A grinding device for the inner wall of metal pipe fittings

A technology of metal pipe fittings and grinding discs, which is applied in the direction of grinding drive devices, metal processing equipment, grinding machines, etc., can solve the problems of poor adaptability and low efficiency, and achieve the effects of good protection, reduced impact damage, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

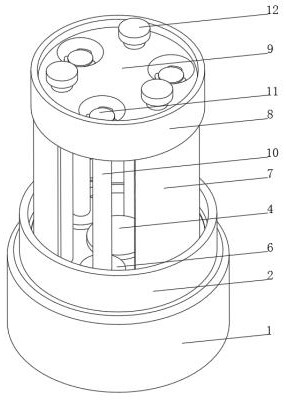

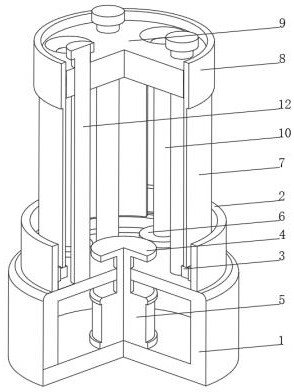

[0035] see Figure 1-4 , the present invention provides a technical solution: a grinding device for the inner wall of a metal pipe fitting, specifically comprising:

[0036] A fixed base 1, the top of the fixed base 1 is fixedly connected with a retaining ring 2, the inner wall of the retaining ring 2 is slidably connected with an inner gear ring 3 through an annular slideway, and the top of the fixed base 1 is fixedly connected with a limit rod 12;

[0037]Drive gear 4, the drive gear 4 is arranged inside the retaining ring 2, the drive shaft of the drive motor 5 is fixedly connected to the bottom of the drive gear 4, the drive motor 5 is arranged inside the fixed base 1, and the side of the drive gear 4 is meshed with a driven gear 6, The side of the driven gear 6 away from the drive gear 4 meshes with the inner wall of the ring gear 3;

[0038] Arc-shaped rotating plate 7, the bottom of the arc-shaped rotating plate 7 meshes with the top of the ring gear 3, the top of the ...

Embodiment 2

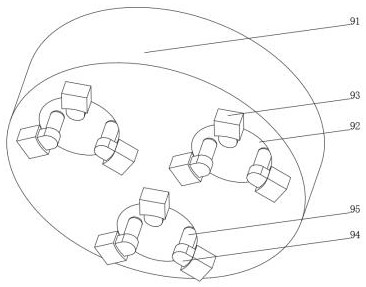

[0046] see Figure 1-5 On the basis of Embodiment 1, the present invention provides a technical solution: the grinding device 11 includes a grinding disc 111, the side of the grinding disc 111 is provided with a chute 112, and the inner wall of the chute 112 is slidably connected with a sliding rod 113, and the sliding rod 113 and the sliding rod 113 are connected to each other. A telescopic spring 114 is arranged between the inner walls of the grooves 112, and one end of the sliding rod 113 extends to the outside of the chute 112 and is fixedly connected with a grinding head 115, the side of the grinding head 115 is provided with a mounting groove 116, and the inner wall of the mounting groove 116 is rotatably connected with a hexagonal grinding rod 117 , the bottom of the grinding disc 111 is fixedly connected with the top of the rotating rod 10, the chute 112 is provided with multiple groups and is evenly distributed on the side of the grinding disc 111, the grinding head 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com