Attapulgite-polyether-b-polyamide mixed matrix membrane as well as preparation and application thereof

A technology of mixed matrix membrane and attapulgite, which is applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of high gas permeability and separation selectivity, easy to produce defects, and high price, and achieve Significant industrial application prospects, improved separation selectivity, and improved permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

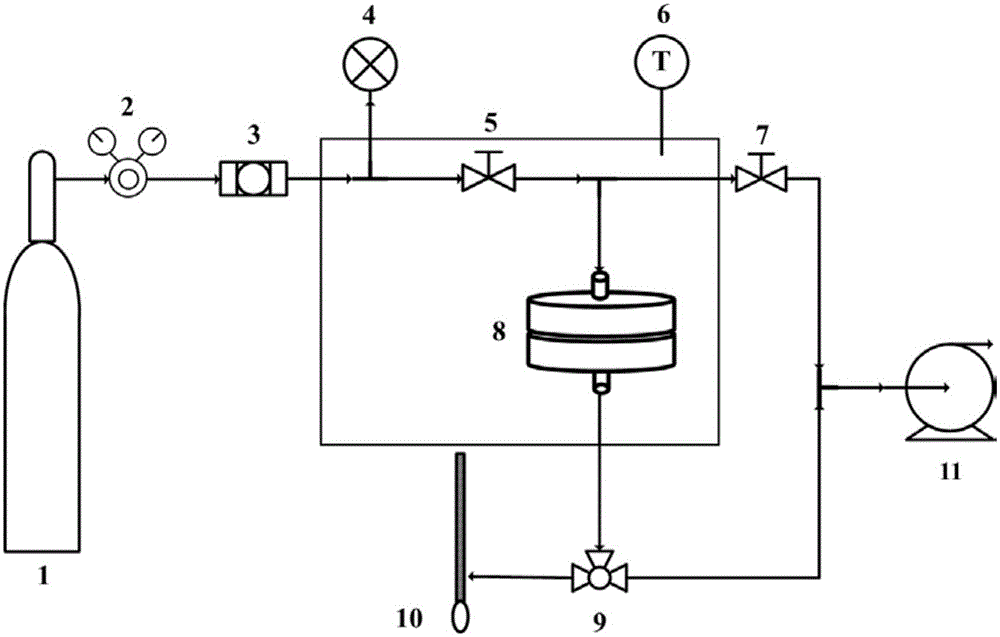

Method used

Image

Examples

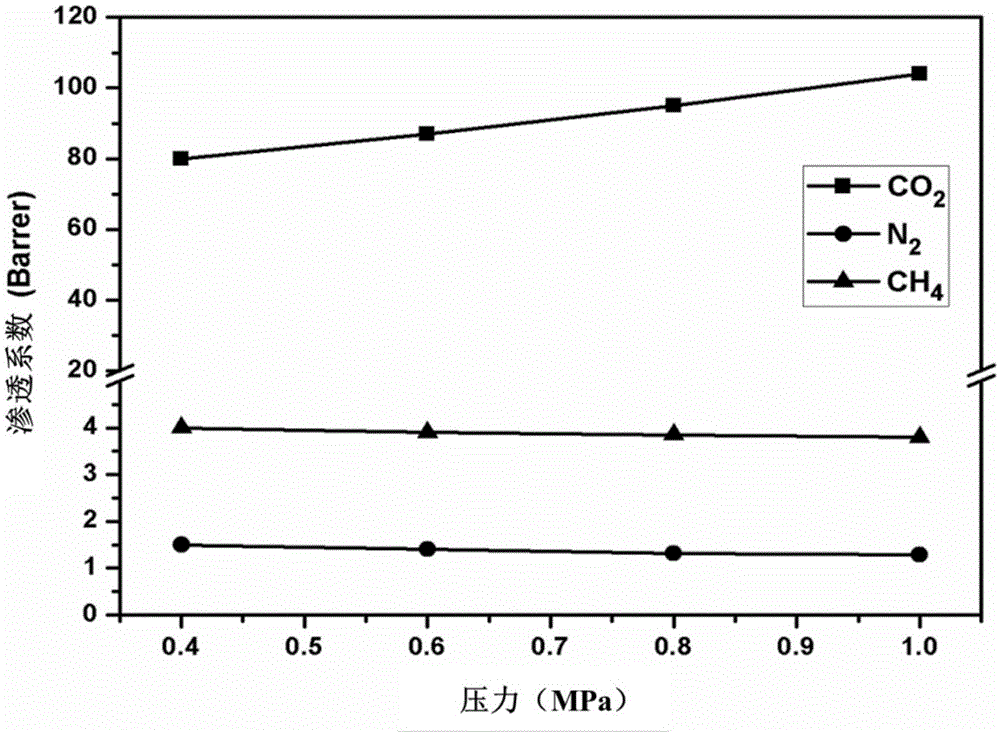

Embodiment 1

[0033] Add 8 grams of PEBAX-1657 particles into 92 grams of ethanol / water (volume ratio 70 / 30) solution, and stir at 80°C for 2 hours under reflux to dissolve completely. Then, 0.4 g of attapulgite was added to the above polymer solution, and the casting solution was obtained by ultrasonication for 60 min. Then stand still for 12 hours for degassing, apply the casting solution on the polytetrafluoroethylene board by scraping, and control the air humidity to 20%; then put it in a vacuum drying oven, and vacuumize for 12 hours at a room temperature of 20°C , then the temperature was raised to 50°C for 48 hours, and then the temperature was raised to 80°C for 48 hours to further remove the residual solvent, and finally the attapulgite / polyether-b-polyamide mixed matrix film was obtained after peeling off the polytetrafluoroethylene plate , the thickness of the film is 60 μm. It has been determined that under the conditions of 30°C and 0.4MPa, CO 2 , N 2 、CH 4 The permeability...

Embodiment 2

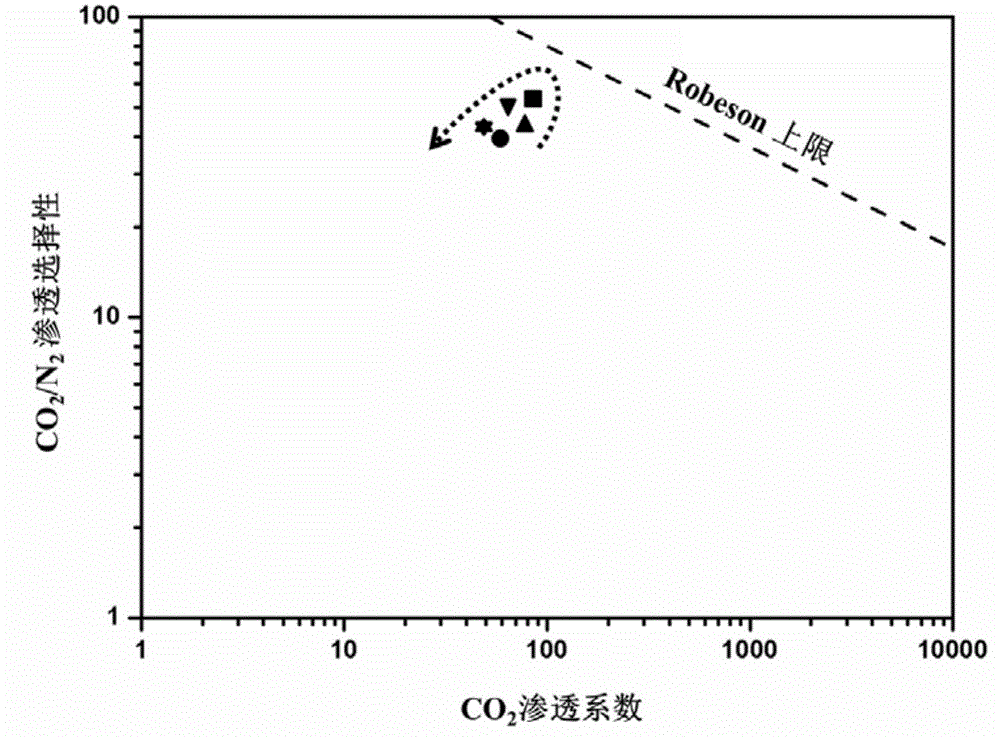

[0037] Add 8 grams of PEBAX-1657 particles into 92 grams of ethanol / water (volume ratio 70 / 30) solution, and stir at 80°C for 2 hours under reflux to dissolve completely. Then add 0.04, 0.16, 0.4, 0.8 grams of attapulgite into four identical polymer solutions, ultrasonicate for 30 minutes, and then stand for 12 hours to defoam to prepare the casting solution. Apply the four parts of casting solution on four polytetrafluoroethylene boards by scraping, and control the air humidity to 5%; then put it into a vacuum drying oven, vacuumize at 20°C for 12h, and then raise the temperature Dry at 50°C for 48 hours, continue to heat up to 80°C and dry for 48 hours, further remove residual solvent, and finally peel off from the polytetrafluoroethylene plate to obtain a polyether-b-polyamide film with a thickness of 60 μm. Under the conditions of 30°C and 0.4MPa, the CO of the membrane was tested by a gas permeation device 2 , N 2 、CH 4 Permeability, membrane performance data are shown...

Embodiment 3

[0046] Add 8 grams of PEBAX-1657 particles into 92 grams of organic solvents (n-butanol, acetic acid and ethanol, respectively), and stir at 80°C for 2 hours under reflux to dissolve completely. Then, 0.4 g of attapulgite was added to the above polymer solution, and the casting solution was obtained by ultrasonication for 60 min. Then stand still for 12 hours for degassing, apply the casting solution on the polytetrafluoroethylene board by scraping, and control the air humidity to 5%; then put it in a vacuum drying oven, vacuumize for 48 hours at 15°C, Then the temperature was raised to 50°C for 12 hours, and then the temperature was raised to 80°C for 48 hours to further remove the residual solvent. Finally, the attapulgite / polyether-b-polyamide mixed matrix film was obtained after peeling off the polytetrafluoroethylene plate. The thickness of the film was 30 μm. It has been determined that, under the conditions of 60°C and 0.4MPa, the CO of the membrane is tested by a gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com