Patents

Literature

1426 results about "Pervaporation membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

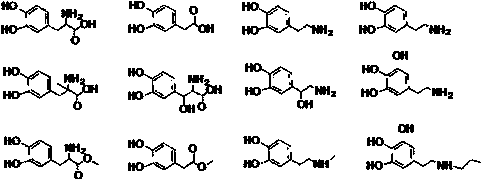

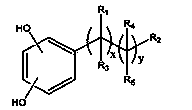

Preparation method and application of anti-pollution hydrophilic separating membrane

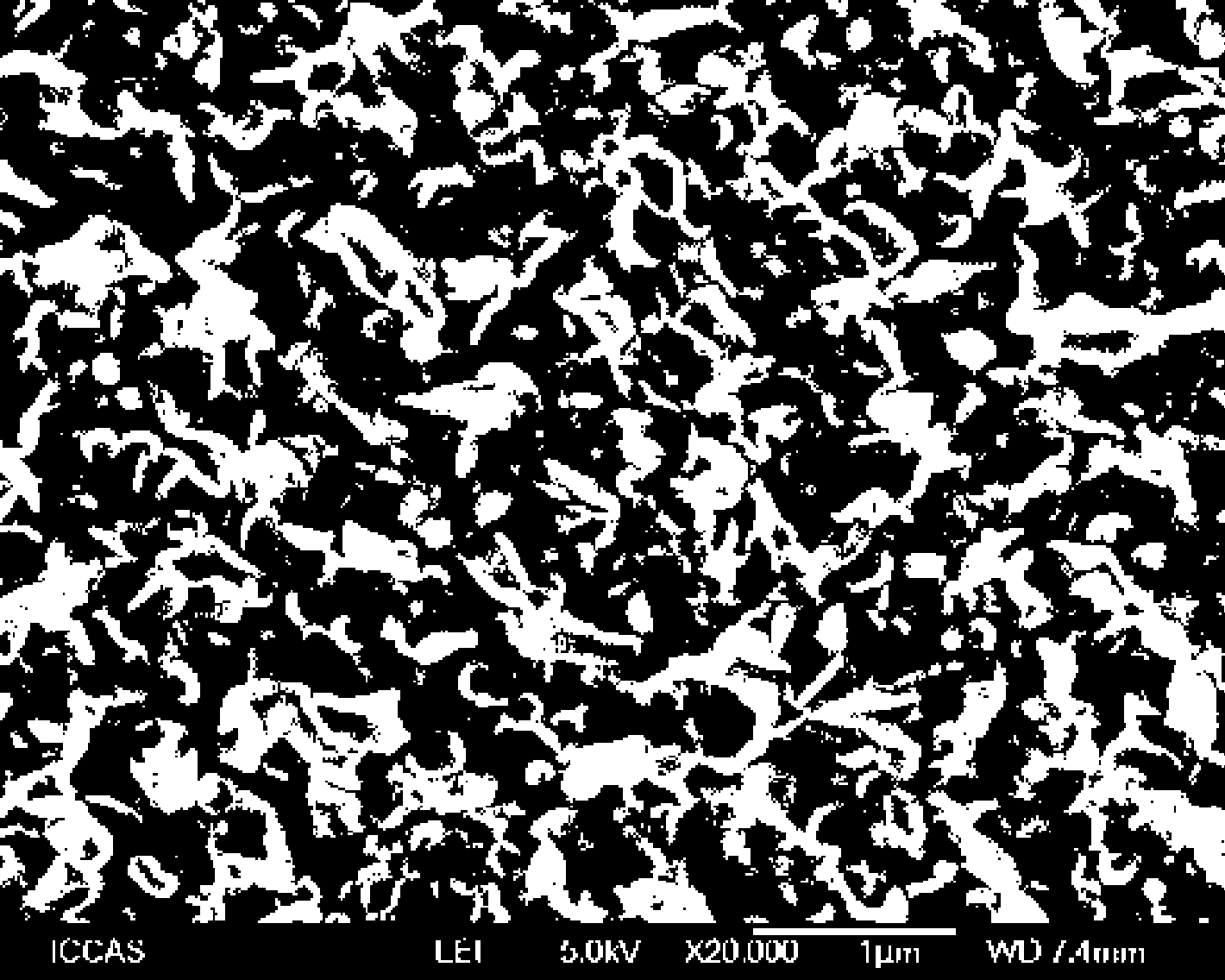

ActiveCN103480278AReduce dosageMeet the needs of hydrophilic immobilizationSemi-permeable membranesMembrane permeabilizationMicrofiltration membrane

The invention discloses a preparation method and an application of an anti-pollution hydrophilic separating membrane. The preparation method is characterized in that a pyrocatechol derivative is used as an accelerant and a curing agent between a separating membrane material and a hydrophilic material, when blending casting film liquid of the separating membrane is prepared, the pyrocatechol derivative is added to blending liquid of the separating membrane material and the hydrophilic material, and the pyrocatechol derivative is subjected to polymerization cross-linking in a phase conversion process of the membrane preparation, so that the effect of fixing the hydrophilic material is achieved. The preparation method of the anti-pollution hydrophilic separating membrane has strong universality and is suitable for the blending of multiple hydrophilic materials and multiple membrane materials. The preparation method is simple, easy to operate, mild in conditions, economic, high-efficiency, environmentally-friendly, easy for industrialization and suitable for the preparation of multi-functional hydrophilic micro-filtration membranes, ultra-filtration membranes, nano-filtration membranes, reverse-osmosis membranes, positive-osmosis membranes, pressure-delay osmosis membranes, pervaporation membranes and the like which are used for liquid and gas separation and membrane reactors.

Owner:YANTAI LVSHUIFU MEMBRANE MATERIAL

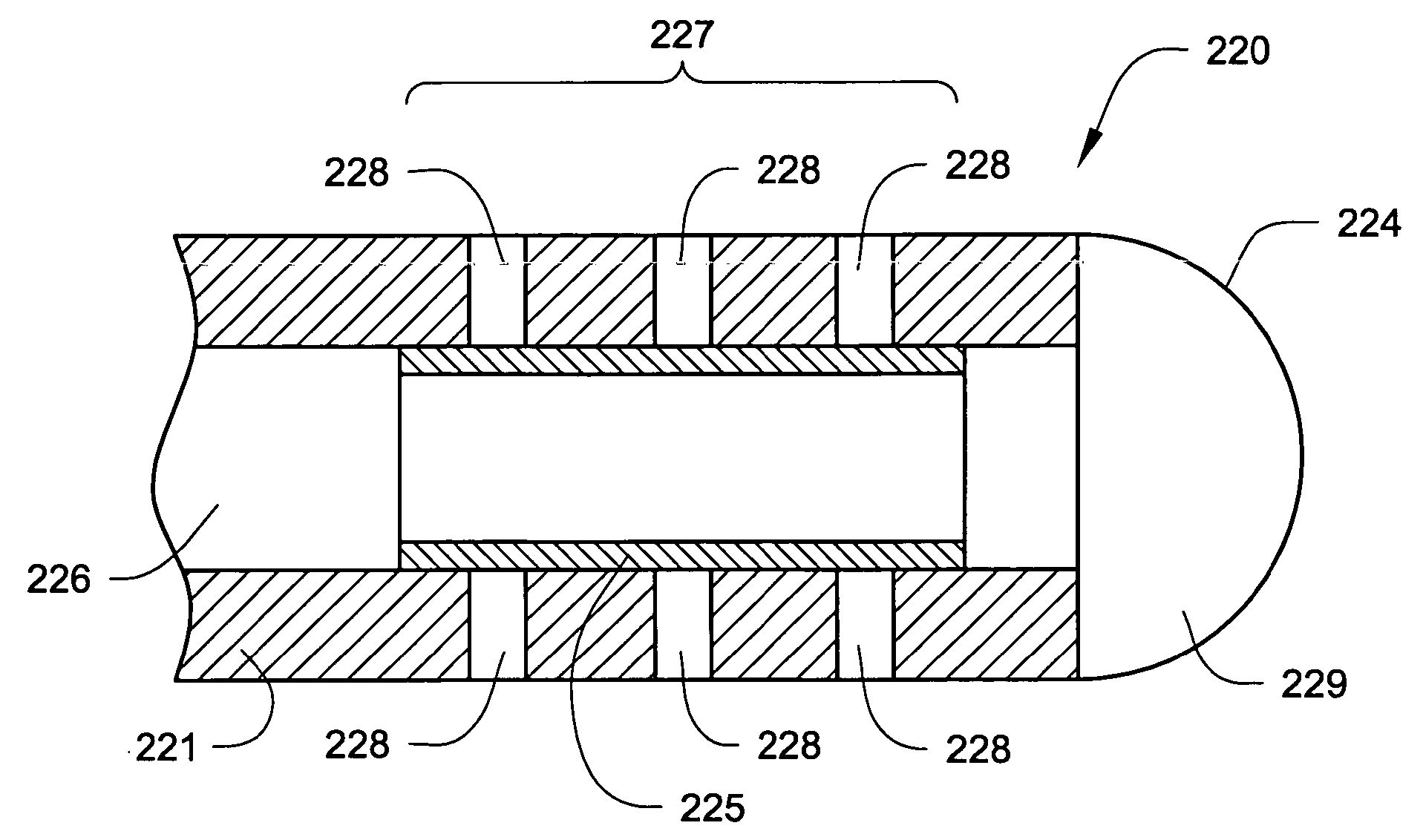

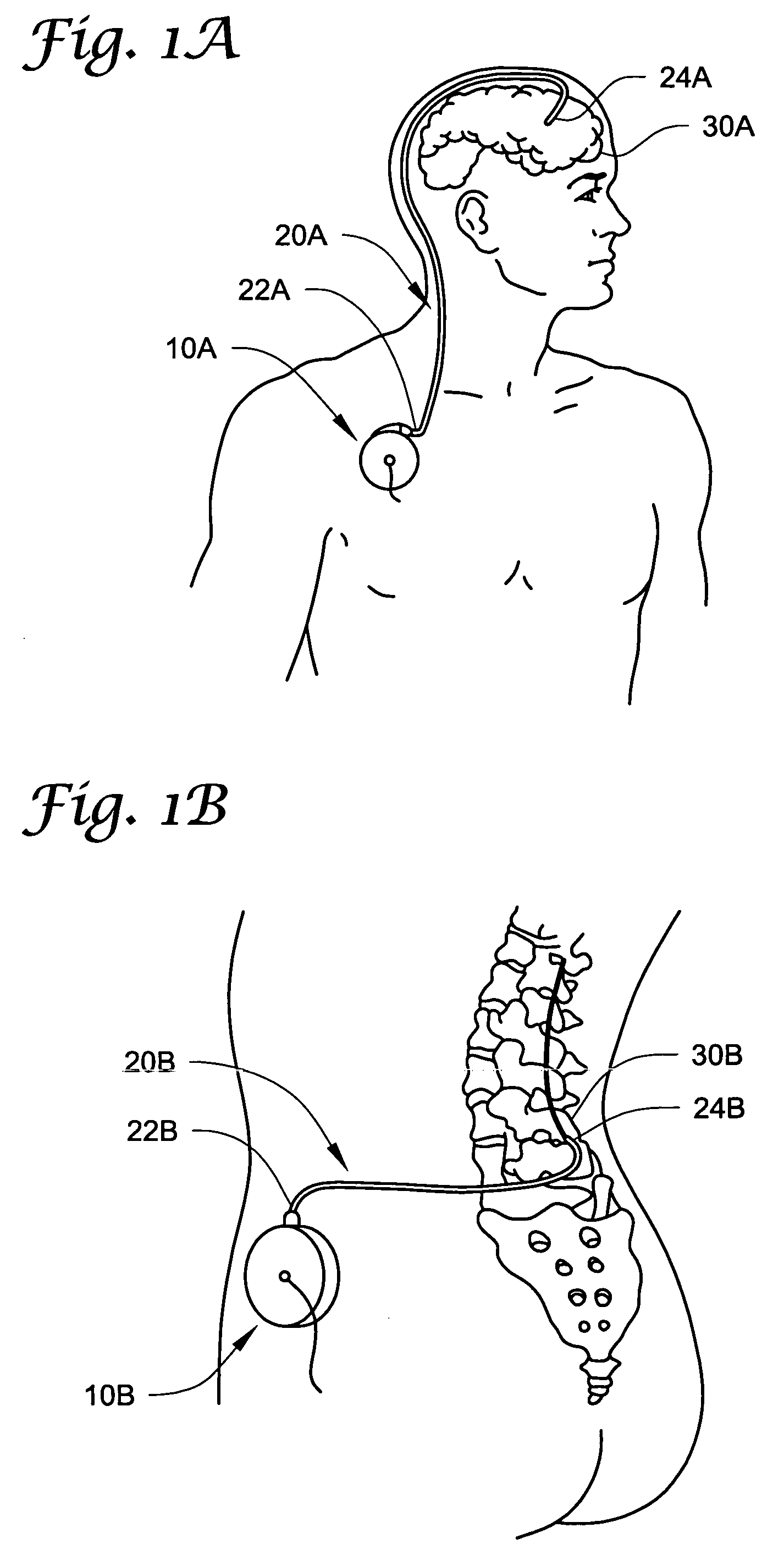

Permeable membrane catheters, systems, and methods

InactiveUS20050137579A1Improve efficacyReduce the amount requiredMulti-lumen catheterMedical devicesBiomedical engineeringMembrane configuration

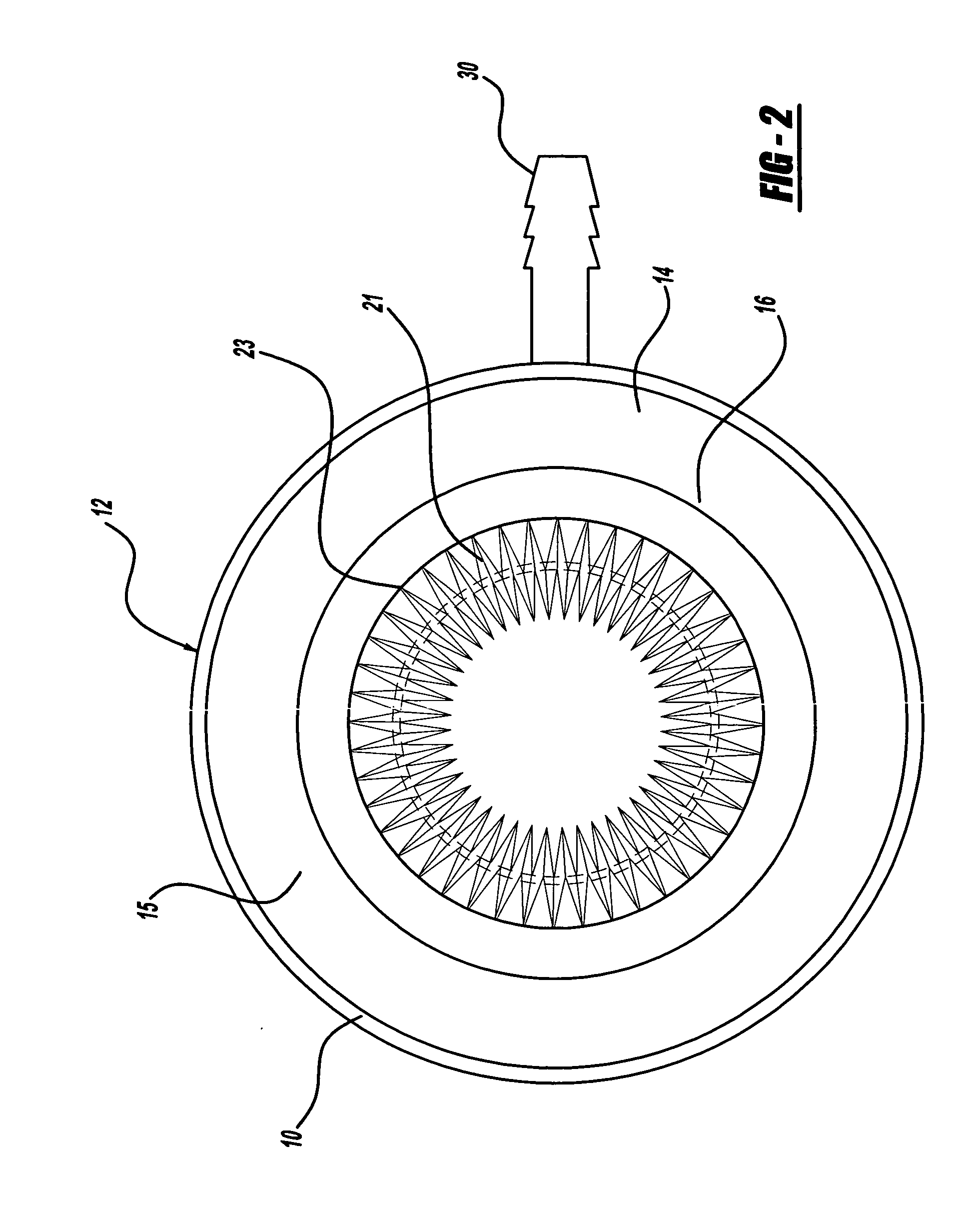

Devices, systems and methods for delivering one or more drugs to one or more internal body locations (such as the cerebrospinal fluid) are disclosed. In various aspects, the systems and methods may involve catheters having infusion sections with permeable membranes and one or more valves that control flow to the infusion sections.

Owner:MEDTRONIC INC

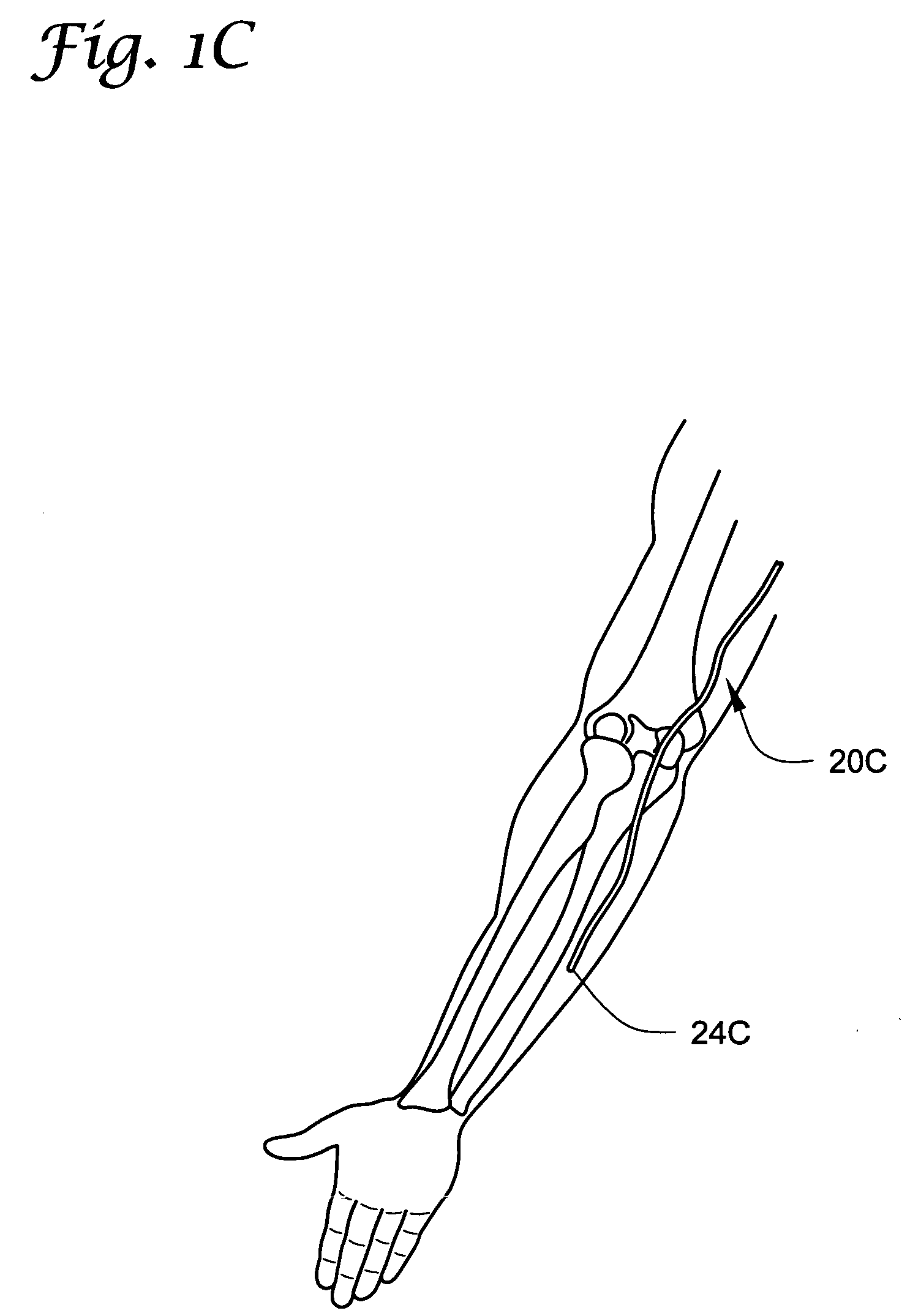

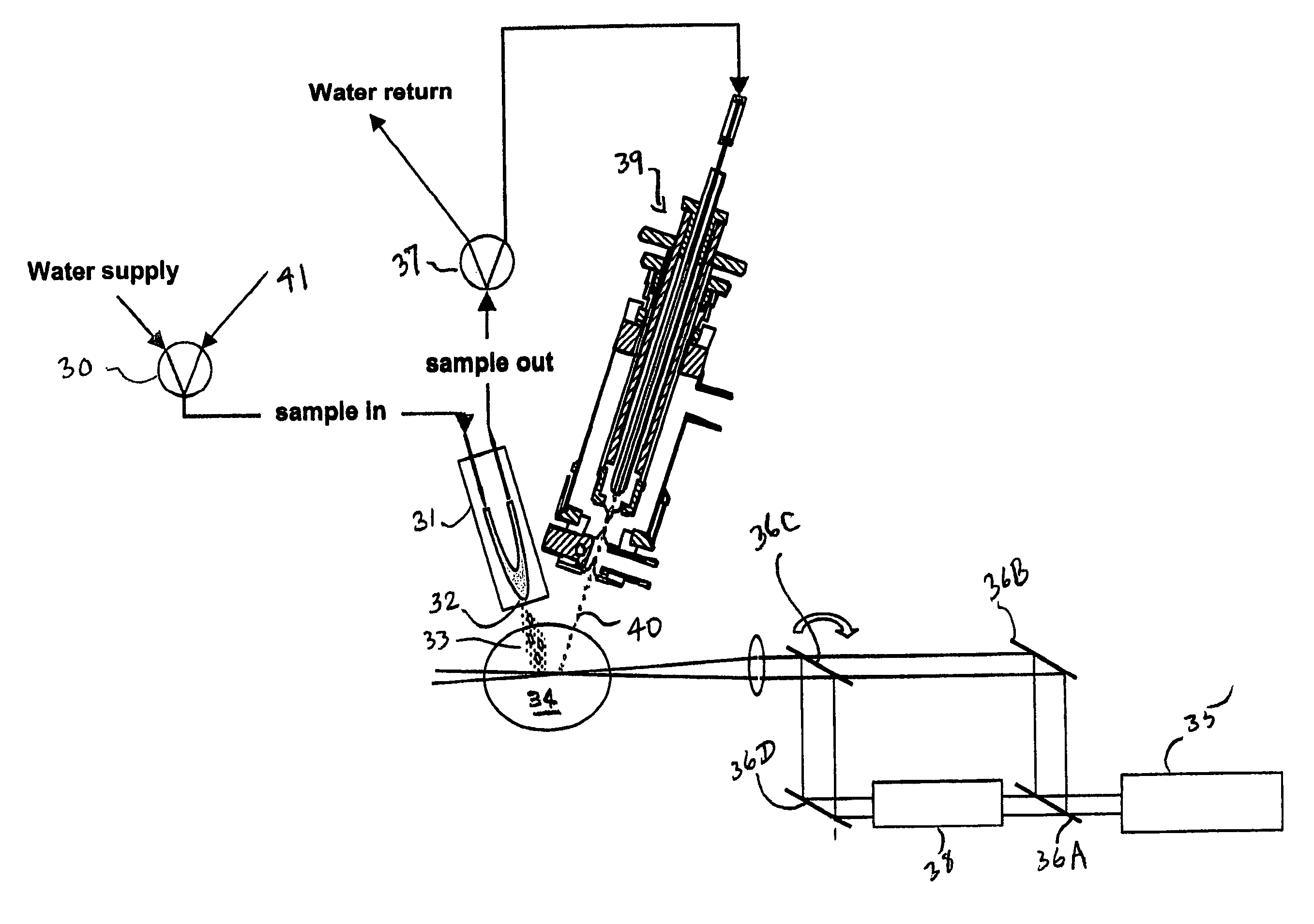

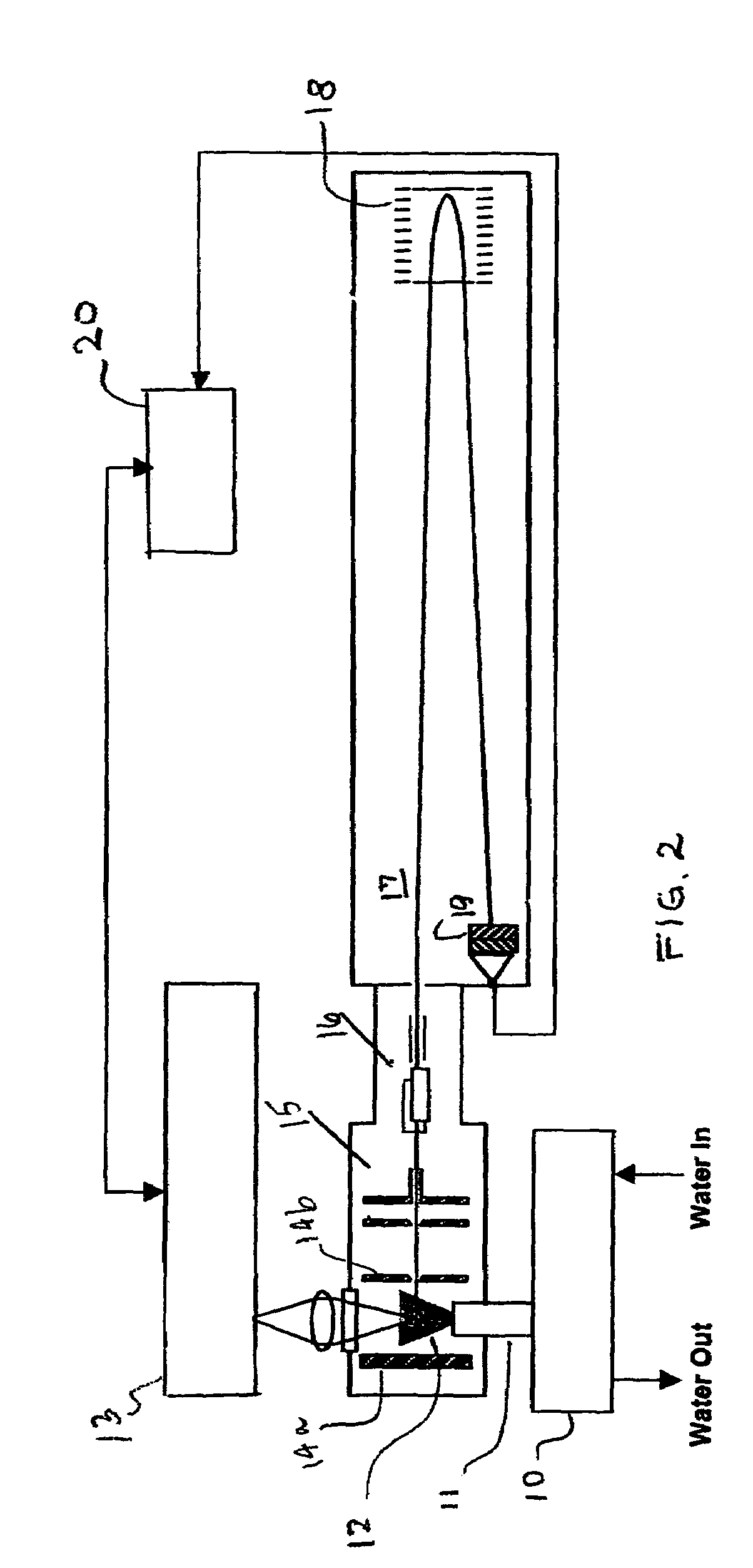

Method and apparatus for the detection and identification of trace organic substances from a continuous flow sample system using laser photoionization-mass spectrometry

InactiveUS7161145B2Time-of-flight spectrometersMaterial analysis by optical meansTime-of-flight mass spectrometryAnalyte

A method and apparatus are provided for identifying analytes at low concentrations in a liquid sample. The liquid sample is introduced through a continuous flow membrane inlet system. The analytes that permeate the membrane are analyzed by photoionization-time-of-flight mass spectrometry. The analytes remaining in the liquid sample that do not permeate the membrane are conducted to a capillary tube inlet that introduces the liquid sample and other analytes as droplets into the photoionization zone. Any analytes remaining absorbed or adsorbed on the membrane are driven through the membrane by application of heat. Analytes may be analyzed by either resonance enhanced multiphoton ionization (REMPI) or single photon ionization (SPI), both of which are provided in the apparatus and can be selected as alternative sources.

Owner:YASUMI CAPITAL

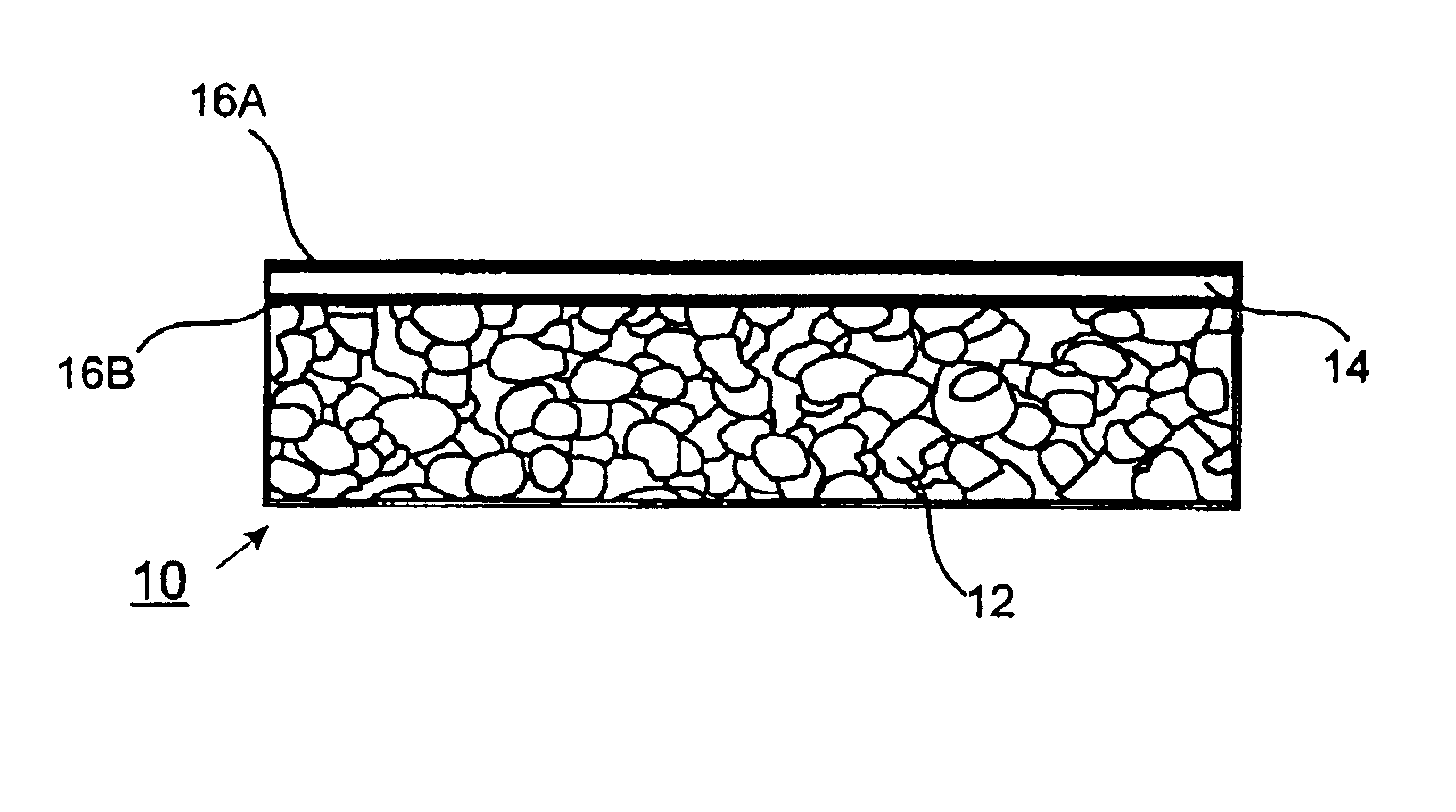

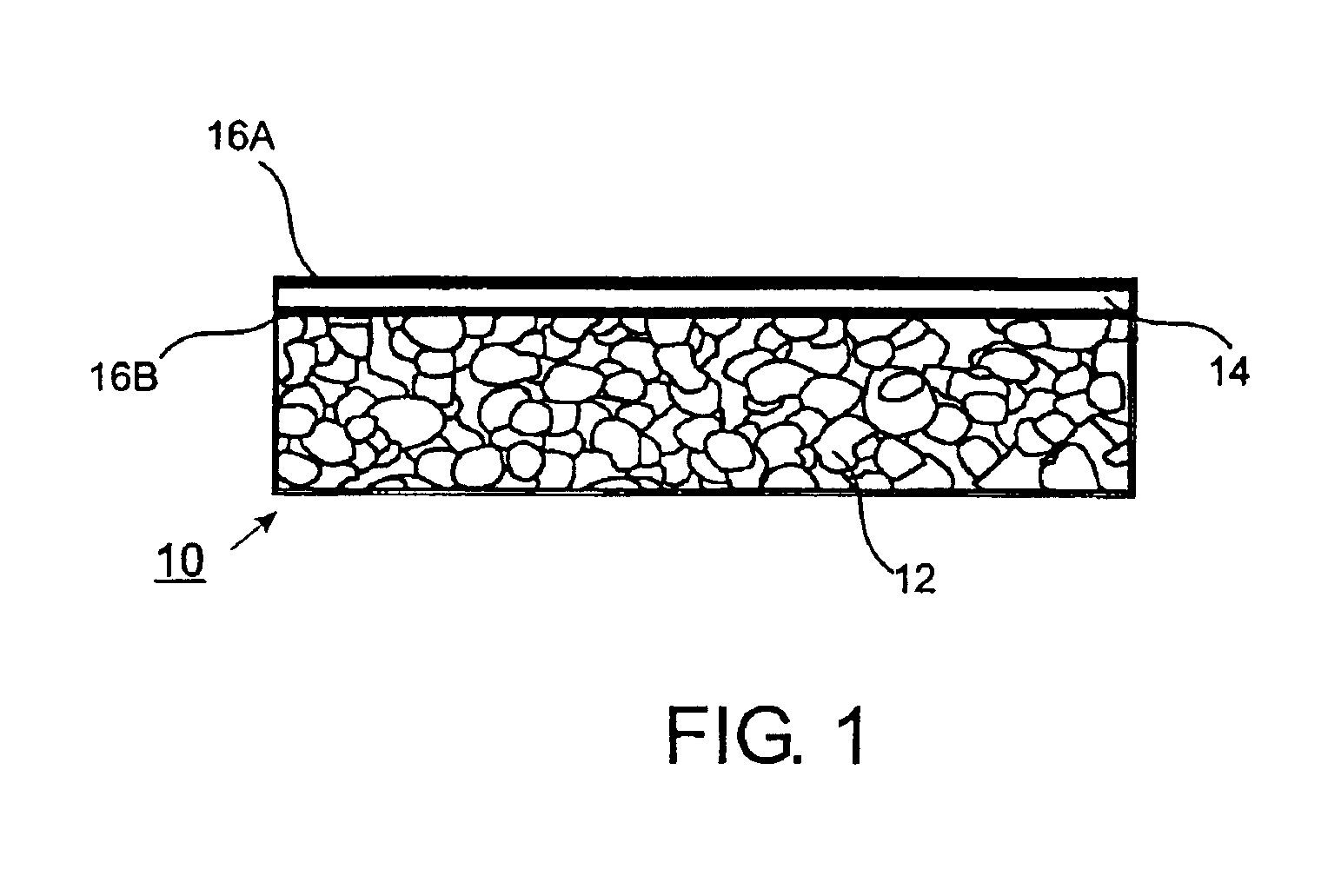

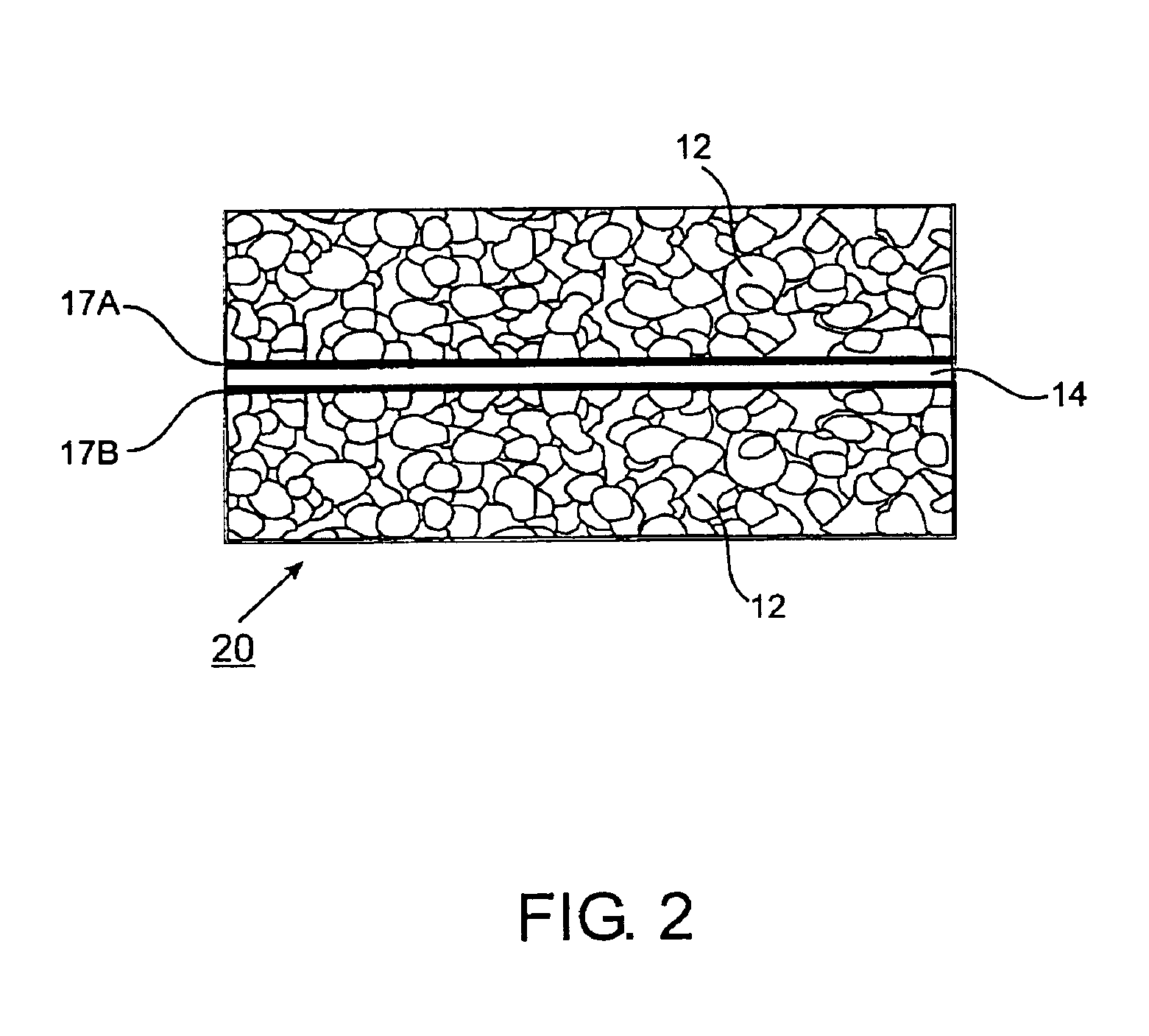

Hydrogen transport membranes

InactiveUS6899744B2Increase ratingsThickness minimizationSemi-permeable membranesMembranesSupport matrixNiobium

Composite hydrogen transport membranes, which are used for extraction of hydrogen from gas mixtures are provided. Methods are described for supporting metals and metal alloys which have high hydrogen permeability, but which are either too thin to be self supporting, too weak to resist differential pressures across the membrane, or which become embrittled by hydrogen. Support materials are chosen to be lattice matched to the metals and metal alloys. Preferred metals with high permeability for hydrogen include vanadium, niobium, tantalum, zirconium, palladium, and alloys thereof. Hydrogen-permeable membranes include those in which the pores of a porous support matrix are blocked by hydrogen-permeable metals and metal alloys, those in which the pores of a porous metal matrix are blocked with materials which make the membrane impervious to gases other than hydrogen, and cermets fabricated by sintering powders of metals with powders of lattice-matched ceramic.

Owner:ELTRON RES

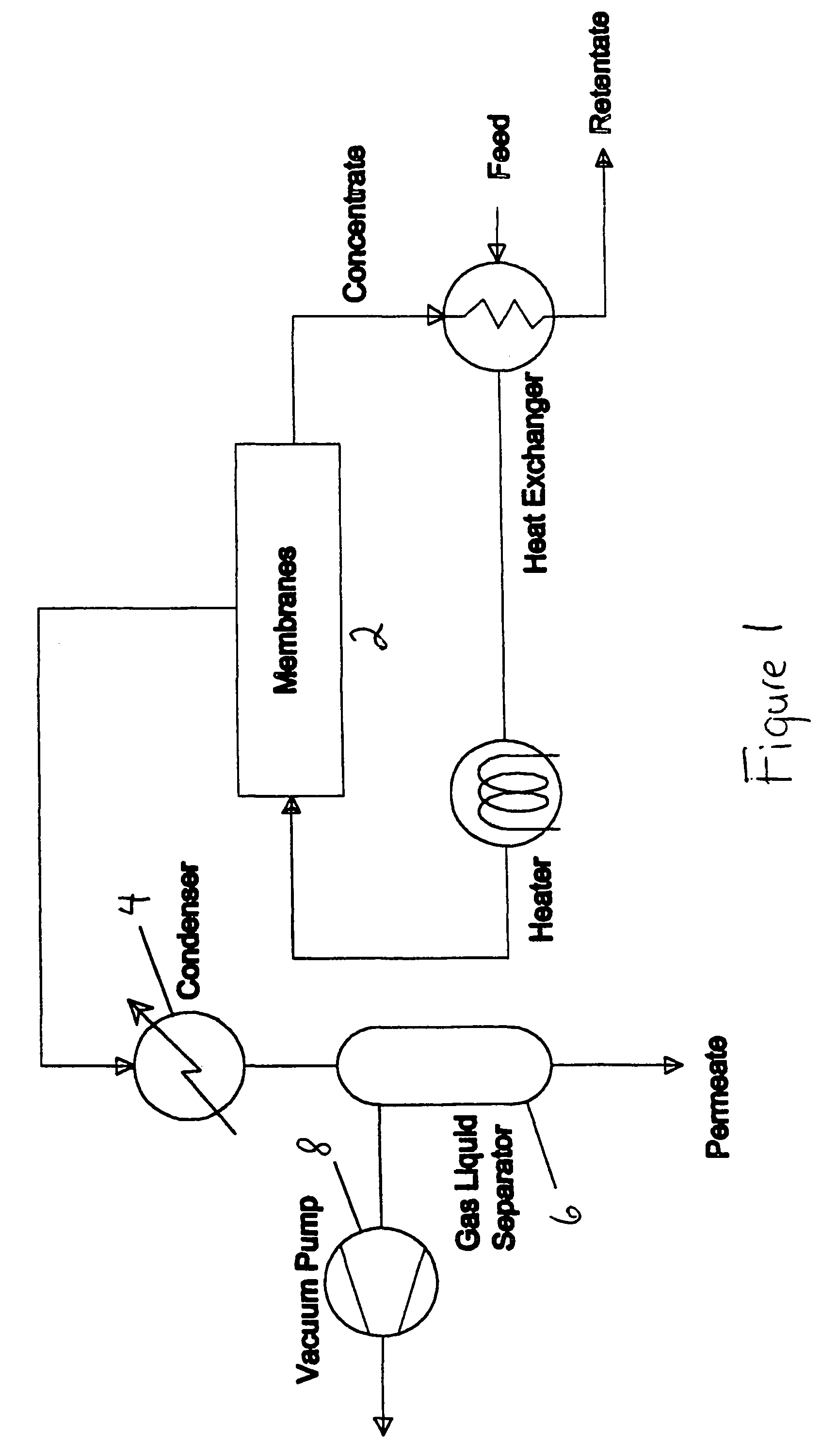

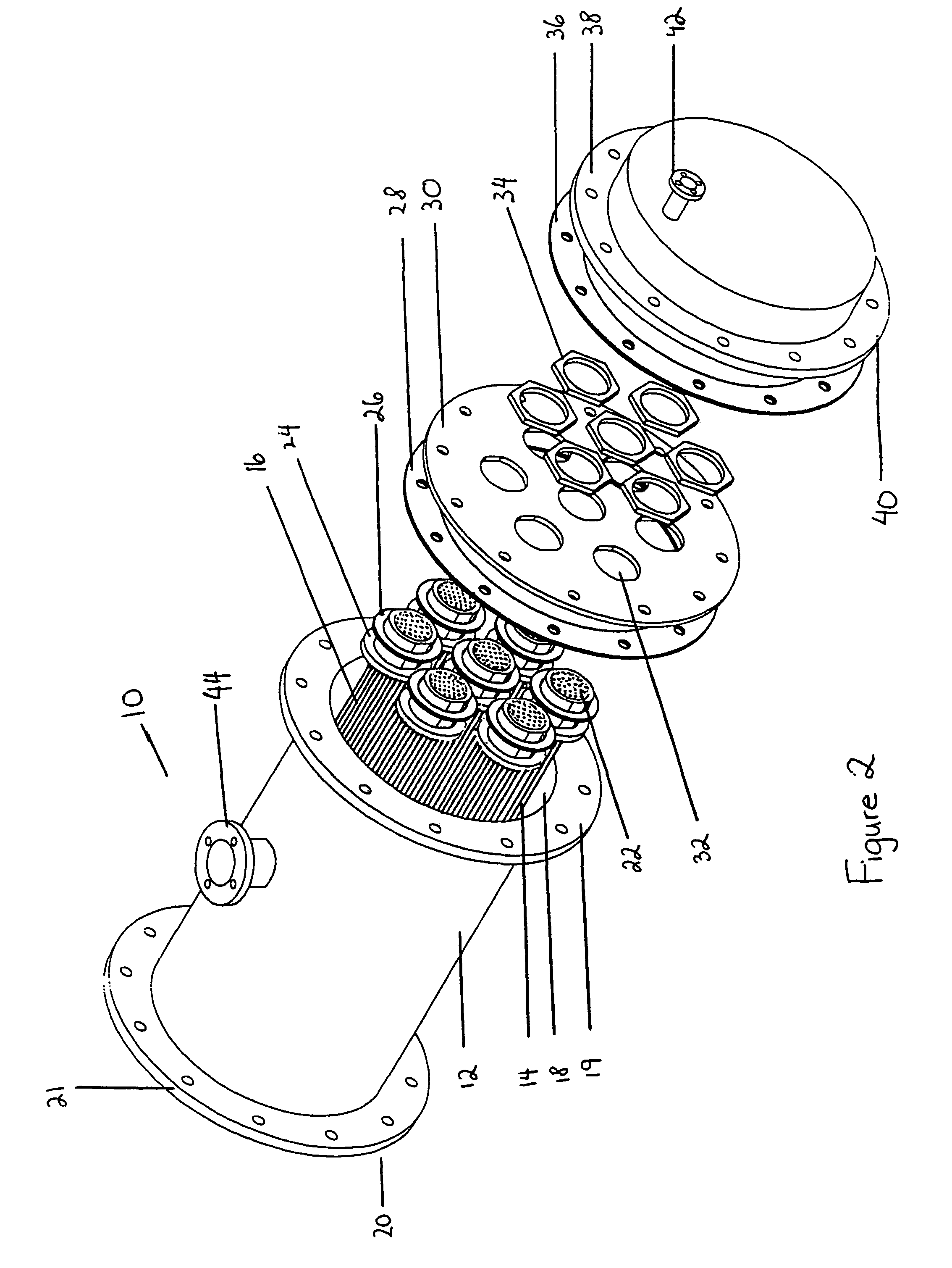

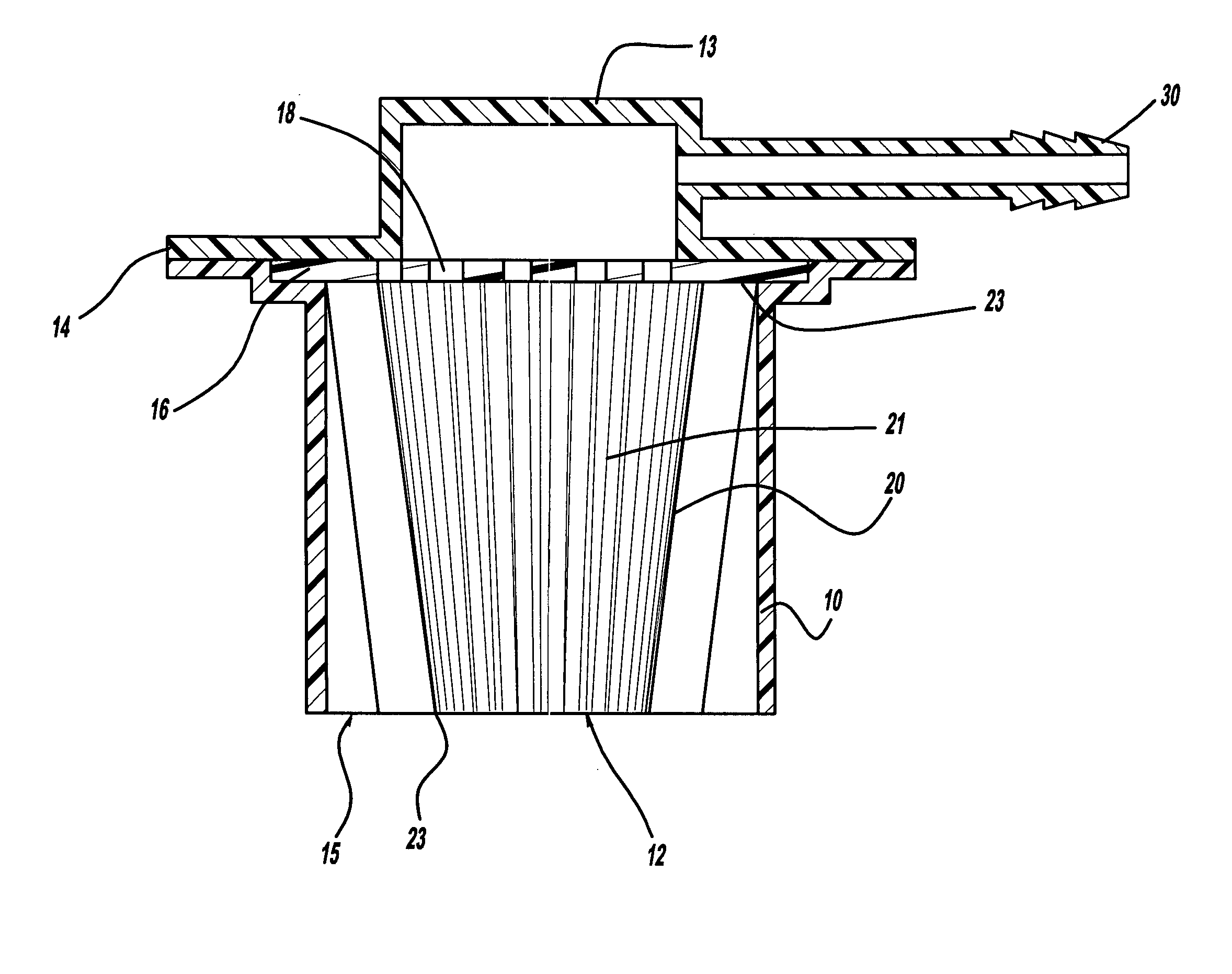

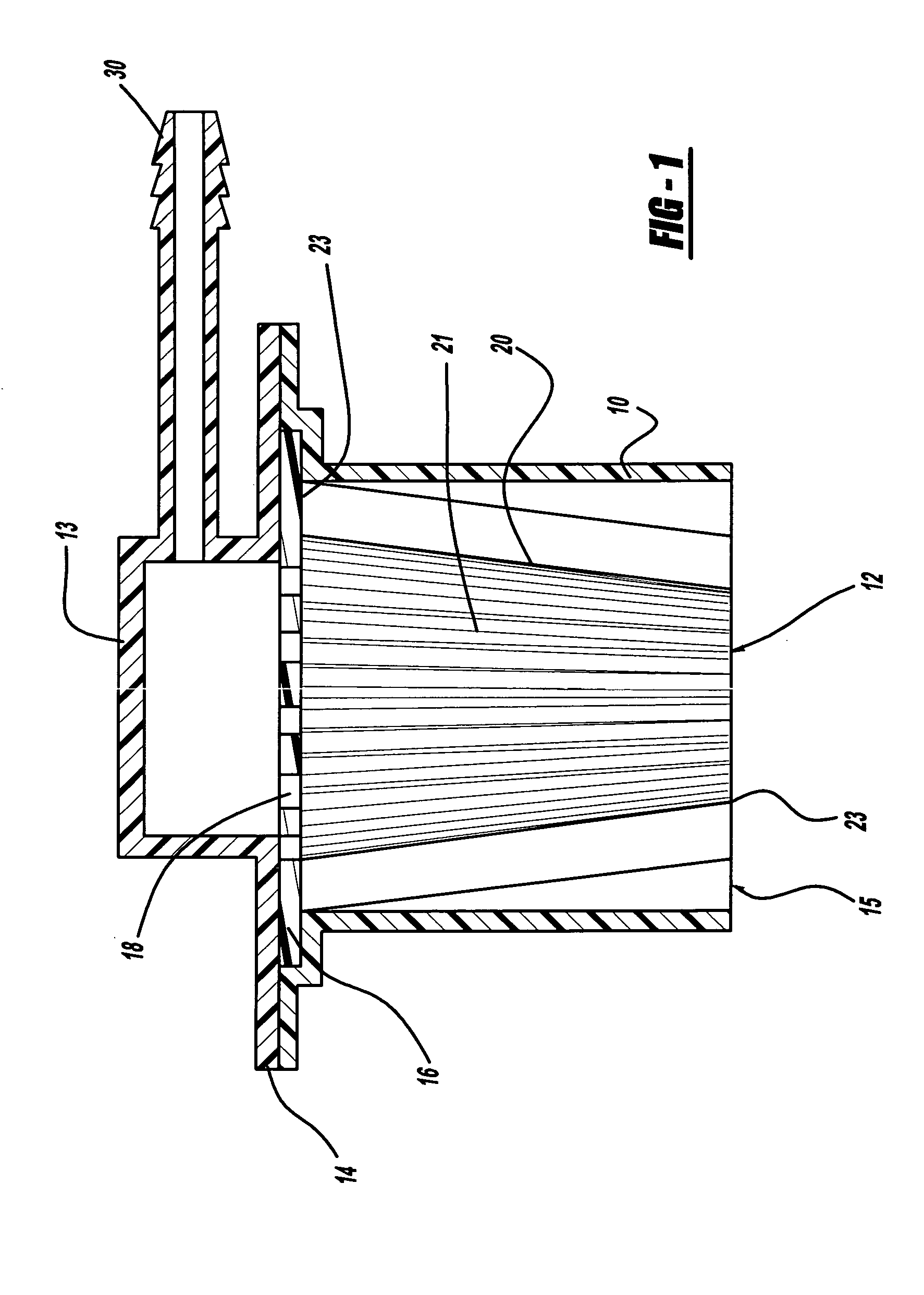

Membrane-assisted fluid separation apparatus and method

InactiveUS7459084B2Easy to disassembleReduce complexityMembranesGeneral water supply conservationFiberHigh concentration

This present invention relates to a fluid separation module adapted to separate a given fluid mixture into permeate and retentate portions using bundles of hollow fiber membranes. The membranes may be composed of different kinds of membranes depending on the application being used to separate the fluid mixture. The fluid separation module may be used to separate fluid mixtures by a number of different processes, including but not limited to, pervaporation, vapour permeation, membrane distillation (both vacuum membrane distillation and direct contact membrane distillation), ultra filtration, microfiltration, nanofiltration, reverse osmosis, membrane stripping and gas separation. The present invention also provides an internal heat recovery process applied in association with those fluid separation applications where separation takes place by evaporation through the membrane of a large portion of the feed into permeate. Desalination and contaminated water purification by means of vacuum membrane distillation are just two examples where the internal heat recovery process may be applied. In these two examples, large portions of the feed are separated by membranes into a high purity water permeate stream by evaporation through the membranes and into a retentate stream containing a higher concentration of dissolved components than present in the feed. In this process the permeate vapour that is extracted from the fluid separation module is compressed by an external compressor to increase the temperature of the vapour higher than the temperature of the feed entering the separation module. Heat from the permeate vapour at the elevated temperature is transferred back to the incoming feed fluid mixture entering the fluid separation module in a condenser / heat exchange.

Owner:LOEB INVESTORS CO 166 LP +1

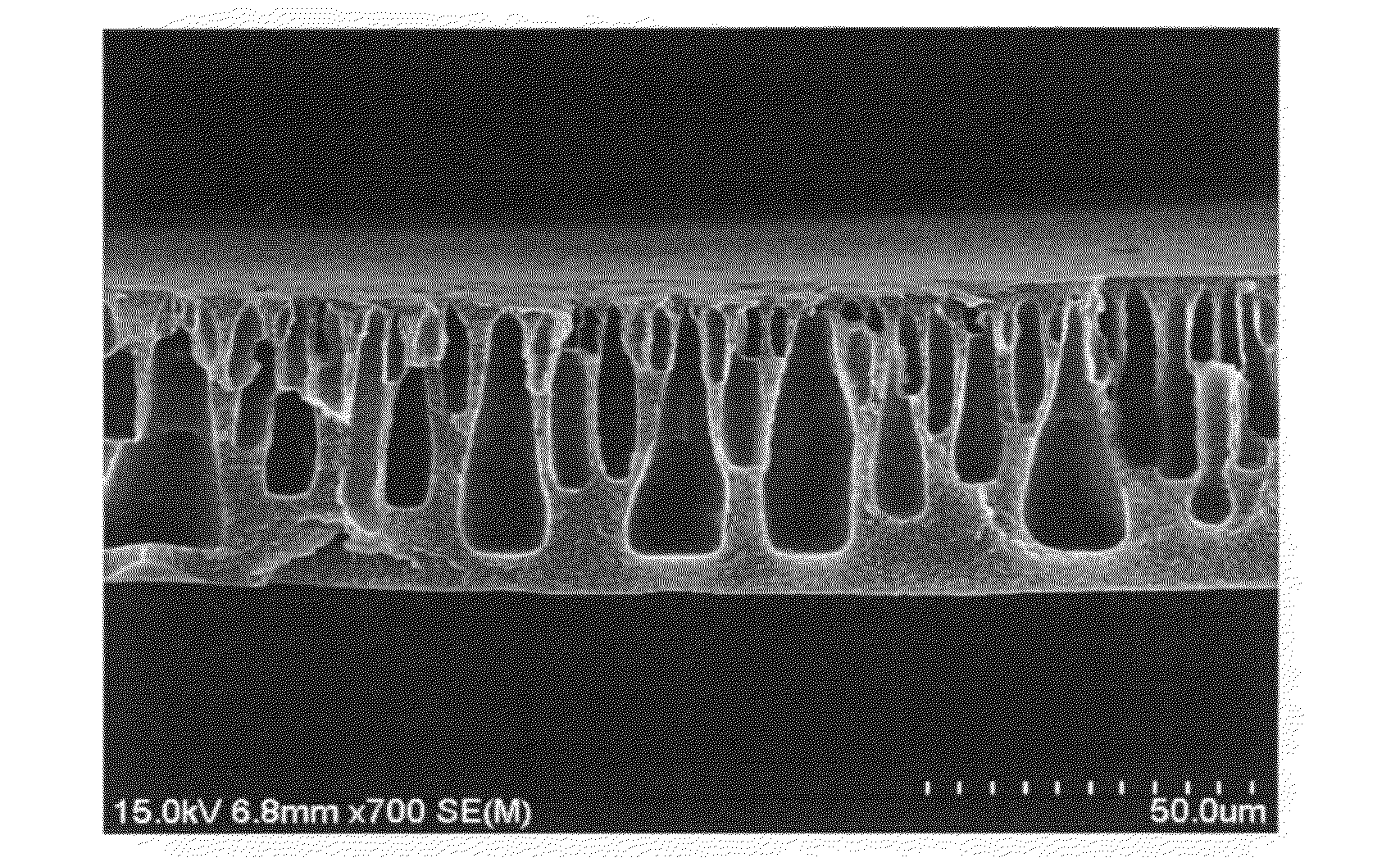

Forward osmosis membrane for seawater desalination and method for preparing the same

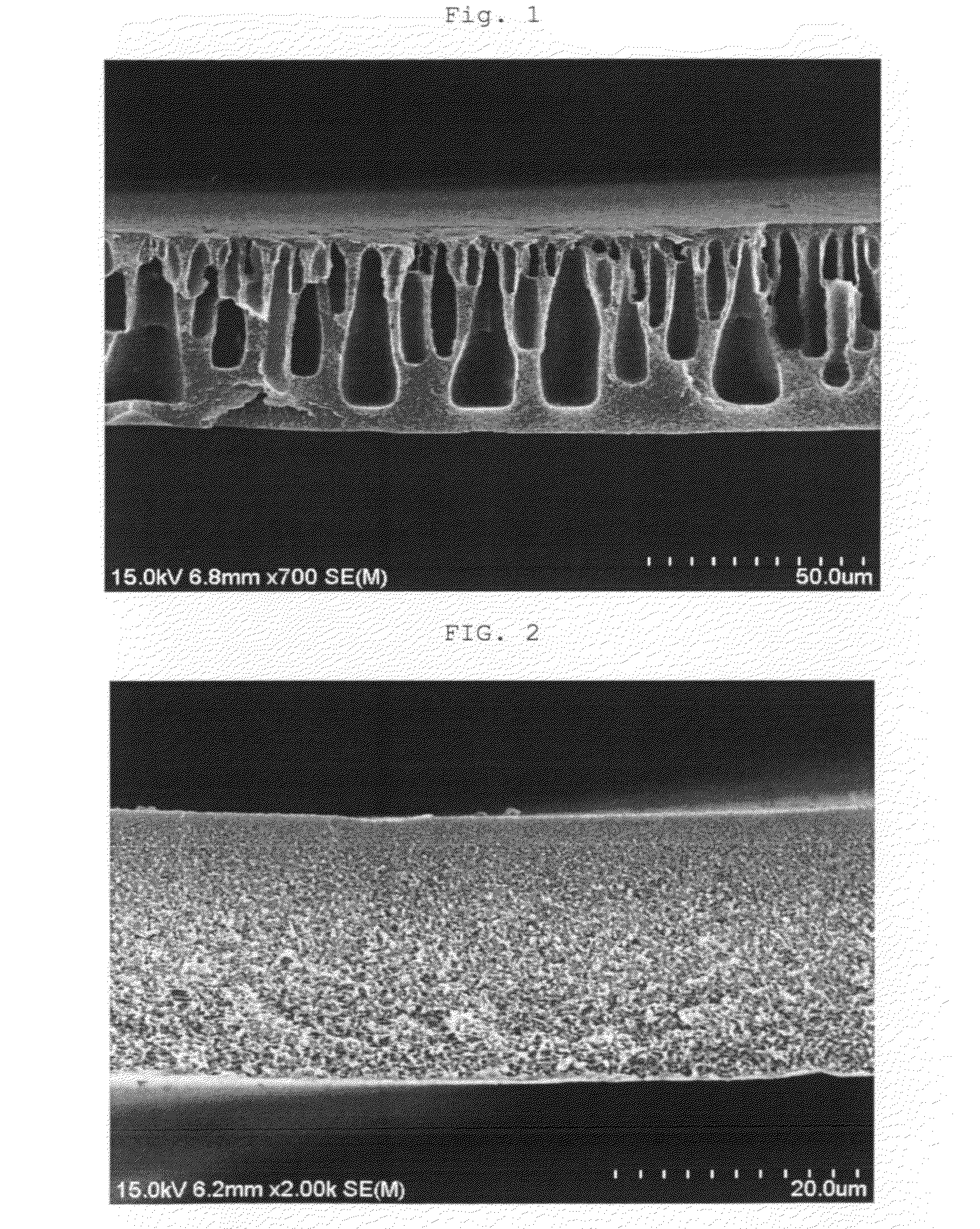

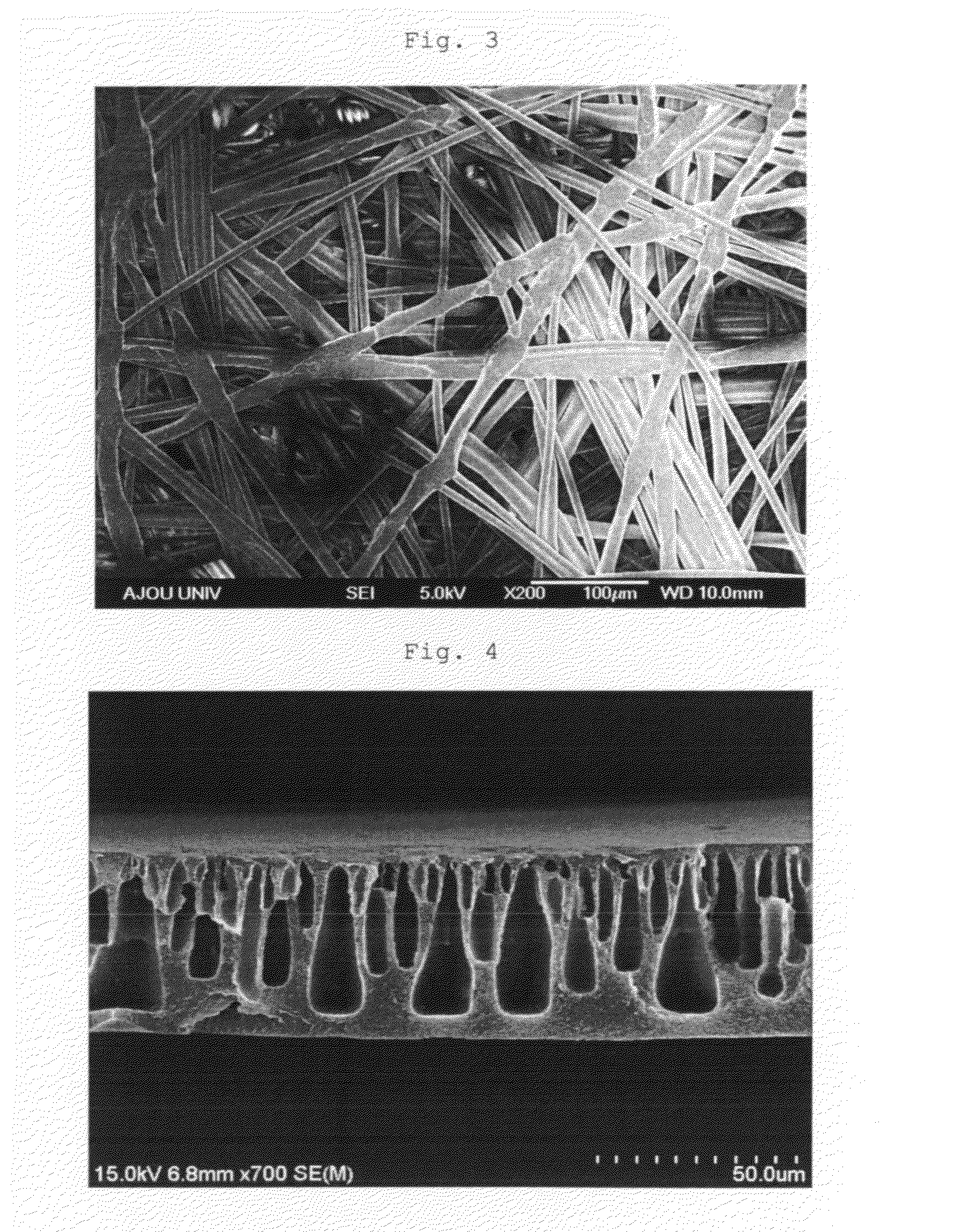

ActiveUS20120043274A1Good water permeabilityHigh porositySemi-permeable membranesMembranesHigh concentrationHydrophilic polymers

A forward osmosis membrane for seawater desalination and a method for preparing the same. The forward osmosis membrane has a composite membrane structure including a nonwoven fabric layer, a hydrophilic polymer layer, and a polyamide layer. The hydrophilic polymer layer formed on the nonwoven fabric layer facilitates an inflow of water from the feed water to the draw solution to enhance flux and realize high water permeability in the direction of osmosis. The polyamide layer not only secures contamination resistance and chemical resistance but also minimizes the back diffusion of salts of the draw solution in the direction of reverse osmosis. Hence, the forward osmosis membrane of the present invention is greatly useful for desalination of high-concentration seawater.

Owner:TORAY ADVANCED MATERIALS KOREA

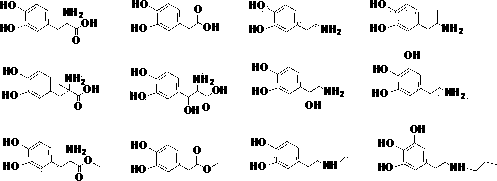

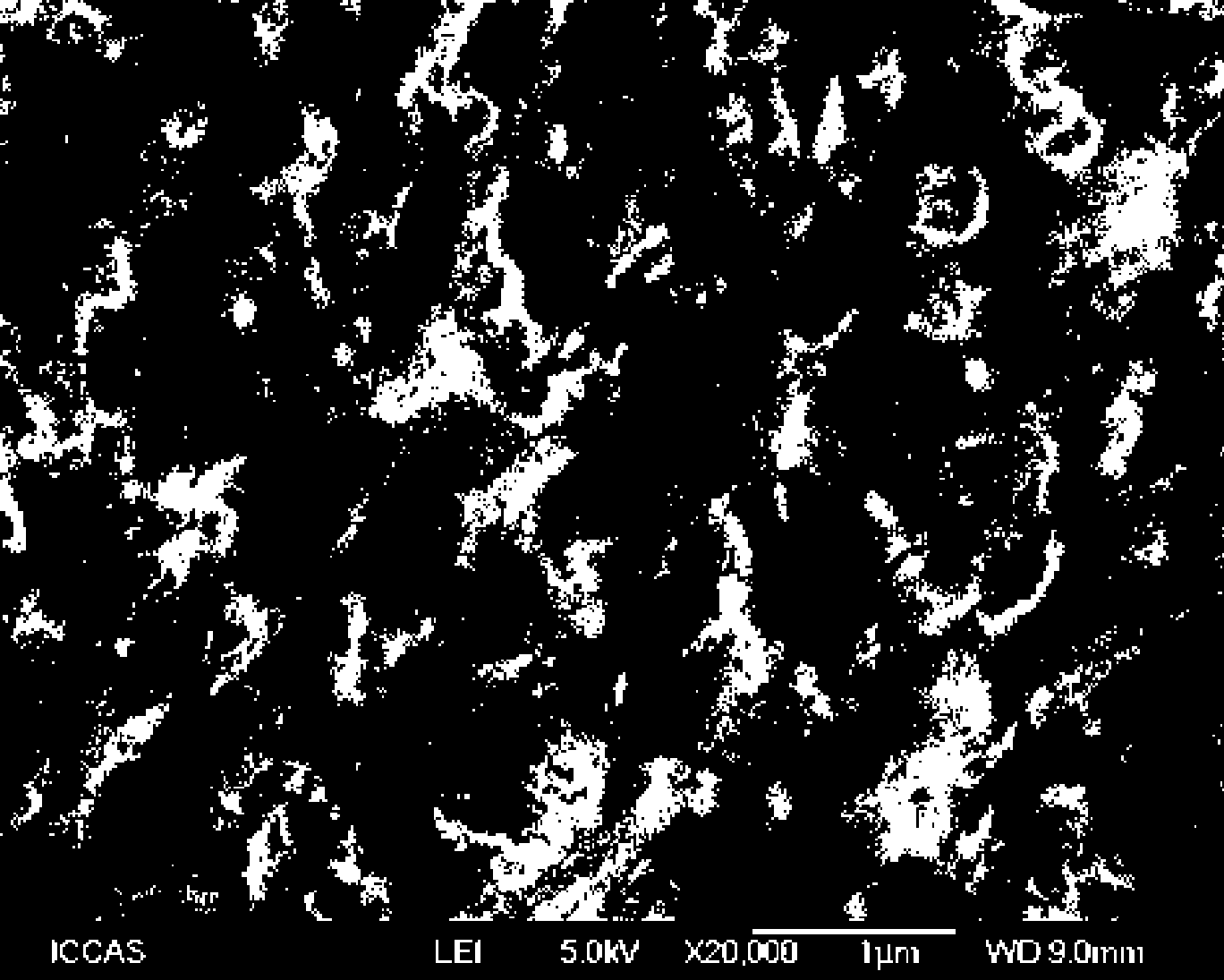

Selective membrane having a high fouling resistance

ActiveUS20070175821A1Improve antifouling performanceMembranesSemi-permeable membranesHydrophilic coatingChemical compound

A selective membrane having a high fouling resistance. In one embodiment, the selective membrane is a composite polyamide reverse osmosis membrane in which a hydrophilic coating is applied to the polyamide layer of the membrane, the hydrophilic coating being made by covalently bonding a hydrophilic compound to residual acid chlorides of the polyamide membrane, the hydrophilic compound including (i) at least one reactive group that is adapted to covalently bond directly to the polyamide membrane, the at least one reactive group being at least one of a primary amine and a secondary amine; and (ii) at least one non-terminal hydroxyl group.

Owner:TORAY ADVANCED MATERIALS KOREA

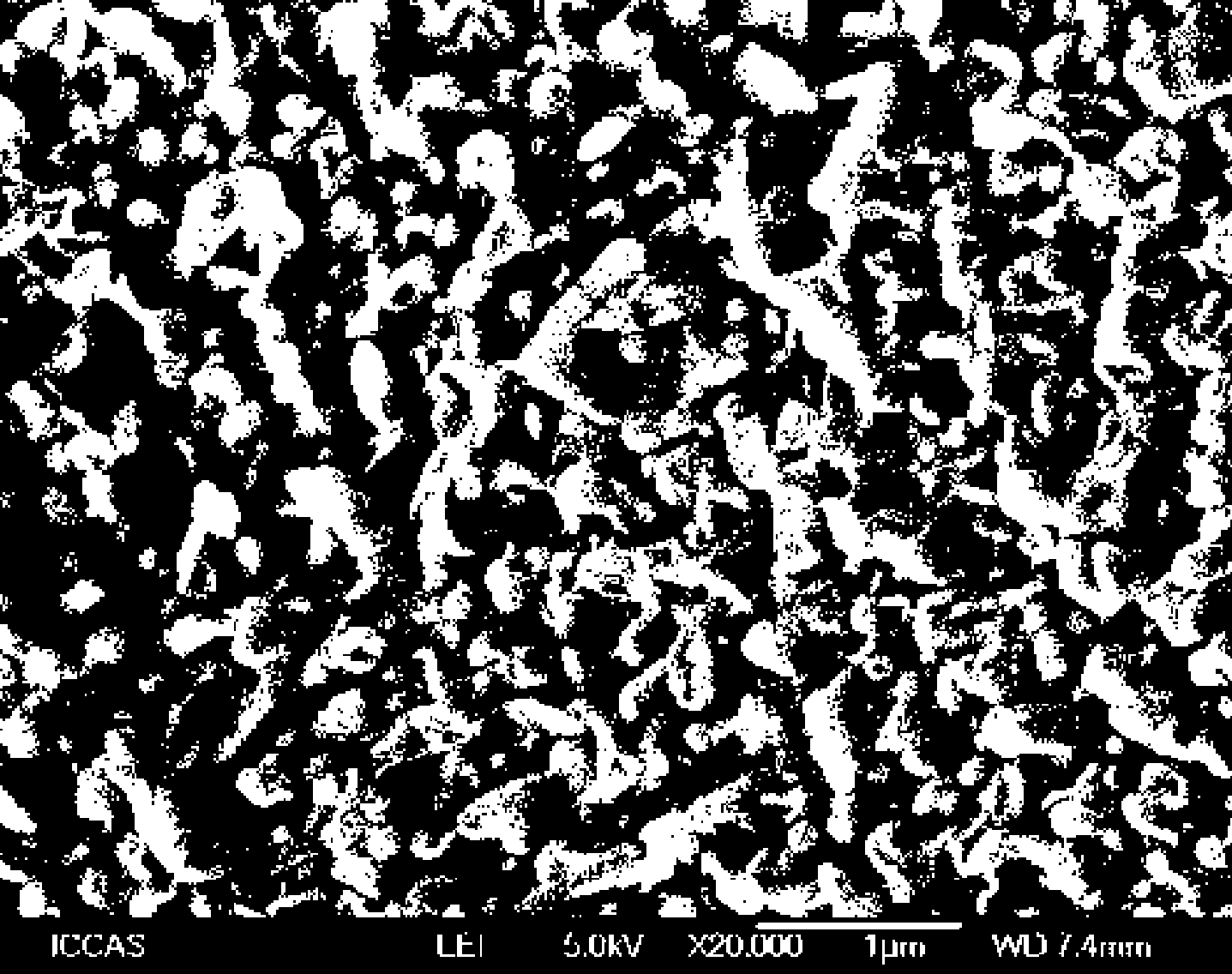

Composite reverse osmosis membrane with high-intensity anti-pollution layer and preparation method thereof

InactiveCN101462024AImprove solubilityEasy to manufactureReverse osmosisWater/sewage treatment bu osmosis/dialysisPolyamideReverse osmosis

The invention discloses a high-strength antipollution layer composite reverse osmosis membrane and a preparation method thereof. The composite reverse osmosis membrane comprises a non-woven fabric layer, a porous supporting layer and a dense polyamide layer, wherein the PVA antipollution layer with high crosslinking degree, which is formed through high-temperature crosslinking after being coated with a PVA solution and a solution containing a crosslinking agent and a catalyst in turn, is arranged on the surface of the dense polyamide layer. The composite reverse osmosis membrane increases the acting force between the antipollution layer and the dense polyamide layer and improves the strength of the PVA antipollution layer by constructing the PVA antipollution layer with high crosslinking degree on the surface of the dense polyamide layer of the prior reverse osmosis membrane so as to improve the scour resistance, the dissolution resistance and the antipollution ability of the reverse osmosis membrane and prolong the service life of the antipollution composite reverse osmosis membrane. Moreover, the composite reverse osmosis membrane also has the characteristics of easy preparation and operation, high water permeability and high salt retardation rate.

Owner:北京时代沃顿科技有限公司 +1

Priority dealcoholization PDMS/PVDF multi-layer compound film and preparation method thereof

InactiveCN101143305ASimple production processReduce manufacturing costSemi-permeable membranesCross-linkSeparation factor

The invention relates to an ethanol-permselective PDMS / PVDF multilayered composite membrane and the preparation method, which belongs to a pervaporation membrane separation field. The multilayered composite membrane is made based on the following processes: firstly, the PVDF porous basal membrane is prepared by a two-faced wiped film of kynoar polyvinylindene fluoride (PVDF) solution on the polyester non-woven fabric support layer using submersion and sedimentation transformation method; secondly, the membrane liquid, which contains dimethyl silicone polymer (PDMS), cross linking agent and catalyst, is prepared, and the PVDF porous basal membrane is immersed in the membrane liquid for 10s-1min. Each of two sides of the PVDF basal membrane are coated with a layer of silicone base by using immersion and painting method, and then the PVDF basal membrane is dried and cross linked, and so the multilayered composite membrane is made. The existing pure PDMS membrane has bad separability to ethanol aqueous solution, and the highest separation factor is 10.8 ([EtOH] equals to 8wt percent, 30 DGE C). The multilayered symmetrical composite membrane made of the invention has an excellent ethanol-permselective property to low concentration ethanol aqueous solution (5wt percent-30wt percent), and for the ethanol aqueous solution which has a concentration of 5wt percent, the separation factor ¿” value equals to 15, and the permeation flux J equals to 450g / m2h, under the temperature of 60 DGE C.

Owner:TSINGHUA UNIV

Reduced fouling of reverse osmosis membranes

ActiveUS20080173583A1Number of neededSmall sizeSpecific water treatment objectivesWater contaminantsPurification methodsReverse osmosis

The present invention provides a new water purification method and system using reverse osmosis. In particular, the present invention provides methods and water purification systems using an ion exchange resin and absorbent media for pretreatment of water being fed to a reverse osmosis treatment system, where the pretreatment reduces fouling of, or deposits or chemical attack on the membrane surfaces and passageways. Particularly, a macroporous resin having an average pore diameter in the range of 1,000 to 500,000 Angstroms and a crush strength or Chatillon value of at least 24 g / bead (710 μm bead diameter) is used.

Owner:PUROLITE CORP

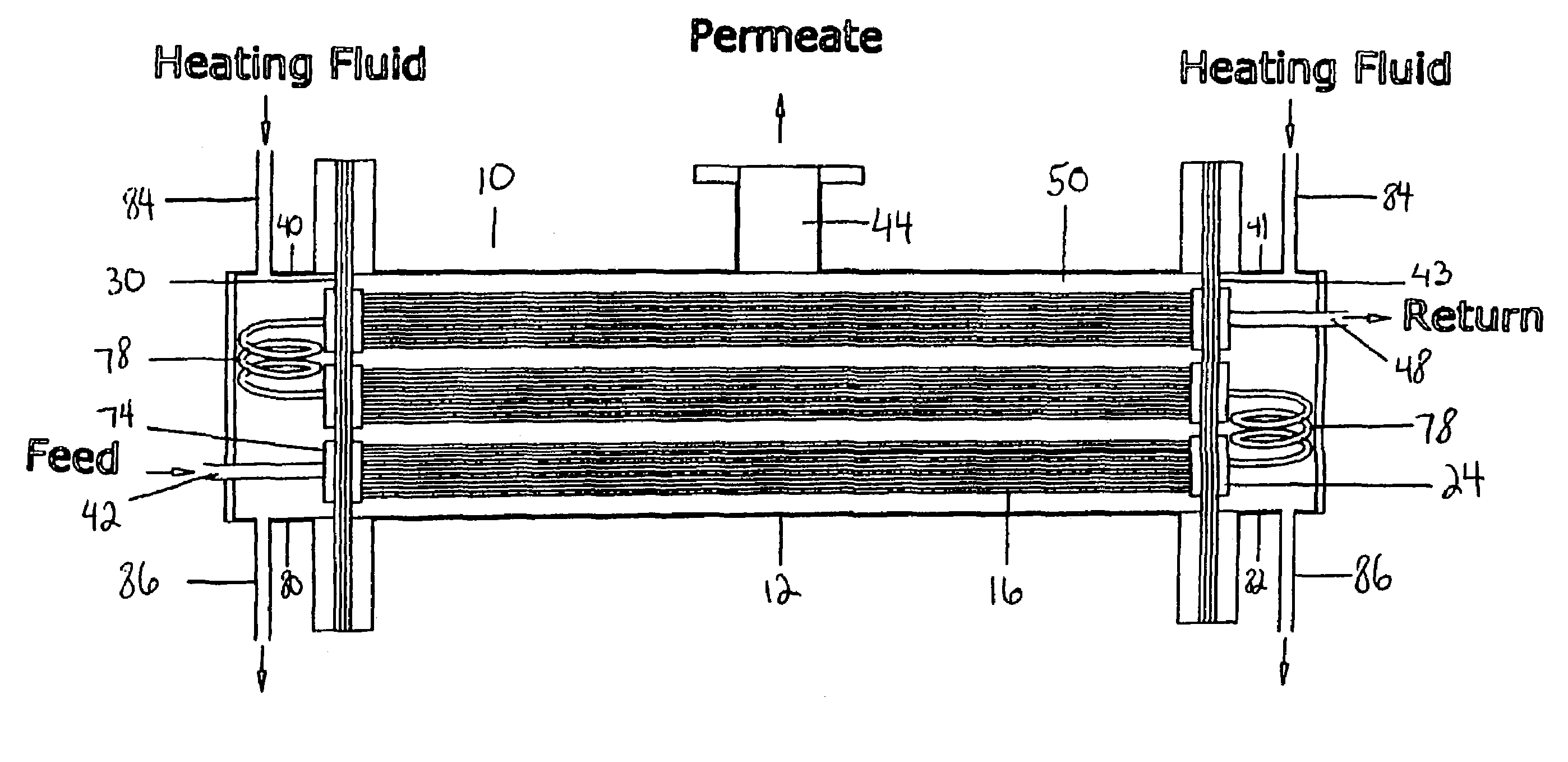

Selective separation of fluid compounds utilizing a membrane separation process

InactiveUS6986802B2Low costCost prohibitiveGas treatmentLiquid degasificationPermselective membraneControl equipment

Apparatus and processes are disclosed for economical separation of fluid mixtures utilizing perm-selective membranes. Broadly, apparatus of the invention comprises a plurality of membrane modules comprising a solid perm-selective membrane and equipment for controlling enthalpy of selected fluids within the apparatus. Advantageously, the membrane modules are disposed in a first product group, a second product group, and at least one intermediate group. Apparatus of the invention is particularly useful for simultaneous recovery of a very pure permeate product, and / or a desired non-permeate stream, from fluid mixtures of two or more compounds which when subjected to appropriately altered conditions of temperature and / or pressure exhibit a bubble point.

Owner:BP CORP NORTH AMERICA INC

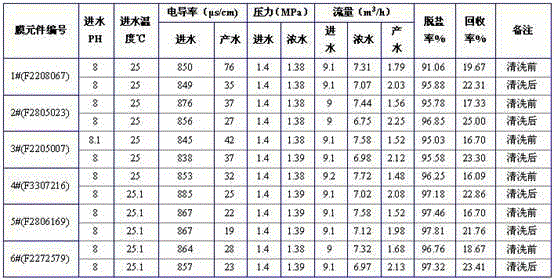

Membrane cleaning agent for cleaning reverse osmosis membrane and application method

ActiveCN102553452AEffective elutionGuarantee continuous and stable operationSemi-permeable membranesReverse osmosisEnvironmental engineering

The invention relates to a membrane cleaning agent for polyacrylamide on a reverse osmosis membrane. Acid chemical cleaning agents and alkaline chemical cleaning agents are prepared in the membrane cleaning agent, and the polyacrylamide and organic and inorganic pollutants wrapped by the polyacrylamide on the surface of the polluted reverse osmosis membrane are dissolved, dispersed, peeled and removed specifically. The membrane cleaning agent has the advantages of being easy to prepare and capable of recovering water producing flux and causing on damage to elements of the reverse osmosis membrane, and raw material can be achieved conveniently.

Owner:蓝星工程有限公司

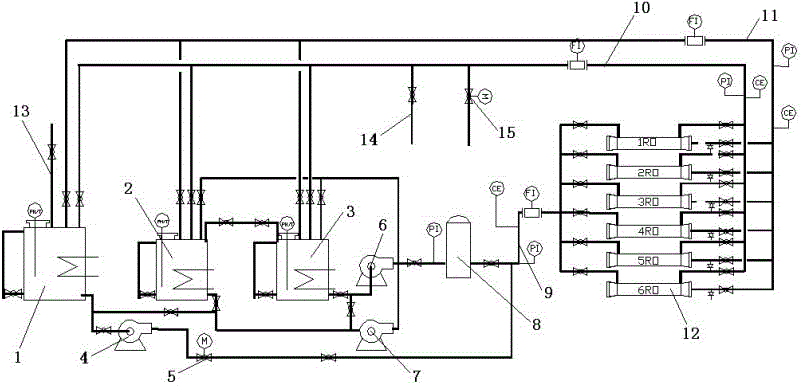

Offline cleaning and evaluating device of reverse osmosis membrane element and application method of device

ActiveCN103331102ARestore performanceEnsure cleaning flowSemi-permeable membranesReverse osmosisEngineering

The invention discloses an offline cleaning and evaluating device of a reverse osmosis membrane element and an application method of the device, belonging to the technical field of water treatment. The method can be used for evaluating the performance of the reverse osmosis membrane element, typically selecting cleaning agents according to the pollutant ingredients and contents and cleaning a single reverse osmosis membrane element in off-line multi-angle and multilevel manner by means of such operations as washing by a large amount of water, reverse washing, positive washing and soaking, and in the cleaning process, the method can be used for monitoring the performance of the reverse osmosis membrane element and controlling such factors as cleaning flow rate, pressure, cleaning time and temperature, so as to improve a cleaning effect. The offline cleaning and evaluating device disclosed by the invention can be also used for evaluating and testing the performance of the agents and the reverse osmosis membrane by simulating the onsite operation conditions.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

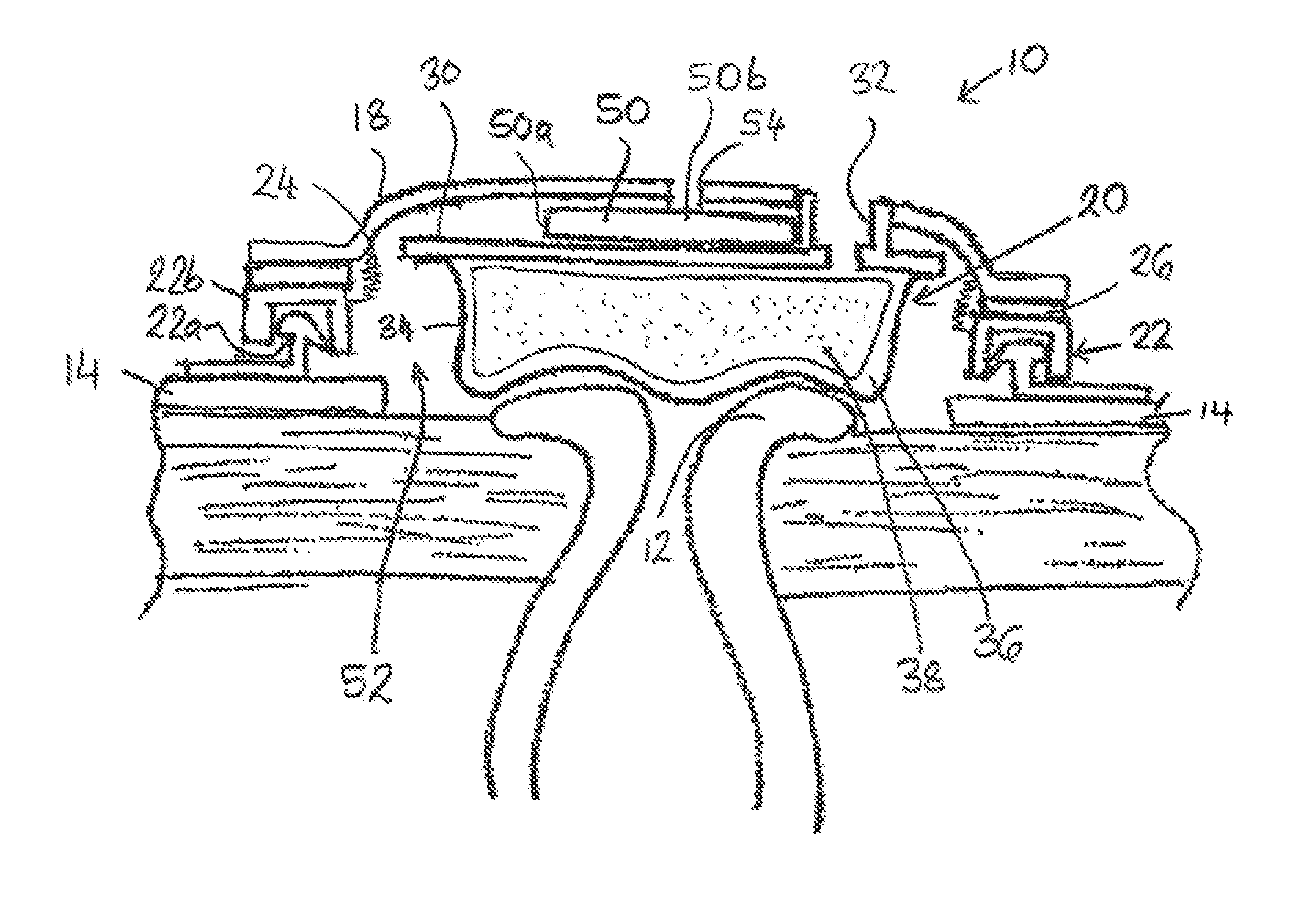

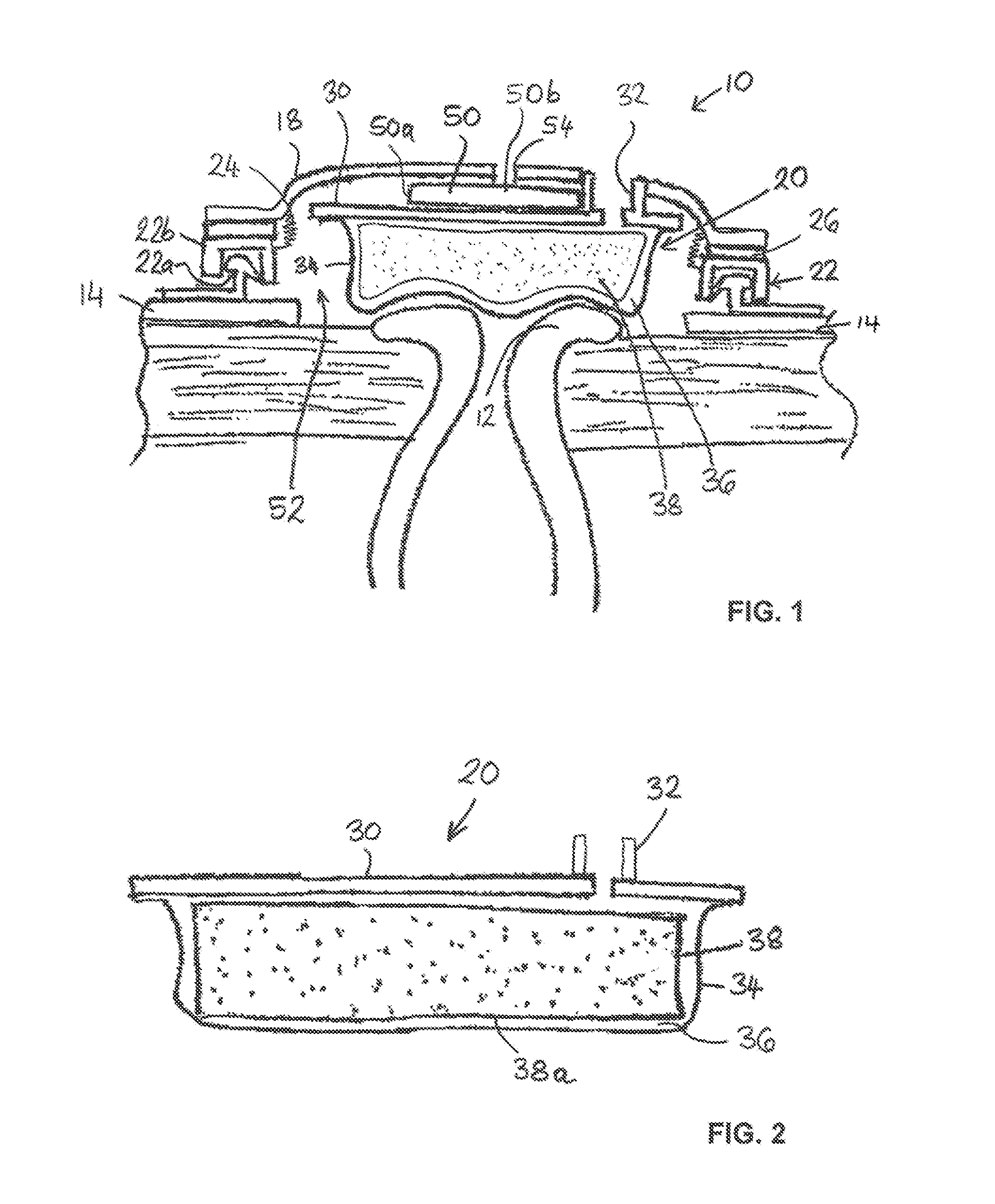

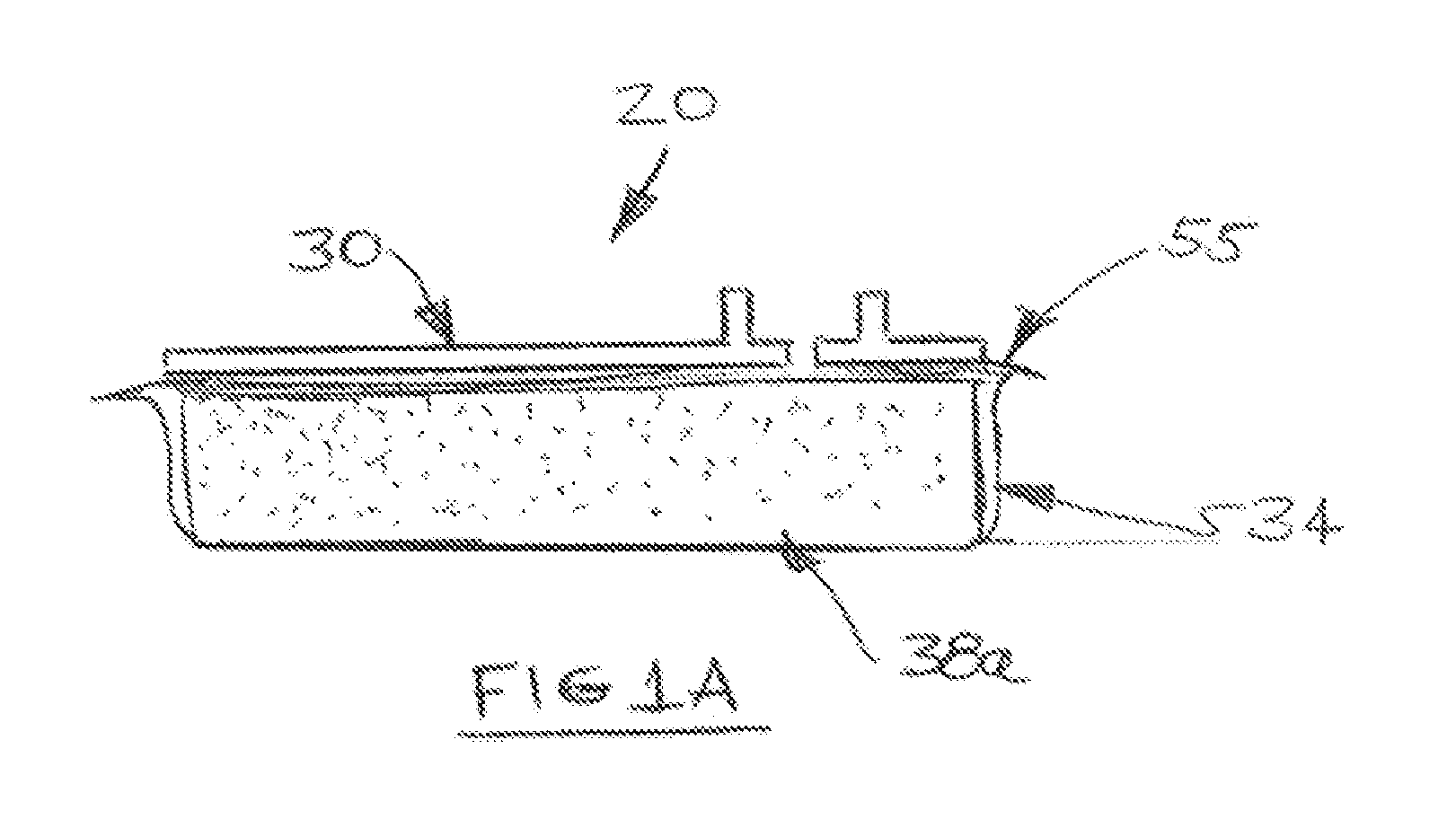

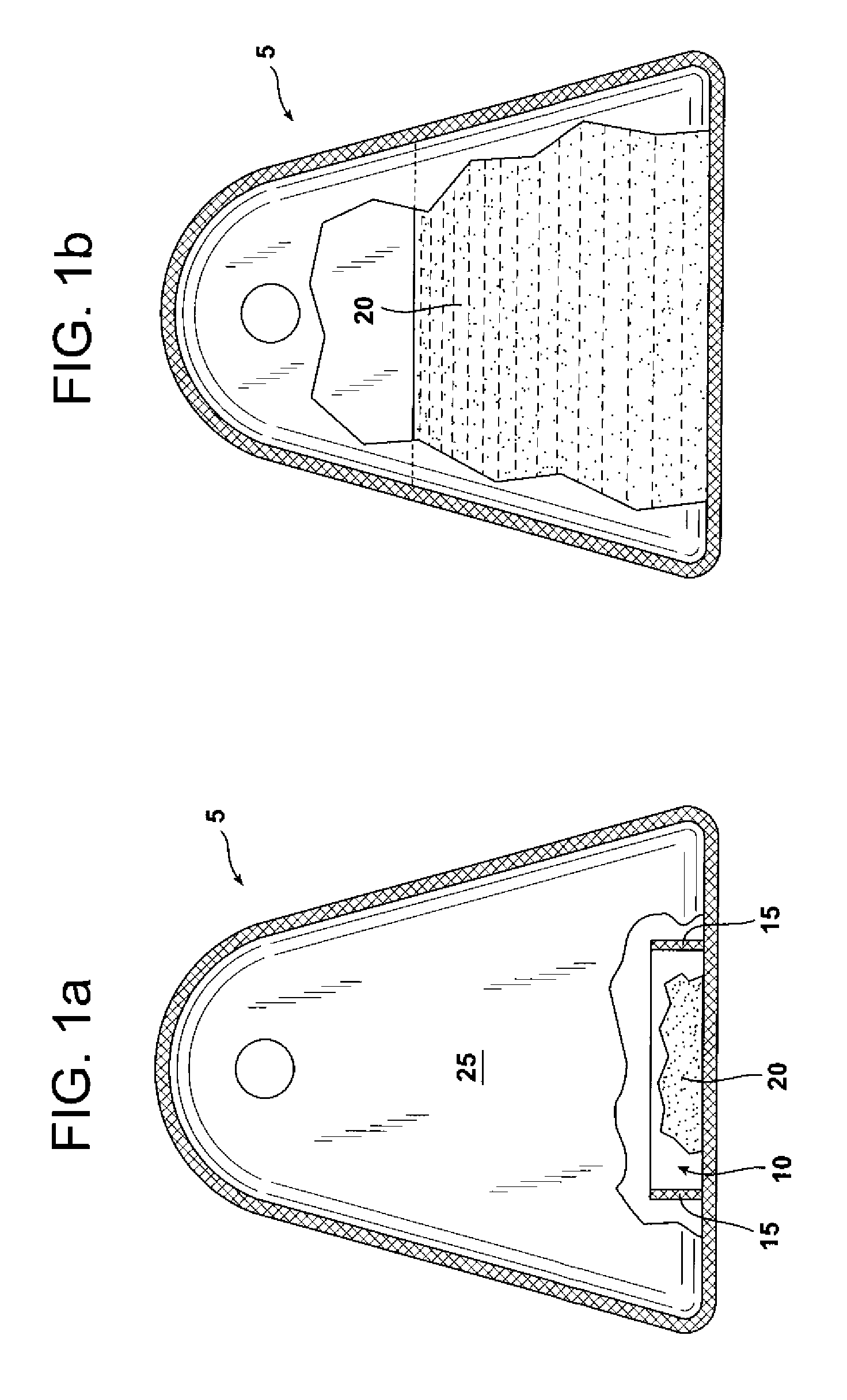

Fluid filled seal for contacting the human body

A medical device such as a controlled discharge ostomy appliance comprises a fluid filled seal for sealing around a body orifice (stoma). The fluid filled seal comprises a fluid chamber including a fluid impermeable membrane that forms a movabable wall of the fluid chamber, one or more ports communicating with the chamber; and resilient foam disposed within the fluid chamber. The foam tends to expand the chamber to seal against the body. The port controls the inlet and exhaust of fluid from the chamber, in response to movement of the body away from, or towards, the seal.

Owner:CONVATEC TECH INC

Refrigerating and freezing device and storage container thereof

The invention provides a refrigerating and freezing device and a storage container thereof. The storage container comprises an electrolysis deoxygenization assembly and a moisture permeability assembly. The electrolysis deoxygenization assembly is used for consuming oxygen in air in a storage space, so that a nitrogen-rich oxygen-deficient air atmosphere beneficial to food preservation is obtainedin the space, the intensity of aerobic respiration of food is reduced, and the aim of long-term preserving the food is achieved. When the electrolysis deoxygenization assembly is used for consuming the oxygen in the storage space, a certain moisture is produced in the storage space, so that the inner part of the storage space is more and more humid. Through the moisture permeability assembly, themoisture in the air in the storage space can be conveyed to the outer part of the space through a pervaporation membrane through vaporization penetration, so that the humidity in the storage space still keeps in the appropriate range, and condensate or dropping water is prevented from being produced in the space. In the refrigerating and freezing device provided by the invention, the electrolysisdeoxygenization assembly and the moisture permeability assembly can be used in a matching way, so that food can be preserved favorably.

Owner:大连海尔电冰箱有限公司 +2

Fuel vent assembly with floatless rollover protection

ActiveUS20050098160A1Reduce manufacturing costNon-fuel substance addition to fuelLarge containersRolloverFuel tank

A valve for use between a vehicle fuel tank vent and a vapor recovery canister in a vehicle fuel tank containing liquid fuel, such a valve comprises: a housing having a fuel tank side and a vapor recovery canister side; and a vapor permeable membrane fixed to the housing to block the passage of liquid fuel.

Owner:FCA US

Adhesive membrane

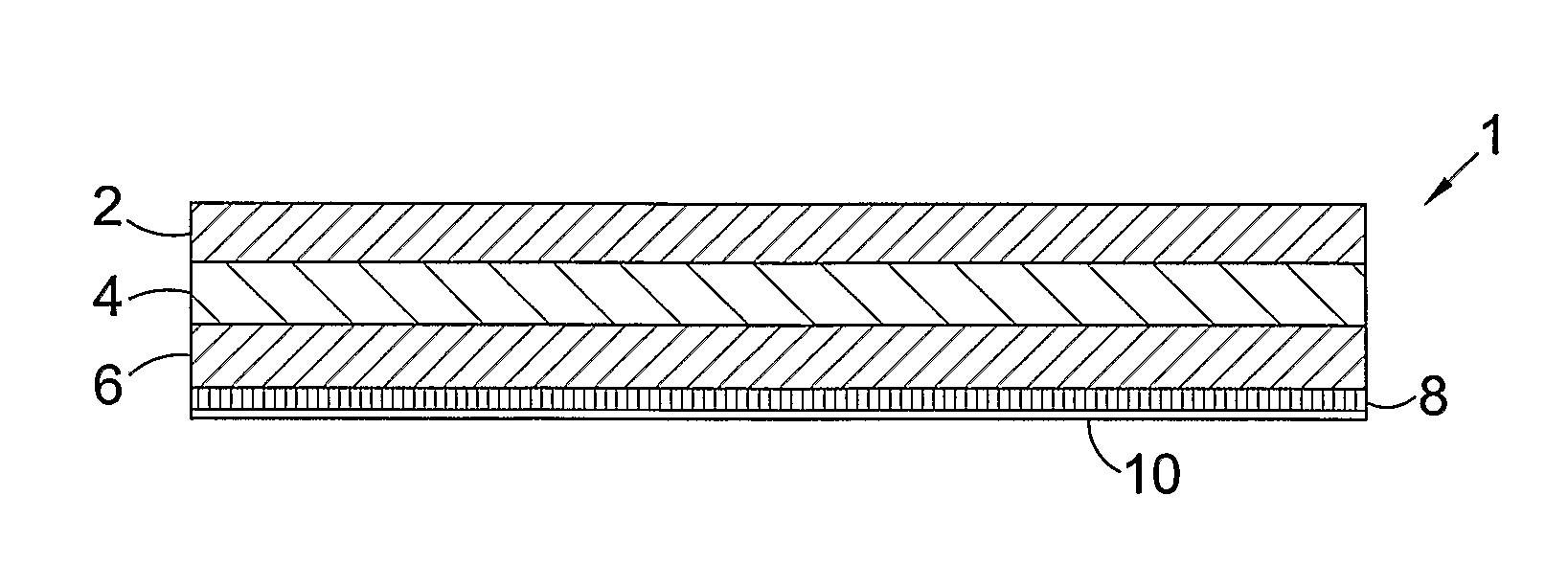

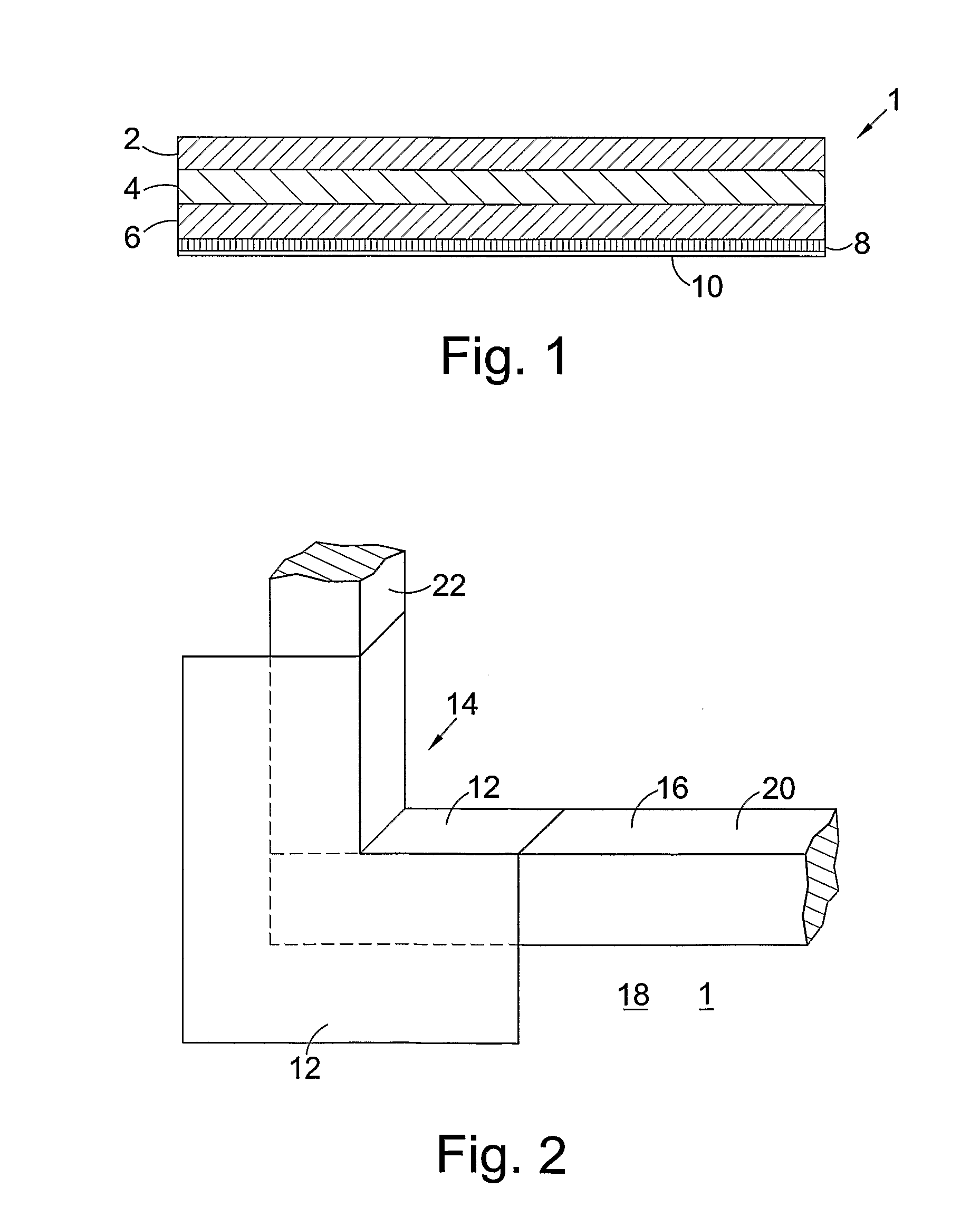

ActiveUS20110185666A1Strong adhesionEasily yet strongly and consistently bonded togetherFloorsAnimal housingPressure sensitiveChemistry

A self-adhesive permeable membrane sheet (1), for use in a building structure, includes a continuous layer of a permeable pressure sensitive adhesive (8) attached to one surface of a permeable membrane sheet (2,4,6). Methods for using the permeable membrane sheet (1) in construction are also provided.

Owner:A PROCTOR GROUP

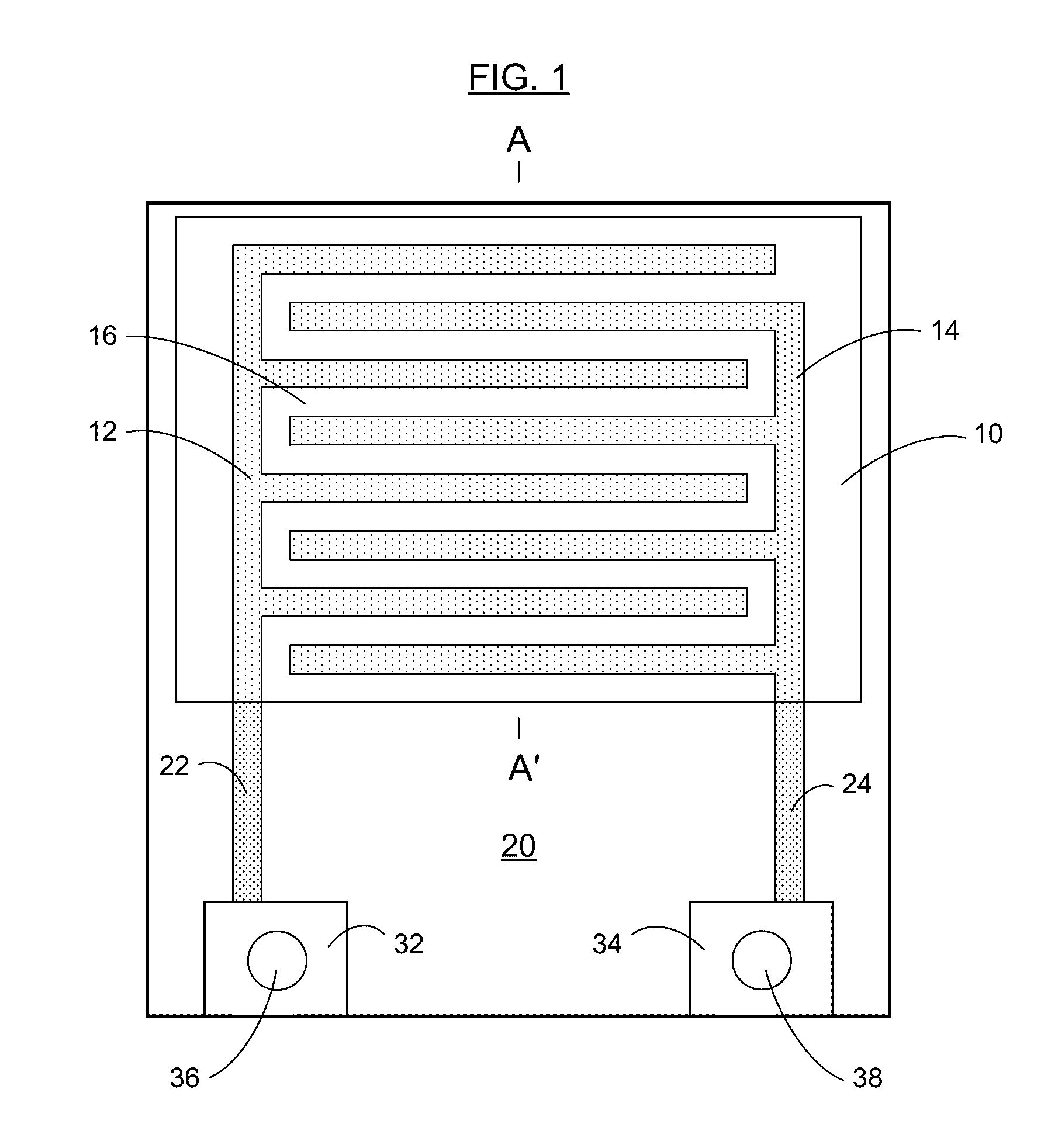

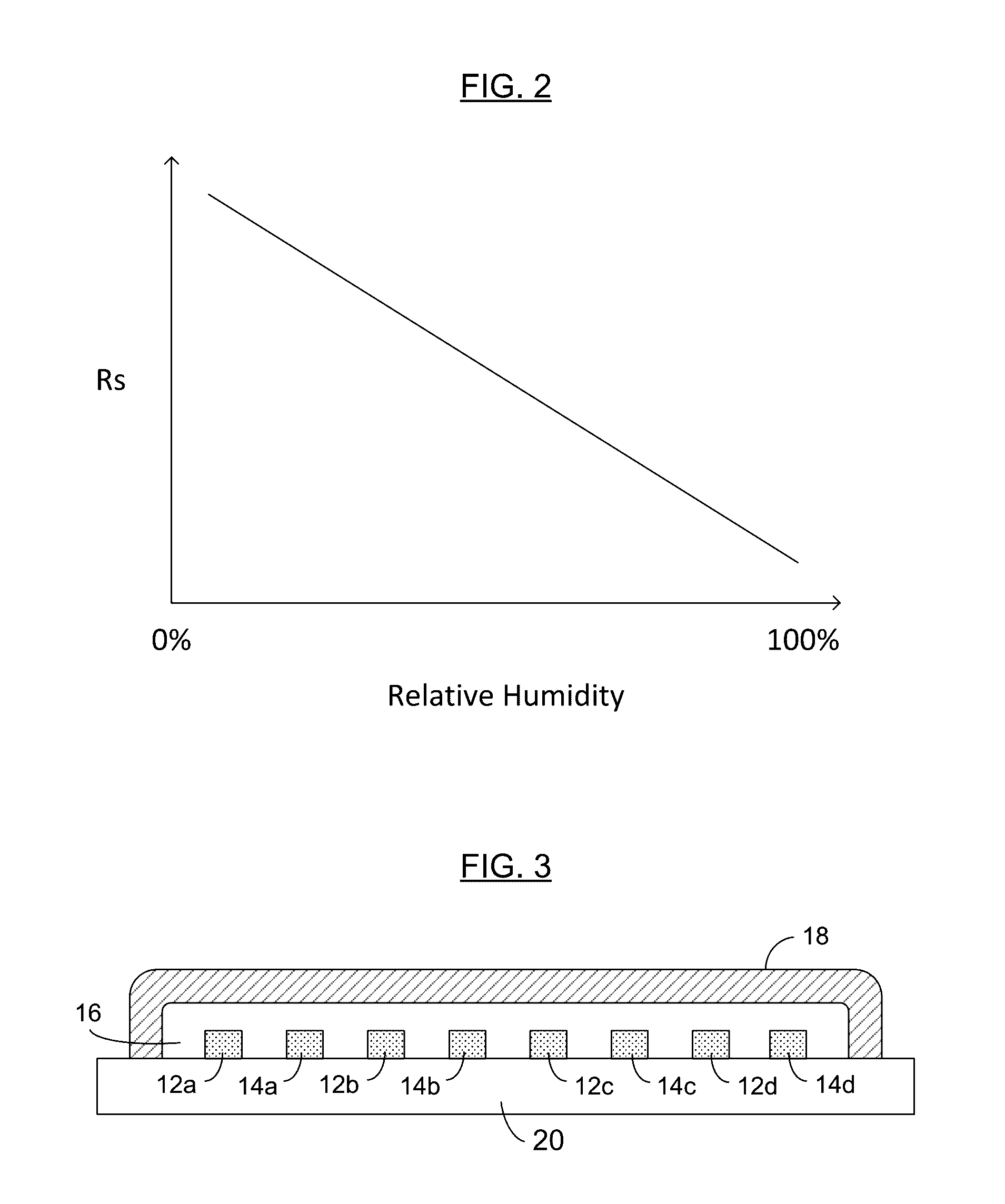

Humidity Sensor, Wireless Device Including the Same, and Methods of Making and Using the Same

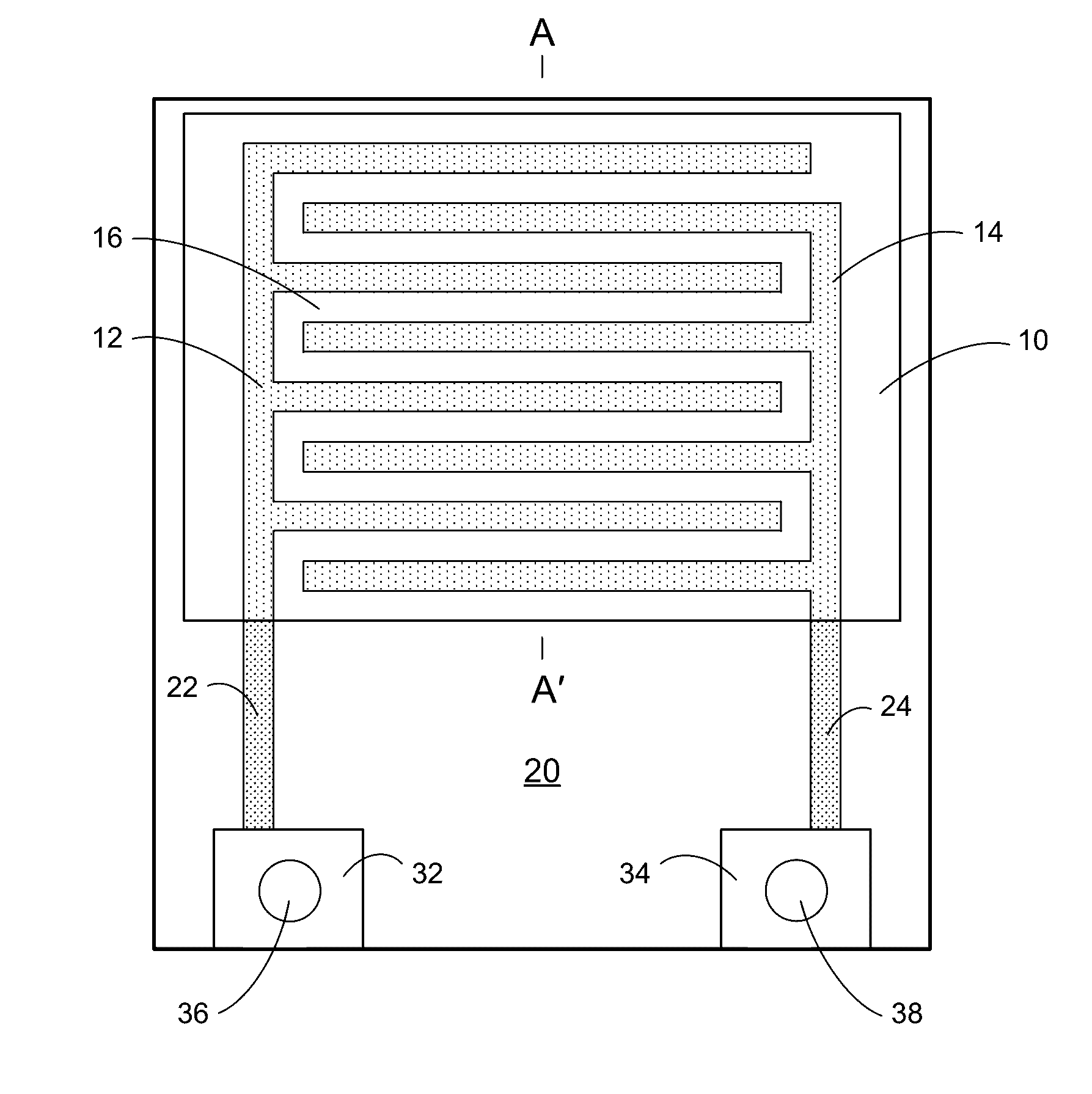

InactiveUS20170038325A1Improve functionalityIncrease usageMaterial resistanceRecord carriers used with machinesElectricityMoisture sensor

A tag or smart label including a humidity sensor, and methods of manufacturing and using the same, are disclosed. The tag or smart label includes a substrate or backplane with a battery or antenna, a humidity sensor, and an integrated circuit thereon. The integrated circuit is in electrical communication with the humidity sensor and the antenna or battery, and is configured to process a signal from the humidity sensor corresponding to the humidity level or value in the environment to be monitored, and provide or generate a signal that represents the humidity level / value. The humidity sensor includes first and second electrodes that are a predetermined distance apart, a humidity-sensitive material having one or more electrical, mechanical or chemical properties that vary as a function of the humidity level / value, and a water- and / or humidity-permeable membrane covering the humidity-sensitive material.

Owner:ENSURGE MICROPOWER ASA

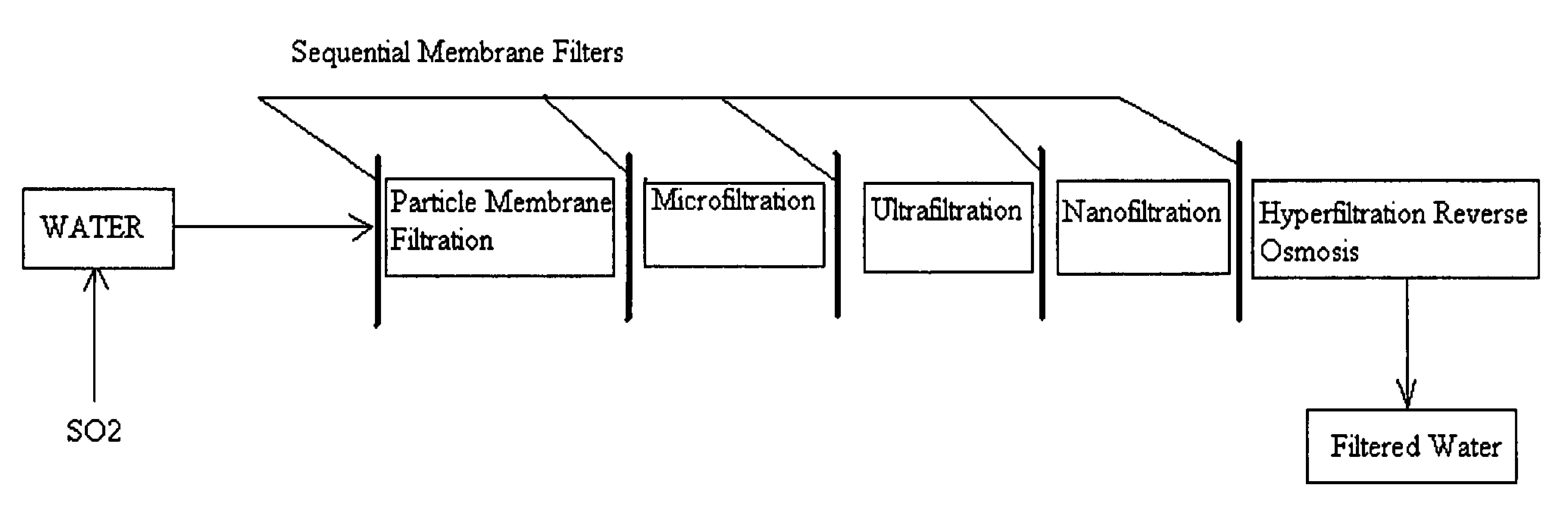

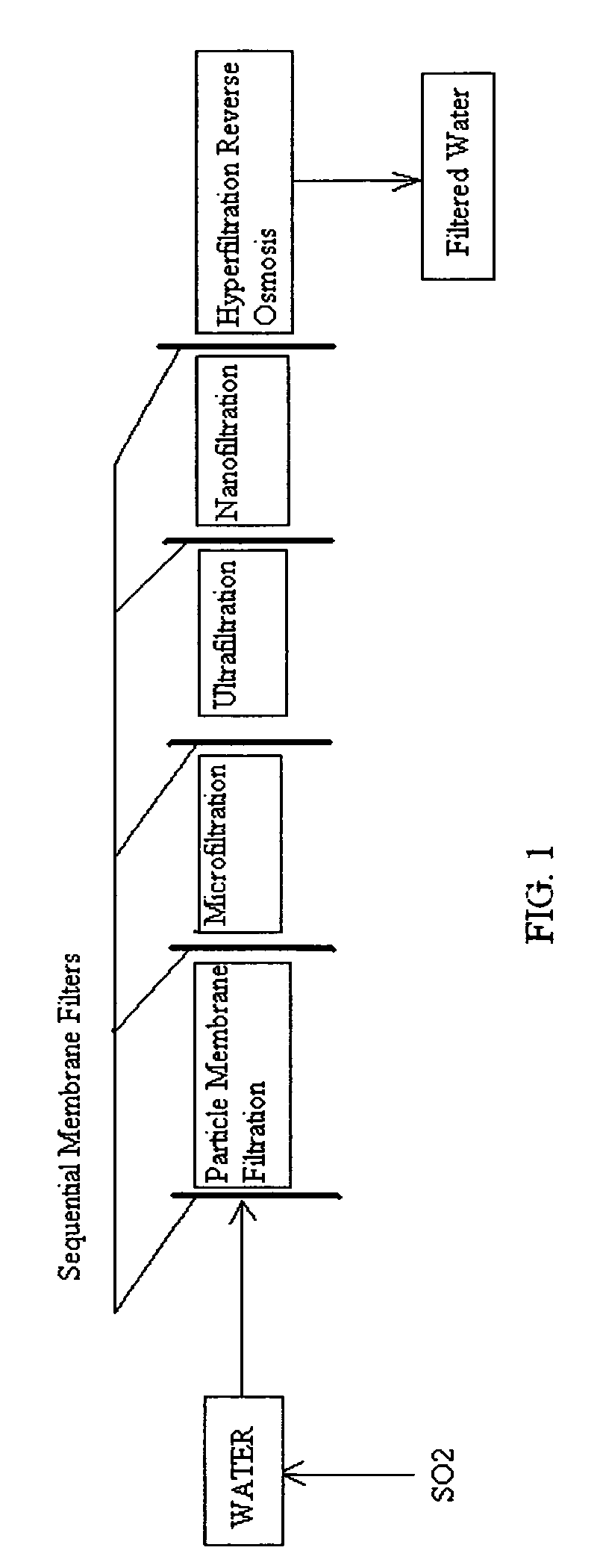

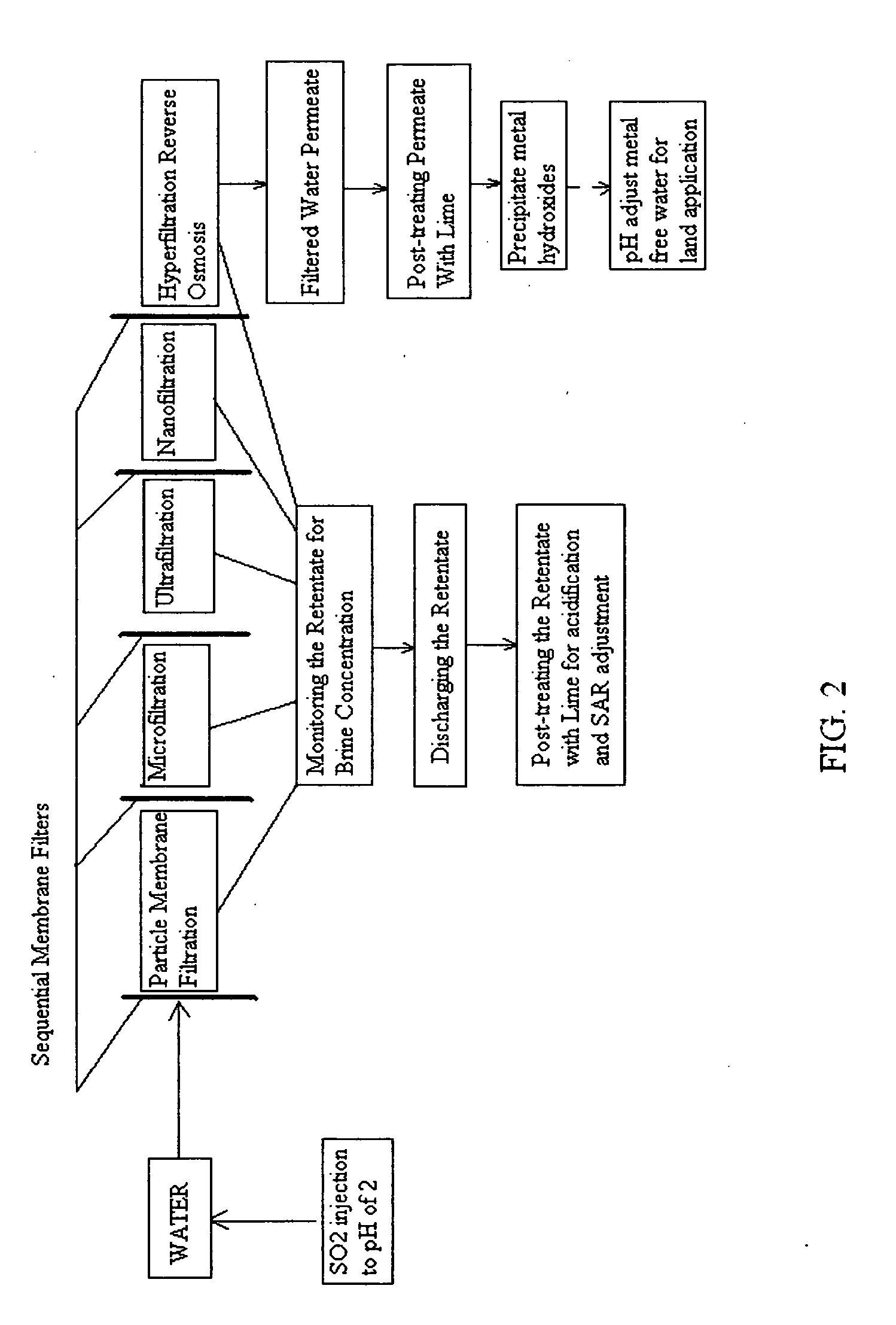

Pre-treatment reverse osmosis water recovery method for brine retentate metals removal

ActiveUS20100193436A1Minimize adhesionPrevent bacterial growthMembranesOther chemical processesRecovery methodPretreatment method

A pre-treatment method for cleaning and maintaining reverse osmosis membrane filters by injecting sulfurous acid into waters with suspended solids in a liquid fraction to be filtered to form sulfurous acid (H2SO3) to acid leach heavy metals into the liquid fraction, reduce alkalinity and mineral scaling, add sufficient SO2 as a biocide to attack bacteria and other micro organisms to prevent membrane fouling, reduce iron to prevent iron deposit build-up, scavenge and remove dissolved oxygen prior to filtration to prevent membrane oxidation, and then sequentially filtering the acidified water through membrane filters to create a metal free permeate and a brine retentate, which can be pH adjusted to remove the heavy metals as metal hydroxide precipitates.

Owner:EARTH RENAISSANCE TECH

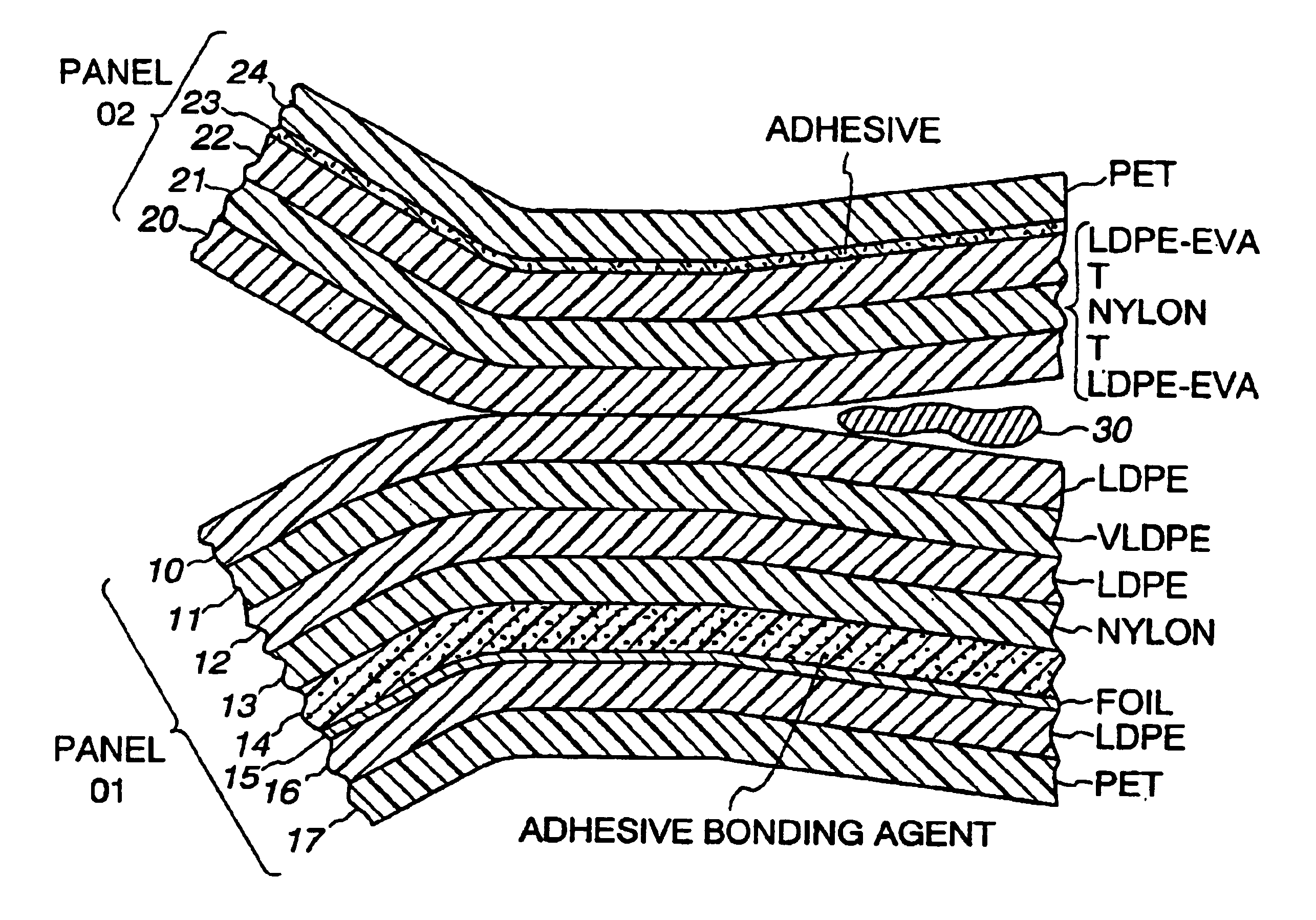

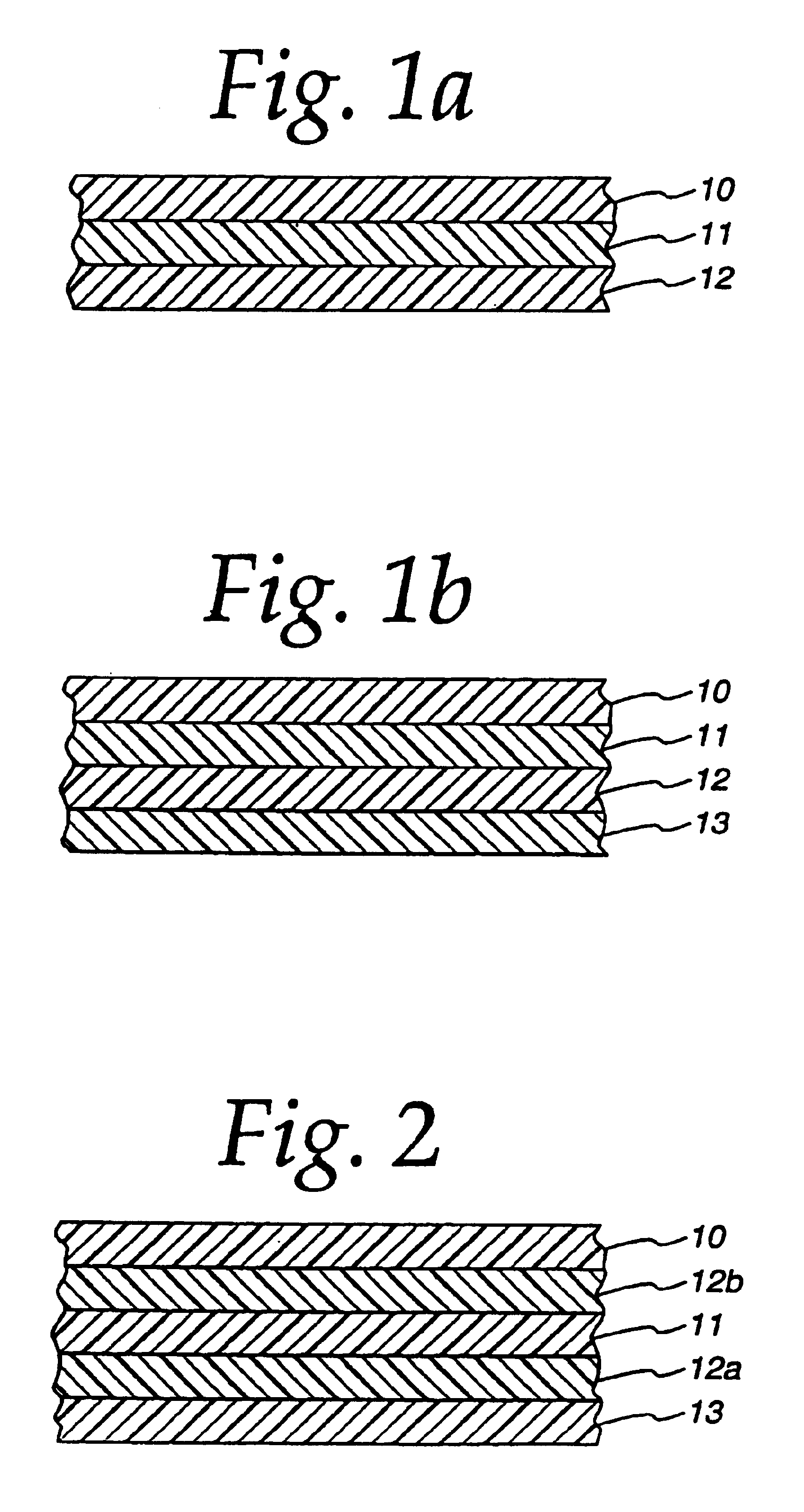

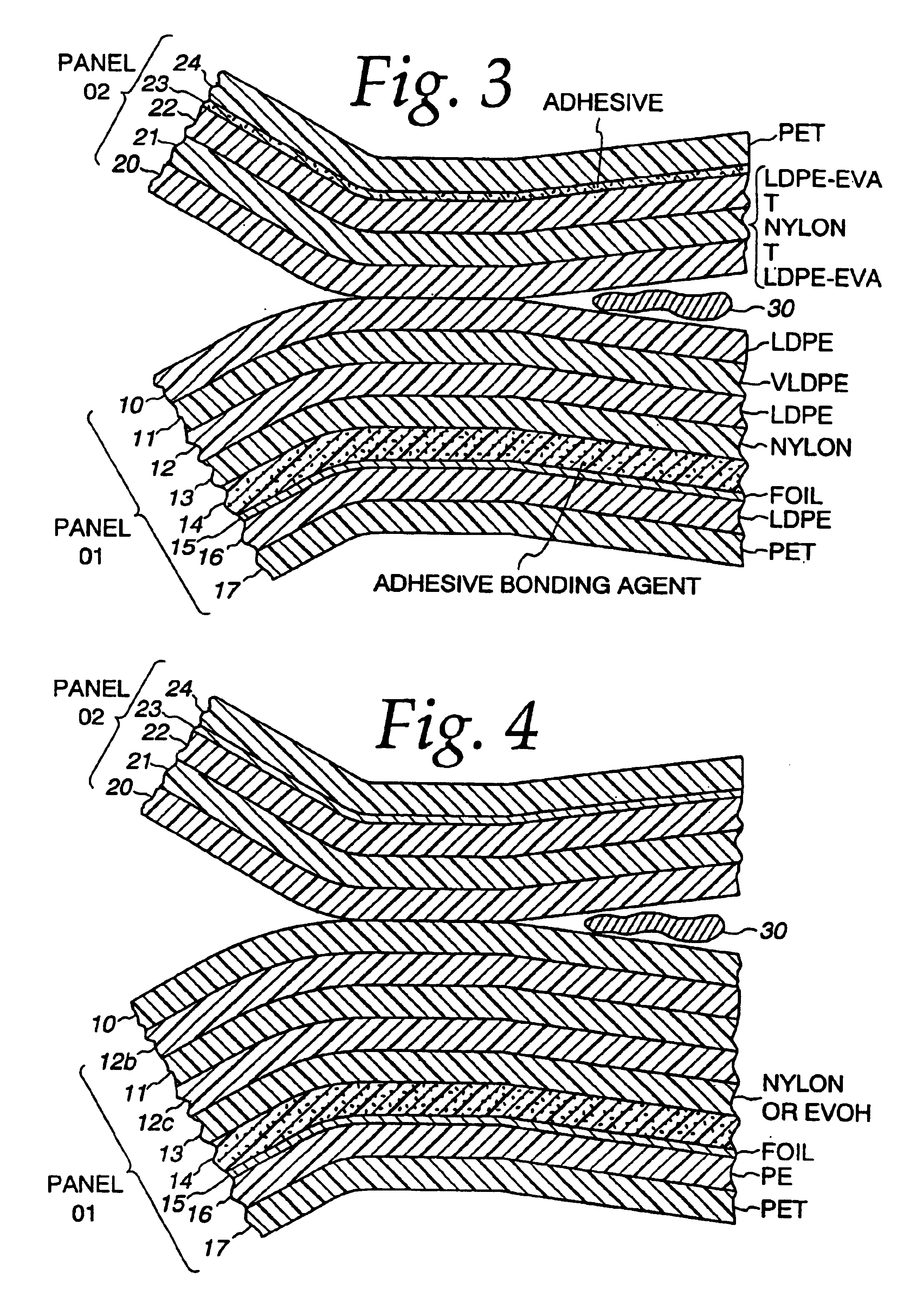

Membrane permeable to aromatic products

InactiveUS6902817B2Great control releaseIncrease permeationWrappersDispensing apparatusEthylene vinyl alcohol copolymerLow-density polyethylene

A multilayer structure with improved permeation for atmospheric diffusion of aromatic products wherein the structure comprises: a permeable membrane wherein said permeable membrane comprises at least two polymeric layers wherein the polymer of each layer is independently selected from the group consisting of polyethylene, very low density polyethylene, low density polyethylene, ethylene methylacrylate copolymer; a release layer wherein said release layer comprises a nylon polymer or a ethylene vinyl alcohol copolymer wherein the release layer is adhered to most inner polymeric layer of the permeable member which comprises the permeable membrane and wherein the adhesion between release layer and the adjacent layer of the polymeric permeable membrane is a relatively weak bond compared to the bond between the layers of the polymeric permeable membrane; and an impermeable membrane wherein said impermeable membrane comprises one or more layers wherein the materials which comprise the individual layers of the impermeable membrane are independently selected from metal or foil and wherein said impermeable portion is laminated to said release layer.

Owner:BEMIS COMPANY INC

Polyether copolyamide pervaporation membrane as well as preparation method and application thereof

InactiveCN103585899AEasy to separateGood film formingWater/sewage treatment bu osmosis/dialysisDistillationSimple Organic CompoundsPolyamide

The invention relates to a polyether copolyamide pervaporation membrane as well as a preparation method and an application thereof, and belongs to the technical field of membrane separation. The preparation method comprises the following steps: mixing polyether copolyamide and a metal organic compound with a solvent at a certain temperature to obtain a membrane casting solution, coating a polyether sulfone composite membrane supported by nonwoven cloth with the membrane casting solution, standing for a period of time in air, and drying in a vacuum drying box for several hours to obtain the polyether copolyamide pervaporation membrane. The polyether copolyamide pervaporation membrane prepared by the method is large in permeation flux, good in separation effect, good in strength, stable in structure and suitable for removing volatile organic compounds, especially volatile ester compounds from water.

Owner:JIANGNAN UNIV

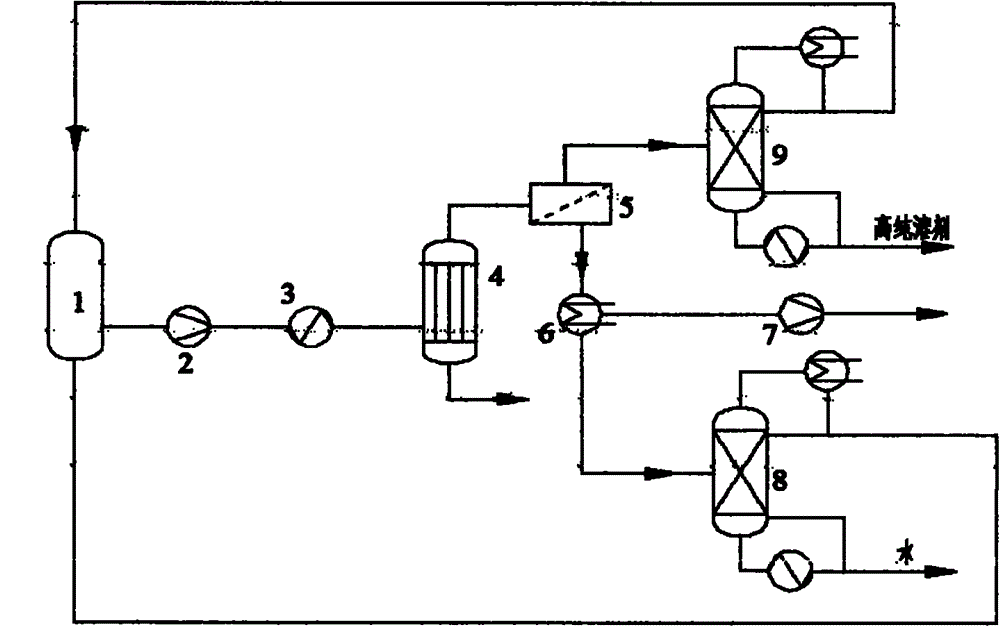

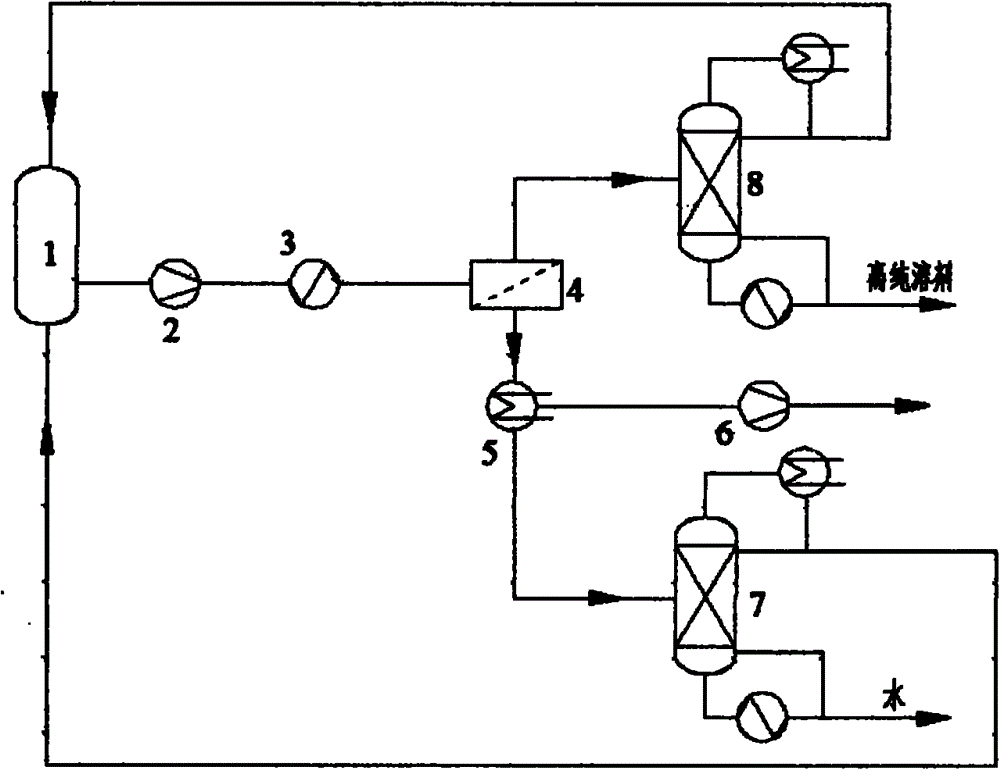

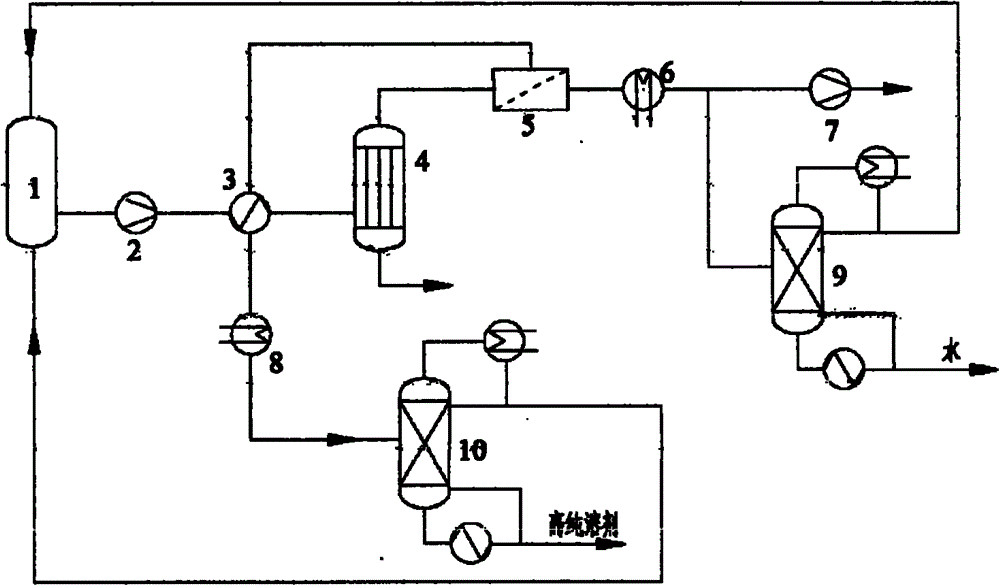

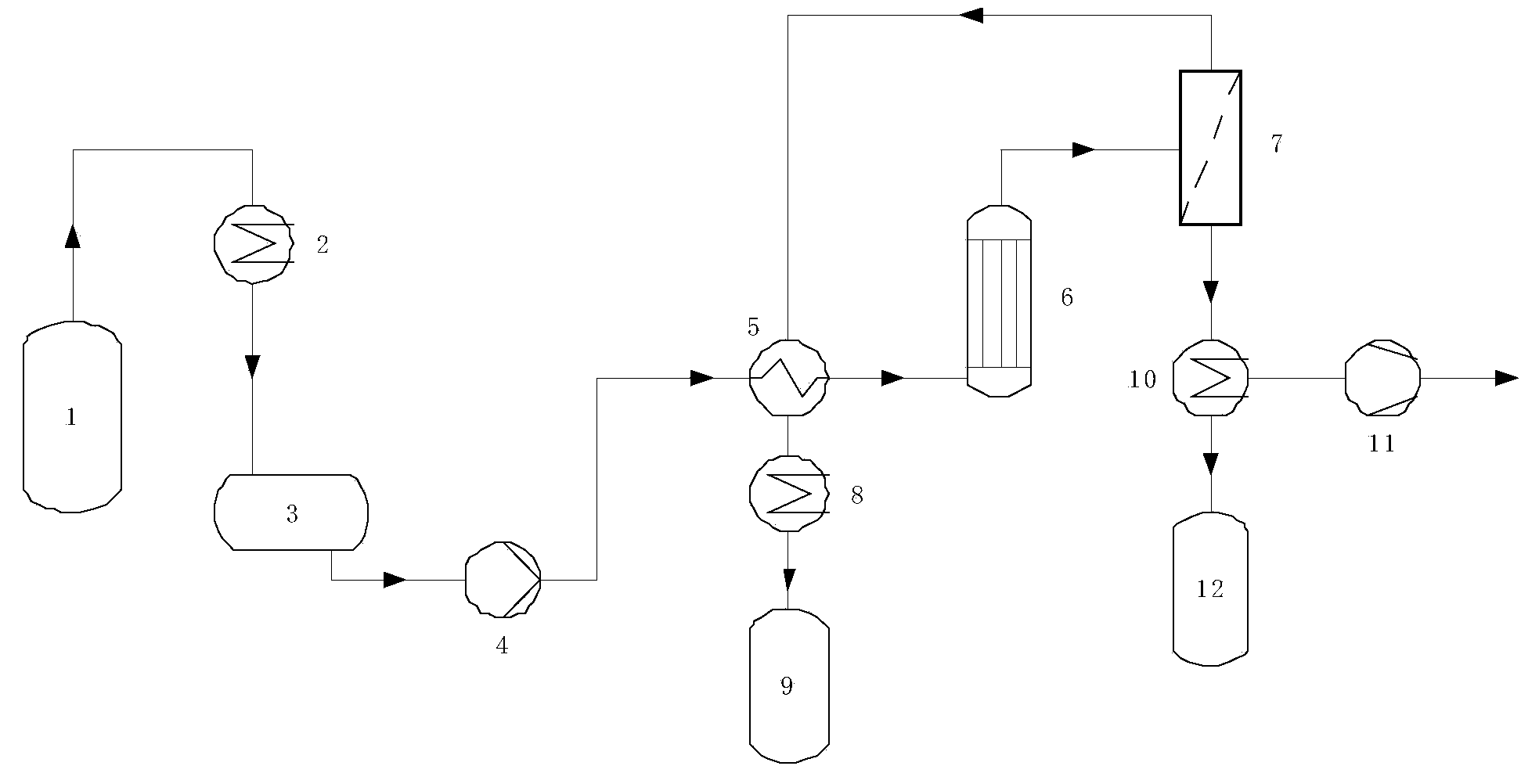

A pervaporation rectification coupled system and a use thereof

InactiveCN104027996AReduce recyclingEmission reductionDistillationFractional distillationOrganic solventCoupling system

A pervaporation rectification coupled system is disclosed. A method of performing organic solvent dehydration by coupling pervaporation and rectification is also disclosed. The system and the method are especially suitable for deep dehydration of organic solvents easily forming azeotropes with water, and belong to the technical field of separation. The method includes processes of: feeding a water-containing organic solvent (with a water content generally larger than the water content of the azeotrope) into a pervaporation membrane separator to perform primary dehydration so as to break azeotropy, feeding the solvent into a rectification tower to perform deep dehydration, returning a water-containing component at the tower top to the membrane separator and dehydrating again. An anhydrous finished product is obtained from the tower bottom. The water content of the organic solvent obtained by the processes and the method is 0.01-1 wt%. Compared with the prior art, the processes are simple, the equipment investment is low, the energy consumption is low, the product quality is high, and production of organic solvents with extremely low water contents, which is out of the reach of various kinds of rectification and other chemical manners, is achieved.

Owner:JIANGSU NINE HEAVEN HIGH TECH

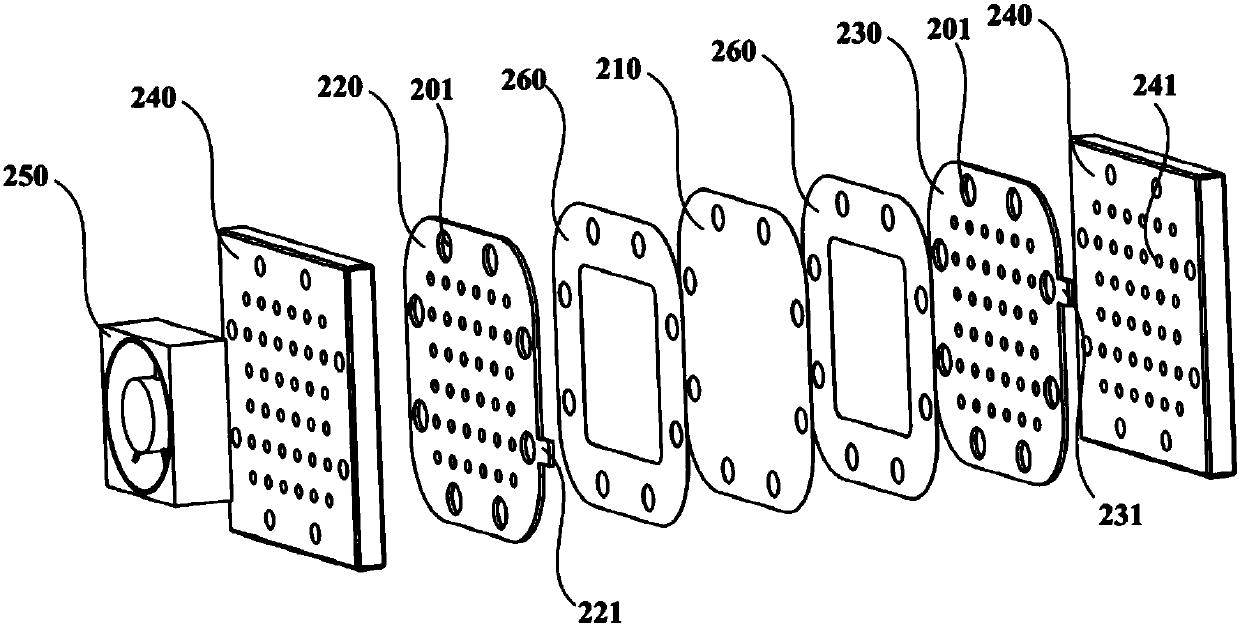

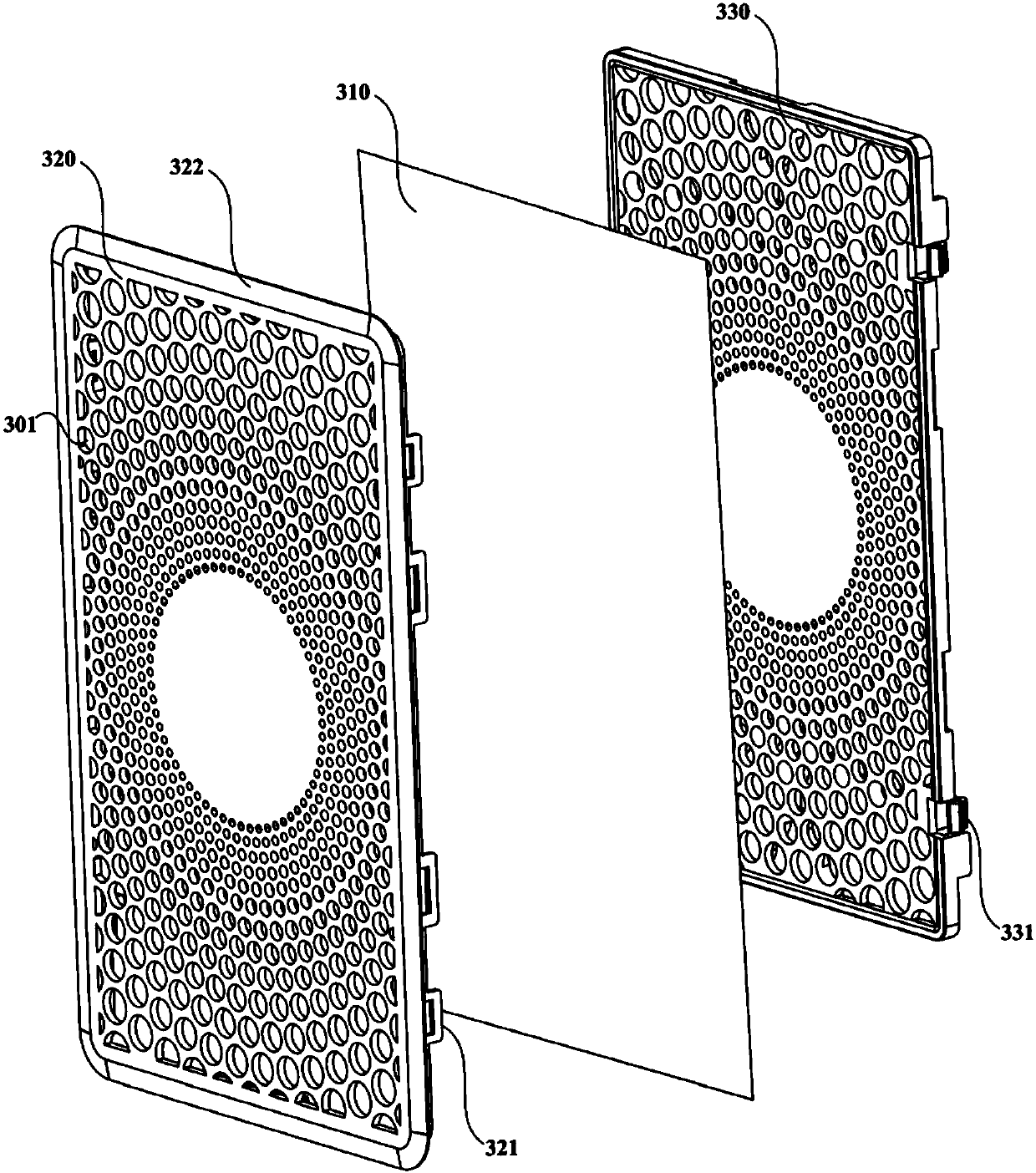

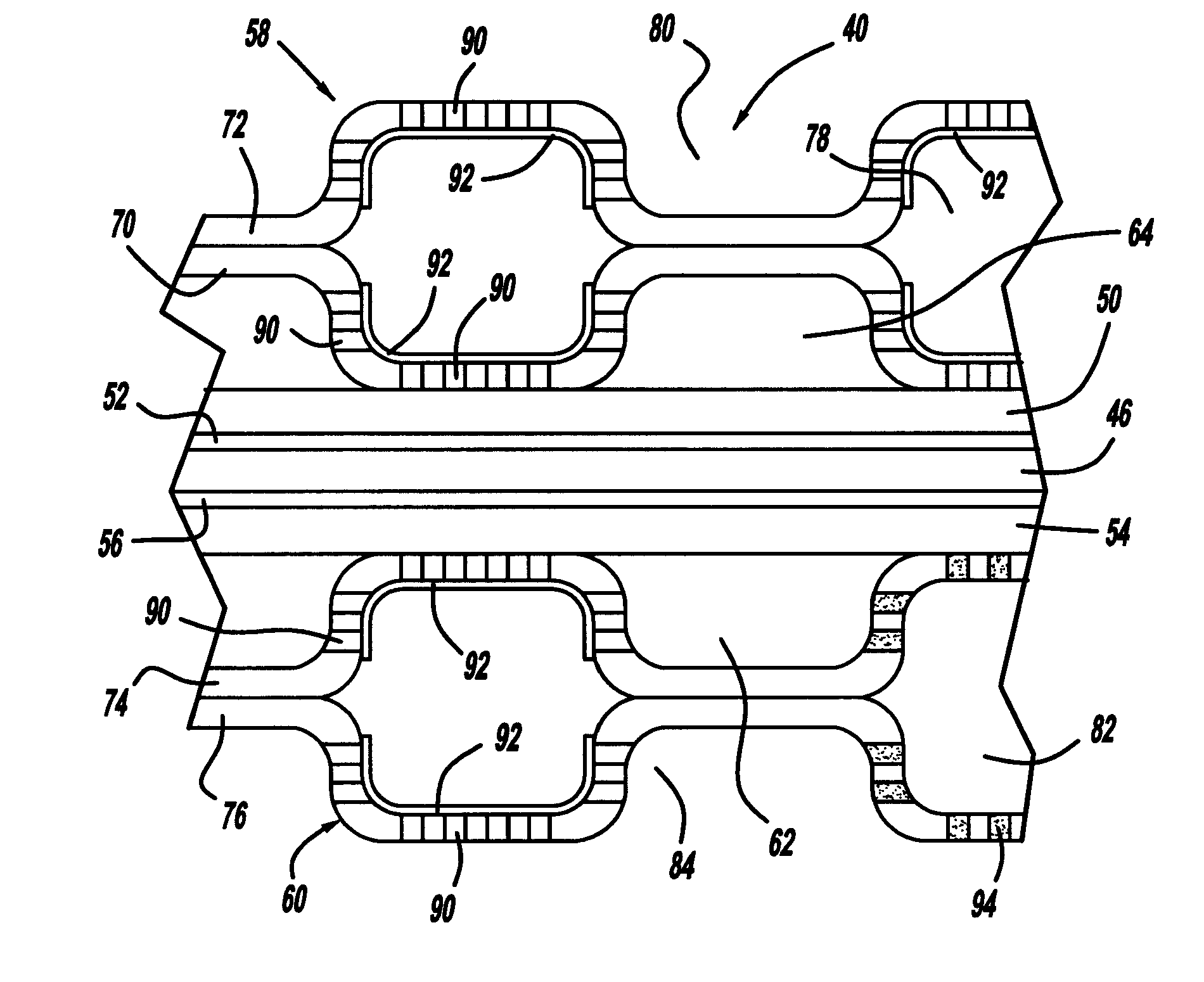

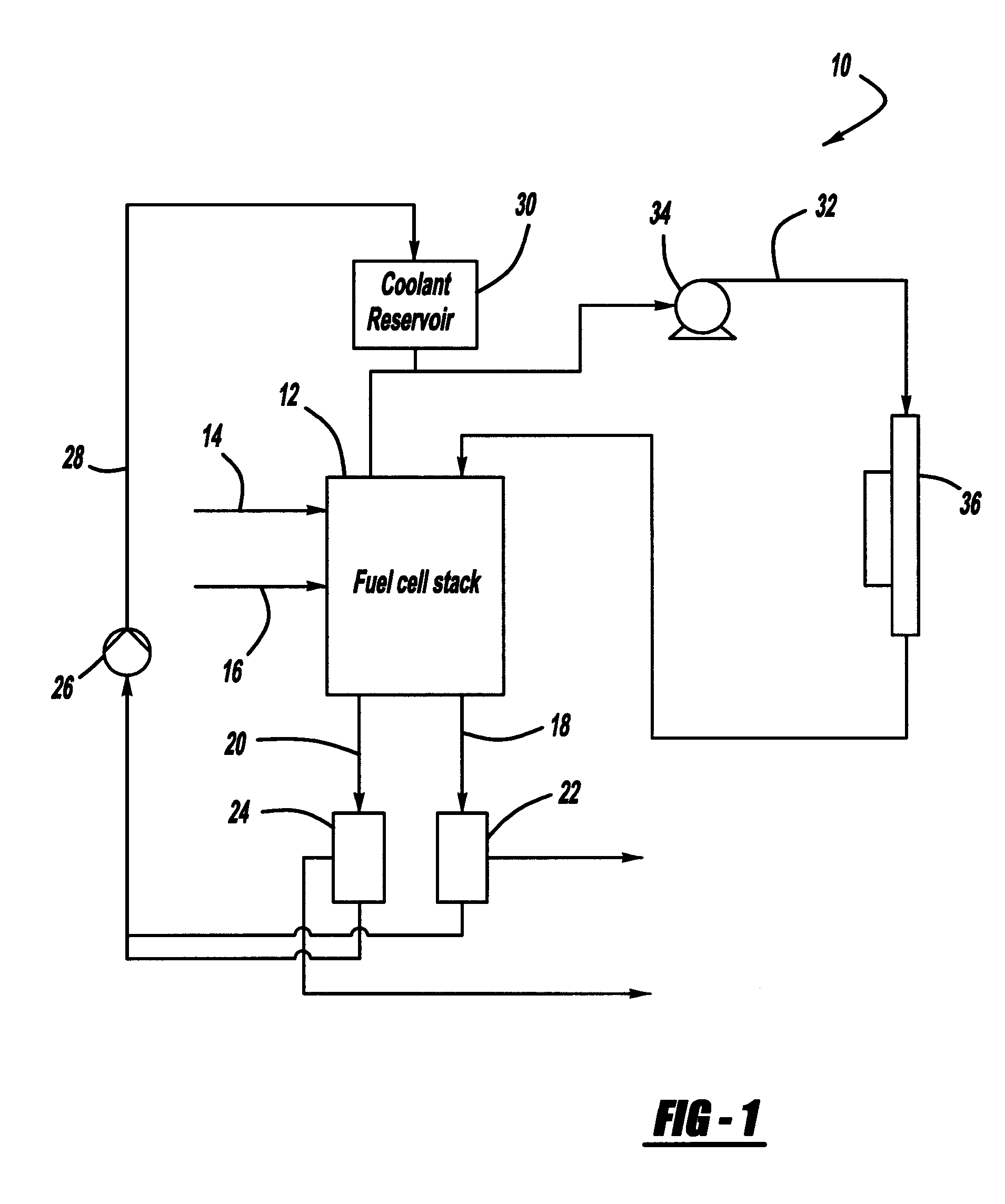

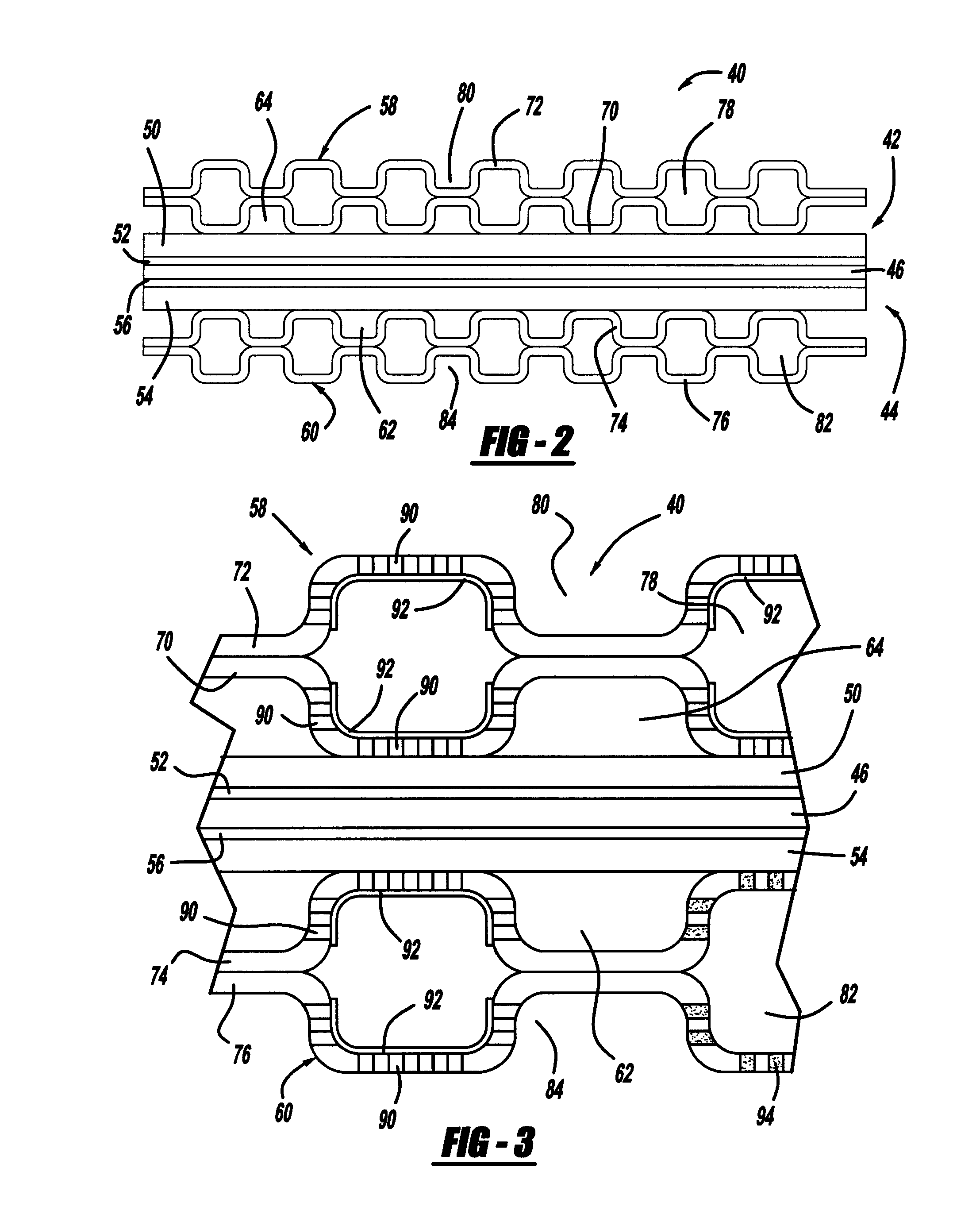

Internal proton exchange membrane humidification and cooling with automotive coolant

A bipolar plate for a fuel cell including pores extending between cooling fluid flow channels and reactant gas flow channels defined by the plate. Pervaporation membranes cover the pores and selectively allow water in the cooling fluid flowing down the cooling fluid flow channels to pervaporate through the membrane and humidify the reactant gas flowing down the reactant gas flow channels. In one embodiment, the bipolar plate includes two stamped unipolar plates secured together.

Owner:GM GLOBAL TECH OPERATIONS LLC

Technique and device for recovering tetrahydrofuran by pervaporation method

ActiveCN103408514AReduce moisture contentHigh recovery rateOrganic chemistryChemical industryThermodynamicsDistillation

The invention relates to a technique for recovering tetrahydrofuran by a pervaporation method, which comprises the following steps: adding crude tetrahydrofuran into a distillation kettle, adding acid or alkali to regulate the pH value to a neutral state, adding a reducer to remove peroxides in the crude tetrahydrofuran, distilling by heating, condensing the distilled hydrous tetrahydrofuran, collecting the hydrous tetrahydrofuran in a storage tank, discharging salt, heavy organic substance and part of water from the kettle bottom, delivering the hydrous tetrahydrofuran to a preheater through a pressure pump, exchanging heat with high-purity tetrahydrofuran steam at the preheater, sending into an evaporator, and sending the hydrous tetrahydrofuran from the evaporator into a pervaporation membrane separator, wherein the infiltration side of the pervaporation membrane separator is connected with a vacuum system; condensing infiltration water by an infiltration liquid condenser, sending into an infiltration liquid tank, and obtaining high-purity tetrahydrofuran at the trapping side of the pervaporation membrane separator; and passing the high-purity tetrahydrofuran through a preheater, condensing through a finished product condenser, and sending into a product tank. The invention has the advantages of simple technical process, high safety factor, low equipment investment, high energy utilization efficiency and high recovery rate.

Owner:JIANGSU NINE HEAVEN HIGH TECH

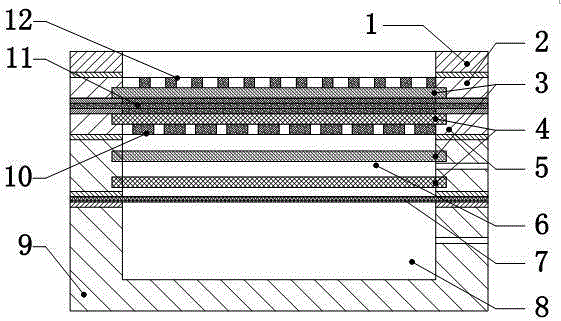

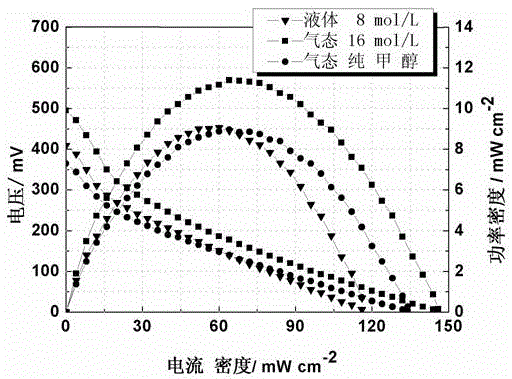

Direct methanol fuel cell capable of realizing pure methanol supply

ActiveCN105140546AAvoid saturationImprove energy utilizationReactant parameters controlSolid electrolyte fuel cellsHigh concentrationFuel cells

The invention discloses a direct methanol fuel cell capable of realizing pure methanol supply. The fuel cell comprises a cell shell, and a pervaporation membrane which is fixed on the cell shell and divides an inner chamber into a methanol fuel chamber and a steam chamber, wherein an anode flow field plate, a membrane electrode and a cathode flow field plate are sequentially arranged above the steam chamber from bottom to top in a stacking manner; a hollow cover plate covering a cathode collector plate is arranged at an open end of the cell shell in an insulation manner; a hydrophilic porous plate with hydrophily is arranged between the anode flow field plate and the anode side of the membrane electrode; a hydrophobic porous plate with hydrophobicity is arranged between the cathode side of the membrane electrode and the cathode flow field plate. According to the invention, continuous vaporization methanol supply is guaranteed, methanol crossover is restrained while cathode water is promoted to be reversely supplemented to the anode to participate in reaction, on the premise of guaranteeing output performance of the cell, the energy density of the cell is increased effectively, high-concentration methanol supply even pure methanol supply of the cell is realized and the service life of the cell is prolonged greatly.

Owner:SOUTH CHINA UNIV OF TECH

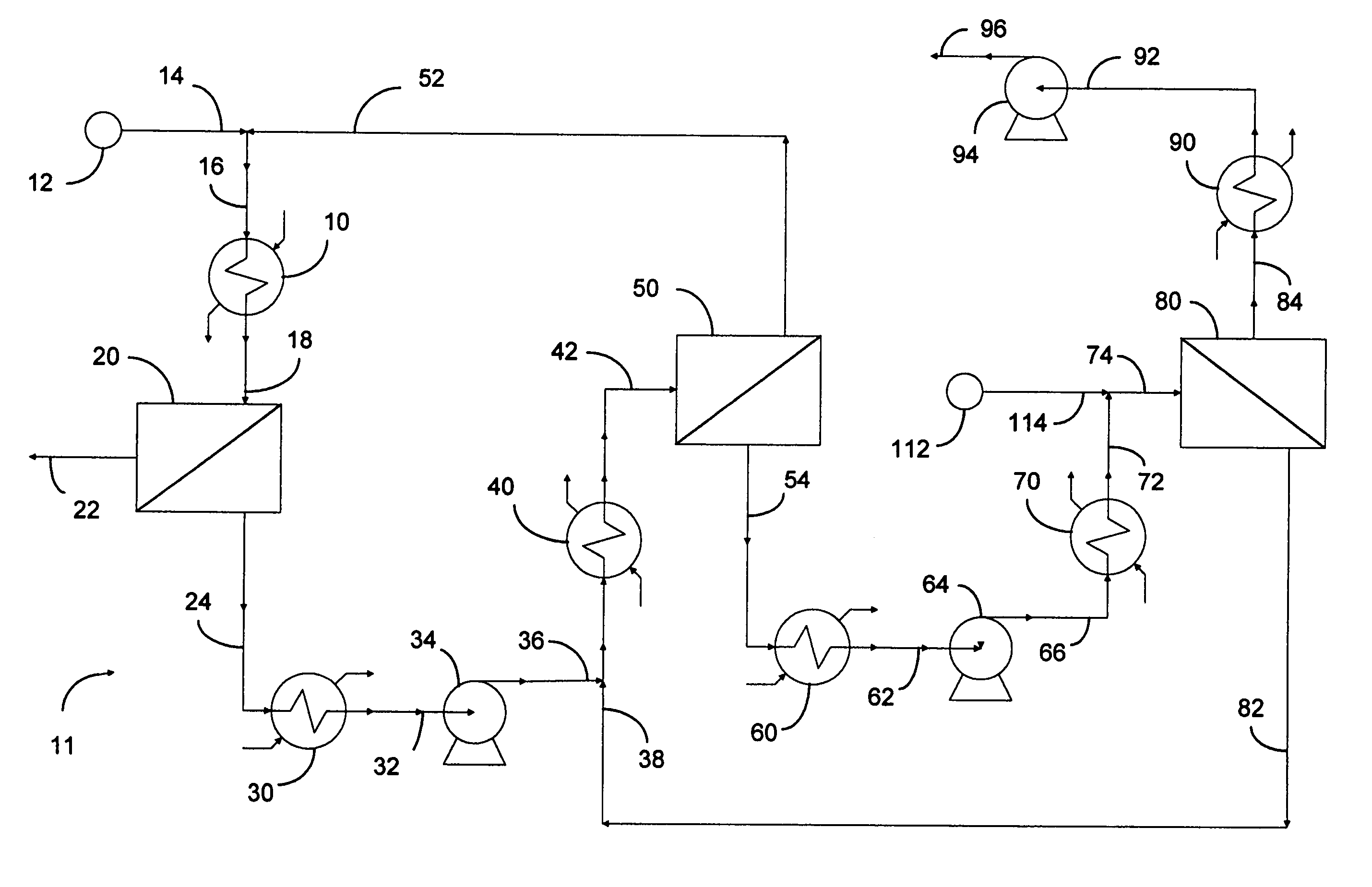

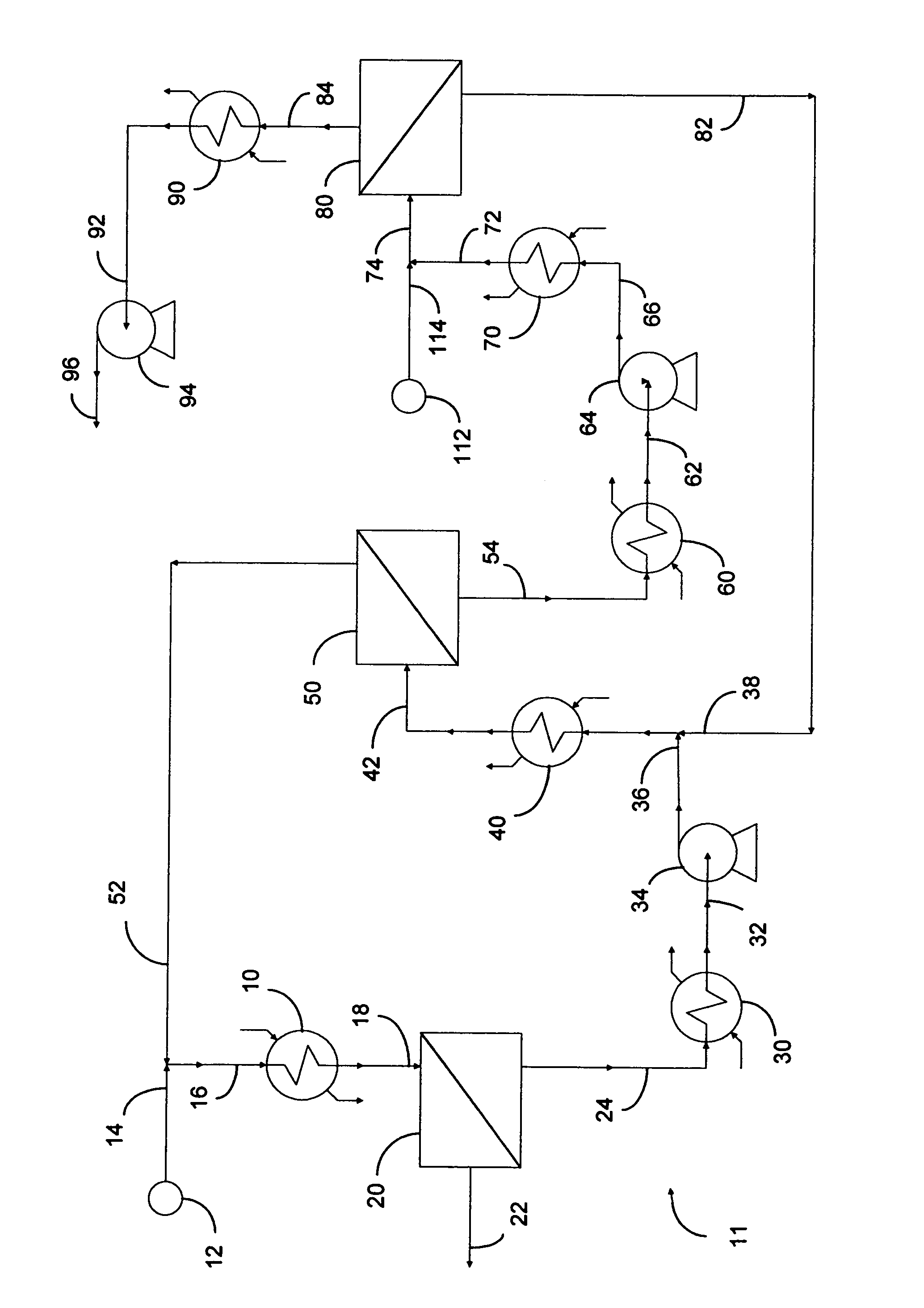

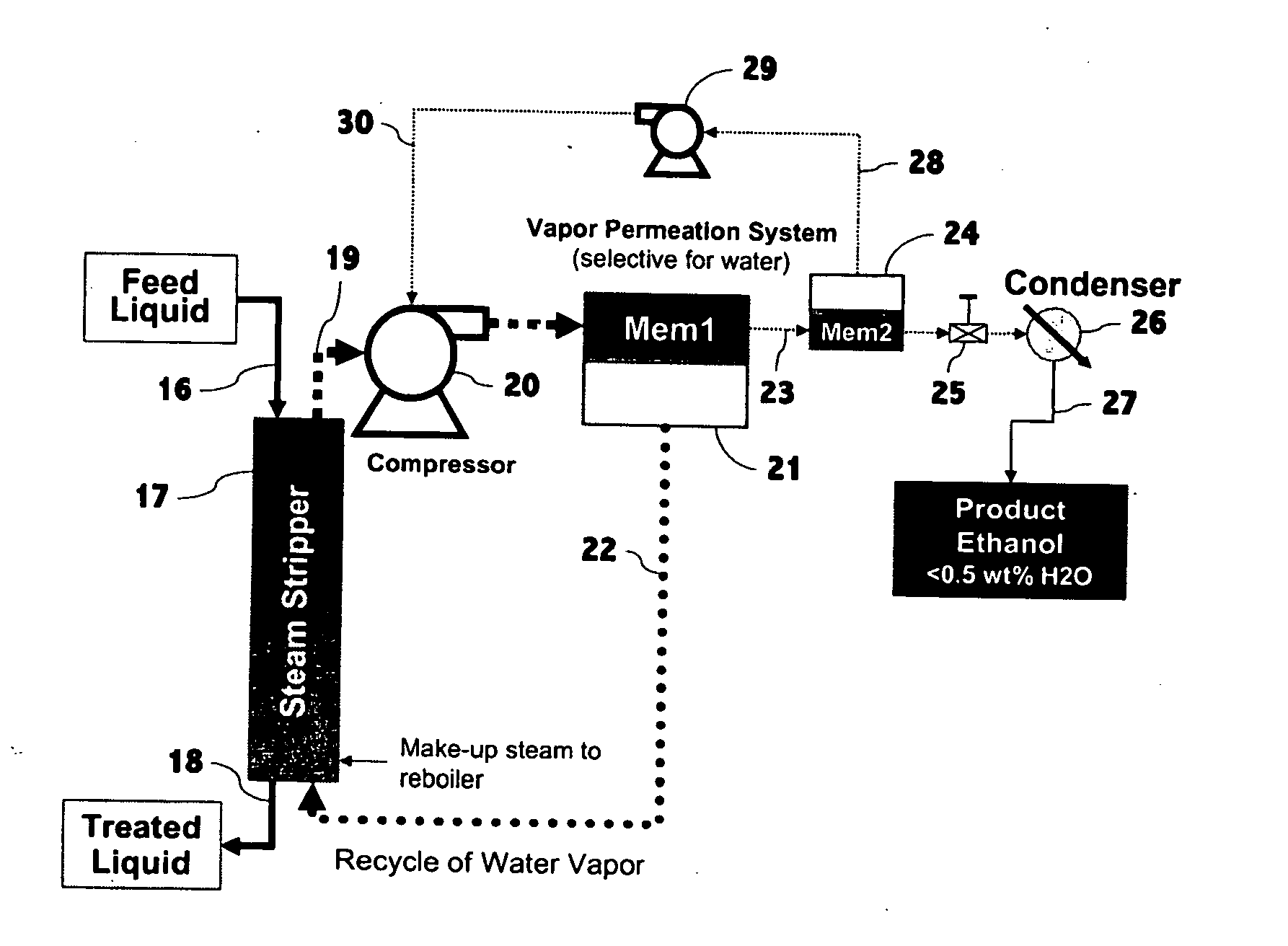

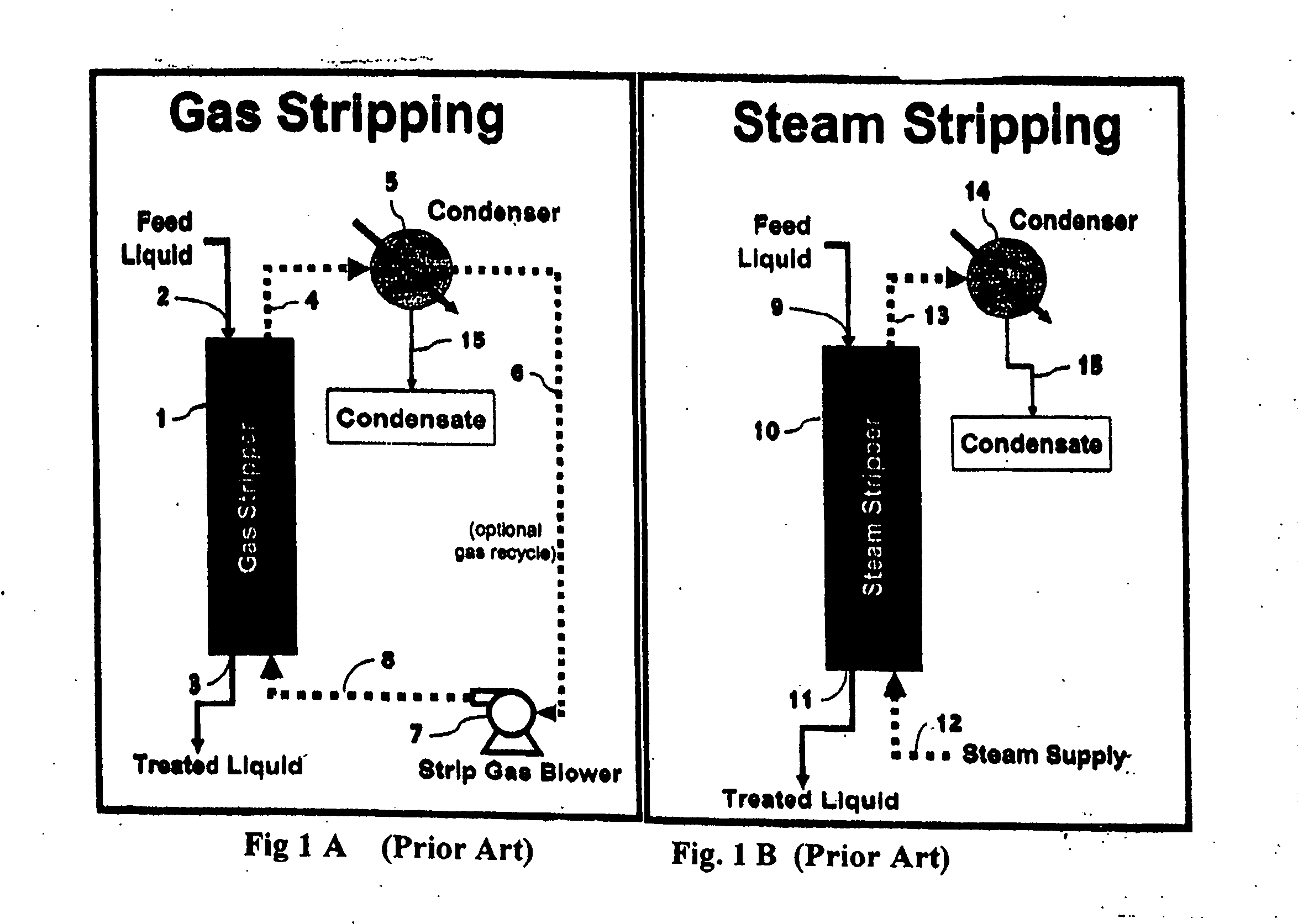

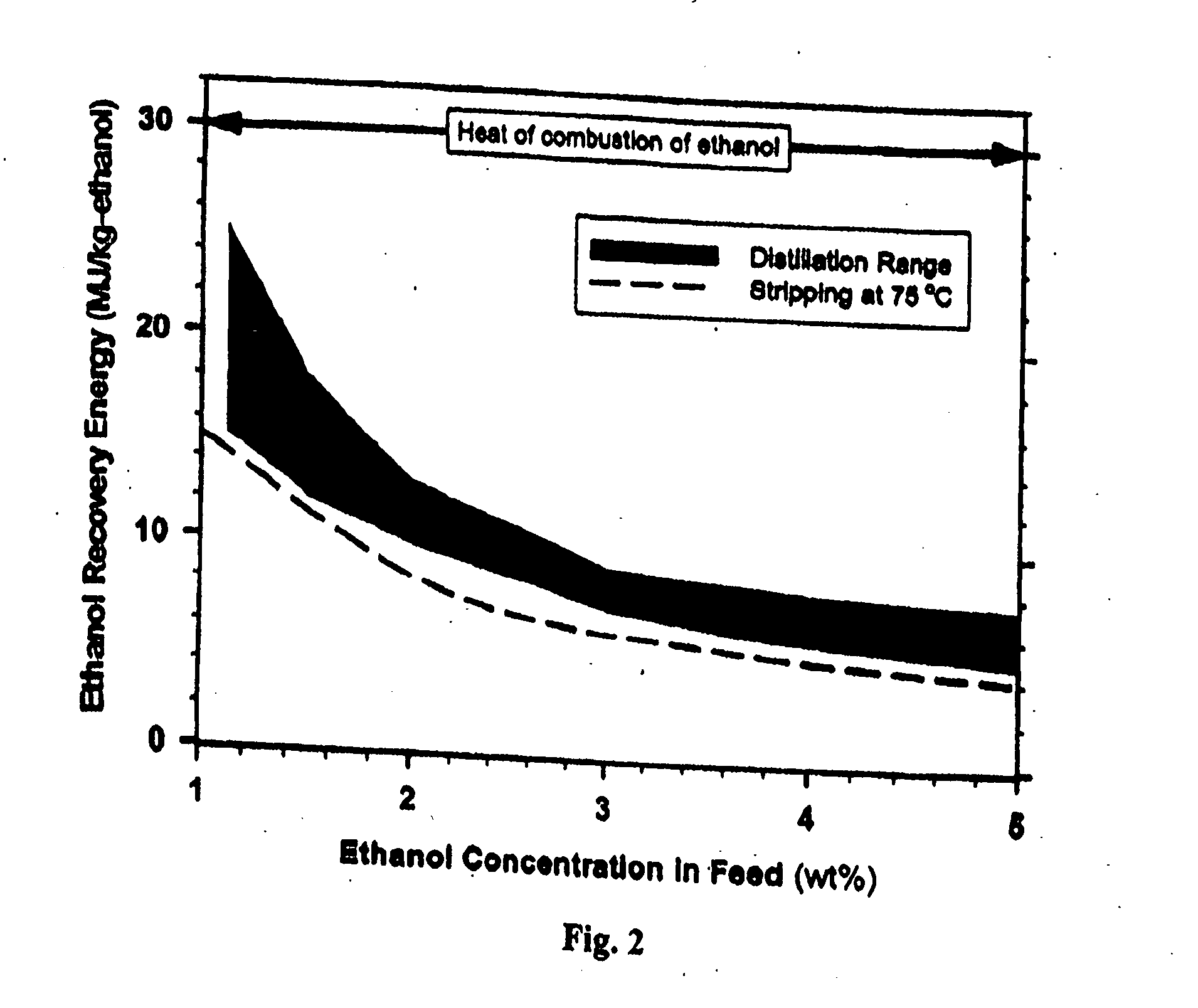

Liquid Separation by membrane assisted vapor stripping process

InactiveUS20130015052A1MembranesFermented solutions distillation/rectificationPhysical chemistrySolvent

An improved process for separation of liquid mixtures involves vapor stripping followed by mechanical compression of the vapor which is then exposed to a permeation membrane for separation of the compressed vapor. The apparatus for separating a liquid mixture of two or more solvents comprises components a stripping column, at least one over-head compressor and, thereafter, at least one selectively permeable membrane wherein the membrane separates the components of the vapor based on the different sorption and diffusion characteristics.

Owner:ENVIRONMENTAL PROTECTION AGENCY US

Method for treating reverse osmosis membranes with chlorine dioxide

InactiveUS20050061741A1Effective treatmentMinimize biofilm formationMembranesWater treatment parameter controlBillionthChlorine dioxide

Disclosed is a method for preventing osmotic membrane fouling comprising treating reverse osmotic feed water and membranes with chlorine dioxide at an extremely low concentration, e.g., as low as one part per billion in the feed water. The effective range may be in the range of 1-900 parts per billion. Also disclosed is a membrane separation system in which fouling is prevented using ultraviolet, pH acid adjustment or an electrochemical generator to produce the chlorine dioxide.

Owner:OCCIDENTAL CHEM CORP

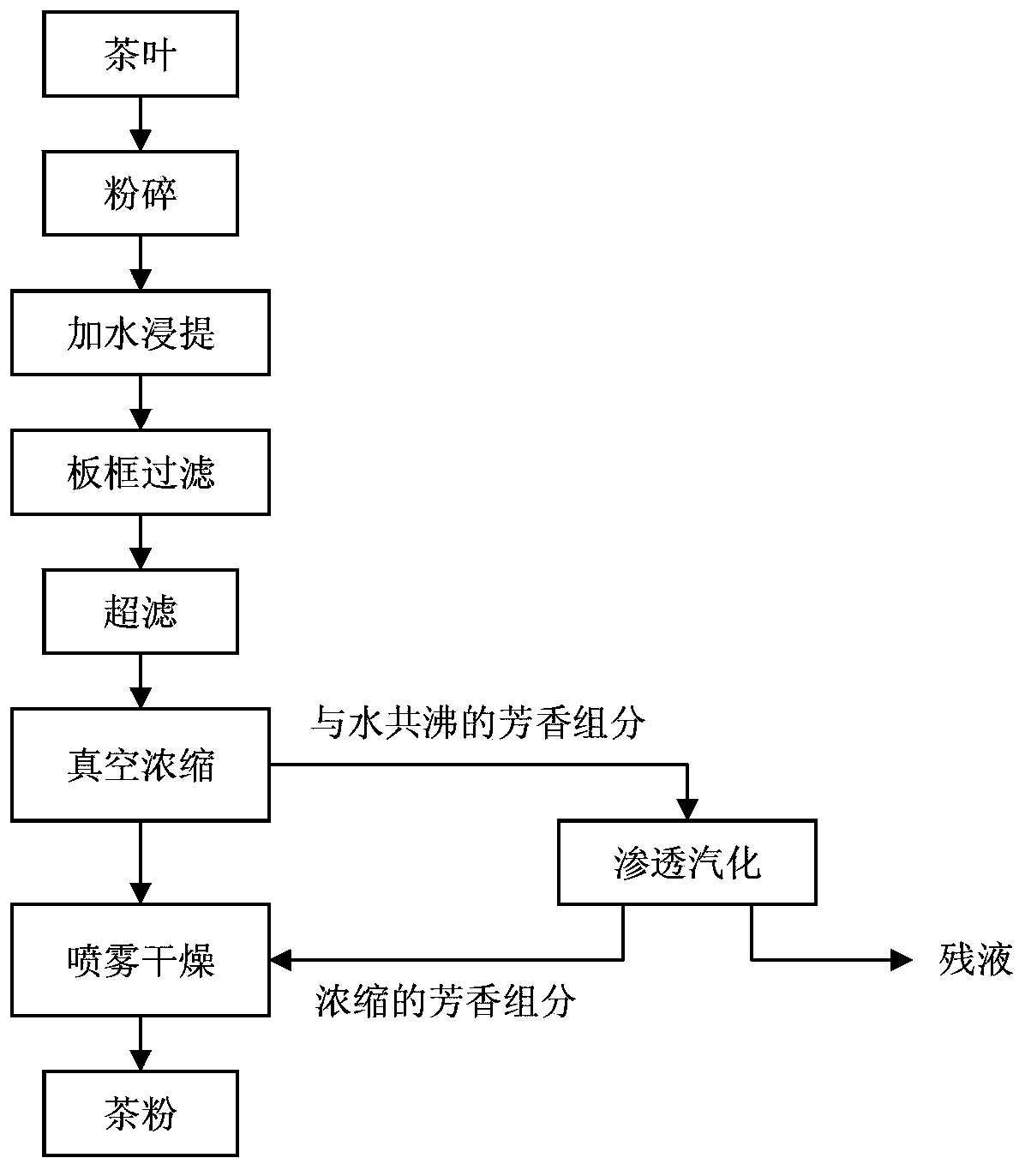

Recovery method for aroma components in production process for instant tea powder

The invention discloses a recovery method for aroma components in a production process for instant tea powder. The recovery method comprises the following steps: crushing tea into coarse powder by using a pulverizer, mixing the obtained tea powder with water and extracting aroma components in the tea; filtering tea soup obtained after extraction by using a multilayer plate and frame type filter press; subjecting a filtrate obtained after plate and frame type filtration to ultrafiltration so as to obtain a clear filtrate and subjecting the filtrate to vacuum concentration; subjecting a concentrate obtained after concentration to spray drying so as to obtain the tea powder, wherein solid content of the concentrate is 40 to 50 wt%; and with condensed water generated in the process of vacuum concentration as a material liquid for pervaporation, carrying out pervaporation membrane separation and subjecting concentrated aromatic substances in the tea to spray drying to recover the aromatic substances to the tea powder. According to invention, most aromatic substances in the tea can be recovered, the quality of the tea powder is improved, and the utilization rate of the tea is increased; compared with a traditional extractive distillation method and the like, the recovery method for the aroma components in the tea through pervaporation membrane separation has the advantages of high separability, low energy consumption, a mild operation temperature, no additive, etc.

Owner:NANJING UNIV OF TECH

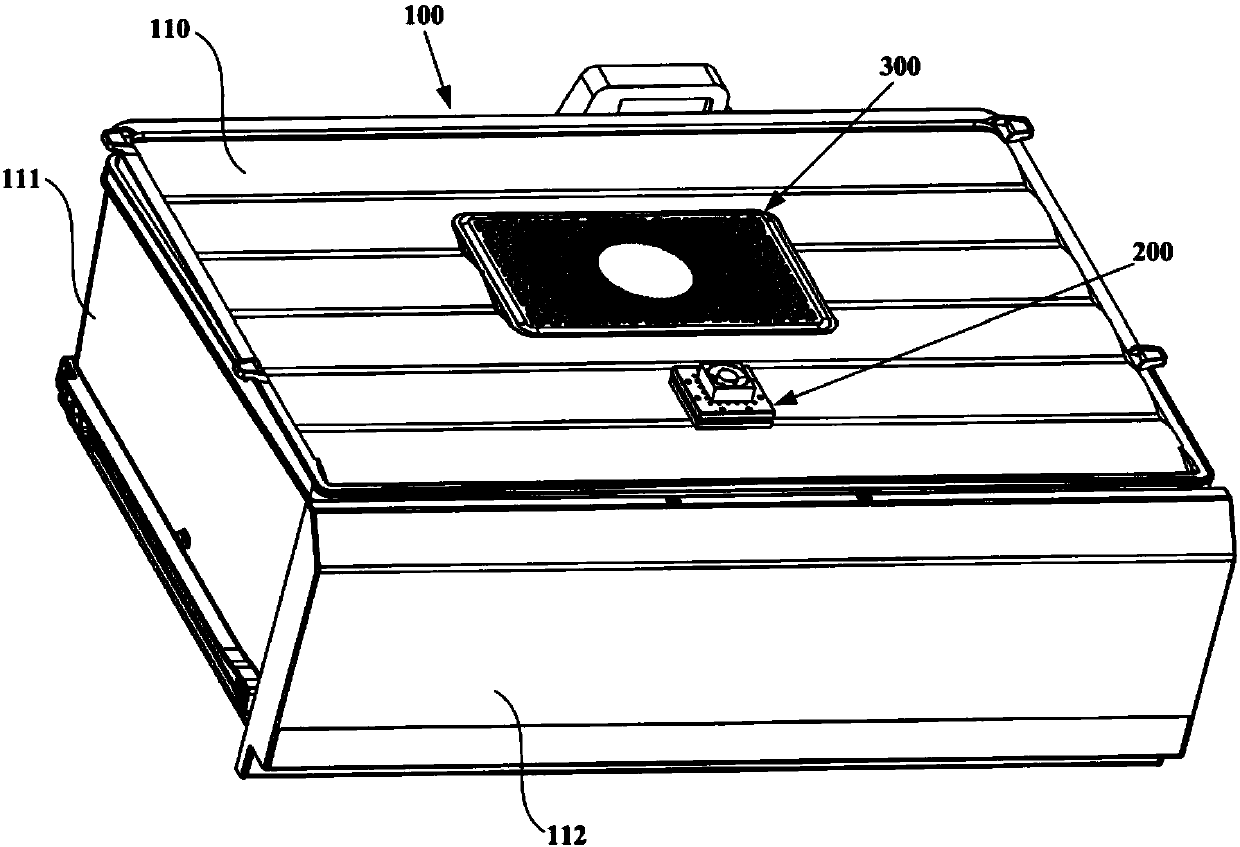

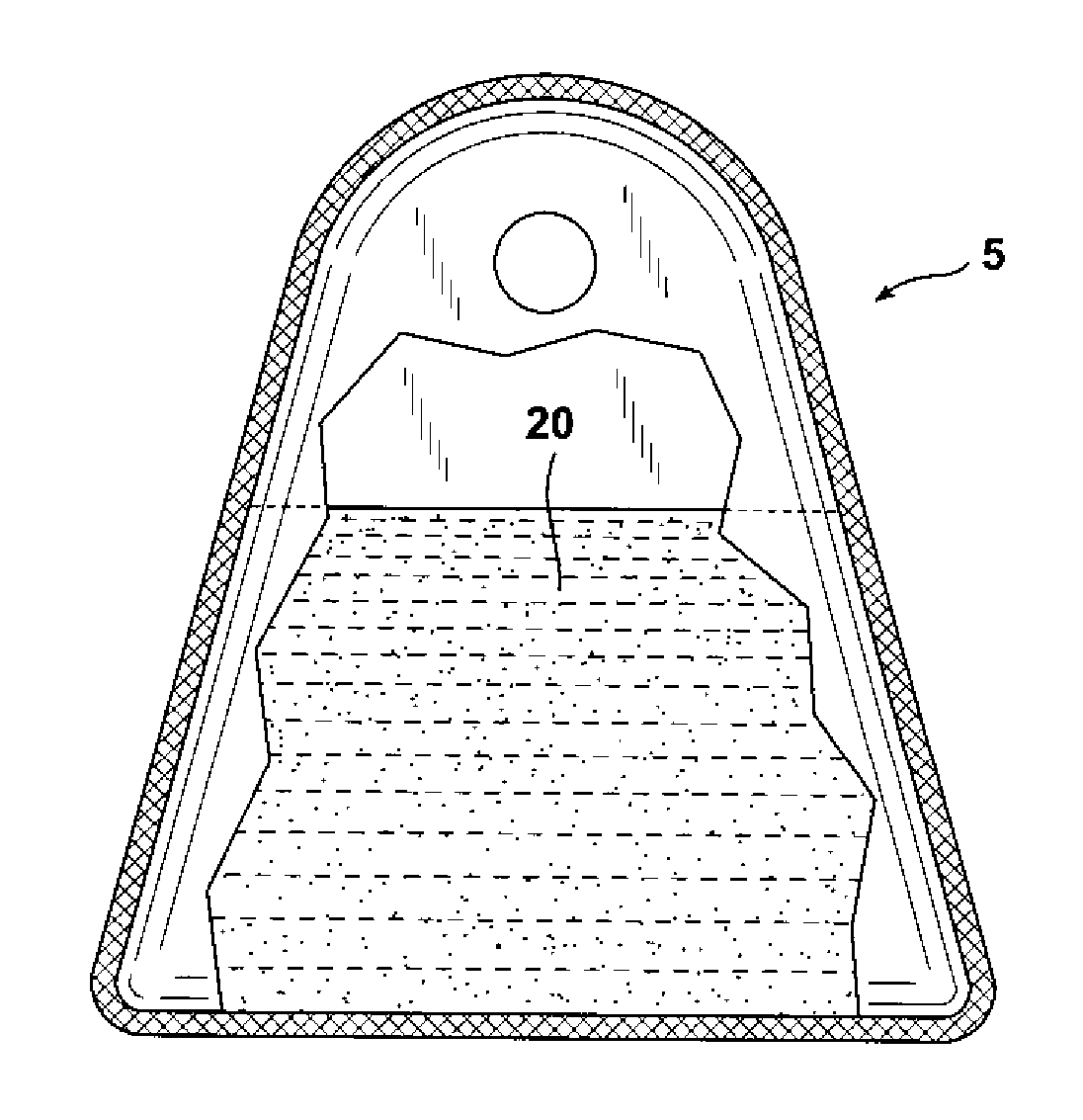

Ostomy Pouch Comprising Absorbent Material

InactiveUS20130035653A1Increase pressureSeal to ruptureEnvelopes/bags making machineryBox making operationsSubject matterAbsorbent material

The presently disclosed subject matter is directed to an ostomy pouch comprising at least one absorbent material housed within the interior of the pouch. Specifically, the absorbent materials are contained within a sachet that includes at least one of the following: a frangible seal, a porous film, or a fluid-permeable film. In use, as fluid enters the interior of the ostomy pouch and contacts the sachet, the porous film and / or the frangible seal weakens to allow fluid to enter the sachet and contact the absorbent material housed within. Alternatively or in addition, in embodiments wherein the sachet includes a fluid-permeable film, fluid directly enters the interior of the sachet. As a result, the absorbent material expands and ruptures the frangible seal and / or the sachet, thereby releasing the absorbent material into the interior of the pouch for full absorption of the fluid.

Owner:CRYOVAC INC

A kind of method for preparing organic pervaporation membrane

ActiveCN102274693ASimple preparation stepsReduce manufacturing costDistillationOrganic matterSolvent

The invention relates to a method for preparing a composite pervaporation membrane. The method comprises the following steps of: dissolving an organic matter in a solvent to prepare a homogeneous phase membrane forming solution; adding a crosslinking agent and a difunctional conditioning agent into the membrane forming solution, uniformly mixing and adding a catalyst; coating the prepared membrane forming solution containing the difunctional conditioning agent on a supporting body; and finally performing aftertreatment on the composite membrane to prepare the composite pervaporation membrane.By the method, the permeability and selectivity of the pervaporation membrane can be improved simultaneously, and the stability of the composite membrane is also improved.

Owner:JIANGSU JIUMO HIGH TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com