Method for realizing on-line production and separation of butanol, acetone and ethanol through adsorbent in-situ adsorption, fermentation, coupling and pervaporation

A technology of pervaporation and adsorbent, which is applied in the biological field to achieve the effects of low fermentation efficiency, improved fermentation efficiency and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Preparation of the pervaporation membrane of the present invention: ZSM-5 is first dried at 80° C. for 24 hours. The gel-forming agent base liquid and curing agent in polydimethylsiloxane (PDMS) are mixed at a ratio of 10:1. Mix the ZSM-5 in the specified weight ratio with the PDMS membrane-making solution mixed at a mass ratio of 10:1, and centrifuge at 8000 rpm for 5 minutes for subsequent operations. The follow-up operation is to ultrasonically treat the film-forming solution for 15 minutes to remove the air bubbles in the film-forming solution, then use a scraper to spread the film-forming solution evenly on the glass plate, and put the glass plate with the film-forming solution in an oven at 100°C 3h film formation. Finally, take out the glass plate from the oven, peel off the prepared pervaporation membrane, and fix it in the membrane pool for pervaporation separation operation. The amount of ZSM-5 added is usually 10-100% of the mass of PDMS, preferably 80%.

...

Embodiment 1

[0051] A method for on-line separation and purification of butanol in fermentation broth by using adsorbent adsorption fermentation coupled with pervaporation;

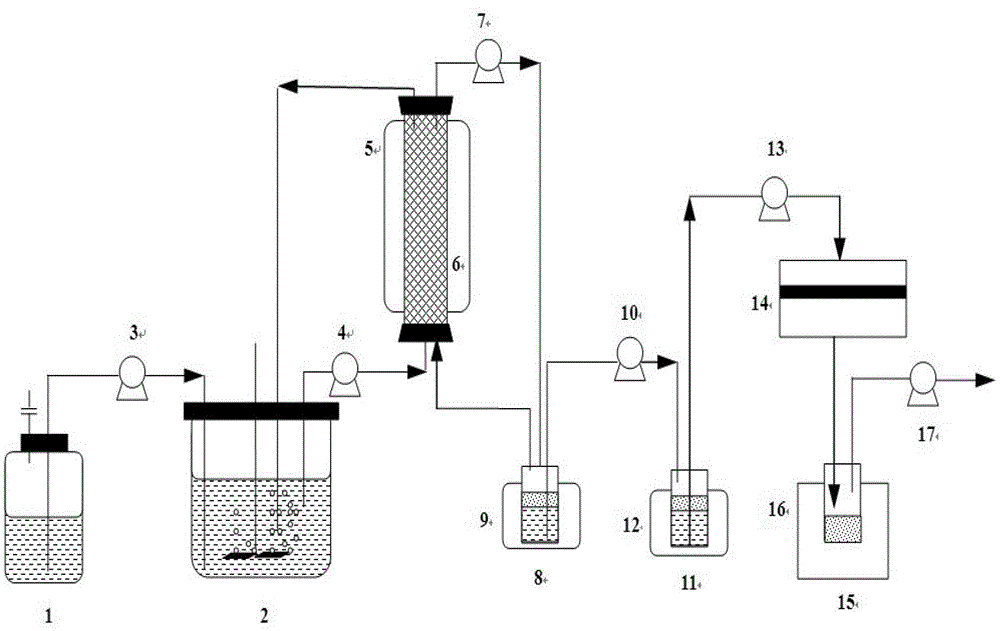

[0052] ① if figure 1 As shown, the seed medium was first passed nitrogen in the seed tank for 10 minutes to deoxygenate, then sterilized at 121°C for 30 minutes, cooled to room temperature, inserted into the acetone butanol ethanol production bacteria, and the production bacteria were cultivated to the most active logarithm of growth growth period. The cultivation time until the logarithmic growth phase is 12-18 hours, preferably 15 hours; the cultivation temperature is 30-40°C, preferably 37°C. After the seed culture is completed, it is ready to be inserted into the fermenter.

[0053] ② if figure 1 As shown, first sterilize the fermentation medium at 121°C for 30 minutes, then pass nitrogen gas for 2 hours to remove oxygen, cool to room temperature, turn on the pump I to transfer the seed liquid containing aceton...

Embodiment 2

[0059] A method for on-line separation and purification of butanol in fermentation broth by using adsorbent adsorption fermentation coupled with pervaporation;

[0060] The difference with embodiment 1 is:

[0061] When the fermentation starts, the pump II is not started. When the fermentation progresses to the logarithmic growth phase of the production bacteria, the pump II is started to make the fermentation liquid circulate between the fermenter and the adsorption device, and start the online in-situ adsorption. The fermentation method is feed-fed fermentation. When the glucose concentration in the fermentation broth drops below 10g / L, glucose is added to continue to provide carbon sources for the fermentation until the fermentation is terminated.

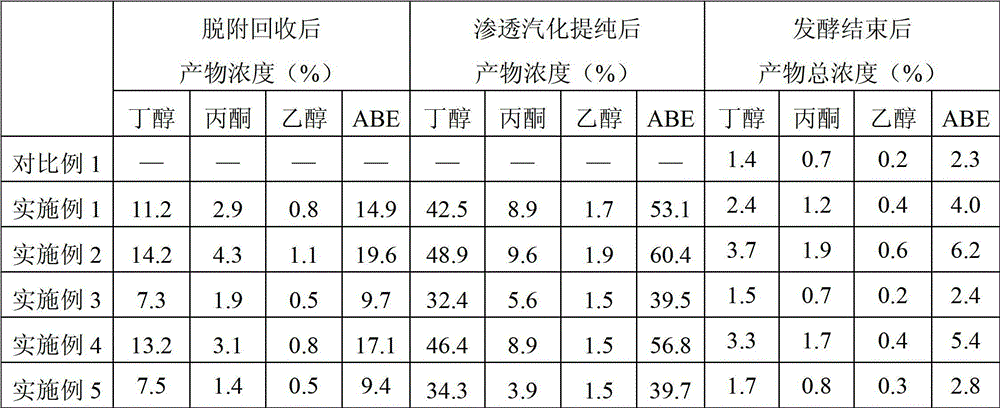

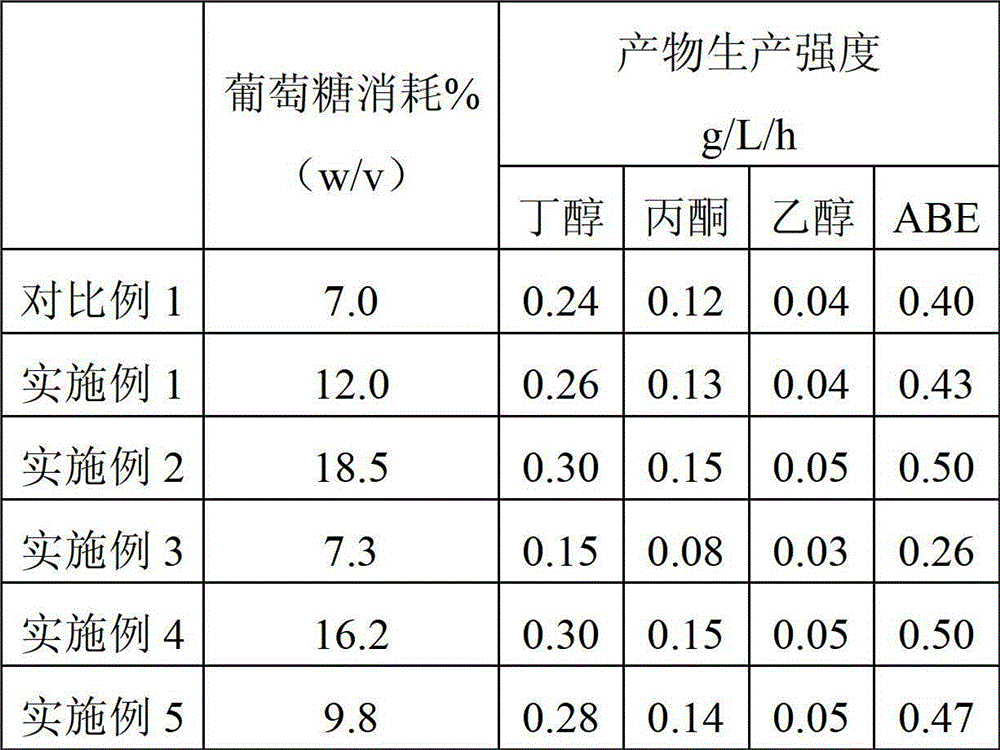

[0062] The experimental data are shown in Table 1 and Table 2.

[0063] Summary: After the fermentation, the concentrations of butanol and ABE total solvent were 3.7% (w / v) and 6.2% (w / v), respectively, which were 264.3% and 26...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com