Helical tooth limited slip differential with automatic locking function

A limited-slip differential and automatic locking technology, applied in the field of auto parts, can solve problems such as tail drift, the vehicle cannot be driven, and slip, and achieve the effect of inhibiting wheel slip and ensuring safe driving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is described in detail below with reference to accompanying drawing and embodiment:

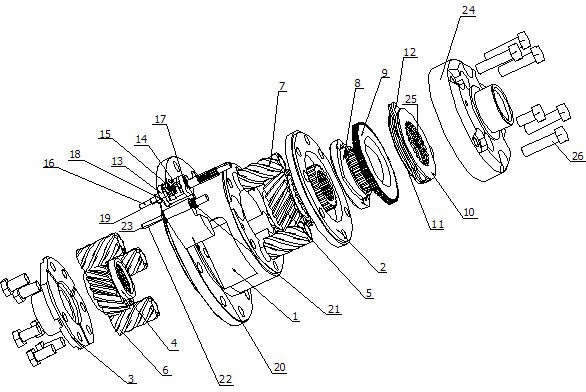

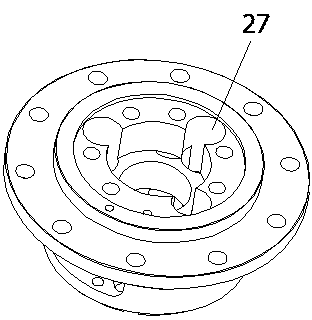

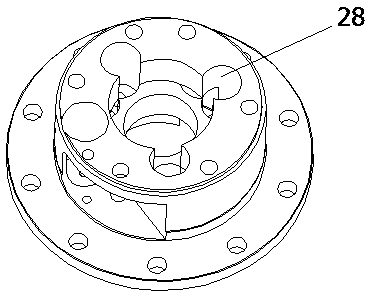

[0041] attached Figures 1 to 7 It can be seen that a helical tooth limited-slip differential with automatic locking function includes a housing 1, and a left side gear 4 and a right side gear 5 are symmetrically arranged in the housing 1; the left side gear 4 and the three The left planetary gear 6 meshes; the three left planetary gears 6 are arranged in three left side planetary gear holes 27 parallel to the housing axis on the left side of the housing 1; the right side shaft gear 5 meshes with the three right planetary gears 7; three Three right planetary gears 7 are arranged in three right side planetary gear holes 28 parallel to the housing axis on the right side of the housing 1; three left planetary gears 6 mesh with three right planetary gears 7 respectively, and the housing 1 There is a locking device.

[0042] The locking device includes a connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com