Patents

Literature

160results about How to "Guaranteed polishing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

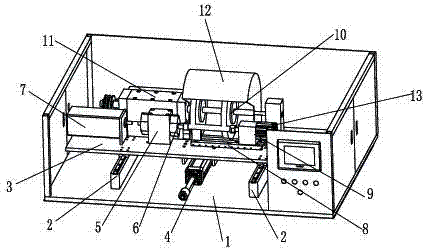

Capsule processing device

The invention discloses a capsule processing device. The capsule processing device comprises a feeding mechanism, a dust removal mechanism and a polishing split charging mechanism, wherein the feeding mechanism comprises a machine body, a supporting rod, a feeding box, a mesh screen, a discharging plate and a discharging disc, the dust removal mechanism is connected with the feeding box through a first air pipe, a medium-efficiency filter is installed in the dust removal mechanism, a dust removal fan is installed on the medium-efficiency filter, the discharging disc is provided with a sealing cover, a plurality of ultraviolet lamp tubes are installed in the sealing cover, the polishing split charging mechanism comprises a shell, a screen barrel, a control chamber, a separating device, a loading bottle, a slide plate, a fixed seat, a hydraulic system and a supporting frame. By adopting the capsule processing device, capsules can be directly bottled in a split charging manner after being polished, the counting accuracy is high, the production efficiency of the capsules is greatly improved, dust on the surfaces of the capsules can be cleaned, and the quality of the capsules can be improved.

Owner:ZHEJIANG YUEXI CAPSULE

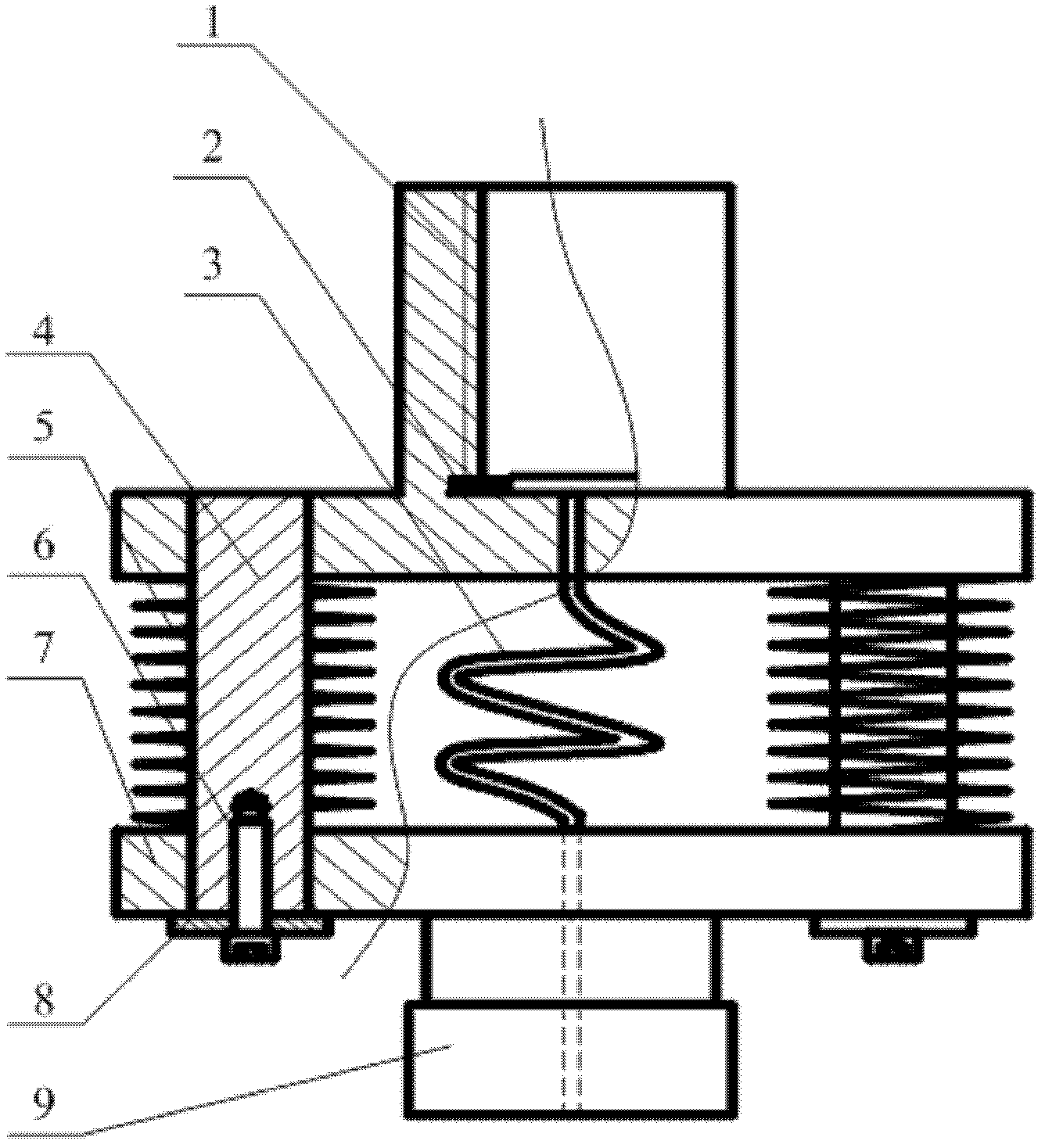

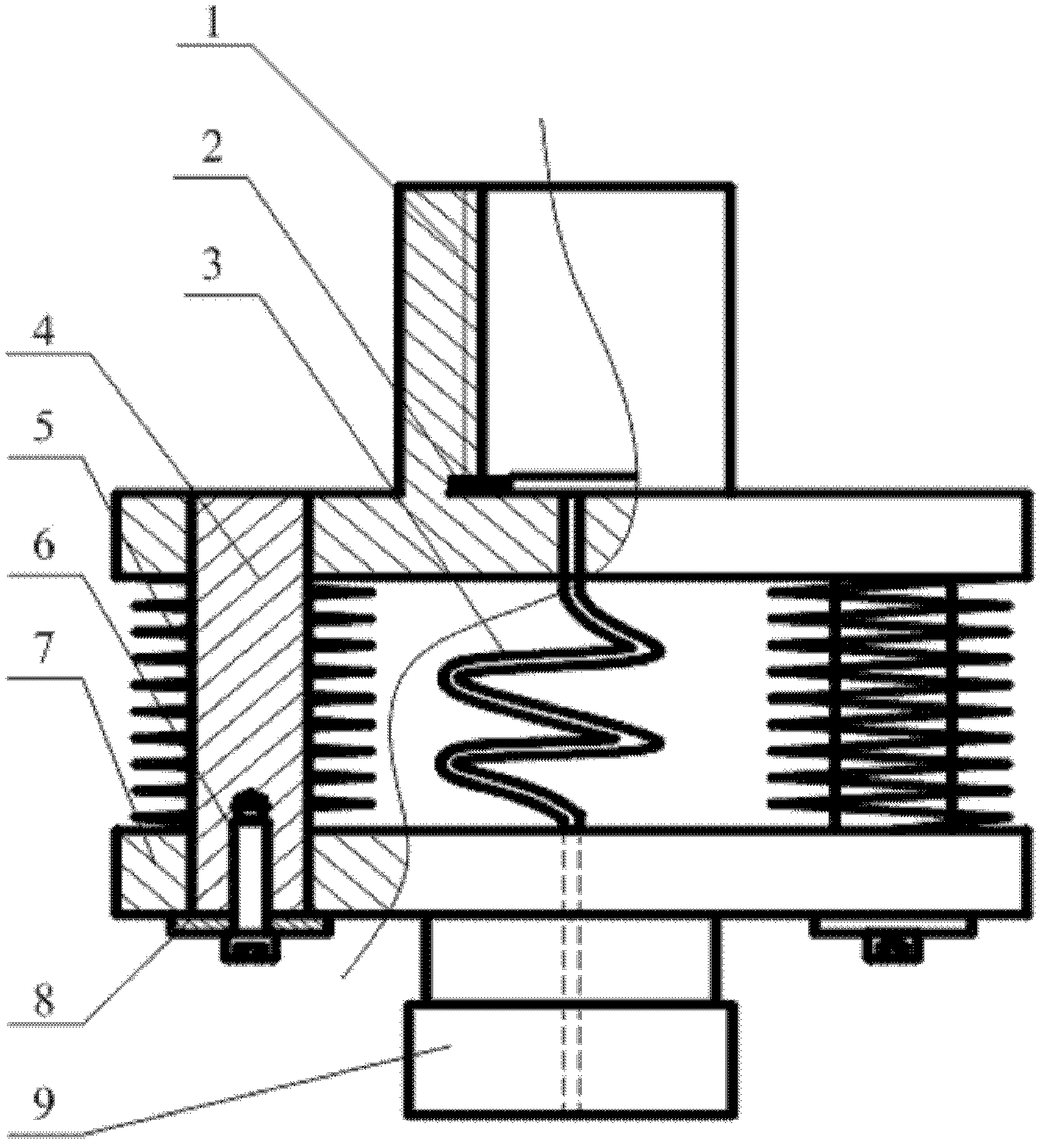

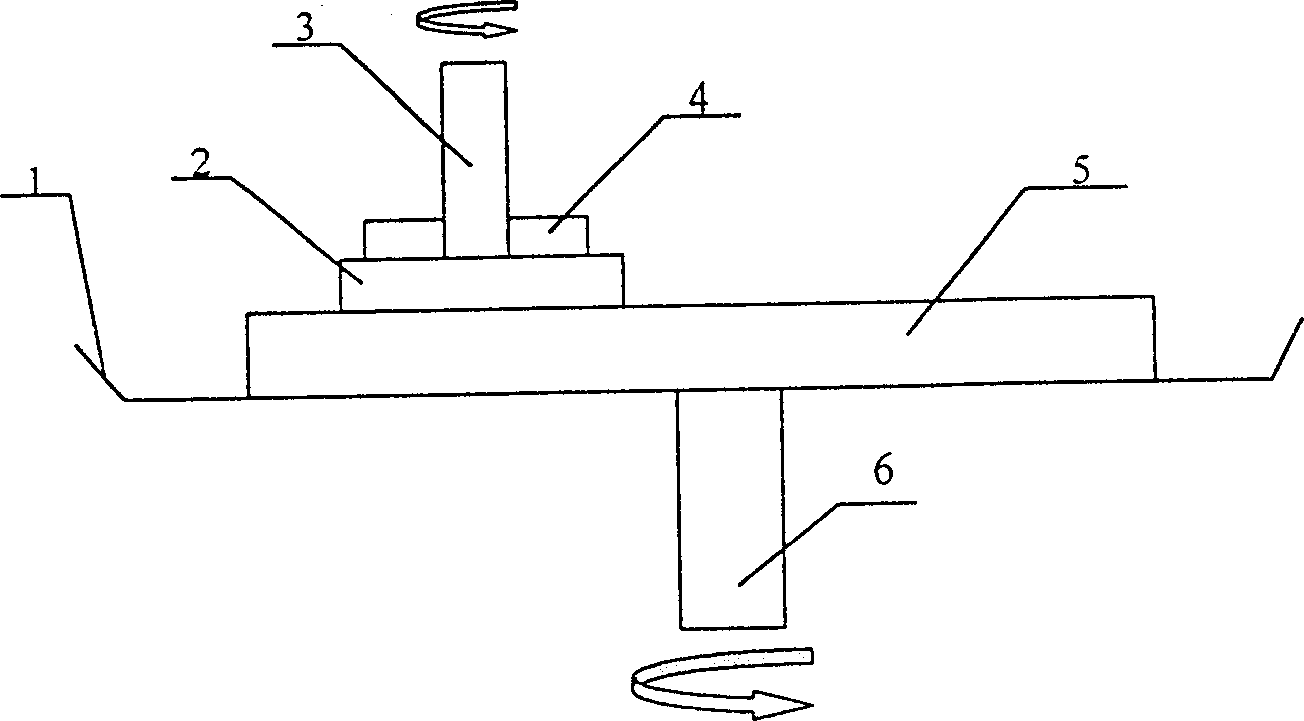

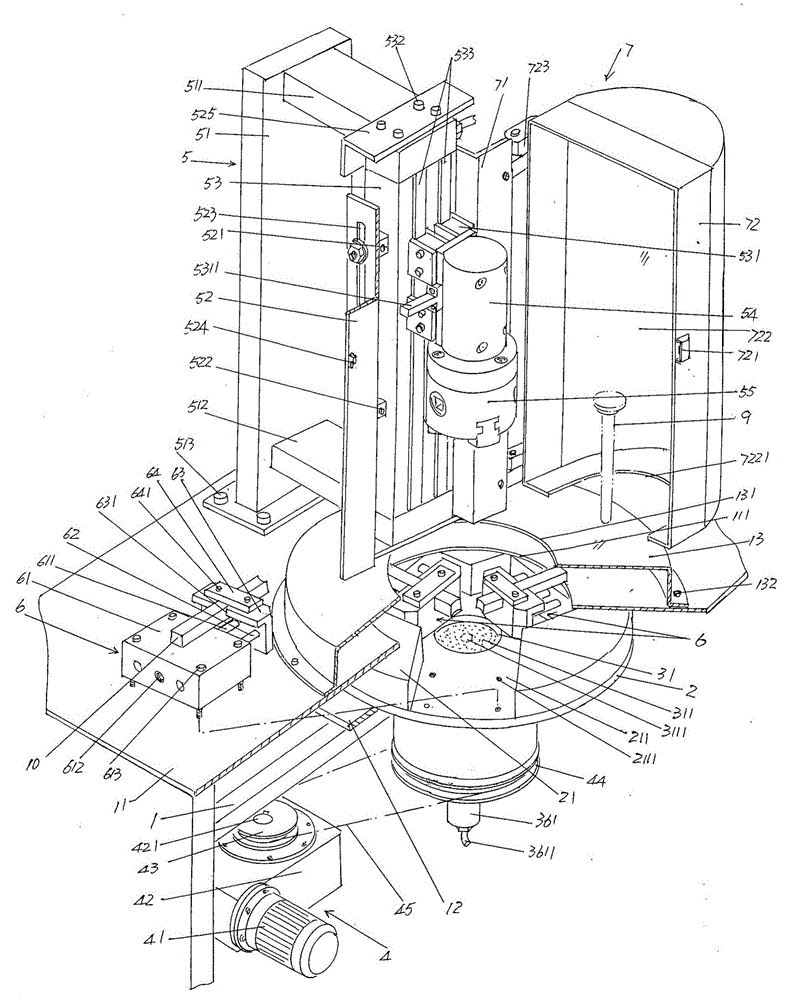

Gap self-adaptive polishing grinding head

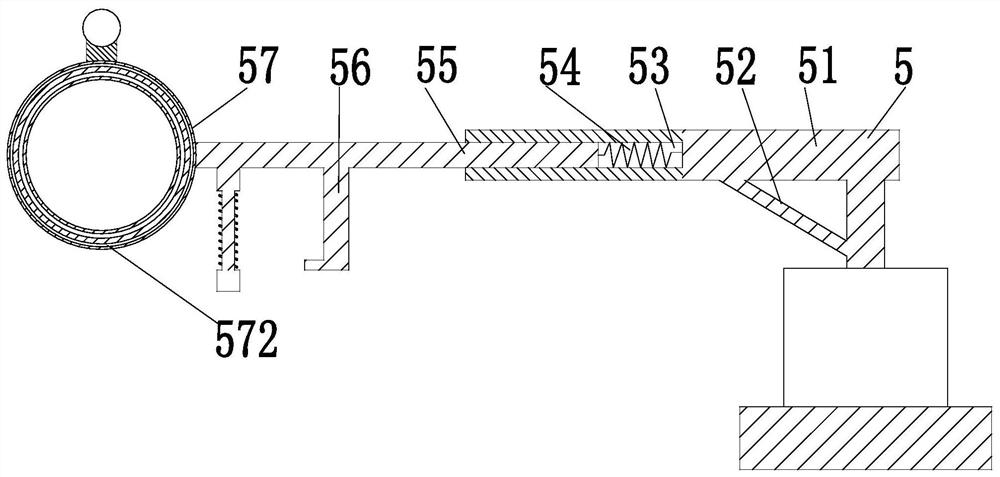

InactiveCN102513927AGuaranteed polishing qualityQuality assuranceGrinding machine componentsSelf adaptiveEngineering

The invention discloses a gap self-adaptive polishing grinding head, which belongs to a polishing grinding head involved in the optics cold processing field, and aims at solving the problem when the present grinding head is used for polishing, the polishing liquid is non-uniform and a gap between the grinding head and a work-piece is overlarge. The gap self-adaptive polishing grinding head comprises a connection element, a gasket ring, a flexible helical pipe, a guide column, a spring, a retainer ring, a grinding head seat and a grinding head body. The gap self-adaptive polishing grinding head can be connected with a machine tool, the polishing liquid flows into the grinding head through an inner hole of a machine tool main shaft and is continuously supplied to the grinding head body through the flexible helical pipe. When in polishing, the grinding head body is firstly used for pressing the surface of the work-piece, so the spring is slightly compressed, when the surface of the work-piece is fluctuated or error appears in the installation and positioning, and the grinding head body can move from top to bottom along the guide column so as to automatically compensate the gap and to guarantee the polishing quality.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

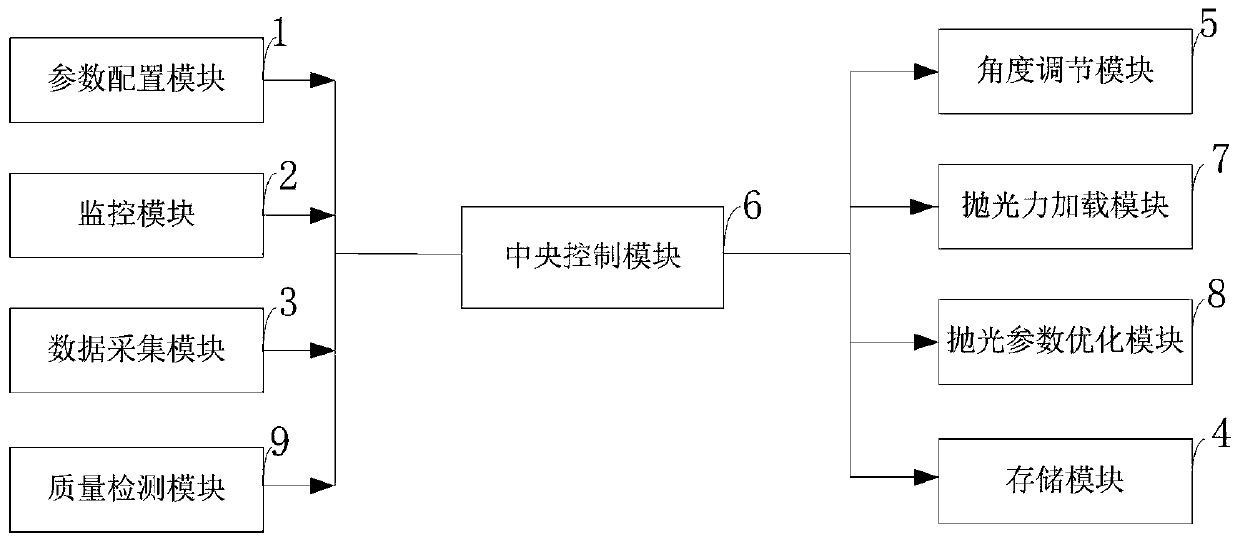

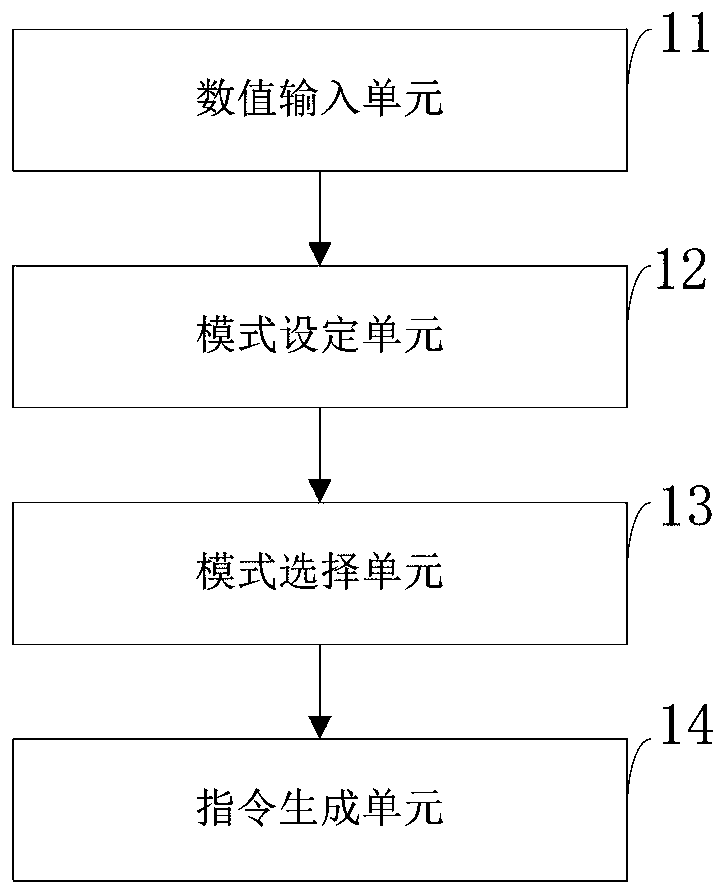

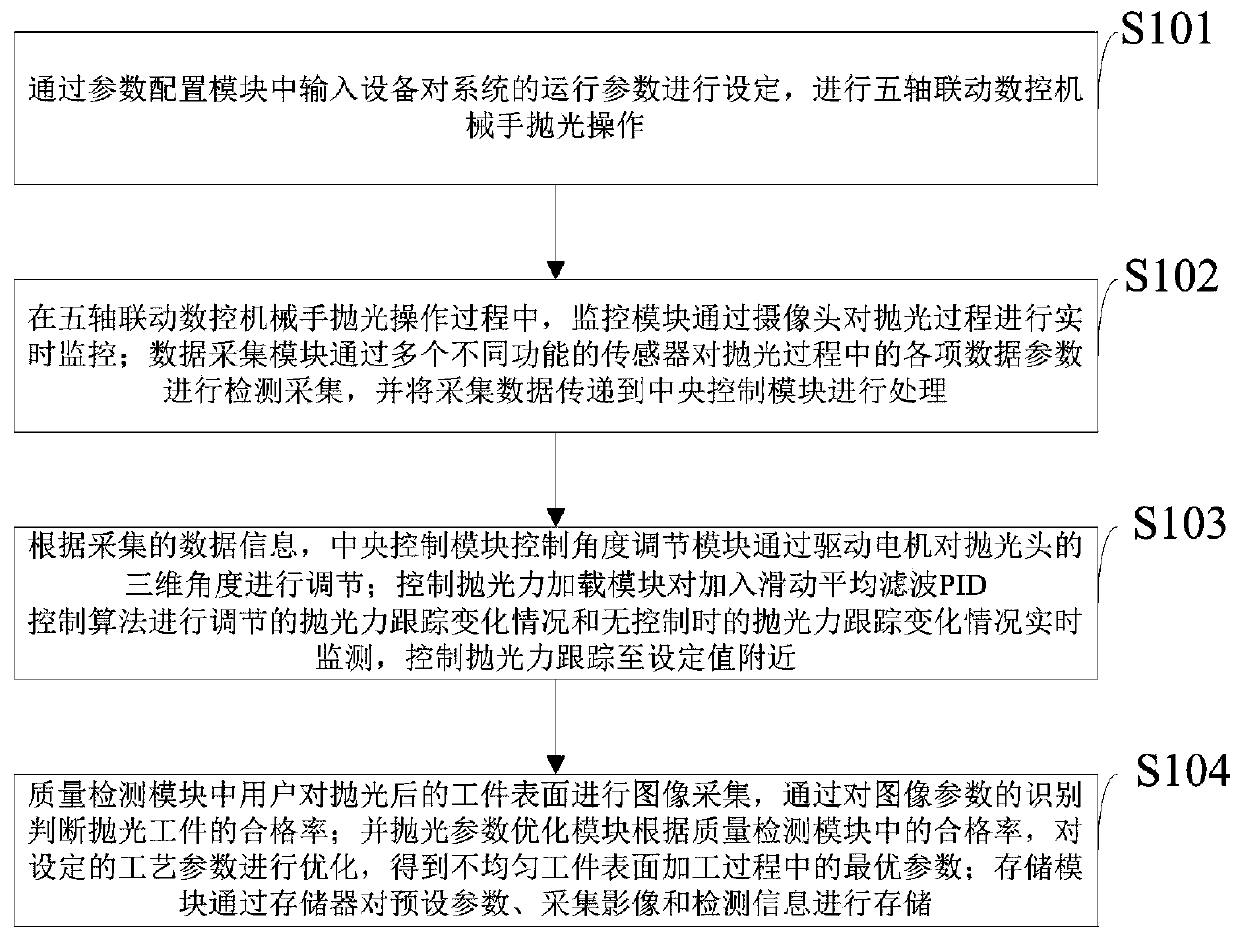

Five-axis linkage numerical control manipulator polishing control system and method

InactiveCN111468989AOptimizing Process ParametersAccurate and fast variable polishing force controlPolishing machinesAutomatic grinding controlNumerical controlControl system

The invention belongs to the technical field of machining, and discloses a five-axis linkage numerical control manipulator polishing control system and method. The five-axis linkage numerical controlmanipulator polishing control system comprises a parameter configuration module, a monitoring module, a data acquisition module, a storage module, an angle adjustment module, a central control module,a polishing force pneumatic loading module, a polishing parameter optimization module and a quality detection module. The parameter configuration module comprises a numerical value input unit, a modesetting unit, a mode selection unit and an instruction generation unit. The monitoring module monitors the polishing process in real time through a camera. The data acquisition module detects and acquires various data and parameters in the polishing process through a plurality of sensors with different functions. According to the five-axis linkage numerical control manipulator polishing control system and method, accurate and rapid tracking variable polishing force control can be achieved in the polishing process, the corresponding polishing force is controlled in real time, and the force control requirement of polishing machining can be effectively met; and on the premise that the polishing quality is guaranteed, the working efficiency is improved.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

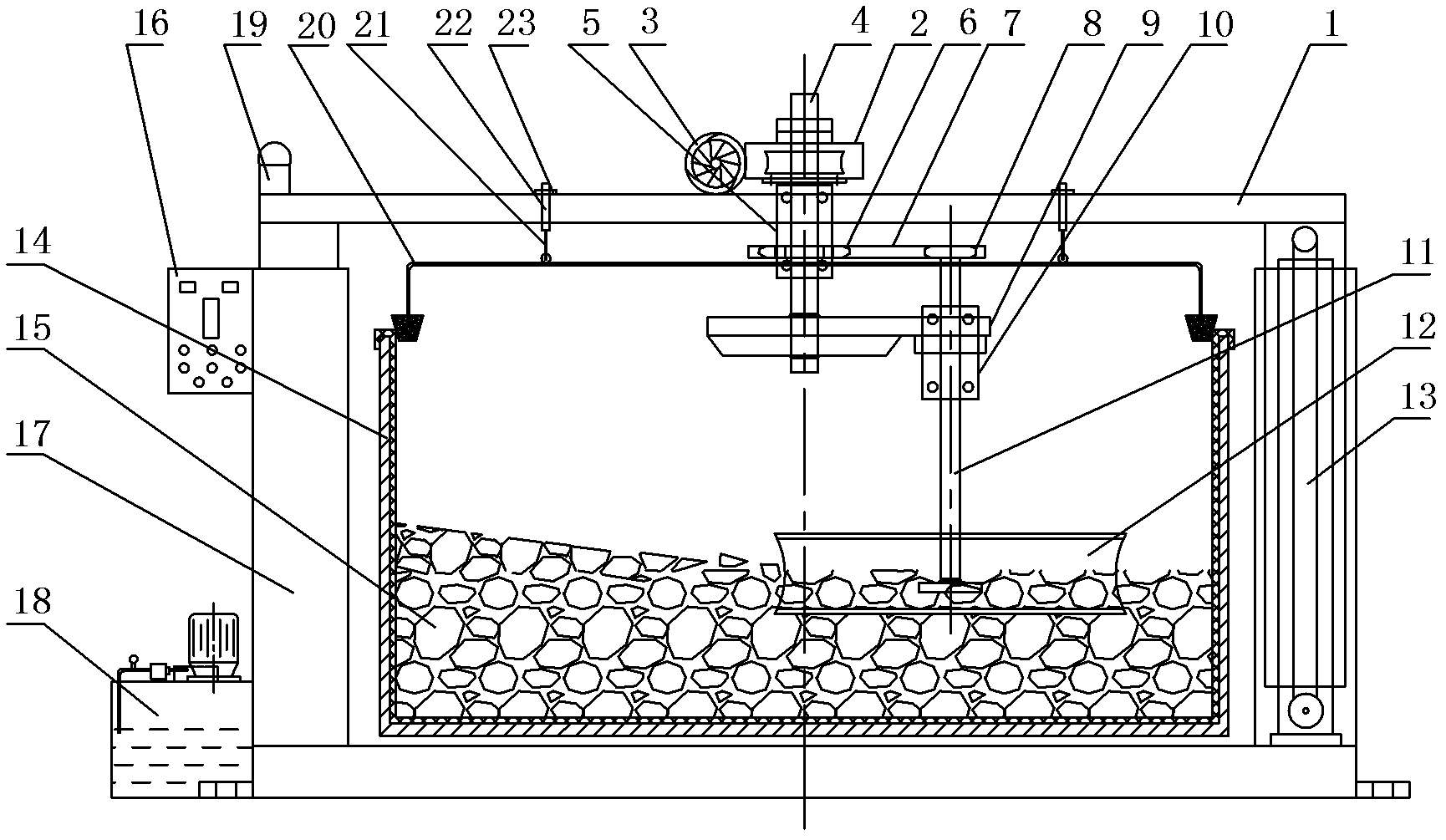

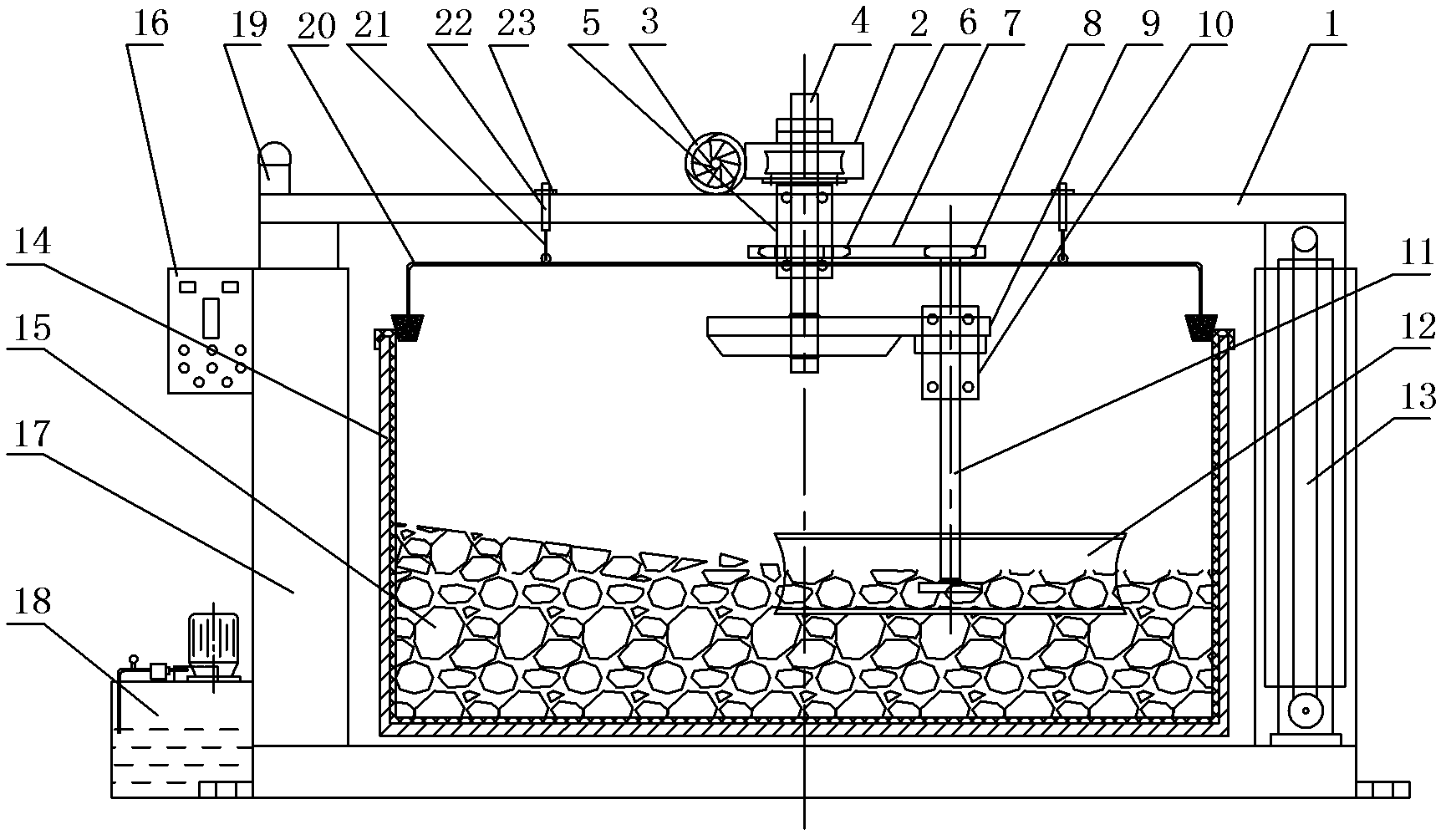

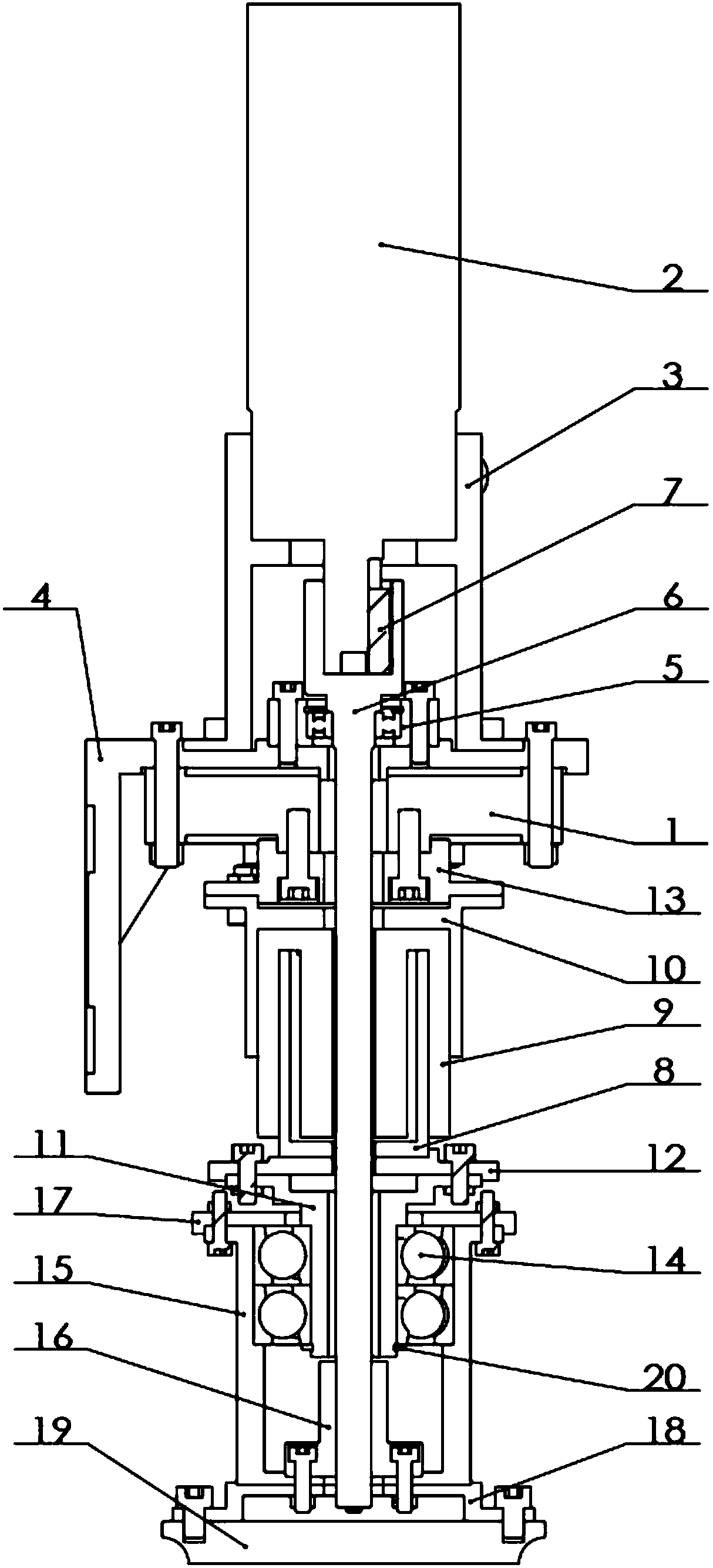

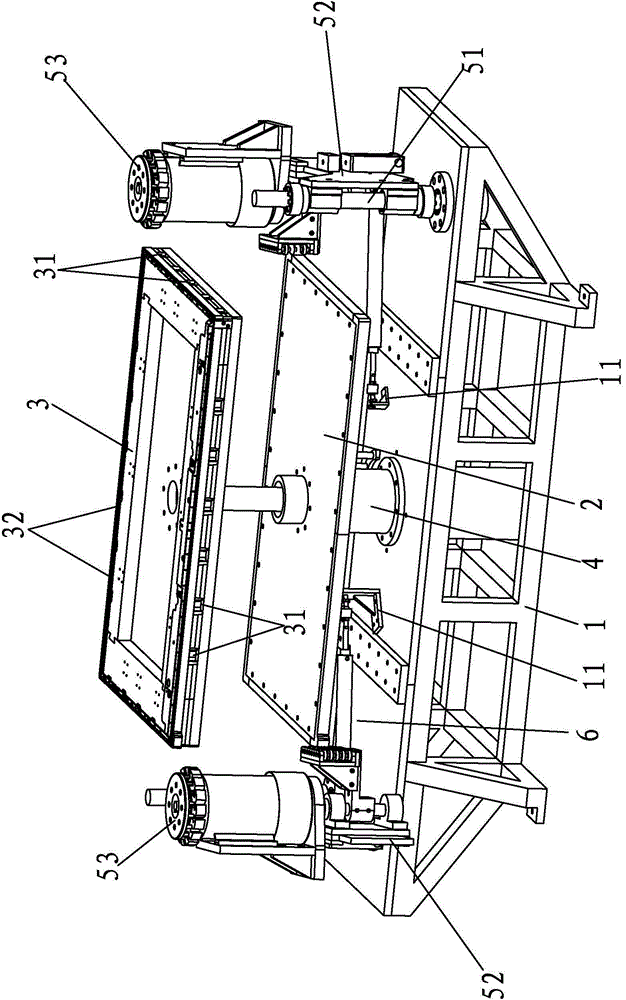

Method for polishing automobile hubs and device

ActiveCN102554752ASmooth rotationStable and safe rotationEdge grinding machinesPolishing machinesHydraulic cylinderAdhesive

The invention discloses a method for polishing automobile hubs and a device. The method for polishing automobile hubs sequentially includes steps of 1, driving an automobile hub to rotate by a rotating device, placing the automobile hub into a polishing device and then leading the automobile hub to realize revolution around the rotating device; 2, roughly polishing the automobile hub which rotates and realizes revolution around the rotating device and rough polishing abrasive materials for the first time; 3, finely polishing the automobile hub which rotates and realizes revolution around the rotating device and fine polishing abrasive materials for the second time; and brilliantly polishing the automobile hub which rotates and realizes revolution around the rotating device and brilliant polishing abrasive materials for the third time. The polishing device comprises a polishing cylinder with a lining made of PU (polyurethane) adhesive, a hydraulic cylinder is disposed on one side of the polishing cylinder, a portal frame is disposed on the upper portion of the hydraulic cylinder, the rotating device used for driving the automobile hub to rotate is arranged on the portal frame, an adjusting screw stem provided with an adjusting nut is disposed on the portal frame, and a suspension cover which is placed above the polishing cylinder is connected onto the adjusting screw stem by an iron chain. By the aid of the method for polishing automobile hubs and the device, polishing efficiency can be improved, labor cost is lowered, a polishing effect is guaranteed, and the device is simple in structure and low in manufacturing cost.

Owner:湖州中云机械制造股份有限公司

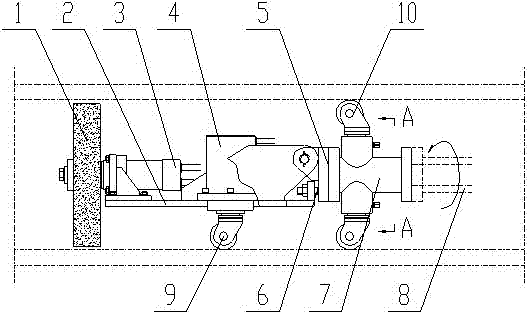

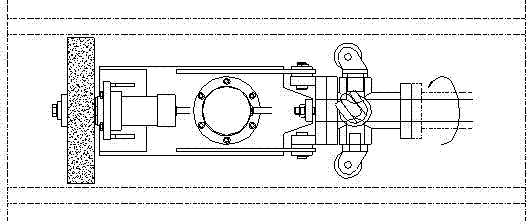

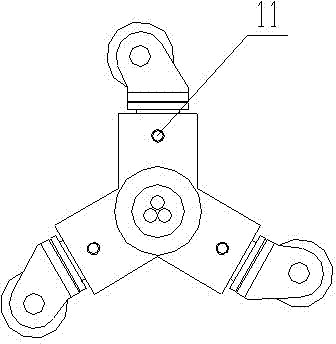

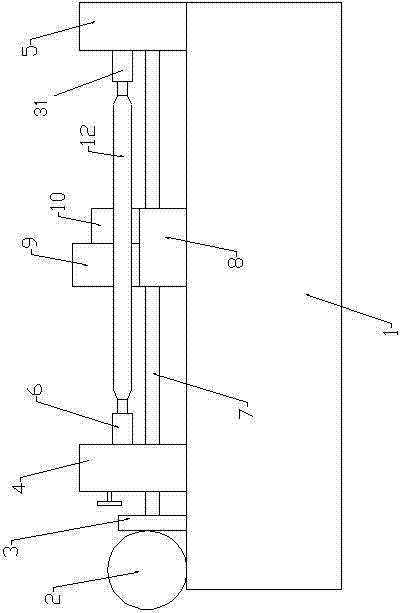

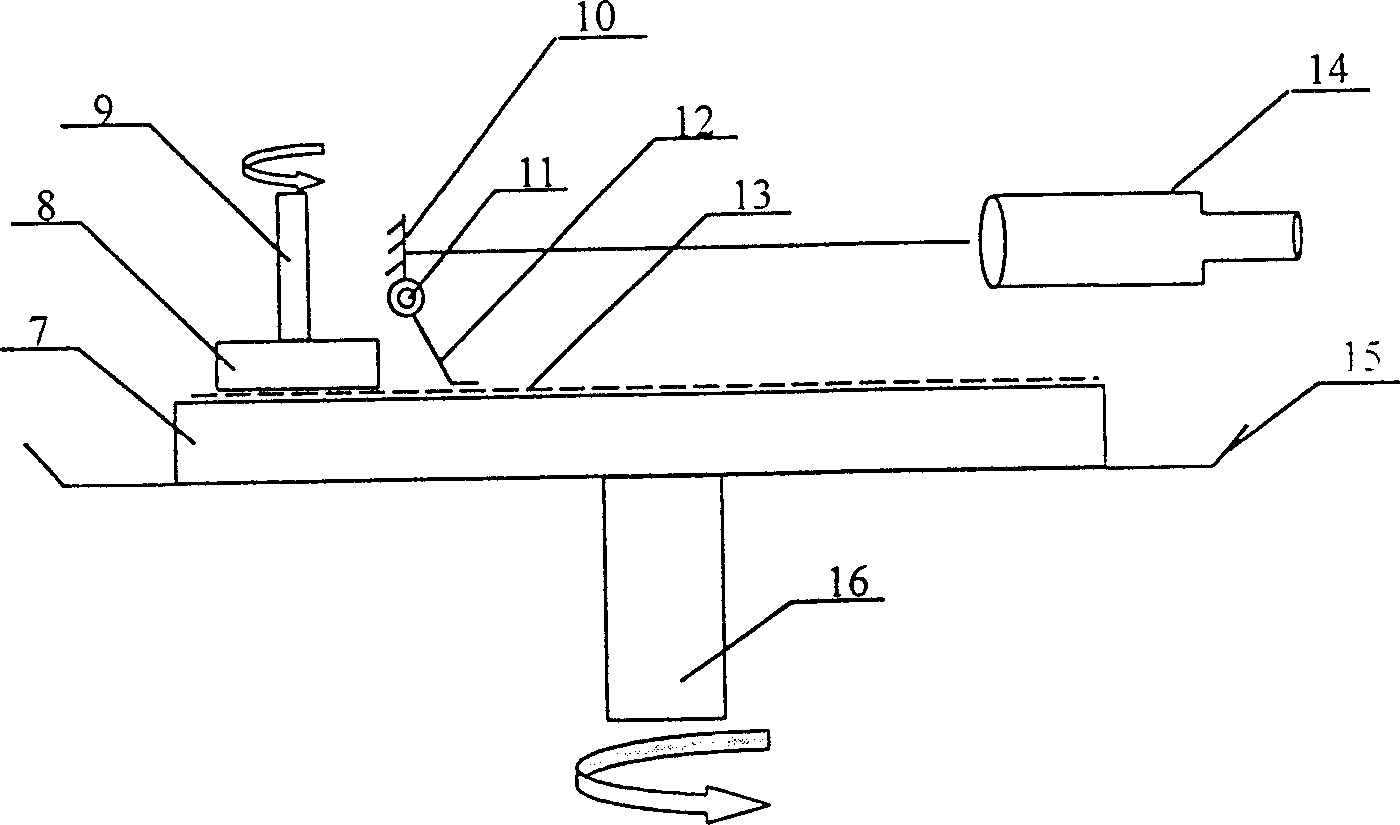

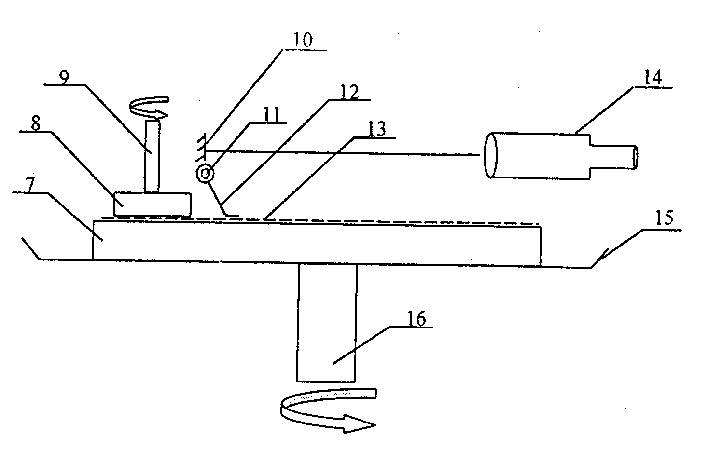

Pipe inner wall grinding and polishing device

InactiveCN103506903AControl the pressing forceImprove work efficiencyRevolution surface grinding machinesEngineeringGrinding wheel

The invention relates to a pipe inner wall grinding and polishing device. The pipe inner wall grinding and polishing device comprises a drawing rod (8), wherein a centering bracket (7) is arranged at the front end of the drawing rod (8); three second adjustable wheels (10) are arranged at the periphery of the centering bracket (7) uniformly; a bracket seat (5) is arranged on the centering bracket (7); the front end of the bracket seat (5) is hinged to a swinging bracket (2); a power part (3) is arranged at the front end of the swinging bracket (2); a grinding wheel (1) is arranged at the output end of the power part (3); a jacking part (4) is arranged in the middle of the swinging bracket (2); a first adjustable wheel (9) is arranged at the output end of the jacking part (4); a swinging bracket swinging angle limiter (6) is fixedly arranged at the rear end of the swinging bracket (2). The pipe inner wall grinding and polishing device provided by the invention improves the grinding or polishing efficiency and can effectively control the pressing force to the pipe inner wall so as to guarantee the final grinding or polishing quality.

Owner:江苏乐基重工机械有限公司

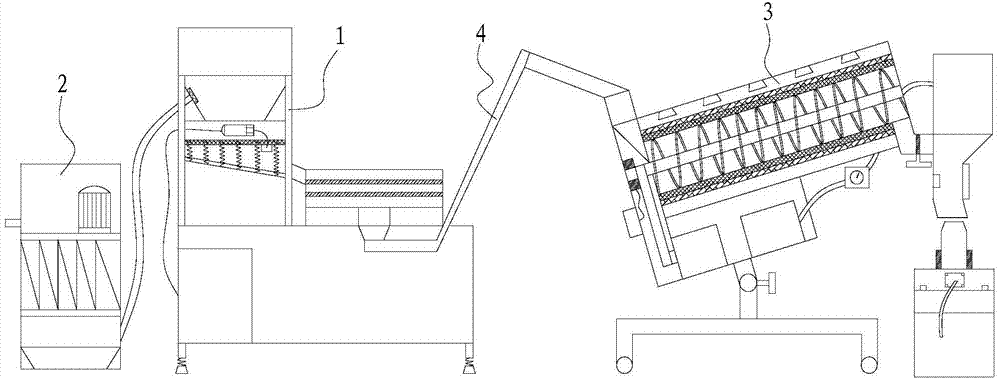

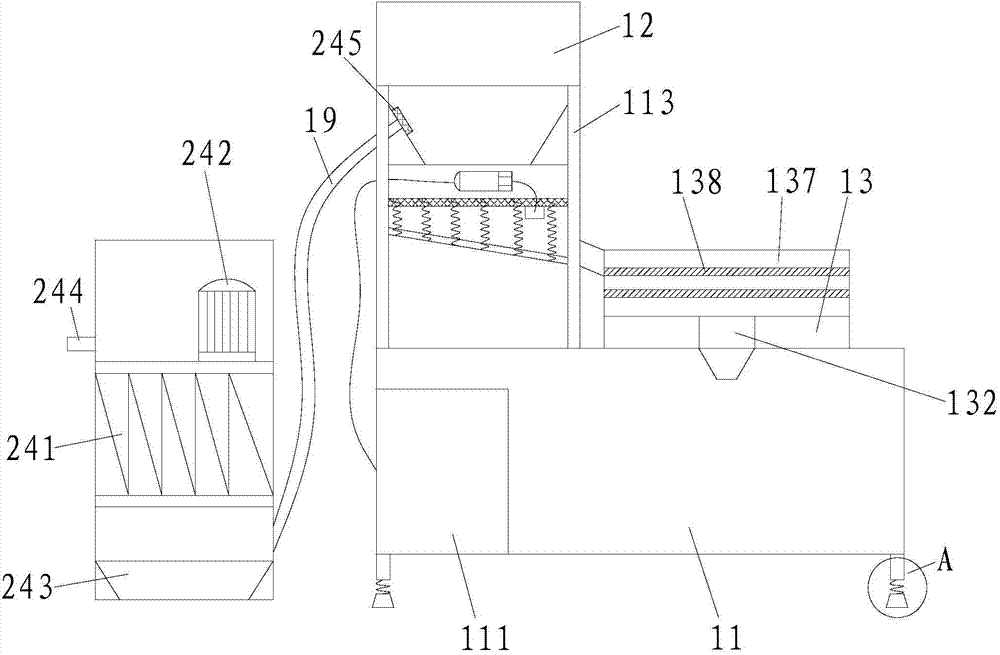

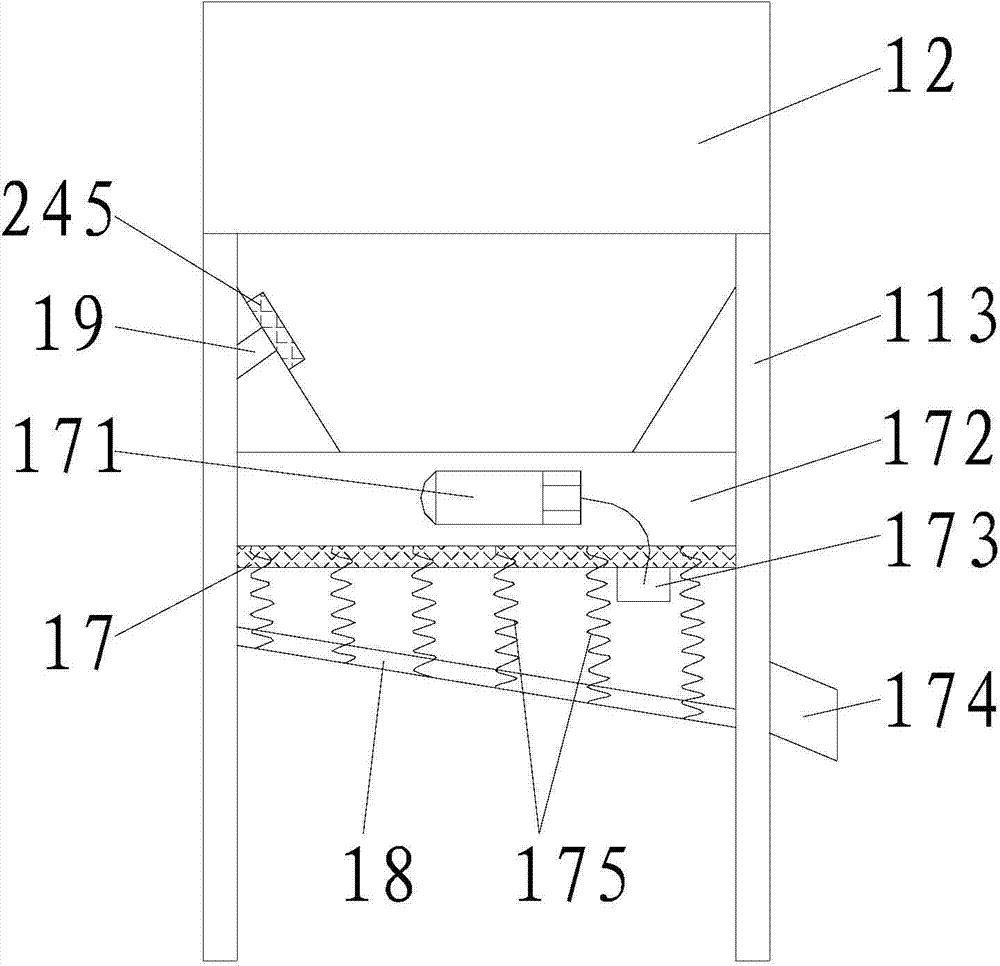

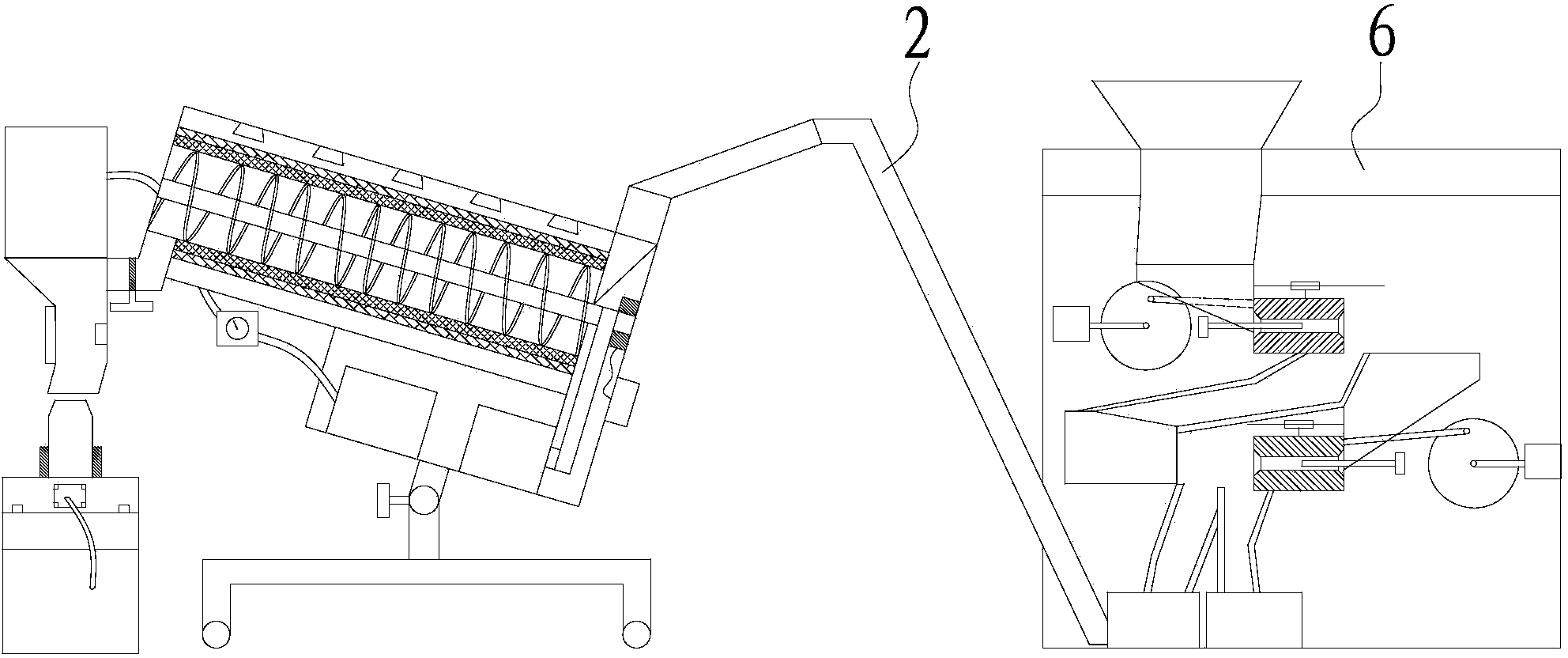

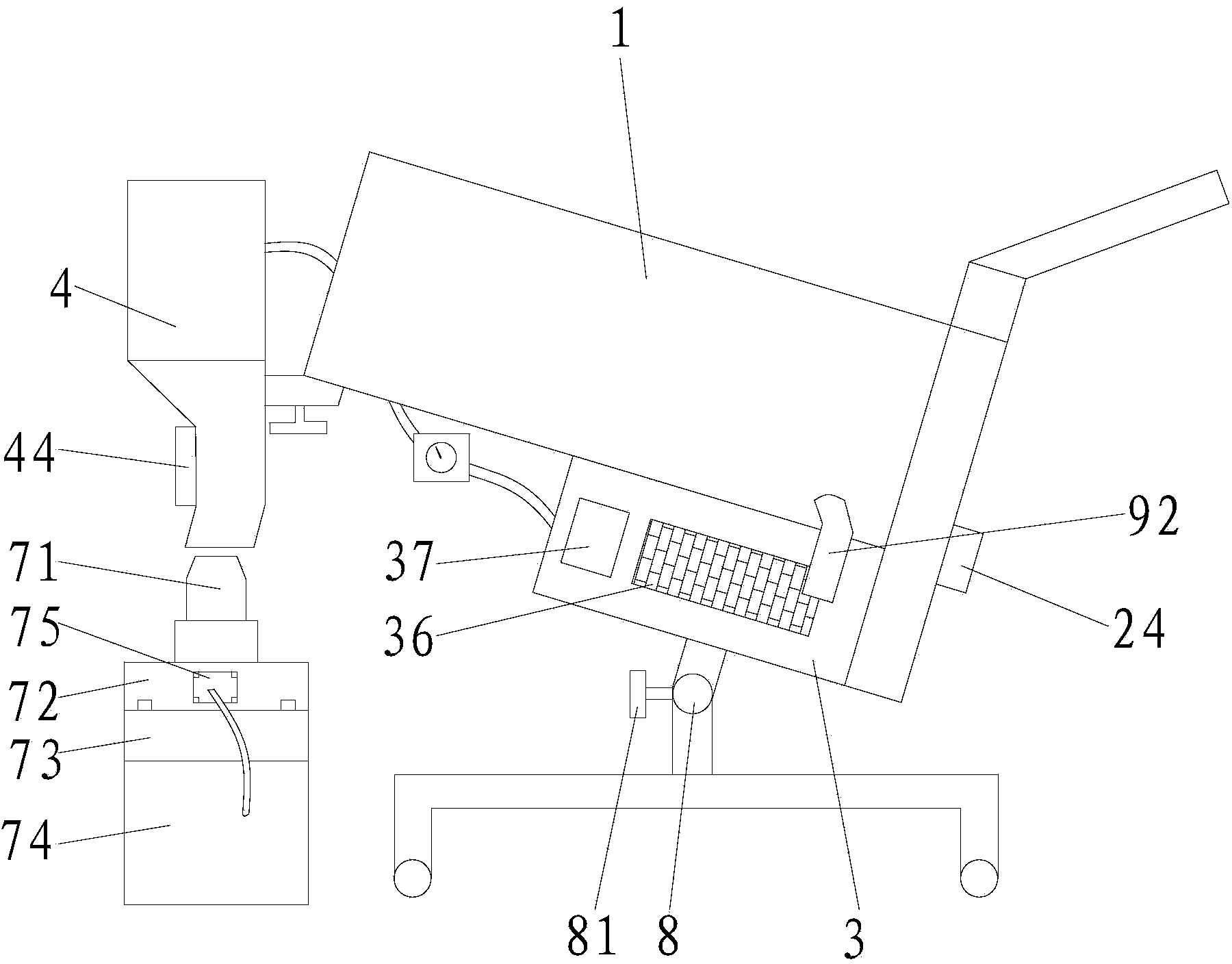

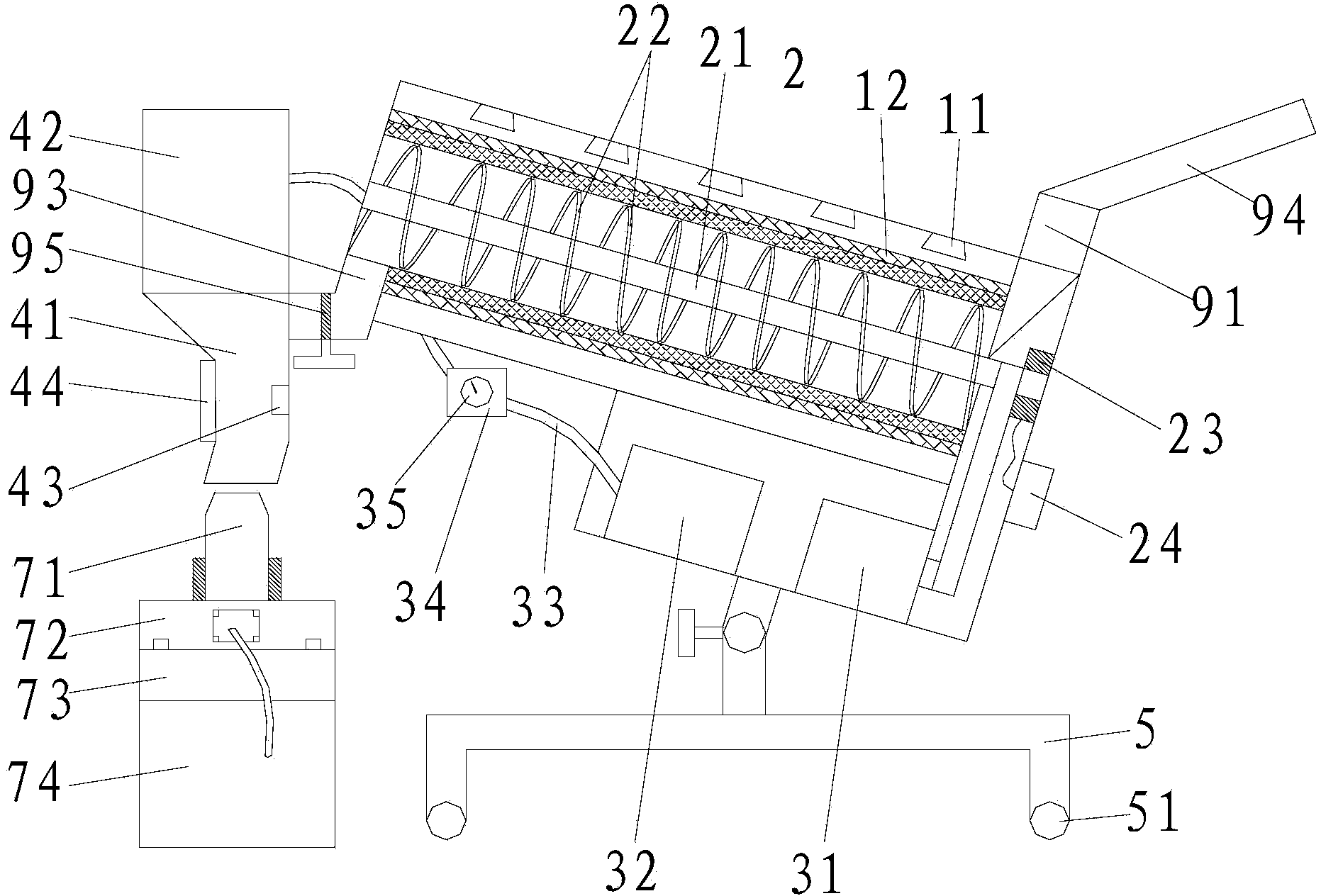

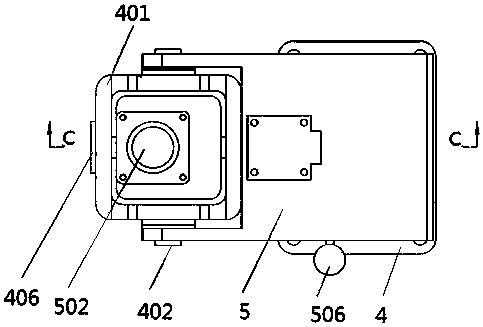

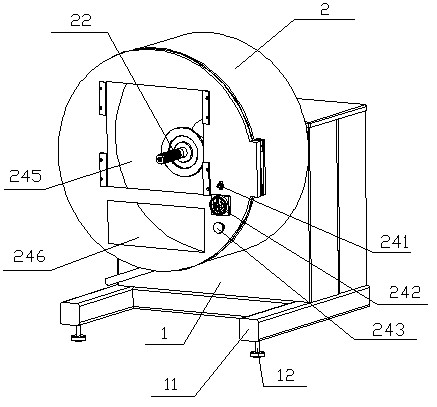

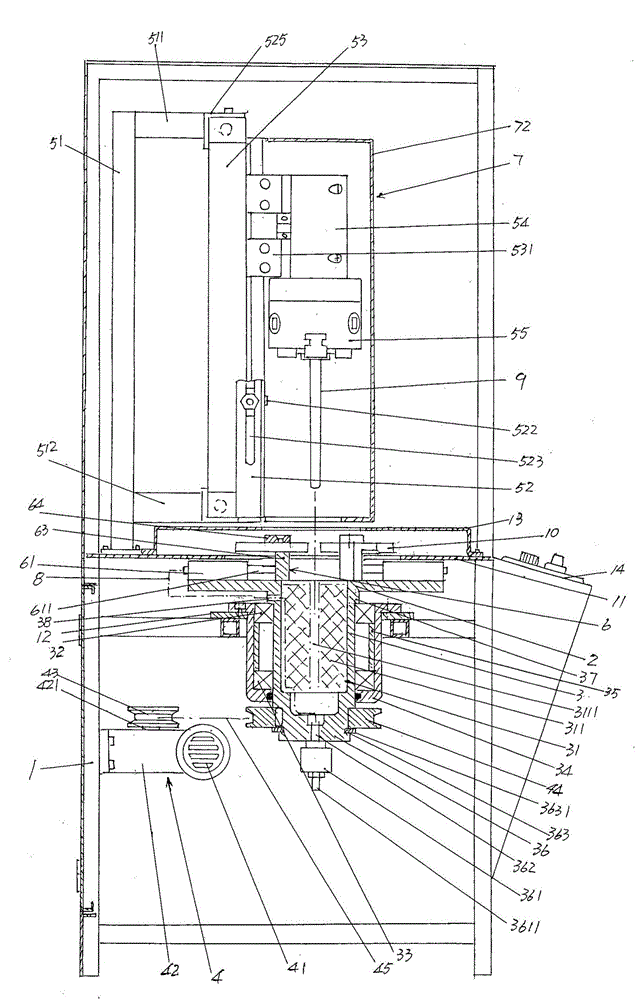

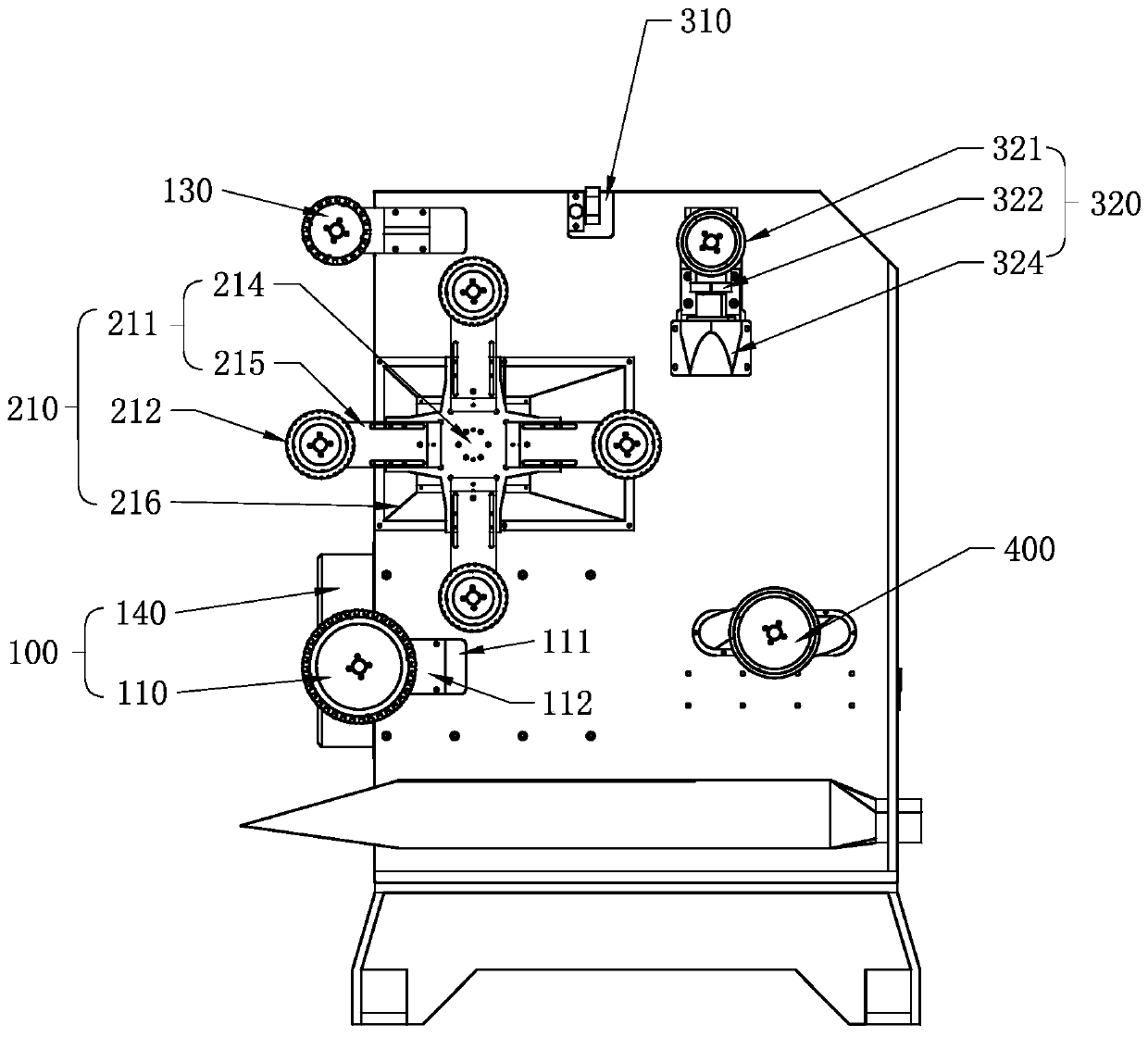

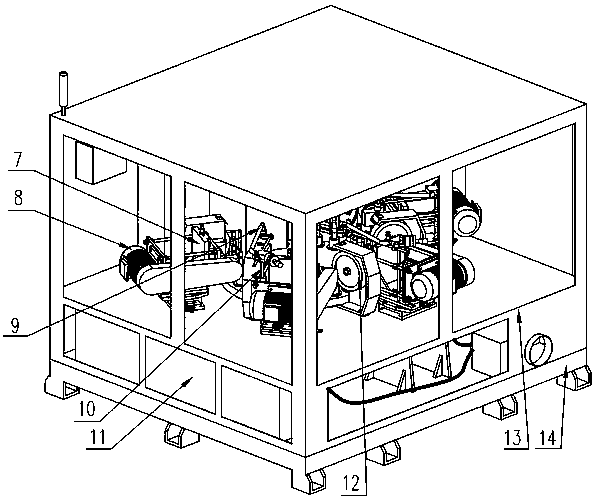

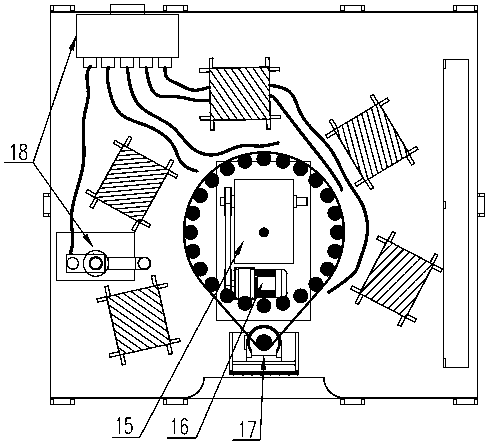

A device for screening and polishing capsules

ActiveCN104386270AAchieve accurate separation and screeningRealize the action control of each cylinder to ensure accurate separation and screeningSievingPolishing machinesEngineeringSlide plate

The invention discloses a device for screening and polishing capsules. The device comprises a screening device, a lifting mechanism and a polishing device. The screening device comprises a rack, a left eccentric wheel, an A-capsule screening plate and a B-capsule screening plate. The polishing device comprises a shell, a screen drum, a control cabin, a sorting device, a loading bottle, a sliding plate, a fixing seat, a hydraulic system and a support frame. One end of the shell is provided with a feed port and a vacuum suction port. The other end of the shell is provided with a discharge port. A rotating shaft is installed within the screen drum. A hair brush is installed on the rotating shaft in a spiral way. A motor and an air compressor are arranged in the control cabin. The motor is connected with the rotating shaft. The sorting device is arranged on the discharge port. A discharge valve is installed on the discharge port. A finished product hopper is connected with a feed chute through the lifting mechanism. The device of the invention can screen the sleeved finished product capsules from the un-sleeved capsules, and can polish the screened capsules.

Owner:ZHEJIANG YUEXI CAPSULE

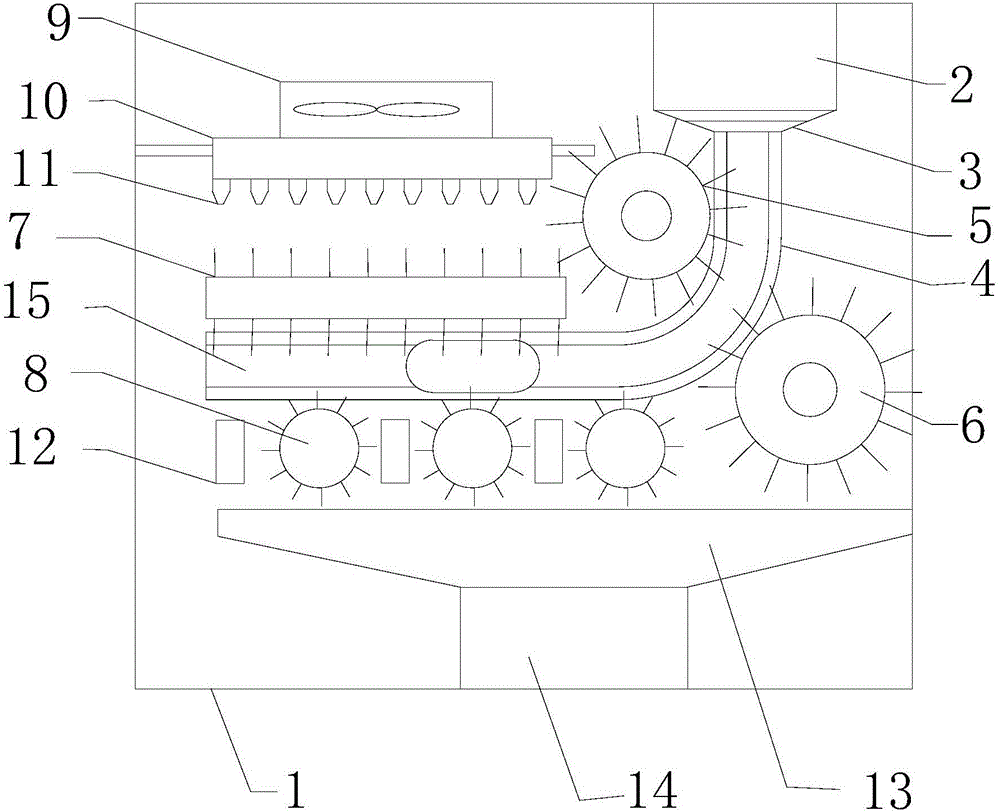

Capsule polishing and conveying device

InactiveCN106363512AOrderly rowsRemove in timePolishing machinesGrinding/polishing safety devicesSpray nozzleEngineering

The invention discloses a capsule polishing and conveying device. The capsule polishing and conveying device comprises a rack, a discharging groove, a vibration discharging device, capsule conveying guide rails, an auxiliary discharging brush roller, an auxiliary transition brush roller, a rotary brush roller, feeding brush rollers, an ion blower, an air blowing plate, air gathering spraying nozzles, observation electric eyes, a dust collection hopper and a dust collection motor. By means of the capsule polishing and conveying device, capsules can be synchronously polished in the conveying process, the polishing faces are even, the polishing efficiency is high, the polished capsules are arranged in order, operation of a next working procedure is facilitated, the structure is reasonable, and operation is simple.

Owner:ZHEJIANG CHUNBAO CAPSULES

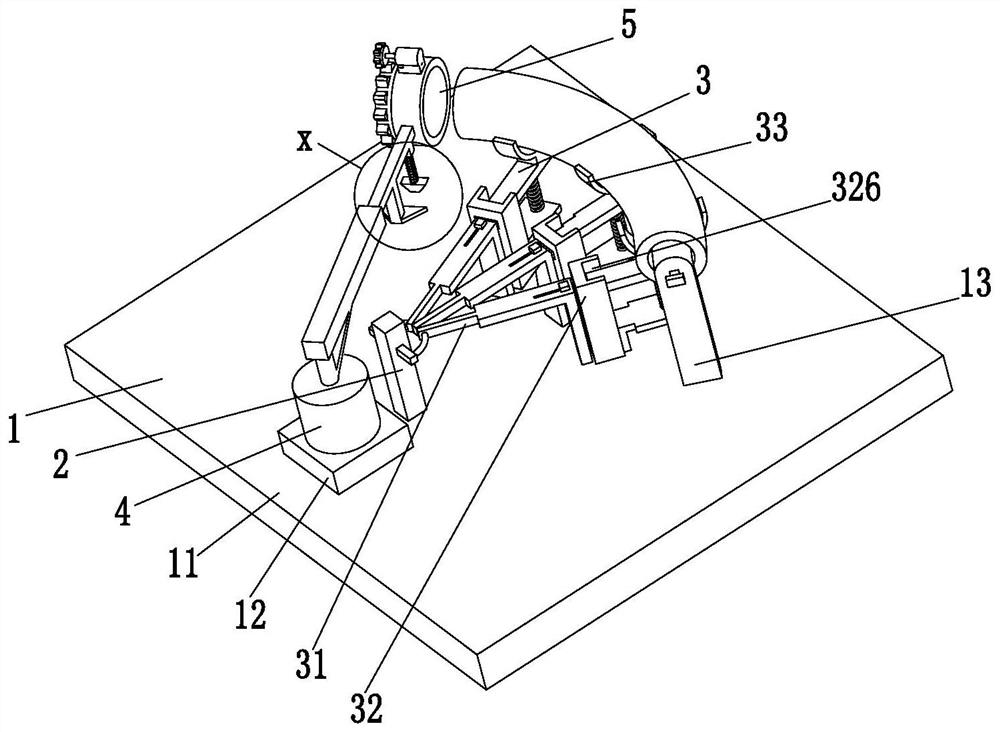

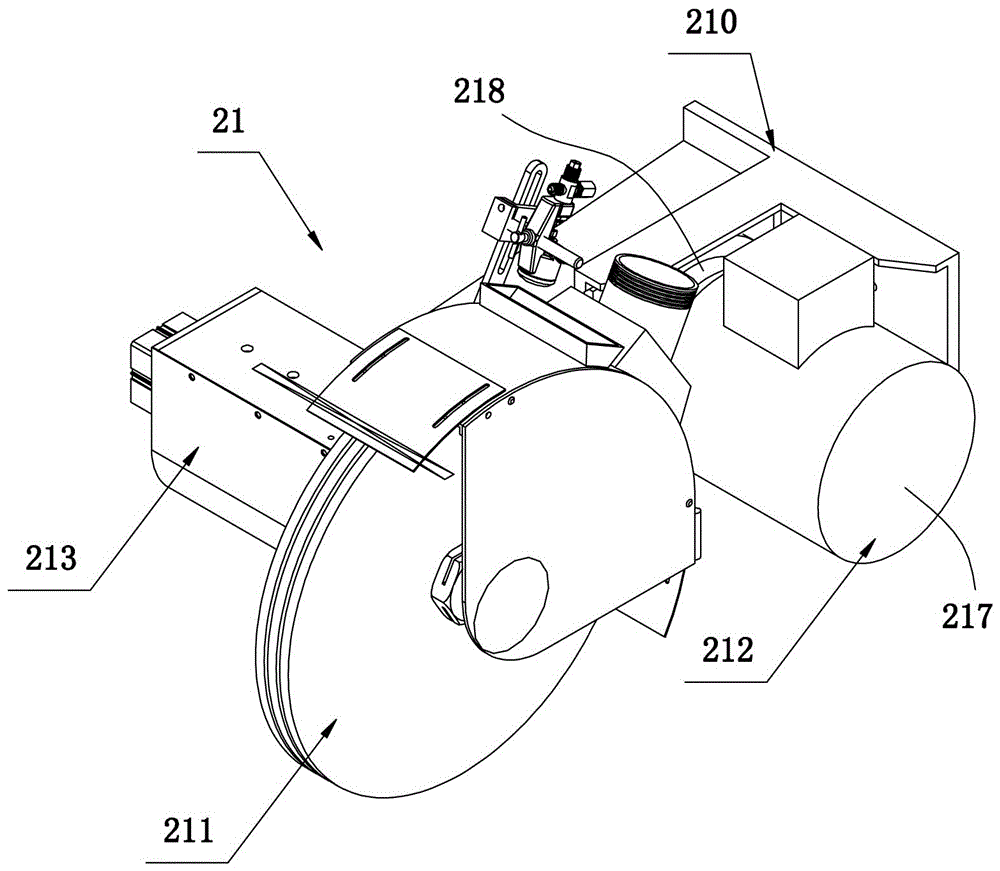

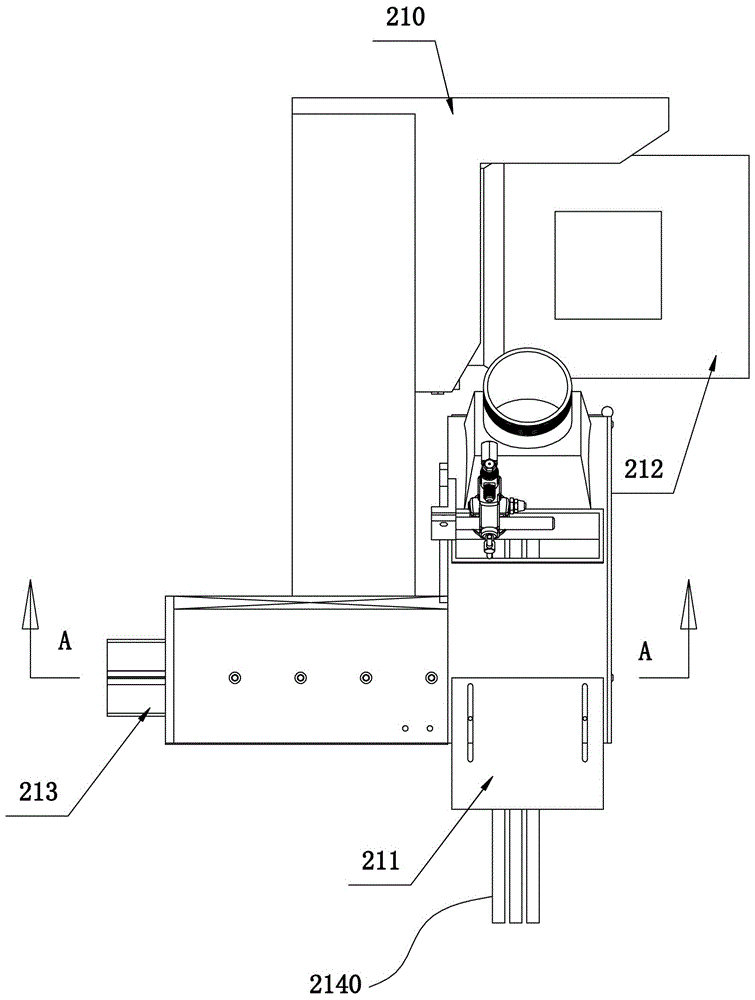

Metal bent pipe polishing machine

ActiveCN111604798ALabor intensiveGuaranteed polishing qualityGrinding carriagesPolishing machinesPhysicsElectric machinery

The invention relates to a metal bent pipe polishing machine. The metal bent pipe polishing machine comprises a fixing base, a mounting rod, a support device, a driving motor and a polishing device. The mounting rod is mounted at the upper end of the fixing base. The support device is arranged at the upper end of the mounting rod in a sliding-fit manner. The driving motor is mounted on the front portion of the upper end of the fixing base. The polishing device is mounted on an output shaft of the driving motor. By means of the metal bent pipe polishing machine, the problems that when a traditional method that a metal bent pipe is polished after being casted to be formed is adopted, due to the bent pipe is complex and irregular in shape, people usually hold the bent pipe with hand to conduct polishing on a rotating abrasive belt, the method is high in labor intensity and low in efficiency, the polishing quality cannot be guaranteed, after the metal bent pipe is clamped according to thetraditional method, omnidirectional polishing cannot be conducted, the metal bent pipe is in contact with a clamping position, polishing can be affected, and mechanized automatic operation cannot be conducted can be solved.

Owner:浙江宏洲管件有限公司

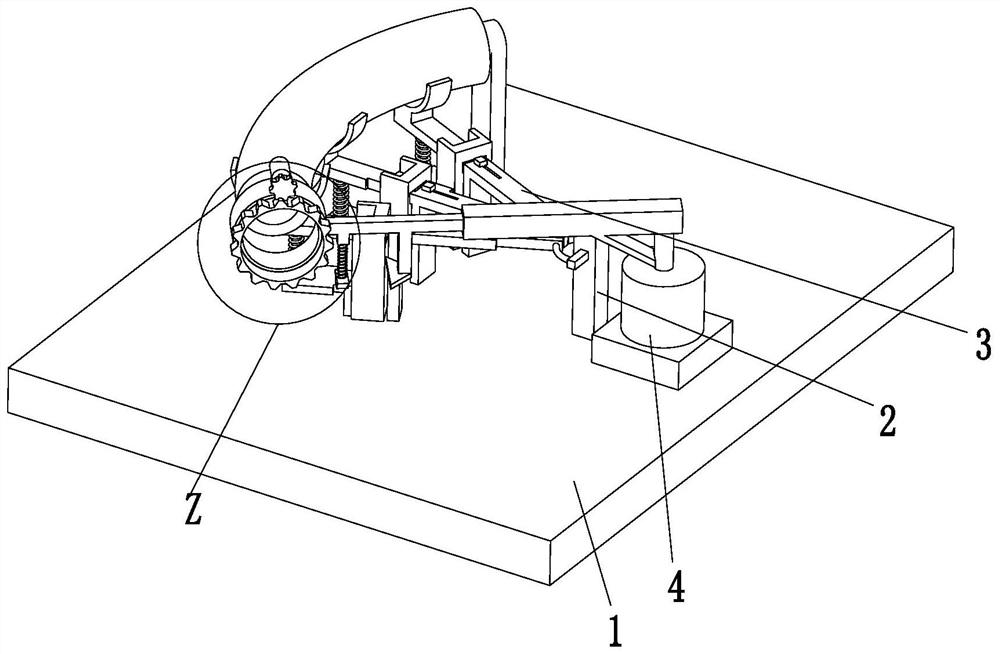

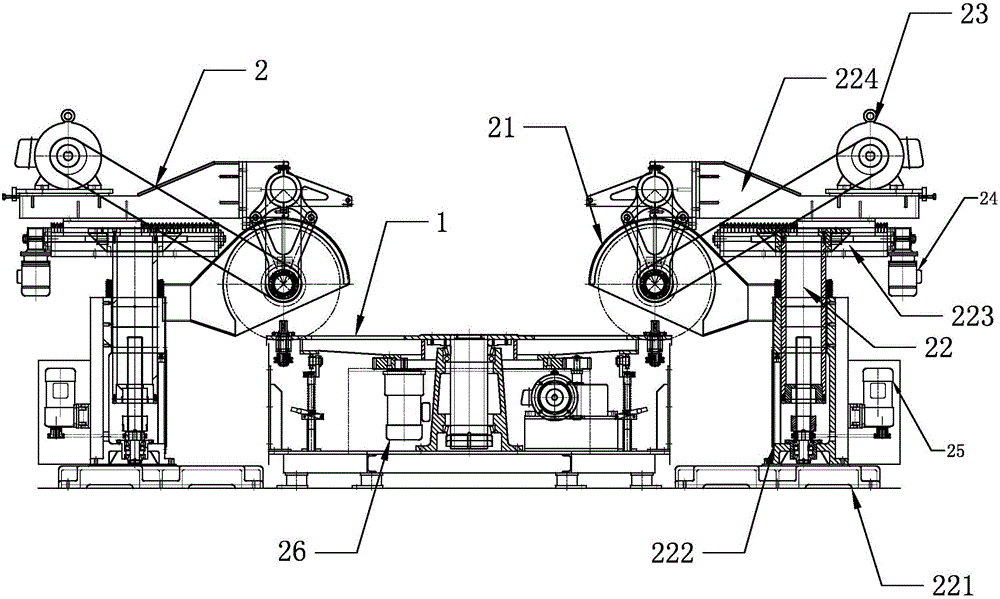

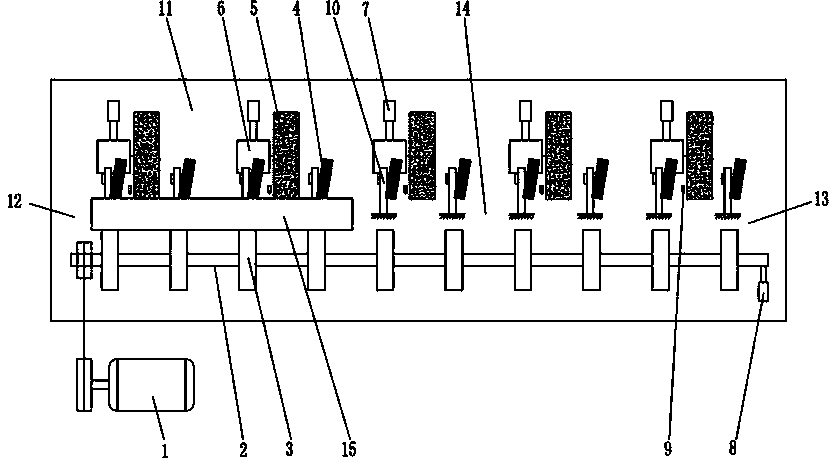

Multi-station polishing machine capable of improving efficiency

InactiveCN106064342ASimple structureSimple control methodPolishing machinesGrinding drivesEngineeringMechanical engineering

A multi-station polishing machine capable of improving efficiency comprises a rack, a polishing mechanism mounted on the rack as well as a workpiece loading and synchronous rotating control working table arranged below the polishing mechanism, wherein the polishing mechanism comprises a polishing fixing beam and at least two polishing heads mounted on the polishing fixing beam at an interval; and the workpiece loading and synchronous rotating control working table comprises a loading fixing base, at least two workpiece clamping mechanical arms rotationally mounted on the top surface of the loading fixing base as well as a synchronous driving device for controlling all the workpiece clamping mechanical arms to rotate synchronously and swing synchronously. With the machine, all workpieces can be polished in the same environment at the same time, the polishing consistency of products is greatly improved, product polishing differences caused by polishing condition deviations are reduced, differences of polishing effects of the same batch of workpieces can be reduced to a certain extent, unified production is facilitated, meanwhile, the control method is simple and easy to implement, and the product polishing accuracy can be improved.

Owner:FUJIAN CHANGJIANG IND

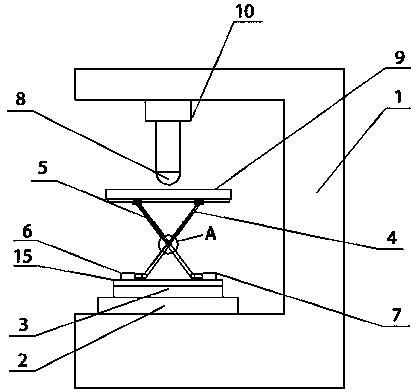

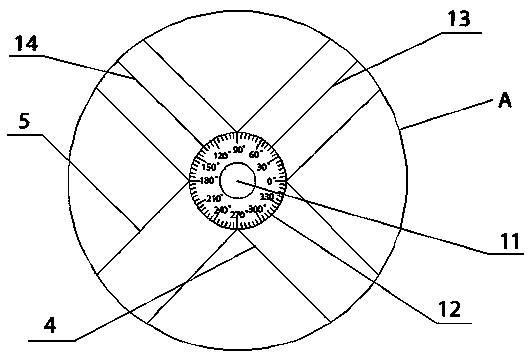

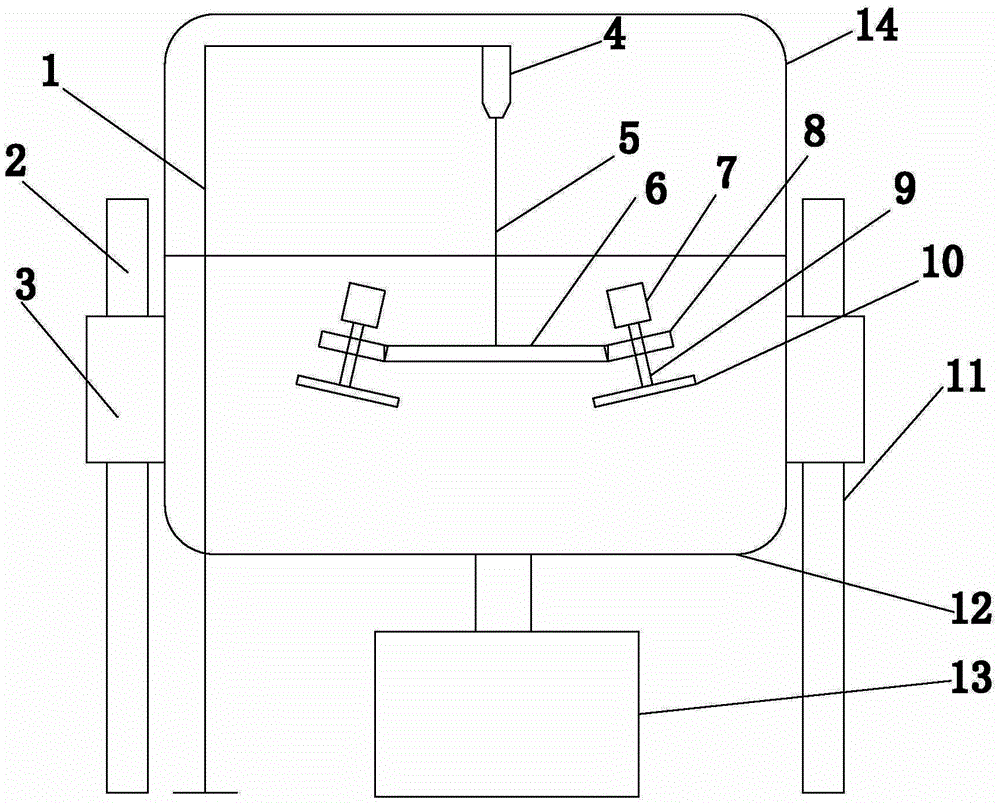

Angle-adjustable polisher

ActiveCN103659542AAccurate contactGuaranteed polishing qualityGrinding machinesMachined surfaceEngineering

The invention relates to an angle-adjustable polisher which comprises a body, a polishing device connected to the top of the body and a workbench. An omni-directional conveyer is further disposed on the body. An angle adjusting device which is movably connected with the workbench is disposed on the omni-directional conveyer. The angle-adjustable polisher has the advantages that the angles of the workbench can be controlled by automation, a polishing head is allowed to be in accurate contact with a to-be-machined surface, and product polishing quality is guaranteed; 360-degree workbench conveying in the horizontal direction can be achieved, and contact of a workpiece and the polishing head is guaranteed; the angle-adjustable polisher is simple in structure, easy to manufacture, energy saving, environmental friendly, practical and efficient.

Owner:平湖佐越机械制造股份有限公司

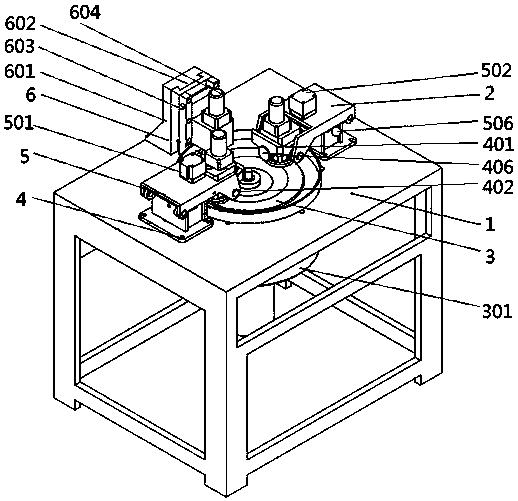

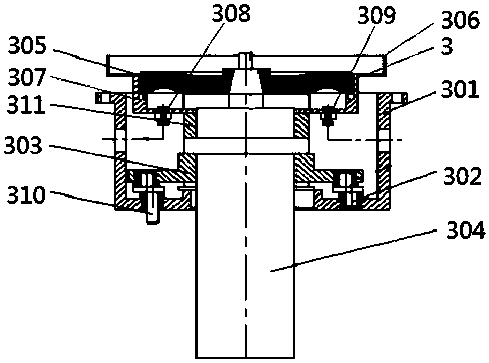

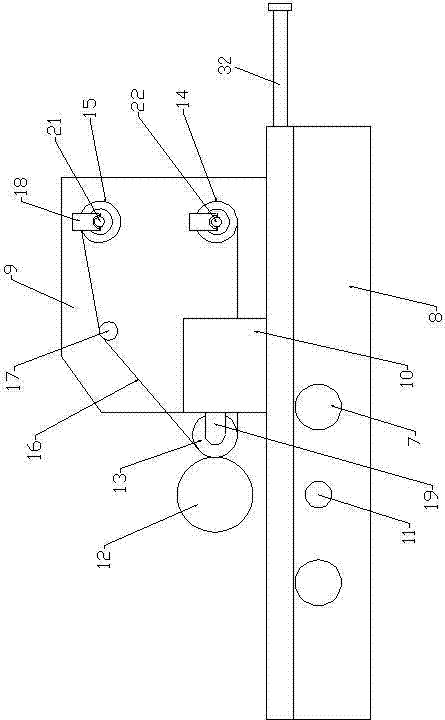

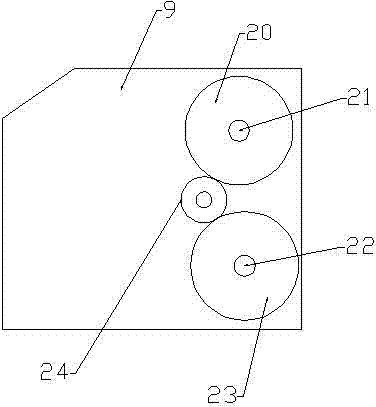

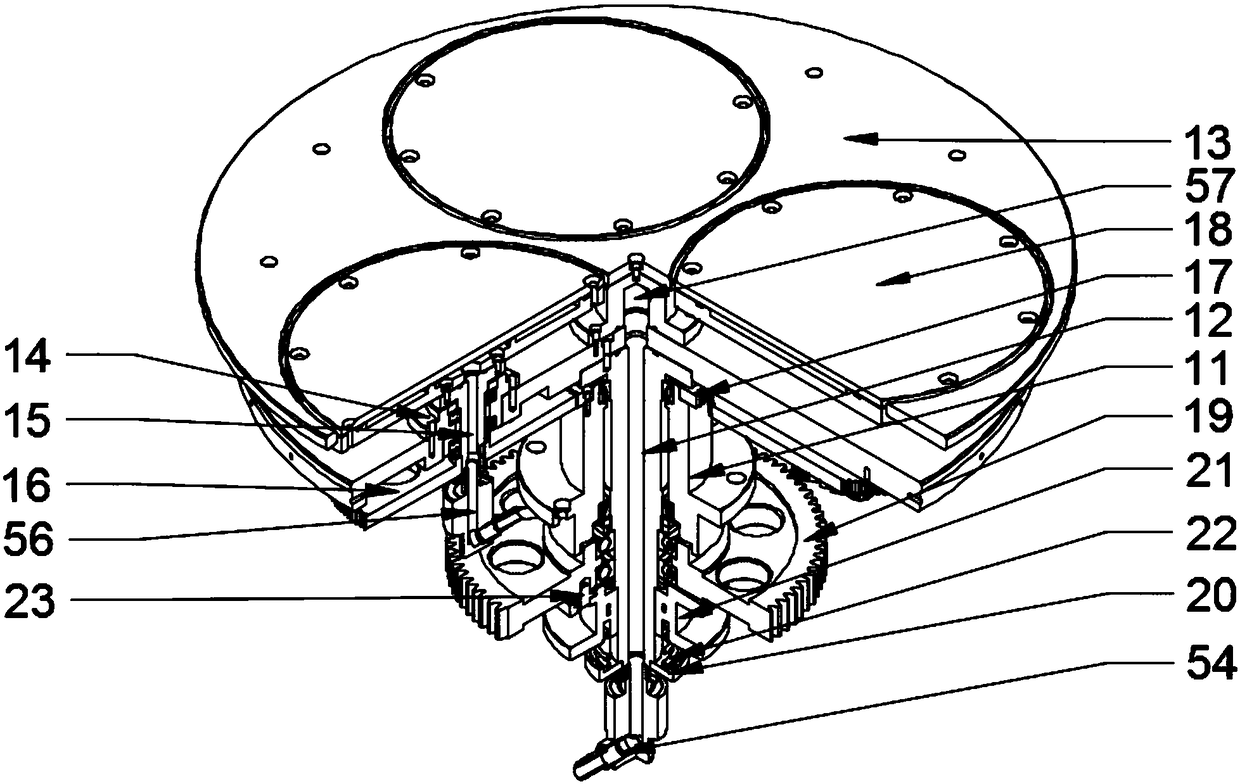

Two-workstation polycrystalline diamond compact polisher

PendingCN107855900AAvoid continuityGuaranteed polishing qualityGrinding machinesGrinding work supportsThermodynamicsPolishing

The invention discloses a two-workstation polycrystalline diamond compact polisher and solves the problem that existing polishers are unreliable in polishing quality and low in polishing efficiency due to unreasonable structure. The polisher comprises a polishing wheel base and a polycrystalline diamond compact clamp seat, a polishing wheel set is arranged in the polishing wheel base and comprisesa driving shell fixedly connected with the polishing wheel base, a plurality of eccentric shafts are arranged on the bottom side of the driving shell, the eccentric shafts are in transmission connection through an eccentric shaft seat, a polishing wheel driving shaft in planet motion is arranged in the eccentric shaft seat, a polishing wheel is fixedly arranged at the upper end of the polishing wheel driving shaft, a waterproof cooling shell is arranged on the periphery of the polishing wheel, a labyrinth sealing structure is arranged between the waterproof cooling shell and the polishing wheel, a closed circulating cooling cavity is formed between the waterproof cooling shell and the polishing wheel, and the polycrystalline diamond compact clamp seat has multiple degrees of freedom. Thetwo-workstation polycrystalline diamond compact polisher is novel in structure and convenient and reliable in polishing and has good popularization and application prospect.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Robot polishing and grinding force control end effector

ActiveCN108818303AReduce the total massWill not cause an explosionGrinding drivesGrinding headsLinear motionRobotic systems

The invention discloses a robot polishing and grinding force control end effector. The robot polishing and grinding force control end effector comprises a rotation part, a linear motion part and a grinding head part. A pneumatic motor is adopted as a power source for the effector, and the total mass of the effector is effectively reduced. Usage of a coupler is avoided, accordingly, the complexityof the mechanism is reduced, and the structure is more compact. The rotation movement of the pneumatic motor is transmitted to a ball spline through a main shaft, and the ball spline transmits the rotation movement to the grinding head part. Since the ball spline has the functions of torque transmission and untight connection, mechanical decoupling of the two freedom degrees of a grinding head isachieved at the position of the ball spline. Compared with the current situation that connection of an effector and a macro robot system is conducted at the top end of the effector, by means of the robot polishing and grinding force control end effector, the polished and ground surface capsizing moment is effectively reduced, and the polishing and grinding quality is improved. By means of the robot polishing and grinding force control end effector, control over the polishing and grinding tool force, the polishing and grinding rotation speed and other important polishing and grinding parameterscan be achieved, the effector is simple in structure, small in mass and high in force control precision and response speed.

Owner:GUANGDONG UNIV OF TECH

Strip-shaped polishing machine

The invention relates to a strip-shaped polishing machine. A polishing machine base is arranged on the outer portion of a guiding rod and the outer portion of a stroke pushing screw rod in a sleeved mode. A polishing transmission shell body and a polishing output shell body are arranged above the polishing machine base. A polishing strip driven shaft and a polishing strip driving shaft with a motor are arranged on the polishing transmission shell body. A polishing wheel is arranged on the polishing output shell body. A first polishing strip rolling shaft is arranged on the polishing strip driving shaft. A second polishing strip rolling shaft is arranged on the polishing strip driven shaft. The polishing wheel, the first polishing strip rolling shaft and the second polishing strip rolling shaft are connected with polishing abrasive belts. The axis of the polishing wheel and the axis of a rolling shaft rotating driving shaft are parallel. Polishing quality is guaranteed, constant-speed taking up of the polishing abrasive belts during operation is achieved, the polishing performance of the contacting face of a rolling shaft is great, polishing accuracy is greatly improved, polishing speed and efficiency are improved, secondary using of the rolling shaft can be guaranteed each time polishing is carried out, expenditure is saved for an enterprise, benefit is brought, energy is saved, and environment is protected.

Owner:HENAN XUYUAN STAINLESS STEEL

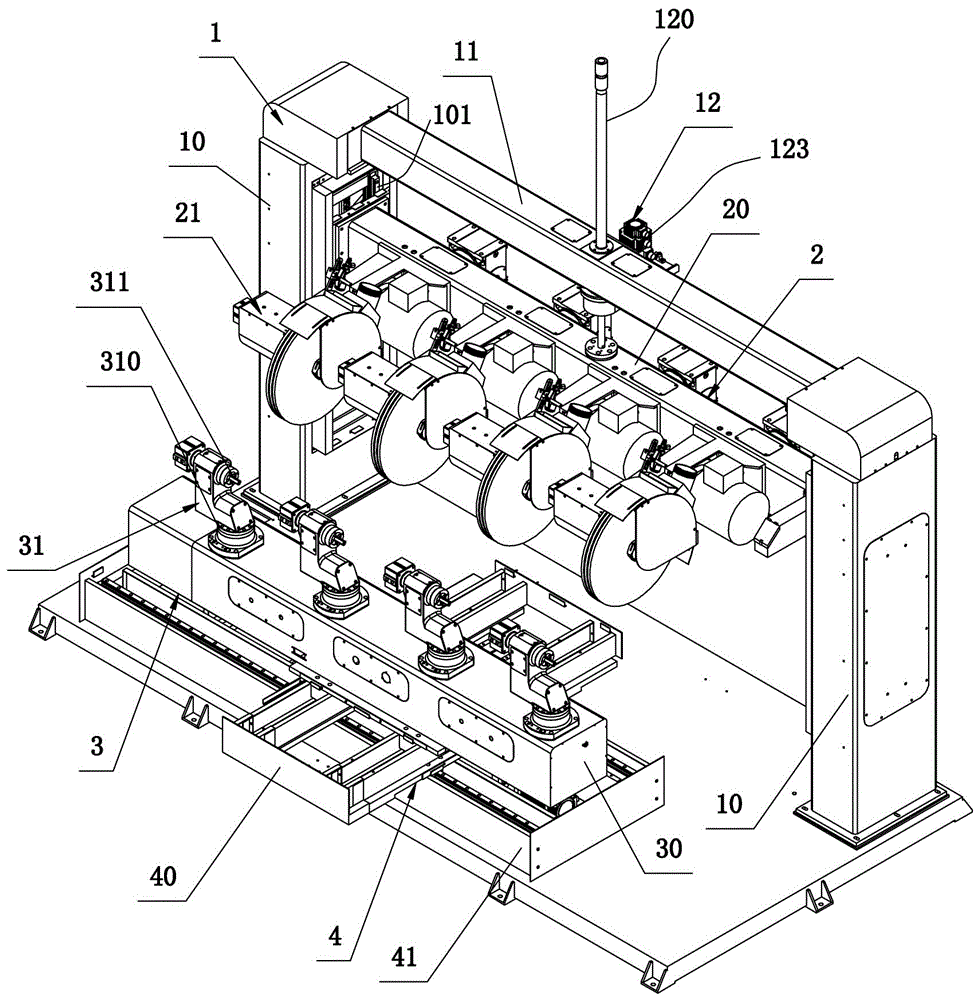

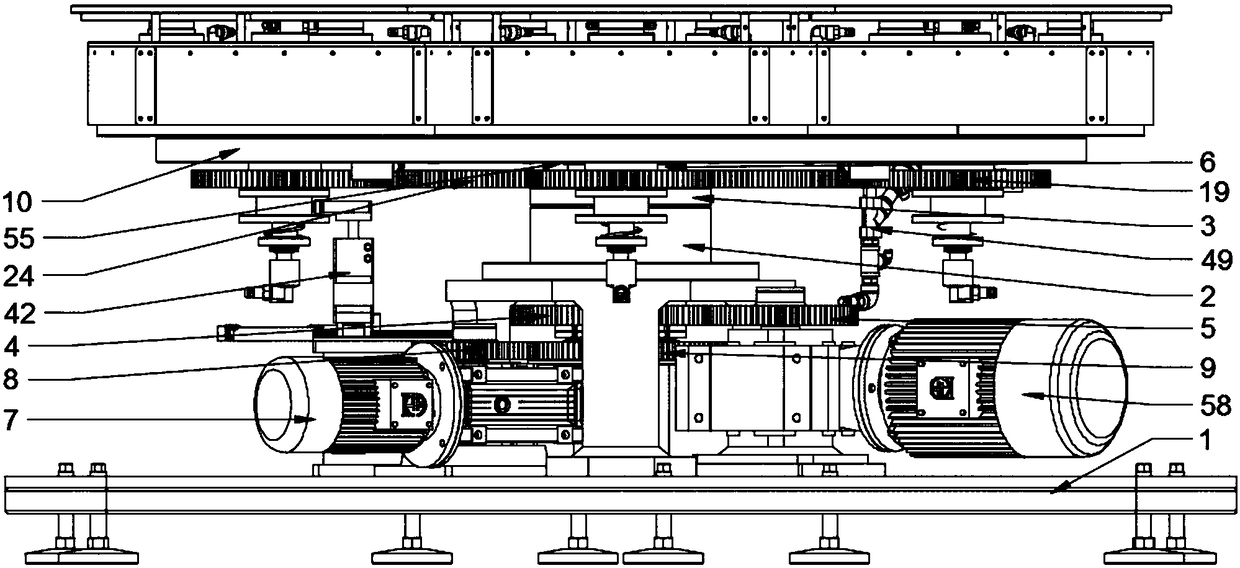

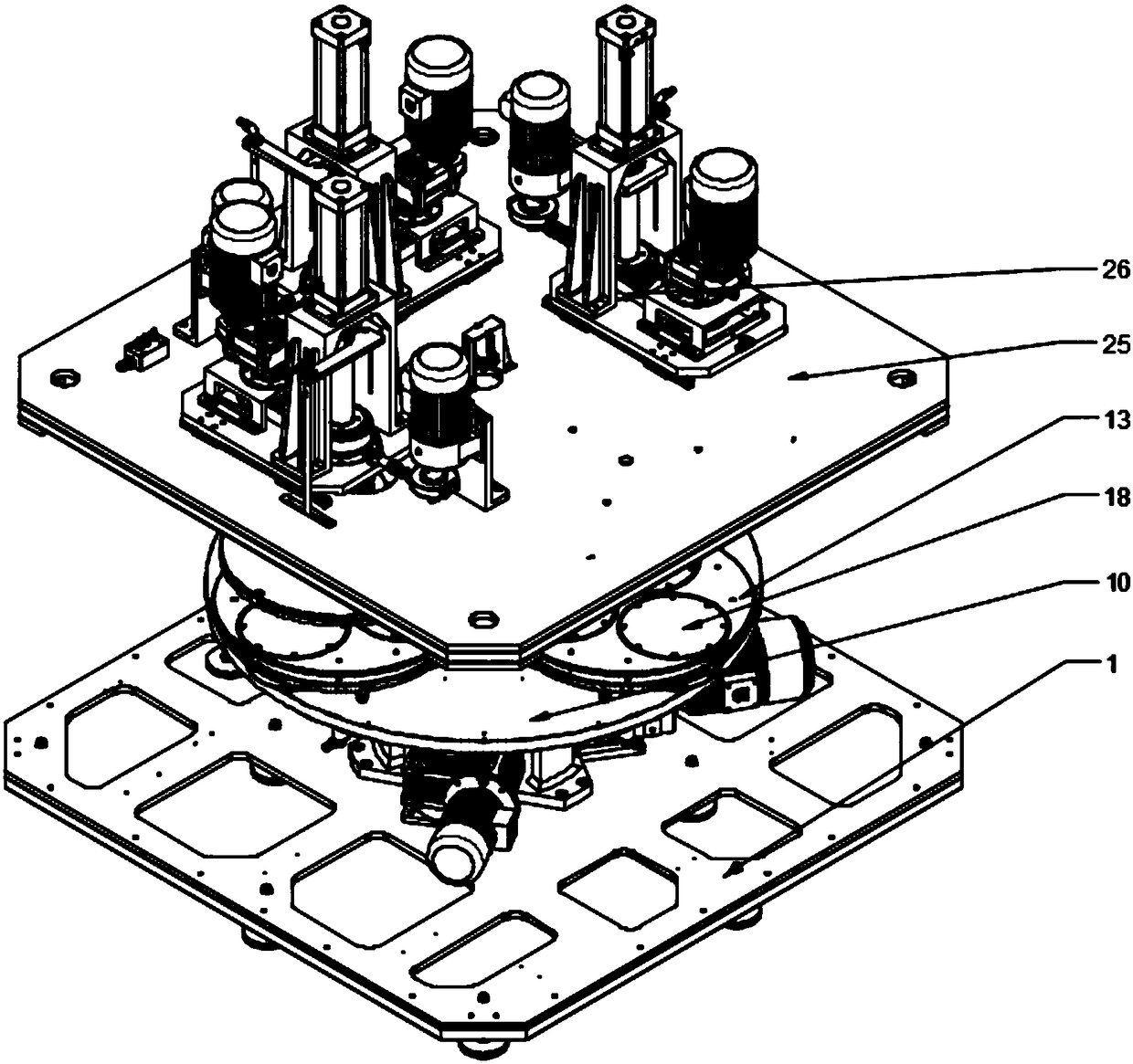

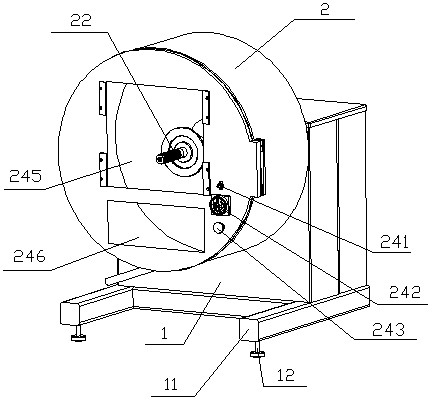

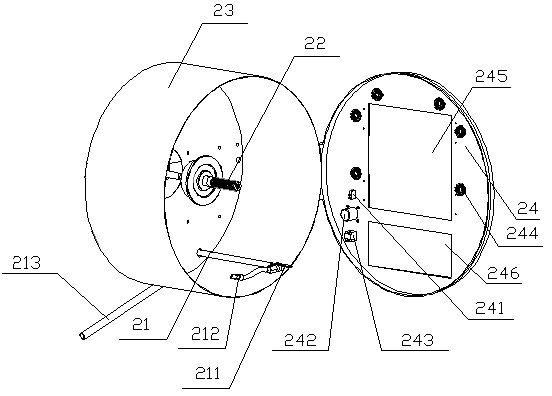

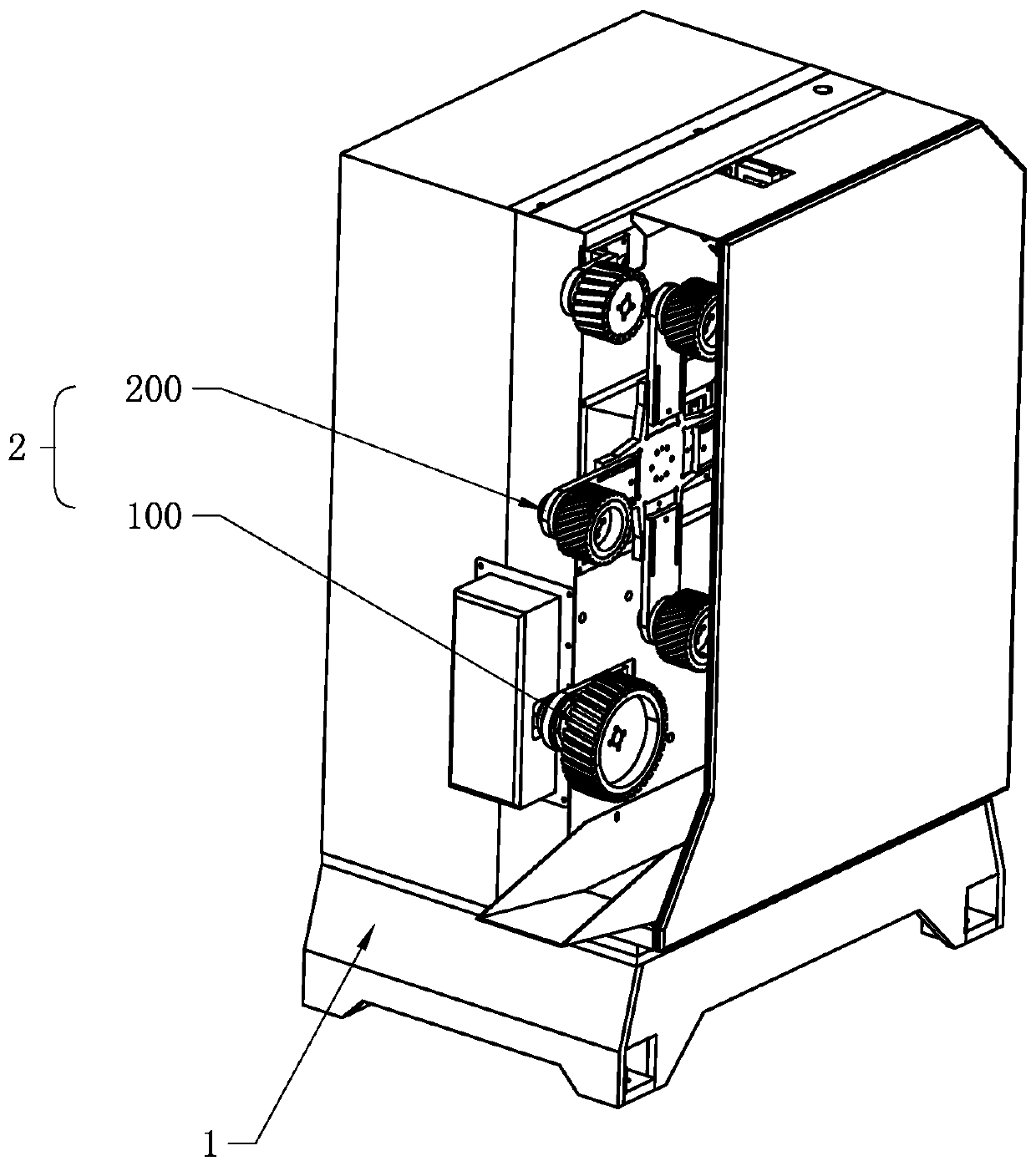

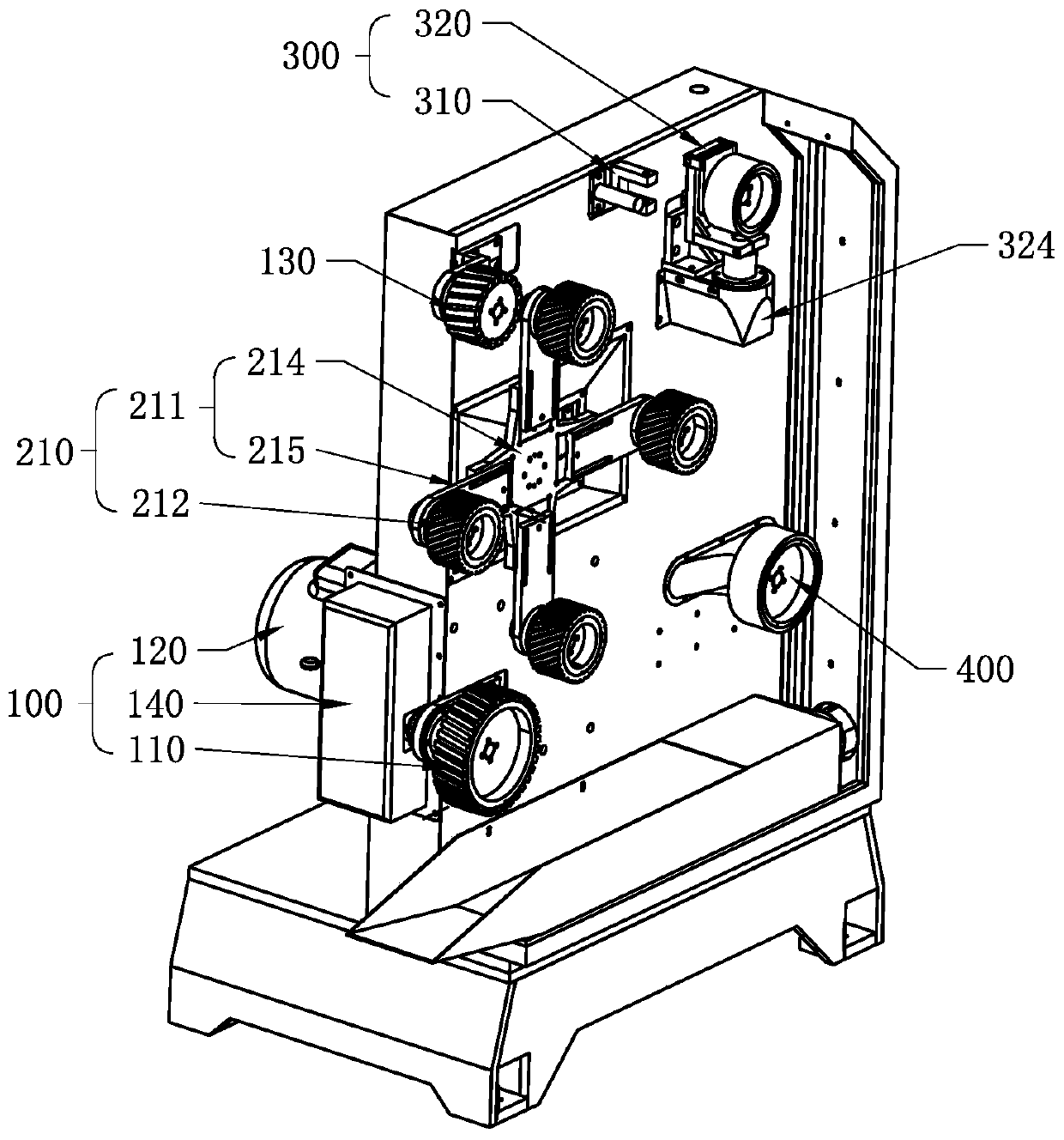

Inversion type mobile phone 3D curved surface polishing machine

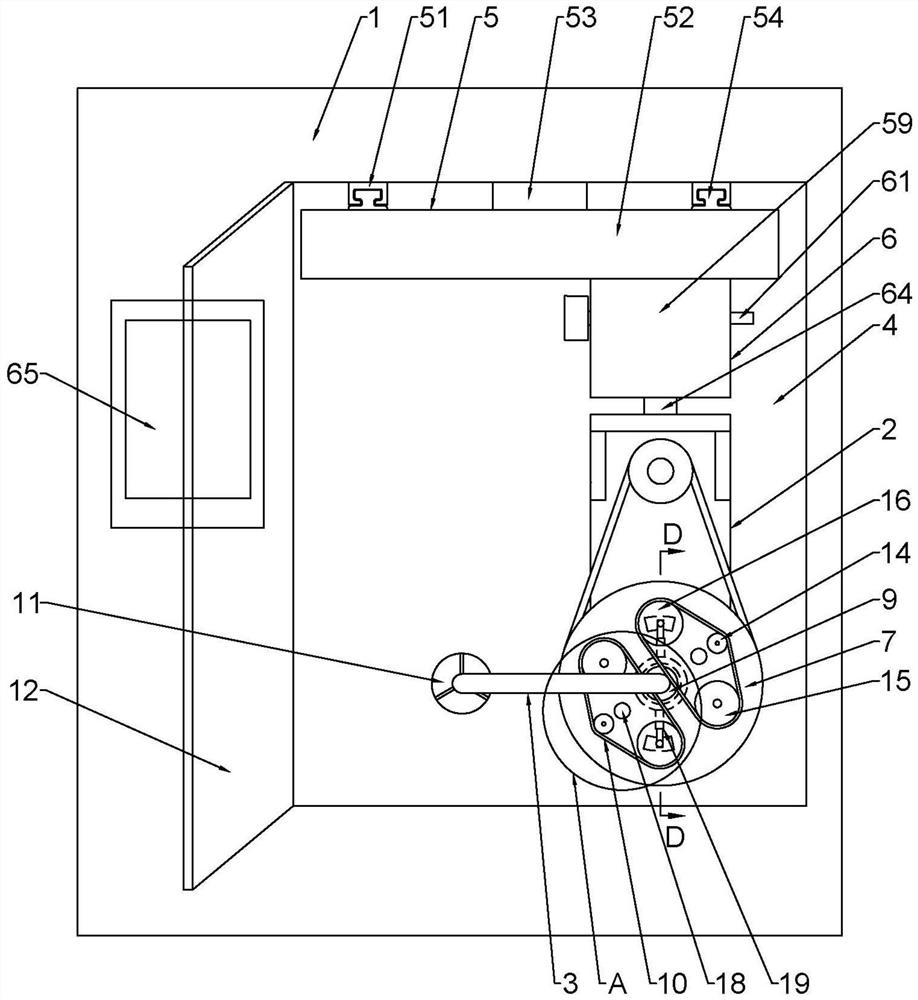

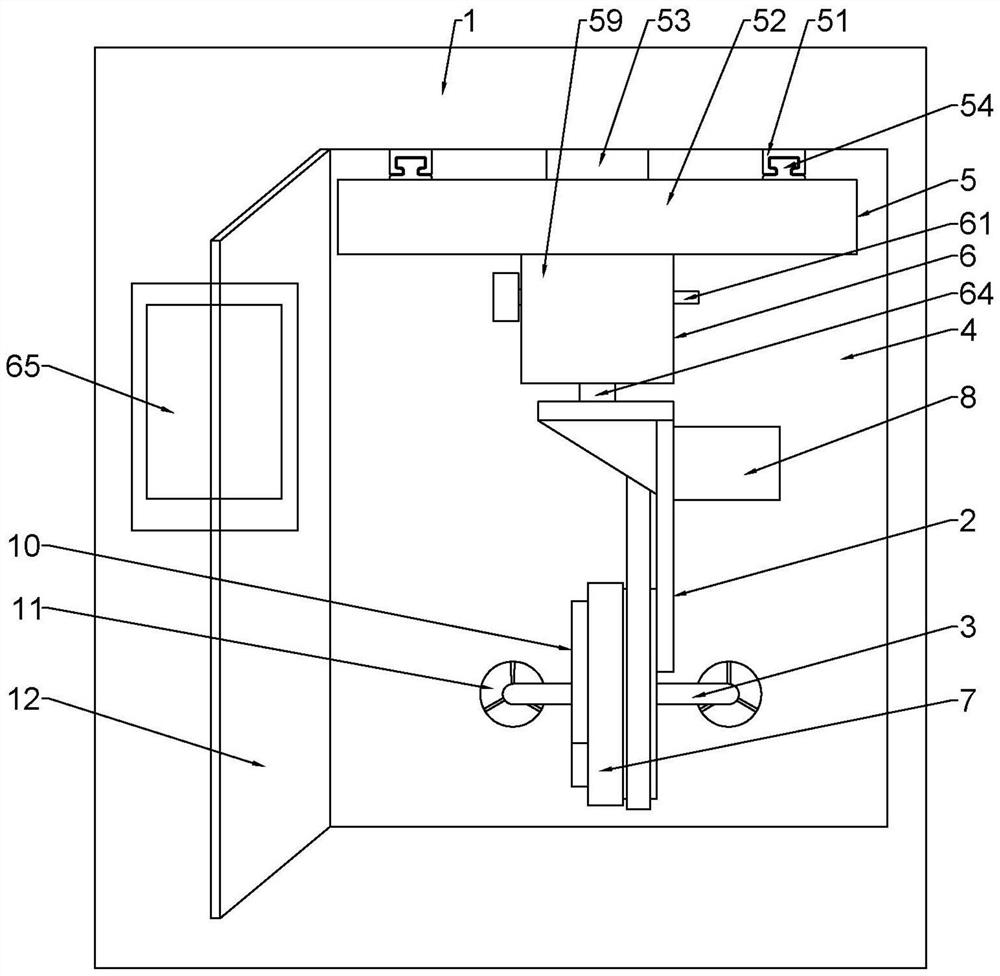

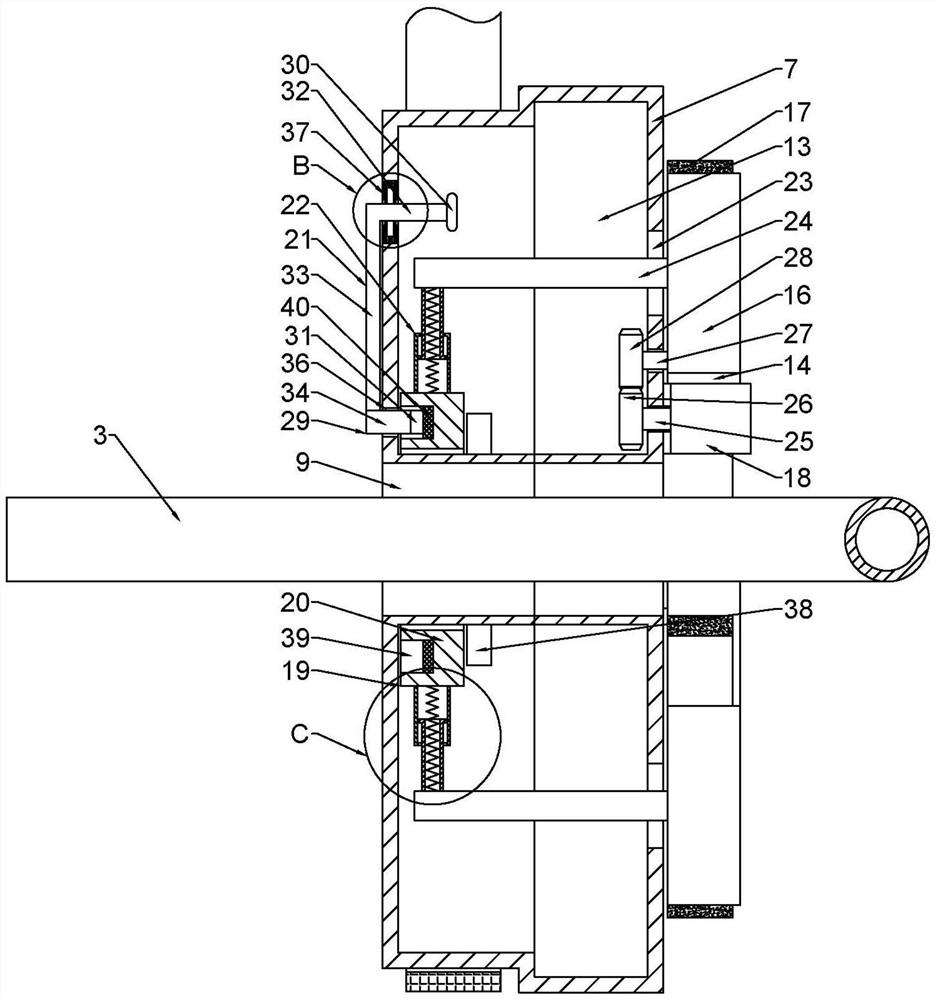

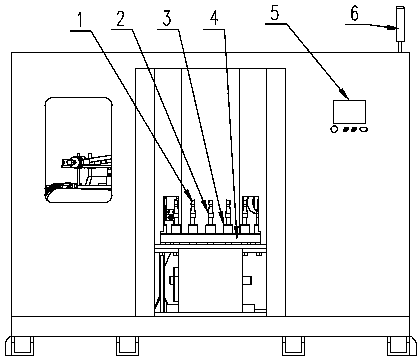

PendingCN108312024AGuaranteed uniformityGuaranteed polishing qualityGrinding machinesEngineeringReducer

The invention discloses an inversion type mobile phone 3D curved surface polishing machine. The inversion type mobile phone 3D curved surface polishing machine comprises a base (1) and is characterized in that a first connecting seat (2) is arranged on the base (1), t he first connecting seat (2) is provided with a sun shaft (3), the sun shaft (3) is rotationally connected with the first connecting seat (2), and the base (1) is provided with a revolution and rotation conjoined speed reducer (58); the revolution and rotation conjoined speed reducer (58) rotates to drive the sun shaft (3) to rotate, the sun shaft (3) is provided with a central shaft (6), and the central shaft (6) is rotationally connected with the sun shaft (3); the base (1) is provided with an inversion conjoined speed reducer, the central shaft (6) is provided with a revolution plate (10), and the inversion conjoined speed reducer (7) rotates to drive the revolution plate (10) to rotate. Compared with the prior art, the inversion type mobile phone 3D curved surface polishing machine has the advantages of good polishing uniformity, high working efficiency, and ensure of the polishing quality.

Owner:安徽顺怡隆机械设备有限公司

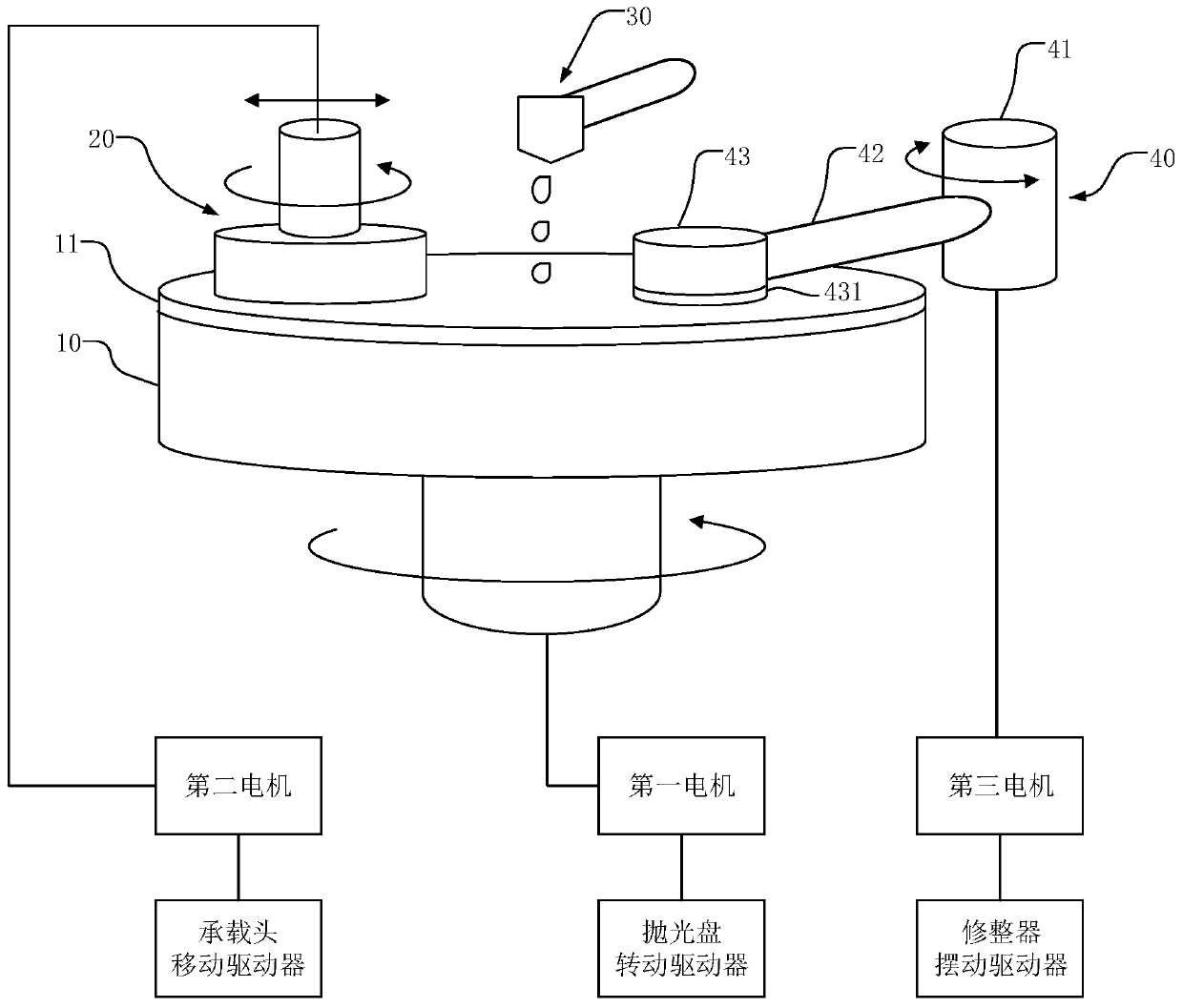

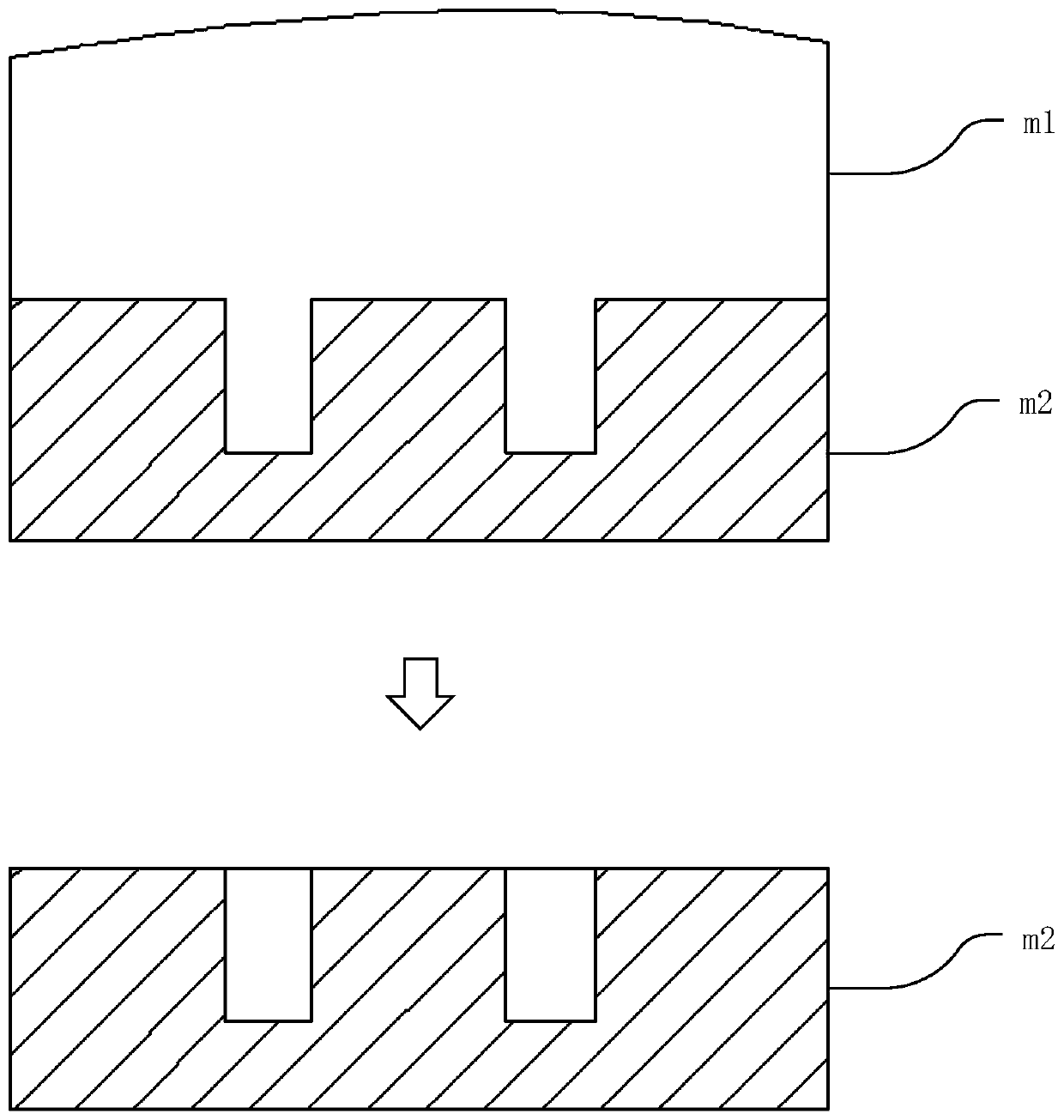

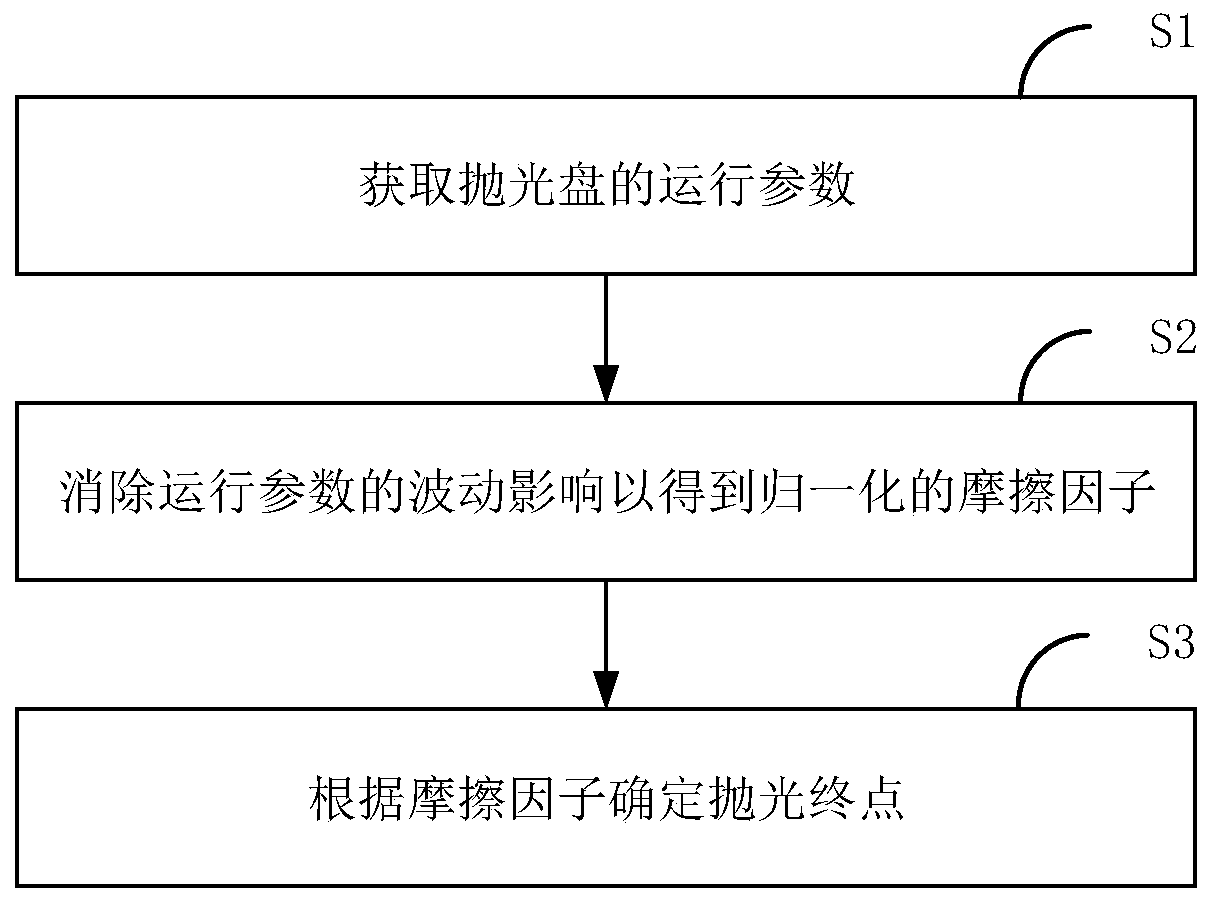

End point detection method and system and chemical mechanical planarization device

ActiveCN110394728AImprove accuracyGuaranteed polishing qualitySemiconductor/solid-state device manufacturingLapping machinesEngineeringChemical-mechanical planarization

The invention is applicable to the technical field of chemical mechanical planarization, and provides an end point detection method and system and a chemical mechanical planarization device. The method comprises the following steps that operation parameters of a planarization disk is acquired during a wafer planarization period; fluctuation influence of the operation parameters is eliminated to obtain a normalized friction factor; and a planarization end point is determined according to the friction factor. According to the method, the accuracy rate of the end point detection in the chemical mechanical planarization process is improved, and the planarization quality is effectively ensured.

Owner:TSINGHUA UNIV +1

Measurer for thickness of float polished liquid film

InactiveCN1387022AImprove processing and polishing conditionsImprove work efficiencyUsing optical meansOptical leverEngineering

A measurer of liquid film thickness of float polishing is characterized by that a optical lever structure is supported by a smooth rotary axle, the optical lever has a curved leg with transition arc at its one end floating on the surface of liquid film and a reflector at its another end, and the parallel optical tubes are used to observe the variation of pitch angle of optical lever. Its advantages are high efficiency and high polishing quality.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Automobile steel ring polishing machine

InactiveCN102218696AEasy to polishGuaranteed polishing qualityPolishing machinesWater pipeMotor drive

The invention provides an automobile steel ring polishing machine which is used for polishing an automobile steel ring. The automobile steel ring polishing machine comprises a case body and a protecting hood fixed on one side of the case body, wherein a motor and a main control circuit are arranged inside the case body; a water pipe and a transmission assembly for installing the automobile steel ring are arranged inside the protecting hood; the motor drives the transmission assembly to rotate; the transmission assembly drives the automobile steel ring to rotate synchronously; and the water pipe is used for water polishing of the automobile steel ring. Therefore, the automobile steel ring is polished conveniently and professionally.

Owner:ZHONGSHAN TAILINGWANG AUTOMOBILE SERVICE

Television border polisher

ActiveCN104440498AHealth problemsAvoid Problems That Affect Polishing QualityPolishing machinesGrinding drivesLiquid-crystal displayEngineering

The invention discloses a television border polisher capable of mechanically and automatically polishing a liquid crystal display television border and having the advantages of high polishing efficiency, time and labor saving, better polishing quality and the like. The television border polisher comprises a base, a lower guide frame and an upper mounting frame, wherein the lower guide frame and an upper mounting frame are sequentially arranged above the base, a rotating motor is mounted on the upper surface of the base, the lower guide frame and the upper mounting frame are connected with an output shaft of the rotating motor, and the base is provided with a polishing device comprising a mounting column, a swing arm and a polishing disc. The mounting column is vertically fixed on the base, the swing arm is movably mounted on the mounting column, a swing driving device is arranged on the base, a mounting plate is fixedly mounted on the swing arm, a guide pulley matched with the side of the lower guide frame is fixedly mounted on the mounting plate, a polishing disc driving motor is vertically arranged on the swing arm, a polishing disc is sleeved with an output shaft of the polishing disc driving motor, the partial part of the circumference of the polishing disc is fitted to the liquid crystal display television border outside the upper mounting frame, and the circumference of the polishing disc is completely or partially a polishing side.

Owner:FUJIAN RICHES ELECTRONICS SCI & TECH

Circular plate type automatic polishing machine

InactiveCN106737097AGuaranteed polishing qualityRealize automatic compensationGrinding carriagesPolishing machinesProgrammable logic controllerControl system

The invention discloses a circular plate type automatic polishing machine. The circular plate type automatic polishing machine comprises a workpiece mounting table and workpiece polishing mechanisms. Each polishing mechanism comprises a polishing wheel and a frame for mounting of the corresponding polishing wheel, and the mounting table is a rotatable circular plate. Each frame comprises a fixed base, a vertical column is mounted on each base and capable of sliding back and forth along the surface of the corresponding base, and a first supporting frame capable of moving up and down along each vertical column sleeves the corresponding vertical column. The polishing machine further comprises a PLC (programmable logic controller) control system and sensors. The circular plate type automatic polishing machine has advantages that each polishing head is capable of moving longitudinally, vertically and bilaterally, the angle and the direction of each polishing wheel can be adjusted in real time according to workpiece surface conditions and sand wheel abrasion conditions to guarantee workpiece surface polishing quality; the whole polishing machine is connected with the PLC system and capable of realizing automatic compensation, polishing force uniformity is guaranteed, great polishing effects are achieved, and multiple workpieces can be machined at the same time, so that production efficiency is greatly improved.

Owner:江门市兄弟机械制造有限公司

Automatic polishing device of punch for glass die

ActiveCN105033832AGuaranteed polishing qualityReduce work intensityPolishing machinesGrinding drivesReciprocating motionPolishing

The invention belongs to the technical field of machining facilities for auxiliary glass die components, and relates to an automatic polishing device of a punch for a glass die. The automatic polishing device comprises a rack, a power transmission mechanism, a punch vertical reciprocating motion mechanism and a polishing medium horizontal reciprocating motion mechanism which is fixed to a rotary disk. A table panel is fixed to the upper portion of the rack and provided with a table panel receding cavity. A rotary disk is located below the table panel. Acting cylinder limiting bases are fixed to the edge part of the side, facing the table panel, of the rotary disk. An acting cylinder limiting cavity is formed by the space between every two adjacent acting cylinder limiting bases. An oil cup is directly formed on the downward side of the rotary disk corresponding to the center position of the rotary disk. An oil cup cavity corresponds to the center of the table panel receding cavity. The power transmission mechanism is arranged on the rack and connected with the oil cup. The punch vertical reciprocating mechanism is arranged on the table panel and corresponds to the center of the table panel receding cavity. Labor resources are saved. The operation intensity of workers is relieved, and safety is guaranteed. The polishing quality on the punch is guaranteed.

Owner:CHANGSHU JIANHUA MOLD TECH

Polishing solution for chemically mechanically polishing germanium crystal and application method

InactiveCN104449404AImprove efficiencyReduce roughnessSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesHardnessSurface-active agents

The invention relates to a polishing solution for chemically mechanically polishing germanium crystal and an application method. The polishing solution comprises a rough polishing solution and a fine polishing solution, wherein the rough polishing solution is mainly prepared from the following raw materials in percentage by weight: 10 to 50% of hydrosol grinding material, 0.2 to 1.5% of an oxidant, 0.5 to 2% of a pH conditioner, 0.2 to 1.5% of a chelating agent, and 0.1 to 1% of a surface active agent, wherein the hydrosol grinding material is 15 to 110nm in particle size and has the concentration being not less than 40wt% (percentage by weight) and hardness being not greater than 7 Mohs; the fine polishing solution is mainly prepared from 0.1 to 0.5% of a surface active agent, and the balance of deionized water. The two-step polishing method is performed for chemical mechanical polishing and comprises two steps of selecting the rough polishing solution and then second the fine polishing solution; the two polishing can be performed through one polishing machine. The polishing solution has the beneficial effect that the problems of low rate, high roughness and pollution of metal ions and particles in chemical mechanical polishing of germanium crystal materials can be solved.

Owner:HEBEI UNIV OF TECH

Polishing machine for shaft

InactiveCN103624668AGuaranteed polishing qualityPolishing machinesGrinding feedersDrive wheelEngineering

The invention discloses a polishing machine for a shaft. The polishing machine comprises a workbench, a main shaft is connected to the workbench, the main shaft is in transmission connection with a main motor, and a plurality of driving wheels are arranged on the main shaft. A plurality of guide wheels are fixed to the workbench, and the guide wheels are parallel to the main shaft. A plurality of polishing wheels in transmission connection with polishing motors respectively are arranged on the workbench, the polishing motors are in transmission connection with polishing wheel feeding air cylinders respectively, and the polishing wheels are parallel to the main shaft. According to the polishing machine for the shaft, the driving wheels and the guide wheels form a shaft moving channel, the shaft rolls and axially moves under the action of the driving wheels and the guide wheels, rough polishing, medium polishing and fine polishing are respectively completed in the rolling and axial moving process so that all the polishing can be completed with one-time mounting, convenience is achieved, and polishing quality is guaranteed.

Owner:ZHEJIANG TAISHAN HEAVY MACHINERY

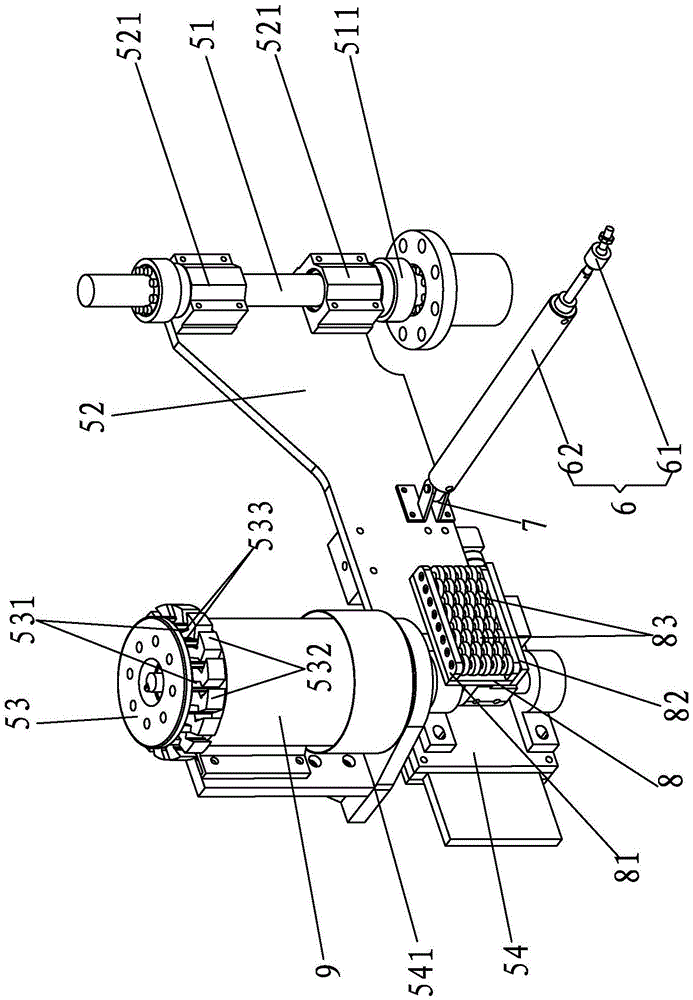

Method and device for polishing automobile hubs

InactiveCN104625936AGuaranteed polishing qualityImprove polishing qualityPolishing machinesGrinding work supportsAdhesiveEngineering

The invention discloses a method and device for polishing automobile hubs. The method includes the steps that a rotating device is used for driving the automobile hubs which are obliquely arranged to rotate automatically, and meanwhile the automobile hubs are made to revolute around the rotating device; a polishing groove is lifted up, and the automobile hubs which rotate automatically and revolute around the rotating device and different polishing abrasive materials are subjected to first-time rough polishing, second-time fine polishing and third-time brilliant polishing. The device comprises a polishing cylinder body with a lining being made of PU adhesives, the polishing cylinder body is provided with lifting mechanisms, and an L-shaped mounting rack is arranged on one side of the polishing cylinder body. The short edge of the L-shaped mounting rack is arranged above the polishing cylinder body, a motor is arranged on the short edge of the L-shaped mounting rack, and the motor is connected with a revolution main shaft. A mounting plate is arranged at the lower end of the revolution main shaft, bearing pedestals which are obliquely arranged are arranged on the mounting plate, the bearing pedestals are provided with rotation shafts, the upper ends of the rotation shafts are connected with motors, and the lower ends of the rotation shafts are fixedly connected with the automobile hubs. By means of the method and device, the polishing quality can be improved, operation is stable and reliable, and using is safe.

Owner:HUZHOU QIANJIN BAOYUN MACHINERY CASTING

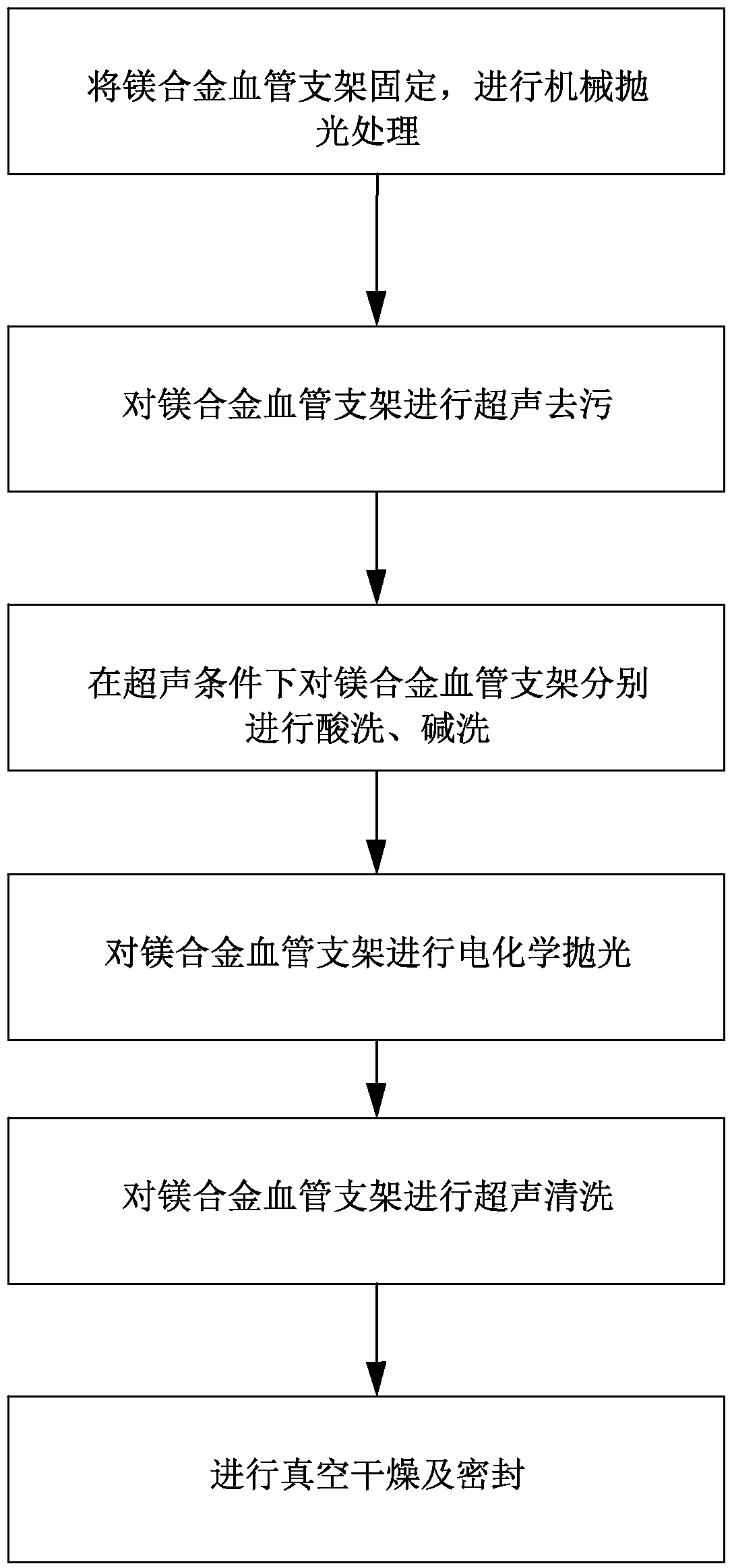

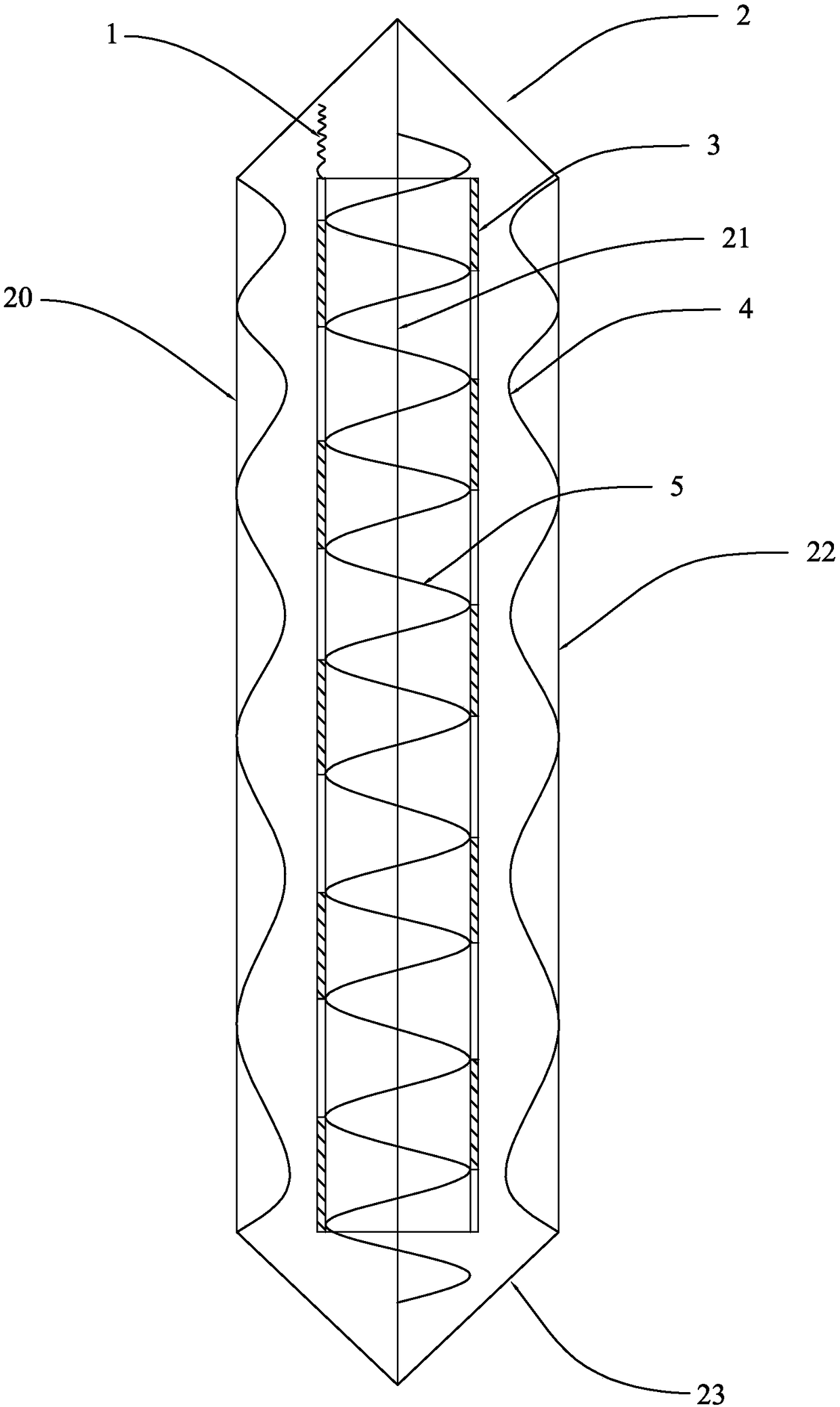

Surface polishing technology of magnesium alloy intravascular stent and assisting mechanism

PendingCN108193260ARemove deep scratchesImprove surface qualityElectrolysis componentsPolishing compositions with abrasivesIntravascular stentVacuum drying

The invention relates to the technical field of metal surface polishing, and discloses a surface polishing technology of a magnesium alloy intravascular stent and an assisting mechanism. The technology comprises the steps of: S1, fixing the magnesium alloy intravascular stent; and mechanically polishing the magnesium alloy intravascular stent; S2, ultrasonically cleaning the mechanically polishedmagnesium alloy intravascular stent; S3, correspondingly performing ultrasonic acid pickling and alkaline washing on the magnesium alloy intravascular stent after cleaning; S4, electrochemically polishing the magnesium alloy intravascular stent; S5, ultrasonically washing the magnesium alloy intravascular stent; and S6, performing vacuum drying and sealing. The assisting mechanism is used for fixing the magnesium alloy intravascular stent during electrochemical polishing. With the adoption of the technology and the assisting mechanism, deep scratches on the surface of the magnesium alloy intravascular stent can be effectively removed, so that the surface quality can be improved, and as a result, the magnesium alloy intravascular stent with smooth surface can be obtained.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

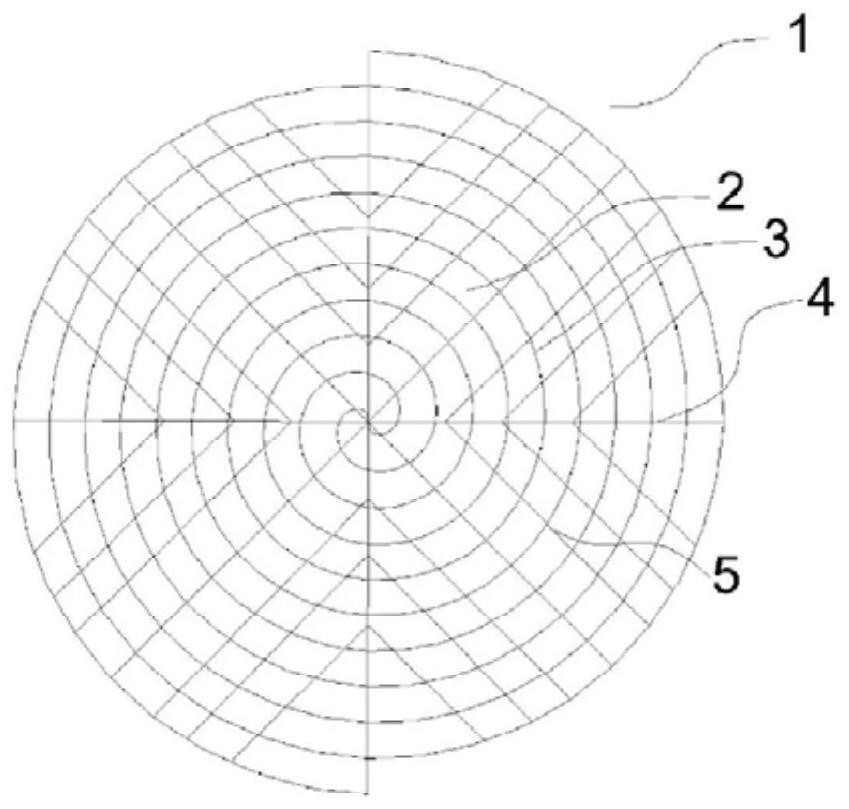

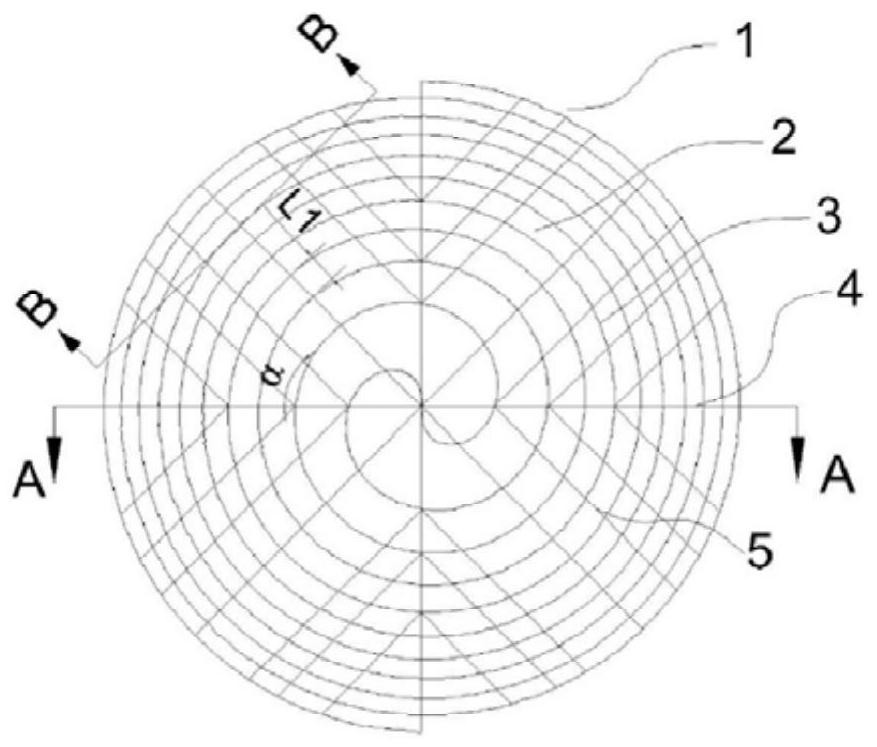

Polishing pad with grooves in surface

PendingCN113752160AControl Tangential AccelerationIncrease storage capacityLapping toolsPolishingRetention time

The invention relates to the technical field of chemical-mechanical polishing, and discloses a polishing pad with grooves in the surface. The polishing pad comprises a circular polishing layer, and the polishing layer is provided with first grooves, second grooves and third grooves; the first grooves are located in the surface of the polishing layer and spirally extend to the edge of the polishing layer with the circle center of the polishing layer as the starting point; the second grooves are located in the surface of the polishing layer and extend to the edge of the polishing layer in the radial direction with the circle center of the polishing layer as the starting point; and the third grooves are located in the surface of the polishing layer and extend to the edge of the polishing layer with certain points on the second grooves as the starting point. According to the polishing pad, the tangential acceleration of a polishing solution can be regulated and controlled through the spirally-extending first grooves, the polishing solution is uniformly distributed, the removal rate is improved, the radial acceleration of the polishing solution can be regulated through the radially-extending second grooves and the third grooves forming Y shapes with the second grooves, the speed change of the polishing solution is delayed, and the retention time of the polishing solution is prolonged.

Owner:广东粤港澳大湾区黄埔材料研究院

Automatic polishing machine for pipe fittings

InactiveCN102886727AGuaranteed polishing qualityImprove polishing efficiencyPolishing machinesPipe fittingEngineering

The invention belongs to the technical field of a pipe processing tool, in particular to an automatic polishing machine for pipe fittings. The automatic polishing machine for the pipe fittings comprises a frame. The frame is provided with a slide rail which is provided with a slide plate. An air cylinder is connected at the bottom of the slide plate. A bracket is arranged at one end of the slide plate. The bracket is provided with a work piece clamp capable of rotating on the bracket. The workpiece clamp is connected with a workpiece rotating motor. A slide frame is arranged at the other end of the slide plate. The slide plate is provided with a push clamp corresponding to the work piece clamp. The push clamp is connected with a push clamp cylinder. The frame is further provided with a polishing disc matched with the workpiece clamp. The polishing disc is connected with a polishing rotating motor. The automatic polishing machine for the pipe realizes automatic production of polishing treatment of the pipe, so that the polishing efficiency is improved to a great extent.

Owner:HUZHOU IRON FORCE METAL PROD

Polishing device

The invention discloses a polishing device. The polishing device includes a machine frame, and the machine frame is provided with an abrasive belt and a power module. The power module includes a powermechanism, a supporting mechanism, a correction mechanism and a tensioning mechanism, wherein the power mechanism is used for driving the abrasive belt to move, the supporting mechanism is used for pressing the abrasive belt towards a product, the correction mechanism is used for limiting the deflection of the abrasive belt, and the tensioning mechanism is used for tensioning or replacing the abrasive belt. The supporting mechanism includes a supporting assembly, a power member, an adjustment assembly, a detector and a controller, wherein the supporting assembly is used for be connected withthe abrasive belt in an abutting mode and pressing the abrasive belt towards the product, the power member drives the supporting assembly to move to be close to or away from the abrasive belt, and theadjustment assembly is used for adjusting the position of the power member, the detector is used for detecting and obtaining position information of the supporting assembly, and the controller is used for receiving the position information and controlling the action of the adjustment assembly. According to the polishing device, the mode of polishing by holding a pressing block with hands can be eliminated, automatic polishing is realized, and the polishing quality is ensured.

Owner:江门市信贝利机械有限公司

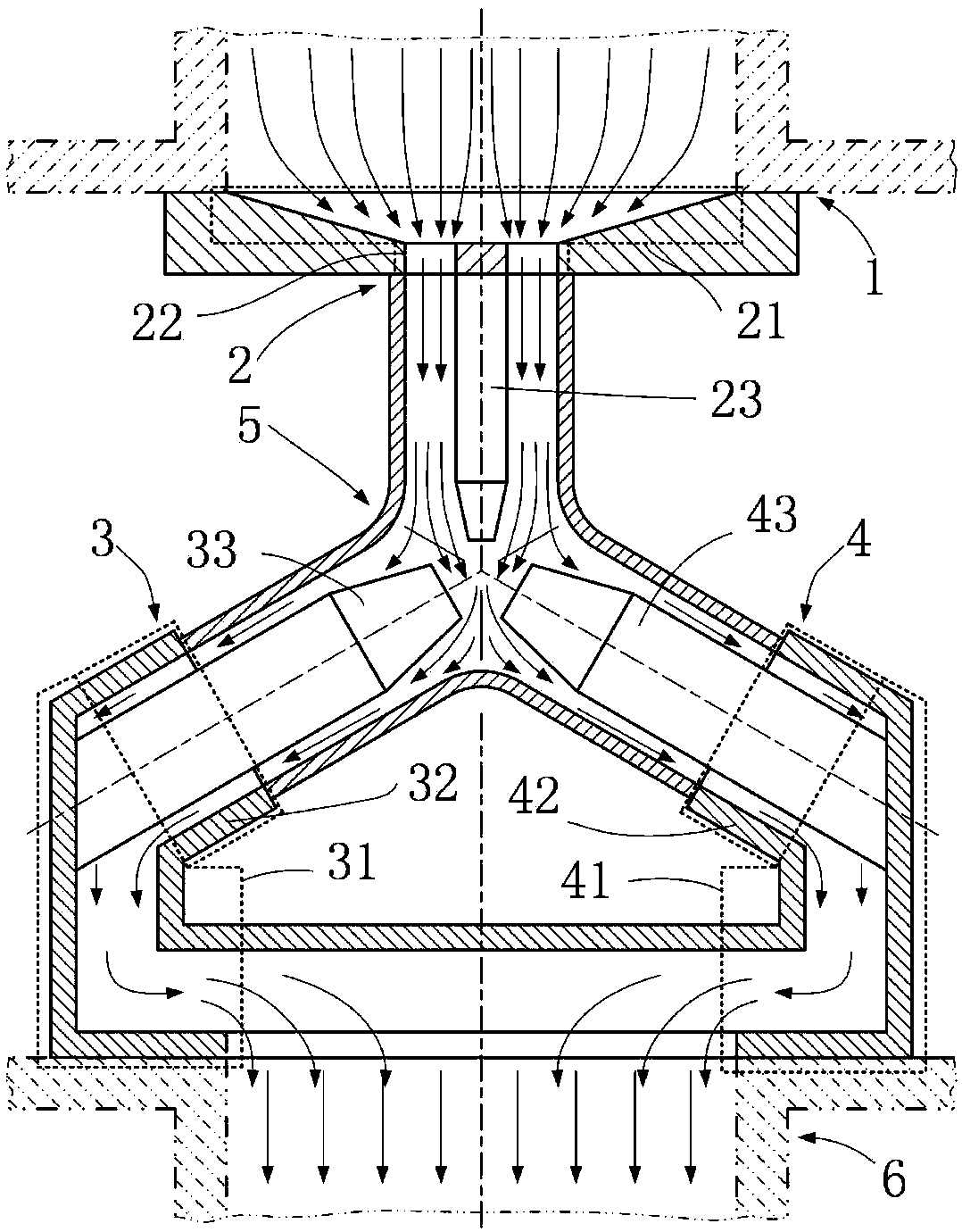

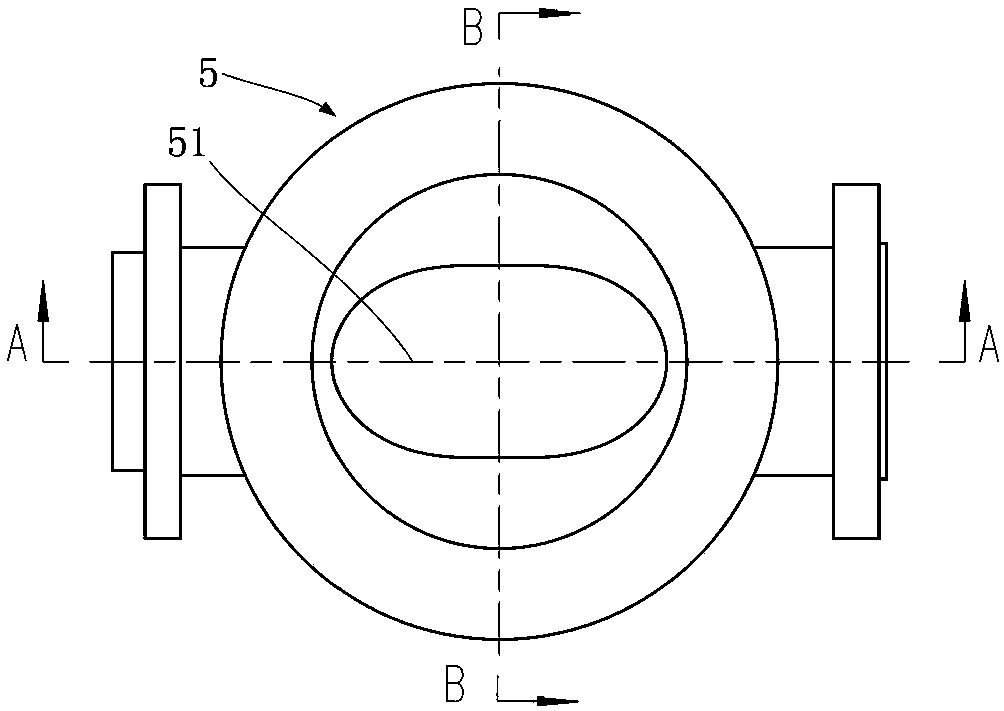

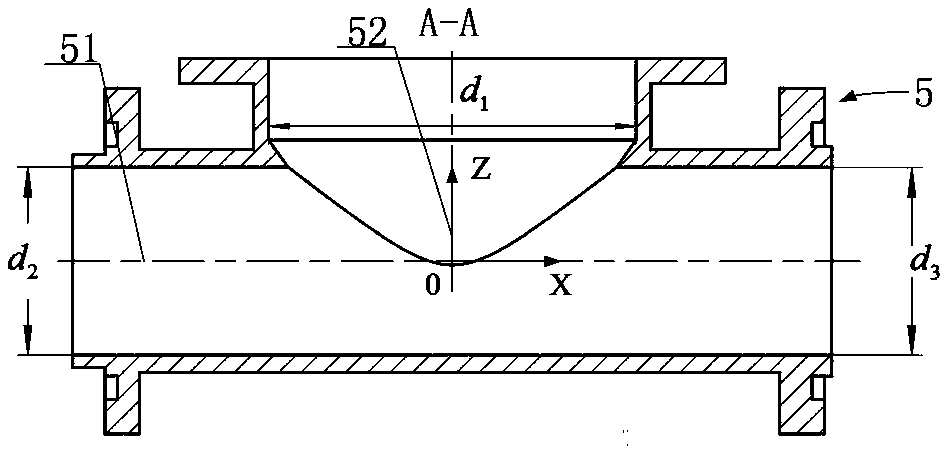

Abrasive flow machining die for uniform polishing of inner wall of cross-hole workpiece and calculating method of cores of abrasive flow machining die

ActiveCN108115543AGuaranteed polishing qualityImprove polishing efficiencyEdge grinding machinesGeometric CADEngineeringDie swell

The invention discloses an abrasive flow machining die for uniform polishing of the inner wall of a cross-hole workpiece and a calculating method of cores of the abrasive flow machining die. The abrasive flow machining die comprises a plurality of passage control units and sealing devices; each passage control unit comprises a transition segment, a guide segment and a core; the passage control units are as many as orifices of a cross-hole workpiece; each passage control unit corresponds to one orifice of the cross-hole workpiece; the passage control units are divided into two groups connectedrespectively with cylinder A and cylinder B in an abrasive flow machining apparatus. The transition segment is arranged at each orifice of a cross-hole workpiece, so that the influence of 'entry effect' upon the cross-hole workpiece is effectively avoided, and the problem that the orifices of the cross-hole workpiece experiences 'over-polishing' is solved. For a cross-hole workpiece, die cores capable of providing equal-allowance uniform polishing for the inner wall of the cross-hole workpiece is are designed; the problem that the cross-hole workpiece experiences non-uniform polishing is solved; polishing quality can be effectively guaranteed, and polishing efficiency can be effectively improved.

Owner:DALIAN UNIV OF TECH

Automatic bent pipe polishing machine

ActiveCN113070792AGuaranteed uniformityAvoid polishing cornersGrinding carriagesBelt grinding machinesPolishingEngineering

The invention discloses an automatic bent pipe polishing machine. The automatic bent pipe polishing machine comprises a machine box, a supporting frame and a bent pipe body, an operation area is arranged on the side face of the machine box, an XY-axis movement mechanism is arranged at the top of the operation area, a rotation driving device is arranged on the XY-axis movement mechanism, the XY-axis movement mechanism is connected with the top of the supporting frame through the rotation driving device, a rotating disc is arranged at the bottom of the supporting frame. the rotating disc is rotationally connected with one side of the supporting frame, a first servo motor is detachably installed on the other corresponding side of the supporting frame, the output end of the first servo motor penetrates through the supporting frame to be connected with a rotating disc belt, a through hole allowing the bent pipe body to penetrate through is formed in the center of the rotating disc, two polishing mechanisms which are distributed in a central symmetry mode with a central axis of the through hole as the center are arranged on one side of the rotating disc, the polishing mechanisms make contact with the surface of the bent pipe body, and the other corresponding side of the rotating disc is rotationally connected with the supporting frame. The automatic bent pipe polishing machine has the beneficial effect that the automatic polishing can be carried out on bent pipes.

Owner:HANGZHOU PANASIA SANITARY WARE

Multi-station automatic round head connecting pipe polishing equipment

PendingCN110181373ARealize indexing rotation movementIncrease brightnessPolishing machinesGrinding drivesWaxMotor drive

The invention discloses multi-station automatic round head connecting pipe polishing equipment. Positioning clamps, a clamp rotation shaft, a disc workbench, a control panel, a sliding table, a motor,an automatic wax spraying device, a divider, a first servo motor, a second servo motor and the like are included. The positioning clamps are fixed to the clamp rotation shaft, workpieces are arrangedon the positioning clamps, and the clamp rotation shaft is arranged on the disc workbench. An output shaft of the first servo motor is connected with an input shaft of the divider, and the disc workbench is arranged on an output shaft of the divider. The second servo motor drives the clamp rotation shaft to do the rotation movement. A polishing wheel is arranged on the sliding table and located on the lateral sides of the positioning clamps, the sliding table is arranged on the machine tool base, and the polishing wheel is driven by a motor and conducts polishing treatment on the workpiece surface; and the automatic wax spraying device is fixed to a support and located on the lateral side of the polishing wheel, and the automatic wax spraying device conducts wax spraying on the workpieces. According to the multi-station automatic round head connecting pipe polishing equipment, the production efficiency and the product surface polishing quality are improved, and the enterprise production cost is reduced.

Owner:GUANGDONG HENGBAO IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com