Patents

Literature

74results about How to "Avoid Yield Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double-stage purification method of long chain dicarboxylic acid aqueous phase

InactiveCN103497100AAvoid bringing inFull retention of depigmentationCarboxylic compound separation/purificationMicrofiltration membraneDicarboxylic acid

The invention discloses a double-stage purification method of a long chain dicarboxylic acid aqueous phase. The double-stage purification method comprises the following steps: (1) heating and demulsifying terminated fermentation broth of long chain dicarboxylic acid produced by a fermentation method, and filtering the terminated fermentation broth through a ceramic microfiltration membrane to obtain a microfiltration membrane supernatant layer; (2) diluting the microfiltration membrane supernatant, and adding an oxidizing agent under a weak alkaline condition to react to obtain supernatant; or diluting the microfiltration membrane supernatant, and adding the oxidizing agent under a weak acidic condition to react to obtain the supernatant; or diluting the microfiltration membrane supernatant, filtering the microfiltration membrane supernatant through a microfiltration membrane, diluting, and adding the oxidizing agent to react to obtain the supernatant; (3) regulating the pH value of the supernatant to 3.0-5.0 through an acid, maintaining the temperature for 1 h, filter pressing through a plate frame, washing a long chain dicarboxylic acid filter cake layer through acidic washing water of a saturated sodium salt, press filtering the acidic water of saturated salt in the dicarboxylic acid filter cake, removing the sodium salt from the pure water, and drying to obtain a long chain dicarboxylic acid product. The double-stage purification method disclosed by the invention is short in process route, low in production cost, high in yield, high in purity, good in aqueous phase crystal morphology, capable of solving the defects of a current aqueous phase method product of low purity, high protein content and bad color and luster, and beneficial for large-scale industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

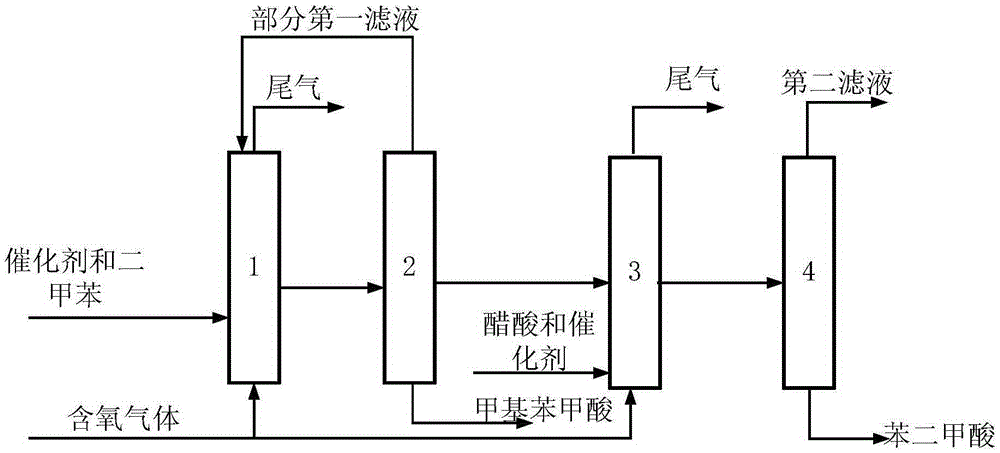

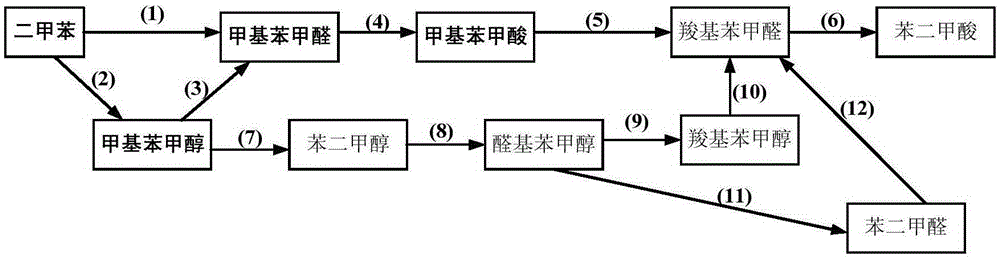

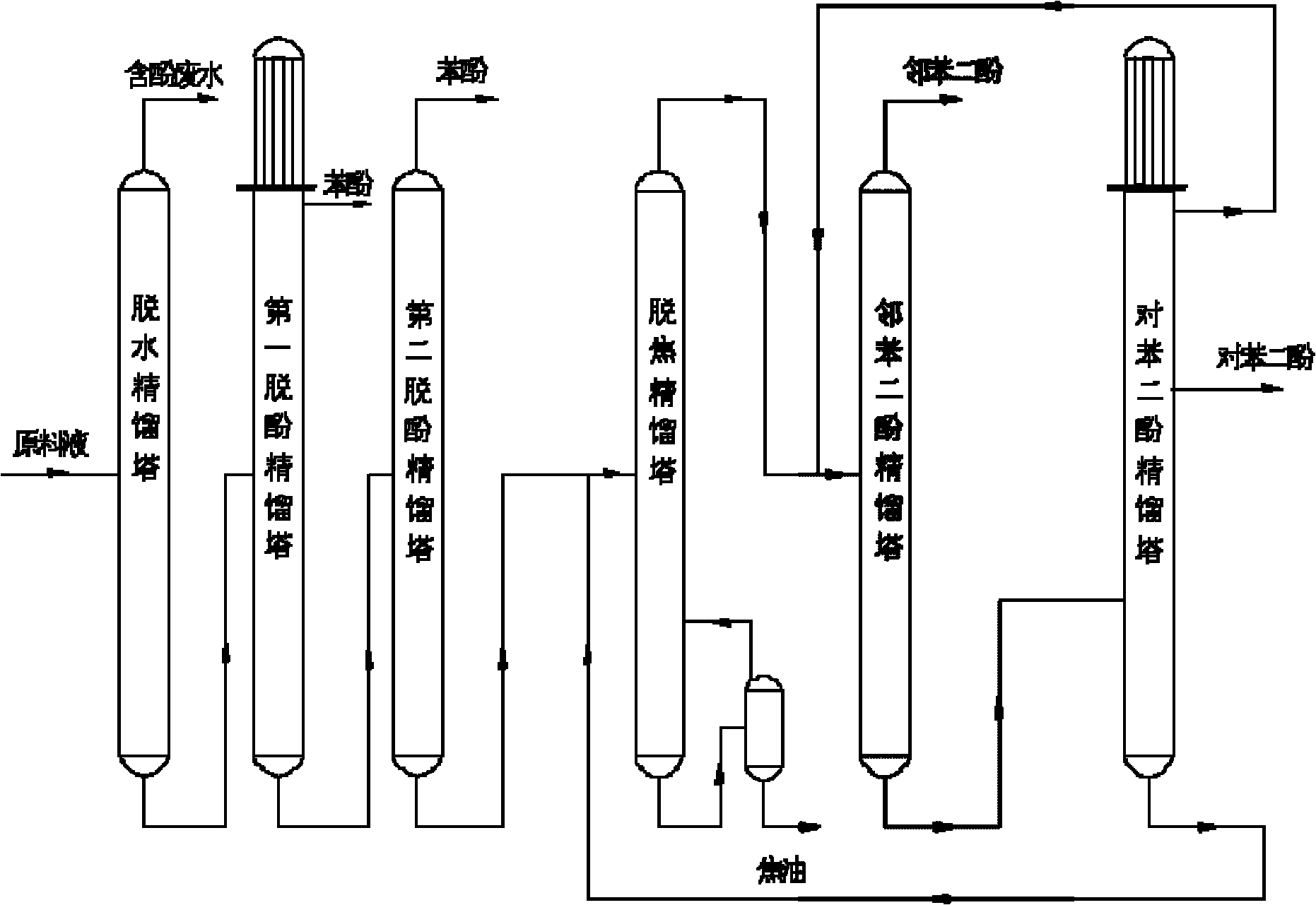

Co-production method for methyl benzoic acid and phthalic acid

ActiveCN105348067AHigh activityRealize online in-situ generationOrganic compound preparationCarboxylic compound preparationBenzoic acidAcetic acid

The invention discloses a co-production method for methyl benzoic acid and phthalic acid. The co-production method comprises the following steps: (1) continuously introducing fresh dimethylbenzene, a catalyst and oxygen-containing gas into a primary oxidation reactor for a reaction to obtain a primary oxidation reaction solution containing methyl benzoic acid and an eight-carbon oxygen-contained compound; (2) carrying out continuous cooling, crystallization and filtration on the primary oxidation reaction solution to obtain filter liquor and filter cake, circulating 1-98% of the filter liquor back the primary oxidation reactor continuously, and continuous rectifying the filter cake continuously, to obtain a low-boiling point front cut fraction, distillation raffinate and a methyl benzoic acid product separately; (3) adding the remaining filter liquor in the step (2) and the obtained front cut fraction and distillation raffinate in the step (2) into a secondary oxidation reactor continuously, and meanwhile continuously introducing a Co / Mn / Br catalyst, acetic acid and oxygen-containing gas into the secondary oxidation reactor for an oxidation reaction to obtain a secondary oxidation reaction mixture; and (4) continuously cooling, crystallizing and filtrating the secondary oxidation reaction mixture to obtain a filter liquor and a phthalic acid product. The co-production method has advantages of a simple process, a low cost, a high yield, good selectivity, good economic benefits, and environmental protection.

Owner:山东友道化学有限公司

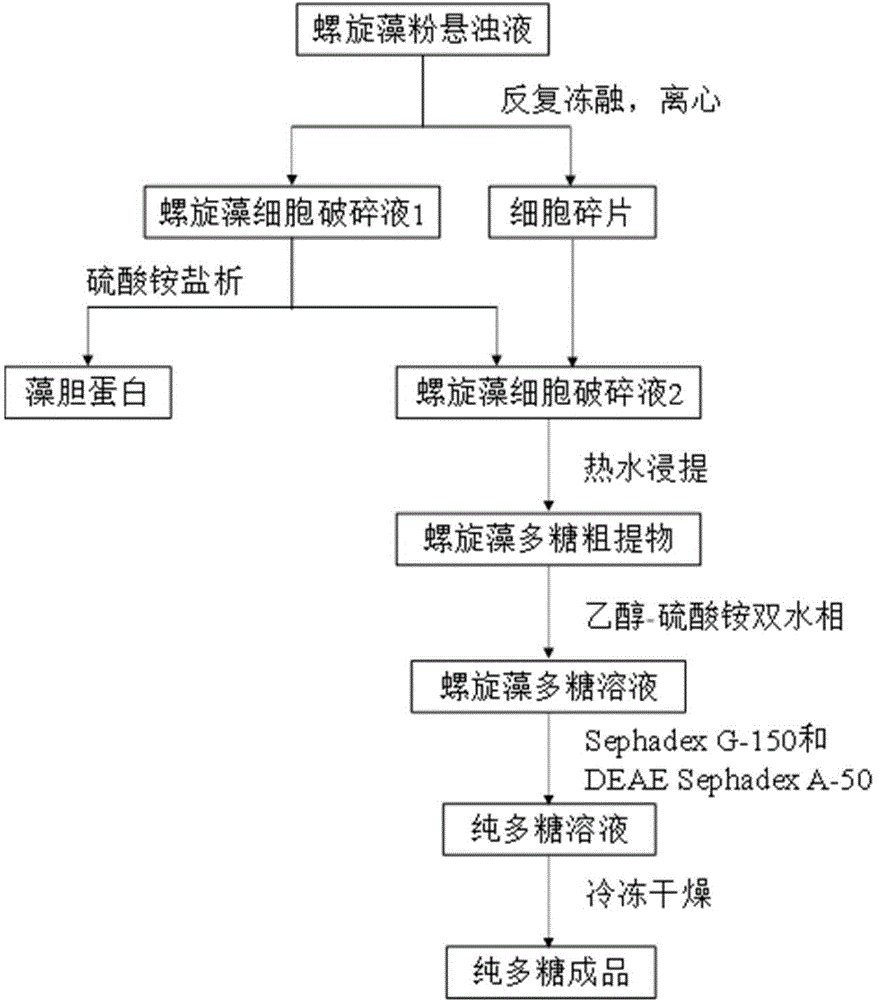

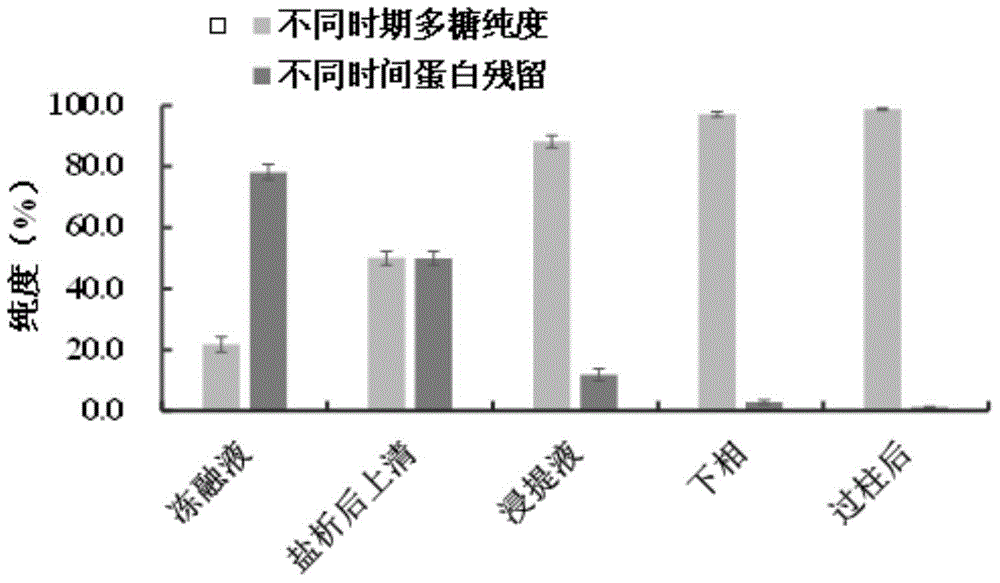

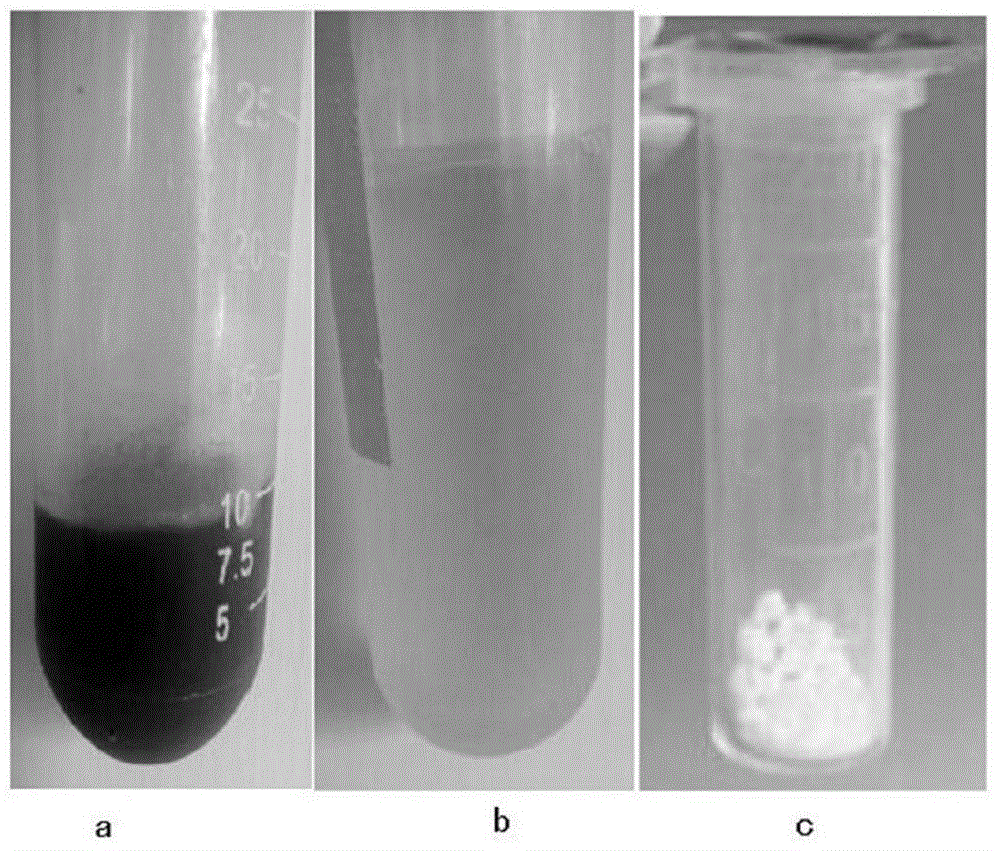

Spirulina phatensis polysaccharide and extraction method thereof

The invention relates to a spirulina phatensis polysaccharide and an extraction method thereof. The extraction method comprises the following steps: after multigelation and wall breaking of a spirulina phatensis powder suspension, centrifuging to obtain a cell lysate 1 and cell debris; adding ammonium sulfate in the cell lysate 1 until the saturation is 50%, after salting-out precipitation, centrifuging to remove phycobiliprotein to obtain a supernatant, and evenly mixing the supernatant and the cell debris to obtain a cell lysate 2; obtaining a spirulina phatensis polysaccharide crude extract by using a hot water extraction method; adding the crude extract to an ethanol / ammonium sulfate aqueous two-phase system, and extracting to obtain a bottom-phase solution of spirulina phatensis polysaccharide with higher purity; after the bottom-phase solution is desalted by dialysis, eluting by using a Sephadex G-150 chromatographic column and a DEAE Sephadex A-50 anion exchange column to obtain a pure spirulina phatensis polysaccharide solution; and freeze-drying, thereby obtaining a pure spirulina phatensis polysaccharide finished product. The extraction method can be used for avoiding the traditional complicated protein removal operation steps, has low cost, high yield, and high purity and activity of polysaccharide, and is suitable for intermittent and large-scale production and processing.

Owner:SHANTOU UNIV

Decolorization method for raffinose raffinate

ActiveCN101367845AUniform particle sizeHigh mechanical strengthIon-exchange process apparatusIon-exchanger regenerationSorbentAbsorption column

The present invention discloses a method for decoloring raffinose extract by adopting fixed bed type adsorptive separation. In the method, after raffinose alcohol extract is condensed and alcohol is removed, aqueous solution, the solid content of which is 10 percent, is prepared; pH is regulated to 4 to 6; the prepared solution passes through a fixed bed absorption column containing particulate active carbon, non-polar absorption resin or weak-polar absorption resin in order to remove pigments such as gossypol; and finally, 60 percent to 75 percent ethanol is used to regenerate the absorption column. In the method, the decoloring rate of the extract is more than 90 percent, and the yield of raffinose is higher than 95 percent. The method has the advantages of simple process flow, convenient adsorbent regeneration, low production cost, easy industrialized production, and the like.

Owner:ZHEJIANG UNIV

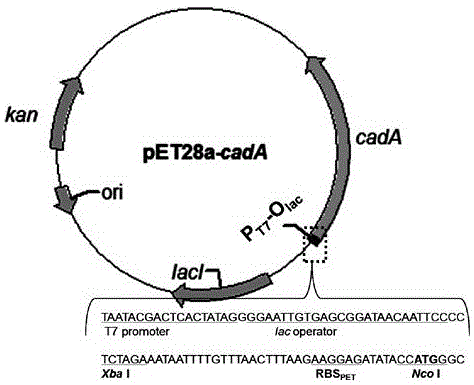

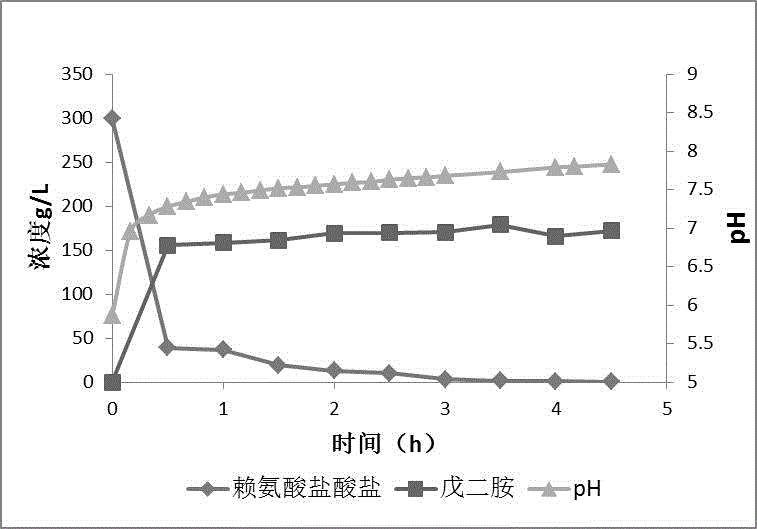

Method for producing pentamethylene diamine by using carbon dioxide desorption process through fermentation

ActiveCN105861586AReduce the amount of strong alkaliReduce the amount of salt residueMicroorganismsMicroorganism based processesCulture cellDesorption

Owner:HEILONGJIANG EPPEN NEW MATERIALS LTD

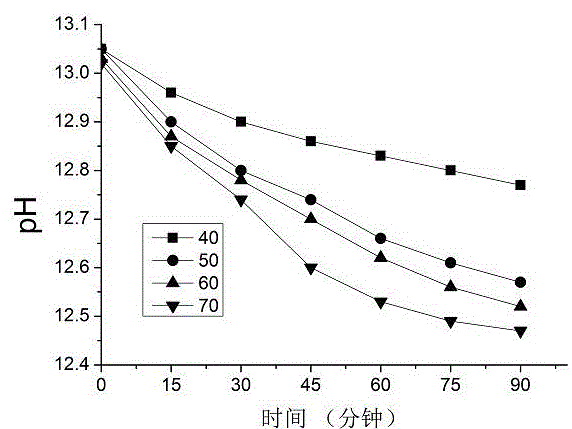

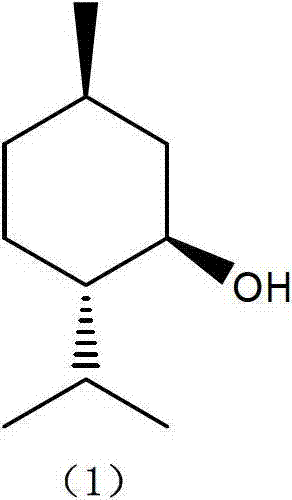

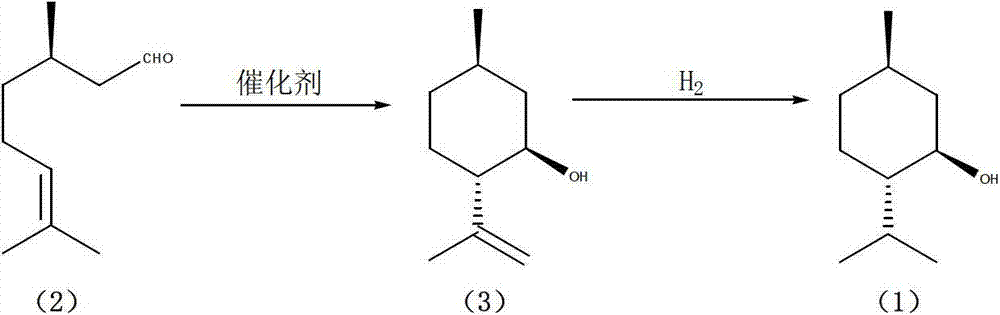

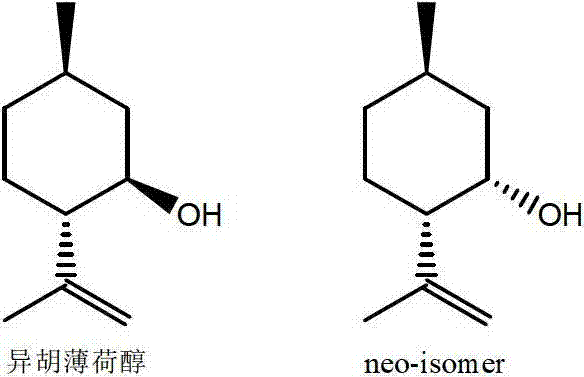

Method for preparing L-menthol

InactiveCN103086845AAvoid purification difficultiesAvoid Yield ProblemsPreparation by isomerisationMolecular sieve catalystsZinc bromideMolecular sieve

The invention discloses a method for preparing L-menthol, which comprises the following steps:(1) reacting d-citronellal in a solvent in the presence of a catalyst, and collecting isopulegol from the reaction product, wherein the catalyst is a zinc-bromide-modified NaY molecular sieve; and carrying out high-pressure hydrogenation on the obtained isopulegol to obtain the target product L-menthol. The obtained isopulegol can be subjected to high-pressure hydrogenation to obtain the target product L-menthol without purification. The invention has the characteristics of mild reaction conditions, high stereoselectivity, high yield and the like, and is simple to operate; and the catalyst is simple to recover, and can be used repeatedly. The method disclosed by the invention avoids the problems of difficulty in product purification, low yield and the like in the traditional synthesis technique of the compounds, and greatly lowers the production cost.

Owner:上海统益生物科技有限公司

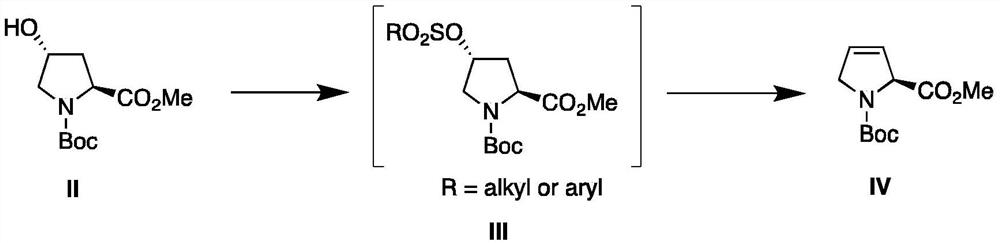

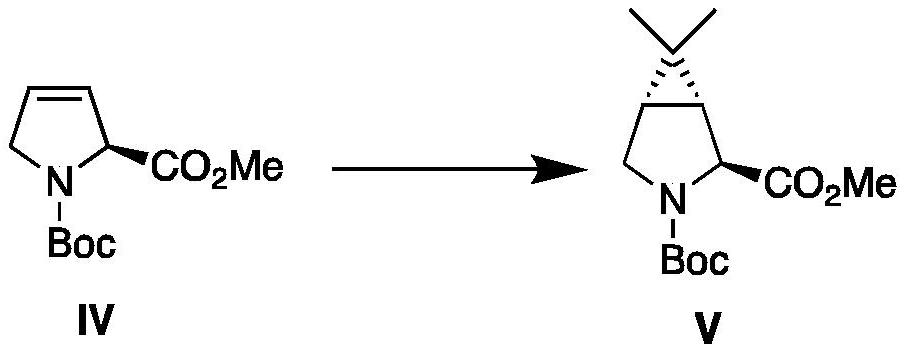

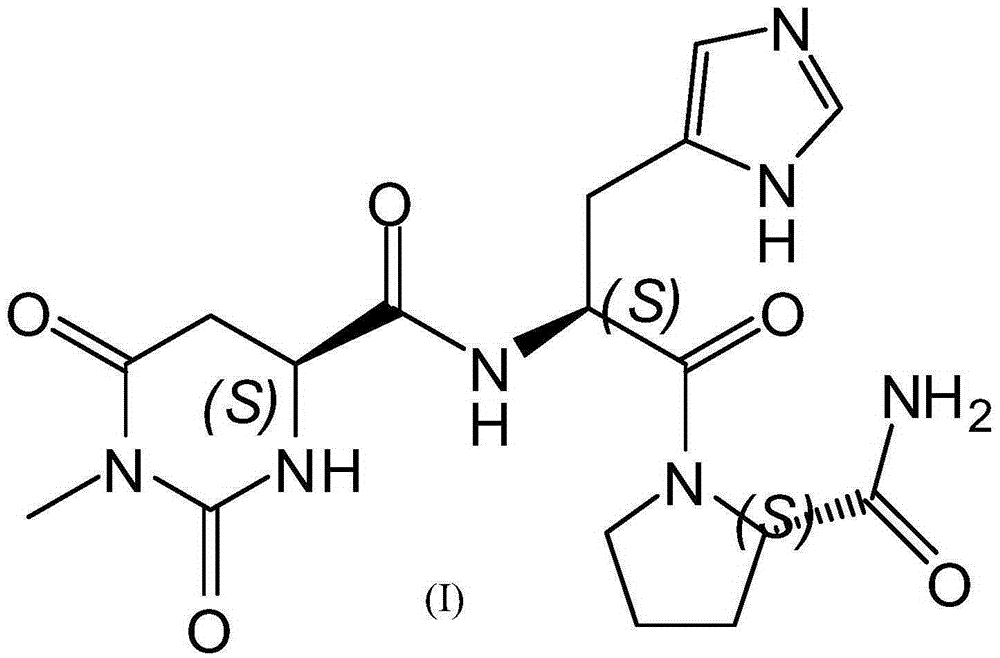

Preparation method of anti-new crown drug Paxlovid intermediate

ActiveCN114133350AAvoid reactionAvoid Yield ProblemsOrganic chemistryBulk chemical productionMetaclazepamPharmaceutical Substances

The invention discloses a preparation method of an intermediate of an anti-new crown drug Paxlovid. According to the preparation method, cheap and easily available N-Boc-trans-4-hydroxy-L-proline methyl ester (compound II) is taken as an initial raw material, the Paxlovid intermediate can be obtained through a plurality of steps of reactions, and the structural formula of the anti-new crown drug Paxlovid intermediate is as shown in the formula I. The method has the advantages of simple process, low production cost, easiness in industrial production and the like.

Owner:ZHEJIANG LEPU PHARMA CO LTD

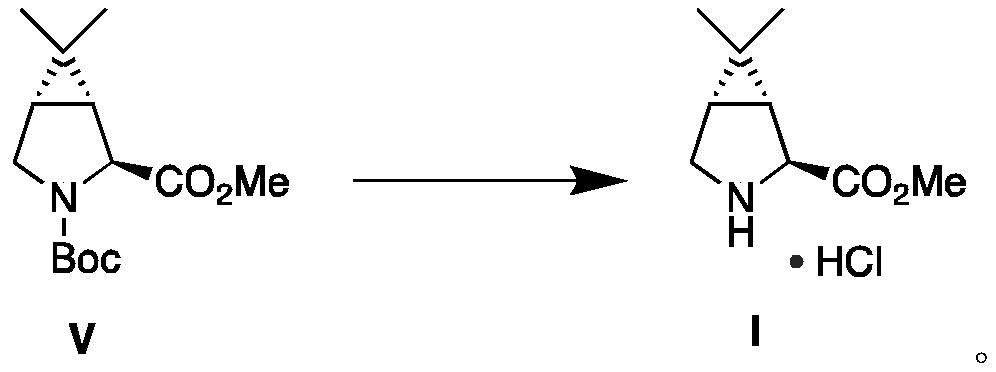

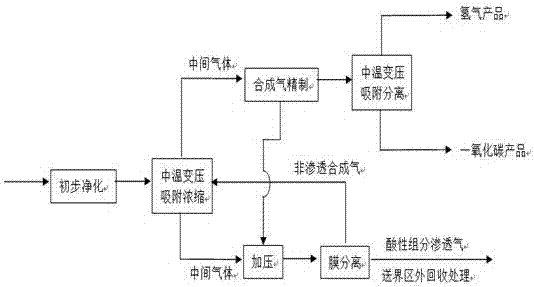

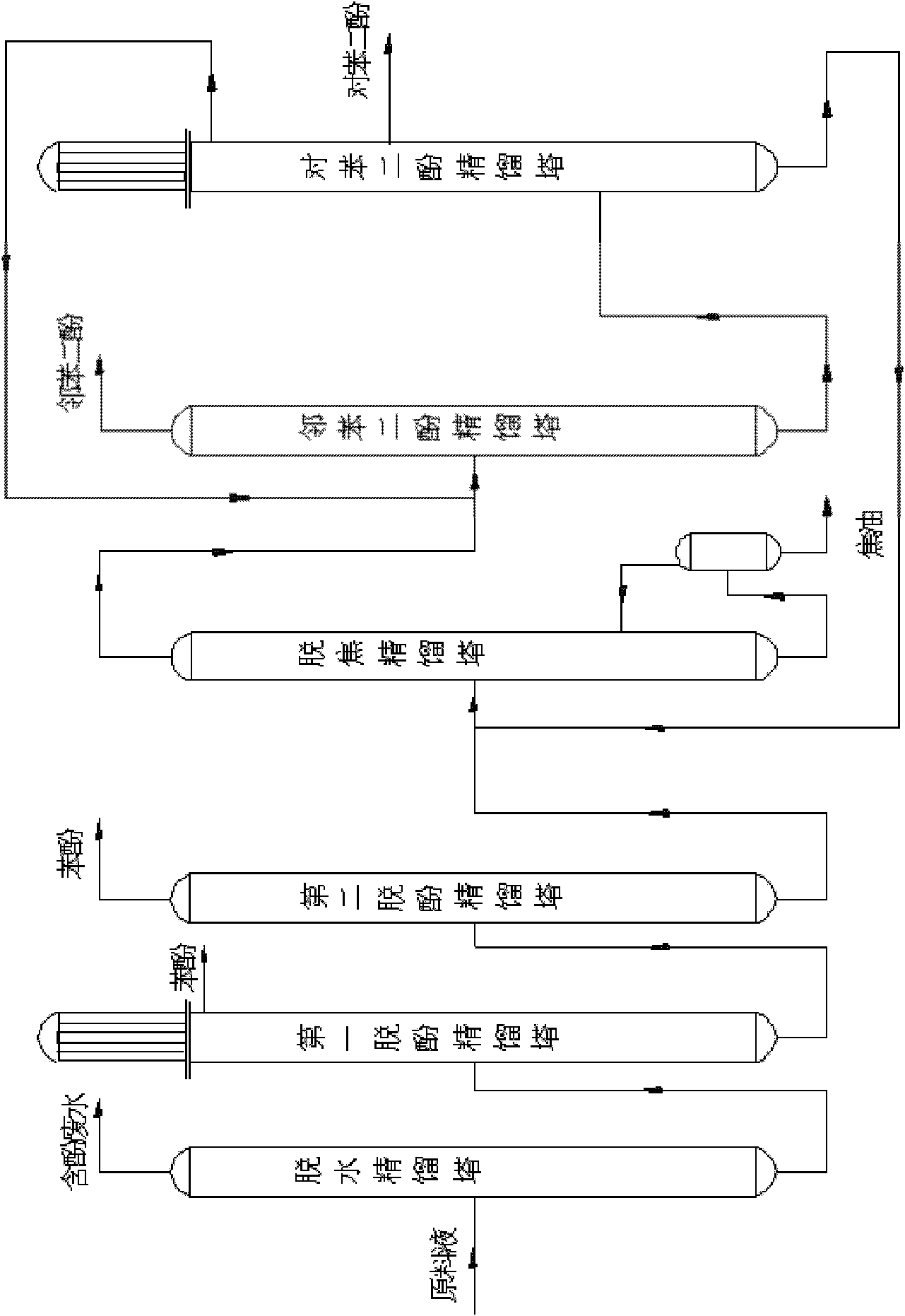

Purification and separation method of syngas by full temperature range-pressure swing adsorption (FTrPSA)

ActiveCN107285279ASave the cooling capacity required for the operating temperature of -75~-34°CSave coolingHydrogen separation using solid contactHydrogen/synthetic gas productionSeparation technologyImpurity

The invention discloses a purification and separation method of a syngas by FTrPSA, and relates to the technical field of H2 production, CO production and purification and separation for a PSA gas. Compared with the prior art, the purification and separation method of the syngas by FTrPSA disclosed by the invention separates coarse removal and refined removal of impurities of acidic components and the like in the syngas purification process, an intermediate gas is refined by the syngas and subjected to an intermediate temperature PSA separation process to obtain a qualified syngas product or H2 and CO products, the operating temperature and operating pressure are the same as those of an intermediate temperature PSA concentration process, so that the load and energy consumption of the syngas in the refining and intermediate temperature PSA separation are reduced, the integration degree of purification and separation process and the purity of the produces are improved, furthermore, a concentrated gas is subjected to a membrane separation process to obtain further recycled syngas and remove the acidic components, so that the load of the membrane separation process is reduced and the yield of the products is improved.

Owner:SICHUAN TECHAIRS

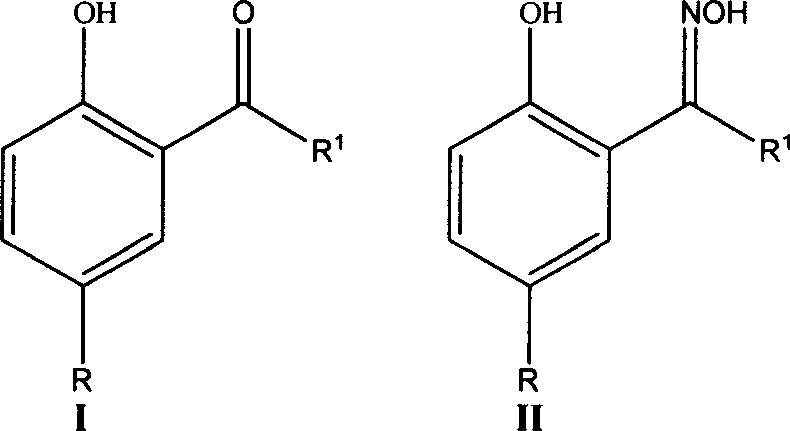

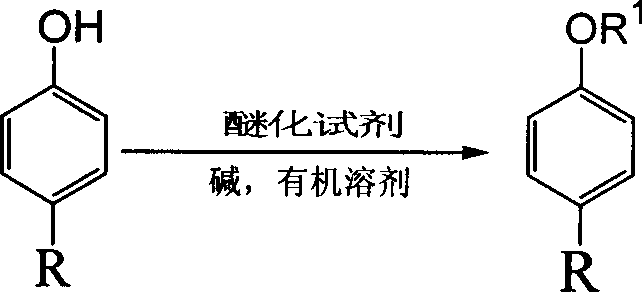

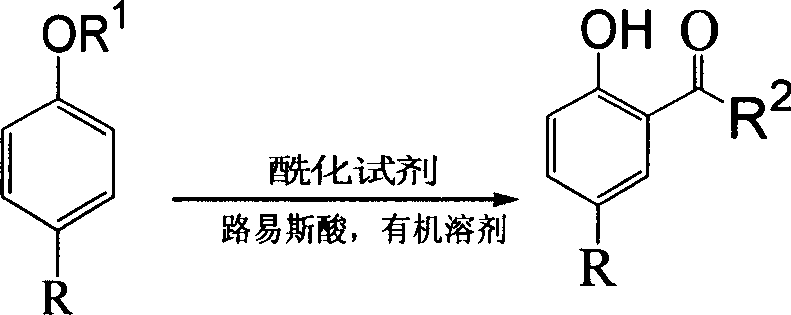

Synthetic method for preparing 2-acyl 4-allcyl phenol

InactiveCN1821203AEasy to recycleEmission reductionOrganic compound preparationCarbonyl compound preparationHalohydrocarbonPhenol

The present invention relates to the synthesis process of different kinds of 2-acyl-4-alkyl phenol, which is the important intermediate of metal extractant 5-alkyl-2-hydroxyalkyl benzopheonone oxime. Through a two-step reaction under relatively mild condition, the present invention can obtain the target product in high yield and high selectivity, and the solvent, the reaction produced halohydrocarbon and the catalyst aqua may be reused without exhaust. The synthesis process has industrial production foreground obviously.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

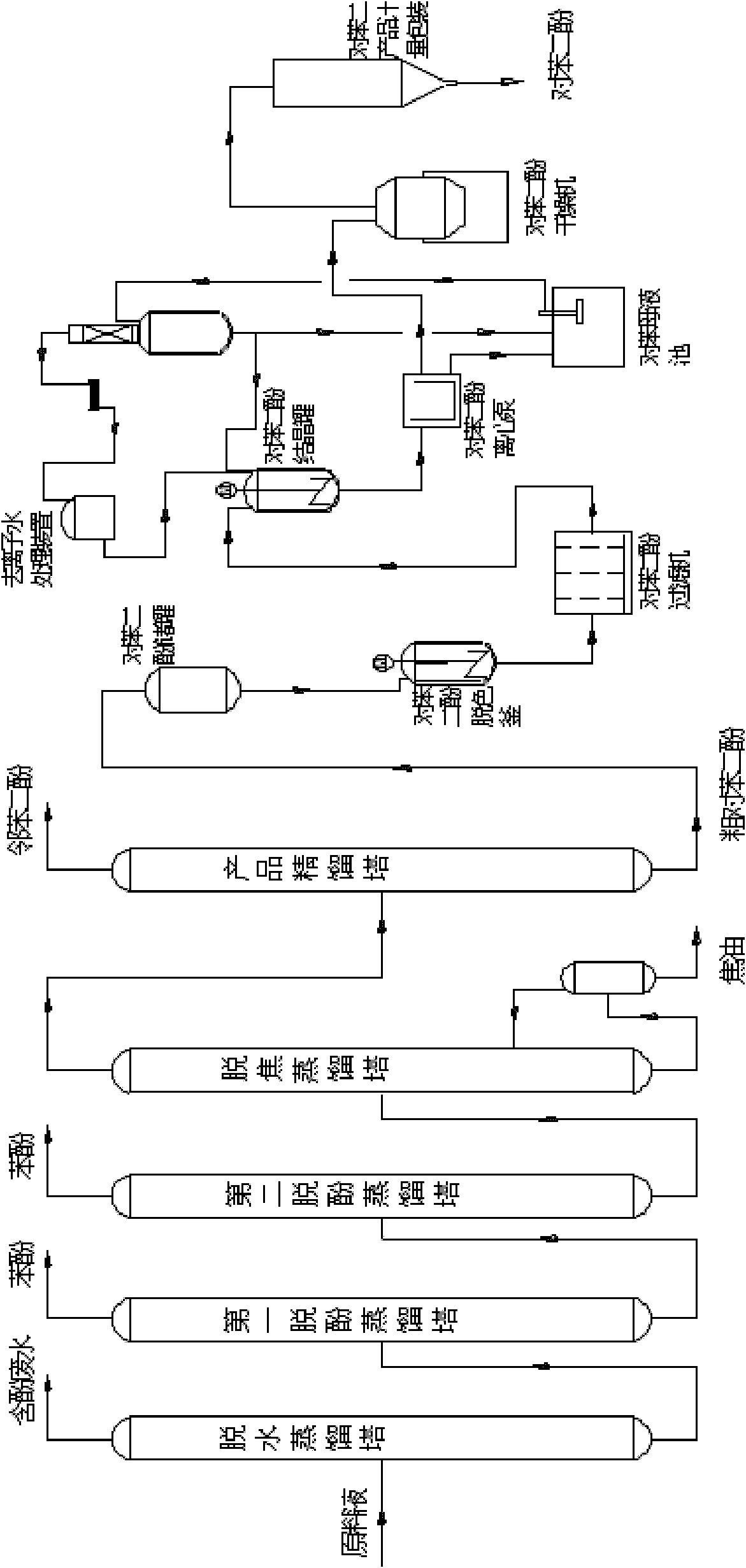

Method and device for separating mixed substances in reaction solution for oxidation of phenol with hydrogen peroxide

InactiveCN101830780AEasy to controlWon't clogOrganic chemistryOrganic compound preparationHydroquinone productsPhenol

The invention discloses a method and a device for method and device for separating mixed substances in reaction solution for oxidation of phenol with hydrogen peroxide. The method comprises the following steps: (a) rectifying raw material solution by allowing the raw material solution to pass through a dehydration rectifying tower, a first dephenolizing rectifying tower, a second dephenolizing rectifying tower and a decoking rectifying tower; (b) delivering the overhead distillate of the decoking rectifying tower to a pyrocatechol rectifying tower, and obtaining a pyrocatechol overhead distillate after rectification; and (c), delivering coarse hydroquinone which is drawn from the bottom of the pyrocatechol rectifying tower and contains a small amount of pyrocatechol and tar to a hydroquinone rectifying tower, drawing a hydroquinone product from the side of the upper segment of the hydroquinone rectifying tower after rectification and separation, returning the hydroquinone and tar mixture drawn from the bottom of the tower to the feed inlet of the decoking rectifying tower, and returning the overhead distillate, which contains a large amount of hydroquinone and a small amount of pyrocatechol, of the decoking rectifying tower to the feed inlet of the pyrocatechol rectifying tower. The method avoids the problems such as long process flow, low yield and high cost of the conventional process.

Owner:TIANJIN UNIV

Production method of glycidyl methacrylate

InactiveCN105218487AReduce productivityChemical reduction industrial equipmentOrganic chemistryPtru catalystIndustrial equipment

The invention relates to a production method of glycidyl methacrylate. The method comprises a reaction process and a post-treatment process. The reaction process is characterized in a one-step synthesis method. According to the reaction process, methacrylic acid and sodium carbonate are subjected to a neutralization reaction in excessive epichlorohydrin, such that sodium salt is prepared; without solid-liquid separation, system water content is removed with an azeotropic solvent; under the catalysis effect of a phase transfer catalyst, the glycidyl methacrylate is prepared. The post-treatment process comprises the following steps: a reaction finished liquid is washed; liquid separation is carried out, such that an organic phase is obtained; solvent recovery is carried out with a film evaporation device; and finished product distillation is carried out with a molecular distillation device. With the production method provided by the invention, production process and industrial equipment can be simplified, and operation is convenient. During the post-treatment process, phenomena of poor product polymerization rate and yield caused by high temperature, poor heat transfer effect, low distillation efficiency and the like of a conventional kettle distillation method can be avoided. With the method provided by the invention, product quality and yield can be effectively ensured. The obtained product has a purity higher than 98% and a yield of 85-90%.

Owner:DALIAN RES & DESIGN INST OF CHEM IND

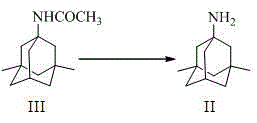

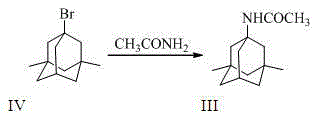

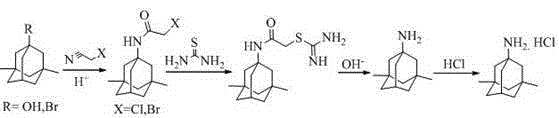

Method for preparing memantine hydrochloride

ActiveCN104557567ARaw materials are easy to obtainEasy to operateOrganic compound preparationCarboxylic acid amides preparationKetone solventsMemantine hcl

The invention discloses a method for preparing memantine hydrochloride. The method is characterized in that the method provided by the invention uses 1-bromo-3,5-dimethyladamantane (represented by a general formula IV in the description) as a starting material which is subjected to an amination reaction with acetamine to obtain a key intermediate 1-actamido-3,5-dimethyladmantane (represented by a general formula III in the description); the compound represented by the general formula III is subjected to alcoholysis in a mixture system of inorganic base and n-butyl alcohol for deacetylated to obtain memantine; memantine is treated using hydrochloric acid in a ketone solvent to obtain memantine hydrochloride. The method provided by the invention overcomes deficiencies in the prior art and has the advantages that the raw materials are simple and readily available, the reaction steps are simple and short, and the operations are convenient and fast, therefore, the method is suitable for industrial production.

Owner:CHONGQING PHARMA RES INST

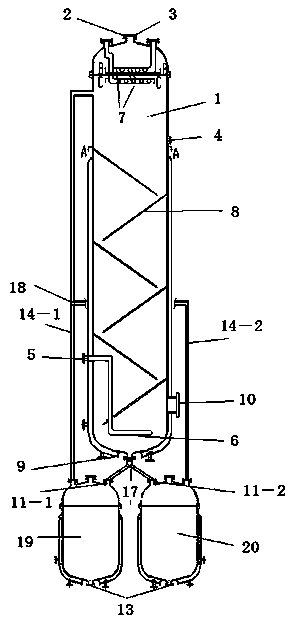

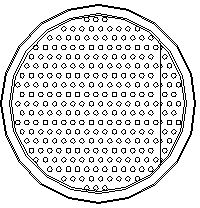

Gas-liquid-solid multiphase reaction-separation synchronous reactor

ActiveCN104338500AAchieving Synchronous SeparationSolve the blockageChemical/physical/physico-chemical processesChemical reactionPressure balance

The invention relates to a gas-liquid-solid multiphase reaction-separation synchronous reactor comprising two parts which are a reaction system and a separation system. The reaction system comprises a bubbling gravity reaction tower. A gas raw material introducing port and a gas distributor are arranged on a lower part in the reaction tower. A plurality layers of alternative cooling coils are arranged in a gas-liquid separation zone at the upper part of the bubbling gravity reaction tower. Gravity sedimentation plates are arranged in a reaction zone at the middle-lower part of the bubbling gravity reaction tower. The separation system comprises two thermostatic sedimentation towers with a same structure and a same size. Pressure balance tubes are connected between the tops of the thermostatic sedimentation towers and the top of the bubbling gravity reaction tower. The reactor provided by the invention is applied in gas-liquid-solid multiphase reactions in which product specific gravities are higher than those of reactants and in which the products and the reactants are immiscible, such that synchronous chemical reaction and separation is realized. According to a traditional production mode, a multiphase substance is transferred to a separator through a pipe for separation. With the gas-liquid-solid multiphase reaction-separation synchronous reactor provided by the invention, reaction and solid product separation can be synchronized, and the traditional production mode is not needed.

Owner:YUANJIANG HUALONG CATALYST TECH

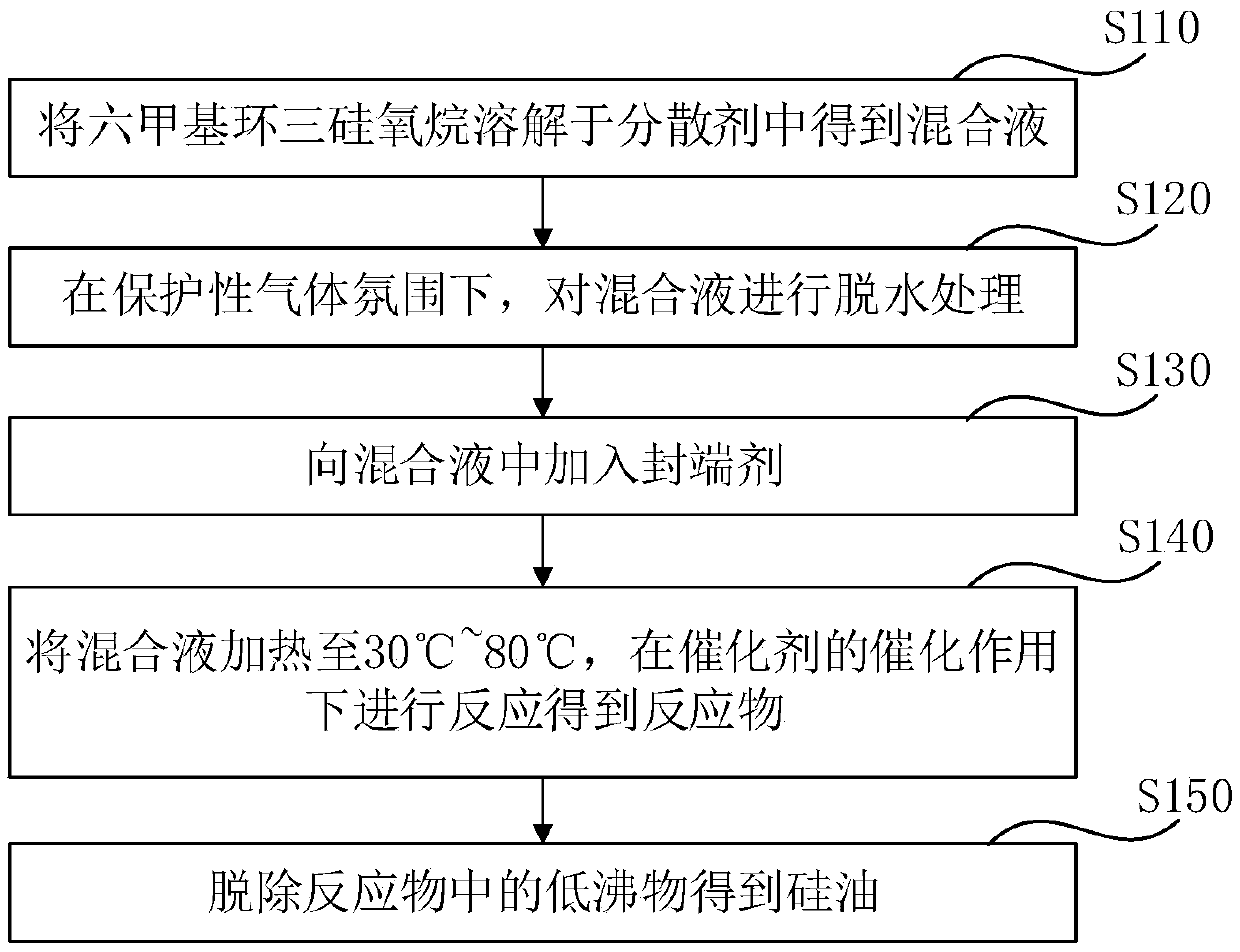

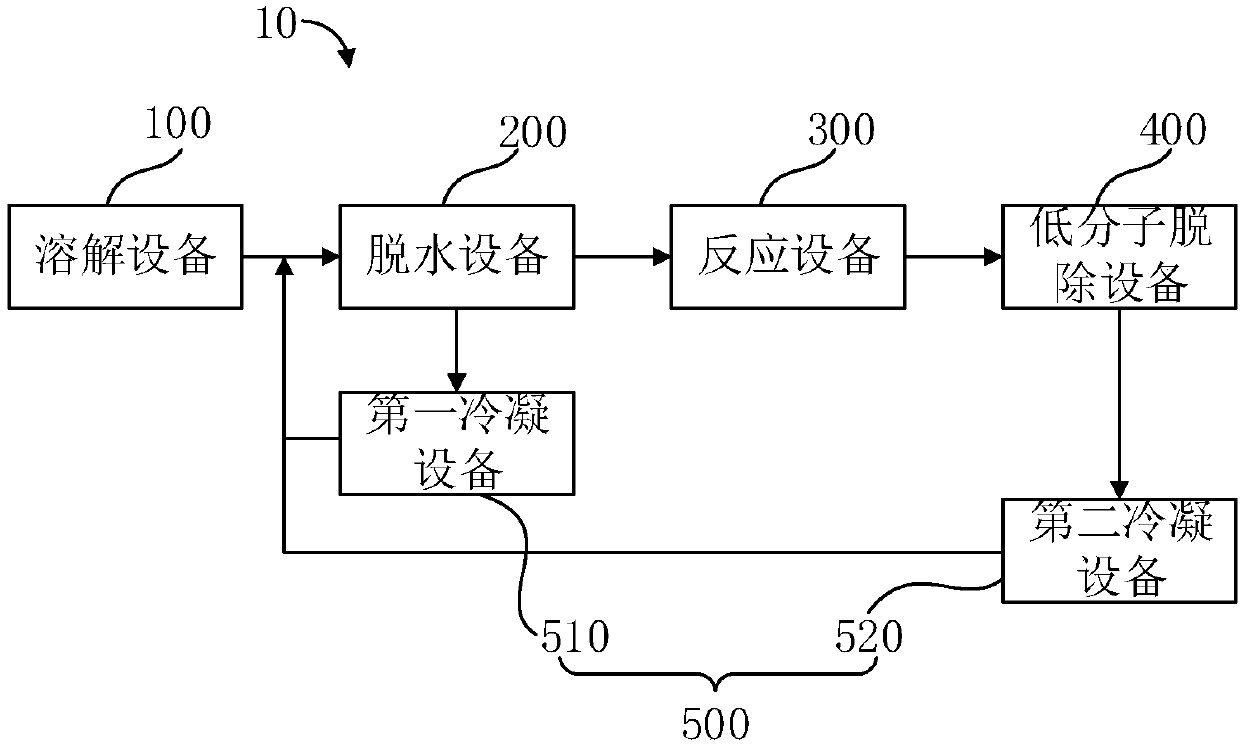

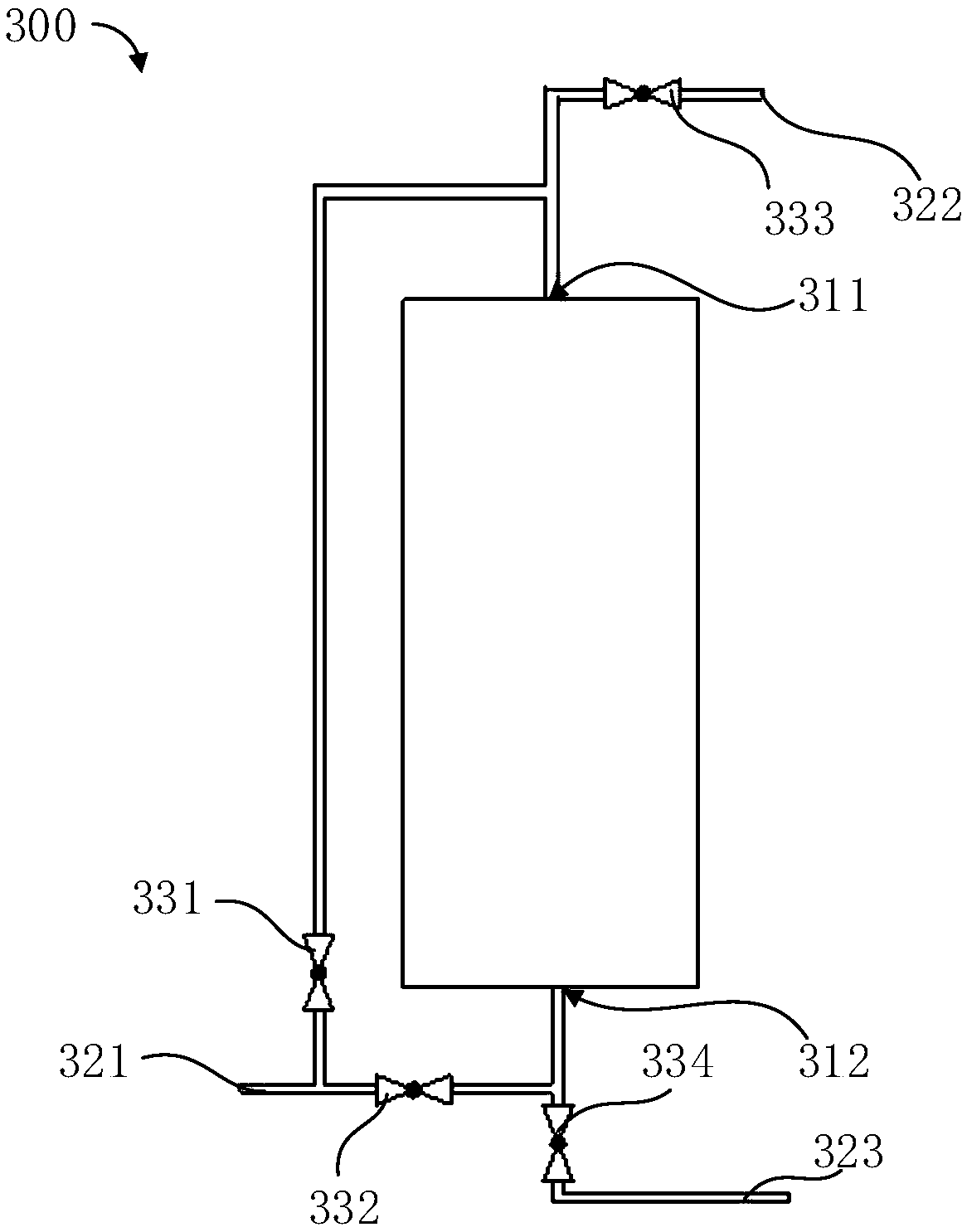

Silicone oil and continuous preparing method thereof

The invention relates to silicone oil and a continuous preparing method thereof. The continuous preparing method of the silicone oil comprises the following steps of dissolving hexamethylcyclotrisiloxane into dispersing agent to obtain mixed liquid; dehydrating the mixed liquid; adding an end-capping agent into the mixed liquid; heating the mixed liquid to 30 DEG C-80 DEG C and conducting a reaction to obtain a reactant; removing low-boiling-point substances in the reactant to obtain the silicone oil. When the mixed liquid is dehydrated, condensate is adopted to spray dehydrated spilth; when the low-boiling-point substances in the reactant are removed to obtain the silicone oil, the condensate is adopted to spray the removed low-boiling-point substances. By means of the continuous preparing method of the silicone oil, the danger is avoided that hexamethylcyclotrisiloxane is directly heated and molten into a liquid phase, which easily causes an explosion; the problems are solved that hexamethylcyclotrisiloxane is condensed in a condenser and a vacuum pipe, which causes that a reaction system is clogged, the product unit consumption and energy consumption are too high, and the yieldis lowered.

Owner:GUANGZHOU DAOLIN SYNTHETIC MATERIALS CO LTD

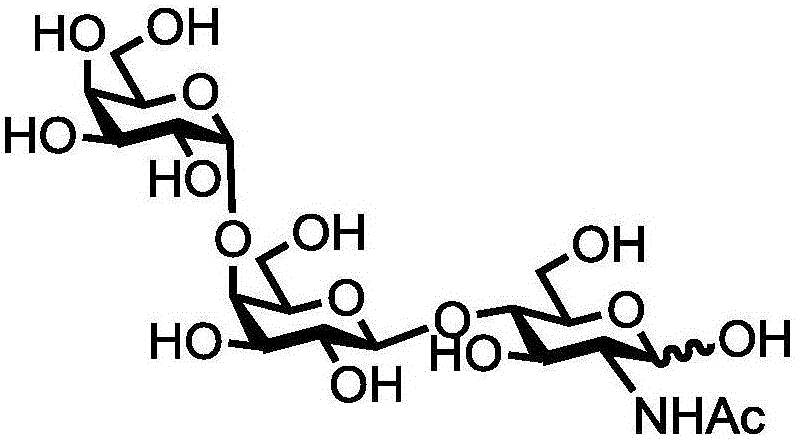

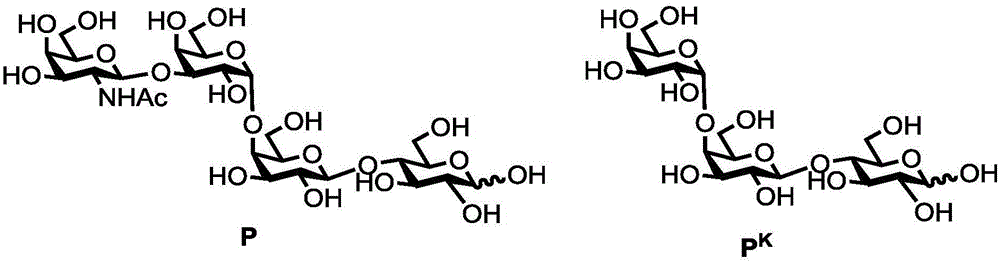

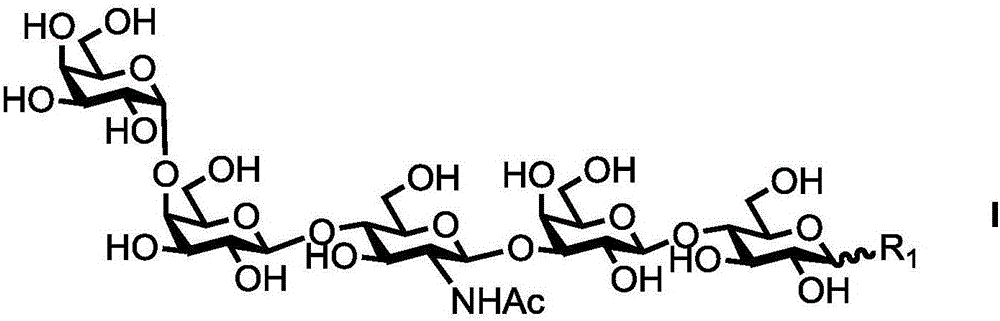

Human blood group antigen P1 pentasaccharide synthesis method

The invention discloses a human blood group antigen P1 pentasaccharide synthesis method. The method includes steps: adopting a one-pot multienzyme system for coupling galactose to trisaccharide as shown in a formula (III) through a beta1-4 glucosidic bond to synthesize tetrasaccharide as shown in a formula (IV); adopting the one-pot multienzyme system for coupling galactose to the tetrasaccharide as shown in the formula (IV) through an alpha1-4 glucosidic bond to synthesize pentasaccharide as shown in a formula (I), wherein in the formula (I), the formula (III) and the formula (IV), R1 refers to hydroxyl, azide substituted alkyl, alkynyl substituted alkyl, sulfydryl substituted alkyl, alpha- or beta- configuration substituted alkyl, alpha- or beta- configuration serine residue and alpha- or beta- configuration threonine residue. By integration of high regioselectivity and high efficiency of enzymatic synthesis, P1 antigen pentasaccharide is synthesized for the first time. Glycosyltransferase, glucose nucleoside generating enzymes and glucokinse adopted in the synthesis method are all derived from prokaryotes, and high protein expression quantity, high substrate adaptability and high catalytic efficiency are realized.

Owner:SHANDONG UNIV

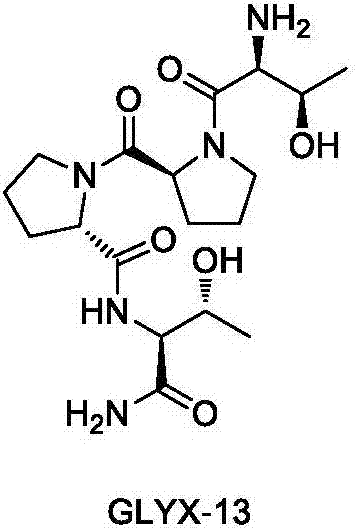

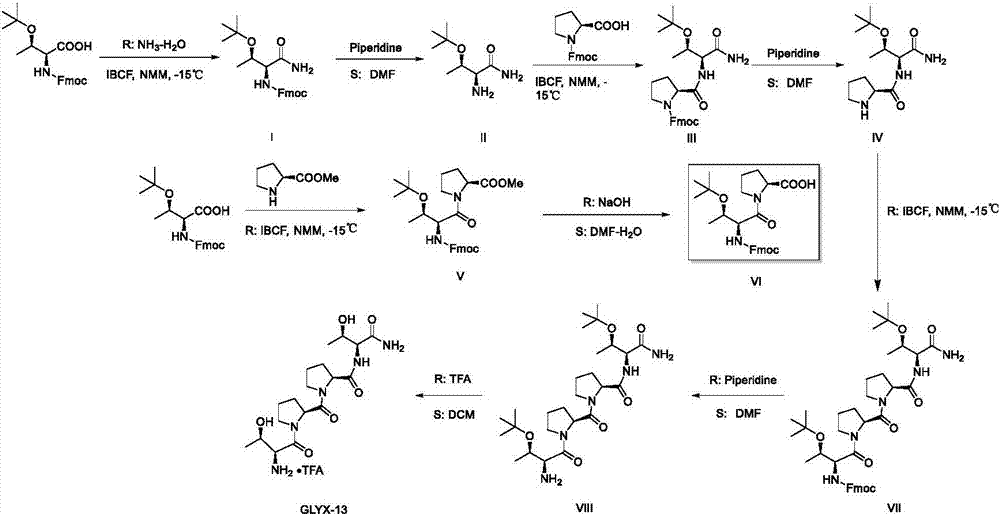

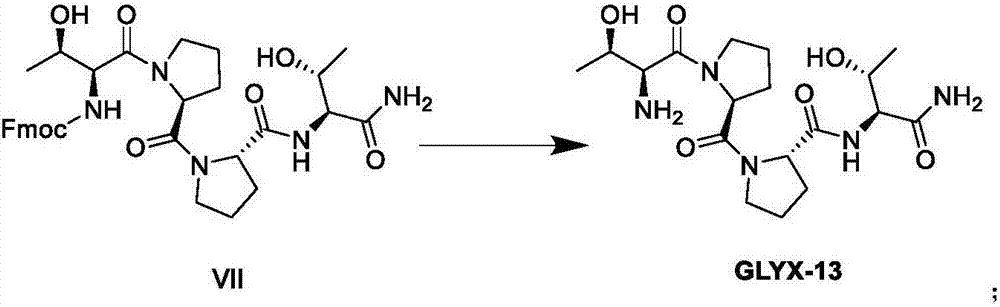

A preparing method of GLYX-13 and a compound used for preparing the GLYX-13

ActiveCN107474107AHigh purityEasy to handlePeptide preparation methodsBulk chemical productionL-threonineTert butyl

The invention belongs to the field of medicine compounds, and provides a preparing method of GLYX-13 and a compound used for preparing the GLYX-13. Fmoc-O-tert-butyl-L-threonine, Fmoc-L-proline, N-carbobenzyloxy-L-threoninamide and proline benzyl ester hydrochloride are adopted as initial raw materials of the method. By adoption of the method, the GLYX-13 can be prepared in a high yield in an industrial scale through eight easy and economical synthetic steps, the GLYX-13 can be prepared through simple process operation in a good yield and at a low cost without the need of utilizing expensive peptide condensation agents or controlled, precursor-chemical or highly corrosive deprotection agents.

Owner:NHWA PHARMA CORPORATION +1

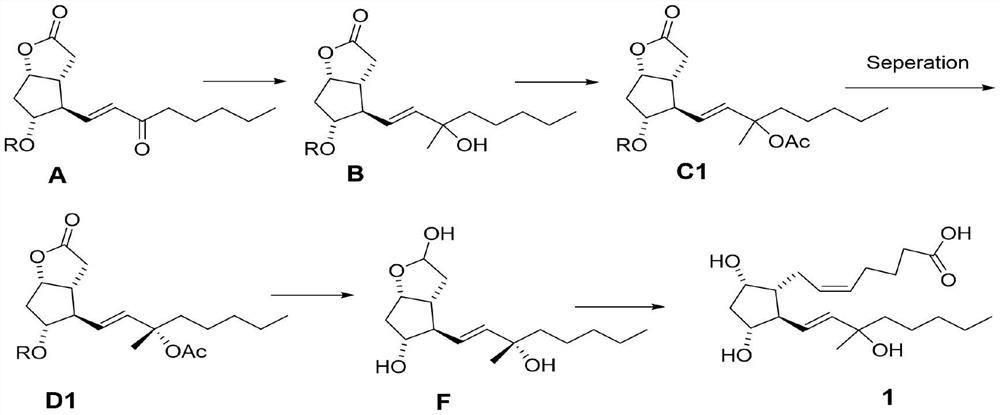

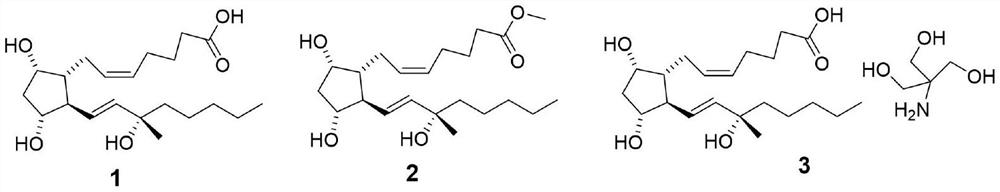

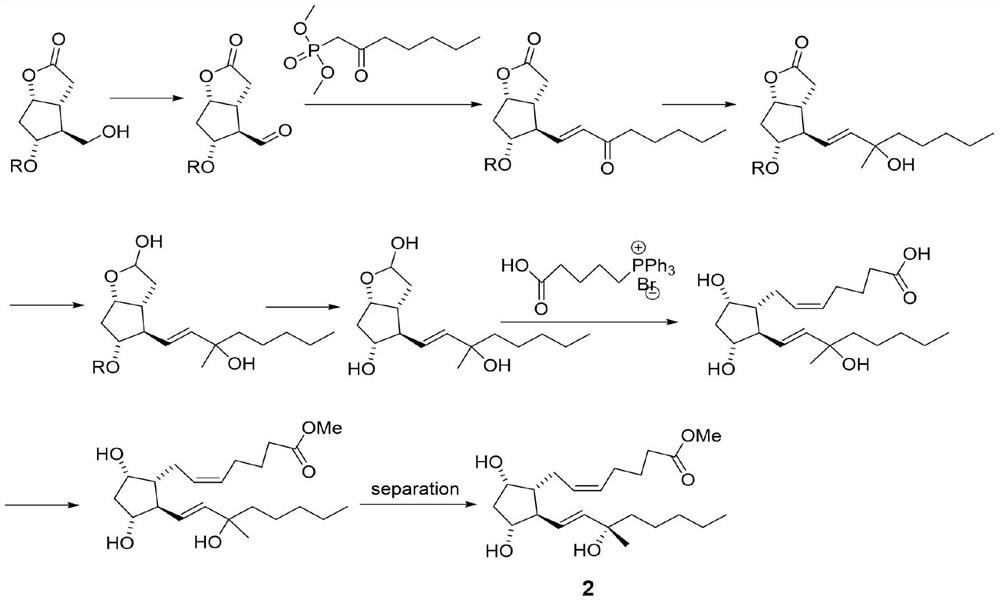

Carboprost 15-site isomer separation method

PendingCN112645861AReduce riskAvoid Yield ProblemsOrganic compound preparationOrganic chemistry methodsChemical separationPharmaceutical Substances

The invention discloses a carboprost 15-site isomer impurity separation technical method, and belongs to the technical field of pharmaceutical chemical separation. The method comprises the steps: carrying out PG protection on the compound B with the 15-site hydroxyl tertiary alcohol to obtain 15-site S-type carboprost D and 15-site R-type carboprost E (forming the 15-site hydroxyl tertiary alcohol compound C), and separating to obtain a pure product of the 15-site carboprost D or the 15-site carboprost E. On the basis, the invention also provides a method for preparing the carboprost series products, wherein the method is suitable for industrial amplification. According to the method, after proper protecting group derivation, the isomer can be separated by adopting common silica gel column chromatography, the operation is simple, the quality of the obtained product meets the requirement, the production cost is greatly reduced, and the comprehensive benefit of the product is improved.

Owner:CHEMVON BIOTECH CO LTD

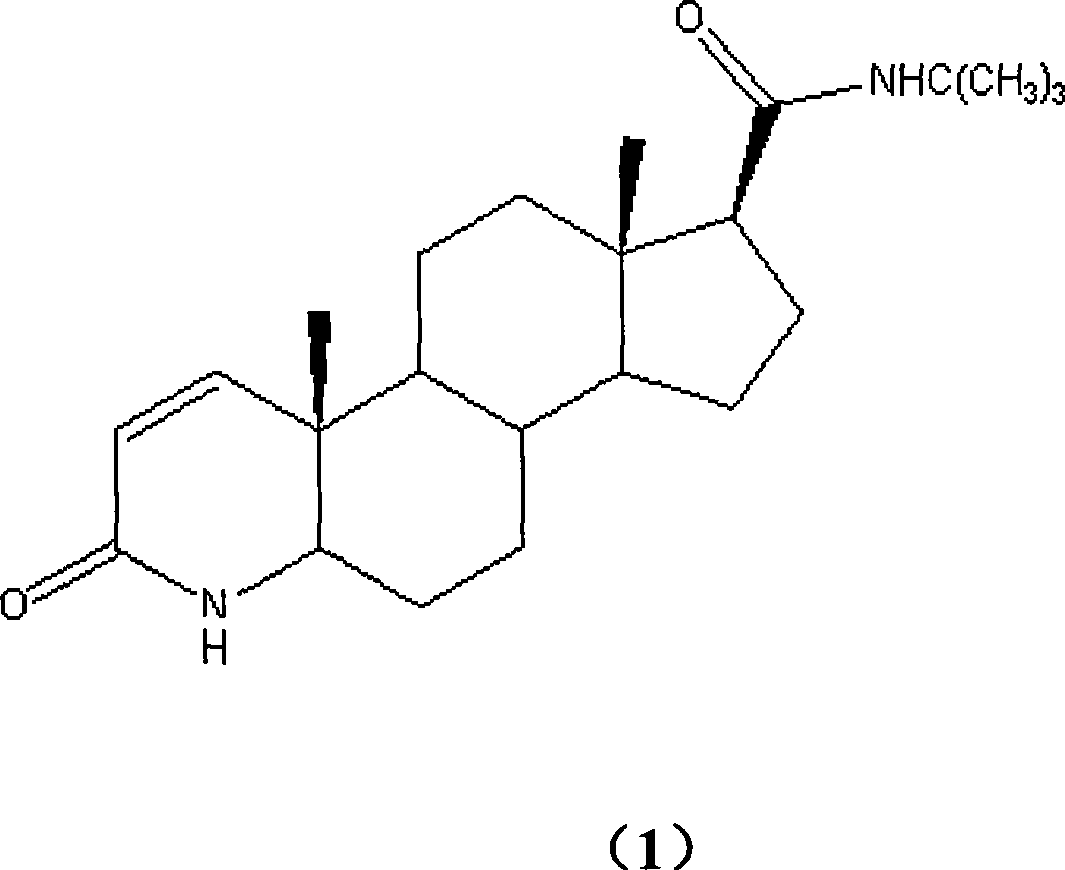

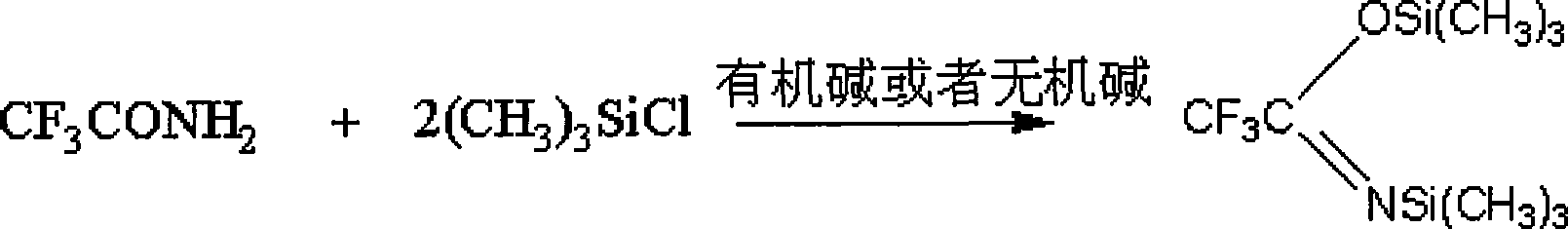

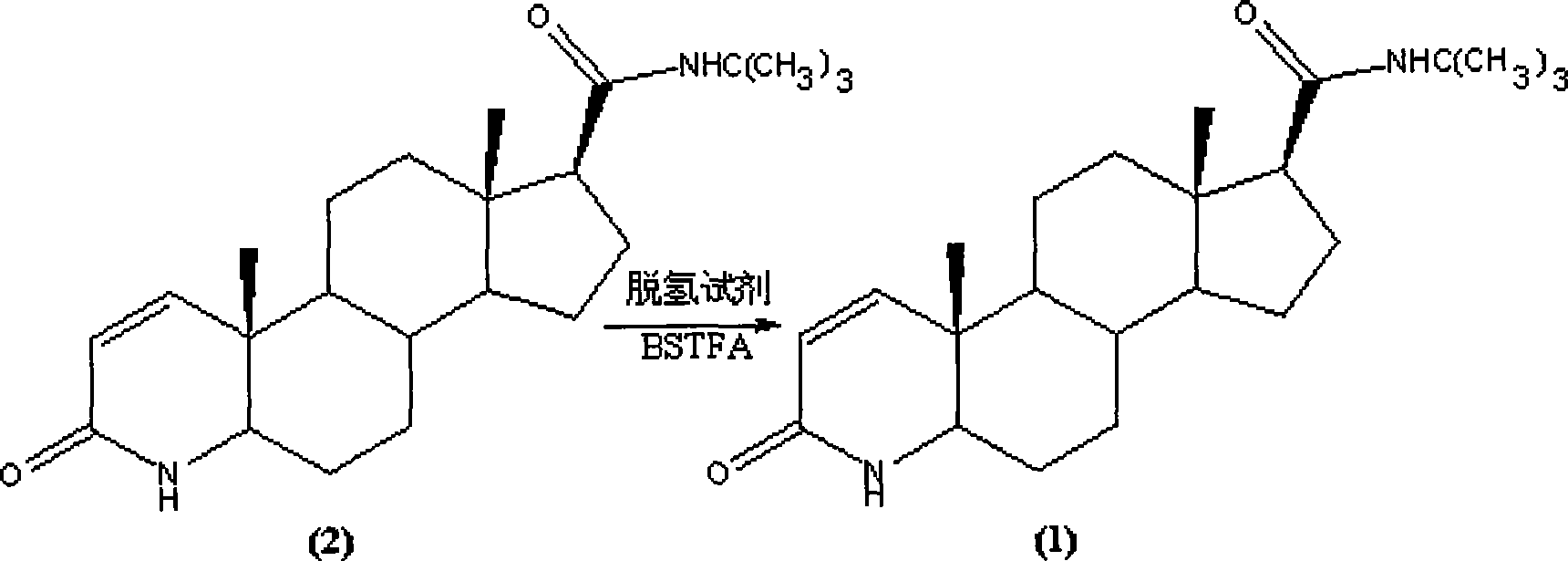

Method for synthesizing finasteride

InactiveCN101418033AAvoid purification difficultiesAvoid Yield ProblemsSteroidsUrinary disorderTrimethylsilyl chlorideDehydrogenation

The invention provides a method for synthesizing finasteride. The method comprises the following steps: (1) dissolving trifluoroacetamide in solvent, reacting the solvent with trimethylchlorosilane in the presence of organic alkali or inorganic alkali, filtering out solid from reaction products, and collecting filtrate; and (2) dissolving the filtrate obtained in step (1) in the solvent, adding 3-carbonyl-4-aza-5 alpha-androstane-17 belta-tert-butylformamide and dehydrogenation agent into the solvent for reaction, and collecting target products from reaction products. The method has the advantages that the method has higher yield, high selectivity, and is simple and safe; after simple purification, the purity of the finasteride can reach more than 99 percent; moreover, the method has easily obtained reagents used in the whole reaction, simultaneously having high reaction yield and mild reaction conditions, reclaiming the solvent and facilitating the industrialized production.

Owner:湖南玉新药业有限公司

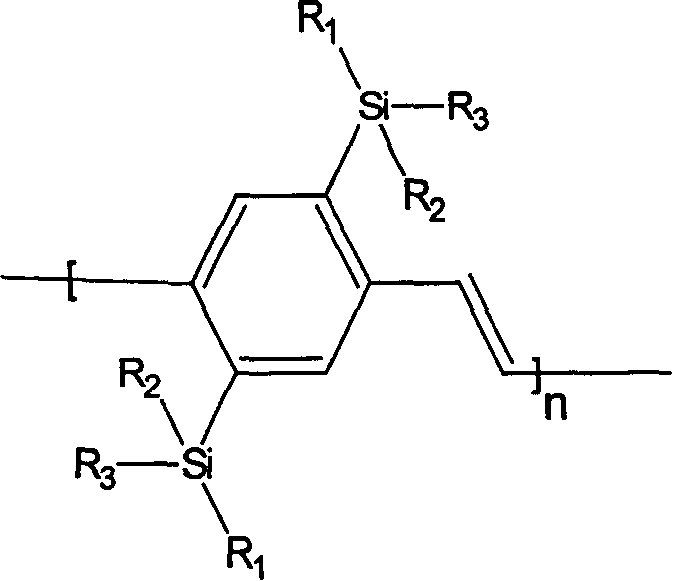

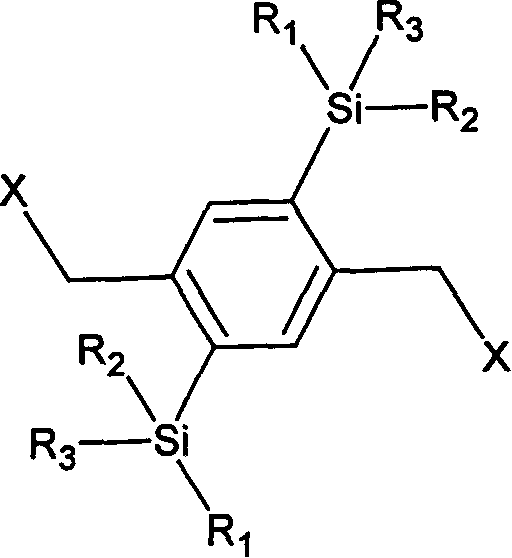

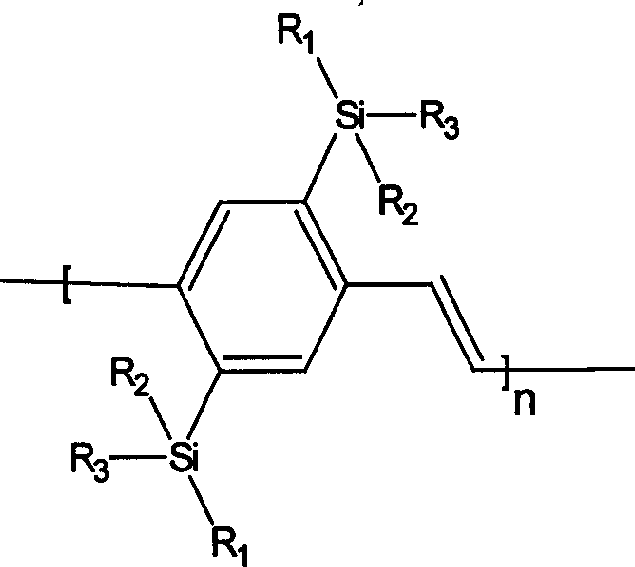

Silicon group containing 1, 4-phenylene vinylidene and its preparation method and use

InactiveCN1631931ASmall dispersionImprove luminosityElectrical apparatusElectroluminescent light sourcesLithiumThermal stability

The invention is the method for preparing 1,4- containing silicon silicon group (Si-PPV) and its application. Compared with the present technology which has complex equipment, low lightening efficiency and unsatisfying heat stability, the invention uses polymer 3 as the raw material, generates 4 which then has coupling reaction with 6, generating 7, and the acquiring the active monomer through mole without water existence, the active monomer is changed into Si-PPV through Gilch reaction. The polymer has outstanding film-making performance, heat stability and lightening efficiency.

Owner:徐良衡

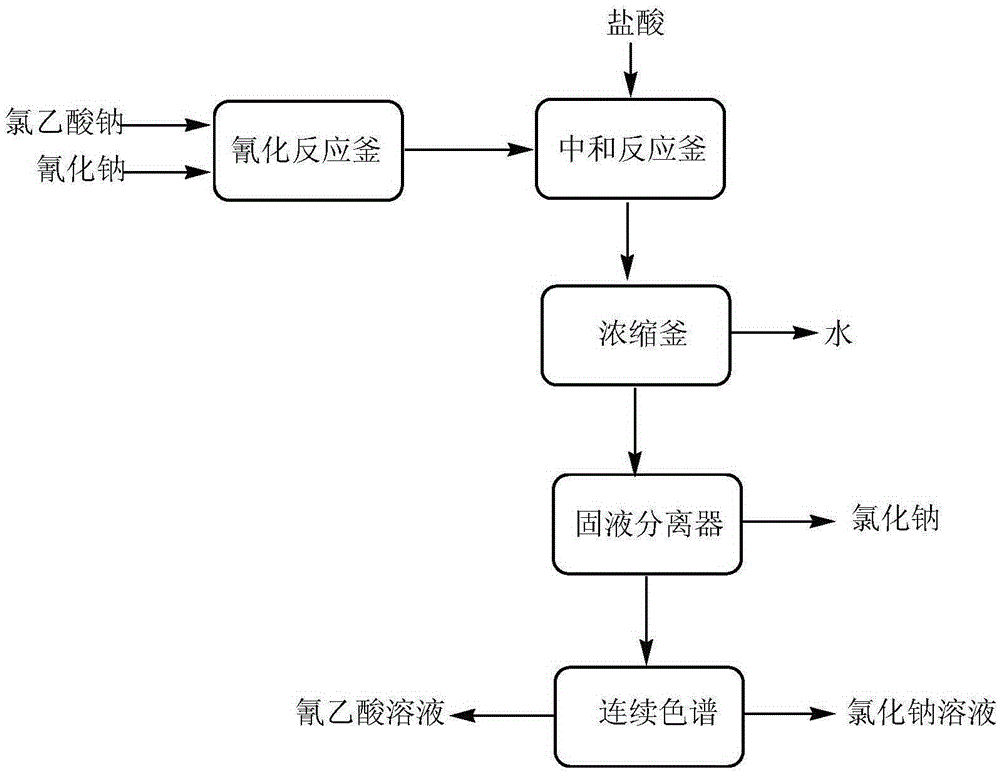

Preparation method of cyanoacetic acid and derivatives thereof

ActiveCN105294491APrevent massive decompositionAvoid Yield ProblemsOrganic compound preparationCarboxylic acid esters preparationDecompositionDesalination

The invention discloses a preparation method of cyanoacetic acid and derivatives thereof. Evaporation concentration of part of water in a mixture containing cyanoacetic acid and sodium chloride is carried out, and filtration is performed to remove the precipitated part of sodium chloride solids, thus avoiding the disadvantages of mass decomposition of cyanoacetic acid and low yield caused by the traditional distillation desalination, at the same time after desalination, the solution containing cyanoacetic acid and sodium chloride is separated into a cyanoacetic acid solution and a sodium chloride solution by continuous chromatography, thus avoiding decomposition in a cyanoacetic acid concentration process. The method provided by the invention has the advantages of simple operation, low production cost, high product yield and small amount of three wastes, and is a clean and environment-friendly production method, and can acquire a low chlorine ion content cyanoacetic acid solution or high content solid cyanoacetic acid product and derivatives thereof.

Owner:CHONGQING UNISPLENDOUR CHEM

Production process of high-quality trimethyl orthoacetate

InactiveCN106699522AEfficient removalAvoid Yield ProblemsOrganic compound preparationOximes preparationSolventIon-exchange resin

The invention discloses a production process of high-quality trimethyl orthoacetate. The production process comprises the following steps: performing salification reaction on acetonitrile, methanol and chlorine hydride in the presence of a solvent unsym-trimethyl benzene, so as to obtain ethyleneimine methyl ether hydrochloride; then adding the ethyleneimine methyl ether hydrochloride into a methanol solution; dropwise adding an aminomethanol solution to regulate a pH value, performing alcoholysis reaction to obtain a trimethyl orthoacetate crude product; filtering out solid ammonium chloride, and recycling the solid ammonium chloride; adsorbing filtrate by use of strong-basicity macroporous ion-exchange resin so as to remove chloridion; and finally performing continuous rectification, thereby obtaining a trimethyl orthoacetate product with content greater than 999.5% and yield greater than 85%. The production process is simple in process, the product is stable and reliable, and the used unsym-trimethyl benzene solvent is low in toxicity and safe to use.

Owner:QINGDAO SENMEIKE CHEM TECH CO LTD

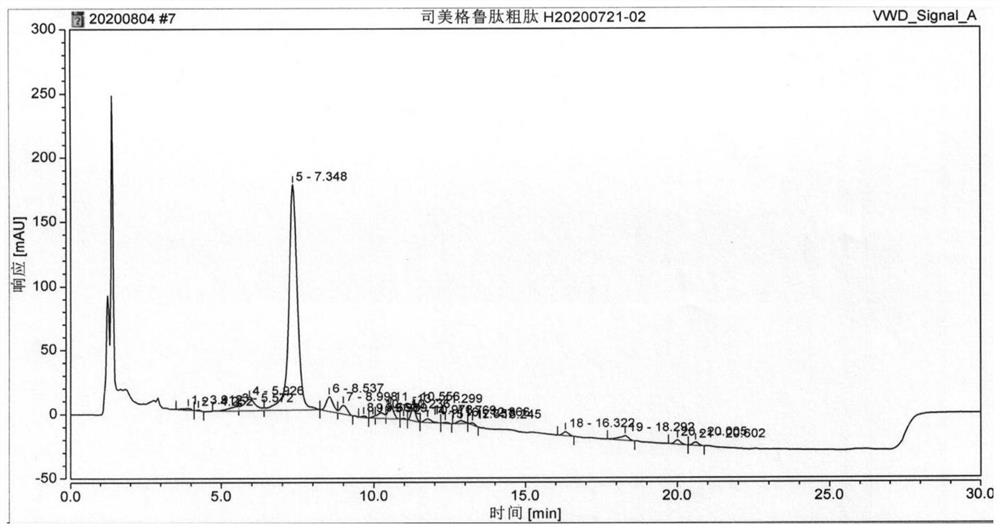

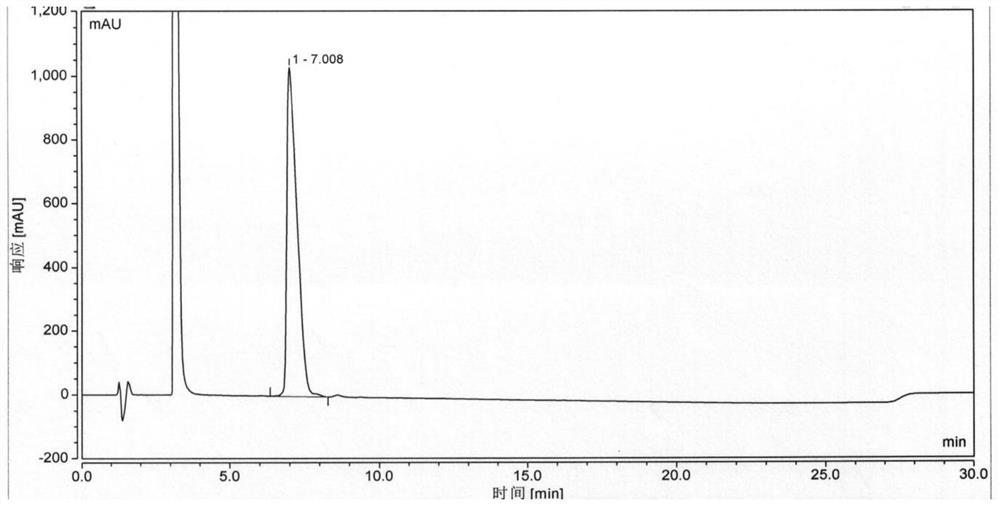

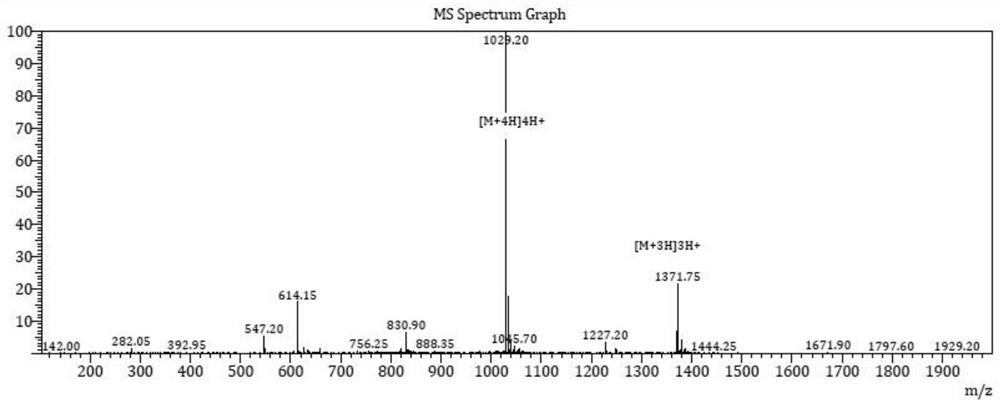

Synthesis method of semaglutide

InactiveCN112028986AHigh purityAvoid efficiencyPeptide preparation methodsBulk chemical productionAmino acid side chainDipeptide

The invention discloses a synthesis method of semaglutide. The synthesis method comprises the following steps: (1) taking Fmoc-Gly-Wang resin as a solid-phase carrier and removing an Fmoc protection group; gradually coupling amino acids from a C end to an N end in sequence; coupling to 20 amino acid R-Lys (Fmoc)-OH at the N end of a main chain; (2) removing a side chain Fmoc protection groupof the 20 amino acid at the N end of the main chain and coupling side chain amino acids in sequence; (3) removing a 20 amino acid R protection group at the N end of the main chain and coupling residual amino acids of the main chain in sequence according to a peptide sequence to obtain semaglutide full-protection peptide resin, wherein dipeptide fragments are selected as 18 -19 amino acids at the N end and 1 -2 <nd> amino acids at the N end; and (4) cracking and precipitating the semaglutide full-protection peptide resin through a cracking solution to obtain semaglutide crudepeptide. The method disclosed by the invention is simple and convenient; the prepared semaglutide has high purity and industrial production is facilitated.

Owner:哈尔滨吉象隆生物技术有限公司

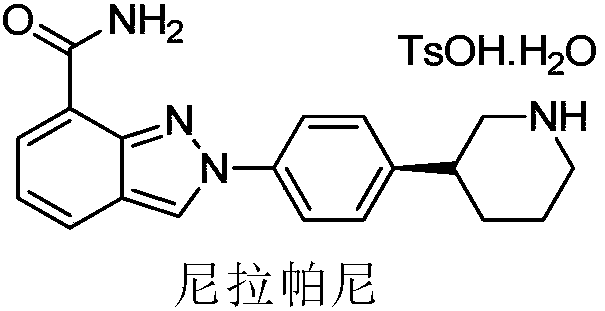

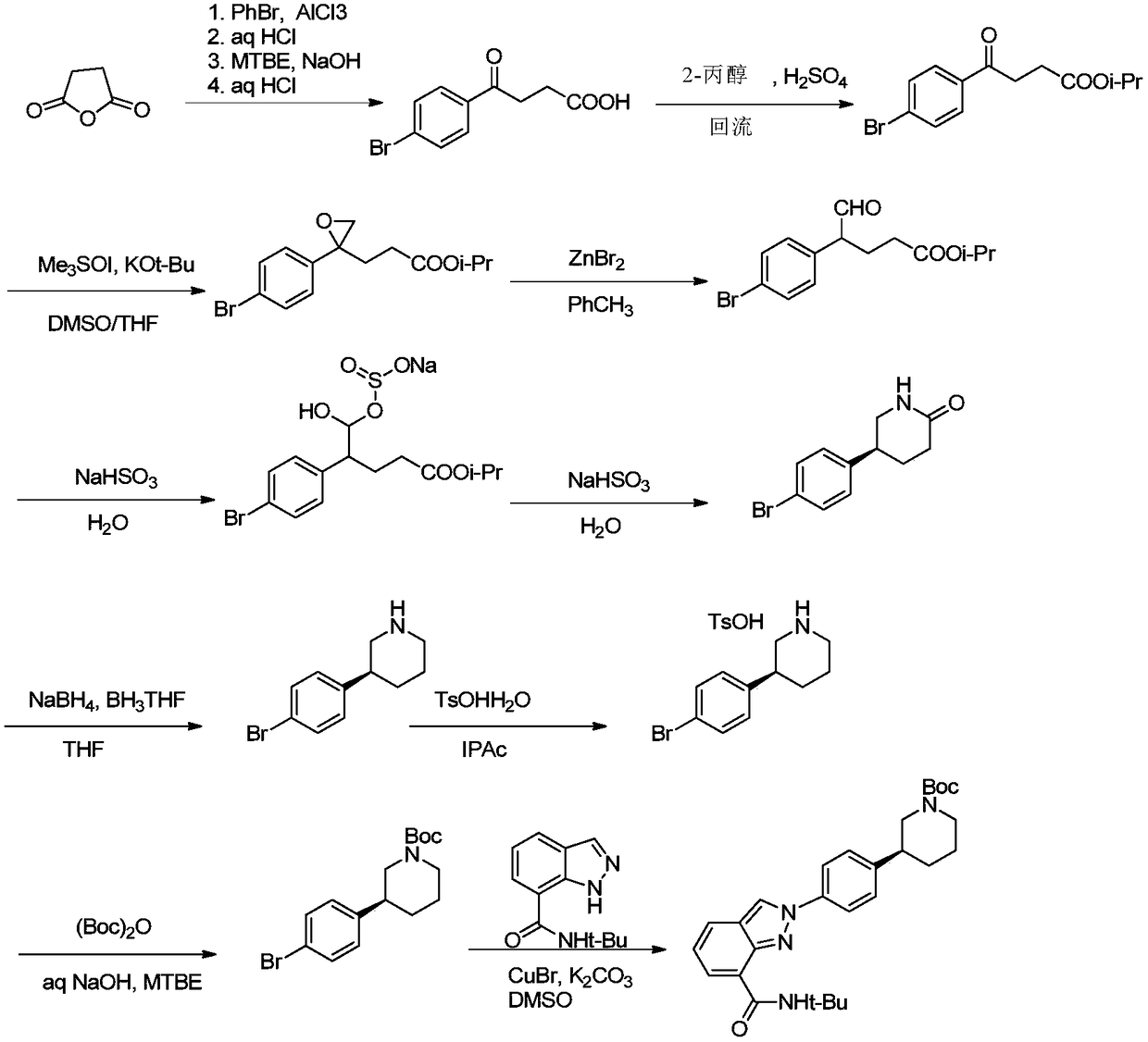

Method of synthesizing (S)-3-(4-bromophenyl)-piperidine or salt thereof with chiral induction

ActiveCN109456253ARaw materials are cheap and easy to getSimple and fast operationOrganic chemistryDiastereomerCrystallization

The invention relates to a method of synthesizing (S)-3-(4-bromophenyl)-piperidine or salt thereof with chiral induction. Particularly, the method comprises the following steps of by taking methyl ortho-4-bromophenylacetate and (S)-(-)-2-methyl-2-propanesulfinamide as starting materials, sequentially performing reactions including condensation, replacement, reduction, ring closure, removal of chiral induced groups and the like, and the (S)-3-(4-bromophenyl)-piperidine or the salt thereof can be obtained, wherein after the reduction reaction, a high-purity single diastereoisomer can be obtainedwith recrystallization; and after the ring closure reaction, a high-purity single diastereoisomer can be further obtained with recrystallization. The method provided by the invention has the advantages of cheap and available raw material, simple operation, high yield, and low cost and is suitable for industrial production.

Owner:SHANGHAI VASTPRO TECH DEV CO LTD

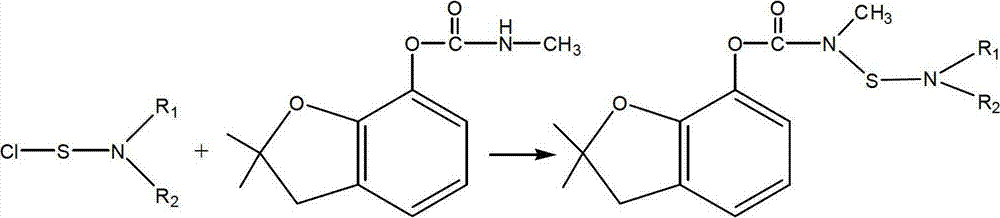

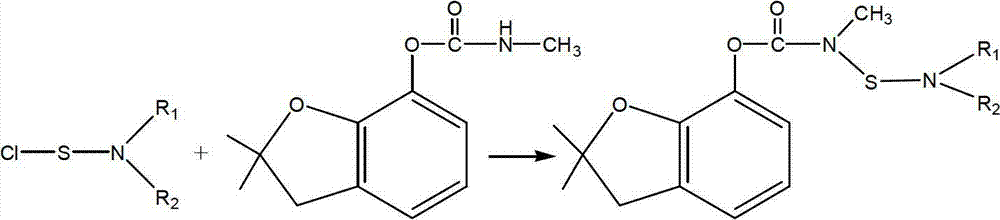

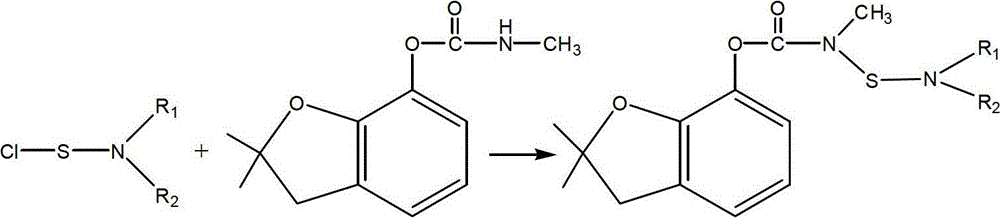

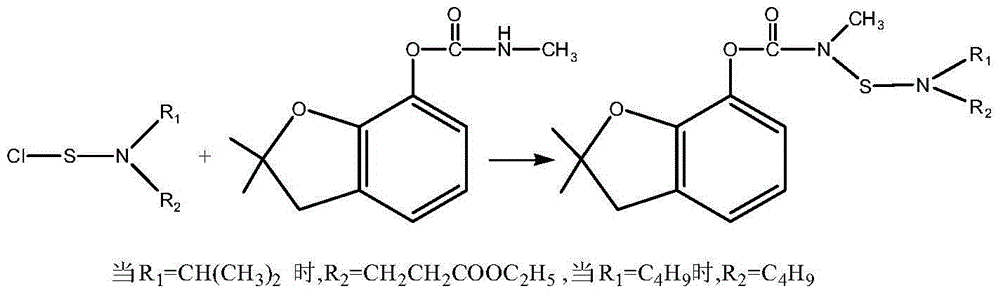

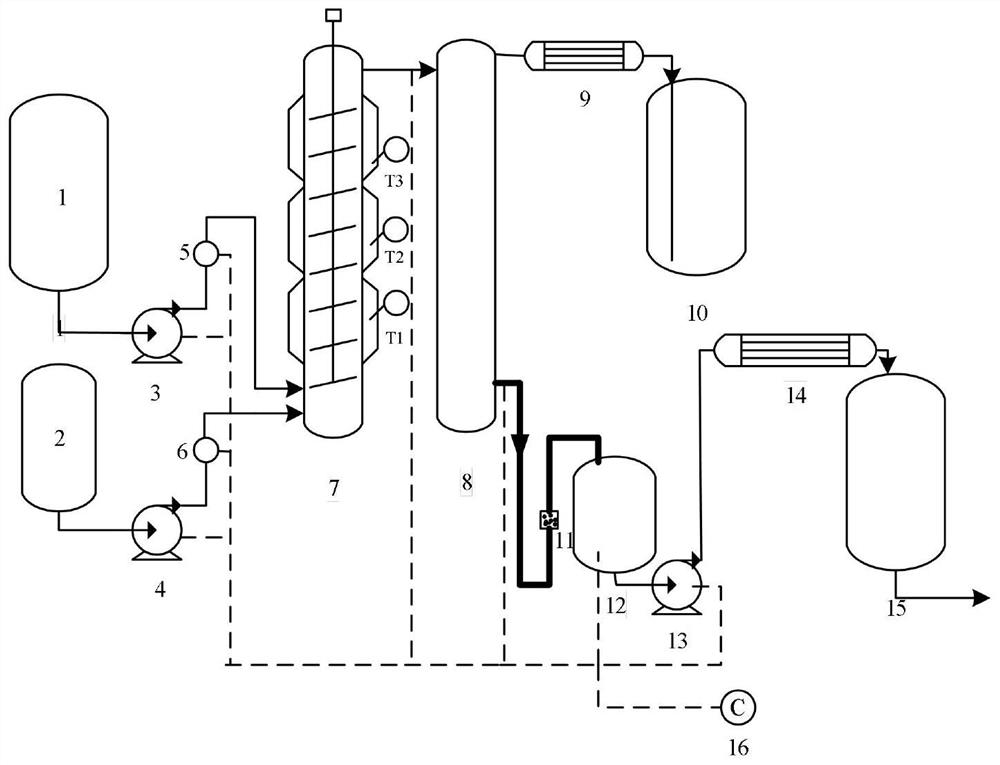

Preparation method for sulfur-containing carbofuran derivative with less than 0.1% of harmful impurity carbofuran

ActiveCN102786503ATroubleshoot incomplete responsesSolve the technical problem of high carbofuran contentOrganic chemistryCarbofuranEthane Dichloride

The invention discloses a preparation method for sulfur-containing carbofuran derivative with less than 0.1% of harmful impurity carbofuran. The preparation method comprises the following steps of: using di-n-butylamine or N-isopropyl-beta-alanine ethyl ester derivative and sulfur monochloride as raw materials to prepare into disulphide in the presence of an acid-binding agent triethylamine and an organic solvent 1, 2-dichloroethane; and then reacting with a chlorinating agent sulfuryl chloride to obtain nitrogen sulfur chlorine; and finally reacting with carbofuran under the effect of a cosolvent N-methyl-2-pyrrolidone or dimethylformamide so as to obtain the sulfur-containing carbofuran derivative with not less than 96% of quality percentage composition and less than 0.1% of main harmful impurity carbofuran. By adopting the preparation method, the problem that the carbofuran cannot be completely reacted during being reacted can be solved, the defects due to low content and low yield of sulfur-containing carbofuran derivatives such as benfuracarb and carbosulfan caused by a solid-liquid two-phase reaction can be avoided, the technical problem due to relatively high content of main harmful impurity carbofuran can be solved, and the content of the sulfur-containing carbofuran derivatives such as benfuracarb and carbosulfan can reach a value not less than 96%, and the yield is 97 to 98%, and the main harmful carbofuran in the product is less than or equal to 0.1%, so that the preparation method has a wide popularization and application prospect.

Owner:湖南海利常德农药化工有限公司

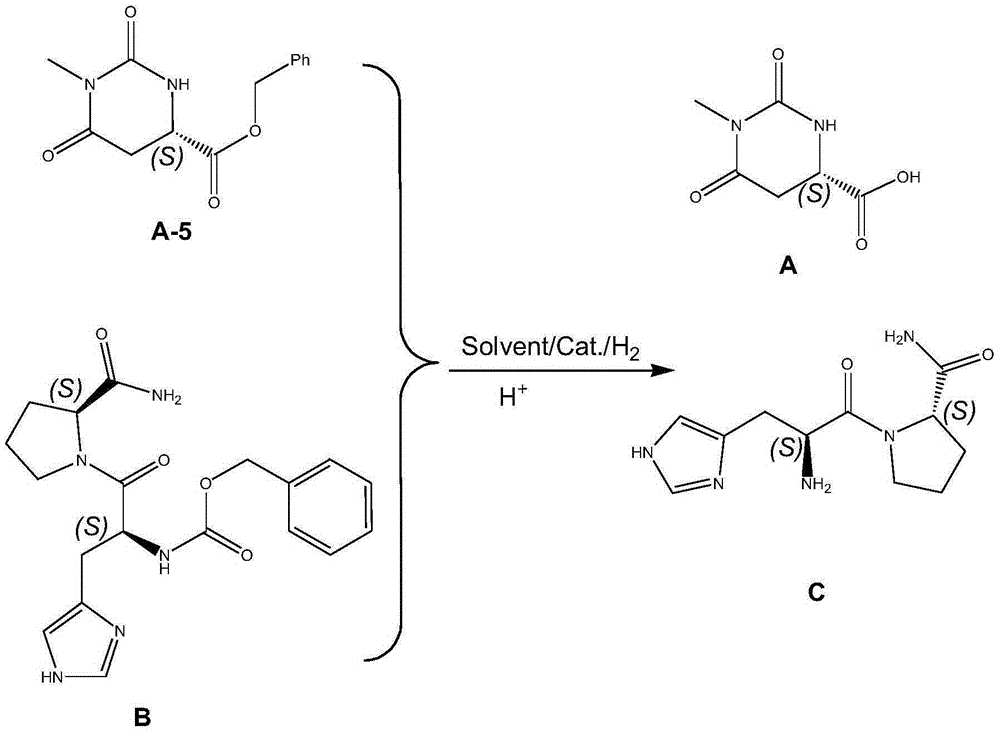

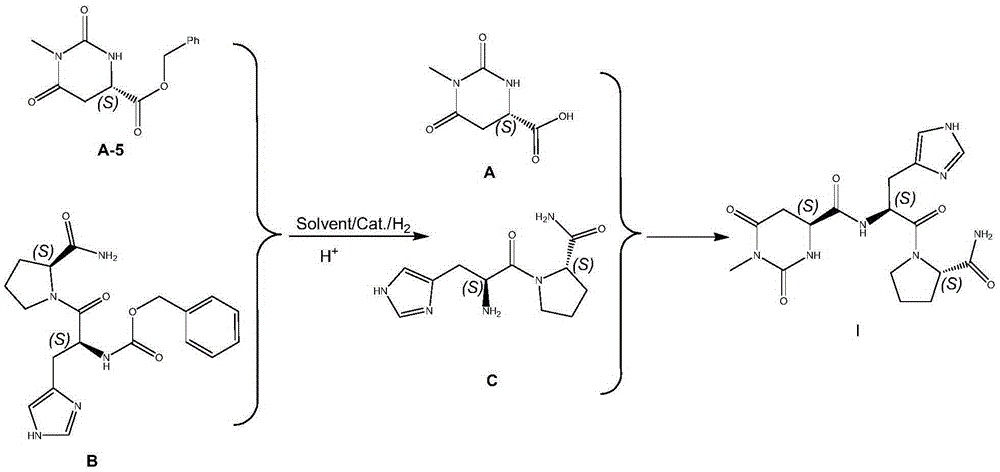

Preparing method for taltirelin and midbody of taltirelin

ActiveCN105254573AAvoid using effectsAvoid toxic reagents such as methyl iodideOrganic chemistryL-AspartateTaltirelin

The invention discloses a preparing method for taltirelin and a midbody of taltirelin. The preparing method comprises the steps that L-aspartic acid-4-methyl ester or other hydrochloride serves as raw materials, a compound A-5 is obtained through ammonolysis, carboxyl protection and cyclization, the compound A-5 and a compound B are simultaneously subjected to deprotection through a one-pot reaction under the acid condition, and 1-methyl-L-4,5-dihydro orotic acid (a compound A) and a compound C are obtained. The compound A and the compound C can be used for a next-step condensation reaction through separation or without separation, and taltirelin shown in the formula I is prepared through the condensation reaction. According to the technical scheme, the prepared compound A and compound C or taltirelin has the advantages that the utilization rate of the raw materials is high, operation changes gradually, the preparation steps are few, the reaction condition is mild, the requirement for production equipment is low, the yield is high, and cost is low.

Owner:重庆莱美隆宇药业有限公司

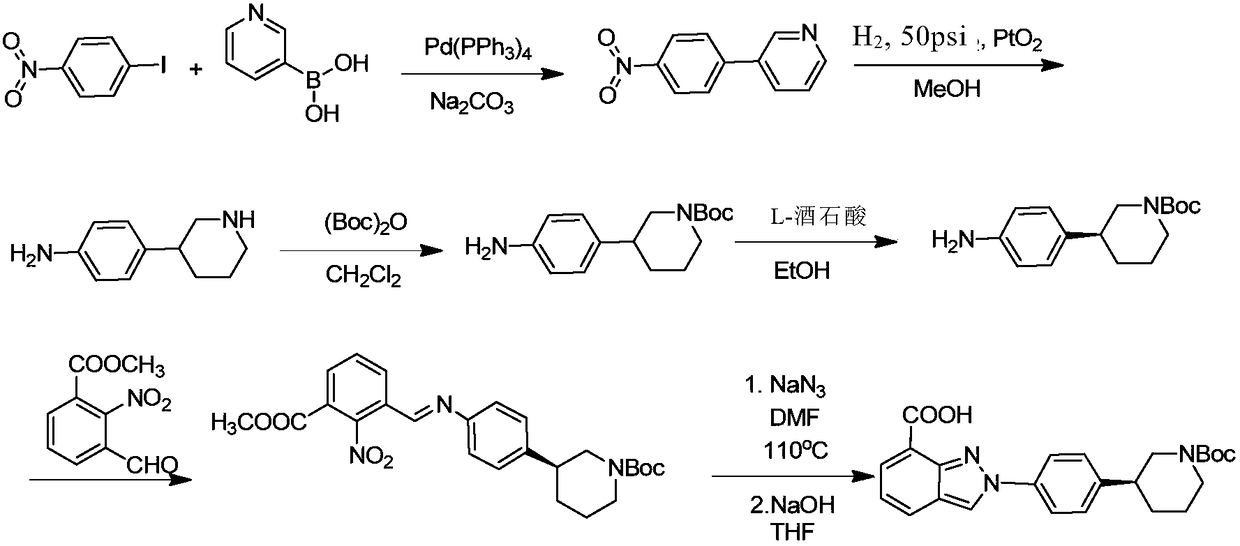

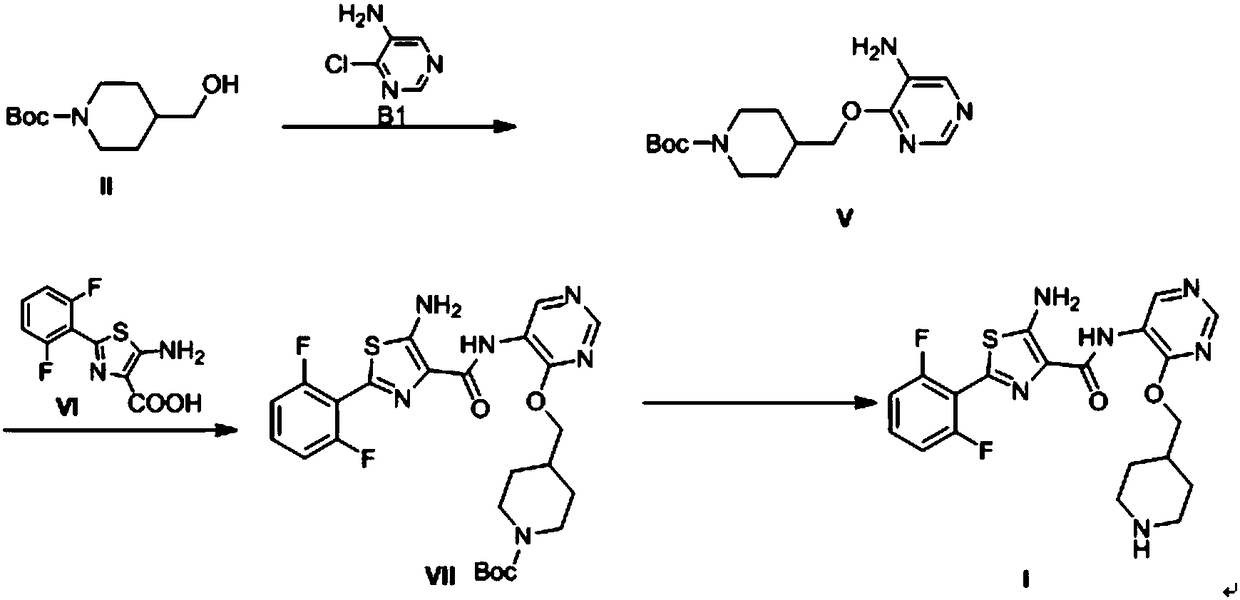

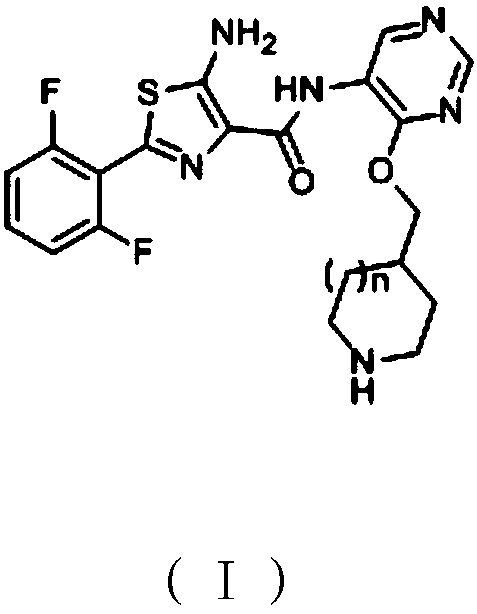

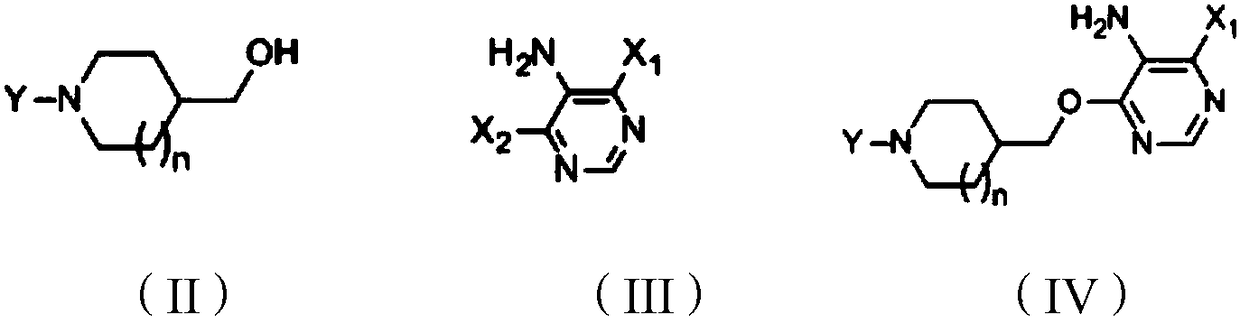

Preparation method of PIM kinase inhibitor and intermediate of PIM kinase inhibitor

The invention relates to a preparation method of a PIM kinase inhibitor and an intermediate of PIM kinase inhibitor. The invention provides a preparation method of a compound as shown in a formula I or pharmaceutical salt thereof, or a compound as shown in a formula V. The preparation method comprises the following steps. The method has the characteristics of simplicity and convenience in production, low production cost, high production efficiency, excellent product quality, stable quality, low pollution, high safety and the like, can effectively solve the problems of reaction impurity uncontrollability and yield reduction caused by raw material instability, and is convenient for industrialized enlargement production.

Owner:SHANGHAI FANGYU HEALTH PHARMA TECH CO LTD

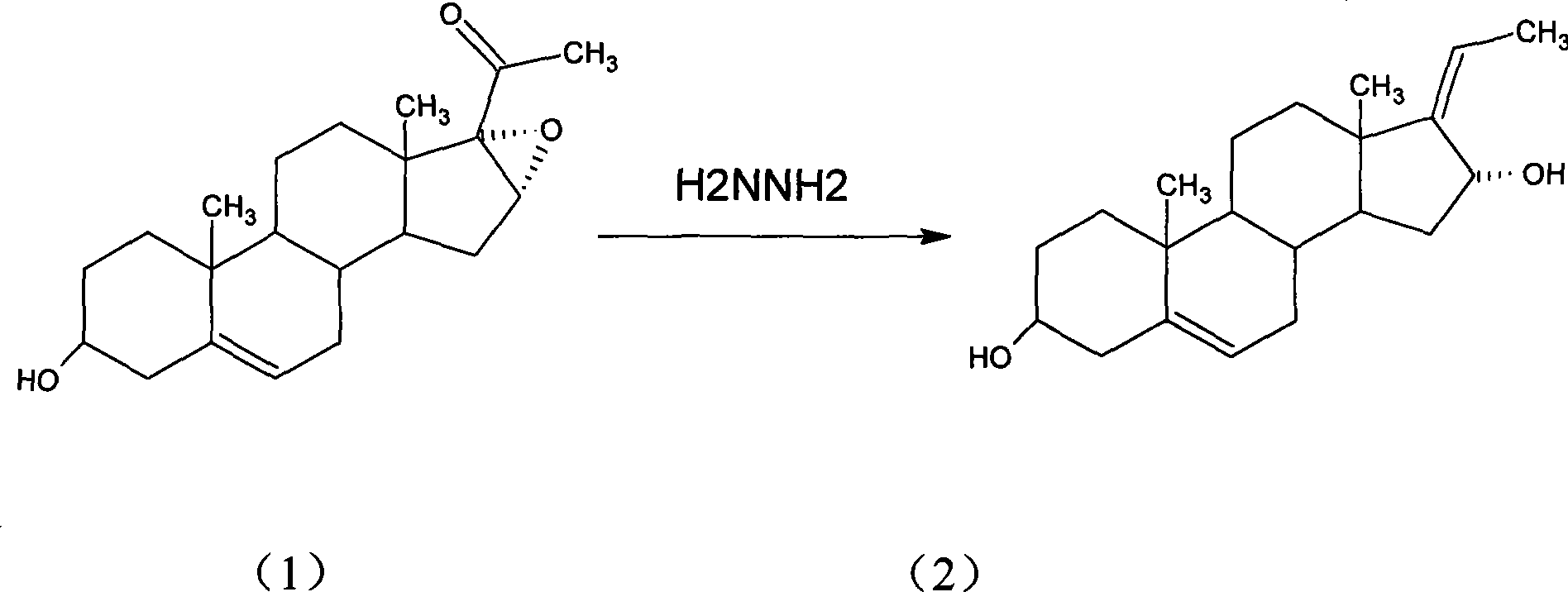

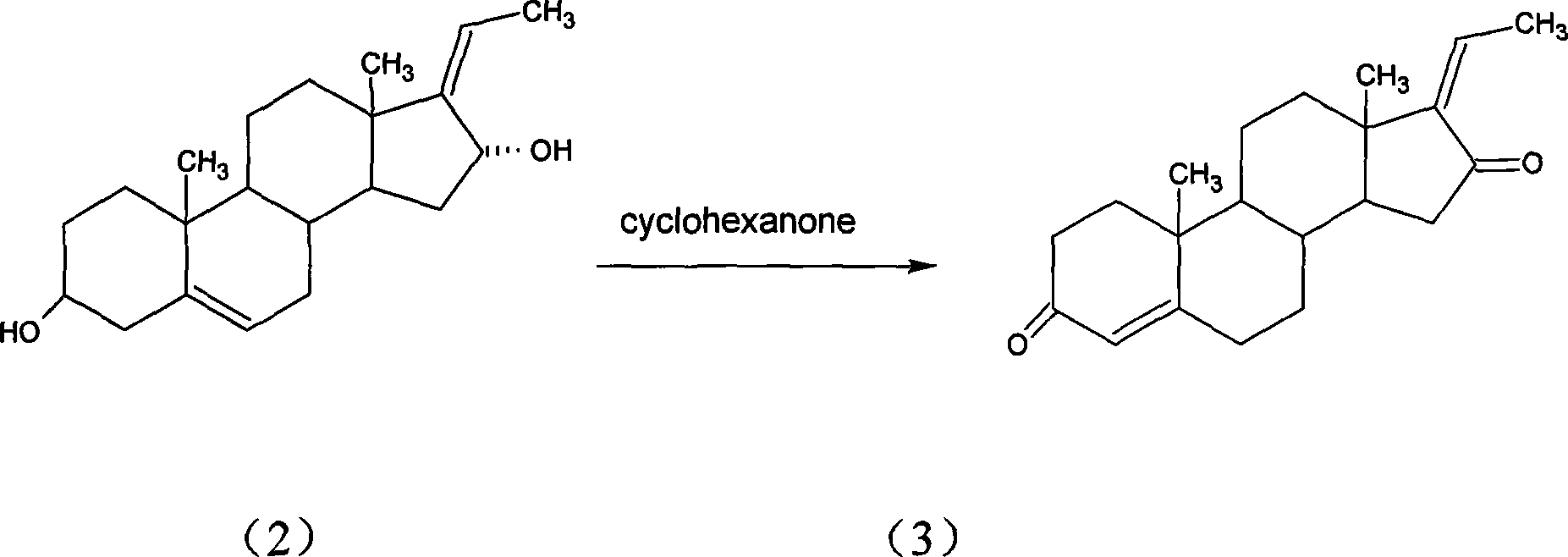

Method for producing diene sterone

The invention provides a preparation method of diene sterone, which comprises (1), reacting pregna-16, 17-epoxy-5-ene-3-hydroxy-20-ketone with water via hydrazine hydrate reaction in solvent with the presence of catalyst at catalytic amount, collecting pregna-5, 17(20)-diene-3, 16-glycol for reaction product, while the catalyst is one of hydroxide, phosphate, carbonate or organic alkali of alkali metal or alkali earth metal, (2), reacting pregna-5, 17(20)-diene-3, 16-glycol with cyclohexanone in the presences of aluminum isopropoxide and solvent, collecting pregna-4, 17(20)-diene-3, 16-diketone for reaction product. The inventive product has same Z-E ratio as natural extract, with simple operation, high yield, low cost, simple post treatment and good industrialization prospect.

Owner:邵阳市科瑞化学品有限公司

Method for purifying N-phenylmaleimide

The invention discloses a method for purifying N-phenylmaleimide. The method utilizes an N-phenylmaleimide crude product as a raw material and comprises selecting a distillation kettle with an inner copper block, transferring the N-phenylmaleimide crude product into the distillation kettle, setting kettle pressure of less than or equal to 1.5kPa, heating the N-phenylmaleimide crude product to 90-110 DEG C, carrying out primary vacuum distillation to obtain a front fraction, replacing a receiving bottle when there is no liquid reflux in the distillation kettle under the primary vacuum distillation condition, carrying out heating to 110-130 DEG C, carrying out secondary vacuum distillation to obtain an N-phenylmaleimide fraction, and stopping distillation when there is no liquid reflux in the distillation kettle under the secondary vacuum distillation. The method is free of additives, prevents new impurities, produces a high purity product and has a high yield.

Owner:Z RIVER GRP LTD

Preparation method for sulfur-containing carbofuran derivative with less than 0.1% of harmful impurity carbofuran

ActiveCN102786503BTroubleshoot incomplete responsesSolve the technical problem of high carbofuran contentOrganic chemistryCarbofuranEthane Dichloride

The invention discloses a preparation method for sulfur-containing carbofuran derivative with less than 0.1% of harmful impurity carbofuran. The preparation method comprises the following steps of: using di-n-butylamine or N-isopropyl-beta-alanine ethyl ester derivative and sulfur monochloride as raw materials to prepare into disulphide in the presence of an acid-binding agent triethylamine and an organic solvent 1, 2-dichloroethane; and then reacting with a chlorinating agent sulfuryl chloride to obtain nitrogen sulfur chlorine; and finally reacting with carbofuran under the effect of a cosolvent N-methyl-2-pyrrolidone or dimethylformamide so as to obtain the sulfur-containing carbofuran derivative with not less than 96% of quality percentage composition and less than 0.1% of main harmful impurity carbofuran. By adopting the preparation method, the problem that the carbofuran cannot be completely reacted during being reacted can be solved, the defects due to low content and low yield of sulfur-containing carbofuran derivatives such as benfuracarb and carbosulfan caused by a solid-liquid two-phase reaction can be avoided, the technical problem due to relatively high content of main harmful impurity carbofuran can be solved, and the content of the sulfur-containing carbofuran derivatives such as benfuracarb and carbosulfan can reach a value not less than 96%, and the yield is 97 to 98%, and the main harmful carbofuran in the product is less than or equal to 0.1%, so that the preparation method has a wide popularization and application prospect.

Owner:湖南海利常德农药化工有限公司

Methyl tetrahydrophthalic anhydride continuous production system and method

PendingCN112661735AThorough responseReduce investmentOrganic chemistryMaleic anhydrideProcess engineering

The invention discloses a methyl tetrahydrophthalic anhydride continuous production system and method. The production system comprises a tower reactor, a C5 storage tank, a maleic anhydride storage tank, a film evaporator, a C5 receiving tank, a heat insulation evaporator and a finished product tank, the C5 storage tank is connected with the tower reactor through a first magnetic pump, and the maleic anhydride storage tank is connected with the tower reactor through a second magnetic pump; the tower reactor is connected with the film evaporator, the film evaporator comprises a steam outlet and a liquid outlet, the steam outlet is connected with the C5 receiving tank through a first condenser, the liquid outlet is connected with a heat insulation evaporator, and a catalyst fixer is arranged between the liquid outlet and the heat insulation evaporator; and the heat insulation evaporator is connected with a second condenser through a third magnetic pump and then connected with the finished product tank. According to the methyl tetrahydrophthalic anhydride continuous production system, continuous production of methyl tetrahydrophthalic anhydride is truly achieved, compared with a traditional process, the efficiency is improved by about 200%, reaction is more thorough, meanwhile, the C5 amount input is reduced, energy consumption is reduced, and the product yield and quality are improved.

Owner:JIAXING ZHENGDA CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com