Pipe inner wall grinding and polishing device

A technique for polishing devices and inner walls of tubes, which is applied in grinding/polishing equipment, grinding machines, and machine tools designed for grinding workpiece rotating surfaces. It can solve problems such as low work efficiency, easy vibration, and difficult control of pressing force. Achieve the effect of improving work efficiency and ensuring the quality of grinding or polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

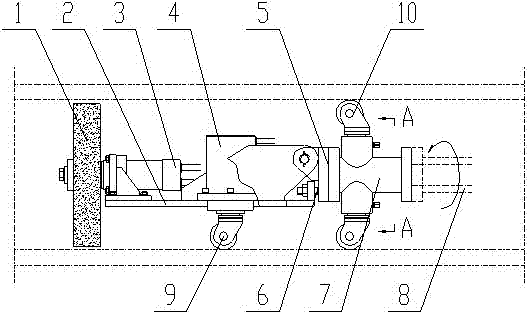

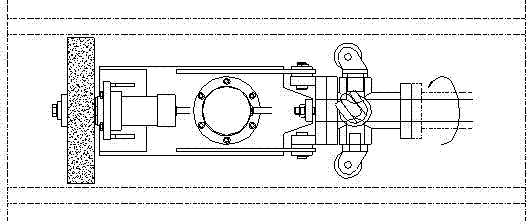

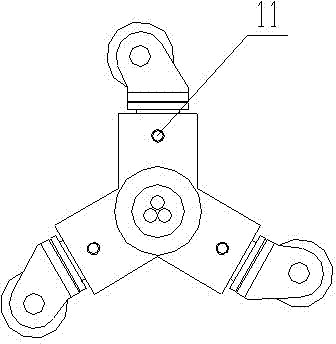

[0028] see Figure 1~Figure 3 , a pipe inner wall grinding and polishing device of the present invention, which includes a draw bar 8, the draw bar 8 adopts a hollow tubular rod inside, and the inside can pass through cables, hydraulic or pneumatic pipelines, etc., and the front end of the draw bar 8 is set There is a centering support 7, and three second active wheels 10 with adjustable radial telescopic distance are evenly arranged around the centering support 7 to play the role of centering support, and the second active wheels 10 are connected by set screws 11 It is fixed with the centering bracket 7, the bracket seat 5 is arranged on the centering bracket 7, the front end of the bracket seat 5 is hinged with a swing bracket 2, and the front end of the swing bracket 2 is fixed with a power part 3, so The power part 3 adopts a motor or a hydraulic motor, etc., the output end of the power part 3 is provided with a grinding wheel 1, and the middle part of the swing bracket 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com