Central buffering connector

A connector and central technology, applied in the field of central buffer connectors, can solve the problems of unfavorable passenger service life, complex shape, high production and maintenance costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

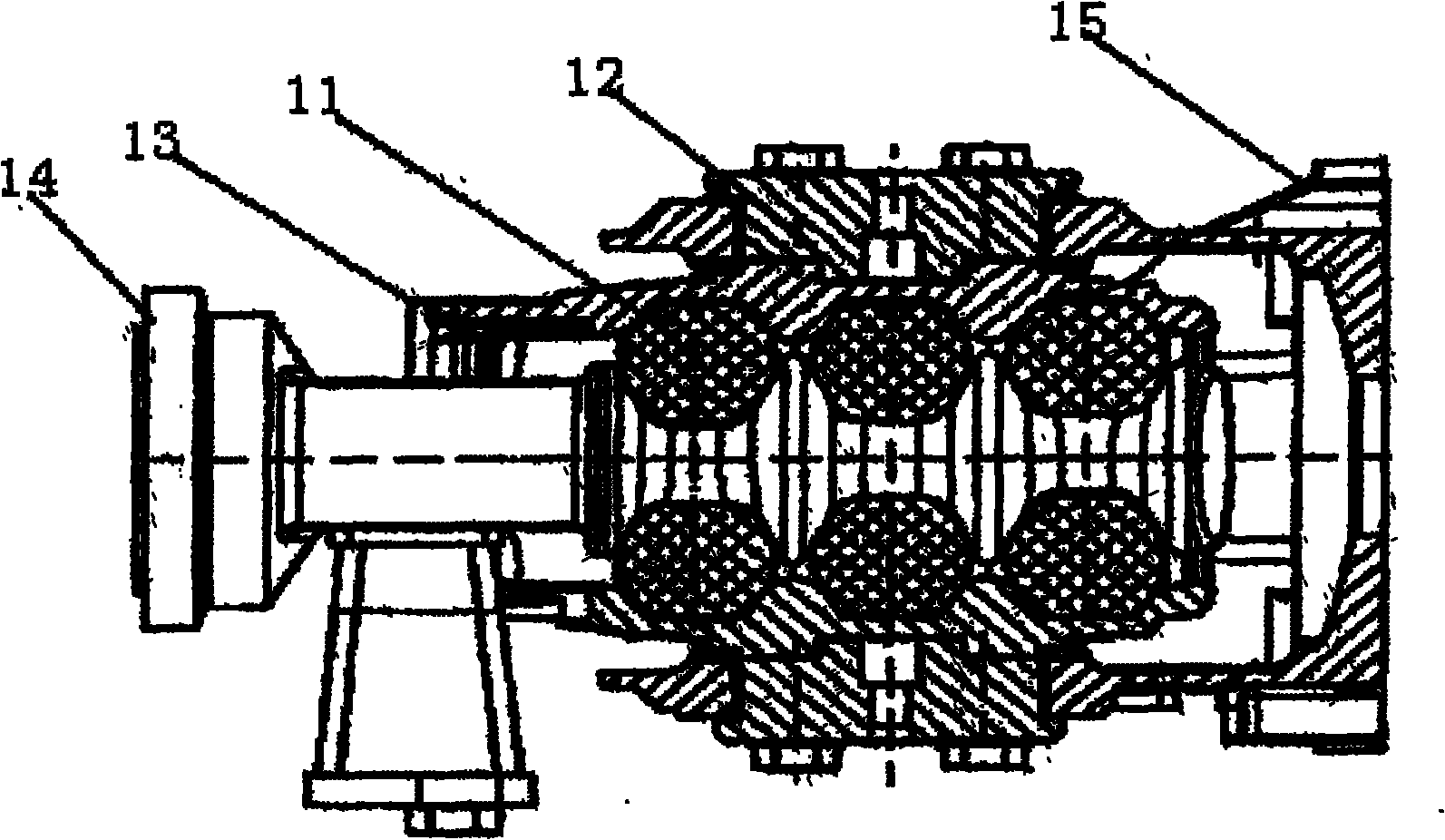

[0017] Such as figure 1 As shown, the central buffer connector of the prior art includes a connecting rod 14, an elastic ring 11, a housing 13, a hinged device 12 and a support seat 15. The housing 13 is composed of upper and lower parts, and the elastic ring 11 is pre-pressed on the housing. In the annular groove formed between the body 13 and the connecting rod 14. The rear end of the connecting rod 14 is connected with the hinge device 12, and is hinged on the connecting plate of the rail vehicle in a horizontally swingable manner through the support seat of the hinge device 12. When the connecting rod 14 is subjected to a normal amount of traction or impact force, the connection rod 14 will move axially relative to the housing 13 , thus shearing the elastic ring 11 to buffer the traction force or impact force. The hinge device 12 undertakes the horizontal swing of the connecting rod 14 on the one hand, and bears the function of impact protection on the other hand. This s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com