Patents

Literature

133 results about "Phycobiliprotein" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phycobiliproteins are water-soluble proteins present in cyanobacteria and certain algae (rhodophytes, cryptomonads, glaucocystophytes) which capture light energy, which is then passed on to chlorophylls during photosynthesis. Phycobiliproteins are formed of a complex between proteins and covalently bound phycobilins that act as chromophores (the light-capturing part). They are most important constituents of the phycobilisomes.

Method for simultaneously separating high-purity phycocyanin and allophycocyanin and application thereof

InactiveCN102329381AReduce purification costsLow costPeptide preparation methodsAlgae/lichens peptidesPhosphateAmmonium sulfate

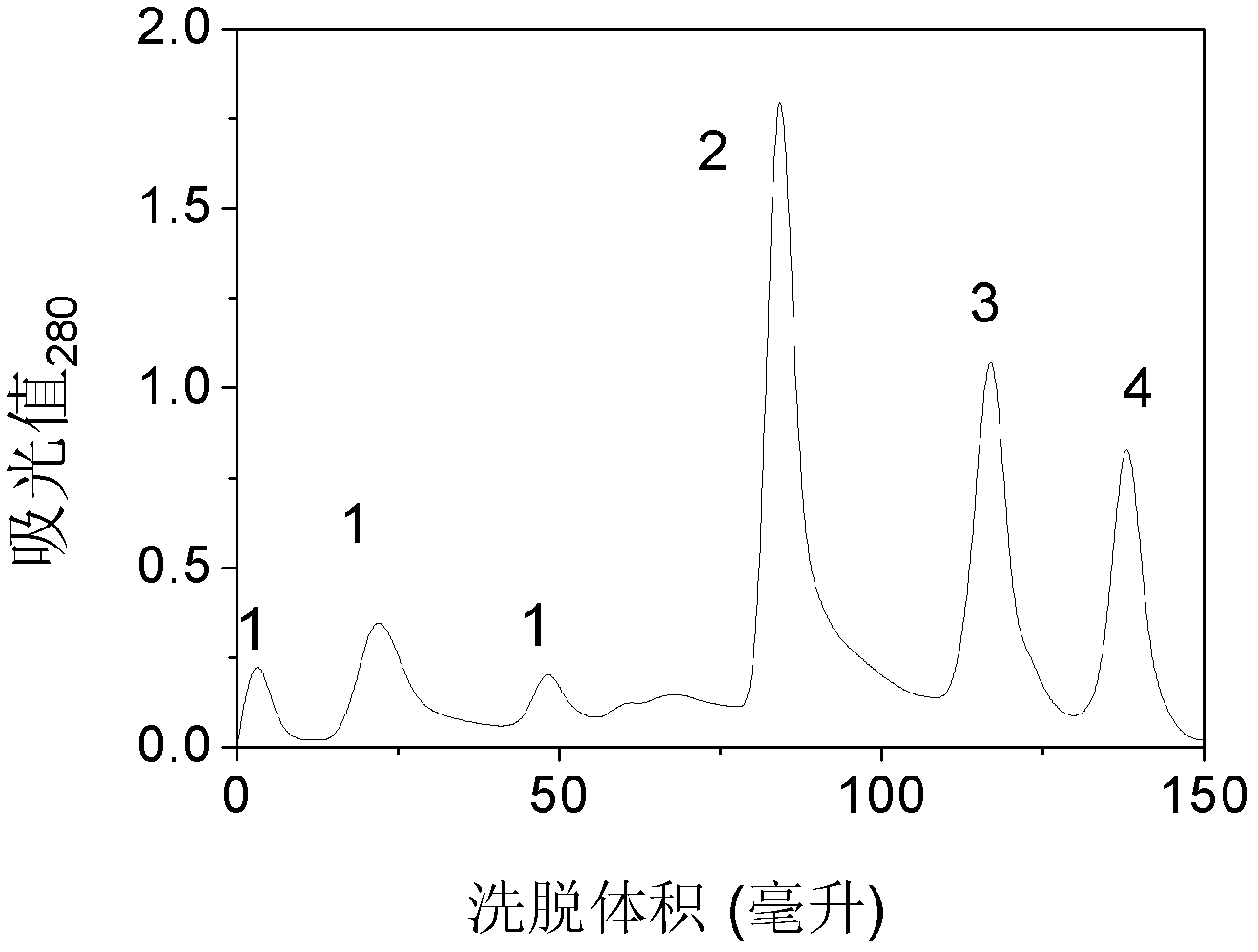

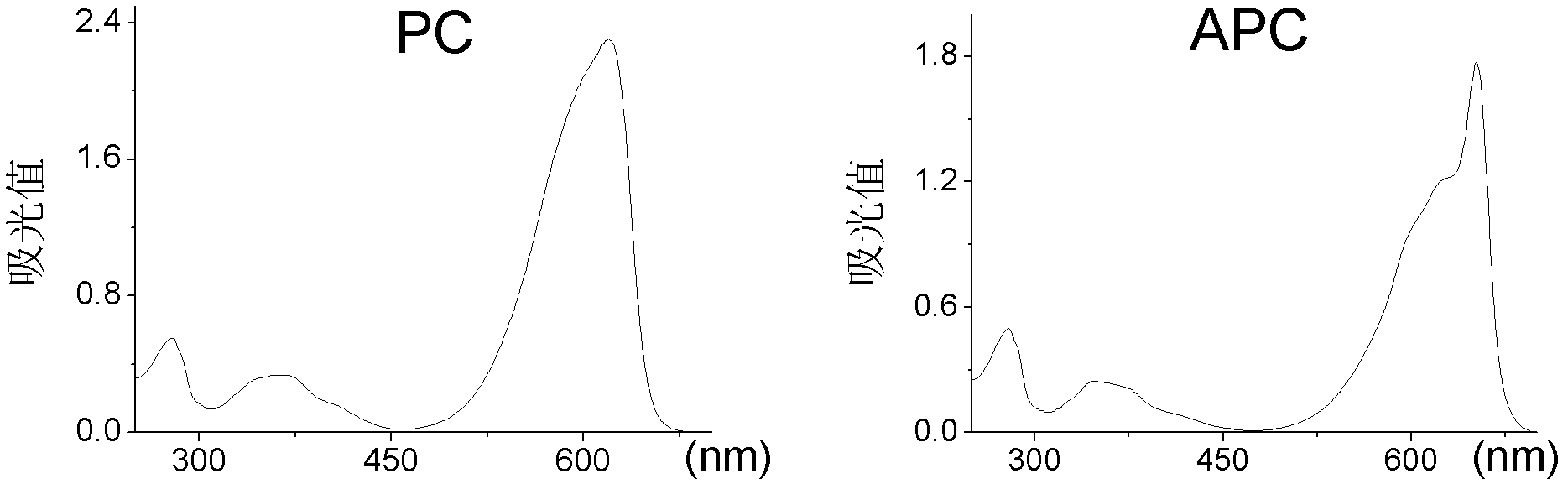

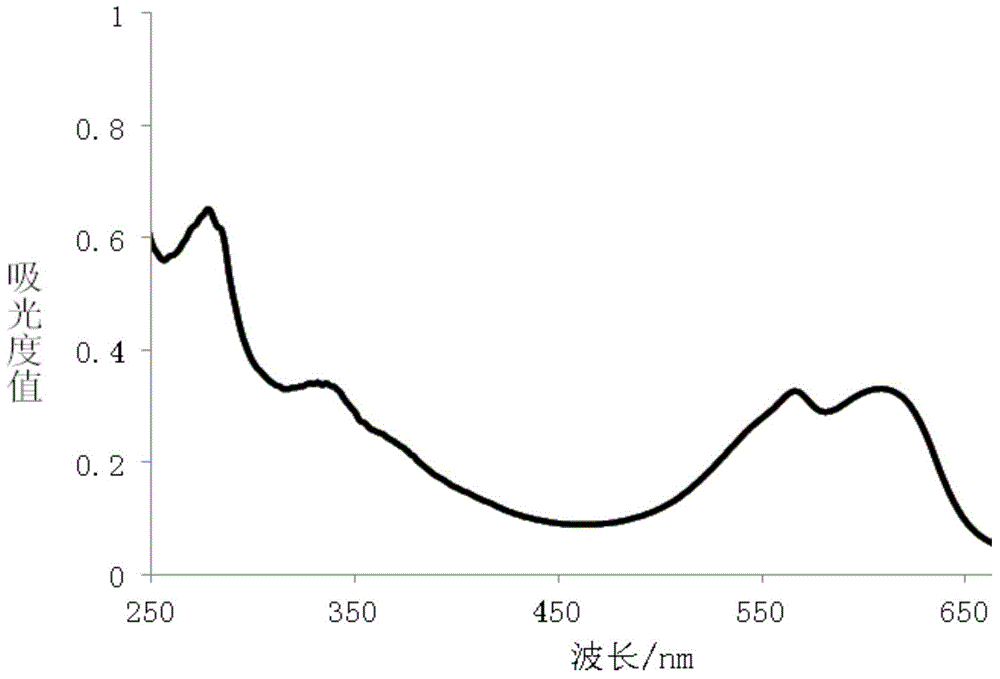

The invention discloses a method for simultaneously separating high-purity phycocyanin and allophycocyanin and application thereof. The method comprises the following steps of: repeatedly freezing and thawing spirulina dry powder, ultrasonically crushing, and centrifuging, wherein supernate is a crude phycobiliprotein extracting solution; then adding ammonia sulfate, and taking out the supernate when the saturation degree is 25-35%; then, adding ammonia sulfate, taking out precipitates when the saturation degree is 60-70%, dialyzing for precipitation to obtain a primarily purified phycobiliprotein extracting solution, and loading the primarily purified phycobiliprotein extracting solution to a hydroxyapatite column; and collecting 0.02-0.03M phosphate buffered solution which contains 0.1-0.2M sodium chloride and has the pH value of 6.5-7.2, and 0.1-0.12M phosphate buffered solution which contains 0.1-0.2M sodium chloride and has the pH value of 6.5-7.2, wherein the 0.02-0.03M phosphate buffered solution is phycocyanin and the 0.1-0.12M phosphate buffered solution is allophycocyanin. The method disclosed by the invention can be used for simultaneously preparing phycocyanin with a purification factor reaching 4.5 and allophycocyanin with a purification factor reaching 3 as well as analogues containing selenium and tellurium, and the purification scale of the method is amplified so as to acquire high-purity protein of a gram level through primary chromatography, so that the purification cost is greatly reduced, and the method can be used for producing the phycocyanin and the allophycocyanin.

Owner:JINAN UNIVERSITY

High-purity biliprotein separating process

The present invention includes the following steps: hypotonic process to prepare extraction of algae, mixing hydroxyl apatite and the extraction of algae and eliminating the other components of extraction of algae in the supernatant; washing hydroxyl apatite with combined biliprotein with low concentration phosphate buffering liquid to eliminate other components; eluting phycocyanin or phycoerythrin from hydroxyl apatite with medium concentration phosphate buffering liquid and collecting phycocyanin or phycoerythrin; and eluting hydroxyl apatite with higher concentration phosphate buffering liquid to obtain allophycocyanin component. The present invention has high yield and purify of biliprotein and is favorable to production in industrial scale.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Spirulina phatensis polysaccharide and extraction method thereof

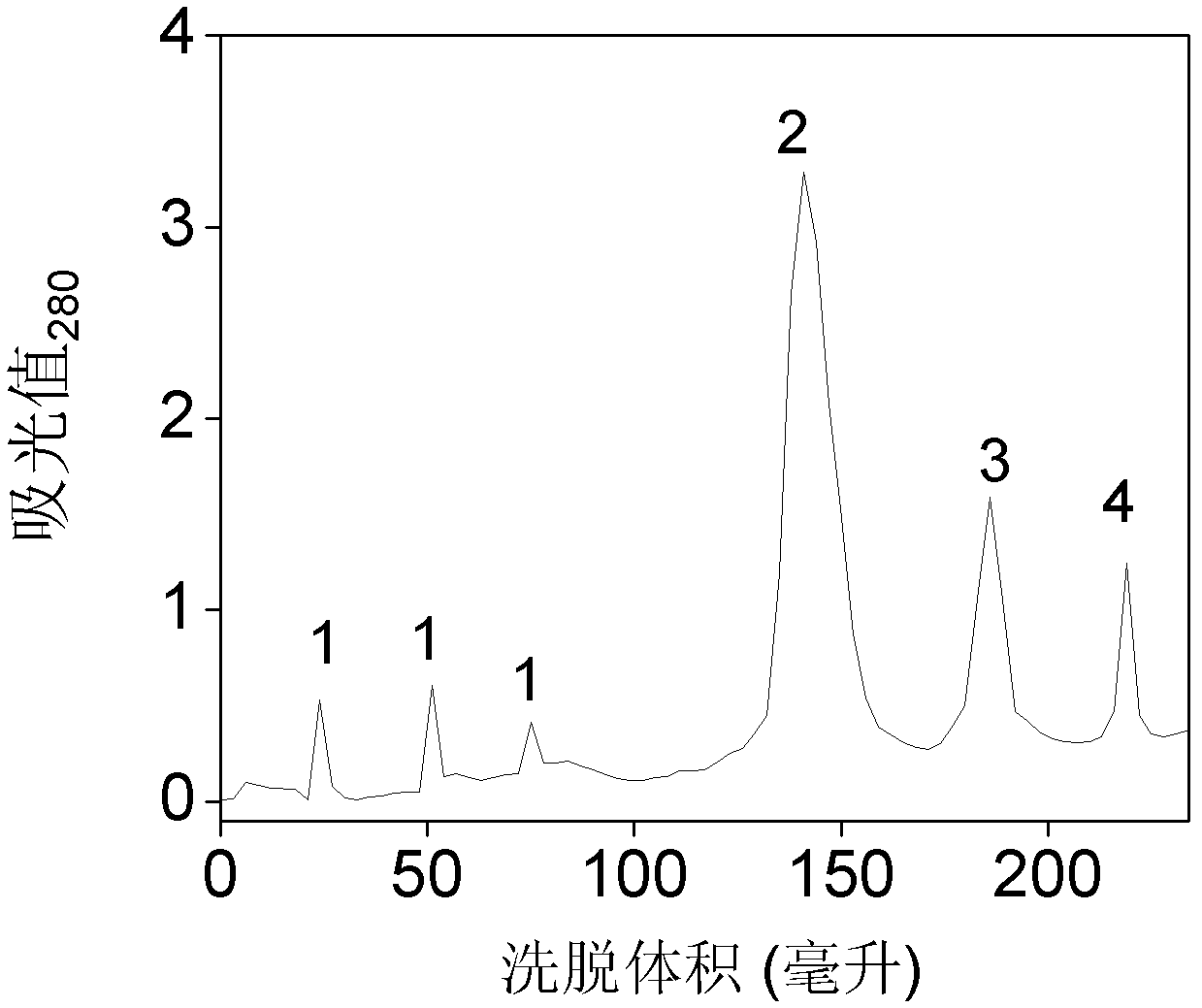

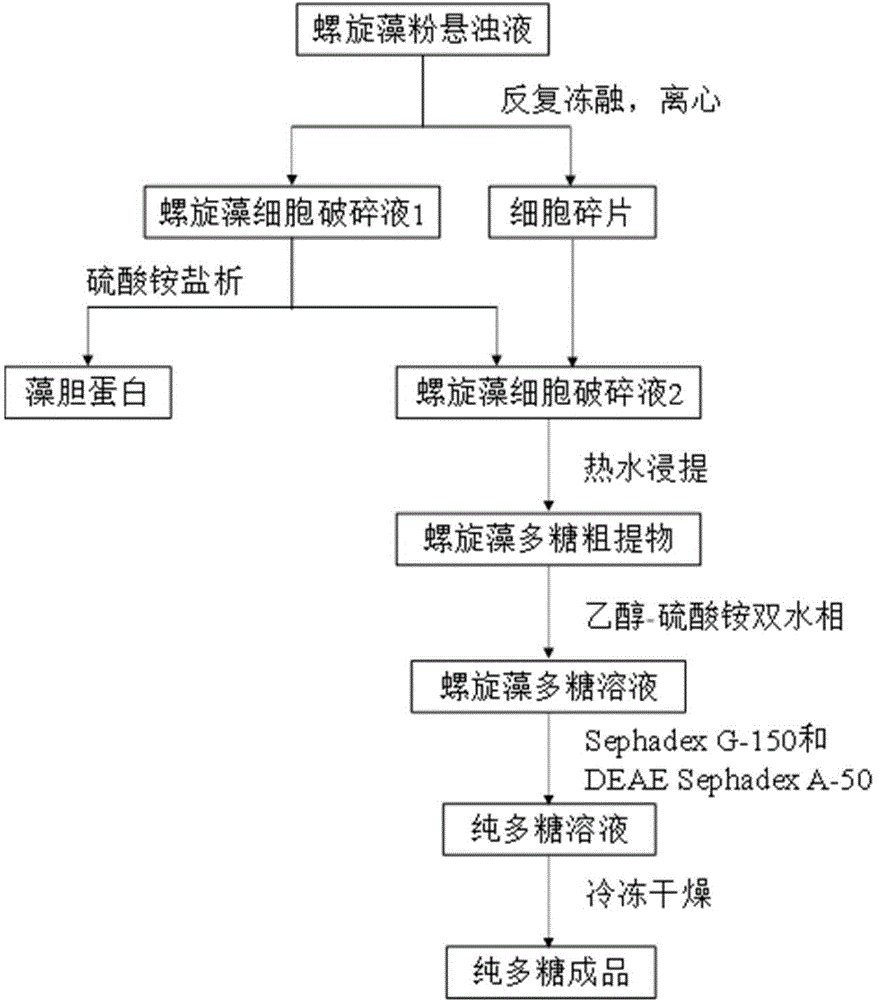

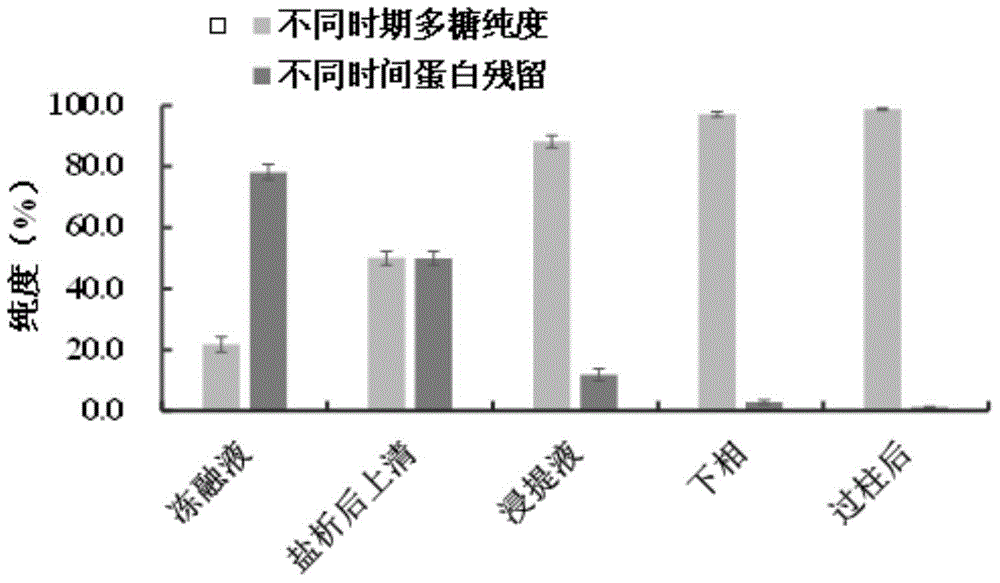

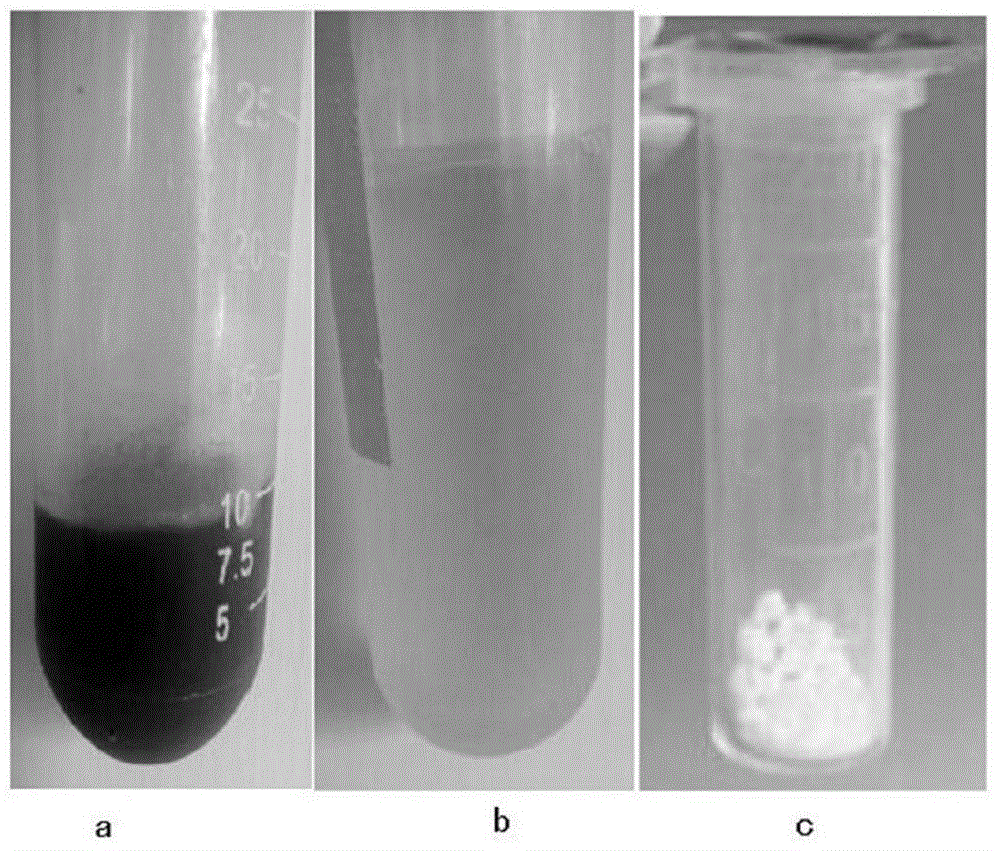

The invention relates to a spirulina phatensis polysaccharide and an extraction method thereof. The extraction method comprises the following steps: after multigelation and wall breaking of a spirulina phatensis powder suspension, centrifuging to obtain a cell lysate 1 and cell debris; adding ammonium sulfate in the cell lysate 1 until the saturation is 50%, after salting-out precipitation, centrifuging to remove phycobiliprotein to obtain a supernatant, and evenly mixing the supernatant and the cell debris to obtain a cell lysate 2; obtaining a spirulina phatensis polysaccharide crude extract by using a hot water extraction method; adding the crude extract to an ethanol / ammonium sulfate aqueous two-phase system, and extracting to obtain a bottom-phase solution of spirulina phatensis polysaccharide with higher purity; after the bottom-phase solution is desalted by dialysis, eluting by using a Sephadex G-150 chromatographic column and a DEAE Sephadex A-50 anion exchange column to obtain a pure spirulina phatensis polysaccharide solution; and freeze-drying, thereby obtaining a pure spirulina phatensis polysaccharide finished product. The extraction method can be used for avoiding the traditional complicated protein removal operation steps, has low cost, high yield, and high purity and activity of polysaccharide, and is suitable for intermittent and large-scale production and processing.

Owner:SHANTOU UNIV

Method for extracting phycobiliprotein from spirulina

InactiveCN104292327AIncrease contentHigh purityDepsipeptidesPeptide preparation methodsCosmetic industryPhycocyanin

The invention provides a method for extracting phycobiliprotein from spirulina. The method comprises the following steps: adding water into spirulina mud to obtain a spirulina cell suspension, performing ultrasonic treatment to obtain spirulina lysate, centrifuging the lysate and taking the lysate, sequentially filtering through filter membranes which are respectively 0.8mu m and 0.45mu m, to obtain phycocyanin crude extracting liquid, then sequentially ultrafiltrating the crude extracting liquid through an ultrafiltration membranes with molecular weight cut-off of 300KD and 100KD, collecting a filtrate of the molecular section, and performing freezing and drying to the filtrate to obtain phycobiliprotein powder. According to the method, the defect of using chemical reagent to extract phycobiliprotein in the prior art is overcome, no residuals exist in the preparation, and the environment pollution does not exist. The extraction rate of the phycobiliprotein is greater than 80%, the content of phycobiliprotein is more than 60%, and the purity of the phycobiliprotein is more than 1.5. The overall technological process is safe and reliable, fast and efficient. Compared with the traditional method, by using the method, the content of the phycobiliprotein is high before using of chromatography, the phycobiliprotein with the purity not only can meet the requirement of food and cosmetic industries, but also can be applied to aspects of medical and health products, and the like.

Owner:何忠志

Method for simultaneously separating and purifying reagent-grade phycocyanin and allophycocyanin

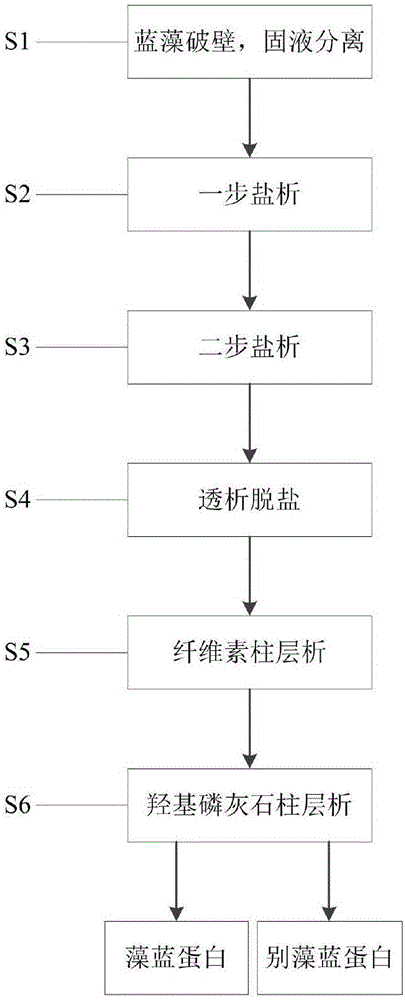

ActiveCN106478810AImprove the efficiency of comprehensive extraction and purificationPeptide preparation methodsDepsipeptidesCellulosePhosphate

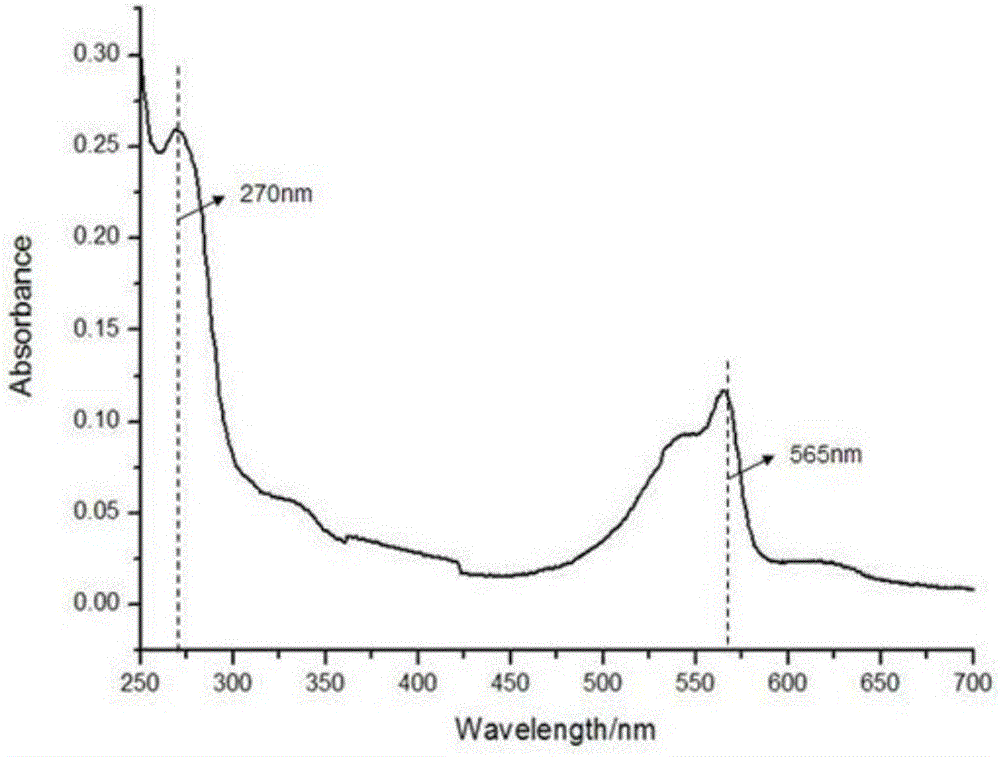

The invention provides a method for simultaneously separating and purifying reagent-grade phycocyanin and allophycocyanin. The method comprises the following steps: breaking walls of blue-green algae and carrying out solid-liquid separation to obtain a phycobiliprotein crude extraction solution; carrying out two-step salting-out to obtain sediment; dissolving the sediment by utilizing a phosphate buffering solution; by taking the phosphate buffering solution as a dialysis solution, dialyzing a dissolved solution so as to obtain a dialyzed phycobiliprotein solution; finally, carrying out cellulose column chromatography and hydroxylapatite column chromatography to obtain the reagent-grade phycocyanin and the reagent-grade allophycocyanin. According to the method provided by the invention, water-bloom fresh blue-green algae is used as a raw material and the reagent-grade phycocyanin and the reagent-grade allophycocyanin are separated and purified by adopting salting-out combined with column chromatography; compared with a traditional chromatography process, high-purity phycocyanin and allophycocyanin can be simultaneously extracted and purified under the premise of considering the recovery rate of protein, and the efficiency of comprehensively extracting and purifying high-value protein in blue-green alga cells is improved and can be amplified.

Owner:HEFEI UNIV OF TECH

Nostoc sphaeroides nutrition powder as well as preparation method and application thereof

ActiveCN104323342ADough treatmentFood ingredient as taste affecting agentNutritive valuesWhey protein

The invention relates to the food field and particularly relates to nostoc sphaeroides nutrition powder as well as a preparation method and application thereof. The nostoc sphaeroides nutrition powder comprises the following components in parts by weight: 5-15 parts of soybean meal, 1-4 parts of whey protein powder, 0.1-1 part of dried nostoc sphaeroides, 1-5 parts of crude nostoc sphaeroides phycobiliprotein extract powder, 1-3 parts of dry nostoc sphaeroides polysaccharide powder and 1-5 parts of fruit powder. The preparation method of the nostoc sphaeroides nutrition powder comprises the following steps: uniformly mixing the components and grinding the components into fine powder, passing the powder through a 55-65-mesh sample separating sieve to obtain the nostoc sphaeroides nutrition powder. The nostoc sphaeroides nutrition powder which is prepared from nostoc sphaeroides and cereals as raw materials has a very high nutritive value and a health function, and can meet the needs of consumer groups in different age stages and body constitutions. The nutrition powder disclosed by the invention can be independently eaten and also can be applied to the food fields of rice flour, noodles, cakes, biscuits, bread, nutritious foods and the like.

Owner:HUNAN YANDI BIOLOGICAL ENG

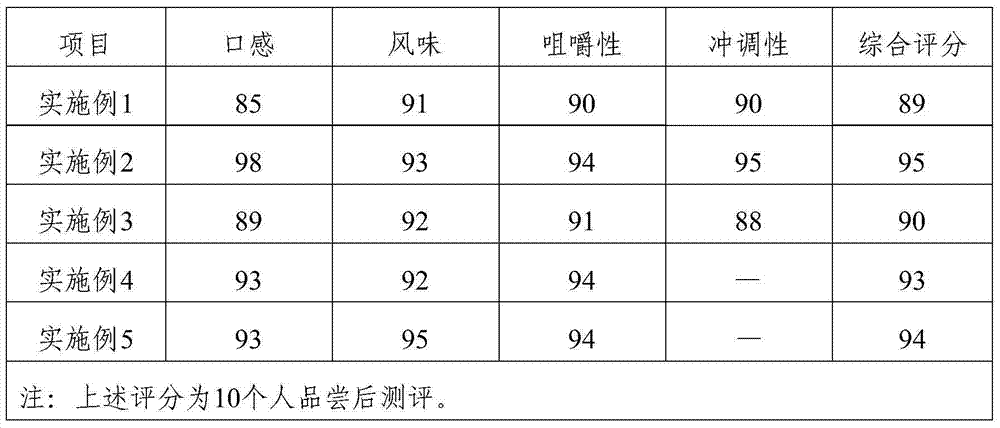

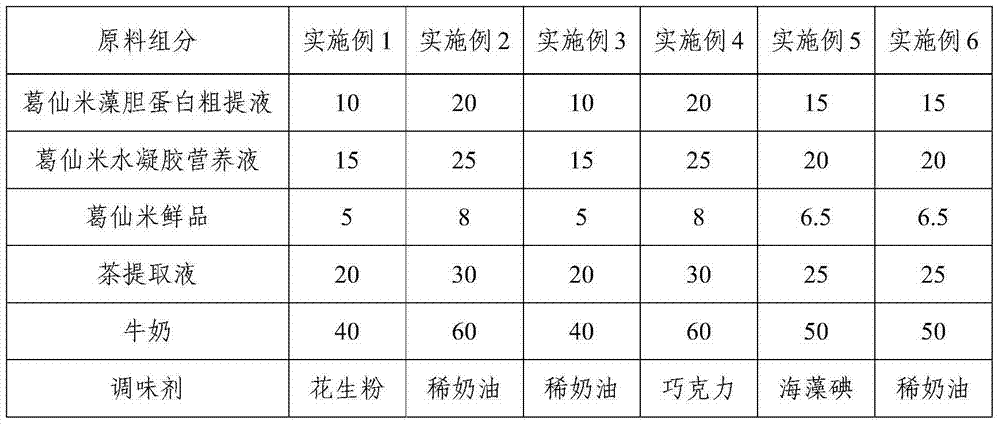

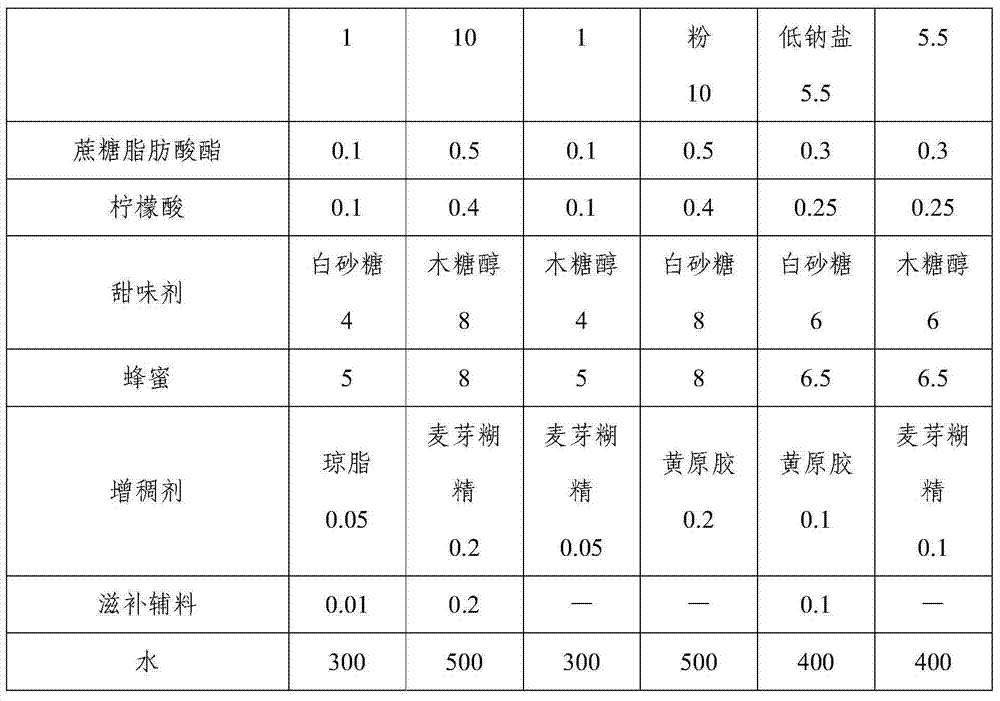

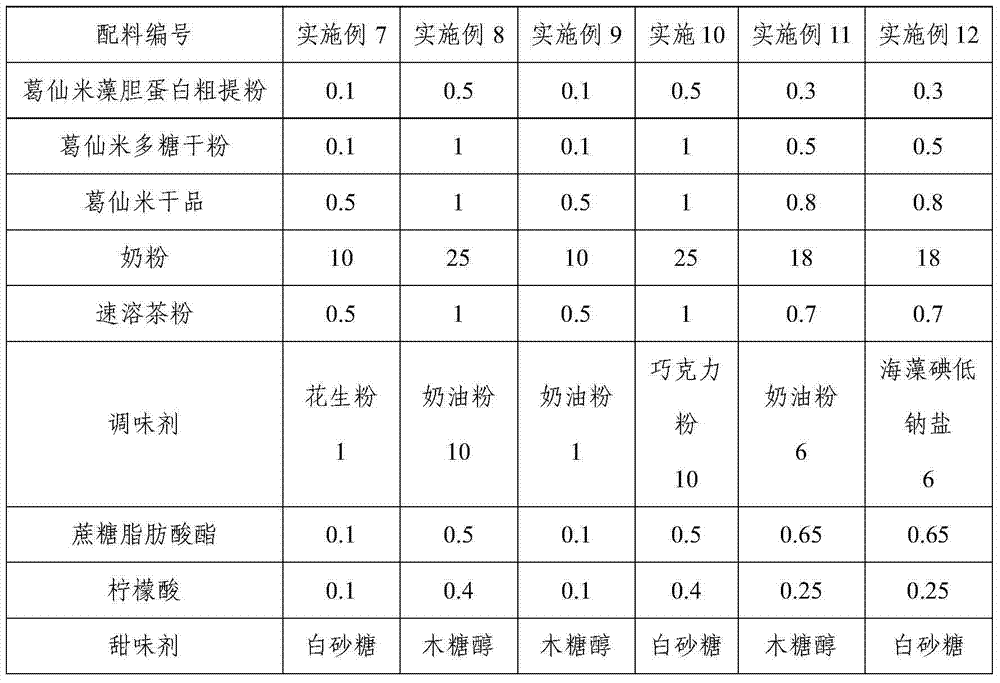

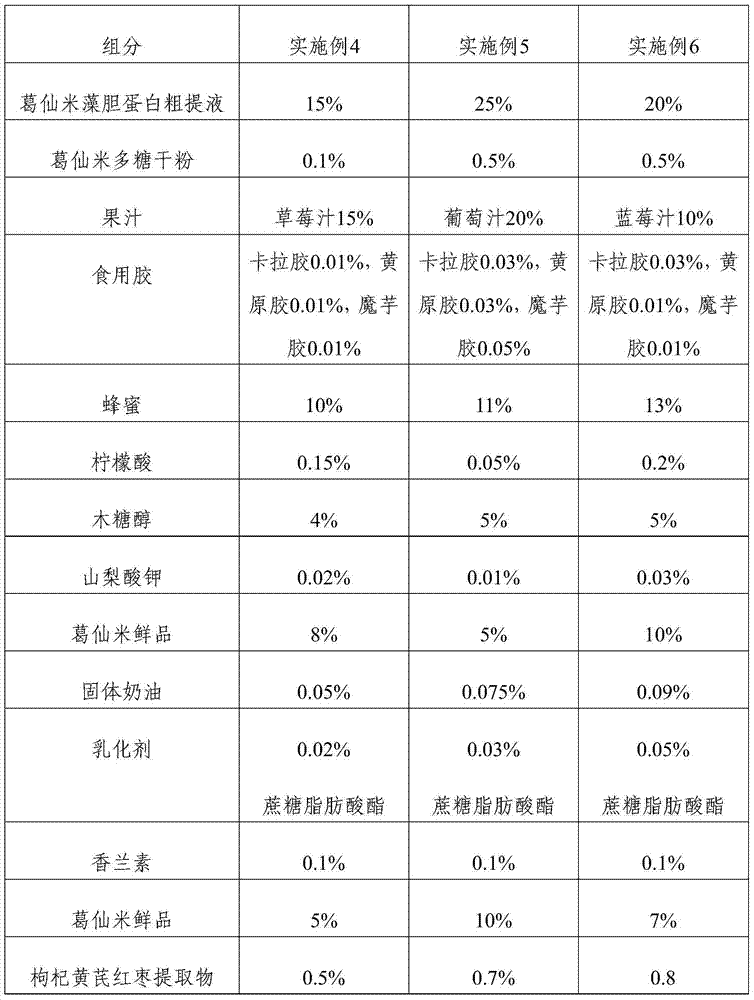

Nostoc sphaeroids kutz milk tea, nostoc sphaeroids kutz milk tea powder and preparation method

The invention relates to the food field, in particular to a nostoc sphaeroids kutz milk tea, a nostoc sphaeroids kutz milk tea powder and a preparation method thereof. The nostoc sphaeroids kutz milk tea comprises the following components in parts by weight: 20 to 30 parts of tea extracting solution, 40 to 60 parts of milk, 10 to 20 parts of rough extract of nostoc sphaeroids kutz phycobiliprotein, 15 to 25 parts of nostoc sphaeroids kutz polysaccharide gel nutrient solution, 1 to 10 parts of flavoring agent. 0.1 to 0.5 part of sucrose fatty acid ester, 0.1 to 0.4 part of citric acid, 4 to 8 parts of sweetening agent, 5 to 8 parts of honey, 0.05 to 0.2 part of thickener and 200 to 500 parts of water. In the invention, the rough extract of nostoc sphaeroids kutz phycobiliprotein and the nostoc sphaeroids kutz polysaccharide gel nutrient solution are added into the milk tea as the natural pigment and stabilizer respectively, so that the color of the milk tea is bright, the taste is mellow; the more important thing is that the nostoc sphaeroids kutz milk tea has unique function of health care.

Owner:CHANGDE YANDI BIOTECH LTD CO +1

Method for separating and purifying high-purity phycobiliprotein from spirulina

InactiveCN101519425AOvercome the disadvantages of lower yieldAvoid cloggingPeptide preparation methodsApatitePhosphate

A method for separating and purifying high-purity phycobiliprotein from spirulina is characterized in that the following steps are carried out at the temperature of 4 DEG C: taking out the spirulina, first breaking spirulina body by ultrasound with the ultrasound time of 10 minutes in a way of gap breaking, and then obtaining initial spirulina extraction solution by centrifugating at high speed for 30 minutes; next, adding ammonium sulfate into the extraction solution to reach 40% saturation, extracting supernatant after centrifugating at medium speed for 15 minutes, adding the ammonium sulfate continuously to reach 50% saturation, and extracting precipitation after centrifugating at medium speed for 15 minutes; then centrifugating the precipitation at high speed for 30 minutes after dissolving the precipitation by using phosphate buffer solution with extremely low concentration, filtering the obtained supernatant by using microporous filtering film with low pore size, desalinating the filtered solution, and adding the desalinated solution to hydroxyapatite column; finally eluting and collecting the phycocyanin from the hydroxyapatite column by using 0.040 M to 0.060 M phosphate salt buffer solution (pH7.0, containing 1 mmol / L EDTA); and eluting and collecting the changed phycocyanin from the hydroxyapatite column by using 0.10 M to 0.12 M phosphate salt buffer solution (pH7.0, containing 1 mmol / L EDTA).

Owner:SHANGHAI FISHERIES UNIV

Preparation method and application of immobilized algal toxin degrading bacteria

ActiveCN103436518AImprove degradation rateImprove toleranceMicroorganism based processesPeptide preparation methodsFiberPhylum Cyanobacteria

The invention discloses a preparation method and an application of immobilized algal toxin degrading bacteria. The preparation method of the immobilized algal toxin degrading bacteria comprises the steps: selecting activated carbon fibers as an immobilization material, after carrying out washing, boiling, hydrochloric acid soaking, drying and other pretreatment steps of the immobilization material, adding into an LB culture medium according to a certain specific value, then inoculating a bacterial strain for degrading microcystins (MCs), and carrying out immobilized culture to obtain the immobilized algal toxin degrading bacteria. In the application of the immobilized algal toxin degrading bacteria, while the activated carbon fibers adsorb algal toxins, the algal toxin degrading bacteria immobilized on the activated carbon fibers can degrade the algal toxins, can greatly shorten the time of degradation of the MCs, and simultaneously can biologically regenerate the activated carbon fibers. The bacterial strain for degrading the MCs has the MC-LR degradation rate of up to 91% or more, and is especially suitable for degradation of the MCs generated in a process of extracting phycobiliproteins from water-blooming cyanobacteria.

Owner:ANHUI UNIVERSITY

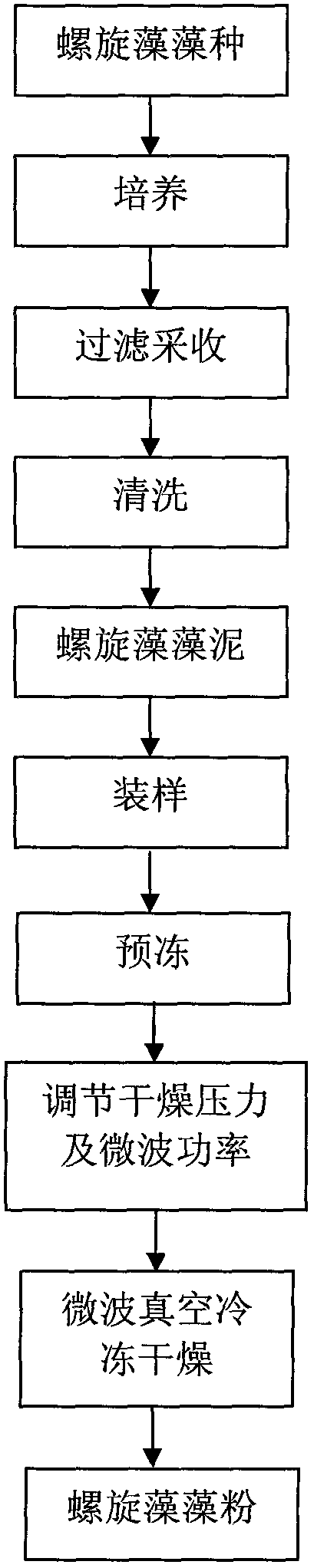

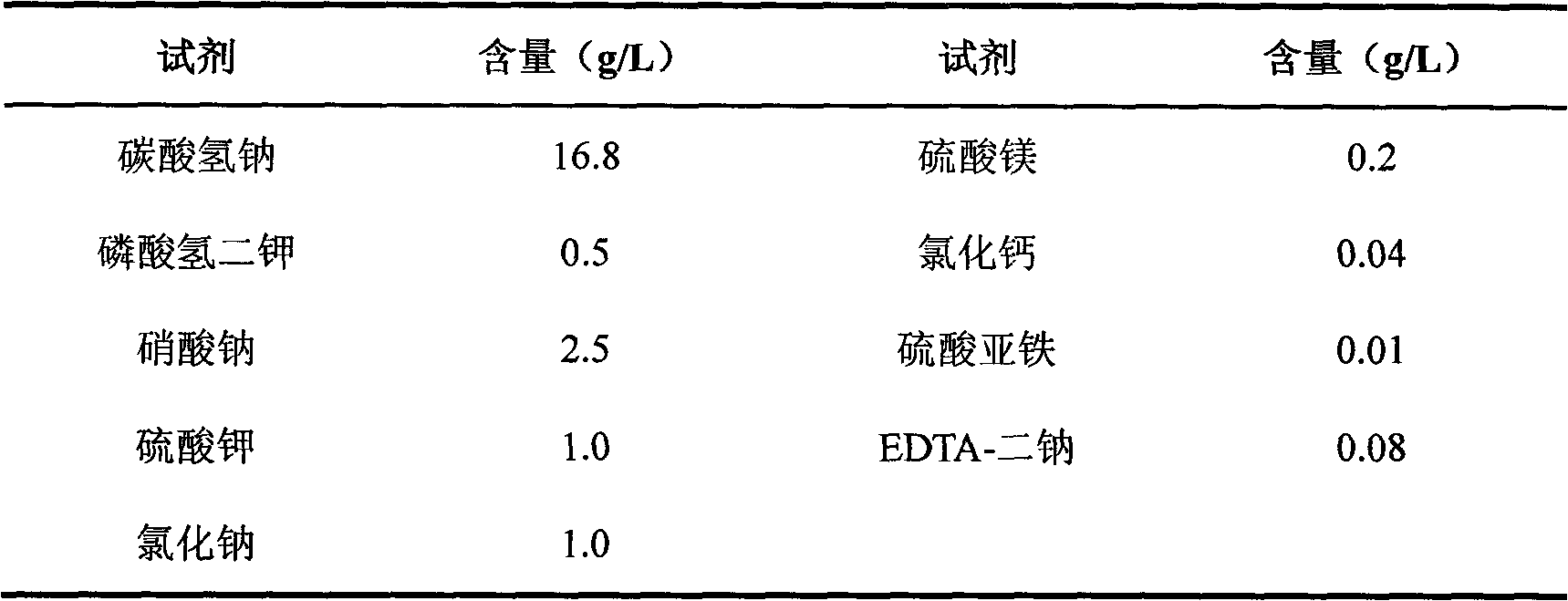

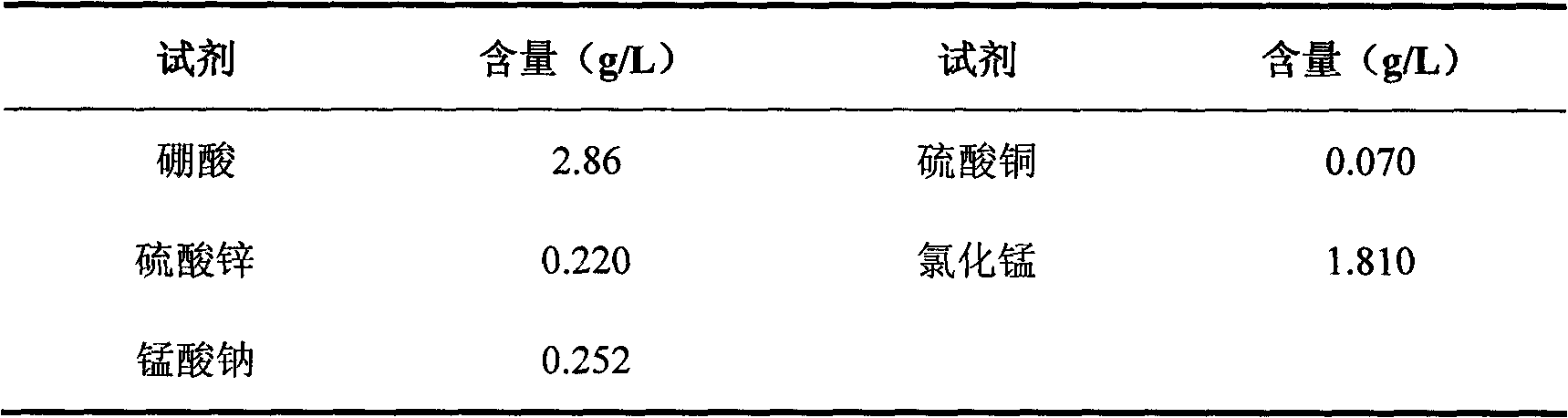

Method for preparing spiral seaweed powder by utilizing microwave vacuum freeze drying

The invention discloses a method for preparing spiral seaweed powder by utilizing microwave vacuum freeze drying. The method disclosed by the invention comprises that fresh spiral seaweed is taken as a raw material, culture, harvesting, precooling and microwave vacuum freeze drying are carried out, thus finally obtaining the spiral seaweed powder. Determination on physical property parameters such as sensory quality, moisture content and fluidity as well as phycobiliprotein content of the dried product shows that microwave vacuum freeze dried spiral seaweed powder has excellent quality and energy consumption is greatly reduced, and the method disclosed by the invention can be applied to spiral seaweed production as the best method and also can be applied to the field of health care food development.

Owner:ORDOS XINYULI SPIRULINA IND GRP

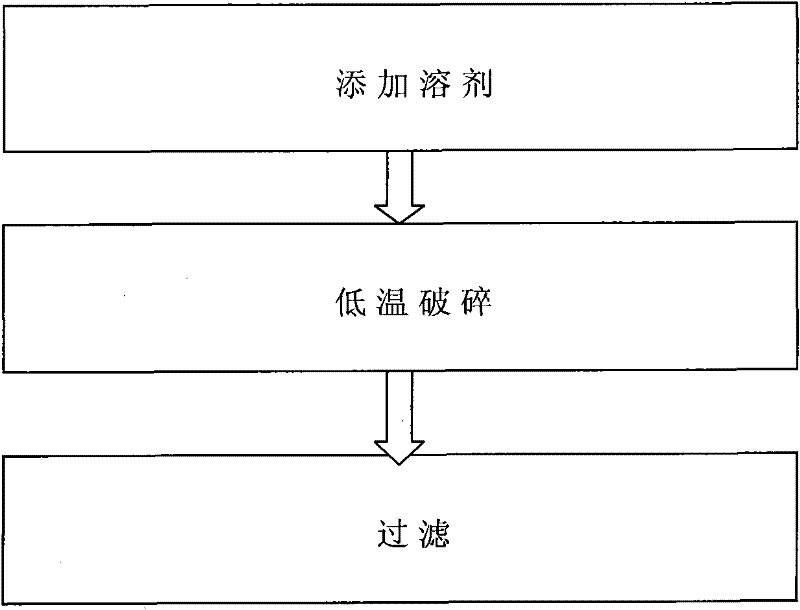

Extraction method of water-soluble spirulina phycobiliprotein

InactiveCN101575359APromote digestionEasily absorbableCosmetic preparationsToilet preparationsFood additiveWater soluble

The invention relates to an extraction method of water-soluble spirulina phycobiliprotein. The extraction method of the water-soluble spirulina phycobiliprotein comprises the following steps: soaking a spirulina raw material into water, stirring and freezing the solution at a temperature of 20 DEG C below zero for 48 hours, taking out and rapidly melting the frozen matter, centrifugating and filtering the solution, extracting the phycobiliprotein from the centrifugal liquid and remaining the spirulina dreg for extracting spirulina polysaccharide; and purifying, concentrating, spraying and drying the obtained centrifugal liquid into the spirulina phycobiliprotein. The extraction method of the water-soluble spirulina phycobiliprotein is simple to operate; the extracted spirulina phycobiliprotein is water-soluble powder so as to be easy for human bodies to desist and absorb, and the water-soluble powder can be further processed to be used as a raw material of food additives, functional foods and medicaments, a natural blue pigment of foods and cosmetics, and the like, thereby having wide serviceable range; and the pretreated spirulina dreg in the extraction process can be remained for extracting the spirulina polysaccharide so as to improve the utilization rate of the spirulina raw material.

Owner:QINGDAO HAIZHIJIAO BIOTECH

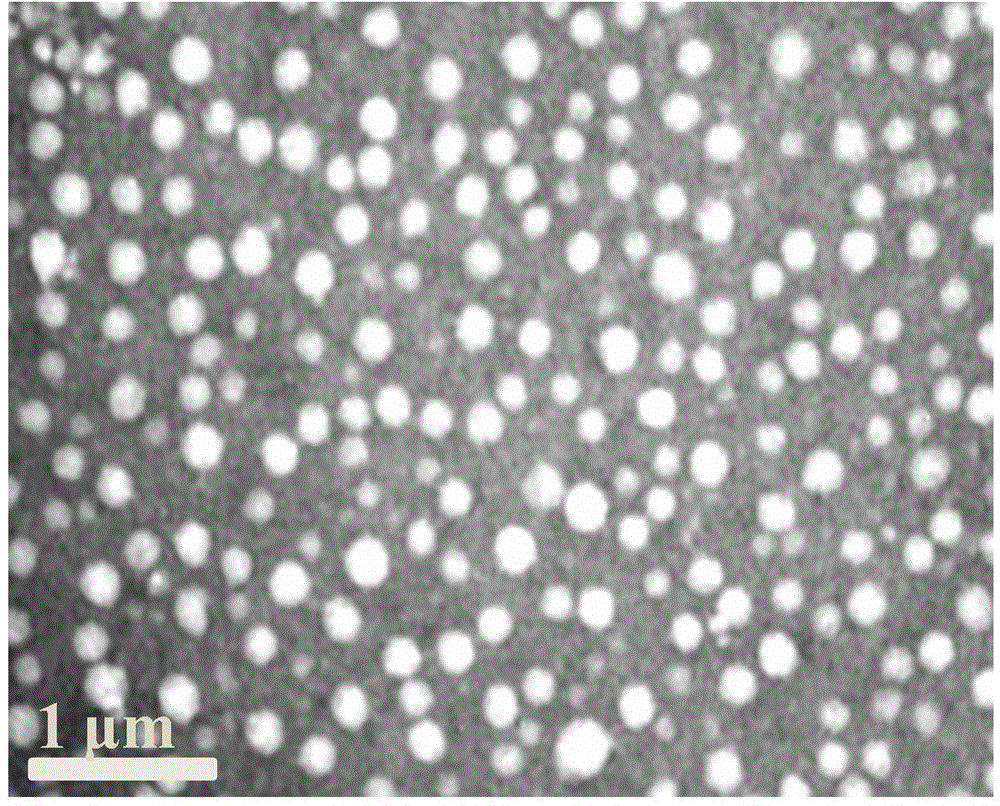

Antitumor drug carrier and application method thereof

ActiveCN104667289AImprove stabilityEasy to storeMacromolecular non-active ingredientsAntineoplastic agentsTumor targetSide effect

The invention relates to the field of biological medicines, and particularly provides an antitumor drug carrier and an application method thereof. The antitumor drug carrier is a phycobiliprotein nano particle. On the basis of the difference between normal cells and tumor cells, the phycobiliprotein nano particle without toxicity and immunogenicity is adopted as the antitumor drug carrier; the tumor-targeting capability is given; meanwhile, antitumor drugs are efficiently loaded; the antitumor drugs specifically reach the tumor lesion part; the treatment effects of high selectivity and low toxicity are realized; and the defects that a traditional cytotoxic drug is poor in selectivity and relatively high in toxic and side effect, and the drug resistance is easily generated are overcome. The preparation method provided by the invention is simple and feasible; and the prepared product can be stably stored in a water solution and is beneficial to storage.

Owner:GUANGDONG JINAN ESTABLISHED SELENIUM SOURCE NANO TECH RES INST CO LTD

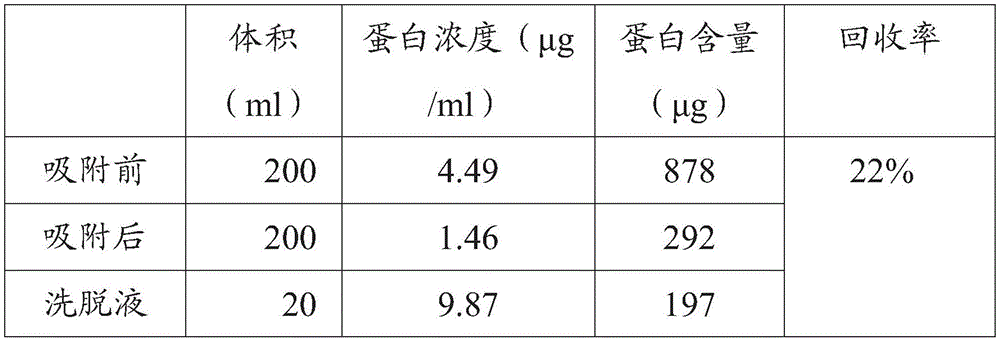

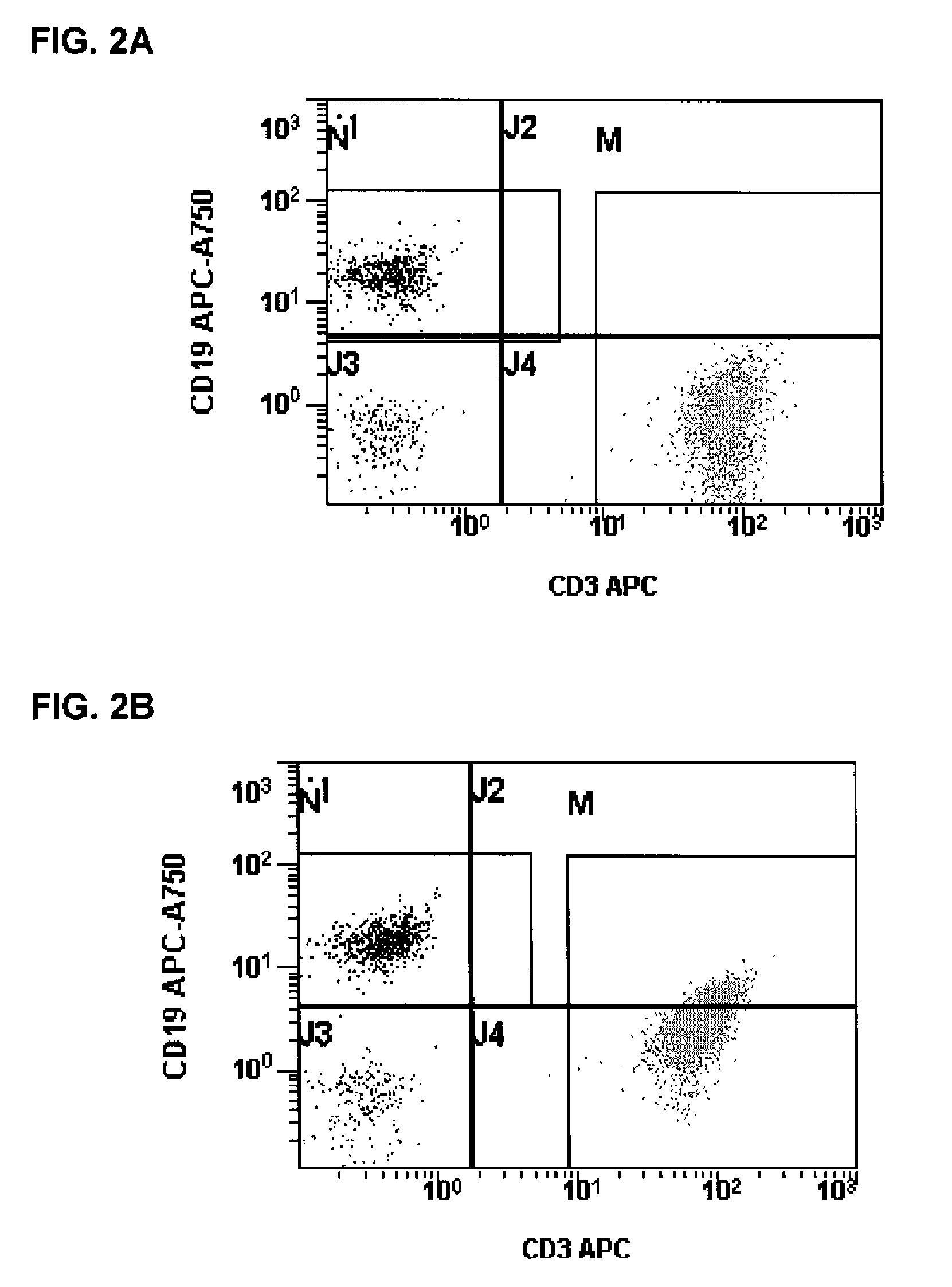

Method for adsorbing and removing phycobiliprotein and microcystin-LR by modified attapulgite

InactiveCN101734746ALow costRich reservesOther chemical processesWater/sewage treatment by sorptionMicrocystinWastewater

The invention discloses a method for adsorbing and removing phycobiliprotein and microcystin-LR by modified attapulgite compounded by organic polymer, comprising the steps of compounding the attapulgite and chitosan powder according to the ratio of 50-100:0.5-2 by mass, adding the compounded mixture into waste water containing phycobiliprotein and microcystin-LR according to the ratio of 0.1-2g / L, stirring, standing, and spooning or filtering to remove the floc. The invention has the characteristics of low cost, high removal efficiency and environmental friendliness, and has larger application value and market prospect.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Nostoc sphaeroids kutz sweetmeat and production method thereof

InactiveCN106561945AIncrease profitGood nutrition and health benefitsConfectionerySweetmeatsFruit juiceSugar

The present invention relates to a nostoc sphaeroids kutz sweetmeat and a production method thereof, wherein the nostoc sphaeroids kutz sweetmeat is prepared from the following raw materials by weight: 50-70 parts of fresh nostoc sphaeroids kutz, 25-45 parts of dendrobium candidum, 5-10 parts of nostoc sphaeroids kutz polysaccharide dry powder, 10-20 parts of fruit juice powder, and 10-25 parts of white sugar or rock candy. The production method comprises: decocting dendrobium candidum and nostoc sphaeroids kutz polysaccharide dry powder to obtain an extraction liquid; adding fruit juice powder and white sugar or rock candy to the extraction liquid according to a certain ratio, uniformly mixing, adding fresh nostoc sphaeroids kutz being subjected color protection hardening, and impregnating; and drying at a temperature 35-40 DEG after completing the impregnating so as to obtain the product. According to the present invention, the nostoc sphaeroids kutz sweetmeat has advantages of complete nutrition and excellent taste, and has health functions of invigoration, health enhancing, aging resistance, oxidation resistance, antitumor, and the like; and the production method is simple and easy to perform, and the activities of the phycobiliprotein and the polysaccharide of the nostoc sphaeroids kutz cannot be damaged to the greatest extent.

Owner:CHANGDE YANDI BIOTECH LTD CO +1

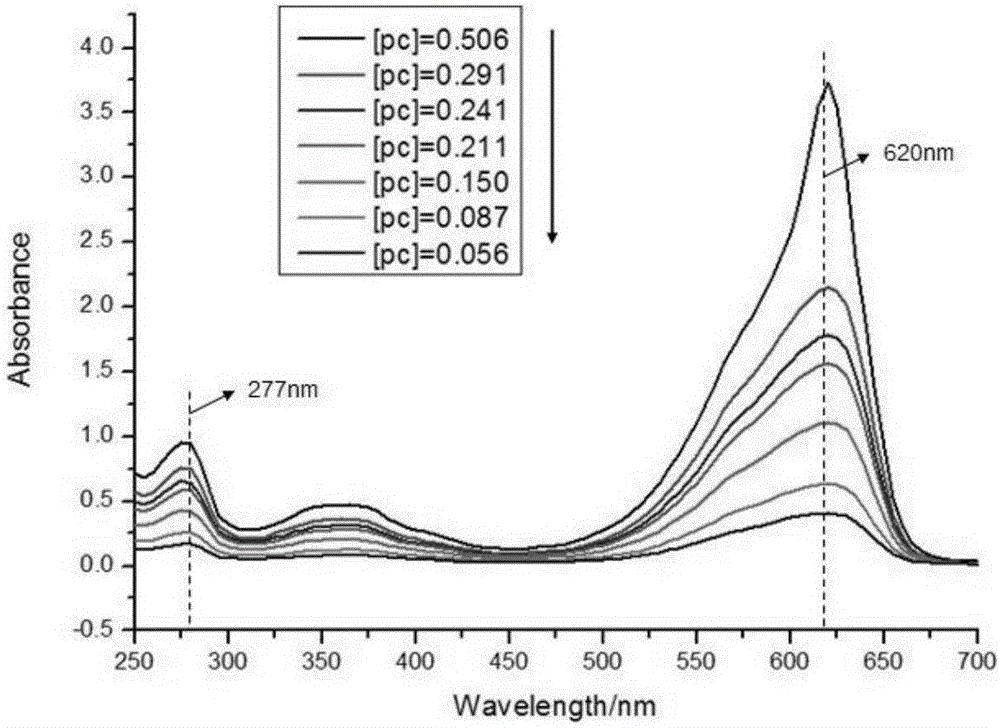

Sphaeroides phycobiliprotein extraction process

The invention relates to a sphaeroides phycobiliprotein extraction process. According to the invention, the sphaeroides phycobiliprotein extraction process and stability thereof are studied. The sphaeroides phycobiliprotein extraction process is optimized with single factor experiments. As a result, when NaCl concentration is 0.24mol / L, pH value is 7 and an extraction time is 4.2h, the phycobiliprotein yields are the highest, which are relatively 7.004%, 7.438%, and 5.942%. As a result of phycocyanin stability experiments, phycocyanin is relatively stable when the temperature is below 30 DEG C, an alcohol concentration is below 10% and the pH value is 6-8.

Owner:ZHENGZHOU GUOSHOU BIOLOGICAL TECH CO LTD

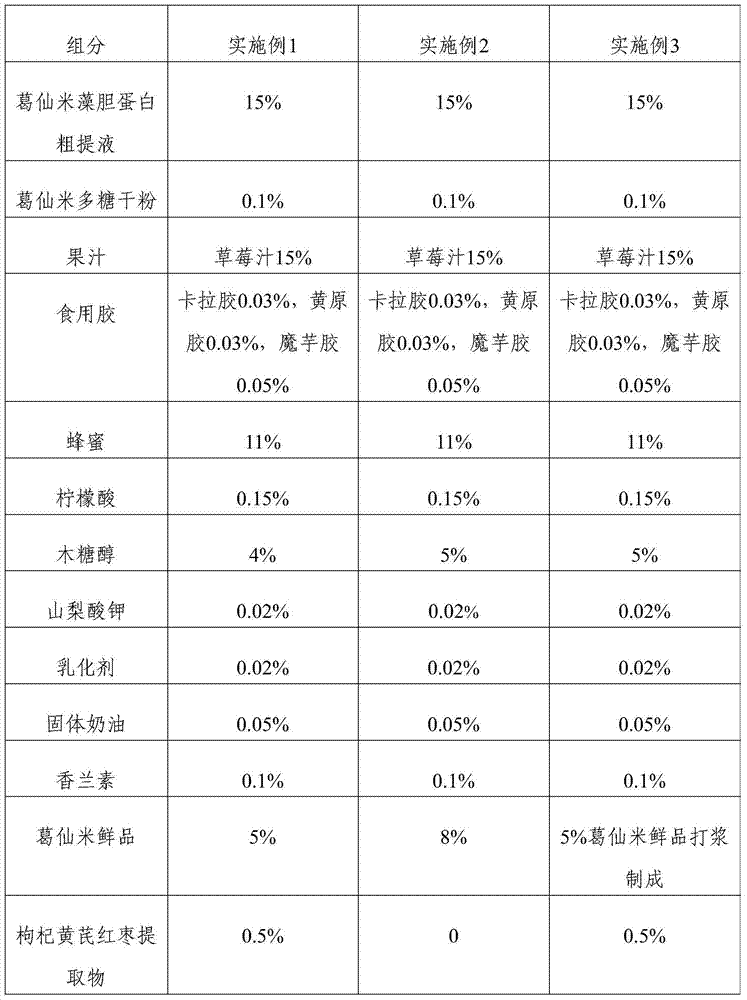

Nostoc sphaeroids kutz jelly and preparation method

ActiveCN104323065ASimple manufacturing methodActivity is not destroyedFood preparationFruit juiceNutrient solution

The invention relates to the food field, in particular to a nostoc sphaeroids kutz jelly. The nostoc sphaeroids kutz jelly comprises the following components in percentage by weight: 15 to 25 percentage of rough extract of nostoc sphaeroids kutz phycobiliprotein, 0.1 to 0.5 percentage of dry polysaccharide powder, 10 to 20 percentage of juice, 0.03 to 0.2 percentage of edible gum, 10 to 13 percentage of honey, 0.05 to 0.2 percentage of citric acid, 4 to 5 percentage of xylitol, 0.01 to 0.03 percentage of potassium sorbate, 0.01 to 0.05 percentage of emulsifier, 0.01 to 0.1 percentage of solid cream, 0.1 to 0.2 percentage of vanillin, and the balance of water. The nostoc sphaeroids kutz jelly disclosed by the invention not only has bright color and brings fresh and pleasure sensation to human vision, but also has the function of oxidation resistance and enhances human immunity. Through the compound use of the nostoc sphaeroids kutz gel nutrient solution and edible gel, the dosage of the edible gel is reduced, and the jelly is better in taste.

Owner:CHANGDE YANDI BIOTECH LTD CO +1

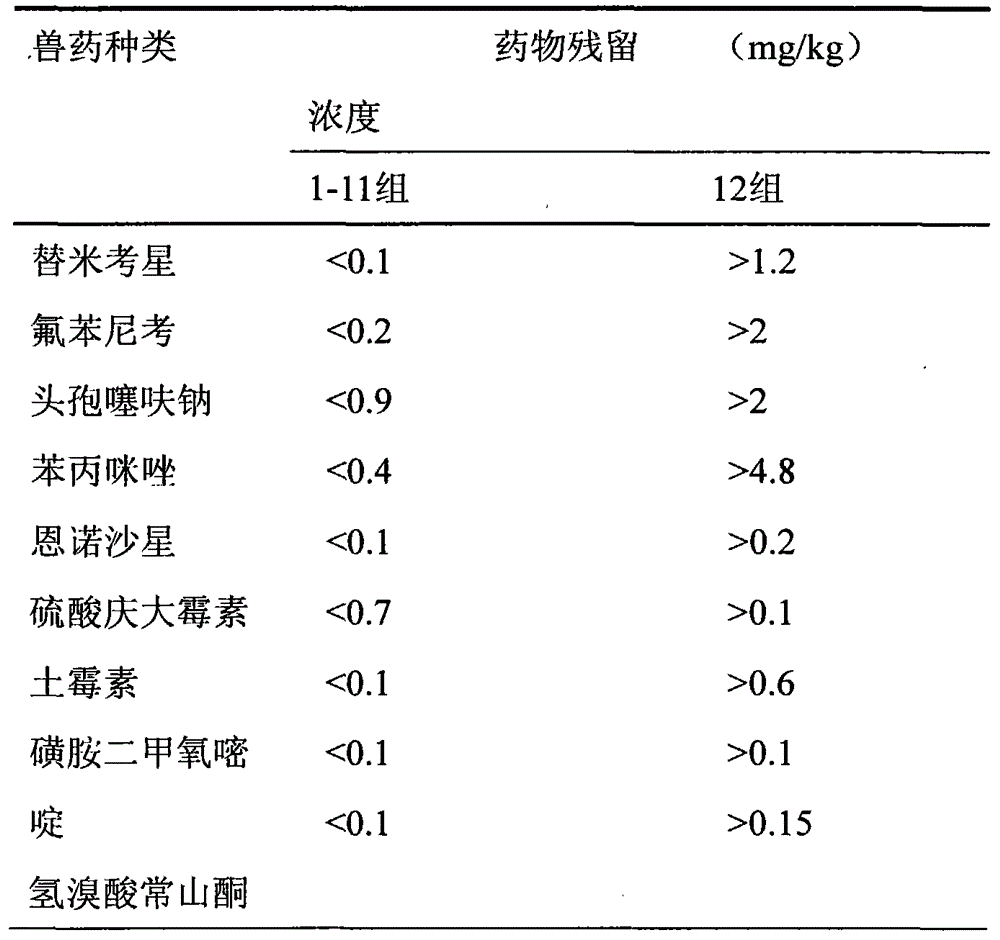

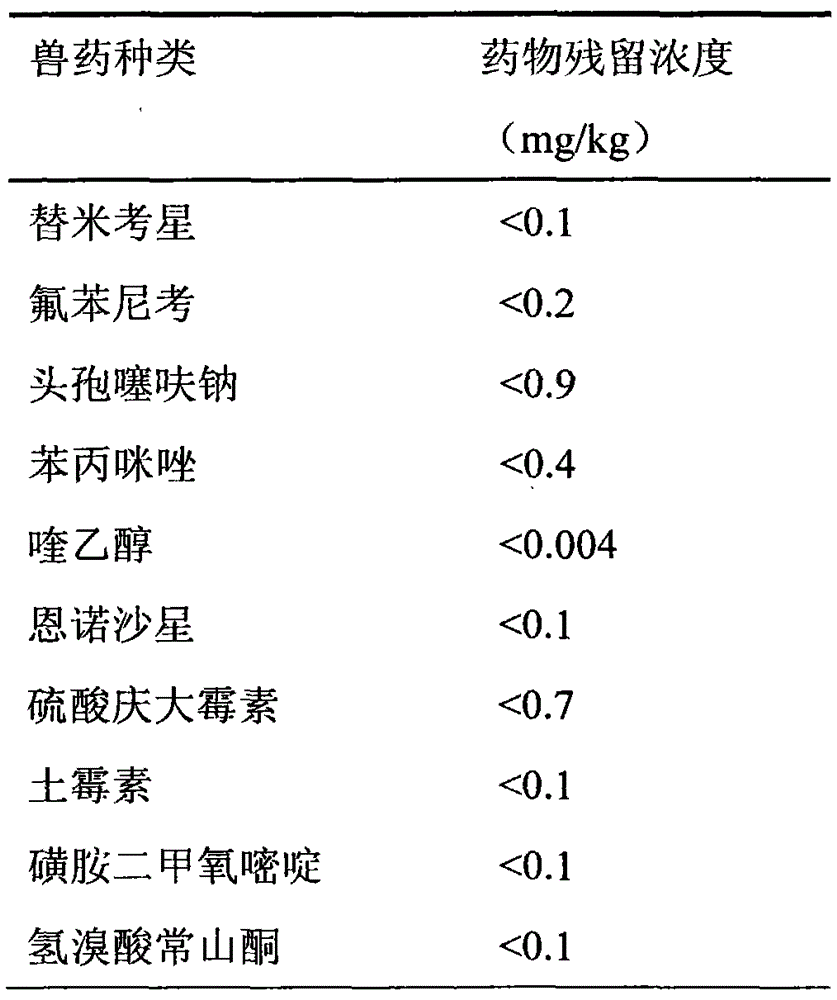

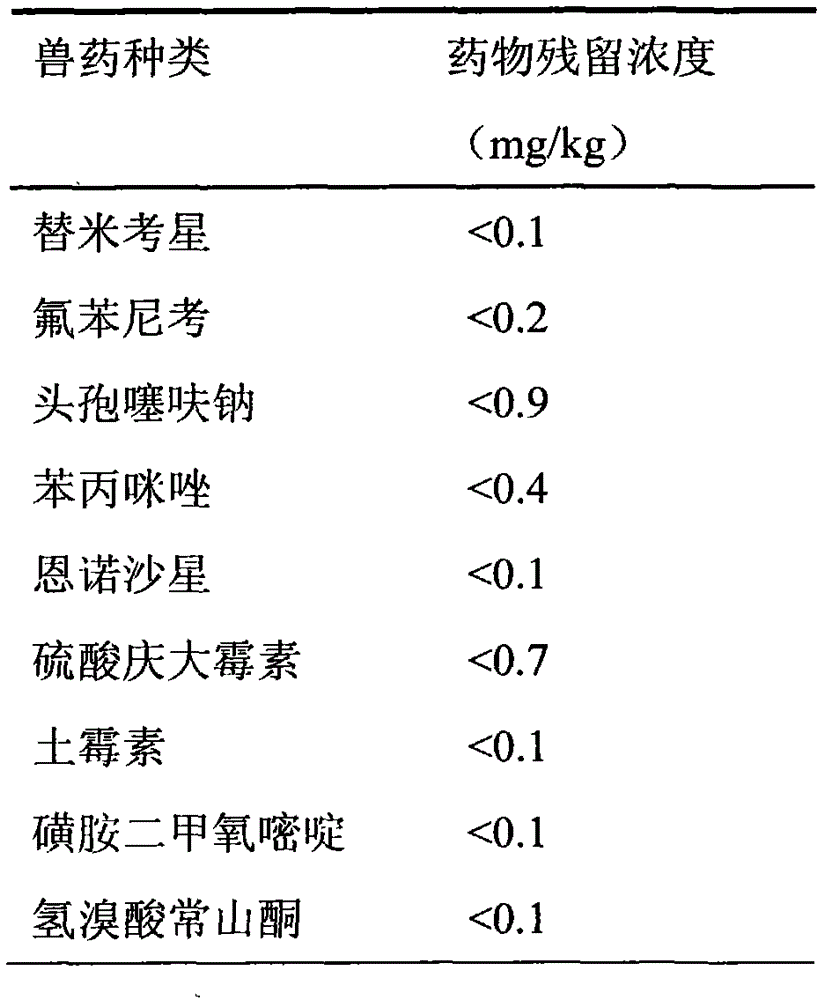

Natural compound feed additive for removing veterinary drug residues

InactiveCN104543404AAchieve productionGuarantee normal productionAnimal feeding stuffAstaxanthinVeterinary Drugs

The invention discloses a natural compound feed additive for removing veterinary drug residues. The natural compound feed additive is prepared from the following components in parts by weight: 1 part of procyanidine, 1 part of astaxanthin, 1 part of resveratrol, 1 part of curcumin, 1 part of allicin, 1 part of porphyra polysaccharide, 1 part of porphyra polyphenol, 1 part of phycobiliprotein, 1 part of tea polyphenol, 1 part of quercetin, 1 part of chitosan and 1 part of tangeretin; and the ratio of the feed additive to the feed is (1:100) to (1:500) in use. According to the method, the residues of tilmicosin, florfenicol, ceftiofur sodium, thiabendazole, enrofloxacin, gentamicin sulfate, oxytetracycline, sulfadimethoxine and halofuginone hydrobromide in livestock or poultry bodies can be effectively reduced; the natural compound feed additive has the characteristics of being free of pollution and free of public hazard, and can be applied to removal of veterinary drug residues from food animals of which the veterinary drug residues exceed the standard due the factors such as veterinary drug application and environmental pollution, so as to ensure the hygiene and safety of animal food.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

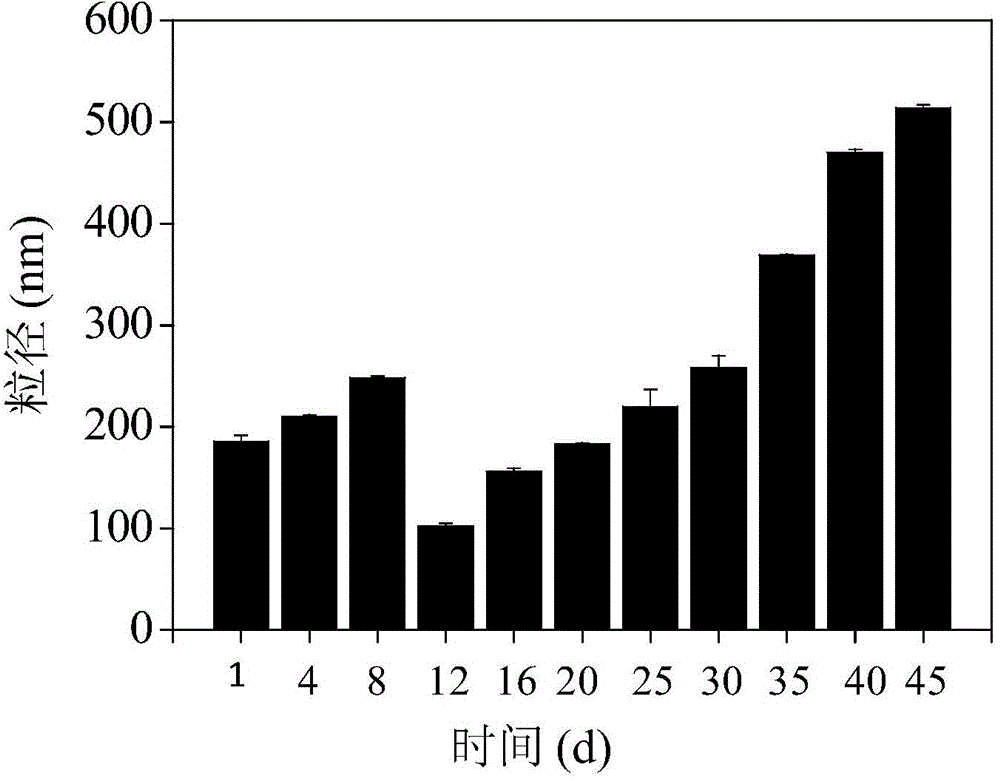

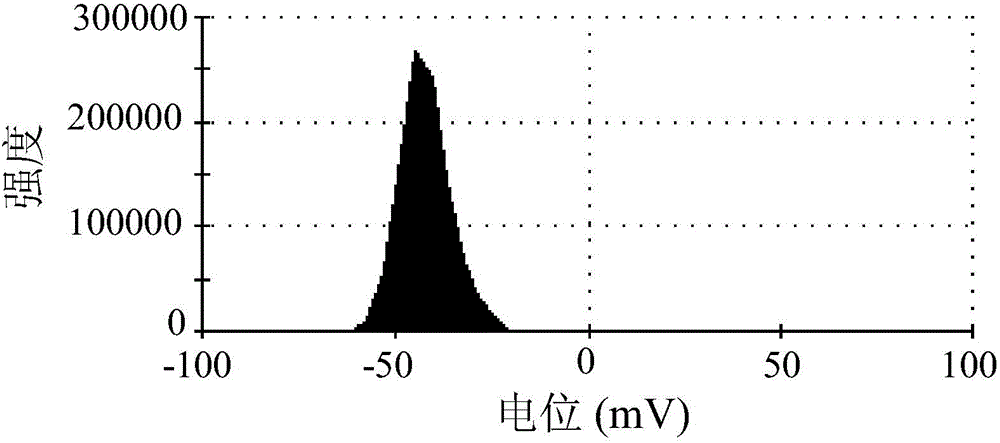

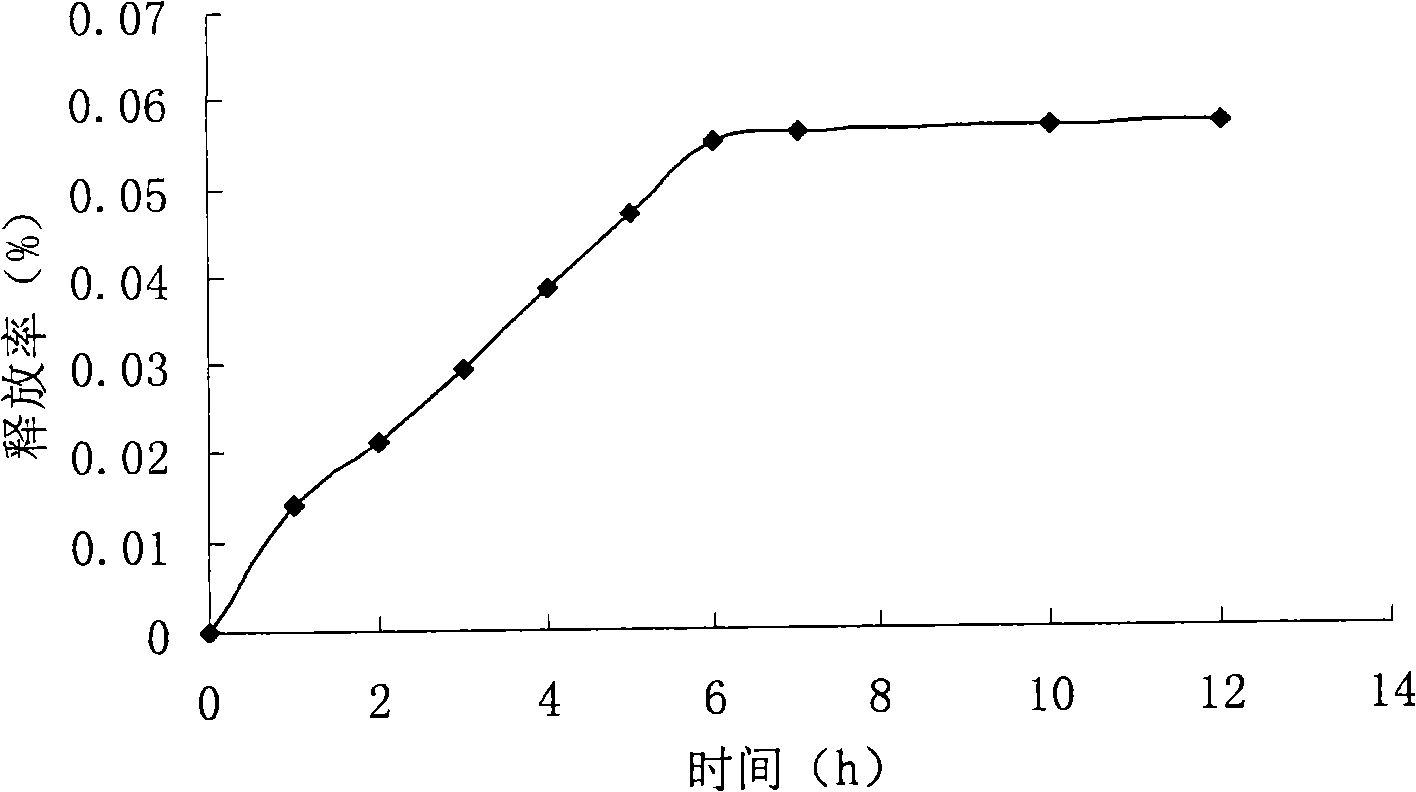

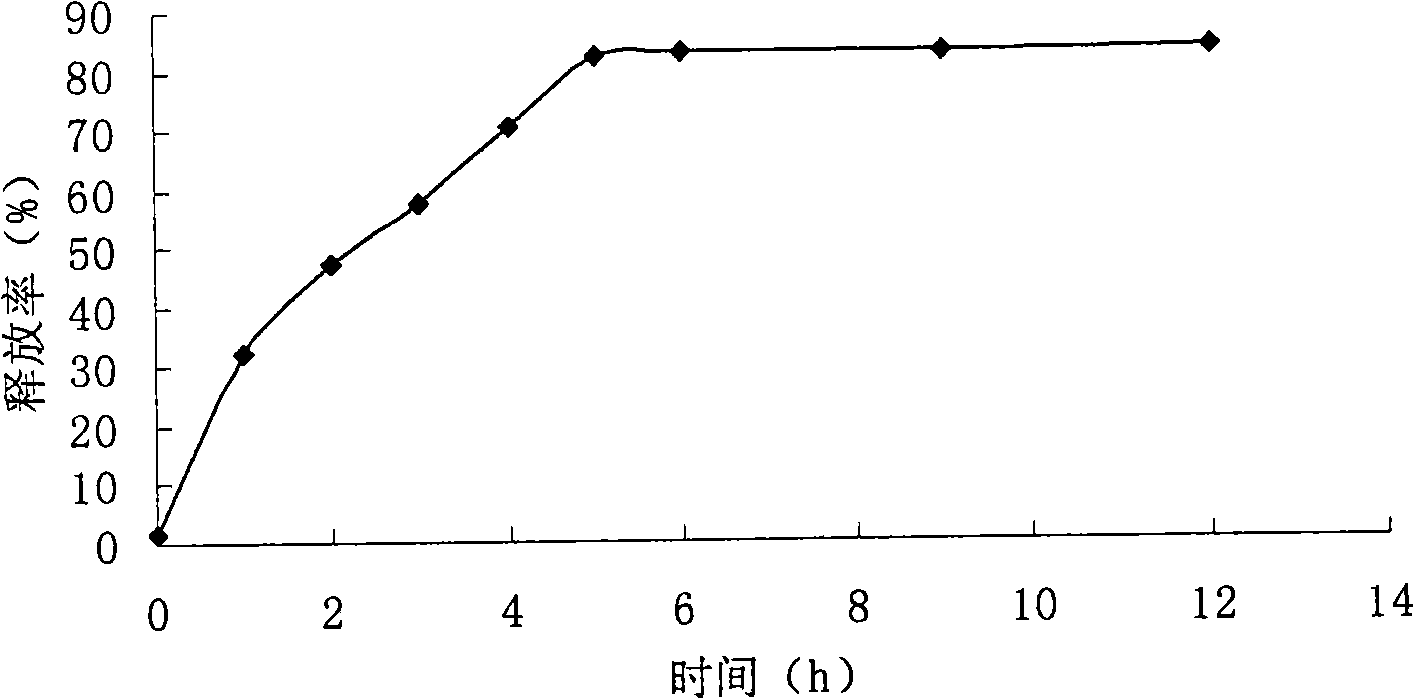

Controllable sustained-release fine particle of phycobiliprotein and preparation method thereof

InactiveCN101292731AControl releaseImprove stabilityAlgae medical ingredientsMicroorganism/unicellular-algae proteins working-upControlled releaseCalcium alginate

The invention discloses a controllable slow-released granule of phycobiliprotein, which consists of wall material and core material made from the dry powder of the phycobiliprotein; the weight ratio of the core material to the wall material is 1: 4-8. The weight percentages of each composition of the wall material are 1 percent to 10 percent of sodium alginate, 0.1 percent to 10 percent of calcium alginate and 0.1 percent to 5 percent of chitosan, and the rest is water. The controllable slow-released granule of the phycobiliprotein takes the sodium alginate, calcium alginate and chitosan after extraction and processing as the wall material and takes the dry powder of phycobiliprotein as the core material, and phycobiliprotein micro-capsules are prepared by a method of low-temperature embedding under the acidic condition; thus the prepared controllable slow-released granule of the phycobiliprotein can realize controllable slow releasing in a living organism environment; the preparation technique of the invention is simple and practical, and the prepared wall material is edible and is characterized by being enteric-coated; the controllable slow-released granule of the phycobiliprotein can realize controllable slow releasing, can avoid the environmental influences such as light, heating, acid and alkali, etc., thereby effectively prolonging the storage time of the phycobiliprotein and greatly increasing the stability of the phycobiliprotein.

Owner:JIMEI UNIV

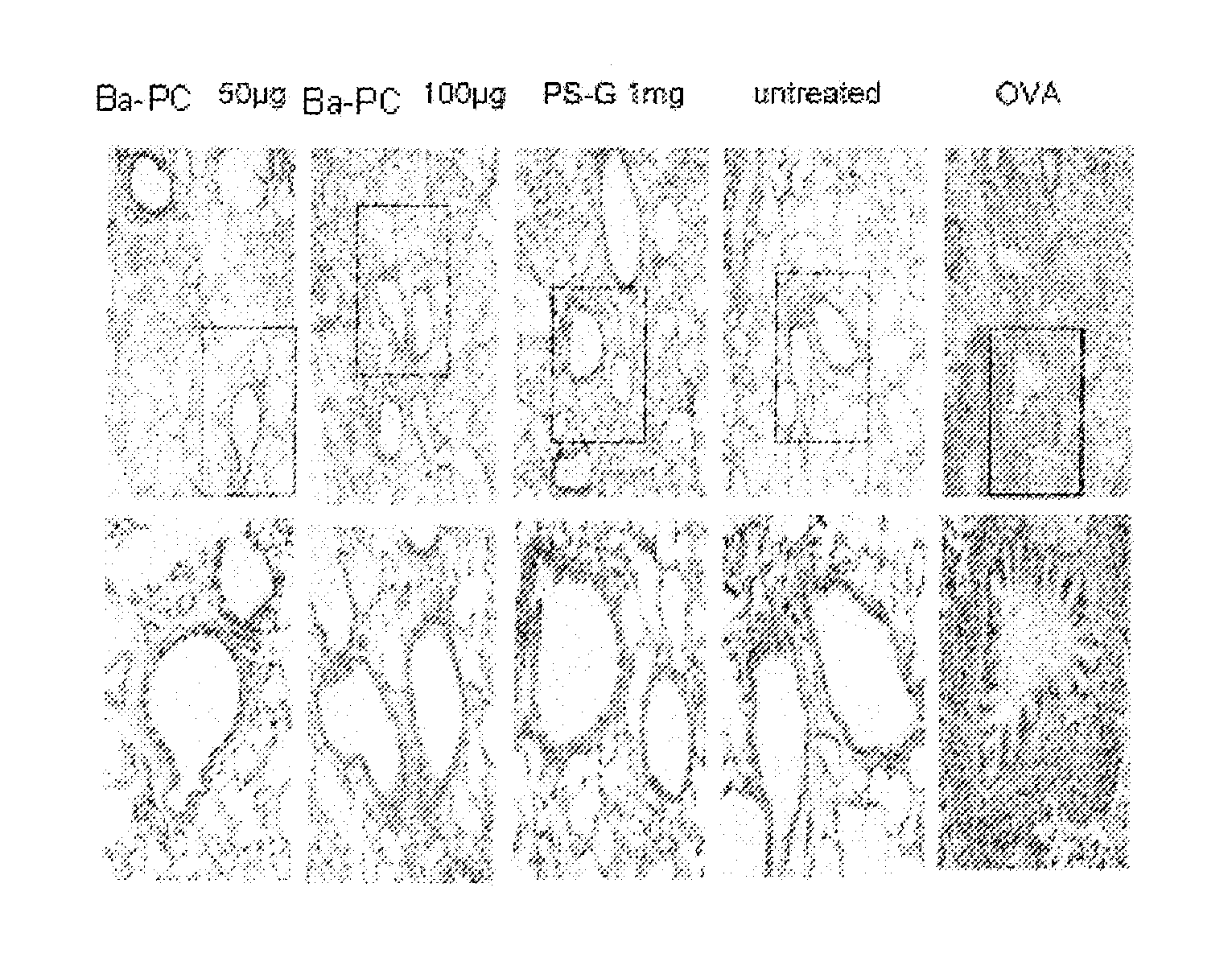

Methods for Treating Allergic Disease

InactiveUS20110038882A1Safe to drinkSafe to eatPeptide/protein ingredientsAntipyreticT cellDisease cause

A method for treating or alleviating allergic disease in a mammal in need thereof having administering to the mammal a therapeutically effective amount of a pharmaceutical composition having phycocyanin is provided. A method for modulating balance between Th1 and Th2 immune response in a mammal in need thereof, having administering to the mammal an effective amount of phycocyanin, wherein immune response of the mammal is skewed toward the Th1 immune response is also provided. Phycocyanin from Bangia atropupurea (Ba-PC) is identified to regulate mammalian immunological response indicating that Ba-PC can direct skewed immune response toward Th1 response through modulating DC function, increase proliferative activity of antigen-specific T cells and alleviate airway inflammation, confirming that phycobiliproteins are effective in treating allergic disease.

Owner:NAT TAIWAN UNIV

Method for separating phycobiliprotein from laver processing wastewater

ActiveCN105601732AAchieve the purpose of usingReduce pollutionDepsipeptidesPeptide preparation methodsWastewaterIon exchange

The invention discloses a method for separating phycobiliprotein from laver processing wastewater. The method comprises the following steps: (1) filtering laver processing wastewater to remove impurities to obtain laver processing wastewater without impurities; (2) adsorbing phycobiliprotein in the laver processing wastewater without impurities with ion exchange packing so as to obtain phycobiliprotein adsorbed ion exchange packing; and (3) eluting the phycobiliprotein adsorbed ion exchange packing with 0.1-0.5M of sodium chloride-PBS buffer solution to obtain purified phycobiliprotein. According to the method, purified high-active-value phycobiliprotein can be reclaimed from laver processing wastewater, so that the aim of waste utilization can be achieved; meanwhile, environmental pollution caused by direct drainage of laver processing wastewater can be reduced due to extraction of the phycobiliprotein.

Owner:南通中国科学院海洋研究所海洋科学与技术研究发展中心 +1

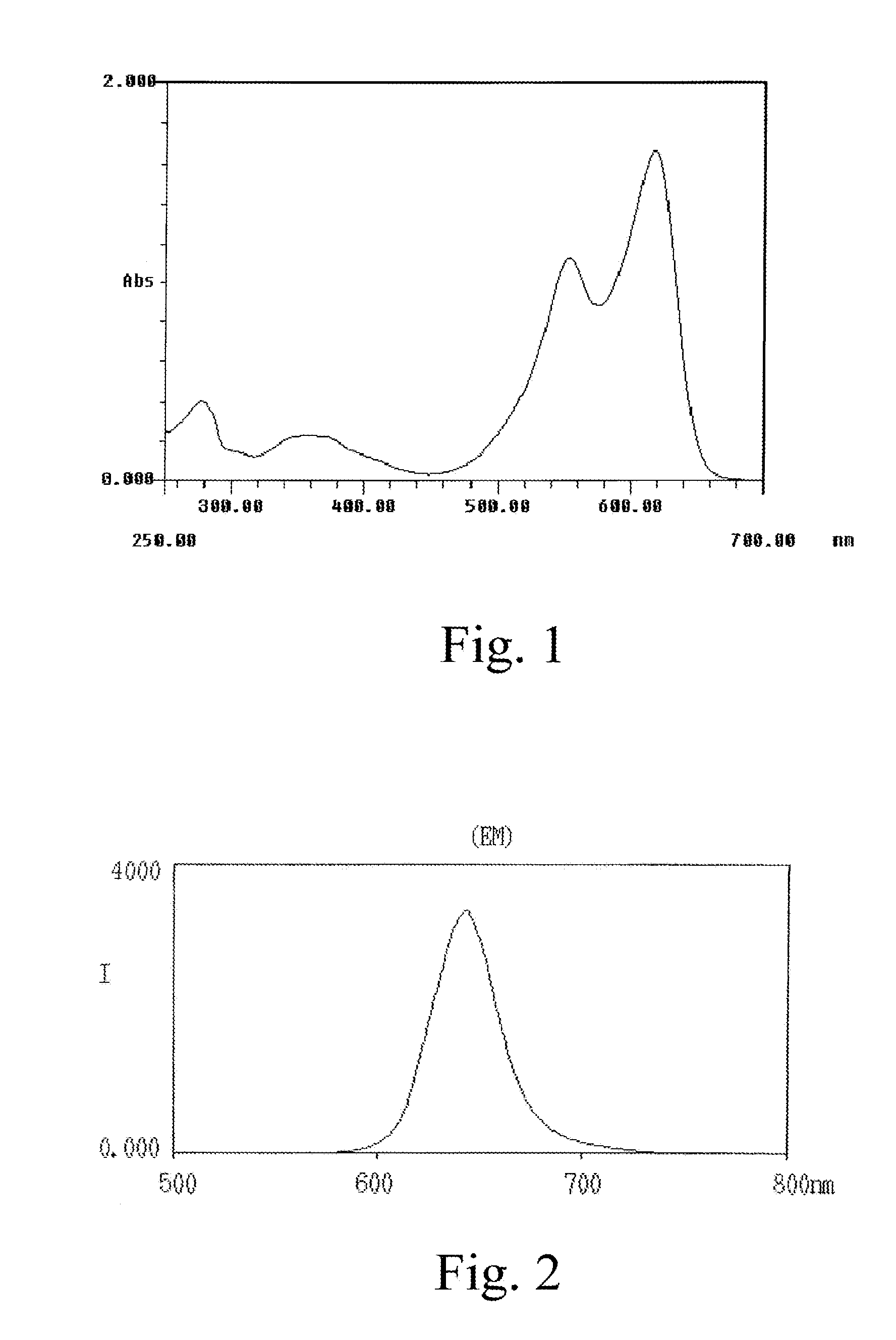

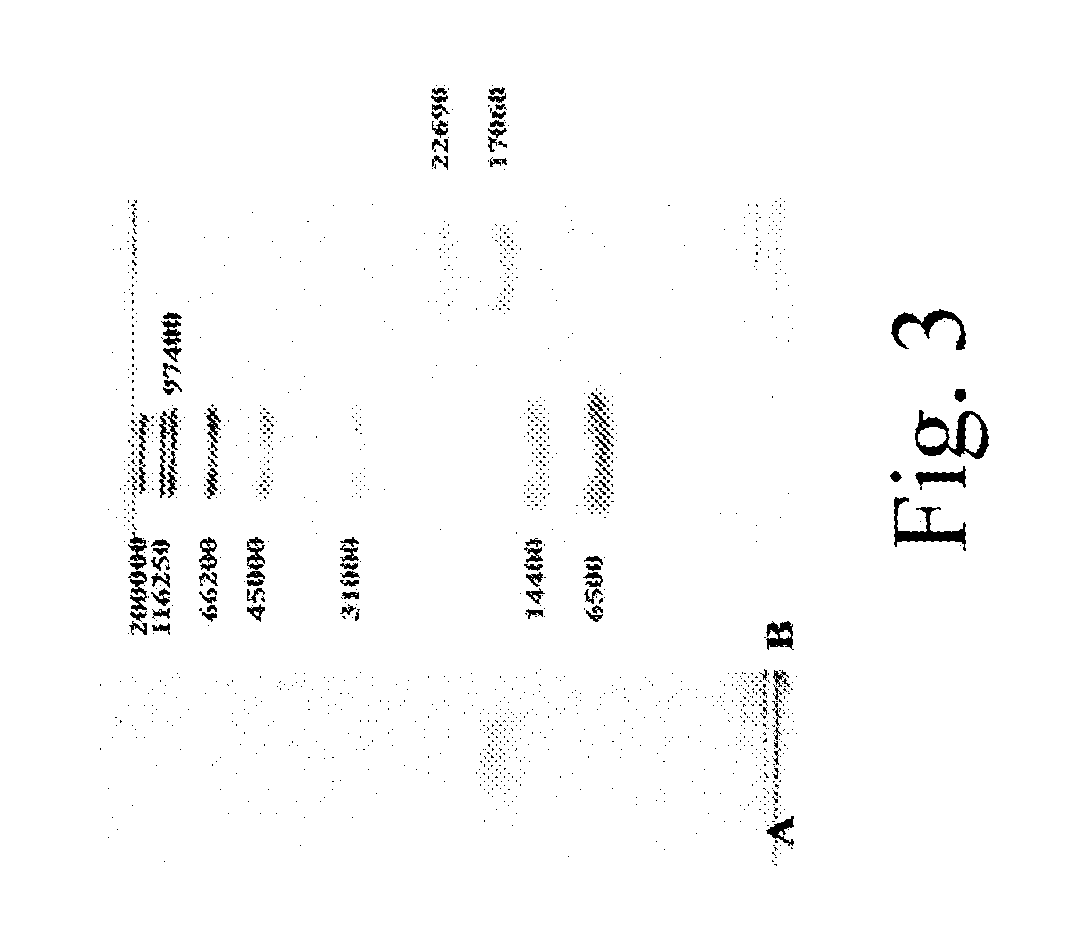

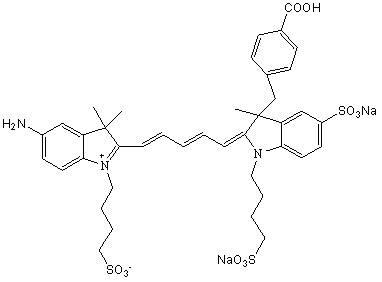

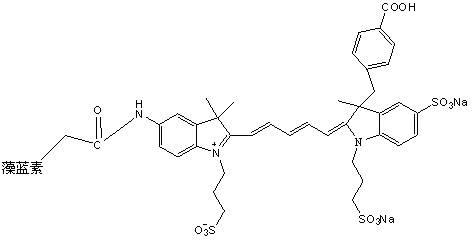

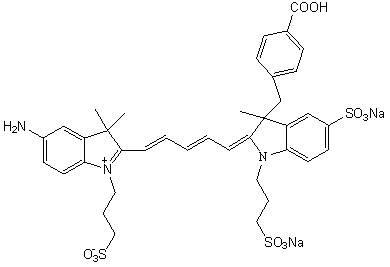

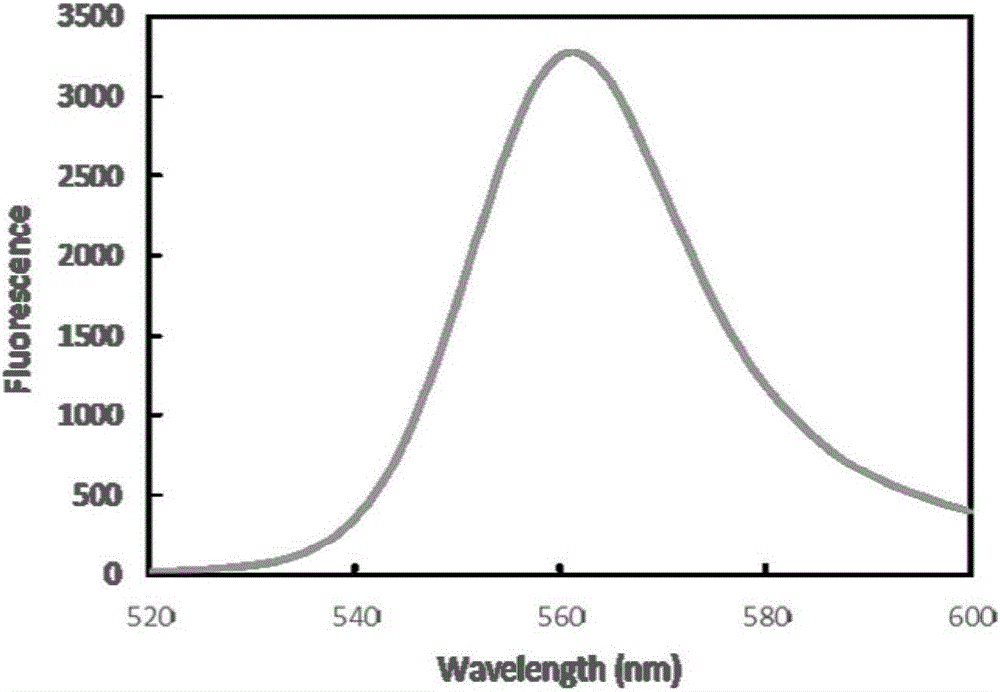

Near-infrared fluorescent probe with maximum Stoke displacement

InactiveCN102127059ALarge Stoke displacementSmall molecular weightOrganic chemistryBiological testingMolecular recognitionTumor marker

The invention relates to a near-infrared fluorescent probe with maximum Stoke displacement, belonging to the technical field of specific molecular recognition diagnostic reagents. The invention provides a fluorescent dye with maximum Stoke displacement, which is prepared by coupling phycocyanobilin in phycobiliprotein with a near-infrared fluorescent dye. The fluorescent dye has maximum Stoke displacement reaching above 300nm, has the characteristic of smaller molecular weight, can be used for marking matters with small molecular weight, such as folic acid and the like, and is used for specific fluorescence detection of a tumor marker, an antibody and the like.

Owner:江苏迈健生物科技发展股份有限公司

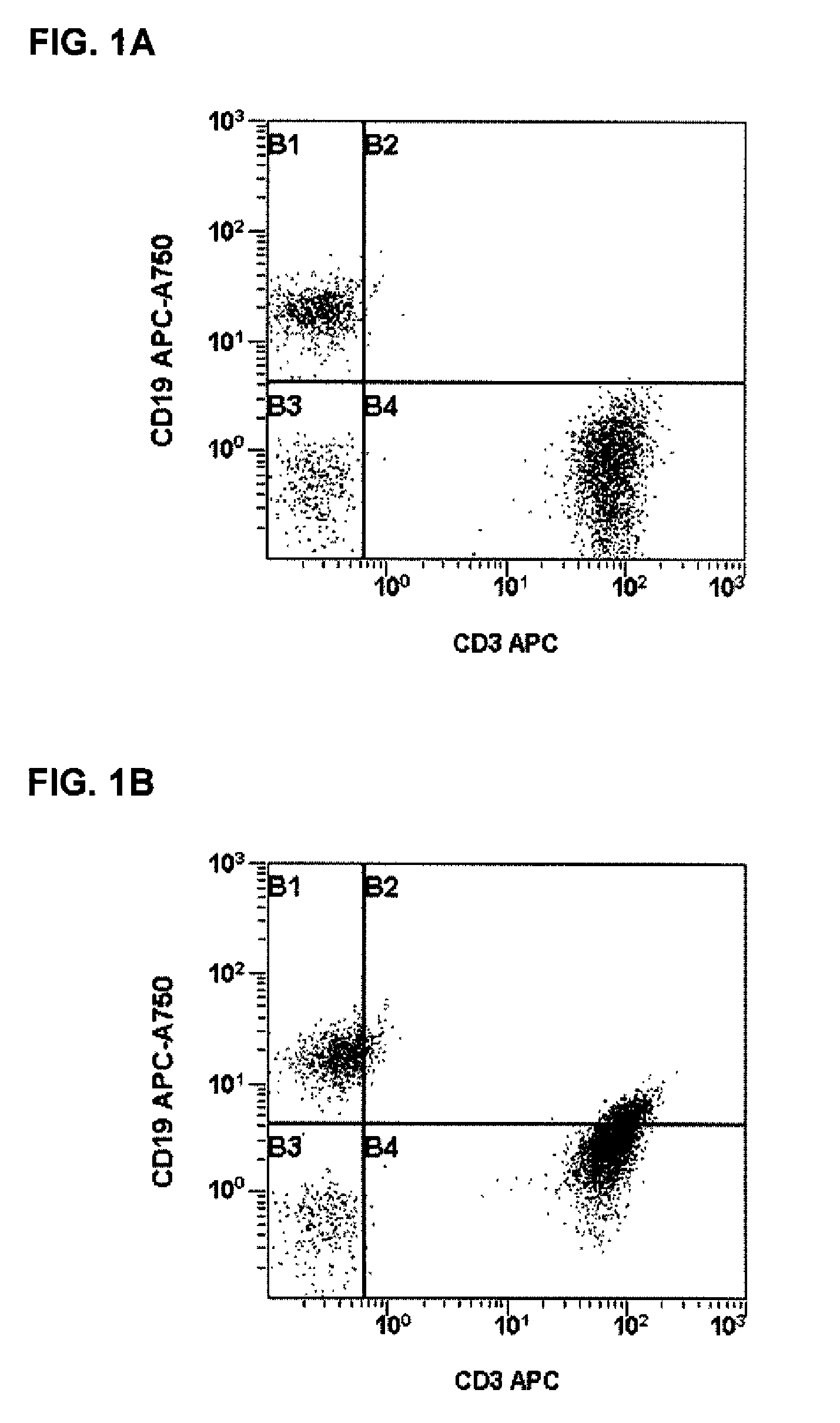

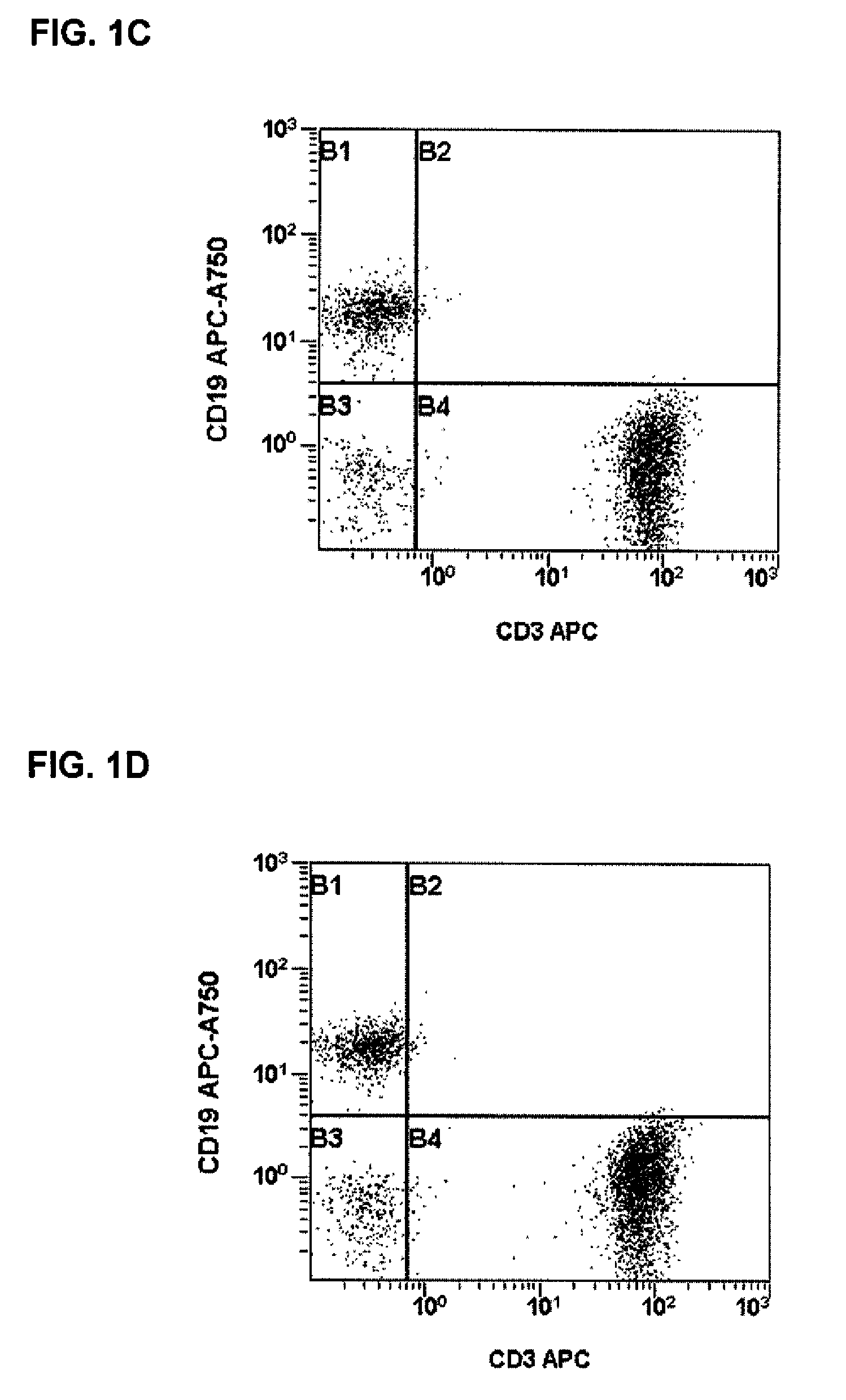

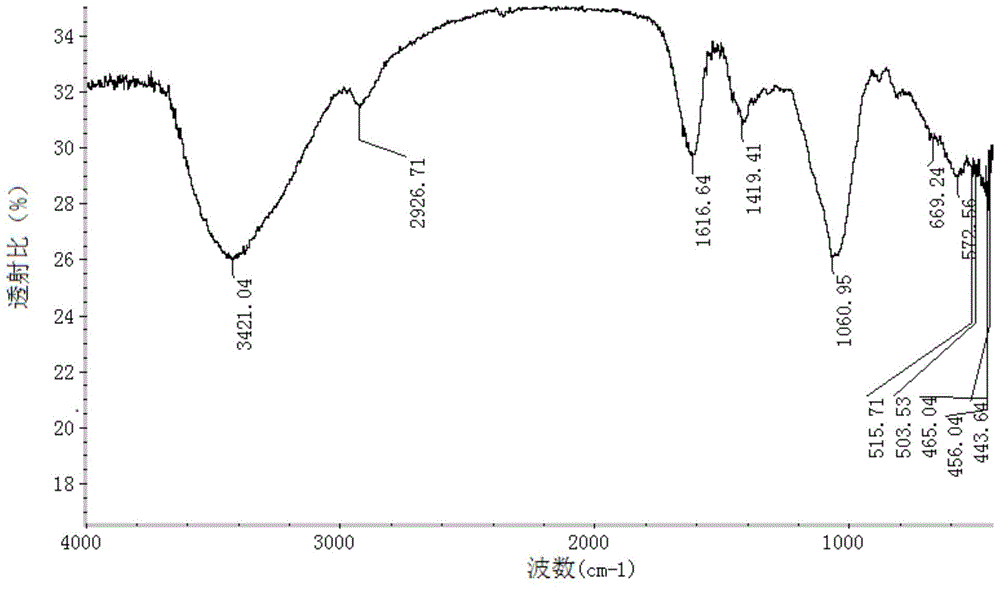

Multicolor flow cytometry compositions containing unconjugated phycobiliproteins

Novel compositions containing (i) ligand conjugated phycobiliprotein tandem dyes and (ii) unconjugated phycobiliproteins are provided wherein the phycobiliproteins are derived from the same bacterial or eukaryotic algae species. The phycobiliproteins must be the same or different, but must contain some non-crosslinked subunits which exchange. Also provided are methods for preparing these compositions, kits containing these compositions or components of the same, and methods of using these compositions for cellular and non-cellular analysis.

Owner:BECKMAN COULTER INC

Method of extracting bio-active substances from algae

ActiveCN105237614AEfficient extractionHigh yieldPeptide preparation methodsInorganic saltsSalting out

The invention relates to the field of deep processing of algae and discloses a method of extracting bio-active substances from algae. The method includes the following steps: 1) performing cell disruption to an algae sample to dissolve-out phycobiliprotein, and performing solid-liquid separation to obtain a crude extract liquid; 2) mixing the crude extract liquid with inorganic salts to perform salting out, wherein the concentration of the inorganic salts is 15-25% by weight in the mixture system, and performing solid-liquid separation to obtain a liquid phase; 3) selectively mixing the liquid phase with inorganic salts to perform salting out, wherein the concentration of the inorganic salts is 30-55% by weight in the mixture system, and performing solid-liquid separation to collect precipitates; and 4) mixing the liquid phase obtain through the solid-liquid separation in the step 2) or 3) with inorganic salts to perform salting out, wherein the concentration of the inorganic salts is 58-65% by weight in the mixture system, and performing solid-liquid separation to collect precipitates. The method also can comprise a step of extracting polysaccharides. The method can extract the bio-active substances from algae at a high efficiency.

Owner:神农架天然美妆原料研究院

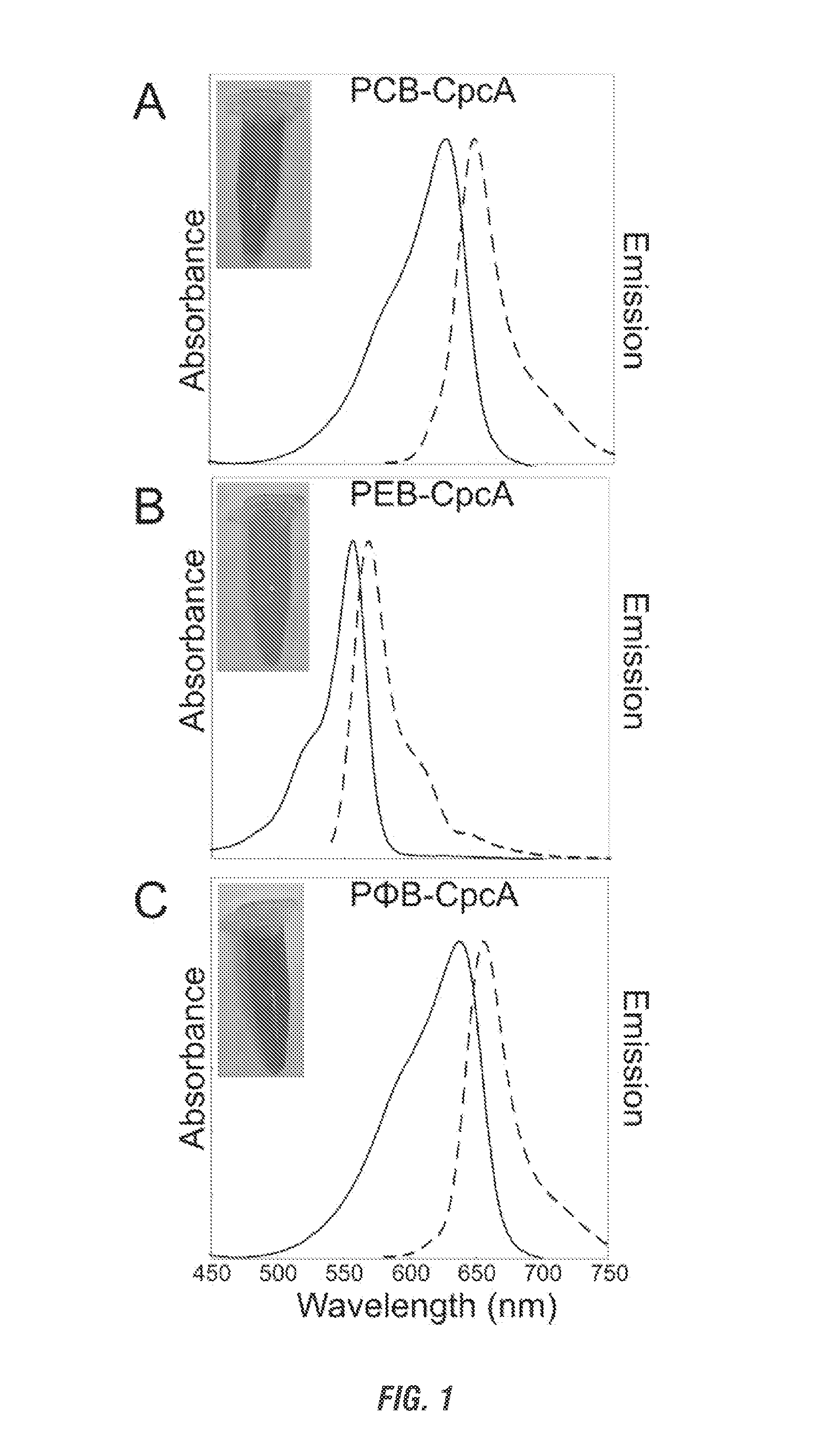

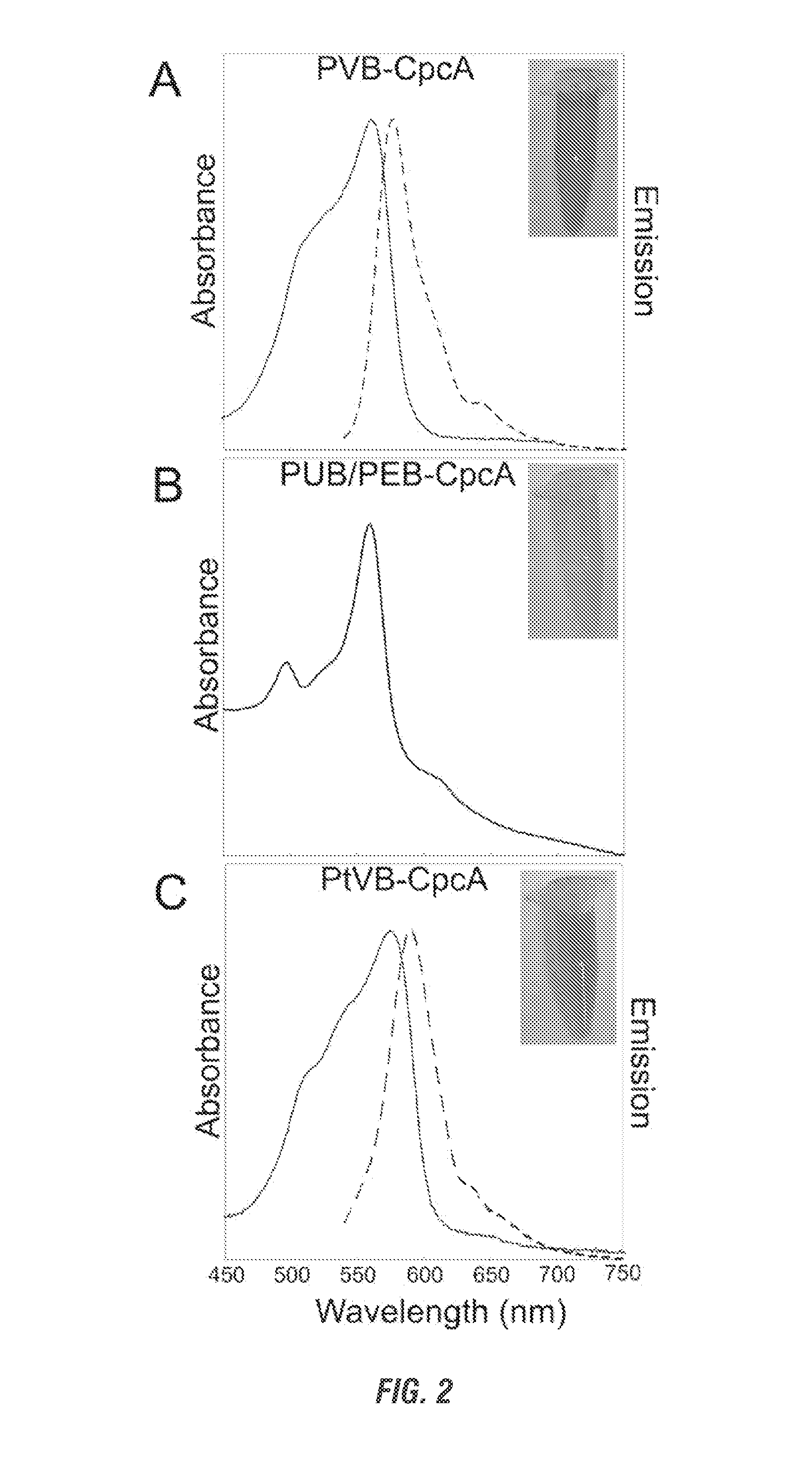

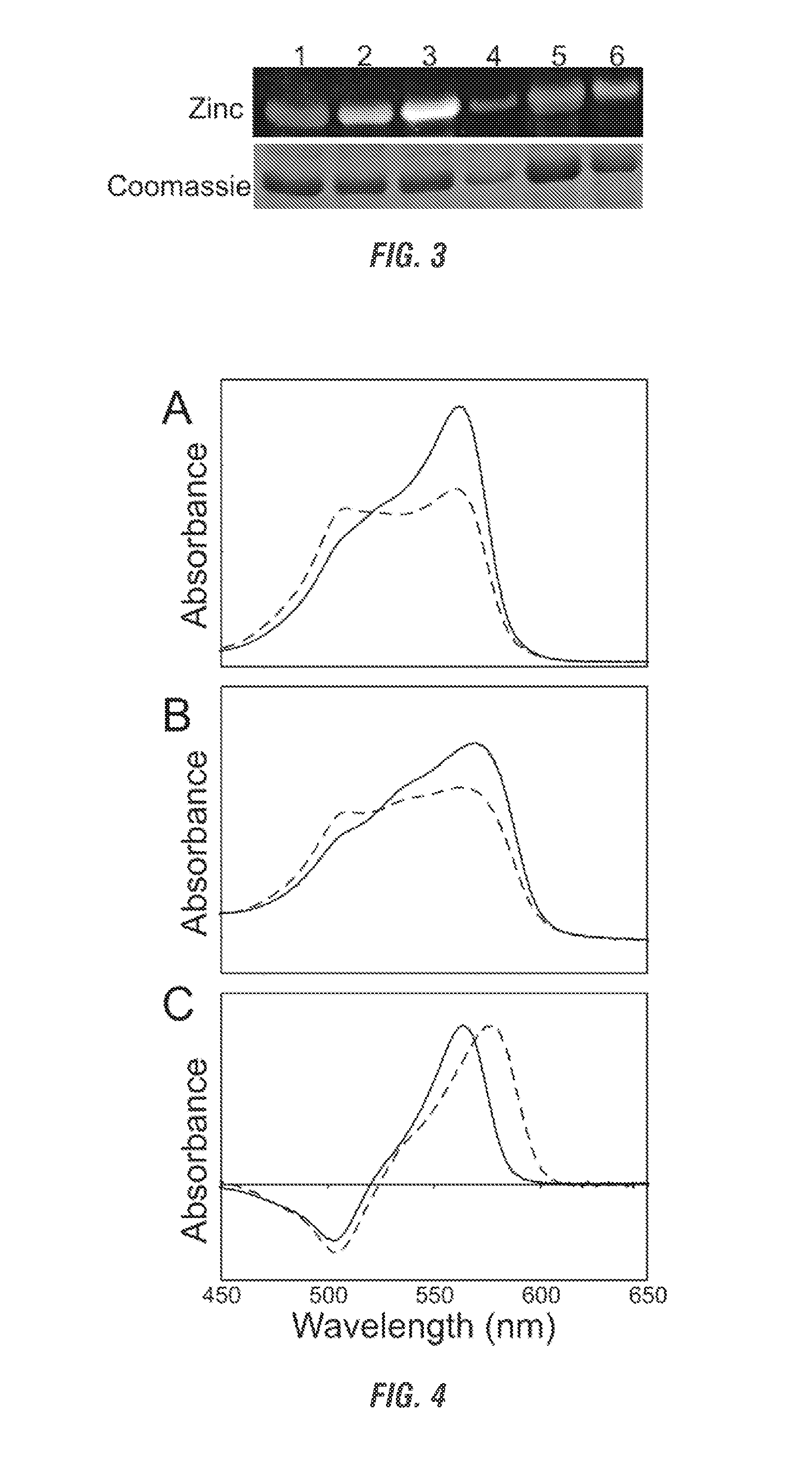

Recombinant phycobiliproteins with enhanced fluorescence and photochemical properties

InactiveUS20130171677A1Efficiency and SpecificityImprove propertiesBacteriaAntibody mimetics/scaffoldsFluorescenceApolipoproteins E

Novel fluorescent phycobiliprotein fusion proteins and methods of use are described. The novel phycobiliproteins can be produced in a cell comprising two or more heterodimeric lyases, an apoprotein and a bilin reductase, which components react to form the phycobiliprotein fusion protein. Also described are phycobiliprotein based transcription reporter cells and assays, which cells conditionally express a heterologous, fluorescent, phycobiliprotein domain even in anoxic conditions.

Owner:PENN STATE RES FOUND +1

A method for improving the antioxidant components of asparagus extract

InactiveCN102266357AHigh in phycobilirubinImprove antioxidant capacityAlgae medical ingredientsAntinoxious agentsBiotechnologyAntioxidant capacity

Owner:朱益生

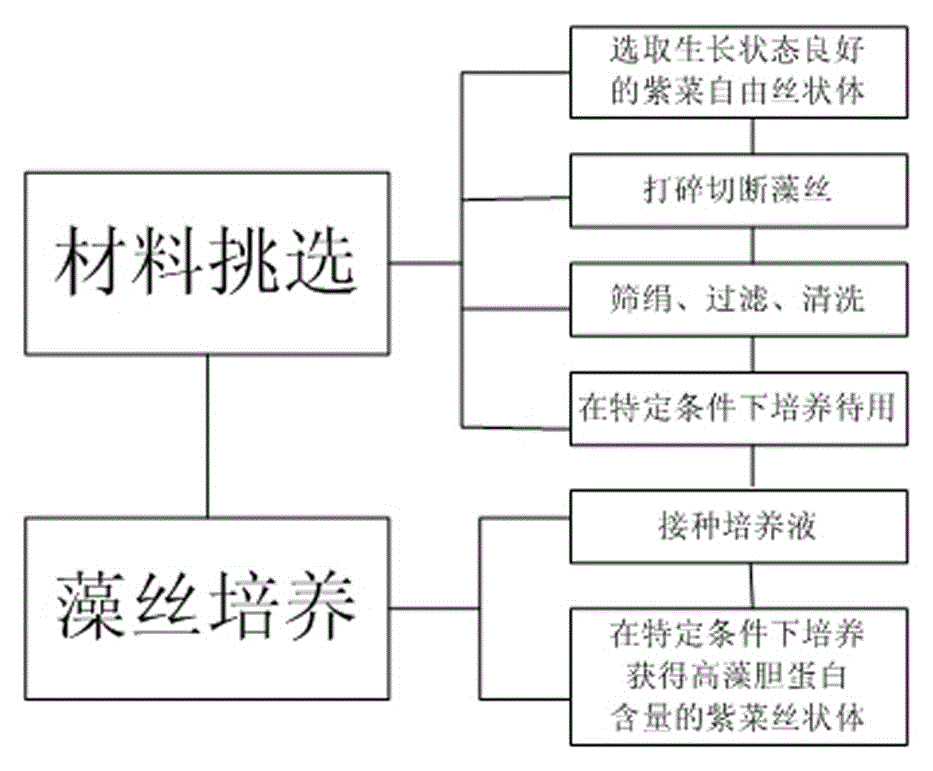

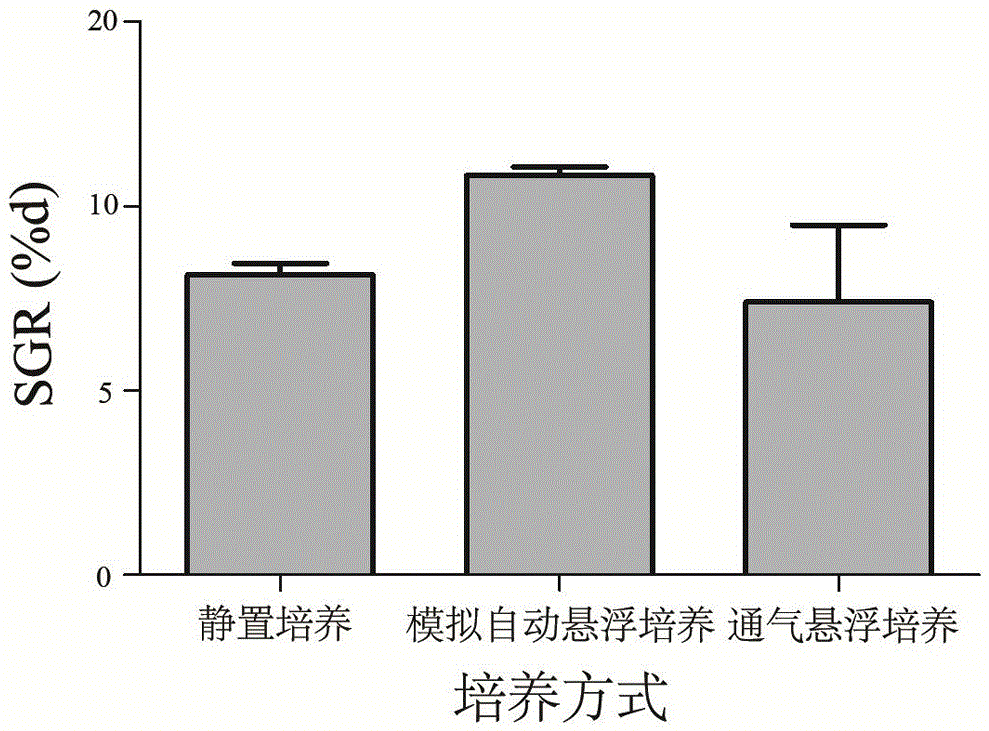

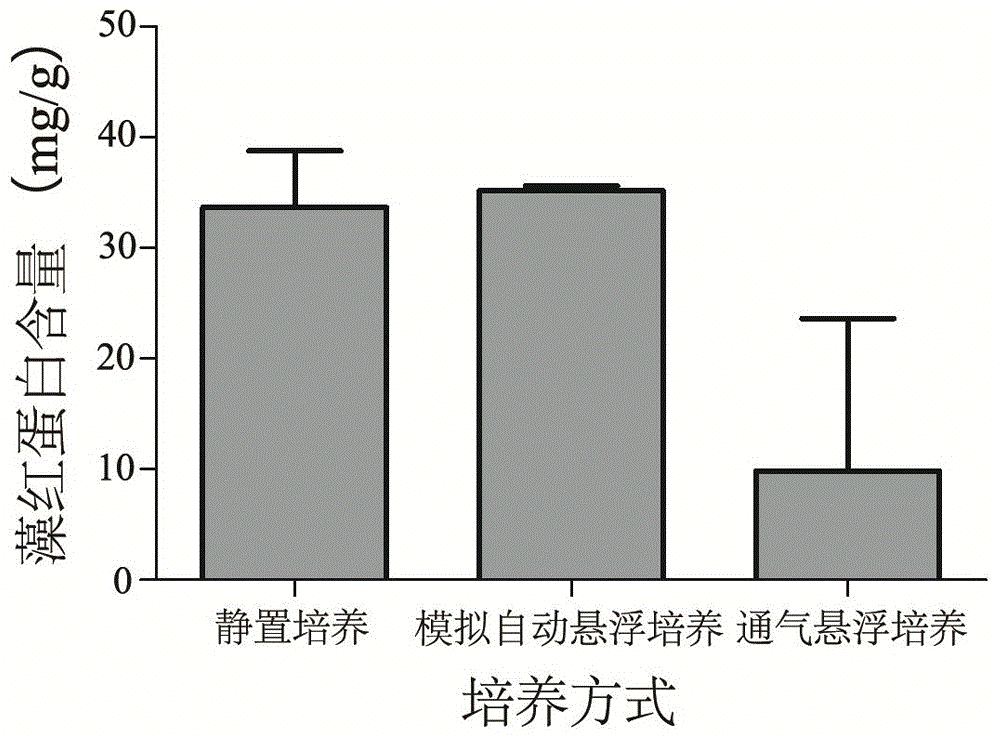

Laver free filament factory cultivation method based on function foodstuff development

InactiveCN105123491ABright colorComplete appearanceCultivating equipmentsSeaweed cultivationWound healingCulture fluid

The invention relates to an algae cultivation method, and specifically relates to a laver free filament factory cultivation method based on function foodstuff development; the method comprises the following steps: s1, material selection: selecting laver free filaments with good growth state, mixing the laver free filaments with a nutrient solution in proportion, using a pulverizer to break and cut the laver free filaments, bolting and filtering the algae and using disinfection seawater to wash, adding fresh nutrient solution and placing the algae under specific parameters for cultivation, replacing the nutrient solution in every 7days until wound heals for 14-15days, and preparing; s2, algae filament cultivation: selecting the filaments cultivated in the s1, inoculating the filaments in a culture container according to initial density 0.8-1.2g: 1L nutrient solution, placing the nutrient solution in specific parameters for cultivation, and replacing the nutrient solution in every 7days. Compared with the prior art, the laver free filament factory cultivation method based on function foodstuff development can keep a high growth rate of the laver free filament and improve phycobiliprotein content in the laver free filaments, thus satisfying development function food stuff requirements.

Owner:SHANTOU UNIV

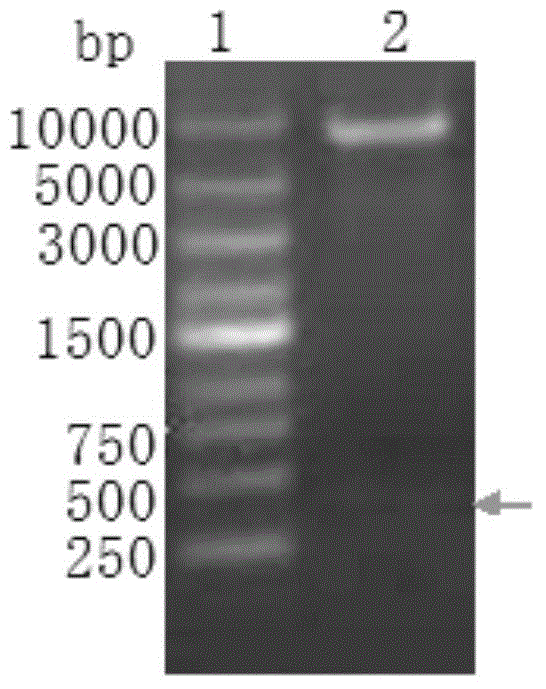

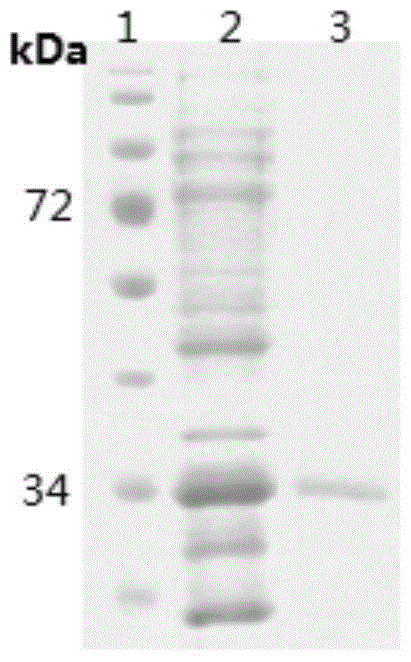

Method for production of streptavidin labeled phycocyanin fluorescent protein and application

InactiveCN104372053AImprove bindingHigh activityPeptide preparation methodsFermentationBiotin-streptavidin complexAntibiotic Y

The invention relates to the phycocyanin fluorescent protein field, and particularly relates to a method for production of a streptavidin labeled phycocyanin fluorescent protein and an application. A streptavidin synthetic gene, a phycocyanin subunit synthetic gene, a catalytic enzyme synthetic gene and a chromophore synthetic gene are recombined in a same expression plasmid, and combination expression of multiple genes is realized; through optimization of induction and purification conditions, the fusion protein having stable fluorescent activity is prepared. Combination expression of fluorescent activity fusion phycobiliproteins are completed by adopting the single plasmid, the problems that the stability of multiple plasmids in an engineering strain and non-synchronization of expression of genes are avoided, and the use of antibiotics in the fermentation process is reduced. The method can effectively improve the stability of the fluorescent protein, besides, greatly reduces the production cost of phycocyanin fluorescent labeled preparations, and has good practical value and application prospects in the biomedical field, particularly in the production of fluorescent probes.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

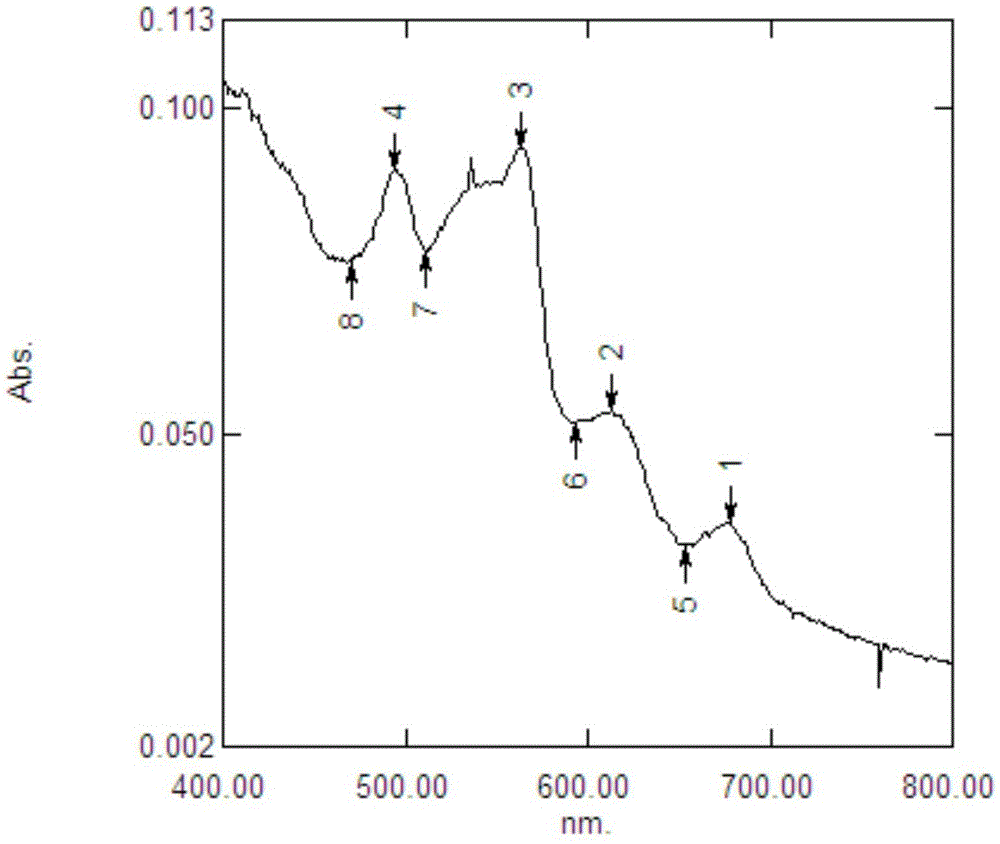

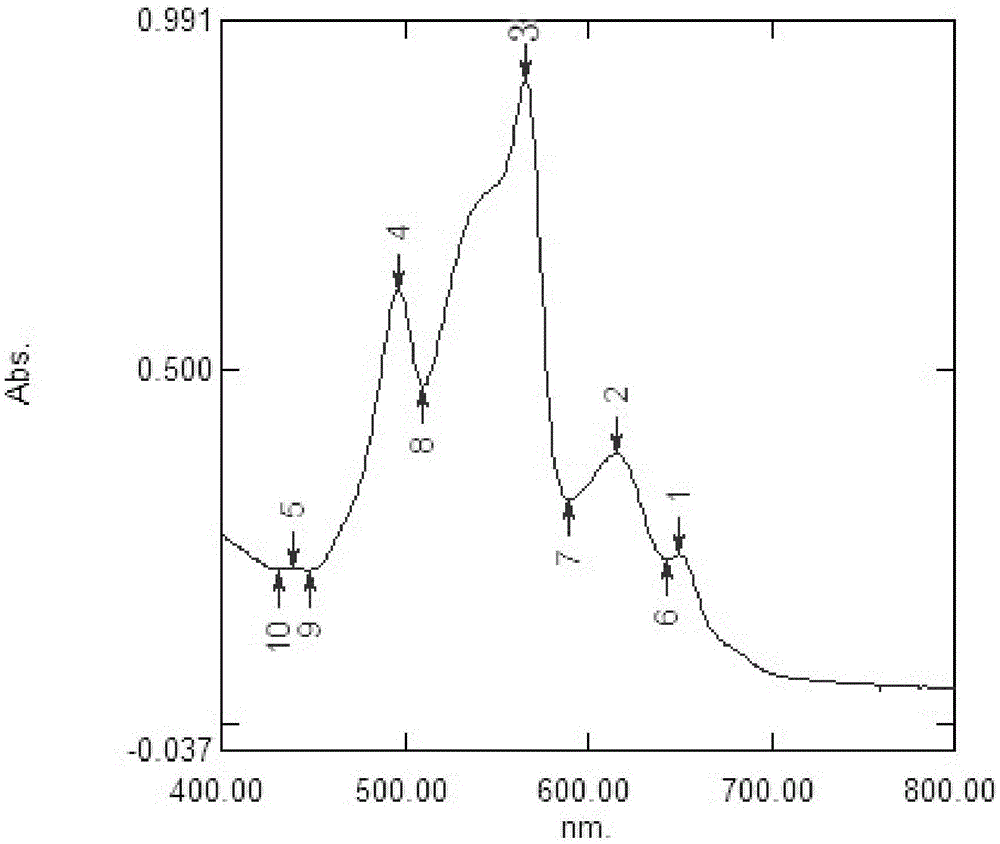

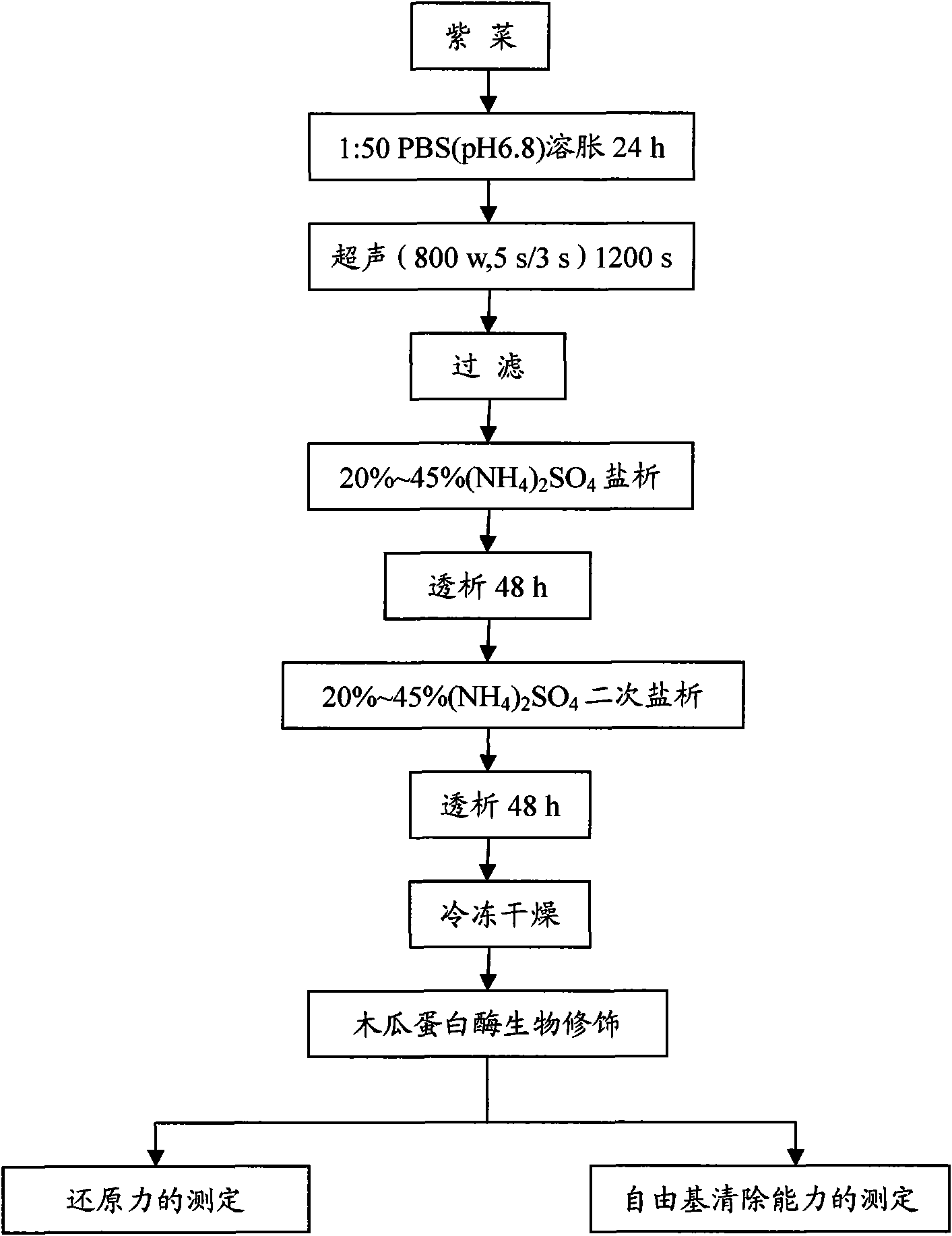

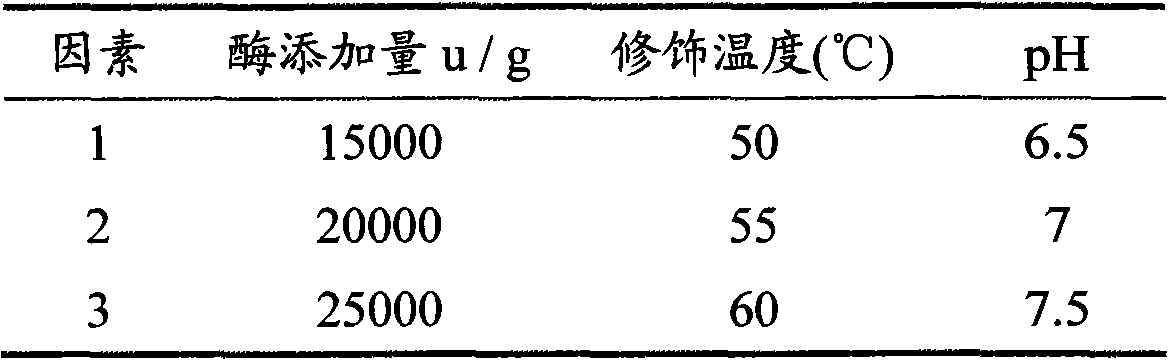

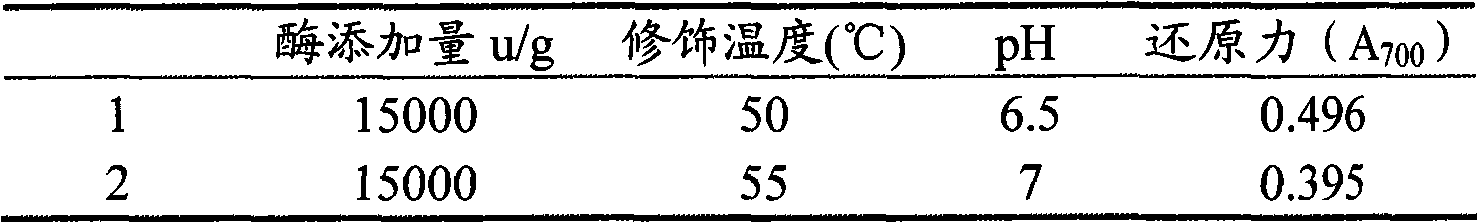

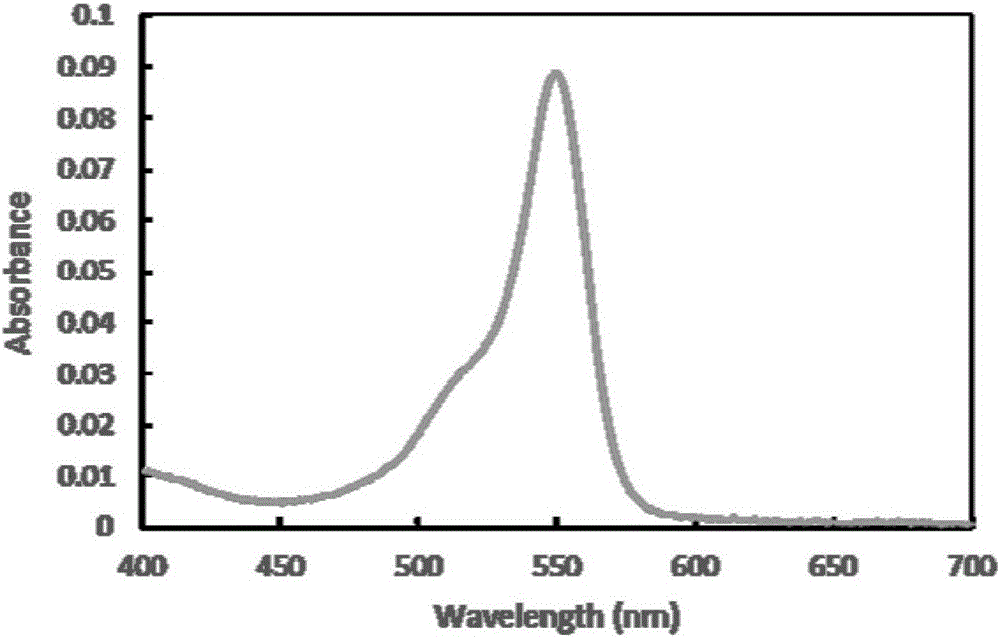

Bio-modification preparation method for improving activity of laver phycoerythrin

InactiveCN101624613AImproves antioxidant activityHigh activityPeptide preparation methodsAlgae/lichens peptidesPhycoerythrinCell wall

The invention relates to a bio-modification preparation method for improving activity of laver phycoerythrin, belonging to the technical field of marine organism functional composition preparation. Laver swells after being treated by PBS buffer solution, and crude extract is obtained by using ultrasonic wave cell-break technique to break cell walls; the crude extract is precipitated by ammonium sulfate with saturation of 20-45 percent and filtered to obtain laver phycoerythrin with purity (A562 / A280) reaching to 3.04; and the laver phycoerythrin is biologically modified by papain with concentration of 15000-25000mu / g at pH value of 6.5-7.5 and temperature of 50-60 DEG C for two hours. The activity of modified phycoerythrin is remarkably improved, the reducing power (A<700NM>) is increased to 0.573, and the hydroxyl redica removing capability is increased to 51.03 percent, and the reducing power and the hydroxyl redica removing capability are increased by 0.329 and 35.17 percent respectively. In the invention, the method for improving the antioxidant activity of laver phycoerythrin is established, and the bio-modified phycobiliprotein has more application values in medical and food fields.

Owner:NANJING AGRICULTURAL UNIVERSITY

Method for extracting nutrients from spirulina in grading manner

ActiveCN104086649AGuaranteed not to be brokenHigh energy consumptionDepsipeptidesHigh concentrationWater soluble polysaccharides

The invention provides a method for extracting nutrients from spirulina in a grading manner. Mashed fresh spirulina is used as raw material and dehydrated by using high-concentration ethanol, chlorophyll and carotenoid are simultaneously extracted from the mashed spirulina, and phycobiliprotein and water-soluble polysaccharide are extracted from the spirulina residue (which is subjected to ethanol extraction) by using a phosphate buffer solution. The method has the characteristics of low energy consumption and low cost, multiple nutrients in the spirulina can be obtained by grading extraction, the extraction condition is mild, and the extracted nutrients are unlikely to be destroyed.

Owner:藻能珍稀生物科技研发(广州)有限公司

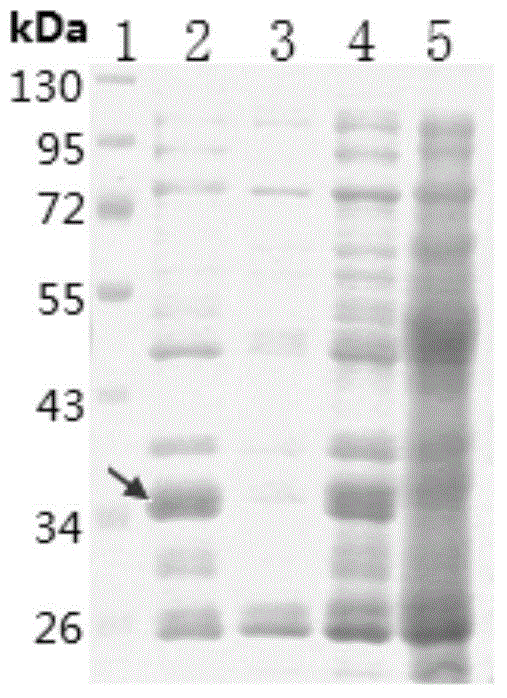

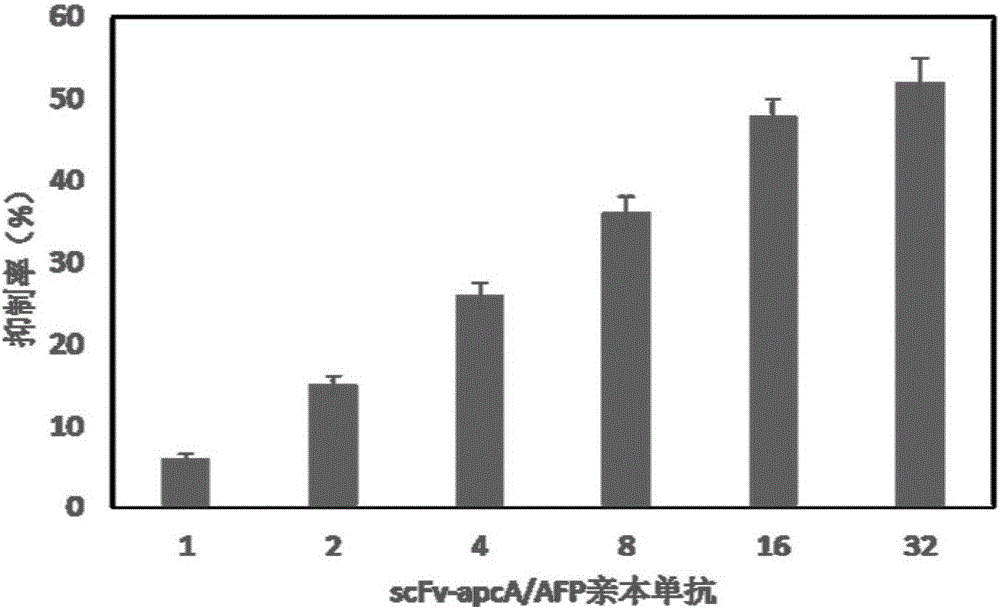

Preparation method of fusion fluorescent protein in escherichia coli

ActiveCN105018552AReduce manufacturing costSimple preparation processFermentationVector-based foreign material introductionEscherichia coliSingle-Chain Antibodies

The invention belongs to the field of fluorescent protein and recombinant antibodies in biotechnology and particularly relates to a preparation method of fusion fluorescent protein in escherichia coli. The method is characterized in that AFP single-chain antibody genes and allophycocyanin alpha subunit genes are spliced through linker sequence to form chimeric genes, and the chimeric genes, phycobiliprotein lyase genes and phycobilin biosynthetic enzyme genes are expressed in the escherichia coli to obtain fusion fluorescent protein covalently binding phycoerythrin or fusion fluorescent protein covalently binding phycocyanobilin. The method has the advantages that biotechnology is used to produce the fusion protein, of single-chain antibodies and allophycocyanin alpha subunits, in the escherichia coli, the method is environmental friendly and low in cost, and the fusion protein is applicable to fields such as biology and biomedical detection.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com