Machine shell punching and burr trimming device

A technology for repairing burrs and casings, which is applied in the field of stamping devices, can solve problems such as low processing efficiency and poor quality of burrs, and achieve the effects of convenient repair and replacement, improved efficiency, and improved processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

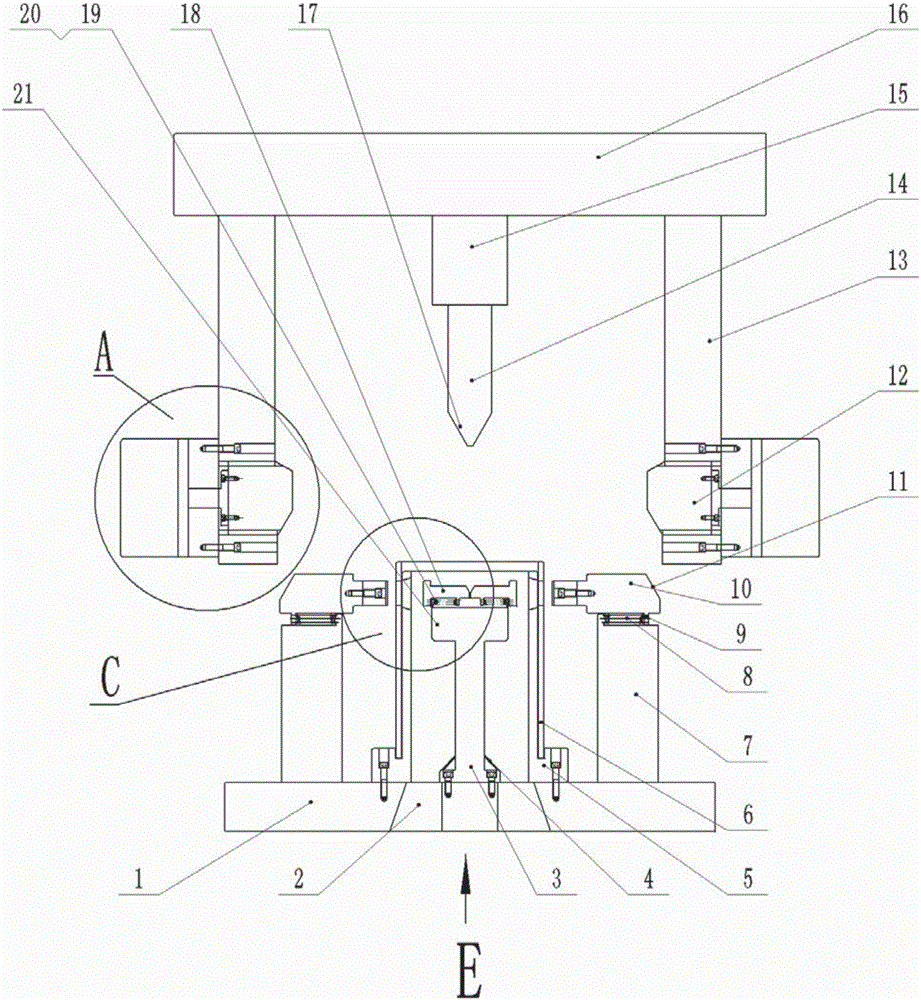

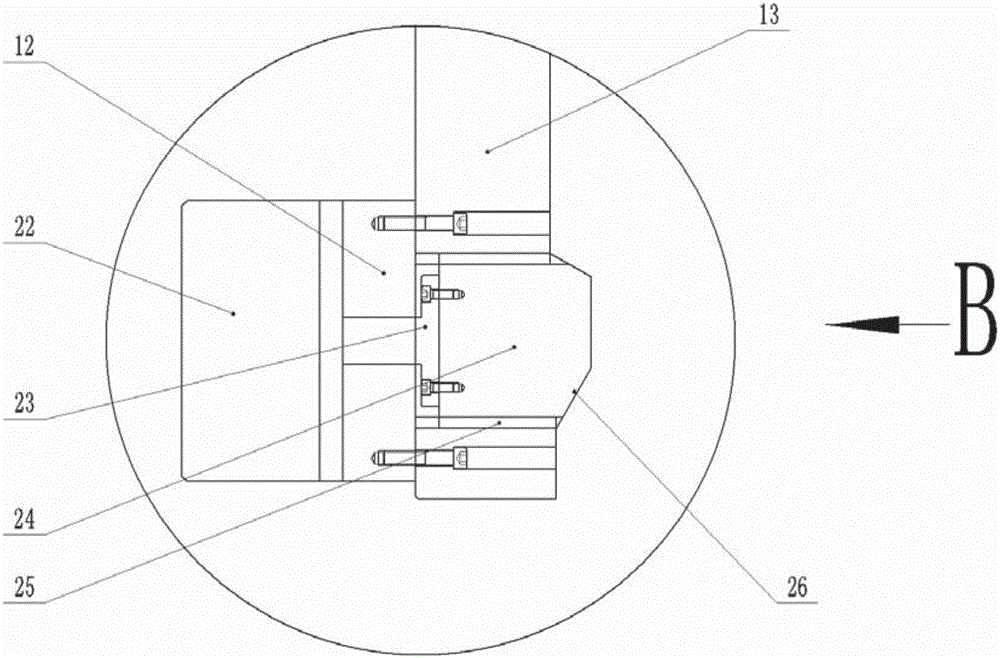

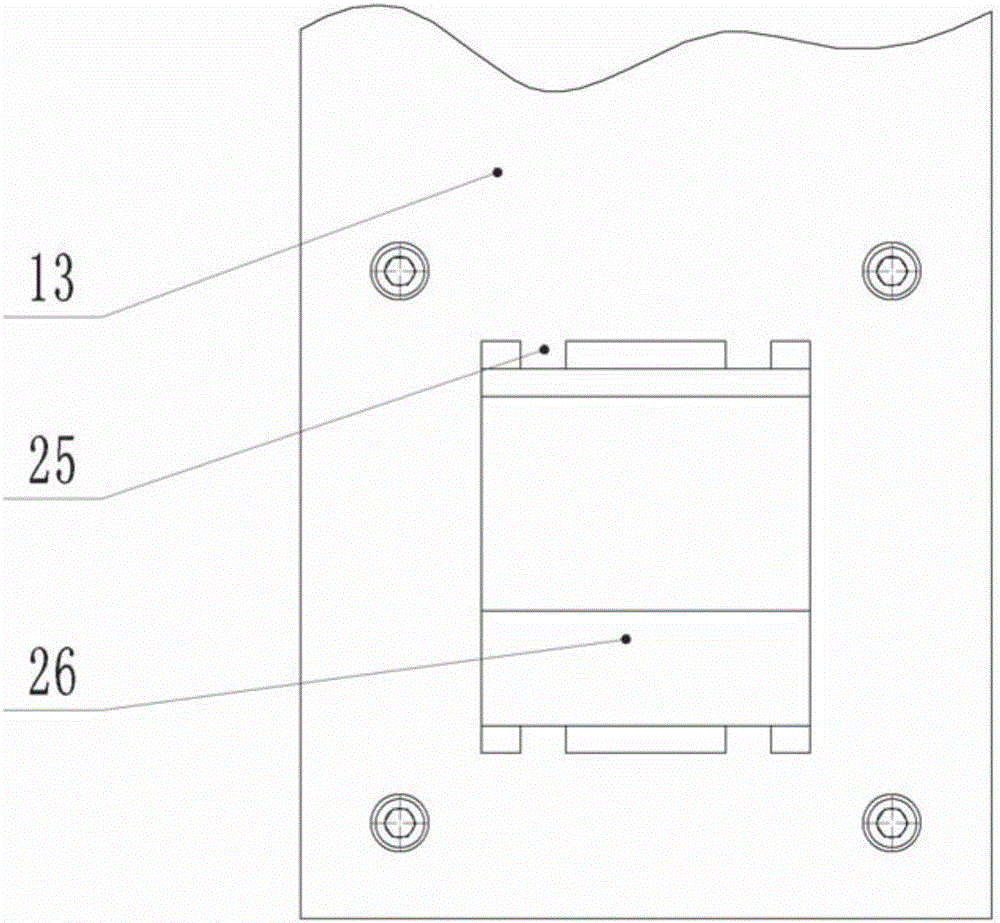

[0035] Such as figure 1 As shown, a casing punching and deburring device described in the embodiment of the present invention includes: the casing seat 5 is a hollow cylinder, the casing seat 5 is fixed on the base 1 by bolts, and the casing 6 is placed on the casing The outside of shell seat 5; The position of the hole 30 of casing seat 5 corresponding casing 6 is processed blanking hole 29, and the waste material after punching falls by blanking hole 29. The bottom of the casing seat 5 is processed with grooves and flanging, so that the bottom of the casing 6 enters the groove, and the casing 6 is positioned. The outer mold 10 is movably connected with the outer mold base 7 through the outer mold dovetail mechanism 9, and the outer mold spring 8 is installed in the middle, so that the outer mold can move and reset in the horizontal direction, and the outer mold base 7 is fixedly connected with the base 1; the thrust mechanism 12 is movably installed At the bottom of the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com