Bolt self-locking anti-loosening structure

An anti-loosening and self-locking technology, applied in the directions of bolts, screws, nuts, etc., can solve the problems of reducing the anti-loosening effect and poor reliability, and achieve the effect of good application prospects, low production cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention. The accompanying drawings illustrate by taking right-handed hexagonal bolts and nuts, a single helical anti-loosening groove, a single anti-loosening convex tooth, the bottom of the helical anti-loosening groove and the crest of the anti-loosening convex tooth as examples.

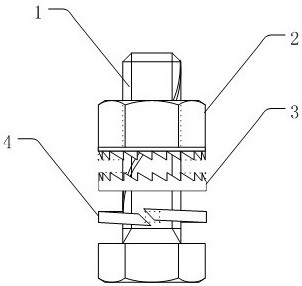

[0039] Such as figure 1 Shown is a schematic diagram of the self-locking and anti-loosening structure of the bolt, including the anti-loosening bolt 1, the anti-loosening nut 2, the anti-loosening locking ring 3, and the spring washer 4.

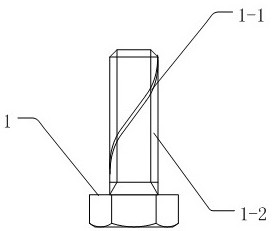

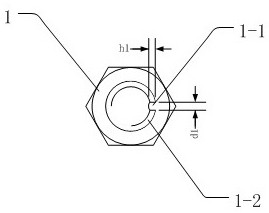

[0040] The anti-loosening bolt 1 is provided with a helical anti-loosening groove 1-1, the helical anti-loosening groove 1-1 runs through the threaded section of the anti-loosening bolt 1, and the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com