A system based on a supergravity cyclone oil purification device and its efficacy testing method

A super-gravity and flow-cleaning technology, which is applied in fluid pressure actuation system testing, fluid pressure actuation devices, fluid pressure actuation system components, etc., can solve the problem of synchronous separation of solid particles and moisture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

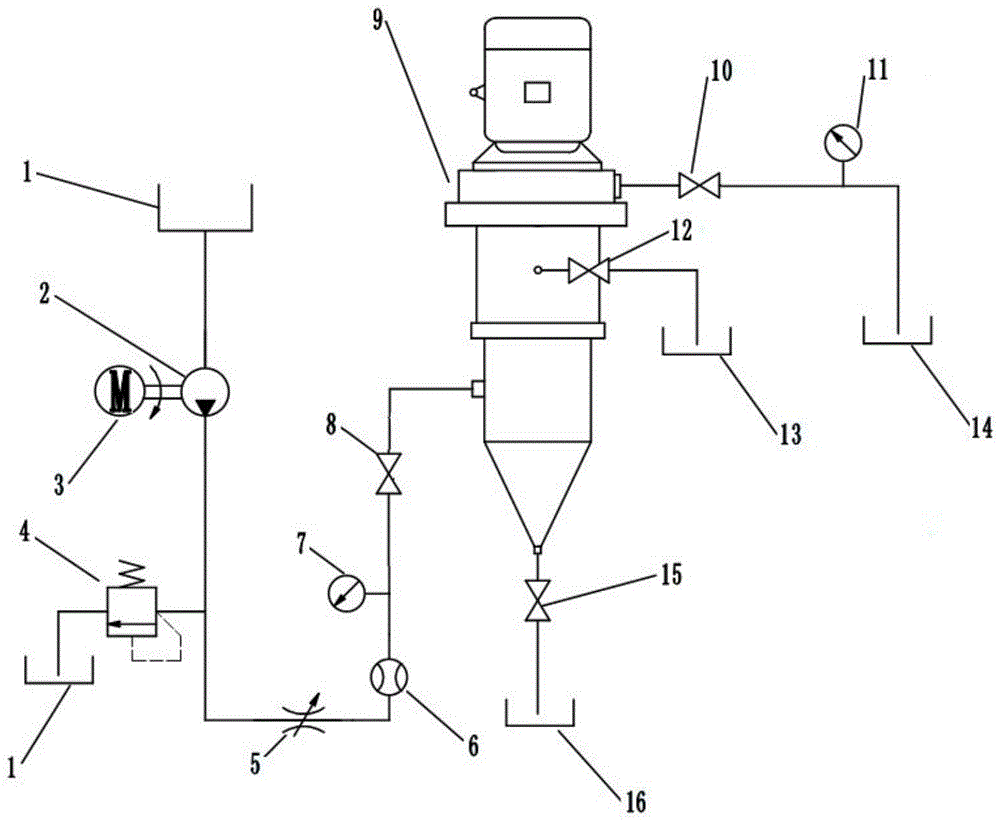

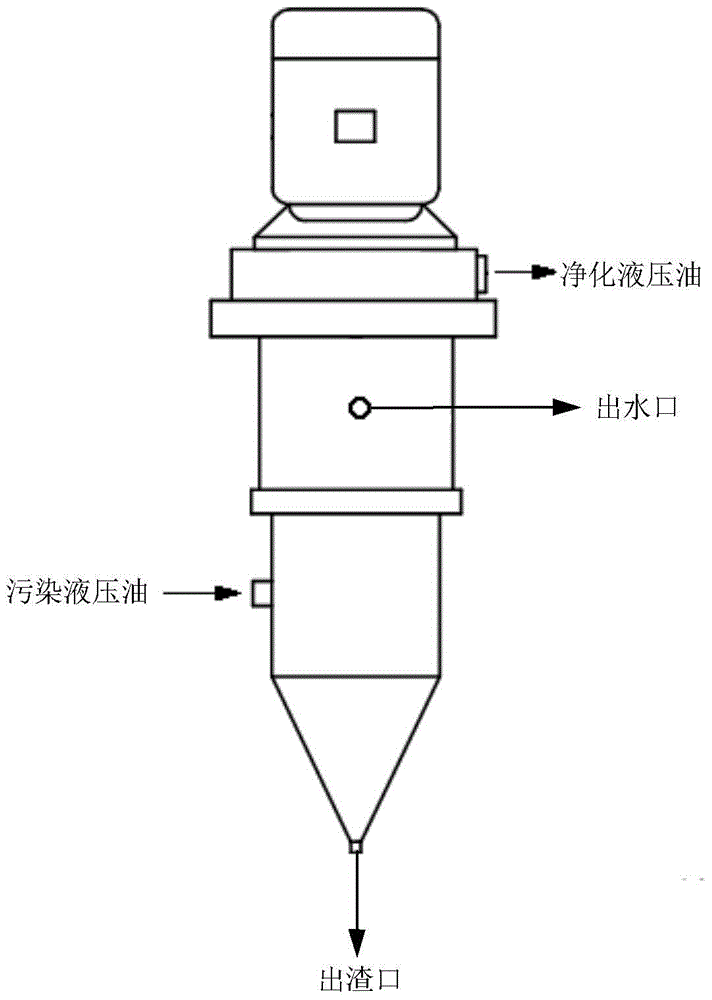

[0020] Such as figure 1 As shown, a hydraulic oil purification efficiency test system includes a fuel tank 1, a hydraulic pump 2, a motor 3, a relief valve 4, a throttle valve 5, a flow meter 6, an inlet pressure gauge 7, an inlet sampling valve 8, and a supergravity rotary valve. Flow purification device 9, oil outlet sampling valve 10, oil outlet pressure gauge 11, water outlet sampling valve 12, moisture collector 13, purified hydraulic oil collector 14, slag outlet sampling valve 15, solid particle collector 16 . The oil tank 1 is used to provide working medium; the motor 3 is used to drive the hydraulic pump 2 to supply oil to the system; the overflow valve 4 is used to adjust the system pressure and ensure that the system works within the rated pressure range; the section The flow valve 5 is used to regulate the system flow; the flow met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com