Ultrasonic combined adaptive anti-fatigue precision machining system and method of multi-curvature curved surface

A precision-machined, multi-curvature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

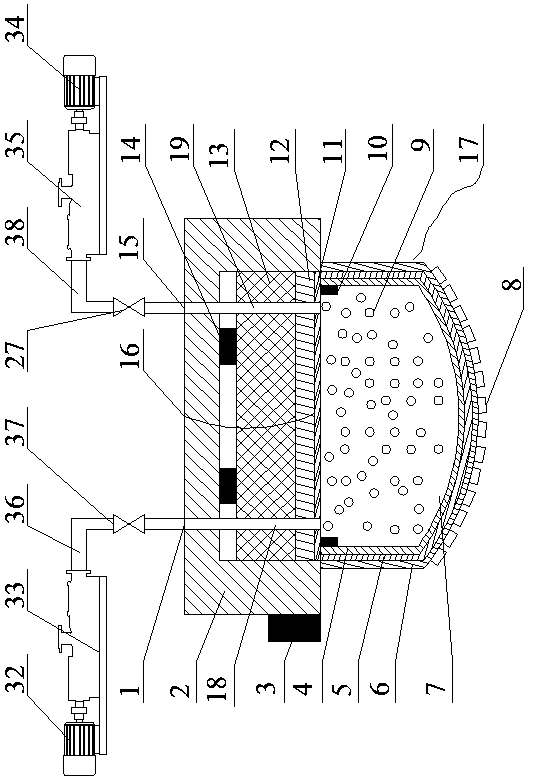

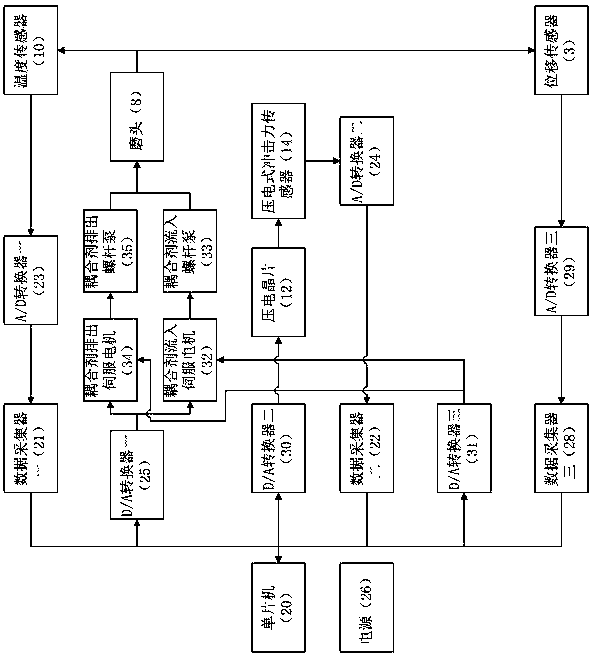

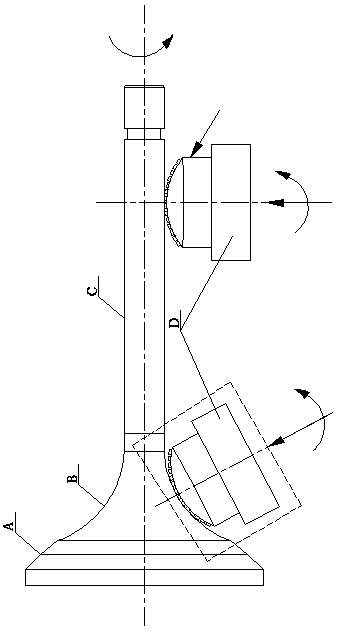

[0052] as attached figure 1 As shown, the multi-curvature surface ultrasonic composite self-adaptive anti-fatigue precision machining system of the present invention has a structure including a flexible grinding head device and a control unit, and the control unit is electrically connected to and controls the flexible grinding head device, the ultrasonic coupling agent circulation structure and the impact The vibration structure, the flexible grinding head device is used to process the multi-curvature surface of the parts, and the control unit is used to control the working state of the flexible grinding head device;

[0053] The flexible grinding head device includes a flexible adjustment box 17, an ultrasonic coupling agent circulation structure and an impact vibration structure. The impact vibration structure is installed in the flexible adjustment box 17. The flexible adjustment box 17 is composed of two parallel sides and an arc-shaped bottom surface. The U-shaped semi-cl...

Embodiment 2

[0057] The ultrasonic composite self-adaptive anti-fatigue precision machining method based on the multi-curvature surface of embodiment 1, the method comprises the following steps:

[0058] (1), turn on the power supply 26, and supply power to the piezoelectric wafer 12 and the single-chip microcomputer 20 through the cable 16;

[0059] (2) After the piezoelectric wafer 12 is energized, it produces longitudinal reciprocating telescopic movement and outputs ultrasonic waves. The energy of the ultrasonic waves is transmitted to the steel ball 9 in the flexible adjustment box 17. The steel ball 9 is formed on the flexible adjustment box 17 and the protective film 11. The high-speed vibration in the cavity of the piezoelectric wafer 12 amplifies the output amplitude to more than 100 microns;

[0060] (3) At the same time, the couplant flows into the servo motor 32 and the couplant flows into the screw pump 33, and the ultrasonic couplant 7 enters the flexible adjustment box 17 an...

Embodiment 3

[0067] The invention takes the engine valve (the material is the nickel-based superalloy Inconel751), which is a key component with a typical multi-curvature complex surface, as the processing object. The invention can improve the precision machining efficiency and fatigue strength of the valve. Based on the flexible grinding head polishing technology Combined with ultrasonic vibration strengthening technology to develop anti-fatigue self-adaptive precision machining technology for complex curved surfaces, conduct research on the material removal mechanism and the formation mechanism of the machined surface under the synergistic effect of ultrasonic vibration and flexible grinding, and reveal the strengthening mechanism of the surface; From the anti-fatigue performance of the surface after anti-fatigue precision machining, a bridge is built between the processing technology and the service performance of the surface and even the fatigue life. The invention can solve the common ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com