Spirulina phycocyanin and extraction method thereof

A technology of phycocyanin and extraction method, which is applied to the preparation methods of peptides, chemical instruments and methods, depsipeptides, etc., can solve the problems of low product yield, long elution time, long operation period, etc., and achieve good anti-oxidation Free radical scavenging effect and fluorescence intensity, simple extraction process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

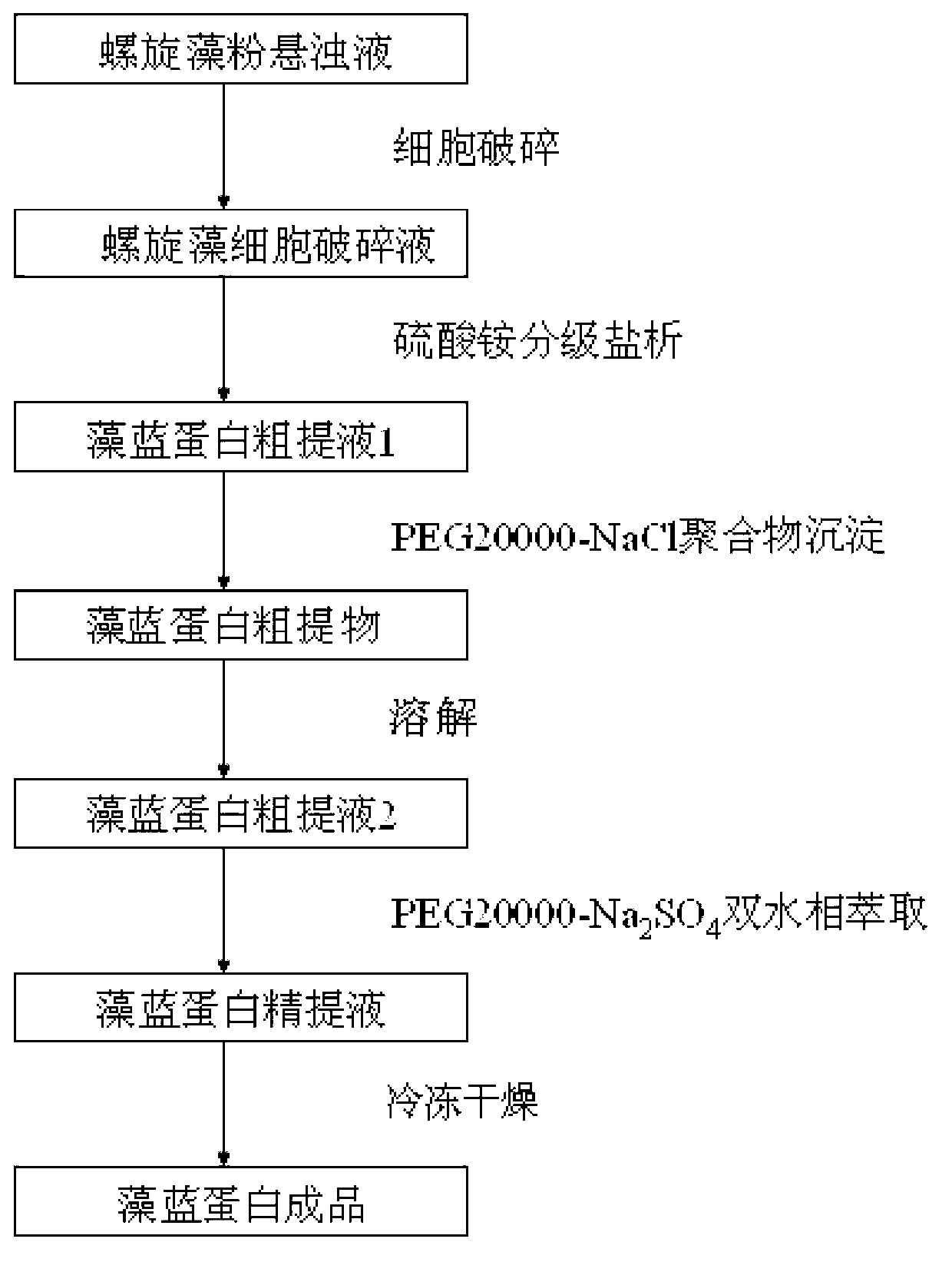

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 prepares phycocyanin extract

[0046] (1) Preparation of Spirulina powder suspension: Weigh 5g of Spirulina platensis powder and dissolve it in 100mL of phosphate buffer (0.01mol / L, pH=7) to prepare Spirulina powder suspension;

[0047] (2) Preparation of spirulina cell disruption solution: put the spirulina powder suspension at 4°C for 4 hours, then freeze at -20°C, mince the ice cubes, and repeat freezing and thawing at 4°C to -20°C. Broken until the operation was repeated three times, centrifuged at 9000rpm for 30min, and the spirulina cell broken liquid was obtained;

[0048] (3) Preparation of phycocyanin crude extract 1: First, add 17.6g of ammonium sulfate to the spirulina cell disruption solution, stir well, dissolve to 30% saturation, let stand at 4°C for 12 hours, centrifuge at 9000rpm for 30min to take the supernatant , then add 12.7g of ammonium sulfate to the supernatant, stir well, dissolve to 50% saturation, let it stand at 4°C for 12 hours,...

Embodiment 2

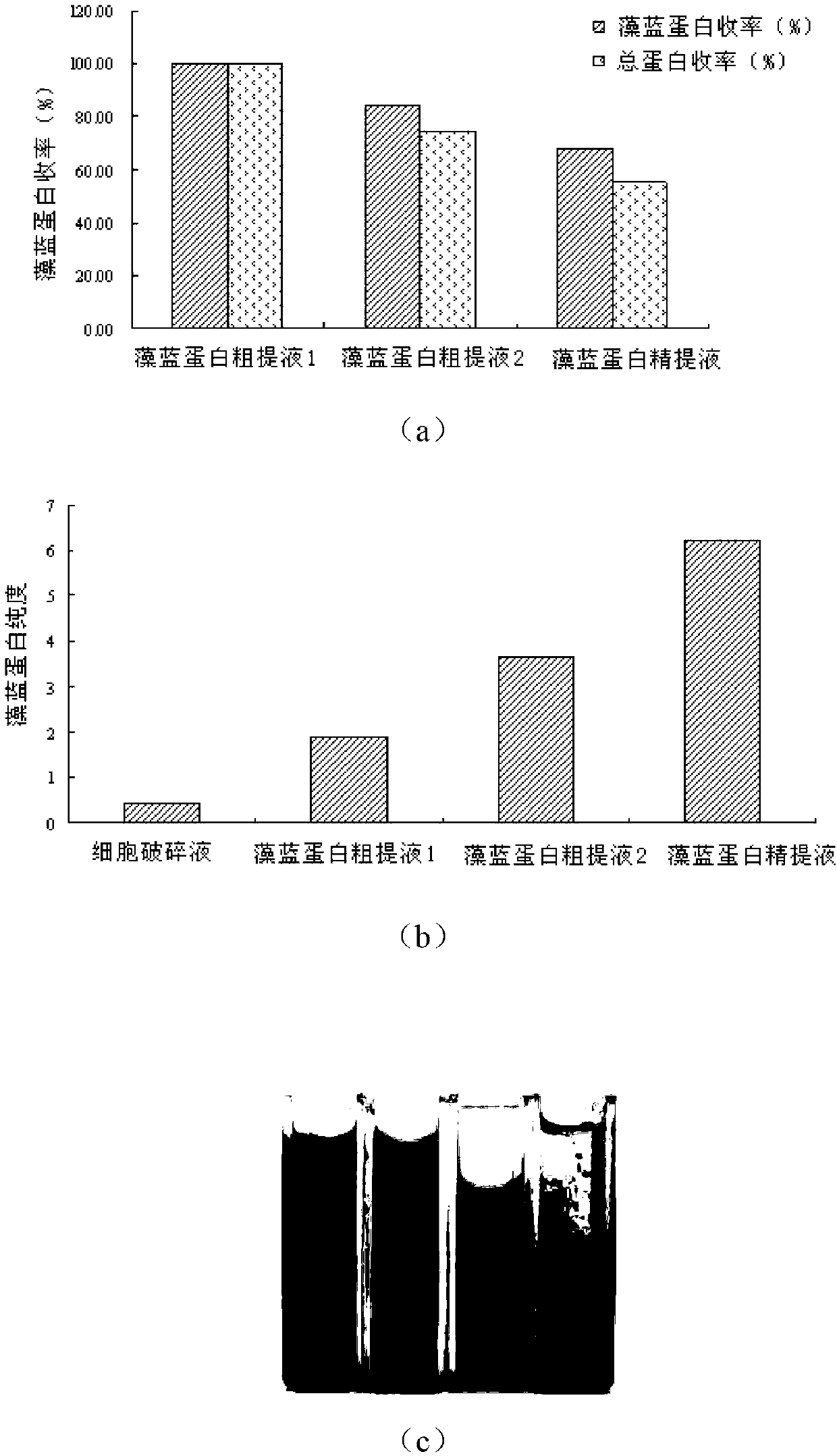

[0063] Example 2 Antioxidant Activity Determination Index Evaluation

[0064] The sample solution in this embodiment is the phycocyanin extract in different extraction steps.

[0065] DPPH system: take 2mL sample solution respectively, add 2mL of 1×10 -4 mol / LDPPH solution, after mixing, react in the dark at room temperature for 2 minutes, and centrifuge at 4000rpm for 10 minutes, and take the supernatant for testing. An equal volume of deionized water was used instead of the sample solution as the control group, and an equal volume of 95% ethanol was used instead of the DPPH solution as the blank group. Measure the absorbance A at 517nm, and extract the solvent (phosphate buffer saline or PEG20000 / Na 2 SO 4 The lower phase solvent of the two-phase system) and 95% ethanol mixed solution are used as a blank to adjust to zero, and six groups of parallel experiments are done, and the average value is taken.

[0066] Clearance rate (%)=[1-(A sample group-A blank group) / A contr...

Embodiment 3

[0073] Embodiment 3 Fluorescent Activity Measurement Index Evaluation

[0074] Fluorescence microscope observation method: DEAE-SephadexA50 pretreatment: Weigh 5g of DEAE-SephadexA50 and suspend it in 500mL distilled water, soak for 1h, pour off the upper layer of fine particles, add 0.5M NaOH at a ratio of 1(g):15(mL) and soak for 30min, pump Filtered, washed with distilled water to pH = 7, and then repeated the above process with 0.1M HCl. Take 5mL of 0.1mg / mL separated and purified phycocyanin product solution (0.01mol / LpH=7.0 phosphate buffer as solvent), add 100mg of pretreated and filtered DEAE-SephadexA50 adsorption medium, and separate at 4°C After static adsorption for 4h and 12h, the UV-visible absorbance values A620 and A652 in the solution were measured with a spectrophotometer respectively, and the phycocyanin adsorbed by 1g DEAE-SephadexA50 adsorption medium was calculated to be 7.91mg and 15.76mg respectively. The DEAE-SephadexA50 adsorbed phycocyanin was was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| greyscale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com