Gas-liquid-solid multiphase reaction-separation synchronous reactor

A multiphase reaction and reactor technology, applied in chemical instruments and methods, chemical/physical/physicochemical processes, chemical/physical processes, etc., can solve the problem of increasing equipment investment and energy consumption, pollution of solvent environment, and reaction products Reduce selectivity and yield, increase the residence time of reaction products, etc., to achieve the effect of benefiting gas-liquid separation, avoiding complex equipment structure, and reducing the amount of liquid materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

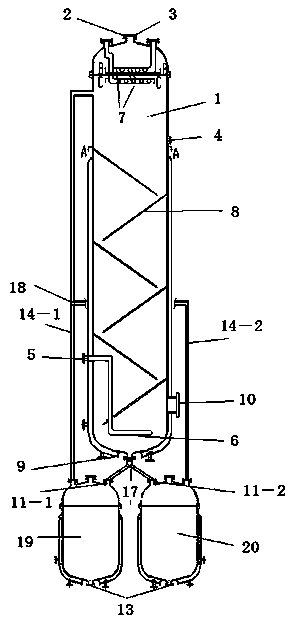

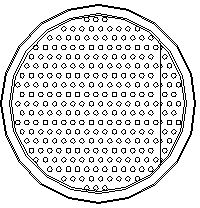

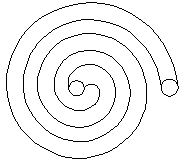

[0018] Referring to the accompanying drawings, this embodiment includes two parts: a reaction system and a separation system; the reaction system includes a bubbling gravity reaction tower 1, the diameter-to-height ratio of the bubbling gravity reaction tower 1 is 1:30, and the middle and lower part of the bubbling gravity reaction tower 1 It is the reaction zone, and the upper part of the bubbling gravity reaction tower 1 is a gas-liquid separation zone; 1 / 3 from the top of the reaction tower is provided with a reaction liquid outlet 4, and the top of the bubbling gravity reaction tower 1 is provided with a reaction gas outlet 2 and a condensed liquid inlet Inlet 3, gas raw material inlet 5 and gas distributor 6 are arranged in the lower part of the bubbling gravity reaction tower 1; alternate cooling coils 7 are arranged in the gas-liquid separation area on the upper part of the bubbling gravity reaction tower 1, and the bubbling gravity reaction tower 1. The middle and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com