Patents

Literature

232 results about "Aluminium preparations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Smelting preparation method of high-strength aluminum alloy profile

The invention discloses a smelting preparation method of a high-strength aluminum alloy profile. The smelting preparation method comprises the following operation steps: (1) configuring an aluminum alloy melt: mixing the following raw materials in parts by weight: 55-60 parts of 6063 aluminum ingot, 30-40 parts of waste aluminum product, 5-10 parts of chromium carbide and 5-7 parts of glass slag powder, adding the raw materials into a smelting furnace, heating till a furnace charge is softened and collapses, and scattering a layer of covering agent on the surface of a molten solution for covering; and properly stirring the melt after the furnace charge is completely molten so as to enable the temperature in a melting bath to be uniform and consistent and finally adding a magnesium ingot into the melt. The waste aluminum material is added into the raw materials for mixing so as to be conductive to stabilizing the performances of the aluminum profile and reducing the possibility of affecting the quality of the aluminum profile due to the appearance of the non-detected materials during the smelting of aluminum liquid; the formula is further optimized so as to increase the strength and the hardness of an aluminum alloy and be conductive to improving the comprehensive properties of the aluminum alloy profile; and the surface of the aluminum alloy profile is chromized, so that the anti-corrosion capability of an oxide film on the surface of the aluminum alloy profile and the bonding force between the aluminum alloy profile and a coating are improved.

Owner:惠州市荣利发五金铝制品有限公司

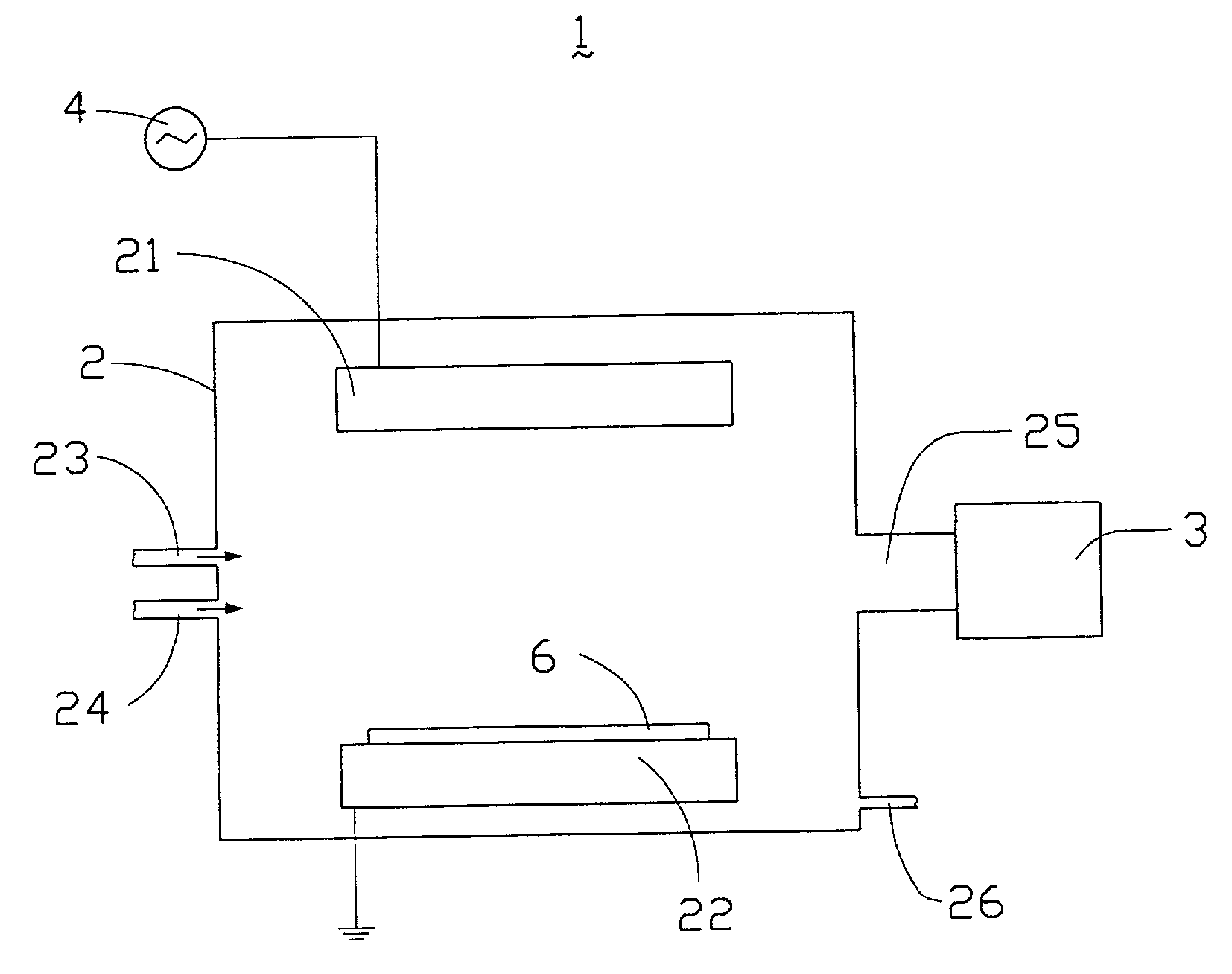

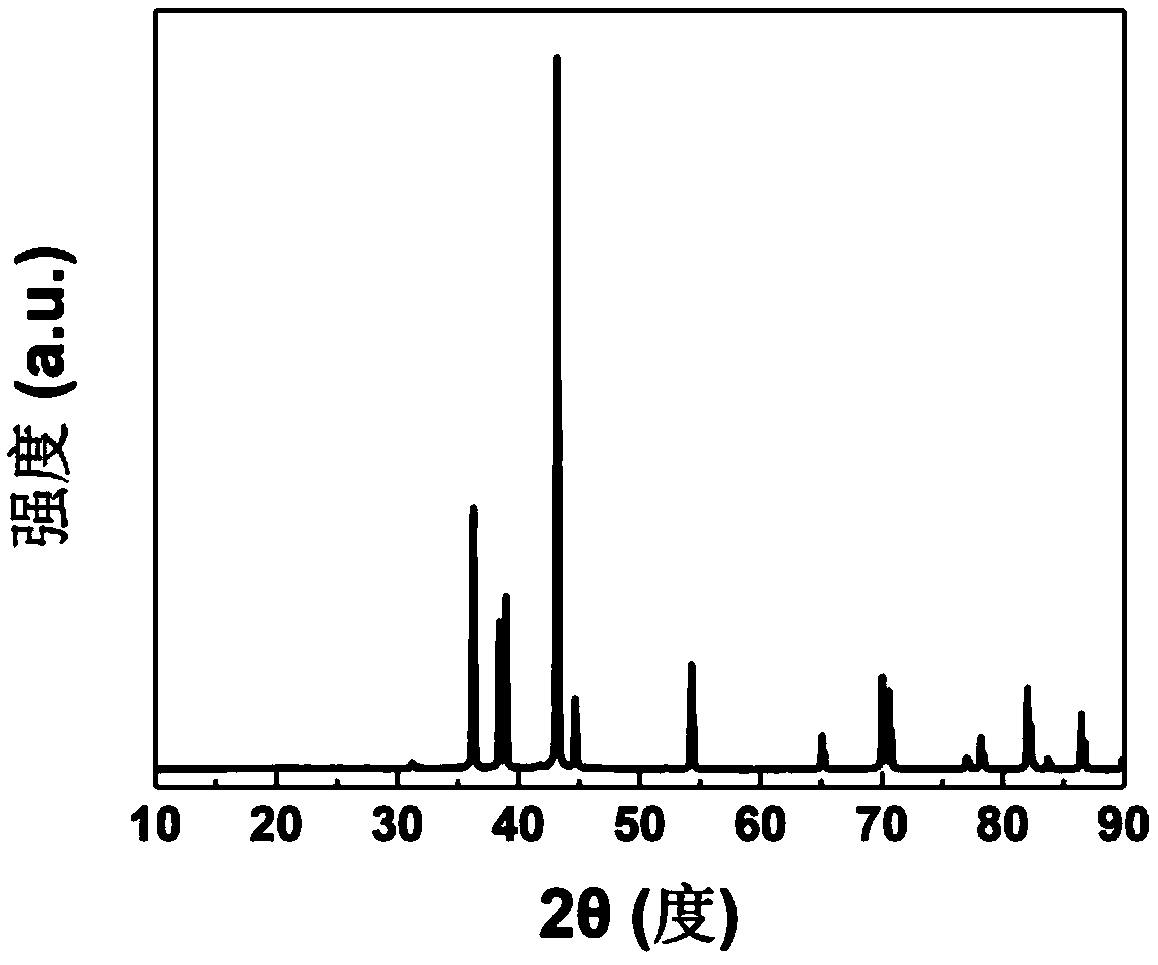

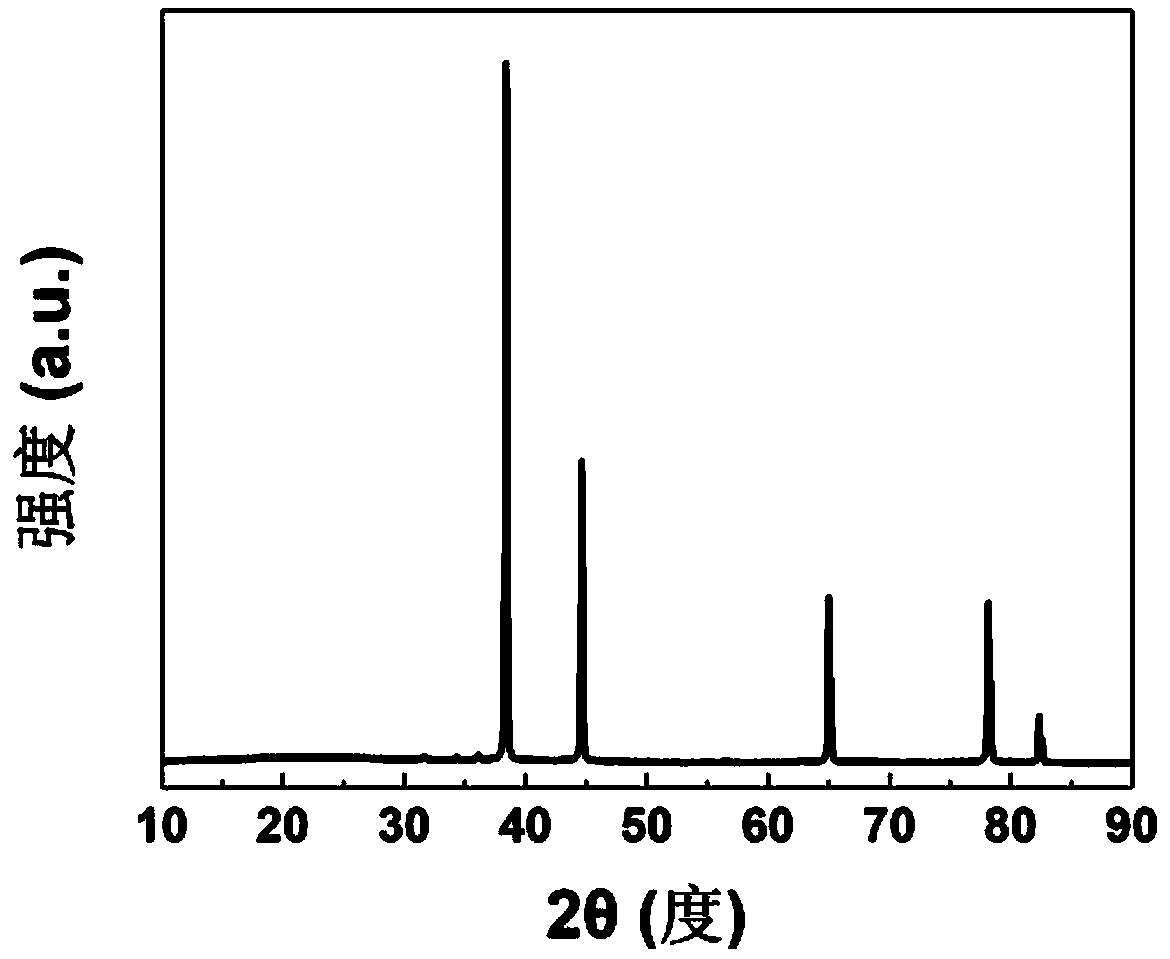

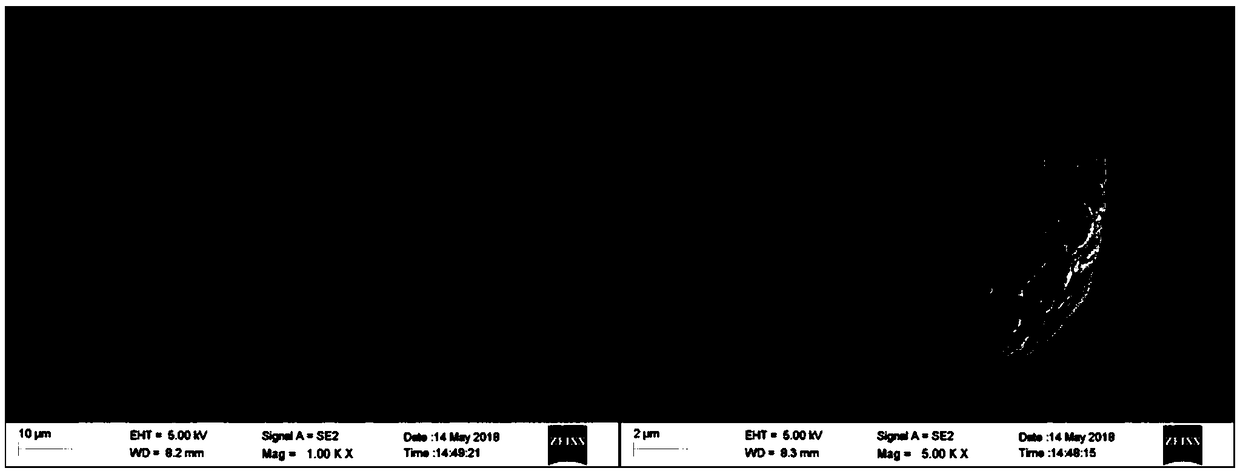

Preparation method of wear-resistant toughened composite ceramic layer on surface of aluminum alloy product

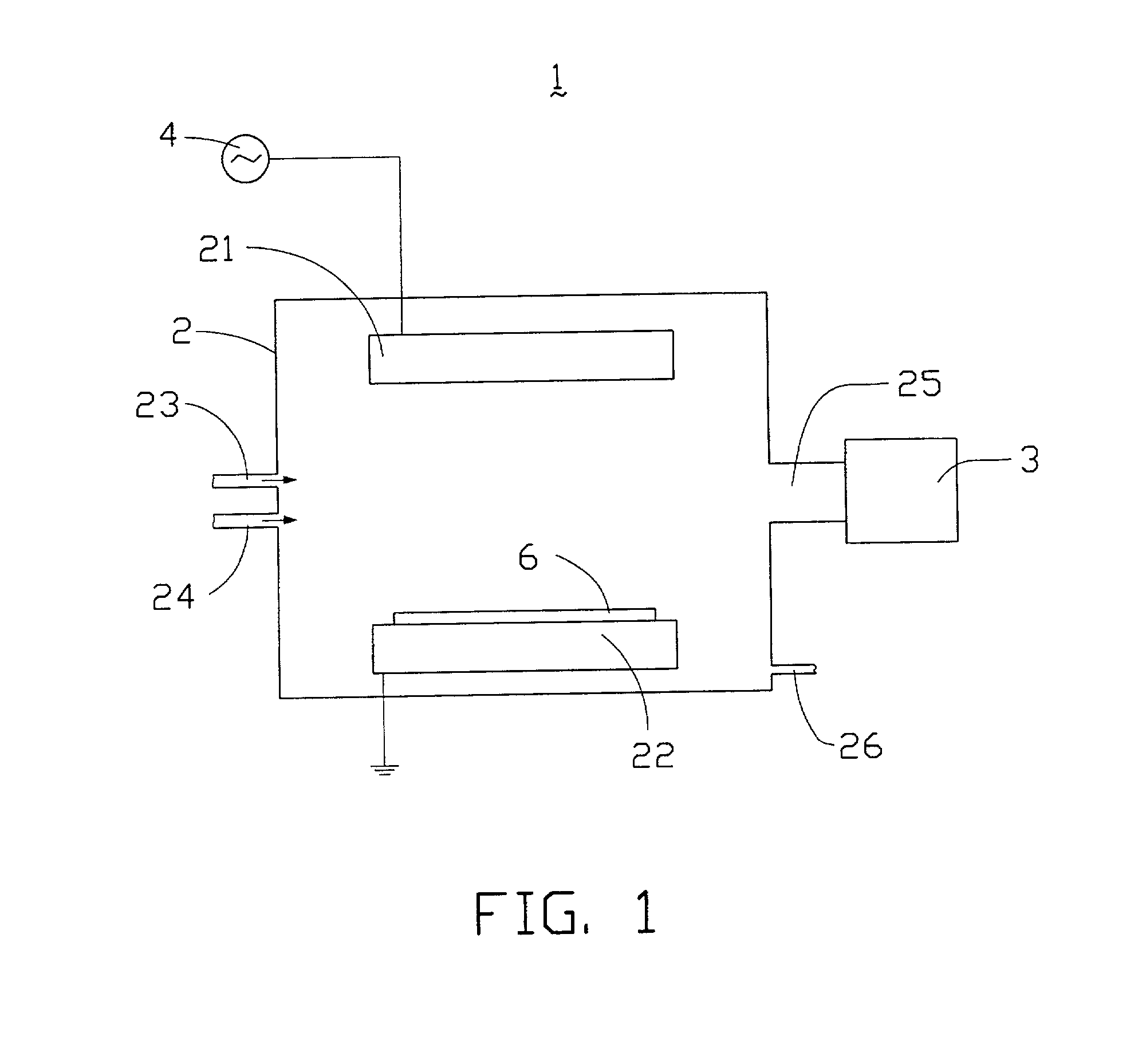

InactiveCN102605402AImprove bindingImprove wear resistanceAnodisationMicro arc oxidationComposite ceramic

The invention relates to a preparation method of a wear-resistant toughened composite ceramic layer on the surface of an aluminum alloy product. The wear-resistant toughened composite ceramic layer is prepared by a micro-arc oxidation technology and a cold hole sealing method on the surface of the aluminum product for industrial use. The method comprises the following steps: forming a composite ceramic film layer on the surface of the aluminum alloy by the micro-arc oxidation process, wherein in the film layer, aluminum oxide is taken as a substrate, and dispersed silicon carbide nano-particles and zirconium oxide nano-particles are taken as toughened phases; then performing cold hole sealing on micro-holes of the composite ceramic film layer formed in the process of micro-arc oxidation, and generating nickel oxide and aluminum hydroxide filling phases in the micro-holes, so as to densify the composite ceramic film layer. The wear resistance, the corrosion resistance and the obdurability of the material are significantly improved through the composite film layer, so that the purpose of industrial use is achieved; and meanwhile the industrial application range of the material can be enlarged by the composite film layer.

Owner:SOUTHEAST UNIV

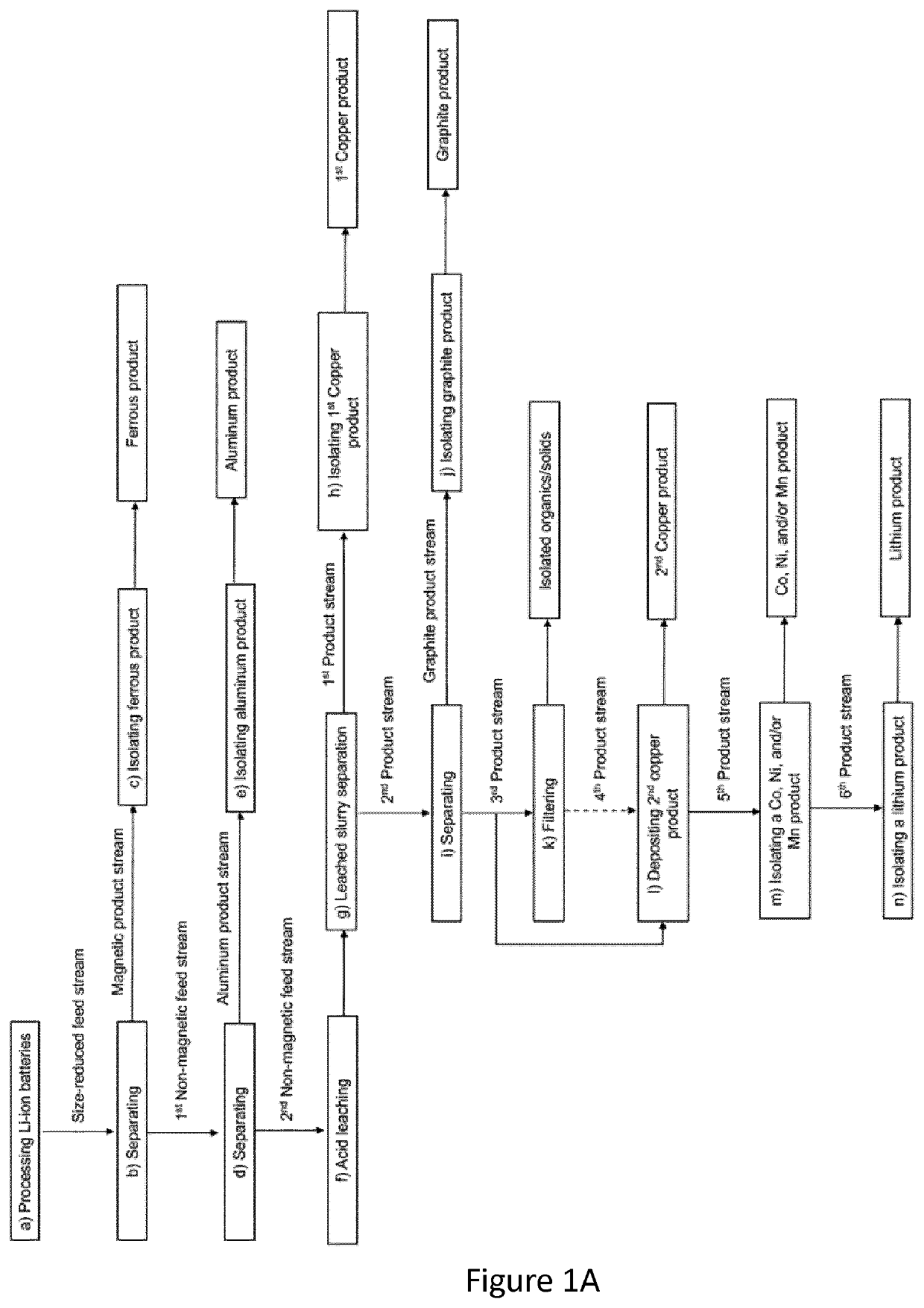

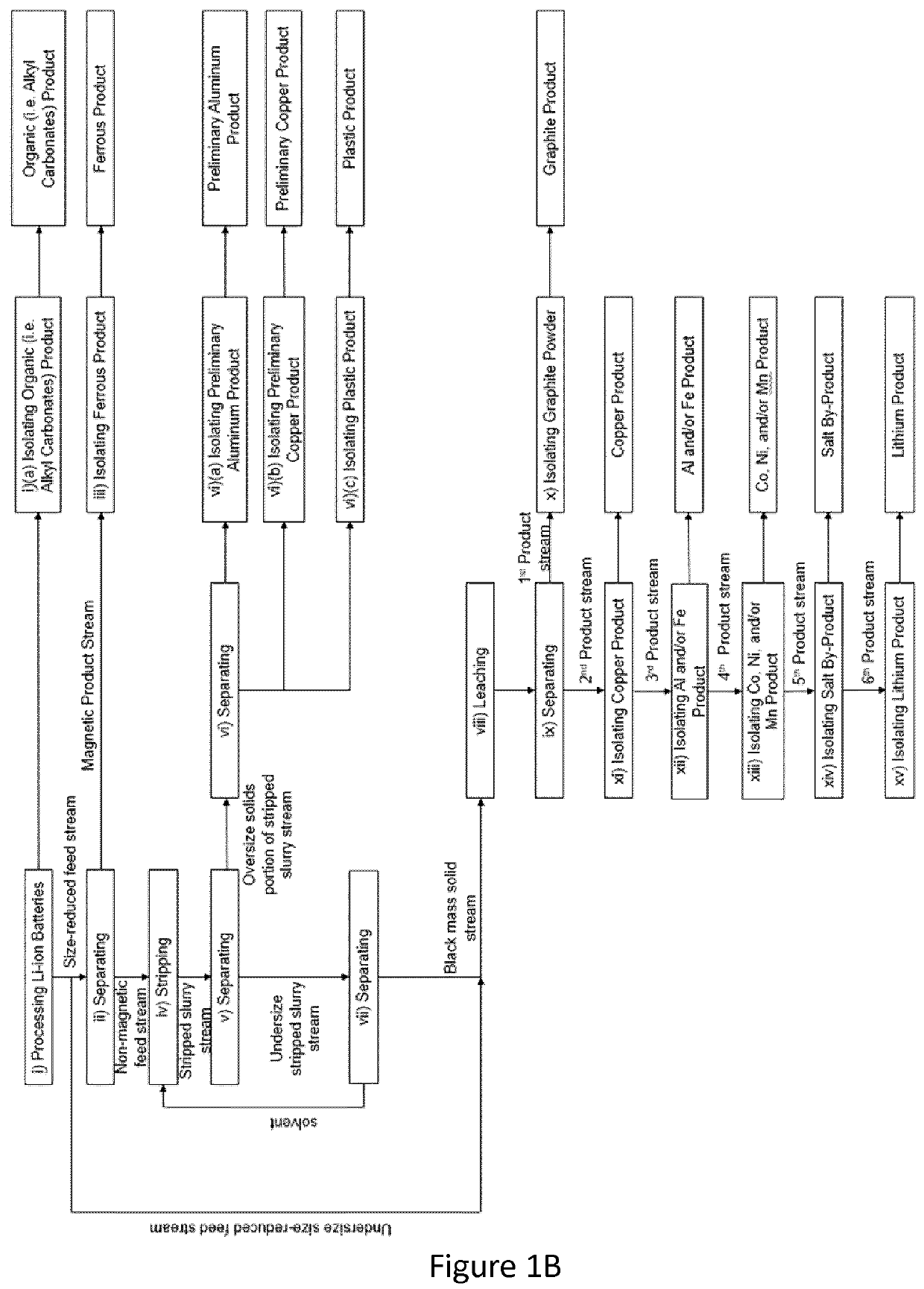

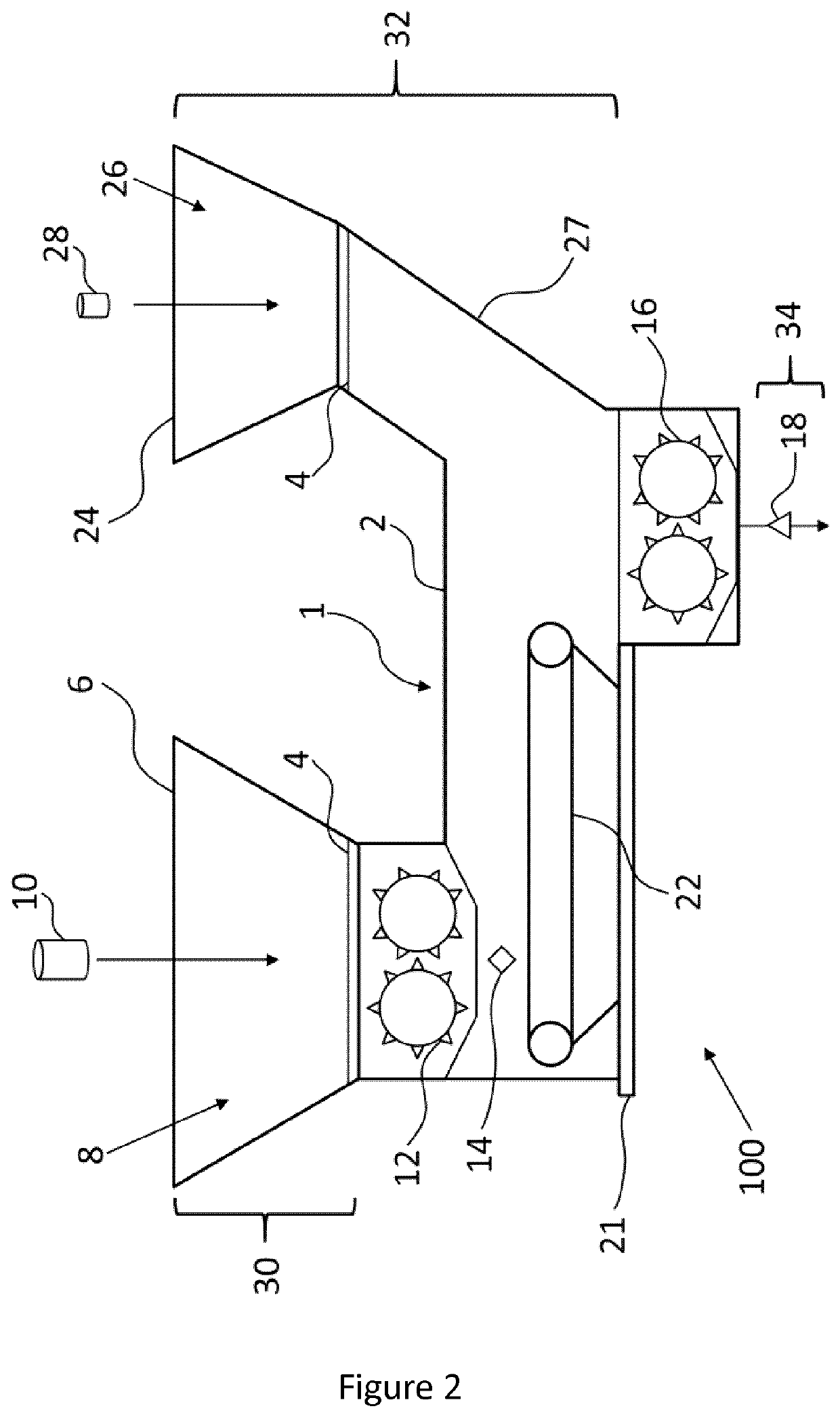

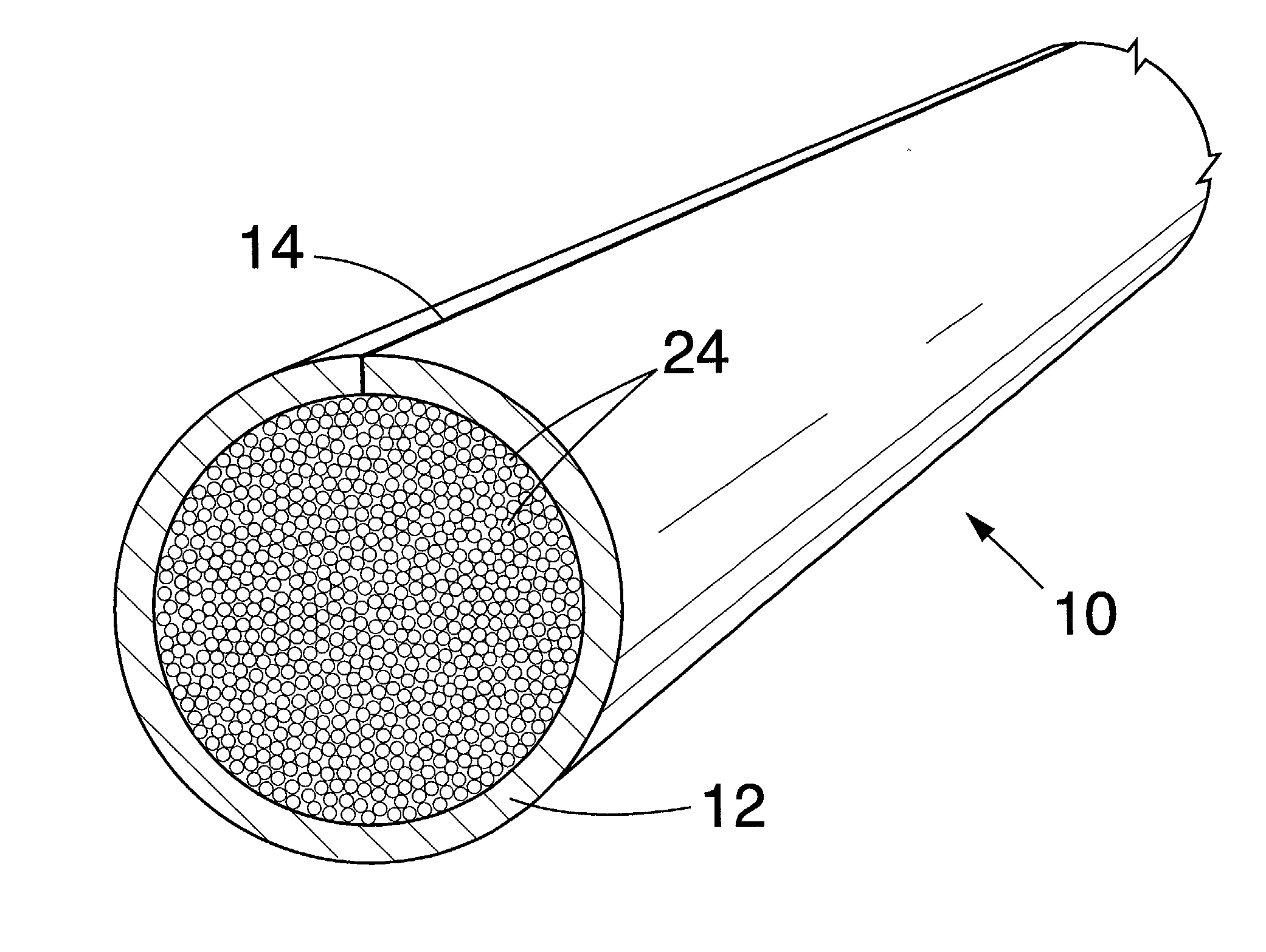

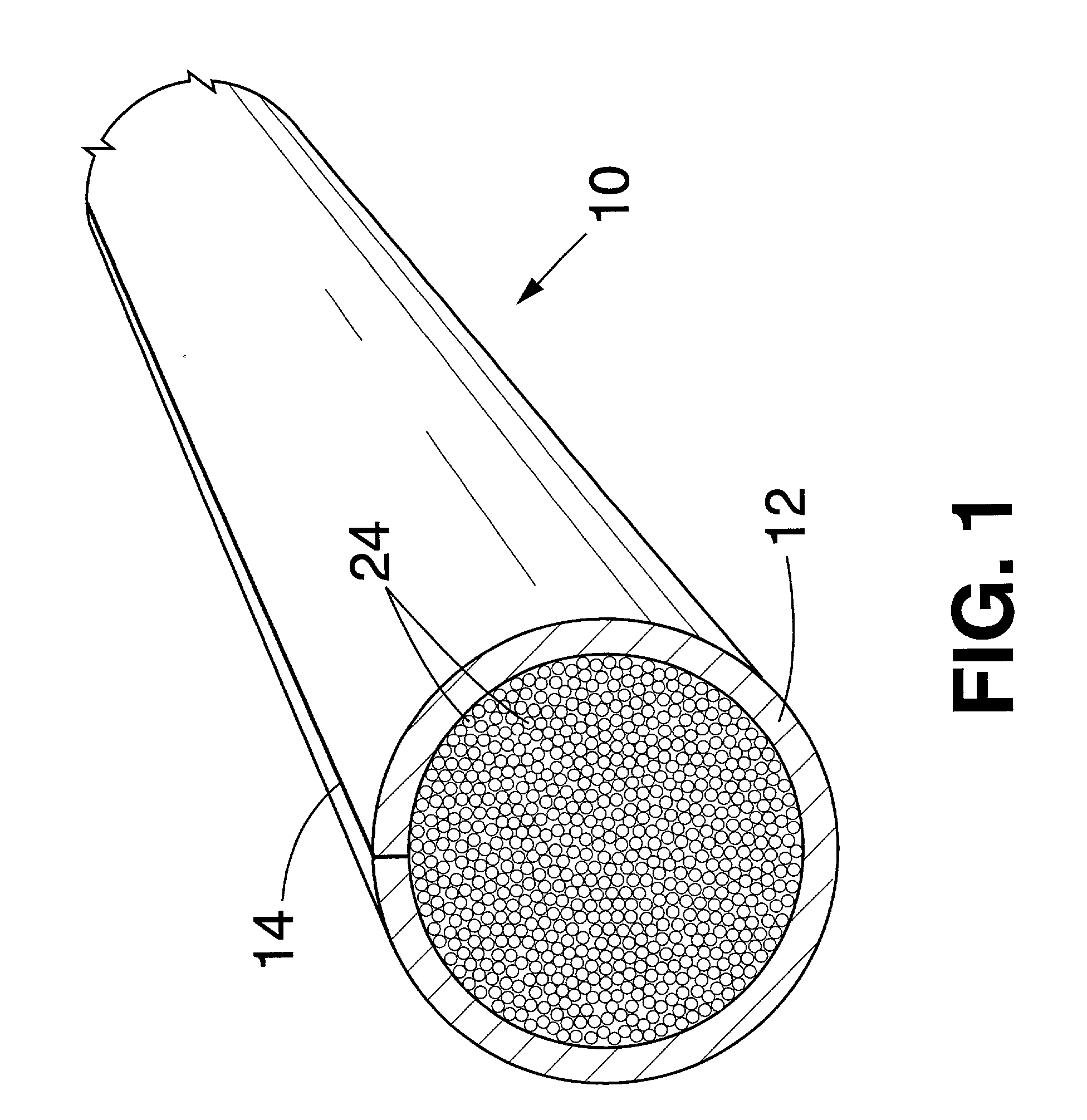

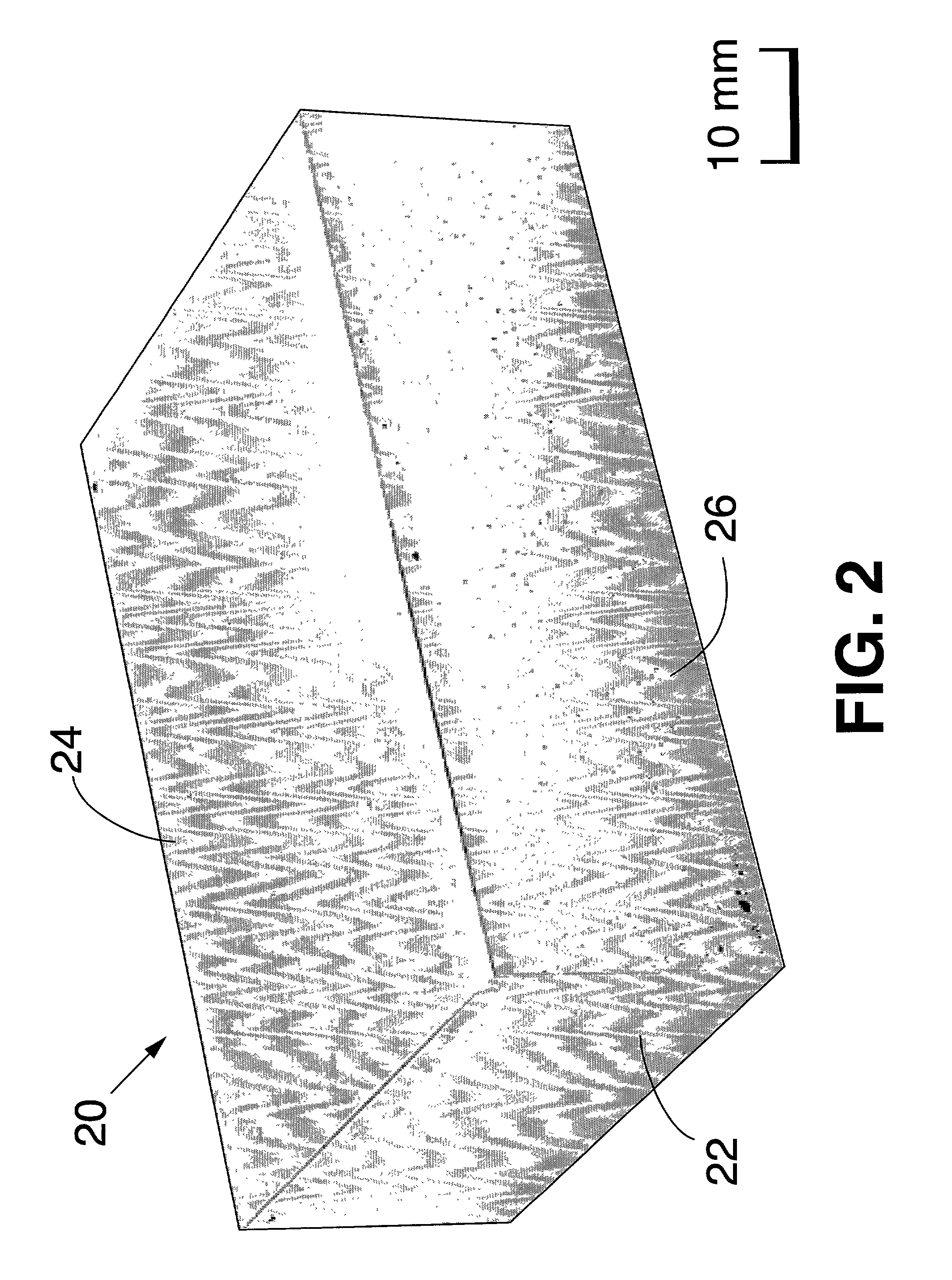

Process, apparatus, and system for recovering materials from batteries

ActiveUS20200078796A1Small sizeWaste accumulators reclaimingFlotationAluminium preparationsProcess engineering

The present application provides a process to recover materials from rechargeable lithium-ion batteries, thus recycling them. The process involves processing the batteries into a size-reduced feed stream; and then, via a series of separation, isolation, and / or leaching steps, allows for recovery of a copper product, cobalt, nickel, and / or manganese product, and a lithium product; and, optional recovery of a ferrous product, aluminum product, graphite product, etc An apparatus and system for carrying out size reduction of batteries under immersion conditions is also provided.

Owner:LI CYCLE CORP

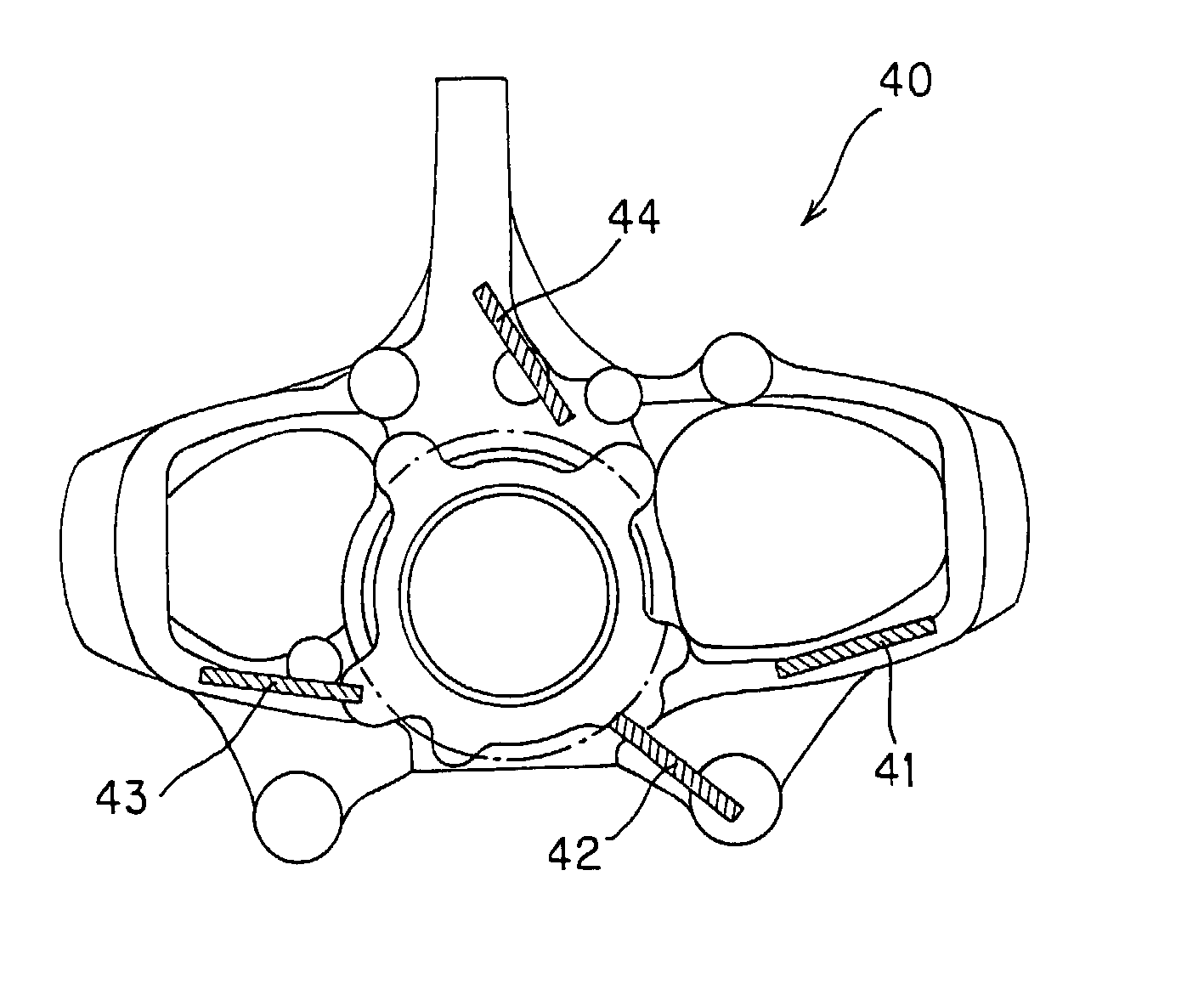

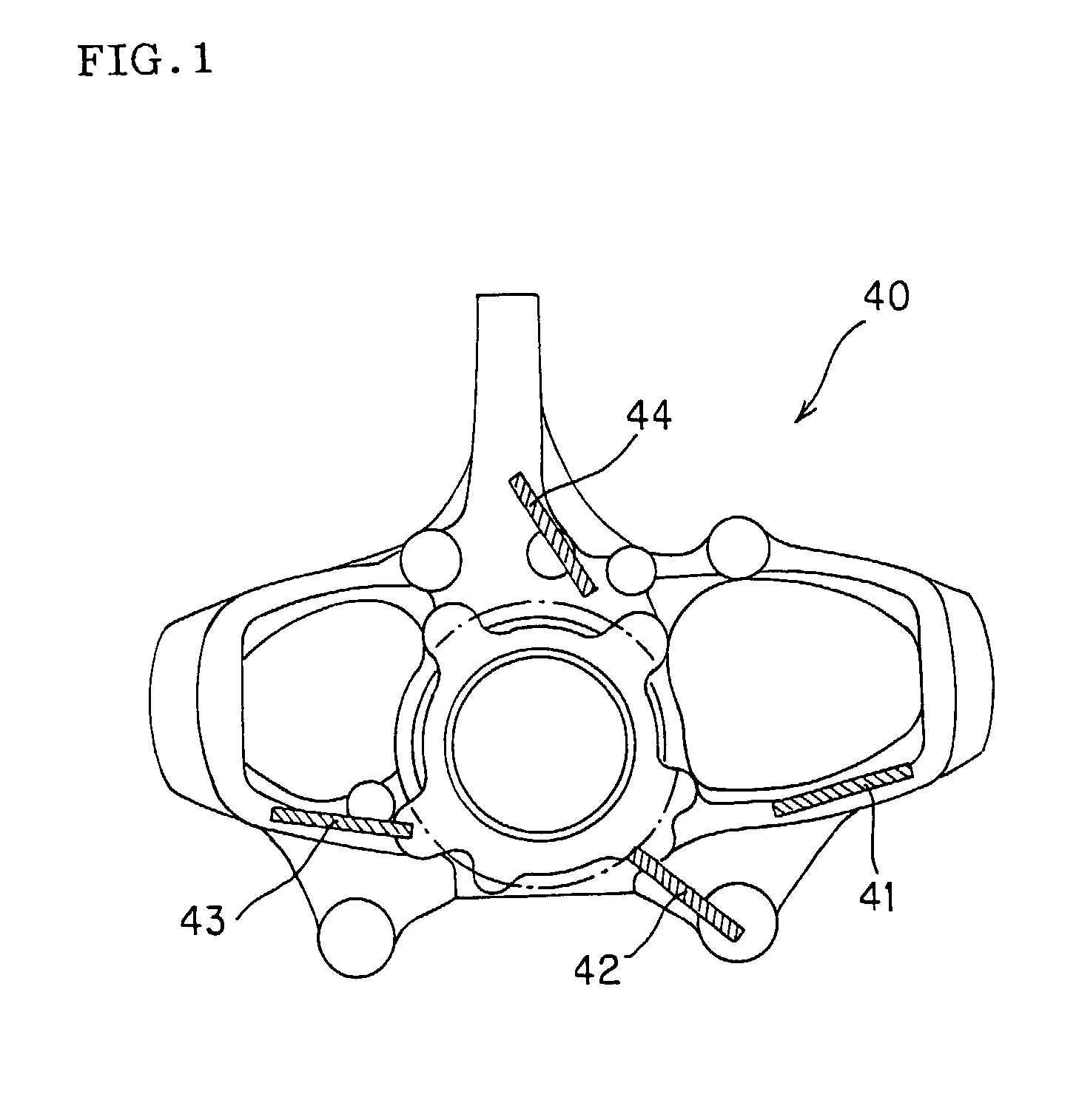

Aluminum alloy for casting-forge, and aluminum casting forged product and manufacturing method therefor

InactiveUS20030010412A1High strengthLow costSuspensionsSteering linkagesConventional castingManganese

An aluminum casting forged product is provided by using an aluminum alloy for casting forge including a useless raw material for forging such as flash as a raw material and by controlling a weight percentage of an alloy element such as silicon, magnesium, copper, and manganese; the product having an enhanced fluidity, and an improved castability, with retaining a sufficient strength, preventing useless intermetallic compounds from forming, restraining deterioration due to oxidation and corrosion, and further improved strength by a forging effect: and there is also provided a simple manufacturing method, with a high yield and high productivity. An aluminum casting forged product of high tensile strength, high proof, and elongation, higher mechanical properties than those of the conventional casting forged product, high corrosion resistance, and high quality without defects, and being low in cost is also obtainable as a thick-wall aluminum product.

Owner:ASAHI TEC CORP +1

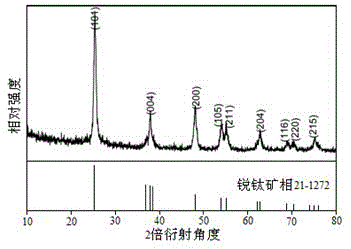

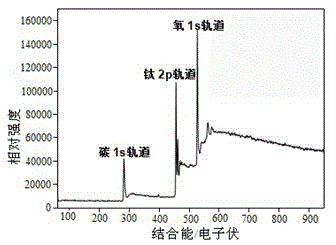

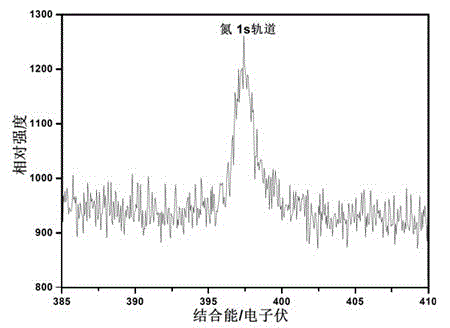

Aluminum product coated with nitrogen-doped graphene/nitrogen-doped TiO2 photo-catalytic material

InactiveCN103949278AImprove adsorption capacityPromote decompositionDispersed particle separationCatalyst activation/preparationDoped grapheneMeth-

The invention provides an aluminum product coated with a nitrogen-doped graphene / nitrogen-doped TiO2 photo-catalytic material. The aluminum product is prepared according to the following steps: preparing graphene oxide by using a method disclosed from the page 4806 to the page 4814 of volume 2010-4 of the journal of Nanometer of the American Chemical Society; adding deionized water, and performing ultrasonic dispersion to obtain graphene oxide dispersion liquid; respectively adding a hexamethylene tetramine solution and a titanium trichloride solution, uniformly mixing, performing hydrothermal reaction, centrifugally washing a precipitate, and drying to obtain the nitrogen-doped graphene / nitrogen-doped TiO2 composite photo-catalytic material; washing and drying an aluminum profile needing to be coated; adding the composite photo-catalytic material into acetonitrile or methyl methacrylate, and performing ultrasonic dispersion; and uniformly spraying the dispersion liquid onto the surface of the aluminum profile, and drying to obtain the aluminum product coated with the nitrogen-doped graphene / nitrogen-doped TiO2 composite photo-catalytic material. According to the aluminum product, photo-catalysis can be generated under the irradiation of indoor light, indoor air is purified, and indoor pollutants are reduced.

Owner:SHANGHAI RONGFU NEW MATERIAL

A kind of aluminum product chemical polishing liquid and preparation method thereof

The invention discloses chemical polishing solution for aluminum products and a preparation method thereof, which relate to chemical polishing solution. The invention provides chemical polishing solution for aluminum products, which has the advantages of producing little yellow smoke, avoiding polluting environment, containing no nitric acid and the like, achieves the same polishing effect as a nitric acid improved 'three-acid' polishing process which is equal to the conventional 'three-acid' process and can reduce release of nitric oxides to protect the environment from being polluted, and apreparation method thereof. The chemical polishing solution for aluminum products is prepared from the following raw materials: sulfuric acid, phosphoric acid, boric acid, passivator, antifog brightener, citric acid, tartaric acid and water. The preparation method comprises the following steps: adding the solid raw materials into water; after the solid raw material dissolve, adding phosphoric acid and sulfuric acid in turn; and after the solution is cool, transferring the solution to a volumetric flask to fix the volume. The using method of the chemical polishing solution for aluminum products comprises: heating the chemical polishing solution for aluminum products to 95 to 110 DEG C; immersing dry and clean aluminum products to be polished into the chemical polishing solution for aluminum products, treating for 30 to 100 seconds, and taking aluminum products out; and immersing the collected aluminum products to be polished in nitric acid for bright dipping for 25 to 120 seconds, washing and thus, accomplishing the polishing of aluminum products.

Owner:XIAMEN UNIV

Smelting preparation method of aluminum alloy section with good stability

ActiveCN103103399AImprove performanceAffect qualitySolid state diffusion coatingAluminium preparationsSurface oxidation

The invention discloses a smelting preparation method of an aluminum alloy section with good stability. The smelting preparation method comprises the following operating steps of: (1) preparing an aluminum alloy melt which is prepared form the following raw materials in parts by weight: 55-65 parts of 3003 aluminum ingots, 32-42 parts of discarded aluminum products, 5-10 parts of boron carbide and 5-10 parts of nanometer silica sand powder; and adding the raw materials into a smelting furnace, heating till the furnace charges begin to soften and collapse, and then spreading a layer of covering agent on the surface of the melt, wherein the covering agent comprises the following components in parts by weight: 10-20 parts of CaO, 10-25 parts of Al2O3, 35-45 parts of SiO2, 12-30 parts of C and 12-23 parts of pulverized fuel ash. According to the smelting preparation method, the performance of the aluminum section can be kept stable as the discarded aluminum material is added in components, and the probability that the quality of the aluminum section is influenced as a material is not detected during smelting of molten aluminum is reduced; and the surface of the aluminum alloy section is subjected to chromation, so that the anticorrosive capability of an oxide film on the surface of the aluminum alloy section and the binding force between the aluminum alloy section and a coating are improved.

Owner:武汉鸿劲金属铝业有限公司

Smelting preparation method of heat insulation aluminum alloy profile

InactiveCN103103416AImprove performanceHigh strengthMetallic material coating processesChromium carbideAluminium preparations

The invention discloses a smelting preparation method of a heat insulation aluminum alloy profile. The smelting preparation method comprises the following operation steps: (1) configuring an aluminum alloy melt: mixing the following raw materials in parts by weight: 50-60 parts of aluminum ingot, 30-40 parts of waste aluminum product, 5-10 parts of chromium carbide and 5-7 parts of glass slag powder, adding the raw materials into a smelting furnace, heating till a furnace charge is softened and collapses, and scattering a layer of covering agent on the surface of metal for covering; and properly stirring the melt after the furnace charge is completely molten so as to enable the temperature in a melting bath to be uniform and consistent and finally adding a magnesium ingot into the melt. The waste aluminum material is added into the raw materials for mixing so as to be conductive to stabilizing the performances of the aluminum profile and reducing the possibility of affecting the quality of the aluminum profile due to the appearance of the non-detected materials during the smelting of aluminum liquid; the formula is further optimized so as to increase the strength and the hardness of an aluminum alloy and be conductive to improving the comprehensive properties of the aluminum alloy profile; and the surface of the aluminum alloy profile is chromized, so that the anti-corrosion capability of an oxide film on the surface of the aluminum alloy profile and the bonding force between the aluminum alloy profile and a coating are improved.

Owner:东莞市旺美铝制品有限公司

Smelting preparation method for anti-cracking aluminum alloy section bar

InactiveCN103103400AImprove performanceHigh strengthSolid state diffusion coatingAluminium preparationsSmelting process

The invention discloses a smelting preparation method for an anti-cracking aluminum alloy section bar. The smelting preparation method comprises the following operation steps: (1) preparing aluminum alloy melt, wherein the aluminum alloy melt is prepared from the following materials in parts by weight: 55-65 parts of 3003 aluminum ingots, 32-42 parts of waste aluminum products, 5-10 parts of boron carbide and 5-10 parts of nanometer quartz sand powder; adding the materials to a smelting furnace; scattering a layer of covering agent to the surface of the melt to cover the melt when the furnace materials are heated up to be softened and collapsed, wherein the covering agent comprises the following components in parts by weight: 10-20 parts of CaO, 10-25 parts of Al2O3, 35-45 parts of SiO2, 12-30 parts of C and 12-23 parts of coal ashes. According to the smelting preparation method disclosed by the invention, the waste aluminum materials are added to the material ingredients, and the waste aluminum materials are smelted by one step and stable in components, and so the waste aluminum waste materials added to the ingredients are beneficial to stabilizing the performances of the aluminum section bar and reducing the possibility that the quality of the aluminum section bar is affected by undetected materials during the smelting process of the melt. The dosage proportion of the relevant ingredients in the aluminum section bar formula is adjusted, so that the formula is further optimized.

Owner:WUHU HENGKUN AUTO PARTS

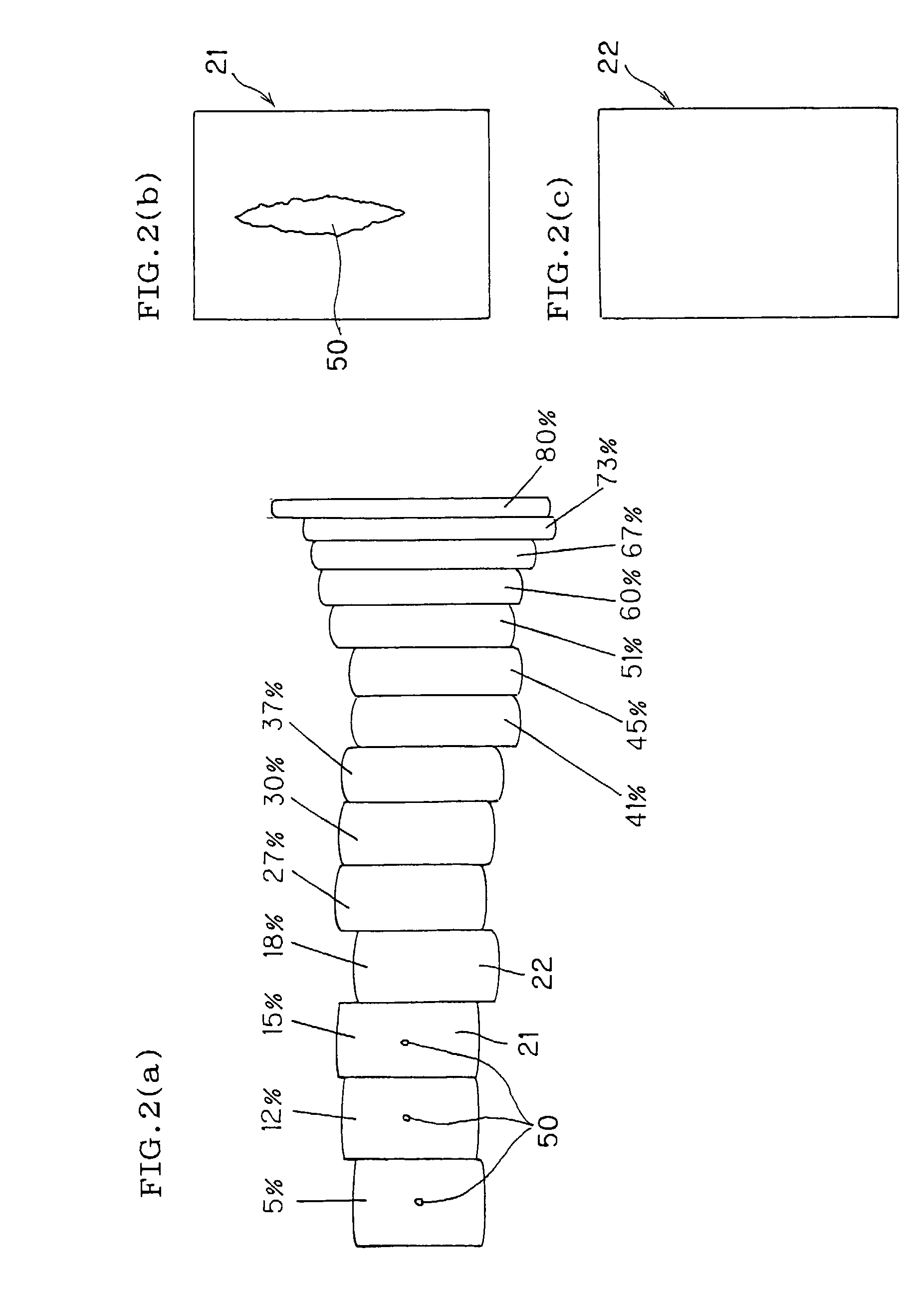

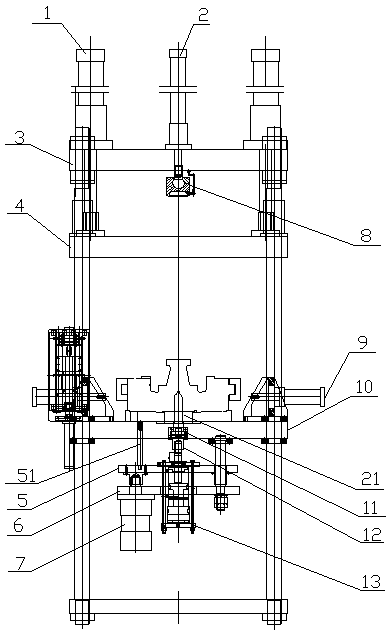

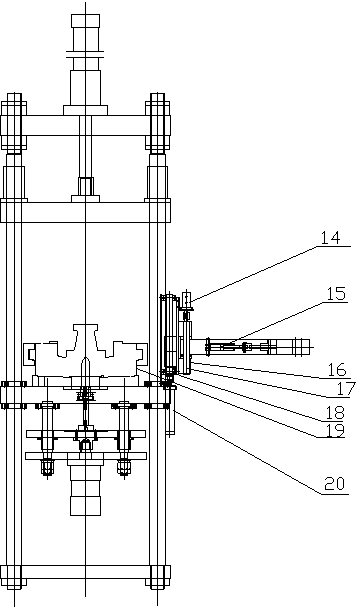

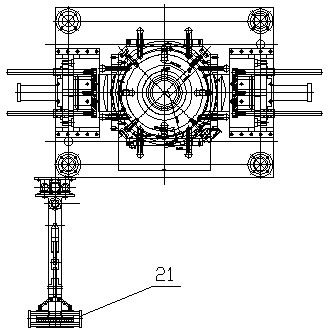

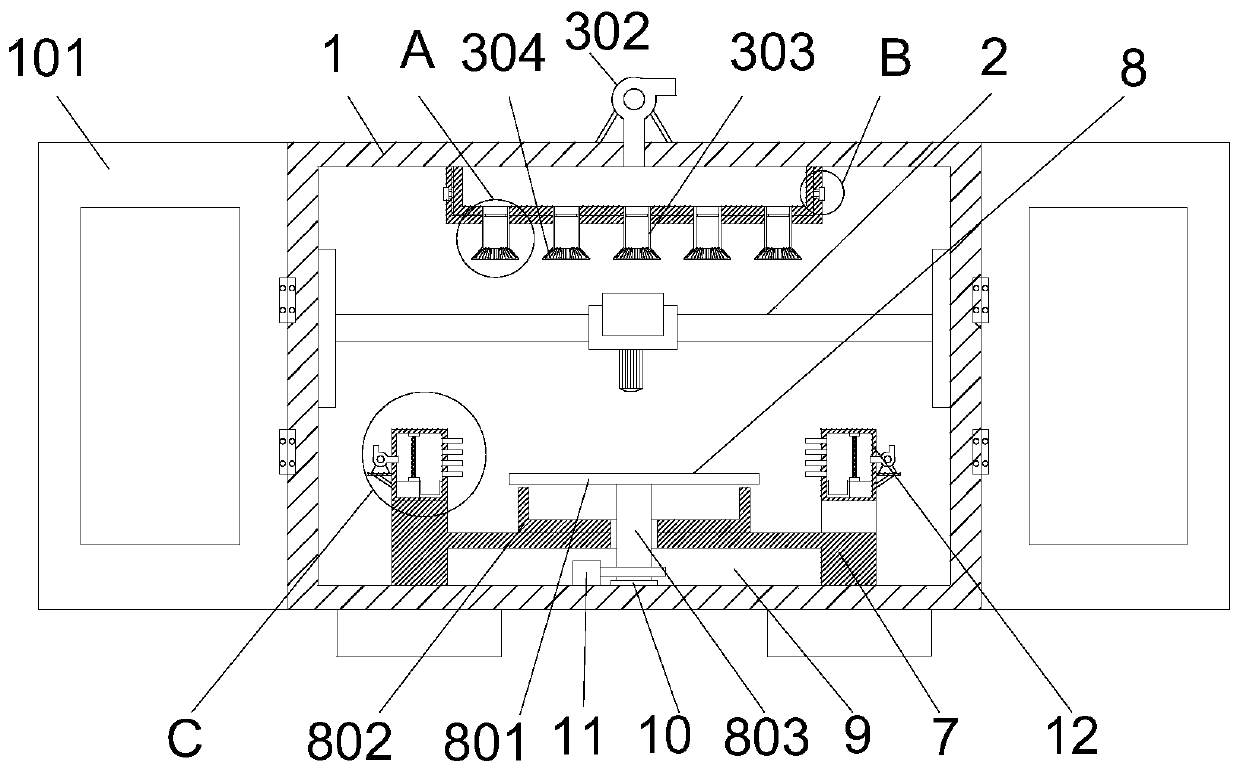

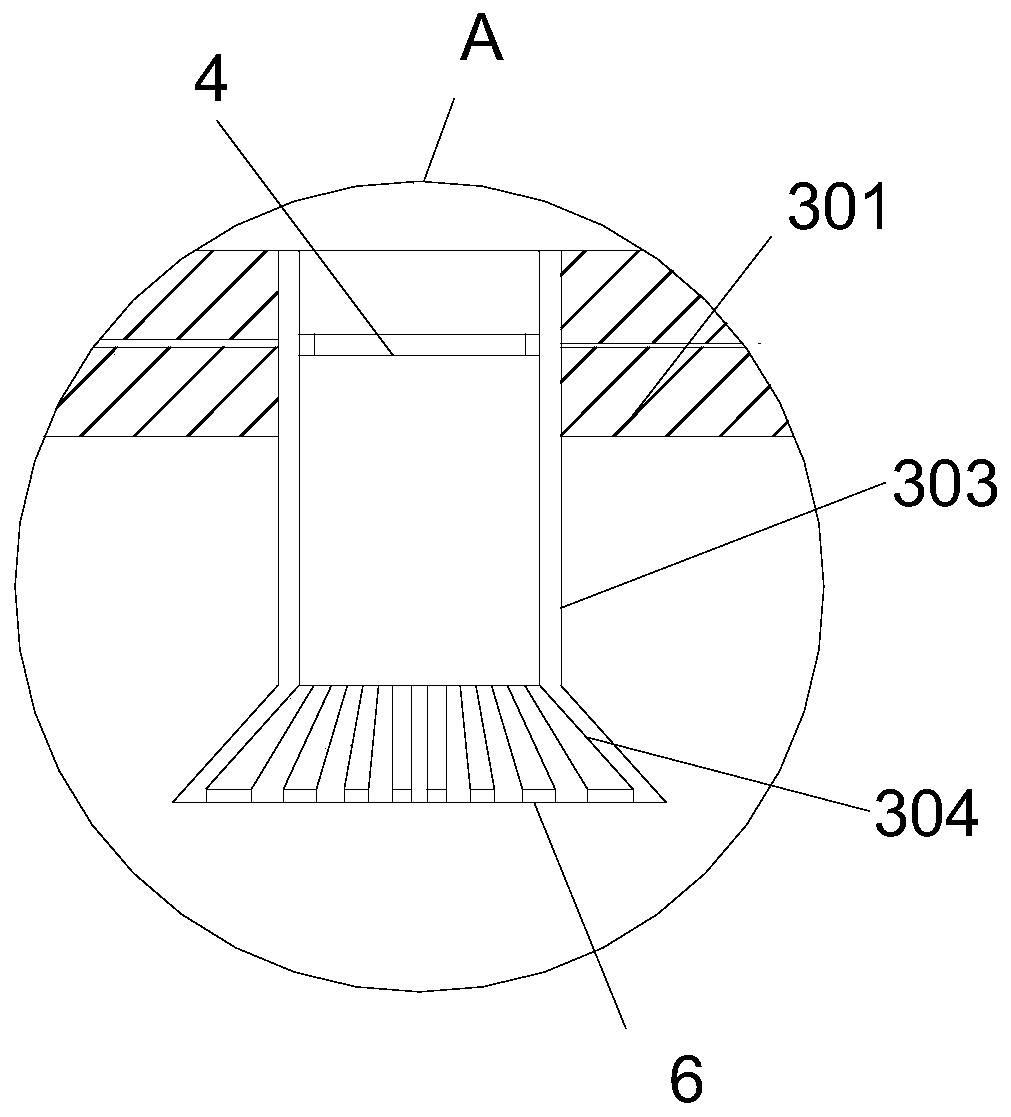

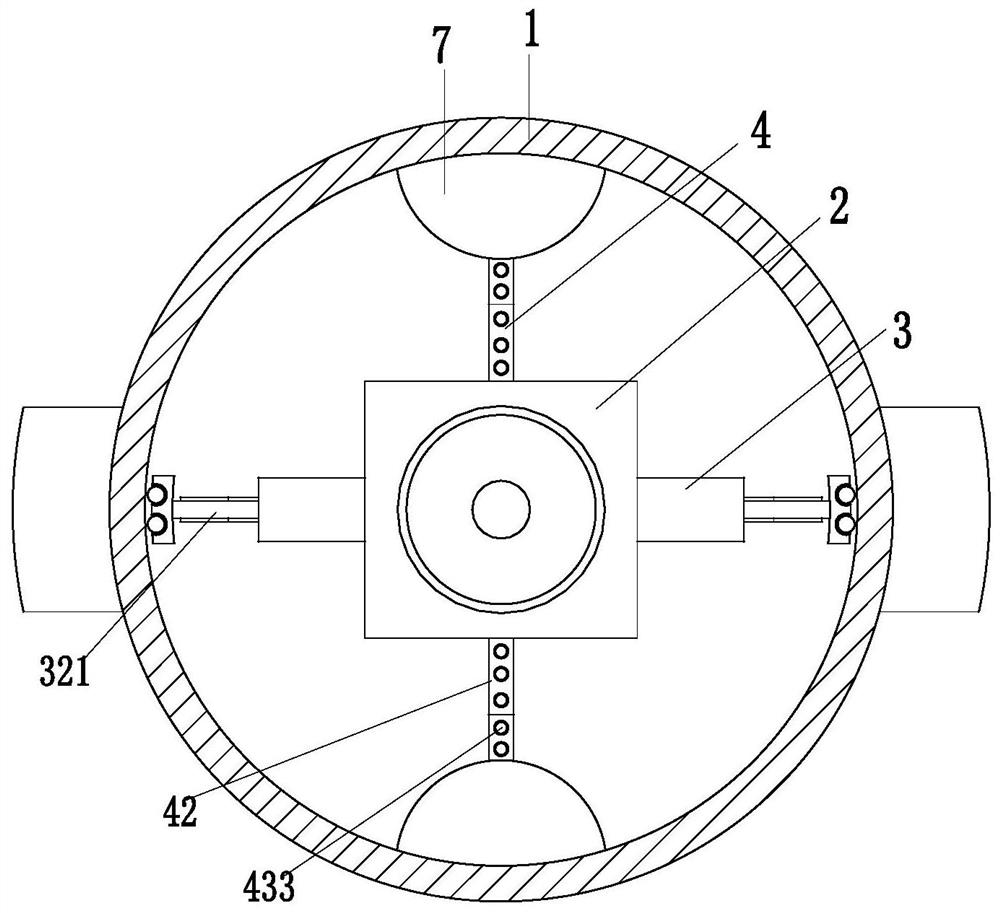

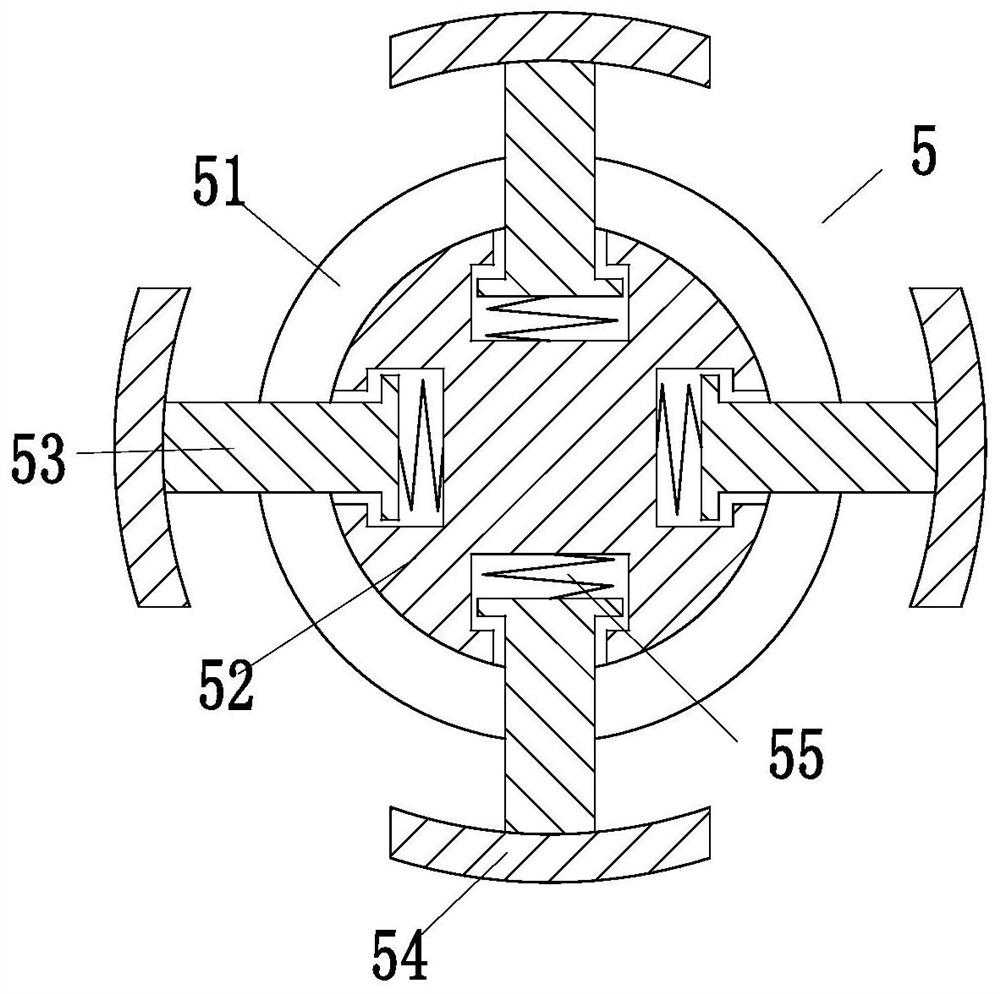

Aluminum product high-pressure casting device and method

The invention discloses a novel aluminum product high-pressure casting machine and relates to the field of metal product casting. A traditional structure is improved, operation is more convenient and accurate, casting efficiency is improved, the density of products is improved by applying high pressure in a sequential increasing mode, the surface quality and the mechanical performance of the products are improved, the weight of the products is reduced under the premise that quality of the products is improved, and energy is saved.

Owner:TAIAN XINCHUANG ALUMINUM PROD CO LTD

Smelting preparation method of chromized aluminum alloy profile

The invention discloses a smelting preparation method of a chromized aluminum alloy profile. The smelting preparation method comprises the following operational steps: (1) configuring an aluminum alloy melt: mixing the following raw materials in parts by weight: 55-60 parts of 6063 aluminum ingot, 30-40 parts of waste aluminum product, 5-10 parts of chromium carbide and 5-7 parts of glass slag powder, adding the raw materials into a smelting furnace, heating till a furnace charge is softened and collapses, and scattering a layer of covering agent on the surface of a molten solution for covering; and properly stirring the melt after the furnace charge is completely molten so as to enable the temperature in a melting bath to be uniform and consistent and finally adding a magnesium ingot into the melt. The waste aluminum material is added into the raw materials for mixing so as to be conductive to stabilizing the performances of the aluminum profile and reducing the possibility of affecting the quality of the aluminum profile due to the appearance of the non-detected materials during the smelting of the aluminum liquid; and the surface of the aluminum alloy profile is chromized, so that the anti-corrosion capability of an oxide film on the surface of the aluminum alloy profile and the bonding force between the aluminum alloy profile and a coating are improved.

Owner:佛山市聚创家居有限公司

Smelting and preparation method of aluminum alloy profile

InactiveCN103103415AImprove performanceAffect qualityMetallic material coating processesChromium carbideAluminium preparations

The invention discloses a smelting and preparation method of an aluminum alloy profile. The smelting and preparation method comprises the following steps of: preparing an aluminum alloy melt; preparing from the following raw materials in parts by weight: 55-60 parts of aluminum ingots, 30-40 parts of waste aluminum products, 5-10 parts of chromium carbide and 5-7 parts of glass dreg powder, wherein the fineness of the chromium carbide is 5-8 mu m; feeding the raw materials into a smelting furnace, heating till the furnace materials are softened and collapsed down, and scattering a layer of covering agent on the surface of the melt to cover; when the furnace materials are completely smelted, appropriately stirring the melt so as to make the temperatures at every part of the smelting pool uniform; and finally adding magnesium ingots into the melt. By carrying out chromizing treatment on the surface of the aluminum alloy profile, the corrosion resistance of an oxidation film on the surface of the aluminum alloy profile and the binding capability of the aluminum alloy profile with a coating are improved.

Owner:广东江南铝业有限公司

Process of surface treating aluminum articles

InactiveUS20030075452A1Long-lasting attractive appearancePrevent fadingAnodisationSuperimposed coating processMaterials scienceCorrosion resistant

A process of surface treating an aluminum or aluminum alloy article includes the steps of: (1) forming an oxide layer on the aluminum or aluminum alloy article by anodizing; (2) sealing the oxide layer of the article; and (3) forming a protective film on the sealed oxide layer of the article. The process may further comprise a step of coloring the oxide layer of the aluminum or aluminum alloy article between said steps (1) and (2). The aluminum or aluminum alloy article is corrosion-resistant and resistant to damage by contact, by virtue of the protective film formed on the sealed oxide layer in said step (3). In addition, the protective film can also give the aluminum or aluminum alloy article a long-lasting attractive appearance by preventing a colored sealed oxide layer of the aluminum or aluminum alloy article from fading.

Owner:HON HAI PRECISION IND CO LTD

Surface treatment process for anodizing aluminum products

InactiveCN102477573ALong-lasting lusterImprove corrosion resistanceAnodisationElectrolysisCurrent range

The invention provides surface treatment process for anodizing aluminum products. The surface treatment process includes steps of neutralizing and washing by water; degreasing the aluminum products by acid-base solution at the normal temperature; washing the aluminum products by hot pure water with the temperature ranging from 55 DEG C to 65 DEG C; disposing the aluminum products serving as anodes into electrolytic sulfuric acid solution so that anode and cathode electrolysis is carried out under the conditions of the current ranging from 25A to 35A, the temperature ranging from 55 DEG C to 60 DEG C and the pH (potential of hydrogen) value ranging from 1 to 2; then washing the aluminum products by hot water with the temperature ranging from 55 DEG C to 60 DEG C after washing the same by pure water; and finally drying the aluminum products and collecting the same. Accordingly, a dense film much thicker than a natural oxidation film can be formed on the surface of aluminum and alloy thereof after anodizing treatment, the thickness of the dense film ranges from tens of micrometers to hundreds of micrometers, accordingly, the surface luster of metal can be kept for a long time, both corrosion resistance and mechanical strength of the metal are improved to a certain degree, and decorative appearance of the aluminum products further can be formed by dyeing.

Owner:张家港市华杨金属制品有限公司

Smelting preparation method for anti-tarnishing aluminum alloy section bar

The invention discloses a smelting preparation method for anti-tarnishing aluminum alloy section bar. The smelting preparation method comprises the following operation steps: (1) preparing aluminum alloy melt, wherein the aluminum alloy melt is prepared from the following materials in parts by weight: 55-65 parts of 3003 aluminum ingots, 32-42 parts of waste aluminum products, 5-10 parts of boron carbide and 5-10 parts of nanometer quartz sand powder; adding the materials to a smelting furnace; scattering a layer of covering agent to the surface of the melt to cover the melt when the furnace materials are heated up to be softened and collapsed, wherein the covering agent comprises the following components in parts by weight: 10-20 parts of CaO, 10-25 parts of Al2O3, 35-45 parts of SiO2, 12-30 parts of C and 12-23 parts of coal ashes. According to the smelting preparation method disclosed by the invention, the waste aluminum materials are added to the material ingredients for facilitating the stable performances of the aluminum section bar and reducing the possibility that the quality of the aluminum section bar is affected by undetected materials during the smelting process of the melt. The ingredients are further optimized, so that the comprehensive performances of the aluminum alloy section bar are improved; and the chromizing treatment is carried out on the surface of the aluminum alloy section bar, so that the corrosion resistance of the oxide film on the surface of the aluminum alloy section bar and the binding force of the aluminum alloy section bar and the coating are improved.

Owner:中山市佳瑞智能科技有限公司

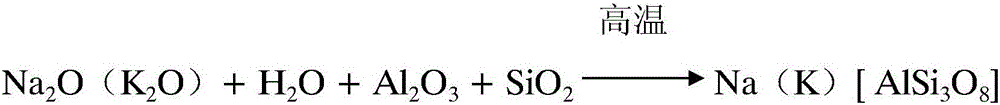

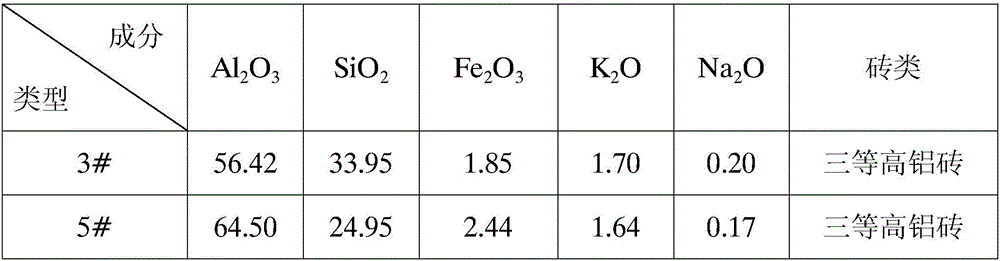

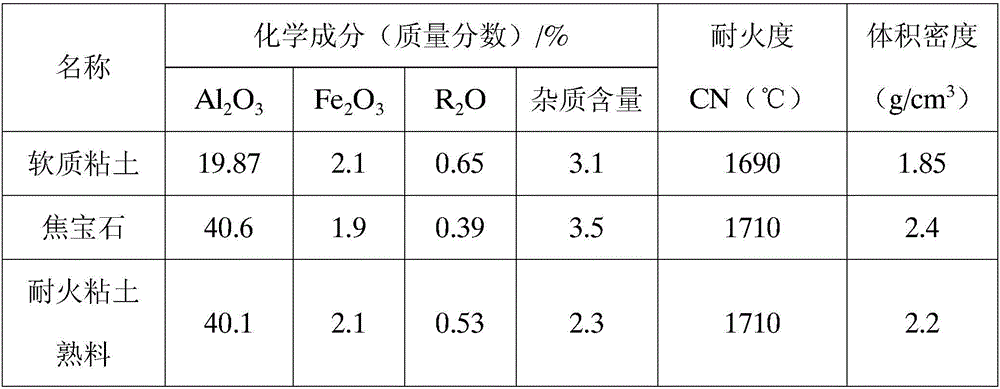

Coke oven low-aluminum lattice brick and production technology

The invention discloses a coke oven low-aluminum lattice brick and a production technology. The coke oven low-aluminum lattice brick is prepared from, by mass, 30% of semisoft clay, 55% of flint clay, 15% of fire-clay grog and 2% of additional organic binding agent sulphite cellulose waste liquor. The lattice brick is a low-aluminum product, the low-aluminum product is a semi-acid refractory product, the size of the product is stable under the high temperature state, the alkali atmosphere resistance is high, the load softening point is high, the high temperature using strength is improved, and the brick is suitable for being used for a coke oven chamber bottom, a heat storage chamber and a perforated strainer; due to the design, the defect that an original material coke oven lattice brick is frequently deformed and blocked is overcome, the novel material is adopted, the service life of the lattice brick can be prolonged, normal heat exchange of a coke oven is smoothly ensured, and coking production stability is effectively guaranteed and supported.

Owner:MAANSHAN IRON & STEEL CO LTD

Highlight anodizing process of aluminum product

ActiveCN103276431AAchieve surface finishLarge area anode highlight effectBelt grinding machinesSurface reaction electrolytic coatingAnodizingAluminium preparations

The invention discloses a highlight anodizing process of an aluminum product. The process comprises the following steps of: grinding and processing the surface of the aluminum product by using a sanding belt; grinding and processing the surface of the aluminum product by using a nylon wheel; carrying out primary polishing by using a linen wheel and green polishing wax in combination; carrying out light polishing by using a cloth wheel and white polishing wax in combination; carrying out an anodic reaction; carrying out wax removal, chemical polishing, neutralization, oxidization, dyeing and hole sealing; carrying out light polishing by using a polishing machine, a consumable cloth wheel and white polishing wax in combination; and carrying out a wiping inspection on the surface of the aluminum product. According to the highlight anodizing process of the aluminum product disclosed by the invention, the physical polishing and the chemical polishing are combined, chemical polishing agents in specific proportions are used, a large-area anode highlight effect can be achieved, a highlight surface processing effect after the aluminum product is anodized is achieved, the aluminum product can be dyed with rich colors, and the provided aluminum product surface processing process is suitable for large-scale industrial production.

Owner:KUNSHAN ESON PRECISION ENGINEERING CO LTD

Preparation method of porous aluminium

ActiveCN108866371ALow purityUniform pore size distributionAluminium preparations5005 aluminium alloy

The invention relates to a preparation method of porous aluminium, and belongs to the technical field of porous aluminium preparation. The method comprises the following steps that 1, aluminium and alow-vapour pressure metal raw material are placed in a vacuum furnace, vacuumizing is not needed, and heating and smelting are conducted in an inert atmosphere directly to obtain aluminium alloy; 2, vacuumizing is conducted on the vacuum furnace in the step 1, firstly, a first step is conducted at a low temperature to remove a low-vapour pressure metal component in the aluminium alloy, and then heating and a second step is conducted to remove the low-vapour pressure metal component in the aluminium alloy to obtain the porous aluminium. According to the preparation method of the porous aluminium, by means of the fusion characteristic and the volatilization characteristic of aluminium, smelting of the aluminium alloy and preparation of the porous aluminium are conducted integratedly, in thewhole preparation process, contact with oxidizing gas is avoided, the preparation method can effectively prevent the aluminium alloy in the middle link and the final porous aluminium are oxidized at ahigh temperature to reduce the purity of the porous aluminium, and the prepared porous aluminium is even in pore diameter distribution, controllable in size and high in porosity.

Owner:SHANDONG UNIV

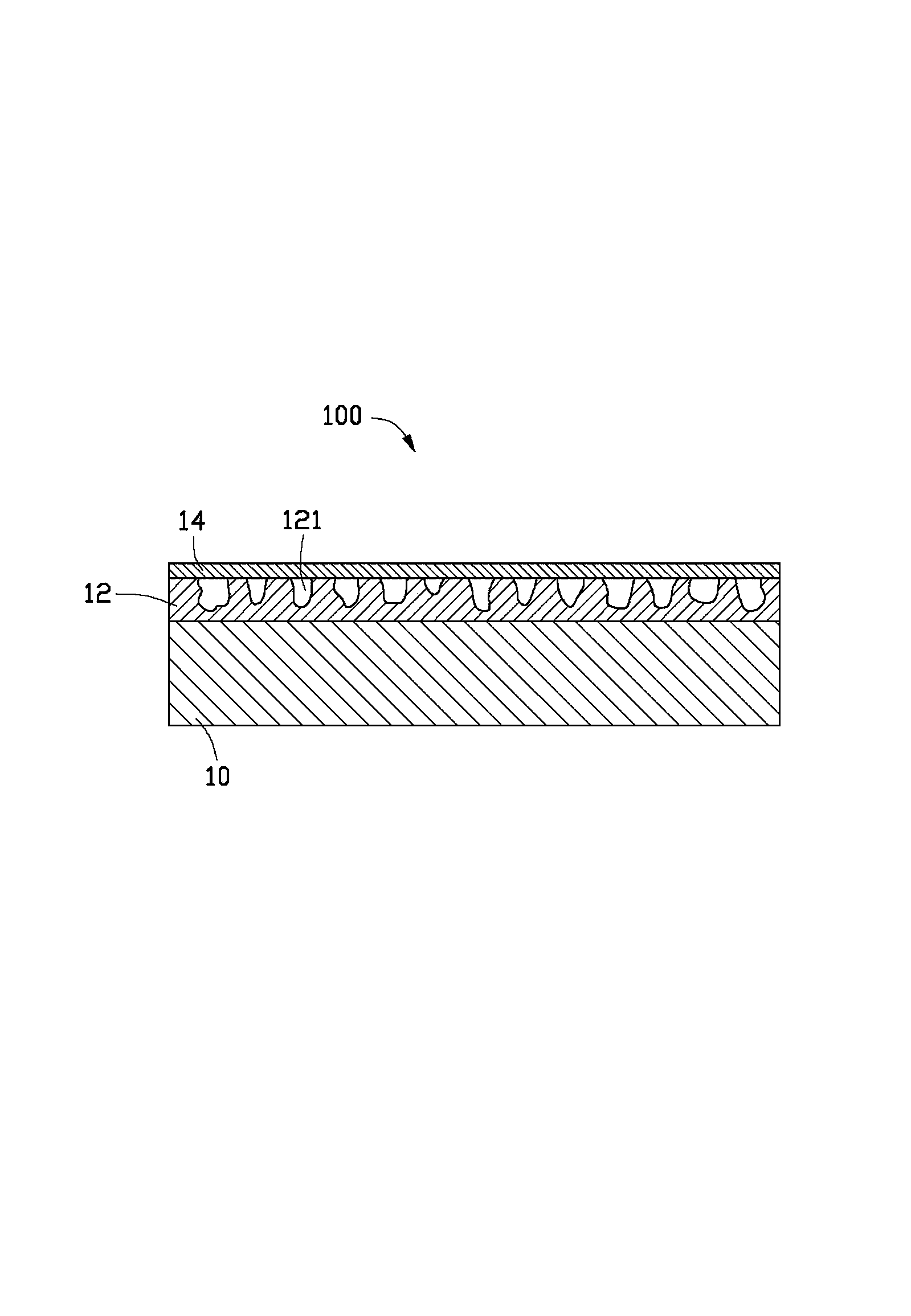

Aluminum alloy surface treatment method and aluminum product

The invention provides an aluminum alloy surface treatment method. The aluminum alloy surface treatment method comprises the following steps of providing an aluminum alloy base material, carrying out solid solution treatment on the aluminum alloy base material so that a silicon element is uniformly dispersed in the aluminum alloy base material, carrying out pickling treatment on the aluminum alloy base material to remove the silicon on the surface of the aluminum alloy base material, carrying out anodic oxidation treatment on the aluminum alloy base material so that a porous alumina membrane is formed on the aluminum alloy base material, carrying out coloring treatment on the aluminum alloy base material, and carrying out aperture-sealing treatment on the aluminum alloy base material so that an alumina monohydrate layer is formed on the porous alumina membrane. The invention provides an aluminum product obtained by the aluminum alloy surface treatment method.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

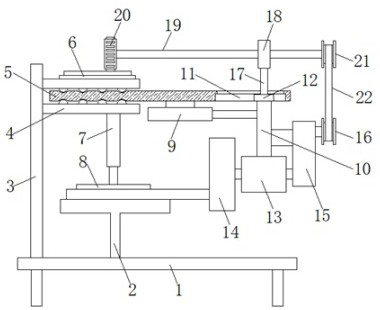

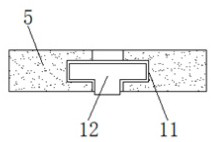

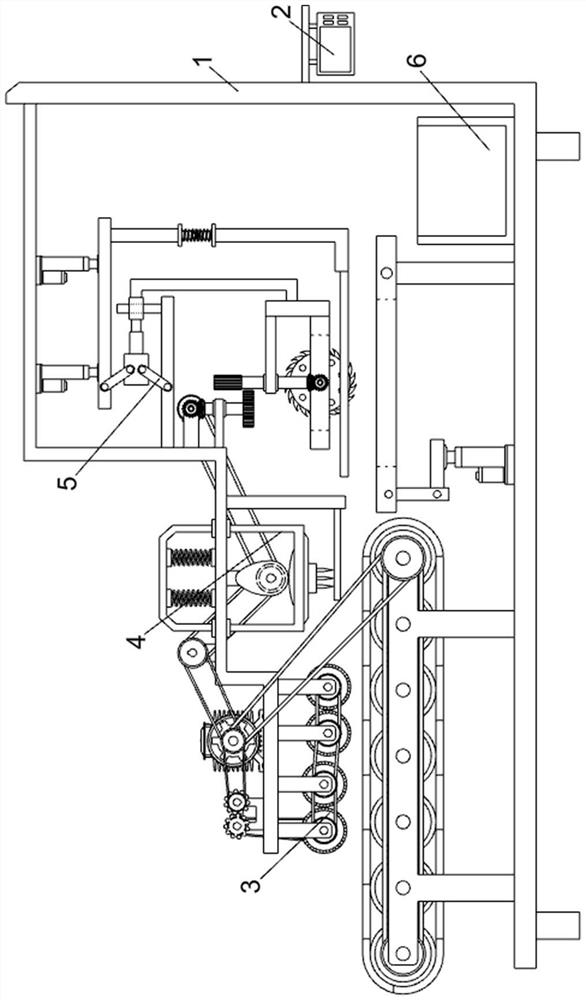

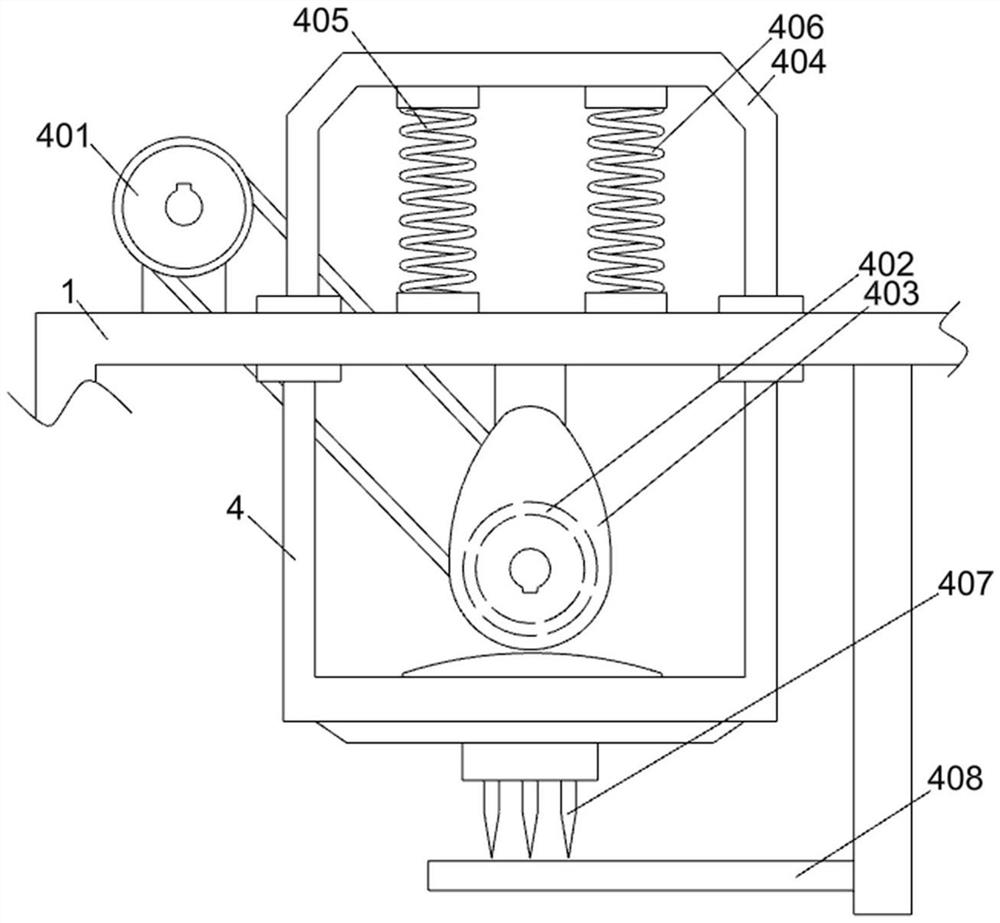

Deburring device for aluminum product processing

InactiveCN111843690ASolve efficiency problemsSolve quality problemsEdge grinding machinesGrinding drivesAluminium preparationsElectric machinery

The invention discloses a deburring device for aluminum product processing, and relates to the technical field of aluminum product processing. In order to solve the problems that currently, an aluminum product is polished depending on manual operation, the efficiency is low, and the polishing quality cannot be ensured, the deburring device comprises a placement plate according to the scheme, a supporting plate is welded to the left side of the placement plate, two clamping plates are welded to the right side of the supporting plate, a rack is fixedly connected to the top of the clamping plateon the top, and a compression mechanism is fixedly connected to the bottom of the clamping plate on the bottom. A placement table fixedly connected with the placement plate is arranged on the lower side of the compression mechanism, a movable plate is slidably connected to the sides, close to each other, of the two clamping plates, and a second push rod motor is fixedly connected with the bottom of the movable plate. By means of the deburring device, the polishing degree can be conveniently controlled, the product polishing quality is thus ensured, moreover, automatic movable polishing can beachieved, and efficient polishing is facilitated. The whole device is driven by one machine, and the degree of integration and automation of the device is improved.

Owner:安徽省裕康铝业有限公司

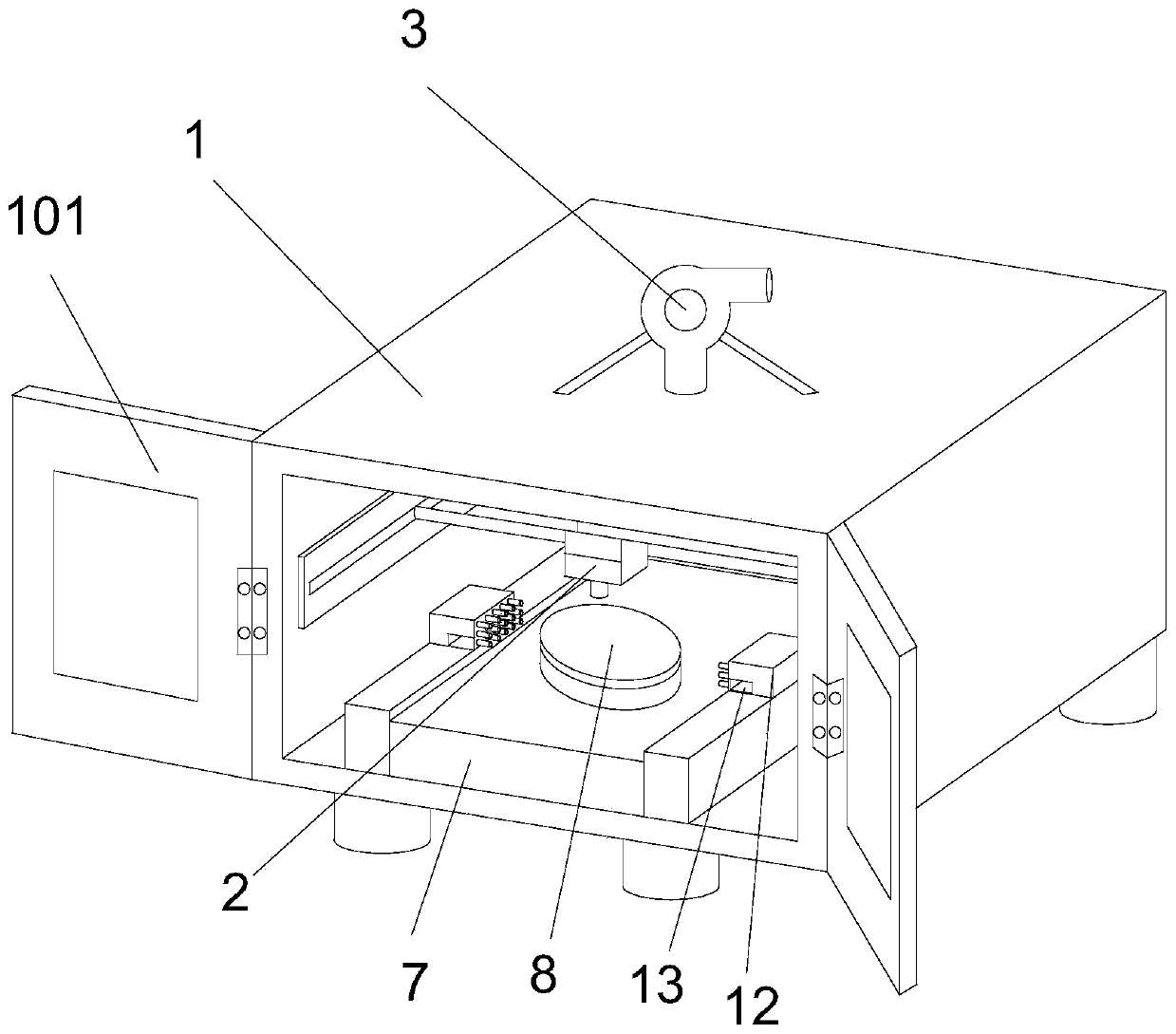

Quick drying device used in spraying paint on aluminium product

InactiveCN111013973AAvoid uniformityAvoid temperaturePretreated surfacesCleaning using gasesAluminium preparationsMetallurgy

The invention discloses a quick drying device used in spraying paint on an aluminium product, and relates to the technical field of sprayed paint drying. The quick drying device comprises a box body and a paint spraying device, wherein the paint spraying device is movably mounted on the inner wall of the box body; a drying device is arranged at the inner top of a cavity of the box body; and a worktable is fixedly mounted in the box body. According to the quick drying device used in spraying paint on the aluminium product, the drying device is arranged at the inner top of the cavity of the boxbody, heating wires start to heat air entering air supply pipes, the heated air is exhausted from air holes in air outlet pipes, since the local space in each air supply pipe is limited, the heating wires in the air supply pipes can heat the air in the air supply pipes well to avoid the problems that air is exhausted under the conditions that the air heating temperature is non-uniform, and the temperature is not up to the standard, which is caused by too large local space, the heated air is uniformly and finely exhausted from the air holes, and the effect of quickly drying the paint sprayed aluminium product is achieved.

Owner:湖州金丰新材有限公司

External paint baking device for processing environment-friendly aluminum products

InactiveCN110918419AAvoid leaningAvoid affecting the outer wall baking operationPretreated surfacesCoatingsAluminium preparationsEngineering

The invention discloses an external paint baking device for processing environment-friendly aluminum products, and relates to the technical field of aluminum product processing. The external paint baking device for processing environment-friendly aluminum products comprises a bottom plate, wherein support legs are fixedly arranged at the bottom of the bottom plate; a side plate is fixedly arranged at the top of the bottom plat; a sliding groove is formed in the side plate; a second threaded rod is longitudinally and rotationally arranged in the sliding groove; a sliding block is slidably arranged in the sliding groove; a connecting piece is fixedly connected to one side of the sliding block; one end of the connecting piece extends to the outside of the side plate and is fixedly provided with an annular mounting seat; a second heating assembly is fixedly mounted on the inner wall of the annular mounting seat; a placing seat is fixedly mounted at the top of the bottom plate; one side, close to the annular mounting seat, of the side plate is fixedly provided with a top plate through bolts; and a supporting plate and a mounting plate are fixed at the bottom of the bottom plate through bolts. The external paint baking device for processing environment-friendly aluminum products has high baking efficiency, excess high local heating temperature during pipeline baking is avoided, andbaking efficiency and product processing quality are improved.

Owner:湖州好灵通铝业有限公司

Method for smelting aluminium alloy doped with magnesium element

The invention discloses a method for smelting aluminium alloy doped with magnesium element, which is characterized by comprising the following preparation steps of: (1) adding lots of discarded aluminium-product furnace charge in a smelting furnace, heating up until the furnace charge starts to soften and fall down, and sprinkling a layer of covering agent on metallic surfaces to cover; (2) slagging off and stirring; (3) adjusting ingredients; (4) refining; (5) discharging; and (6) cleaning. Via the refining treatment aforementioned, high-quality aluminium alloy smelting solution is obtained. In the case that the aluminium alloy smelting solution is used for casting production, the rate of finished products is obviously increased; in particular, the rate of pores in castings is reduced by 1-2% and effectively controlled, so that pores cannot be generated on the surfaces of the castings; the oxide inclusions are obviously reduced and are about at two-level; and the mechanical property of the castings is obviously improved.

Owner:安徽昕悦铸造科技有限公司

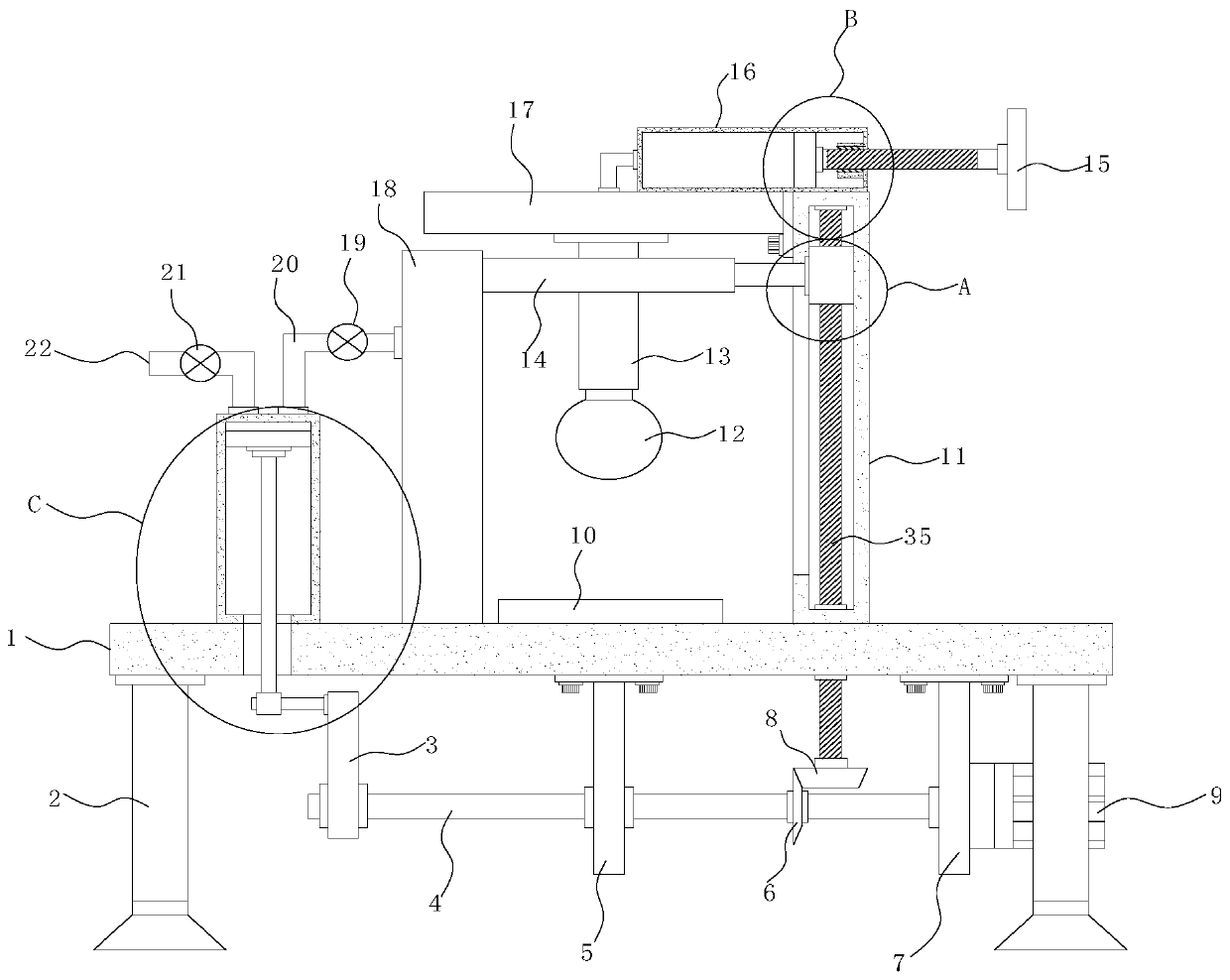

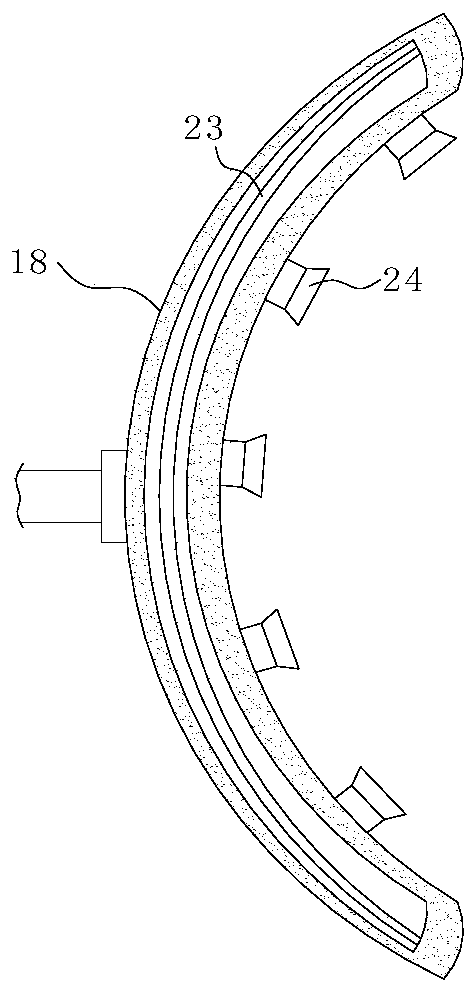

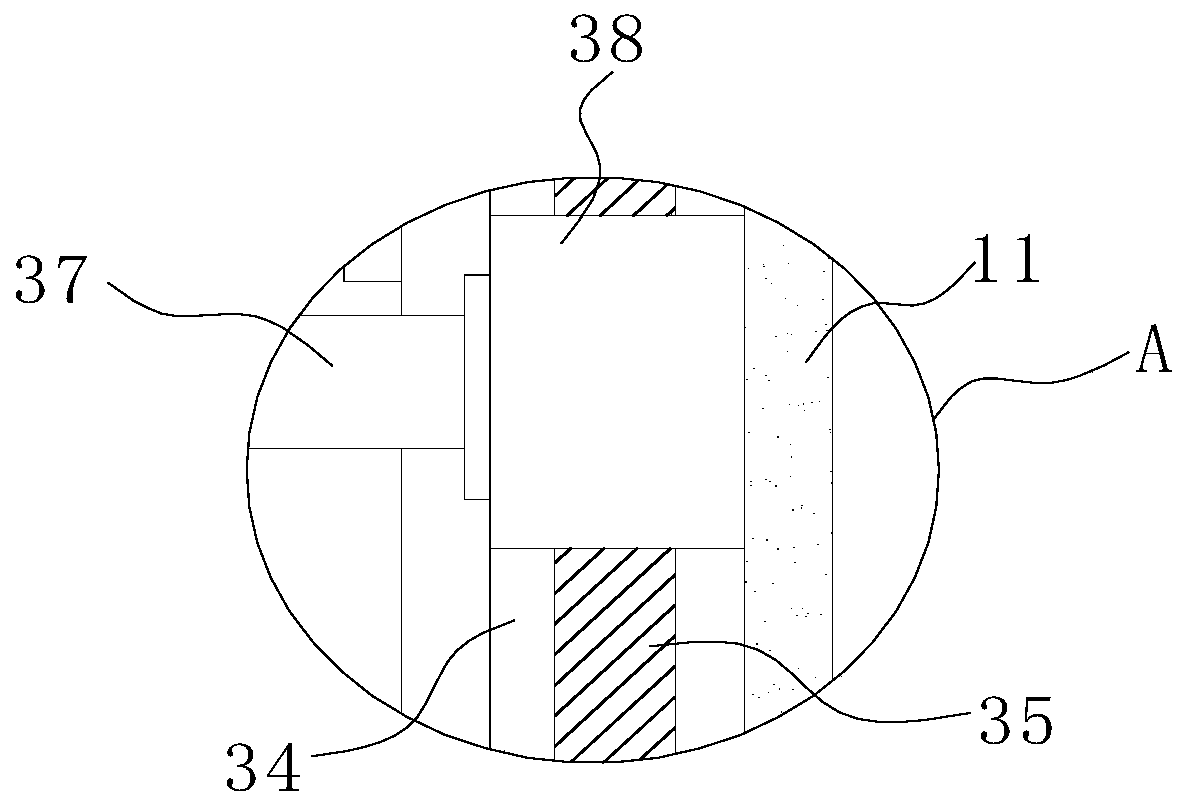

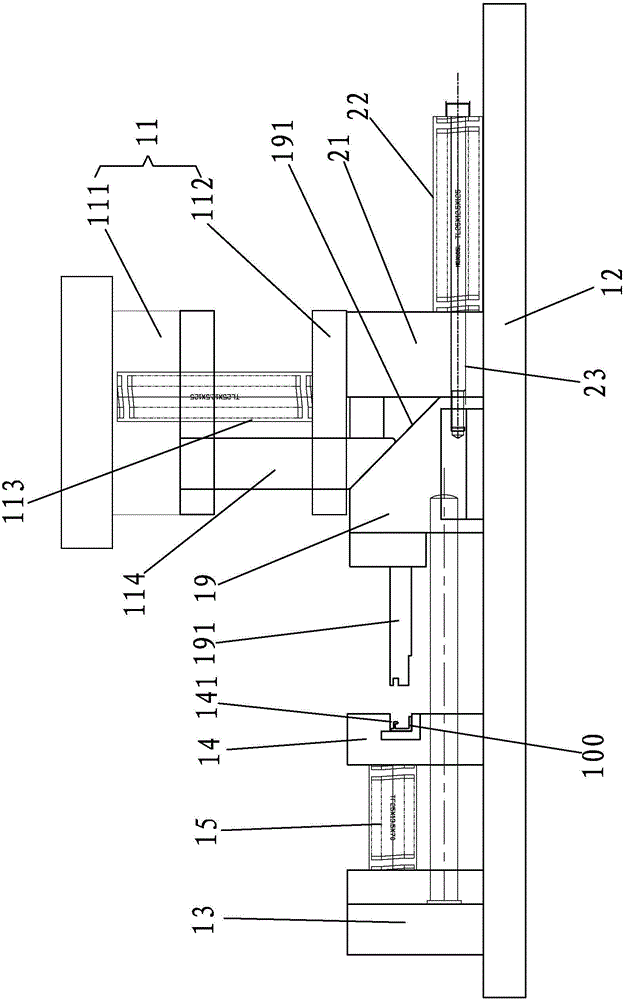

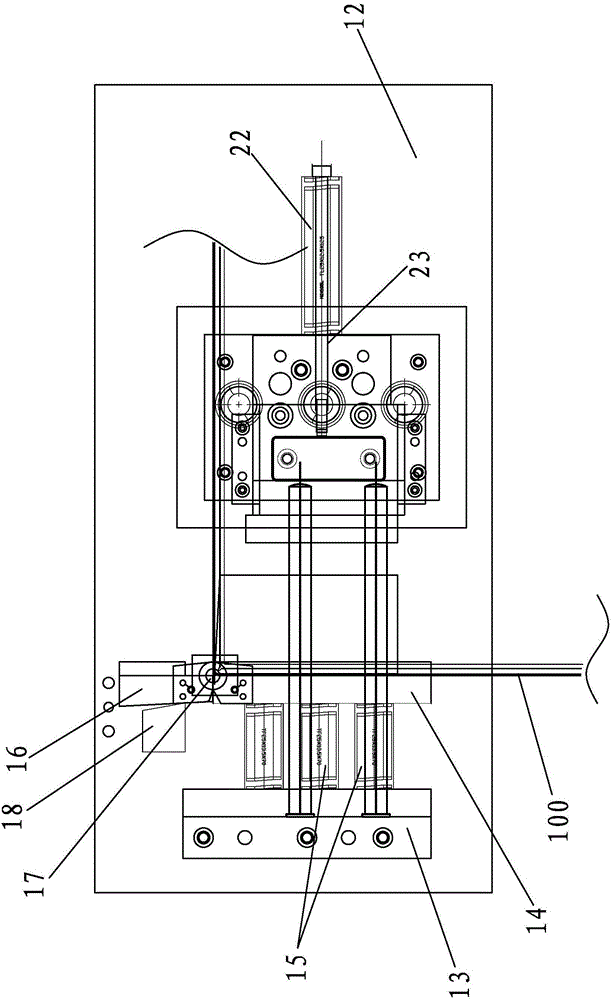

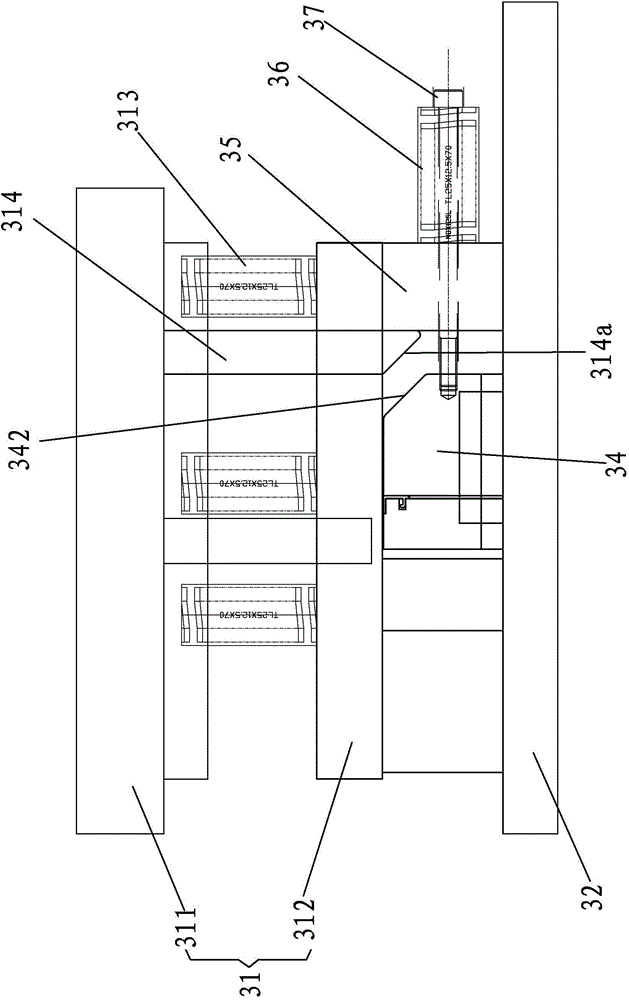

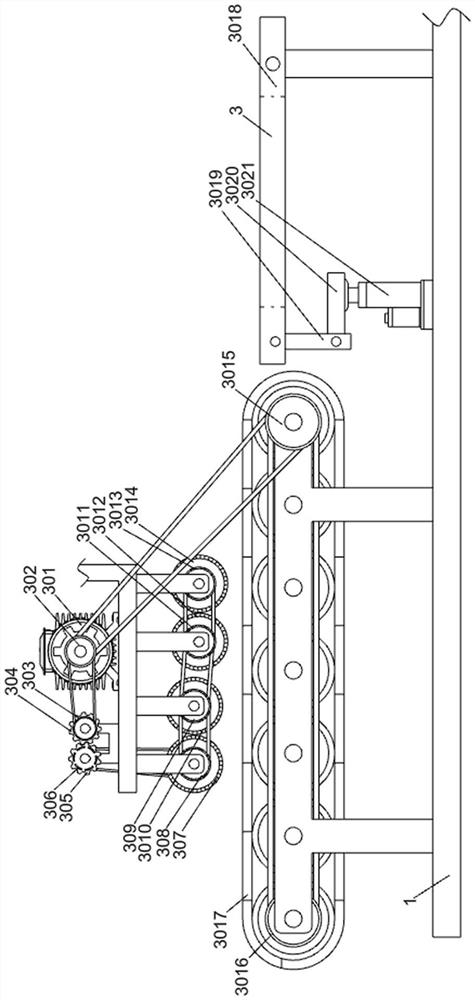

Aluminum product bending system and process

ActiveCN104785620ARealize one-time bending and formingEasy bending stepsShaping toolsEngineeringAluminium preparations

The invention discloses an aluminum product bending system which comprises a bending device for bending a strip-shaped aluminum product at a time, a shaping device for stamping and shaping the bent aluminum product and a trimming device for trimming redundant edges of the shaped aluminum product. The aluminum product is bent in the mode that a movable seat is pushed through a sliding block, so that a bending rod drives the aluminum product to deflect at a certain angle, and the aluminum product is bent at a time. The bending step is simple and convenient, the problem that forming steps are complex due to the fact that the aluminum product can be bent through multiple times of stamping in a traditional stamping mode is solved, and the system has the advantages of being easy to machine, convenient to operate and simple in structure. The invention further discloses an aluminum product bending process with the simple process steps.

Owner:FUJIAN SHISHI TONGDA ELECTRICAL APPLIANCE

Aluminum alloys having improved surface properties and method of making same

InactiveUS20030118855A1Improve wearImproving abrasion and wear and corrosion characteristicArc welding apparatusWelding/cutting media/materialsAluminium alloyWelding process

A method for fusing a durable overlay on an aluminum article includes the steps of: providing an article comprising aluminum; and, applying a hypereutectic cladding layer to a at least one surface of the aluminum article by fusing a consumable welding filler material to the aluminum article using a welding process. An article includes an aluminum alloy casting having a hypereutectic cladding layer fused to at least a portion of a surface thereof.

Owner:UT BATTELLE LLC

Rust-proof sealing agent

The invention relates to a sealing agent, in particular to a sealing agent special for the rust prevention on the surface of an aluminum product. The rust-proof sealing agent is prepared by mixing the following components by weight percent: 62-70% of base oil; 20-25% of rust-proof additive; 1-2% of corrosion inhibitor; 1-2% of antioxygen, 1-2% of rust-proof film-forming agent, 3-5% of dewatering additive and 1-2% of coupling agent. The rust-proof sealing agent provided by the invention is used for the alkali resistance and the corrosion resistance on an aluminum product, can be nautically dried within tens of minutes, and is good in alkali-resistant and corrosion-resistant performance. Furthermore, the existing rust-proof sealing agent can not be dried until being heated in a drying way.

Owner:ZHEJIANG KANGSHENG CO LTD

Smelting preparation method for electrostatic powder-plated aluminum alloy section bar

InactiveCN103103402AImprove performanceAffect qualityLiquid surface applicatorsMetallic material coating processesAluminium preparationsSurface oxidation

The invention discloses a smelting preparation method for an electrostatic powder-plated aluminum alloy section bar. The smelting preparation method comprises the following operation steps: (1) preparing aluminum alloy melt, wherein the aluminum alloy melt is prepared from the following materials in parts by weight: 55-65 parts of 3003 aluminum ingots, 32-42 parts of waste aluminum products, 5-10 parts of boron carbide and 5-10 parts of nanometer quartz sand powder; adding the materials to a smelting furnace; scattering a layer of covering agent to the surface of the melt to cover the melt when the furnace materials are heated up to be softened and collapsed, wherein the covering agent comprises the following components in parts by weight: 10-20 parts of CaO, 10-25 parts of Al2O3, 35-45 parts of SiO2, 12-30 parts of C and 12-23 parts of coal ashes. According to the smelting preparation method disclosed by the invention, the waste aluminum materials are added to the material ingredients for facilitating the stable performances of the aluminum section bar and reducing the possibility that the quality of the aluminum section bar is affected by undetected materials during the smelting process of the melt. The chromizing treatment is carried out on the surface of the aluminum alloy section bar, so that the corrosion resistance of the oxide film on the surface of the aluminum alloy section bar and the binding force of the aluminum alloy section bar and the coating are improved.

Owner:江西凤宇铝业有限公司

Pretreatment device for recycling aluminum products

InactiveCN111975376AImprove resource utilizationPrevent theftSolid waste disposalOther manufacturing equipments/toolsAluminium preparationsProcess engineering

The invention relates to the field of aluminum products, and particularly relates to a pretreatment device for recycling the aluminum products. The technical problem to be solved is to provide the pretreatment device for recycling the aluminum products. The pretreatment device for recycling the aluminum products is characterized by comprising a support frame plate, an operation display screen, a grinding mechanism, a word removal mechanism, a cutting mechanism and a storage cabin, wherein the side surface of the support frame plate is connected with the operation display screen through a support seat, and the support frame plate is connected with the grinding mechanism. According to the pretreatment device, a large number of abandoned license plates are subjected to unified recycling processing, license plate numbers on the surfaces of the license plates are scraped, and the license plates are prevented from being stolen by lawbreakers, meanwhile, the license plate material is recycledfor secondary utilization, the resource utilization rate is improved, the license plate bending position is flattened and convenient to stack, and a large amount of space is saved.

Owner:程军锋

Anti-corrosion and anti-oxidation coating material for electrolytic aluminum anode steel claw and preparation method of anti-corrosion and anti-oxidation coating material

ActiveCN113527917AImprove wear resistanceNot easy to crack and fall offFireproof paintsAnti-corrosive paintsElectrolytic agentFiber

The invention discloses an anti-corrosion and anti-oxidation coating material for an electrolytic aluminum anode steel claw and a preparation method of the anti-corrosion and anti-oxidation coating material, and the anti-corrosion and anti-oxidation coating material comprises the following raw materials in percentage by mass: 40-70% of alpha-Al2O3, 0-30% of gamma-Al2O3 (preferably 5-30%), 2-7% of aluminum silicate fiber and 20-30% of water glass. Various aluminum oxides are used in the raw materials of the anti-corrosion and anti-oxidation coating material for the electrolytic aluminum anode steel claw to the maximum extent, only a small amount of aluminum oxides are contained, other elements can be prevented from entering an electrolyte, and therefore the influence on the quality of an aluminum product is avoided. The coating material is compact in structure, the permeation amount of corrosive gas can be reduced, the corrosion rate of an electrode can be obviously reduced, the corrosion resistance is high, and the wear resistance is good. The coating material disclosed by the invention is enhanced in ductility, suitable for a high-temperature environment, and not easy to crack and fall off when being used in the high-temperature environment.

Owner:HENAN YINGCHUAN NEW MATERIAL INC +1

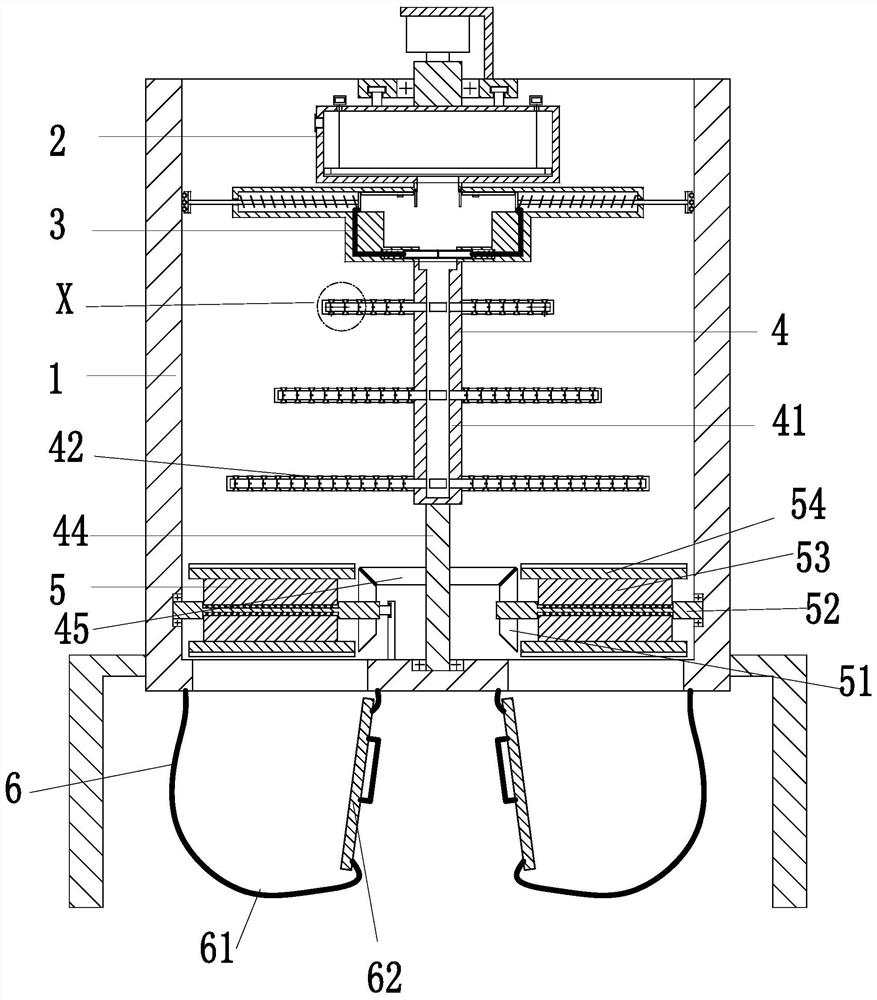

Aluminum material and aluminum product polishing waste acid recycling treatment system and treatment method

ActiveCN111871244ASpeed up fusionImprove uniformityTransportation and packagingRotary stirring mixersAluminium preparationsMetallurgy

The invention relates to aluminum material and aluminum product polishing waste acid recycling treatment system and treatment method, wherein the aluminum material and aluminum product polishing wasteacid recycling treatment system comprises an outer frame, a storage device, a pressing device, a stirring device, two stirring devices, two sealing groups and two extrusion blocks; the storage deviceis installed at the upper end of the outer frame, and the pressing device is installed at the lower end of the storage device; a stirring device is installed at the lower end of the pressing device,two stirring devices are arranged at the left and right ends of the stirring device, two sealing sets are arranged at the lower end of the outer frame, and two extrusion blocks are arranged at the front and rear ends of the inner wall of the outer frame. The invention solves the problems that pure water is generally flushed into a waste acid solution from the upper side, so that the pure water initially entering the waste acid solution is not uniformly distributed, fusion can be performed for a long time even after later stirring treatment, and a traditional stirring paddle difficultly stirs the waste acid solution at the bottom of a frame body, and the dilution of each position is not uniform due to non-uniform stirring of the stirred waste acid solution.

Owner:佛山市铂朗环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com