Patents

Literature

265 results about "Limited-slip differential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A limited-slip differential (LSD) is a type of differential that allows its two output shafts to rotate at different speeds but limits the maximum difference between the two shafts. In an automobile, such limited-slip differentials are sometimes used in place of a standard differential, where they convey certain dynamic advantages, at the expense of greater complexity.

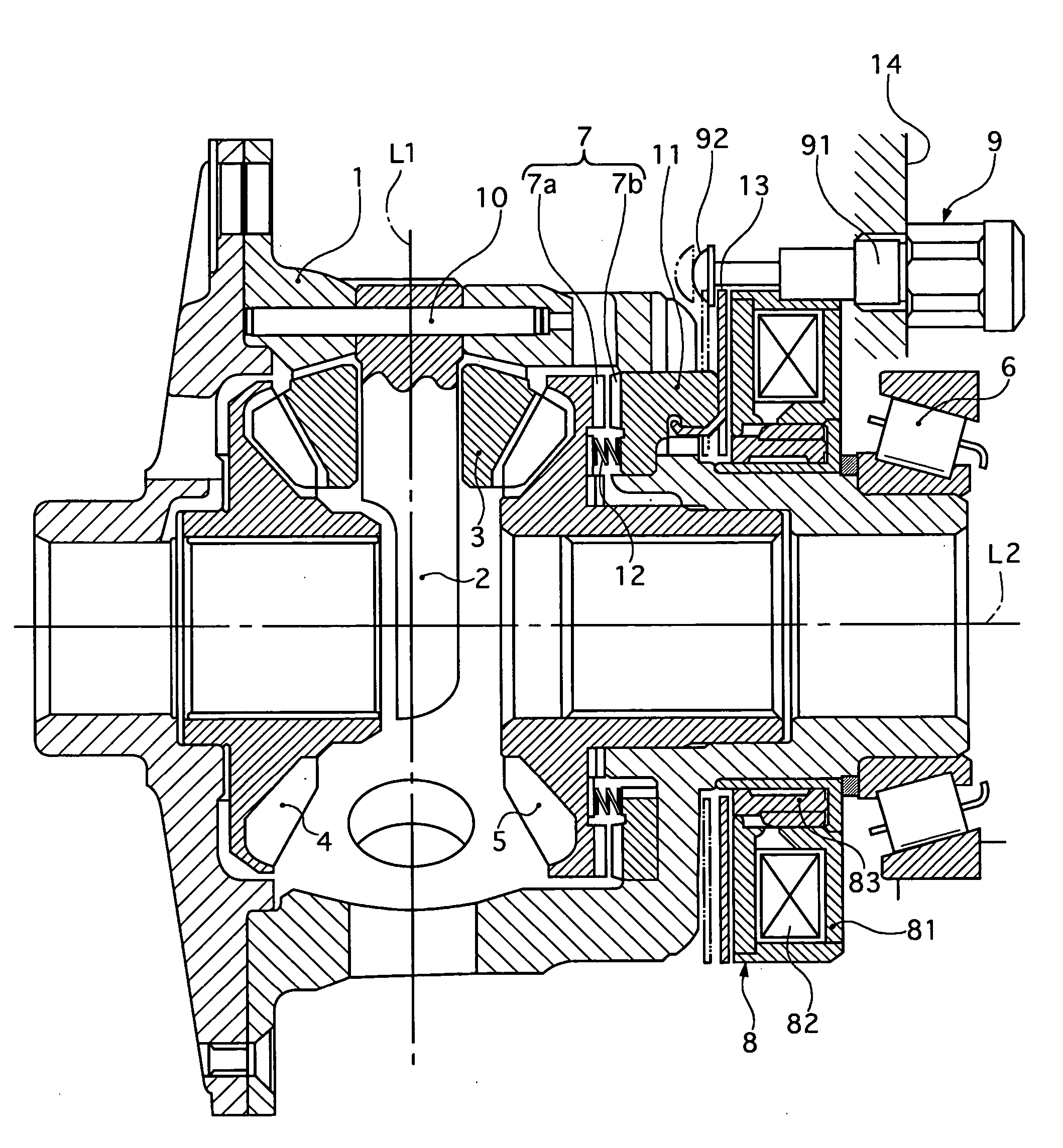

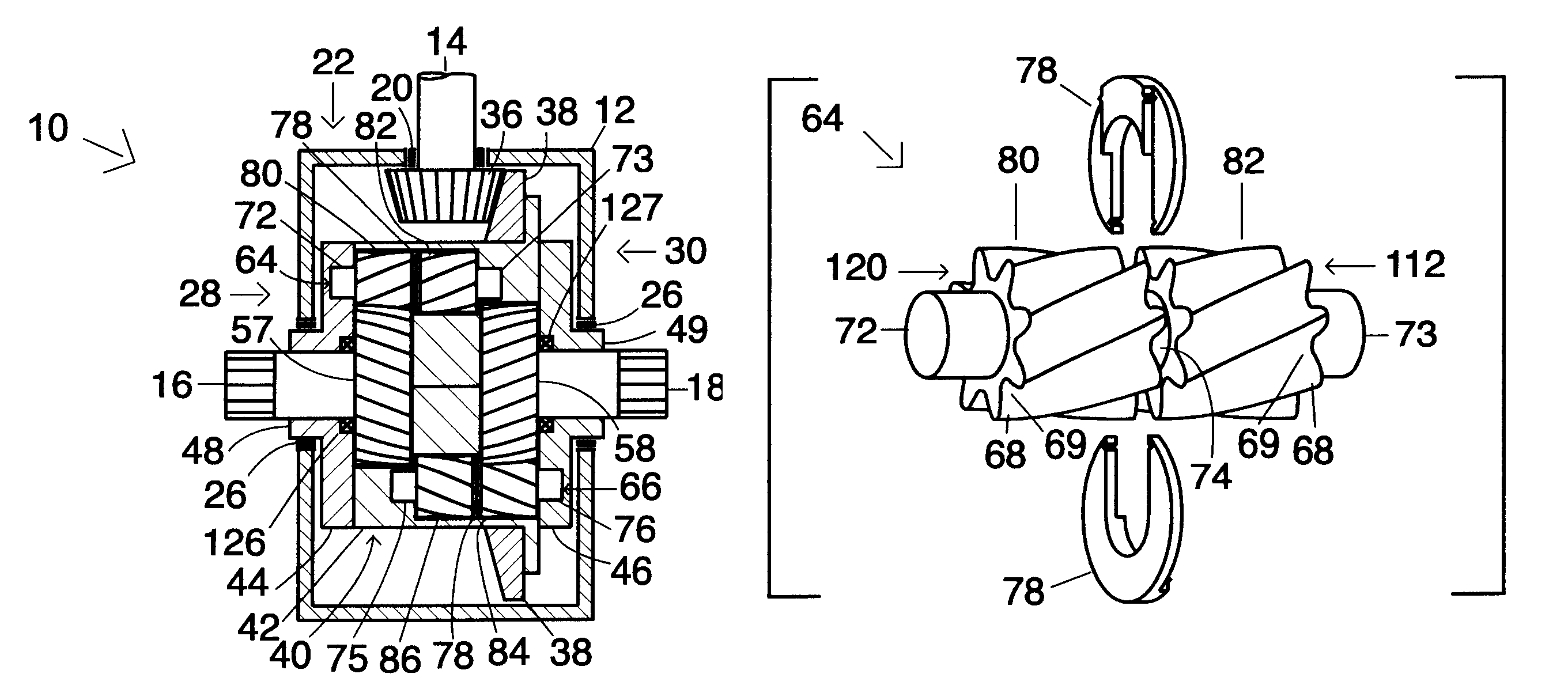

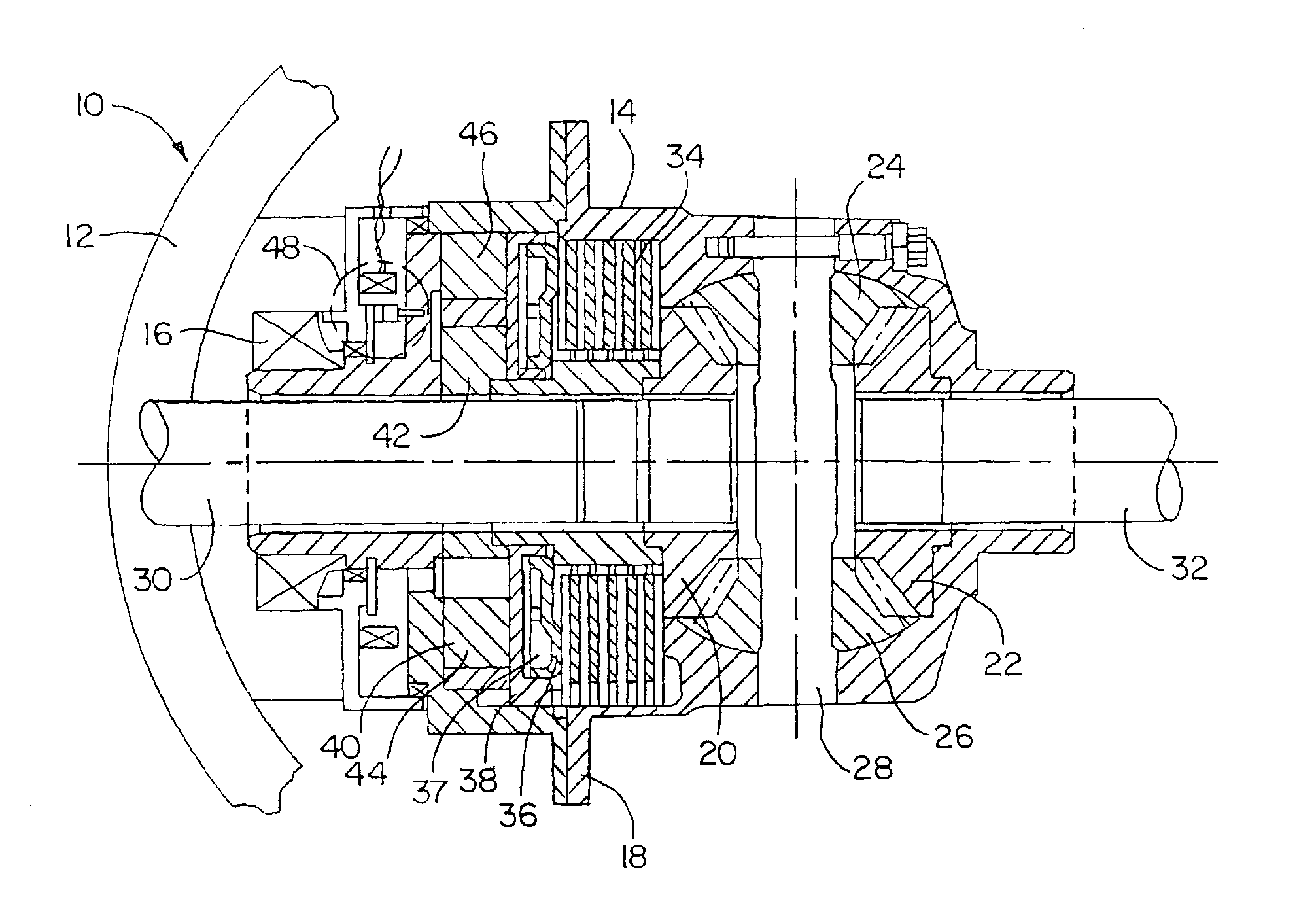

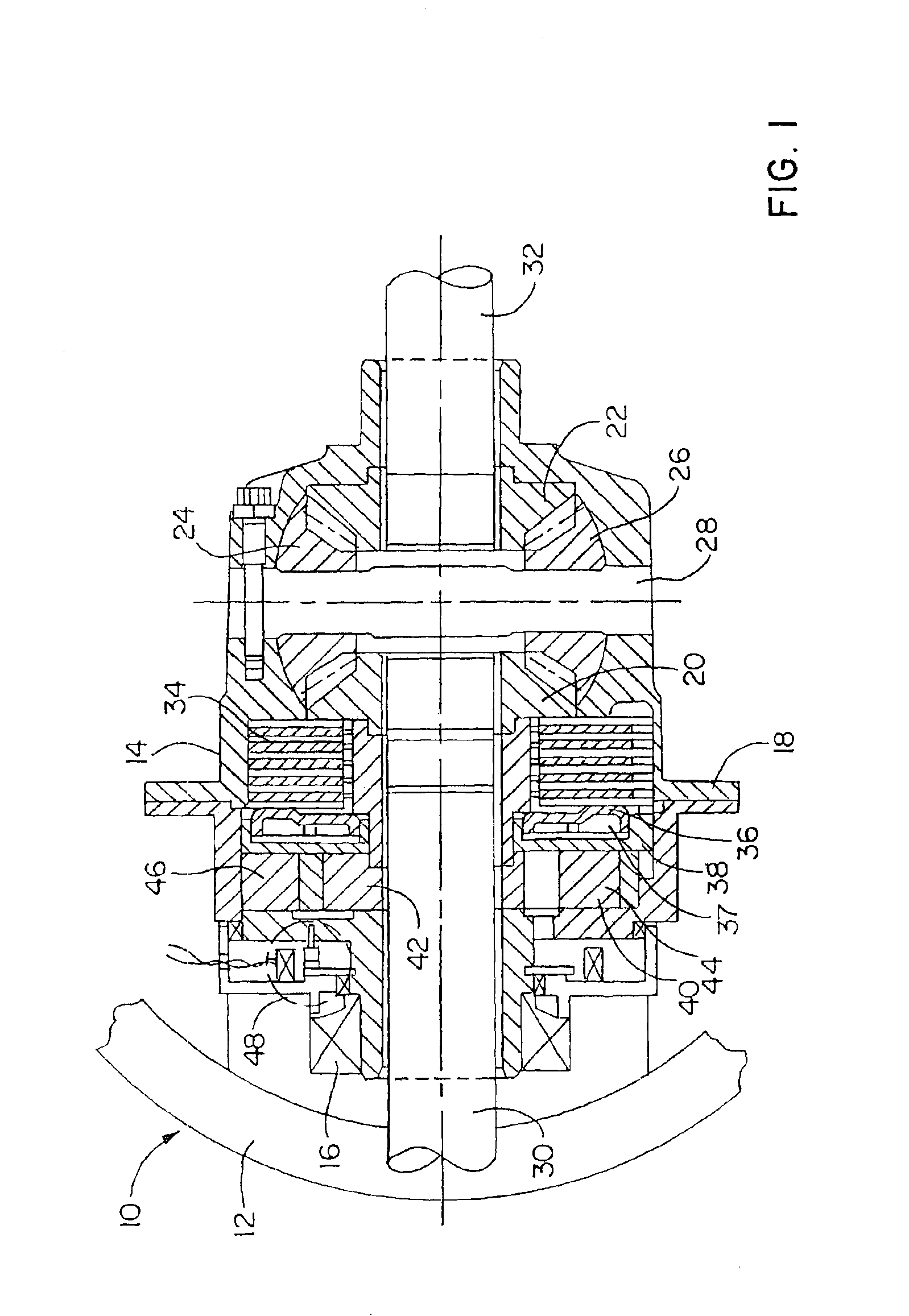

Locking differential with clutch activated by magnetorheological fluid

InactiveUS6428441B1Magnetically actuated clutchesFriction clutchesElectromagnetic couplingLimited-slip differential

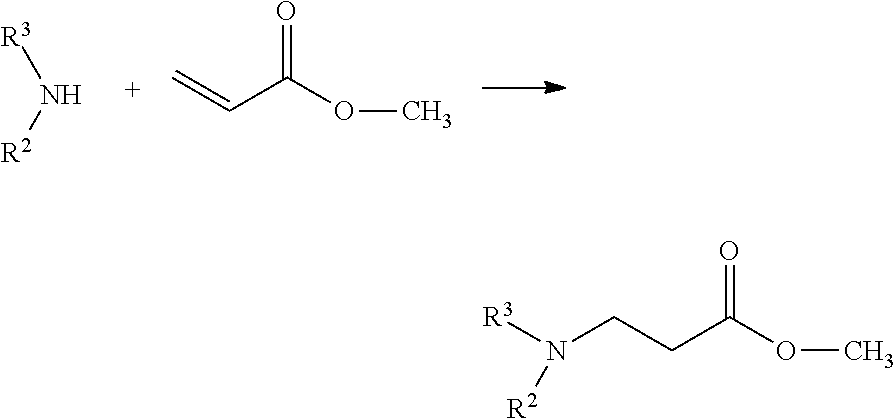

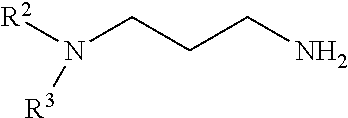

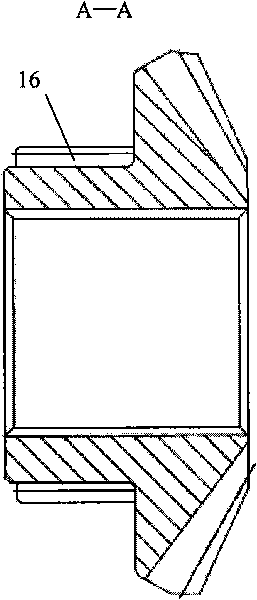

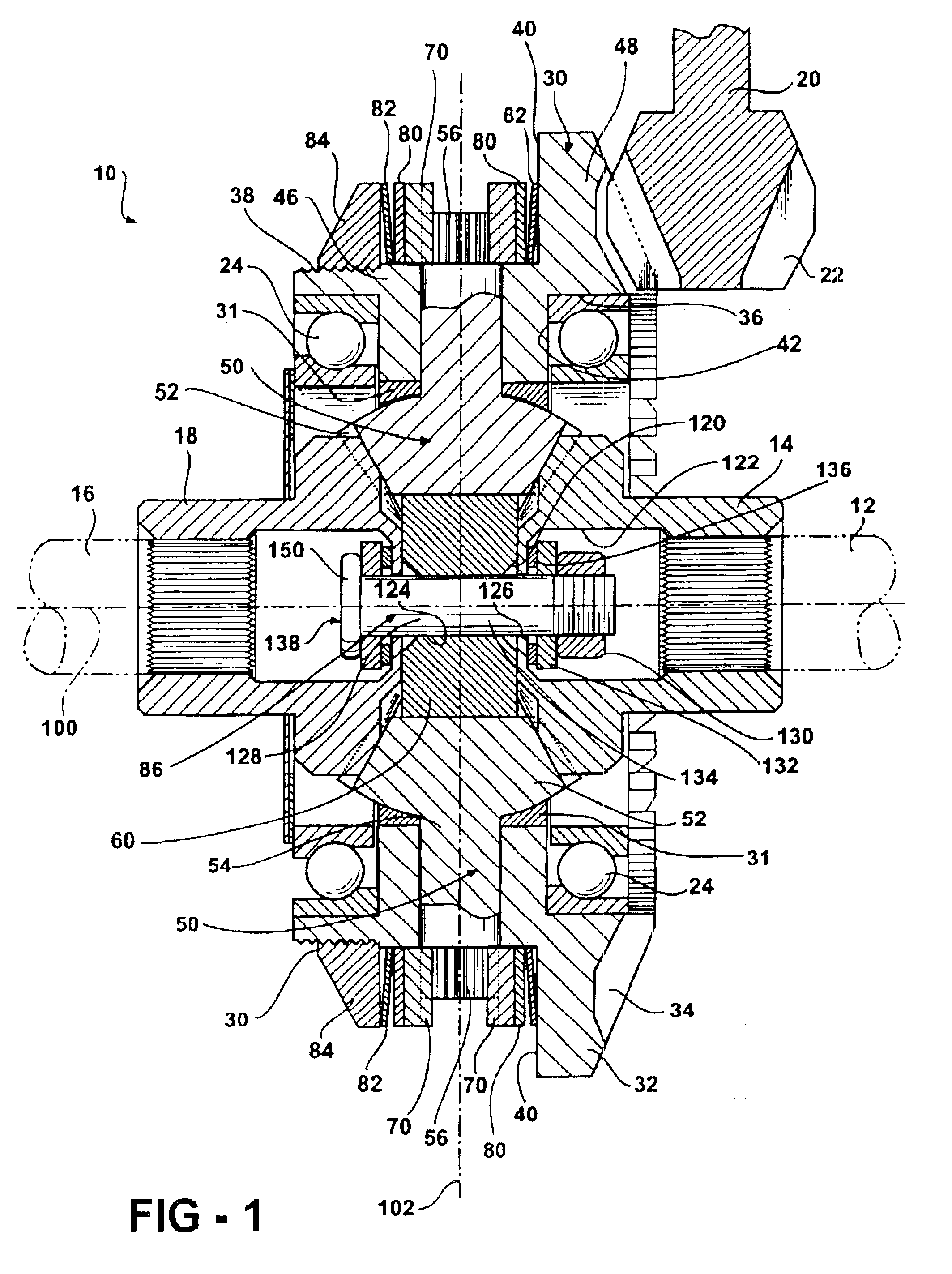

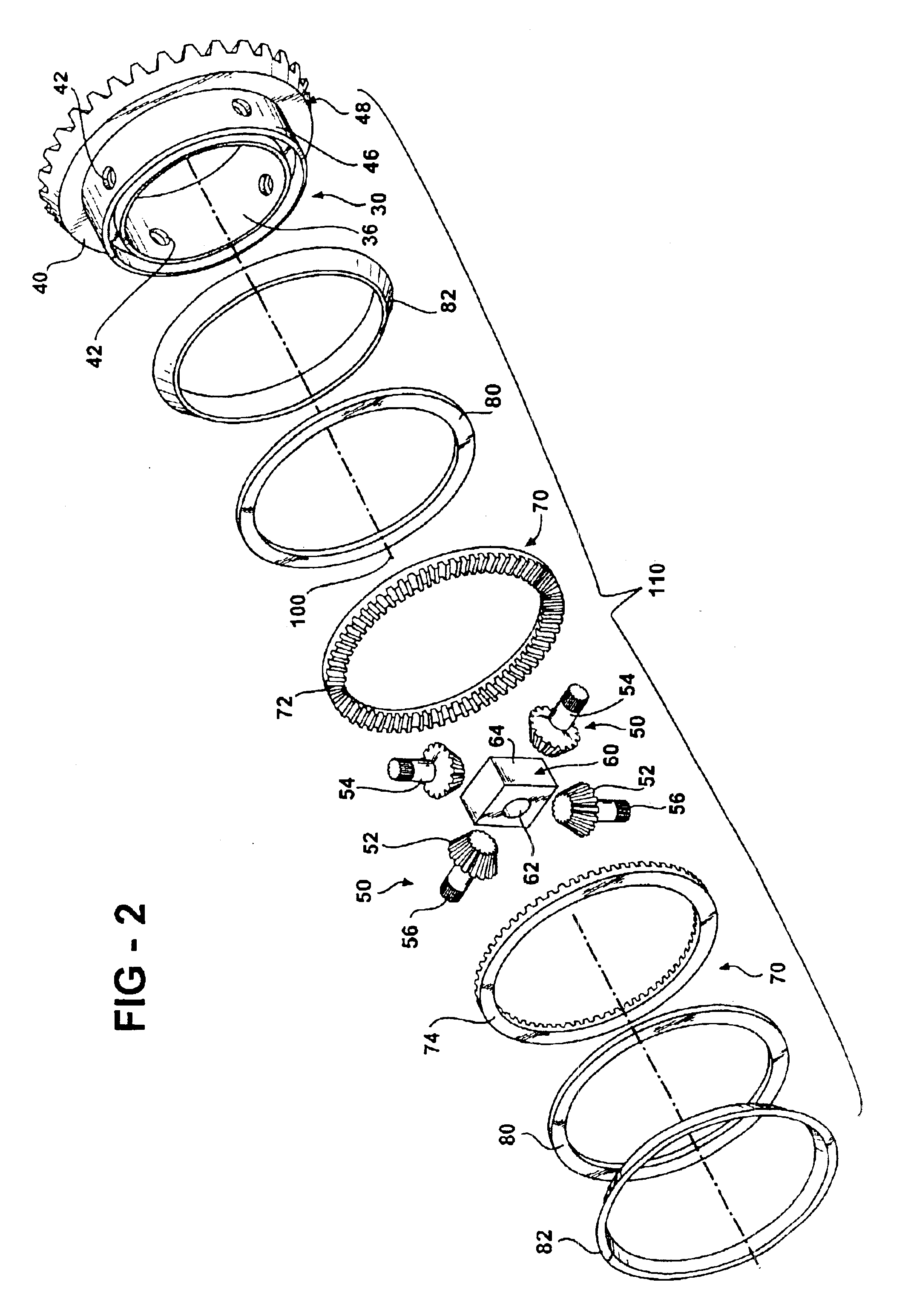

A limited slip differential includes a friction clutch mechanism, an electromagnetic coupling, and a camming mechanism disposed between the friction clutch mechanism and the electromagnetic coupling. The camming mechanism converts shearing forces within the electromagnetic coupling to an axial force applied to engage the clutch mechanism. The camming mechanism includes annular discs having axially inclined ramps, and a roller bearing for movement along the ramps to provide for variable spacing between the annular discs, wherein increased spacing is used to apply the axial force.

Owner:TORQUE TRACTION TECH INC

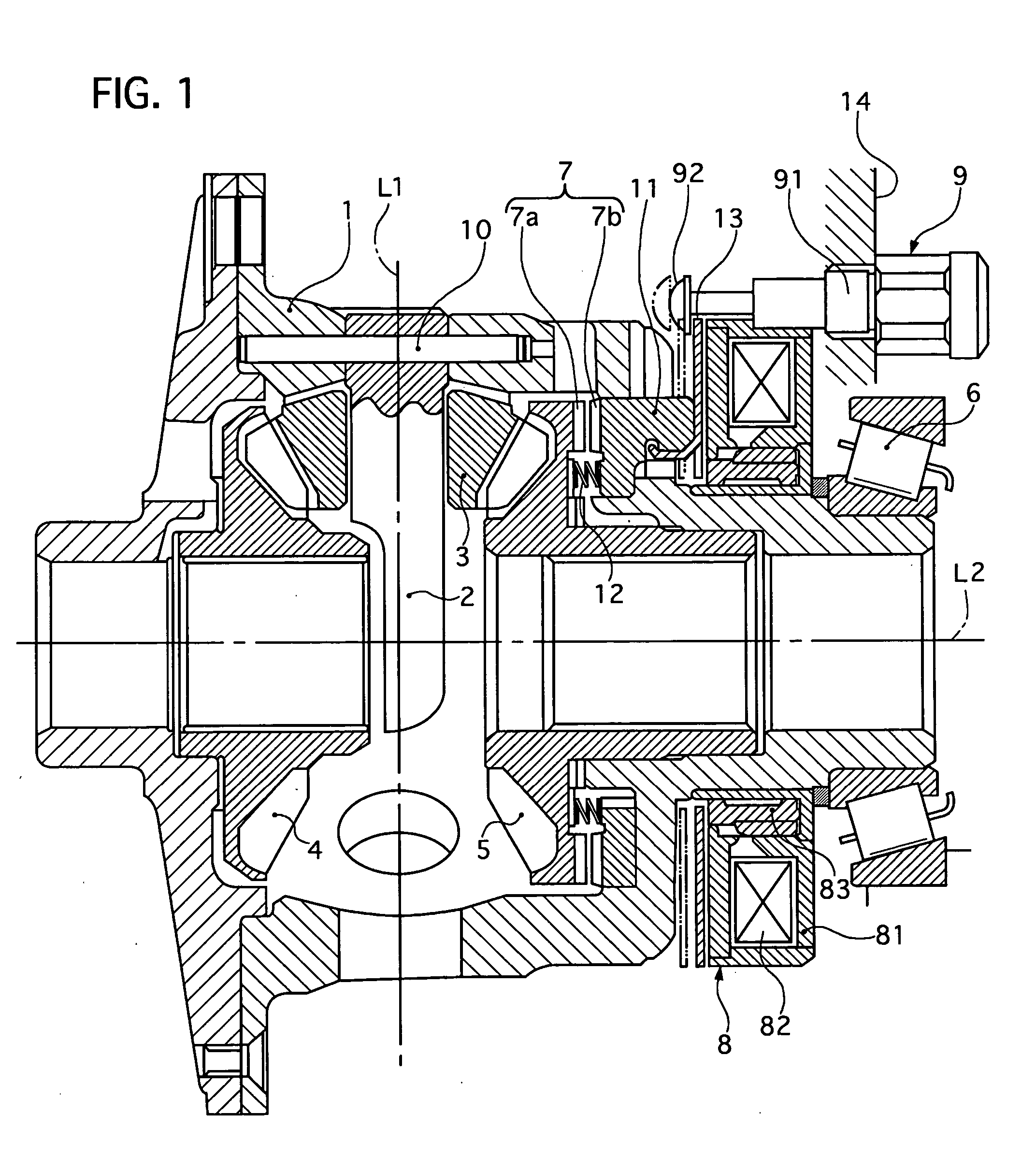

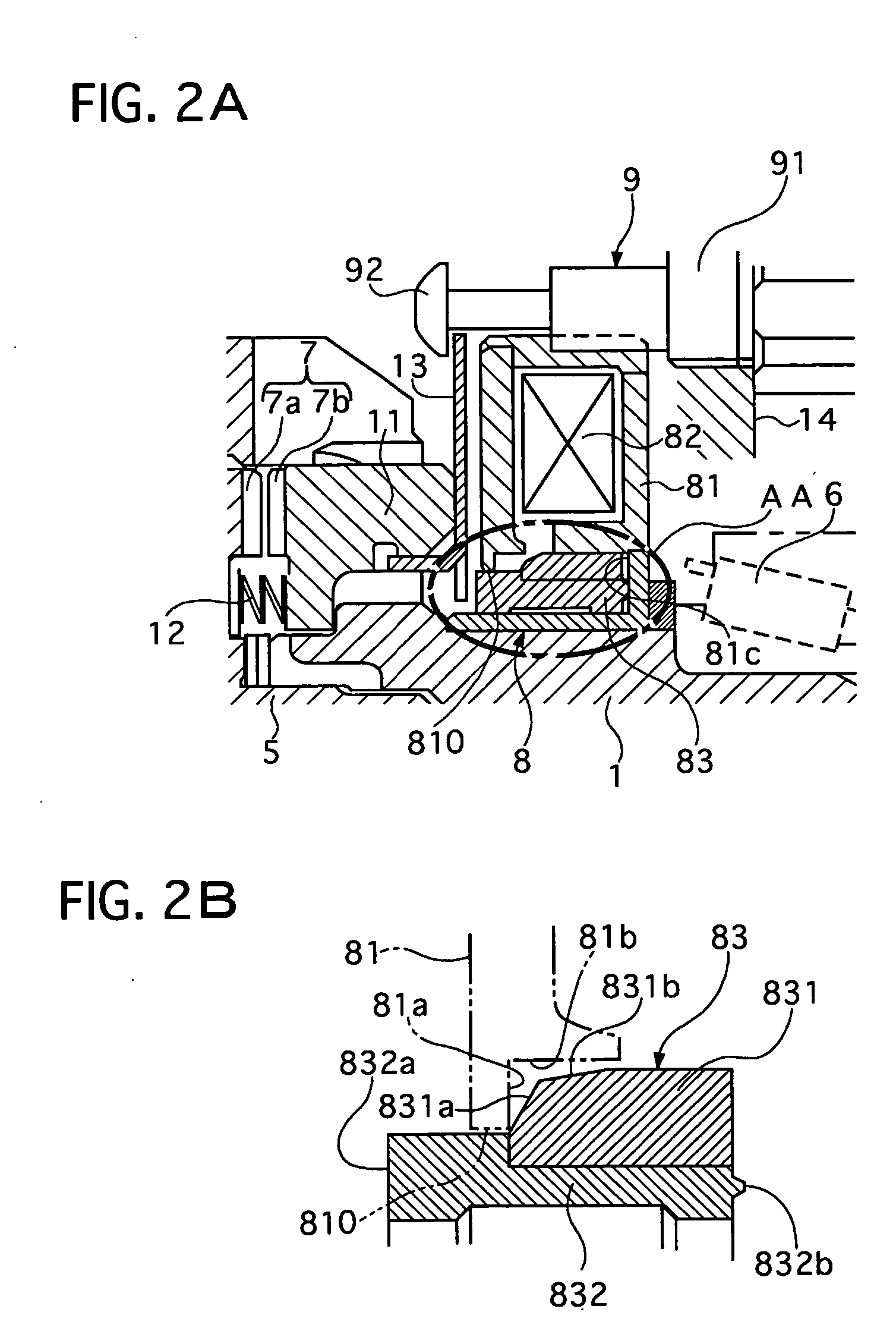

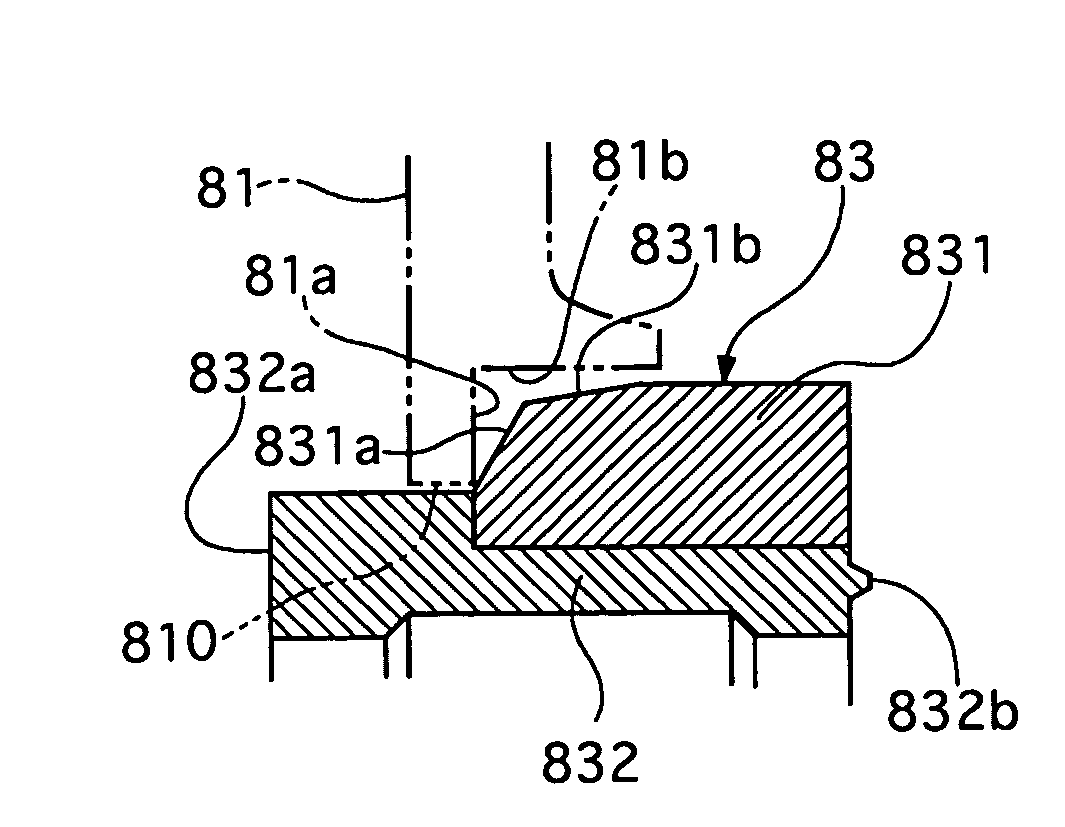

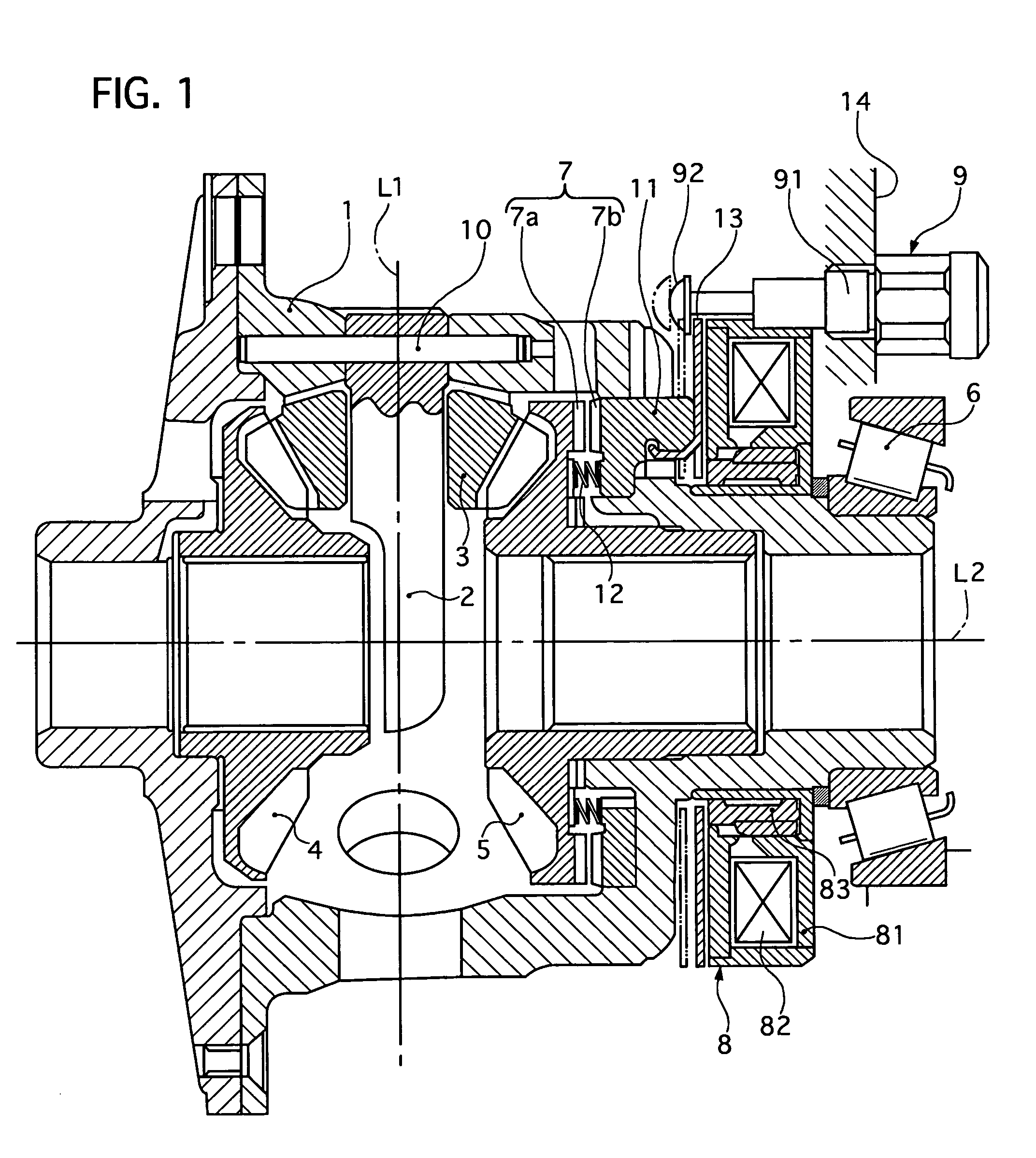

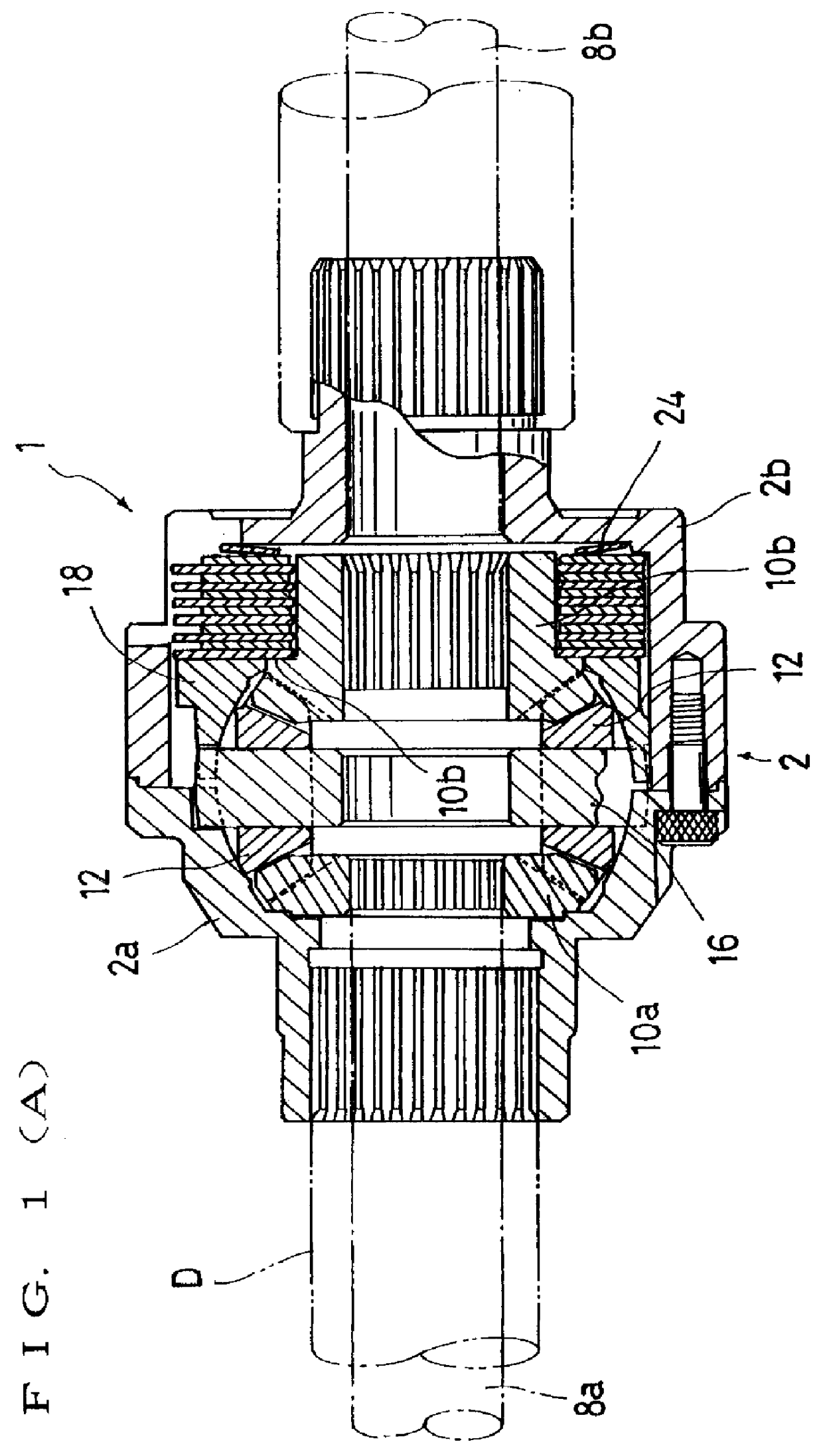

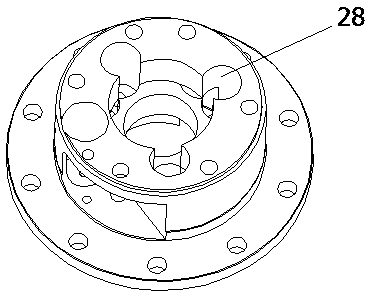

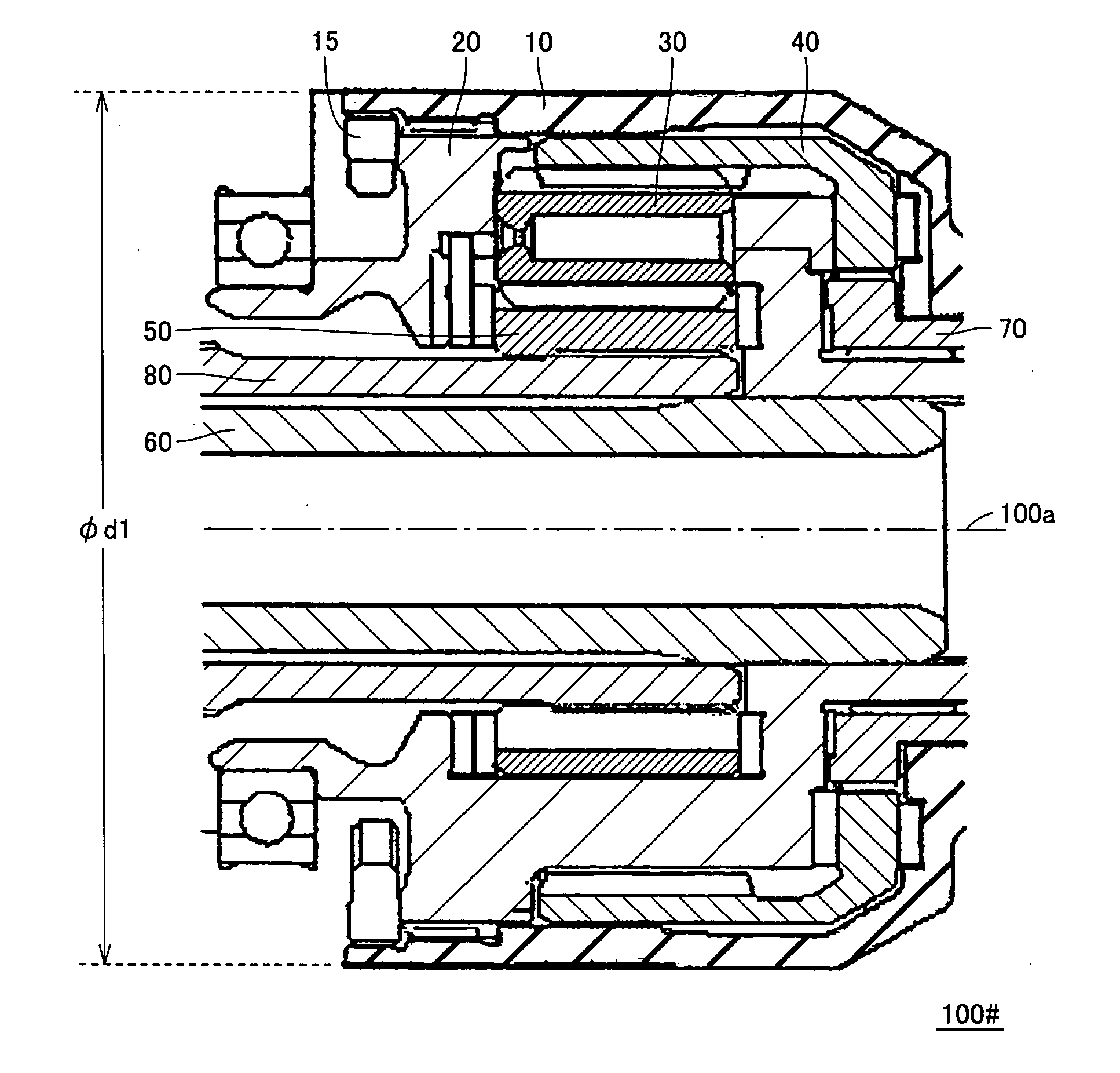

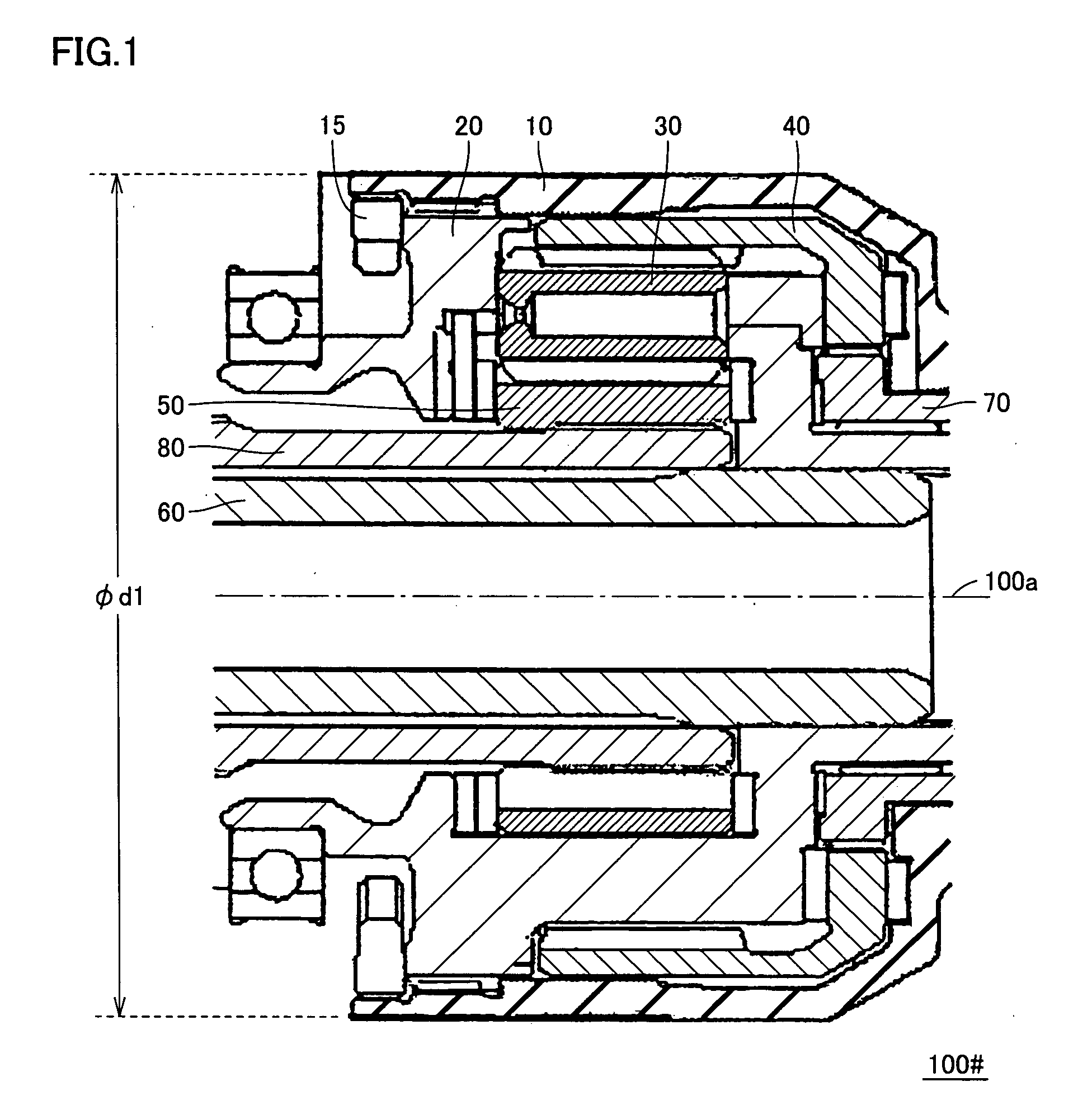

Limited slip differential device

ActiveUS20050187063A1Differential function is limitedMagnetically actuated clutchesDifferential gearingsDifferential functionLimited-slip differential

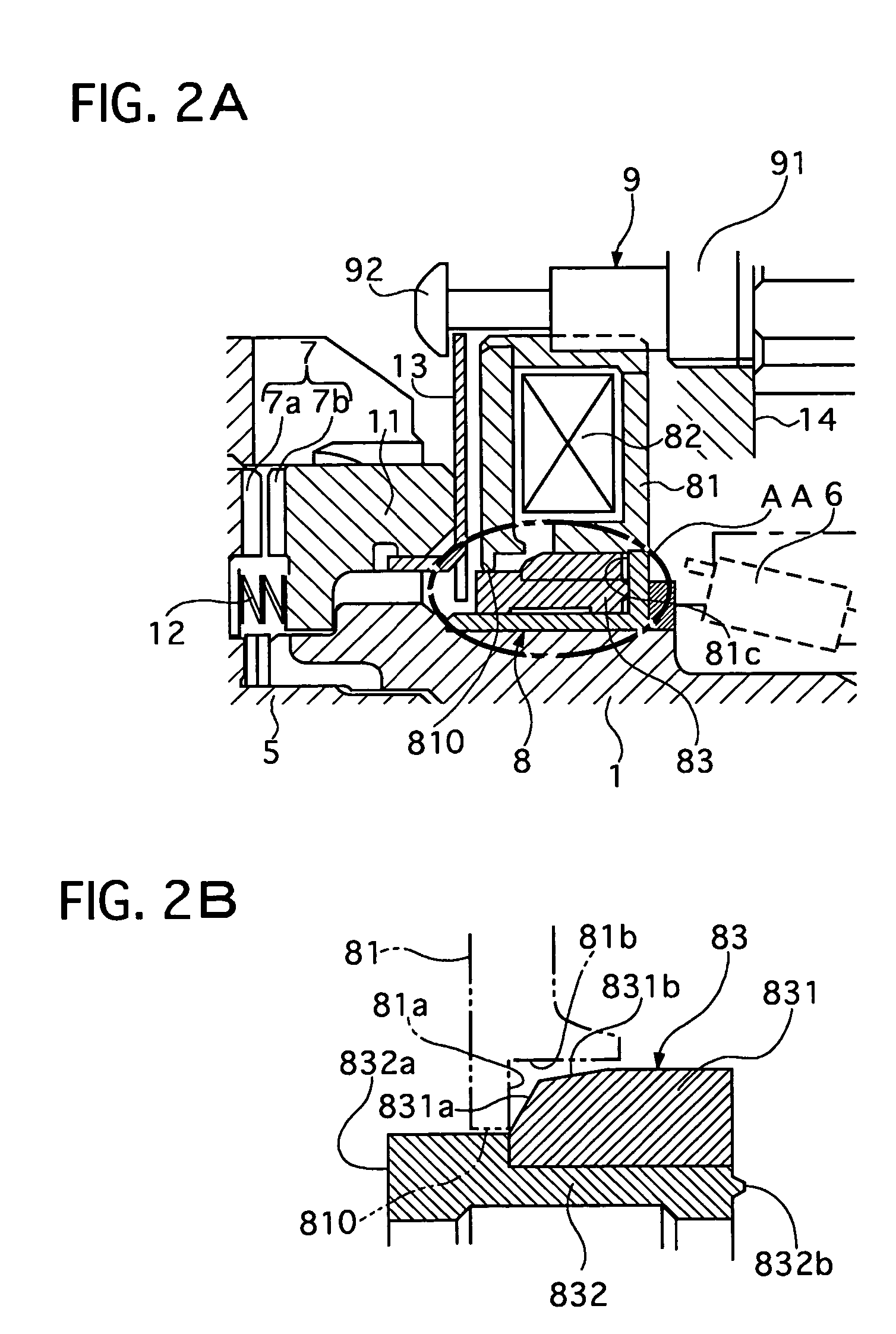

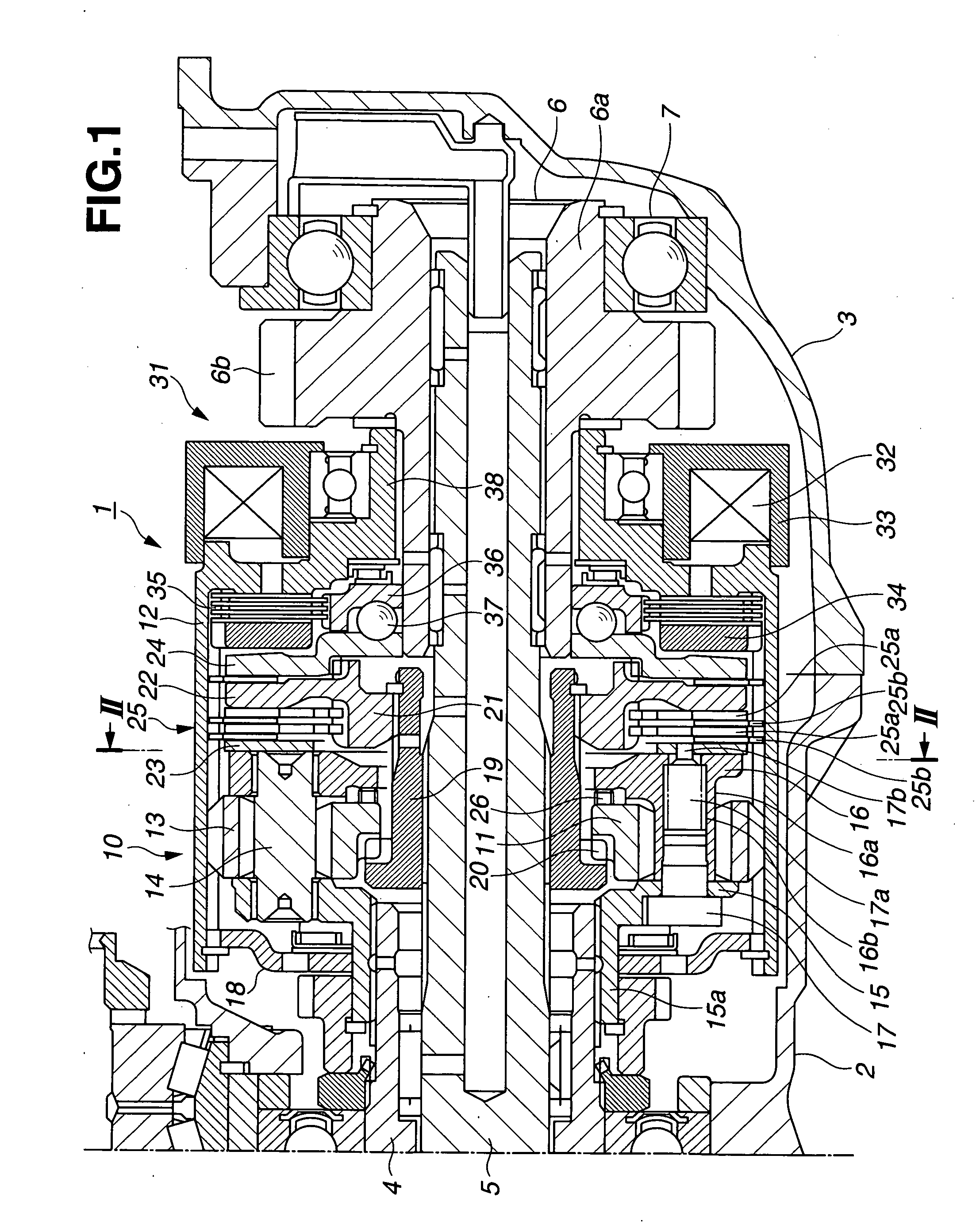

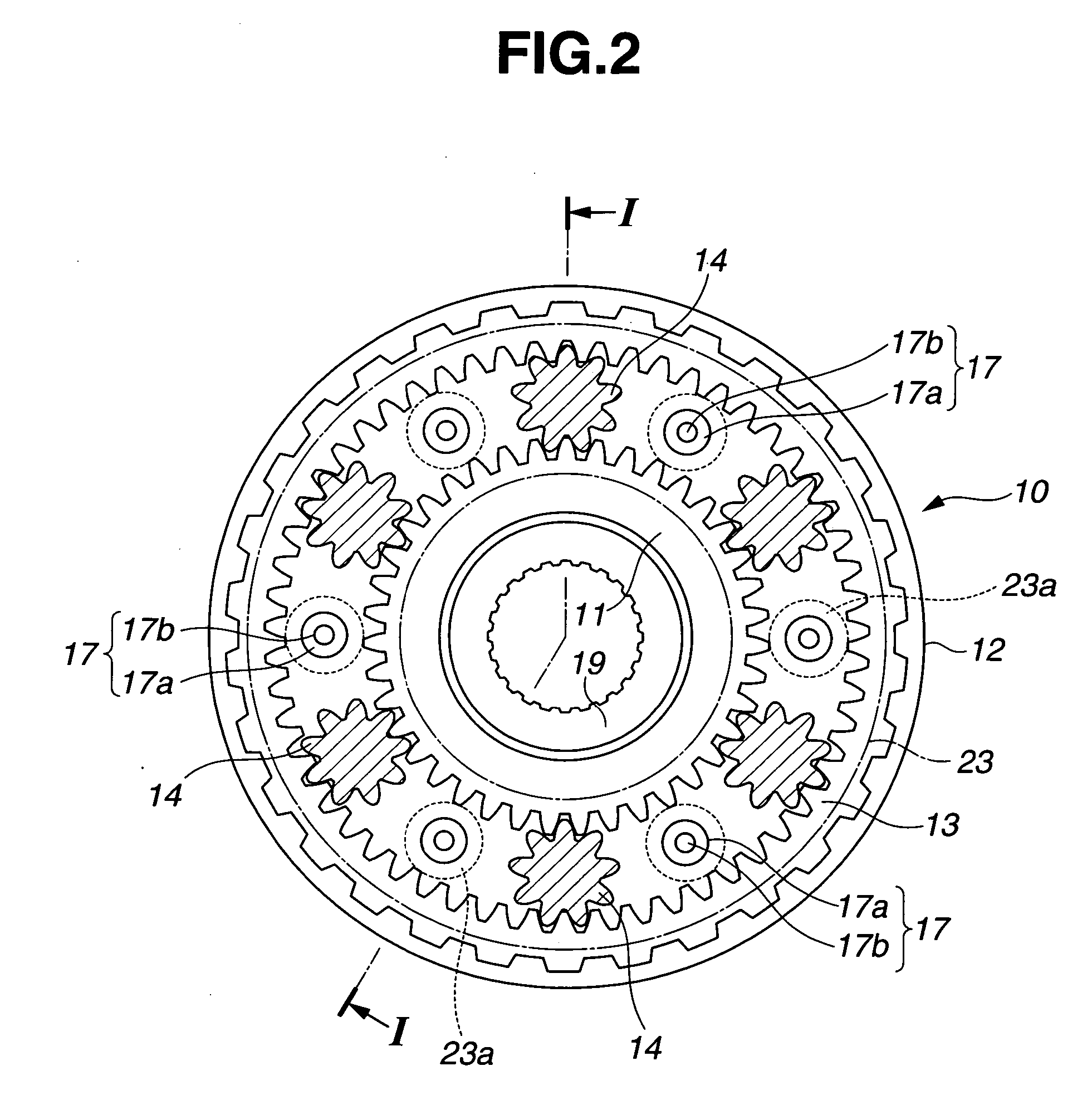

A limited slip differential device has differential gears, a clutch to limit the differential function of the differential gears, and a electromagnetic solenoid including a plunger and a coil. The plunger is set to move forward to engage the clutch by electromagnetic force of the coil in a differential limit state and move backward by a return spring to disengage said clutch in a differential limitless state. The plunger contacts with a contacting member in at least one state of the differential limit state and the differential limitless state, and their contact area is set smaller than a facing area between them in at least the one state.

Owner:GKN DRIVELINE TORQUE TECHNOLOGY KK +1

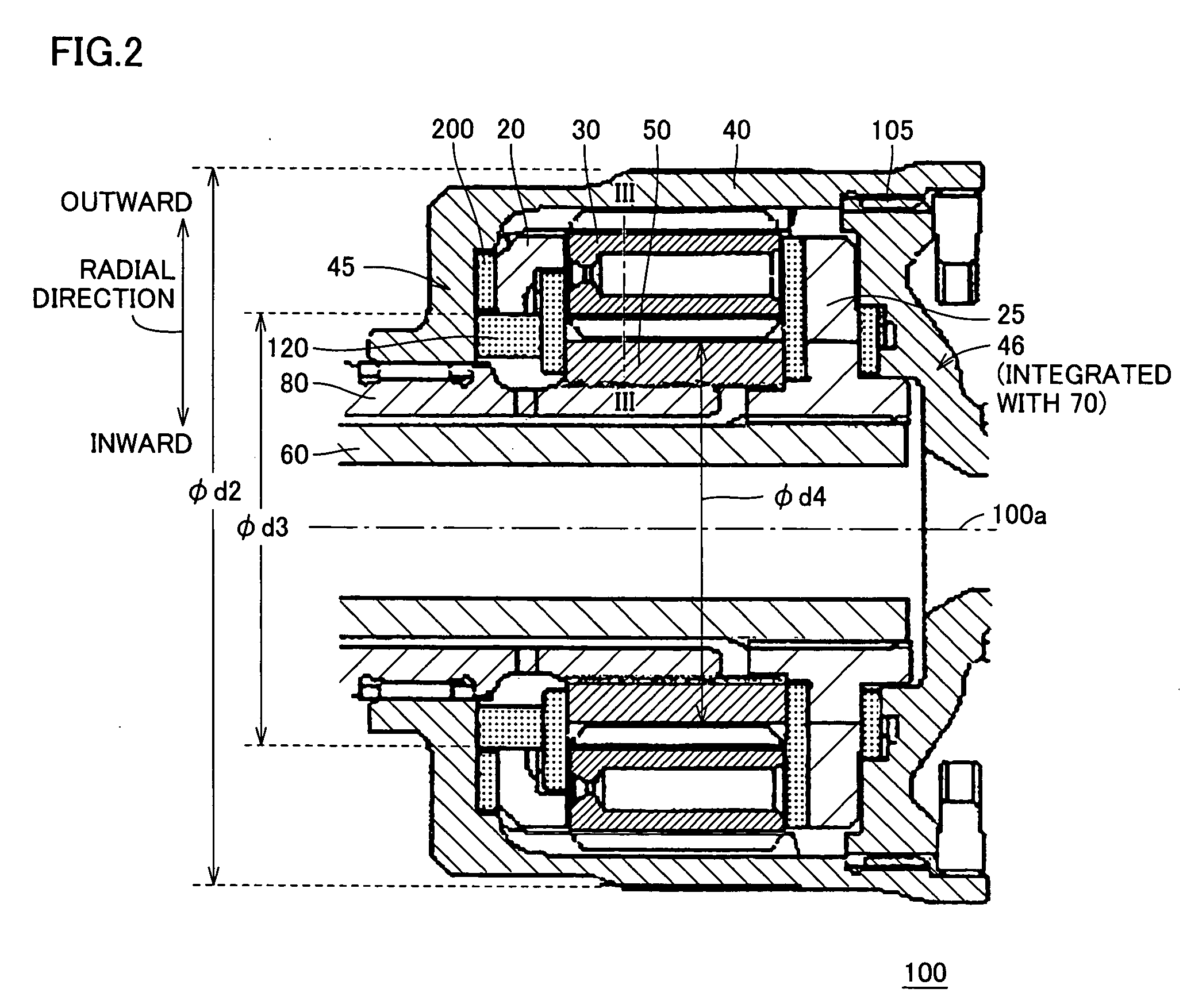

Limited slip differential device

ActiveUS7247118B2Differential function is limitedMagnetically actuated clutchesDifferential gearingsDifferential functionLimited-slip differential

A limited slip differential device has differential gears, a clutch to limit the differential function of the differential gears, and a electromagnetic solenoid including a plunger and a coil. The plunger is set to move forward to engage the clutch by electromagnetic force of the coil in a differential limit state and move backward by a return spring to disengage said clutch in a differential limitless state. The plunger contacts with a contacting member in at least one state of the differential limit state and the differential limitless state, and their contact area is set smaller than a facing area between them in at least the one state.

Owner:GKN DRIVELINE TORQUE TECHNOLOGY KK +1

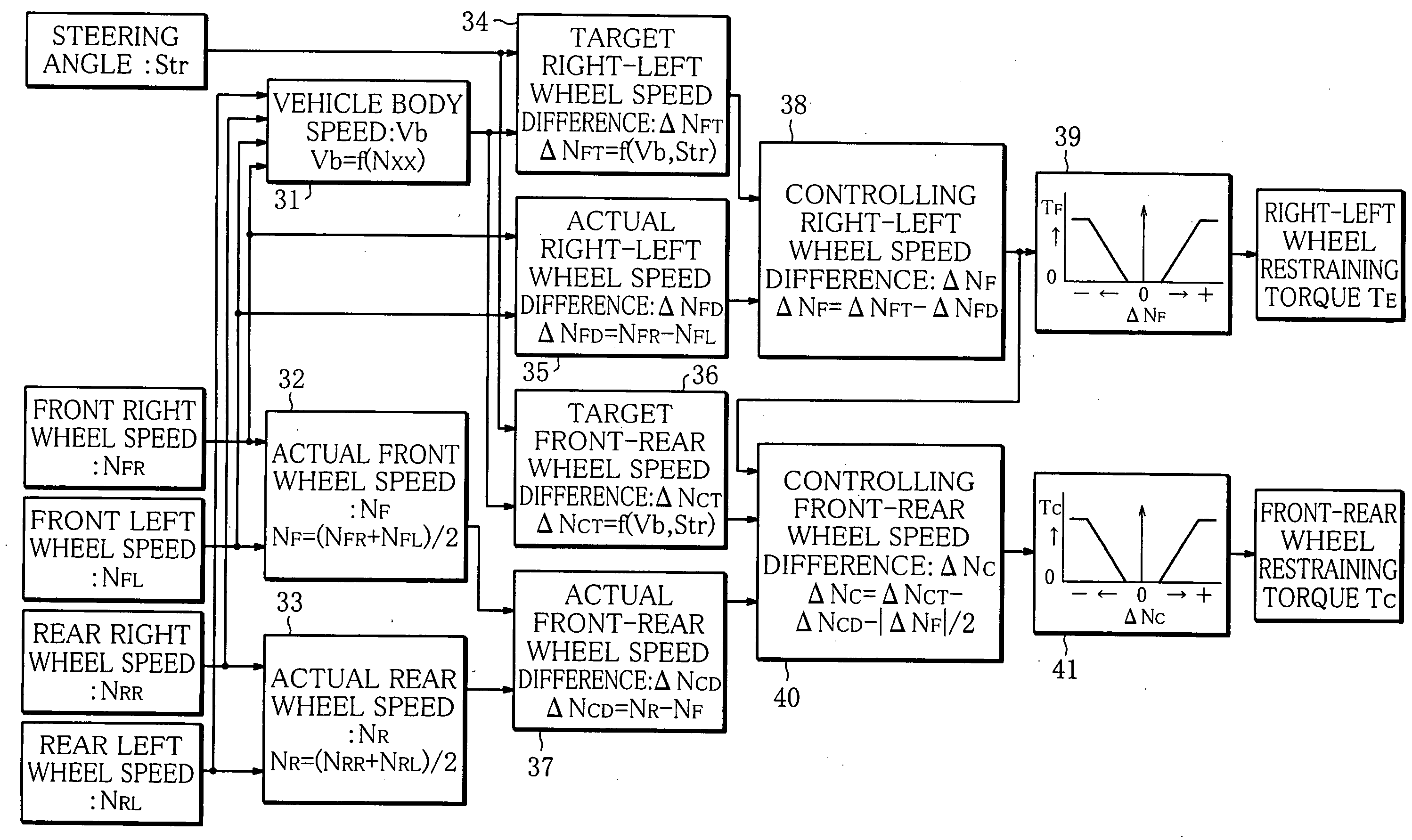

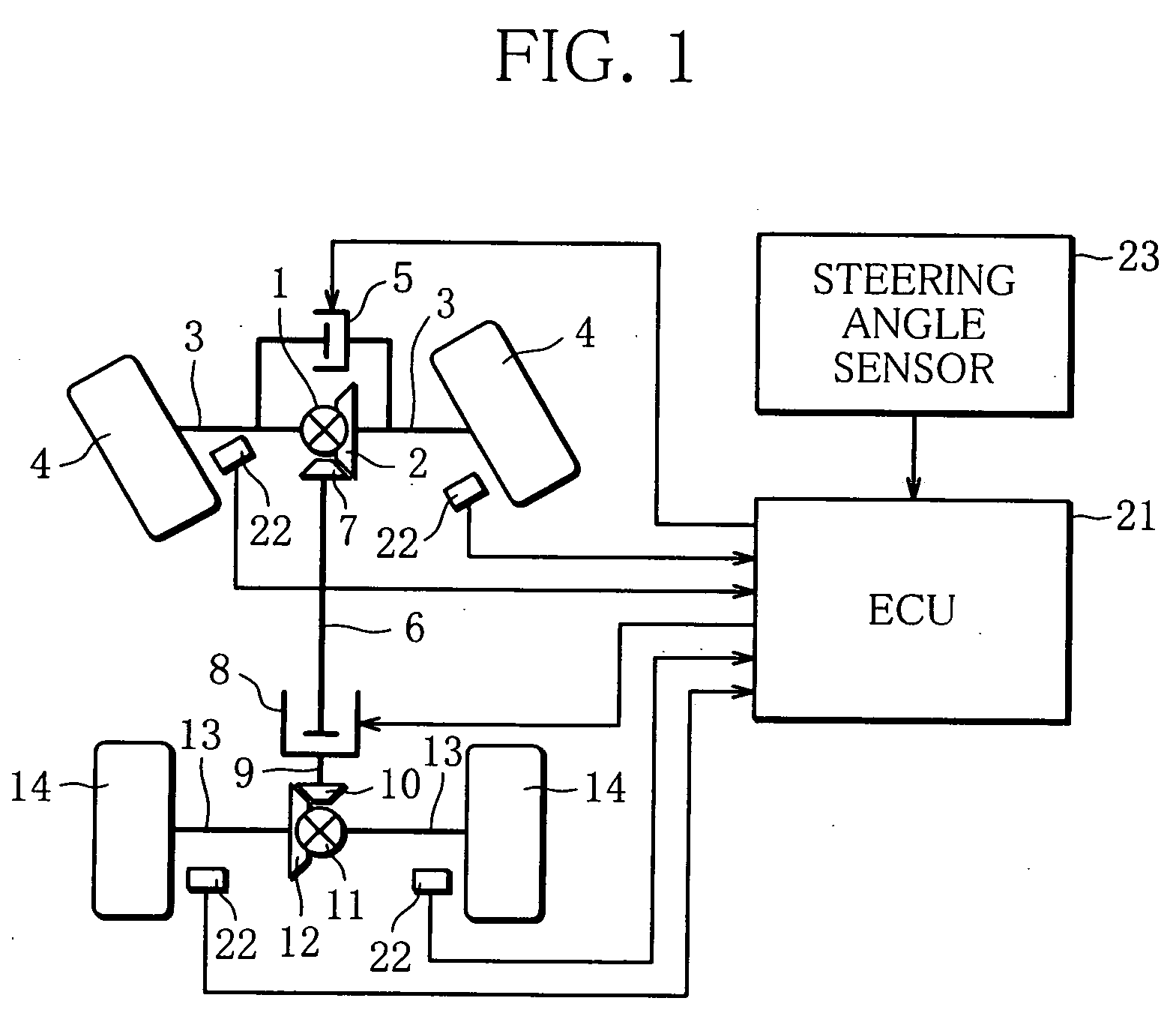

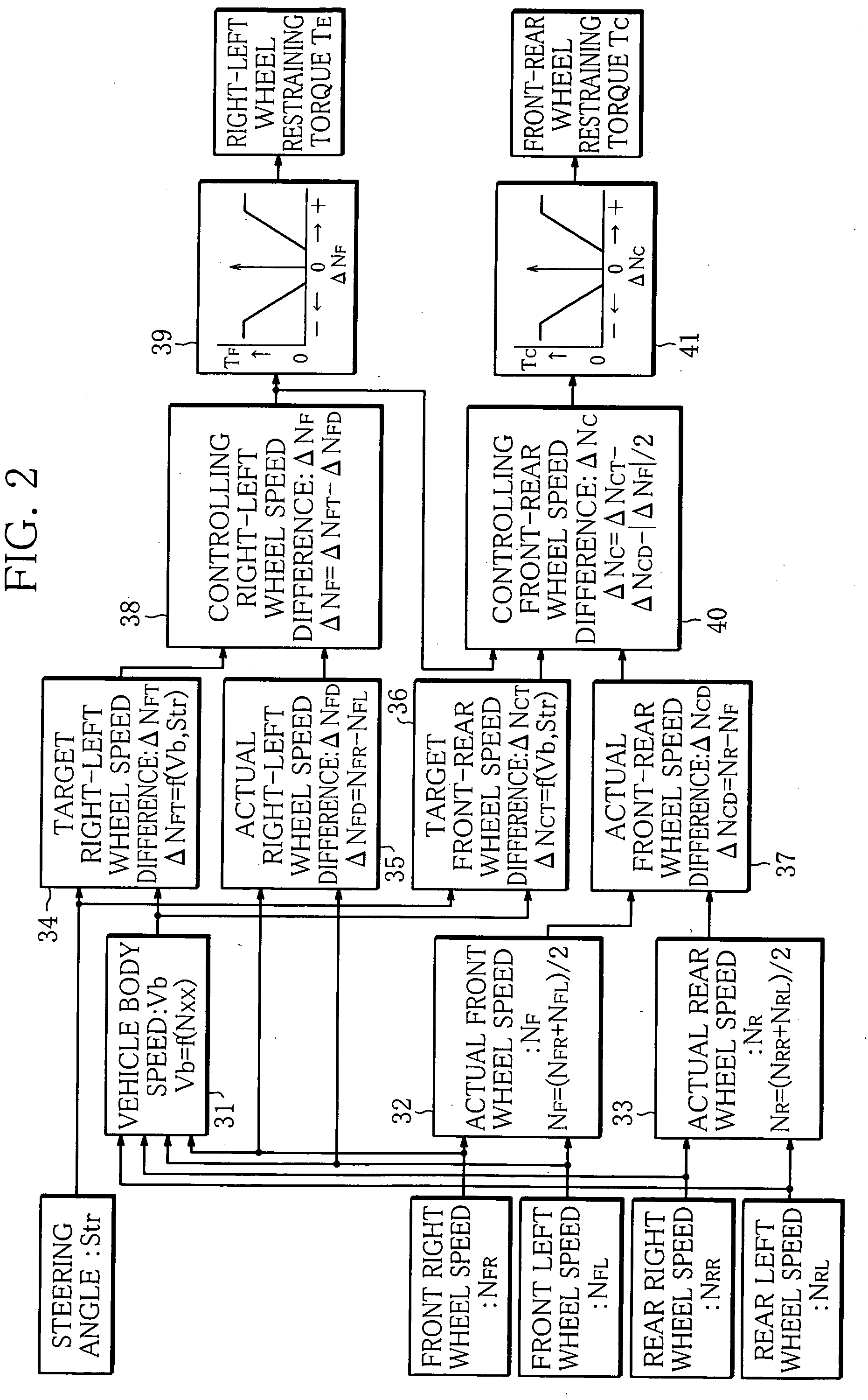

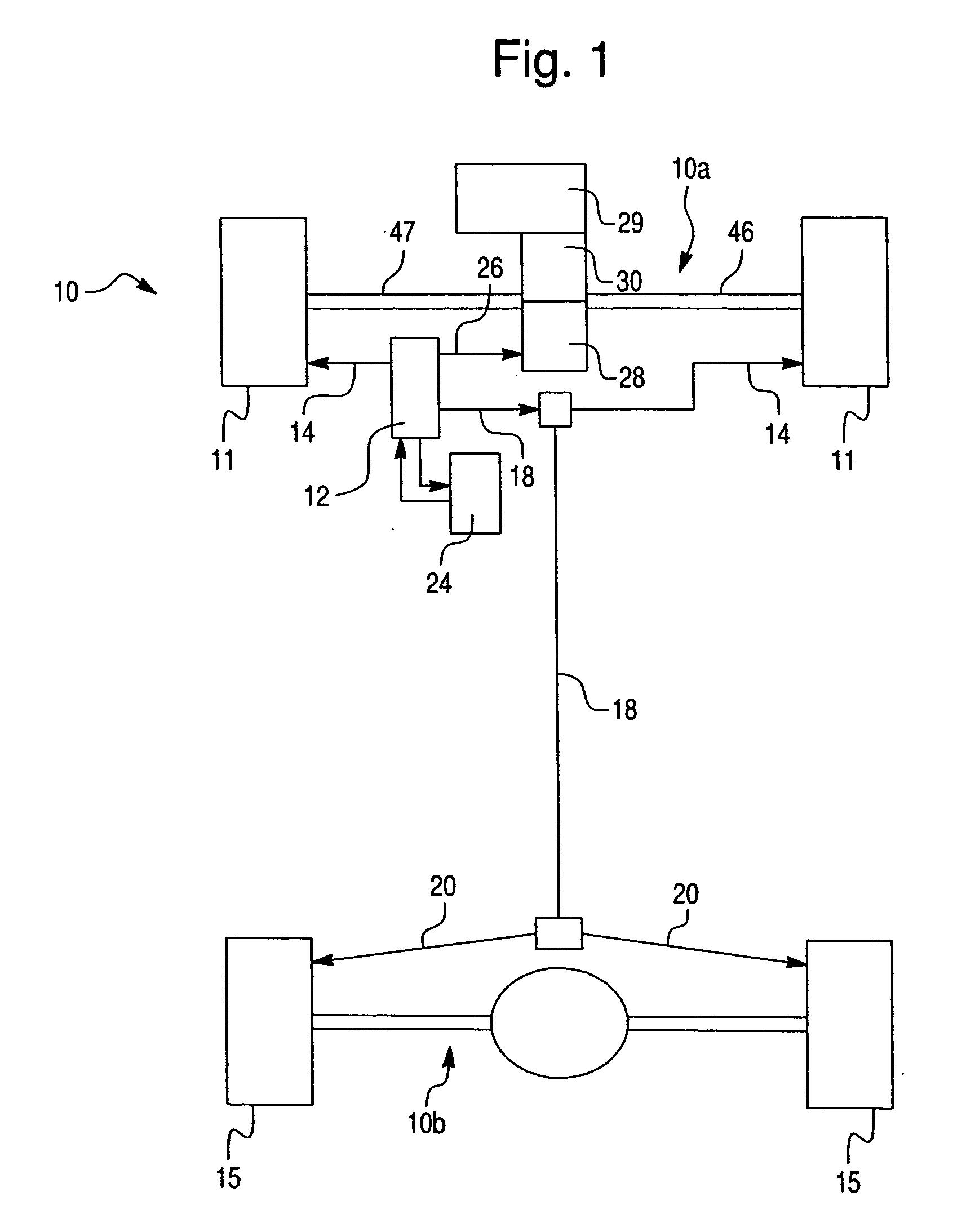

Differential Limiting Control Apparatus For Four-Wheel Drive Vehicle

ActiveUS20090127014A1Improved turning performanceSatisfactory performanceDriver input parametersPropulsion unit safety devicesLimited-slip differentialCoupling

Restraining torque TF of an electronic controlled front limited slip differential (5) arranged between right and left front wheels is controlled in accordance with controlling right-left wheel rotational speed difference ΔNF, which is the rotational speed difference between the right and left front wheels, while restraining torque TC of an electronic controlled coupling (8) arranged between the front and rear wheels is controlled in accordance with controlling front-rear wheel rotational speed difference ΔNC obtained by subtracting ½ of the rotational speed difference between the right and left wheels (|ΔNF| / 2) from the rotational speed difference (ΔNCT−ΔNCD) between the front and rear wheels.

Owner:MITSUBISHI MOTORS CORP

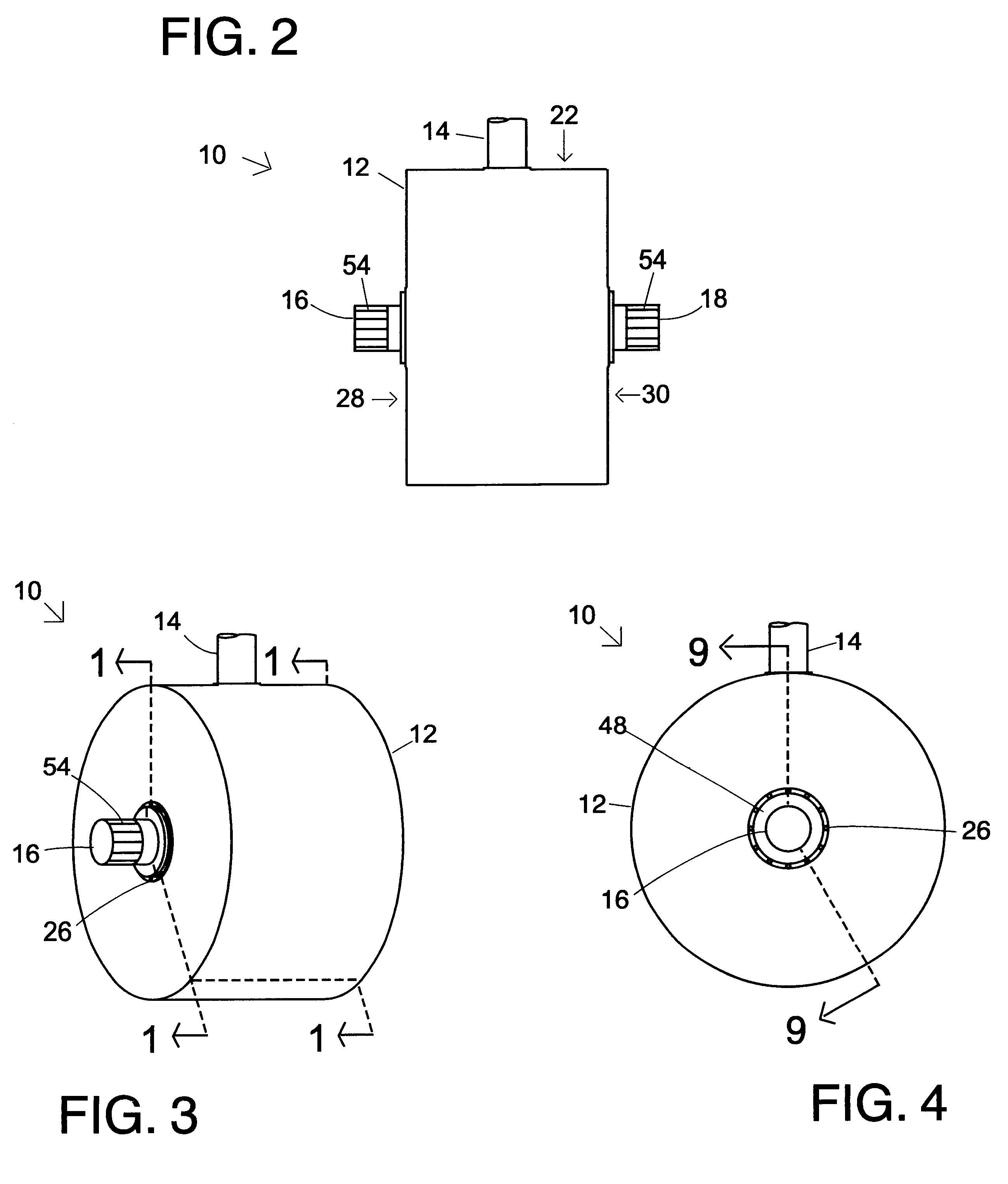

Limited slip differential

A limited slip differential comprising a casing containing a fluid medium, the casing rotatably driven along an axis by an input member; a plurality of opposing pinions therein the casing that are immersed in the casing fluid medium, having substantially parallel rotational axes, the opposing pinions meshing one with the other circumferentially at medial portions of the meshing opposing pinions; the pinions having partitions therebetween lateral and said medial portions of each of the opposing pinions; opposing driven gears, immersed in the casing fluid medium, the opposing driven gears meshing with a plurality of the lateral portions; the opposing driven gears having output shafts adjoined thereto; the casing having opposing holes therethrough, the opposing output shafts rotatably mounted therethrough; and seals adapted to retain said fluid medium therein said casing.

Owner:PERALTA MARK

Limited slip differential gear

A limited slip differential gear that is simple in construction, small in size and light in weight is provided. The limited slip differential gear includes a pair of divided gear cases that are turned by a driving force of an engine. A pressure ring provided in one of the gear cases is movable in the direction of the wheel axles. Pinion shafts each have an end that is freely engageably supported between the pressure ring and the gear cases. Pinion gears are turnably supported by the pinion shafts. A pair of side gears mesh with the pinion gears positioned therebetween to transmit the driving force to both wheel axles. A multiple disc clutch mechanism provided between one of the gear cases, the side gears and the pressure ring limits differential motion of the side gears when the pressure ring is moved in an axial outward direction.

Owner:ROUTE SIX

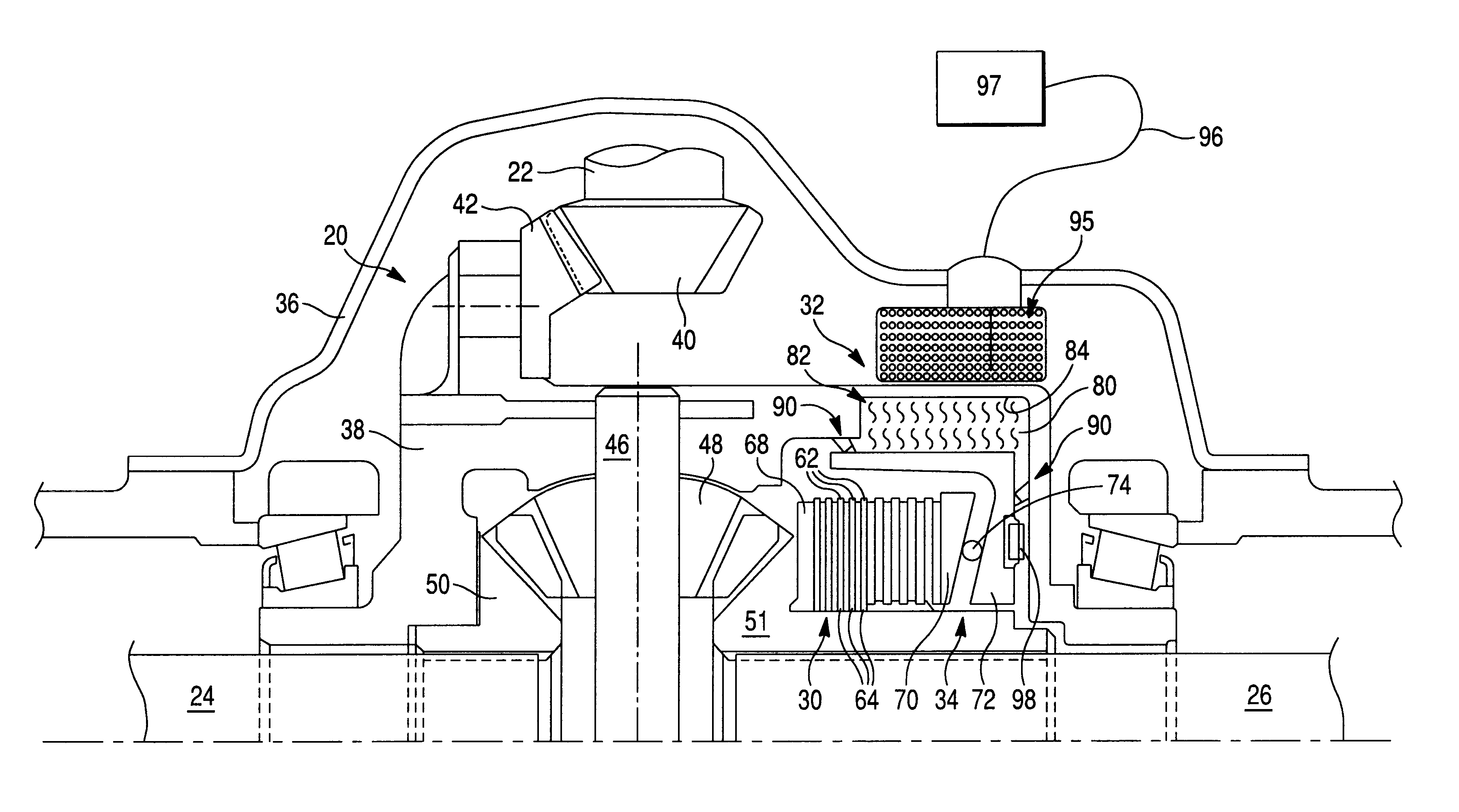

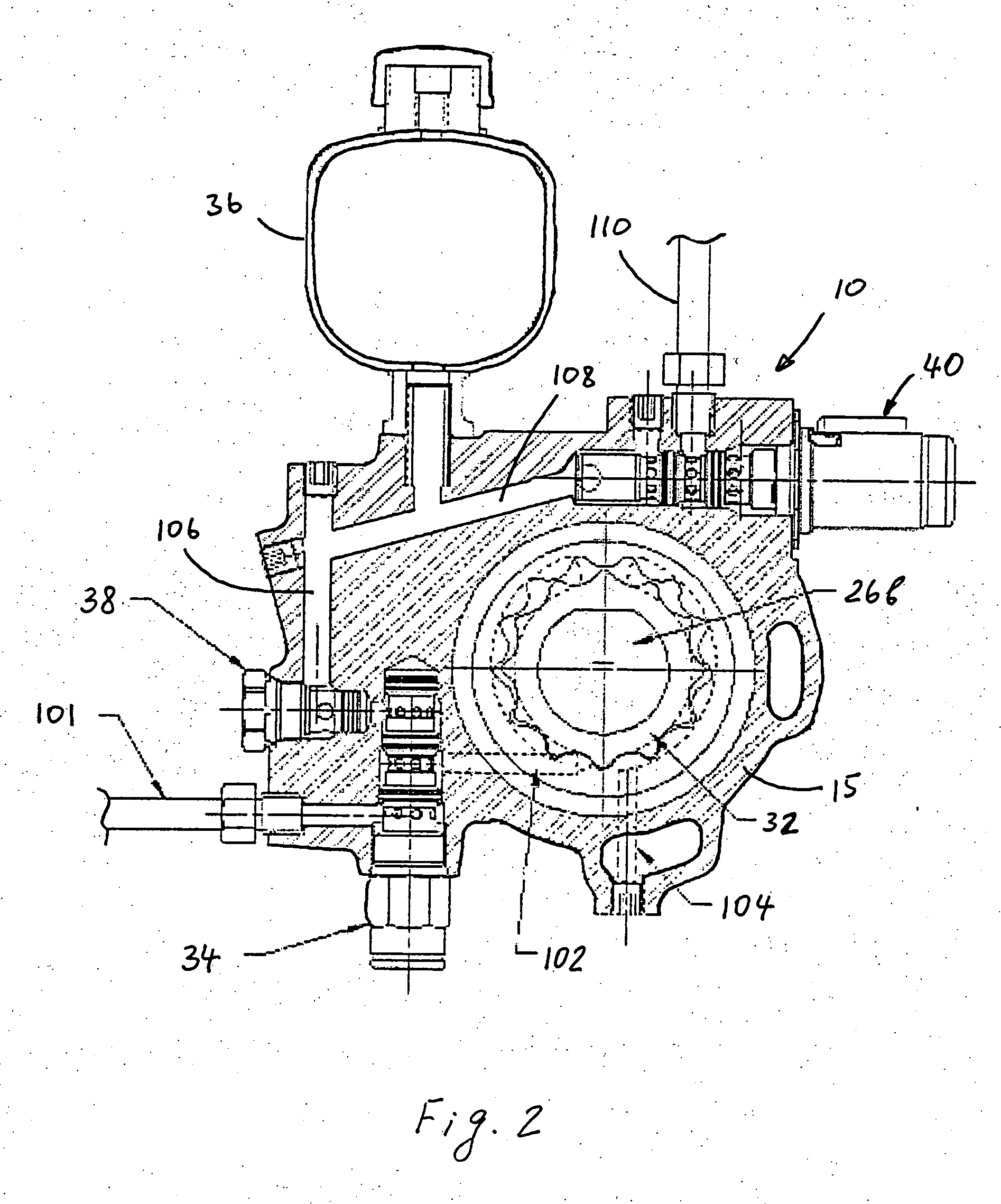

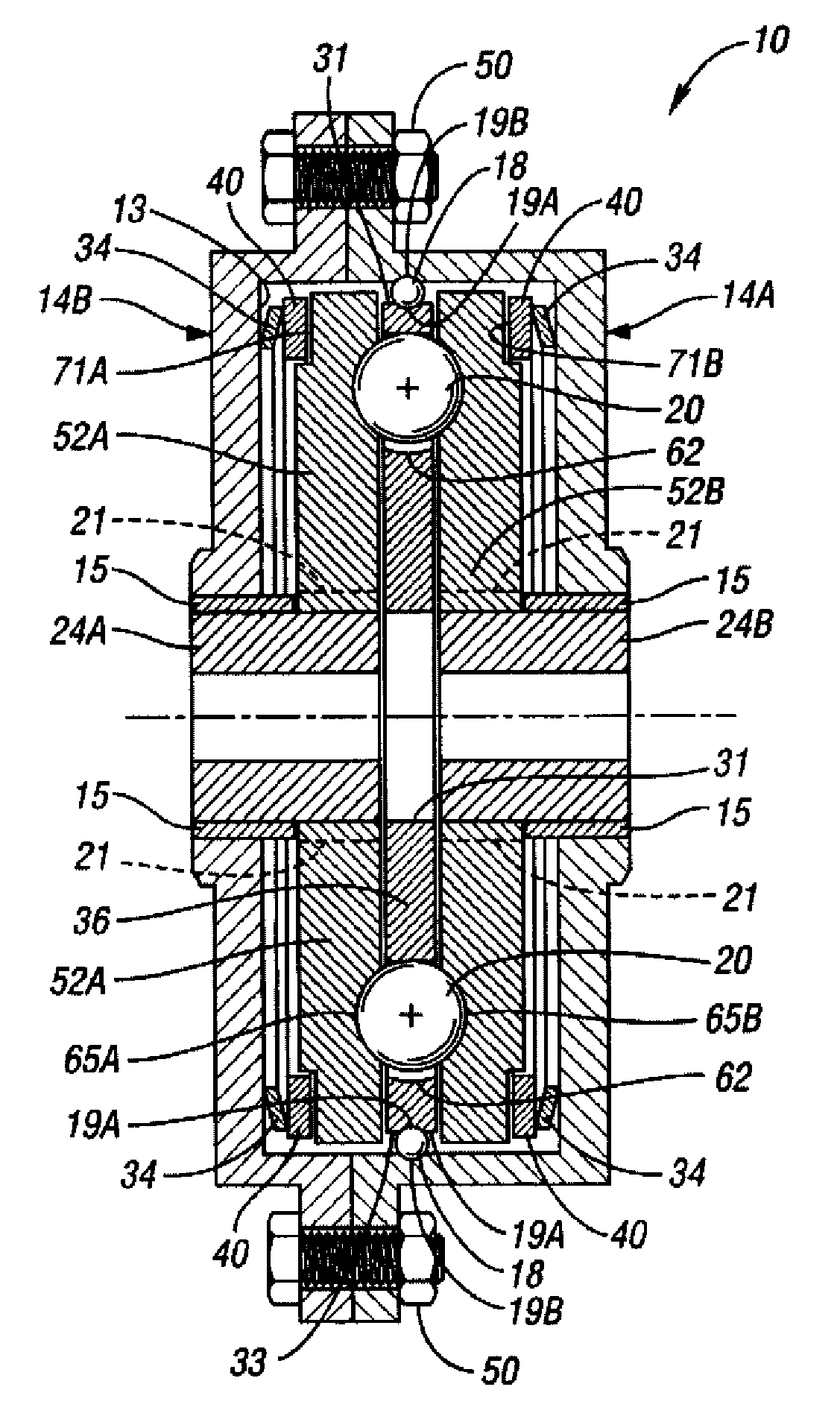

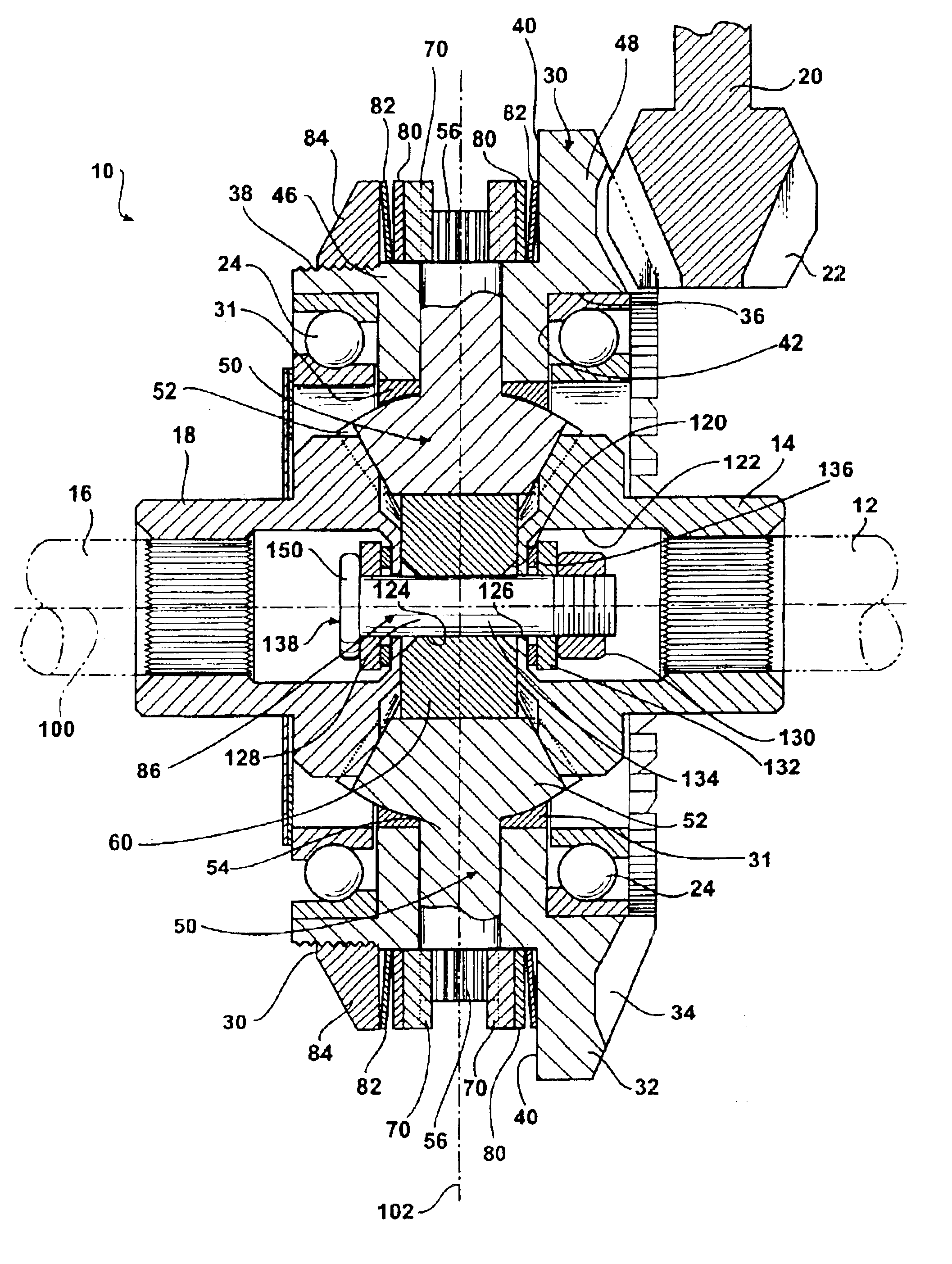

Hydraulic clutch actuator for limited slip differential assembly

InactiveUS20050167228A1Avoid flowKeep the conditionFluid couplingsMechanical actuated clutchesSeparated stateLimited-slip differential

A torque transmitting apparatus for a motor vehicle comprises a housing rotatably supporting a differential assembly including a differential case and at least one output shaft. The torque transmitting apparatus further comprises at least one friction clutch assembly for selectively engaging and disengaging the differential case and the at least one output shaft, and a hydraulic clutch actuator for operating the at least one friction clutch assembly between a disengaged condition and an engaged condition. The hydraulic clutch actuator includes a hydraulic pump providing a hydraulic fluid under pressure and a hydraulic pressure accumulator selectively communicating with the pump for charging the accumulator with the hydraulic fluid under pressure. The hydraulic accumulator is provided for selectively communicating with the at least one friction clutch assembly for selectively setting the clutch assembly in the engaged condition.

Owner:DANA AUTOMOTIVE SYST GRP LLC

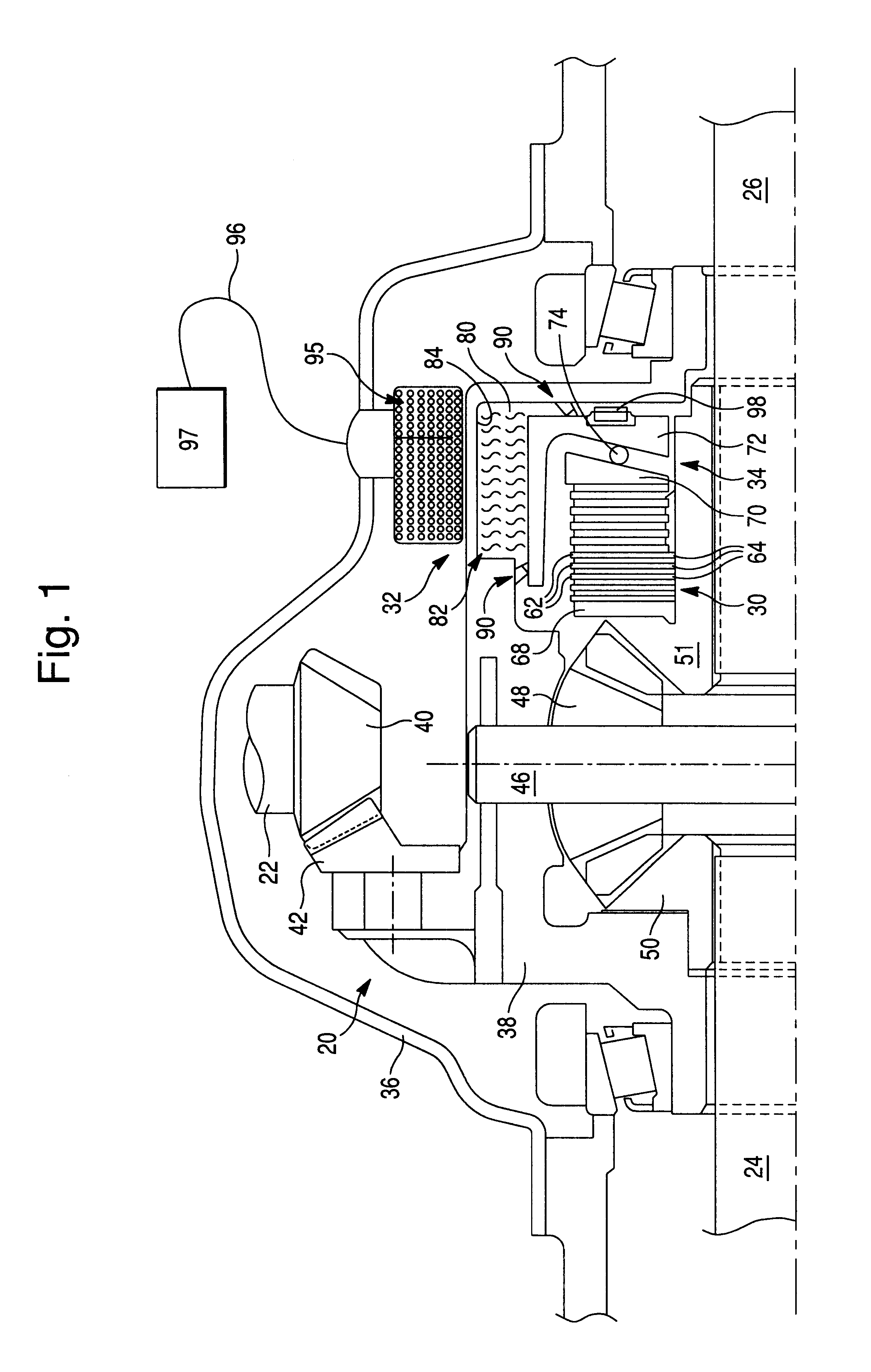

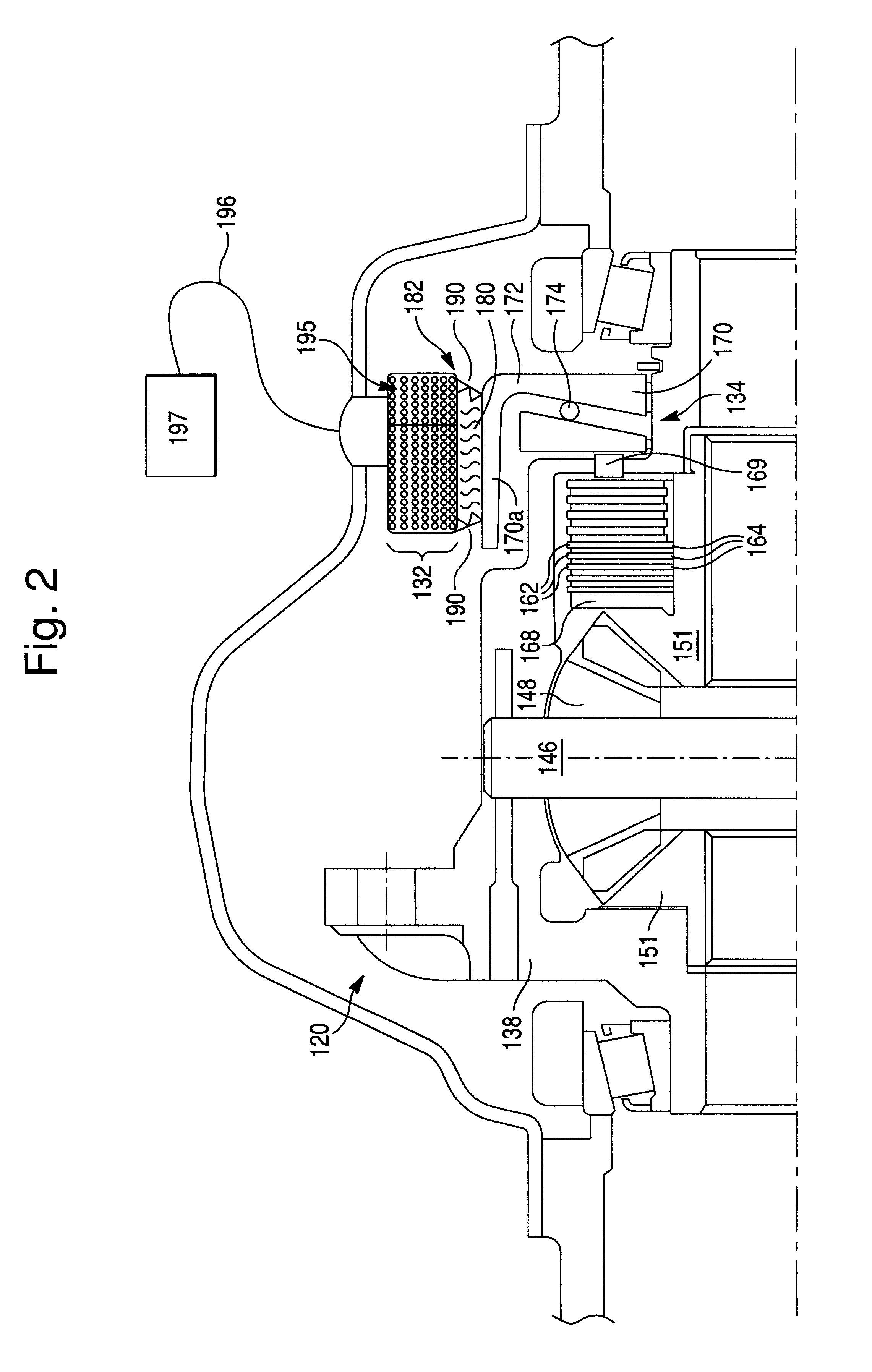

Limited slip differential with positive lube flow to clutch plates

InactiveUS20100304914A1Inhibition of differentiationGear lubrication/coolingDifferential gearingsGear wheelLimited-slip differential

A differential with a differential case, a differential gear set and a clutch pack. Apertures are formed axially through the differential case and the clutch pack to facilitate the introduction of lubricant through the differential case and into the clutch pack. An axle assembly and a method of operating an axle assembly are also provided.

Owner:AMERICAN AXLE & MFG

Lubricating Composition Containing an Ester

InactiveUS20120208731A1Increase coefficient of frictionReduce noiseLiquid carbonaceous fuelsAdditivesLimited-slip differentialDicarboxylic acid

The invention relates to a method of lubricating a limited slip differential comprising supplying to the limited slip differential a lubricating composition containing (a) an oil of lubricating viscosity, and (b) a C4-30-diester of a dicarboxylic acid. The invention further provides for the use of the C4-30-diester of a dicarboxylic acid as a friction modifier, typically in a limited slip differential.

Owner:THE LUBRIZOL CORP

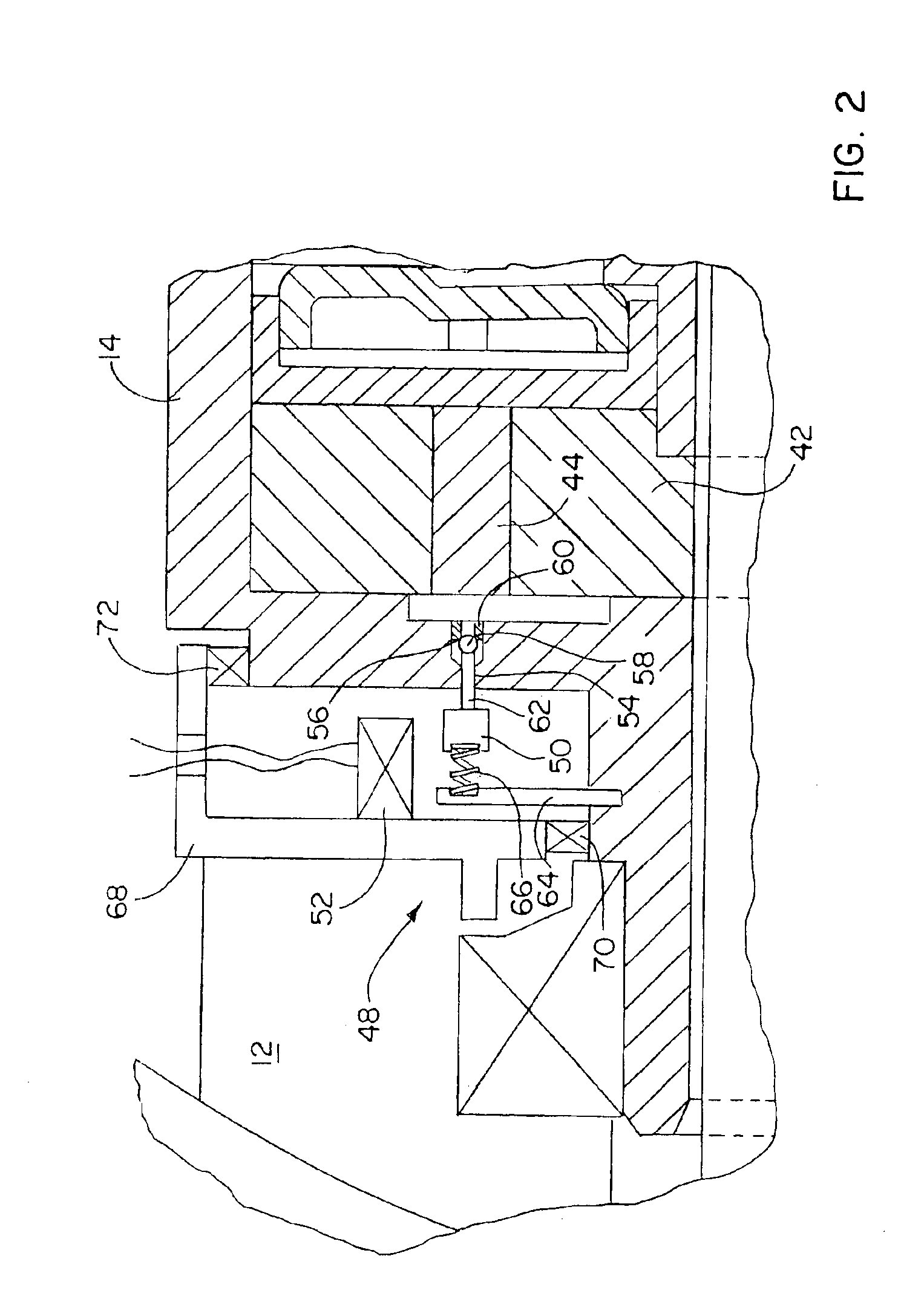

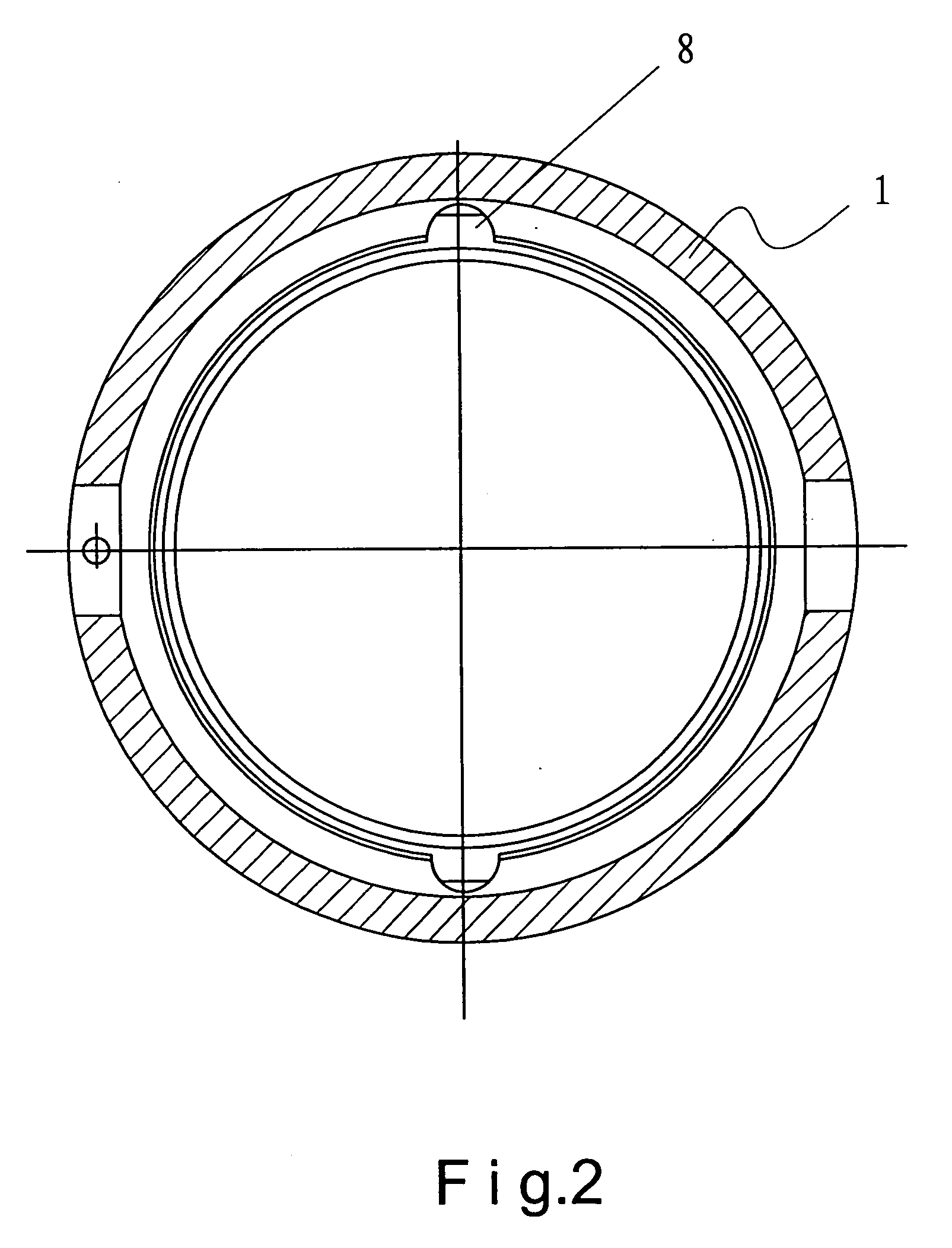

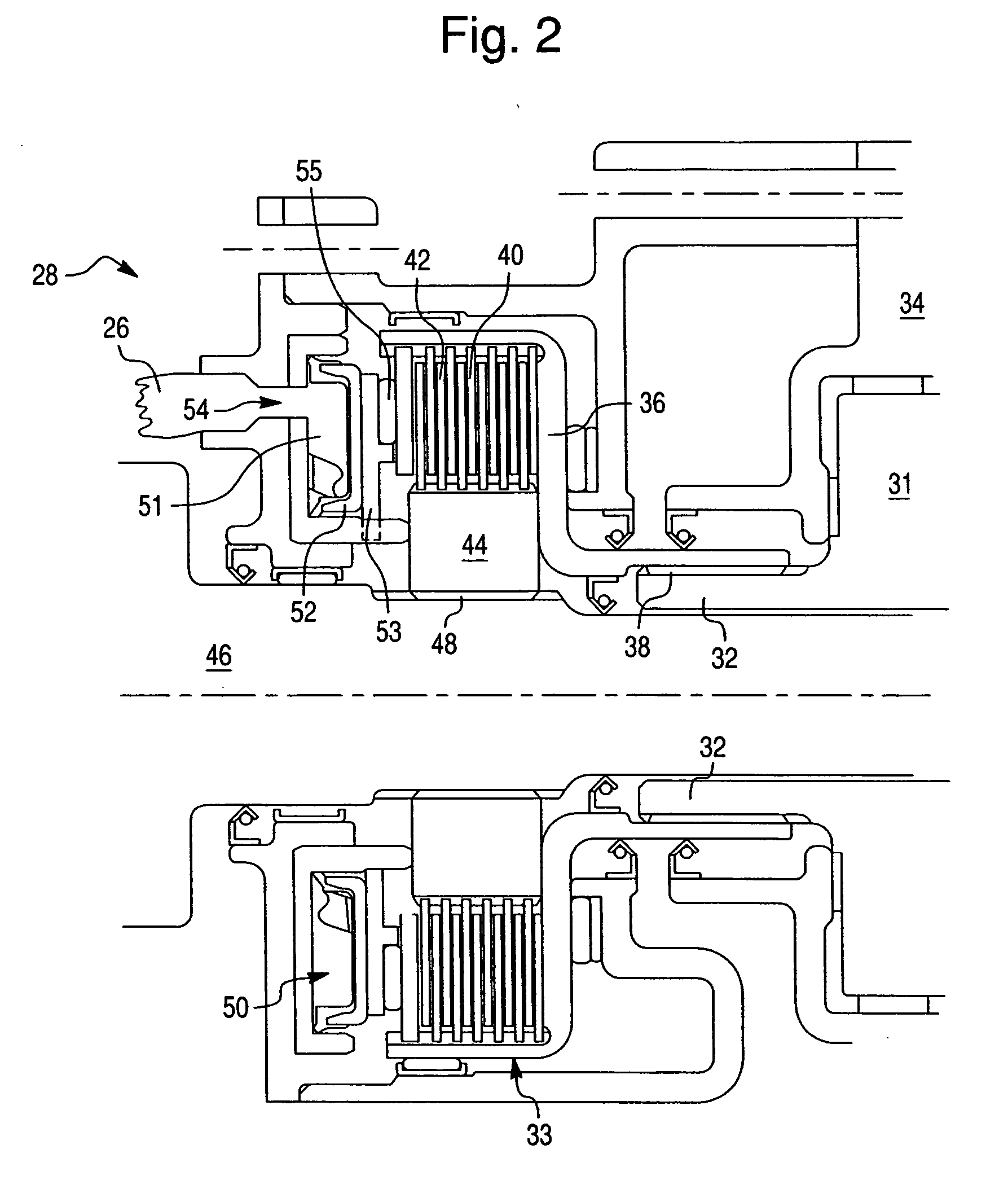

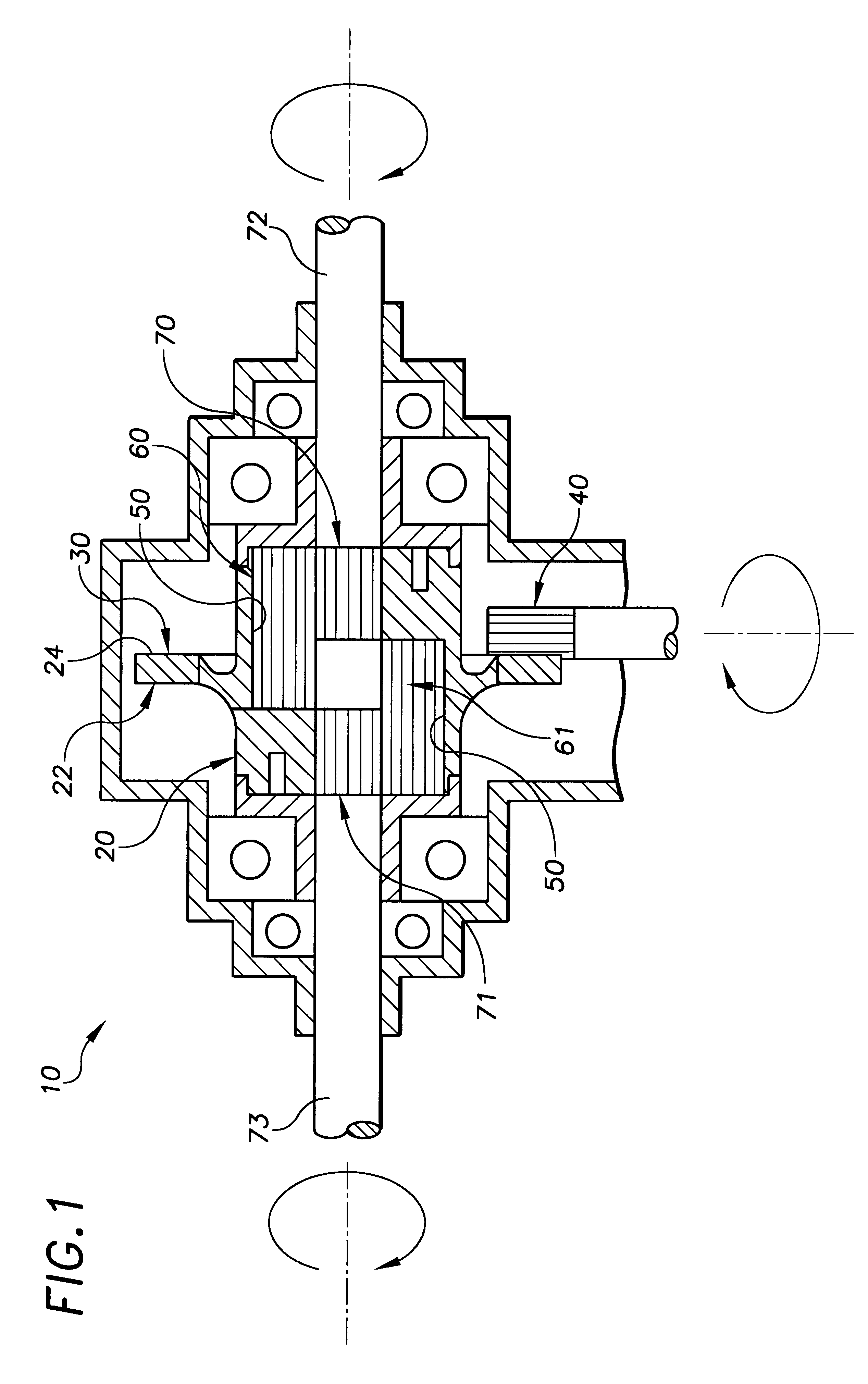

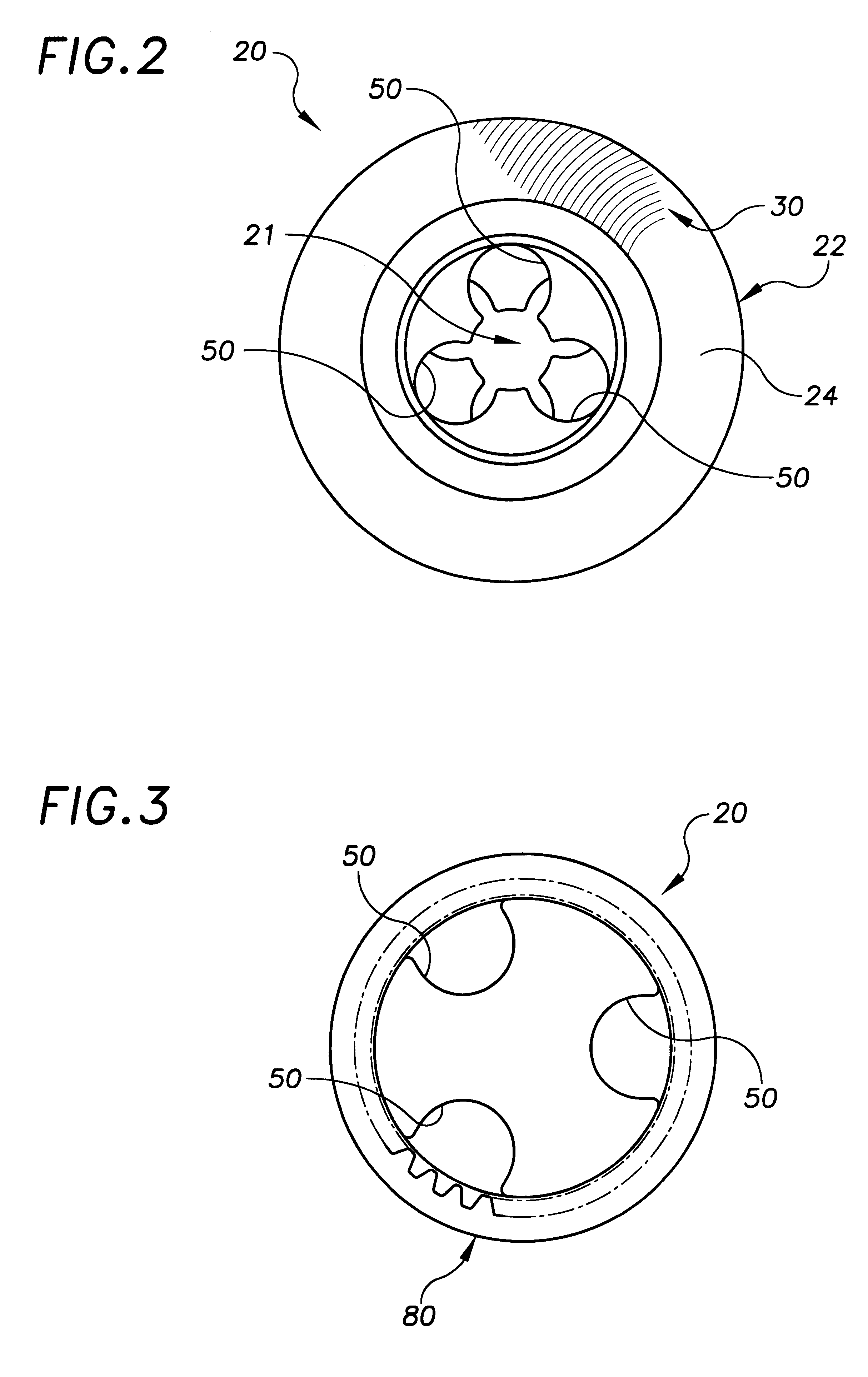

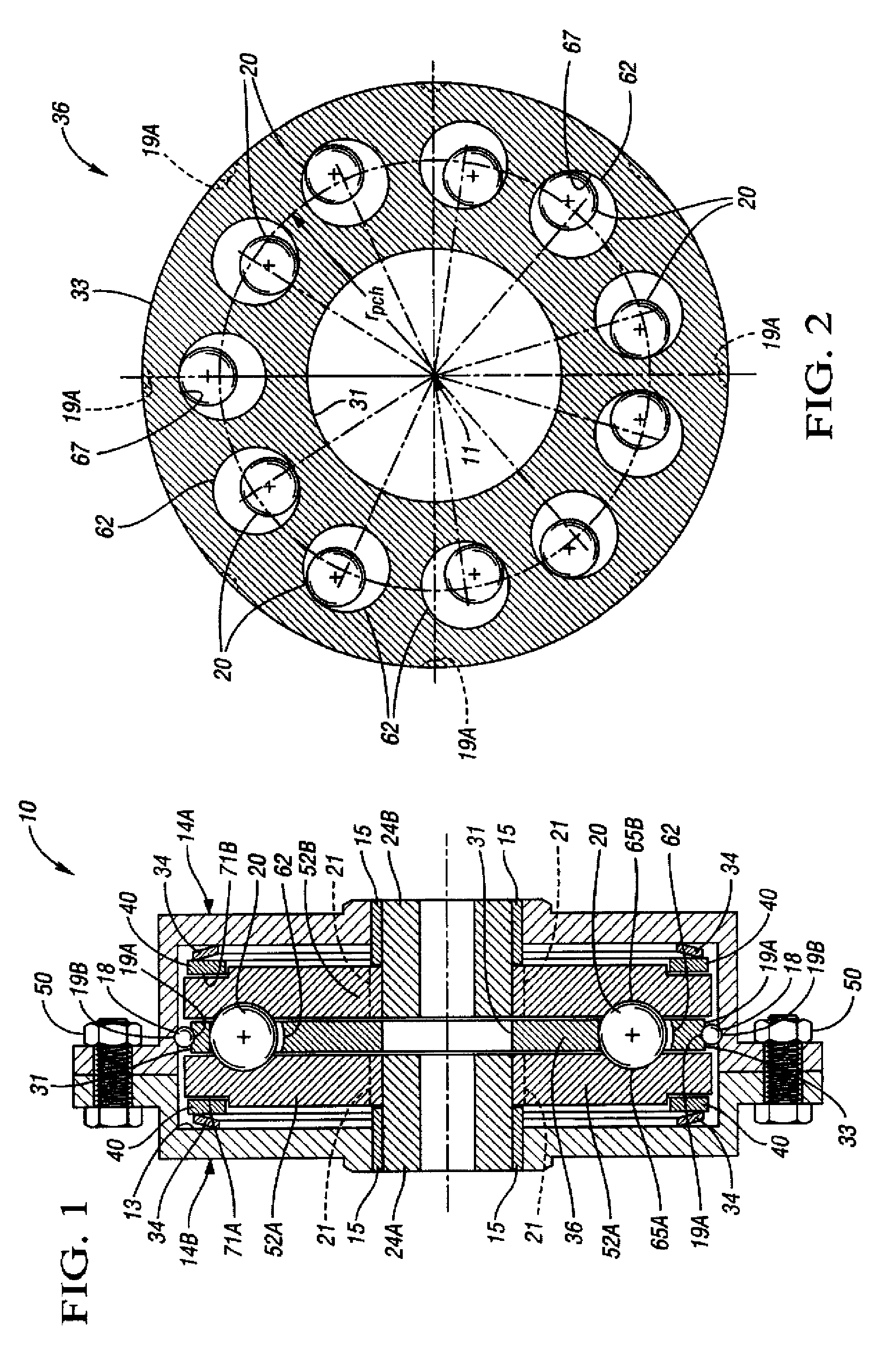

Limited slip differential and engagement sensing mechanism therefor

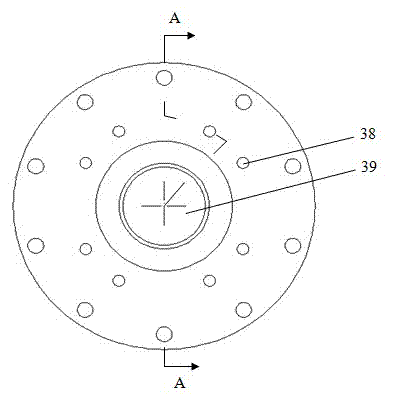

ActiveUS7357749B2Overcome problemsDifferential gearingsControl devicesLimited-slip differentialMechanical engineering

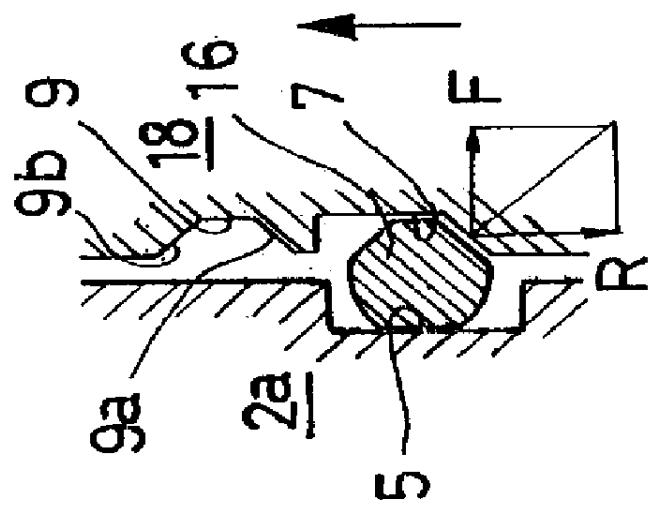

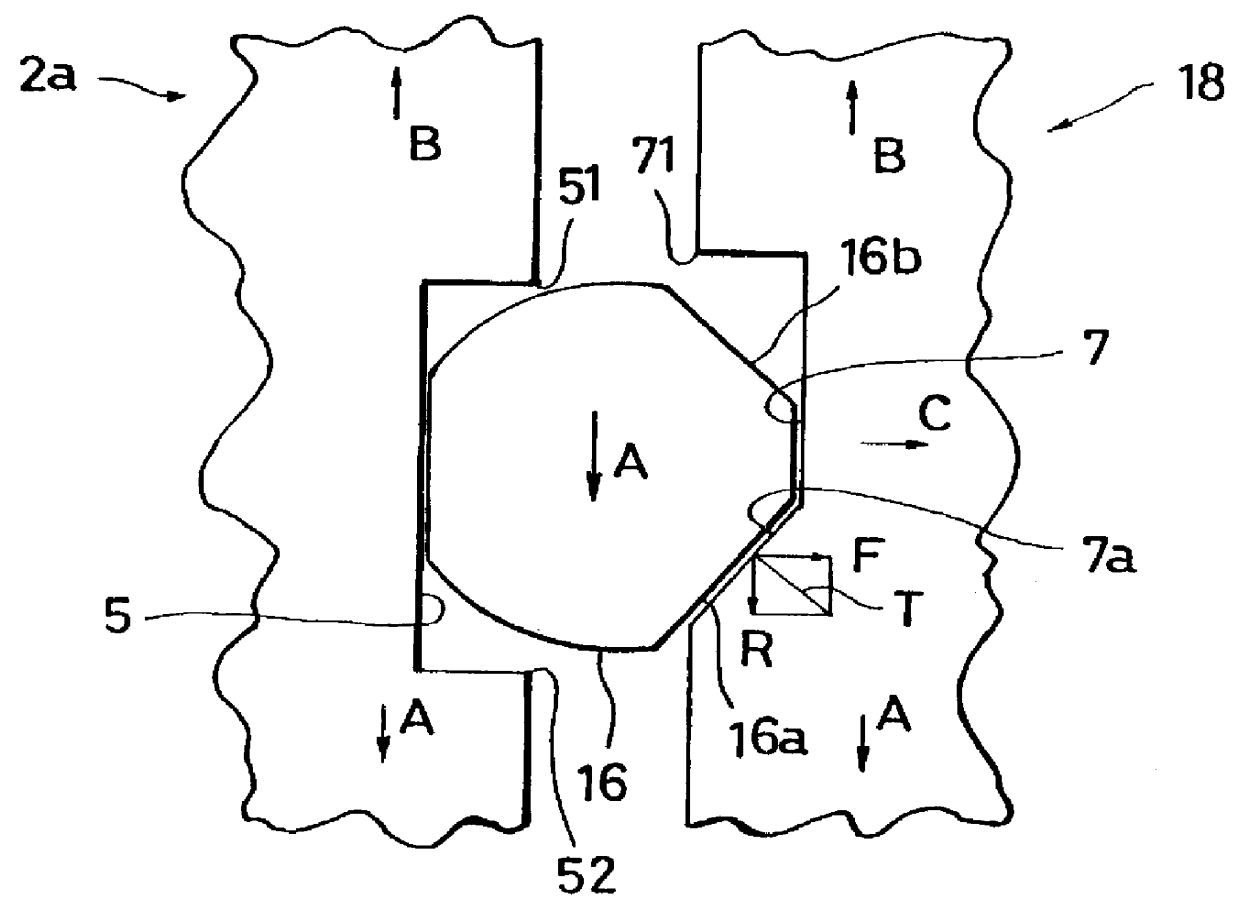

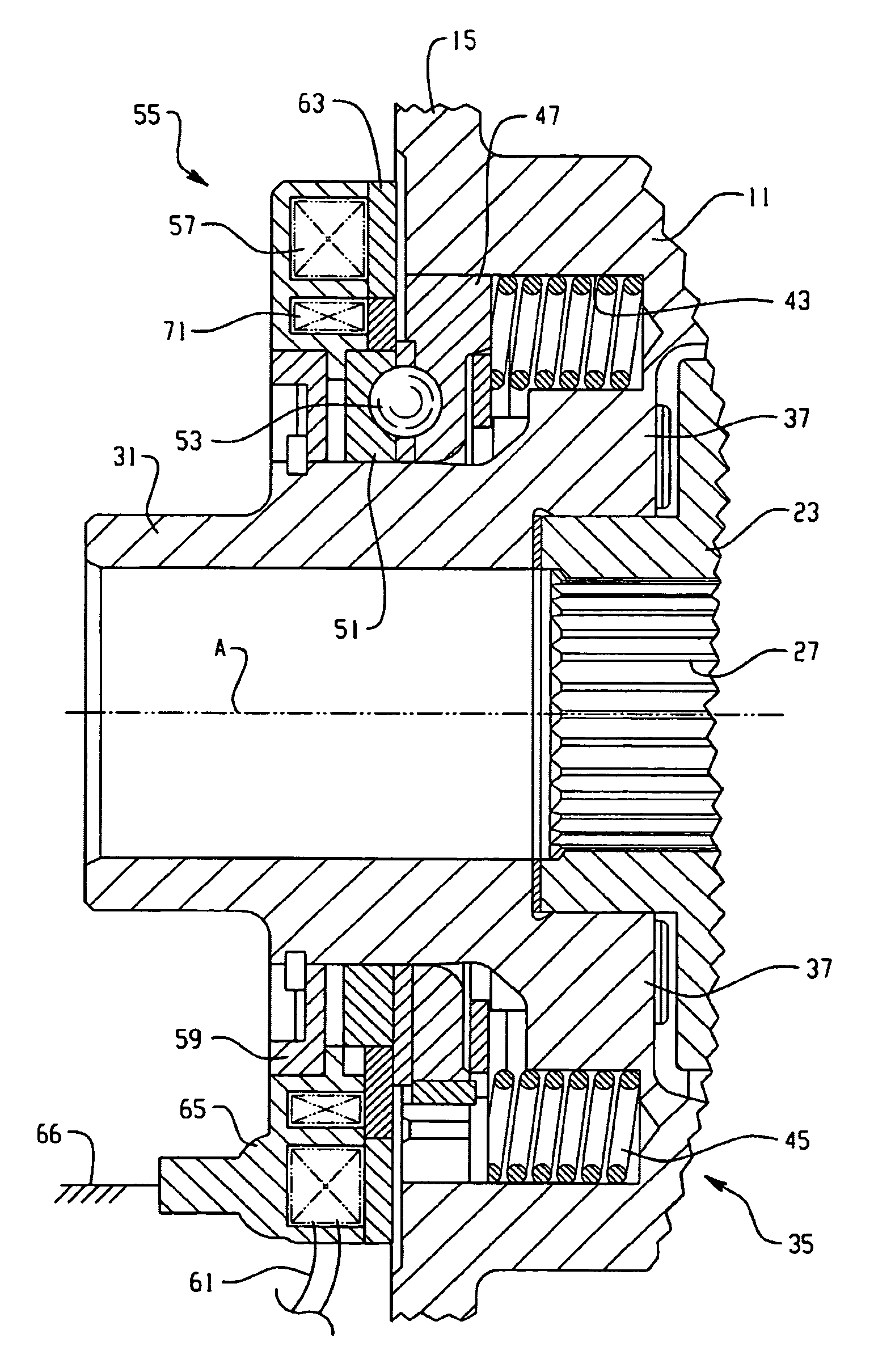

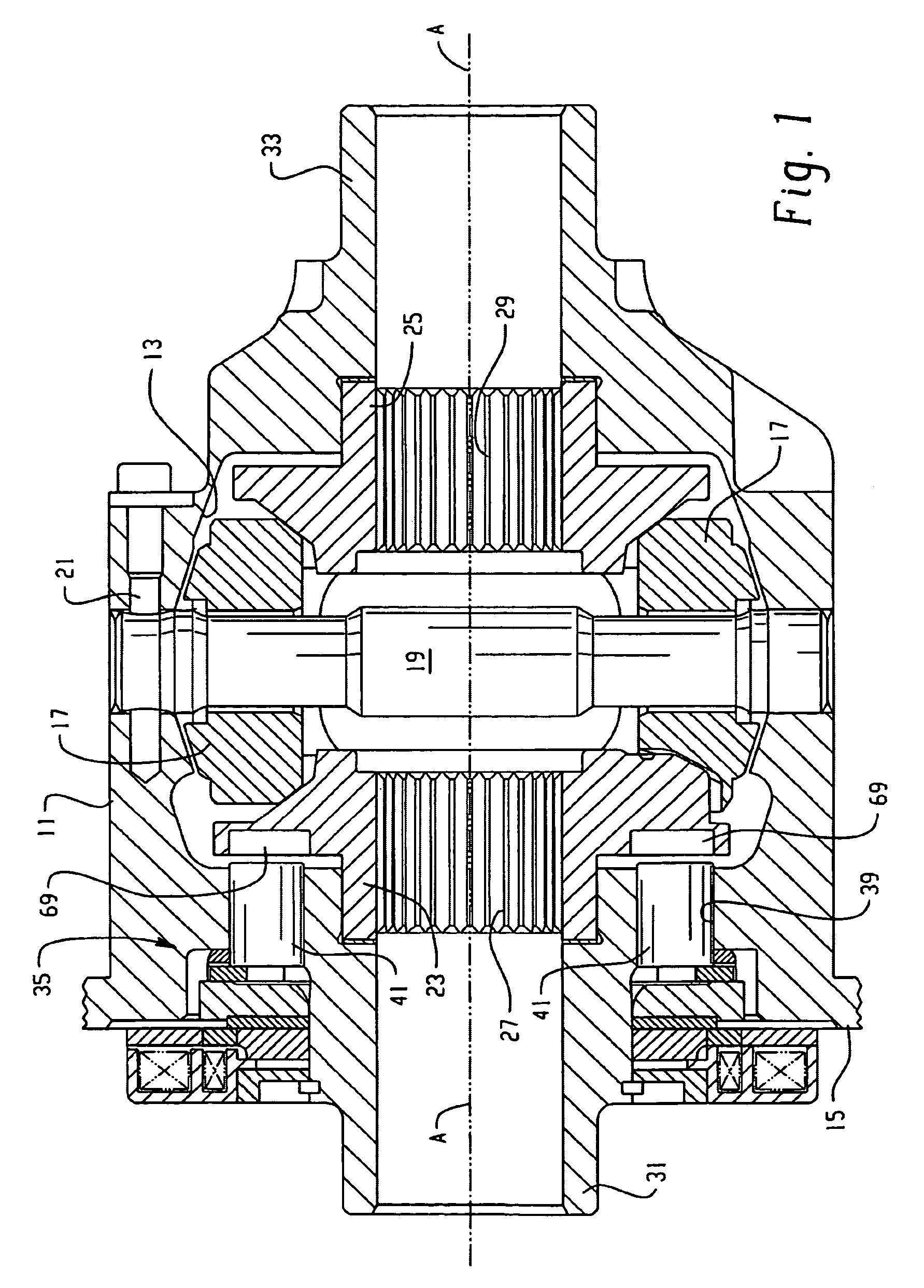

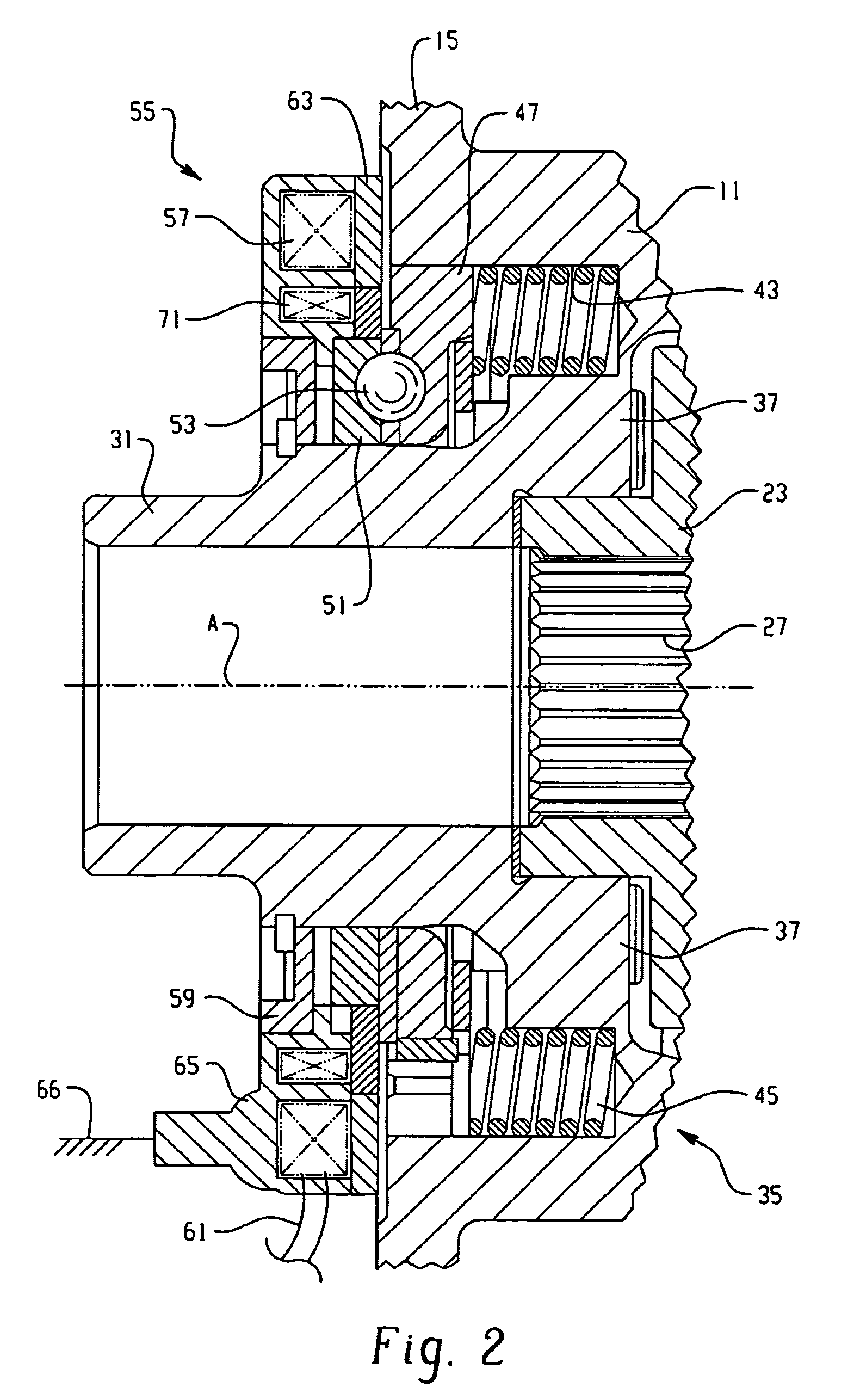

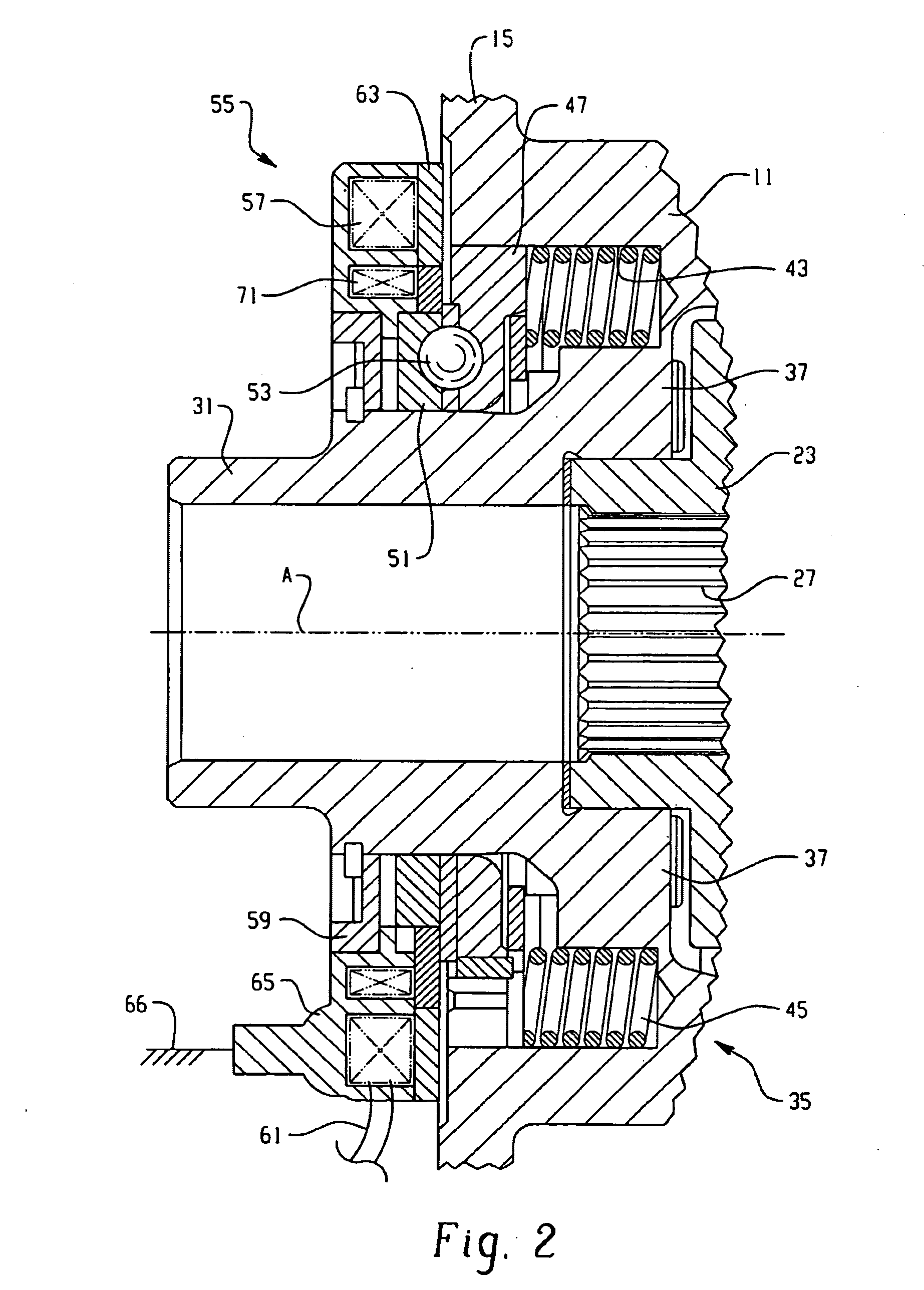

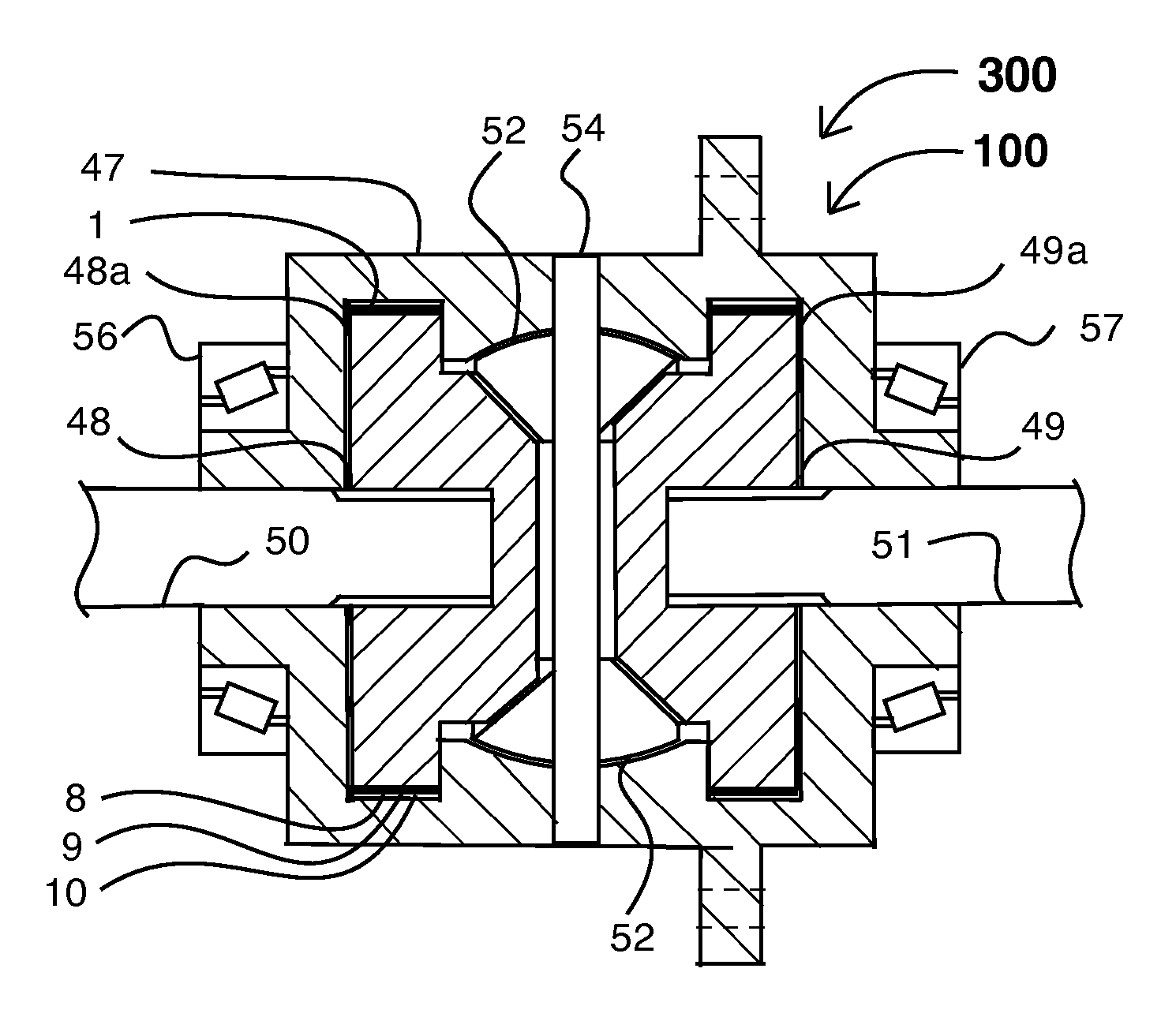

A differential having means (35) operable to limit rotation of an output gear (23) relative to a gear case (11), and actuation means (55) for actuating the rotation limiting means, from an unactuated (FIG. 1) to an actuated condition (FIG. 4). The rotation limiting means includes a member (47), toward one axial end of the gear case and moveable between a first position, the unactuated condition of said rotation limiting means, and a second position, the actuated condition. A sensor assembly is adjacent the one axial end of the gear case and includes a sensor element (71) and a wall-like member between the rotation limiting means and the actuation means. The wall-like member includes a non-ferromagnetic portion (73) between the sensor and the moveable member. Movement between the first and second positions results in a corresponding change in the electromagnetic flux (F) coupling the sensor element and the moveable member.

Owner:EATON INTELLIGENT POWER LTD

Control device for a four-wheel drive vehicle

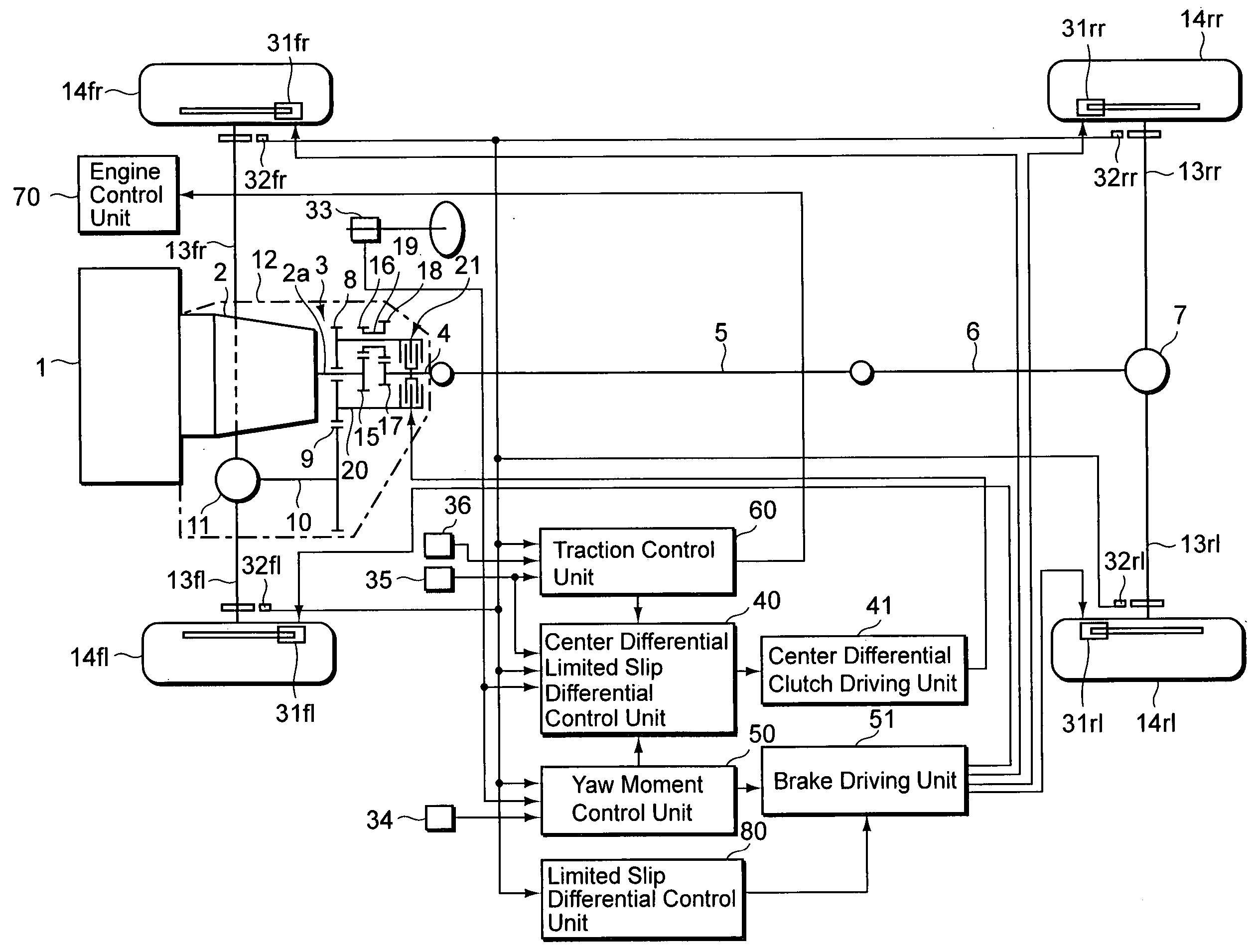

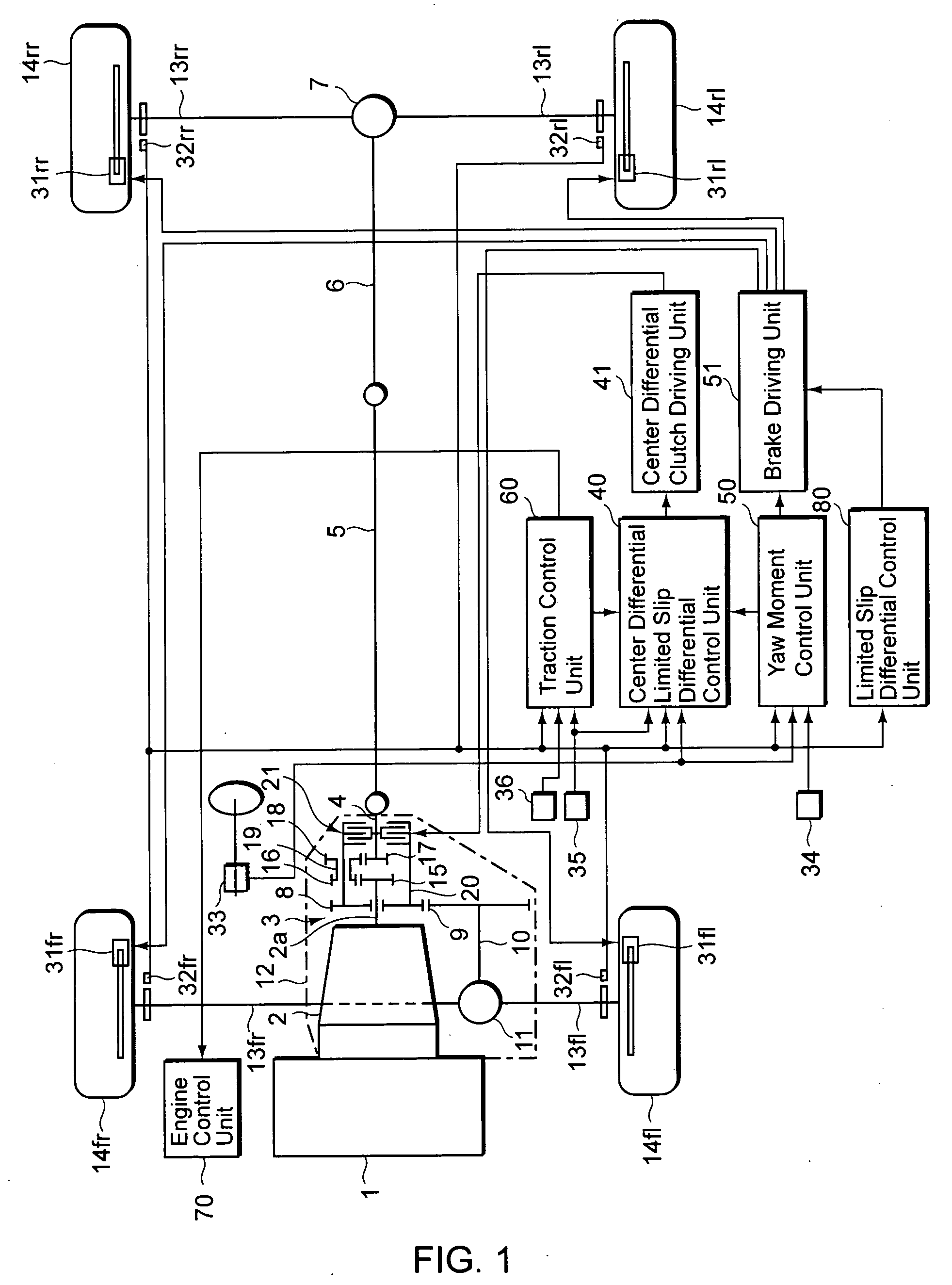

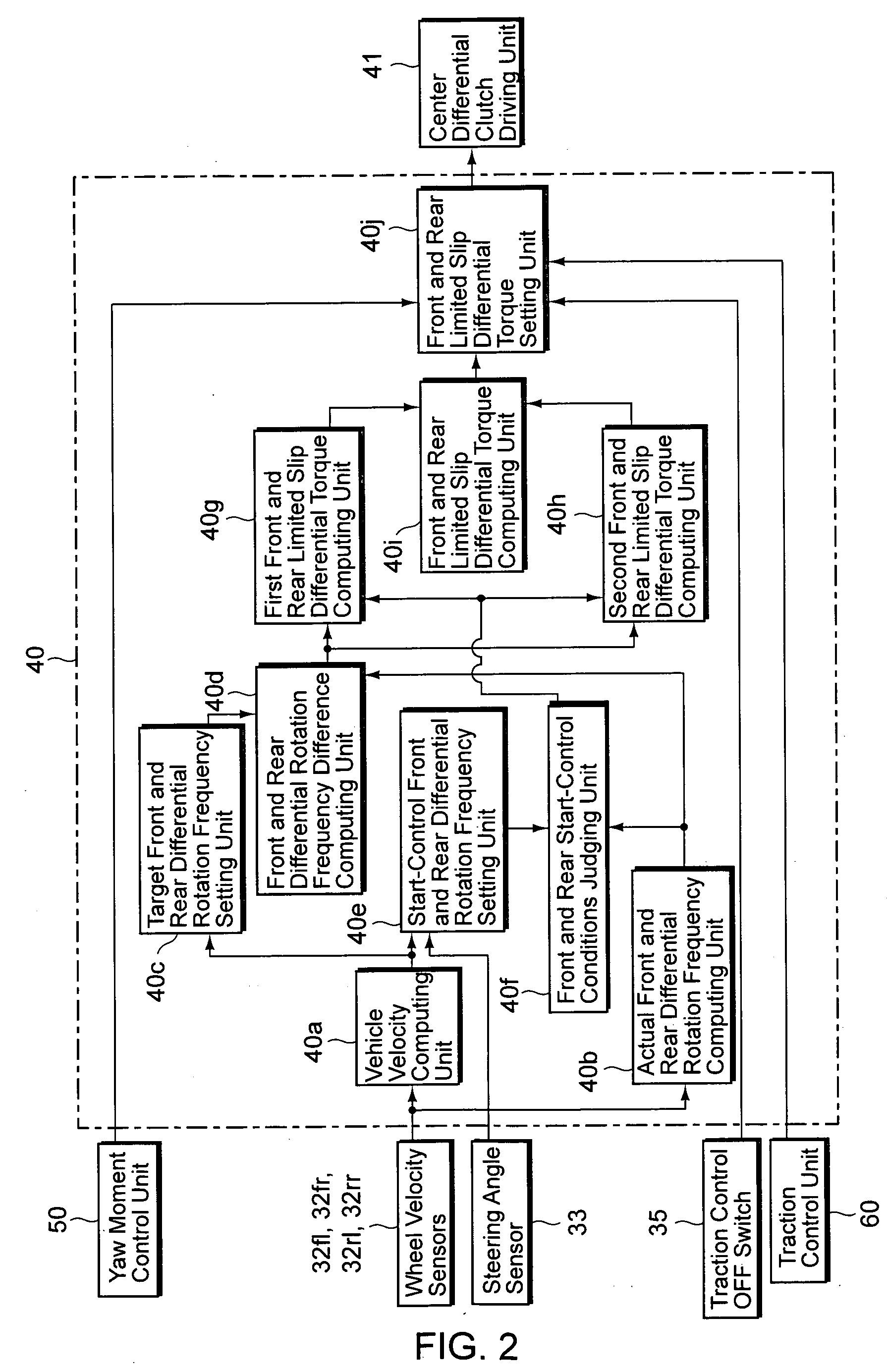

InactiveUS20060162981A1Maintain stabilityDifferential gearingsBraking systemsVehicle behaviorDistribution control

The objective of the present invention is to provide a control device for maintaining vehicle behavior stability by suppressing the transfer of excess driving force to the rear wheels even when the traction control is not effective. According to the present invention, there is provided a control device for a four-wheel drive vehicle, including: a yaw moment control unit for selecting a wheel based on a driving state and generating yaw moment on the vehicle by applying braking force to the selected wheel; a driving force control unit for identifying excess driving force based on the driving state and reducing the identified excess driving force; a limited slip differential control unit for limiting a differential between a front right wheel and a front left wheel; a front and rear driving force distribution control unit for controlling engagement torque of a clutch unit which varies torque distribution between front and rear axles via a center differential; and a switch unit for selecting an operation state or a non-operation state of the driving force control unit, wherein the front and rear driving force distribution control unit sets the engagement torque of the clutch unit at a value when the yaw moment control unit operates while the driving force control unit is in the non-operation state, the value being greater than that of the engagement torque of the clutch unit when the yaw moment control operates while the driving force control unit is in the operation state.

Owner:SUBARU CORP

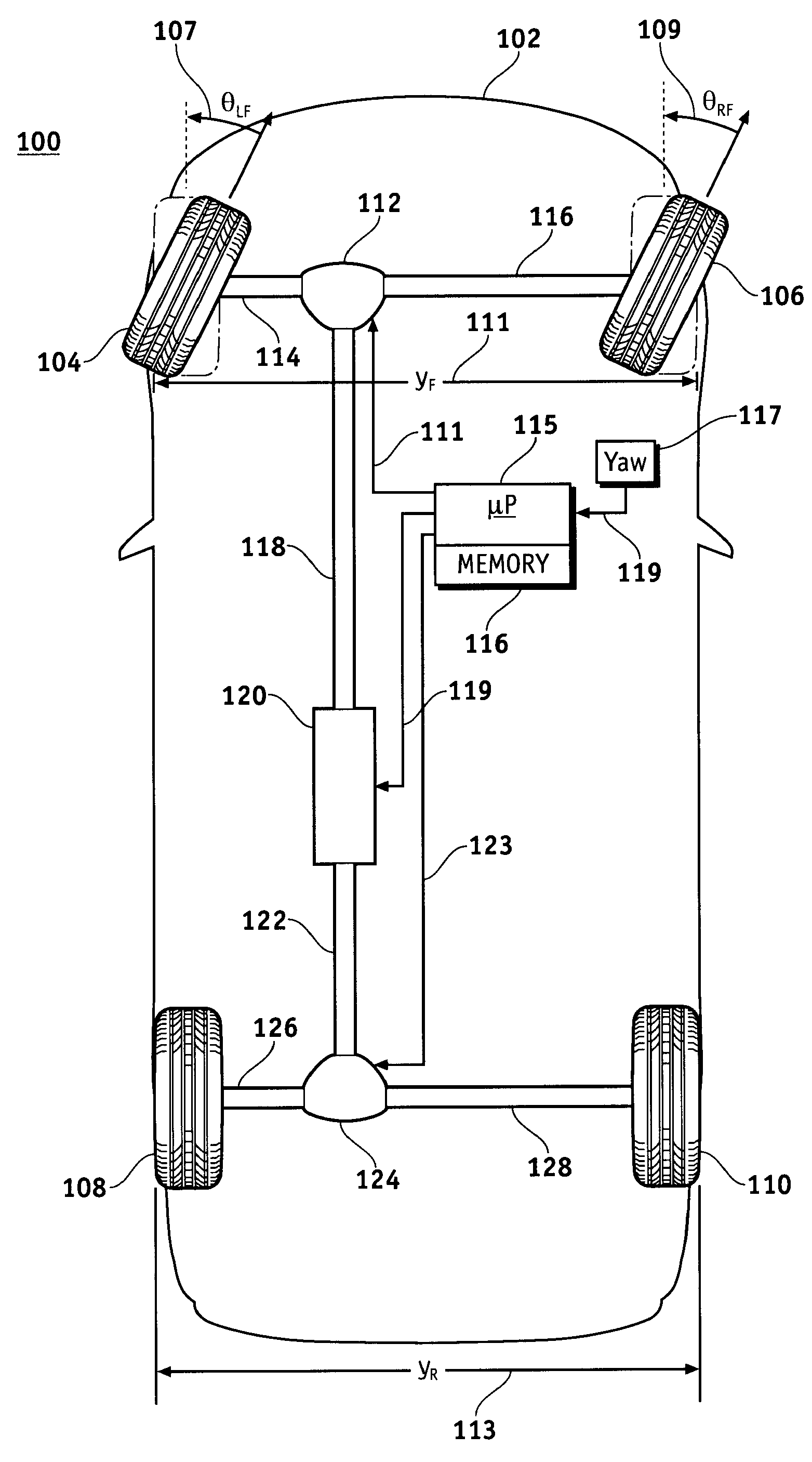

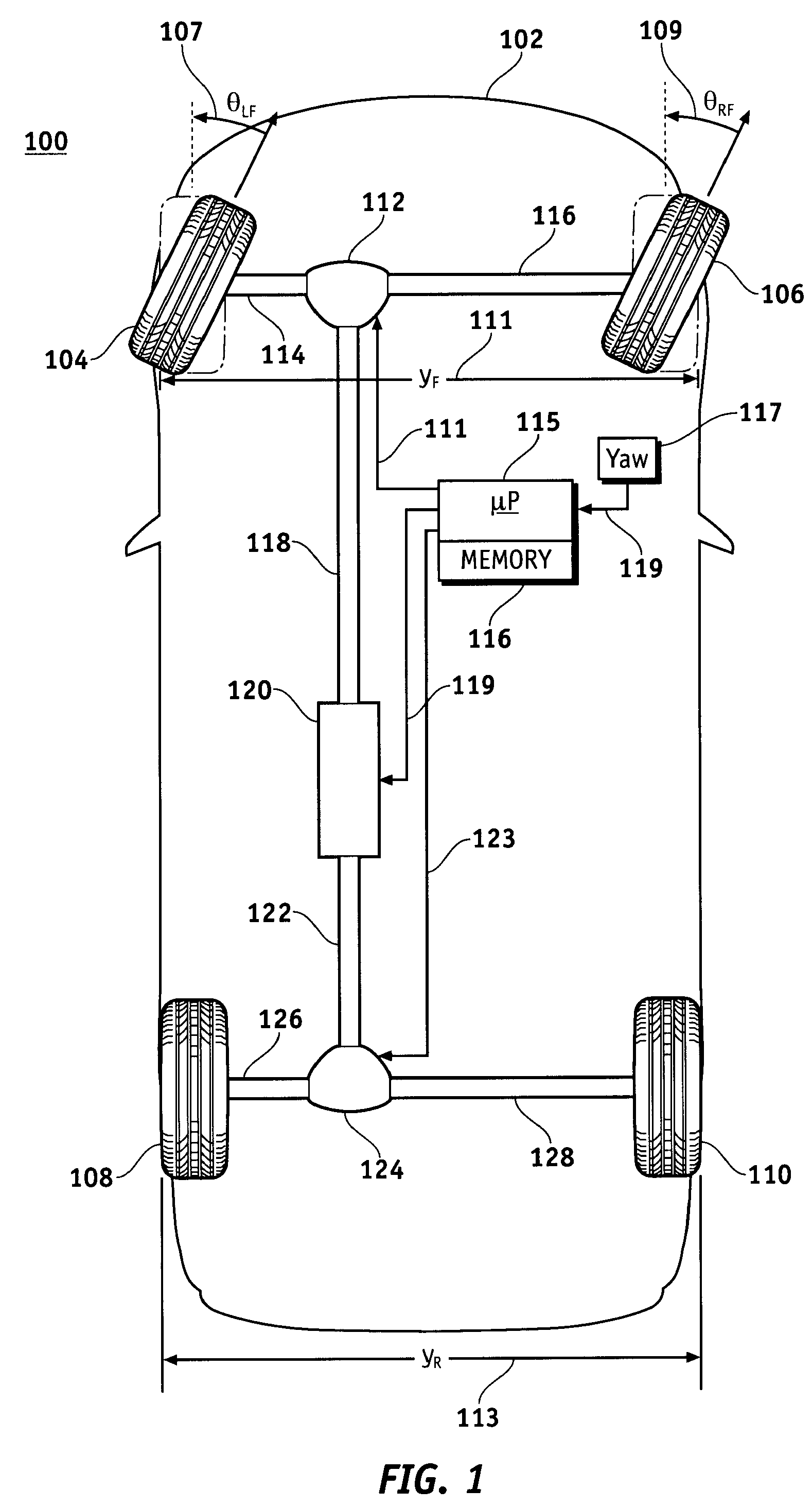

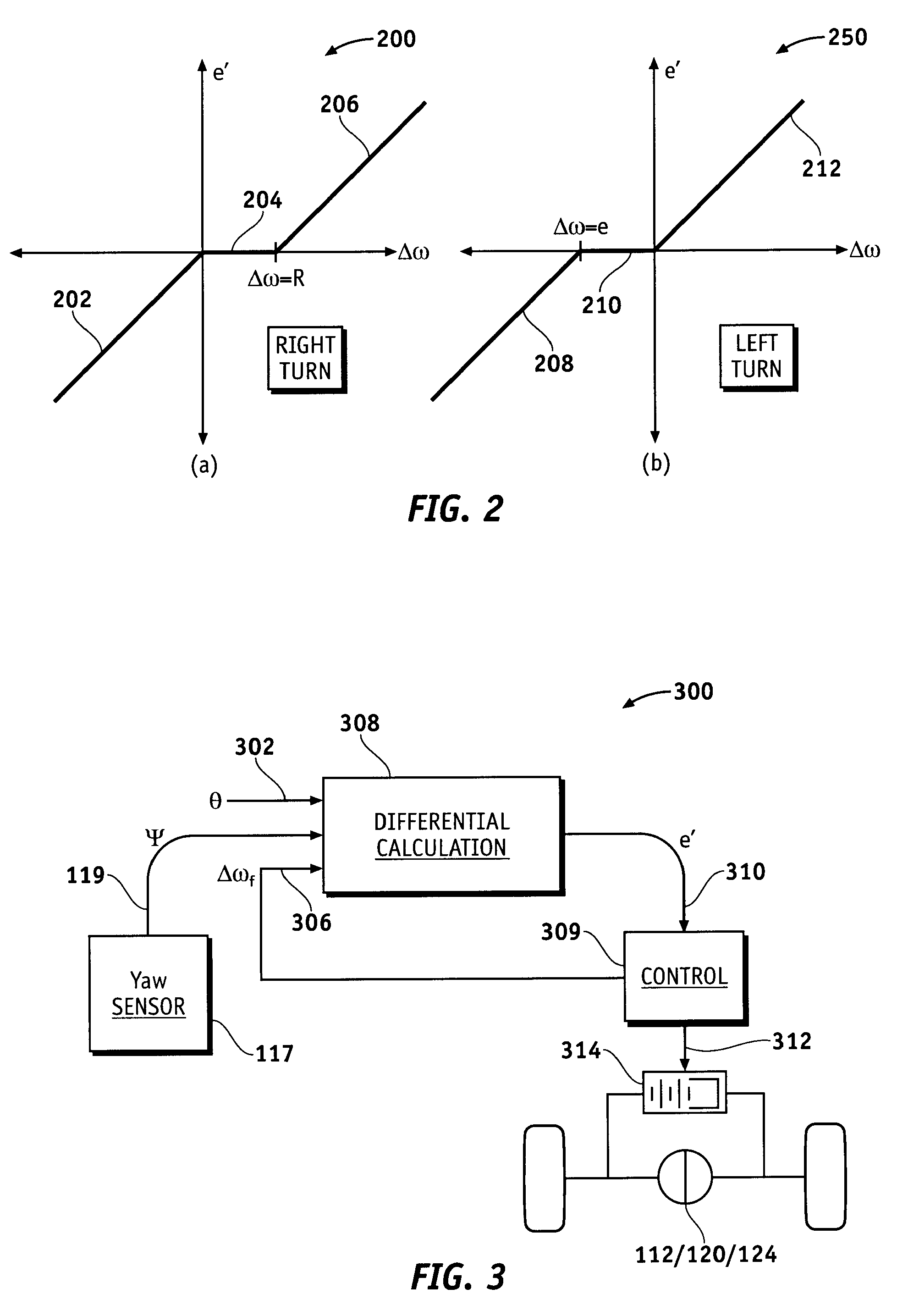

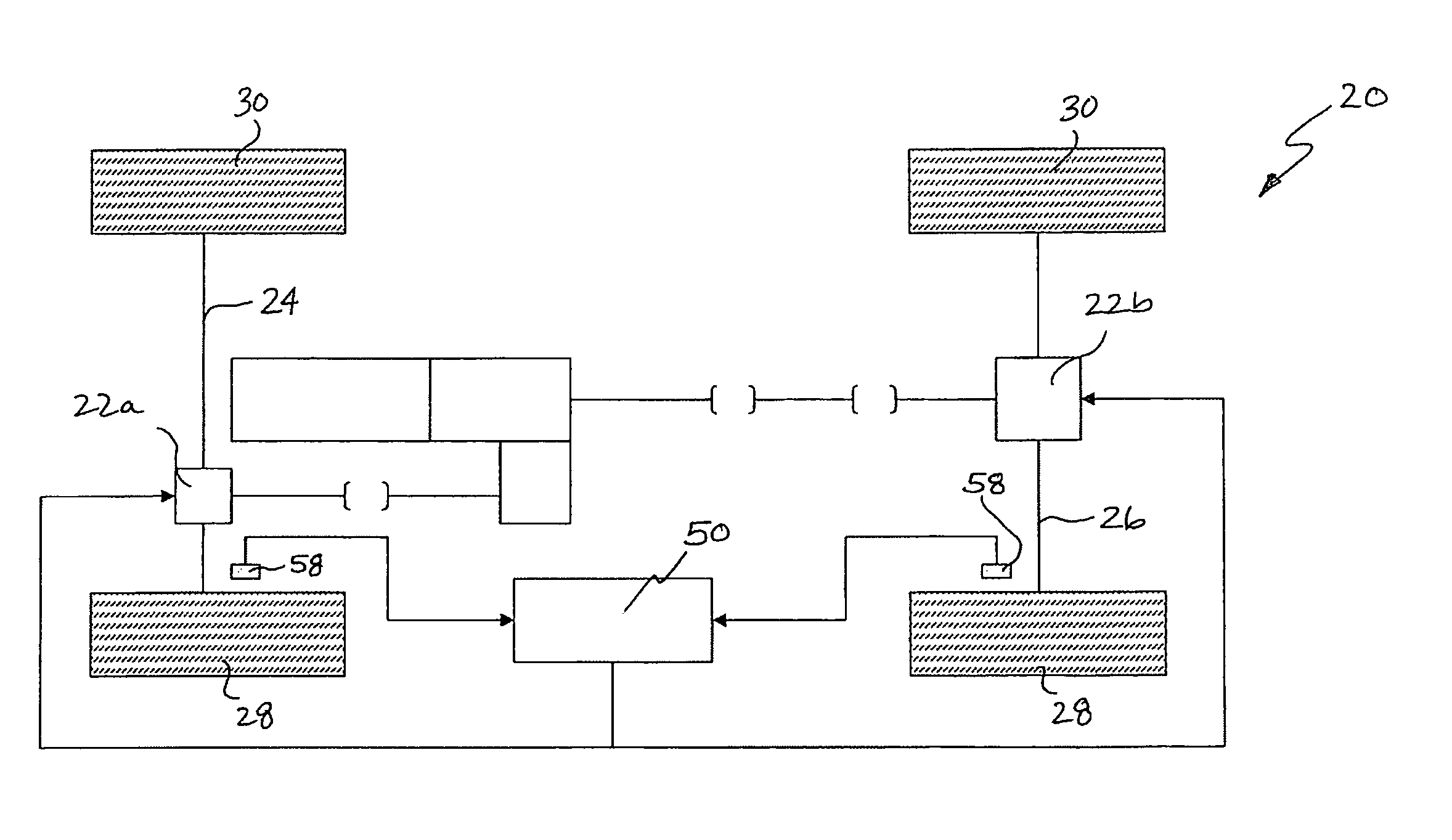

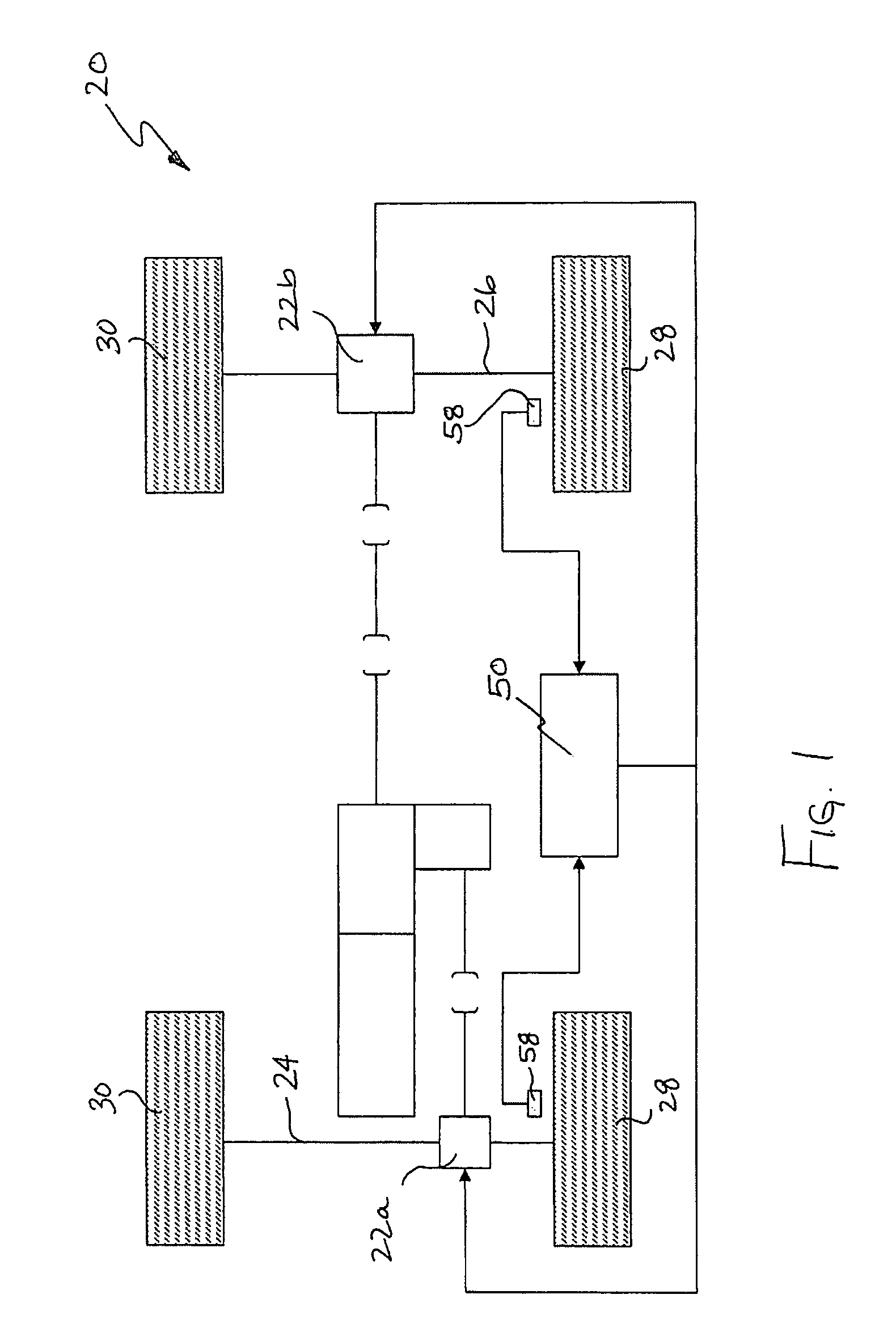

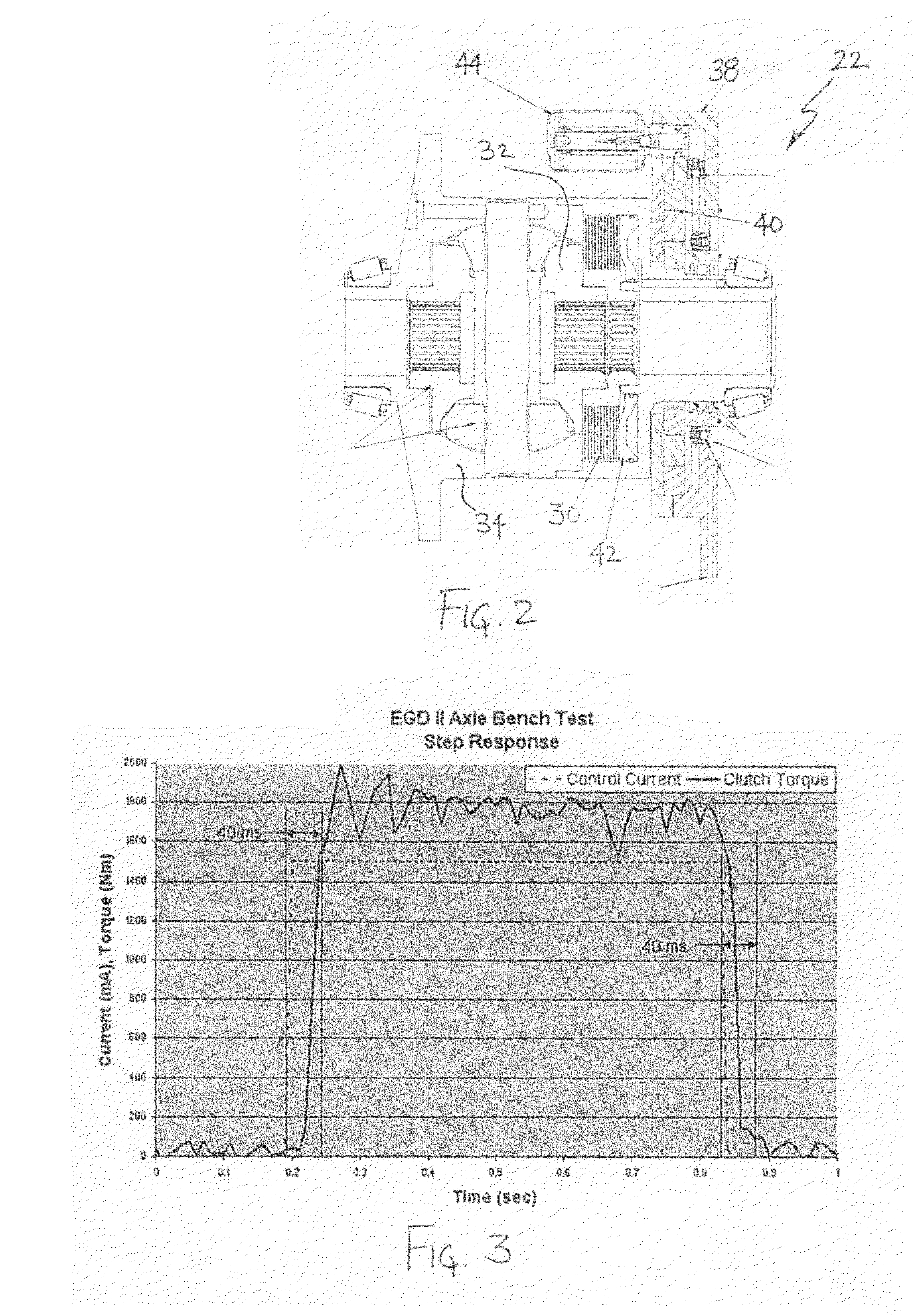

Method and apparatus for generating a cornering-corrected eLSD control signal

ActiveUS7444222B2Reduce needInternal combustion piston enginesAnalogue computers for trafficLimited-slip differentialControl signal

Methods and apparatus are provided for generating a slip control for an active driveline device (such as an electronic limited slip differential (eLSD)) that corrects for longitudinal tire slip in the turning wheels of a vehicle. Indicia of a yaw rate of the vehicle are obtained by the eLSD, which then determining a target velocity difference for the turning wheels based at least in upon the yaw rate, along with other factors such as difference in wheel rotation speed or the wheel-road angle of the vehicle. Using these measured parameters, a slip control signal can be applied to the eLSD as a function of the determined target velocity difference.

Owner:GM GLOBAL TECH OPERATIONS LLC

Limited slip differential with integrated solenoid valve and plenum

InactiveUS6902506B2Shorten speedOperating means/releasing devices for valvesCheck valvesSolenoid valveLimited-slip differential

Owner:FCA US

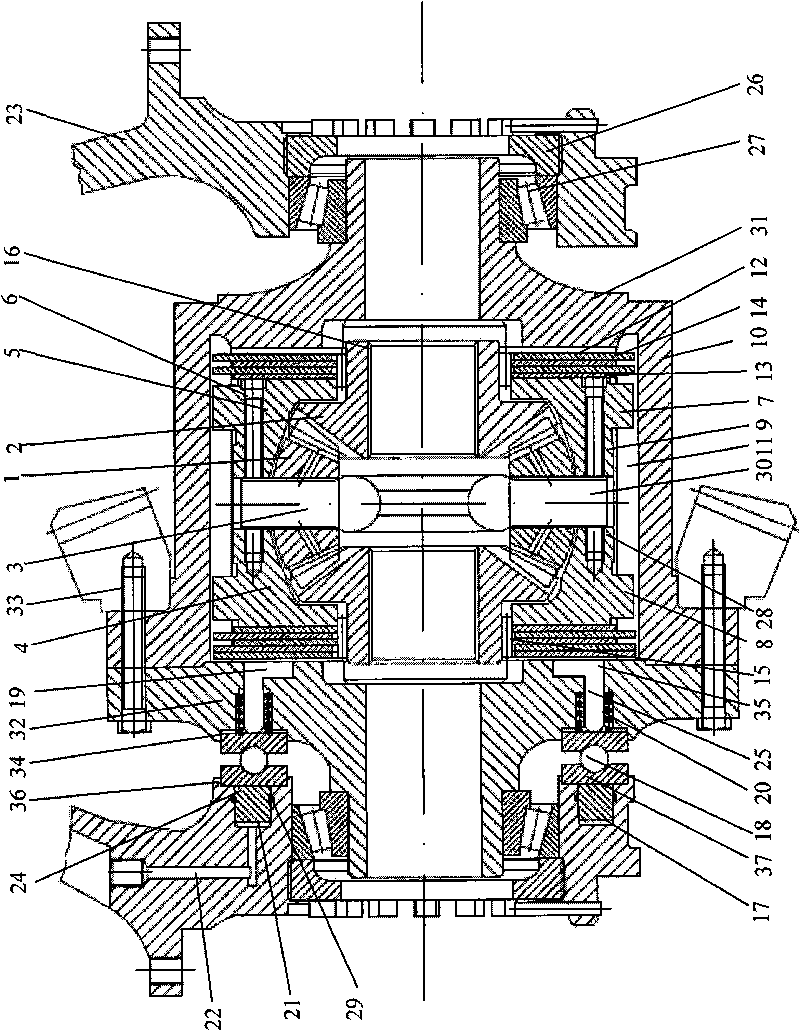

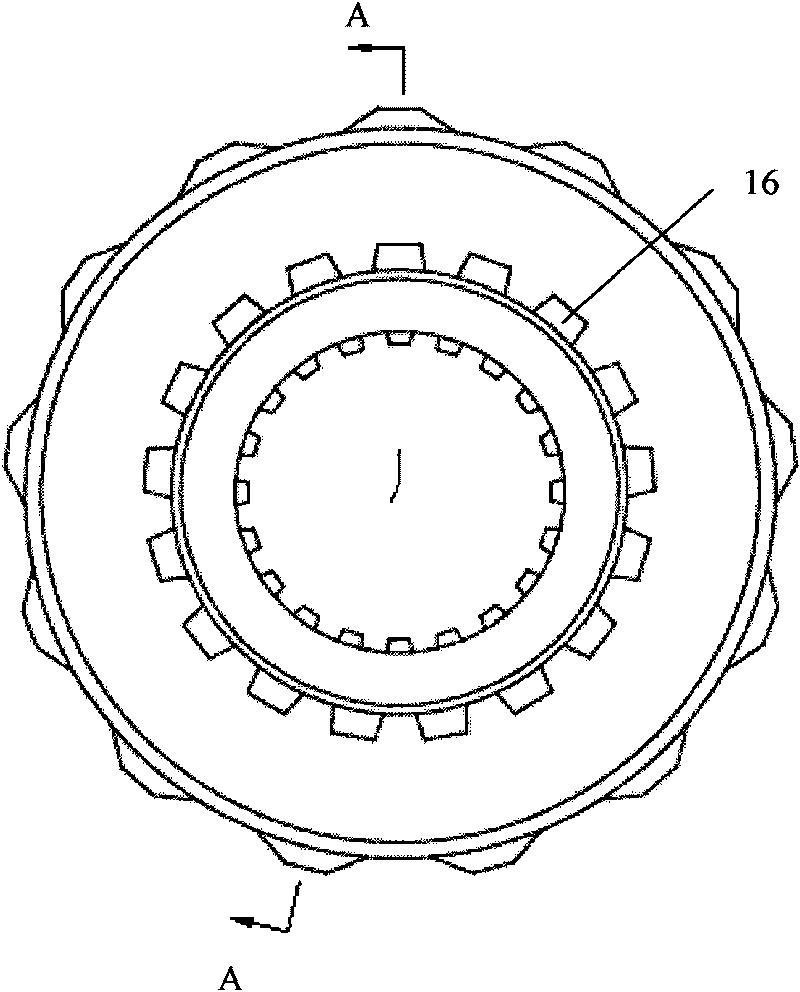

Driving limited-slip differential

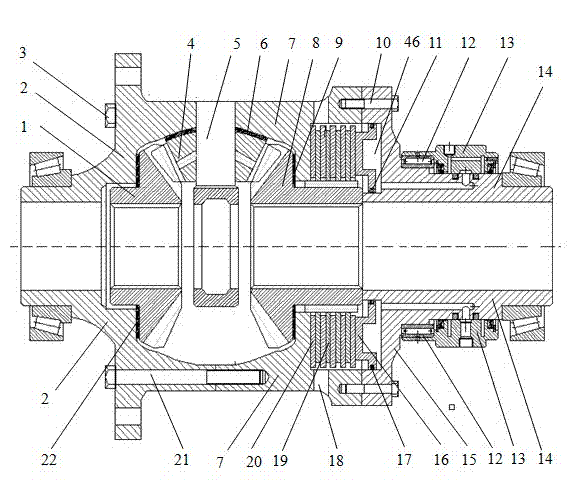

InactiveCN101737478AGuaranteed steering flexibilityGuaranteed steering stabilityDifferential gearingsControl devicesHydraulic cylinderLimited-slip differential

The invention discloses a driving limited-slip differential, comprising an outer shell, an inner shell, a planetary gear train, a limited-slip friction pair and a hydraulic pressure thrust mechanism, wherein, the joint cross of the planetary gear train is placed in a cross round groove of a left semi-shell and a right semi-shell of an inner shell and is fixedly connected with the left semi-shell and the right semi-shell; a first cavity which is matched with a compression ring of the hydraulic pressure thrust mechanism and a seat ring of a thrust bearing is arranged in the outer shell; the compression ring is arranged in the first cavity; a lateral end face of the compression ring is adjacent to the limited-slip friction pair; a push rod is arranged on the other lateral end face; a return spring is sheathed on the push rod; the poppet of the differential is internally provided with an oil duct and a secondary cavity which is matched with a circular ring hydraulic cylinder of the hydraulic pressure thrust mechanism and the seat ring of the thrust bearing; the circular ring hydraulic cylinder is arranged in the second cavity; the two seat rings of the thrust bearing are respectively placed in the first cavity and the second cavity; the seat ring of the first cavity and the return spring are tightly contacted with the head part of the push rod; the seat ring of the second cavity is tightly contacted with the piston of the circular ring hydraulic cylinder; and the oil duct is communicated with the cylinder body of the circular ring hydraulic cylinder.

Owner:ZHEJIANG SCI-TECH UNIV

Stability-enhanced traction and yaw control using electronically controlled limited-slip differential

ActiveUS7801657B2Enhance the vehicle lateral dynamicsImprove stabilityVehicle testingRegistering/indicating working of vehiclesLimited-slip differentialControl system

A control system for a vehicle having first and second wheels is provided that includes a differential apparatus adapted to distribute torque between the first and second wheels and a traction controller for controlling operation of the differential apparatus from vehicle launch up to a predetermined vehicle speed. The traction controller is configured to engage the differential apparatus in a first operating state according to at least one vehicle operating parameter indicative of a low traction operating condition and to further control engagement of the differential apparatus in a second vehicle operating state during the low traction operating condition according to a difference between an actual vehicle yaw rate and a predetermined target vehicle yaw rate. The control system also includes a stability controller for controlling engagement of the differential apparatus at or above the predetermined vehicle speed.

Owner:EATON INTELLIGENT POWER LTD

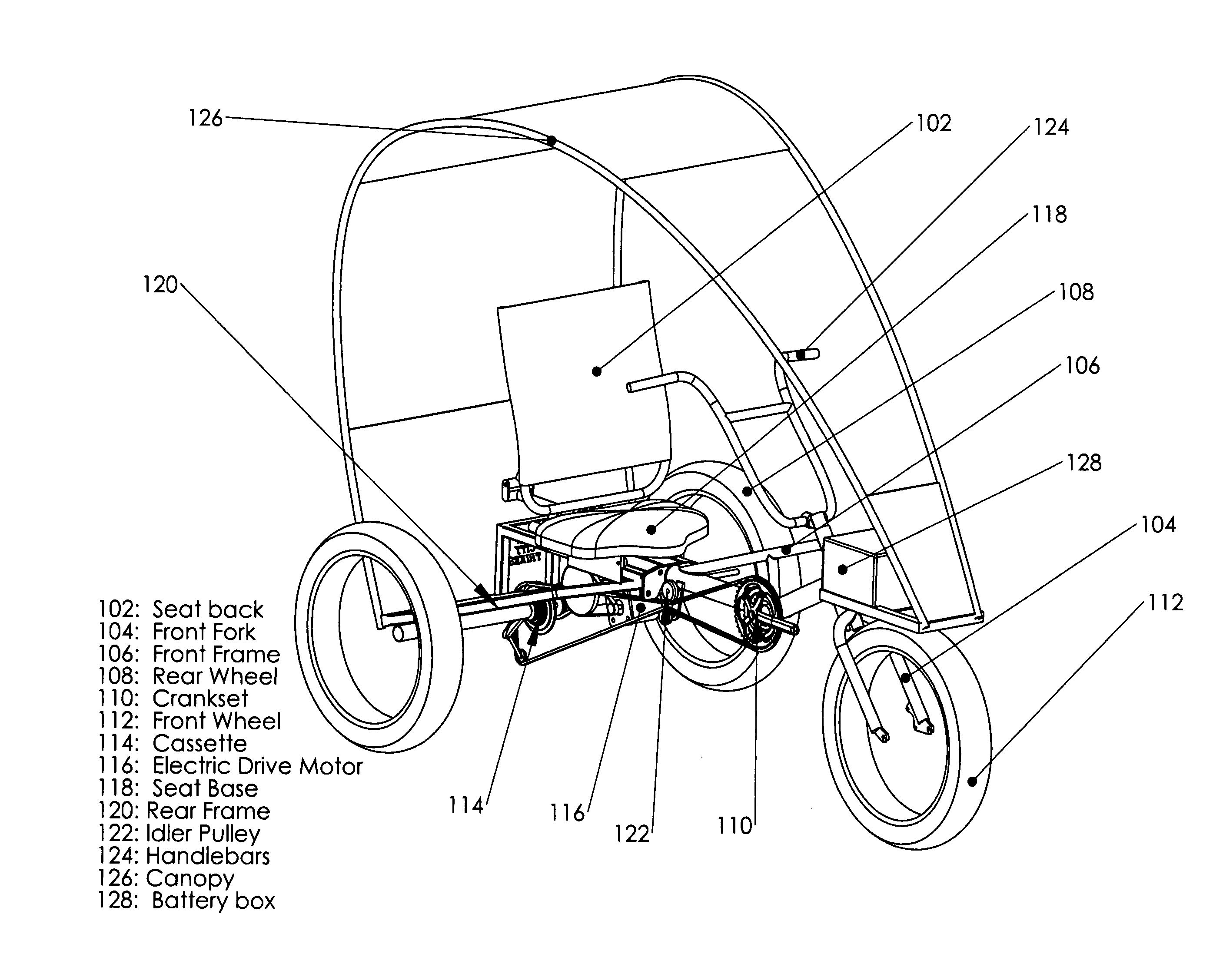

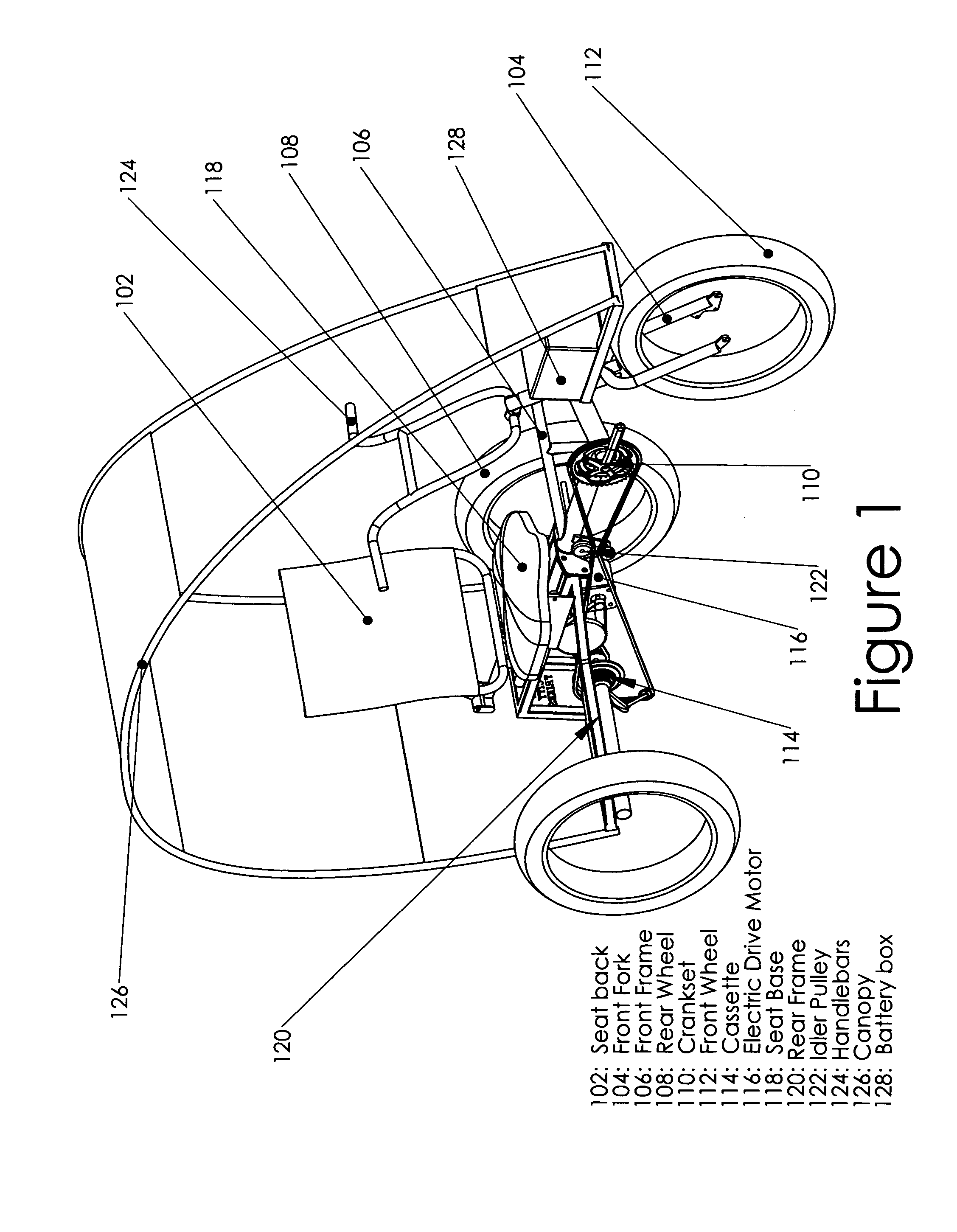

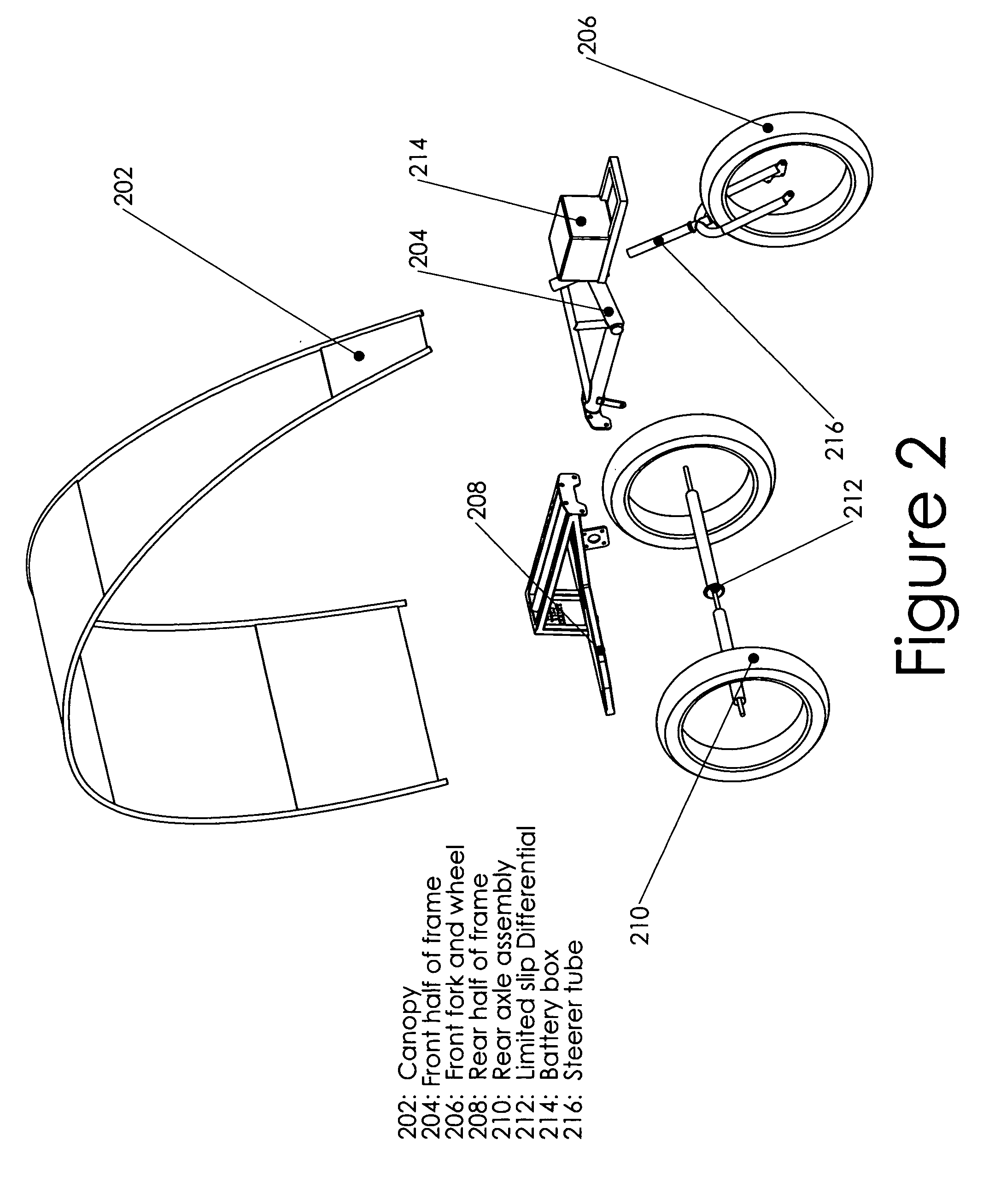

Recreational and utility three or four-wheeled recumbent cycle with on-demand zero emmissions electric motor and multi-geared manual pedal drive

InactiveUS20100314179A1Lower resistanceFresh airAuxillary drivesWeather guardsElectrical batteryGear wheel

One embodiment of a single person recumbent three or four-wheeled, zero emissions utility and recreational cycle vehicle provided with an electric motor driven from a battery and a multiple geared manual pedal mechanism with rear axle derailleur allowing the user to either select individually, or select simultaneously, electric powered or manual pedaling locomotion; also incorporating a rear axle limited slip differential and extra wide tires; and incorporating modular frame, canopy and rear axle design and construction, front and rear disc brakes, a highly-visible canopy; and incorporating a multi-purpose trailer or accessory hitch or receiver for attaching on-board cargo and material carrying devices or for towing of other vehicles for transport of personnel and materials.

Owner:GIBSON ROBERT DENIS

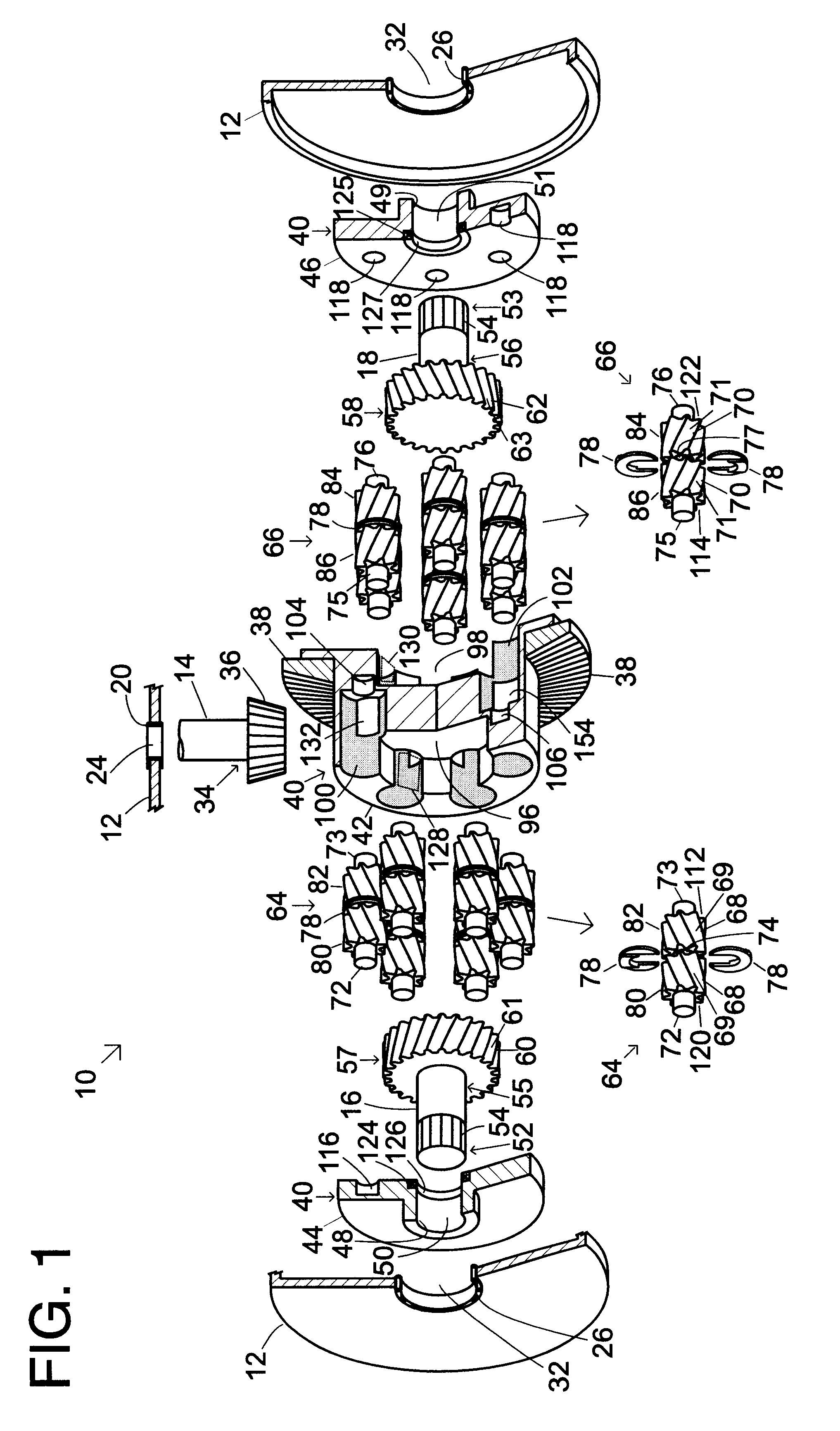

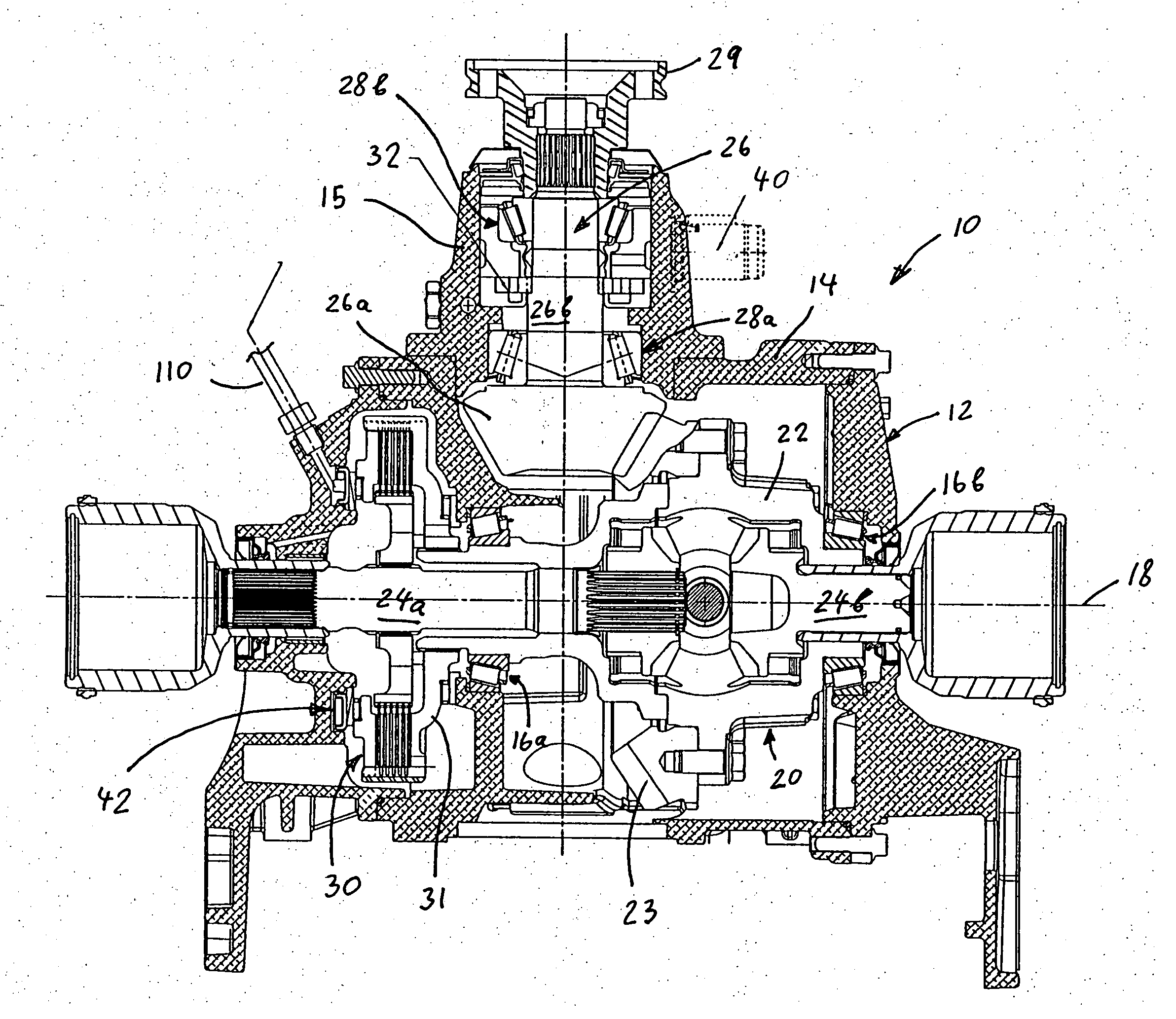

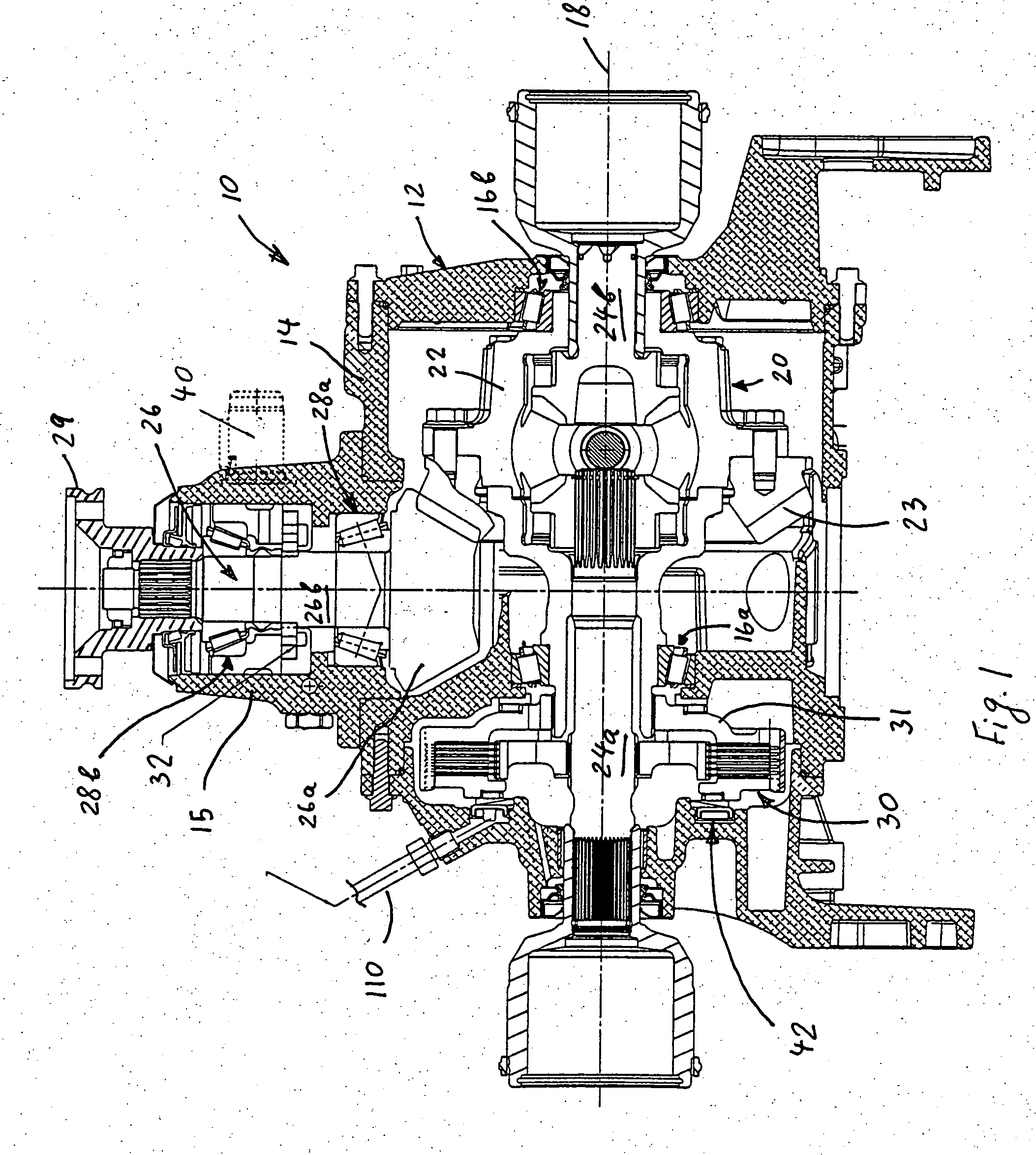

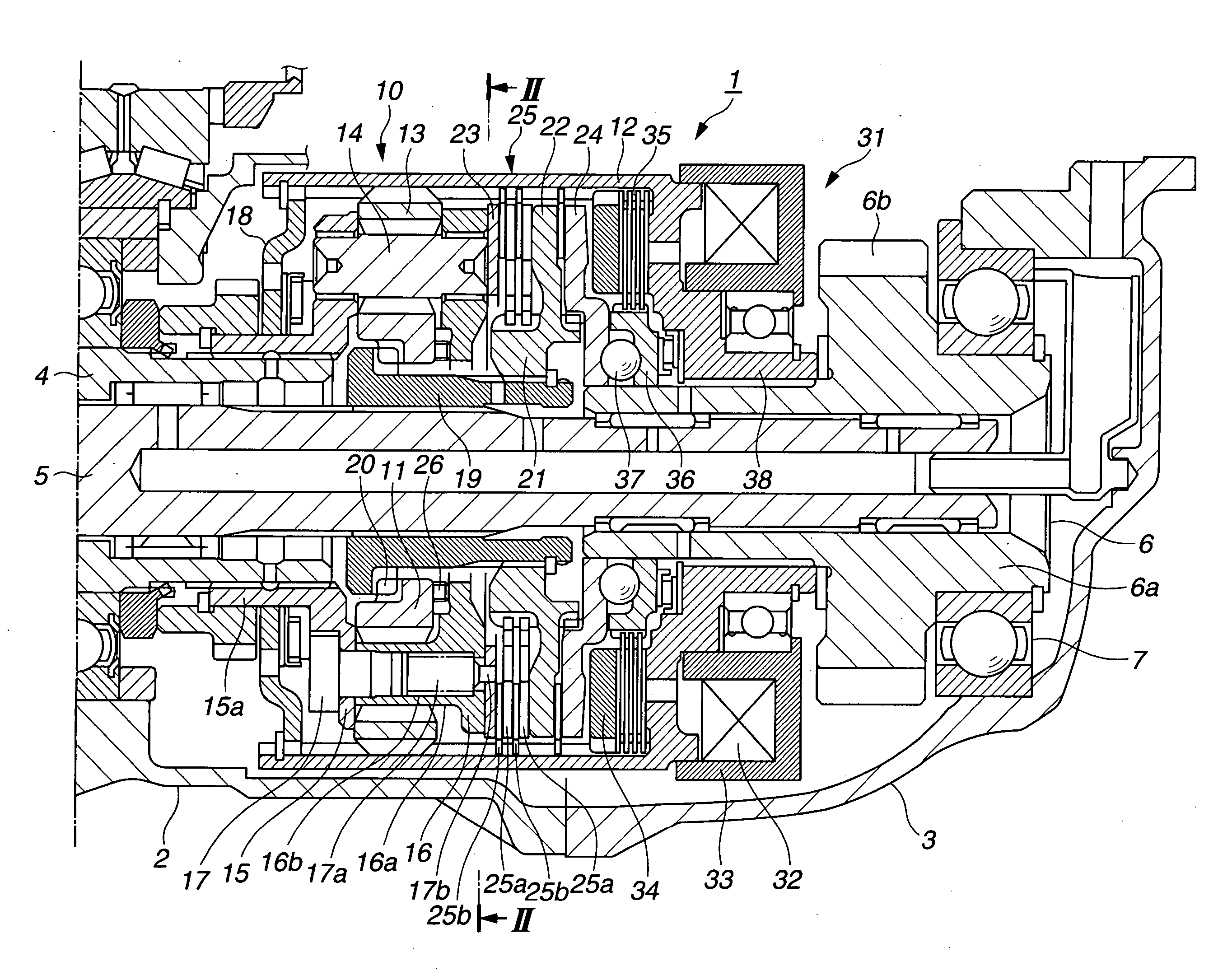

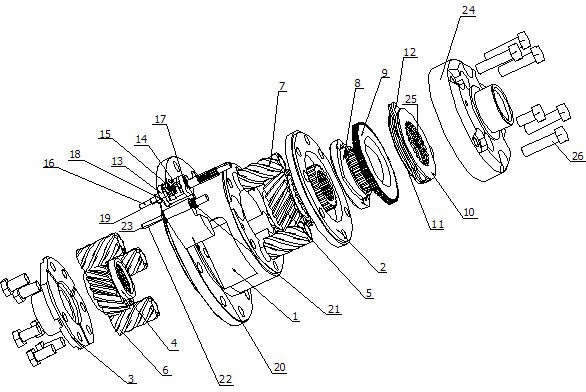

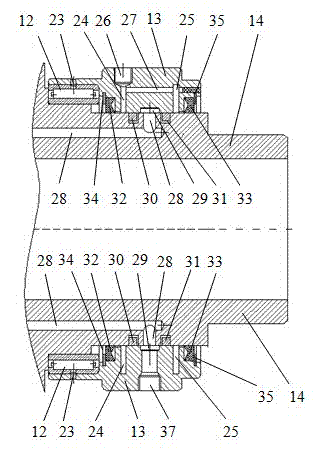

Differential unit with limited slip differential mechanism

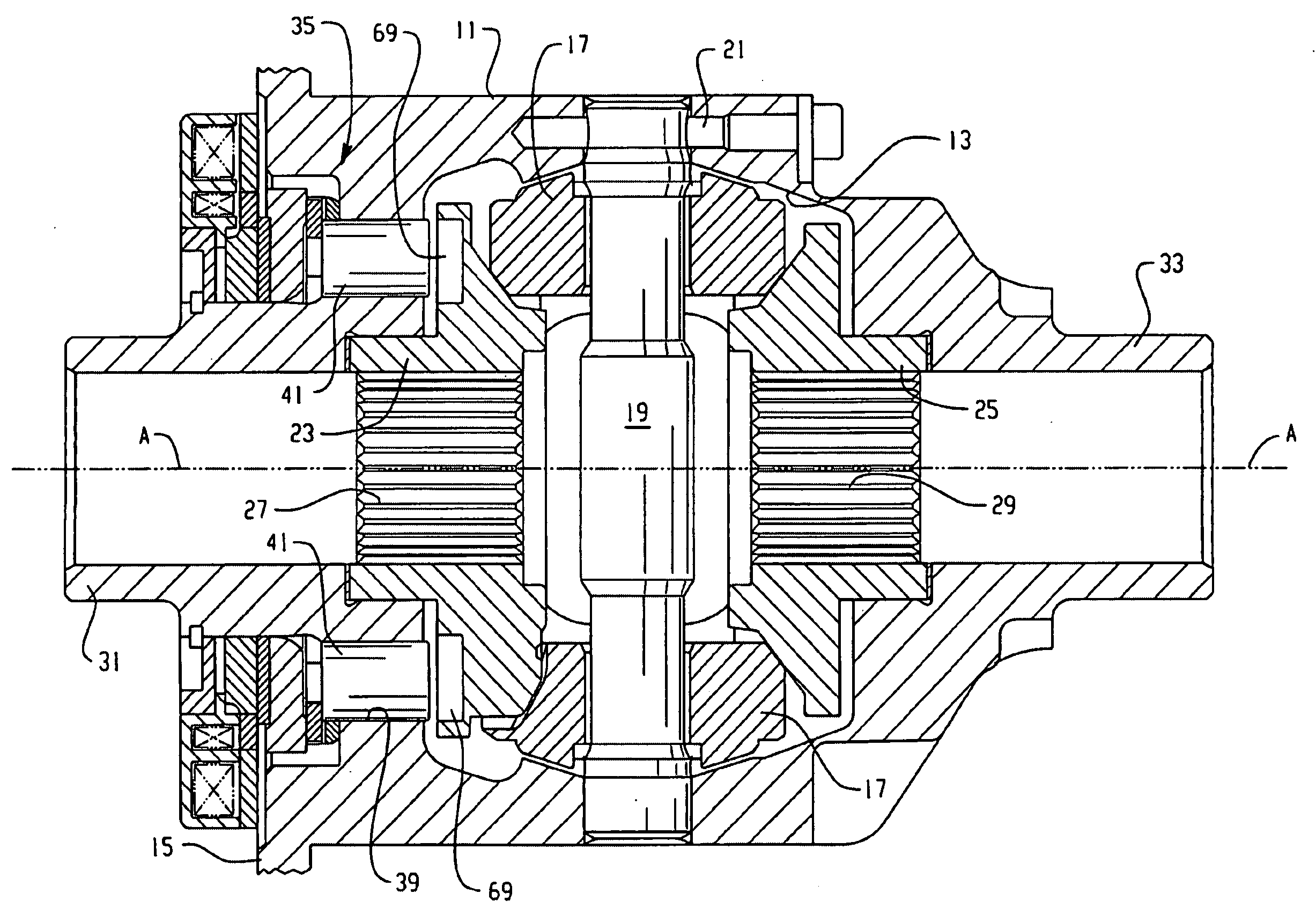

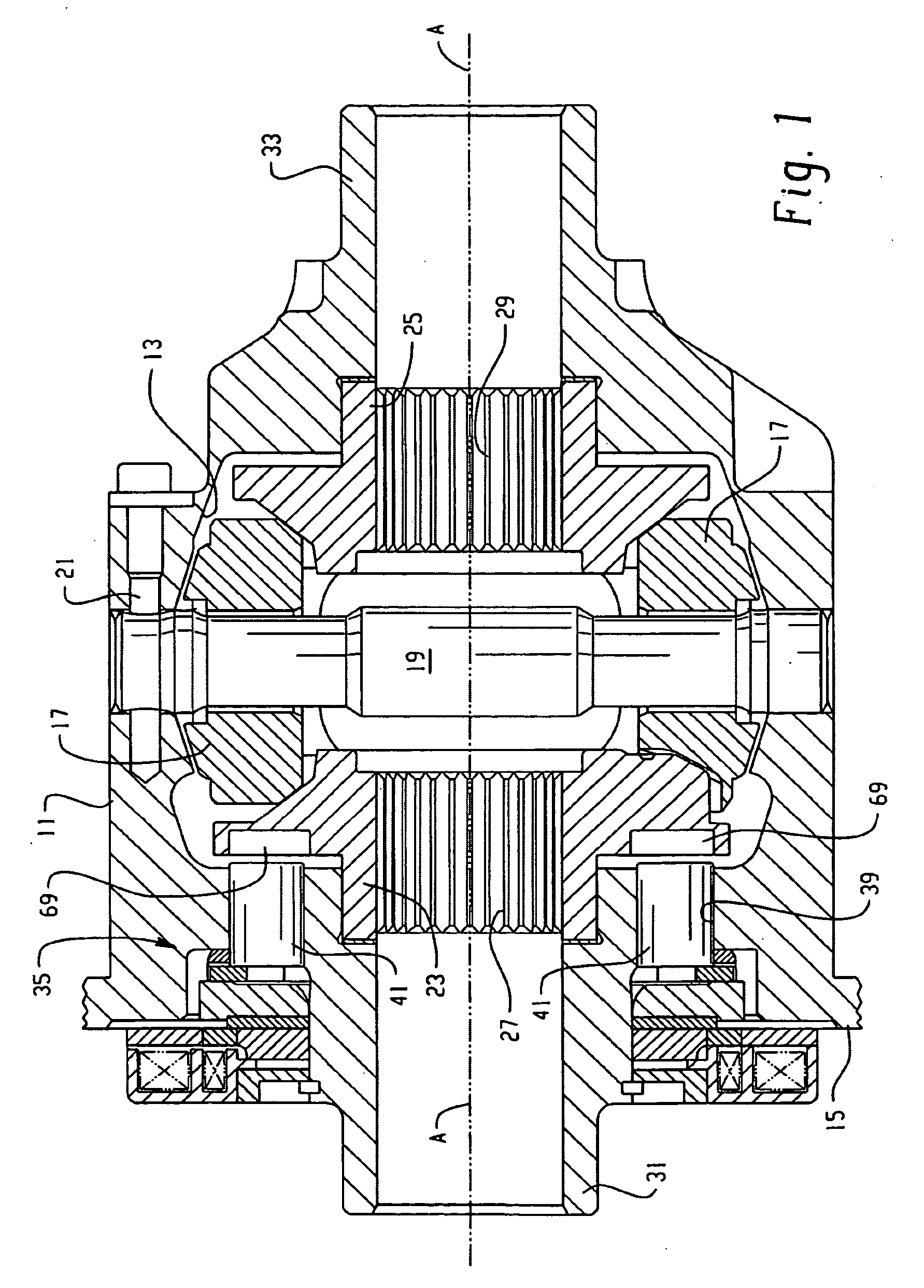

InactiveUS20060281599A1Simple structureEasy to assembleFriction clutchesDifferential gearingsDrive shaftLimited-slip differential

The differential unit with a limited slip differential mechanism of the present invention comprises a planetary gear mechanism for torque distribution of drive torque inputted to an input shaft from an engine between a front drive shaft and a rear drive shaft, and a multiple disc clutch for limiting differential rotation of the planetary gear mechanism, wherein, when a clutch plate receiving clutch engaging force applied to the multiple disc clutch is fixed to a side surface of a planetary carrier of the planetary gear mechanism, pins are formed on the ends of bolts for fixing the planetary carrier, and positioning and fixing is carried out by fitting the pins into check holes formed in the clutch plate.

Owner:SUBARU CORP

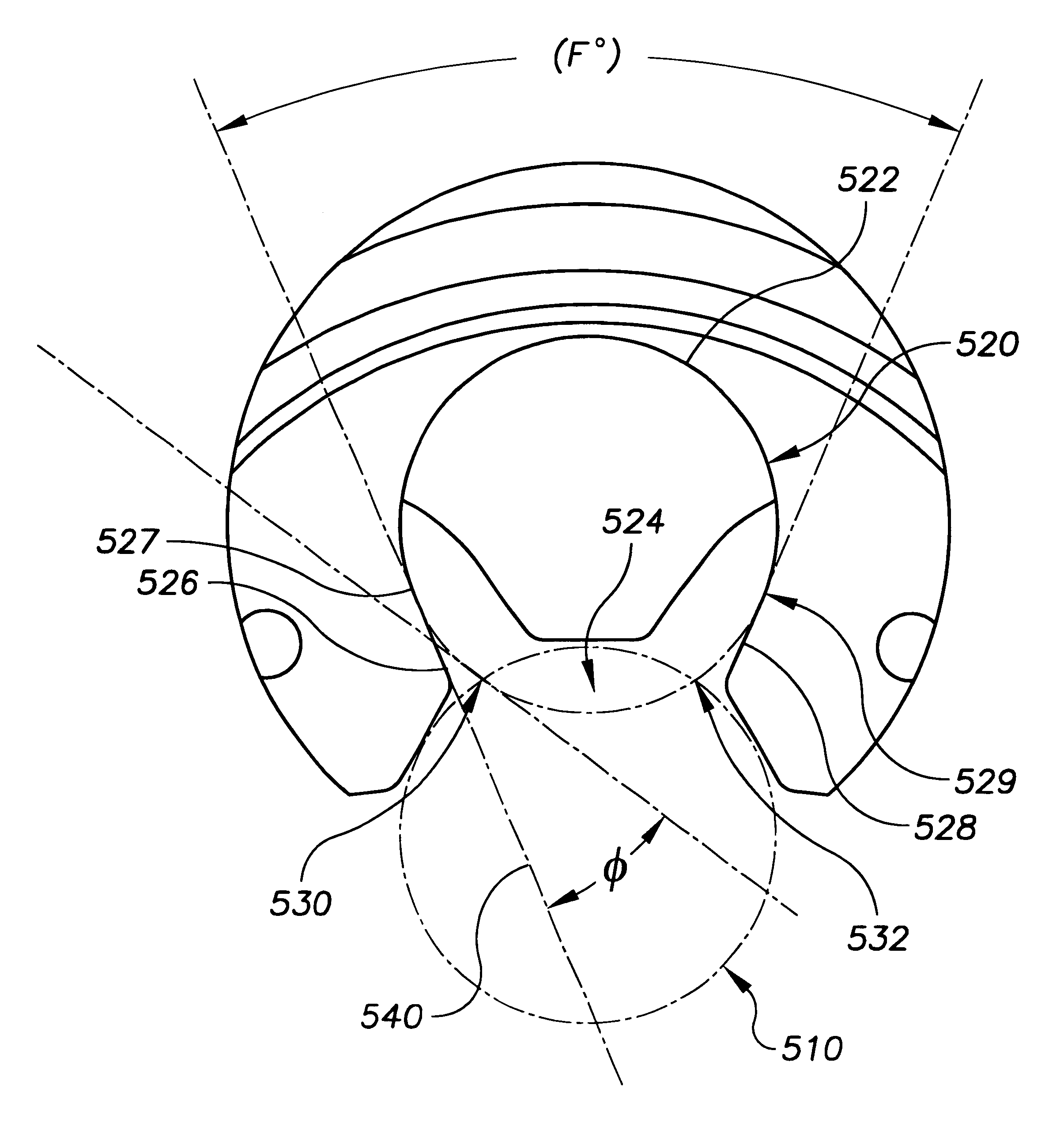

Limited slip differential and engagement sensing mechanism therefor

ActiveUS20070142157A1Optimization mechanismOvercome problemsDifferential gearingsControl devicesLimited-slip differentialFerromagnetism

A differential having means (35) operable to limit rotation of an output gear (23) relative to a gear case (11), and actuation means (55) for actuating the rotation limiting means, from an unactuated (FIG. 1) to an actuated condition (FIG. 4). The rotation limiting means includes a member (47), toward one axial end of the gear case and moveable between a first position, the unactuated condition of said rotation limiting means, and a second position, the actuated condition. A sensor assembly is adjacent the one axial end of the gear case and includes a sensor element (71) and a wall-like member between the rotation limiting means and the actuation means. The wall-like member includes a non-ferromagnetic portion (73) between the sensor and the moveable member. Movement between the first and second positions results in a corresponding change in the electromagnetic flux (F) coupling the sensor element and the moveable member.

Owner:EATON INTELLIGENT POWER LIMITED

Four-wheel drive vehicle-based moment of force distribution control system

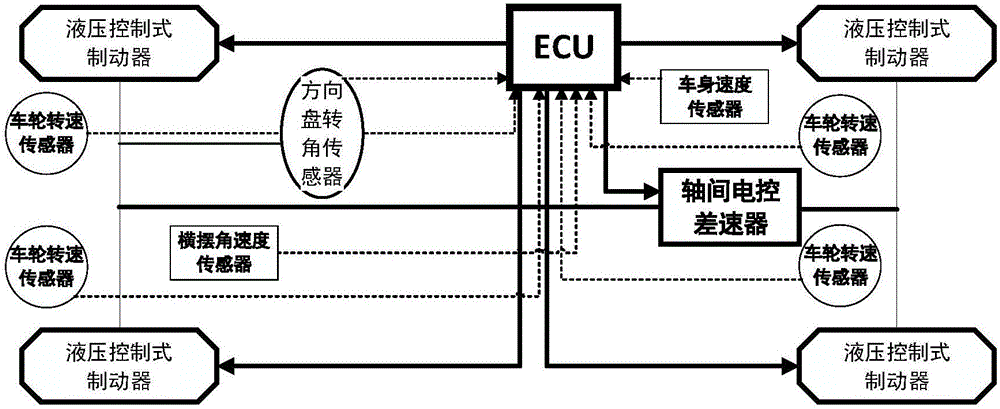

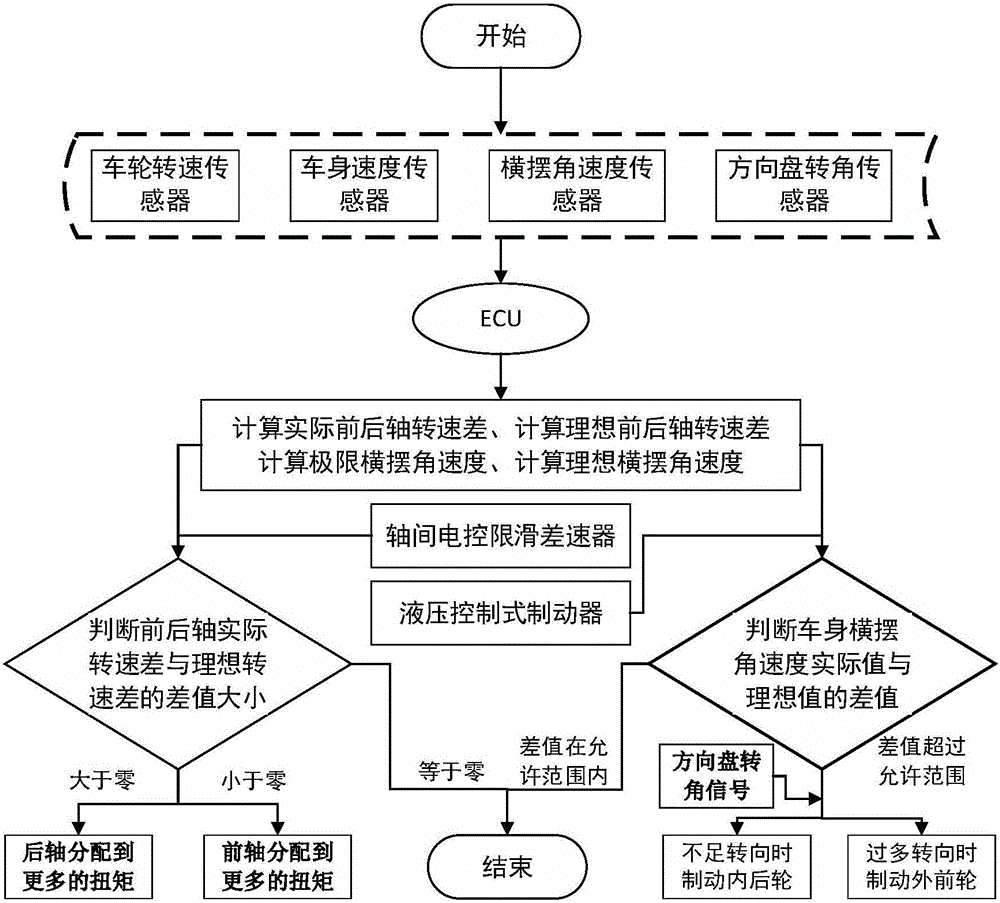

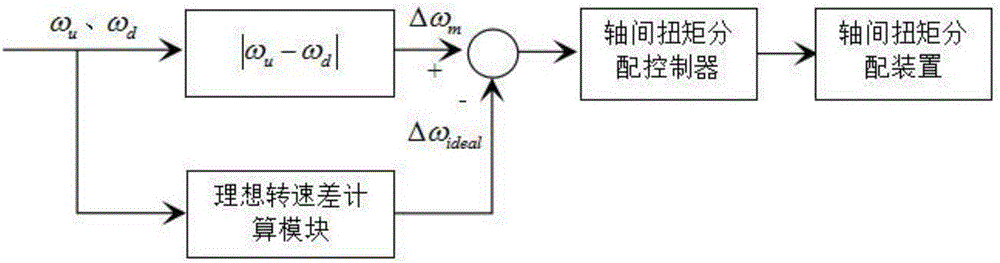

InactiveCN105857304AEnsure handling stabilityGuaranteed powerExternal condition input parametersOther vehicle parametersDistribution controlEngineering

The invention discloses a four-wheel drive vehicle-based moment of force distribution control system. The four-wheel drive vehicle-based moment of force distribution control system comprises an ECU (Electronic Control Unit), wheel rotating speed sensors, a steering wheel rotating angle sensor, a vehicle body speed sensor, a hydraulic control brake, a yaw velocity sensor and an inter-axis electric control limited slip differential, wherein all of the wheel rotating speed sensors, the vehicle body speed sensor, the yaw velocity sensor and the steering wheel rotating angle sensor are connected with the input end of the ECU; both the inter-axis electric control limited slip differential and the hydraulic control brake are connected with the output end of the ECU. According to the four-wheel drive vehicle-based moment of force distribution control system, a vehicle shows high dynamic performance and operating stability after moment of force distribution comprehensive control and inter-axis moment of force distribution control are applied to the vehicle, so that the four-wheel drive vehicle-based moment of force distribution control system has high practicability in the application of improving the traction trafficability, the directional stability or the steering maneuverability of the vehicle.

Owner:WUHAN UNIV OF TECH

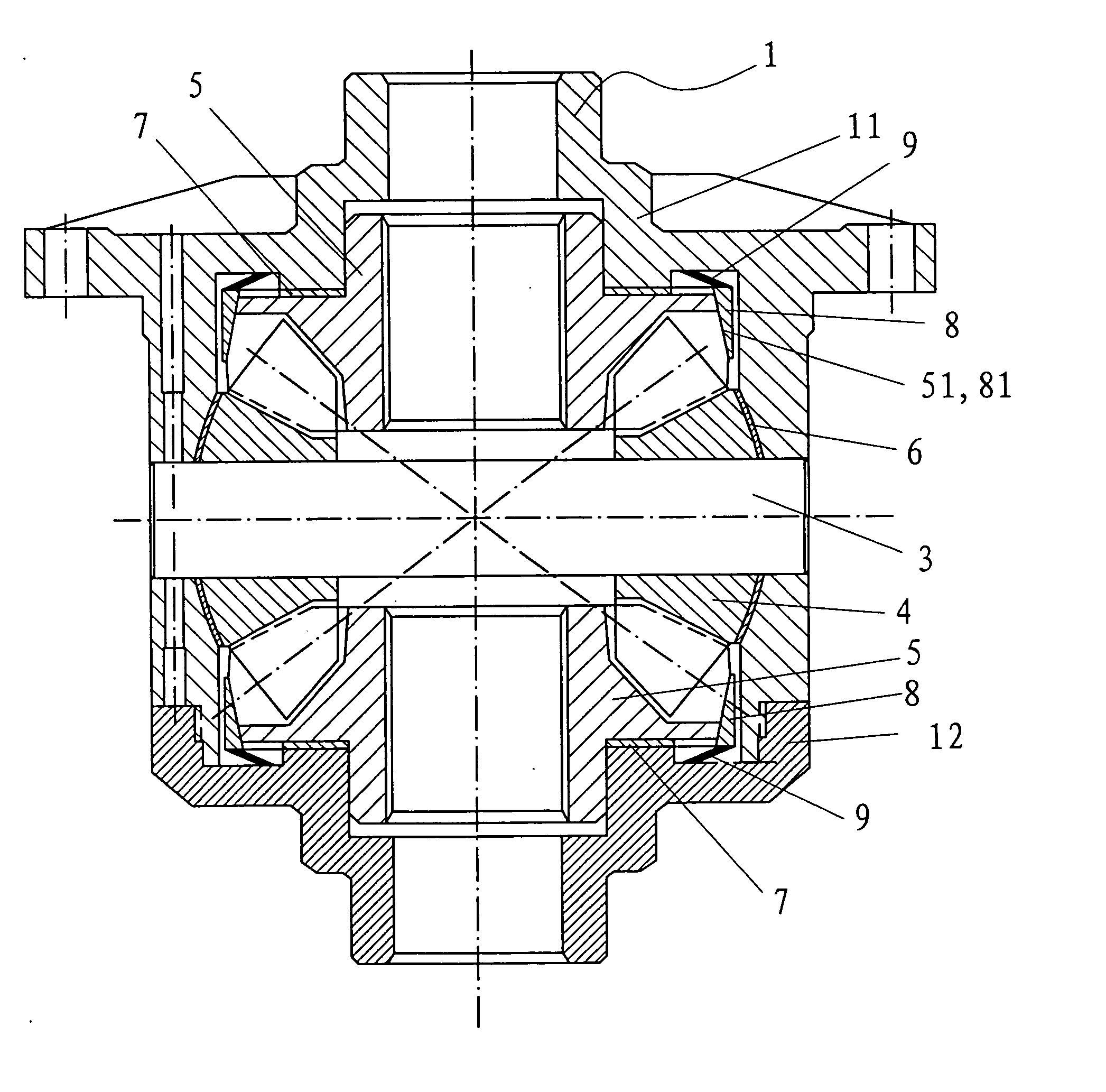

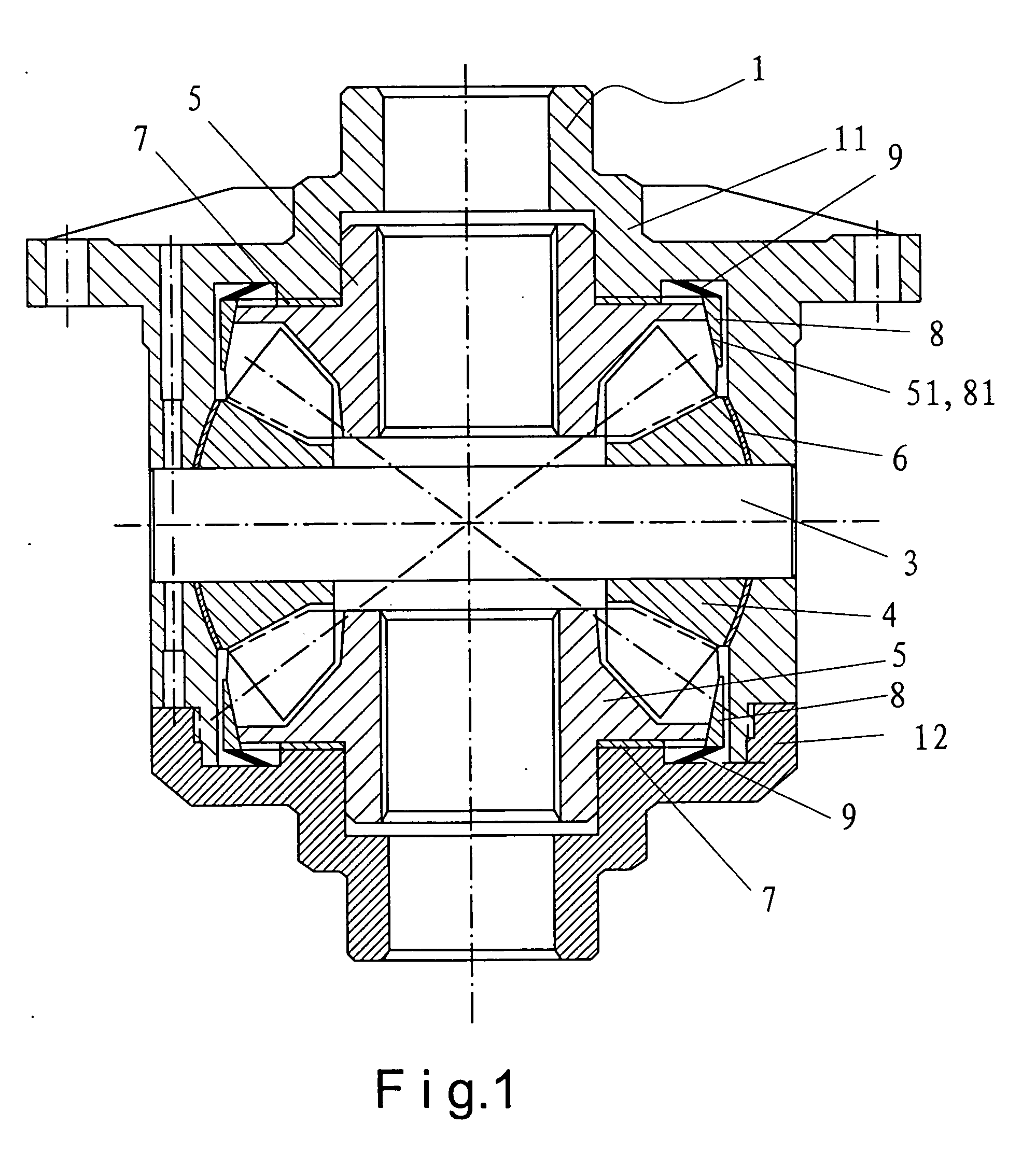

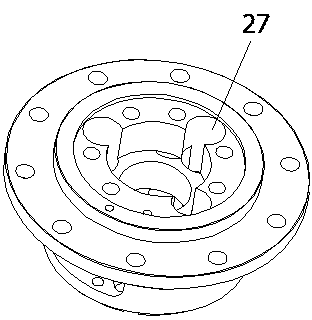

Preload limited-slip differential

InactiveUS20050288144A1High single-wheel tractionLower resistanceDifferential gearingsControl devicesCyclical fluctuationLimited-slip differential

This invention relates to a type of preload limited-slip differential, by means of the friction between the back cone (51) of the side gear (5) and the friction ring (8) to realize the preload function of the differential, thus the length of the differential is not increased, the structure is very compact. Moreover, the gear ratio between the pinions (4) and side gears (5) periodically fluctuates to ensure higher one-wheel traction and lower turning resistance, and the contradictory requirements of good cross-country ability and steering agility are well balanced.

Owner:WANG XIAOCHUN +1

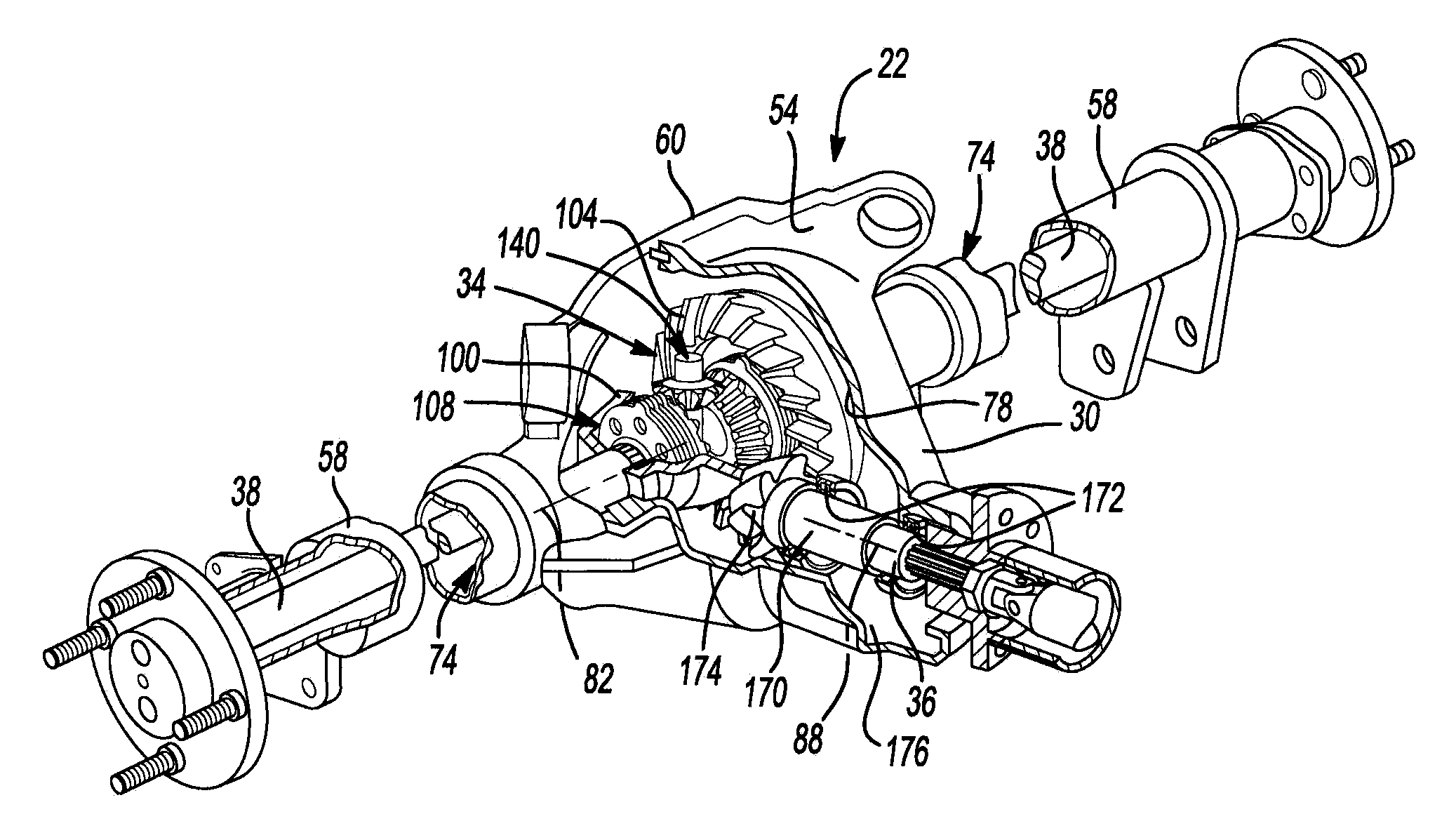

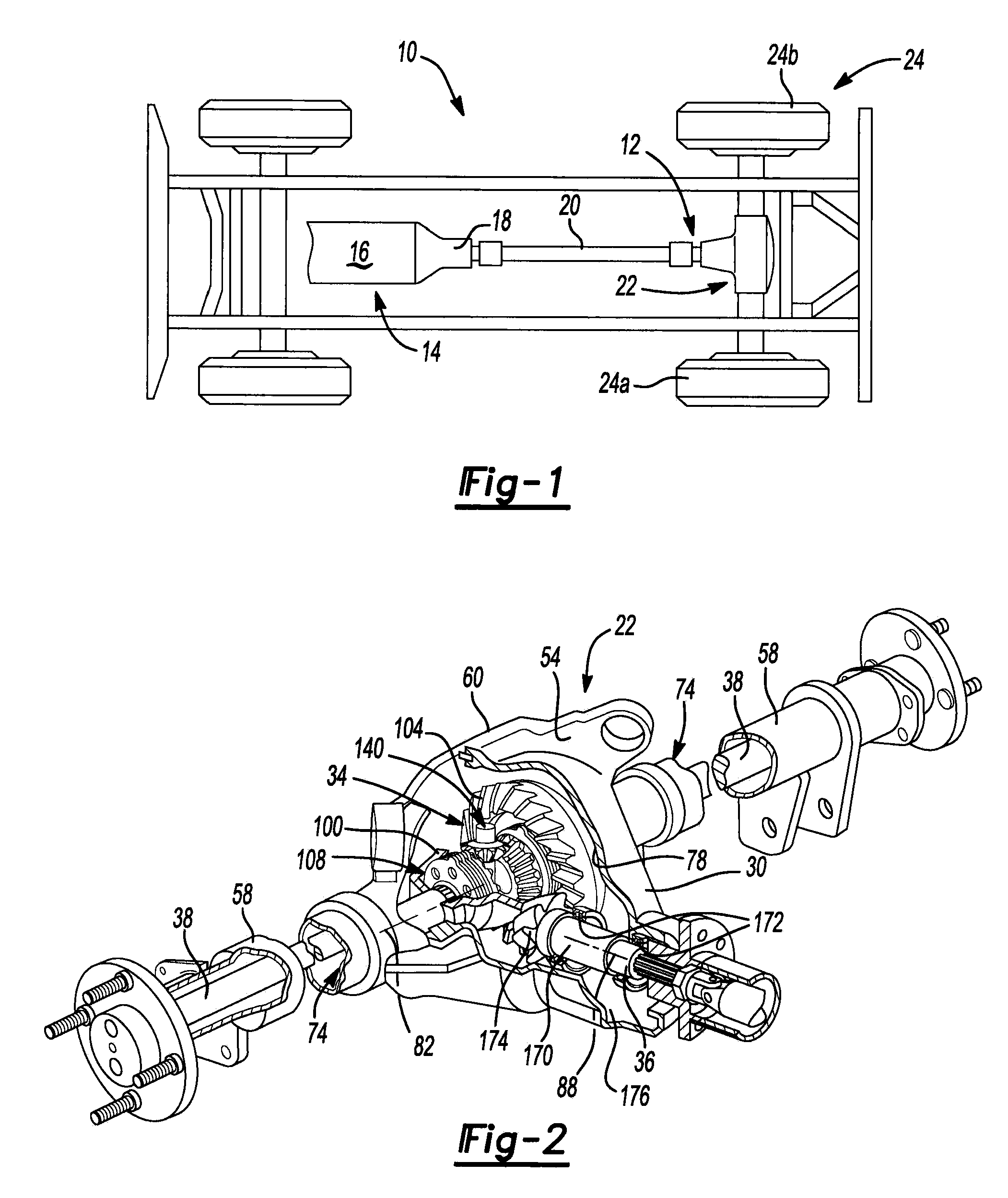

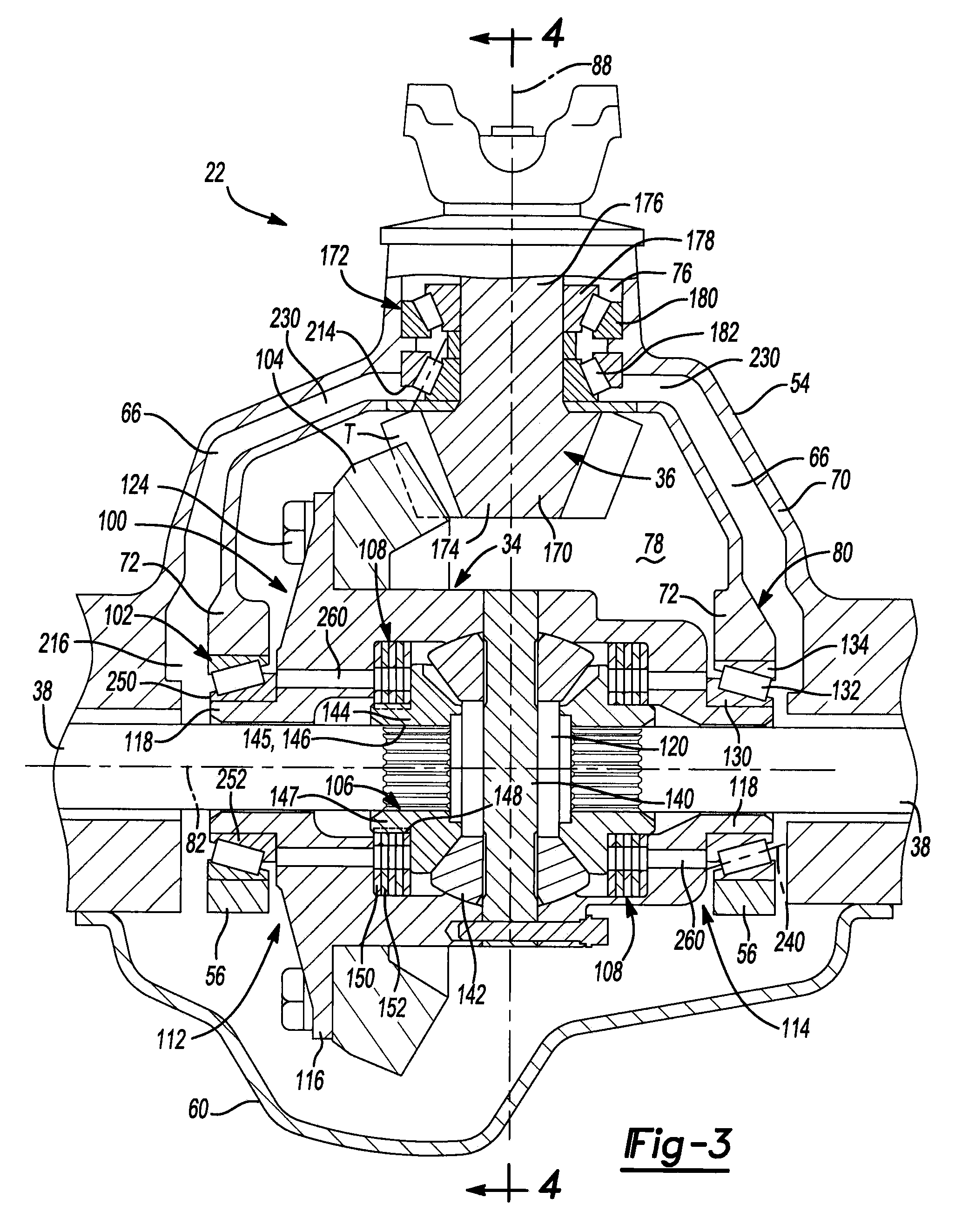

Drive system for motor vehicle

InactiveUS20060169564A1Fluid actuated clutchesDifferential gearingsLimited-slip differentialEngineering

A drive system designed to use a vehicle's existing hydraulic system to operate a controllable limited slip differential assembly. The limited slip differential assembly may be associated with the front axle, the rear axle, or the driveline between the front and rear axles. The differential assembly may also be used in combination that includes front, rear, or intermediate differential assemblies. The drive system further includes a friction clutch assembly for selectively engaging and disengaging an input member with an output member of the differential assembly, a fluid clutch actuator for selectively frictionally and variably loading the clutch assembly, and a fluid pump that is a common source of pressurized fluid for the fluid clutch actuator and the existing hydraulic system of the motor vehicle other than the fluid clutch actuator of the drive system. The fluid clutch actuator is actuated by fluid pressure generated by the fluid pump.

Owner:DANA AUTOMOTIVE SYST GRP LLC

Helical tooth limited slip differential with automatic locking function

ActiveCN103807405APrevent slidingSafe drivingDifferential gearingsControl devicesLimited-slip differentialGear wheel

The invention relates to a helical tooth limited slip differential with an automatic locking function, which comprises a shell. A left half axle gear and a right half axle gear are laterally symmetrically arranged in the shell; the left half axle gear and the right half axle gear are respectively meshed with planetary gears; the shell is provided with a locking device. The helical tooth limited slip differential with the automatic locking function, which is disclosed by the invention, makes up the defect that a locking differential is equivalent to a common open differential under the nonlimiting condition and cannot limit sliding of wheels. A helical tooth limited slip functional part of the helical tooth limited slip differential can automatically work, does not need to be artificially interfered and transfers the torque in real time, can well inhibit the wheels from sliding on ice and snow, muddy, sloppy and gravel pavements and ensures that a vehicle safely runs. The differential also has a function of locking the wheels in the limit state that the wheels at one side of the vehicle are suspended in the air and completely lose the adhesive force.

Owner:TANGSHAN AIT GEAR BOX

Limited slip differential

InactiveUS6599217B2Improve reliabilityImprove performanceDifferential gearingsControl devicesLimited-slip differentialAcute angle

A limited slip differential having a carrier with a plurality of recesses disposed symmetrically relative to a gear opening. The gear opening having a gear diameter, and each of the plurality of recesses having a recess diameter. The gear diameter intersecting the recess diameter of each of the plurality of recesses at corresponding first and second intersections, an acute angle between a line tangent to the recess diameter at the first intersection and a tangent line of the recess diameter along which first and second chamfers extend is between approximately 30 degrees and approximately 32 degrees.

Owner:ILLINOIS TOOL WORKS INC

Turn flow type hydraulic limited slip differential

InactiveCN102829152AControllable locking coefficientDoes not affect steering characteristicsDifferential gearingsInlet channelLimited-slip differential

The invention discloses a turn flow type hydraulic limited slip differential which comprises a shell, a differential mechanism and a limited slip friction pair. The differential mechanism and the limited slip friction pair are located in the shell. The turn flow type hydraulic limited slip differential further comprises a circular piston and an oil conveying disc. The shell is internally provided with a circular groove. The circular piston is placed in the circular groove. The oil conveying disc is installed on the shell. The shell rotates coaxially with the oil conveying disc. The oil conveying disc is provided with a circular oil inlet groove. The shell is internally provided with an oil inlet channel which communicates the circular groove with the circular oil inlet groove so that high pressure oil from a hydraulic system enters the circular groove through the circular oil inlet groove and the oil inlet channel so as to push the circular piston to compress the limited slip friction pair. The oil conveying disc is further provided with a circular oil return groove. High pressure oil leaked at a gap between the oil conveying disc and the shell returns to the hydraulic system through the circular oil return groove. The compressing force of the limited slip friction pair is controllable and adjustable. The hydraulic operating mechanism of the differential is small in size, and the pressure oil leaked can be recycled, so that the pressure oil is prevented from being leaked out of the differential.

Owner:ZHEJIANG SCI-TECH UNIV

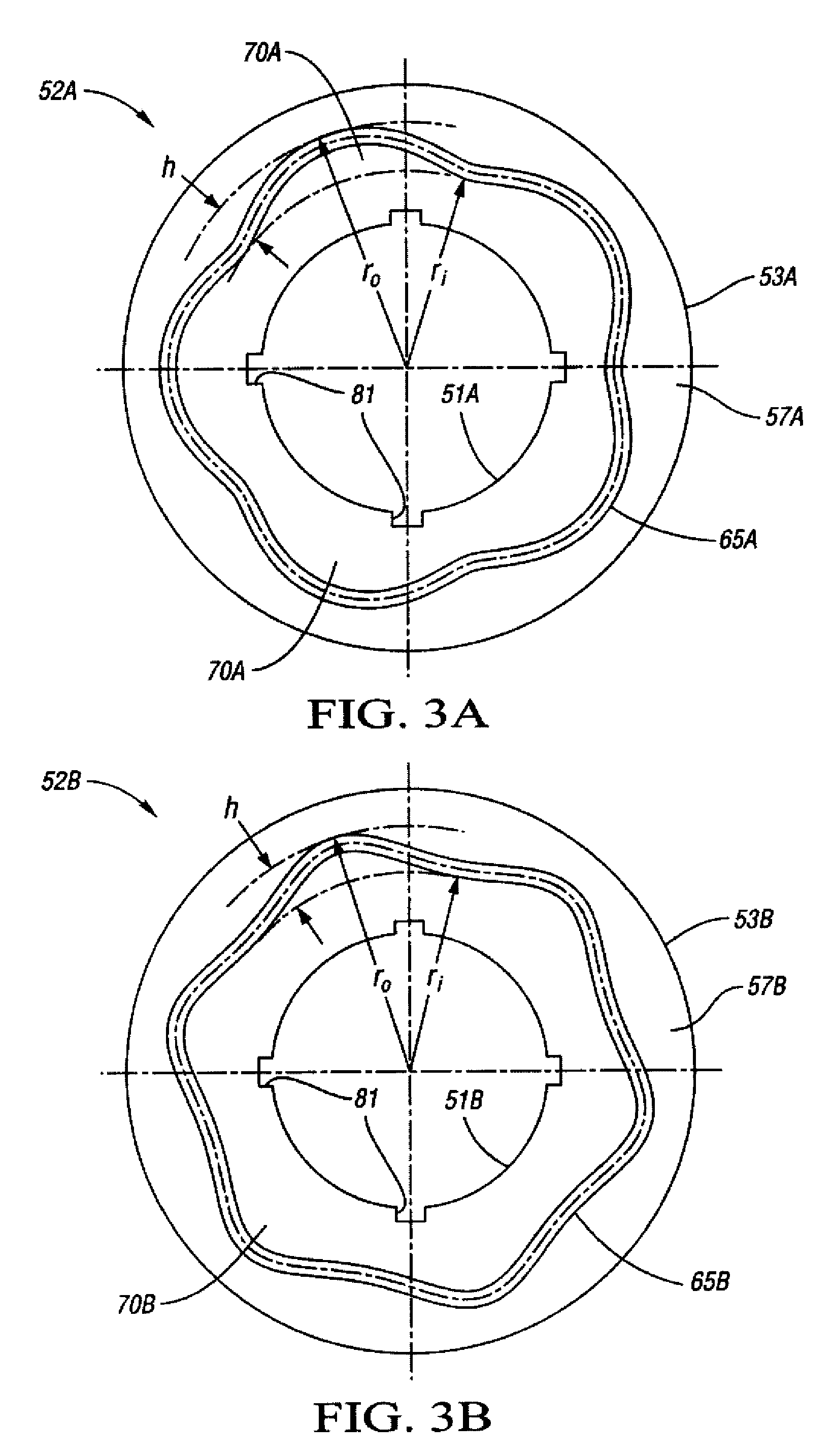

Cycloid limited slip differential and method

A differential is provided comprising a rotatable differential housing, first and second output members, a first cycloid disk having an epitrochoid groove, a second cycloid disk having a hypotrochoid groove, a coupling disk connected having a plurality of holes each containing a sphere, wherein the spheres are engageable with the grooves for transferring torque between the cycloid disks. A method is also provided for distributing torque in a vehicle having two axles including at least one drive axle, including attaching one axle to a cycloid disk having a continuous epitrochoid groove, attaching another axle to a cycloid disk having a continuous hypotrochoid groove, attaching a rotatable housing to a center coupling disk having a plurality of holes, and positioning a torque transfer sphere that is engageable with the grooves in each of the holes, wherein the spheres are configured for distributing torque along the drive axles.

Owner:GM GLOBAL TECH OPERATIONS LLC

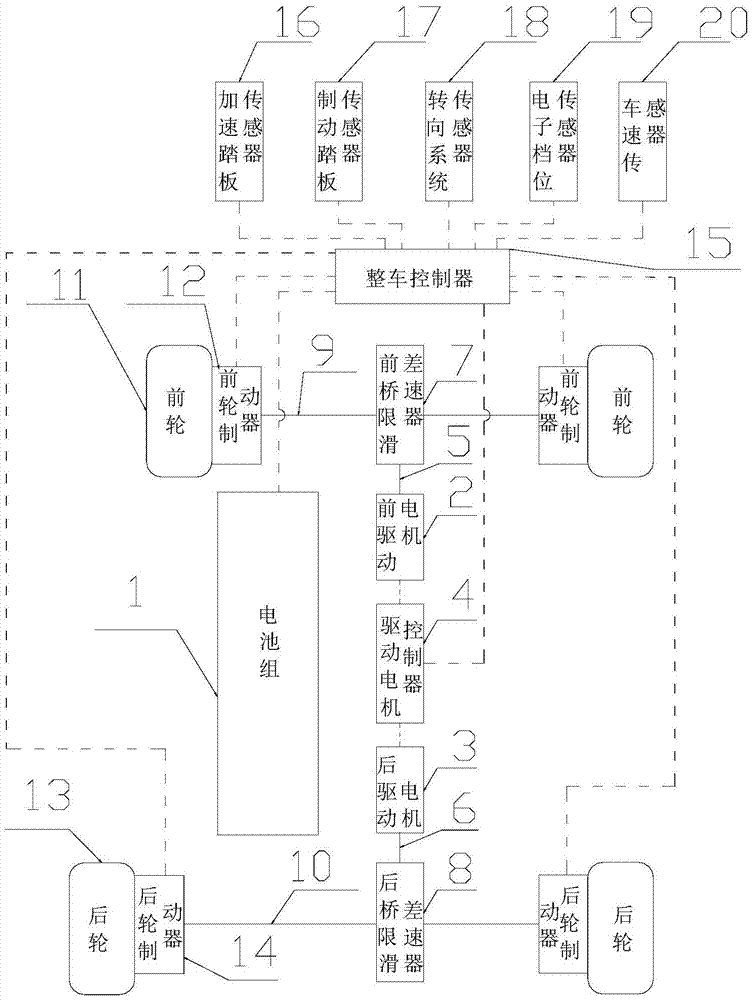

Electric vehicle driving device

InactiveCN105438007AReasonable powerImprove driving efficiencySpeed controllerLimited-slip differentialDrive shaft

The invention discloses an electric vehicle driving device which comprises a battery pack, a front driving motor, a rear driving motor, a driving motor controller, a front transmission shaft, a rear transmission shaft, a front axle limited slip differential, a rear axle limited slip differential, a front transmission semi-shaft, a rear transmission semi-shaft, a front wheel, a front wheel brake, a rear wheel, a rear wheel brake, an entire vehicle controller, an accelerator pedal sensor, a brake pedal sensor, a steering system sensor, an electronic gear sensor and a vehicle speed sensor. According to the invention, by adopting two driving motors for driving in a matched mode, the driving efficiency of the driving motors is greatly improved; and by adopting an integrated driving motor controller instead of a clutch device, mechanical devices of an electric vehicle are reduced, and the management control capability of a driver for switching a front-drive mode, a rear-drive mode and a four-drive mode is increased.

Owner:枫盛汽车(长兴)有限公司

Limited slip differential

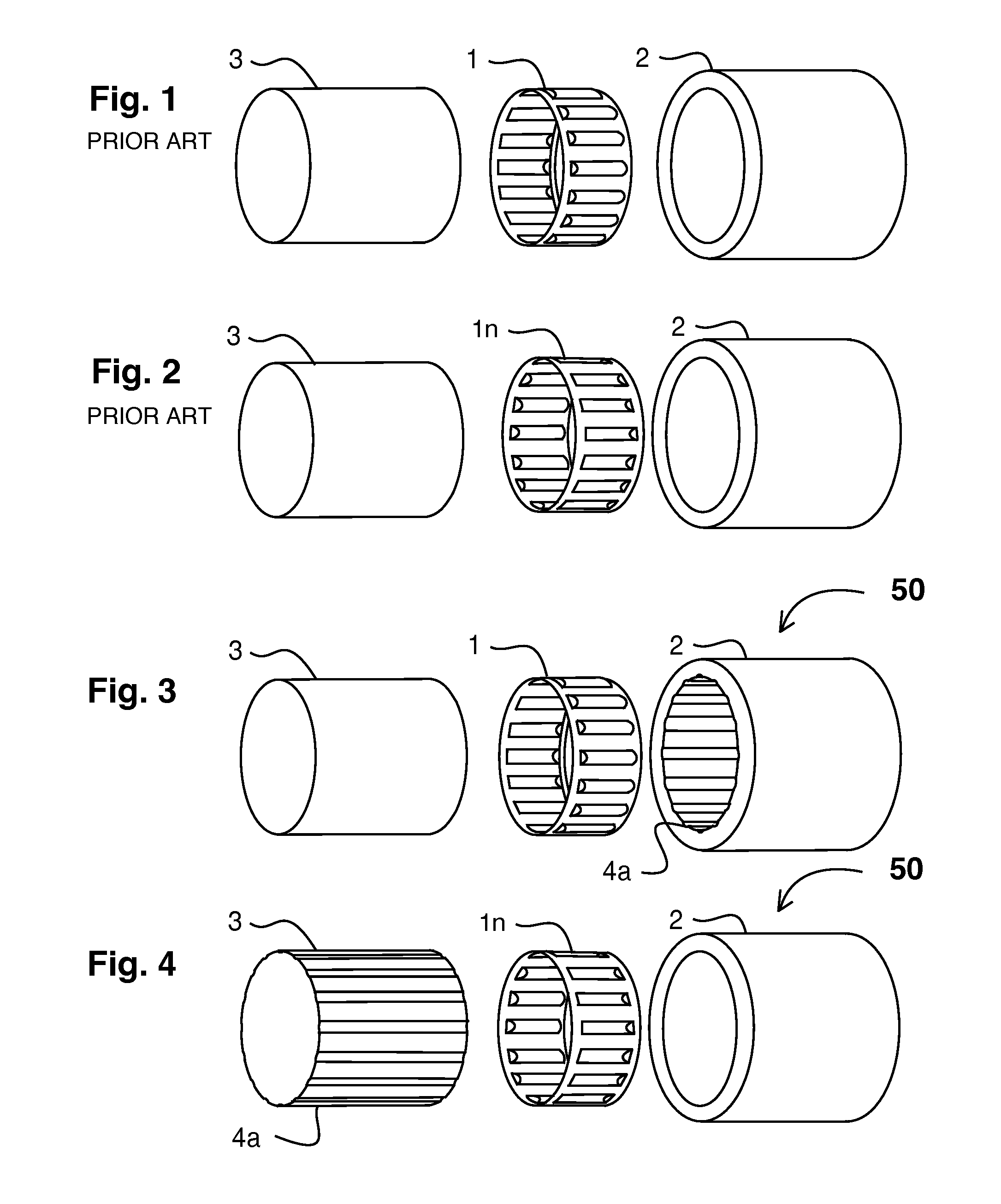

InactiveUS6849021B2Reduces material usageShorten assembly timeDifferential gearingsControl devicesLimited-slip differentialGear wheel

A lightweight limited slip differential for a tubular or independent axle assembly. The differential biases the torque applied to the wheels through clutch rings engaged on the pinions. The pinions include a mating surface that engage a similar profile on the clutch rings. The clutch rings may be frictionally restrained or coupled together so that the pinion movement is restrained to bias the torque between the wheels.

Owner:FORD GLOBAL TECH LLC

Torque Limiting System

InactiveUS20160230866A1Simple and durable and cost-effectiveImprove functionalitySlip couplingCouplings for rigid shaftsLow speedLimited-slip differential

The present invention relates to torque transfer and torque limiting system technology and applications. This invention relates to providing improved torque limiting systems that employ tolerance rings for controlling transmitting power between a single power-input shaft and one or more power-output shafts, which can protect mechanical equipment and drivetrains from damage by mechanical overload. Relating to motor vehicle differentials, the present invention can control differentiation between two power-output shafts, or drive shafts by providing friction internal to said differential and limit “undesirable” slip or differentiation between wheels, as might occur when one wheel encounters a low-traction condition, providing a limited-slip differential.

Owner:BAIR LING TECH LLC

Drive force transmission apparatus, control method of drive force transmission apparatus, and limited slip differential

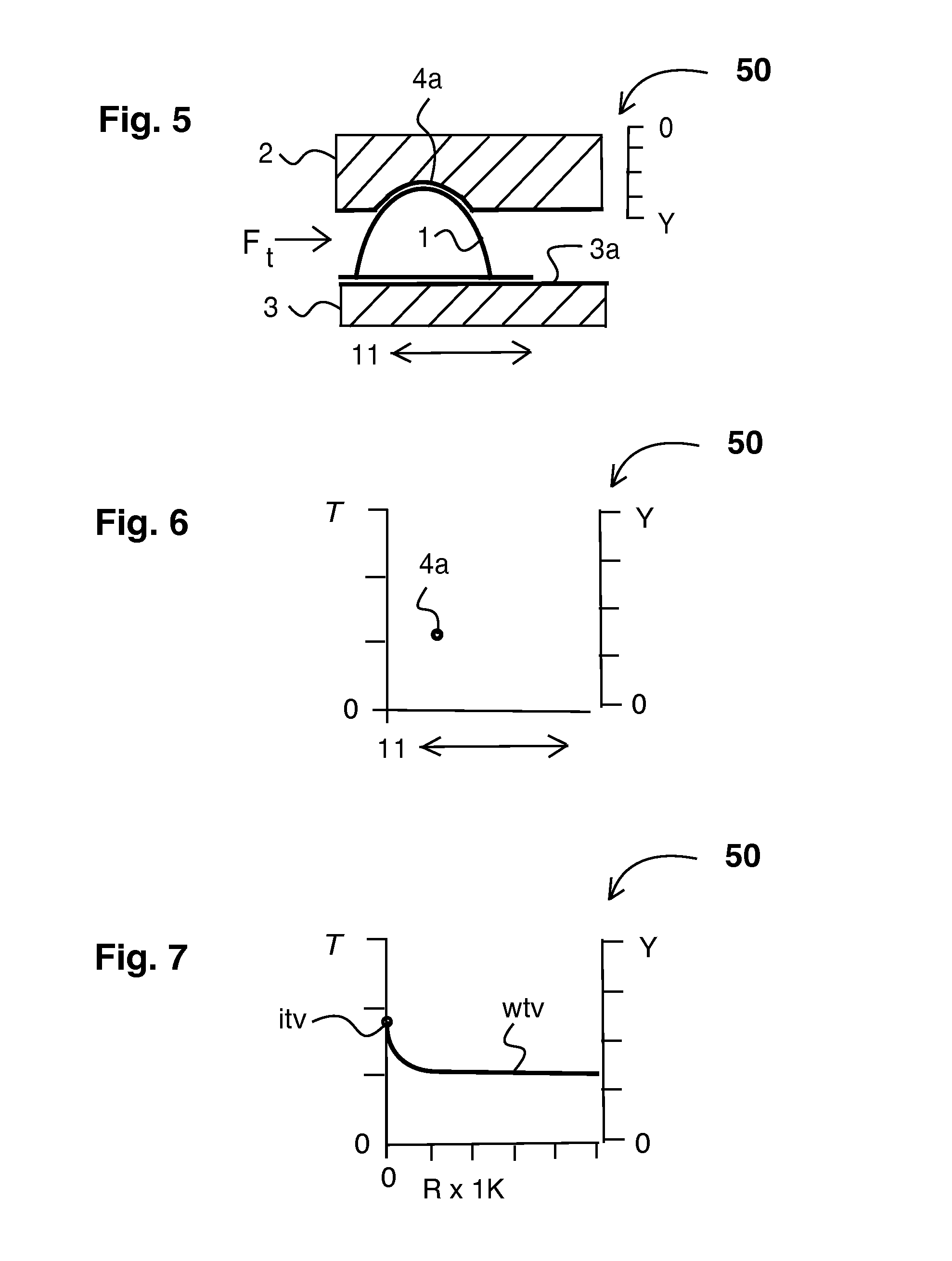

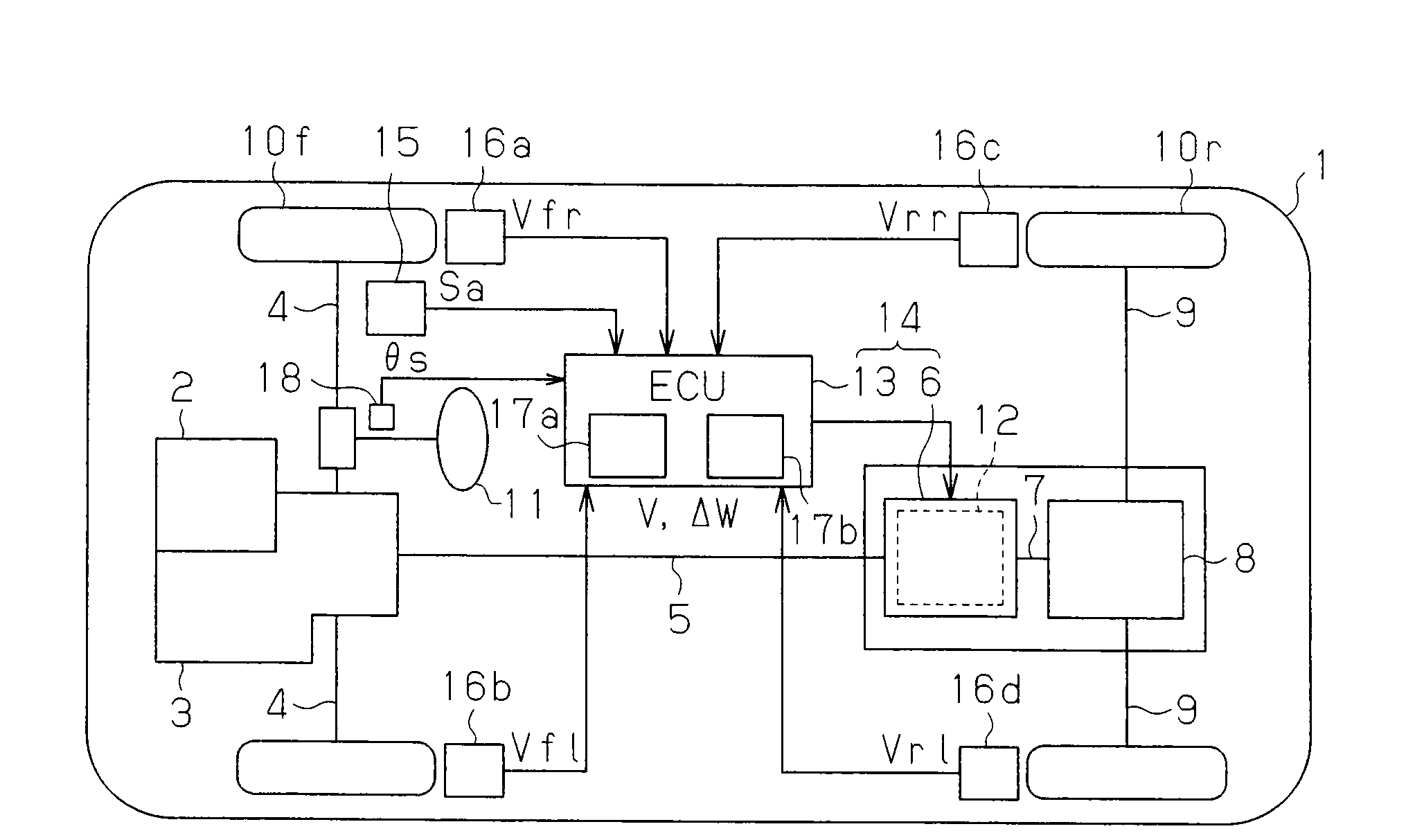

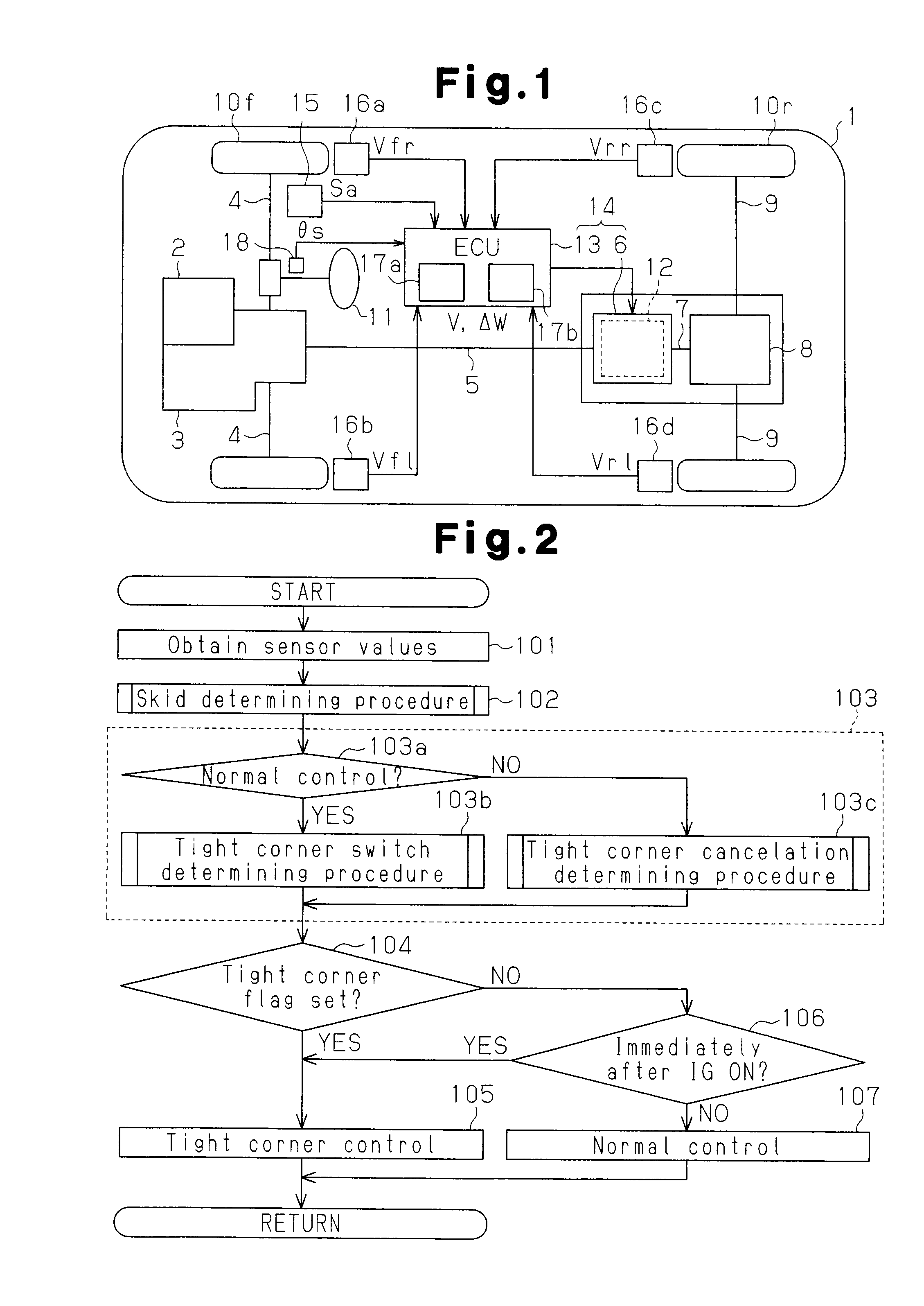

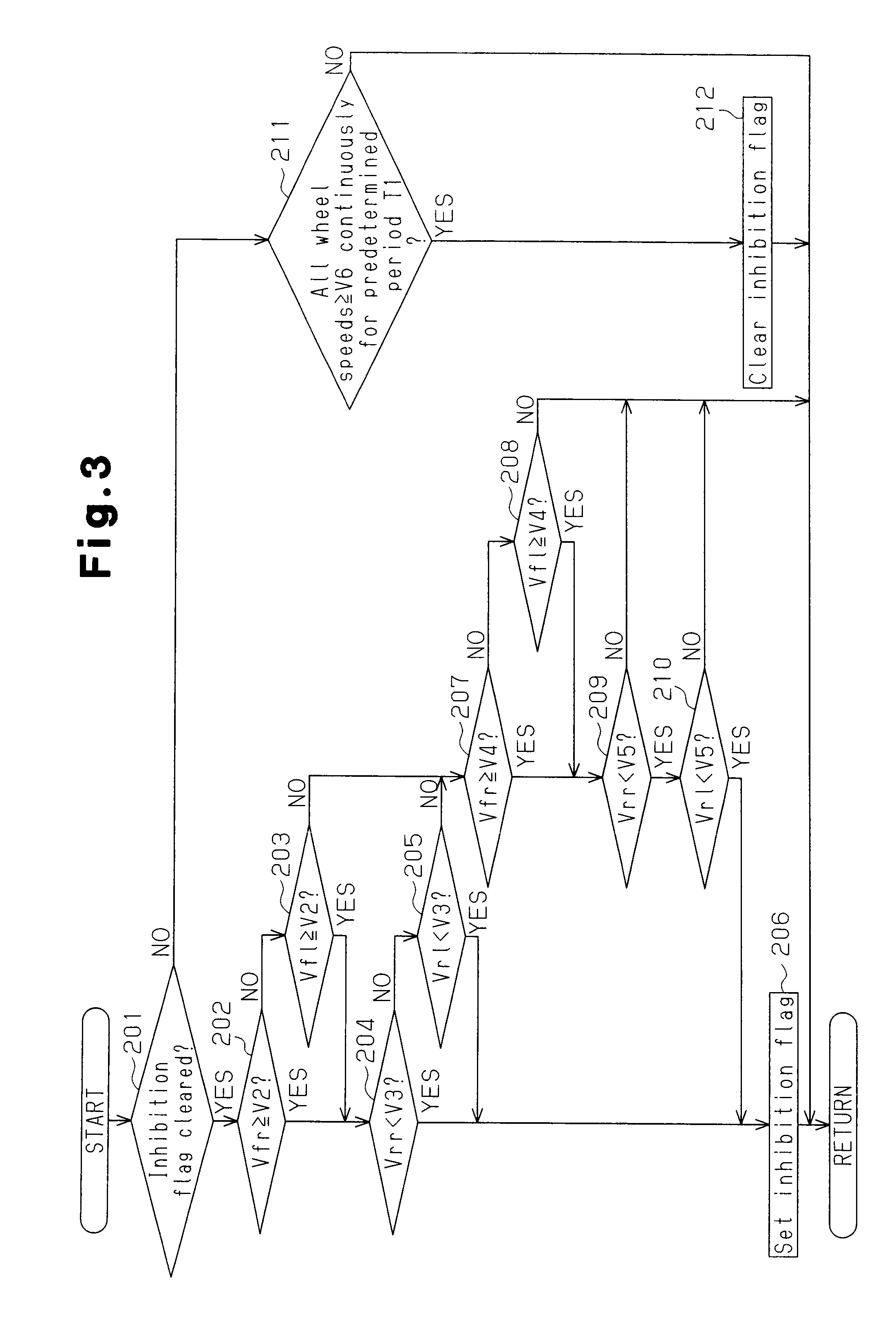

ActiveUS20090248268A1Improve traction performanceReduce coefficient of frictionDigital data processing detailsAutomatic steering controlTurn angleSteering wheel

When determining that a vehicle is not skidding, the ECU carries out tight corner control if vehicle speed is smaller than the upper limit value of the vehicle speed range corresponding to the starting state of the vehicle and the steering wheel turning angle of a steering wheel is greater than or equal to the minimum value of the steering wheel turning angle at which the tight corner braking phenomenon may occur. When determining that the vehicle is skidding, the ECU inhibits the tight corner control even if the vehicle speed is smaller than the upper limit value and the steering wheel turning angle is greater than or equal to the minimum value of the steering wheel turning angle at which the tight corner braking phenomenon may occur.

Owner:JTEKT CORP

Limited slip differential device suitable for downsizing

InactiveUS20050266954A1Reduce overall outer diameterSecurely holdDifferential gearingsControl devicesLimited-slip differentialMiniaturization

Helical teeth are provided on surfaces of a pinion gear, a ring gear and a sun gear, and ring gear is arranged on a concentric axis with sun gear in a relatively rotatable manner. The helical teeth of pinion gear engage with both helical teeth of sun gear and ring gear. Carrier is arranged on the concentric axis with sun gear in a rotatable manner relative to sun gear and ring gear, and supports pinion gear in a rotatable manner. With a structure of ring gear sandwiching carrier and ring gear with a first sidewall portion and a second sidewall portion provided to extend inwardly in a radial direction, a thrust reaction force generated to perform a differential limitation function can be held without providing a housing to cover ring gear from the outside. With this, downsizing of a limited slip differential device can be attained.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com