Preparation method of porous aluminium

A technology for porous aluminum and aluminum alloys, which is applied in the field of preparing porous aluminum by vacuum volatilization of elements, can solve the problems of pollution by-products, uncontrollable porous aluminum porosity, low porous aluminum porosity, etc., and achieves easy mass production. , the effect of reducing purity and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

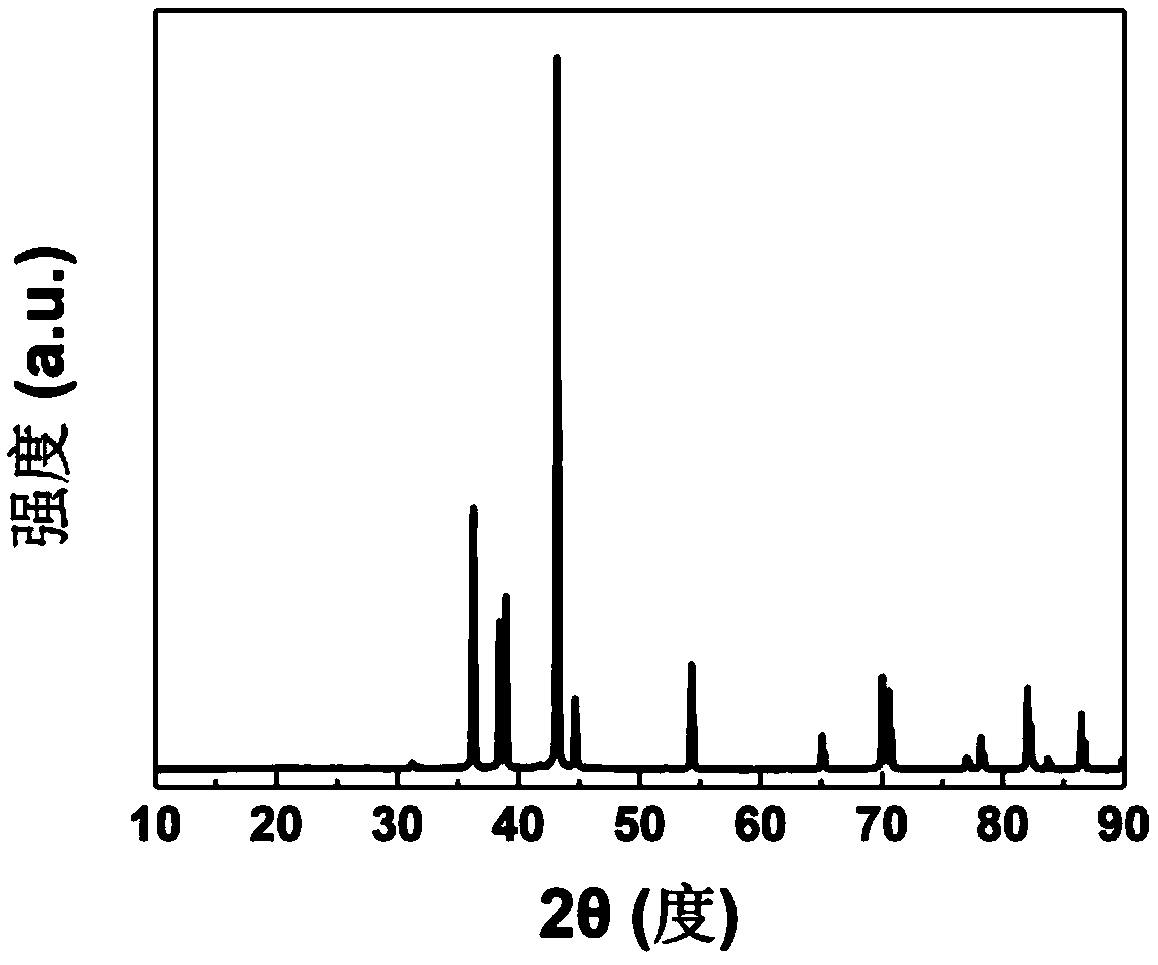

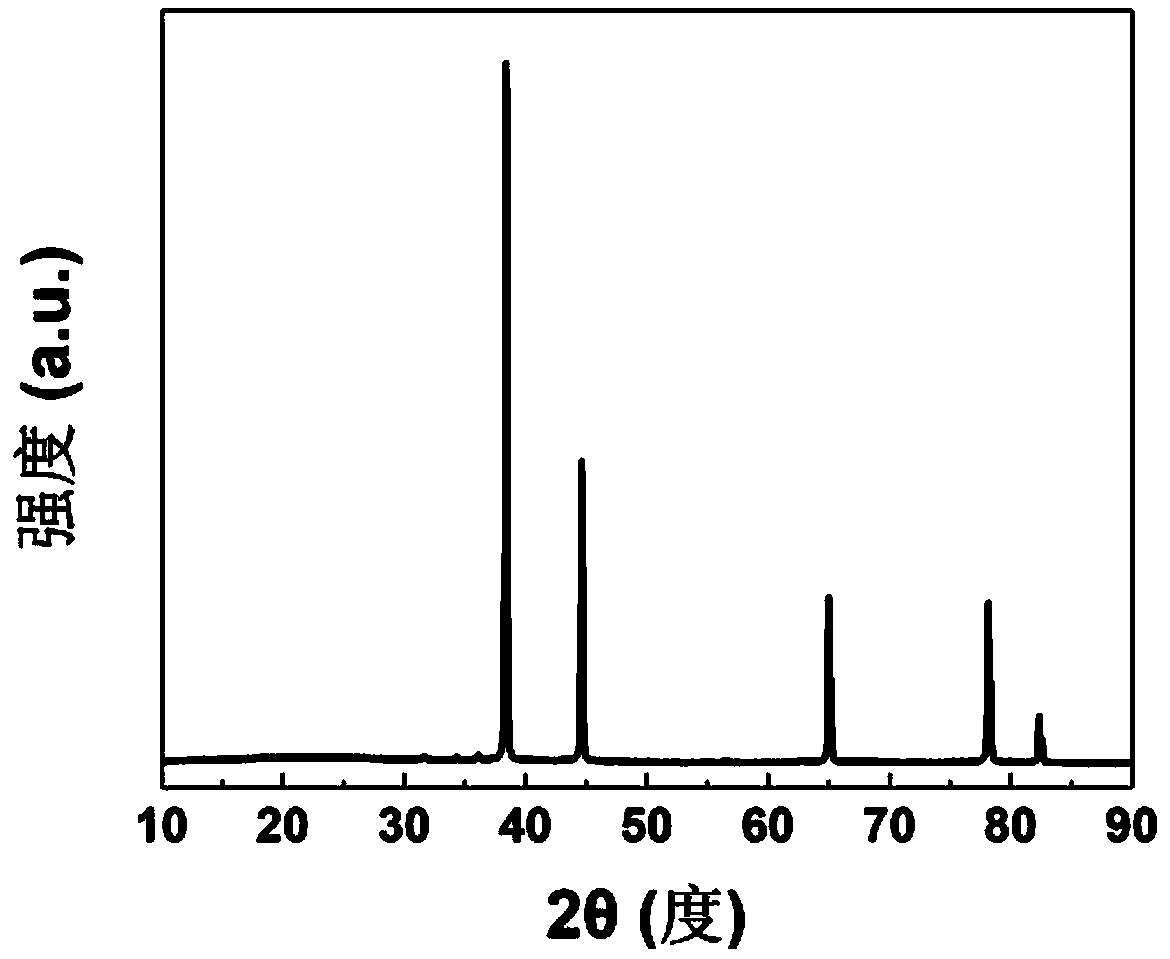

[0037] A method for preparing porous aluminum, comprising the following steps: take 1g of aluminum powder and 2g of zinc powder, and heat them under an argon atmosphere at 700°C for 5 hours to obtain an aluminum-zinc alloy; The zinc element in the aluminum-zinc alloy is removed for 2 hours in the first step, and the second step is removed at 600°C for 0.5 hours to obtain three-dimensional porous aluminum.

Embodiment 2

[0039] A method for preparing porous aluminum, comprising the steps of: taking 1g of aluminum powder and 2g of lithium powder, heating them under an argon atmosphere at 660°C for 10 hours to obtain an aluminum-lithium alloy; The lithium element in the aluminum-lithium alloy is removed in the first step for 5 hours, and then the second step is removed at 500°C for 2 hours to obtain three-dimensional porous aluminum.

Embodiment 3

[0041] A method for preparing porous aluminum, comprising the following steps: take 1g of aluminum powder and 2g of potassium powder, and heat them under a nitrogen atmosphere at 760°C for 1 hour to obtain an aluminum-potassium alloy; Potassium in the aluminum-potassium alloy is removed in the first step for 0.5h, and then removed in the second step at 700°C for 0.1h to obtain three-dimensional porous aluminum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com