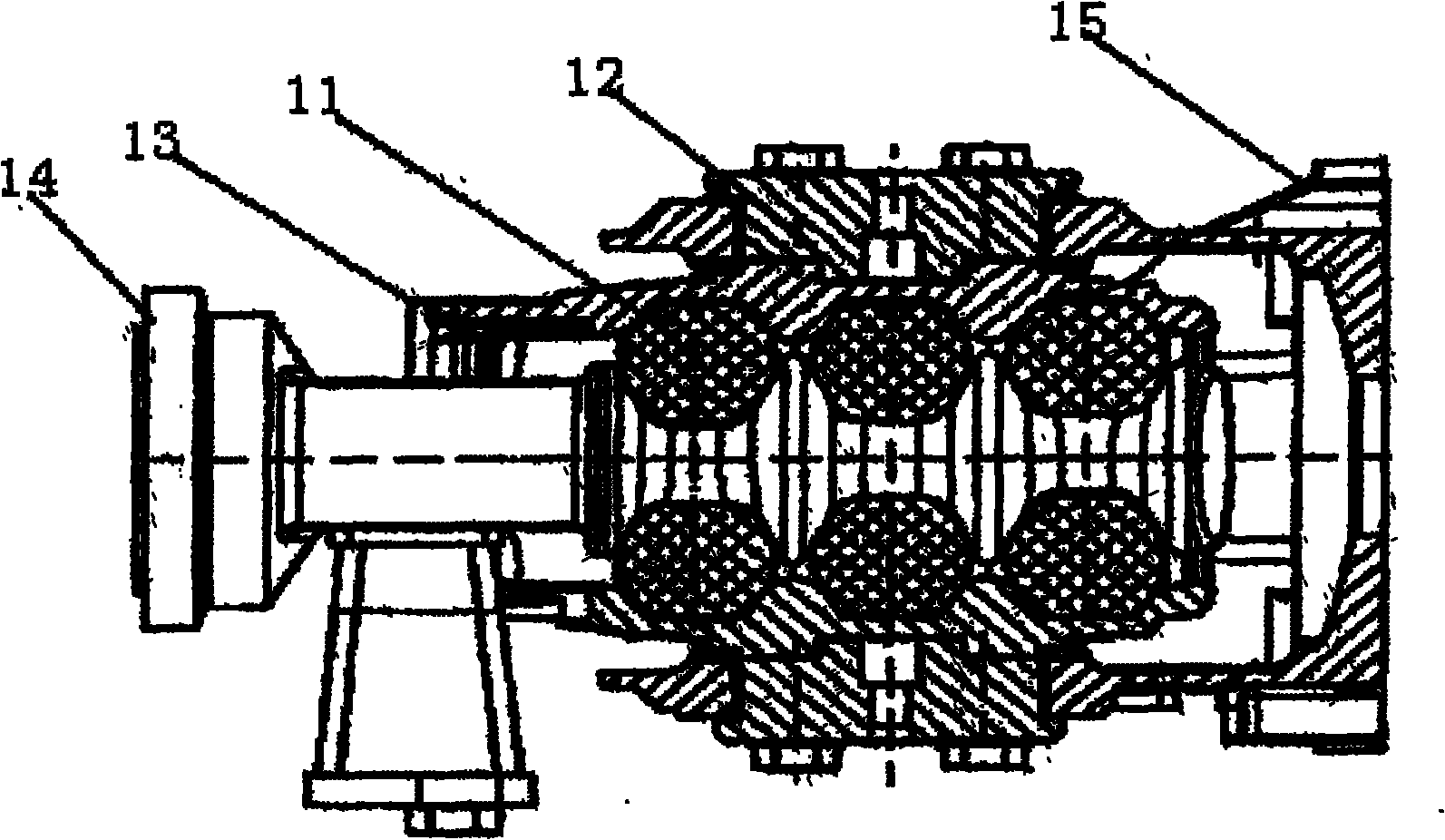

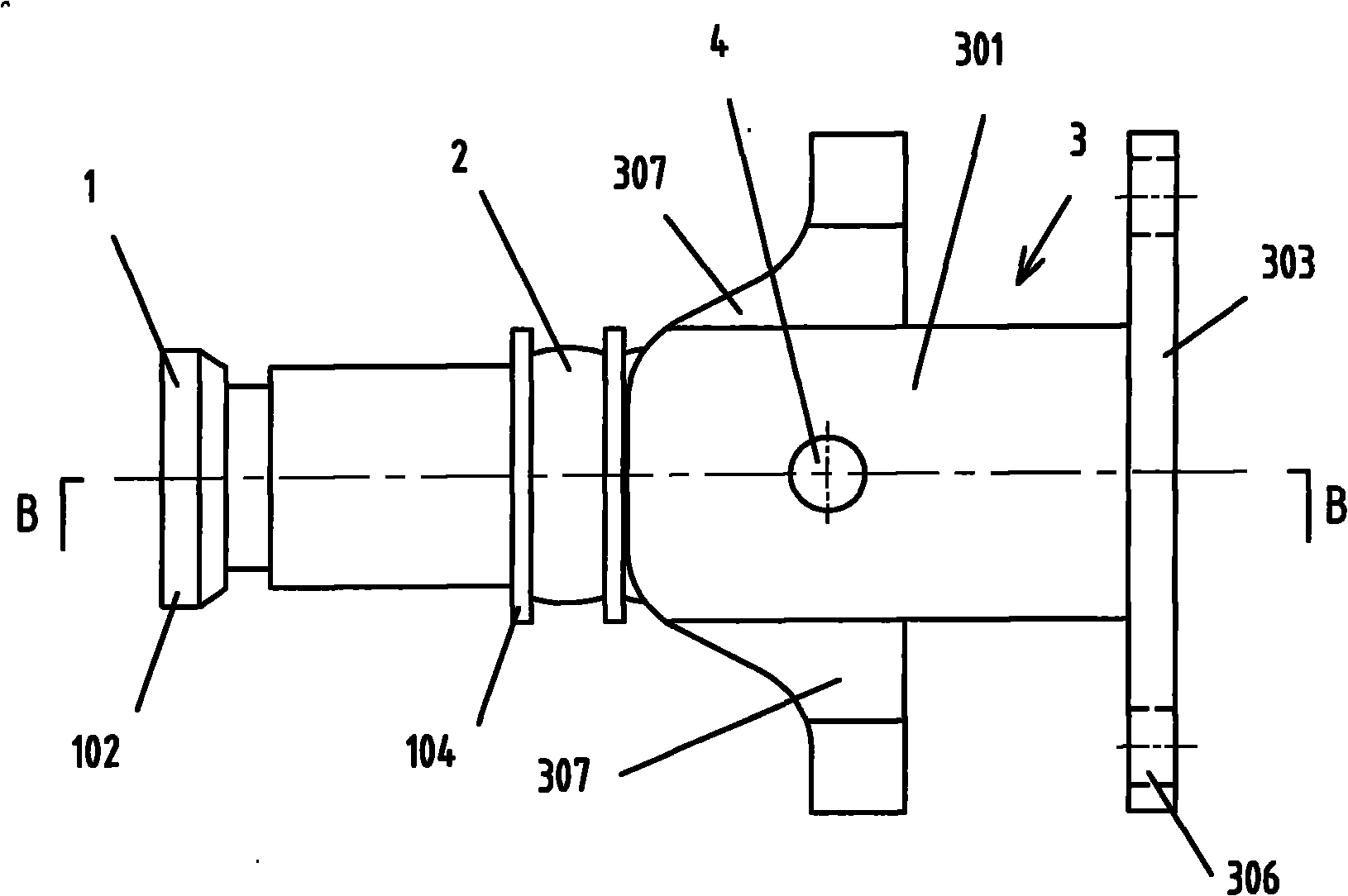

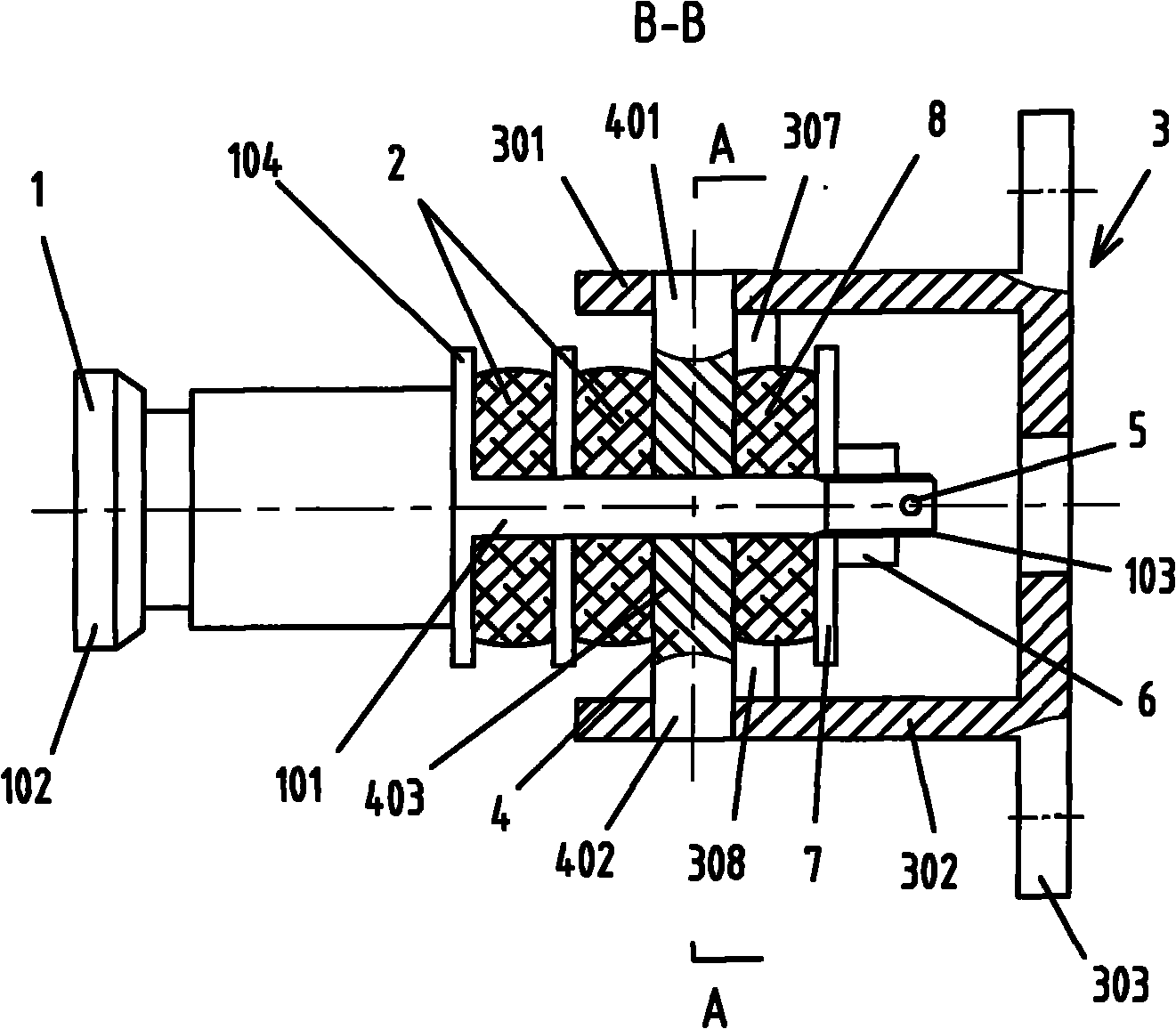

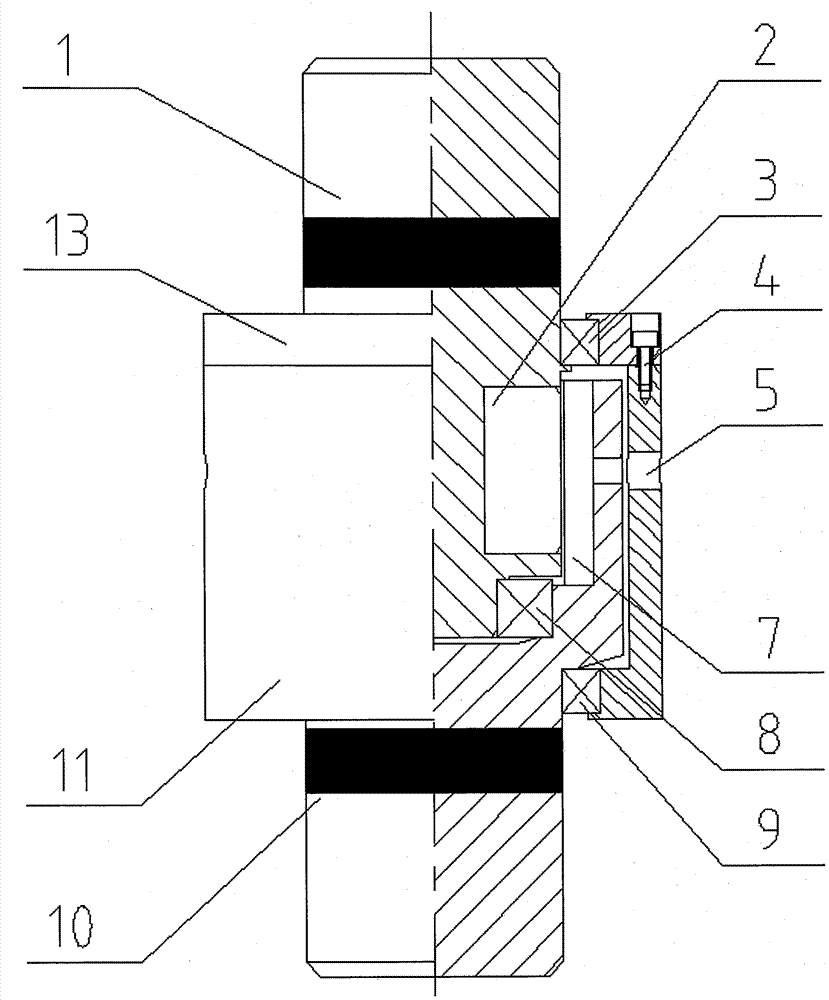

Central buffering connector

InactiveCN101985302AAvoid Rigid ImpactImprove comfortDraw-gearStructural engineeringMechanical engineering

The invention discloses a central buffering connector. The central buffering connector is applied to railway traffic vehicles, and comprises a connecting shaft, an installation seat, a first elastic element, an intermediate partition plate, a second elastic element, an elastic element pressing plate and a pre-fastening element, wherein the connecting shaft is provided with a front pressure bearing section and a back connecting section; the first elastic element, the intermediate partition plate, the second elastic element and the elastic element pressing plate are sequentially sleeved on the back connecting section of the connecting shaft in a loose fit mode; one side of the first elastic element is pressed against an elastic element stopper on the connecting shaft; the other side of the first elastic element is pressed against one side of the intermediate partition plate; one side of the second elastic element is pressed against the other side of the intermediate partition plate; the other side of the second elastic element is pressed against the elastic element pressing plate; the pre-fastening element is arranged on the end part of the back connecting section and pressed against the elastic element pressing plate; the two ends of the intermediate partition plate are provided with a first rotating shaft and a second rotating shaft respectively; and the first rotating shaft and the second rotating shaft are hinged with the two ends of the installation seat respectively. The central buffering connector can buffer small impact force between vehicles and has a simple structure.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

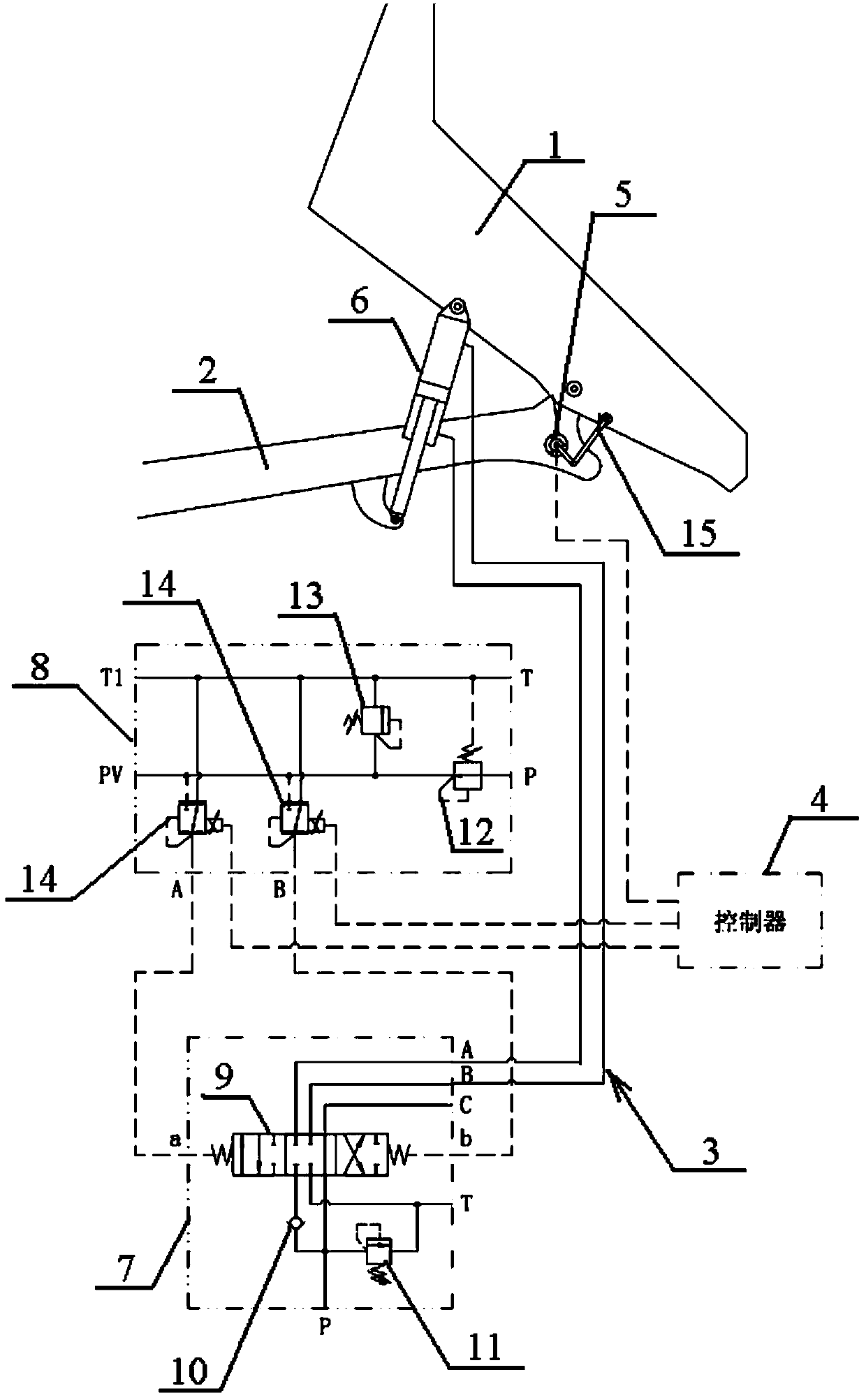

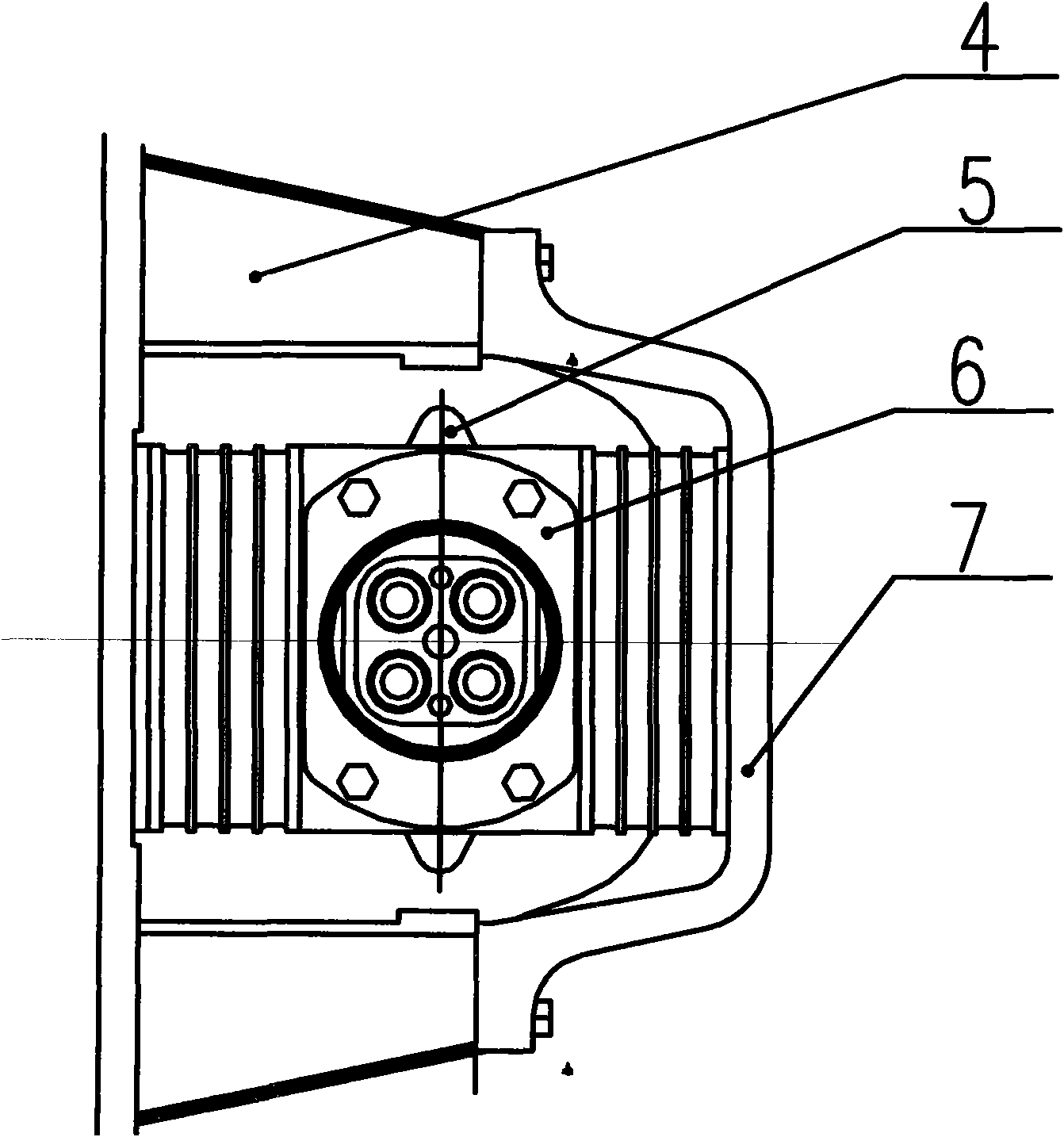

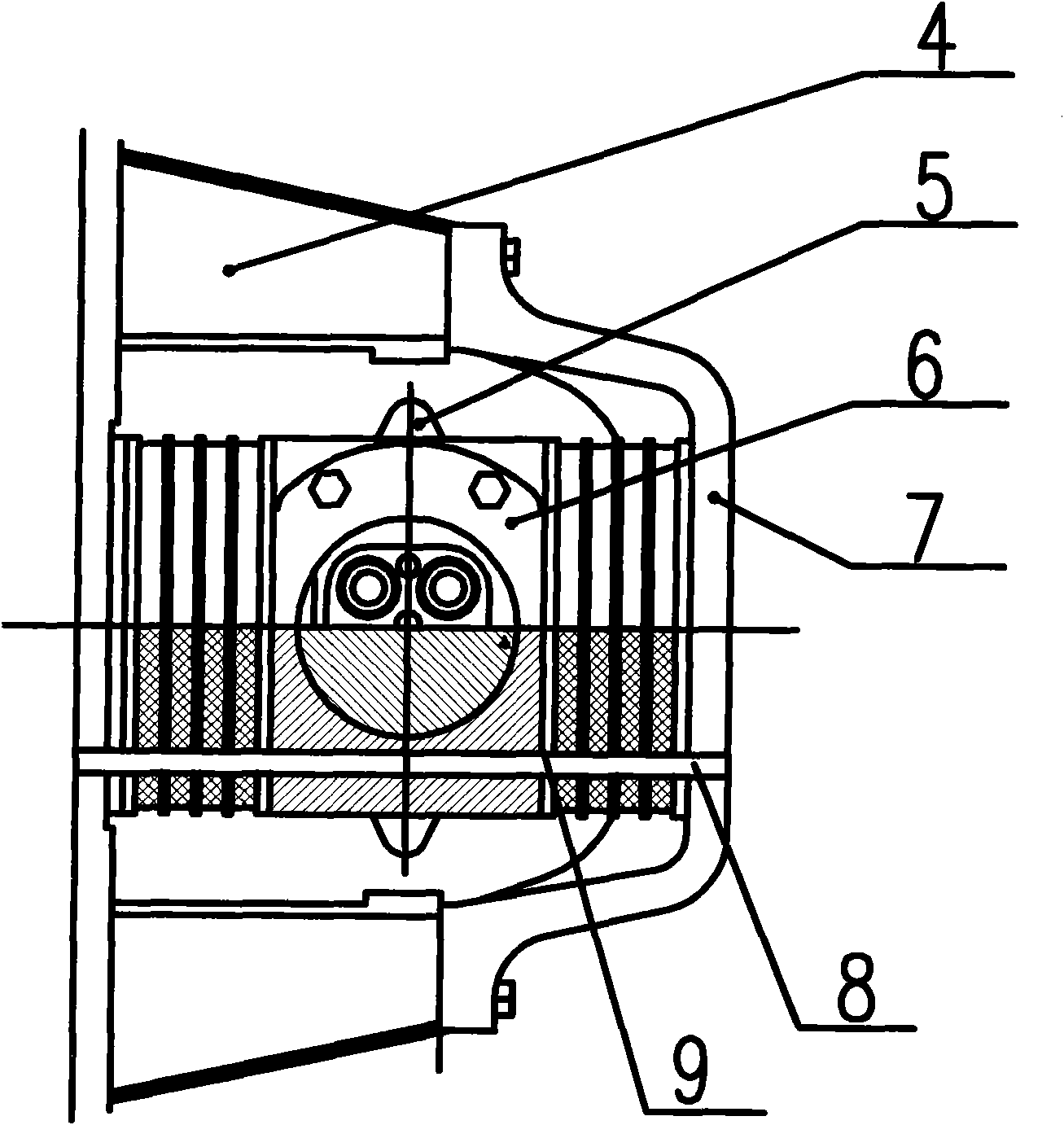

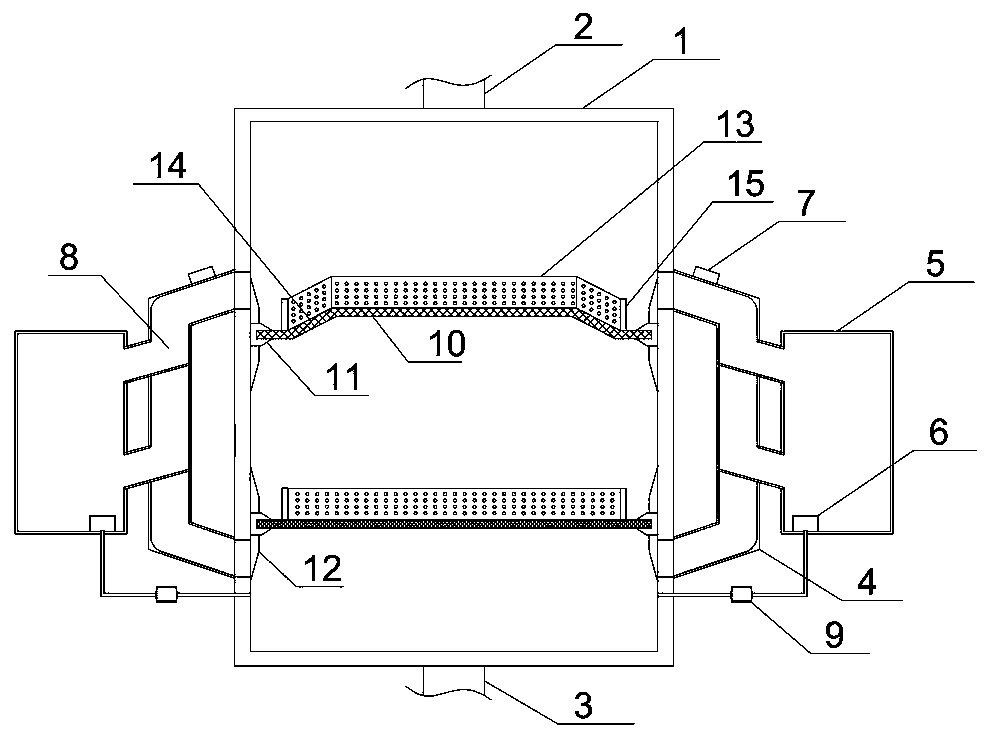

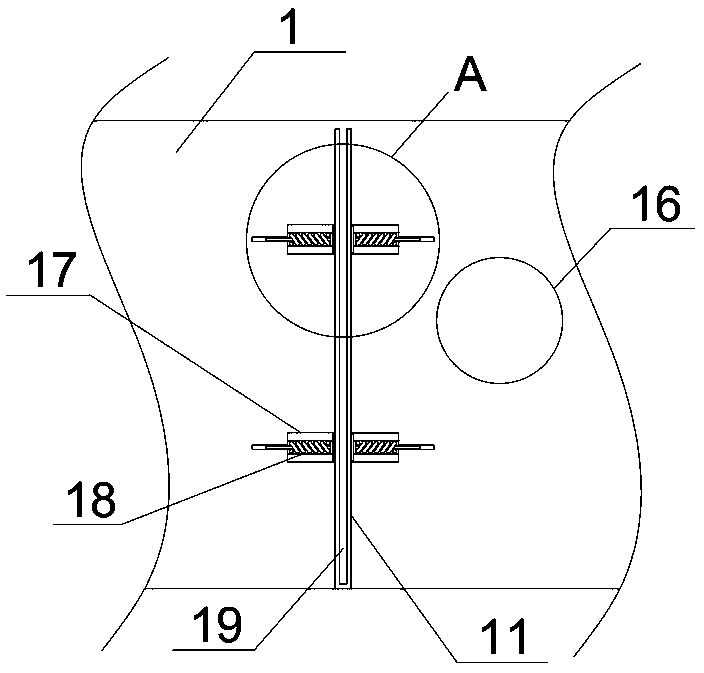

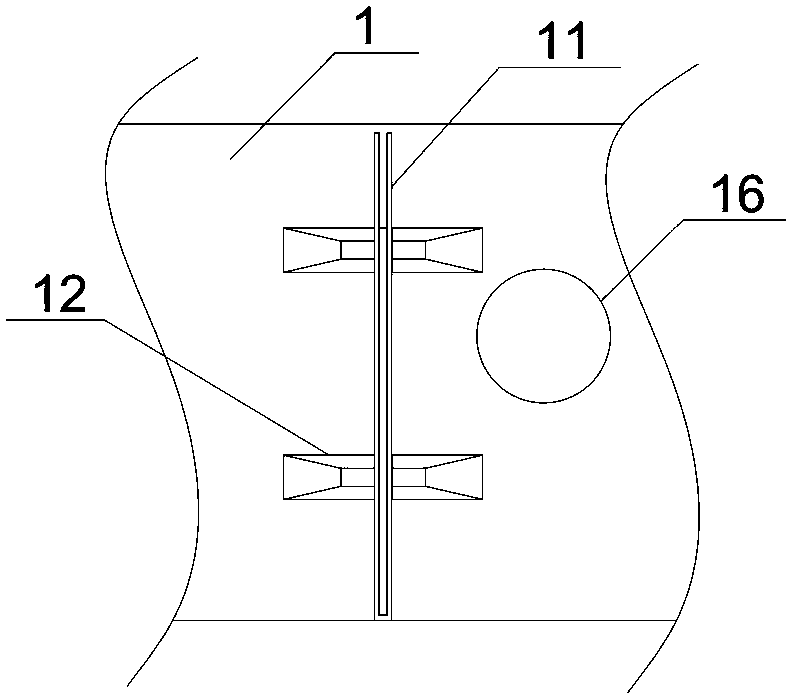

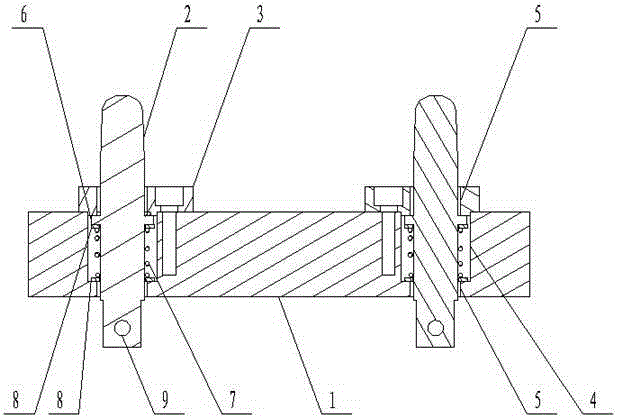

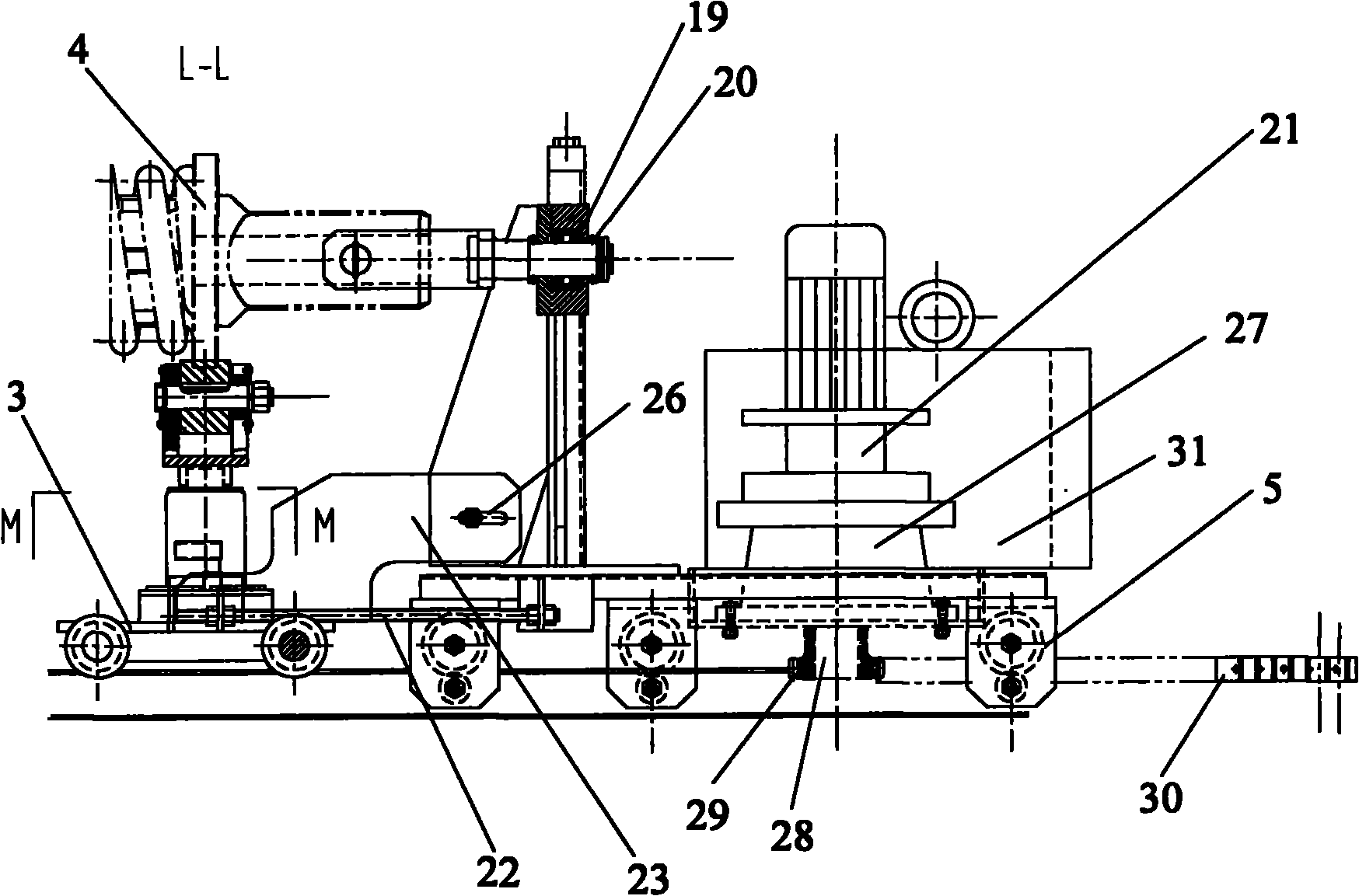

Lifting stationarity control system and mining dump truck

InactiveCN103386914AAvoid Rigid ImpactExtended service lifeVehicle with tipping movementVehicle frameControl system

The invention discloses a lifting stationarity control system and a mining dump truck and belongs to the field of mechanical control. The Lifting stationarity control system comprises a truck bed 1, a frame 2, a lifting mechanism 3, a controller 4, and an angular displacement sensor 5, wherein the truck bed 1 is hinged to the frame 2; the lifting mechanism 3 can extend and contract to drive the truck bed 1 to ascend or descend relative to the frame 2; the controller 4 is connected with the lifting mechanism 3; the angular displacement sensor 5 is arranged on the truck bed 1 and the frame 2 and is connected with the controller 4; the angular displacement sensor 5 is used for detecting an angular displacement signal of the truck bed 1 relative to the frame 2 and transmitting the signal to the controller 4; and the controller 4 is used for controlling the movement velocity of the truck bed 1 through the lifting mechanism 3 according to the signal. According to the technical scheme of the invention, angle valves collected by the angular displacement sensor are used as controller input signals and signal acquisition section is wide, so that the defects that the rotation angle of an electronic control handle is small and the controllability of a value element is bad are avoided, the effects of throttling and buffering are realized, and the service life of parts is prolonged.

Owner:SANY HEAVY EQUIP

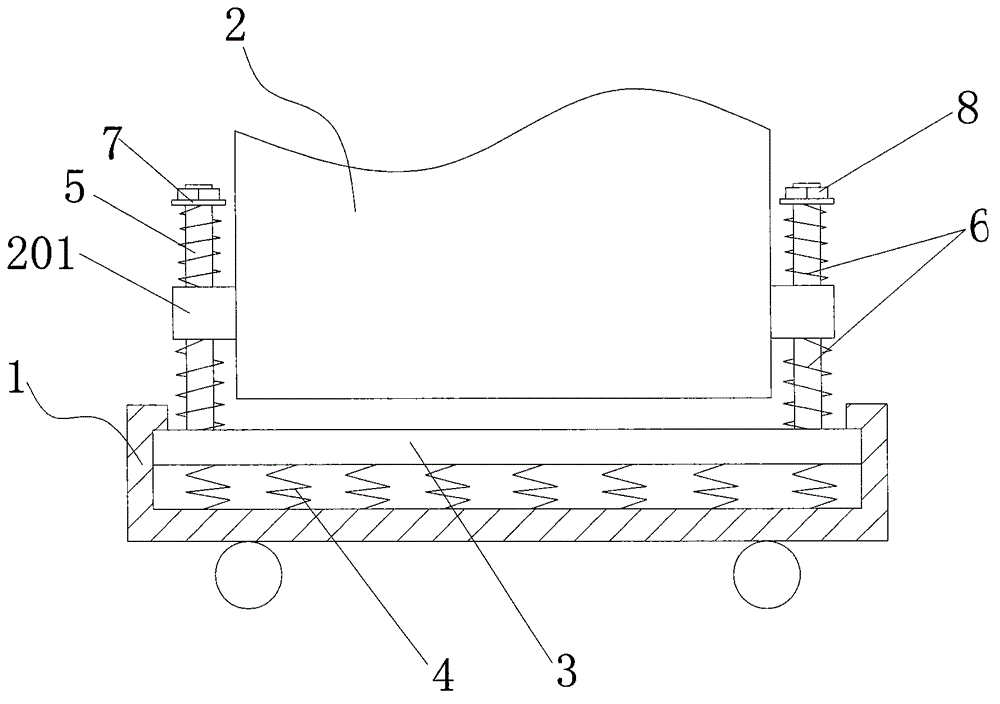

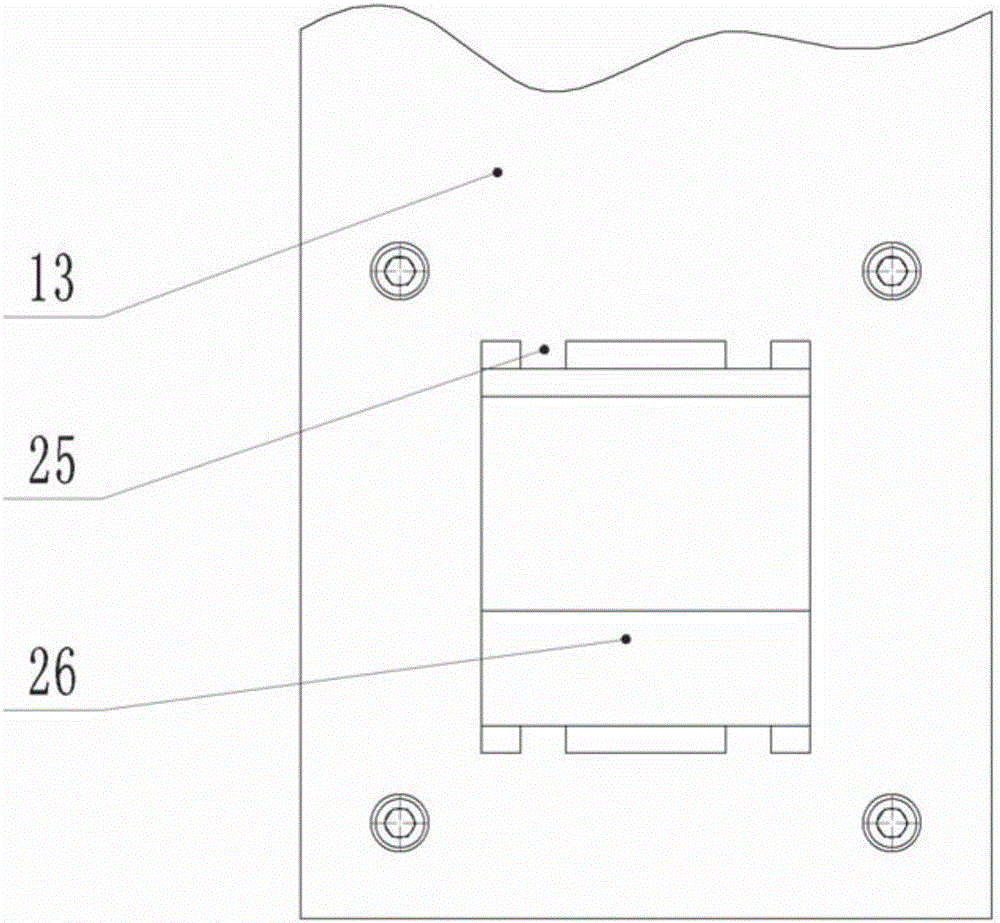

Damping device for computer mainframe box

InactiveCN104571385ARealize the first level of shock absorptionRealize the second level of shock absorptionDigital processing power distributionEngineeringGasket

The invention relates to a damping device for a computer mainframe box. The damping device comprises a U-shaped base and a mainframe body, wherein a supporting bottom plate is arranged inside the U-shaped base; a damping device part is arranged between a bottom surface of the U-shaped base and the supporting bottom plate; guide posts are arranged at the two sides of an upper end surface of the supporting bottom plate; the guide posts are connected with a slide sleeve on the mainframe body; supporting springs are arranged on positions, which are positioned on the guide posts, at upper and lower sides of the slide sleeve; locking gaskets and locking nuts are arranged at the upper ends of the guide posts. According to the damping device disclosed by the invention, during vibration, the supporting bottom plate moves up and down along the inner part of the U-shaped base under the action of the damping device part, so that first-stage damping of the mainframe body is realized; meanwhile, the slide sleeve on the mainframe body moves up and down along the guide posts under the action of the supporting springs, so that rigid impact of vibration to the mainframe body is avoided, second-stage damping of the mainframe body is realized, a damping effect of the mainframe is guaranteed, and electronic elements are protected.

Owner:HEFEI MENGLONG ELECTRONICS TECH

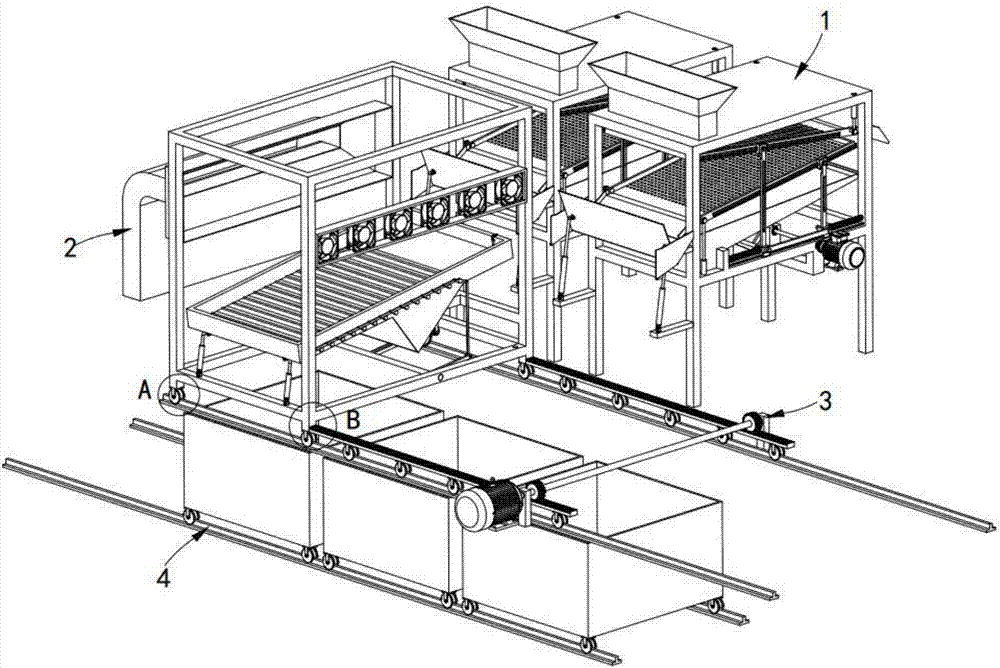

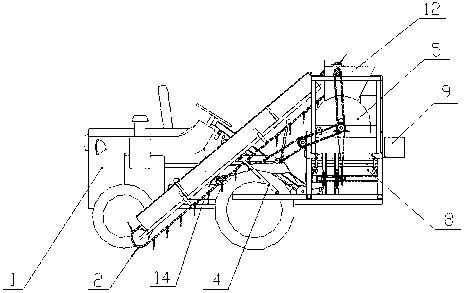

Switchable combination working line for grain screening and impurity removing

InactiveCN106903050ARealize automatic outputImprove work efficiencySievingGas current separationButt jointAgricultural engineering

The invention discloses a switchable combined working line for grain screening and impurity removal, which includes a symmetrically arranged resonance screening mechanism, a grain hulling mechanism, a switching mechanism and a storage mechanism. Docking with multiple resonance screening mechanisms, when the grain husking mechanism completes the removal of light impurities such as grain husks and shriveled grains from the output of the previous resonance screening mechanism, the grain husking mechanism can move laterally to the next resonance screening mechanism The rear side removes light impurities from the output grain, which doubles the work efficiency. At the same time, the grain hulling mechanism cooperates with the storage mechanism to realize the automatic output of the grain into the grain box, and when the grain box is full , can quickly switch grain boxes, high degree of automation.

Owner:奥林精密机械科技(长兴)有限公司

Machine shell punching and burr trimming device

The invention provides a machine shell punching and burr trimming device. A machine shell base is fixed to a base. A machine shell is installed on the machine shell base. An outer die is installed on the outer side of each position, where a hole is to be machined, on the machine shell, and a burr trimming tool rest is installed on the inner side of each position, where a hole is to be machined, on the machine shell. The outer dies and outer die bases are movably connected. The outer die bases are fixed to the base. The burr trimming tool rests are movably connected with a support. During work, an upper base moves downwards, thrust acting faces of thrust mechanisms act on the stress faces of the outer dies, punching cutters act on the machine shell to form the holes, waste materials obtained through punching are discharged through discharge holes and discharge channels, the upper base continues to move downwards, a straight stamping rod acts on tool rest stress faces, the burr trimming tool rests move to the two sides, and burr trimming of the inner side faces of the holes is completed. The work is completed, the upper base moves upwards, the thrust mechanisms contact under the effect of oil cylinders, and the thrust mechanisms are prevented from colliding with the outer dies. Various types of combined movement is adopted, the punching and burr trimming of the machine shell are completed at one station through one-time stamping, the machining precision of products is improved, and meanwhile the production efficiency is greatly improved.

Owner:浙江炜驰机械集团股份有限公司

Traction method and system for rail transportation

The invention relates to a traction method and a system for rail transportation. A soft elastic composite material is used as an elastic vibration-damping structure; a center pivot block is connected with a traction pin by an elastic nylon center pin sleeve, and the nylon sleeve with certain elasticity avoids the rigid shock between the center pivot block and the traction pin and simultaneously realizes the unconstrained rotation between the traction pin and the center pivot block when a vehicle makes a turning; two traction pads are respectively arranged in the front and at the back between the center pivot block and a bogie frame in the traction direction, the traction pads are rubber-metal compound elastic elements, two end plates of the traction pads are respectively provided with a connecting pin, and the connecting pin on the traction pad is directly inserted into a connecting hole for the center pivot block and the bogie frame; and the two traction pads connect the center pivotblock and the bogie frame, transfer traction force and brake force and buffer the shock load in transverse direction, vertical direction and other directions, so that the vehicle has better dynamicalperformance in operation.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

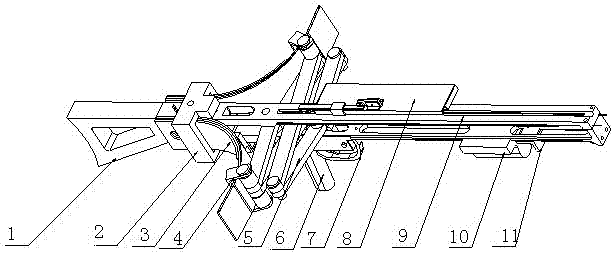

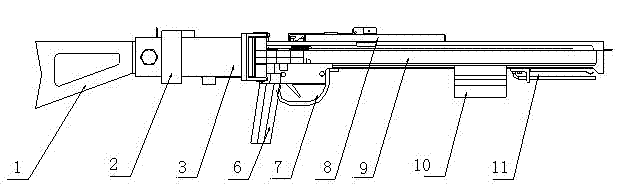

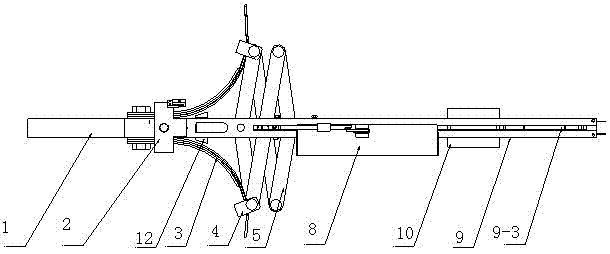

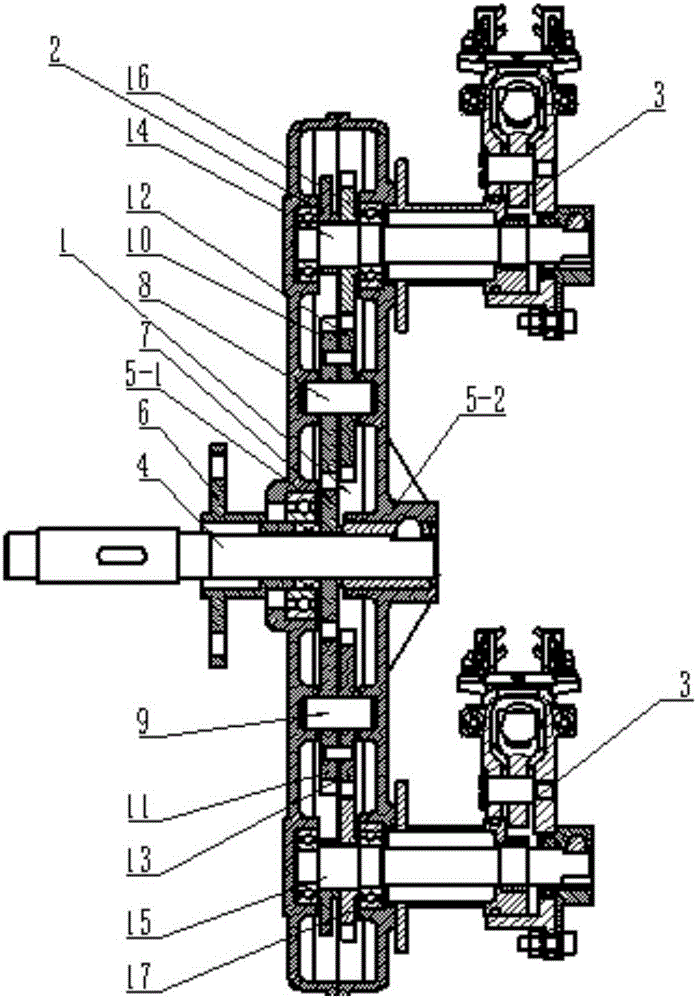

Portable strong crossbow

InactiveCN103115524AImprove hit rateLarge launch powerBows/crossbowsMountaineeringEngineeringCanis lupus familiaris

The invention discloses a portable strong crossbow which comprises a crossbow support, a crossbow frame, a gripping handle, a trigger mechanism and an ejection mechanism. The crossbow support is fixedly connected with the rear end of the crossbow frame, a sliding groove is formed in the crossbow frame along the ejection direction, the gripping handle is fixed on the lower portion of the crossbow frame, and the trigger mechanism is arranged on the position, at the front portion, of the crossbow frame. The ejection mechanism comprises a left elasticity plate, a right elasticity plate, and a shear type telescopic mechanism, wherein the left elasticity plate and the right elasticity plate are arranged symmetrically, the rear end of the left elasticity plate and that of the right elasticity plate are fixed on the rear portion of the crossbow frame, the front of the left elasticity plate and that of the right elasticity plate are movably connected with the shear type telescopic mechanism, the shear type telescopic mechanism is connected on the crossbow frame through a rear hinge pin hole and a rear hinge pin, a front hinge pin is arranged in the front hinge pin hole, the shear type telescopic mechanism is installed in the sliding groove through the front hinge pin, and the upper end of the front hinge pin is connected with an arrow pushing stop dog. The lower end of the front hinge pin is connected with the trigger mechanism in a locking mode when the shear type telescopic mechanism retracts. The portable strong crossbow has the advantages that a firing range and a hit rate of the crossbow are improved, and operation is enabled to be more convenient.

Owner:潘佳伟

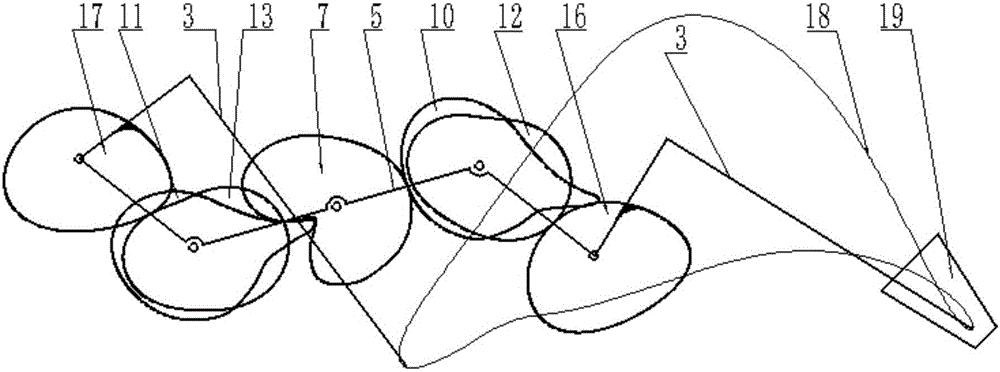

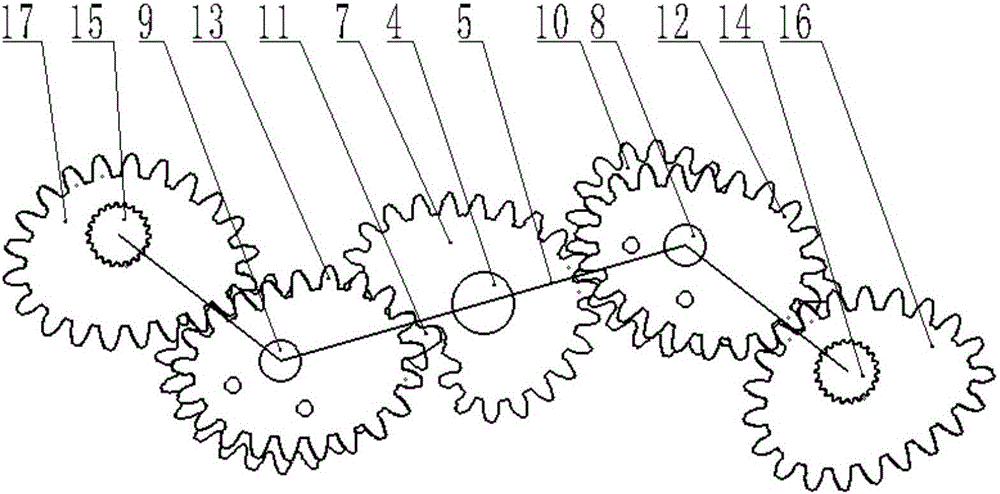

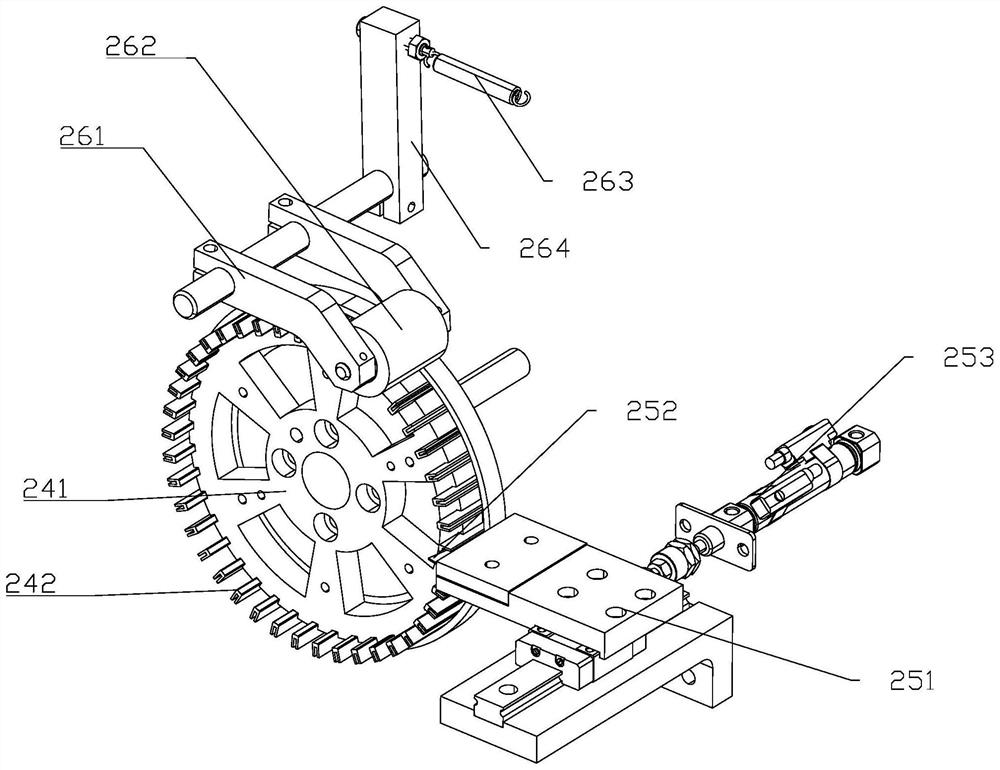

Concave-convex conjugated-Fourier planetary gear train seedling fetching mechanism

ActiveCN106105521ARealize non-uniform speed transmissionReliable transmissionGeometric CADTransplantingConvex conjugateMedial axis

The invention discloses a concave-convex conjugated-Fourier planetary gear train seedling fetching mechanism. An existing seedling fetching mechanism adopts a locking arc, a transmission ratio of a seedling fetching track is changed in a large range and the transmission impact is great. A central shaft is fixed on a planet carrier; an inward concave solar gear is fixed on a rack and hollowly sleeves the central shaft; a first middle outward convex gear sleeves a first middle shaft; a first middle Fourier gear is fixed on the first middle outward convex gear; a second middle outward convex gear sleeves a second middle shaft; a second middle Fourier gear is fixed on the second middle outward convex gear; a first planet gear is connected with a first planet shaft through a spline; a second planet gear is connected with a second planet shaft through a spline; a first gear gap eliminating cam is connected with the first planet shaft through a spline; a second gear gap eliminating cam is connected with the second planet shaft through a spline; and one end of the first planet shaft and one end of the second planet shaft stretch out of the planet carrier to be fixed on a shell body of a transplanting arm respectively. The concave-convex conjugated-Fourier planetary gear train seedling fetching mechanism is simple in structure and stable in transmission.

Owner:ZHEJIANG SCI-TECH UNIV

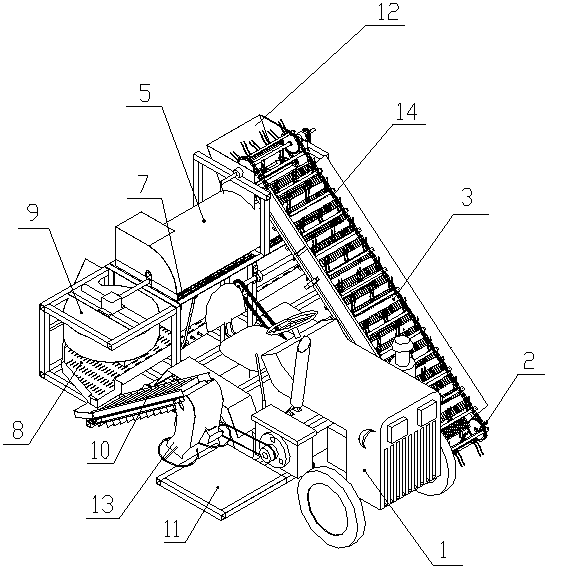

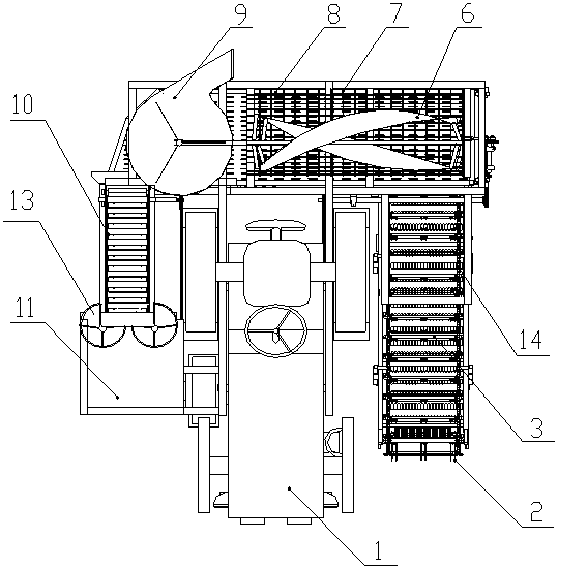

Backsack peanut picking combine

InactiveCN103039179AImprove integrityImprove picking efficiencyDigger harvestersThreshersAgricultural engineeringStructural engineering

A backsack peanut picking combine comprises a power device, a picking and conveying device, a fruit picking and cleaning device and a fruit lifting and collecting device. The picking and conveying device comprises a picking device, a picking bottom plate and a conveying chain I, the picking device is a spring tooth picking device and comprises a supporting plate and an elastic pointing rod fixed on the supporting plate, the fruit picking and cleaning device sequentially comprises a fruit picking auger, a concave grid and a vibrating screen from top to bottom, the fruit picking auger comprises an auger shaft, spiral stirring rods and auger coupling rods, the spiral stirring rods are fixedly connected with the auger shaft through the auger coupling rods, the number of the auger coupling rods is even, and the auger coupling rods are symmetrically and evenly arranged with a midpoint of the auger shaft as the center. The number of the spiral stirring rods is even, and the auger coupling shaft rods at two ends of each group of the spiral stirring rods are symmetrically and evenly arranged with the midpoint of the auger shaft as the center. The backsack peanut picking combine achieves integrity of peanuts to the greatest extent and effectively solves the problem that fruit and seedling separation is not thorough and cleaning is bad.

Owner:QINGDAO AGRI UNIV

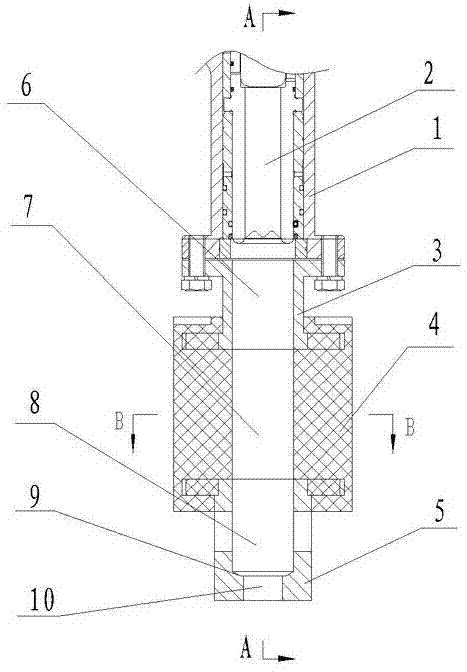

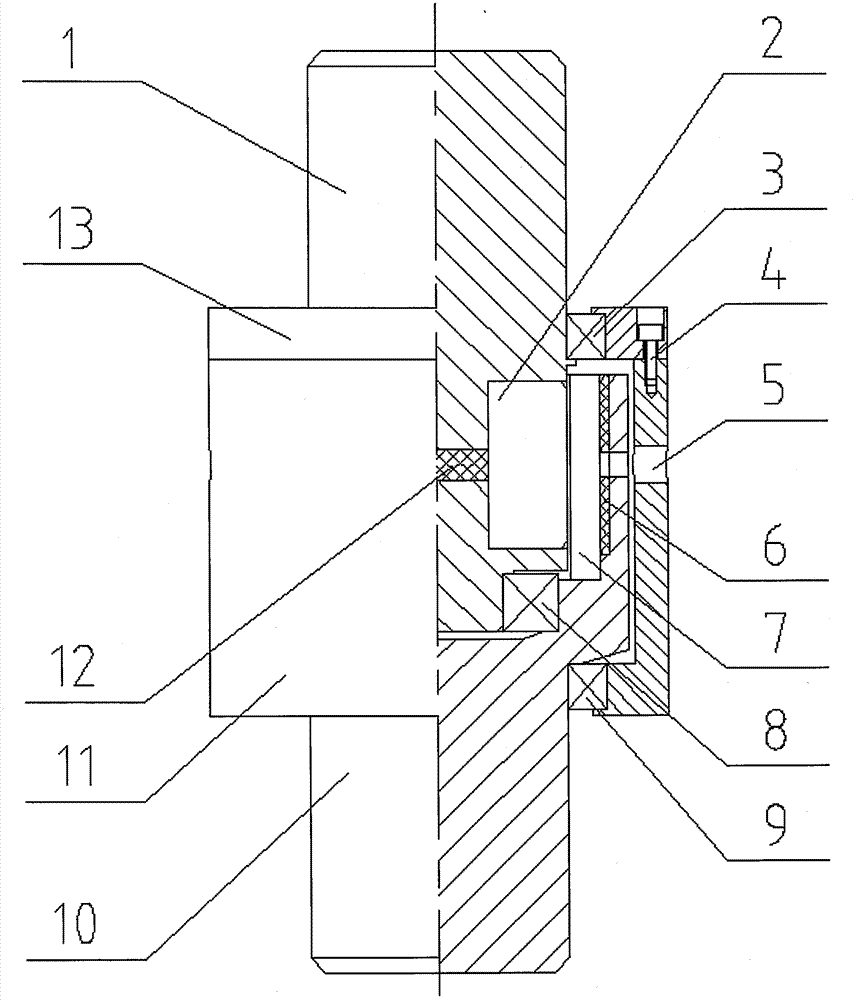

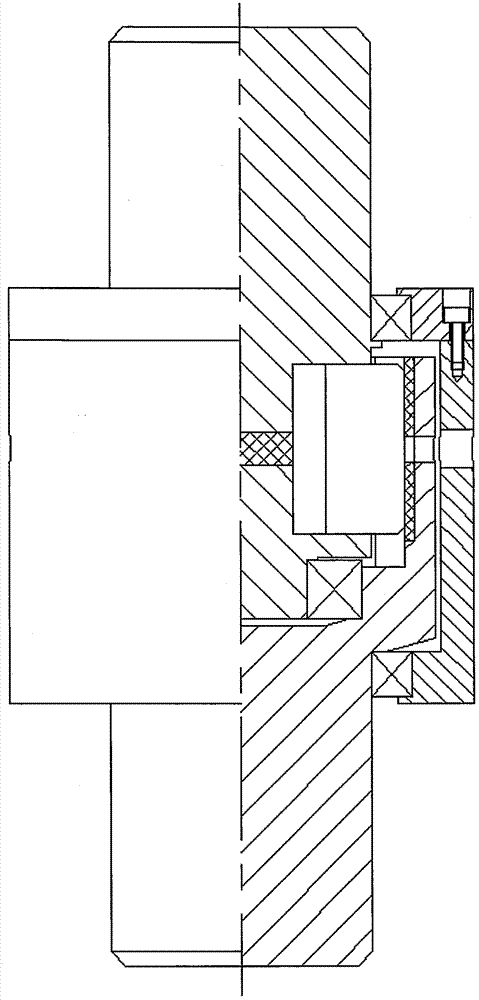

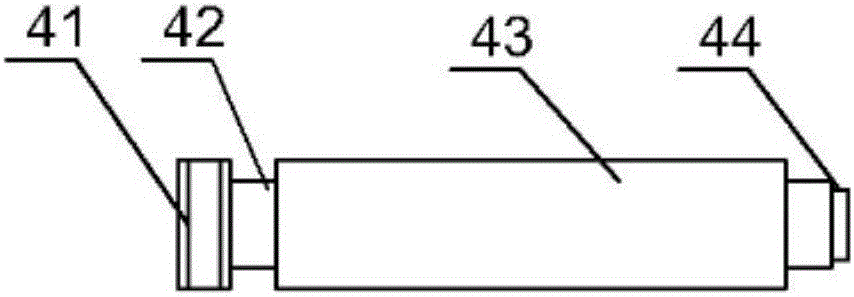

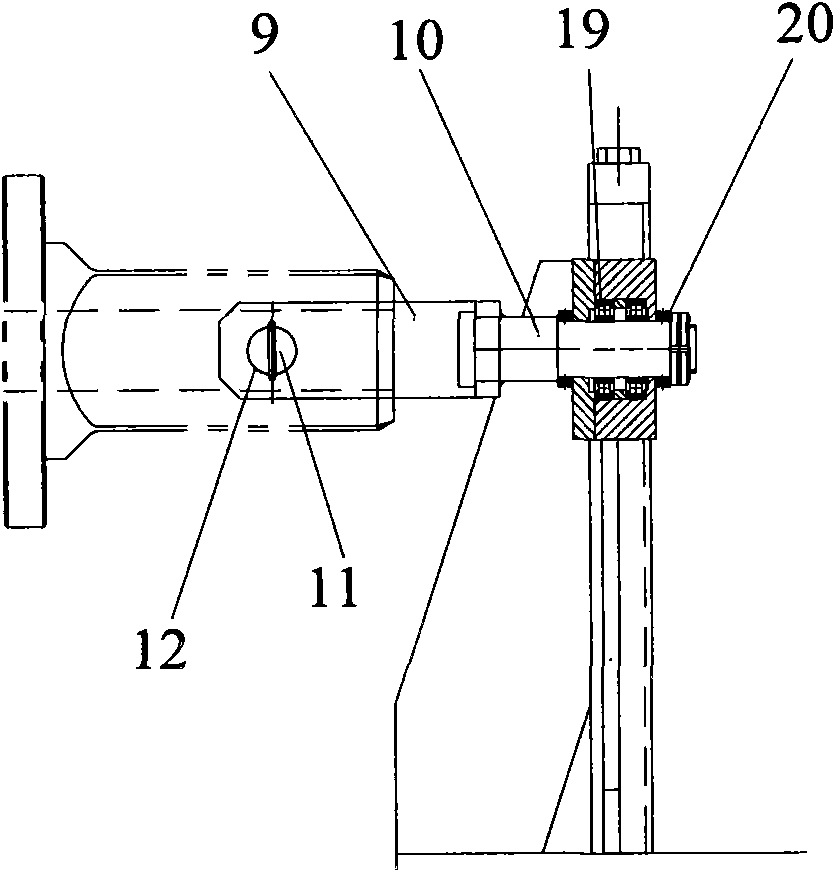

Drill rod buffer positioning device of hydraulic rock drill

ActiveCN103541655AQuick changeExtended service lifeConstructionsReciprocating drilling machinesDrillFlange

The invention relates to a drill rod buffer positioning device of a hydraulic rock drill. The drill rod buffer positioning device comprises a nose body of the rock drill and a drill rod tail sleeve mounted in the nose body and is characterized by further comprising an upper connecting plate, a buffer body and a lower connecting plate which are sequentially connected. The upper connecting plate is connected with a nose body flange. A through drill rod tail cavity is coaxially formed in the buffer body and the upper connecting plate. A drill rod tail cavity, a shoulder and a drill rod cavity are coaxially arranged on the lower connecting plate. An upward drill rod tail insertion groove is formed on the same side of each of the upper connecting plate, the buffer body and the lower connecting plate. The drill rod buffer positioning device has the advantages that rebound impact generated on a drill rod is absorbed by the buffer body, rigid impact among parts is avoided, and service lives of the drill rod and a machine body are prolonged; the shoulder axially limits a drill rod tail, and drill rod holding is unnecessary when the drill rod is vertical; the drill rod buffer positioning device is simple in structure, reasonable in design and simple to use.

Owner:荣成中磊科技发展有限公司

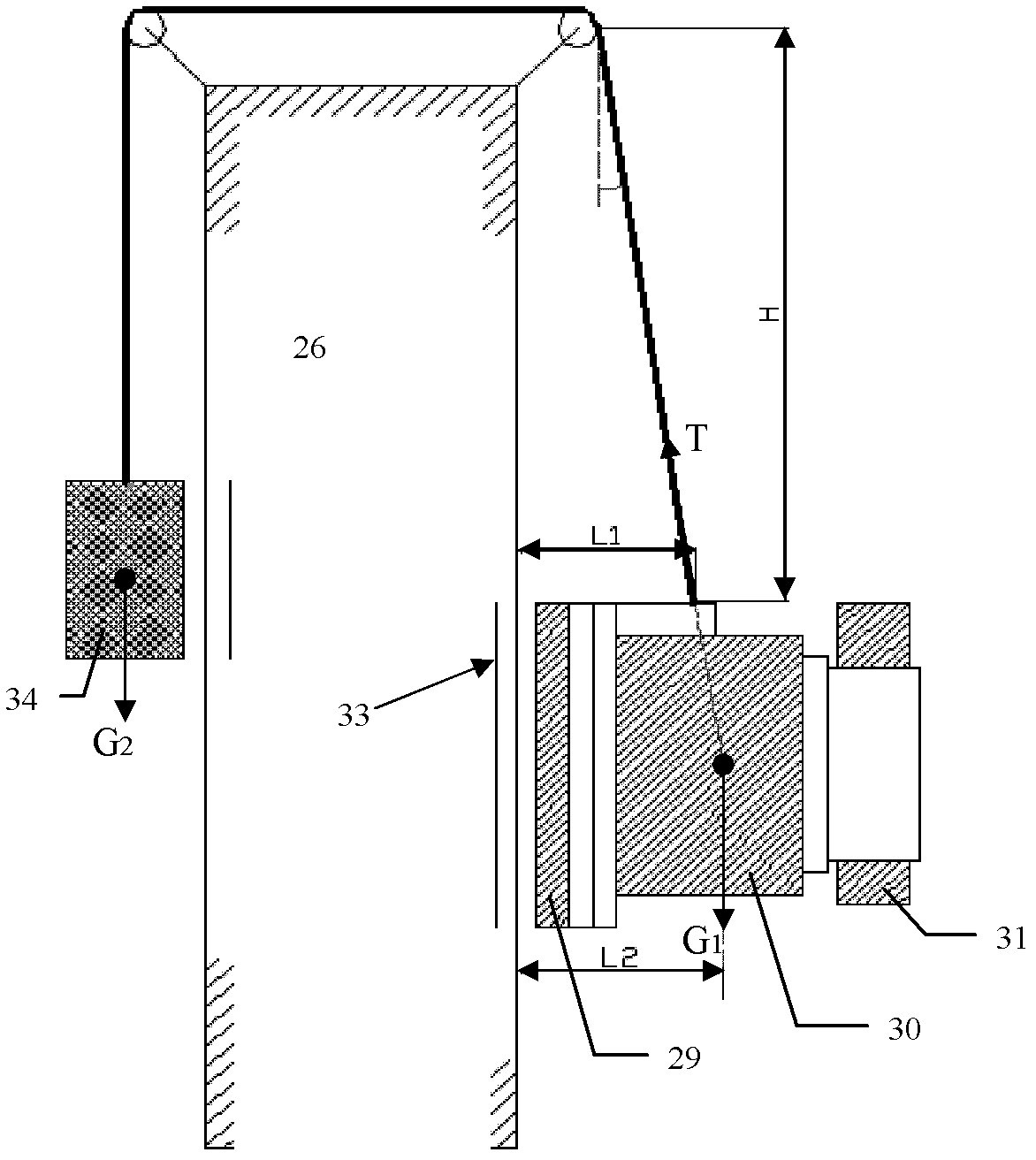

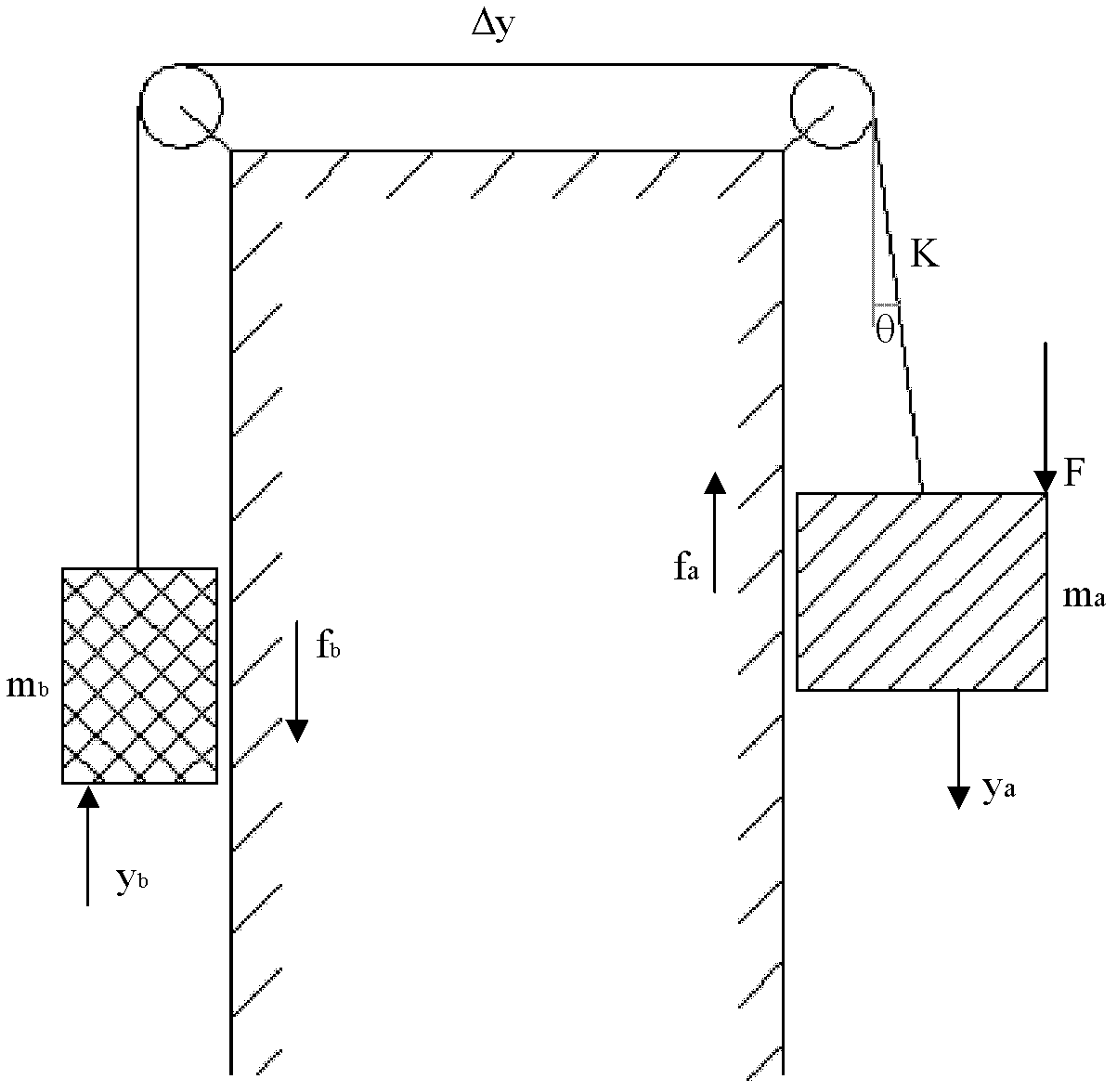

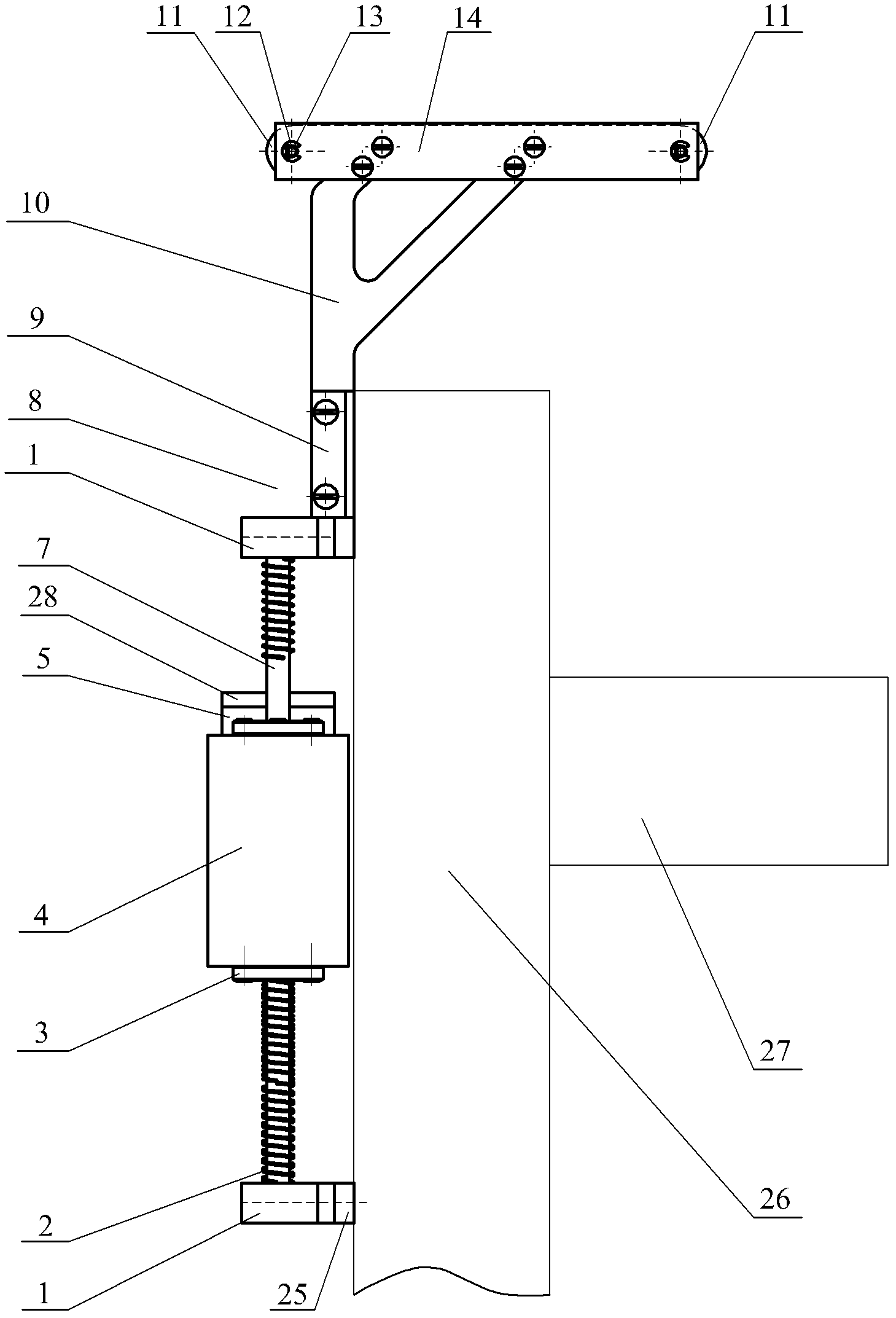

Vertical axis counterweight device for complex curve multi-axis linkage processing machine tool

ActiveCN102357833AImprove stress conditionImprove workabilityMaintainance and safety accessoriesBall screwOptical axis

The invention provides a vertical axis counterweight device for a complex curve multi-axis linkage processing machine tool and relates to a counterweight device for the complex curve multi-axis linkage processing machine tool. The counterweight device is used for solving the problems of limited bearing capacity and barycentre deviation of a linear motor platform or ball-screw guide rail applied to a vertical axis of the complex curve multi-axis linkage processing machine tool. A big counterweight block is connected to two small counterweight blocks; the big counterweight block is connected toa hanging ring bolt; a flange linear bearing is arranged in each bearing through hole of the big counterweight block; a principal axis is arranged in inner holes of each two flange linear bearings; the flange linear bearings are in sliding fit with the principal axis; each principal axis is connected to two principal axis supporting bases; a limiting spring is sleeved on each principal axis; two supporting axes are vertically arranged between two guide wheel connecting plates; each of the supporting axes is connected to two guide wheel connecting plates; each guide wheel is connected to each of the supporting axes through axle-hole fitting; and two ends of a rope are connected to the hanging ring bolt and a load. The vertical axis counterweight device is applied to the complex curve multi-axis linkage processing machine tool.

Owner:HARBIN INST OF TECH

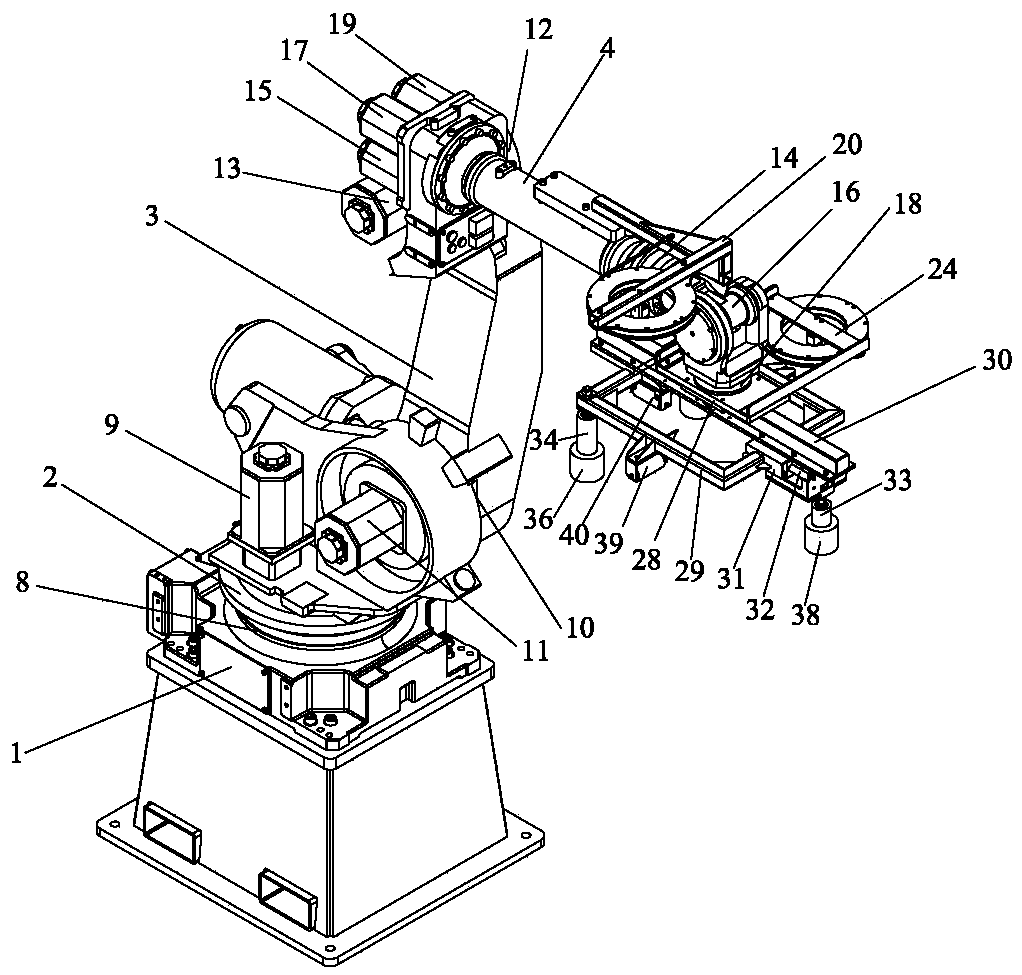

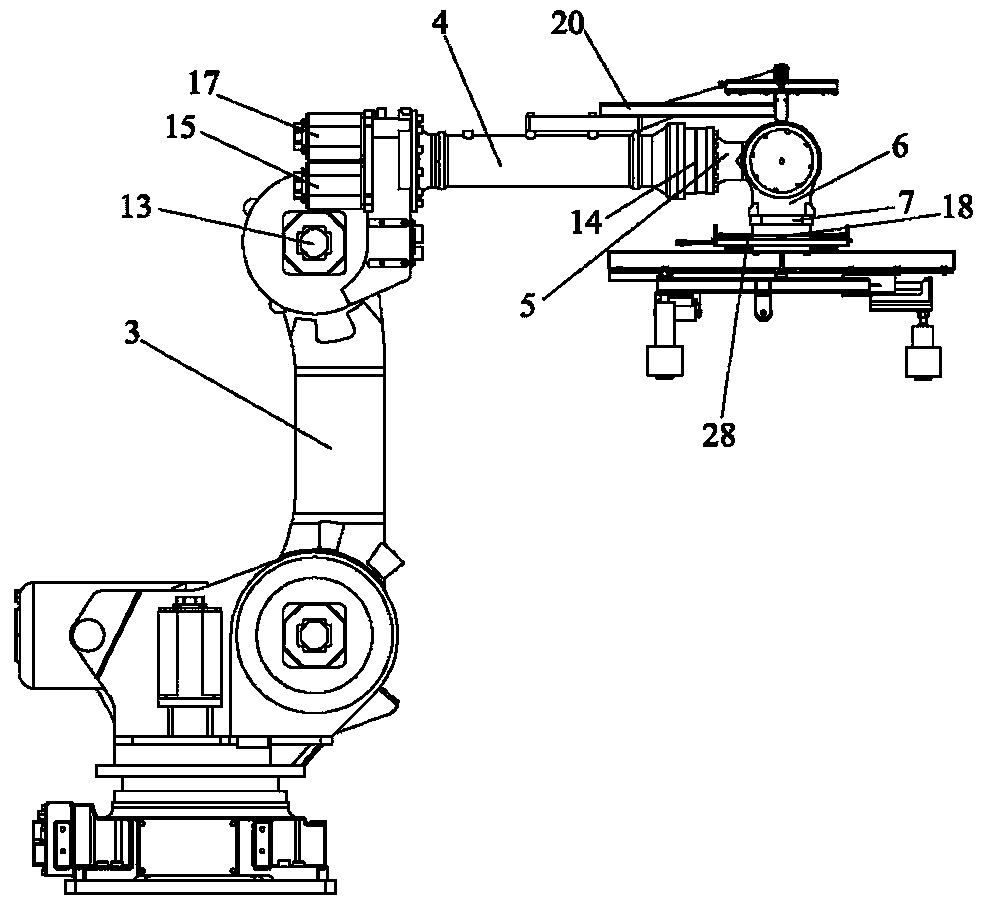

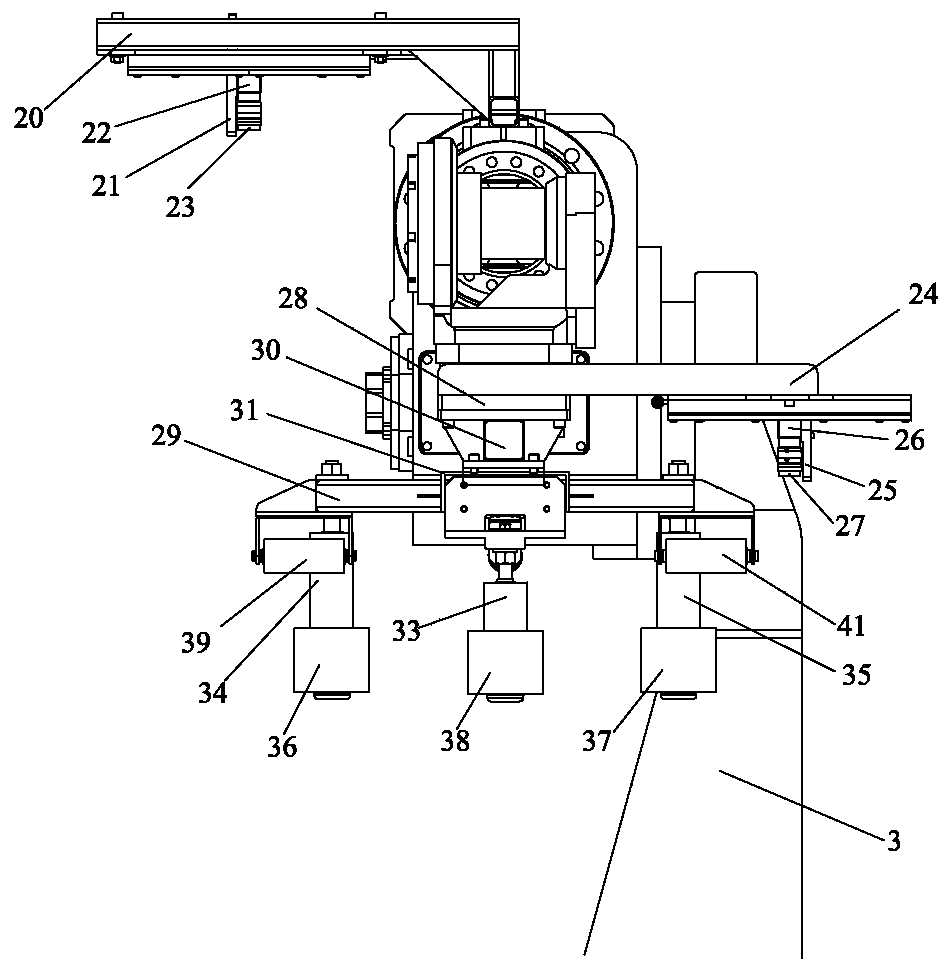

Wheel hub die casting carrying six-axis industrial robot

PendingCN109968343AEasy to operateImprove working accuracyProgramme-controlled manipulatorGripping headsDie castingEngineering

The invention discloses a wheel hub die casting conveying six-axis industrial robot which comprises a base, a rotating seat, a first mechanical arm, a second mechanical arm, a third mechanical arm, afourth mechanical arm, a fifth mechanical arm, a carrying mechanism and a visual positioning system connected successively. The carrying mechanism comprises a mounting rack, a movable claw, a first fixed claw and a second fixed claw, the mounting rack is connected to the fifth mechanical arm through a flange, and the movable claw is driven by an electric hydraulic push rod fixed to the mounting rack to move; the visual positioning system comprises two visual positioning assemblies fixed to the second mechanical arm and the flange, separately. Each visual positioning assembly comprises a supporting rack, a mounting plate fixed to the supporting rack, an industrial camera fixed to the mounting plate and a lens connected to the industrial camera. The wheel hub die casting conveying six-axis industrial robot is convenient to operate, can carry wheel hub castings of different dimensions, and is wide in application range. The wheel hub die casting conveying six-axis industrial robot positions and grabs a wheel hub die casting through the visual positioning system, and is high in operational precision and efficiency.

Owner:GUANGDONG INST OF INTELLIGENT MFG

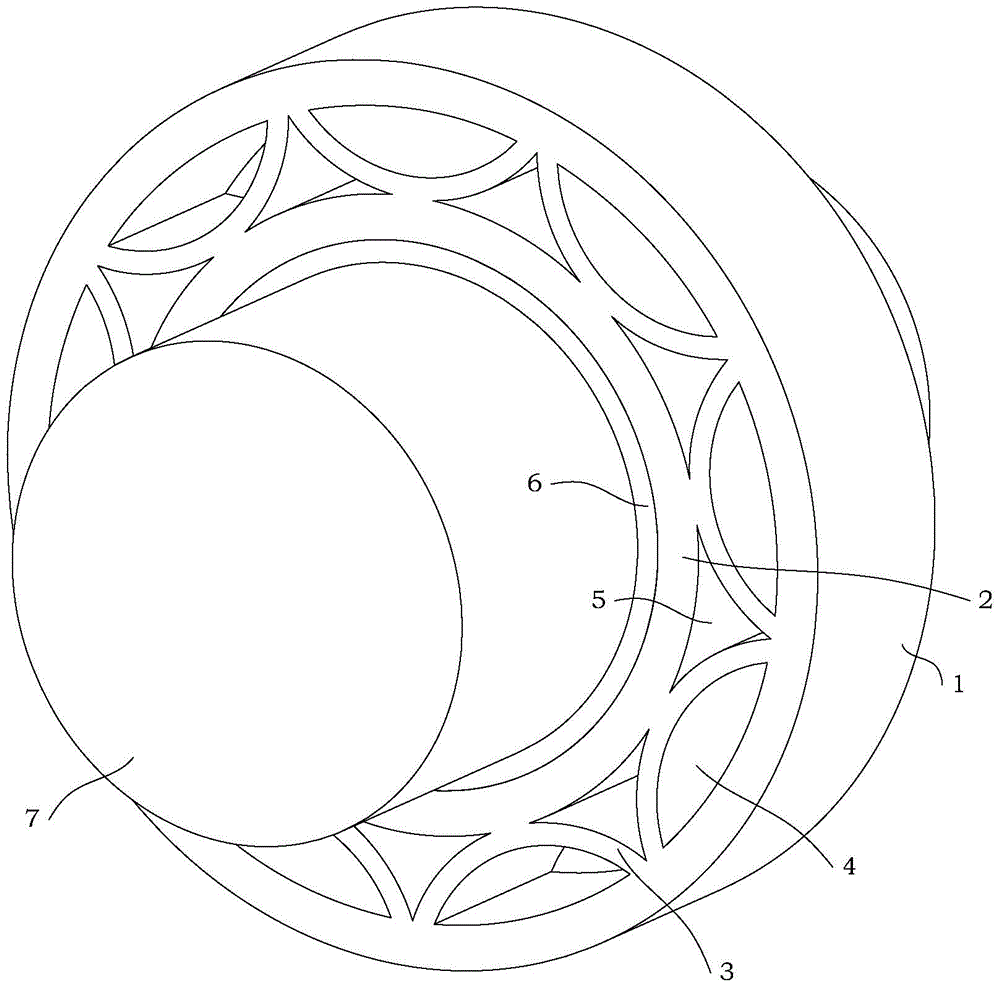

Clutch capable of being triggered at high speed in uncontrollable manner and maintaining low speed

The invention provides a clutch capable of being triggered at a high speed in an uncontrollable manner and maintaining a low speed. The clutch mainly comprises an input shaft, an output shaft and a centrifugal clamping block. According to the clutch, under the circumstance without supply and control of external energy, the clutch can also work normally. When the input shaft operates at overspeed, the output shaft and the input shaft are connected automatically, transmission is stable, and large torque can be transferred. Particularly after connecting is completed, when the rotating speed of the input shaft is reduced to the low speed from the high speed and even rotating stops, the stable connection maintaining state can still be achieved. The clutch has the beneficial effects of being simple in structure, high in reliability, good in maintainability, low in cost and the like.

Owner:上海熠优电梯安全科技有限公司

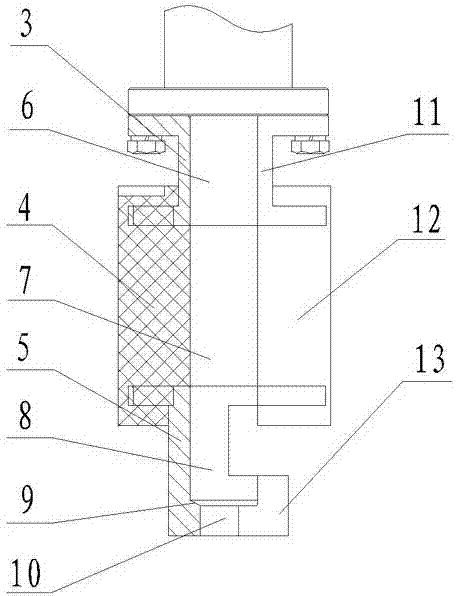

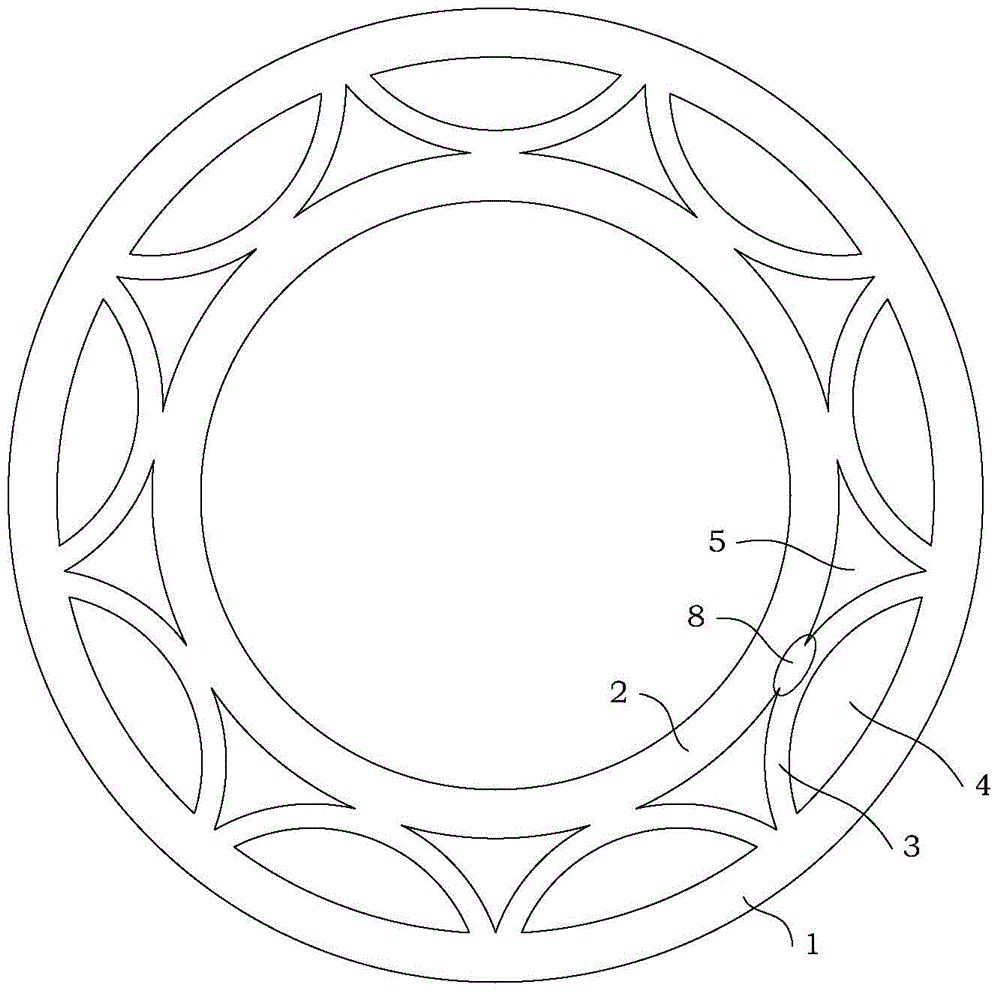

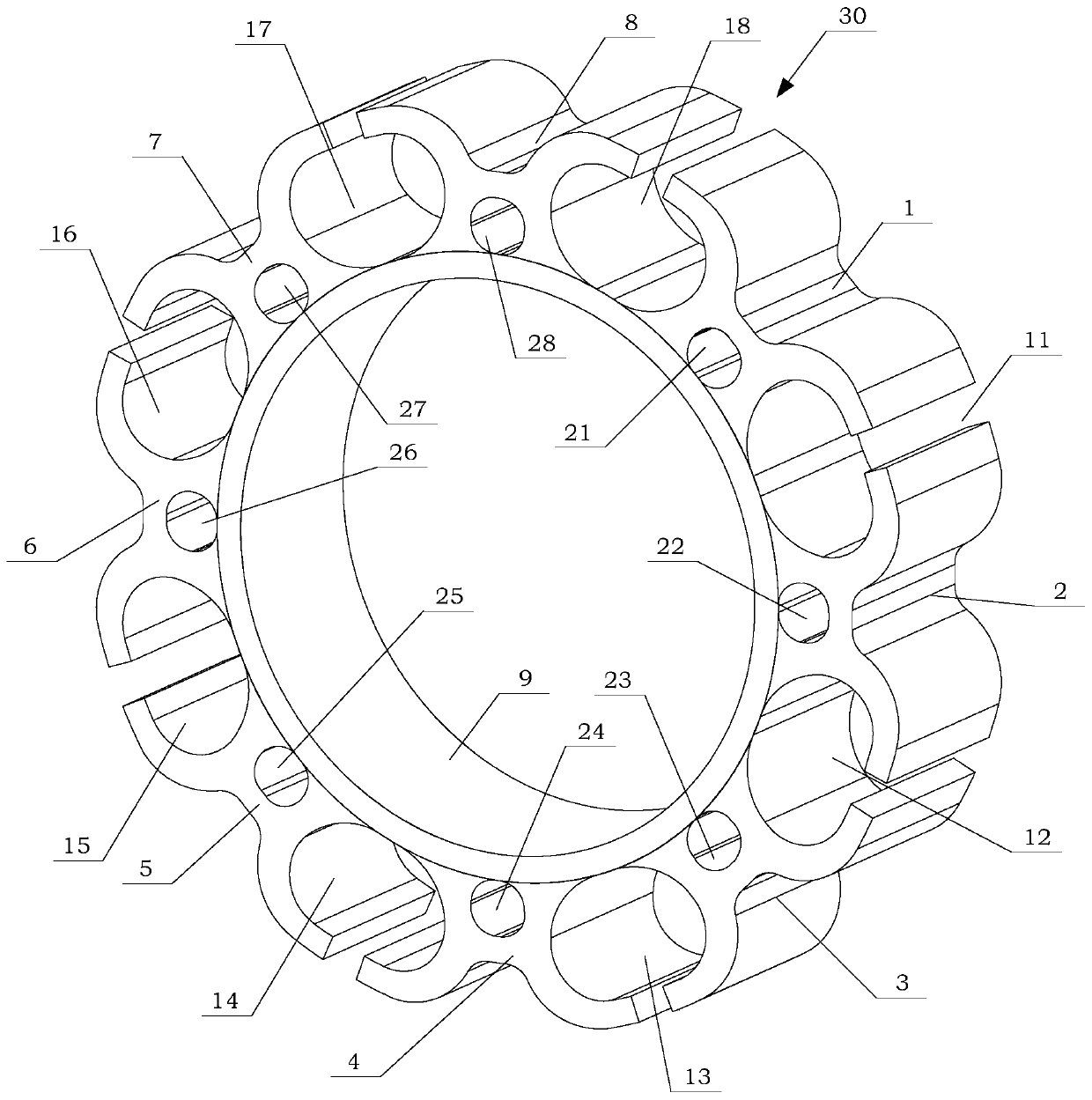

Radial-bearing flexible protecting bearing for magnetic suspension high-speed rotating equipment

InactiveCN104632884AAvoid damageExtended service lifeElastic bearingsBearing unit rigid supportEngineeringMechanical engineering

The invention discloses a radial-bearing flexible protecting bearing for magnetic suspension high-speed rotating equipment. The radial-bearing flexible protecting bearing is an integrally machined structural component and is characterized in that a bearing outer ring, a bearing inner ring and flexible reeds are designed on the protecting bearing, wherein the flexible reeds are arranged between the bearing outer ring and the bearing inner ring, external gaps are formed between the flexible reeds and the bearing outer ring, and internal gaps are formed between the flexible reeds and the bearing inner. According to the radial-bearing flexible protecting bearing, a flexible reed structure is designed between the bearing inner ring and the bearing outer ring, and the joints between the flexile reeds and the bearing inner ring are flexible formation point, so that when great impact is caused because a rotor is unstable, lots of kinetic energy of the rotor can be absorbed by virtue of the elastic deformation of the flexible reeds, without damaging other parts in the equipment.

Owner:BEIHANG UNIV

Anti-blocking device of sewage cyclone

ActiveCN110882570AReduce filter pressureReduce jam frequencyStationary filtering element filtersFiltrationWastewater

Belonging to the technical field of blockage prevention of sewage cyclones, the invention discloses an anti-blocking device of a sewage cyclone. The anti-blocking device comprises a box body with an open top, and an inlet and an outlet that are respectively disposed at the front end and rear end of the box body, the outlet is connected to the sewage cyclone, the box body is internally equipped with a filter screen unit comprising a plurality of filter screens, two sides of the box body are respectively equipped with an auxiliary filter unit communicated with the box body, water inlets of the auxiliary filter units are communicated with the front side of the filter screen unit, and water outlets of the auxiliary filter units are communicated with the rear side of the filter screen unit; impurity discharge ports of the auxiliary filter units are communicated with impurity treatment boxes; and a filter screen at the most front end in the filter screen unit has guide parts adjacent to thewater inlets of the auxiliary filter units at both ends close to the side wall of the box body. The anti-blocking device provided by the invention can perform auxiliary filtration while filtering wastewater in the box body through the filter screens, reduces the filtration pressure of the first filter screen, and effectively reduces the occurrence rate of blockage.

Owner:HAITIAN WATER GRP CO LTD

Electric wall outerskin remover with steel wire roller

InactiveCN106836837AProtection securityReduce manufacturing costBuilding repairsTransmission beltElectric machinery

The invention provides an electric wall outerskin remover with a steel wire roller. The electric wall outerskin remover comprises a belt pulley, a drive motor, a transmission belt, a steel wire roller, a bottom plate, a shell, an adjusting knob, a secondary handle, a switch, a grab handle, a blanking hopper, a dust inlet pipe, a dust collector and a dust collecting bag, wherein the belt pulley is fixed at the end part of the drive motor; the drive motor is arranged in the shell; the steel wire roller is connected with the belt pulley through the transmission belt; the bottom plate is arranged at the lower part of the shell; the adjusting knob is connected with the steel wire rope; and the secondary handle is arranged at the end part of the grab handle. Through arrangement of the steel wire roller, the adjusting knob and the transmission belt, the problem of knife collapse is effectively solved, the problems that a rigid cutter body is great in damage to a wall and easily generates a crack and peels off a wall body are solved; the problem that the outerskin on the uneven wall surface is difficult to remove is solved; the security of the drive motor is effectively protected; adjustment of the planning depth of the wall according to the actual requirements is facilitated; and market popularization and application are facilitated.

Owner:GUIZHOU UNIV

Quick connecting device of power battery for electric vehicle

InactiveCN105185943AAvoid Rigid ImpactReduce harmSmall-sized cells cases/jacketsElectric vehiclePower battery

The invention discloses a quick connecting device of a power battery for an electric vehicle. The quick connecting device comprises an insulation base, two pole terminals and a limiting device, wherein the two pole terminals are arranged on the insulation base in a penetrating way along the vertical direction; the limiting device is used for limiting the displacement stroke of the pole terminals on the insulation base in the vertical direction; gaps are arranged between the pole terminals and the insulation base. The quick connecting device disclosed by the invention has the advantages that the structure is simple, the connecting is reliable, the damage to the pole terminals is reduced, poor contact of a battery caused by deformation of the pole terminals can be avoided, and the battery protection ability is increased; in addition, the pole terminals can be rotated relative to the insulation base due to the gaps between the pole terminals and the insulation base, so that the friction of connecting positions between the pole terminals and the battery is reduced, and the service life is prolonged.

Owner:力帆科技(集团)股份有限公司

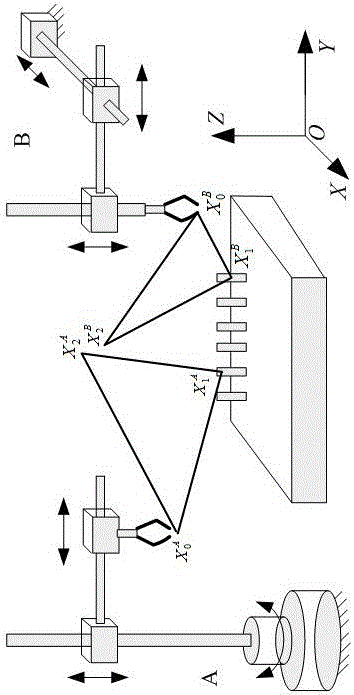

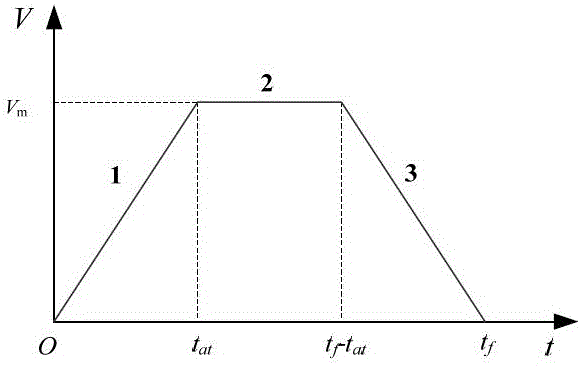

Double-mechanical arm cooperative control method for full-automatic blood type serology analysis system

The invention discloses a double-mechanical arm cooperative control method for a full-automatic blood type serology analysis system. The method comprises the following steps: after receiving a blood sample or reagent transferring task instruction, performing quick interference judgment on the basis of task routes of two mechanical arms, and then reasonably allocating the motion time of the two mechanical arms according to a judging result, and planning the motion tracks of the mechanical arms on the basis of a trapezoidal speed mode, thereby effectively avoiding impact on the start and stop processes of the system, fully exerting the time advantage and increasing the blood sample transferring efficiency. The control method can adapt to a time-varying task instruction; for different operation requirements, the two mechanical arms can quickly complete the existing tasks without interference within the finite time; the operand is small; the expansion is easy; the engineering practicability is strong.

Owner:广州誉康医药有限公司

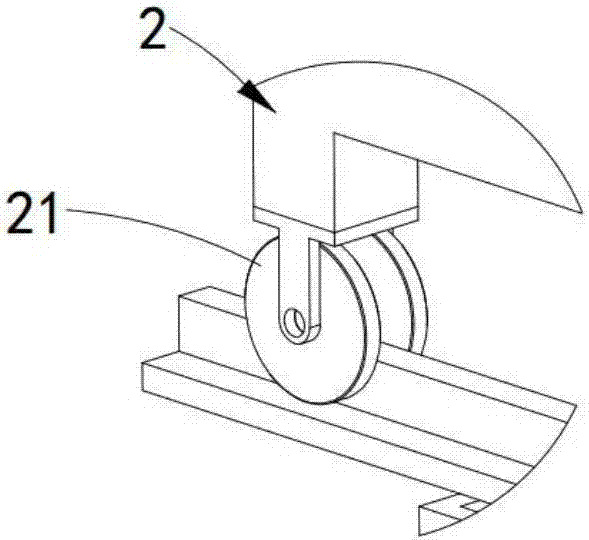

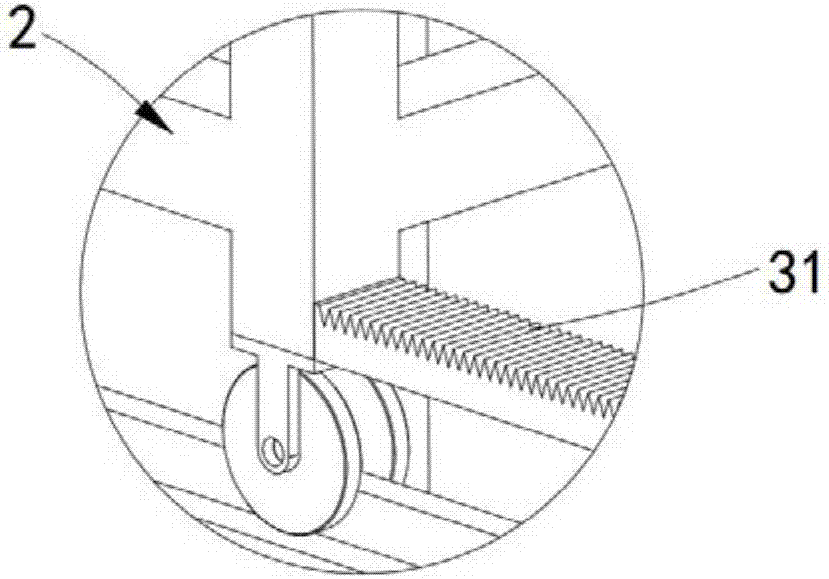

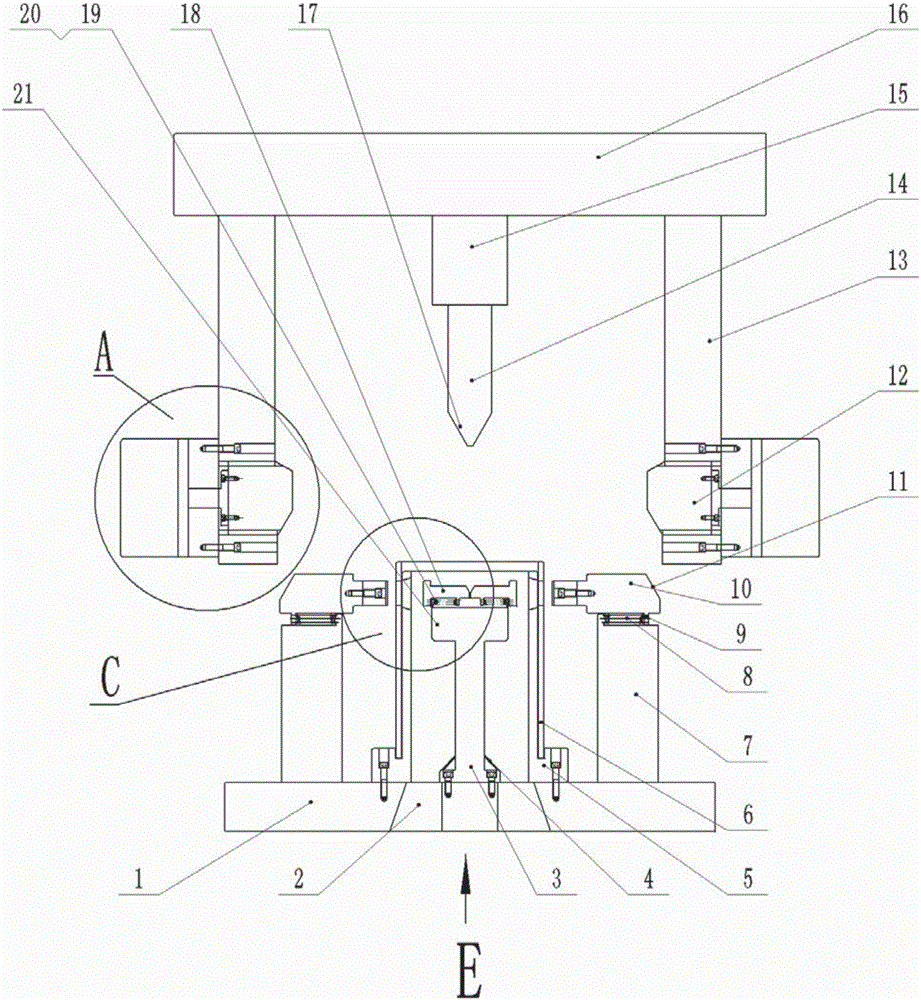

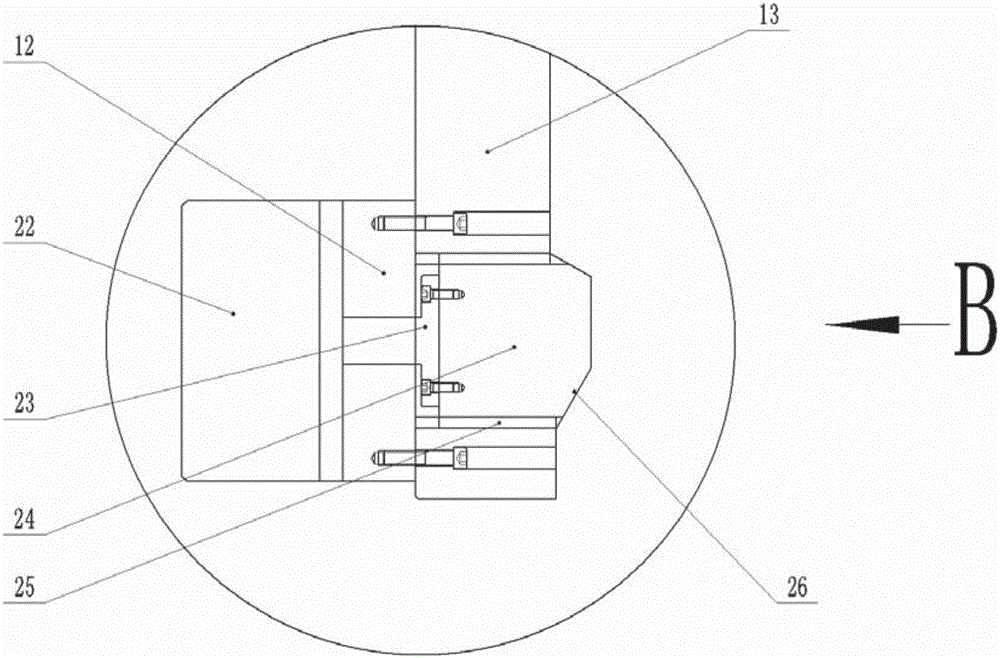

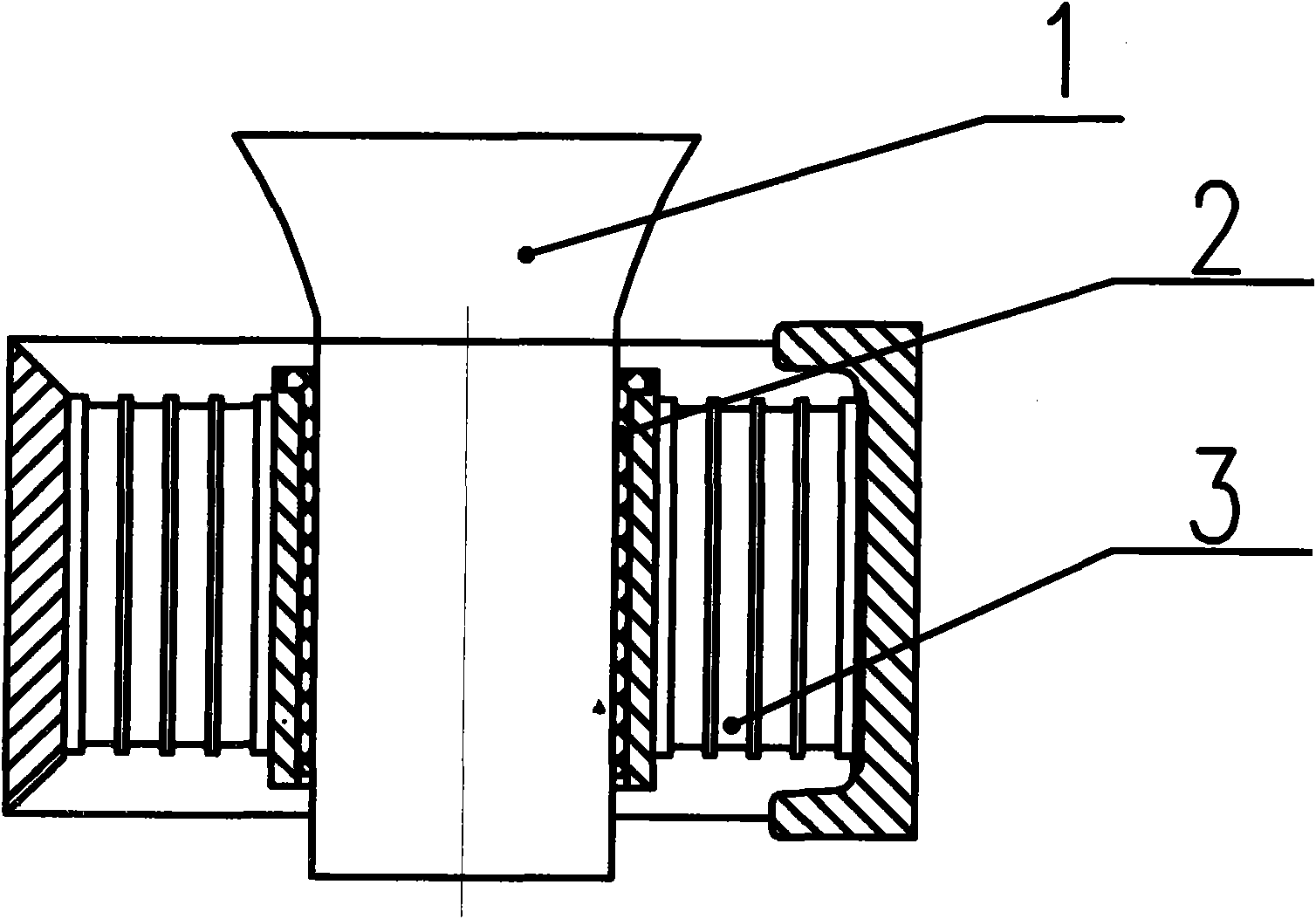

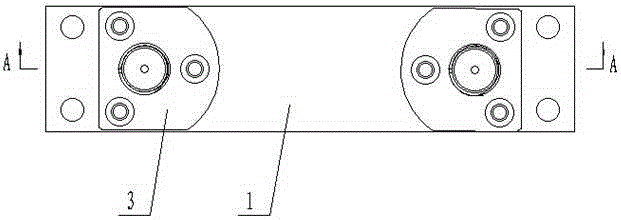

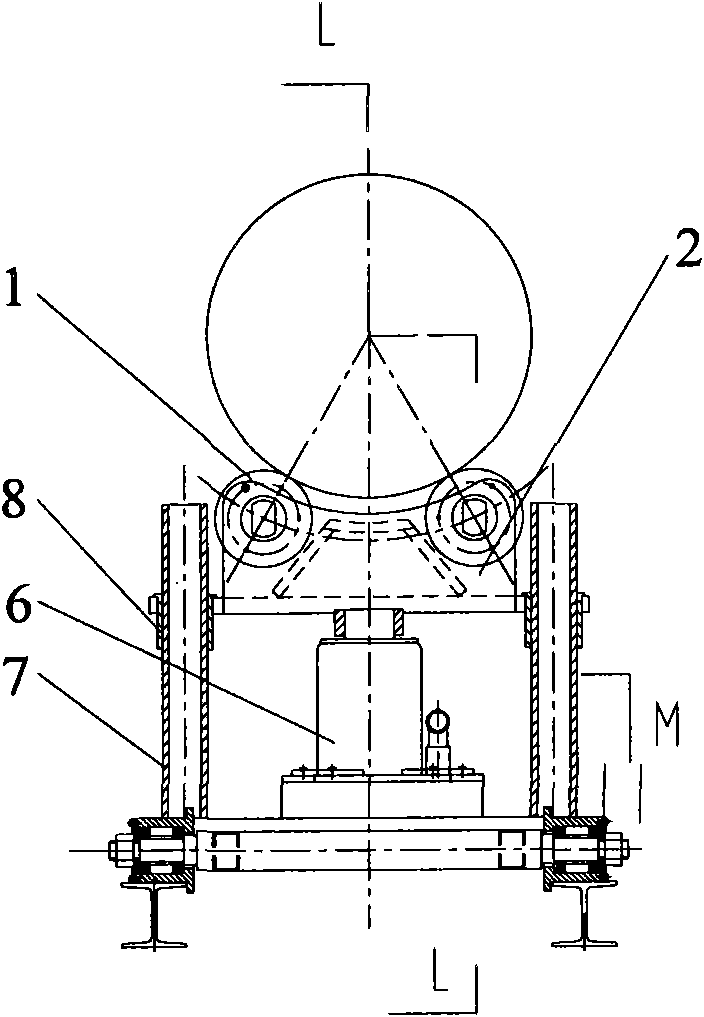

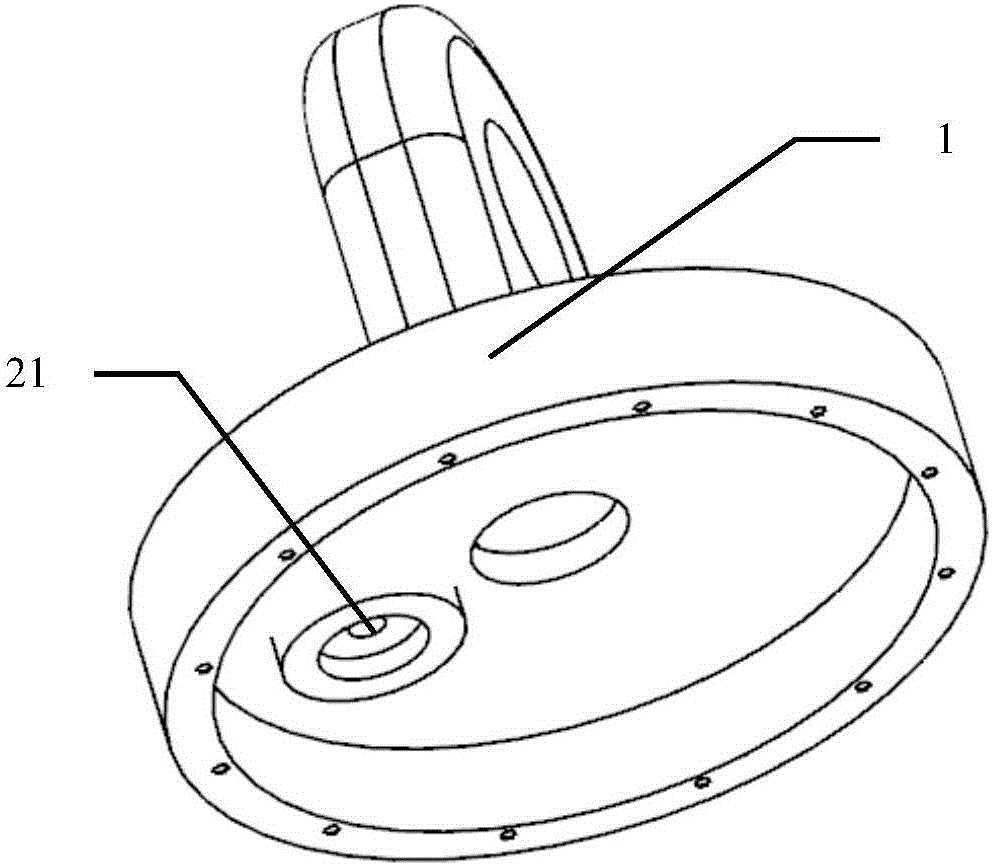

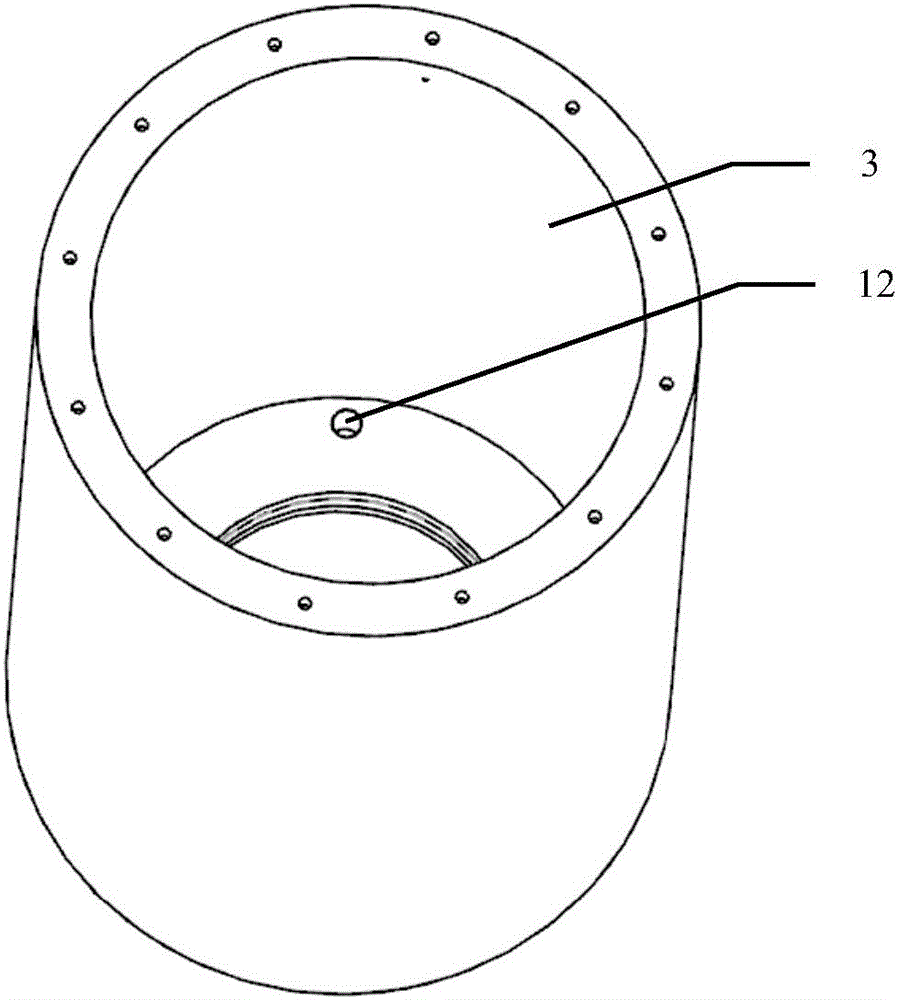

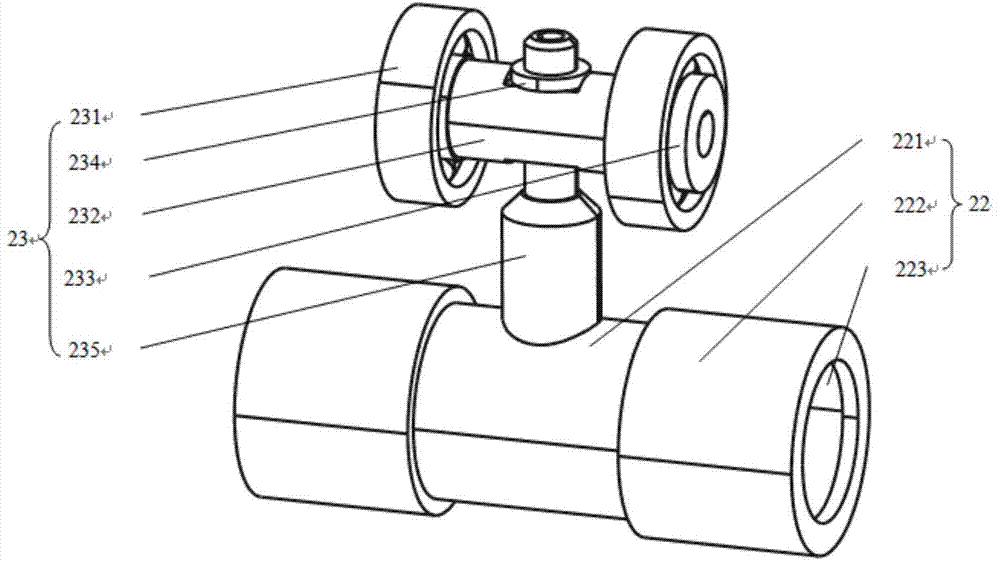

Supporting mechanism

InactiveCN101858480ASmooth rotationEasy to adjustStructural/machines measurementStands/trestlesPush and pullPush pull

The invention relates to a supporting mechanism, which is used for supporting a slender rod piece. The slender rod piece is provided with a centre rod. The supporting mechanism is provided with a supporting device and a push-pull device. The supporting device comprises supporting wheels (1) which are arranged in pairs, and the supporting wheels can lift so as to openly bear the centre rod; and the push-pull device comprises a push-pull head structure which is connected with the centre rod so as to push and pull the centre rod and can lift. The supporting mechanism can flexibly adapt to slender rod pieces with different diameters or specifications.

Owner:BEIJING SANY HEAVY MASCH CO LTD

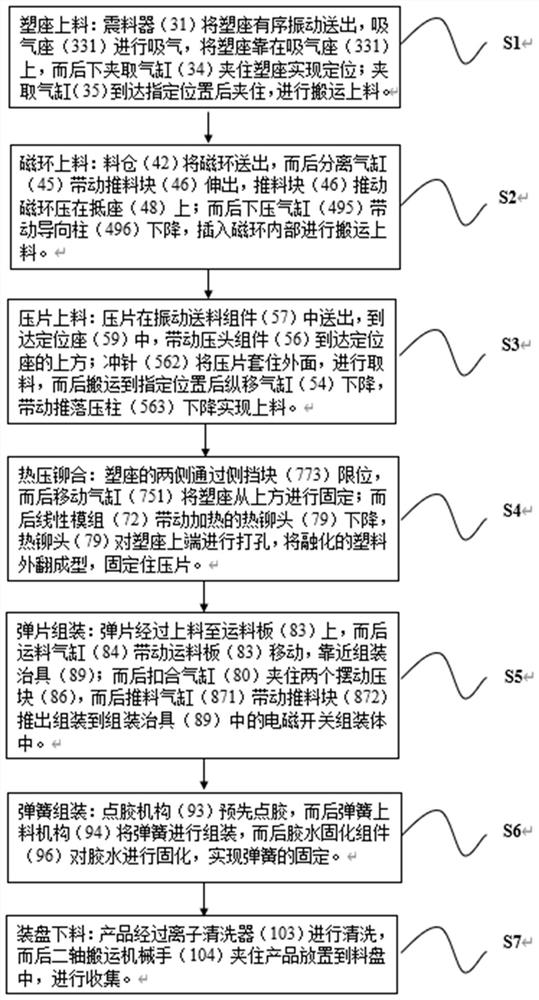

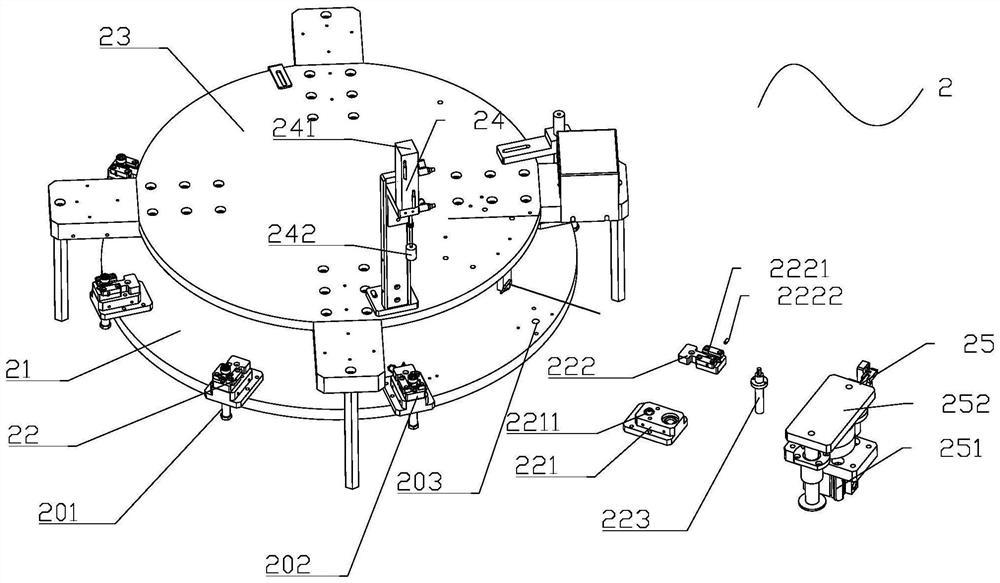

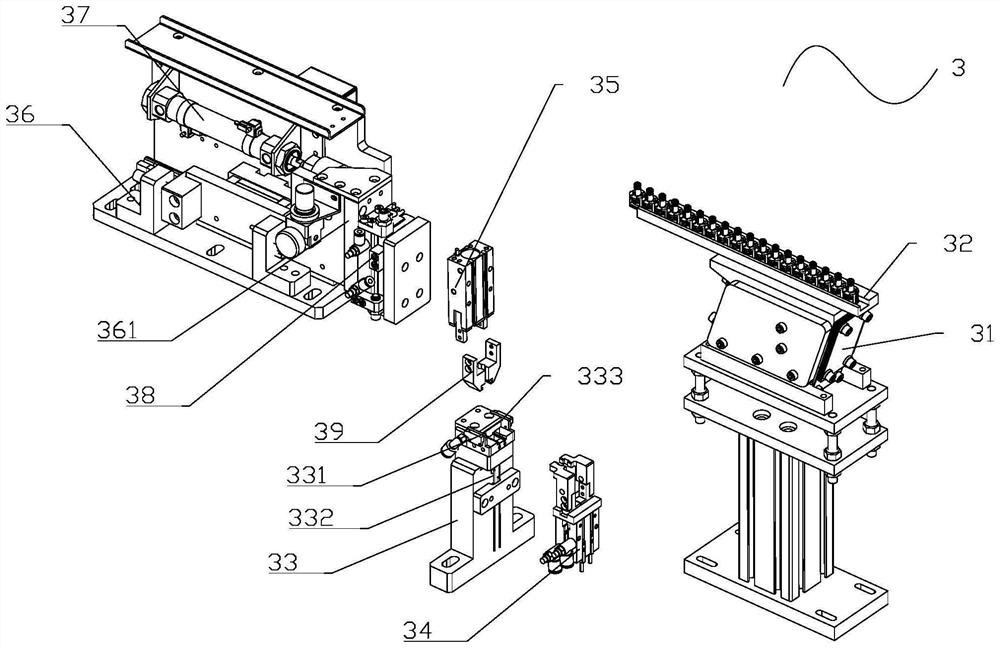

Electromagnetic switch production method and production equipment thereof

InactiveCN112017884AAvoid bending deformationAchieve positioningElectric switchesAdhesive glueEngineering

The invention discloses electromagnetic switch production equipment. The electromagnetic switch production equipment comprises a rack and a turntable conveying device, a plastic seat feeding device, amagnetic ring feeding device, a pressing sheet feeding device, a linear conveying device, a hot melting assembling device, a fixed clamping seat assembling device, a spring assembling device and a cleaning discharging device which are mounted on the rack, wherein the turntable conveying device is connected with the linear conveying device, and the plastic base feeding device, the magnetic ring feeding device and the pressing sheet feeding device are sequentially arranged on the outer side of the turntable conveying device. The hot melting assembling device and the fixed clamping seat assembling device are arranged on the side of the linear conveying device; the linear conveying device and the spring assembling device are connected through a transferring jig mechanism. And the cleaning discharging device is connected with the spring assembling device. The turntable is efficient in conveying and accurate in machining; the plastic base, the pressing sheet and the fixed clamping base areaccurate in feeding, efficient, accurate in spring separation and firm in glue connection; and cleaning and discharging are conducted in sequence, and the product collecting efficiency is high.

Owner:李丹

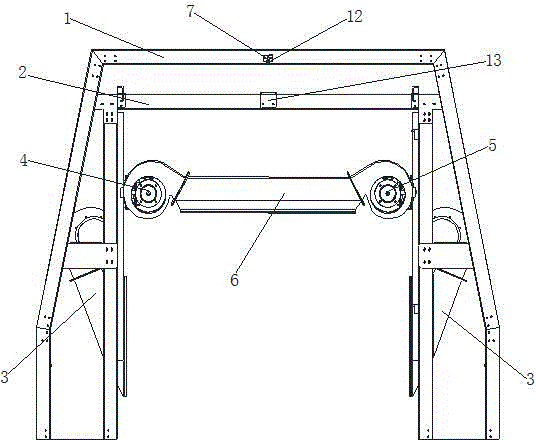

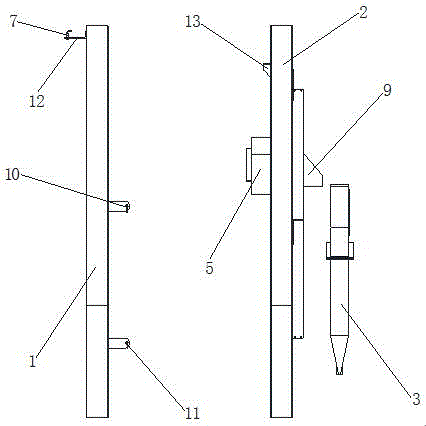

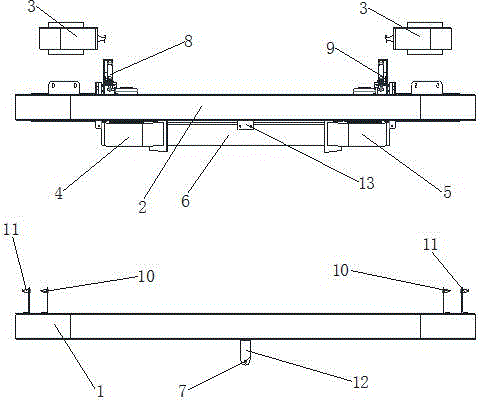

Drying system of automatic car washing machine

InactiveCN106274827ABlow drying effect is goodAvoid Rigid ImpactCleaning apparatus for vehicle exteriorsAgricultural engineeringBody surface

The invention discloses a drying system of an automatic car washing machine. The drying system comprises a first gantry, a second gantry, a top blowing assembly, side blowing assemblies and a control board. The top blowing assembly comprises a first top draught fan set, a second top draught fan set, a top draught fan wind tunnel, a distance measuring sensor and a servo motor; the first top draught fan set is connected with a first top draught fan swinging mechanism, the second top draught fan set is connected with a second top draught fan swinging mechanism, the wind outlets of the first top draught fan set and the second top draught fan set communicate to the left wind inlet and the right wind inlet of the top draught fan wind tunnel, and the wind outlets of the top draught fan wind tunnel follow the shape of the car and have a fixed distance relative to the car body surface; and the servo motor, the distance measuring sensor, the side blowing assemblies and draught fan startup optoelectronic switches arranged on the first gantry are connected with the control board. According to the drying system of the automatic car washing machine, the drying effect is good, the rigid impact, vibration and noise when the top blowing machine assembly is lifted can be avoided, and the service life of electric-mechanical components is favorably prolonged.

Owner:NANJING LYTON AUTOMATION EQUIP CO LTD

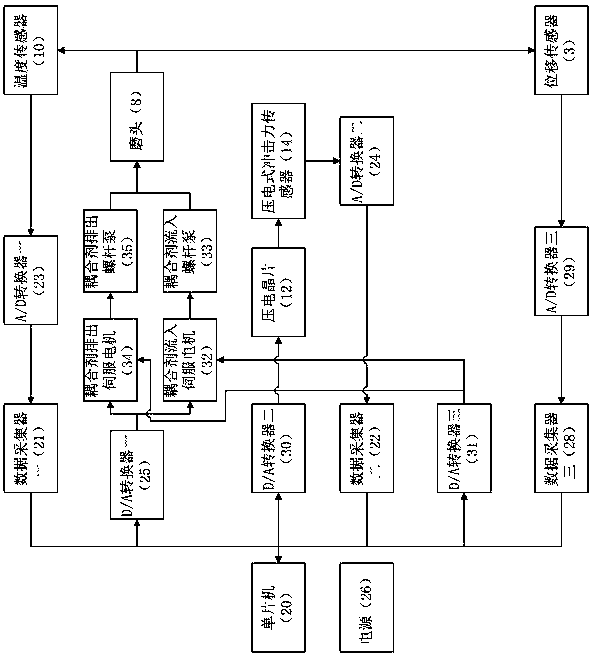

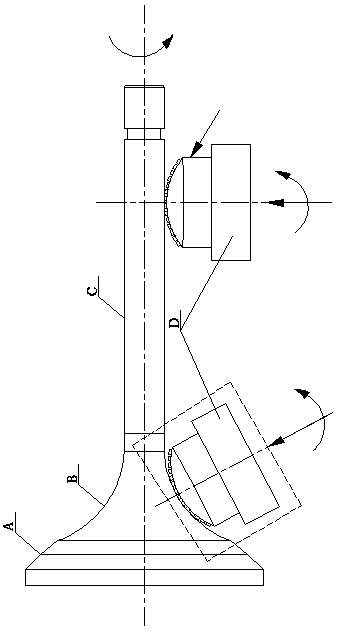

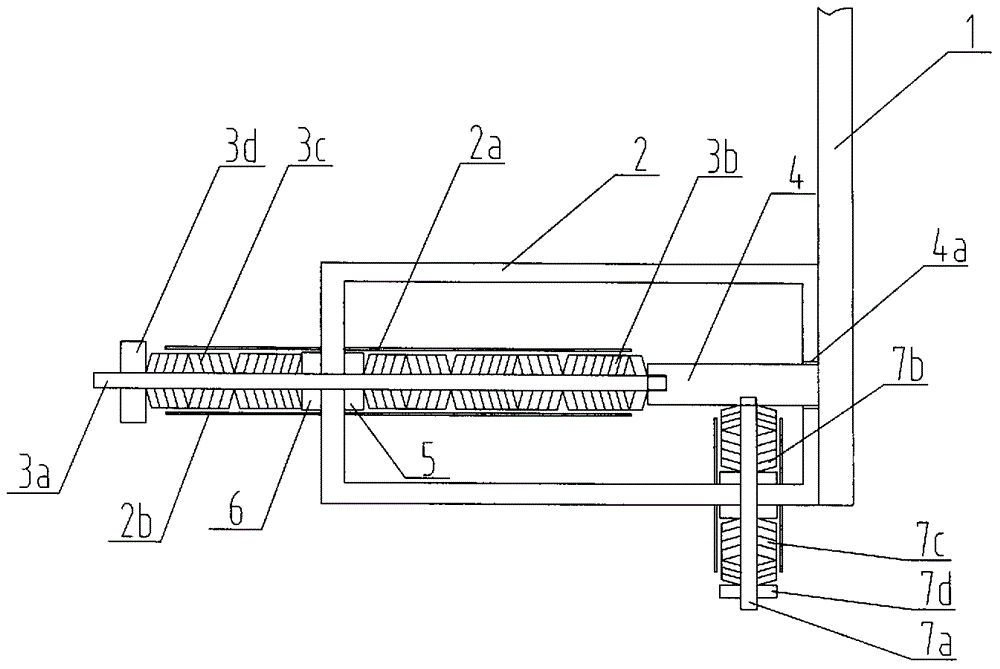

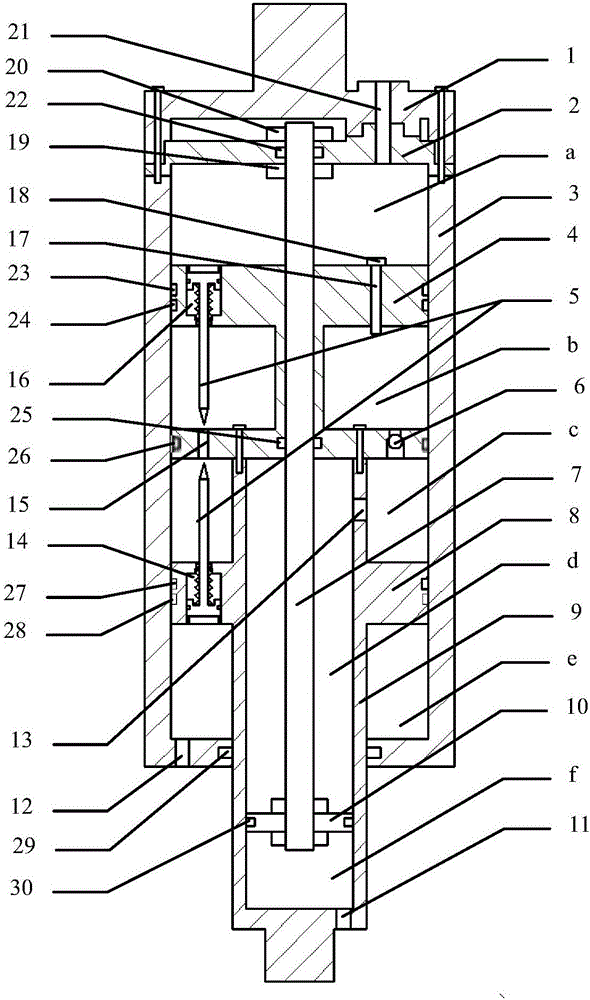

Ultrasonic combined adaptive anti-fatigue precision machining system and method of multi-curvature curved surface

ActiveCN108481138AImprove polishing efficiencyImprove fatigue lifeGrinding machine componentsGrinding machinesCouplingEngineering

The invention discloses an ultrasonic combined adaptive anti-fatigue precision machining system and method of a multi-curvature curved surface, and belongs to the field of mechanical precision machining common technologies. The ultrasonic combined adaptive anti-fatigue precision machining system and method of the multi-curvature curved surface aim to solve the technical problem of how to machine acurved surface of a key part with the multi-curvature curved surface while guaranteeing that the part has the anti-fatigue performance of a part with the multi-curvature curved surface. According tothe adopted technical scheme, the ultrasonic combined adaptive anti-fatigue precision machining system structurally comprises a flexible grinding head device and a control unit. The control unit is electrically connected with and has control over the flexible grinding head device, an ultrasonic coupling agent circulation structure and an impact vibration structure. The flexible grinding head device is used for machining the multi-curvature curved surface of the part. The control unit is used for having control over the working state of the flexible grinding head device. The flexible grinding head device comprises a flexible adjustment box body, the ultrasonic coupling agent circulation structure and the impact vibration structure. The impact vibration structure is arranged in the flexibleadjustment box body. The interior of the flexible adjustment box body communicates with the ultrasonic coupling agent circulation structure. The invention further discloses the ultrasonic combined adaptive anti-fatigue precision machining method of the multi-curvature curved surface.

Owner:QILU UNIV OF TECH

Curtain wall

The invention discloses a curtain wall, and belongs to the field of buildings. The curtain wall comprises a curtain wall plate, a keel, a first connecting assembly and a connecting plate; the connecting plate is fixed at the vertex angle position of the back face of the curtain wall plate; the keel is of a hollow structure; a gap is formed in a position, corresponding to the connecting plate, of the keel; the connecting plate is located in the gap; the first connecting assembly comprises a first connecting rod, a first elastic part, a second elastic part and a first locking part; the first end of the first connecting rod penetrates through the keel and is installed on the connecting plate, and the first connecting rod and the connecting plate are arranged in parallel; the first elastic part sheathes the connecting rod; one end of the first elastic part abuts against the inner wall of the keel, and the other end of the first elastic part abuts against the connecting plate; the locking part is arranged at the second end of the connecting rod; the second elastic part sheathes the first connecting rod; and one end of the second elastic part abuts against the first locking part, and the other end of the second elastic part abuts against the outer wall of the keel. According to the curtain wall, a phenomenon that four corners of the curtain wall plate deform or break due to uneven loading can be avoided.

Owner:中建幕墙有限公司

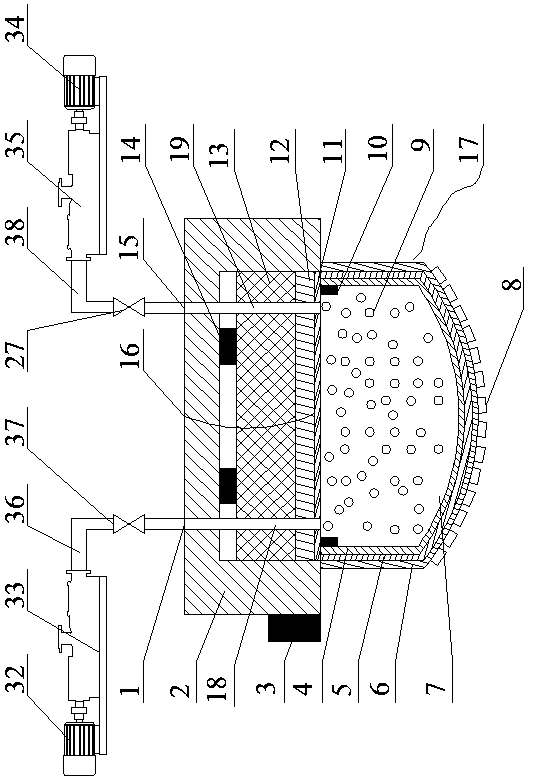

Multiple operating condition damping self-adaption hydro-pneumatic spring and control method thereof

ActiveCN106523574ASatisfy ride comfortImprove driving stabilitySpringsLiquid based dampersBody rollControl theory

The invention provides a multiple operating condition damping self-adaption hydro-pneumatic spring and a control method thereof. The multiple operating condition damping self-adaption hydro-pneumatic spring mainly comprises a cylinder barrel, a pull rod, a pull rod piston, a rod barrel, a cylinder barrel piston and a rod barrel piston. The pull rod is fixed in the cylinder barrel, the upper end of the pull rod is fixed on the top of the cylinder barrel, and the pull rod piston is fixed to the lower end of the pull rod; the pull rod piston is arranged in the rod barrel to form a first piston structure, the cylinder barrel piston is connected to the upper end of the rod barrel, and an upper end opening of the rod barrel is sealed by the lower end face of the cylinder barrel piston; and a second piston structure is formed by the cylinder barrel piston and the cylinder barrel, the rod barrel piston is further arranged on the outer wall of the rod barrel, and a third piston structure is formed by the rod barrel, the rod barrel piston and the cylinder barrel. According to the multiple operating condition damping self-adaption hydro-pneumatic spring and the control method thereof, the demand that the natural frequency of a car body is basically changeless under the condition that a car is in different loading operating conditions is met, and heeling and pitching vibration of the car body owing to the typical limiting conditions of the car such as emergency braking and corner turning at a high speed can be effectively restrained and attenuated on the basis that car riding comfort is met, so that the demand of car riding stability is met.

Owner:HUNAN UNIV

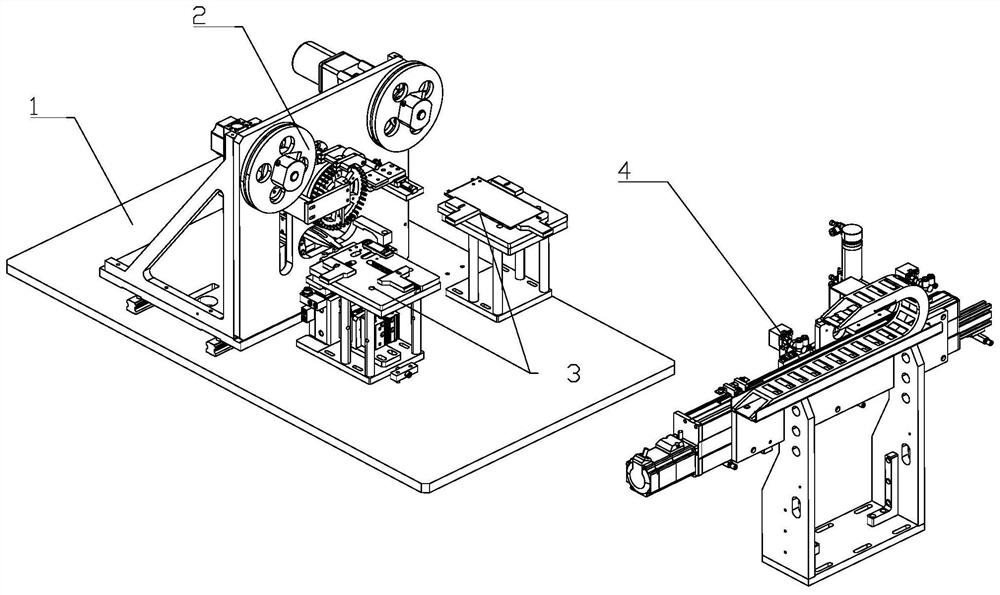

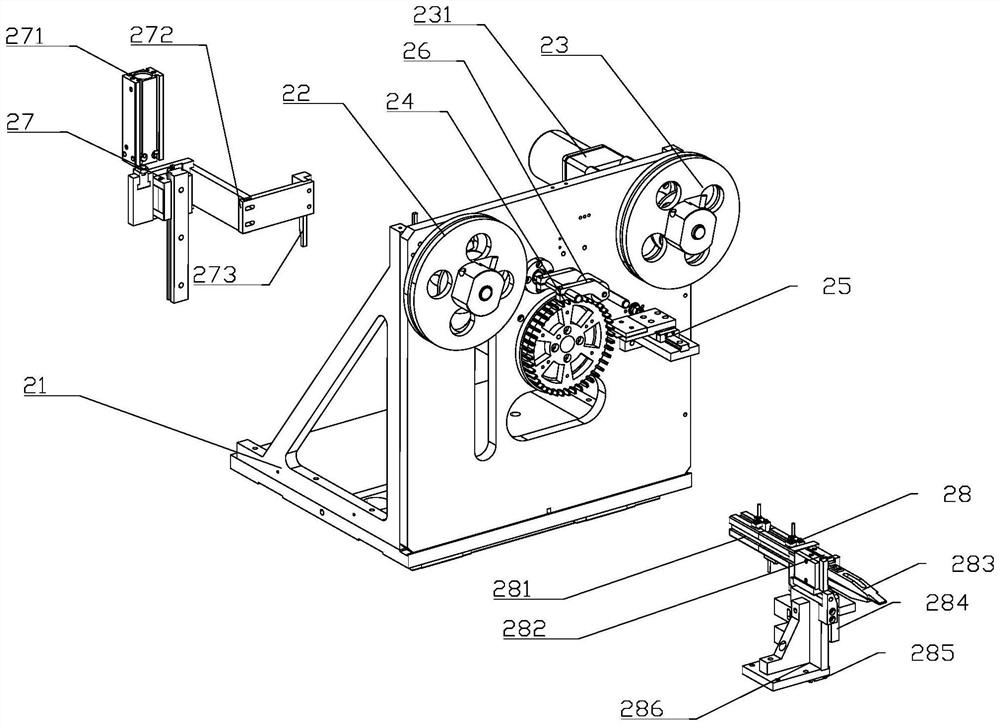

Lithium battery pack tab adhesive tape pasting machine and adhesive tape pasting method

InactiveCN112259924AEasy to pasteAchieve circulationAssembling battery machinesFinal product manufactureEngineeringMechanical engineering

The invention discloses a lithium battery pack tab adhesive tape pasting machine. The lithium battery pack tab adhesive tape pasting machine comprises a rack, and an adhesive tape pasting device, a positioning device and a carrying device which are mounted on the rack, wherein the adhesive tape pasting device corresponds to the position above the positioning device, and the carrying device and theadhesive tape pasting device are located on the two sides of the positioning device respectively; the adhesive tape pasting device is used for cutting adhesive tape and pasting the adhesive tape to tabs of the lithium battery packs in the positioning devices, and the carrying device is used for feeding and discharging the lithium battery packs and carrying the lithium battery packs between the positioning devices. The machine has the advantages of being high in adhesive tape pasting efficiency, accurate in adhesive tape pasting and automatic in feeding and discharging.

Owner:周俊英

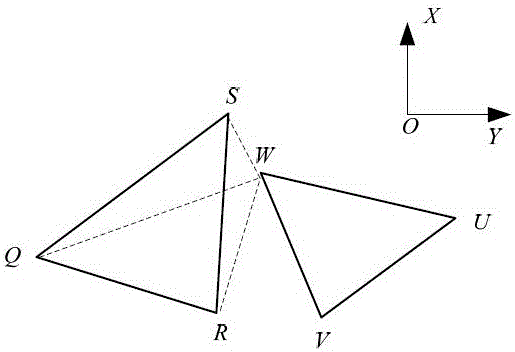

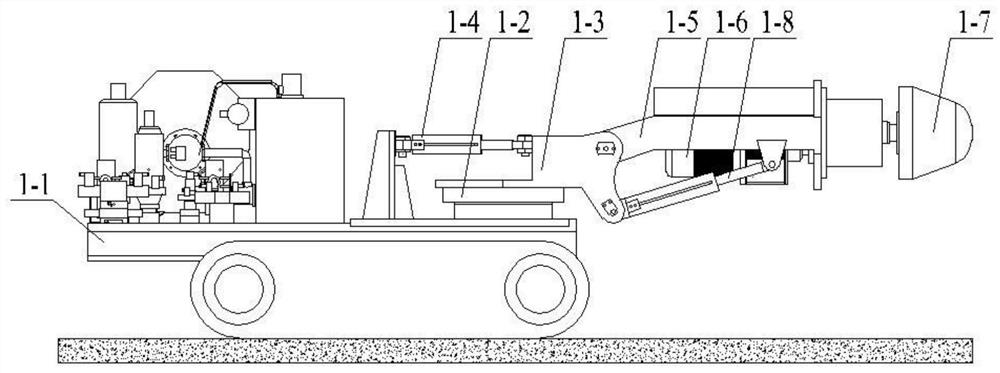

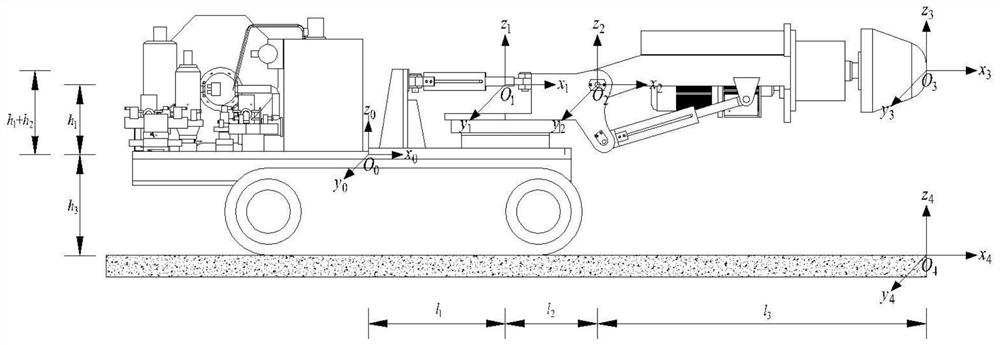

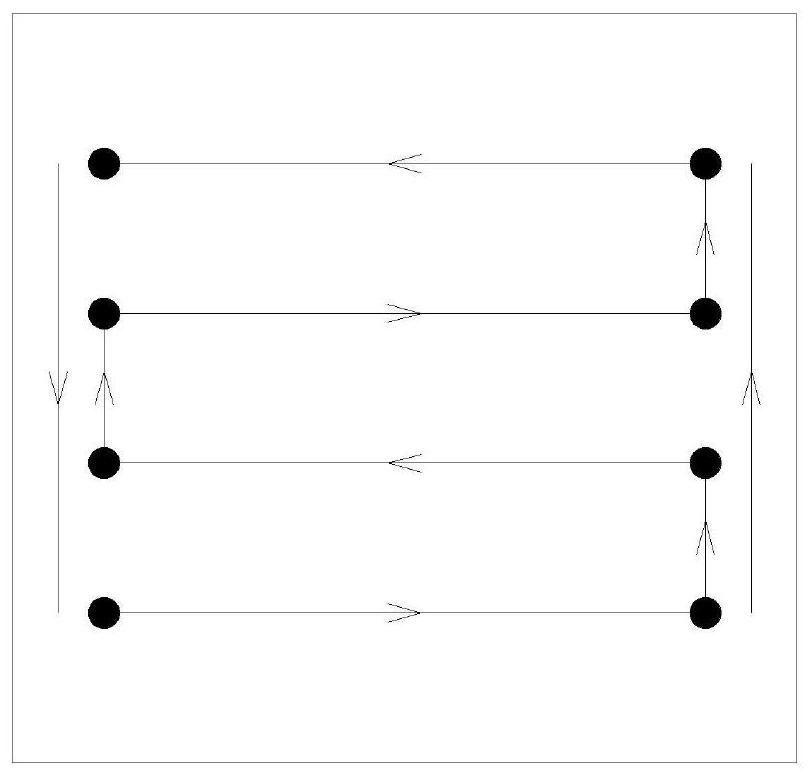

Optimization method for automatically forming cutting motion of section of cantilever longitudinal shaft type heading machine

ActiveCN112983412AImprove stabilityHigh forming precisionData processing applicationsMining devicesControl systemEngineering

The invention discloses an optimization method for automatically forming a cutting motion of the section of a cantilever longitudinal shaft type heading machine. The optimization method comprises the following steps of establishing five coordinate systems in a roadway, calculating the coordinate of the ith cutting tooth of a cutting head in an O0-X0Y0Z0 coordinate system according to the coordinate of the ith cutting tooth of the cutting head in an O3-X3Y3Z3 coordinate system, planning the track of the cutting head during horizontal movement by adopting a high-order polynomial transition linear interpolation method, planning the track of the cutting head during non-horizontal movement by adopting a combined sine function curve, and then determining a coordinate sequence of all inflection points on the section of the roadway in a cutting path according to the form of the section of the roadway. According to the optimization method, a correction method is provided for the inflection point positions of the S-shaped cutting paths of different roadway section types, the forming precision of the sections can be further increased, and the method is easy to implement through programs in an automatic section forming control system.

Owner:CHINA UNIV OF MINING & TECH

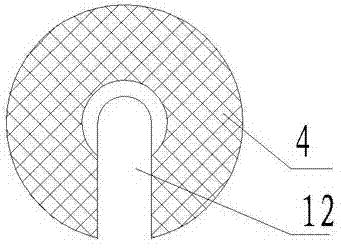

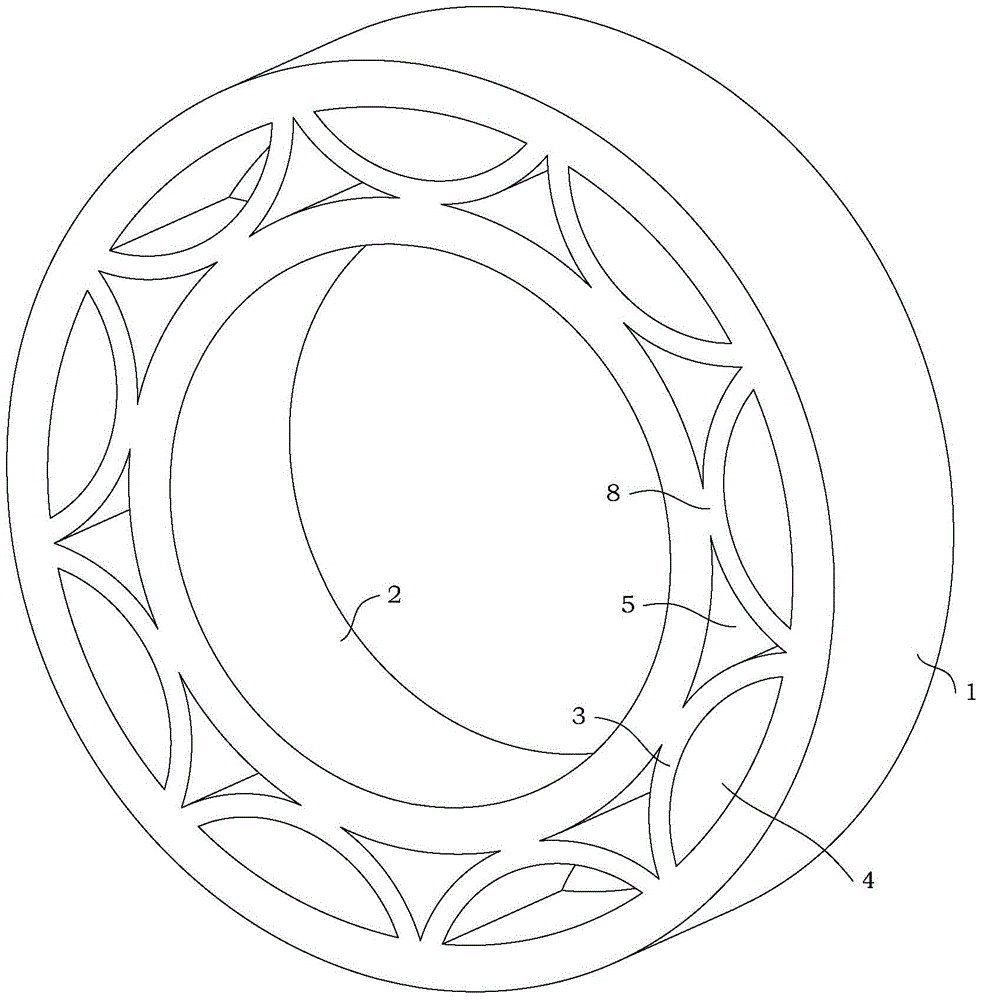

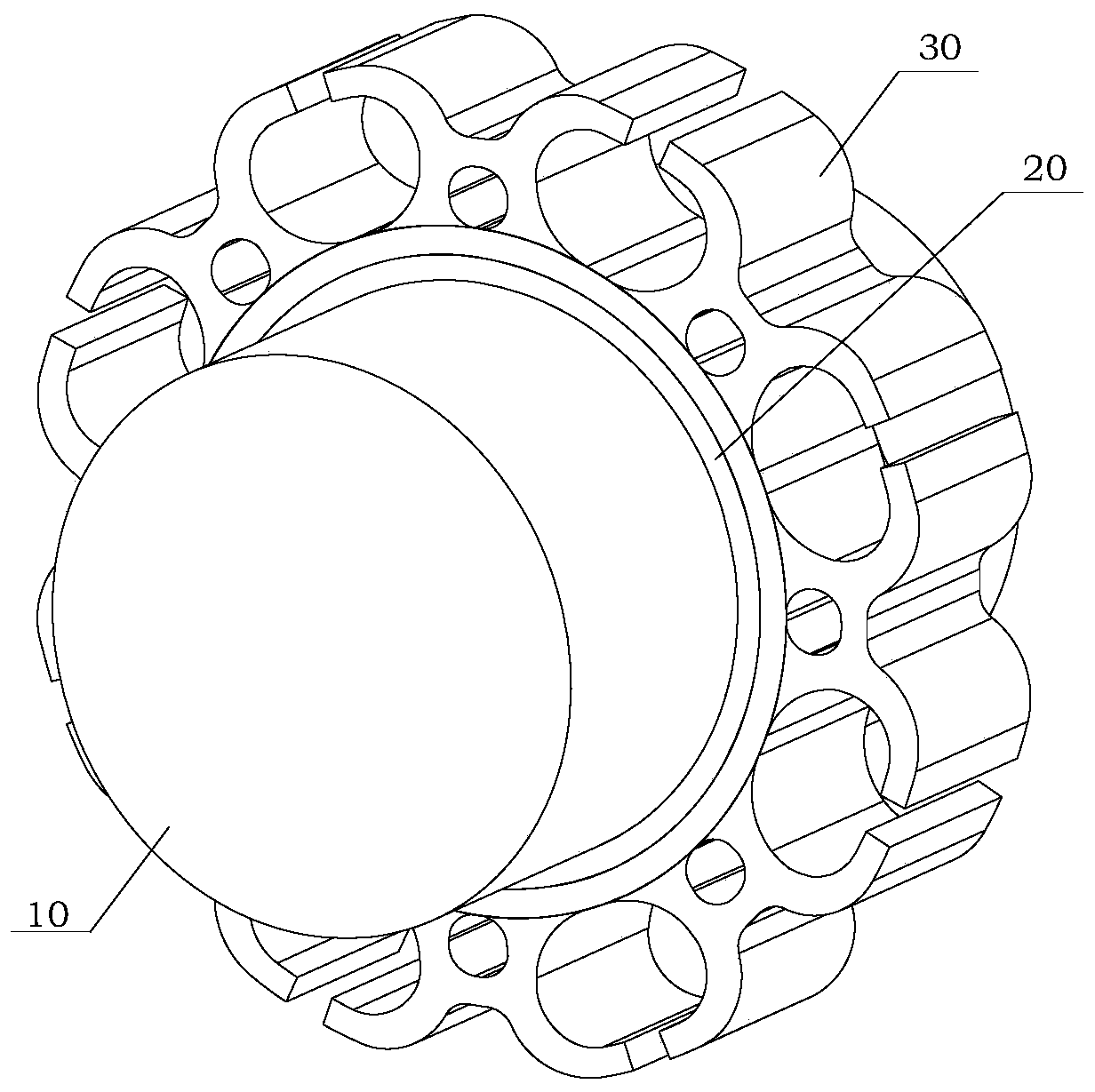

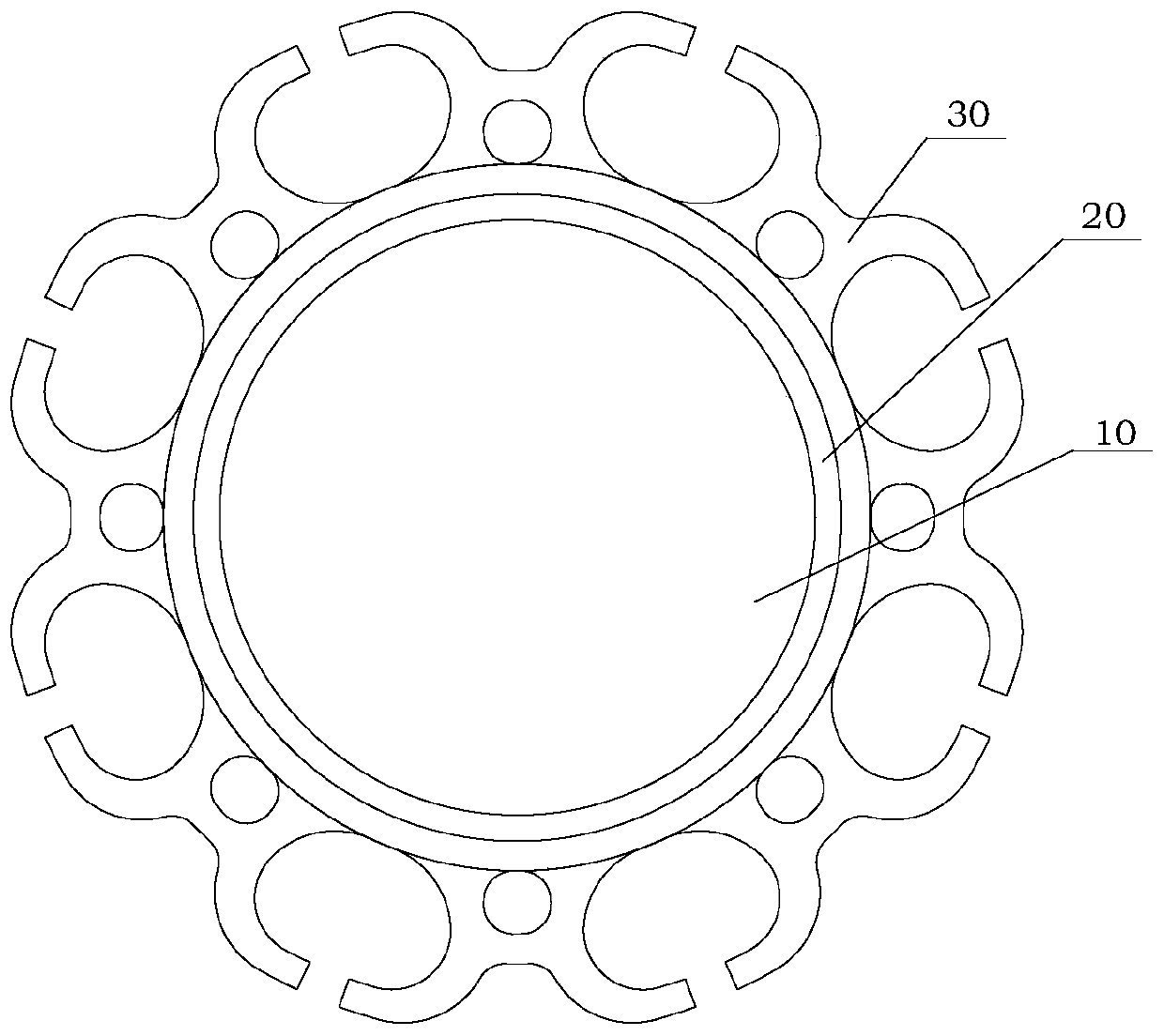

Segmented open flexible segment radial protection bearing for magnetic bearing

ActiveCN110725858AAvoid stuck and stalled situationsAvoid Rigid ImpactElastic bearingsBearing unit rigid supportMagnetic bearingEngineering

The invention discloses a segmented open flexible segment radial protection bearing for a magnetic bearing. The radial protection bearing is an integrated machined forming structural member. The radial protection bearing is composed of eight open flexible bodies of the same structure and an inner ring, an open arc-shaped hole is formed between every two adjacent open flexible bodies, and elliptical through holes are formed in the open flexible bodies and the outer ring surface of the inner ring. The radial protection bearing utilizes a segmented open flexible segment structure and is matched with flexible deformation of the open arc-shaped holes and the elliptical through holes. When a rotor is unstable and generates huge impact, the radial protection bearing can use elastic deformation ofa segmented open flexible segment to absorb a large amount of kinetic energy of the rotor, and other parts in a high-speed rotary magnetic suspension mechanism cannot be damaged.

Owner:BEIHANG UNIV

Guide rail type permanent magnet chain filtering system for cold-rolling cooling liquid treatment

The invention discloses a guide rail type permanent magnet chain filtering system for cold-rolling cooling liquid treatment. The guide rail type permanent magnet chain filtering system comprises a magnetic chain mechanism, a pollution cleaning mechanism, a slag recycling mechanism and a motor transmission mechanism, wherein the pollution cleaning mechanism as a key improvement comprises a roller way unit with a space closed-loop structure, sleeve type slag scrapers correspondingly arranged on magnetic sticks in the length direction in a sleeved manner and guide components for connecting the roller way unit with the sleeve type slag scrapers; when the magnetic sticks drive the slag scrapers to do linear motion together along the chain transmission direction, the slag scrapers and the guide components are fixedly connected to do motion and are restrained by a trace of the roller way unit, and therefore, metal dust adsorbed by the magnetic sticks can be scraped off. According to the guide rail type permanent magnet chain filtering system, the phenomenon that a magnetic stick deforms or is damaged due to rigid contact between the pollution cleaning mechanism which moves to an extreme position and the magnetic stick can be effectively avoided; furthermore, the overall size of the system can be greatly reduced, and the running speed and the following efficiency can be obviously improved. The guide rail type permanent magnet chain filtering system can be widely applied to filtering, purifying and magnetic separation of various types of industrial water which contains iron dust and is adhered with dirt.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com