Patents

Literature

50results about How to "Control the pressing force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

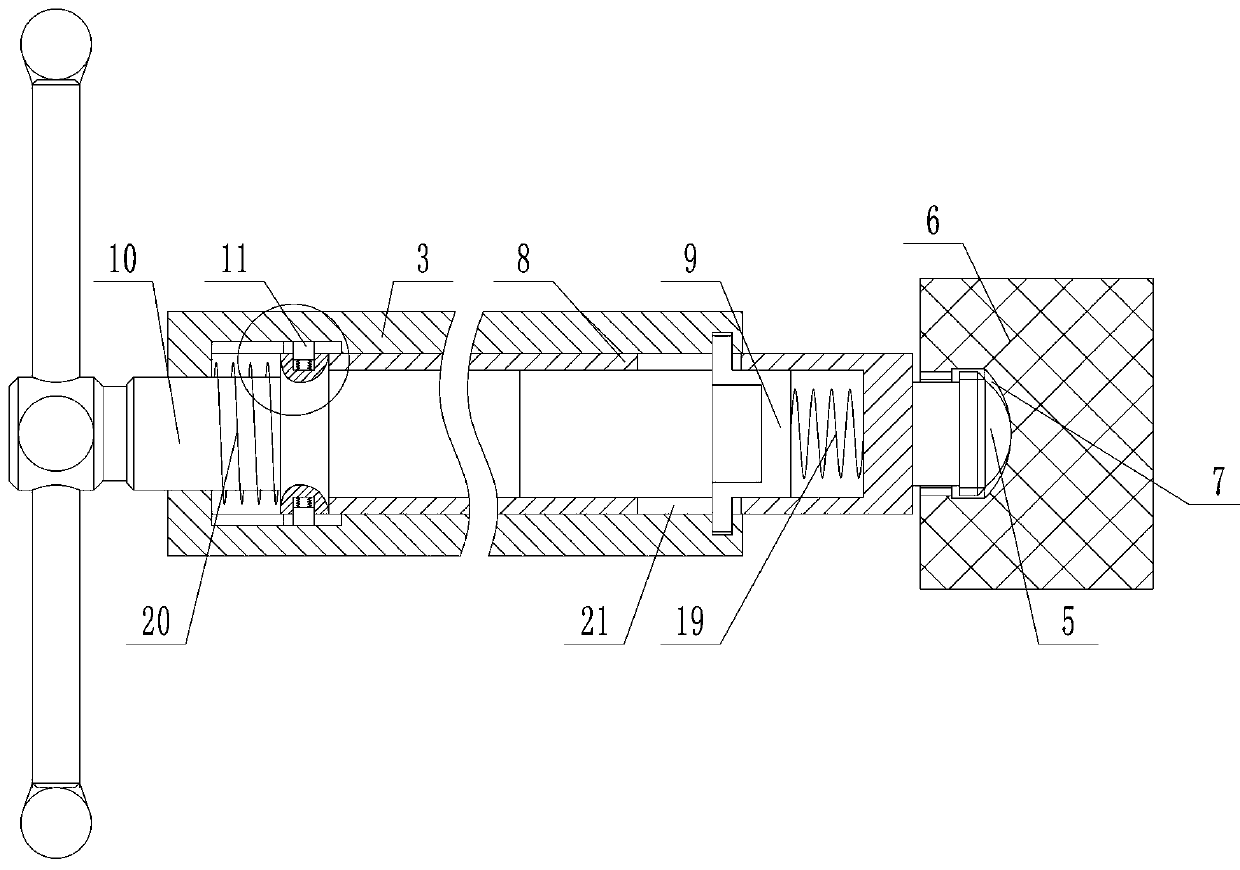

Pipe inner wall grinding and polishing device

InactiveCN103506903AControl the pressing forceImprove work efficiencyRevolution surface grinding machinesEngineeringGrinding wheel

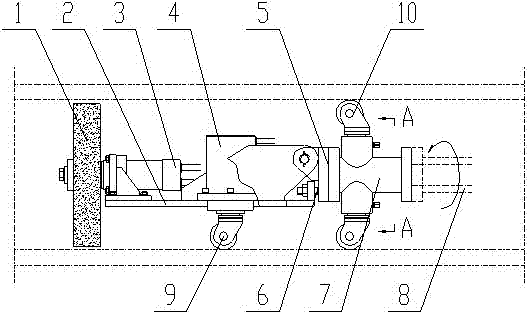

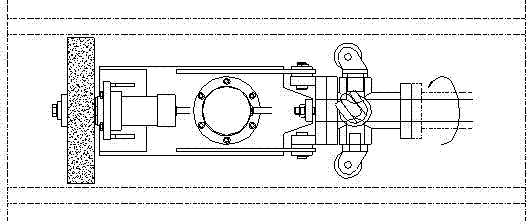

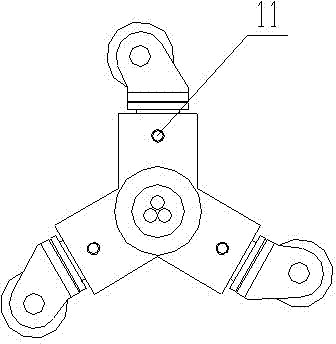

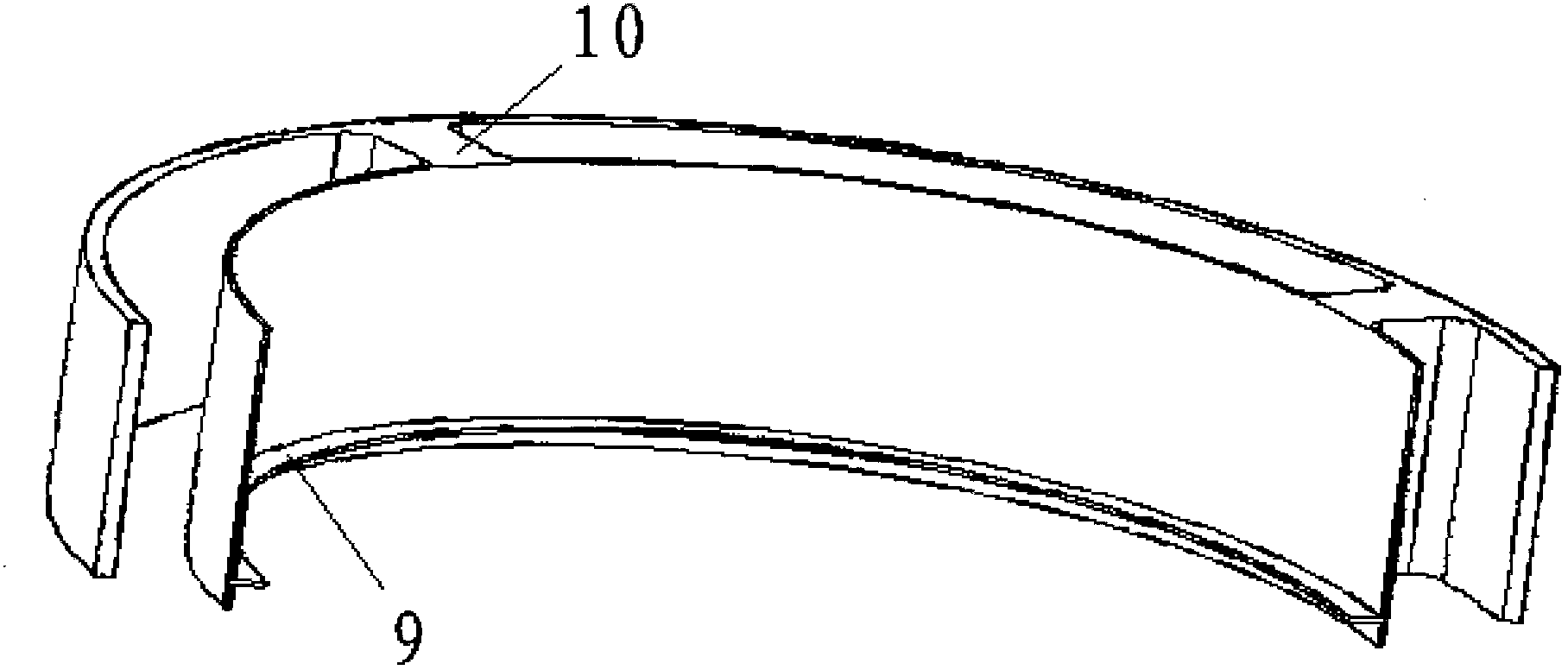

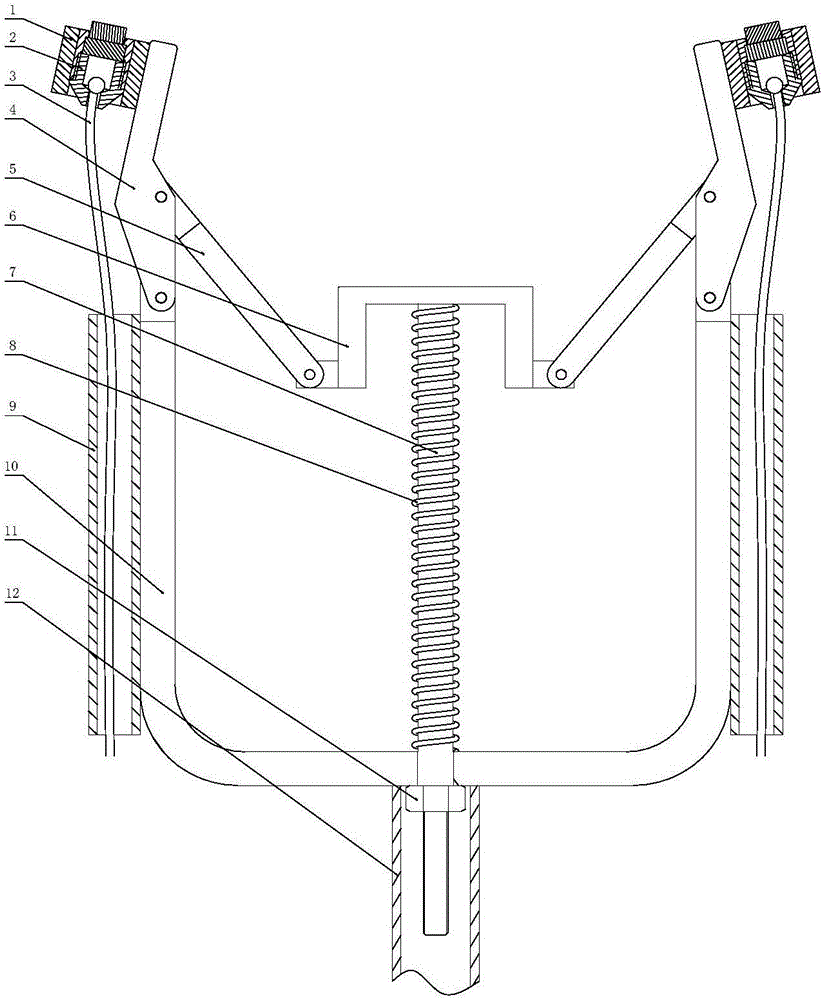

The invention relates to a pipe inner wall grinding and polishing device. The pipe inner wall grinding and polishing device comprises a drawing rod (8), wherein a centering bracket (7) is arranged at the front end of the drawing rod (8); three second adjustable wheels (10) are arranged at the periphery of the centering bracket (7) uniformly; a bracket seat (5) is arranged on the centering bracket (7); the front end of the bracket seat (5) is hinged to a swinging bracket (2); a power part (3) is arranged at the front end of the swinging bracket (2); a grinding wheel (1) is arranged at the output end of the power part (3); a jacking part (4) is arranged in the middle of the swinging bracket (2); a first adjustable wheel (9) is arranged at the output end of the jacking part (4); a swinging bracket swinging angle limiter (6) is fixedly arranged at the rear end of the swinging bracket (2). The pipe inner wall grinding and polishing device provided by the invention improves the grinding or polishing efficiency and can effectively control the pressing force to the pipe inner wall so as to guarantee the final grinding or polishing quality.

Owner:江苏乐基重工机械有限公司

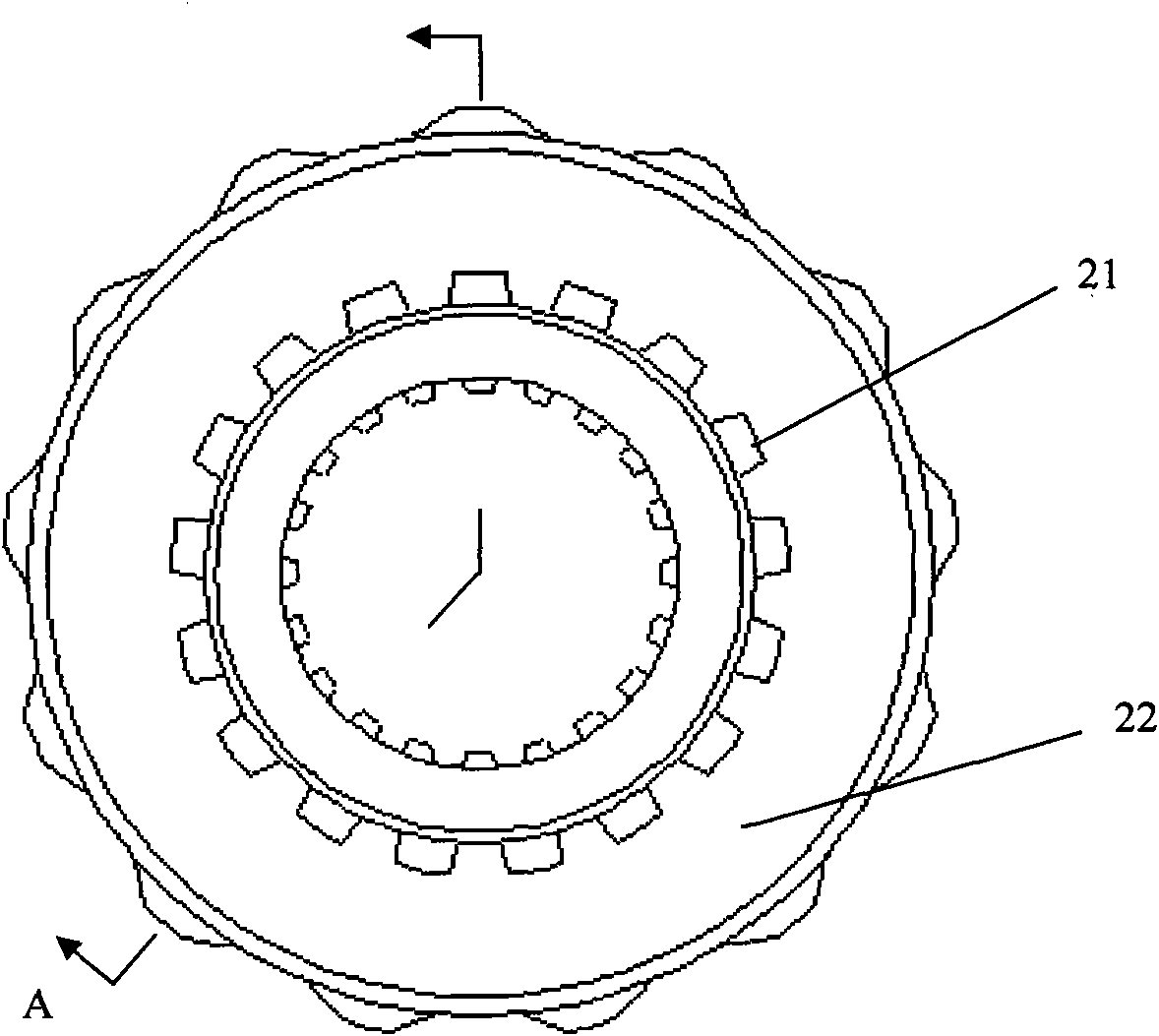

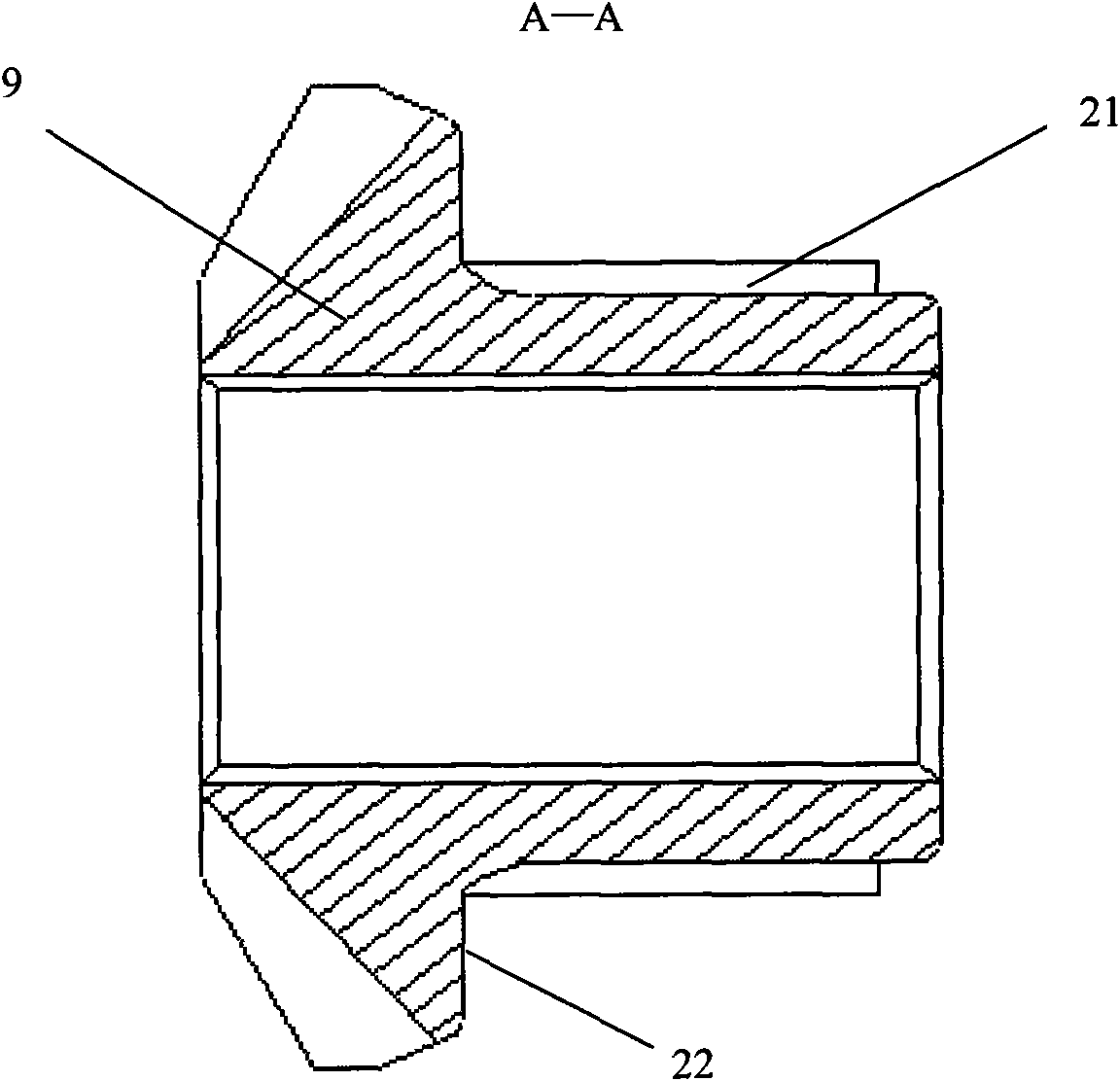

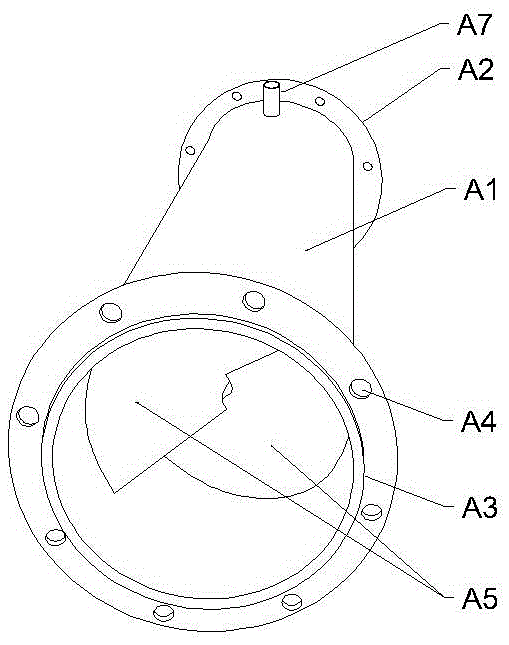

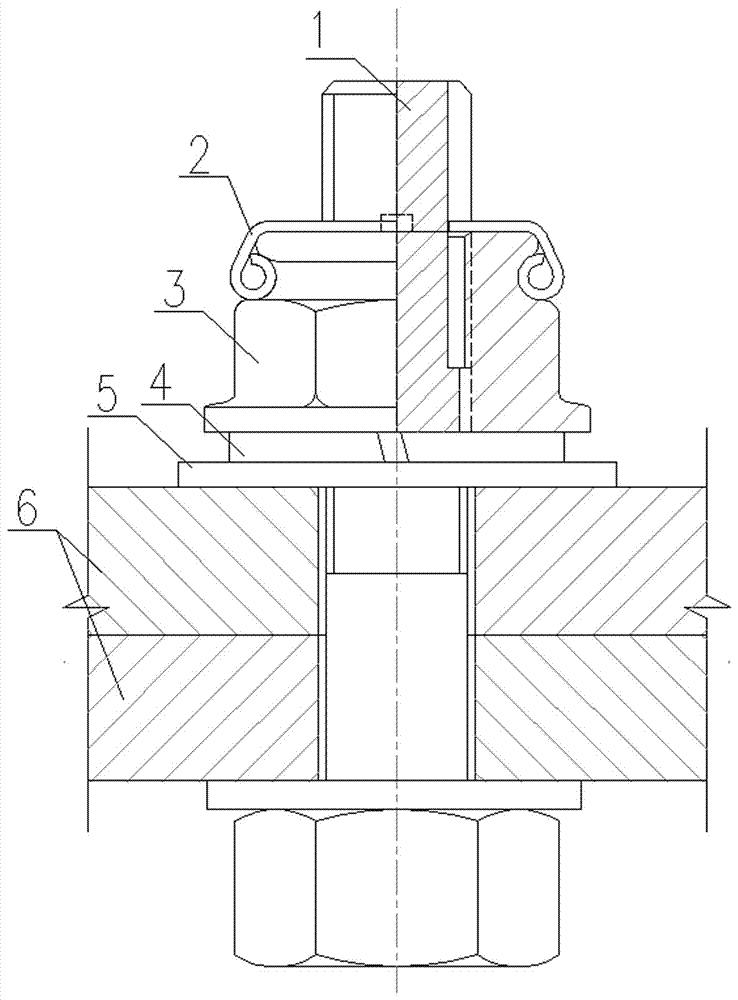

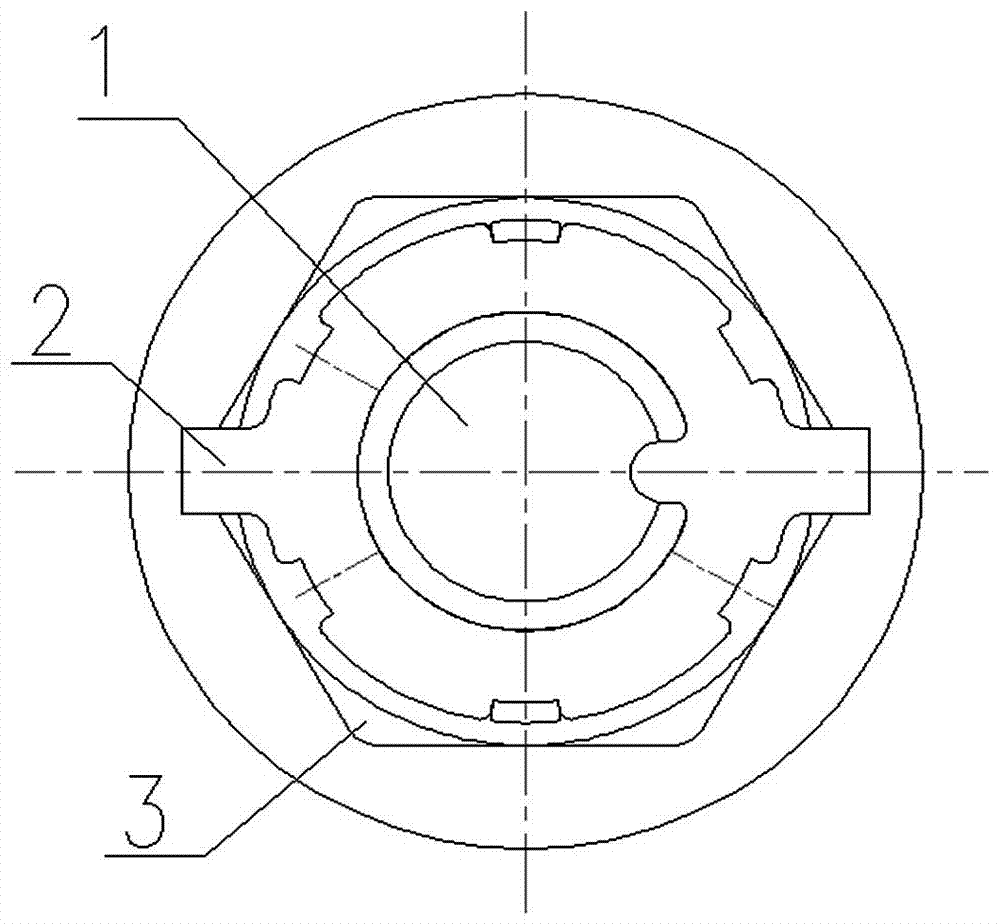

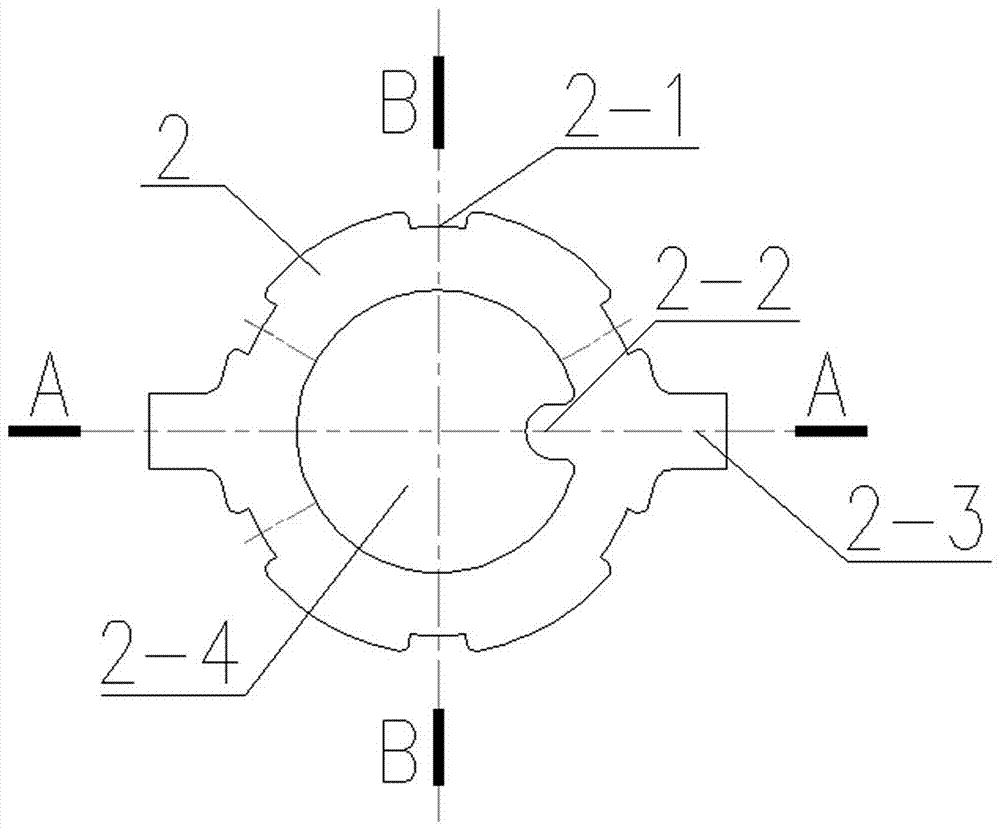

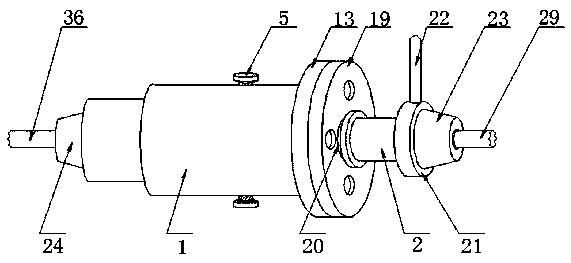

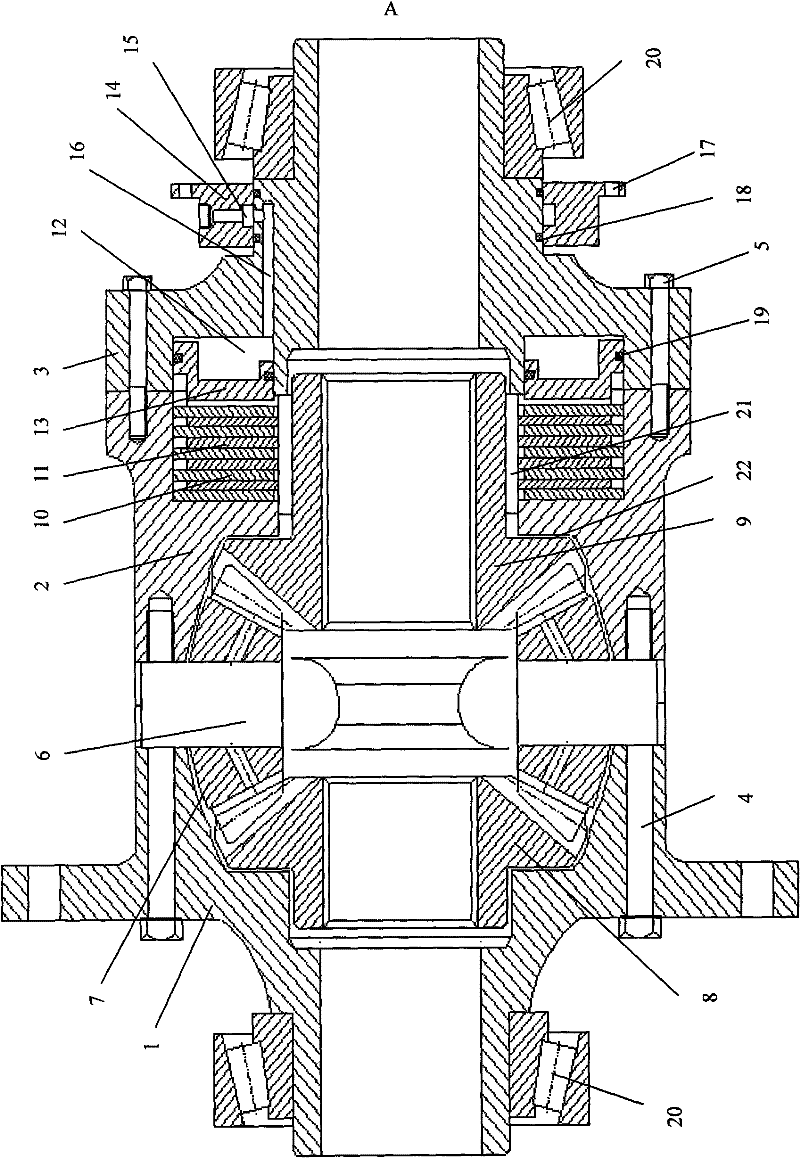

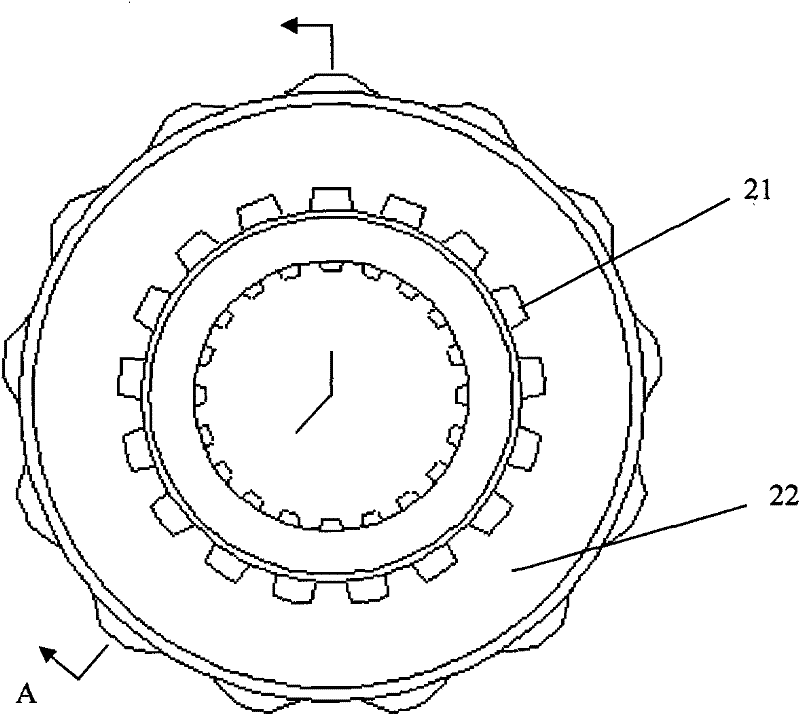

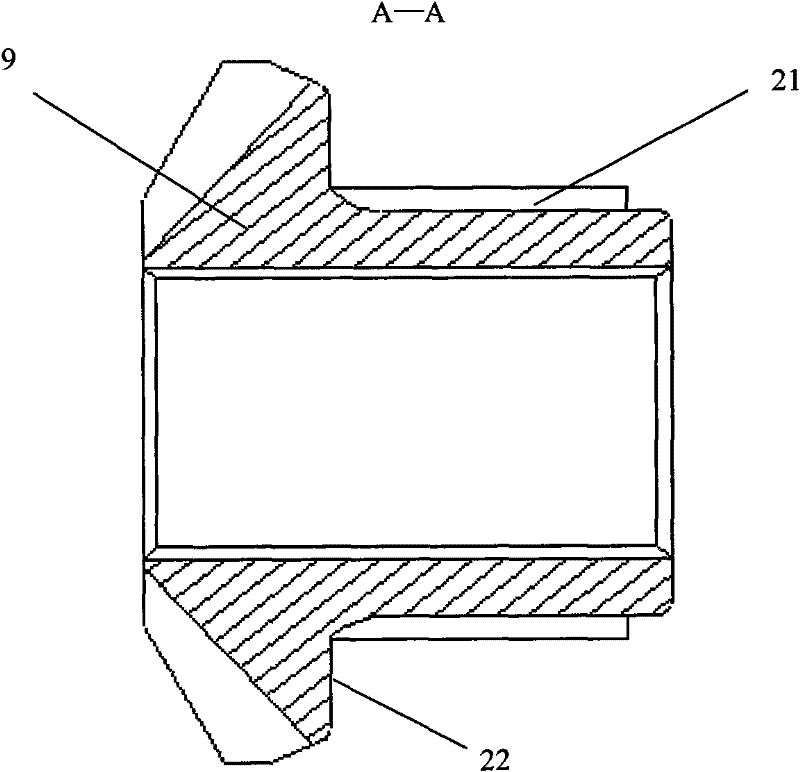

Hydraulic limited slip differential

InactiveCN101793317ALocking coefficient controlControl the pressing forceGearboxesDifferential gearingsLimited-slip differentialGear wheel

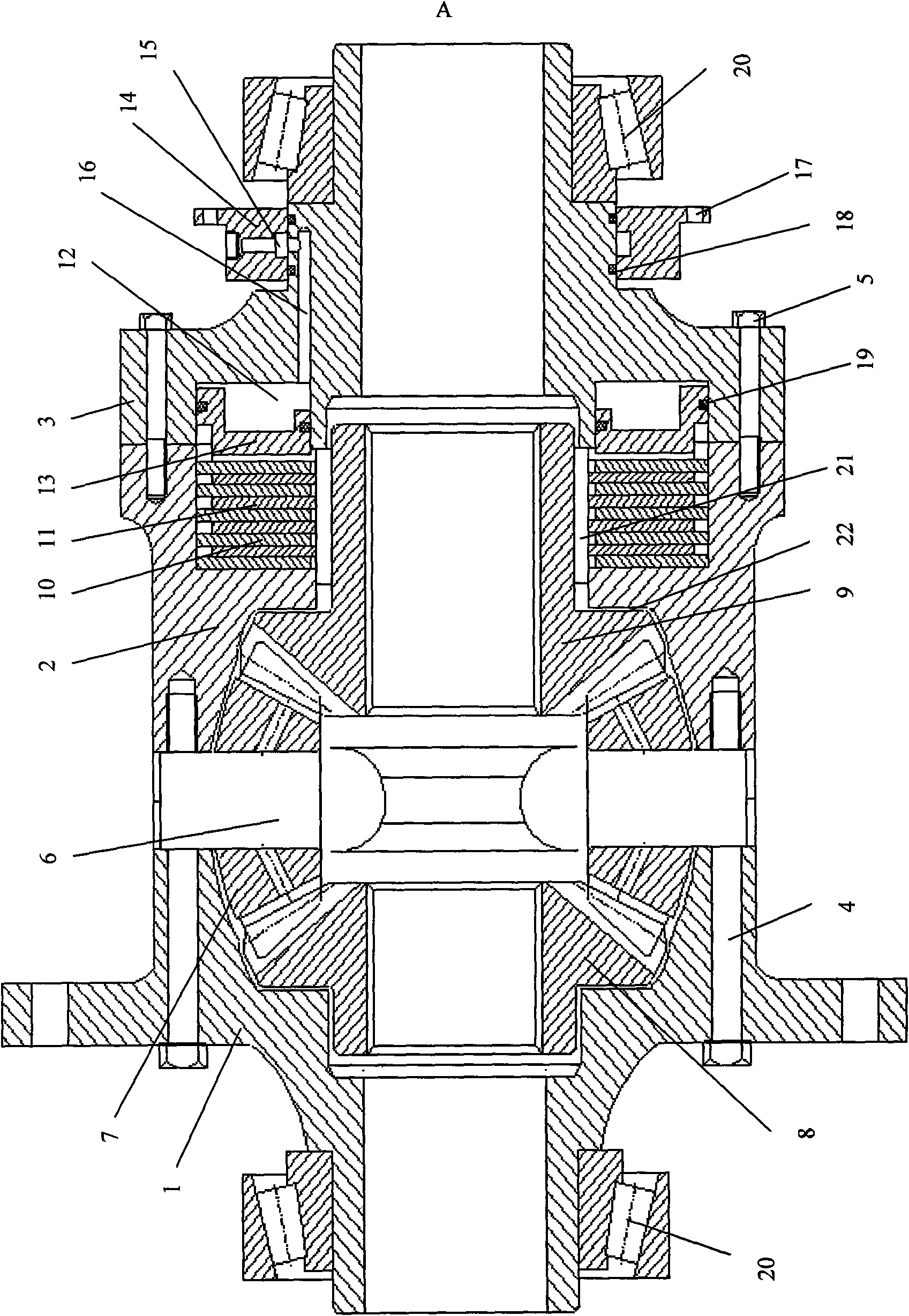

The invention discloses a hydraulic limited slip differential, which comprises a housing, a planetary gear train and a hydraulic limited slip mechanism, wherein the hydraulic limited slip mechanism comprises a limited slip friction pair, a hydraulic device and an oil conveying disc, and the hydraulic limited slip mechanism is arranged at one side or two sides of the planetary gear train; the planetary gear train, the limited slip friction pair and the hydraulic device are arranged in the housing; the tooth back of the half axle gear of the planetary gear train is separated from the limited slip friction pair by the housing, and the driving friction plate of the limited slip friction pair is connected with the housing by spline teeth; the driven friction plate of the limited slip friction pair is connected with the half axle gear at the same side through spline teeth, and the hydraulic device comprises an annular oil cylinder and an annular piston; the annular oil cylinder is separated from the limited slip friction pair by the annular piston, and the oil conveying disc is arranged on the neck journal of the housing; and an oil sink is arranged on the oil conveying disc and is communicated with the annular oil cylinder. The invention has the advantages that: when in work, the reaction force of the friction pair on the annular piston only acts on the housing of the differential and does not affect other external parts, and the work is smooth.

Owner:ZHEJIANG SCI-TECH UNIV

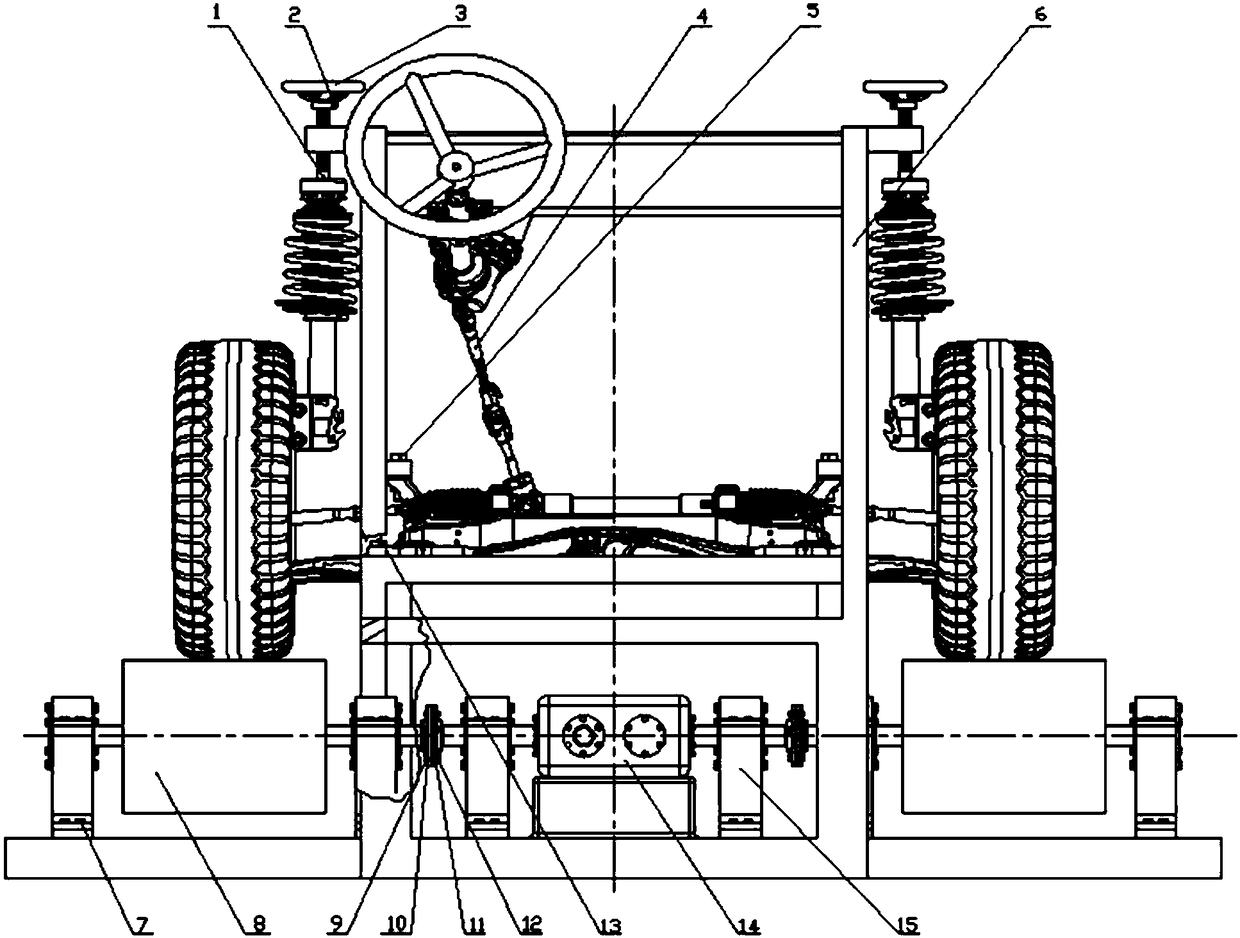

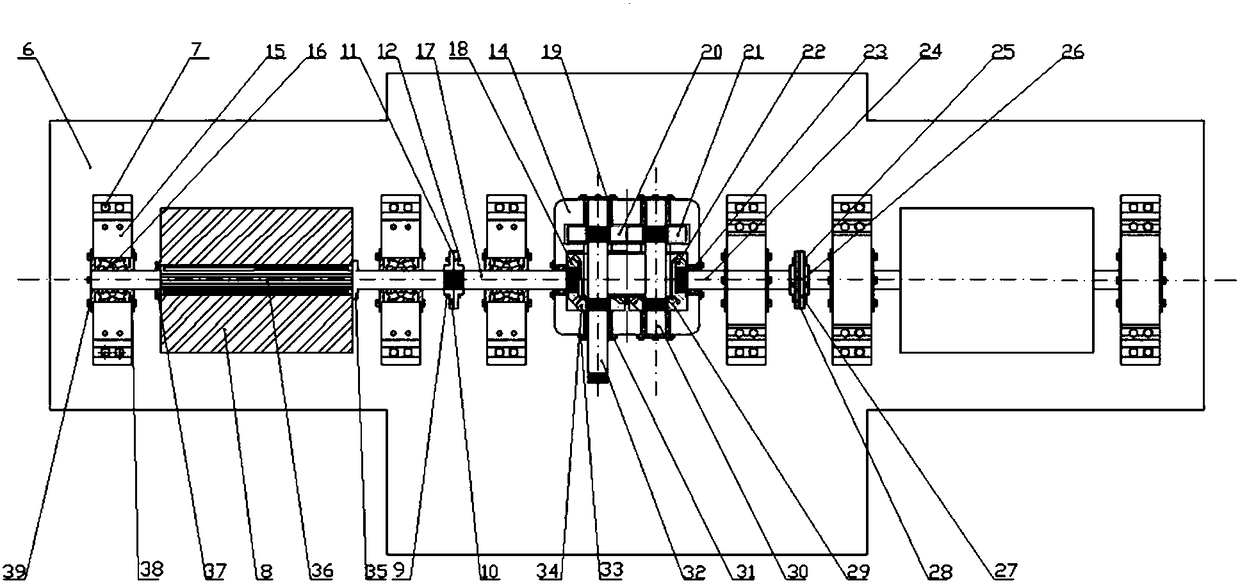

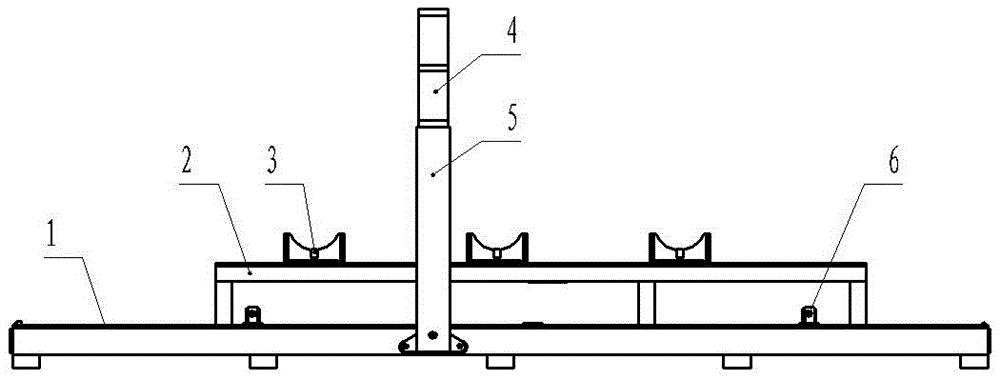

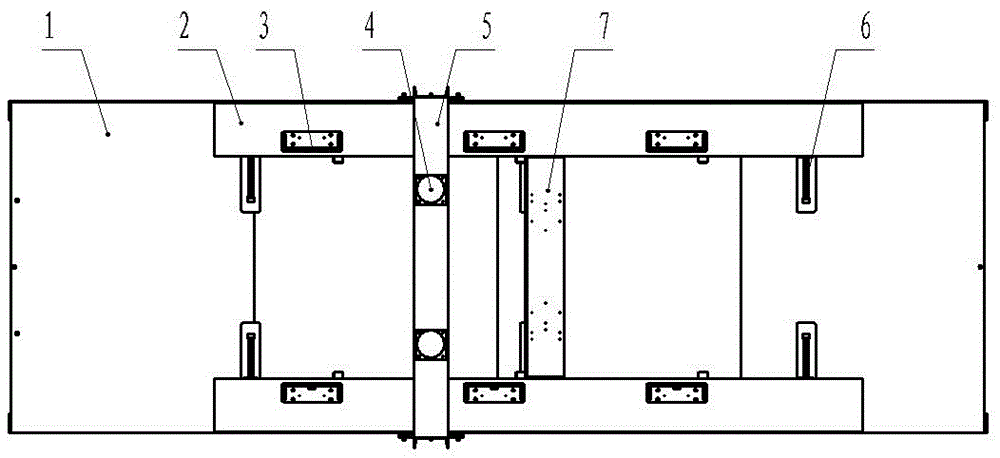

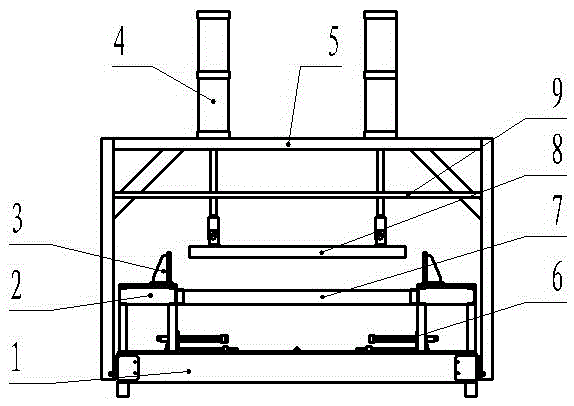

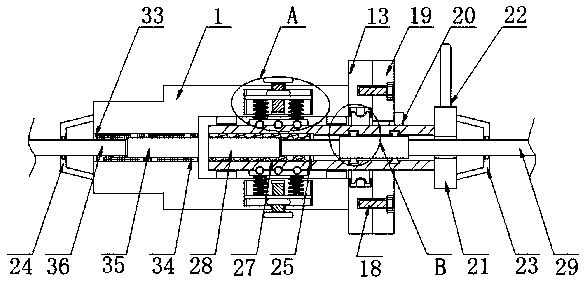

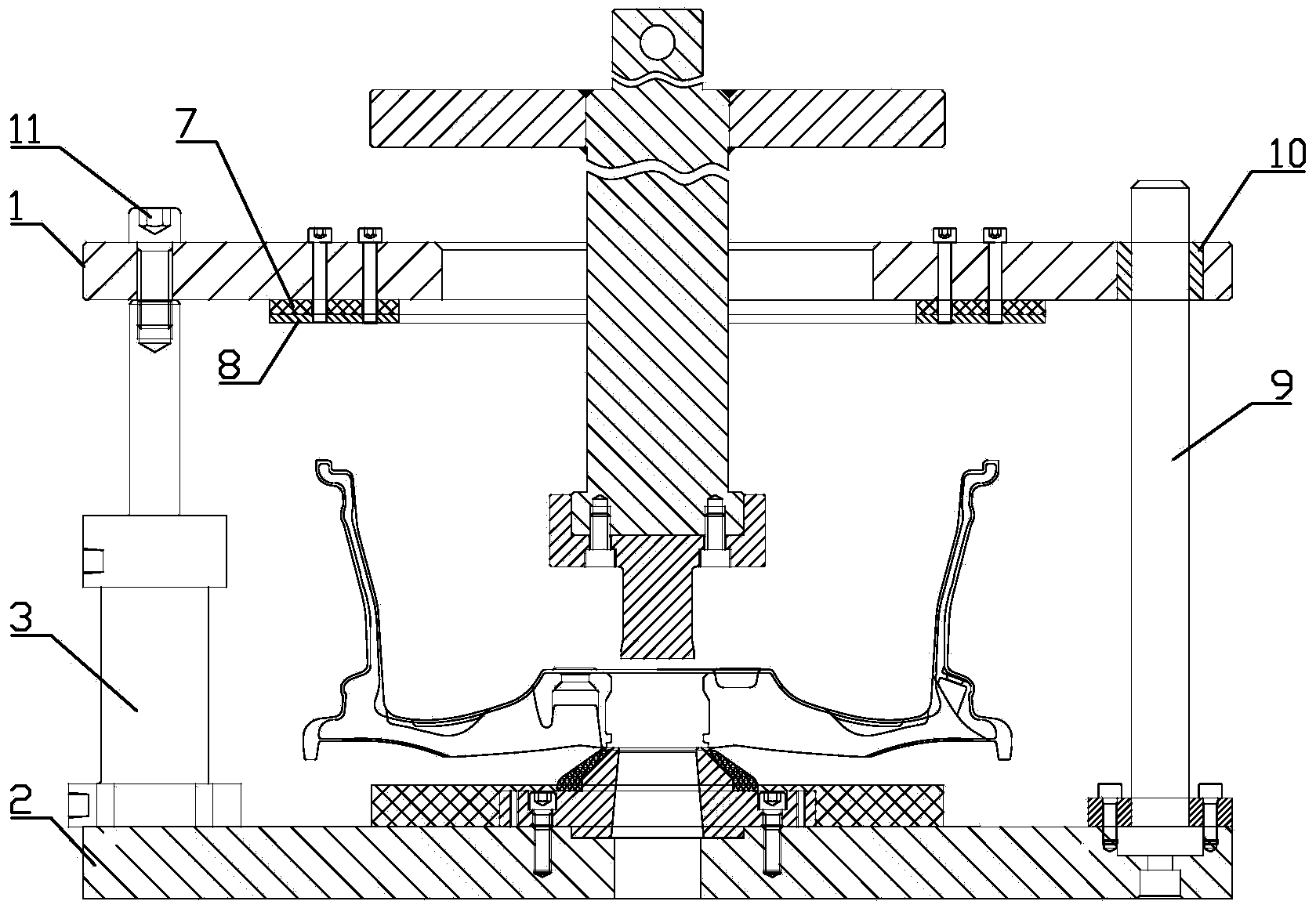

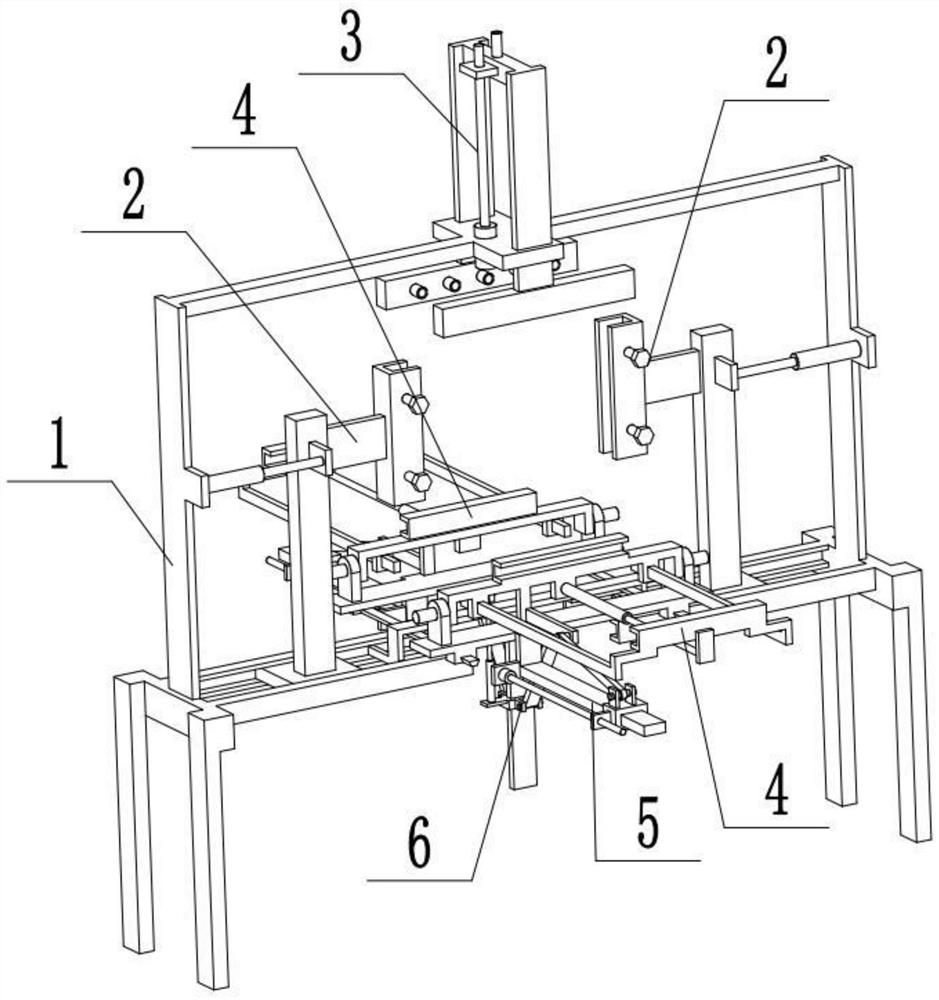

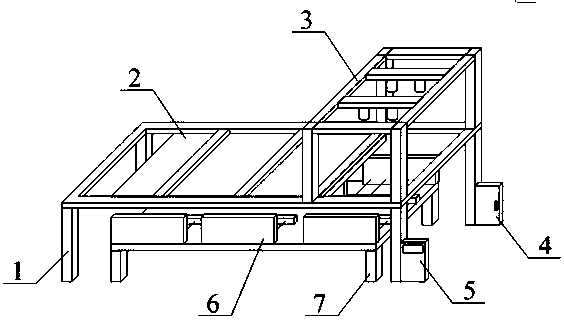

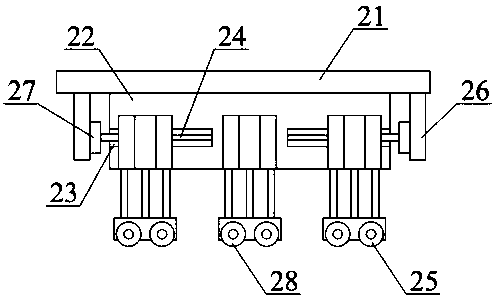

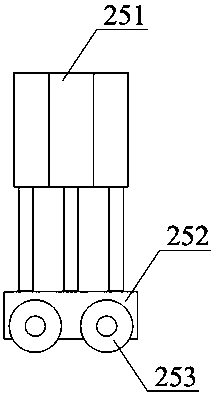

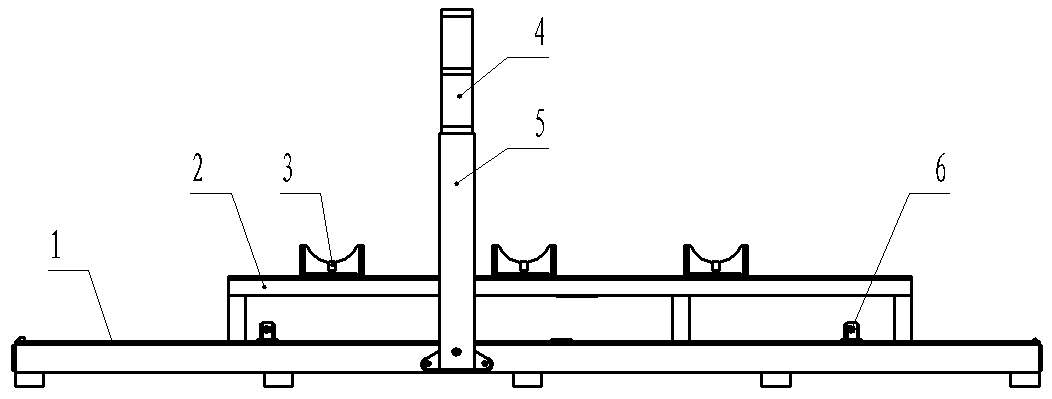

Roller-type multi-road-condition simulated testing stand of electric power assisted steering system

InactiveCN108168902AMock tests are real and reliableIncrease diversityVehicle testingElectric power steeringStanding frame

The invention discloses a roller-type multi-road-condition simulated testing stand of an electric power assisted steering system. The testing stand comprise a testing stand frame, compression mechanisms, rollers, a roller driving mechanism and an electric power assisted steering device, the two rollers are erected at the two sides of the testing stand frame respectively and installed on a bearingpedestal, the roller driving mechanism is arranged between the rollers, each roller is provided with a wheel, the bottom of the wheel makes contact with the surface of the corresponding roller, the two compression mechanisms are arranged at the two sides of the upper portion of the testing stand frame respectively, and the electric power assisted steering device is mounted on the testing stand frame, and connected with the two wheels. The rollers and the roller driving mechanism are arranged additionally on the basis of a present electric power assisted steering testing stand, and during test,the roller driving mechanism drives the rollers to roll, the rollers drive the wheels to rotate via friction between the rollers and the wheels, the wheels realizes roller of the wheels while rotating, real vehicle road test is realized in the reverse direction, and simulated test approaches the real test more and is more reliable.

Owner:HUNAN UNIV OF SCI & TECH

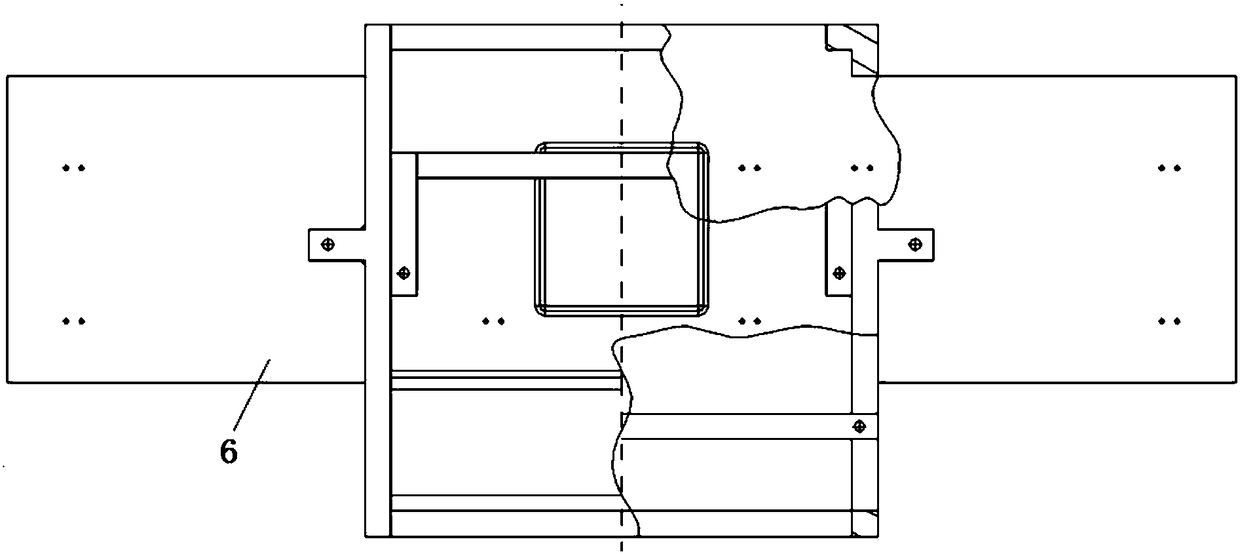

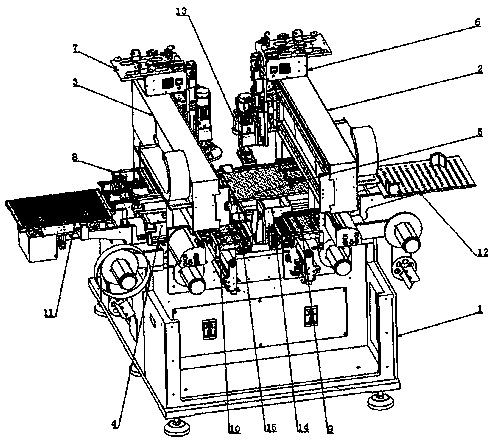

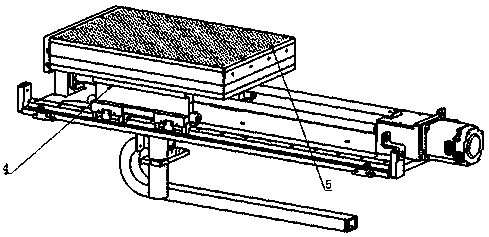

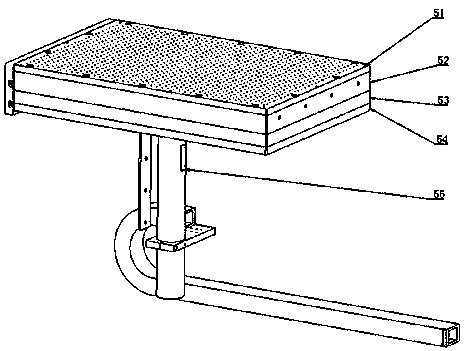

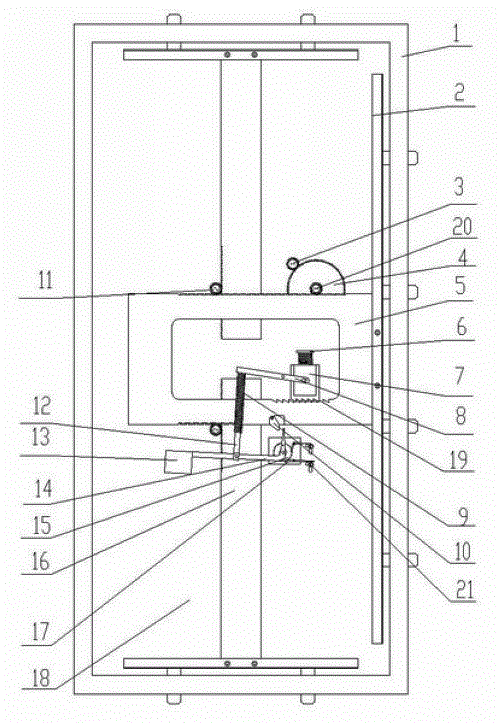

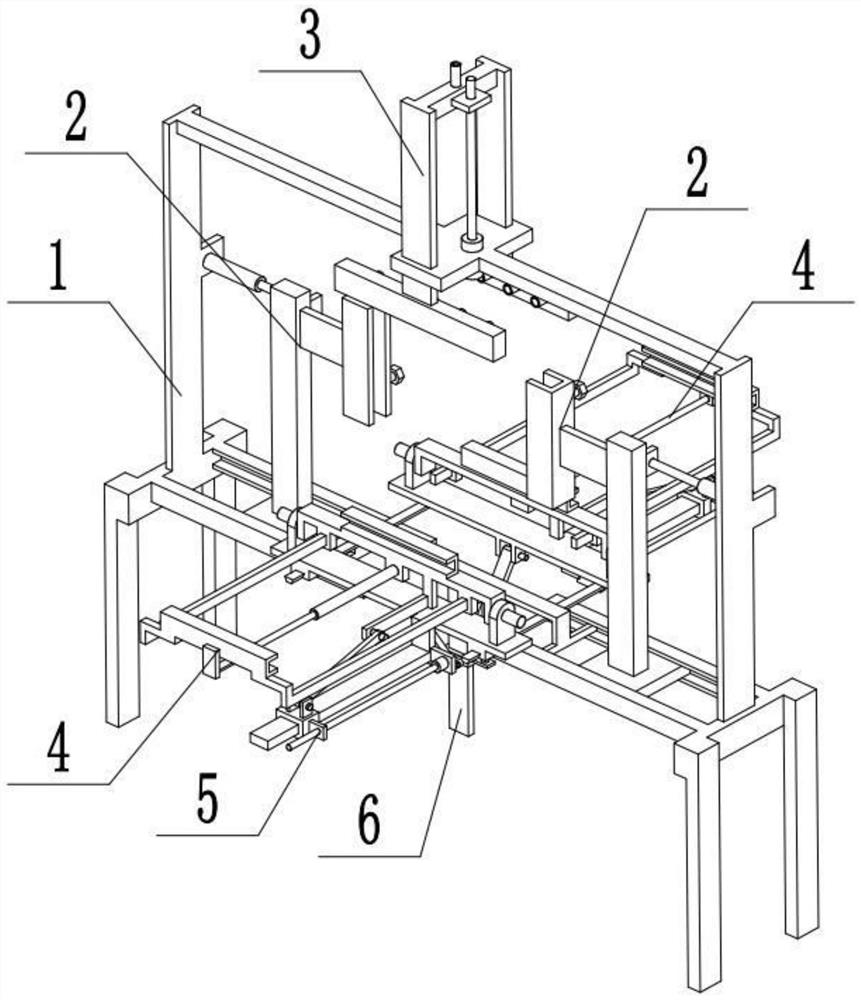

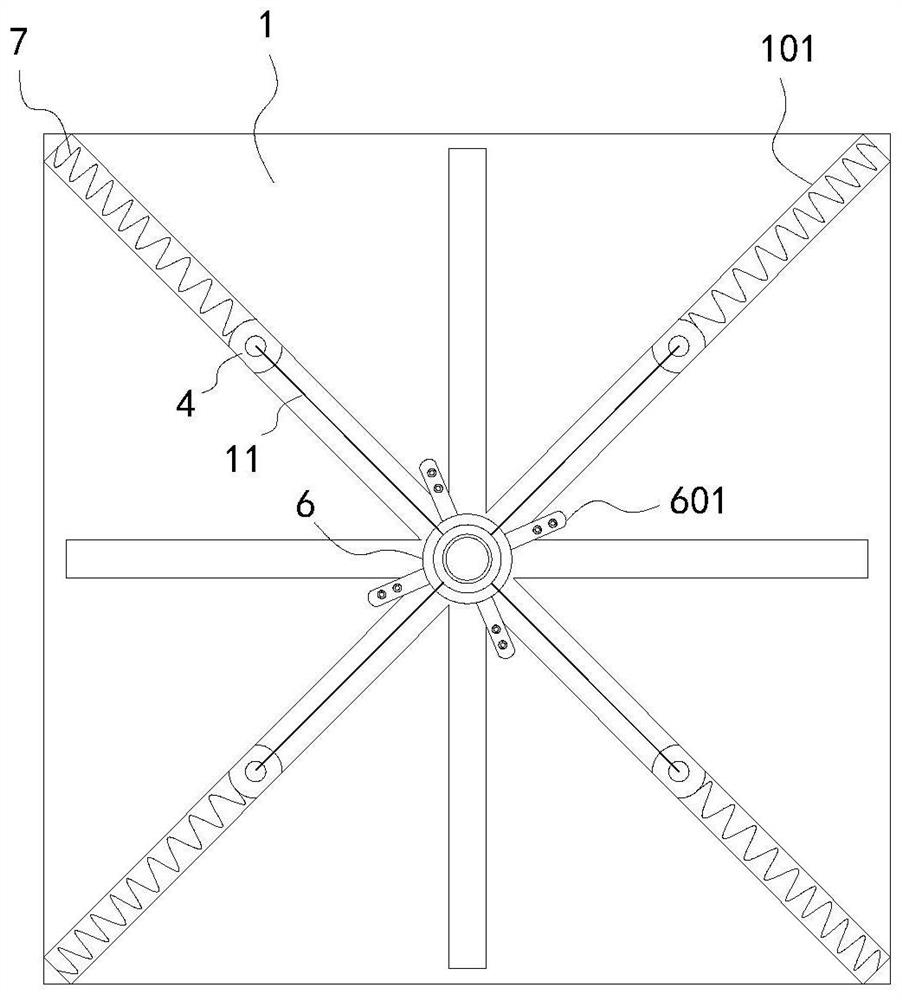

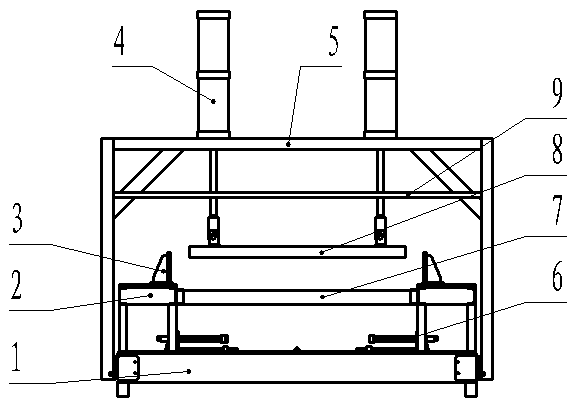

Full-automatic multifunctional laminating machine

InactiveCN110505765ASave handling timeRealize continuous laminating productionCircuit bendability/stretchabilityPrinted circuit secondary treatmentLinear motionEngineering

The invention provides a full-automatic multifunctional laminating machine comprising a machine frame, a first X axis linear motion module group, a second X axis linear motion module group, a Y axis straight line motion module group, a laminating platform, two laminating heads, double carrying feeding discharging arms, two feeding devices, a feeding box, and a discharging box. The laminating machine is provided with the double carrying feeding discharging arms, and then the feeding and the discharging can be carried out at the same time, and therefore FPC board conveying time can be saved. A plurality of laminating machines can be assembled in a cooperated manner, and by adopting a way of sharing the feeding box and the discharging box, the continuous laminating production of the FPC boards can be realized, and reinforced sheets of various specifications can be laminated continuously. The two laminating heads and the corresponding feeding devices are used to absorb the reinforced sheets alternately and repeatedly, and are attached to predetermined positions to be provided with the FPC in an attached way, and therefore laminating efficiency is greatly improved. Meanwhile, an image processor is provided in a matched manner, and the laminating precision is improved. The laminating heads are provided with springs, and by controlling the amount of compression of the springs, the pressing strength of the laminating heads applied to the FPC boards during the laminating can be controlled, and the FPC boards can be prevented from being damaged.

Owner:SHENZHEN BANGZHENG PRECISION MACHINERY CO LTD

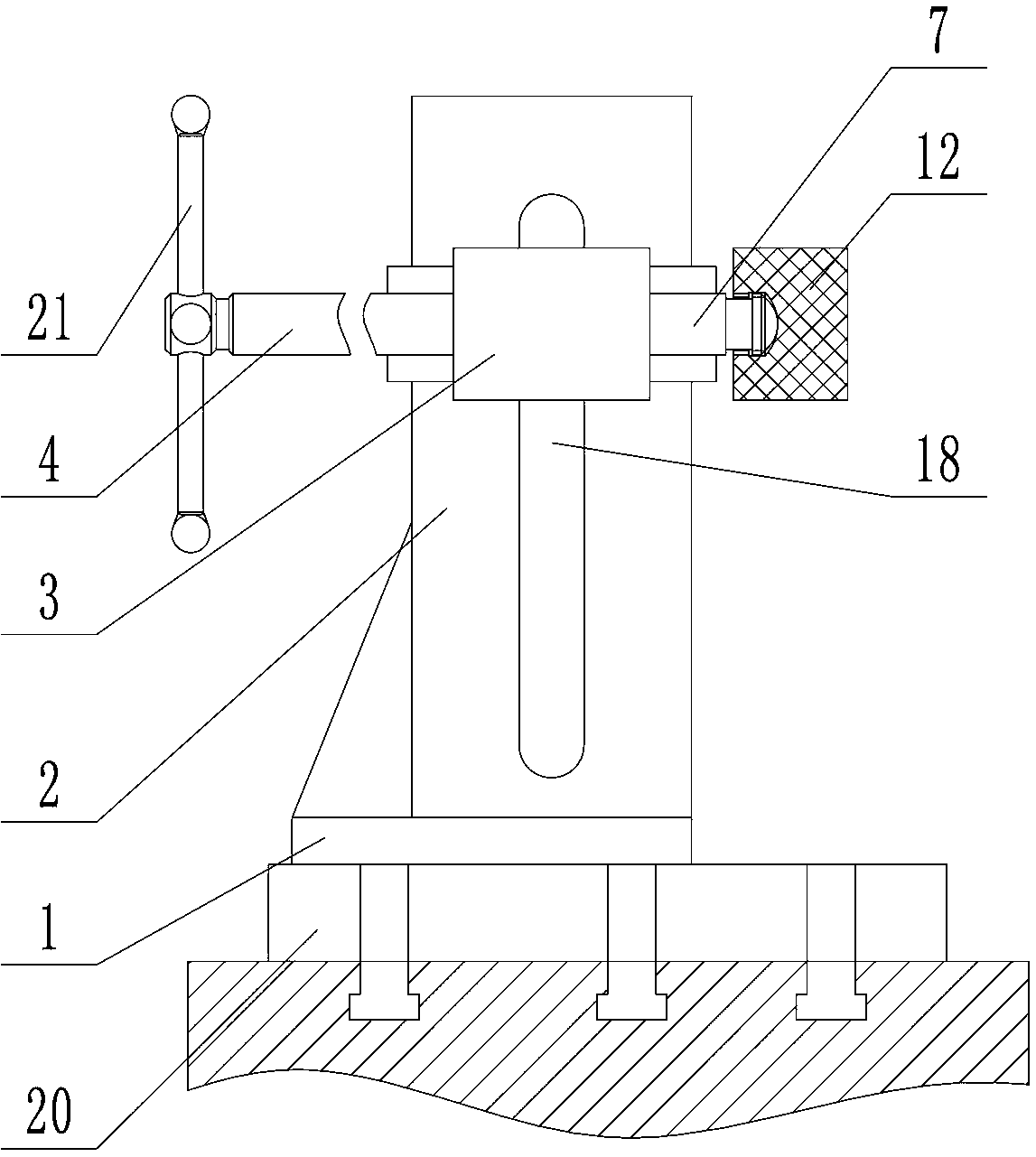

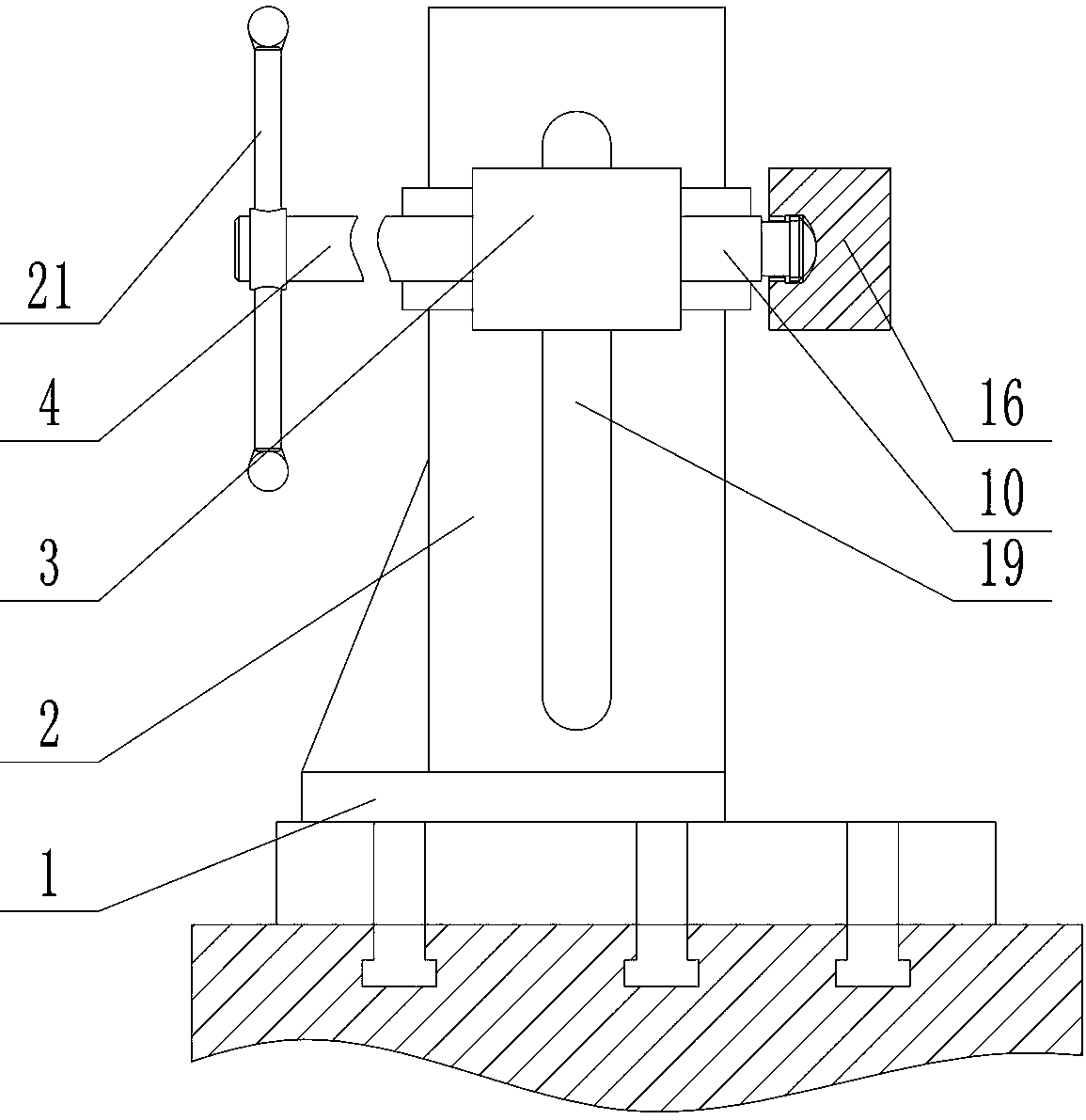

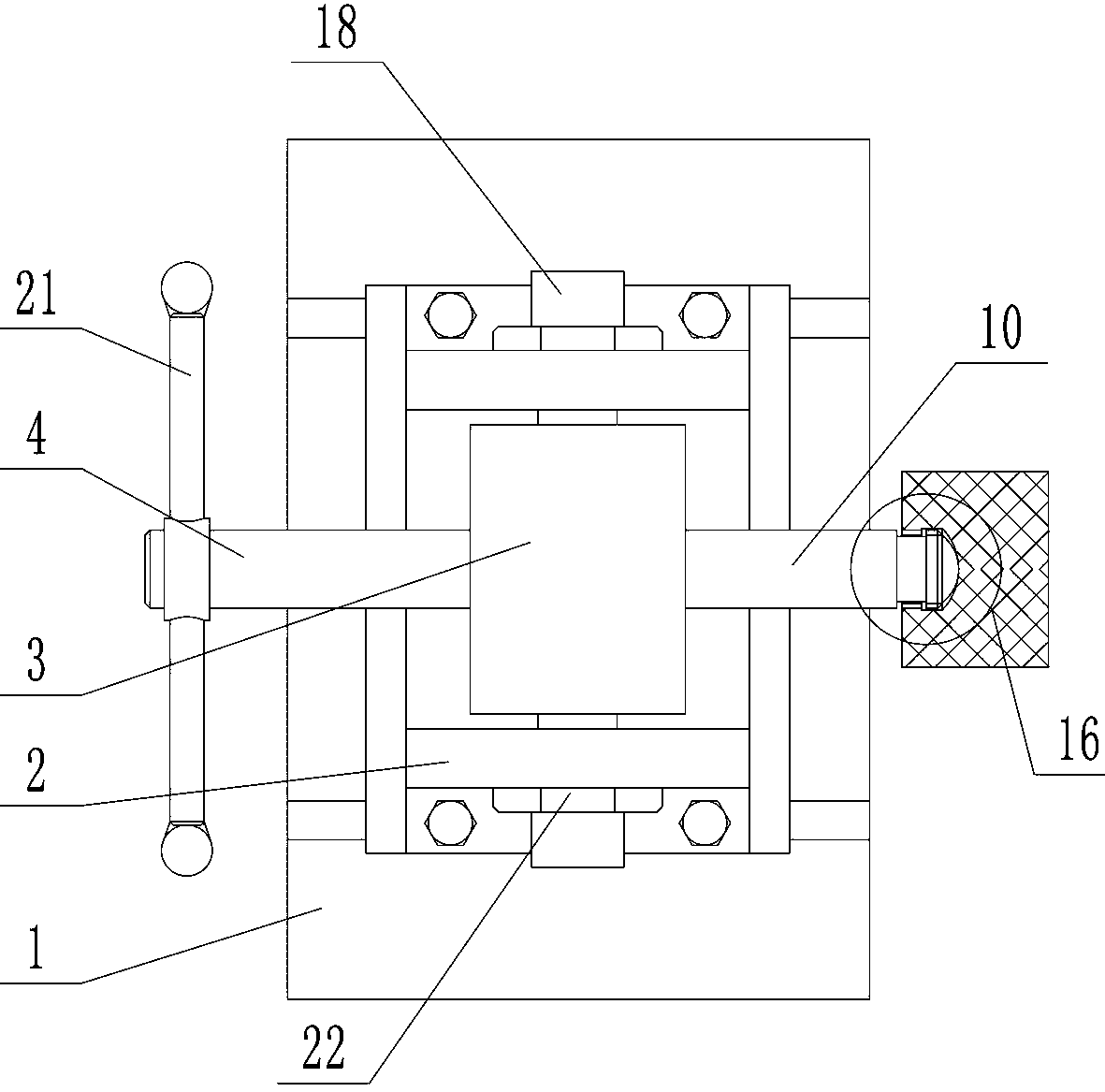

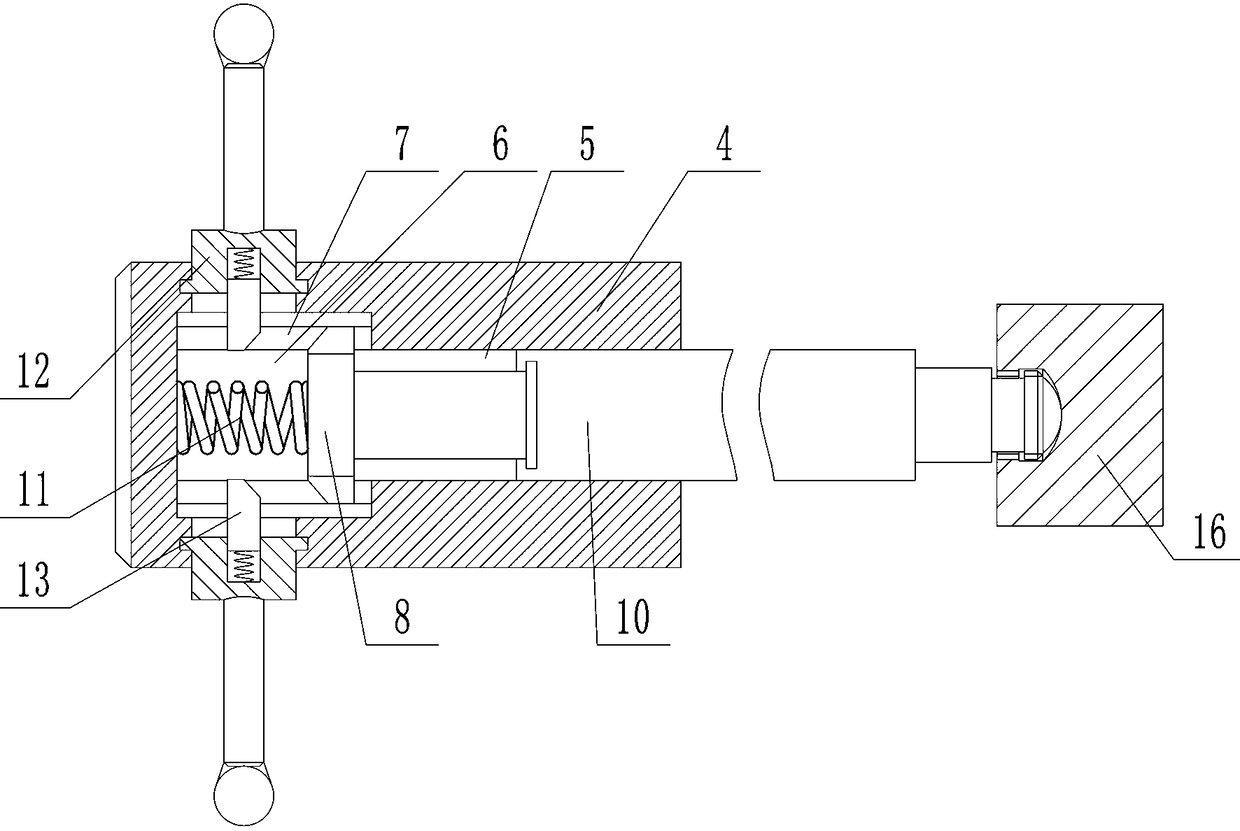

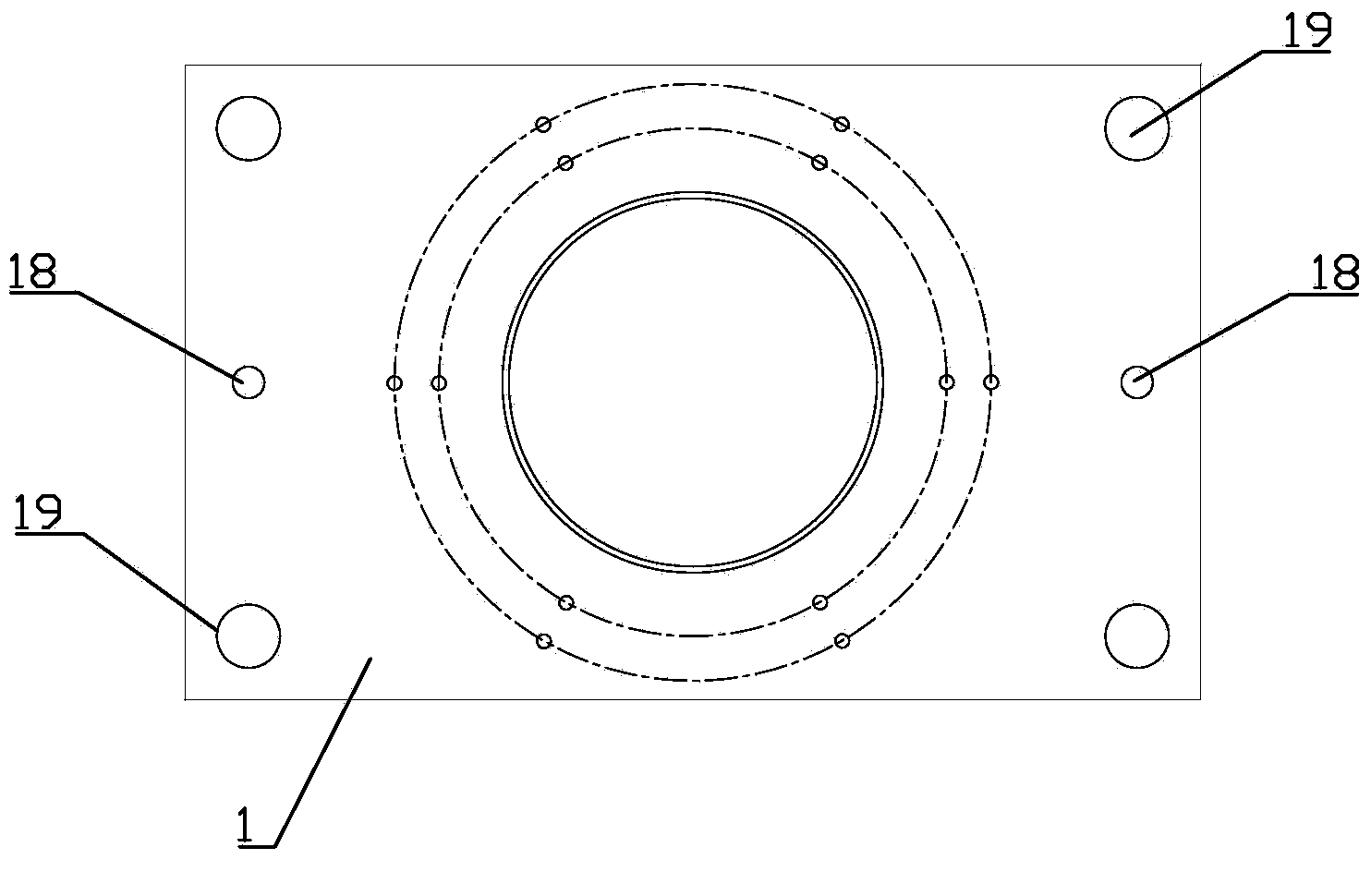

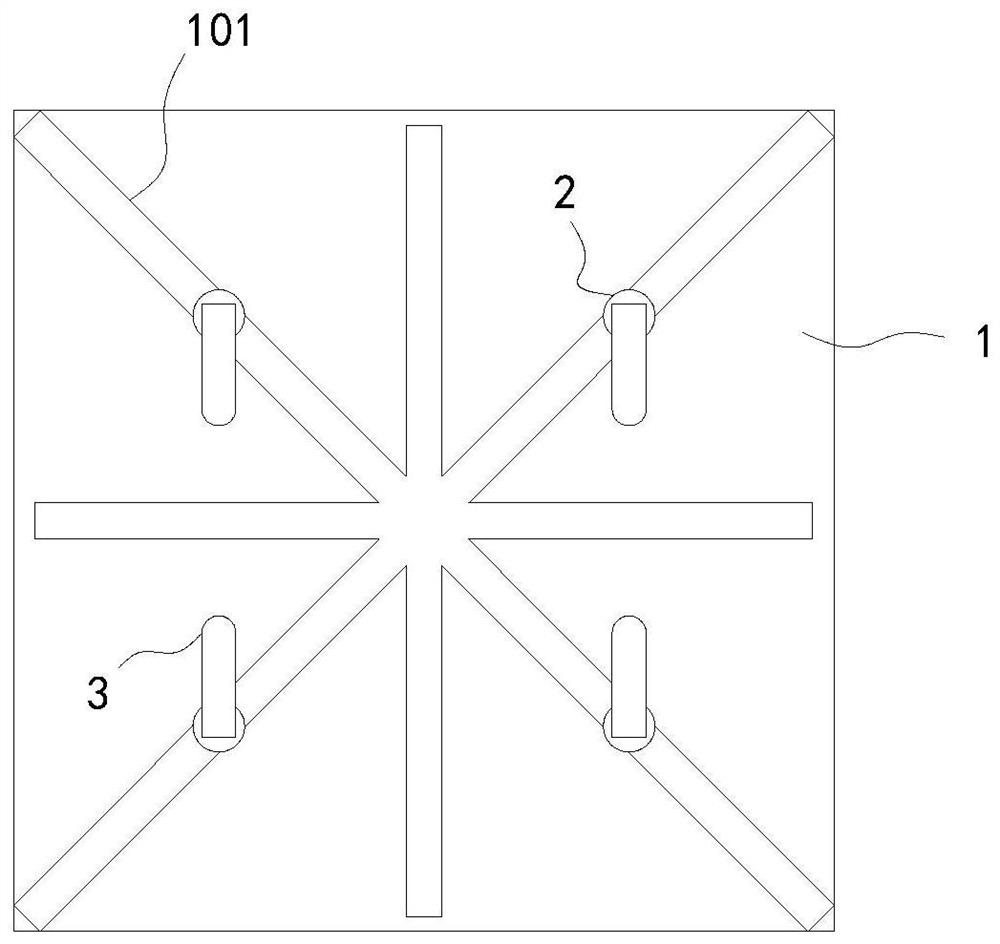

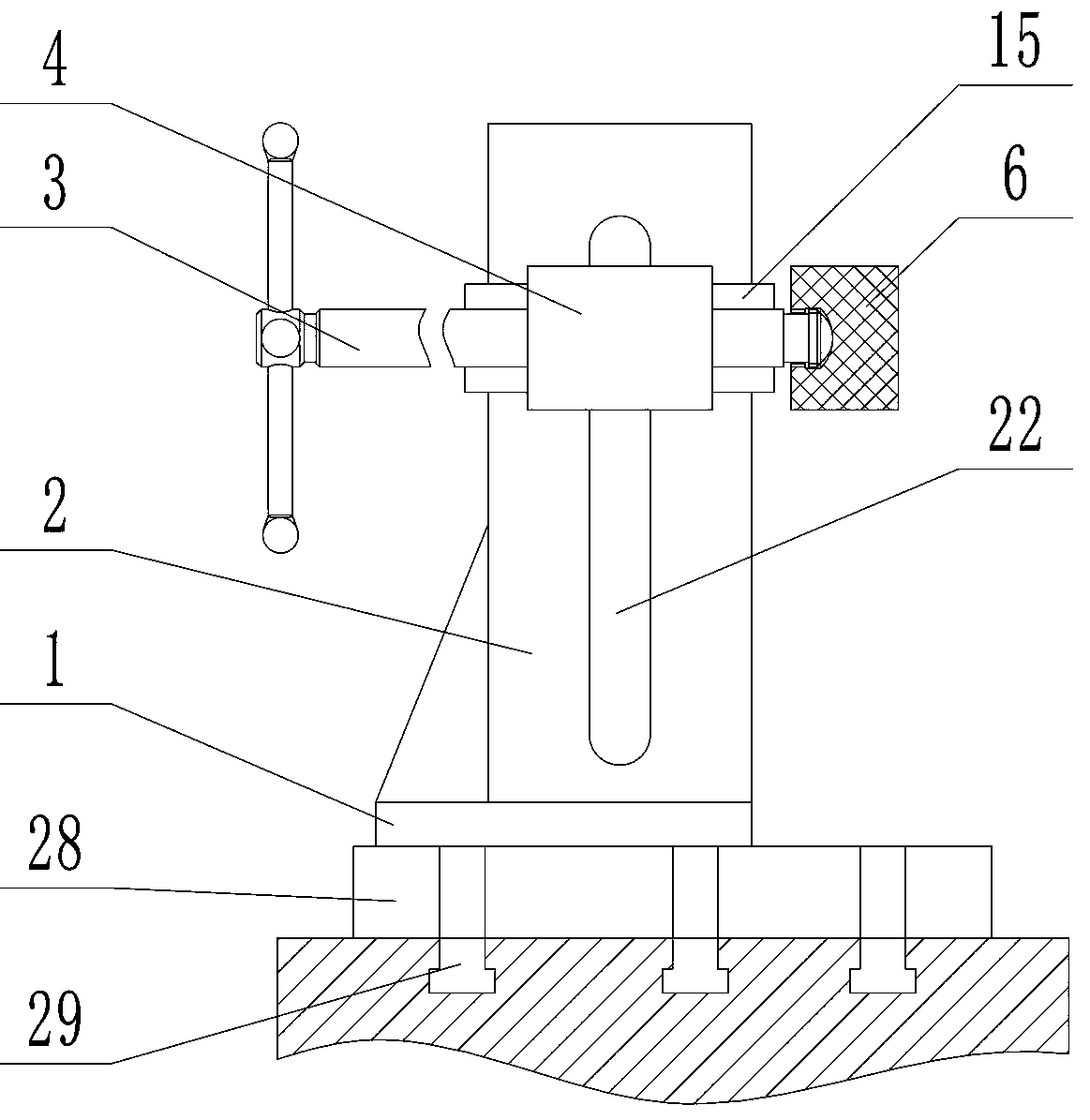

Clamp with controllable clamping force and for machining

ActiveCN109352377ARealize positioning and pressingClamping force controlPositioning apparatusMetal-working holdersCircular discHigh volume manufacturing

The invention discloses a clamp with controllable clamping force and for machining. Positioning and clamping for a workpiece are achieved very well, the tight-pressing force on the workpiece can be controlled very well, the damages to the workpiece is avoided, and the effect of improving the machining efficiency is achieved on the large-batch production. According to the technical scheme, the clamp comprises a foundation plate; guiding plates are disposed above the foundation plate; a sliding block is disposed between the two guiding plates; a threaded rod is inserted into the left side wall of the sliding block in a penetrating mode; a circular disc is mounted on the threaded rod; an ejector rod is inserted into the sliding block in a penetrating mode; and a spring is connected between the left end of the circular disc and the bottom wall of a blind hole. In an initial state, the circular disc is located on the leftmost side of the blind hole under the action of the spring, wedge grooves which are formed in the right side of the threaded rod and uniformly distributed circumferentially are formed in the outer edge of the ejector rod; clamping blocks which are uniformly distributedcircumferentially and can extend and retract in a radial direction are disposed on the inner wall of the position, matched with the ejector rod, of the threaded rod; and when the threaded rod moves rightwards relative to the ejector rod, the clamping blocks can be clamped into the wedge grooves so that the threaded rod can rotate only in one direction, and the threaded rod can move only leftwardsif the threaded rod rotates in one direction. The clamp is novel in conception.

Owner:江苏天氟隆防腐设备有限公司

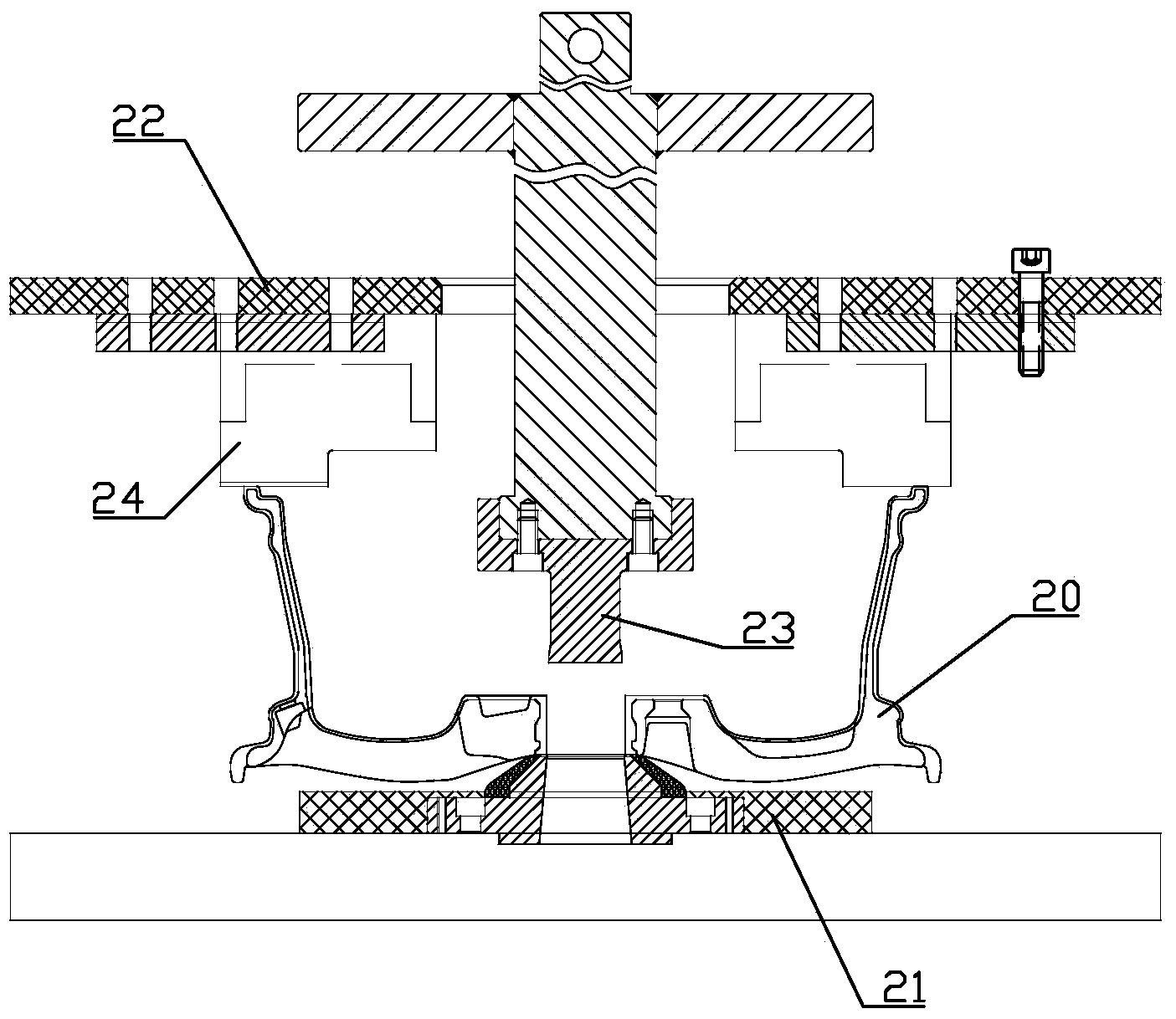

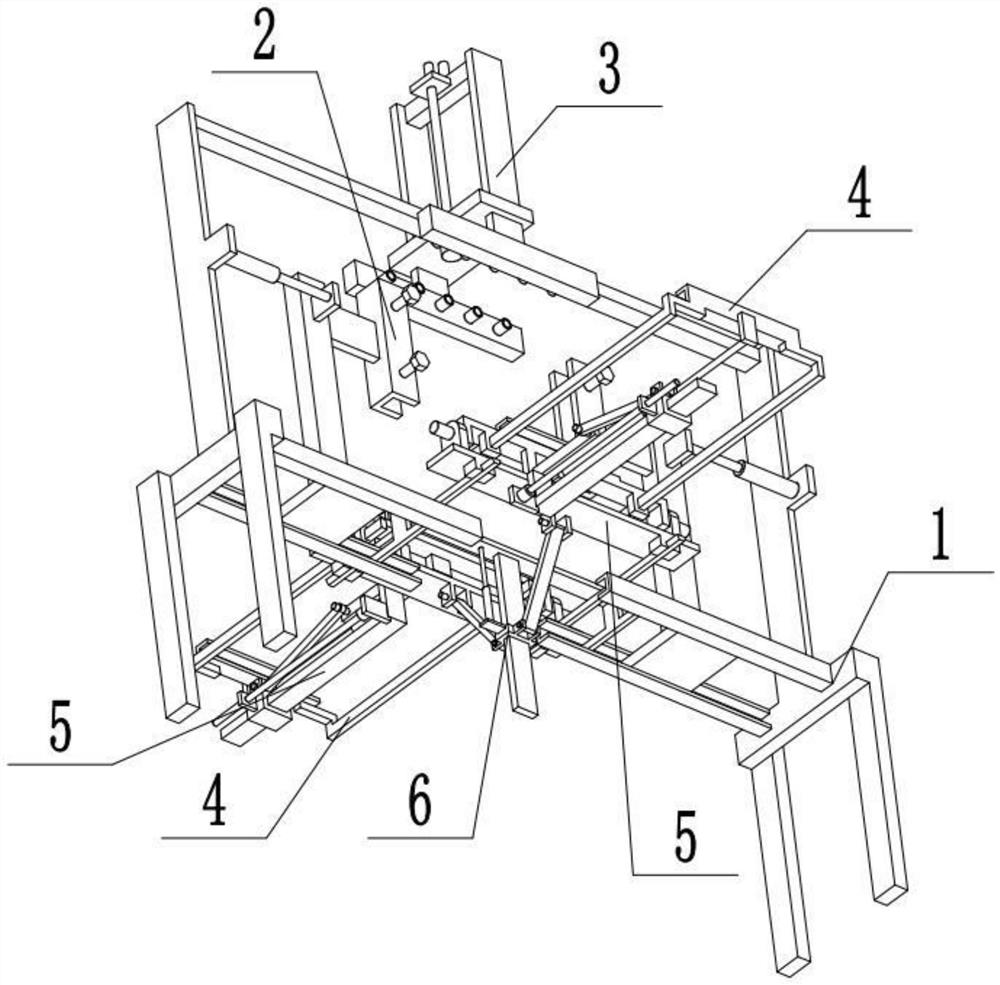

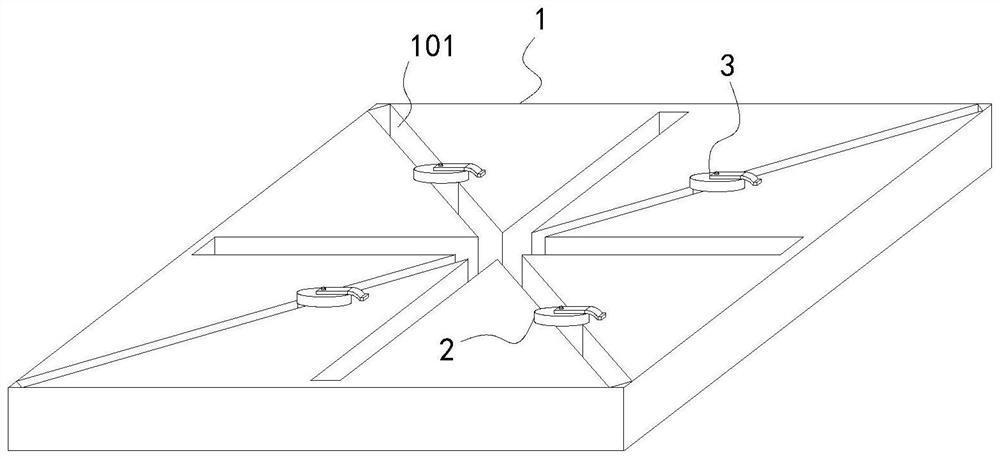

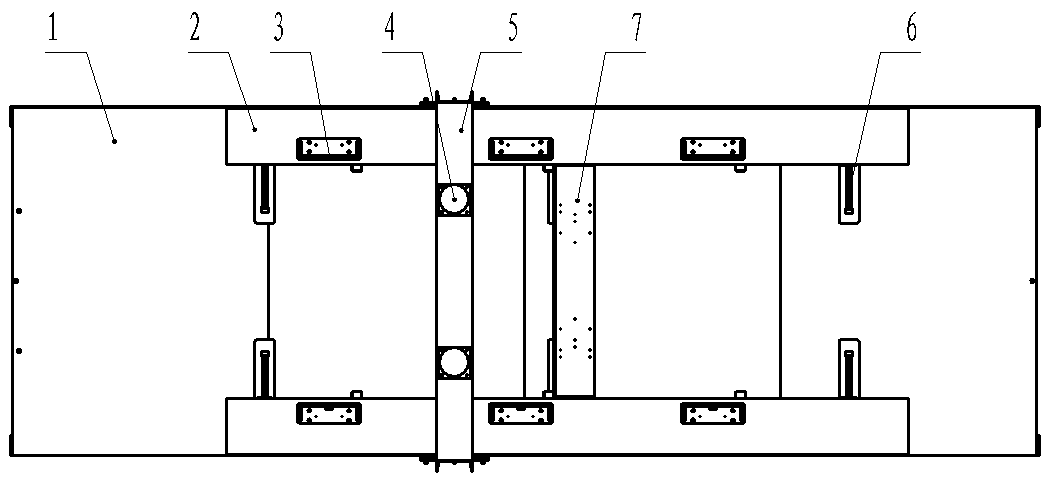

Semitrailer air suspension axle installation positioning device

ActiveCN106142024ALower skill requirementsGuaranteed accuracyWelding/cutting auxillary devicesAuxillary welding devicesAir suspensionEngineering

The invention discloses a semitrailer air suspension axle installation positioning device, and relates to the technical field of car manufacturing. The semitrailer air suspension axle installation positioning device comprises two supports which are installed on a working platform and are symmetrically arranged; a plurality of positioning bases are installed on each support, and a plurality of jackscrew extending out to the inner side are installed at the lower portion of each support; a compression device is installed above the working platform, and a positioning plate is arranged between the two supports; the positioning bases on one support and the positioning bases on the other support are oppositely arranged; and the compression device comprises a pressing plate and a plurality of power cylinders connected with the pressing plate, and the multiple power cylinders are installed above the working platform through a supporting frame. Compared with the prior art, the semitrailer air suspension axle installation positioning device is adopted for semitrailer air suspension axle positioning installation, the procedure time for repeated measuring and positioning size adjusting is saved, the requirement for skills of operation persons is reduced, the accuracy of all installation sizes is guaranteed, and the product consistence is effectively guaranteed.

Owner:SINOTRUK LIUZHOU YUNLI SPECIAL PURPOSE VEHICLES

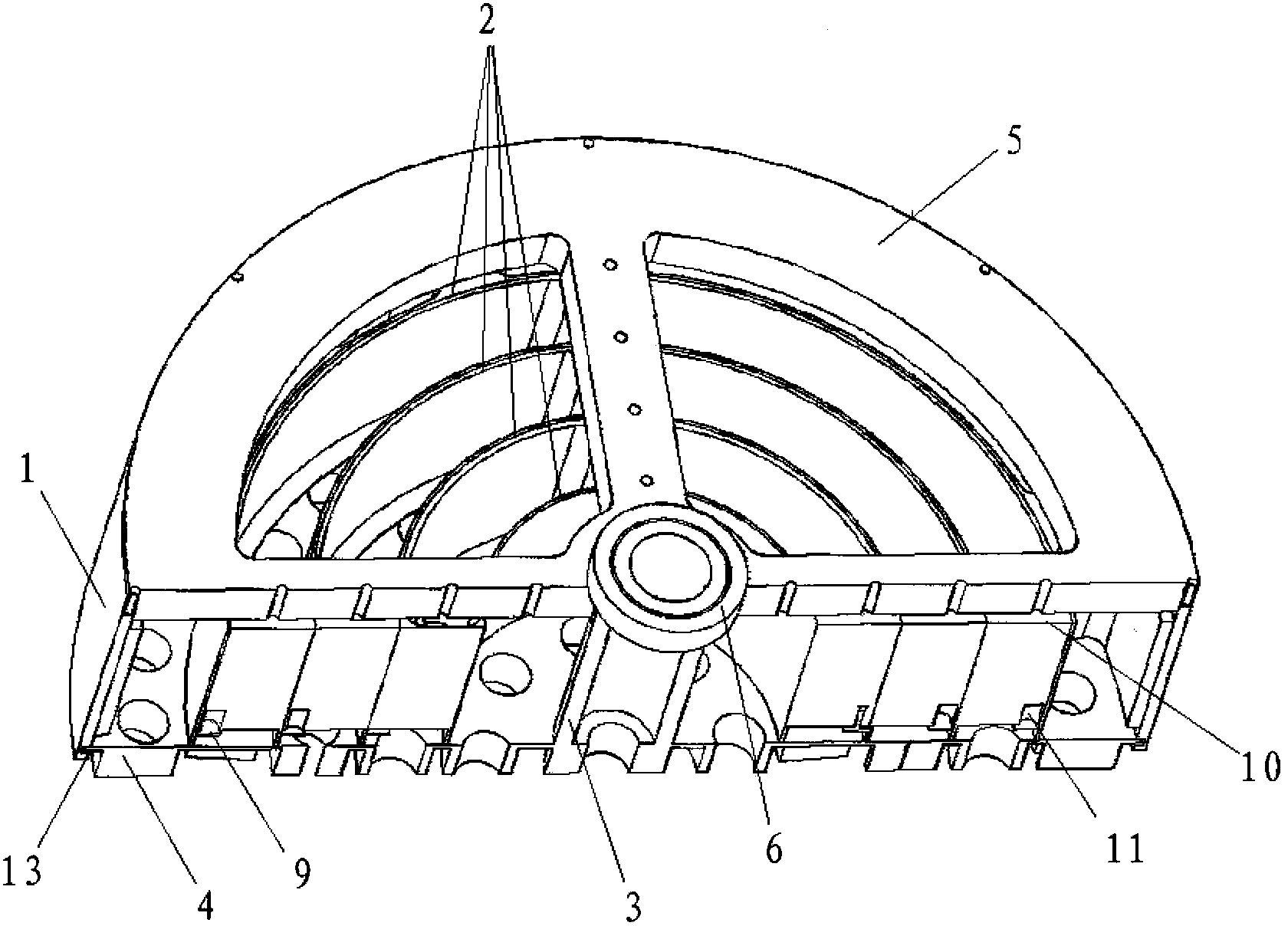

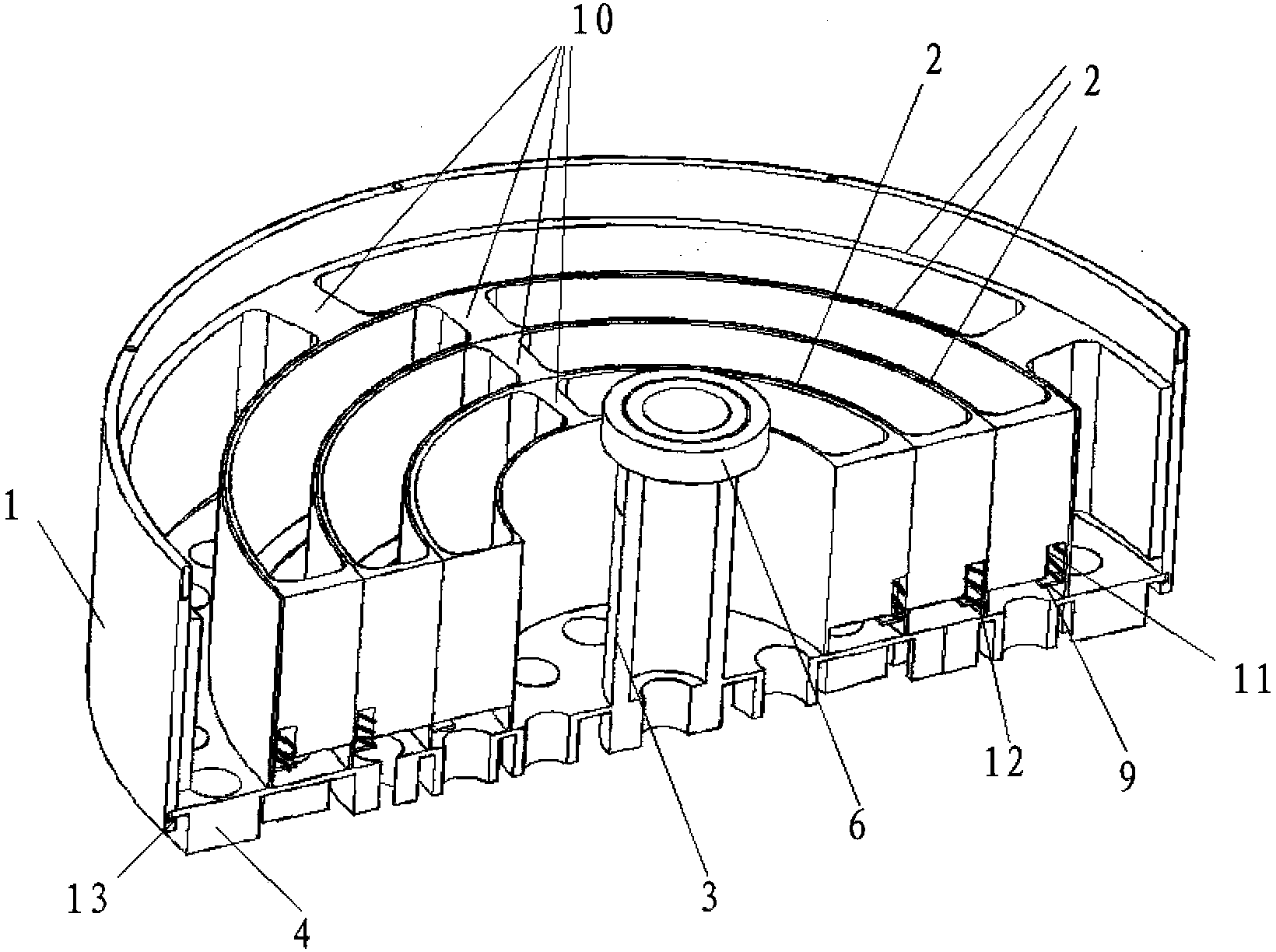

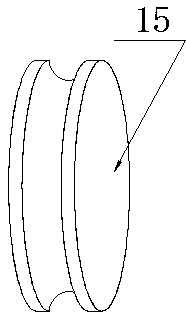

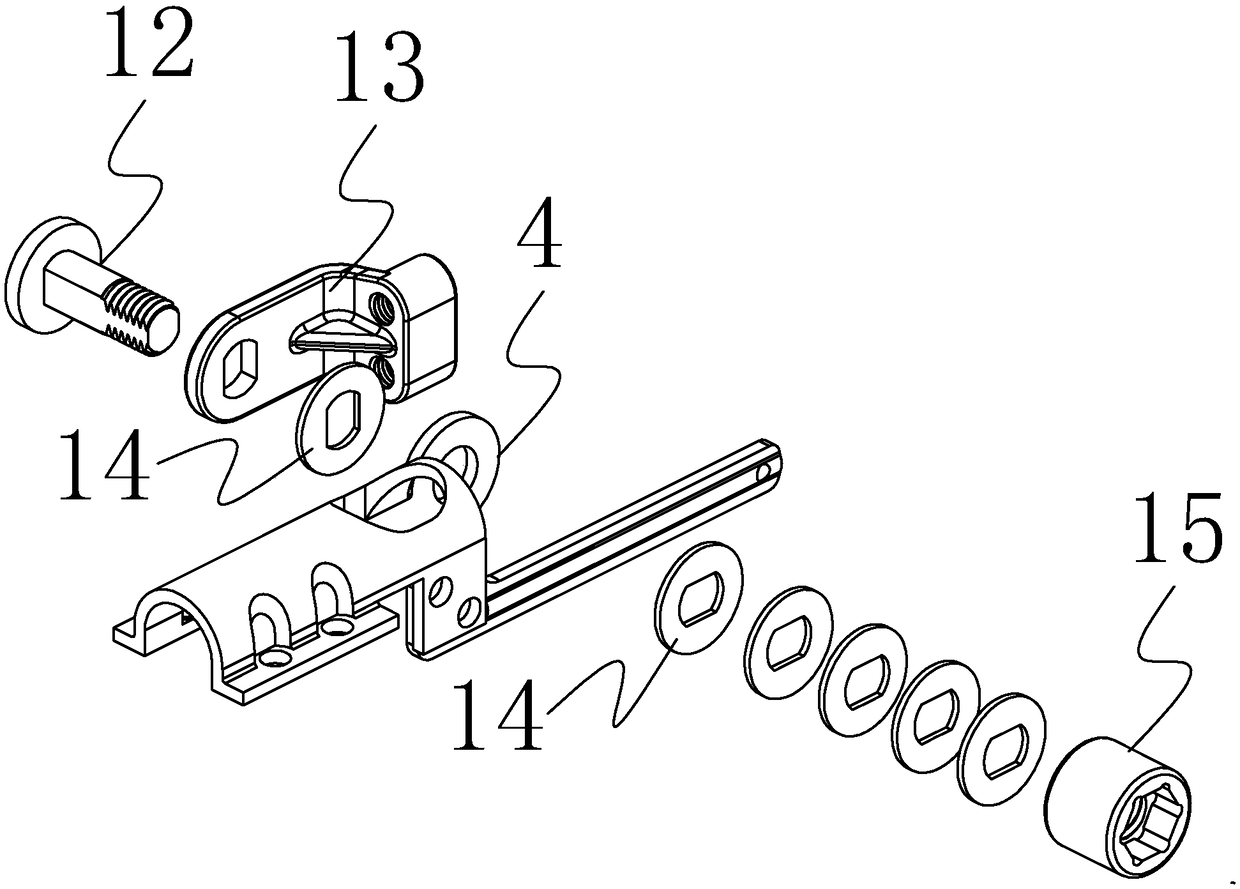

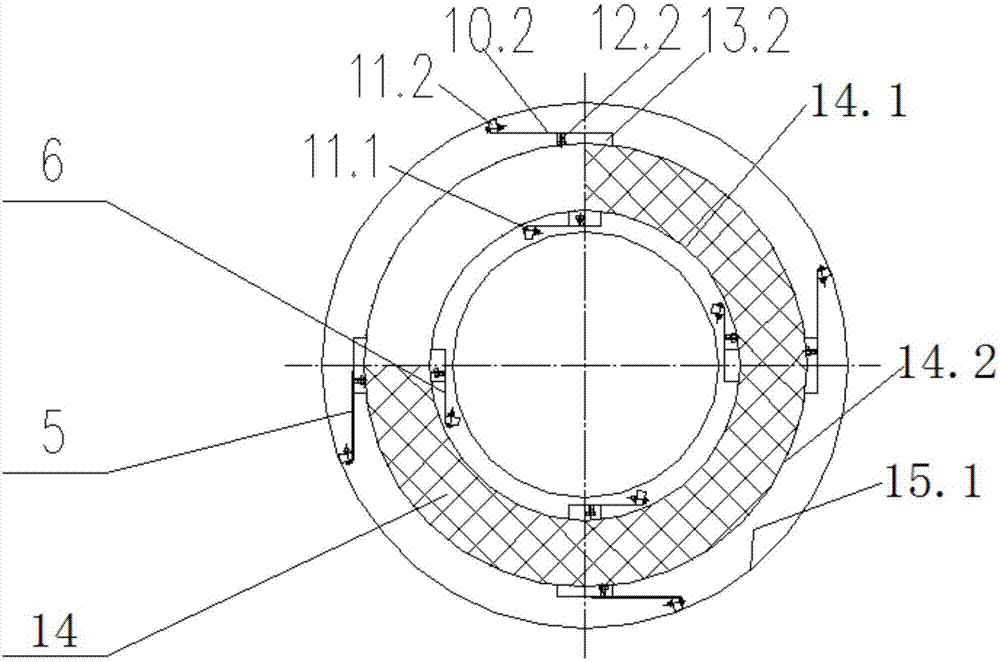

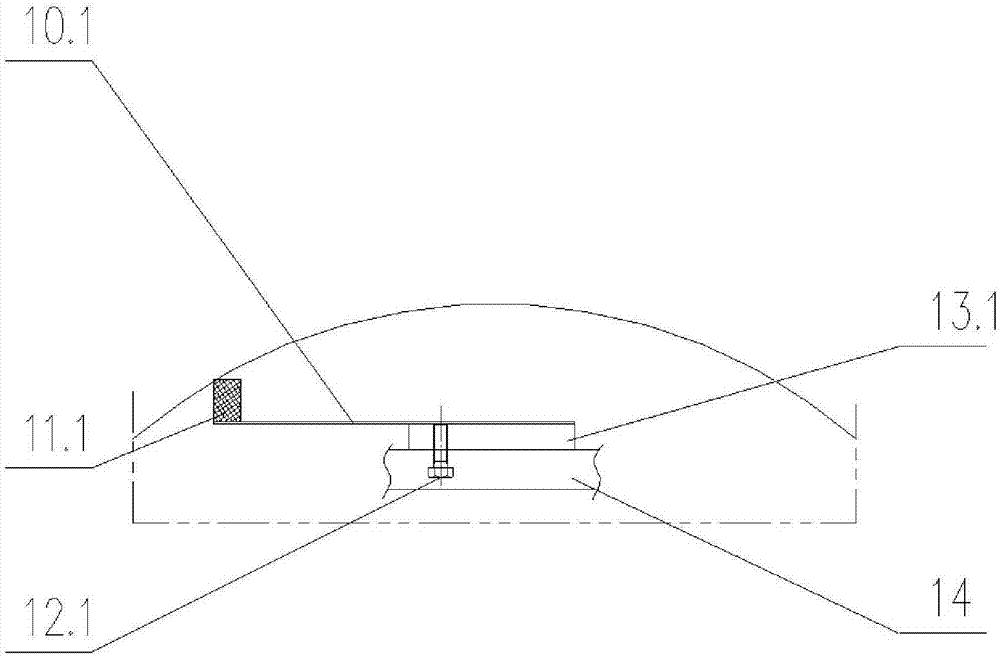

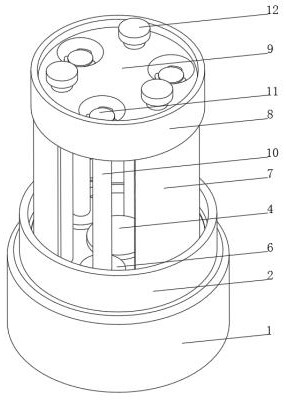

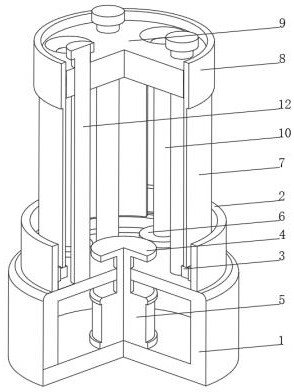

Array mechanism of laser spot projector with adjustable light spot density

ActiveCN104344814ASolve the problem of not being able to extractControl the pressing forceActive open surveying meansLight spotEngineering

The invention belongs to the engineering measurement technology and specifically discloses an array mechanism of a laser spot projector with an adjustable light spot density. The array mechanism comprises a cylindrical base, a rear end cover, a front end cover, a force applying rod and an auxiliary supporting ring. Circular-ring array blocks which are arranged into circles around the center of the rear end cover are arranged on the outer end surface of the rear end cover; a ring-shaped slot is formed between adjacent circular rings; a laser device fixing hole is formed in the center of the circular-ring array blocks. The circular-ring array blocks which are arranged into circles are designed on the rear end cover made of an elastic material, and the ring-shaped slots are formed among the circles, so that elastic deformation formed by the ring-shaped slots is generated between the circular-ring arrays when the force applying rod drives the rear end cover to move, and a normal of each circular hole generates deflection for a certain angle, thereby generating or converging or diverging a laser spot matrix on the target to generate a laser spot array adaptive to a target dimension size, and solving a problem that characteristic spots cannot be extracted under a high-brightness background.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH +1

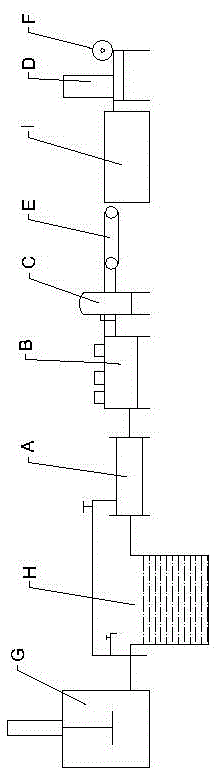

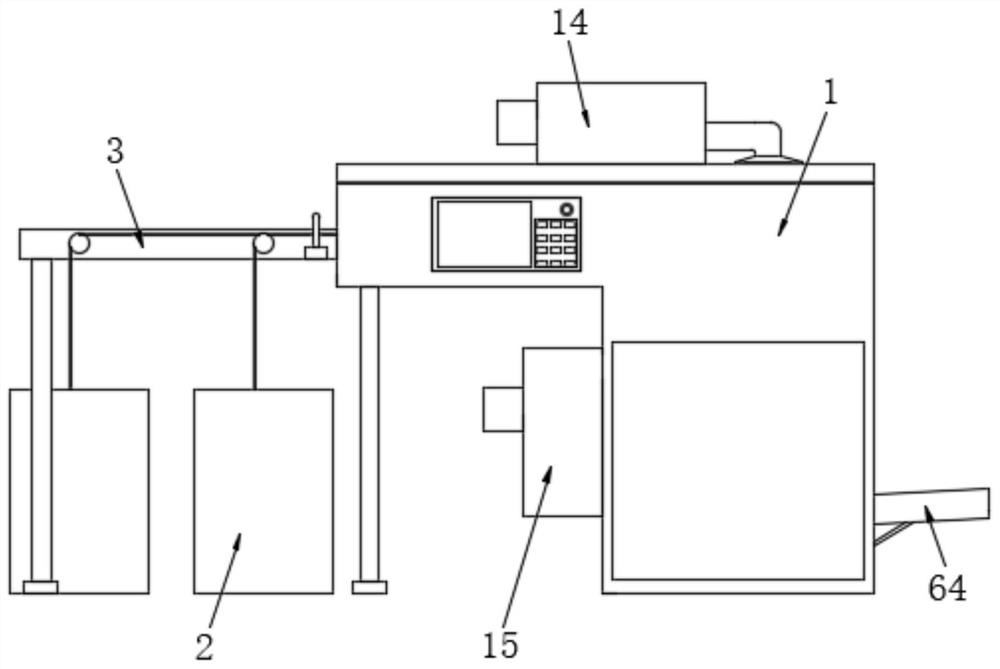

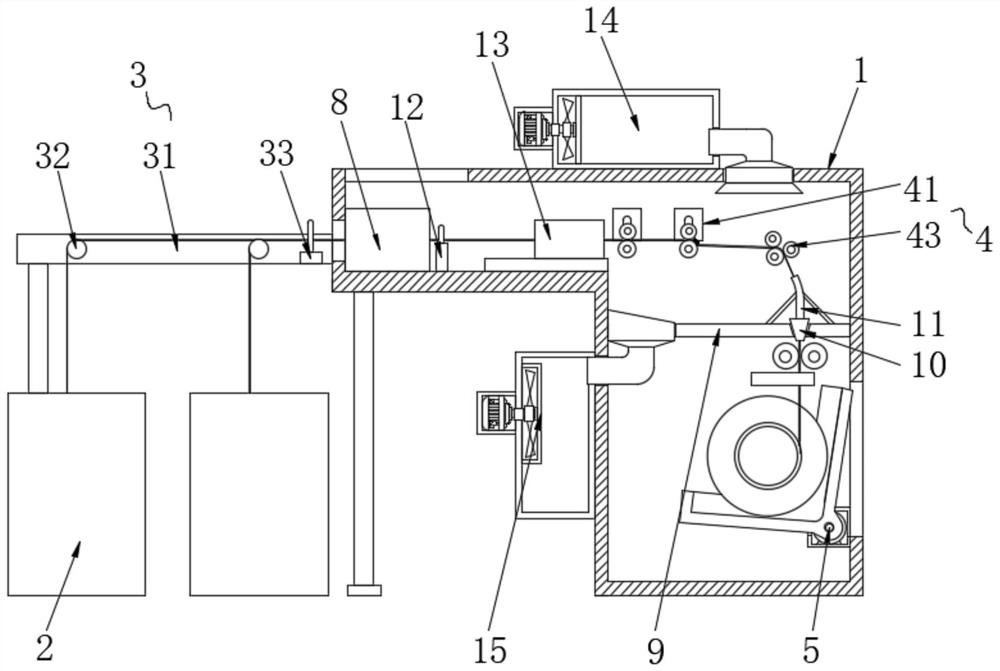

Ultra-thin glass fiber paper production system

The invention provides an ultra-thin glass fiber paper production system. The system comprises a mixing device, a buffering device, a drainage device, a slitting device, a conveying device and a paper rolling device. An outlet of a stirring machine is connected with a dilution pond, the dilution pond is connected with one end of the mixing device, and the other end of the mixing device is connected with a glass fiber paper forming device. The buffering device is arranged at the inlet end of the glass fiber paper forming device, the drainage device is arranged in the glass fiber paper forming device, the conveying device is disposed at the outlet end of the glass fiber paper forming device, the conveying device is connected with an oven, the slitting device is installed at an outlet of the oven, and the paper rolling device is arranged at the output end of the slitting device. The system is high in efficiency and small in occupied area, formed paper is flat in surface, flow speed of glass fibers is uniform, feeding flow speed is controllable and adjustable, and the system is convenient to use, practical and good in use effect.

Owner:ZHEJIANG LANDLONG IND

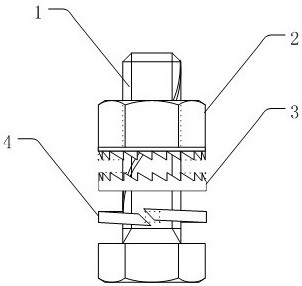

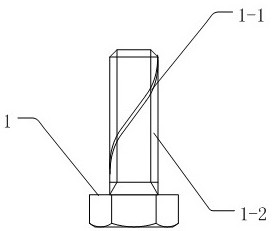

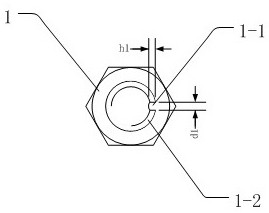

Bolt anti-loosening structure and anti-loosening method thereof

PendingCN106979212AEffective control of pressing forceControl the pressing forceNutsBoltsEngineeringMechanical engineering

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

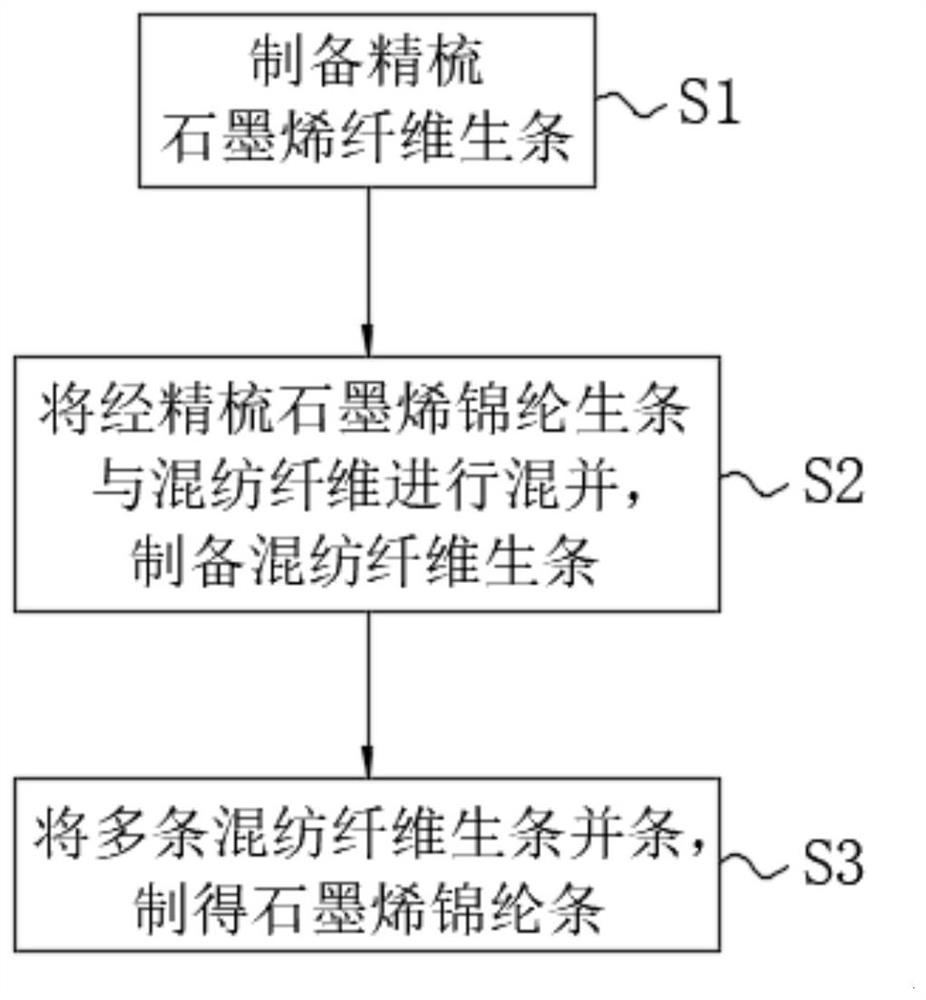

Graphene and polyamide blending and drawing method

The invention discloses a graphene and polyamide blending and drawing method. The method specifically comprises the following steps of S1, preparing combed graphene and polyamide fiber card slivers; S2, preparing blended fiber card slivers; and S3, preparing graphene and polyamide strips, wherein a material discharging assembly is arranged at the position of a material discharging hole in the inner wall of an outer box in a drawing frame in the step S3; a wheel feeding assembly is arranged in the outer box and located in the front of the discharging assembly; a wheel fixing assembly is arranged between the front face and the back face of the inner wall of the outer box; and a static electricity removing mechanism is arranged on the left side of the inner wall of the outer box. The invention relates to the technical field of textile processing. According to the graphene and polyamide blending and drawing method, the wheel feeding assembly and a wheel discharging assembly are matched with each other to convey a winding wheel to a winding station, and a worker only needs to place the winding wheel on a guide rail, so that the labor intensity of the worker is reduced, and the rolled polyamide strips are small in size and convenient to transfer and transport; and in addition, the automation degree of equipment is high, and the practicability is improved.

Owner:向鑫

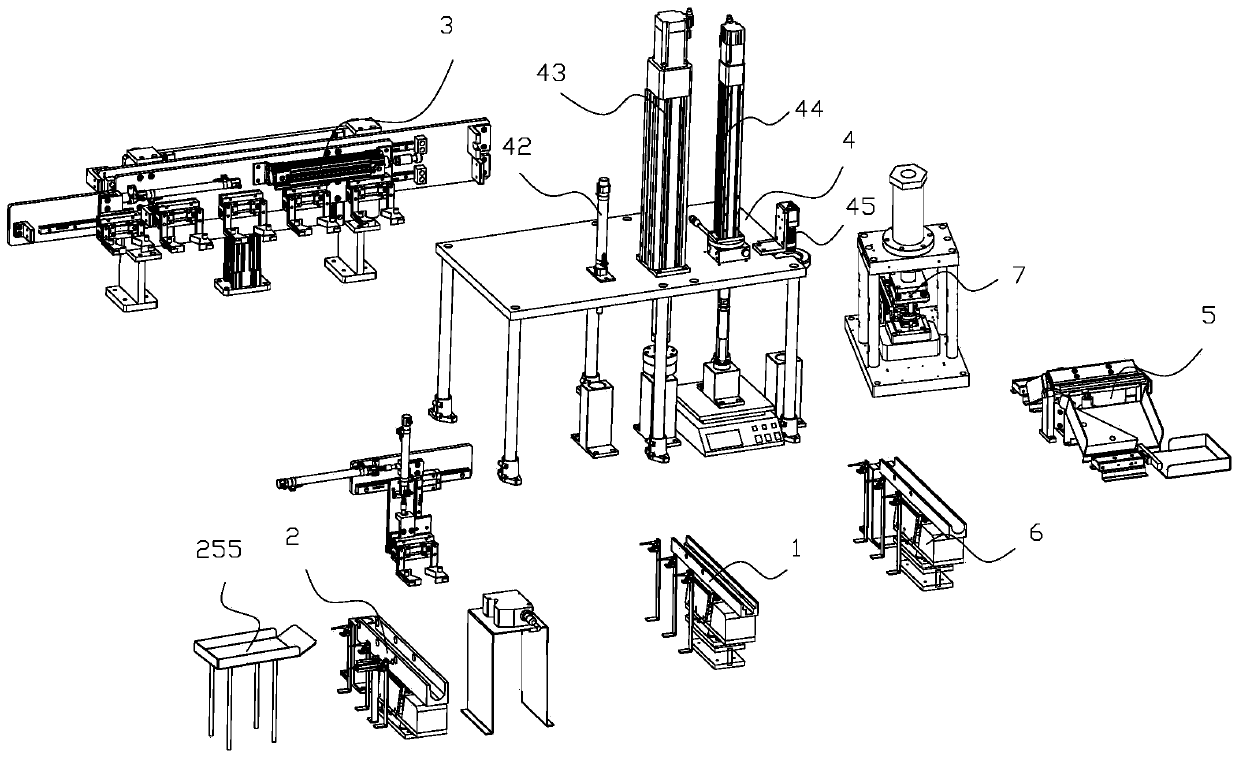

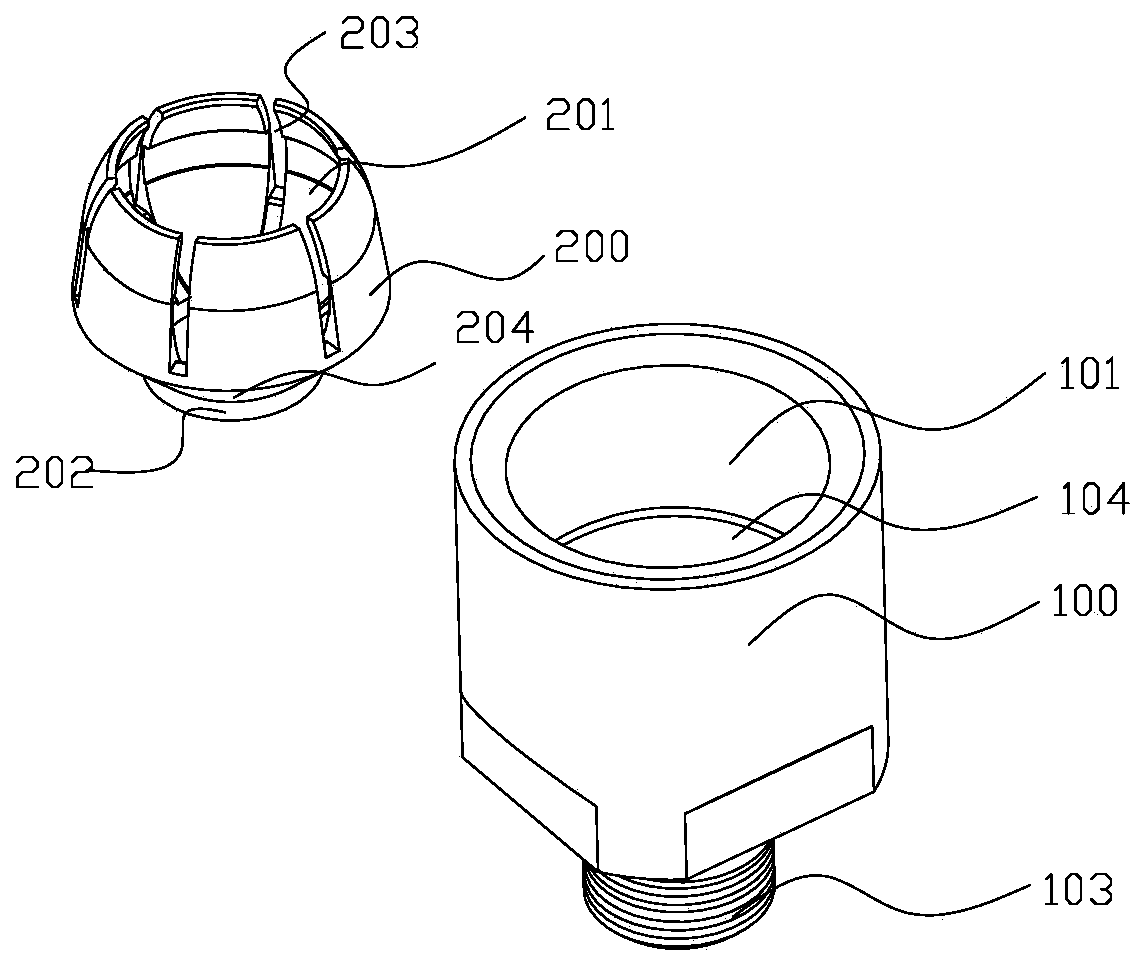

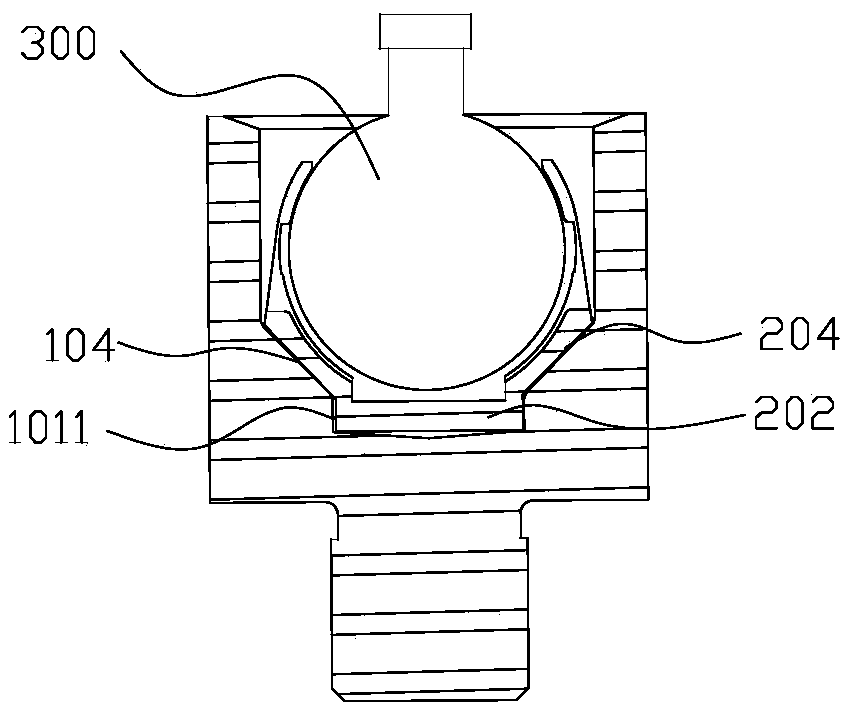

Press fitting and oil injection detecting device and method for universal ball joint production

InactiveCN111451742AEasy for visual inspectionImprove pass rateLiquid surface applicatorsFluid pressure measurement by mechanical elementsEngineeringBall joint

The invention relates to the technical field of universal ball joint production, in particular to a press fitting and oil injection detecting device and method for universal ball joint production. A guide-in assembly, a press fitting assembly, an oil injection assembly and a press fitting detecting assembly are sequentially arranged on an assembling support from the press fitting feeding directionto the press fitting discharging direction. The guide-in assembly is used for carrying out primary positioning guide-in on a ball shell and a connecting seat. The press fitting assembly is used for pressing the ball shell into the connecting seat, and the oil injection assembly is used for injecting oil into the ball shell. The press fitting detecting assembly is used for detecting an assembled ball shell and connecting seat assembly. The press fitting and oil injection detecting device and method have the advantages that the assembling precision of the ball shell and the connecting seat is improved, oil injection operation can be carried out conveniently, the oil injection comprehensiveness is improved, and the ball shell and connecting seat press fitting quality is improved.

Owner:高鑫斌

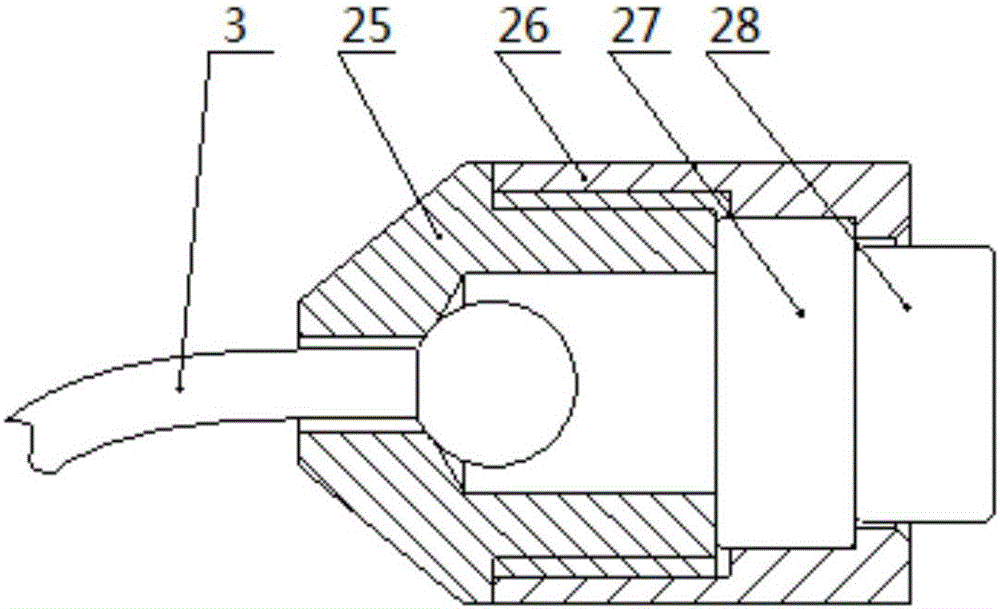

Optical fiber rotary connector for multichannel optical fiber early warning equipment

PendingCN111273407APlay the role of waterproof and dustproofImprove the protective effectCoupling light guidesEngineeringLight signal

The invention discloses an optical fiber rotary connector based on multichannel optical fiber early warning equipment, which comprises a stator shell and a rotor sleeve rotatably connected to the interior of the stator shell, a through hole matched with the rotor sleeve is formed in the stator shell, and the invention relates to the technical field of optical fiber early warning. According to theoptical fiber rotary connector, the rotor sleeve can be used in the stator shell for a long time, and the pressure generated by the pressing plate on the buffer spring is adjusted, so that the pressing force between rollers in the extrusion plate and the surface of the rotor sleeve is controlled; the problem that the optical fiber off-axis deviation becomes larger and larger due to increase of abrasion between the rotor sleeve and the stator shell during long-time rotation is avoided; and through the arrangement of the two movable bearings, the problem that the rotor sleeve deviates and shakesduring rotation can be effectively prevented, so that optical signals are stably transmitted, the coupling efficiency is improved, and good conditions are created for subsequent optical fiber early warning work.

Owner:SHENZHEN SDG INFORMATION CO LTD

Bolt self-locking anti-loosening structure

The invention discloses a bolt self-locking anti-loosening structure. The bolt self-locking anti-loosening structure is characterized by comprising a lock bolt, a lock nut, an anti-loosening locking ring and a spring washer. A spiral anti-loosening groove is formed in the threaded section of the lock bolt, anti-loosening protruding teeth and a plurality of wedge-shaped anti-loosening teeth are arranged on the anti-loosening locking ring, and the lock nut is provided with the multiple wedge-shaped anti-loosening teeth. The spring washer and the anti-loosening locking ring are sequentially installed on the threaded section of the lock bolt, the lock nut is screwed into the lock bolt, the lock nut and the wedge-shaped anti-loosening teeth on the anti-loosening locking ring are the same in structure specification and are meshed with each other, and the anti-loosening protruding teeth on the anti-loosening locking ring are embedded into the spiral anti-loosening groove. According to the bolt self-locking anti-loosening method, the pre-tightening force of the bolt can be effectively controlled within a constant and effective range, loosening of the bolt and the nut is prevented, and the state of the bolt and the state of the nut are locked.

Owner:陈建军

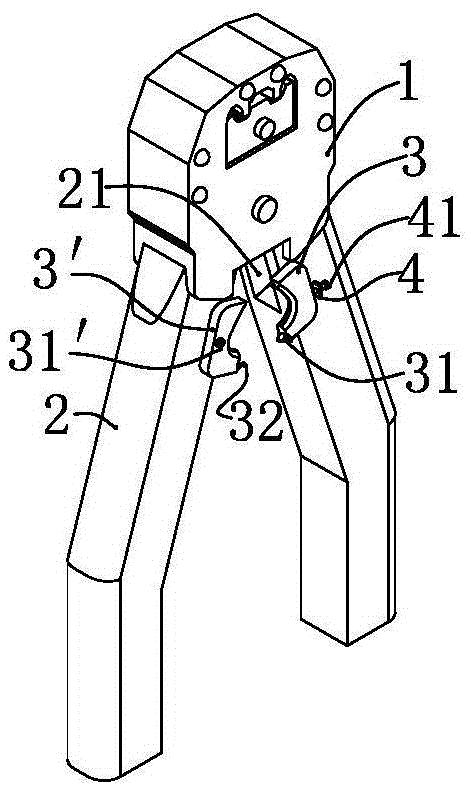

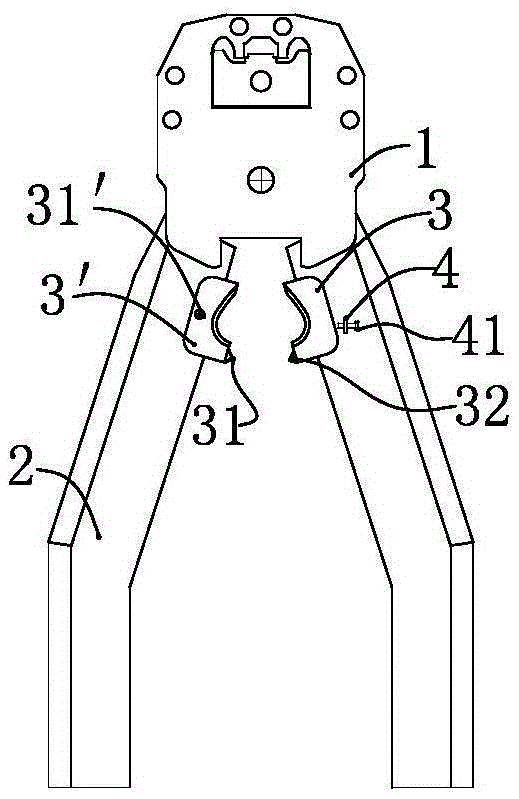

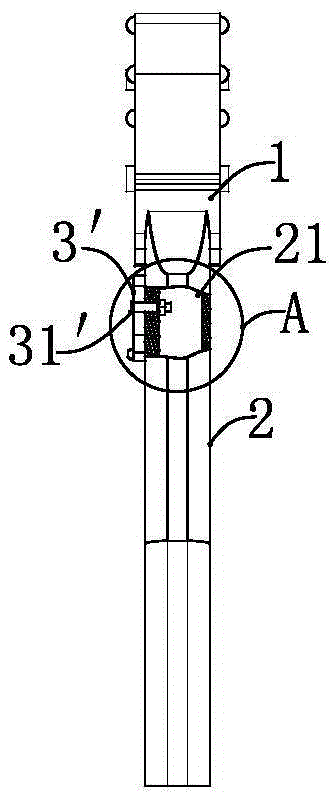

Netting twine pliers for facilitating removing of netting twine sheath

ActiveCN105591264AAvoid damagePrevent back and forth misalignmentLine/current collector detailsEngineeringKnife blades

The invention provides netting twine pliers for facilitating removing of a netting twine sheath. The netting twine pliers settle the problems of difficult sheath removing and easy damage of inner twisted wires in sheath removing in prior art. The netting twine pliers comprise a plier head and plier handles. Furthermore the netting twine pliers comprise a first blade and a second blade which are respectively provided with an arc-shaped cutting edge. The two blades are respectively provided with a clamping projection at the lower end. The first blade is hinged with a right plier handle through a torsion spring. The second blade is fixed to a left plier handle. The two plier handles are inwards pressed. The arc-shaped cutting edges of the two blades are spliced relative to each other. A netting twine is clamped in the cutting edges of the two blades. The arc-shaped cutting edges of the two blades are spliced relative to each other for forming an annular cutting edge. The first blade is pressed and rotates along a hinging portion for performing sheath removing on the netting twine. Furthermore the arc-shaped cutting edge can well control the position of the netting twine in sheath removing, thereby preventing repeated displacement of the netting twine in sheath removing. The netting twine pliers have advantages of simple structure, convenient operation, effective control for a pressing strength, and effective damage reduction of the inner twisted wires.

Owner:SHANGHE COUNTY POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

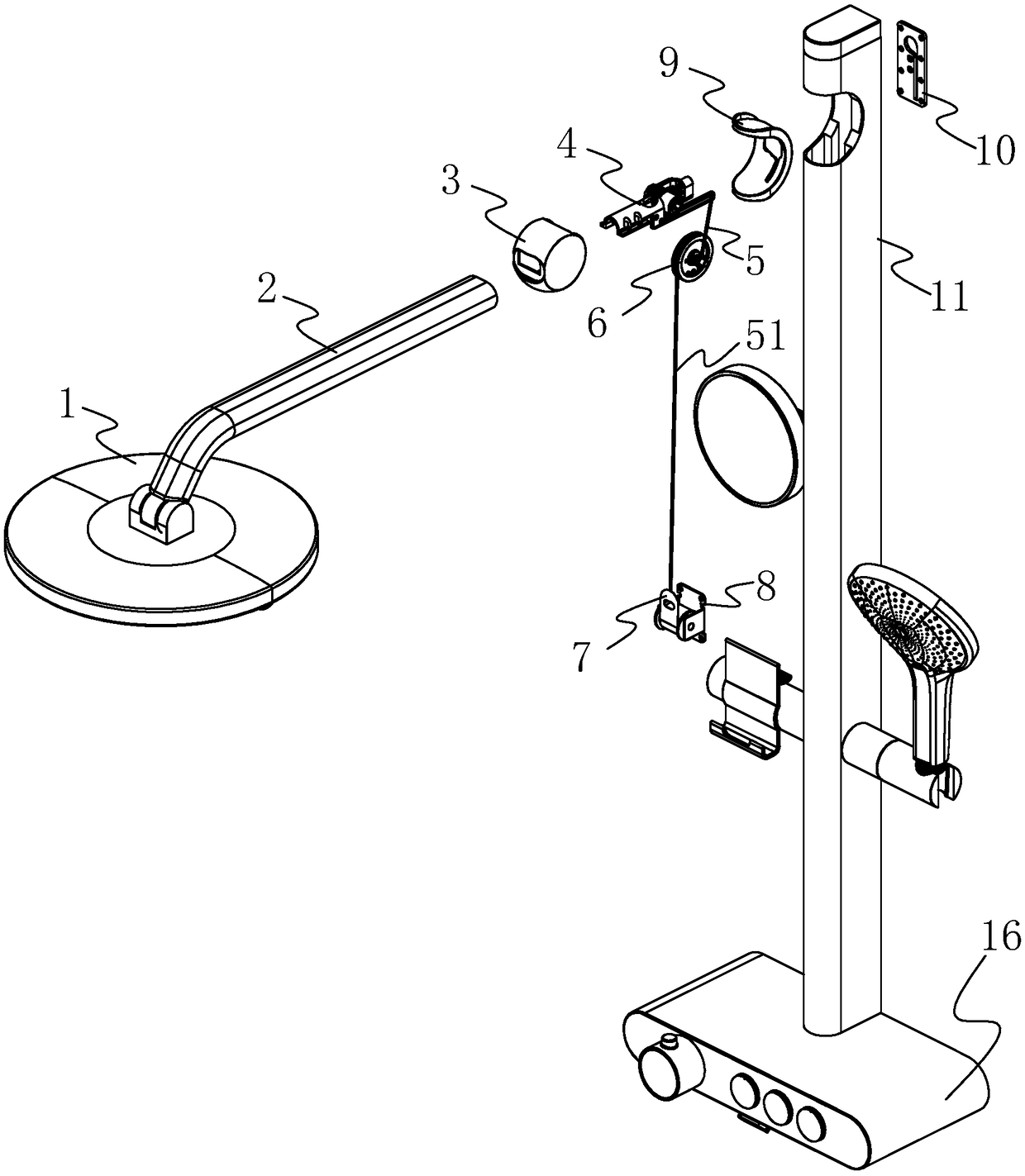

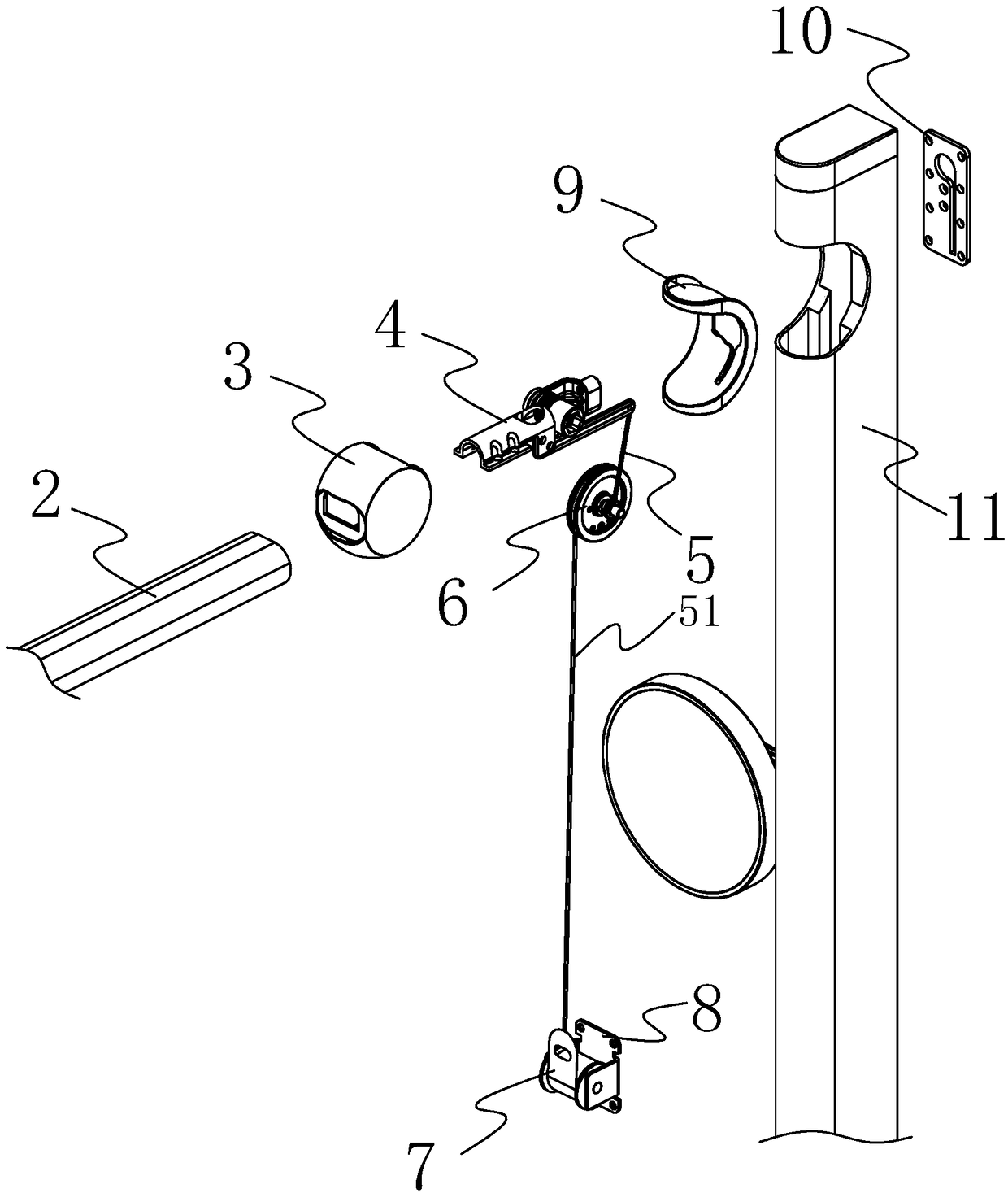

Shower with top sprinkler capable of rotating up and down

ActiveCN109382227AIncrease the angle of the up and down rotationEffective positioningSpray nozzlesEngineeringMechanical engineering

The invention discloses a shower with a top sprinkler capable of rotating up and down. The shower comprises a fixing shower body, a top sprinkler, a balance mechanism and a sprinkler supporting part capable of achieving water passing or provided with a water through pipe to supply water to the top sprinkler. The sprinkler supporting part is rotatably connected to the fixing shower body in the up-down direction, the top sprinkler is arranged on the sprinkler supporting part, and the balance mechanism is connected with the sprinkler supporting part; the top sprinkler, the balance mechanism and the sprinkler supporting part form a lever-type mechanism, and by balancing the weight of the top sprinkler, the top sprinkler keeps in the state after adjustment. The top sprinkler is connected with the sprinkler supporting part and the balance mechanism, the angle of up-down rotation of the top sprinkler is greatly increased, the shower can be adaptive to people different in height, the top sprinkler can also be effectively positioned and keep at any position after adjustment, and users use the shower conveniently.

Owner:JOMOO KITCHEN & BATHROOM

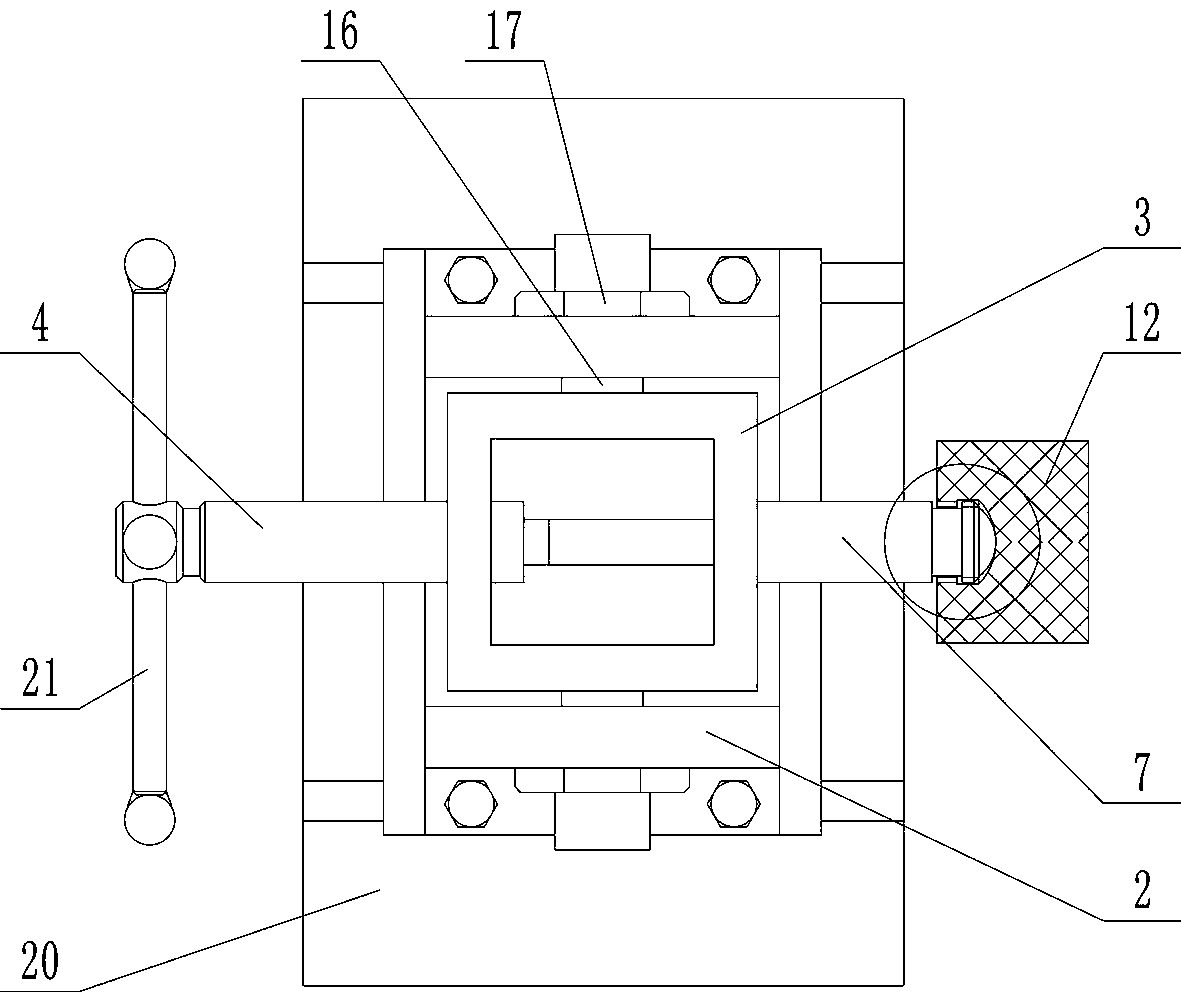

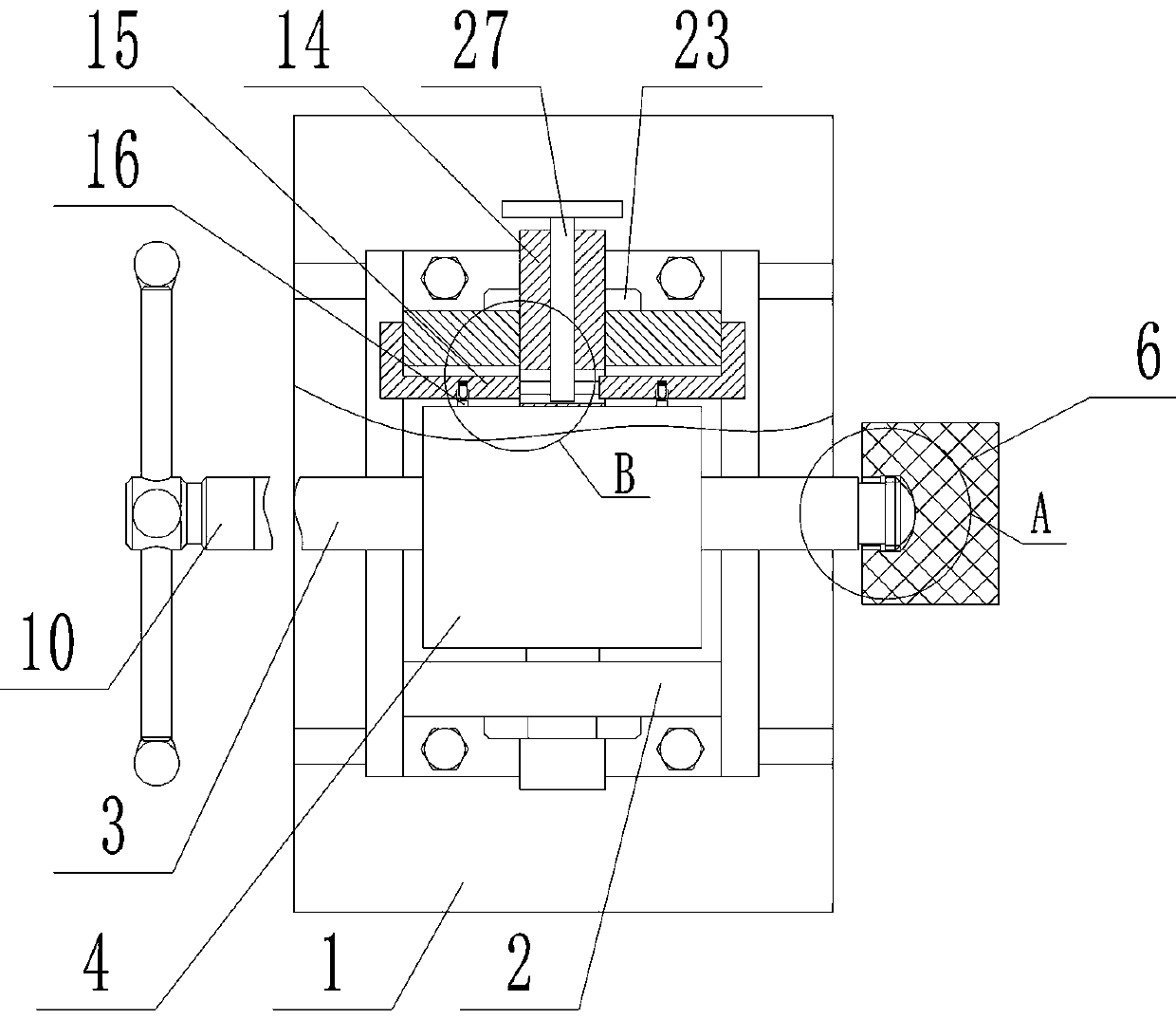

Anti-overpressure pressing device

InactiveCN109483277ARealize positioning and pressingControl the pressing forcePositioning apparatusMetal-working holdersHigh volume manufacturingEngineering

The invention discloses an anti-overpressure pressing device. Positioning and pressing of workpieces are well achieved, the pressing force to the workpieces can be well controlled, damage to the workpieces is avoided, and the effect of improving the processing efficiency for mass production is achieved. According to the technical scheme, the pressing device comprises a sliding block; a screw is inserted in the sliding block; a mounting hole is formed in the screw; a sliding groove is formed in the side wall of the mounting hole; a movable plate is arranged in the mounting hole; a convex blockis arranged on the movable plate; an ejector rod is inserted in a blind hole; an annular sleeve is mounted on the outer edge of the screw in a clamped mode; an inner hole of the annular sleeve is provided with a clamping block; and the annular sleeve can drive the screw to rotate through the clamping block during rotating, the movable plate moves rightwards and jacks the clamping block upwards through the convex block, a groove is formed in one side surface of one end of the outer side of the sliding groove, the highest point of the convex block is flush with the lowest point of the groove, the annular sleeve can only drive the screw to rotate unidirectionally during rotation under the action of the groove when the clamping block is jacked upwards through the convex block, and the screw can only move leftwards due to unidirectional rotation of the screw. The pressing device is novel in conception.

Owner:JIANGSU YUANHUA LIGHT CHEM EQUIP

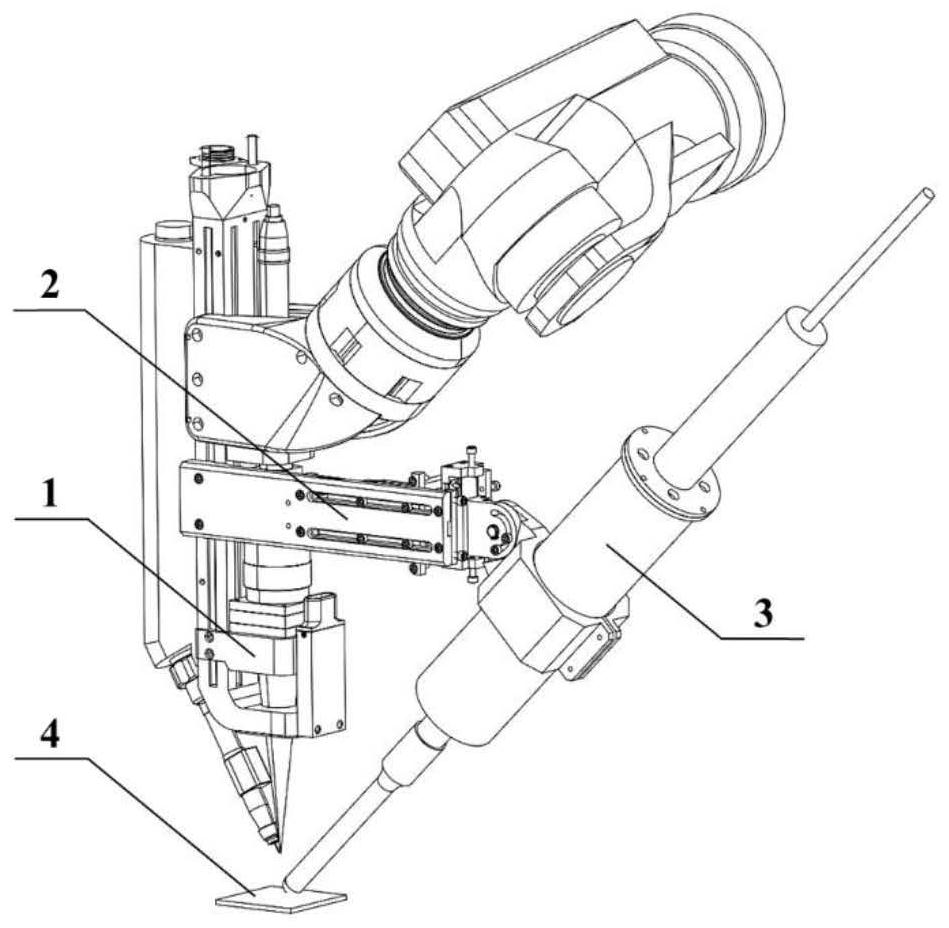

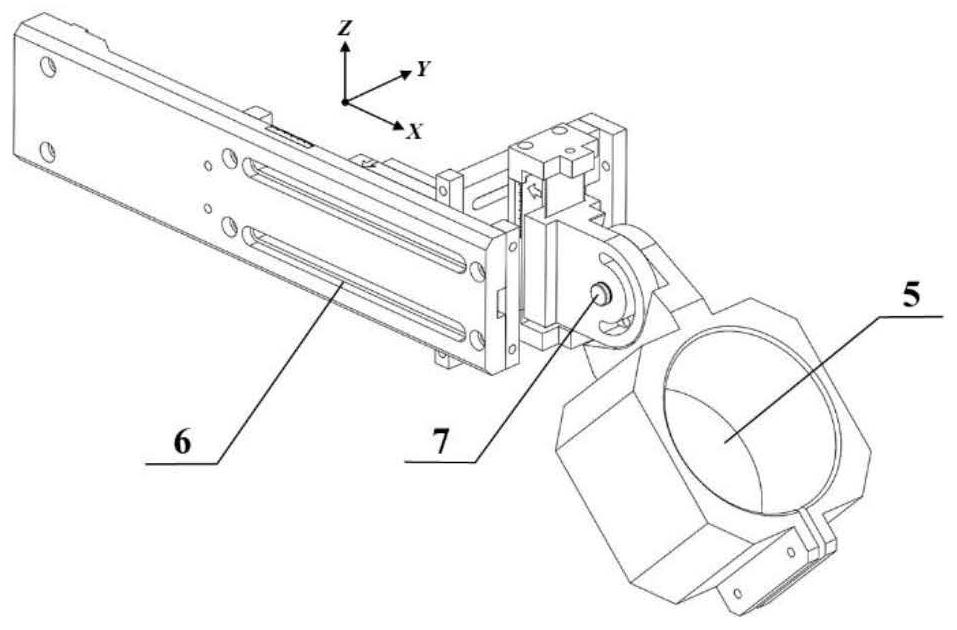

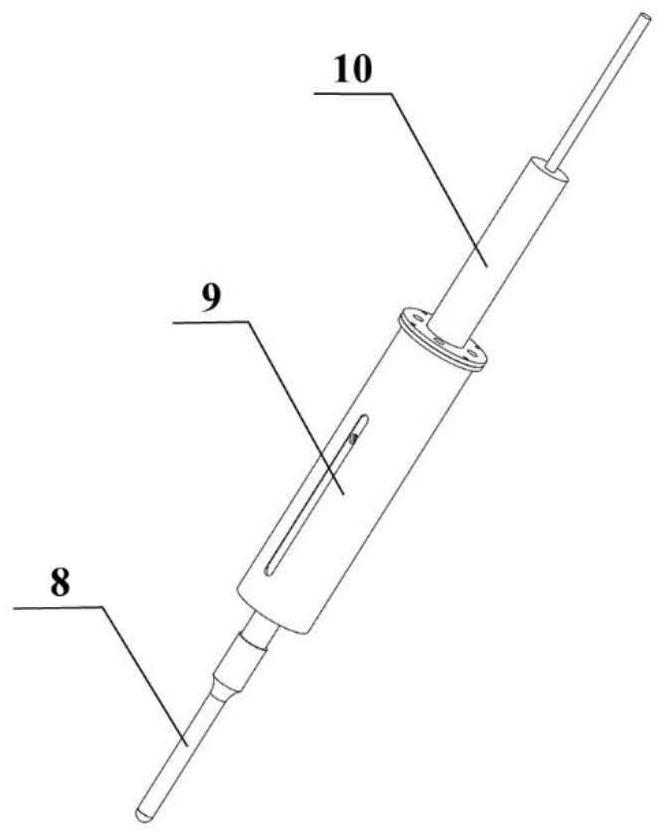

Ultrahigh-strength steel following welding ultrasonic-assisted laser welding system and method

PendingCN114406463AImprove weld solidification crystallization structureSpeed up the flowLaser beam welding apparatusNon-electric welding apparatusPhysicsLaser soldering

The invention discloses an ultrasonic-assisted laser welding system and an ultrasonic-assisted laser welding method for welding ultrahigh-strength steel along with welding, an ultrasonic generating device is connected with a laser welding head through a connecting clamp, and the ultrasonic-assisted laser welding process along with welding is realized under the driving of a robot. A front contact ultrasonic applying mode is adopted, a high-frequency vibration energy field of ultrasonic waves acts on a welding pool through a to-be-welded test plate, and a series of beneficial effects are utilized to improve the solidification and crystallization process of a welding seam. And a tail air cylinder of the ultrasonic generating device continuously provides pressing force for the ultrasonic amplitude-change pole in the welding process. The six-axis robot is adopted for driving, welding of complex tracks and spatial positions can be achieved, an original laser welding system is not changed, and equipment composition is simple. According to the method, the ultrasonic energy field is introduced into the laser welding pool, so that the problems of cold cracks and softening and embrittlement of a heat affected zone easily occurring during welding of the ultrahigh-strength steel for spaceflight can be effectively inhibited, and the comprehensive performance of a joint is improved.

Owner:SHANGHAI JIAO TONG UNIV

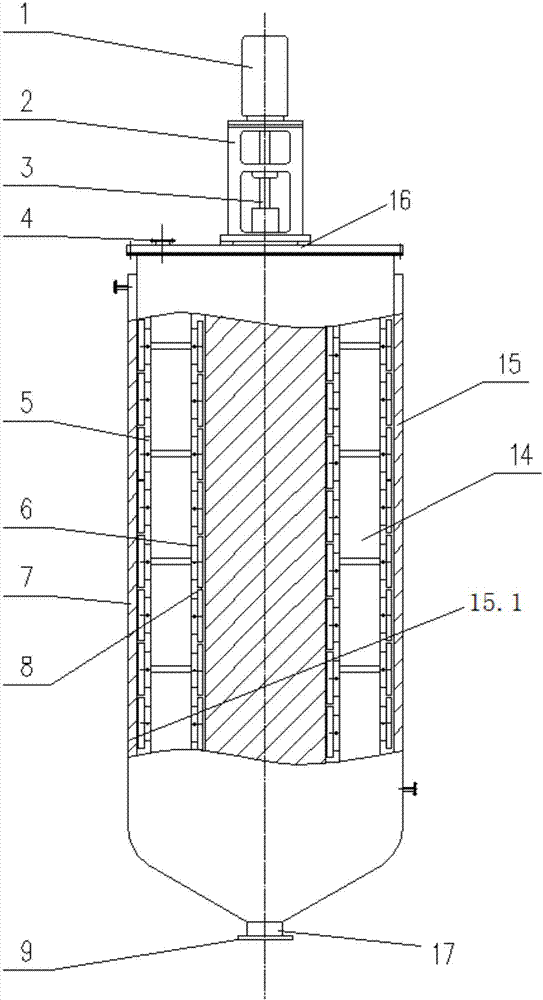

Elastic scraper type crystallizer

PendingCN107537175AIncrease the areaImprove work efficiencySolution crystallizationElectric machineryPhysics

The invention provides an elastic scraper type crystallizer which comprises a cylinder, wherein the upper and lower ends of the cylinder form a closed cylindrical structure through the sealing of an upper flat cover and a lower sealing head; a rack is arranged outside the upper end of a main shaft; the upper end surface of the rack is connected with a motor component; the motor component drives the main shaft to rotate; a rotor main body rotates through rotation of the main shaft; the rotor main body comprises a rotor main body inner wall and a rotor main body outer wall; a cavity formed by the rotor main body inner wall is an inner cooling cavity; a cavity formed by the rotor main body outer wall and the cylinder inner wall is an outer cooling cavity; an inner circle scraping film component is arranged on the rotor main body inner wall; an outer circle scraping film component is arranged on the rotor main body outer wall; a feed port is formed in the upper flat cover; a discharge portis formed in the bottom end of the lower sealing head. The elastic scraper type crystallizer provided by the invention has a simple structure and effectively reduces the friction and scratch of a product caused by rotation, bounce and vibration.

Owner:无锡力马化工机械有限公司

Treasury door locking mechanism

InactiveCN105464494AImprove structural strengthImprove reliabilityConstruction fastening devicesLocking mechanismEngineering

The invention discloses a treasury door locking mechanism, and relates to the field of locks. A treasury door outer side hand wheel is connected with a treasury door inner side gear, the gear is engaged with a transmission gear 1, a pinion on the transmission gear 1 is engaged with one end of the tooth bar of a main locking part, the other end of the tooth bar of the main locking part is respectively engaged with an upper dead bolt and a lower dead bolt through a transmission gear 2, and one side of the main locking part is provided with a dead bolt; the main locking part fits with a locking linkage part, and the tail ends of the upper dead bolt and the lower dead bolt and the dead bolt are inserted to a door frame to lock a treasury door; the main locking part is engaged with the oblique tooth block of the locking linkage part through an oblique tooth on the main locking part, the oblique tooth block is connected with one end of a lever, and the other end of the lever is connected with a pulling rod through a spring; the pulling rod is connected with a deflector rod 1 through a pin roll, one end of the deflector rod 1 is provided with a balancing weight, and the other end of the deflector rod 1 is connected with a ratchet; and the main locking part moves to the right, a movable block on the main locking part pushes the tip of the deflector rod 1, and the whole locking mechanism is fixed by a deflector rod 2 on the above treasury door. The treasury door locking mechanism has the advantages of reliable movement, firm locking and high safety.

Owner:XIANGYANG BOYA PRECISION IND EQUIP

Rope threading device for water surface salvage

ActiveCN106800235AEasy to operateQuick snapRopes and cables for vehicles/pulleyLoad-engaging elementsLocking mechanismEngineering

The invention discloses a rope threading device for water surface salvage. The rope threading device for water surface salvage comprises a leading locking mechanism, two leading ropes and a pushing pressing mechanism, and a peripheral device is a lifting ring of a target object; one ends of the two leading ropes are fixedly connected with the leading locking mechanism; the other ends of the two leading ropes are arranged on a salvage platform; the leading locking mechanism is mounted on the pushing pressing mechanism; the pushing pressing mechanism is in contact with the lifting ring of the target object; under the action of external force, the pushing pressing mechanism enables the leading locking mechanism to achieve locking; the two leading ropes are combined into an integral body to trap the lifting ring of the target object; and the leading pushing mechanism and the pushing pressing mechanism are separated. According to the rope threading device, the defects that time and effort are wasted when a conventional water surface device is utilized for salvage and the device is liable to damage are improved, and salvage of various water surface devices is guaranteed.

Owner:CSIC NO 710 RES & DEV INST

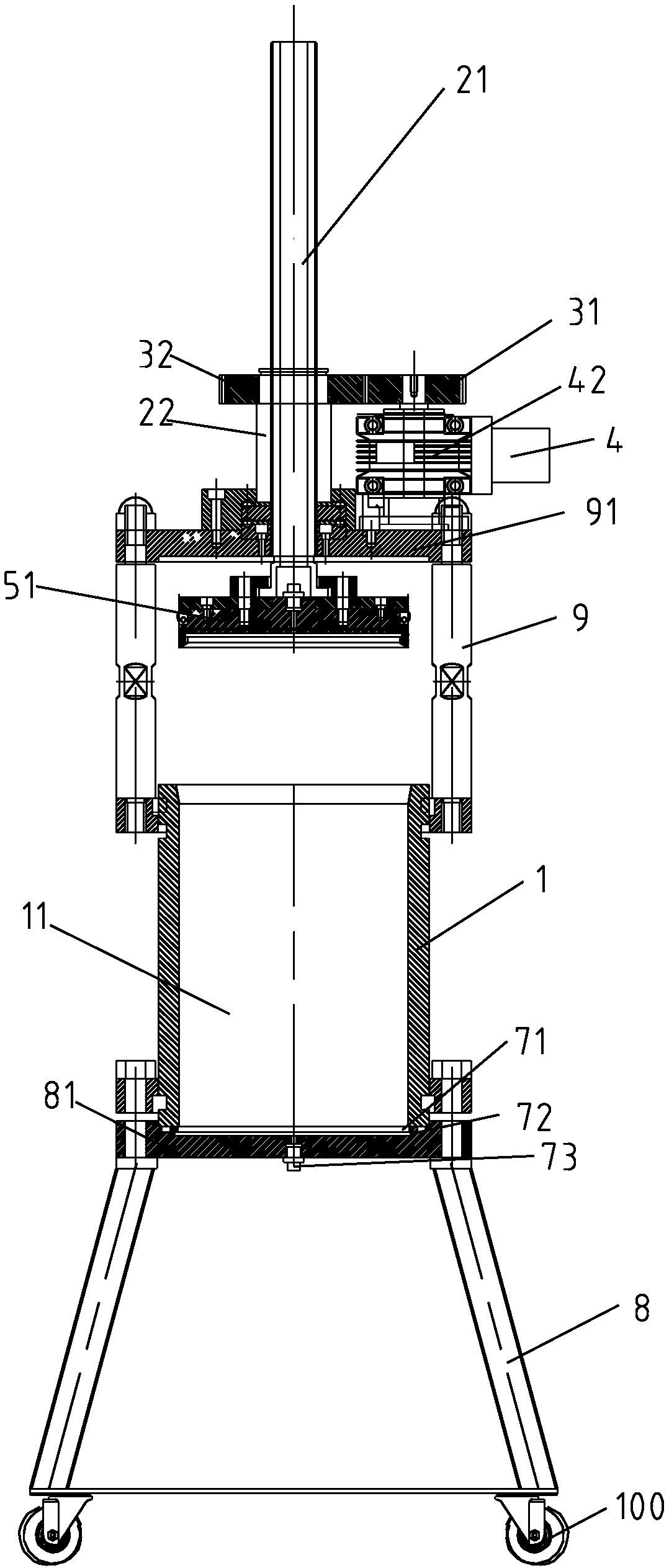

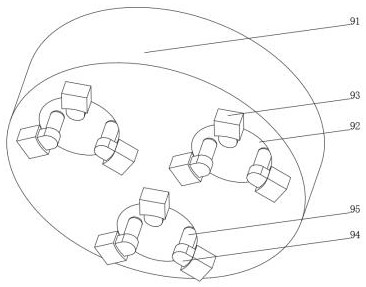

Low pressure chromatography column

PendingCN109011697AUniform pressureGood filtering effectSolid sorbent liquid separationPistonChromatography column

The invention discloses a low pressure chromatography column. The column comprises a body, and further comprises a cylinder, a piston part, and a liquid dispensing assembly for collecting the dispensed liquid flowing from the liquid phaseof the filler in a filler cavity. The cylinder is provided with the filler cavity for accommodating the filler. The piston part comprises a piston assembly and apiston drive assembly connected to the piston assembly to drive the piston assembly to move so that the piston assembly is pressed into the filler cavity to act on the filler. The piston assembly is provided with an infusion distribution component guiding the liquid phaseto the upper surface of the filler in the filler cavity when the piston assembly is pressed in the right place.According to theinvention, the height of a column bed can be adjusted based on requirements, the pressing force on the surface of the filler is precisely controlled, so that the pressure acting on the surface of thefiller is more balanced, and a filtering effect is better.

Owner:常州瑞曦生物科技有限公司

Clamping tool with function of automatic riser removal

The invention relates to a clamping tool with a function of automatic riser removal. The clamping tool comprises a clamping device and a hydraulic system. The clamping device comprises an upper die plate and a base. A press-down unit is mounted at the bottom of the upper die plate. Two bidirectional cylinders are disposed on the base. The hydraulic system comprises a first oil pipe and a second oil pipe; oil return openings of the bidirectional cylinders are parallelly connected with the first oil pipe; oil inlets of the bidirectional cylinders are parallelly connected with the second oil pipe; a pressure switch is connected to the first oil pipe. The hydraulic system is used to synchronously control the bidirectional cylinders to stably drive the press-down unit of the upper die plate so that the press-down unit moves down and presses the rear rim of a hub; no gap exists between a product and the press-down unit; resilience of the product occurring in riser punching is greatly decreased, and product deformation is avoided; meanwhile, the pressure switch is disposed at the oil return openings of the bidirectional cylinders, hub pressing force is effectively controlled, and pressing damage is prevented. The clamping tool is applicable to riser removal for hubs.

Owner:广东戴卡旭汽车零部件有限公司

Preparation method and preparation system of low-formaldehyde solid wood composite floor

InactiveCN112318664ASame installation timeConsistent installation strengthPlywood pressesVeneer pressesSolid woodEngineering

The invention discloses a preparation method and a preparation system of a low-formaldehyde solid wood composite floor. The preparation method and the preparation system have the beneficial technicaleffect that a bottom plate and a back plate can be simultaneously pressed on a core plate coated with glue. The method comprises the following steps that 1, the core plate is placed between two U-shaped plates, two first electric push rods are started to drive the two U-shaped plates to get close to each other, and the core plate is clamped and fixed; 2, two side plates are correspondingly installed and fixed on two side plate fixing mechanisms; 3, a glue coating assembly moves downwards to coat the front end surface and the rear end surface of the core plate with glue, and the glue coating assembly is moved reversely to ascend and reset; 4, two side plate rotating mechanisms are started to drive the side plates on the two side plate fixing mechanisms to rotate upwards to a vertical state;and 5, a pressing control mechanism is started to drive the two side plates to get close to the core plate and to be bonded and pressed at the two ends of the core plate.

Owner:赵亚华

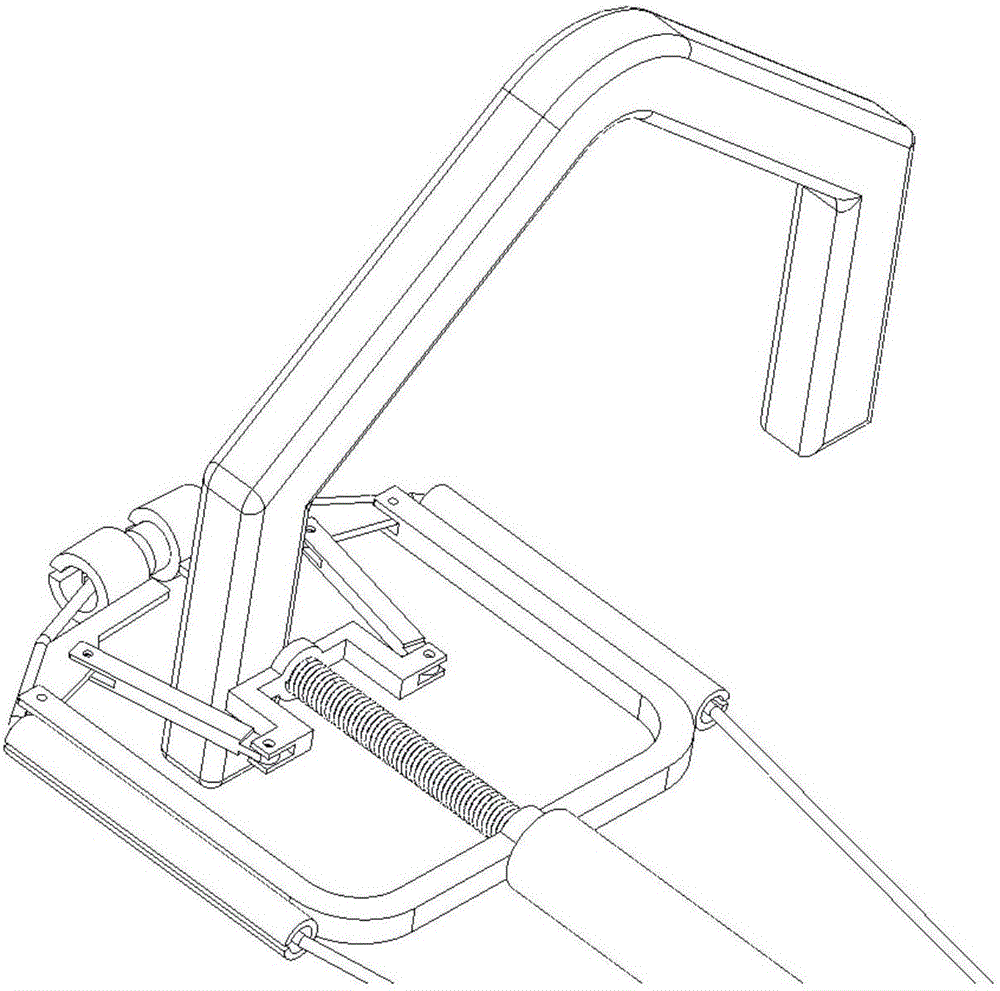

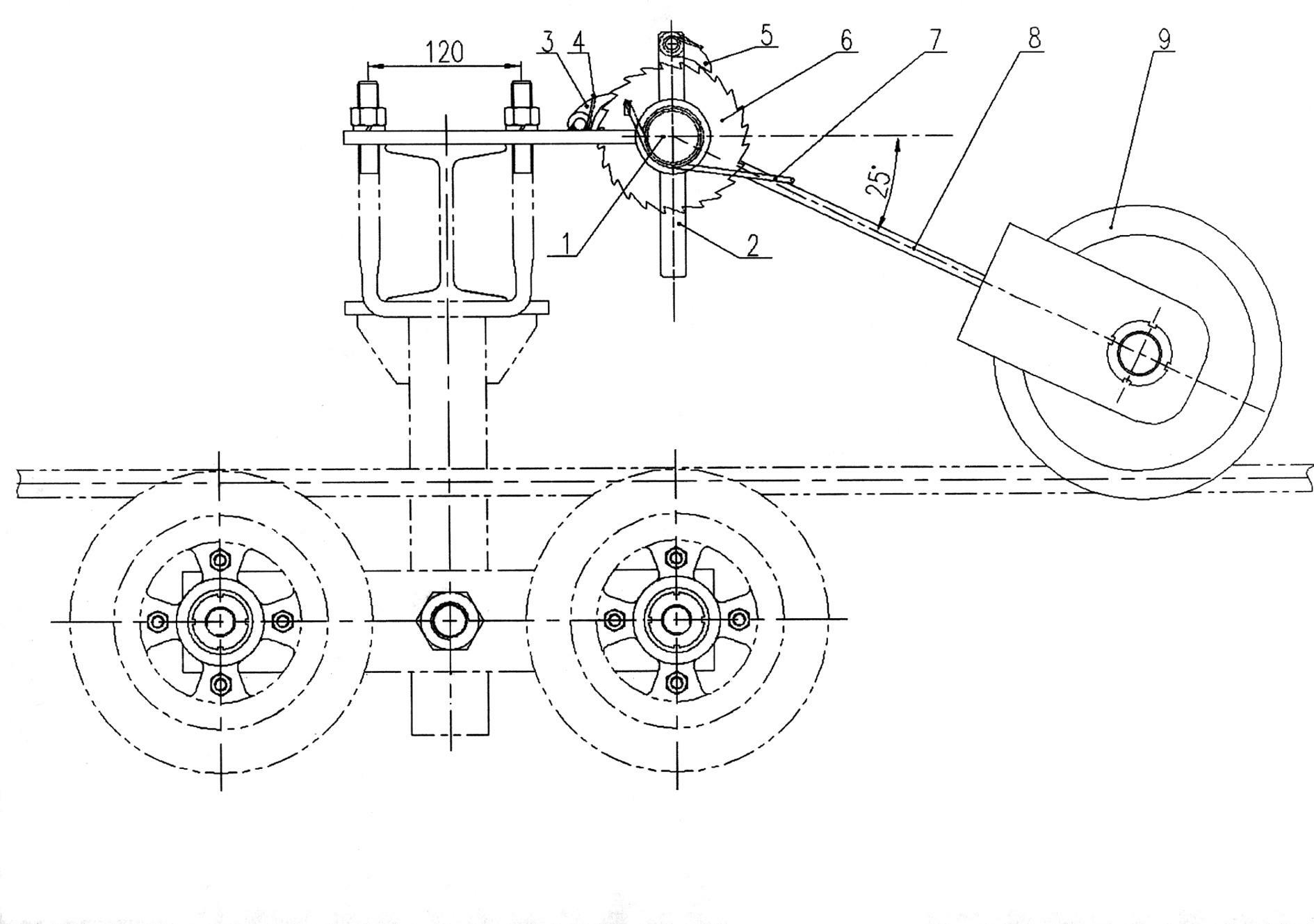

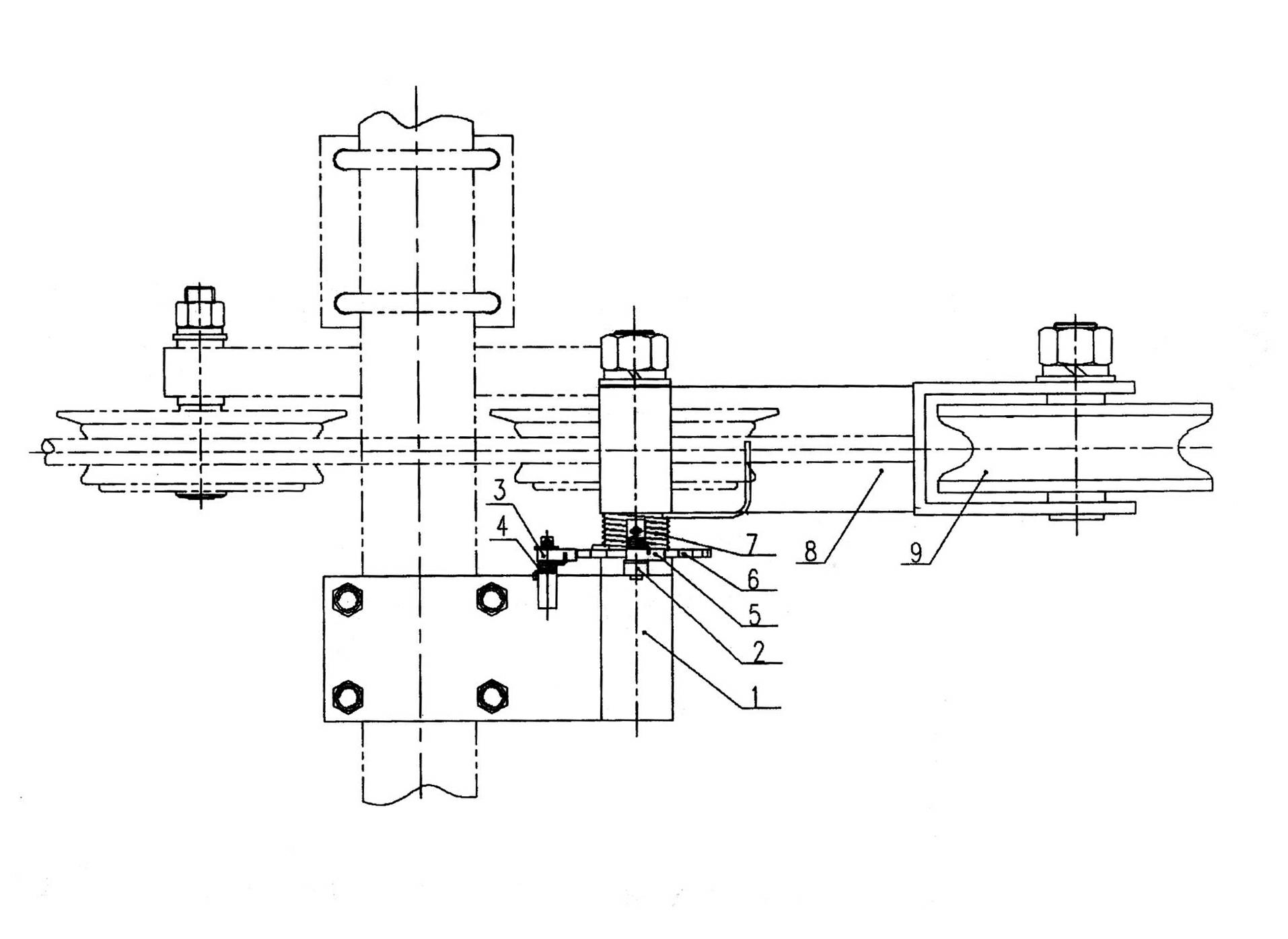

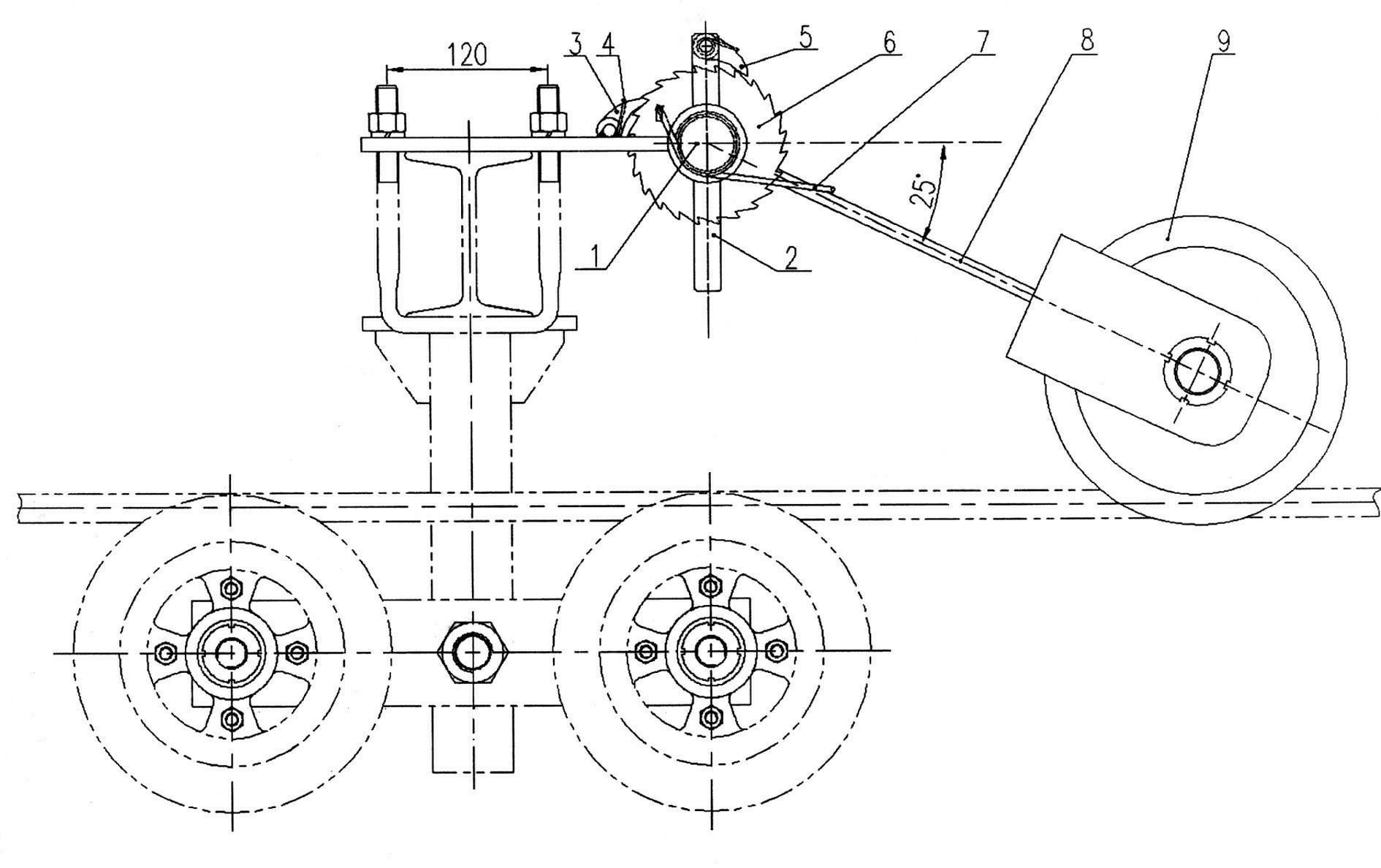

Adjustable ropeway deep-geneva wheel rope dropping preventer

ActiveCN102649435AControl the pressing forcePass smoothlyRope railwaysEngineeringMechanical engineering

The invention relates to an adjustable ropeway deep-geneva wheel rope dropping preventer. A rocker is hollowly sleeved on a connecting shaft assembly, a driving pawl is connected with the rocker through a revolving pair, a stopping pawl is connected with the connecting shaft assembly through a revolving pair, the first end of a big torsional spring is connected with a ratchet wheel, the second end of the big torsional spring is connected with a supporter, one end of the supporter is axially connected with the connecting shaft assembly, the other end of the supporter is connected with the shaft of a deviation-preventing wheel, and the ratchet wheel is sleeved on the connecting shaft assembly. The adjustable ropeway deep-geneva wheel rope dropping preventer can effectively control the force pressing a running ropeway wire rope, moreover, the pressing force can be reliably regulated, the motion is reliable, and the adjustable ropeway deep-geneva wheel rope dropping preventer can be adapted to various roadways with complex environments, can prevent rope dropping, and is highly stable and safe.

Owner:CHANGSHA ZHENGZHONG TECH DEV

A jet printing machine

ActiveCN112874161BAchieve fixationAchieve compactionOther printing apparatusEngineeringPrinting press

The present invention relates to the technical field of inkjet printing machines, in particular to an inkjet printing machine, which includes a bottom plate, a plurality of sliding grooves are provided on the surface of the bottom plate, and at least one of the plurality of sliding grooves is provided with a The fixing assembly is used to fix the paper to be sprayed on the bottom plate; the fixing assembly includes a slider slidingly arranged in the sliding groove, and the top of the slider is fixed with a support plate, when pulled down The first pull cord moves the paddle downwards, and then fixes the paper to be sprayed on the base plate; the center of the bottom surface of the base plate is detachably installed with an adjustment assembly; the invention can quickly adjust the position of the paddle according to different paper sizes The position of multiple picks can be fixed, and then the picks can be moved downward to compress the paper; the entire paper pressing process can be completed by adjusting the components, and there is no need to adjust the positions of the picks one by one.

Owner:江苏瑞彩包装有限公司

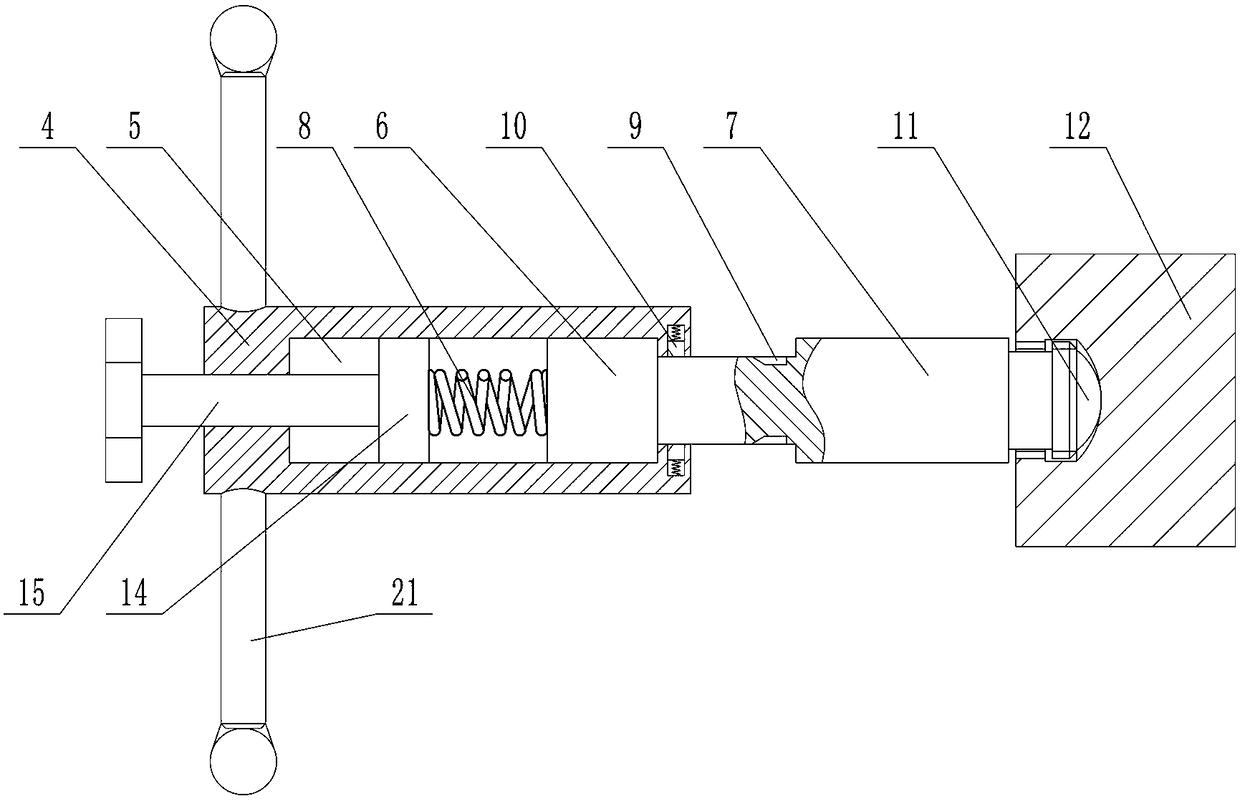

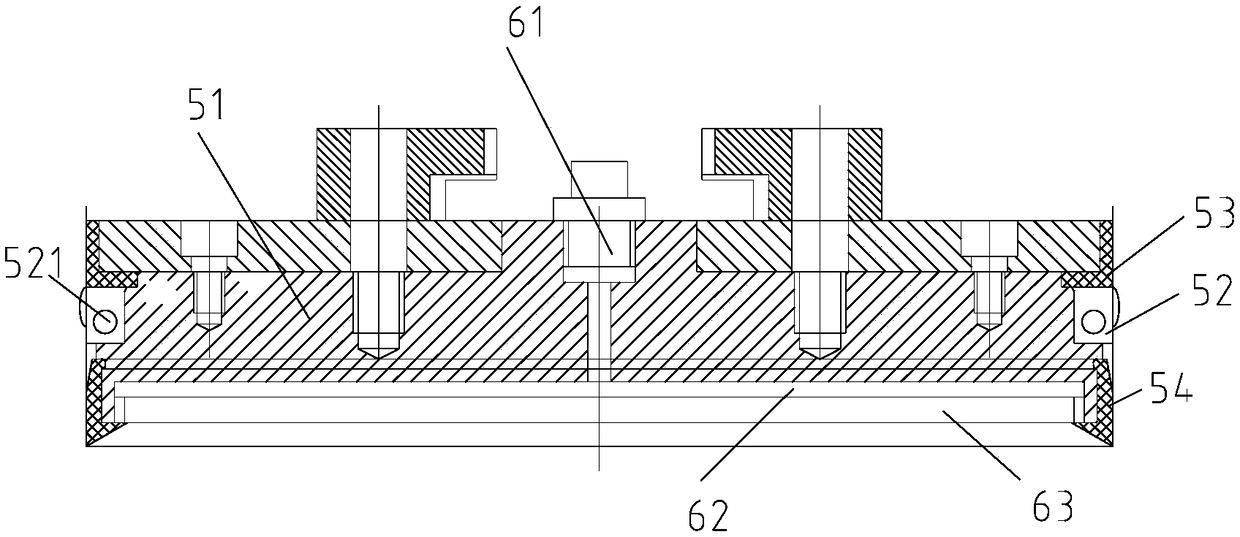

A self-adaptive adjustable fixture for processing aluminum products

ActiveCN109128917BRealize positioning and pressingControl the pressing forcePositioning apparatusMetal-working holdersAluminium preparationsStructural engineering

The invention discloses a self-adaptive adjusted fixture for aluminum product machining; and the fixture preferably realizes positioning and pressing of aluminum product workpieces, and can control the pressing force to the aluminum product workpieces to prevent damage to the workpieces. The fixture comprises a base plate; a slide block is arranged above the base plate; a screw rod is inserted inthe slide block; a bulb body is arranged at the right end of the screw rod; a pressing block sleeves the bulb body; the pressing block can be rotated relative to the bulb body without separating; a sleeve is inserted in the screw rod; a piston is mounted in the sleeve; the screw rod can move to the right side by a pushing piston; a rotating rod is inserted in the left end of the screw rod; the right end of the rotating rod is in contact with the sleeve; a flat key is arranged on the outer edge of the rotating rod; a key slot is formed in the inner side wall of the screw rod; through cooperation between the flat key and the key slot, the rotating rod is rotated to drive the screw rod to move left and right; a wedged groove, positioned on the left side of the key slot, is formed in the innerwall of the screw rod; and when the flat key is positioned in the wedged groove, the rotating rod only can drive the screw rod to rotate in one direction to enable the screw rod to move to the left side. The fixture is novel in concept.

Owner:郑州亨睿精密机械科技有限公司

M1 line door seal automatic pressing machine

InactiveCN111572043ASatisfy the pressing operationControl the pressing forceCharacter and pattern recognitionDomestic articlesStructural engineeringElectric control

The invention provides an M1 line door seal automatic pressing machine. The M1 line door seal automatic pressing machine comprises an installation support, a pressing assembly, a visual induction assembly, an electric control cabinet, a PLC, a centering assembly and a supporting plate. According to the M1 line door seal automatic pressing machine, through the arrangement of the centering assemblyand the visual induction assembly, a visual sensor automatically recognizes a door body model, the PLC controls a centering electric push rod to push centering plates to move, so that the distance between the centering plates is matched with the size of the door body model, the pressing size is adjusted according to needs, the pressing operation of door seals of different sizes is met, and the application range of the pressing machine is widened; and a first compression roller assembly and a second compression roller assembly are arranged, an air cylinder pushes a compression roller plate to move downwards, the door seal is subjected to pressing operation through a compression roller, the PLC controls the downward moving distance of the air cylinder, the pressing force of the compression roller on the door seal is kept consistent, the purpose of controlling the pressing force of the door seal is achieved, and the pressing quality of the door seal is improved.

Owner:滁州尚诺自动化设备有限公司

A grinding device for the inner wall of metal pipe fittings

ActiveCN113649870BReduce impact damageImprove the protective effectRevolution surface grinding machinesGrinding drivesPipe fittingDrive shaft

The invention discloses a grinding device for the inner wall of a metal pipe fitting, which specifically comprises: a fixed base, the top of which is fixedly connected with a retaining ring, the inner wall of the retaining ring is slidably connected with an inner gear ring through an annular slideway, and the top of the fixed base is fixed connected to the limit rod; the drive gear, the drive gear is set inside the retaining ring, the drive shaft of the drive motor is fixedly connected to the bottom of the drive gear, the drive motor is set inside the fixed base, and the side of the drive gear is meshed with a driven gear, the side of the driven gear away from the driving gear meshes with the inner wall of the ring gear; the arc-shaped rotating plate, the bottom of the arc-shaped rotating plate meshes with the top of the ring gear, and the top of the arc-shaped rotating plate is fixedly connected with a rotating ring , The present invention relates to the technical field of metal processing. The inner wall grinding device of the metal pipe fittings can simultaneously polish multiple sets of pipe fittings, has high processing efficiency, can perform secondary grinding on the inner walls of the pipe fittings, and has a good grinding effect.

Owner:南通佰瑞利电动工具有限公司

Hydraulic limited slip differential

InactiveCN101793317BLocking coefficient controlControl the pressing forceDifferential gearingsGearing detailsLimited-slip differentialEngineering

The invention discloses a hydraulic limited slip differential, which comprises a housing, a planetary gear train and a hydraulic limited slip mechanism, wherein the hydraulic limited slip mechanism comprises a limited slip friction pair, a hydraulic device and an oil conveying disc, and the hydraulic limited slip mechanism is arranged at one side or two sides of the planetary gear train; the planetary gear train, the limited slip friction pair and the hydraulic device are arranged in the housing; the tooth back of the half axle gear of the planetary gear train is separated from the limited slip friction pair by the housing, and the driving friction plate of the limited slip friction pair is connected with the housing by spline teeth; the driven friction plate of the limited slip friction pair is connected with the half axle gear at the same side through spline teeth, and the hydraulic device comprises an annular oil cylinder and an annular piston; the annular oil cylinder is separatedfrom the limited slip friction pair by the annular piston, and the oil conveying disc is arranged on the neck journal of the housing; and an oil sink is arranged on the oil conveying disc and is communicated with the annular oil cylinder. The invention has the advantages that: when in work, the reaction force of the friction pair on the annular piston only acts on the housing of the differential and does not affect other external parts, and the work is smooth.

Owner:ZHEJIANG SCI-TECH UNIV

Air Suspension Axle Installation and Positioning Device for Semi-trailer

ActiveCN106142024BGuaranteed accuracyLower skill requirementsWelding/cutting auxillary devicesAuxillary welding devicesManufacturing technologyCompression device

The invention discloses a semitrailer air suspension axle installation positioning device, and relates to the technical field of car manufacturing. The semitrailer air suspension axle installation positioning device comprises two supports which are installed on a working platform and are symmetrically arranged; a plurality of positioning bases are installed on each support, and a plurality of jackscrew extending out to the inner side are installed at the lower portion of each support; a compression device is installed above the working platform, and a positioning plate is arranged between the two supports; the positioning bases on one support and the positioning bases on the other support are oppositely arranged; and the compression device comprises a pressing plate and a plurality of power cylinders connected with the pressing plate, and the multiple power cylinders are installed above the working platform through a supporting frame. Compared with the prior art, the semitrailer air suspension axle installation positioning device is adopted for semitrailer air suspension axle positioning installation, the procedure time for repeated measuring and positioning size adjusting is saved, the requirement for skills of operation persons is reduced, the accuracy of all installation sizes is guaranteed, and the product consistence is effectively guaranteed.

Owner:SINOTRUK LIUZHOU YUNLI SPECIAL PURPOSE VEHICLES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com