Lithium battery pack tab adhesive tape pasting machine and adhesive tape pasting method

A technology of lithium batteries and ear stickers, which is applied in the direction of assembling battery machines, battery pack parts, secondary battery manufacturing, etc., can solve the problems of inaccurate tab positions, easy to unglue the tape, and complicated devices, so as to facilitate handling and loading and unloading , Facilitate adhesive tape pasting, reduce the effect of structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

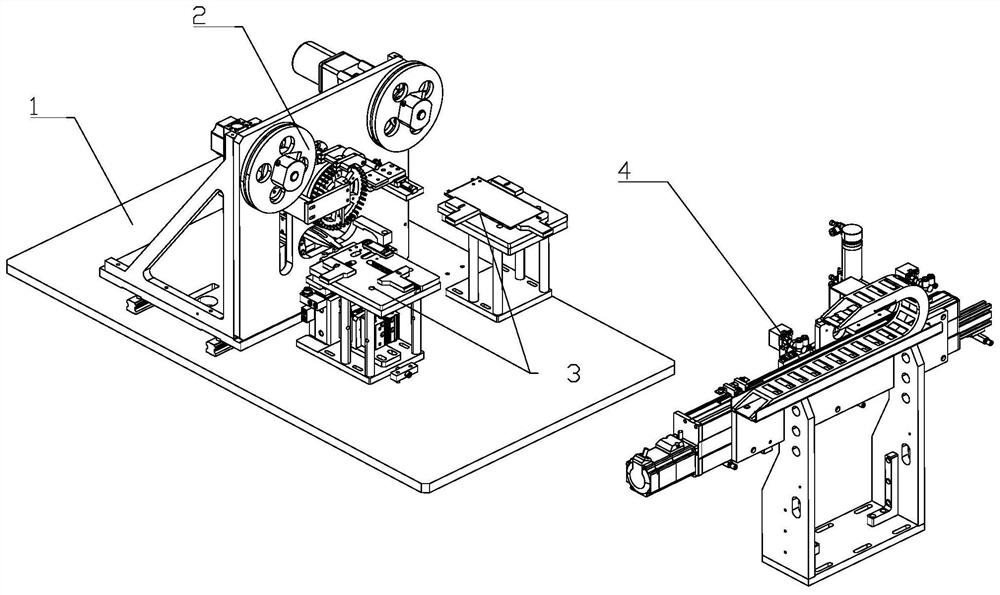

[0028] Such as figure 1 As shown, a lithium battery pack lug gluing machine includes a frame 1 and a gluing device 2 installed on the frame 1, a positioning device 3 and a handling device 4; the gluing device 2 corresponds to the positioning device 3 Above, the handling device 4 and the gluing device 2 are respectively located on both sides of the positioning device 3; the gluing device 2 is used to cut the adhesive paper and paste it on the tab of the lithium battery pack in the positioning device 3, The conveying device 4 is used for loading and unloading the lithium battery pack and conveying between the positioning devices 3 .

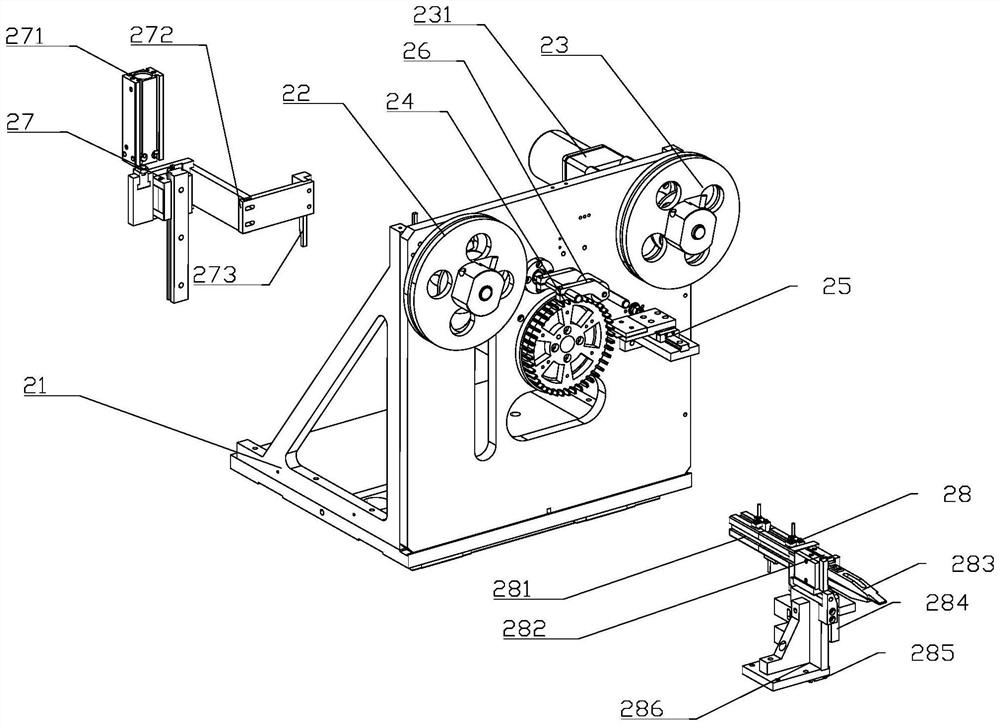

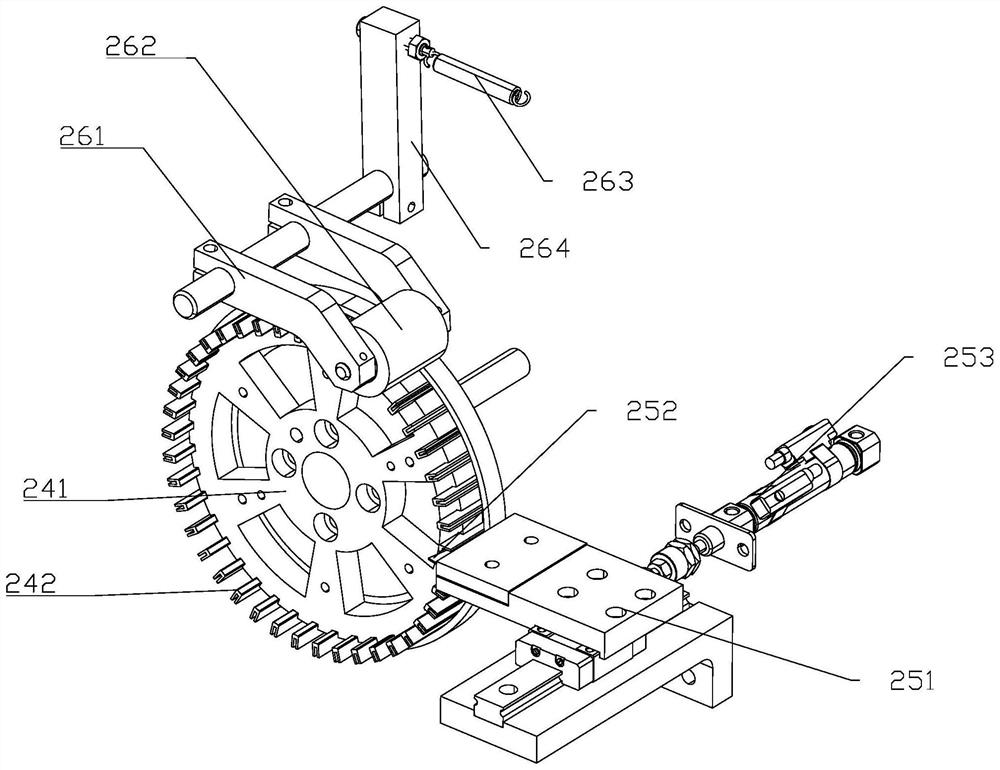

[0029] Such as figure 2 and image 3 As shown, the gluing device 2 includes a fixed seat 21, a feeding tray 22, a receiving tray 23, a rotating drum assembly 24, a cutter assembly 25, a pressing assembly 26, a moving assembly 27 and a tightening assembly 28; Adhesive paper rolls are arranged in the feeding tray 22, and the feeding tray 22 is hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com