Method for polishing automobile hubs and device

A technology of automobile wheel hub and polishing device, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding machines, etc., can solve the problems of inconsistent surface effect, polishing quality defects, harmful health and other problems, so as to save labor and shorten polishing time. , The effect of convenient control of the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

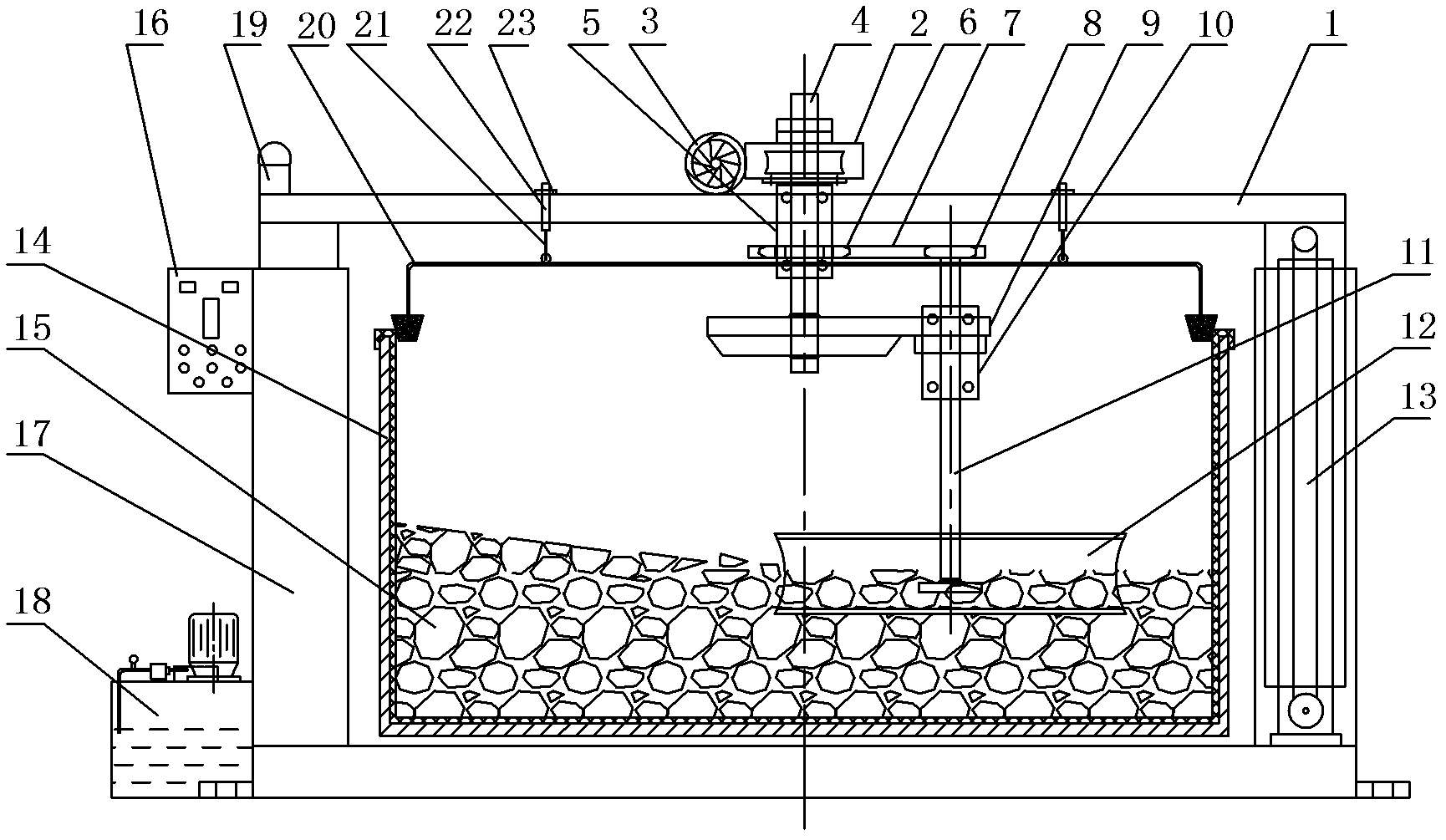

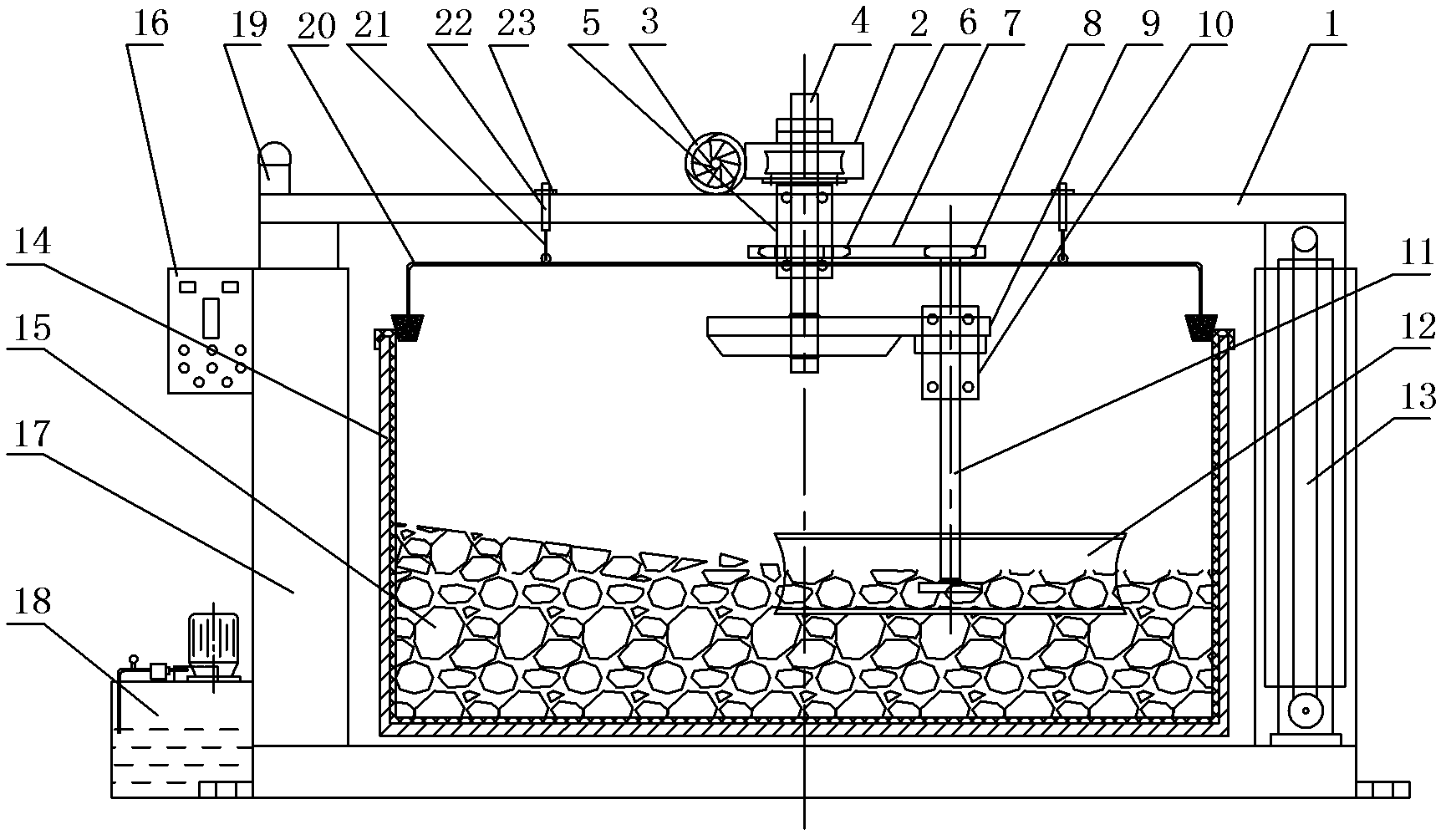

[0026] Example. A kind of automobile wheel hub polishing method, comprises the following steps successively:

[0027] ①Use the rotating device to drive the car hub to rotate and put it into the polishing device, and then let the car hub revolve around the rotating device;

[0028] ② Make the first rough polishing of the car wheel hub that rotates and revolves around the rotating device and the rough polishing abrasive;

[0029] ③ Carry out the second fine polishing with the fine polishing abrasives of the automobile wheel hub that rotates and revolves around the rotating device;

[0030] ④ Carry out the third bright polishing with the bright polishing abrasive on the automobile wheel hub which rotates and revolves around the rotating device.

[0031] The rotation speed of the automobile hub in the step ① is 90-100r / min, preferably 94r / min.

[0032] The rotation speed of the automobile hub in the steps ②, ③ and ④ is 50-60r / min, preferably 54r / min.

[0033] The revolution sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com