Turn flow type hydraulic limited slip differential

A limited-slip differential, hydraulic technology, applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of hydraulic oil leakage and recovery, achieve controllable locking coefficient, improve dynamic performance and Passable, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

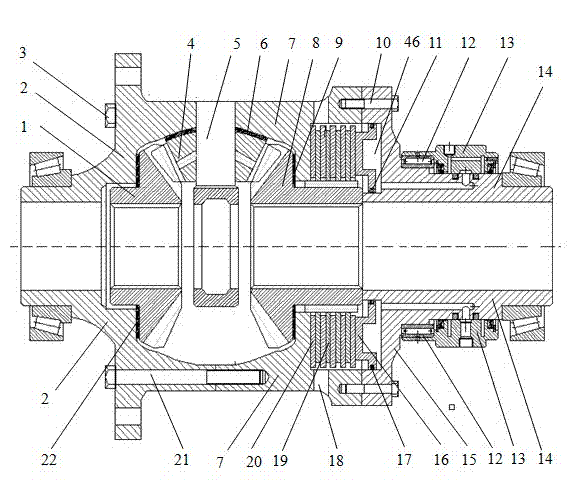

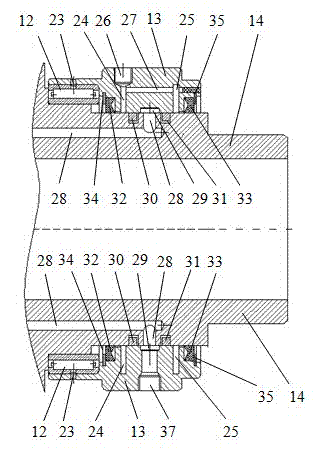

[0037] The return type hydraulic limited-slip differential of the present invention mainly includes a casing, a differential mechanism, a limited-slip friction pair, an annular piston, an oil delivery plate and the like. Figure 1 to Figure 13 The structure of one embodiment of the present invention is shown, and will be described in detail below.

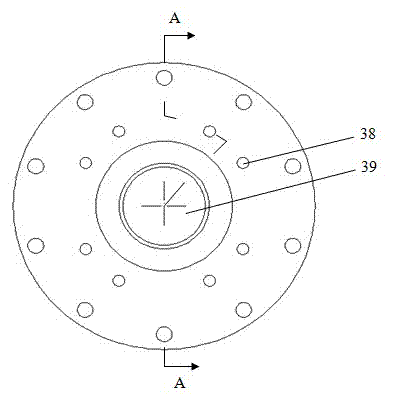

[0038] exist Figure 1 to Figure 13 In the shown structure, the casing of the return type hydraulic limited-slip differential of the present invention is composed of a left casing 2 , a middle casing 7 , and a right casing 15 . Wherein, the left housing 2 is provided with a central hole 39 and a semicircular positioning groove 36; the middle housing 7 is recessed on both sides, and a web 42 with a central hole 44 is provided inside, and the left side of the middle housing 7 is provided with There are positioning grooves 43, and the inner side of the right peripheral edge of the middle housing 7 is provided with some axial grooves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com