Device and method for rapid separation of activated product americium, uranium and gallium

An activated product and fast technology, which is applied in the preparation of measuring devices, analytical materials, and samples for testing, etc., can solve the problems of synchronous separation and purification technology and methods that are not mentioned, and achieve reduced exposure dose, clear function, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

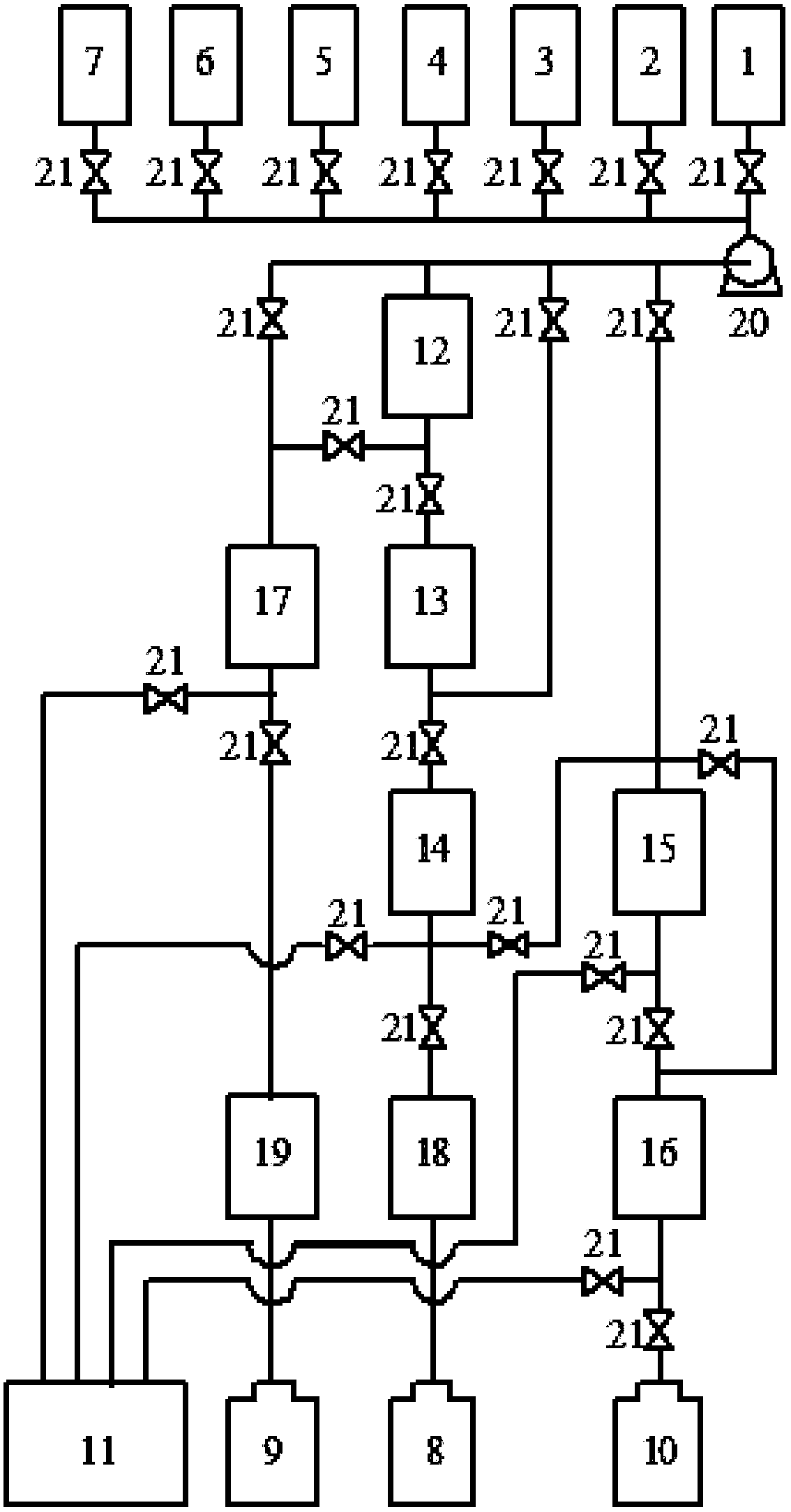

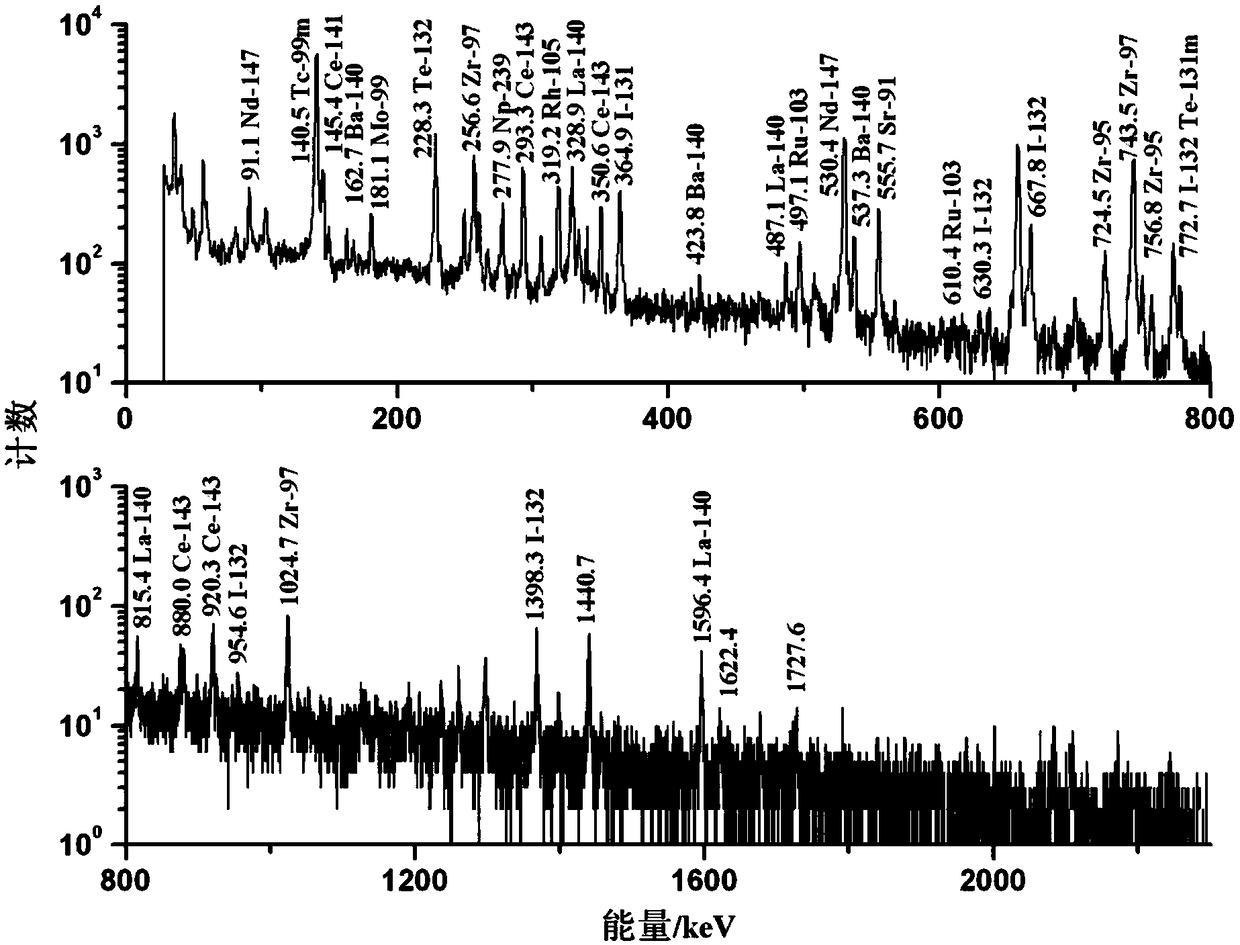

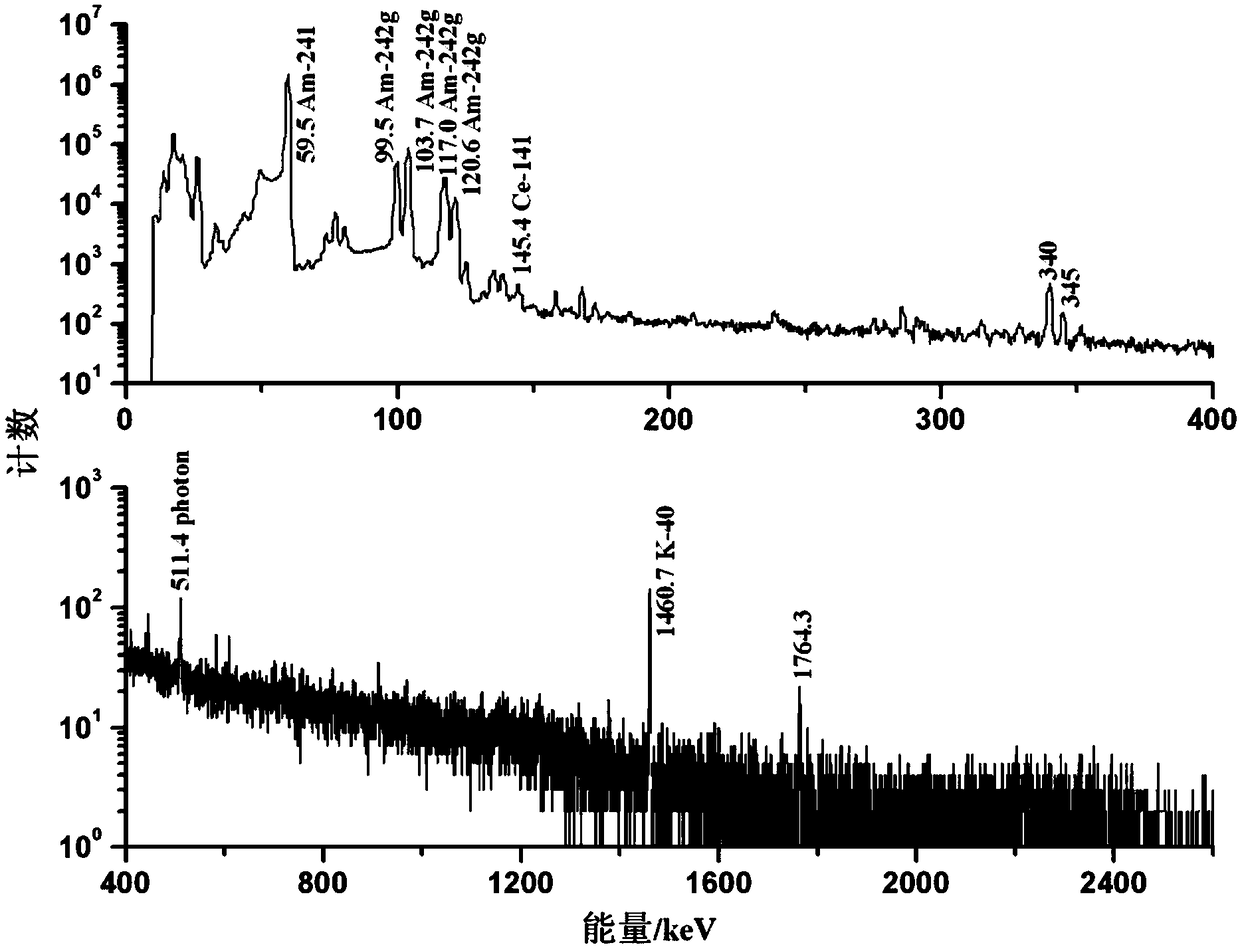

[0083] Dissolve the fissioned sample of nuclear fuel containing americium-uranium-gallium in 20mL 3mol / L HCl medium to form a solution containing americium-uranium-gallium. figure 2 shown.

[0084] Control the flow rate of the americium-uranium-gallium-containing solution at 1mL / min, so that the americium-uranium-gallium-containing solution passes through the first LN chromatographic adsorption column, the Al 2 o 3 The chromatographic adsorption column 13, the first TBP chromatographic adsorption column 14 and the DN chromatographic adsorption column 15 are separated, wherein the first LN chromatographic adsorption column is LN chromatography column, Al 2 o 3 The chromatographic adsorption column 13 is Al 2 o 3 Chromatography column, the first TBP chromatography adsorption column 14 is TBP extraction chromatographic column, DN chromatographic adsorption column 15 is The DN chromatographic column, in which the LN chromatographic column realizes the separation of Am...

Embodiment 2

[0095] Replace the first LN chromatographic adsorption column and the second LN chromatographic adsorption column with the first P204 chromatographic adsorption column and the second P204 chromatographic adsorption column in Example 1, repeat the separation process of Example 1, and obtain the activated product americium , uranium and gallium as gamma radioactive measurement sources, the recovery rates of americium, uranium and gallium are 78.6%, 91.4% and 96.9% respectively, and the decontamination factors for fission products are shown in Table 1, which shows that it is better than 10 4 , the process takes 180 minutes.

[0096] Table 1 The recovery rate and decontamination factor analysis of activation product americium uranium gallium

[0097]

[0098]

[0099] "*" indicates the lower limit of detection assigned for non-detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com