Patents

Literature

115results about How to "Achieve selective separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for selectively extracting and recycling gallium, germanium and indium from sulfuric acid leach liquid of zinc displacement residues

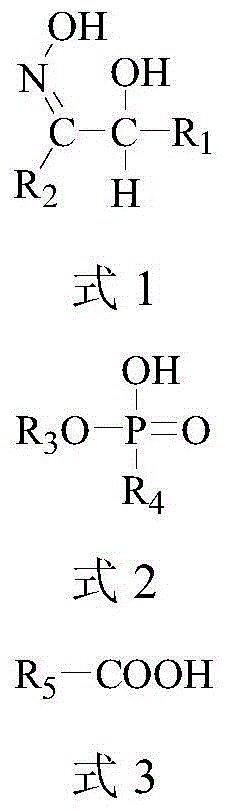

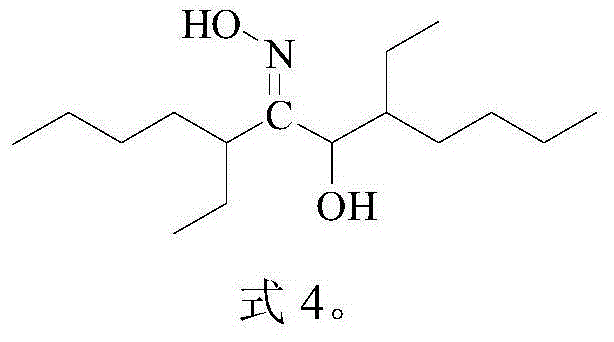

The invention discloses a method for selectively extracting and recycling gallium, germanium and indium from sulfuric acid leach liquid of zinc displacement residues. The method includes selectively extracting the germanium from the sulfuric acid leach liquid of the zinc displacement residues by the aid of synergistic extraction systems comprising hydroxamic chelate extraction agents and acidic phosphorus type extraction agents; recycling acid from germanium extraction raffinate by the aid of a diffusion dialysis process and finely adjusting the germanium extraction raffinate until a pH (potential of hydrogen) value of the germanium extraction raffinate is appropriate; selectively extracting the gallium and the indium from the germanium extraction raffinate by the aid of synergistic extraction systems comprising hydroxamic chelate extraction agents and carboxylic acid extraction agents. The method has the advantages that the germanium, the gallium and the indium can be effectively separated from foreign metal ions of iron, zinc, cadmium, nickel, cobalt and the like; the germanium, the gallium and the indium are high in recycling rate, good germanium, gallium, indium and foreign matter separation effects can be realized, technological processes are short, the extraction agents are long in service life and low in loss, and the method is low in cost and easy to industrialize.

Owner:CENT SOUTH UNIV +1

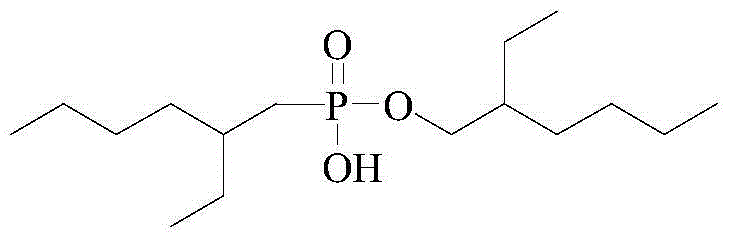

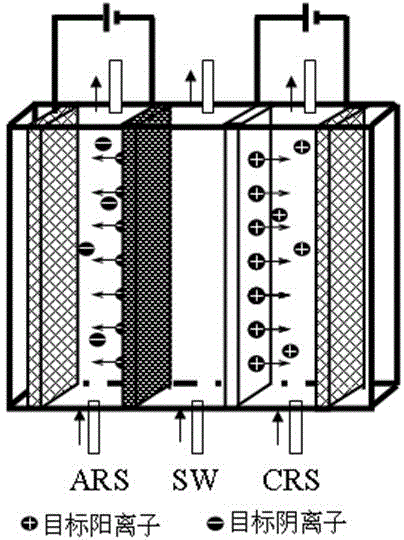

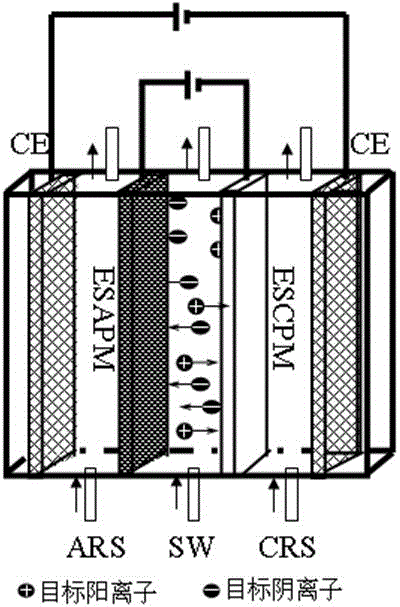

Separation process of electronic control ion selective permeable membrane

ActiveCN102718292AImprove osmotic diffusion transfer rateAchieve selective separationDispersed particle separationElectrode potentialIon exchange

The invention discloses a separation process of an electronic control ion selective permeable membrane. An electronic control ion exchange performance and an electronic control ion selective permeability of a membrane electrode are utilized in a double-diaphragm electrode reactor, oxidation-reduction potentials are alternately imposed on the double-diaphragm electrode reactor to control a synchronously imbedding and a synchronously releasing of targeted negative ions and positive ions, and under the action of field stress imposed by an auxiliary electrode, a separation and a recycle of the negative and positive ions in a dilute solution are achieved. According to the separation process of the electronic control ion selective permeable membrane, by means of the electronic control ion exchange performance of the selective permeable membrane electrode, targeted ions can selectively penetrate through a diaphragm by controlling electrode potentials of the membrane electrode, and thereby the efficient, synchronous, controllable and continuous separation and recycle of the negative and positive ions can be achieved.

Owner:山西翌佳环保科技有限公司

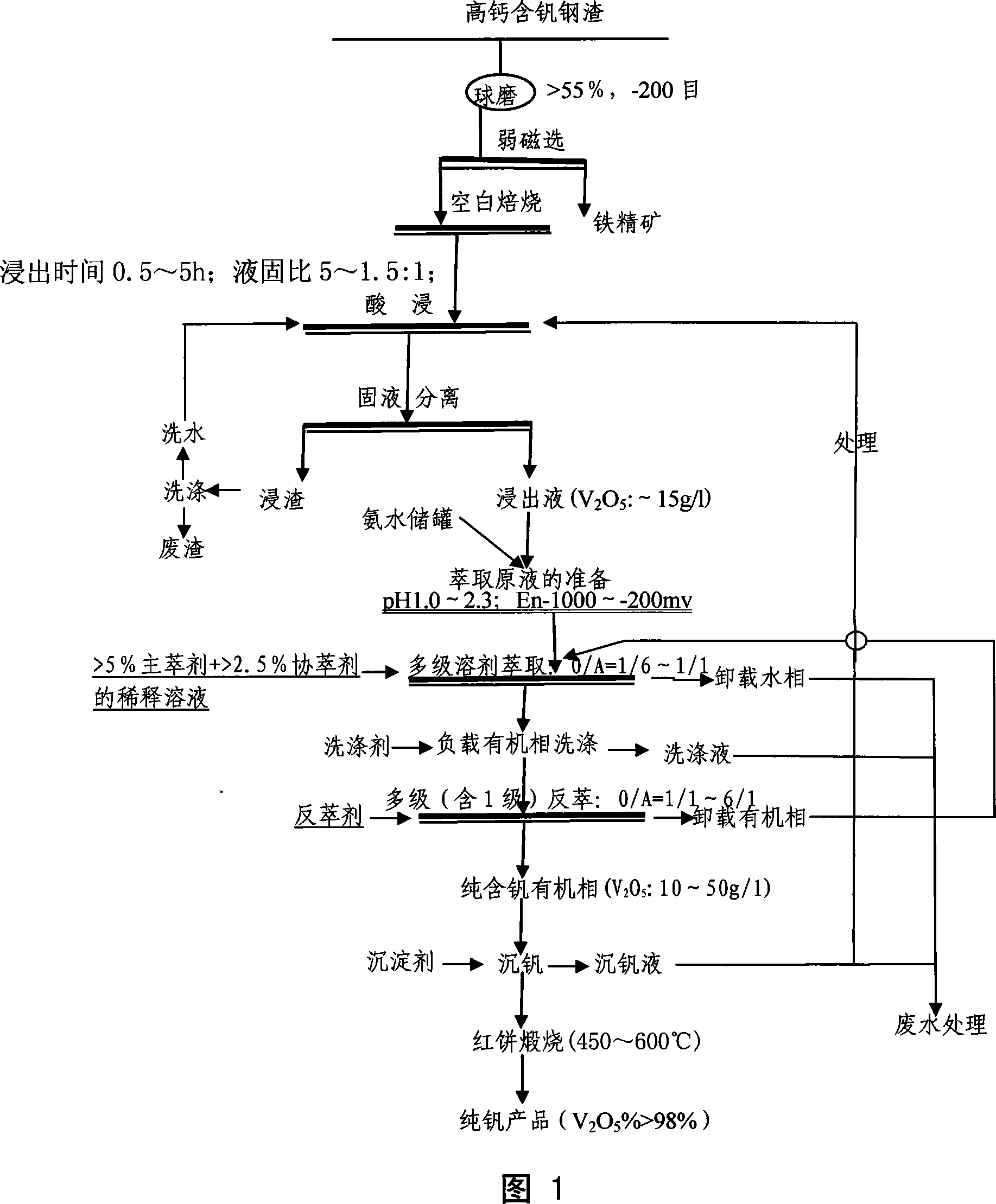

Technique for reclaiming vanadium and iron from high-vanadium high-iron steel slag

InactiveCN101121966AReduce accumulationReduce difficultySolid separationProcess efficiency improvementSlagOxidation reduction

A novel technology is used for recycling iron and vanadium from calcium-rich or iron-rich steel slag. The invention relates to a metallurgical method of extracting vanadium, in particular to a method that extracts vanadium or iron from abandoned steel slag with multidisciplinary technologies. The technology has the following procedures: (1) The calcium-rich or iron-rich steel slag is crushed, the iron contained in the steel slag is recycled by magnetic separation, and the material that will correspondingly change low-valent vanadium is roasted into high-valent vanadium contained in the material, or the material is first roasted and then magnetic separated; (2) the material is soaked with 95-98 percentage concentrated sulfuric acid, and then solid-liquid separation is conducted; (3) the acidity of lixivium is adjusted, to make sure the pH of the lixivium is in 1.0 to 2.3, and the oxidation-reduction potential is -1000 to 200mv; (4) Extraction above grade two is adopted, the extraction phase ratio O / A is 1 / 6 to 1 / 1, and then the aqueous phase unloaded; (5) the organic washing is applied in the load to remove iron, and the washing agent used is sulphate; (6) 0.25M to 1.5M alkaline solution is adopted as a stripping agent for back-extraction, with a phase ratio of O / A 1 / 1 to 6 / 1, so as to deposit vanadium contained in solution. The invention is characterized by simple technology, low cost, small environmental pollution and high recovery ratio in the process of extracting vanadium and iron from calcium-rich or iron-rich steel slag.

Owner:KUNMING UNIV OF SCI & TECH

Comprehensive recovery processing method for waste hybrid copper chloride etching liquid

The invention discloses a comprehensive recovery processing method for waste hybrid copper chloride etching liquid, which belongs to the field of non-ferrous metal and metallurgical valuable metal recover. The technological process of the method mainly comprises the following steps: (1) concentrating copper chloride etching liquid; (2) carrying out spray pyrolysis on a concentrated copper chloride solution so as to form copper oxide composite powder; (3) recovering chlorine so as to prepare a refined hydrochloric acid; (4) leaching the copper oxide composite powder by using a sulfuric acid; and (5) carrying out selective electrodeposition on copper sulfate leaching liquid by using a rotational flow electrolysis system so as to obtain a cathode copper product which of chemical compositions reach 1# copper product standards. The method disclosed by the invention is simple in process, short in flow, environment-friendly, and simple and feasible in operation, can effectively implement the comprehensive recovery of acidic and alkaline copper chloride etching liquid and the direct production of high-quality copper products, and effectively converts chlorine ions in waste liquid into refined hydrochloric acid products, thereby achieving the efficient and comprehensive utilization of resources.

Owner:浙江科菲科技股份有限公司

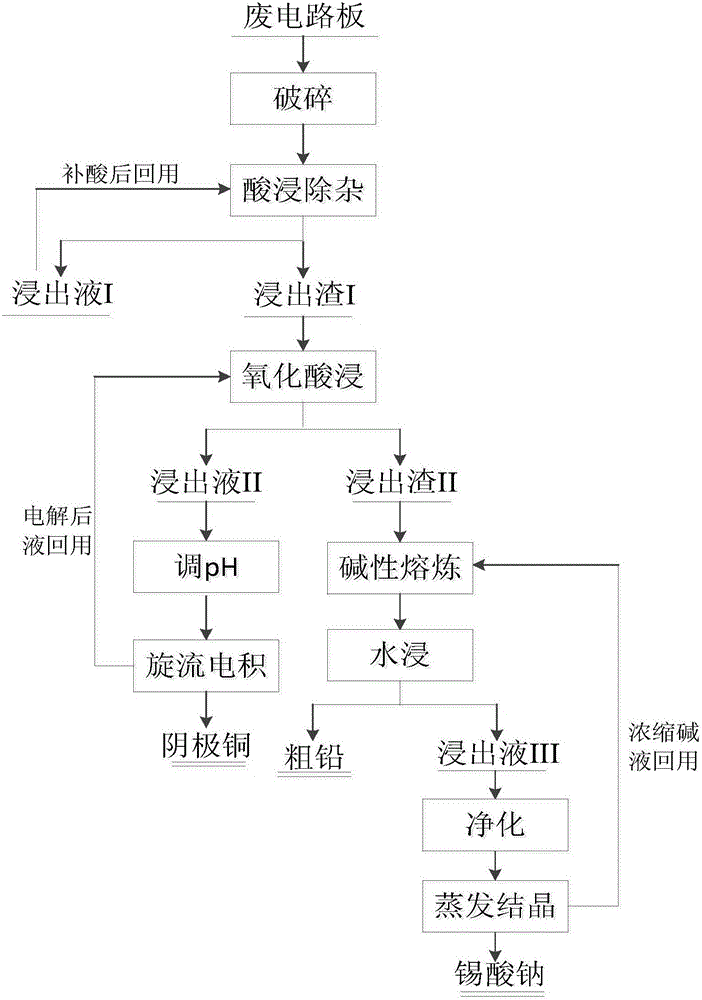

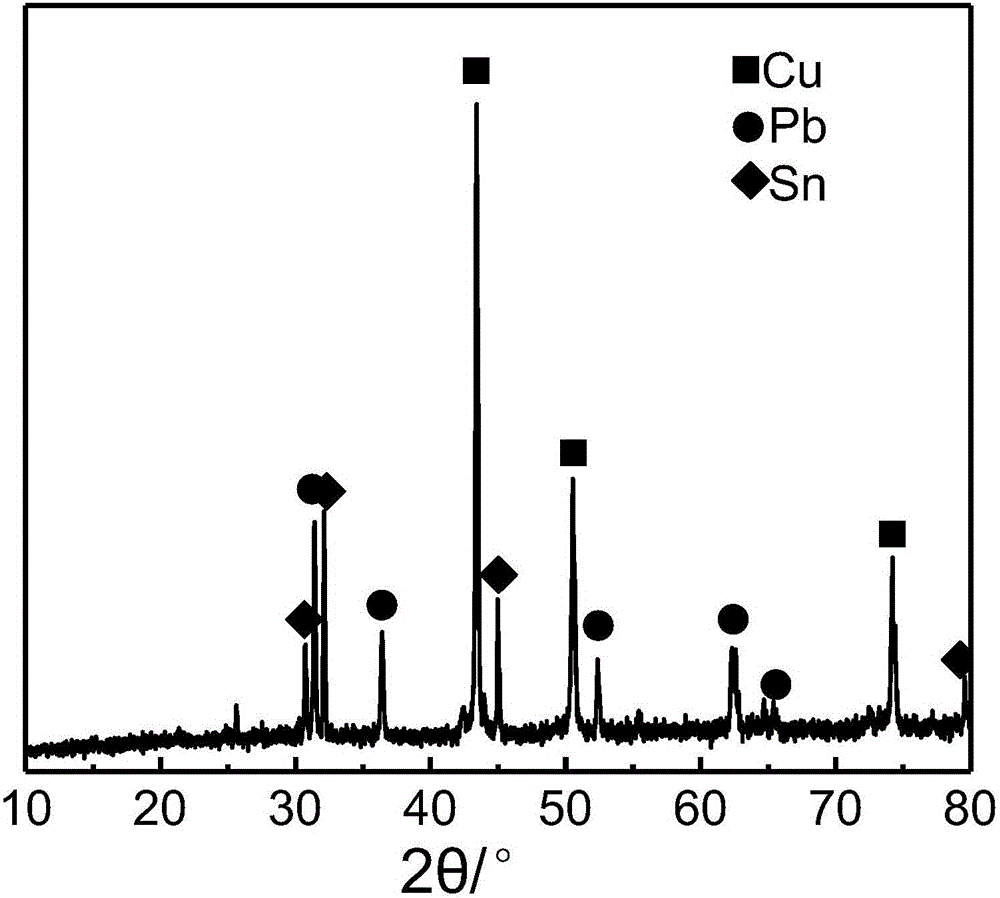

Method for recycling valuable metal in waste circuit board

The invention discloses a method for recycling valuable metal in a waste circuit board. The method includes the following steps that the waste circuit board is subject to smashing and reselection to prepare multi-metal powder; a dilute acid solution is added into the multi-metal powder, agitation leaching is carried out, filtering is carried out, and leaching slag I and leaching liquid I are obtained; an acid solution is added into the leaching slag I according to the liquid-solid mass ratio of the acid solution to the leaching slag I being 10-40:1, then an oxidizing agent is added, agitation leaching is carried out, filtering is carried out after leaching is finished, and leaching slag II and leaching liquid II are obtained; the leaching liquid II is subject to cyclone electrodeposition to obtain cathode copper and an after-electrolysis solution; alkali and a reducing agent are added into the leaching slag II, smelting is carried out under the condition that the temperature ranges from 400 DEG C to 600 DEG C, water leaching is carried out, filtering is carried out, and lead bullion containing precious metal and leaching liquid III are obtained; and the leaching liquid III is purified and is subject to evaporation and concentration to obtain a concentrated alkali solution and sodium stannate crystals. According to the method for recycling the valuable metal in the waste circuit board, the procedure is short, the efficiency is high, the cost is low, cleanness is achieved, and pollution is avoided.

Owner:广西自贸区西江资源循环科技产业股份有限公司

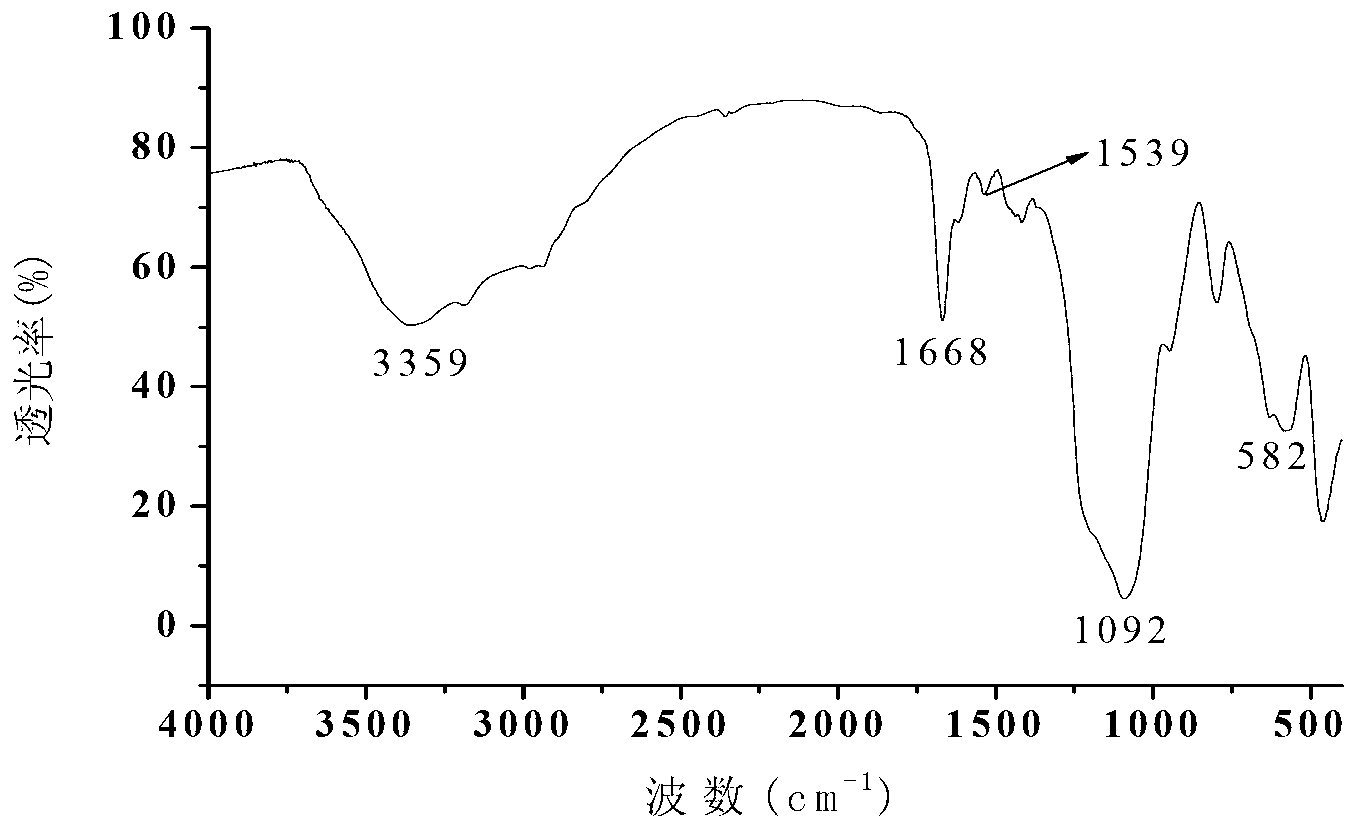

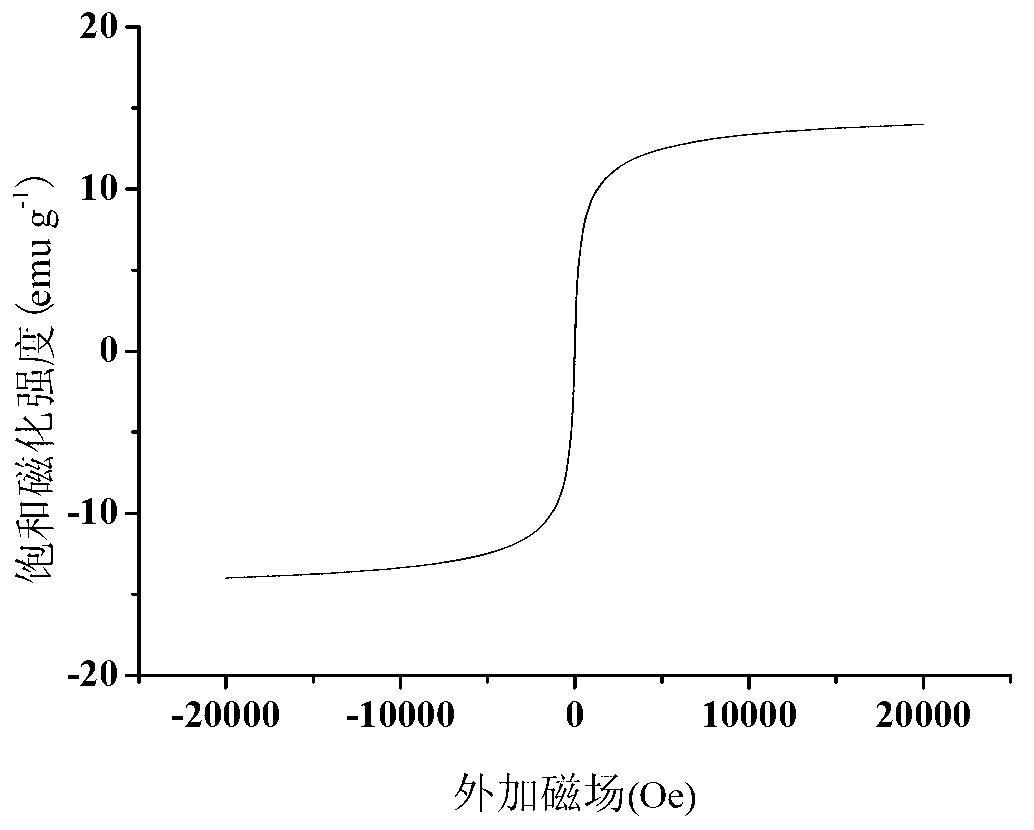

Methods for preparing and using sudan red magnetic molecularly imprinted polymer

InactiveCN103059206AImprove magnetic propertiesFacilitate adsorption and separationOscillatory reactionElution

The invention relates to methods for preparing and using a sudan red magnetic molecularly imprinted polymer. The methods aim to solve the problems that the conventional separated / purified sudan red I magnetic molecularly imprinted polymer has a 'solution polymerization' phenomenon in the synthesis process and the obtained separated / purified sudan red I magnetic molecularly imprinted polymer has a non-uniform spatial network structure. The preparation method comprises the following steps of: 1, preparation of Fe3O4; 2, preparation of magnetic SiO2; 3, preparation of aminated magnetic SiO2; 4, preparation of initiator / magnetic SiO2; and 5, polymerization reaction. The using method comprises the following steps of: adding the sudan red magnetic molecularly imprinted polymer into a sample solution containing sudan red, and then sequentially performing oscillatory reaction, magnetic separation and elution. The method is mainly used for preparing the sudan red magnetic molecularly imprinted polymer.

Owner:NORTHEAST FORESTRY UNIVERSITY

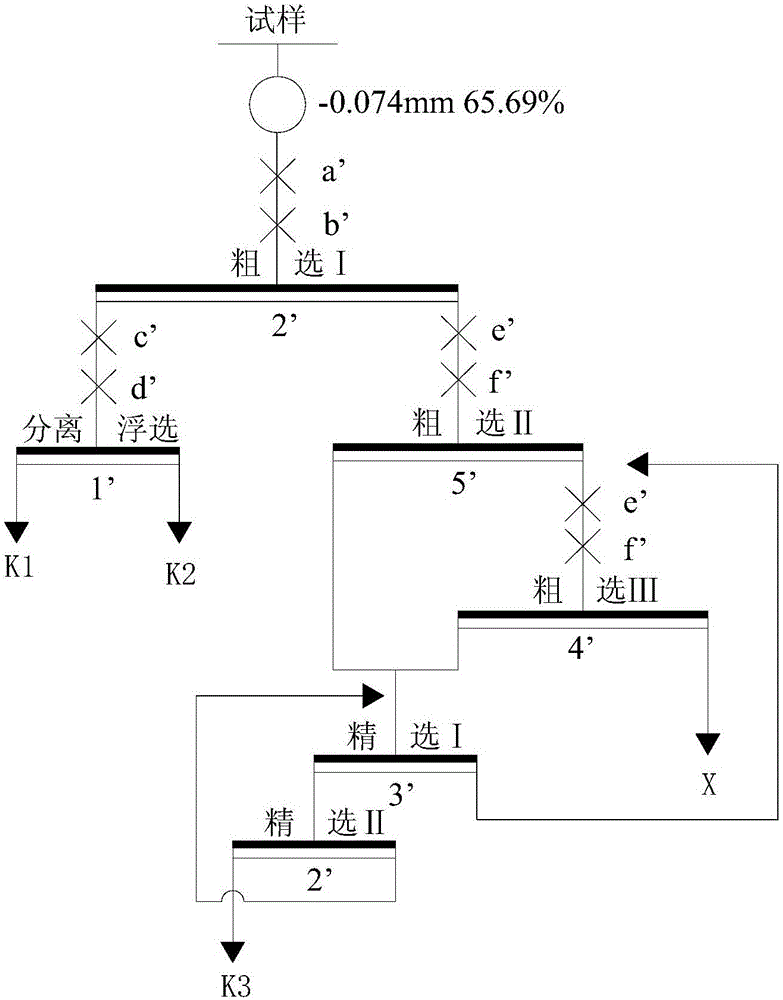

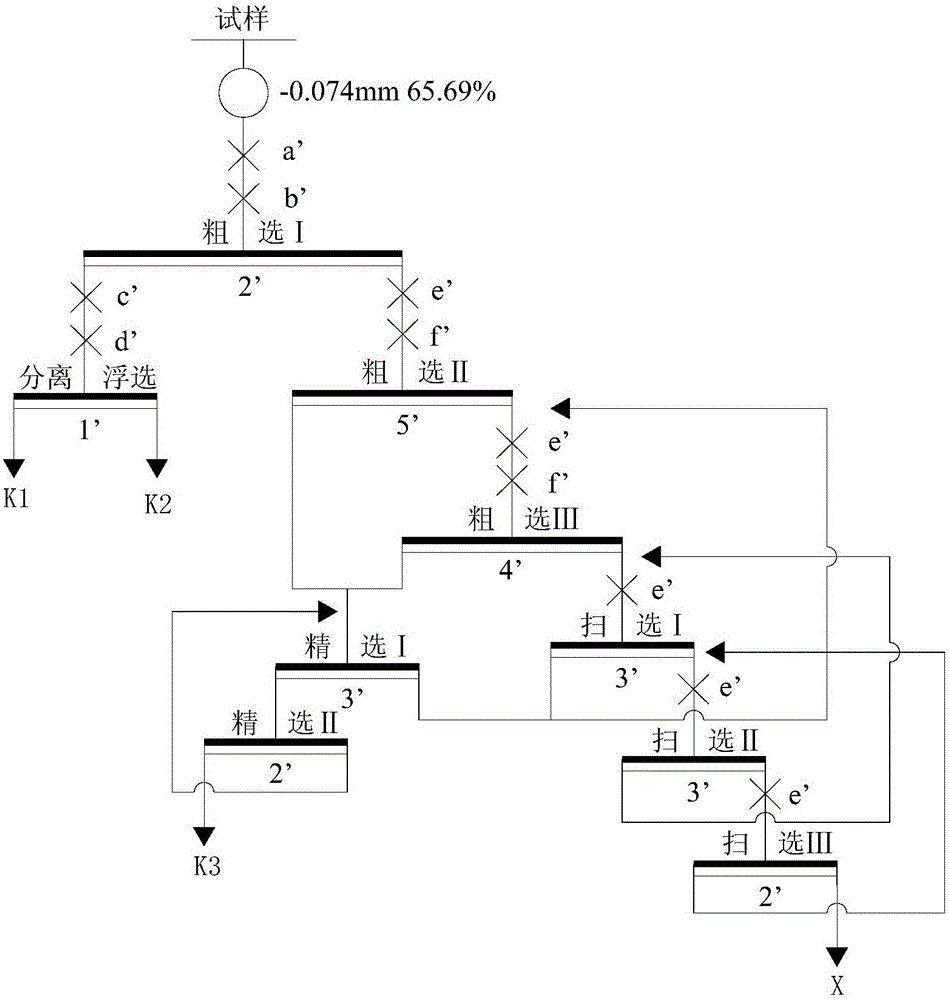

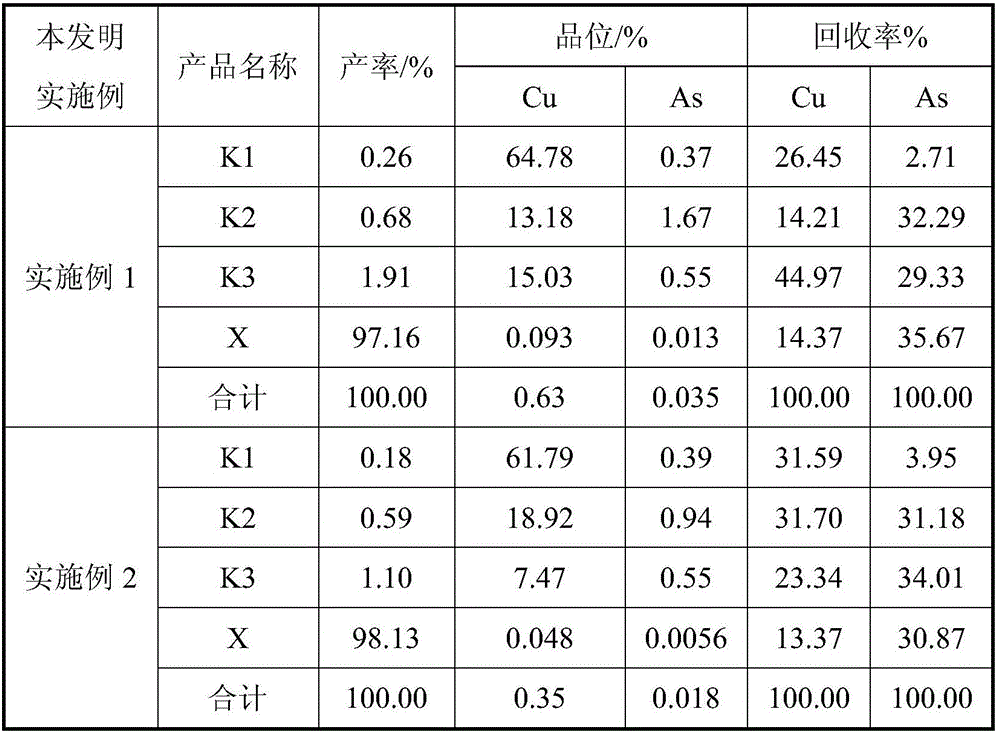

Composite beneficiation inhibitor used for copper-arsenic separating flotation

The invention discloses a composite beneficiation inhibitor used for copper-arsenic separating flotation. A hydrophilic oxide film can be formed on the surface of a mineral containing arsenic and copper to selectively separate a mineral which does not contain the arsenic and the copper from the mineral containing the arsenic and the copper. The composite beneficiation inhibitor is composed of, by weight, 75-95 parts of calcium hypochlorite, 8-25 parts of sodium humate and 8-17 parts of sodium hexametaphosphate. The composite beneficiation inhibitor is prepared sequentially through the steps of mixing, grinding and remixing.

Owner:厦门紫金矿冶技术有限公司

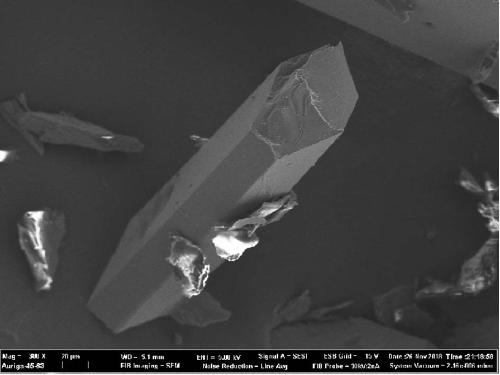

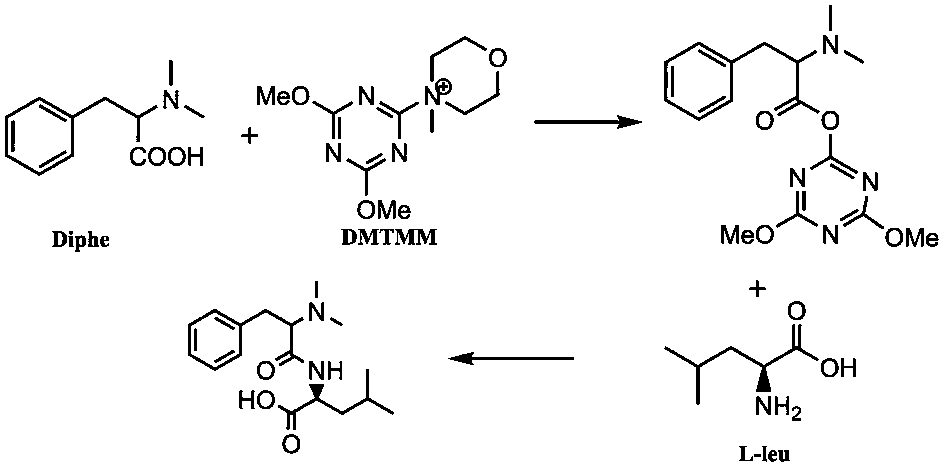

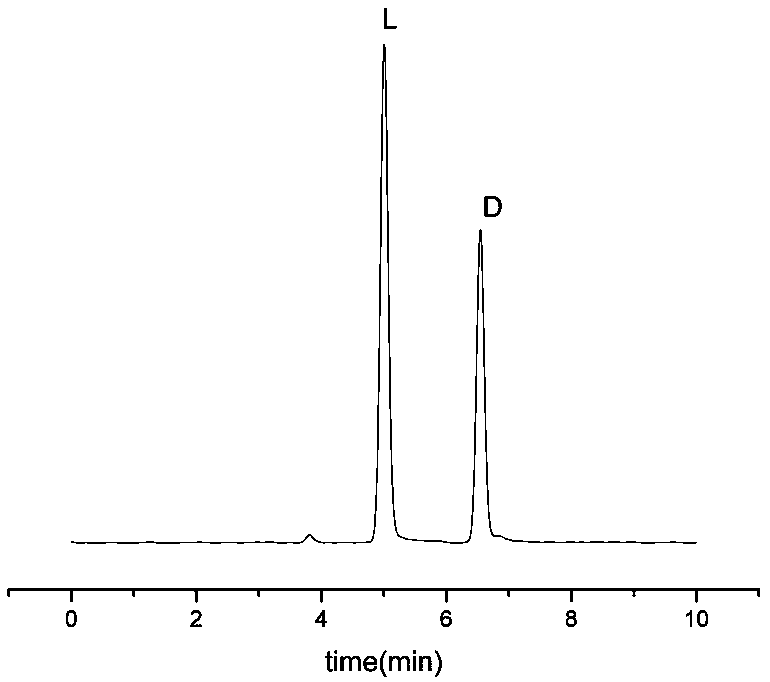

Chiral MOFs functional material as well as preparation method and purpose thereof

ActiveCN110292910AAchieve selective separationEasy to prepareOther chemical processesWater contaminantsSynthesis methodsSolvent

The invention discloses a chiral MOFs functional material. During preparation, zinc nitrate hexahydrate and L-phenylalanine are dissolved into deionized water to obtain a solution A; 1,2-bis(4- pyridyl)ethylene is dissolved into absolute methanol to obtain a solution B; the solution A and the solution B are uniformly mixed and are then transferred into a reaction kettle to be crystallized; after the reaction is completed, the reaction kettle is cooled to room temperature; filtering, washing and vacuum drying are performed; then, orange crystals of the chiral MOFs functional material are obtained. A solvent thermal synthesis method is used for synthesis; the preparation method is simple; convenience and high speed are realized; the popularization is convenient; the raw materials are cheap and can be easily obtained; the cost is low; methyl alcohol and deionized water are used as solvents; the green and environmental-friendly effects are achieved. The chiral MOFs functional material is used for the fast selective separation of racemic amino acids for the first time; the selective absorption of racemic leucine can be realized; the selective absorption on the racemic alanine can also be realized; great application prospects are realized.

Owner:ZHENGZHOU UNIV

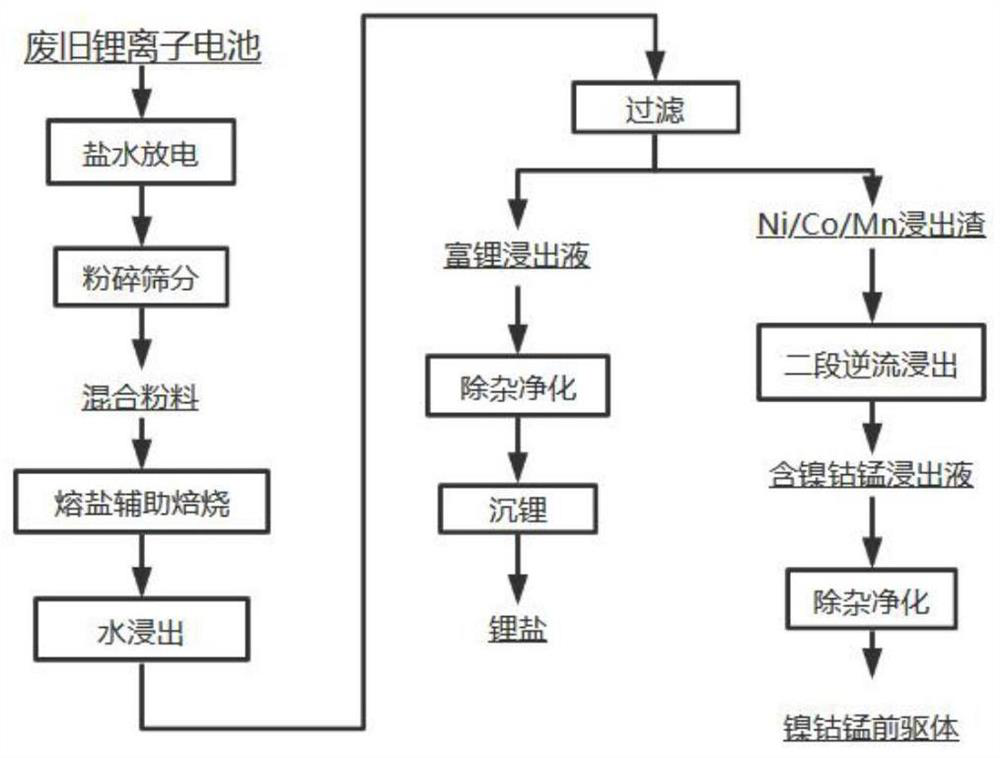

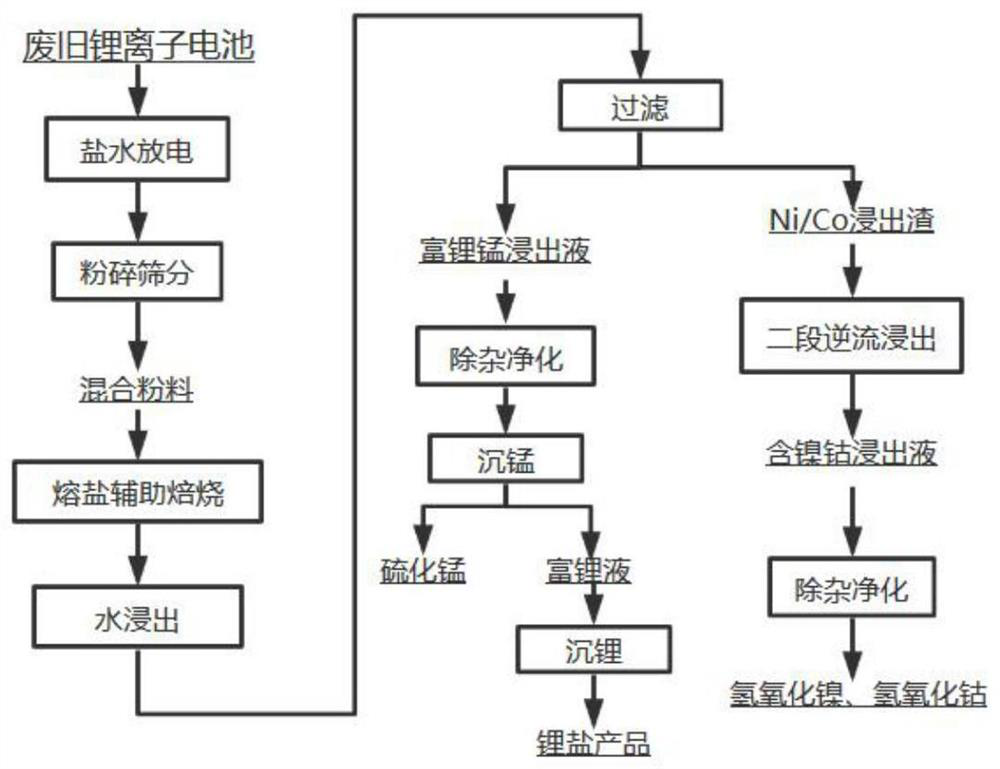

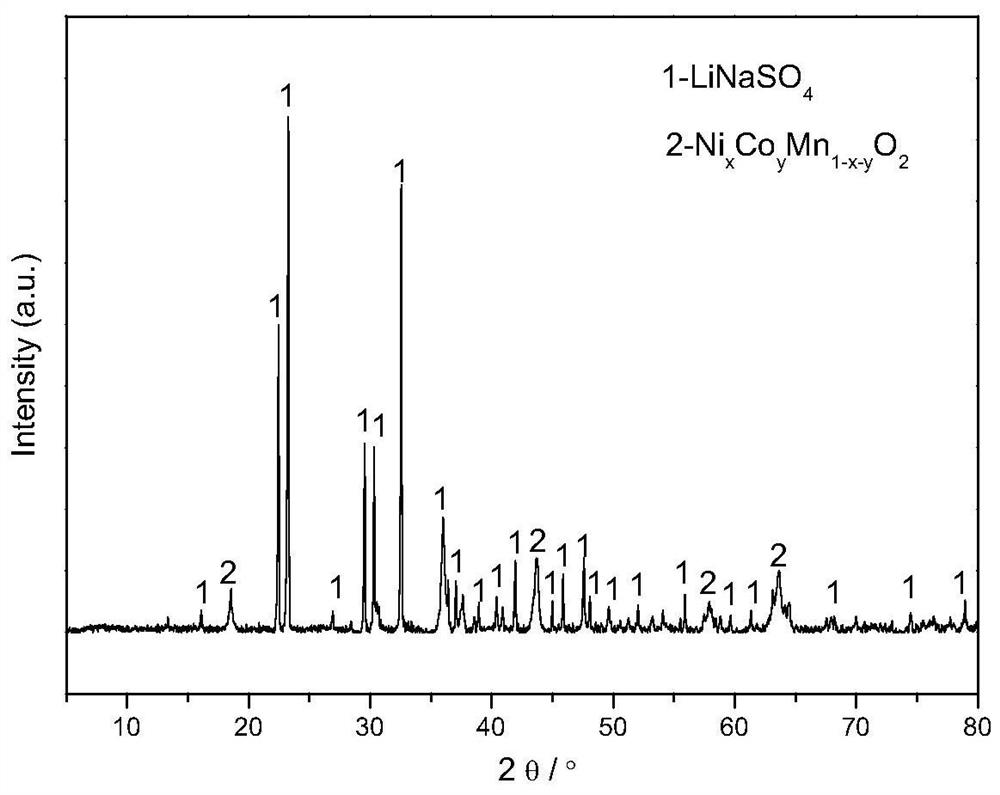

Waste lithium ion battery recovery method

ActiveCN112375913AAvoid concomitant leachingGood choiceProcess efficiency improvementChemistryProcess engineering

The invention belongs to the technical field of waste battery treatment, and particularly discloses a waste lithium ion battery recovery method. A to-be-recovered raw material containing a waste positive electrode active material and an auxiliary agent are roasted at 500-800 DEG C, and then water extraction treatment is performed; and the auxiliary agent is at least one of NaHSO4, KHSO4, CoSO4, NiSO4, MnSO4, NH4HSO4 and (NH4)2SO4. The method overcomes the disadvantages of a traditional recovery method, is simple, practical and economically feasible, realizes comprehensive utilization of wastelithium ion batteries, and is suitable for industrial production.

Owner:CENT SOUTH UNIV

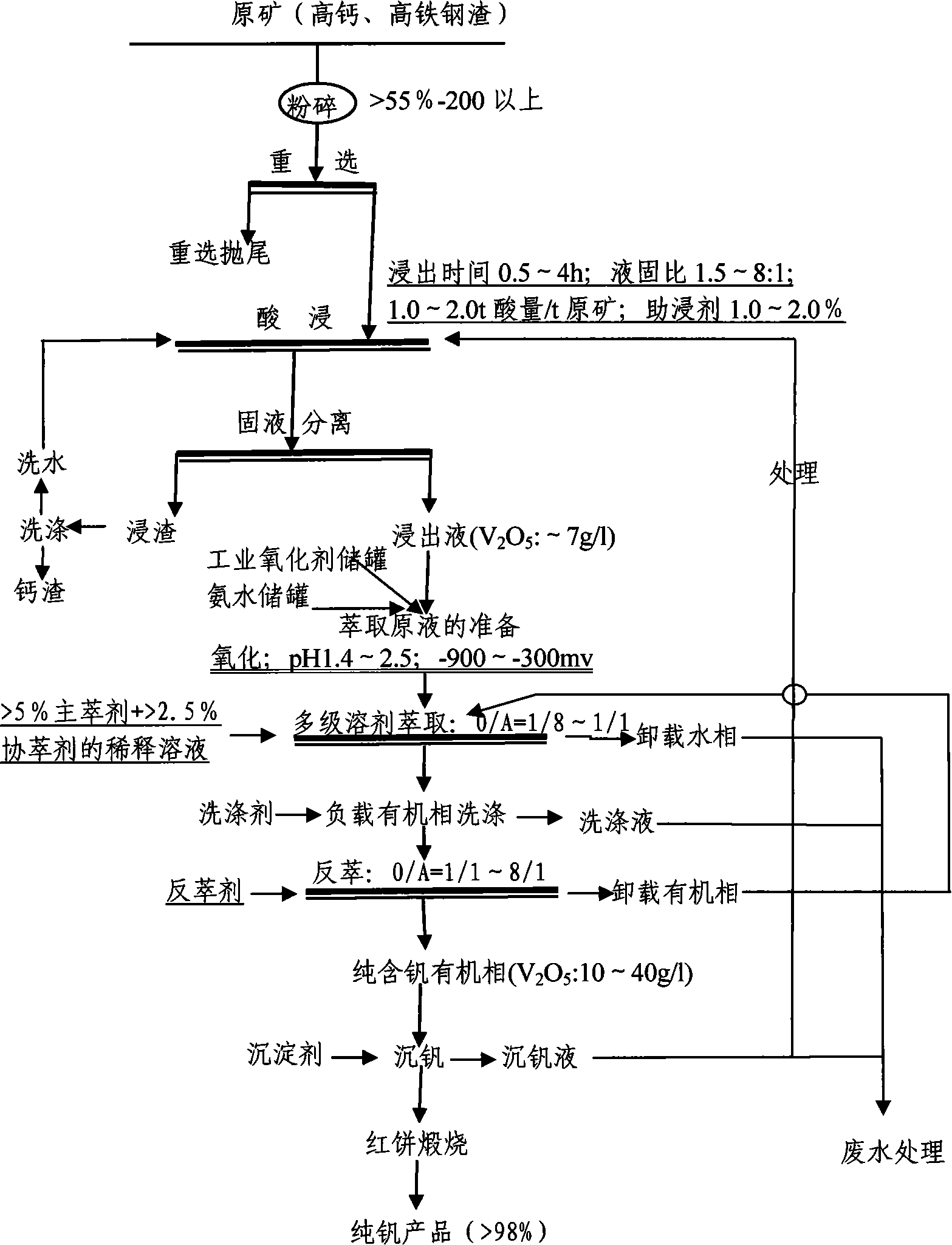

Combined technology for separating and extracting vanadium from high calcium and high ferro steel scoria

InactiveCN101182600AAchieve separationImprove leaching rateProcess efficiency improvementSulfateOxidation-Reduction Agent

A metallurgic combination process for extracting vanadium from high-calcium high-iron steel residues relates to a method for extracting vanadium, in particular to a method for extracting vanadium from the waste steel residues with the metallurgic combination process. The steps of the process are as follows that the high-calcium high-iron steel residues are crushed and the reelection pattern is adopted for stripping down light calcium and other nocuous impurities; the refined ore is directly extracted with 95 to 98 percent concentrated sulphurinc acid and then the process of solid-liquid separation is implemented; the extracted liquid is oxidated and the acidity of the liquid is regulated to make the pH value be 1.4 to 2.5; the redox potential is -900mv to -300mv; by adopting the extraction of more than three grades, the extraction phase ratio of O / A is 1 / 8 to 1 / 1 and the water phase is unloaded; the load is organically washed and iron is stripped down to effectively realize iron-vanadium separation; the detergent is sulfate; the alkaline solution of 0.25 M to 1.5M is used for the reverse extraction agent for reverse extraction and the phase ratio O / A is 1 / 1 to 8 / 1; the process of acidic precipitation of vanadate-leaching Solution is implemented on the reverse extraction solution. The invention has simple process and can effectively extract vanadium from the high-calcium high iron steel residues; in this way, the invention is characterized by low cost, little pollution and high recovery rate.

Owner:KUNMING UNIV OF SCI & TECH

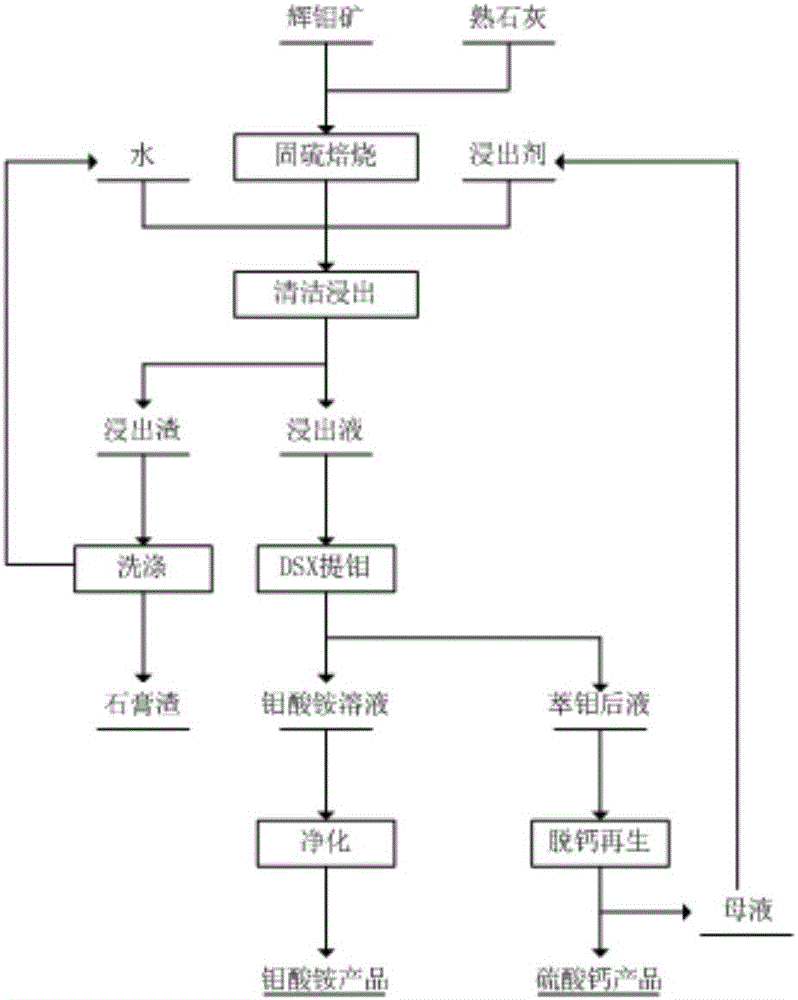

Efficient and clean molybdenum smelting method

ActiveCN105838908AHigh recovery rateSpeed up leachingProcess efficiency improvementEvaporationRaffinate

The invention provides an efficient and clean molybdenum smelting method. The method comprises the steps that lime sulphur-fixed roasting is conducted on molybdenite through a gradient heat preservation method; roasted products are leached with a leaching agent, namely roasted product, and molybdenum-contained leach liquid is obtained; the molybdenum-contained leach liquid is sequentially treated by an acid phosphorus extraction system for extracting molybdenum, and an ammonium hydroxide / ammonium salt system for back-extracting molybdenum, and molybdenum-contained strip liquid and molybdenum raffinate are obtained; impurities in the molybdenum-contained strip liquid are removed through a Mg(OH)2 one-step precipitation method, evaporation and concentration are conducted, and ammonium molybdate products are obtained; and sulfuric acid is added into the molybdenum raffinate for regeneration, calcium sulphate dihydrate products are obtained, and regenerated liquid serves as a leaching agent and is returned back to the leaching process. By the adoption of the method, molybdenum mineral raw materials can be cleaned and treated efficiently, and ammonium molybdate can be prepared, the molybdenum recovery rate reaches 99%, the sulfur fixing rate reaches 98% or over, reagent consumption is low, the production period is short, the process is easy to control, the reaching residue quantity is greatly reduced, zero emission of waste water is achieved, and industrialized application is achieved easily.

Owner:CENT SOUTH UNIV

Double-pyrazole extracting agent derived from o-phenanthroline, and preparation method and application of double-pyrazole extracting agent

ActiveCN108017632AUnique rigid structureImprove extraction kineticsOrganic chemistryRadioactive decontaminationSolubilityLanthanide

The invention discloses a double-pyrazole extracting agent derived from o-phenanthroline with the following structural general formula, and a preparation method and application of the double-pyrazoleextracting agent. In the formula, R is any one selected from n-octyl, n-butyl, isobutyl, ethyl, pyridyl and phenyl. The double-pyrazole extracting agent derived from the o-phenanthroline provided by the invention has a unique rigid structure and an alkyl chain for improving the solubility, and simultaneously only four elements of C, H, O and N are contained, so that the extraction kinetics of a separation extraction system can be greatly increased, the extraction capacity of an organic phase can be increased, secondary pollutants cannot be produced, and thus the environmental protection is facilitated. The extraction agent can be used to separate Ans (actinide elements) / Lns (lanthanide elements), and can not only form a separation extraction system of the Ans / Lns, but also can be used to form a separation reverse extraction system of the Ans / Lns.

Owner:SICHUAN UNIV

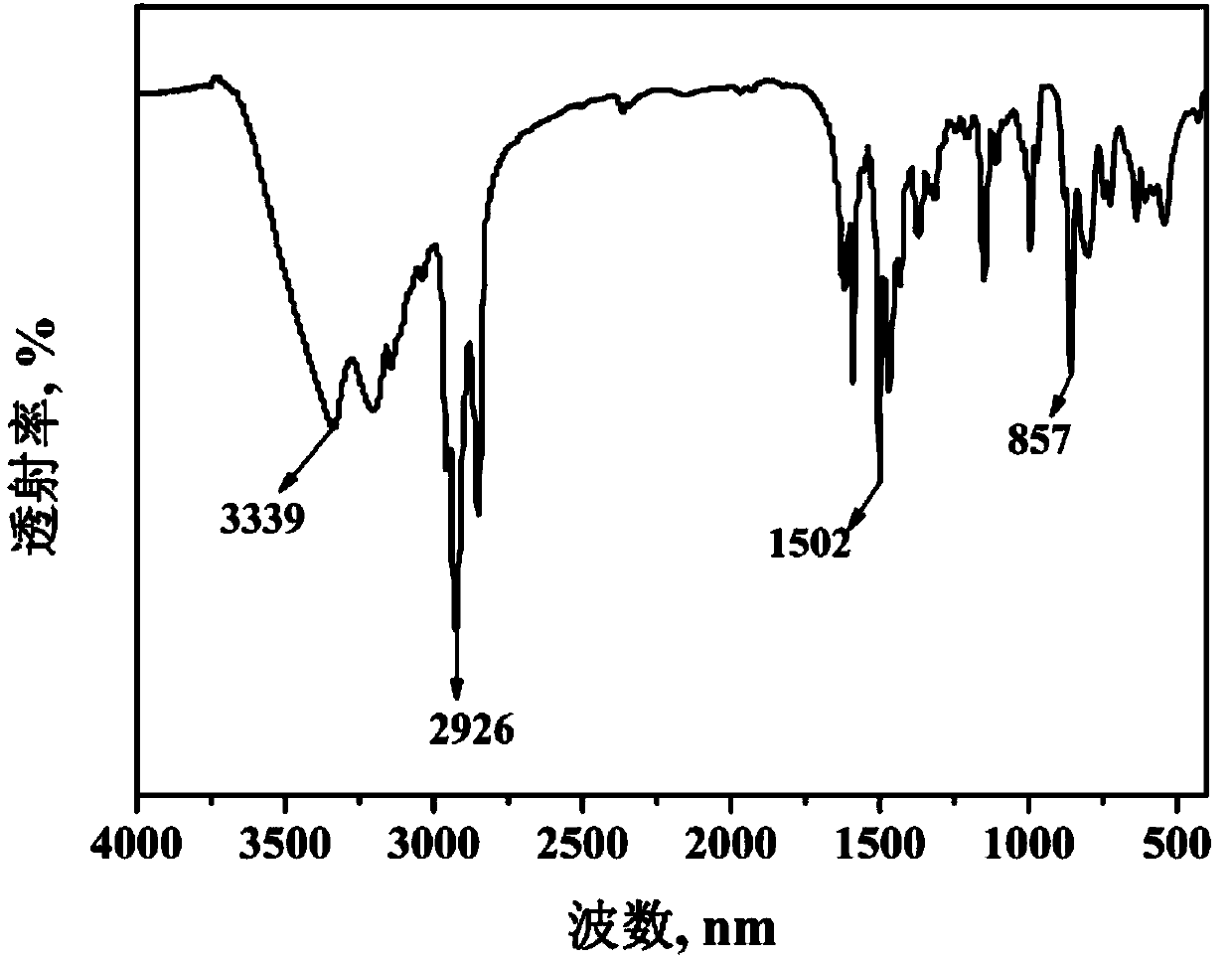

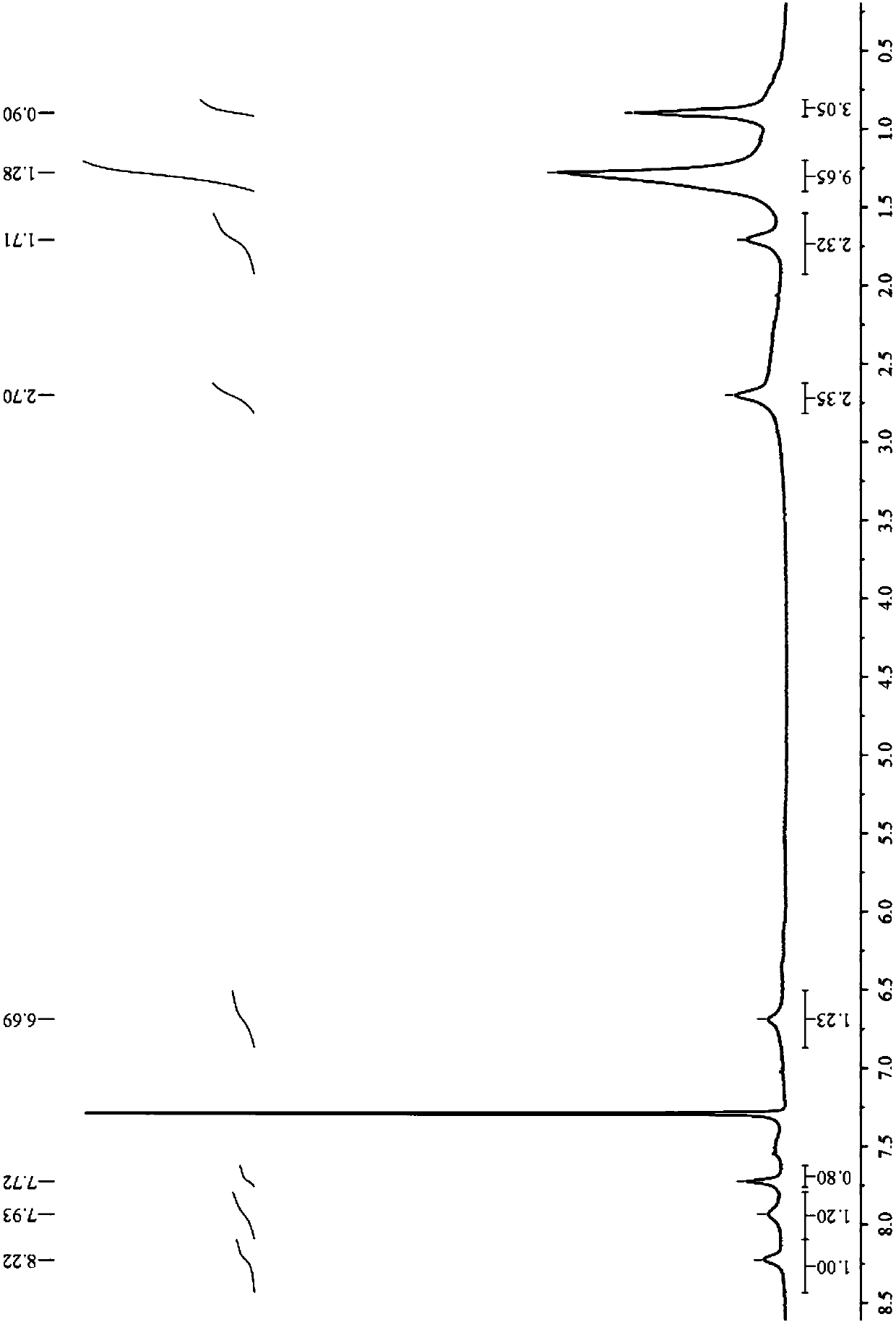

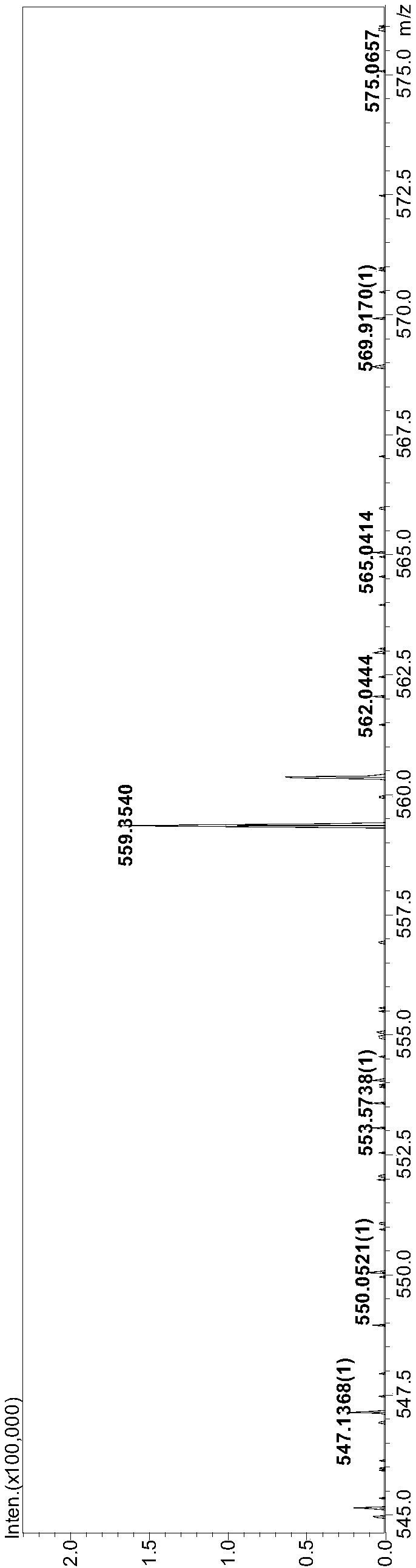

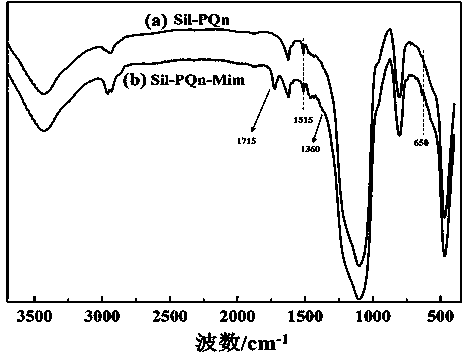

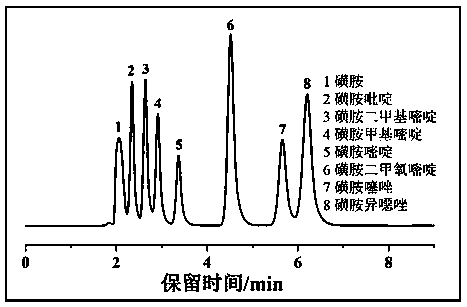

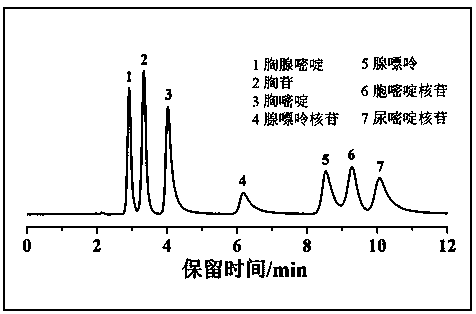

Preparation method and applications of alkylimidazole type ion liquid functionalized quinine silica gel chromatography stationary phase

ActiveCN110404520ANovel structureRaw materials are easy to getOther chemical processesSolid sorbent liquid separationChromatographic separationSilica gel

The invention discloses a preparation method of an alkylimidazole type ion liquid functionalized quinine silica gel chromatography stationary phase. The preparation method comprises: carrying out a reaction on a silane coupling agent and a silica gel matrix in an alkylbenzene solvent to obtain a mercaptopropyl silica gel; carrying out a reaction on the mercaptopropyl silica gel, quinine and azobisisobutyronitrile in an organic solvent, wherein the quinine is polymerized on the surface of the mercaptopropyl silica gel through a surface radical chain transfer reaction to obtain a polyquinine silica gel; and modifying the surface of the polyquinine silica gel with an alkylimidazole type ion liquid through a nucleophilic substitution reaction in an organic solvent by using halogenated isocyanate as a bridging molecule to prepare the alkylimidazole type ion liquid functionalized quinine silica gel chromatography stationary phase. According to the present invention, the chromatographic separation and selection performance results show that the prepared alkylimidazole type ion liquid functionalized quinine silica gel chromatography stationary phase can achieve the baseline separation of sulfonamides and base nucleosides in a hydrophilic interaction mode, and can further achieve the separation of non-polar compounds and chiral compounds in a reverse phase mode.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for preparing silicon separating films with specialized selectivity to natural products

InactiveCN1883780AHigh mechanical strengthStrong pollution resistanceSemi-permeable membranesFunctional monomerAlcohol

Disclosed is a preparation method of silicon separation membrane, having specific selectivity to natural products, which belongs to a membrane preparation technique. The method comprises: dissolving a template agent into an alcohol solution to produce template agent solution, then, adding functional monomers into said produced solution, adding in stabilizer, condensing and refluxing to remove the solvent and produce a silane precursor, dissolving tetraethoxysilane into the alcohol solution, adding in the silane precursor followed by condensing and refluxing to prepare a sol, next, aging at room temperature and dipping treated Al2O3 plate into the sol, finally, sintering in a muffle, eluting the template agent and drying to produce silicon separation membrane. The present invention is characterized in simple preparation, the produced separation membrane realizing selectively separation of a certain substance in molecular scale, water-phase molecule recognition, particularly fit for natural products separation and extensive general uses.

Owner:TIANJIN UNIV

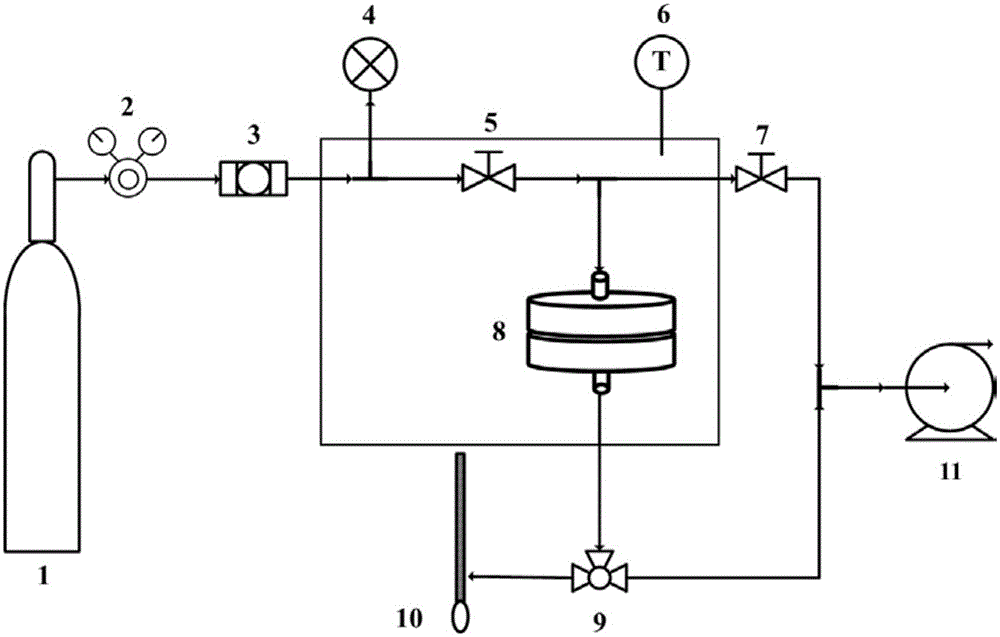

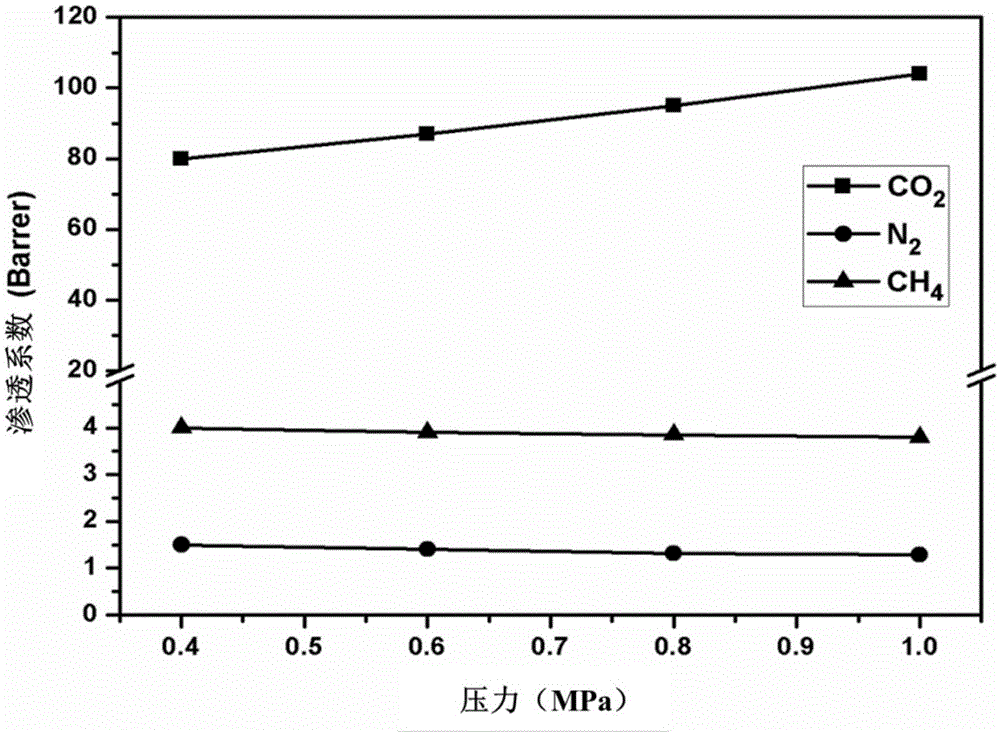

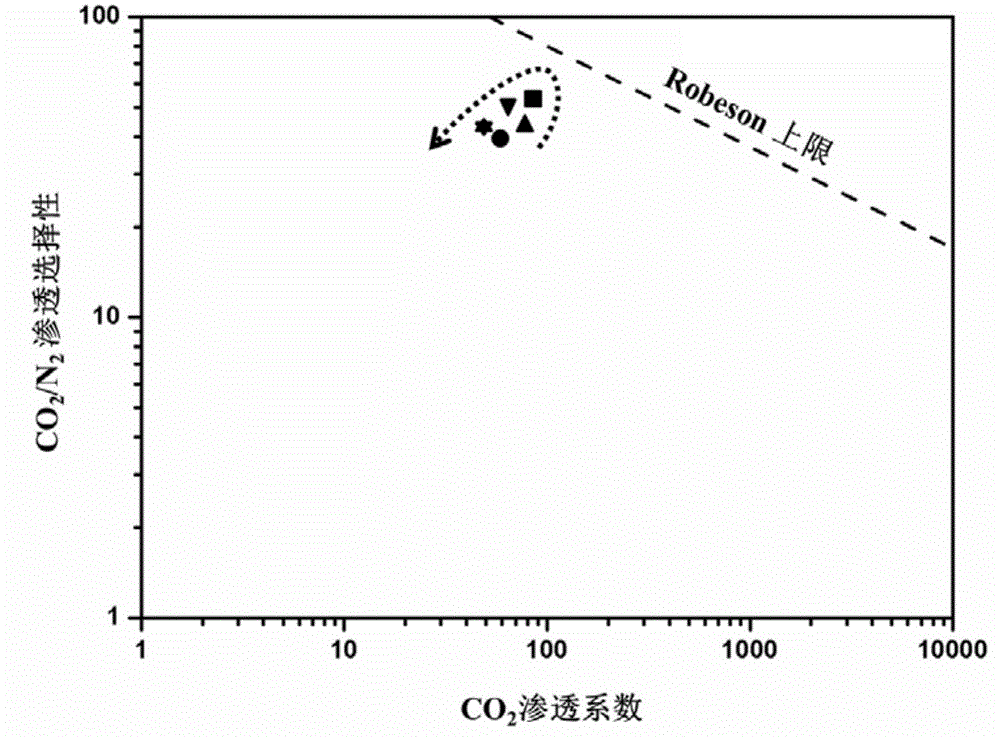

Attapulgite-polyether-b-polyamide mixed matrix membrane as well as preparation and application thereof

ActiveCN105032216AHave selective permeabilityAchieve selective separationSemi-permeable membranesDispersed particle separationFlue gasPolyamide

The invention discloses an attapulgite-polyether-b-polyamide mixed matrix membrane as well as preparation and application thereof. The attapulgite-polyether-b-polyamide mixed matrix membrane is characterized in that a segmented copolymer, namely polyether-b-polyamide (PEBAX), serves as a matrix membrane material; attapulgite serves as a filler and accounts for 0.5-10% of polyether-b-polyamide in mass percent. The attapulgite-polyether-b-polyamide mixed matrix membrane is prepared by uniformly dispersing attapulgite in a matrix membrane solution through ultrasonic dispersion, and then carrying out knife coating. The attapulgite-polyether-b-polyamide mixed matrix membrane has a remarkable property of separating CO2 / N2 and CO2 / CH4 mixed gases (PCO2 is larger than 120 Barrer; alpha CO2 / N2 is larger than 50; alpha CO2 / CH4 is larger than 20). Compared with a pure polyether-b-polyamide membrane, the attapulgite-polyether-b-polyamide mixed matrix membrane is higher in CO2 gas permeability and separation selectivity, and can be applied to purification of flue gas and natural gas.

Owner:NANJING UNIV OF TECH

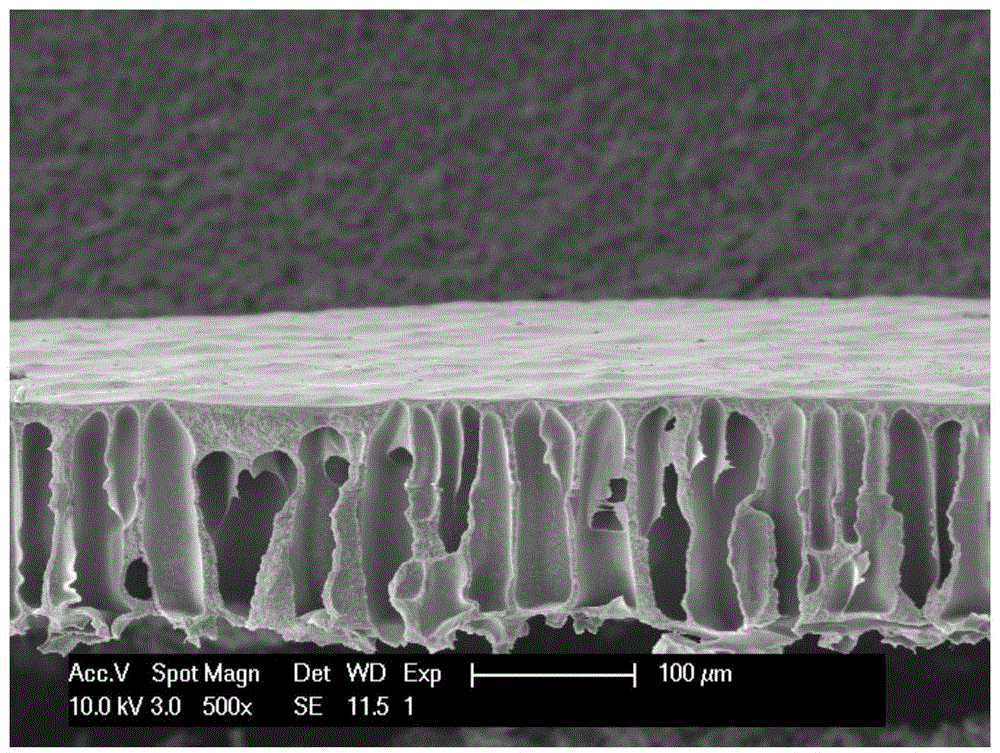

Application of porous separating membrane in zinc-bromine flow battery

InactiveCN105742549AAperture controllableAchieve separationRegenerative fuel cellsCell component detailsPorosityCellulose acetate

The invention discloses an application of a porous separating membrane in a zinc-bromine flow battery. The porous separating membrane is prepared from more than one or two of polysulfone, polyketone, polyimide, polybenzimidazole, polyvinylidene fluoride, polyvinyl pyridine, polyacrylonitrile, polypropylene, polyethylene, polybutadiene or cellulose acetate; the aperture sizes in the porous separating membrane are 0.05-20nm; and the porosity is 20%-60%. The prepared membrane material can effectively achieve separation of different zinc ions and keep the ion selectivity of the membrane. Furthermore, the membrane material can achieve ion transport without introducing an ion exchange group; and the selection range of the flow battery membrane material is expanded.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

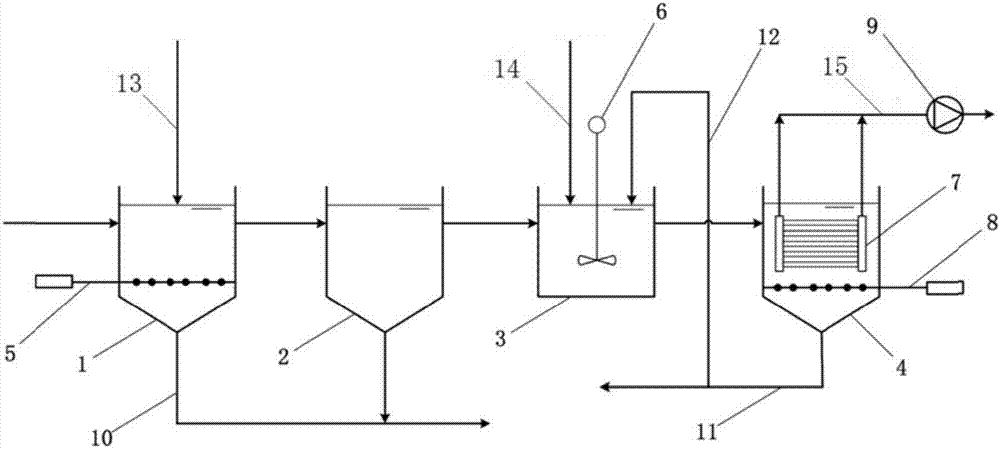

High magnesium and low calcium desulfurization wastewater softening pretreatment device and method

PendingCN107311349AReduce cloggingAchieve selective separationWater contaminantsScale removal and water softeningFlocculationHigh magnesium

The invention relates to a high magnesium and low calcium desulfurization wastewater softening pretreatment device and a method. The high magnesium and low calcium desulfurization wastewater softening pretreatment device comprises a flocculation box, a precipitation box, a softening reaction box and a filter box that are communicated in order. The top of the flocculation box is connected to a first drug adding pipeline, the flocculation box is internally equipped with a first aeration apparatus, and the bottom of the flocculation box is connected to a first slagging pipeline. The bottom of the precipitation box is communicated with the first slagging pipeline. The top of the softening reaction box is connected to a second drug adding pipeline and a seed crystal reuse pipeline, and the softening reaction box is internally equipped with a stirrer. The filter box is internally equipped with a micro-filtration membrane component and a second aeration apparatus, and the bottom of the filter box is connected to a second slagging pipeline. The micro-filtration membrane component is connected to a water outlet pipeline, which is provided with a water outlet pump. The device and the method provided by the invention can achieve selective separation of Ca<2+> in wastewater, compared with the conventional caustic soda / slaked lime-soda ash process, the device and the method provided by the invention reduce the sediment production and lower the softener delivery amount and cost.

Owner:DATANG ENVIRONMENT IND GRP

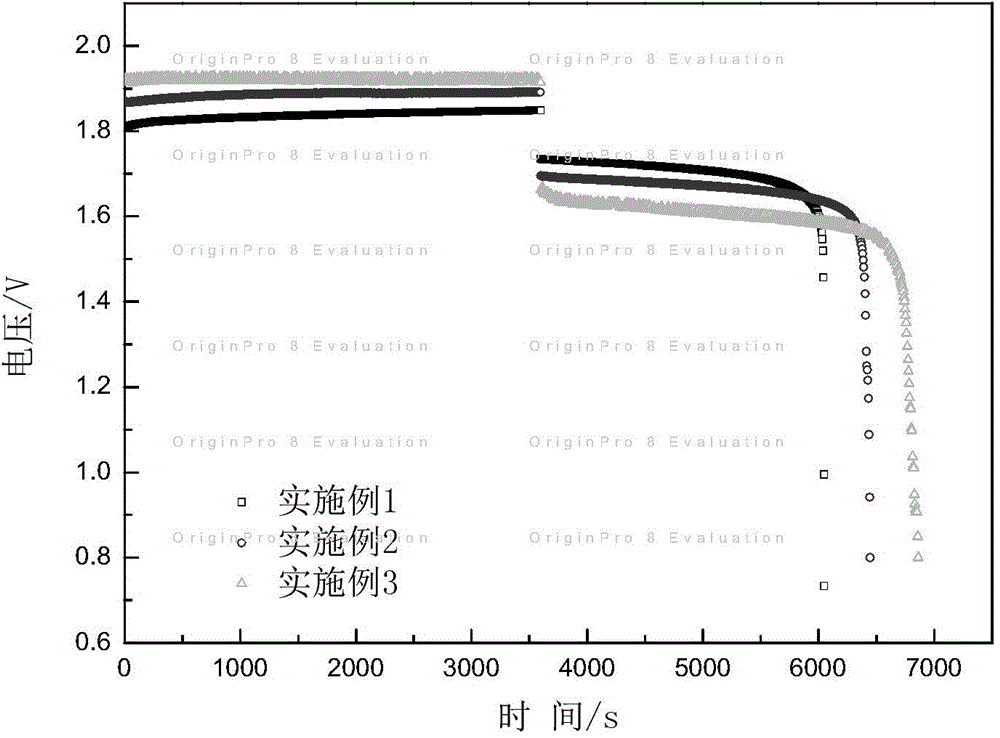

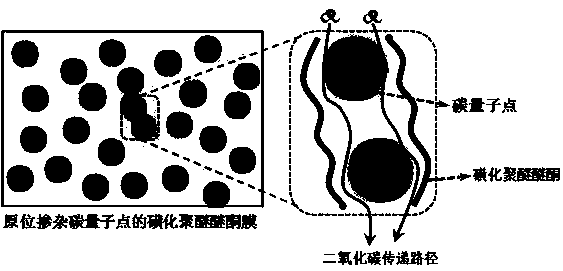

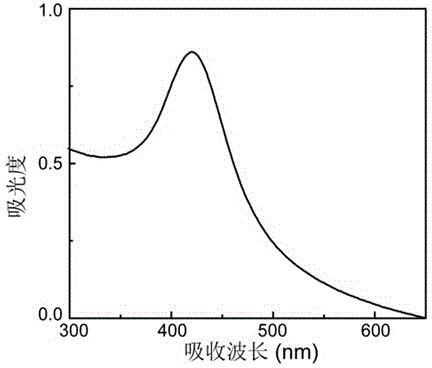

SPEEK (Sulfonated Polyether Ether Ketone) mixed matrix membrane with in-situ doped carbon quantum dots as well as preparation method and application thereof

ActiveCN108745002AImprove free volume fractionHigh crystallinitySemi-permeable membranesGas treatmentSeparation factorPolyether ether ketone

The invention discloses an SPEEK (Sulfonated Polyether Ether Ketone) mixed matrix membrane with in-situ doped carbon quantum dots as well as a preparation method and application thereof. The preparation method comprises the following steps: taking polyvinyl alcohol and polyether ether ketone as raw materials and adding the raw materials in concentrated sulfuric acid, and reacting, thus obtaining an SPEEK composite material with the in-situ doped carbon quantum dots; dissolving the SPEEK composite material into deionized water, thus preparing a membrane casting solution; preparing a functionallayer on the surface of a microporous filter membrane through a coating method, and forming the SPEEK mixed matrix membrane of the in-situ doped carbon quantum dots, the mixed matrix membrane is formed by SPEEK and carbon quantum dots, wherein the carbon quantum dots account for 0.1 to 5.0 percent by mass of the SPEEK.. The preparation method provided by the invention is simple and easy, a prepared functional membrane can be applied to CO2 / N2 gas separation, and higher CO2 permeability and separation factors are obtained.

Owner:TAIYUAN UNIV OF TECH

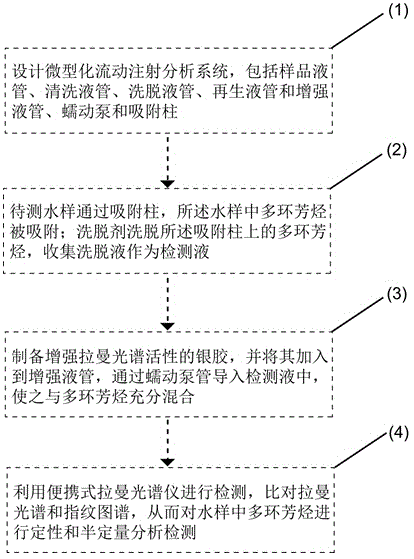

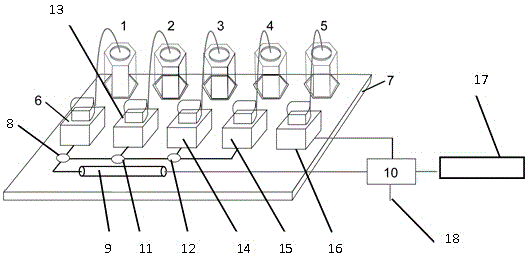

Device and method for detecting polycyclic aromatic hydrocarbon in water sample on site

InactiveCN104865237AAchieve selective separationAchieve enrichmentRaman scatteringPolycyclic aromatic hydrocarbonPeristaltic pump

A device for detecting polycyclic aromatic hydrocarbon in a water sample on site comprises a sample liquid tube, a cleaning liquid tube, an eluent tube, a regeneration liquid tube and an enhancement liquid tube, wherein each of the sample liquid tube, the cleaning liquid tube, the eluent tube, the regeneration liquid tube and the enhancement liquid tube is connected with a peristaltic pump, a first peristaltic pump is connected with a first three-way solenoid valve, a second peristaltic pump is connected with a second three-way solenoid valve, a third peristaltic pump is connected with a third three-way solenoid valve, a fourth peristaltic pump is connected with the third three-way solenoid valve, the third three-way solenoid valve and the second three-way solenoid valve are connected, the second three-way solenoid valve is connected with the first three-way solenoid valve, the first three-way solenoid valve is connected with an adsorption column, the adsorption column is connected with a detection cell, a fifth peristaltic pump is connected with the detection cell, and the detection cell is connected with a Raman spectrometer. The invention further provides a method for detecting the polycyclic aromatic hydrocarbon in the water sample. With the adoption of the device and the method, analysis is rapid, the sensitivity is high, a few samples are used, the application range is wide, operation is simple and convenient, repeated usage can be realized, and carrying is convenient.

Owner:SHANGHAI INST OF TECH

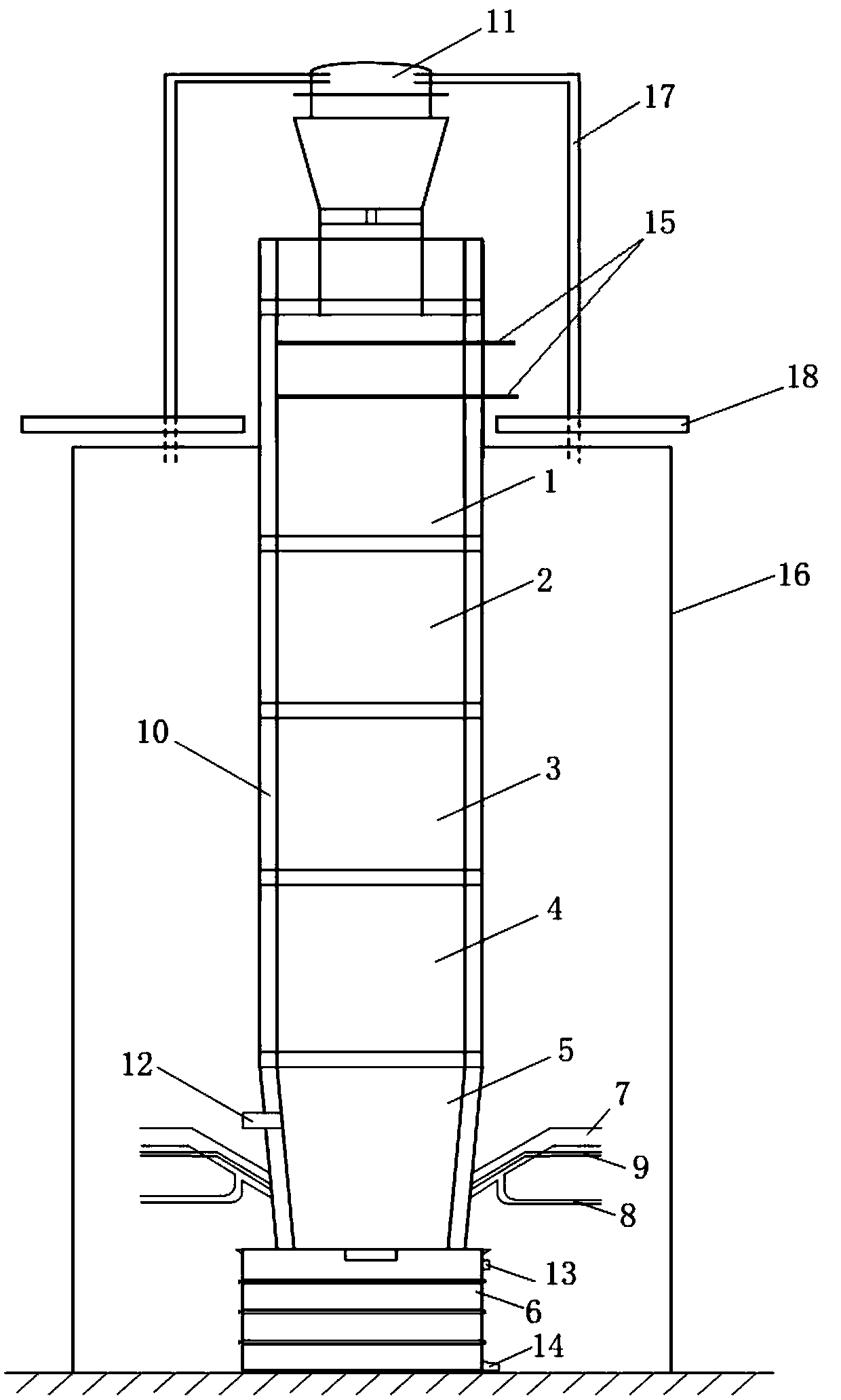

Technology for cleanly and efficiently processing lead-bearing waste residues

PendingCN108950236AGuaranteed temperatureSecurity atmosphereProcess efficiency improvementLead smeltingSmelting process

Disclosed is a technology for cleanly and efficiently processing lead-bearing waste residues. The lead-bearing waste residues produced by lead smelting and lime are matched according to the mass ratioof 1:0.03-0.07 and are then pressed into blocky lead-bearing residue blocks, and after natural drying, by mass, 7%-15% of coke, 9%-11% of silica and 74%-84% of the lead-bearing residue blocks are matched. Materials are sequentially added into a five-section integrated type smelting furnace, ignition blowing-in is conducted for oxygen-enriched intensified smelting, materials added from a smeltingfurnace feeding section (1) pass through a preheating section (2), a sintering section (3), a half-melting section (4), a smelting section (5) and a layering section (6), and the smelting process of the materials is completed. Through the technology, material preheating, sintering, smelting and clarification laying are integrated, heavy metal, valuable metal, gangue and the like are selectively separated well, dangerous waste is processed cleanly and efficiently, and the technology has the advantages that the process is short, operation is simple and convenient, and investment is small.

Owner:个旧市沙甸永和冶炼厂

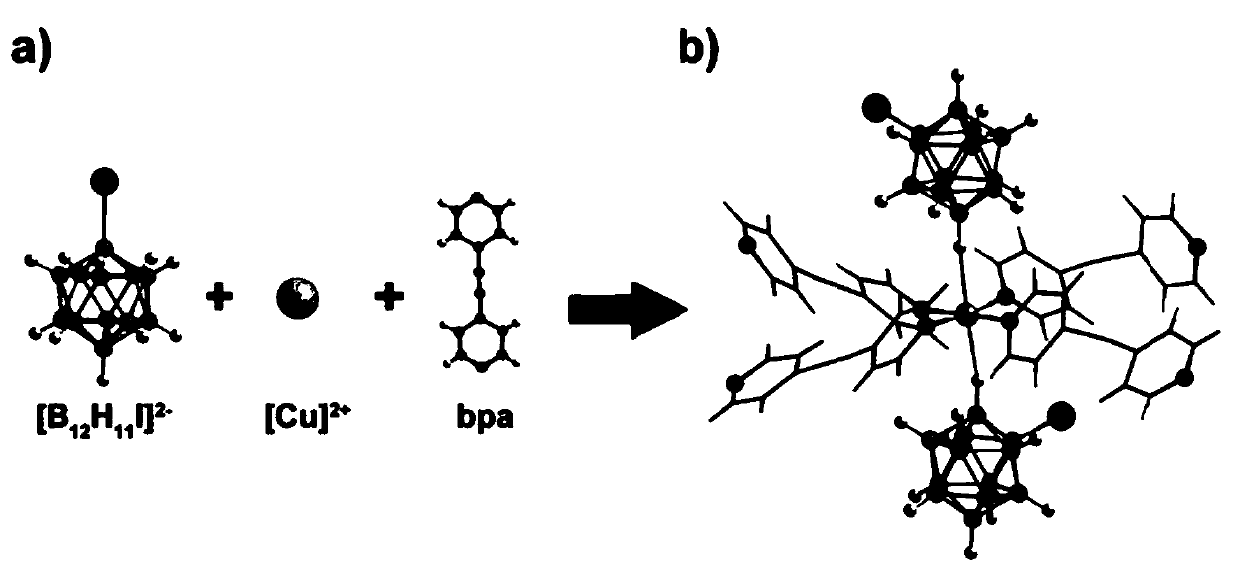

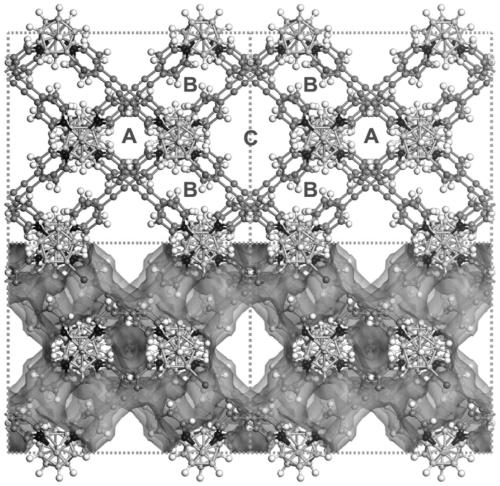

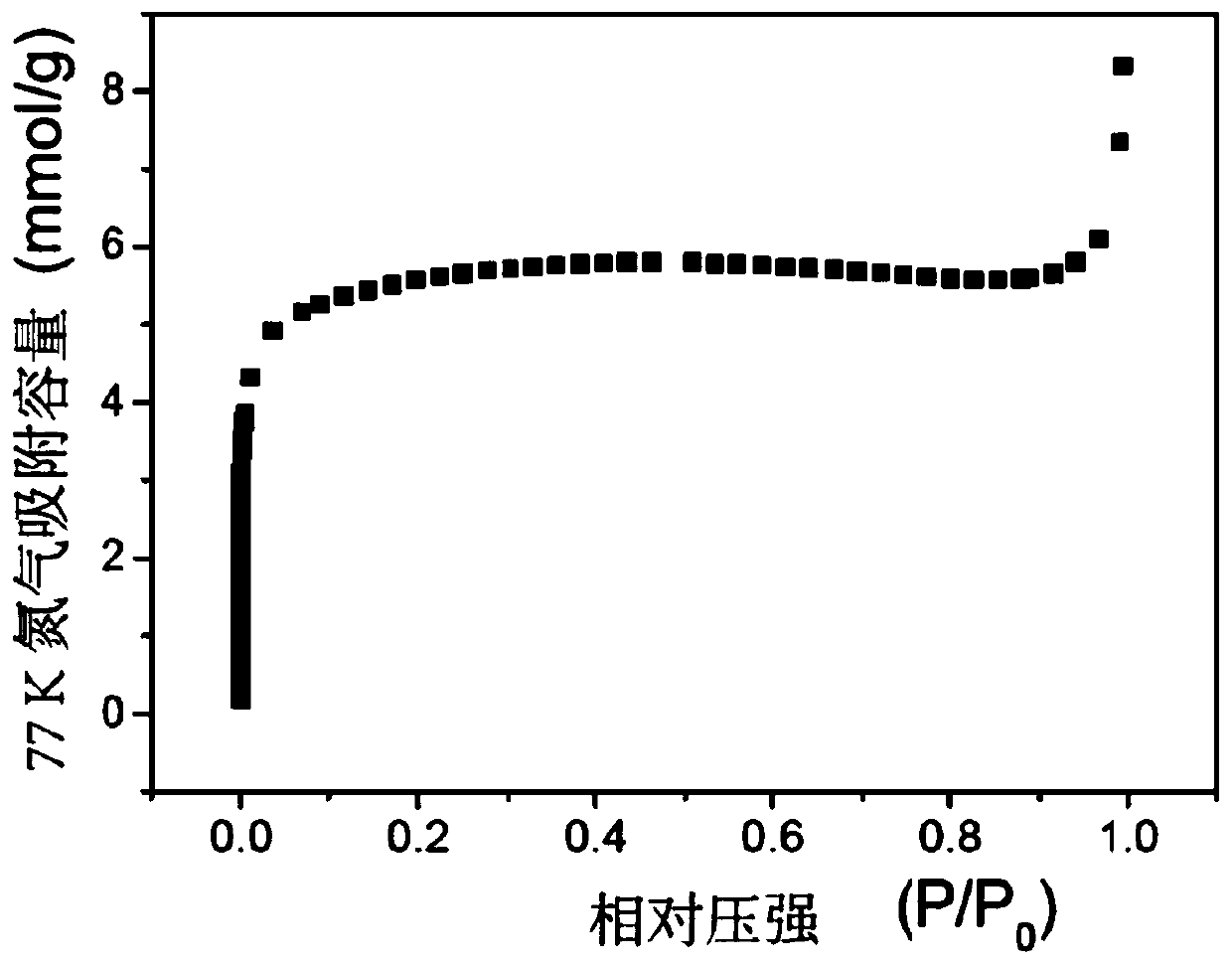

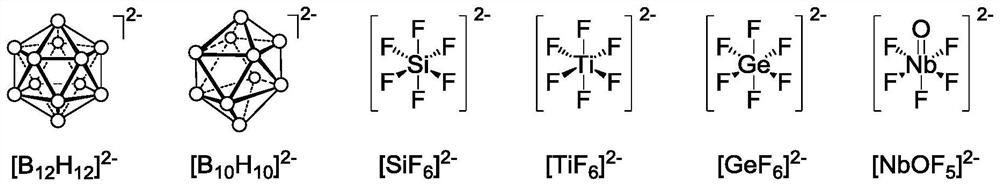

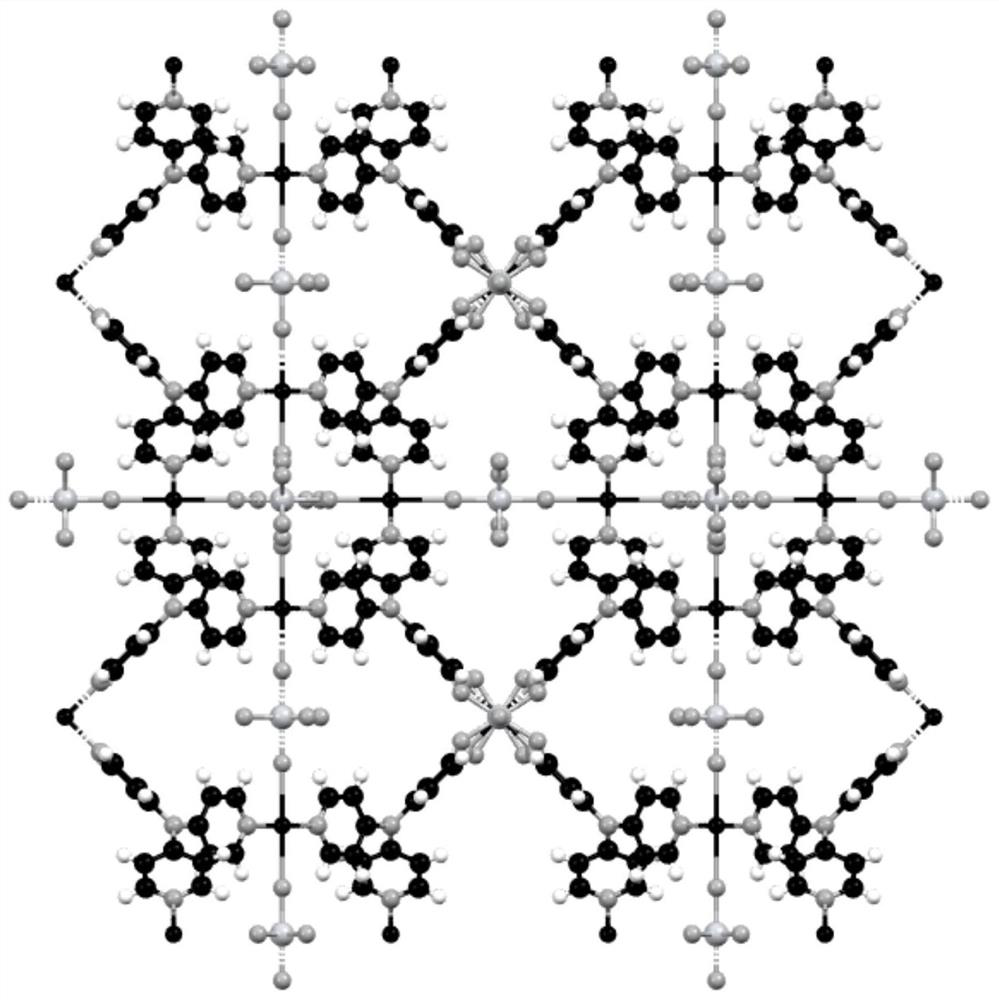

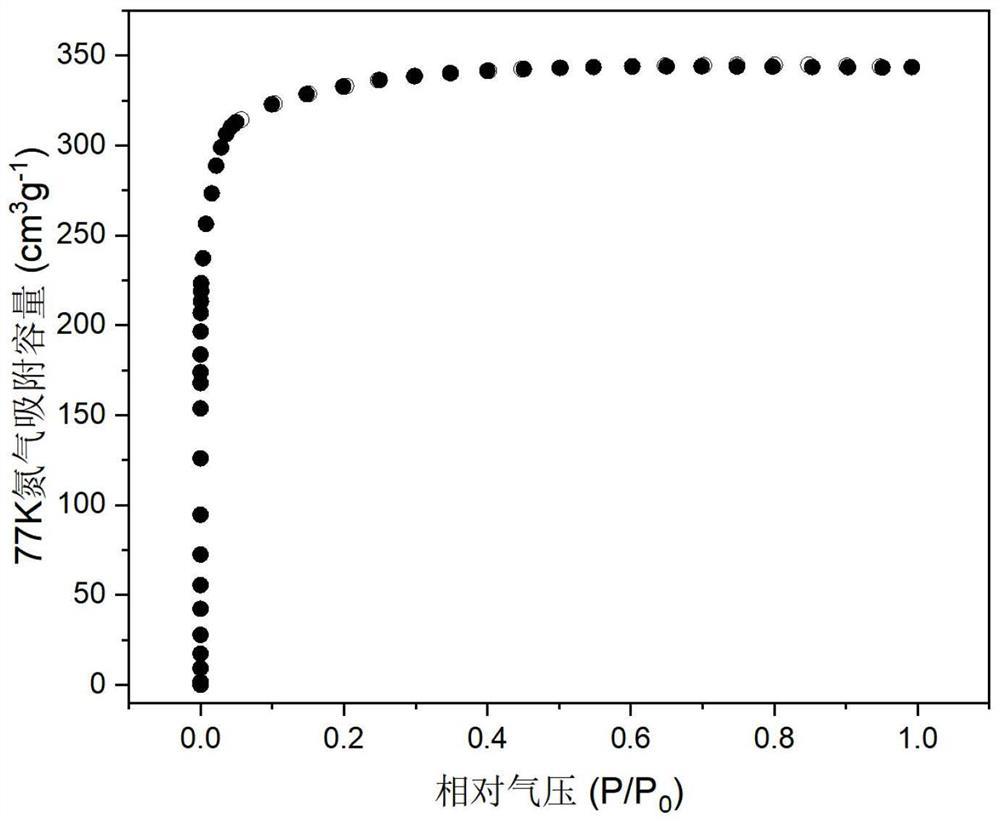

Functional cage borane anion-pillared supramolecular microporous framework material, preparation method and application thereof

ActiveCN110193352AReduce adsorptionImprove adsorption capacityGas treatmentOther chemical processesMethane gasMixed gas

The invention discloses a functional cage borane anion-pillared supramolecular microporous framework material. Metal Cu<2+> ions coordinate with organic nitrogen-containing ligand L to form a two-dimensional plane structure, which is then bridged to iodine-substituted functional cage dodecaborane anion[B12H11I]<2-> to form a three-dimensional layered columnar framework structure. The functional cage borane anion-pillared supramolecular microporous framework material provided by the invention can be used for selective purification of methane, specifically in high selective adsorption and separation of propylene / methane, propane / methane, ethane / methane, ethylene / methane, and acetylene / methane, and the obtained high purity methane gas and recovered low-carbon hydrocarbon of C2-C3 can be usedfor selective adsorption and separation of natural gas, biogas, pyrolysis gas and other industrial mixed gas containing a lot of methane.

Owner:ZHEJIANG UNIV

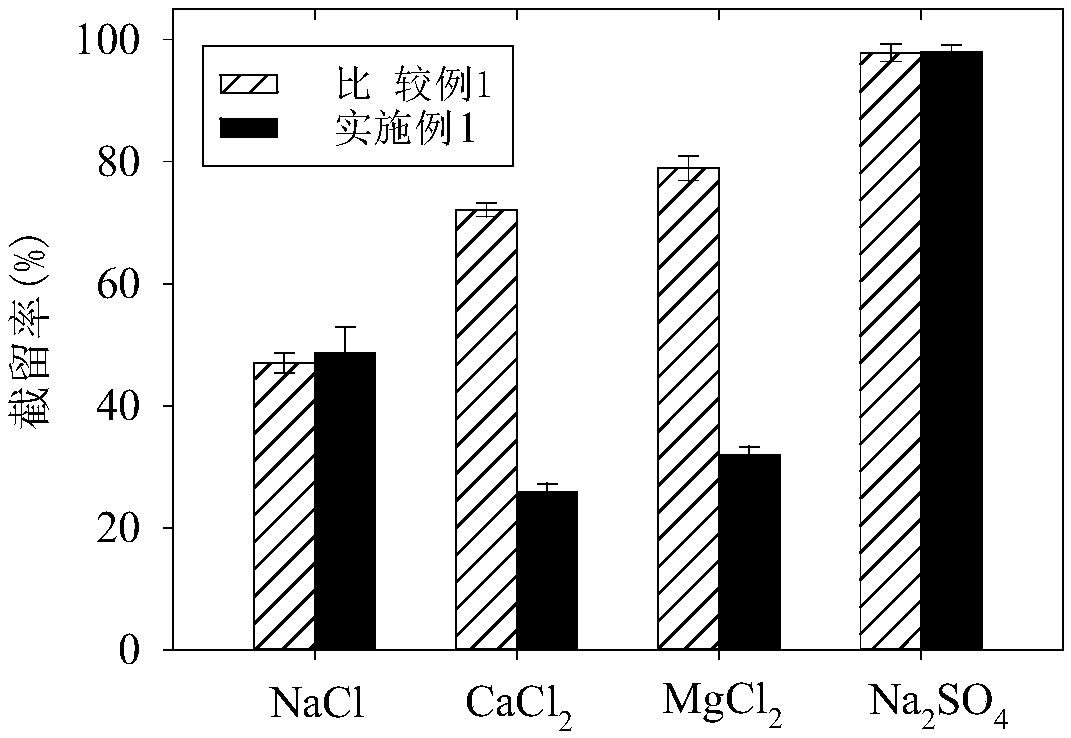

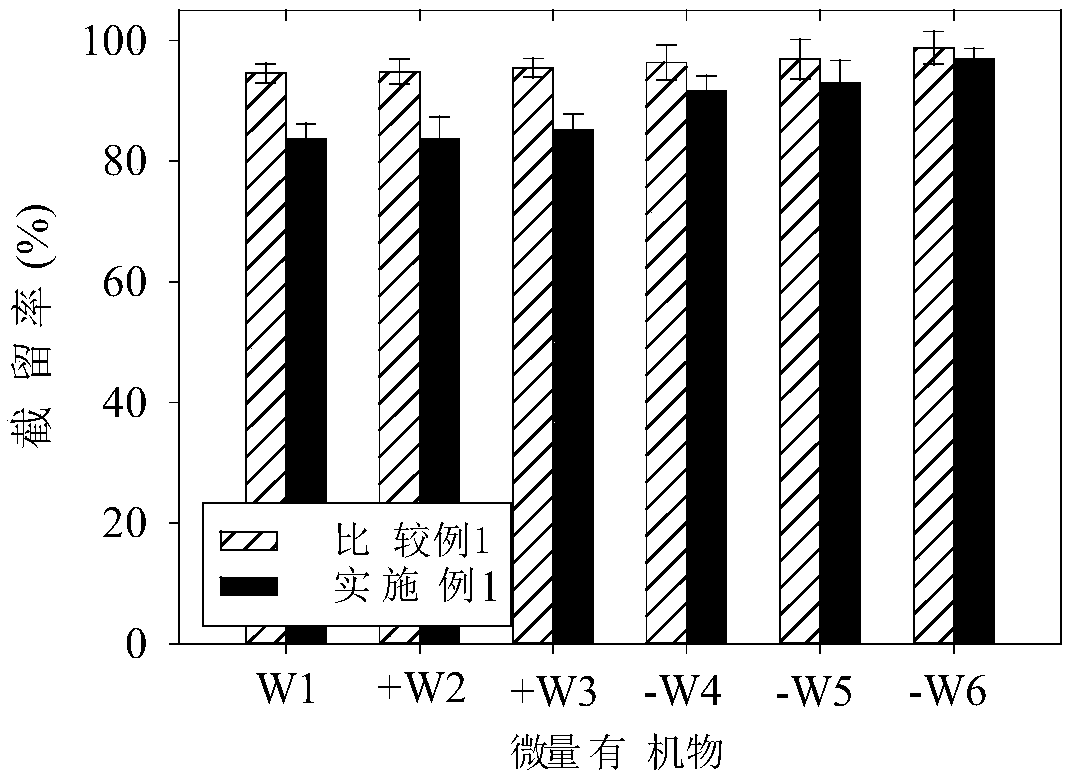

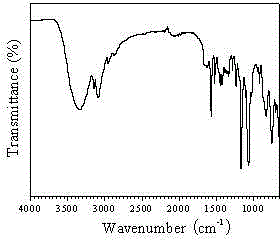

Nanofiltration membrane for selectively separating trace organic substances and calcium-magnesium ions, and preparation method thereof

ActiveCN109046025AMaintain chemical stability and healthLow rejectionSemi-permeable membranesWater contaminantsIonChemistry

The invention provides a nanofiltration membrane for selectively separating trace organic substances and calcium-magnesium ions. The nanofiltration membrane comprises a porous support layer and a filter skin layer, a first solution and a second solution are subjected to interfacial polymerization reaction and heating treatment in sequence to form the filter skin layer, the first solution is a water solution containing polyamine monomers and acid organic matter monomers, and the second solution is formed by dissolving acyl chloride monomers in an organic solvent; in the first solution, the total mass concentration of the polyamine monomers and the acid organic matter monomers is 0.4-1%, and the acid organic matter monomers account for 35-65%; in the second solution, the mass concentration of the acyl chloride monomers is 0.1-0.2%. The invention further provides a preparation method of the nanofiltration membrane for selectively separating the trace organic substances and the calcium-magnesium ions. The nanofiltration membrane has high rejection rate for the trace organic substances but low rejection rate for the calcium-magnesium ions, and chemical stability and health of nanofiltration water are maintained while the trace organic substances are effectively removed.

Owner:TSINGHUA UNIV

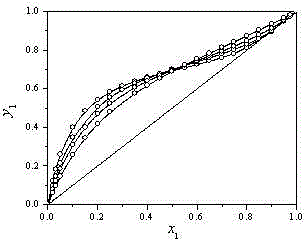

Preparation method of ionic liquid for selectively separating water-ethanol azeotropic system

InactiveCN104892520AAchieve separationImprove catalytic performanceOrganic compound preparationHydroxy compound preparationEthyl groupSolvation

The invention provides a preparation method of ionic liquid for selectively separating a water-ethanol azeotropic system. The preparation method is characterized in that cationic groups in the synthetic ionic liquid have hydroxyl. The preparation method comprises the following steps: reacting N-methylimidazole with 2-bromoethanol under the condition of constant-temperature ultrasonic reflux to prepare bromo-1-methyl-3-(2-hydroxylethyl) imidazole; then, purifying bromo-1-methyl-3-(2-hydroxylethyl) imidazole to obtain the ionic liquid of bromo-1-methyl-3-(2-hydroxylethyl) imidazole. The preparation method has the advantages that the synthesis process is simple, and the prepared ionic liquid is non-volatile, good in stability, friendly to the environment and obvious in 'salt effect'; groups in the ionic liquid are capable of selectively bonding component water in the water-ethanol azeotropic system to generate a solvation reaction under the actions of chemical affinity, hydrogen bond force and electrostatic attraction of ions to produce a nonvolatile ionic liquid-water associated complex so that water vapor pressure is lowered, the volatility of water is reduced, steam phase partial pressure and relative volatility of ethanol are increased and the 'salting out' phenomenon appears and thus the water-ethanol azeotropic system is separated.

Owner:HEFEI UNIV

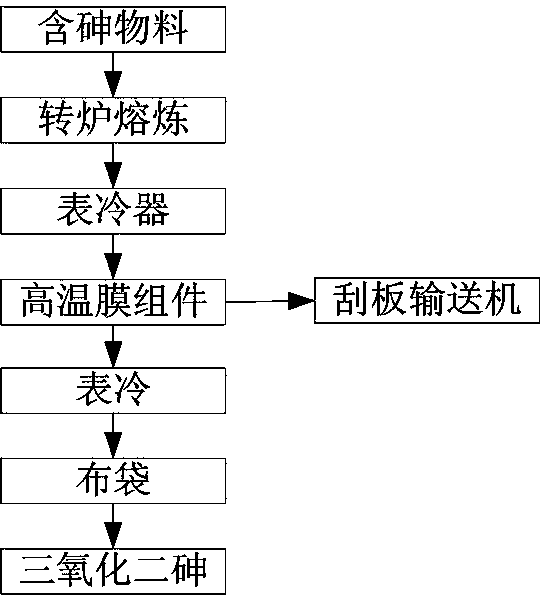

Method for selectively separating arsenic trioxide from non-ferrous metal smelter off-gas

InactiveCN103589869AAchieve selective separationRealize gas-solid separationProcess efficiency improvementArsenic compoundsGas solidArsenic pollution

The invention relates to a method for selectively separating arsenic trioxide from non-ferrous metal smelter off-gas, and belongs to the technical field of the non-ferrous metallurgy. The method is mainly characterized in that the off-gas enters a high temperature membrane module at a temperature of 500-700DEG C, so a gas traverses through a membrane filter core, and dusts are intercepted and adsorbed by a membrane through inertial impaction and the interception or diffusion effect to realize gas-solid separation. The method has the advantages of reasonable, controllable and stable process flow, high arsenic separation rate, high purity of the obtained arsenic extraction product, and no arsenic pollution in the smelting process.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

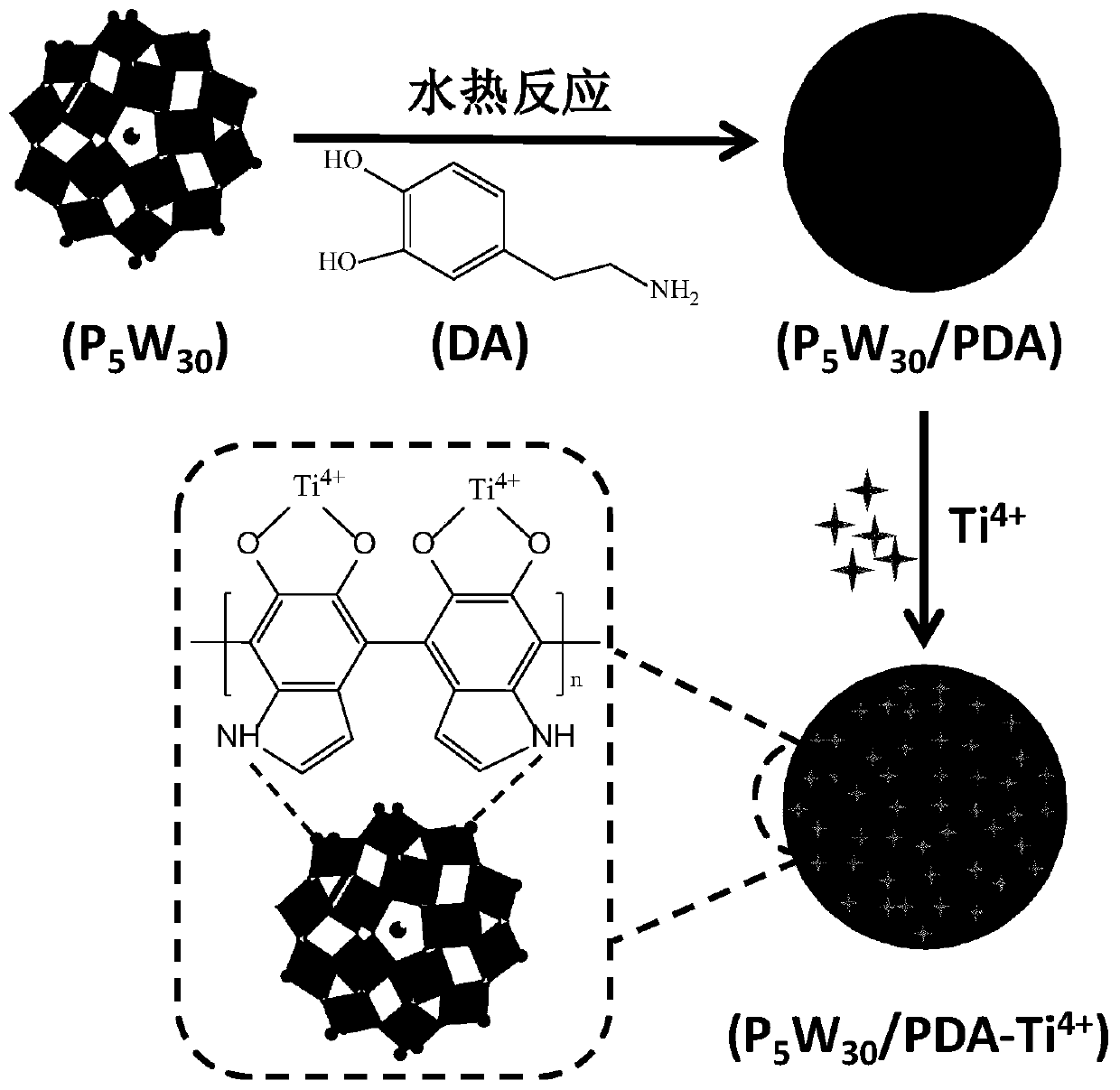

Preparation method and application method of phosphorylated protein enrichment material

ActiveCN110314671AEasy to separateEasy to synthesizeOther chemical processesSolid sorbent liquid separationSolubilityMicrosphere

The invention relates to a preparation method and application method of a phosphorylated protein enrichment material. The preparation method comprises the steps of preparing a corresponding polyoxometalate during preparation; polymerizing dopamine and polyoxometallate to form composite microspheres as a carrier; fixing metal ions to the surfaces of the microspheres to obtain an enrichment materialproduct. An obtained final product is used as an adsorption material for selective separation enrichment of phosphorylated protein. The applied dopamine has good water solubility and is free of toxinand harm and excellent in metal bonding capability. In addition, Pi bonds exist in both the polyoxometallate and phosphate radical groups so that a Pi accumulation effect can be achieved, and the adsorption effect on phosphorylated protein is further improved. The material has the advantages of simple synthesis process, low cost, high selectivity and the like.

Owner:NORTHEASTERN UNIV

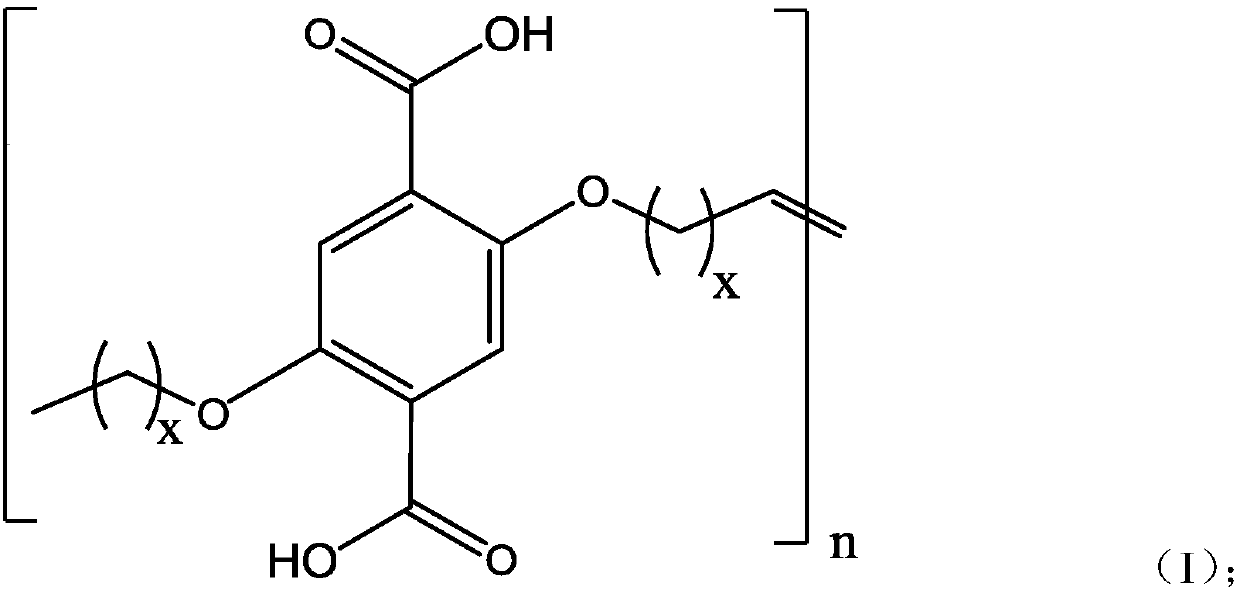

Organic ligand for MOF (Metal Organic Framework) and preparation method of organic ligand as well as separation membrane containing organic ligand MOF and preparation method of separation membrane

ActiveCN107722289AReduce transmission resistanceEasy transferSeawater treatmentWater/sewage treatment bu osmosis/dialysisChemical structureMetal-organic framework

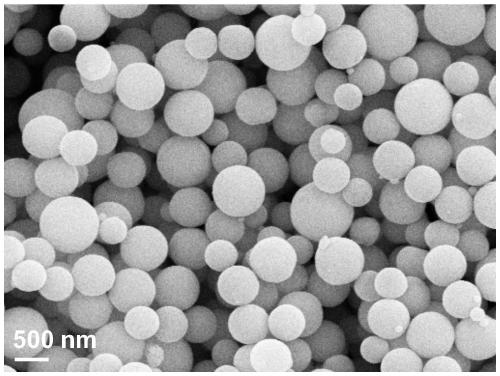

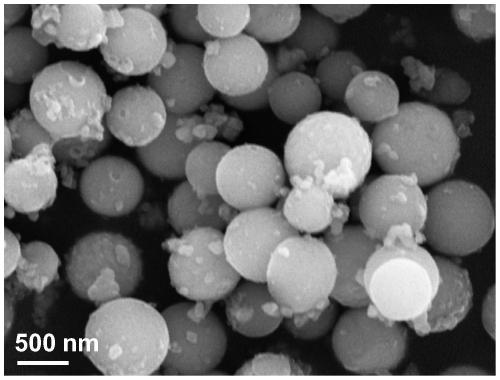

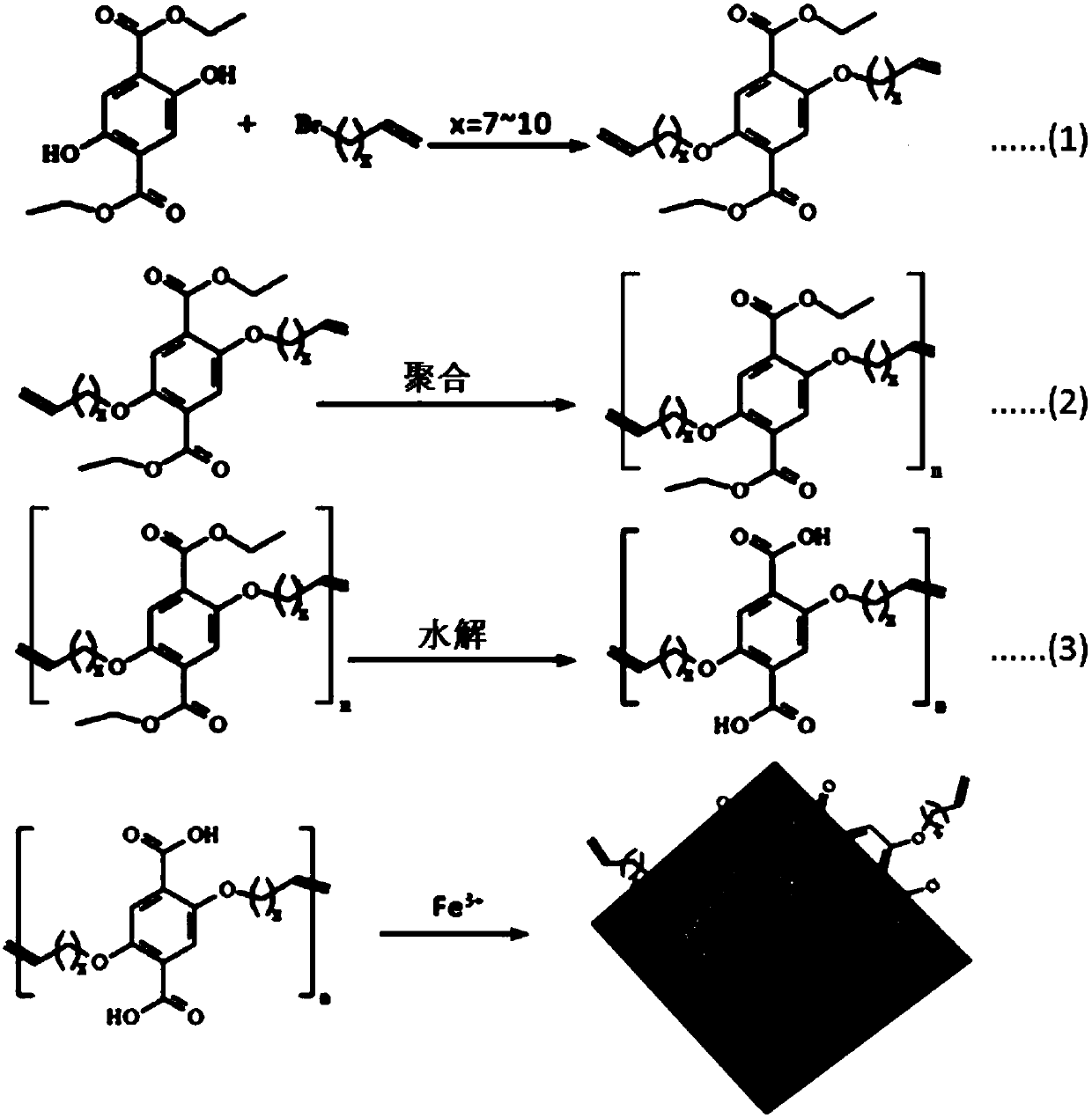

The invention provides an organic ligand for an MOF (Metal Organic Framework). The organic ligand has a structure as shown in a formula (I), wherein x ranges from 7 to 10, and n ranges from 20 to 30.The invention provides the organic ligand MOF; ligand metal in the organic ligand MOF is iron. The invention also provides the separating membrane containing the organic ligand MOF; the separating membrane comprises a basement membrane and the organic ligand MOF compounded on the surface of the basement membrane. According to the organic ligand and the separating membrane disclosed by the invention, a specific chemical structure of the organic ligand is selected from regulation and control over the aperture size of the MOF; the specific chemical structure is combined with a specific ligand metal and the influence of a growing environment of the MOF and a substrate structure, so that selective separation of ions is researched, and the size of the MOF is accurately regulated and controlled;the selective separation of the ions is realized on the basis of a screening action of aperture, so that the selective adsorption separation in a polyvalent ion solution system is better realized.

Owner:UNIV OF SCI & TECH OF CHINA

Hydrothermally stable column cage type metal organic framework material as well as preparation method and application thereof

InactiveCN114177890AGood hydrothermal stabilityImprove cycle performanceGas treatmentOther chemical processesAlkyneAdsorption separation

The invention discloses a hydro-thermal stable column cage type metal organic framework material, a preparation method thereof and application of the hydro-thermal stable column cage type metal organic framework material in the field of selective adsorption separation of gas. The column cage type metal organic framework material is formed by self-assembly of metal ions M, nonlinear multidentate nitrogen-containing ligands L and high-coordination-number inorganic anions through coordination bonds. The column cage type metal organic framework material disclosed by the invention has good hydrothermal stability and cyclicity, and can be used for high-selectivity adsorption separation of acetylene / ethylene, propyne / propylene and other alkyne olefins.

Owner:ZHEJIANG NORMAL UNIVERSITY

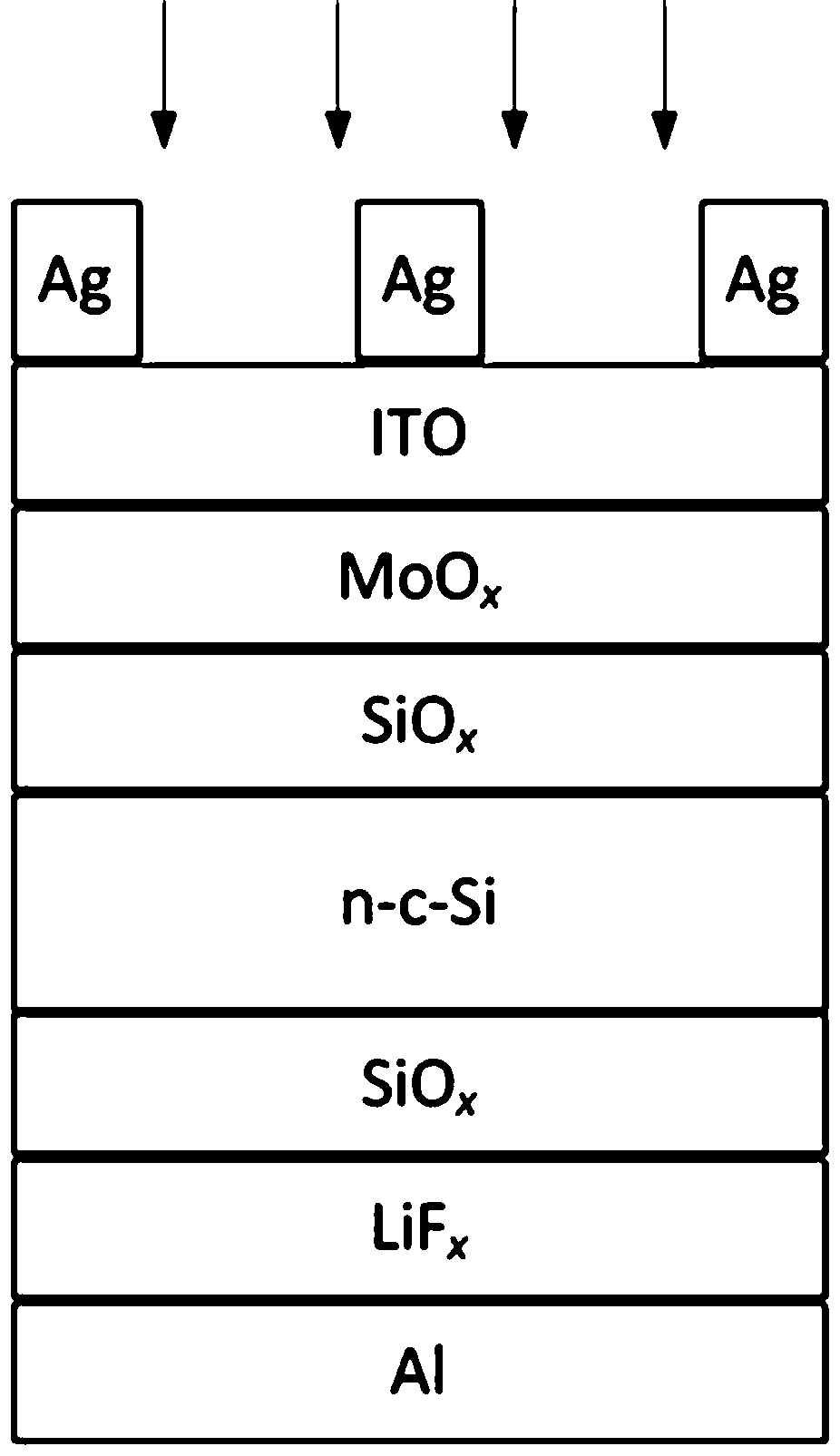

Selective contact crystalline silicon heterojunction solar cell and preparation method thereof

InactiveCN108389929AImprove collection efficiencyReduce interfacial recombination lossFinal product manufacturePhotovoltaic energy generationHeterojunctionCrystalline silicon

The invention discloses a selective contact crystalline silicon heterojunction solar cell and a preparation method thereof. The structure of the solar cell is divided into a plurality of layers from top to bottom: Ag / ITO / MoOx / SiOy / n-c-Si / SiOy / LiFz / Al. During preparation, an ultra-thin SiOy layer (1.0-1.3 nm) grows on the front and rear surfaces of a silicon wafer through the nitric acid oxidationprocess. After that, MoOx, ITO and Ag sequentially grow on the front surface of the silicon wafer, while LiFx and Al sequentially grow on the back surface of the silicon wafer. According to the invention, the selective separation of photogenerated carriers is realized through bending the heterojunction energy band of MoOx / c-Si and LiFz / c-Si respectively based on the high-work function characteristics of MoOx and the low-work function characteristics of LiFz.

Owner:ZHEJIANG NORMAL UNIVERSITY

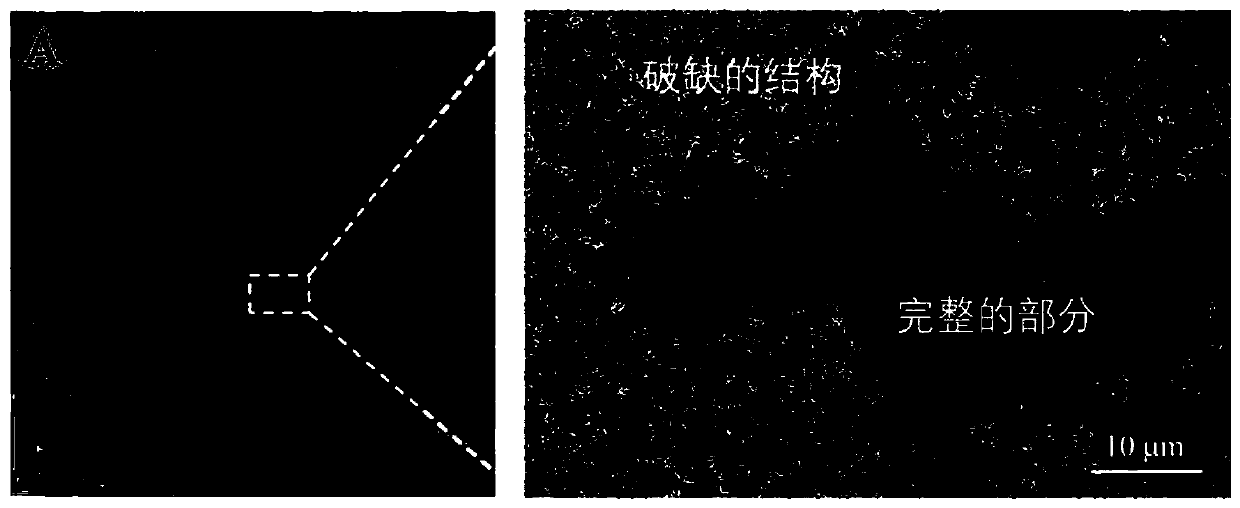

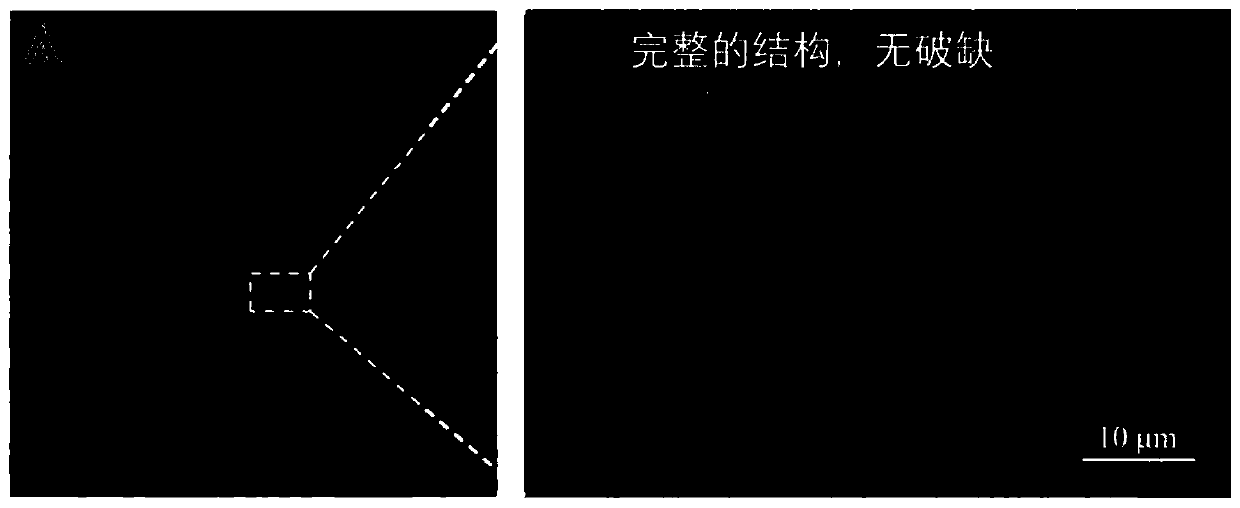

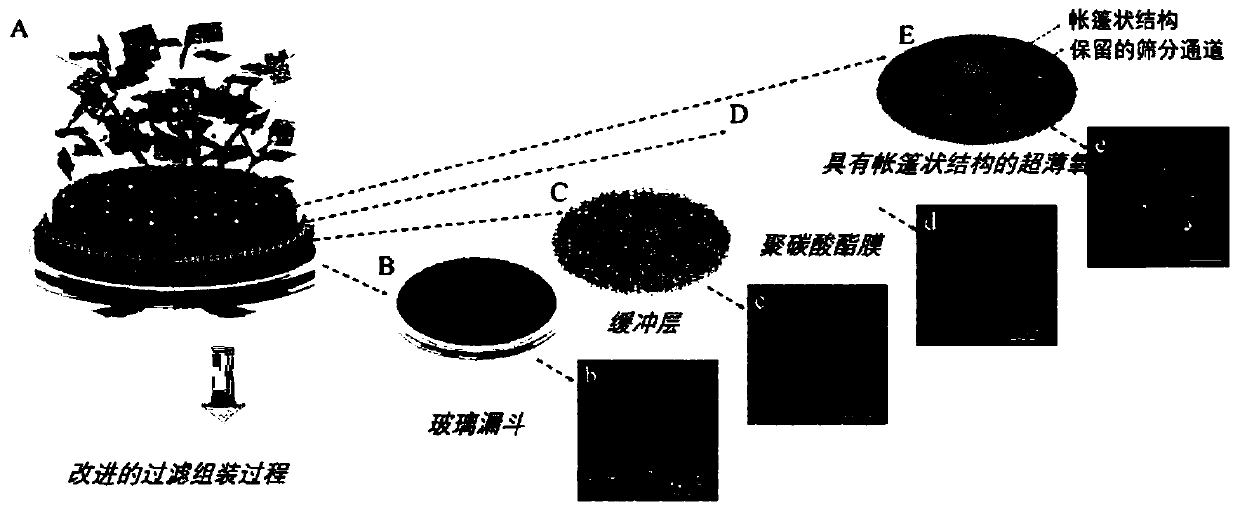

Graphene oxide membrane with tent-like structures, and preparation method and application thereof

ActiveCN110860215AIncrease water fluxAchieve water fluxSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisGraphite oxideNanoparticle

The invention discloses a graphene oxide membrane with tent-like nanostructures as well as a preparation method and application thereof. According to the invention, an improved filter assembly methodis established so as to realize reliable preparation of an ultra-thin graphene oxide membrane on a flexible substrate. By intercalating nanoparticles into an ultra-thin structure, construction of tent-like nanostructures in the ultra-thin structure is realized The special tent-like nanostructures are capable of realizing maximum water flux under the premise of retaining retention performance. By adjusting intercalation ratio of the nanoparticles, regulation on sieving channels of the graphene oxide membrane can be realized on the molecular scale; and moreover, selective separation on small molecules of similar sizes is also enabled. The tent-like nanostructures of the graphene oxide membrane in aqueous solutions of different pH values are stable; and moreover, surface roughness, wettability and surface electrical property of the graphene oxide membrane are adjustable. The graphene oxide membrane with the tent-like nanostructures has excellent separation performance, as well as adjustable structures and properties; and thus, the graphene oxide membrane with the tent-like nanostructures has very broad application prospects in the fields of environmental pollution control and membraneseparation technology.

Owner:ZHEJIANG UNIV

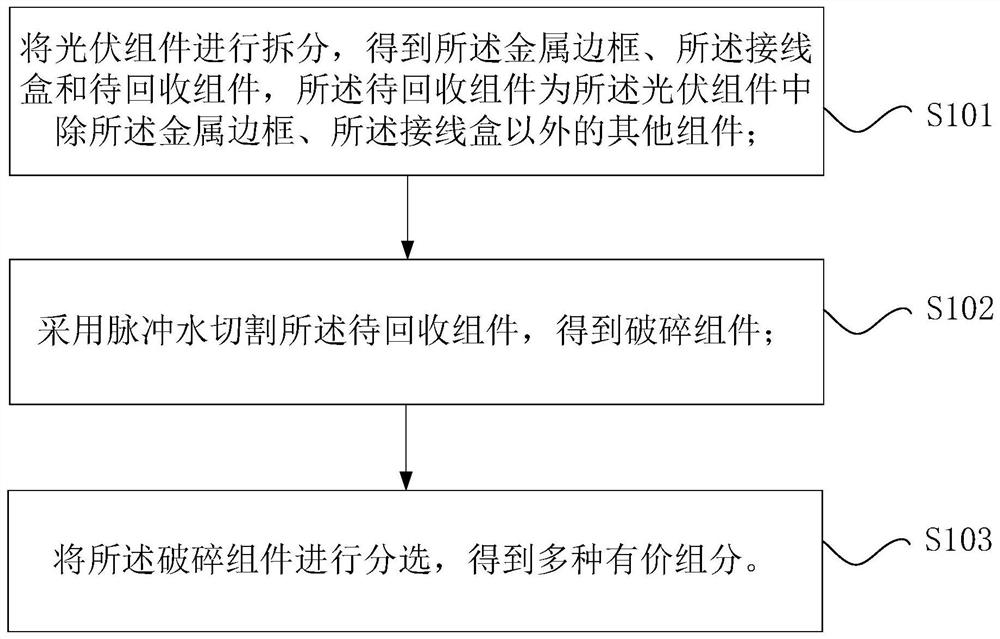

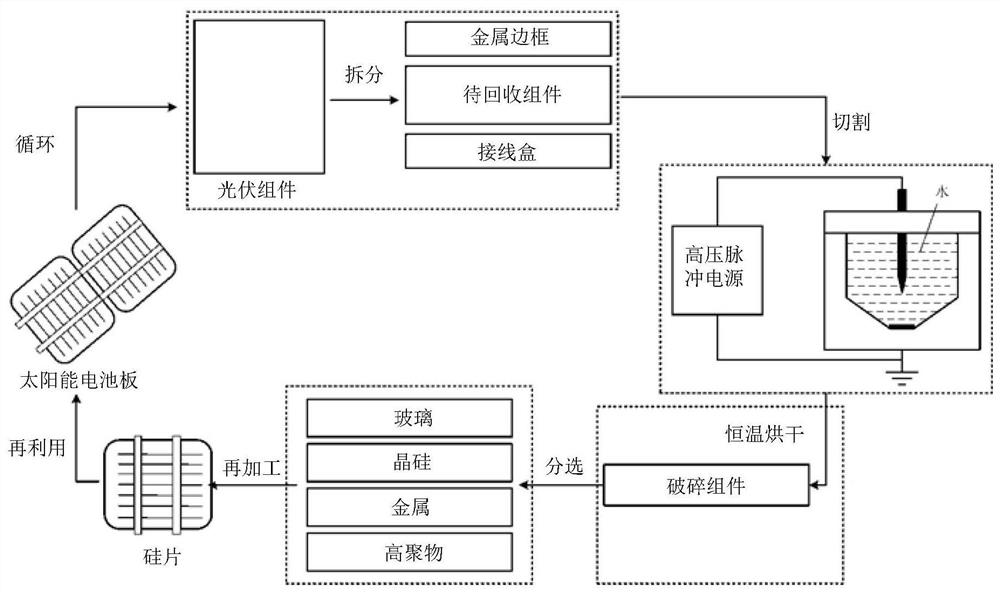

Recovery method of photovoltaic module

InactiveCN112605098AAchieve selective separationReduce energy consumptionWaste processingSolid waste disposalWastewaterProcess engineering

The invention provides a recovery method of a photovoltaic module. The photovoltaic module comprises a metal frame and a junction box, the method comprises the steps that spliting is carried out on the photovoltaic module to obtain the metal frame, the junction box and a to-be-recycled module, the to-be-recycled module is other modules except the metal frame and the junction box in the photovoltaic module; the to-be-recycled assembly is cut by adopting pulse water to obtain a crushing assembly; and sorting is carried out on the crushing assembly, and multiple valuable components are obtained. According to the recovery method, selective separation of the retired photovoltaic module is realized by adopting a pulse water crushing technology, no dust, waste gas or wastewater is generated in the recovery process, no chemical reagent is involved, and therefore the energy consumption is reduced, the recovery efficiency is improved, and secondary production is facilitated.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID QINGHAI ELECTRIC POWER COMPANY +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com