A pervaporation rectification coupled system and a use thereof

A rectification coupling and pervaporation technology, which is applied in the system field of pervaporation and rectification coupling, can solve the problems that it is difficult to meet the requirements of extremely low moisture, increase investment and operation costs, and it is difficult to dehydrate to high-purity products. Save energy and cost, reduce equipment investment, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

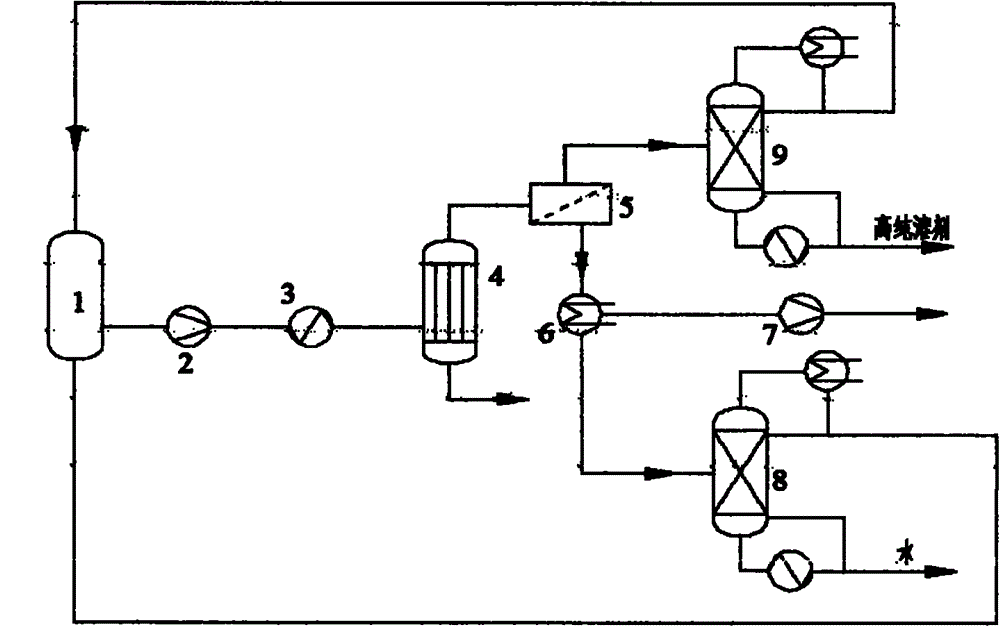

[0026] See figure 1 , a system coupled with pervaporation and rectification, comprising a raw material tank 1, a raw material pump 2, a preheater 3, a pervaporation membrane separator 5, a first rectification tower 8 and a second rectification tower 9, the raw material Tank 1, raw material pump 2, preheater 3 and pervaporation membrane separator 5 are connected successively. A second rectification column 9 is connected to the side. The top of the second rectification tower 9 and the top of the first rectification tower 8 are respectively connected with the raw material tank 1 . The pervaporation membrane separator 5 is composed of 4 NaA type membrane separators connected in series, and the permeation side of the pervaporation membrane separator 5 is also connected with a condenser 6 and a vacuum unit 7 to obtain sufficient water permeation partial pressure difference. An evaporator 4 is also connected between the preheater 3 and the pervaporation membrane separator 5 .

[0...

Embodiment 2

[0030] See figure 1 , the system pervaporation-rectification coupled process of embodiment 1 is used for the dehydration of butanone / water mixed solution, and the steps are as follows:

[0031] Butanone solution with a water content of 11wt.% and a flow rate of 500kg / h is transported from the raw material tank 1 to the preheater 3 through the raw material pump 2, and enters the evaporator 4 after being preheated by the product steam, and the raw material liquid is heated to above 135°C In the form of steam, it enters the pervaporation membrane separator 5 composed of 7 T-type molecular sieve membrane separators in series for dehydration and separation. The pressure of the retentate side of the membrane is controlled at a gauge pressure of 150-200kPa, and the absolute pressure of the permeate side is 3000-5000Pa. The permeate with a water content of 92.5wt.% enters the rectification tower 8 after being condensed, and a methyl ethyl ketone solution with a water content of about...

Embodiment 3

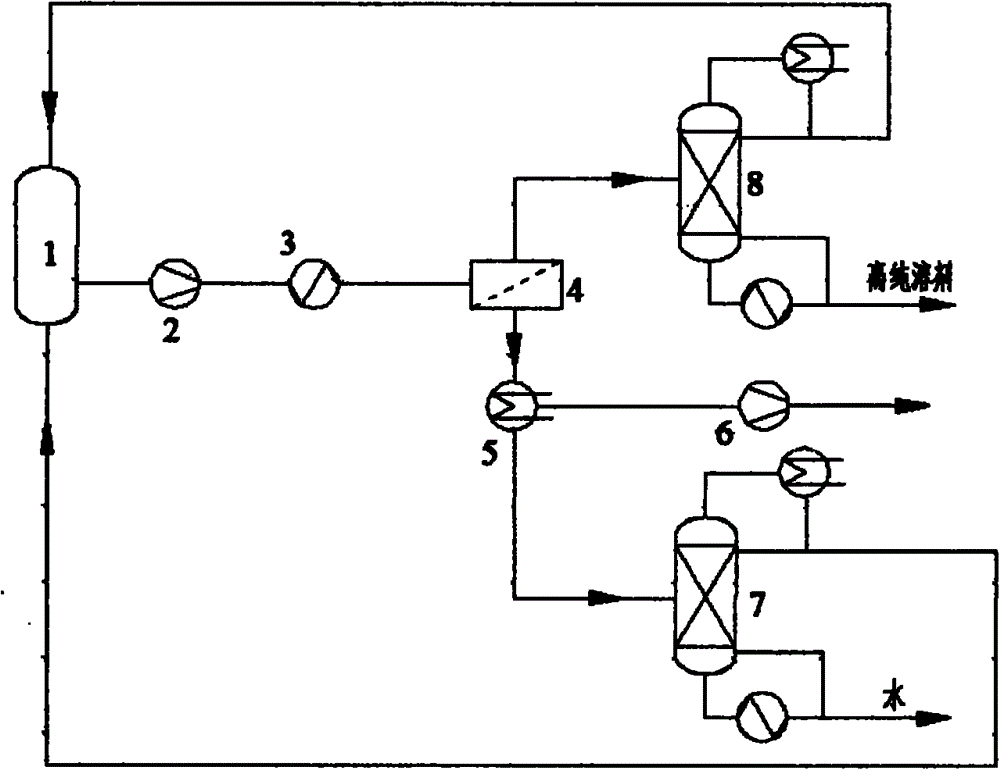

[0033] See figure 2 , a system coupled with pervaporation and rectification, comprising a raw material tank 1, a raw material pump 2, a preheater 3, a pervaporation membrane separator 4, a first rectification column 7 and a second rectification column 8, the raw material Tank 1, raw material pump 2, preheater 3 and pervaporation membrane separator 4 are connected in sequence, and the permeation side of the pervaporation membrane separator 4 is connected with a first rectification column 7, and the pervaporation membrane separator 4 retentates A second rectification column 8 is connected to the side. The top of the second rectification tower 8 and the top of the first rectification tower 7 are respectively connected with the raw material tank 1 . The pervaporation membrane separator 4 is composed of 12 PVA membrane separators connected in series. The permeation side of the pervaporation membrane separator 4 is also connected with a condenser 5 and a vacuum unit 6 to obtain s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com