Patents

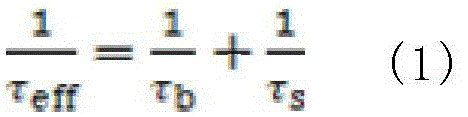

Literature

86 results about "Back diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

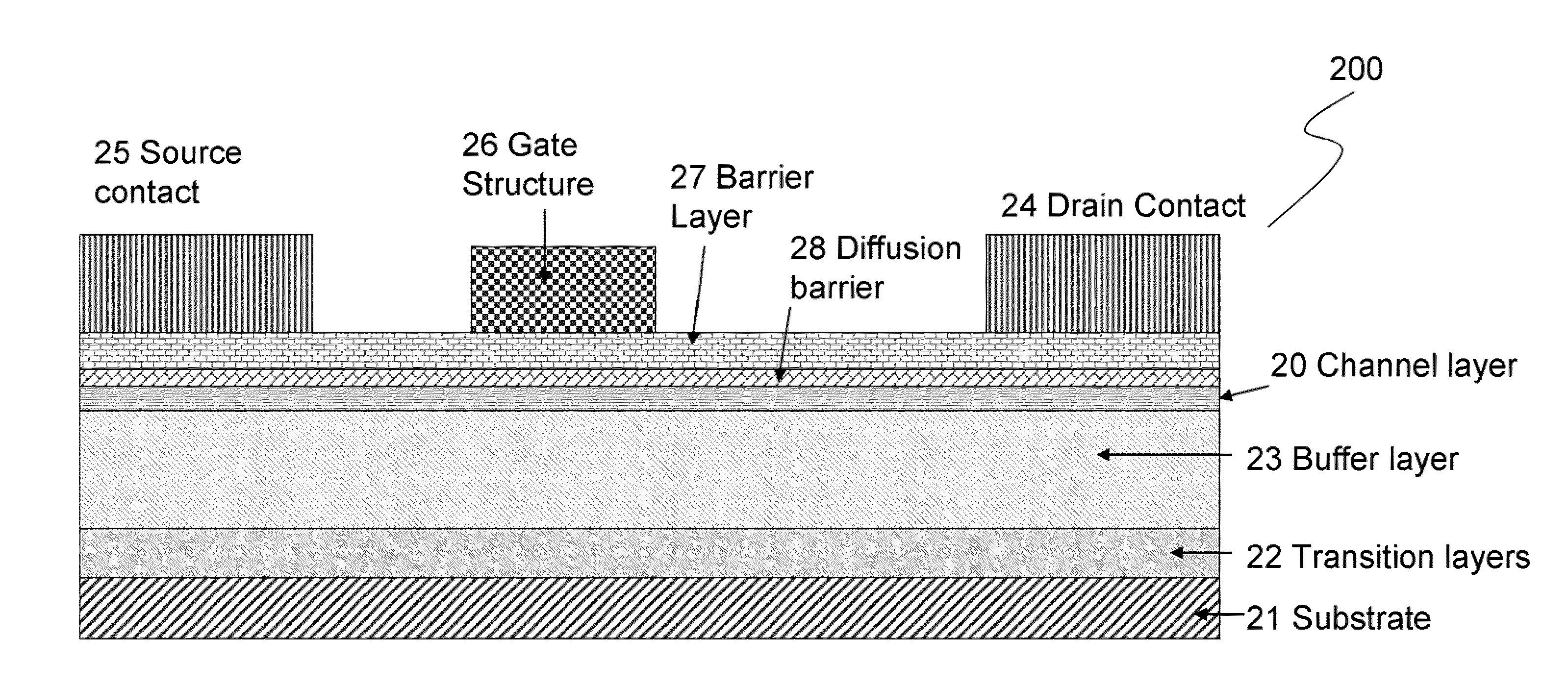

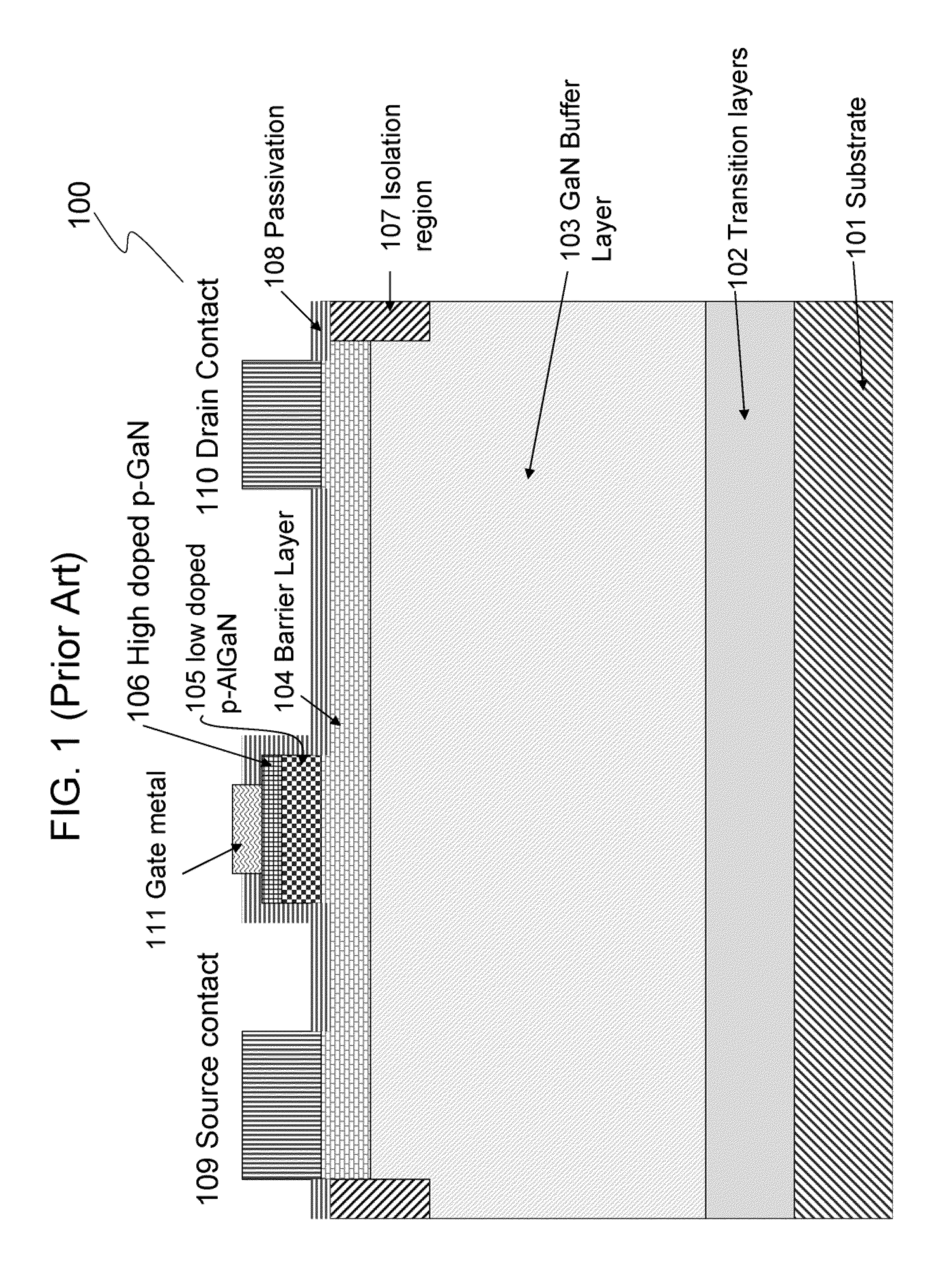

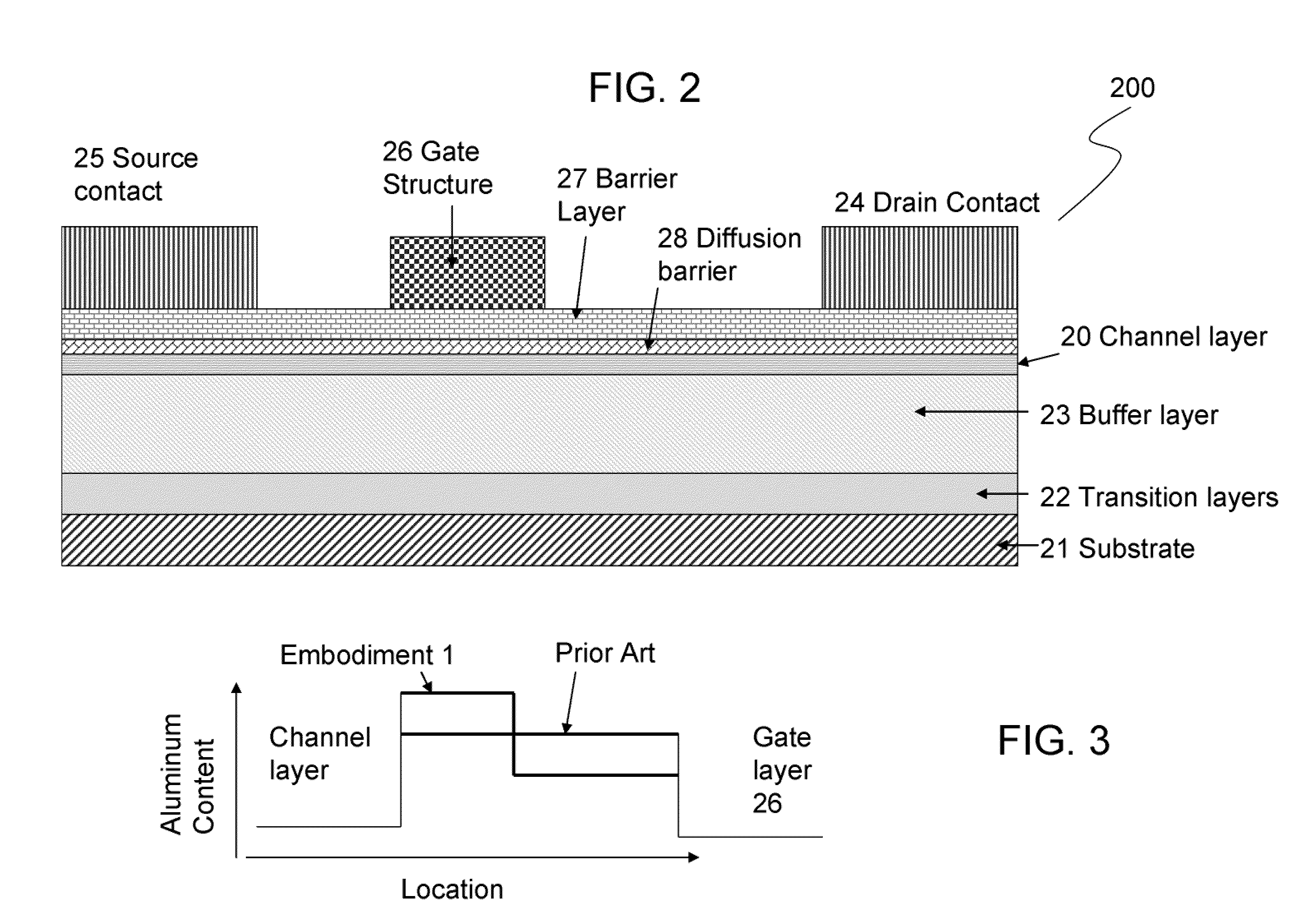

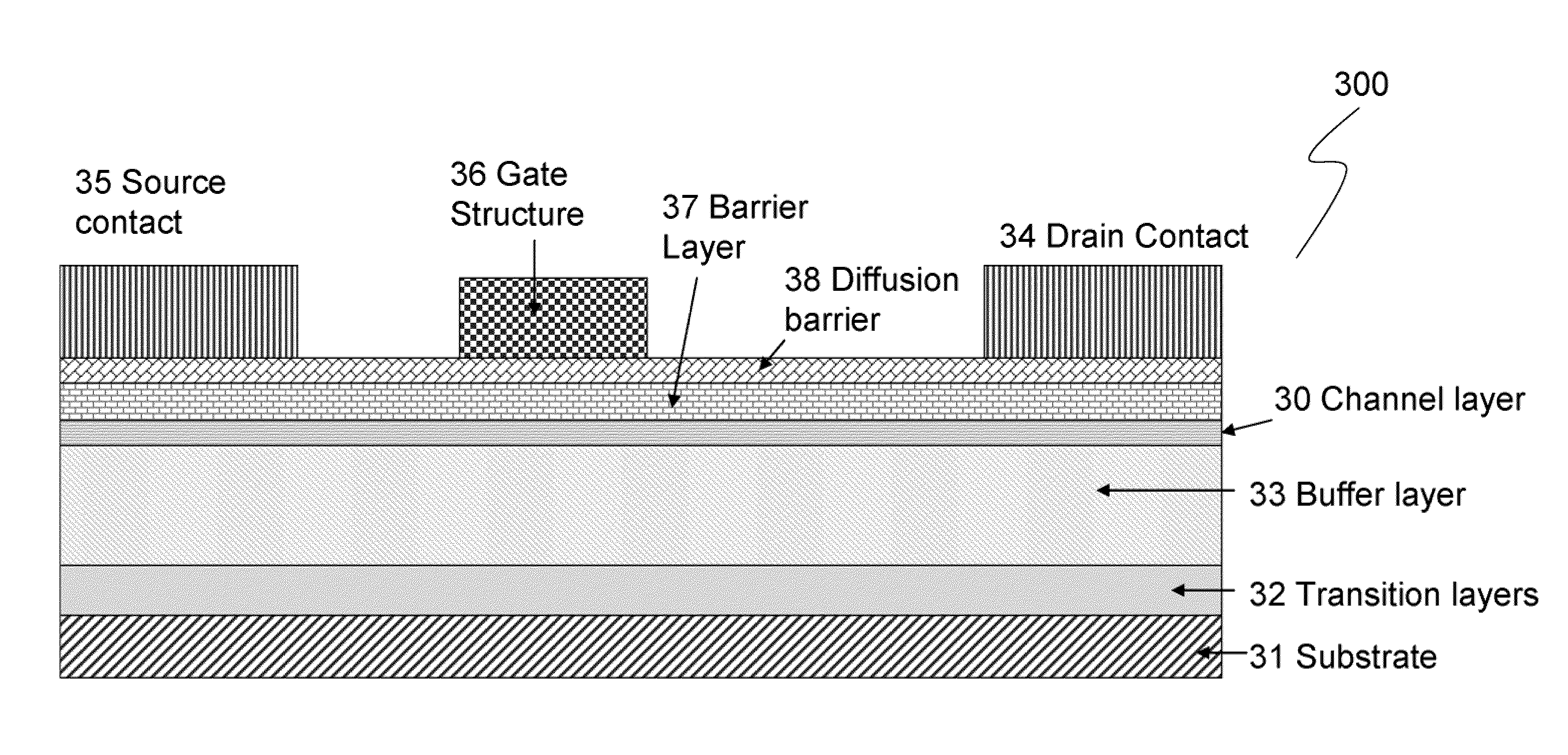

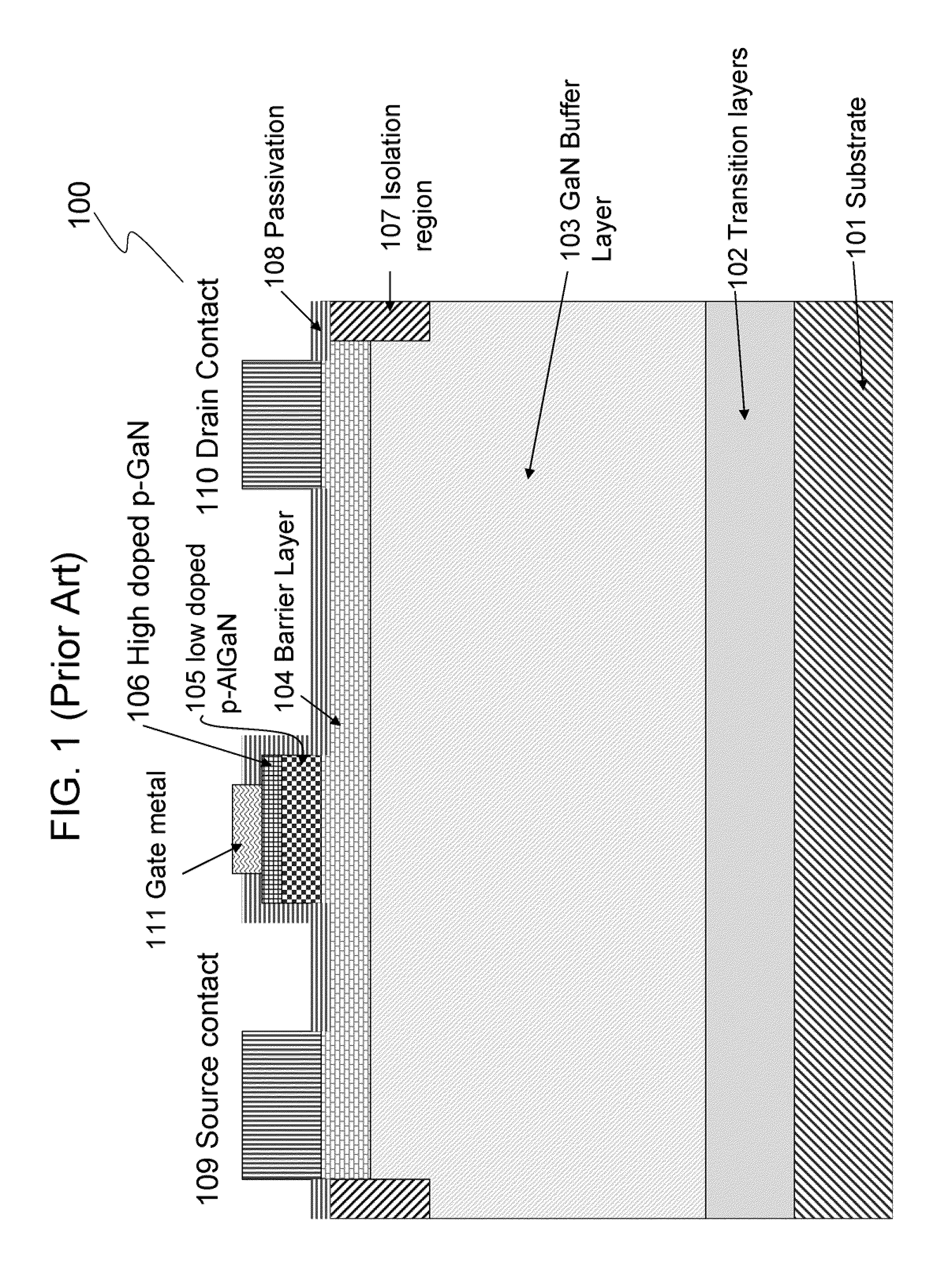

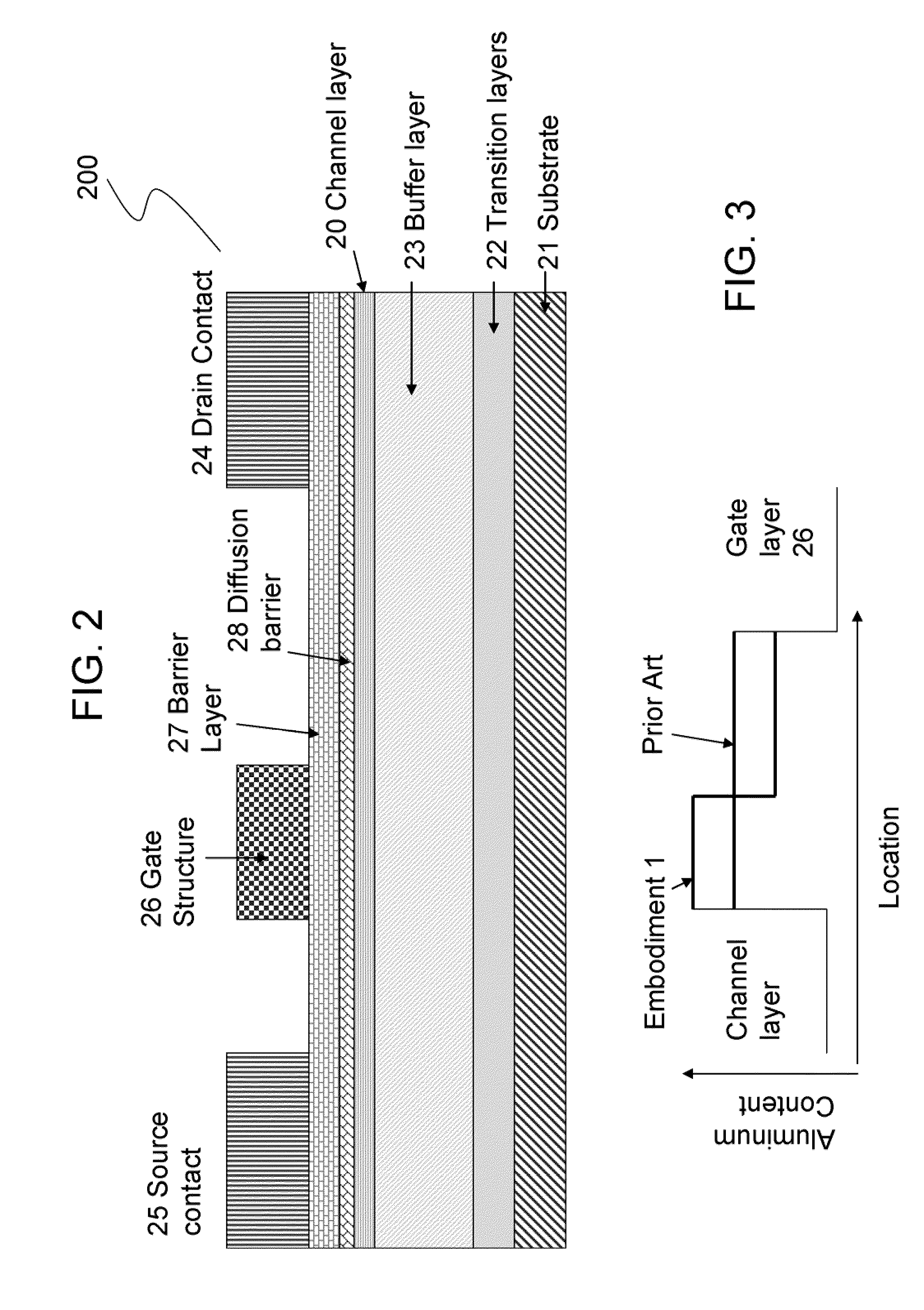

Back diffusion suppression structures

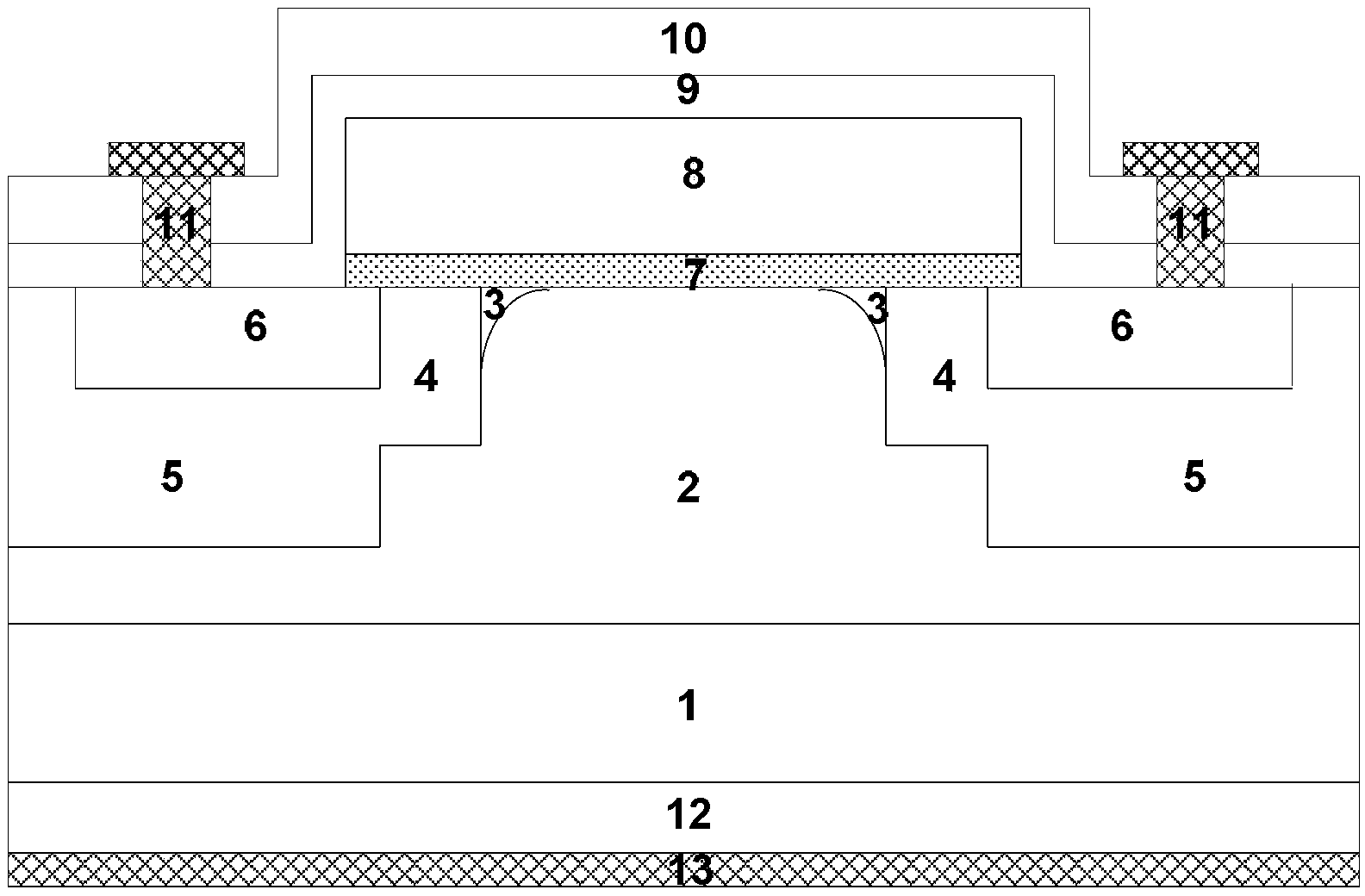

ActiveUS20100258841A1Avoid disadvantagesSemiconductor/solid-state device manufacturingSemiconductor devicesDiffusion barrierBack diffusion

An enhancement-mode GaN transistor, the transistor having a substrate, transition layers, a buffer layer comprised of a III Nitride material, a barrier layer comprised of a III Nitride material, drain and source contacts, a gate containing acceptor type dopant elements, and a diffusion barrier comprised of a III Nitride material between the gate and the buffer layer.

Owner:EFFICIENT POWER CONVERSION CORP

Forward osmosis membrane for seawater desalination and method for preparing the same

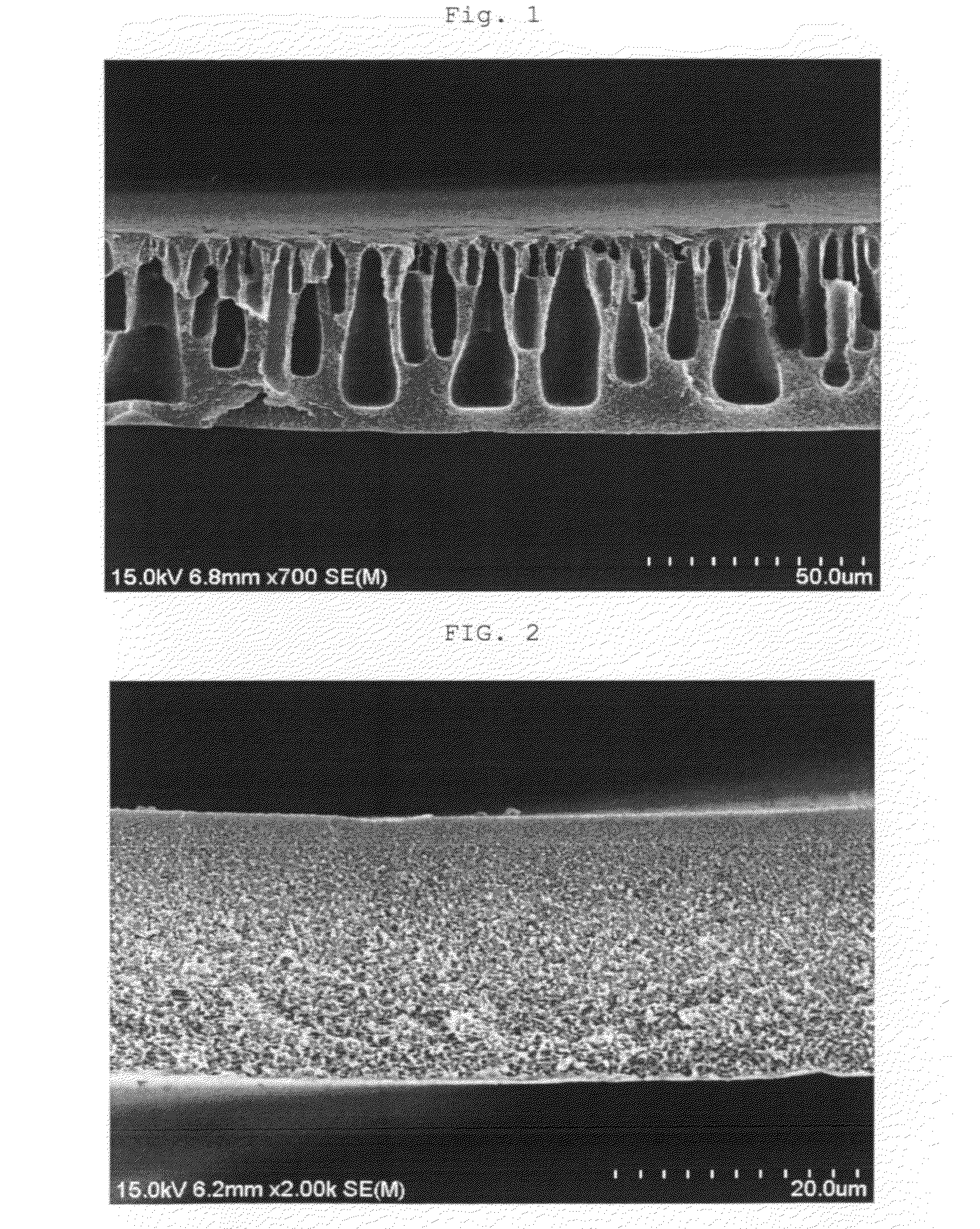

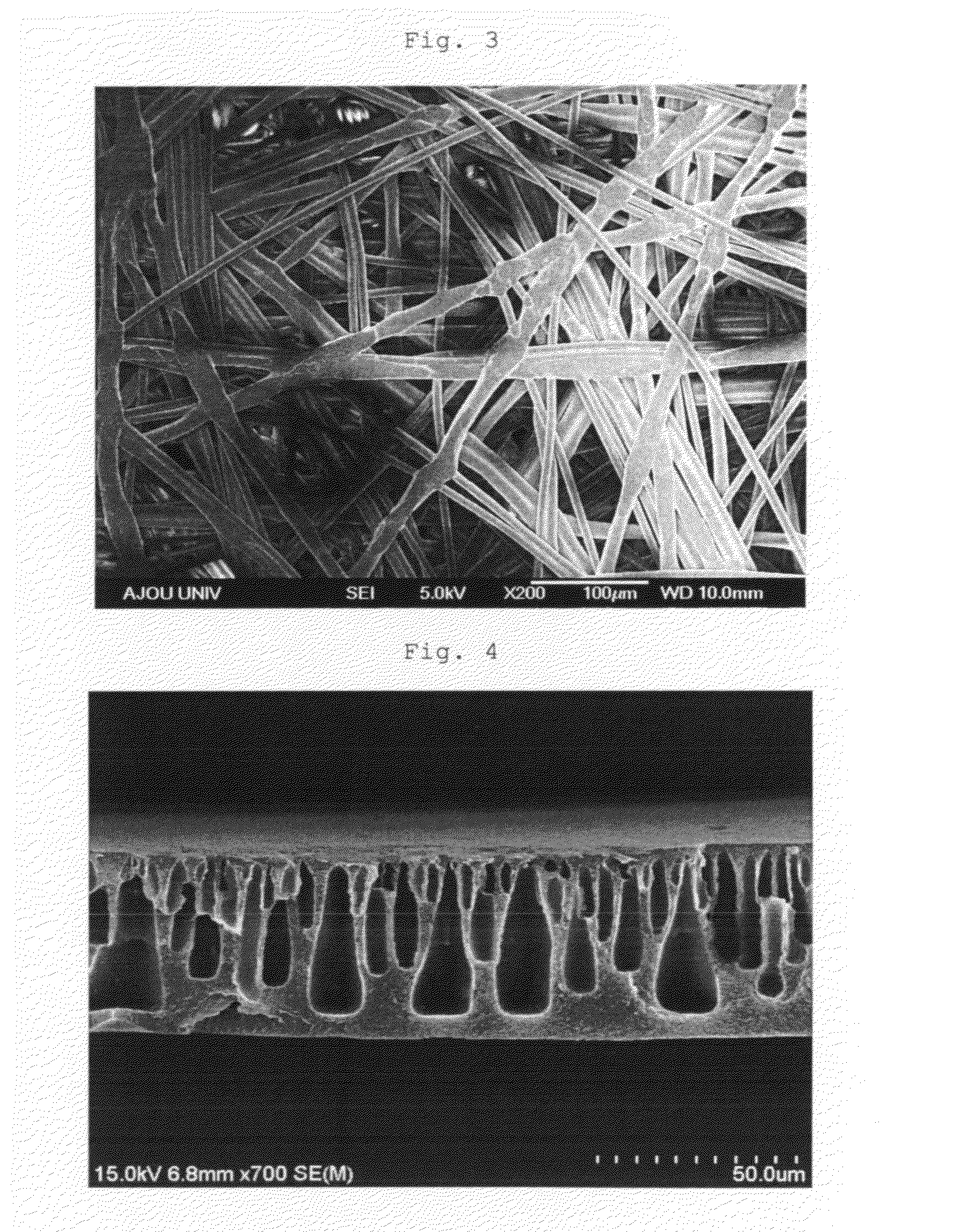

ActiveUS20120043274A1Good water permeabilityHigh porositySemi-permeable membranesMembranesHigh concentrationHydrophilic polymers

A forward osmosis membrane for seawater desalination and a method for preparing the same. The forward osmosis membrane has a composite membrane structure including a nonwoven fabric layer, a hydrophilic polymer layer, and a polyamide layer. The hydrophilic polymer layer formed on the nonwoven fabric layer facilitates an inflow of water from the feed water to the draw solution to enhance flux and realize high water permeability in the direction of osmosis. The polyamide layer not only secures contamination resistance and chemical resistance but also minimizes the back diffusion of salts of the draw solution in the direction of reverse osmosis. Hence, the forward osmosis membrane of the present invention is greatly useful for desalination of high-concentration seawater.

Owner:TORAY ADVANCED MATERIALS KOREA

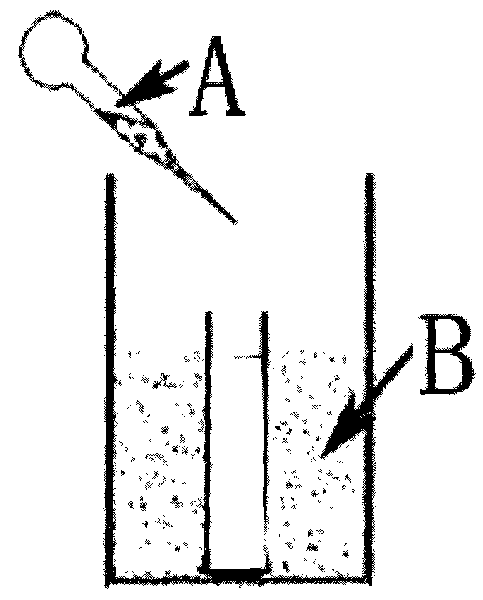

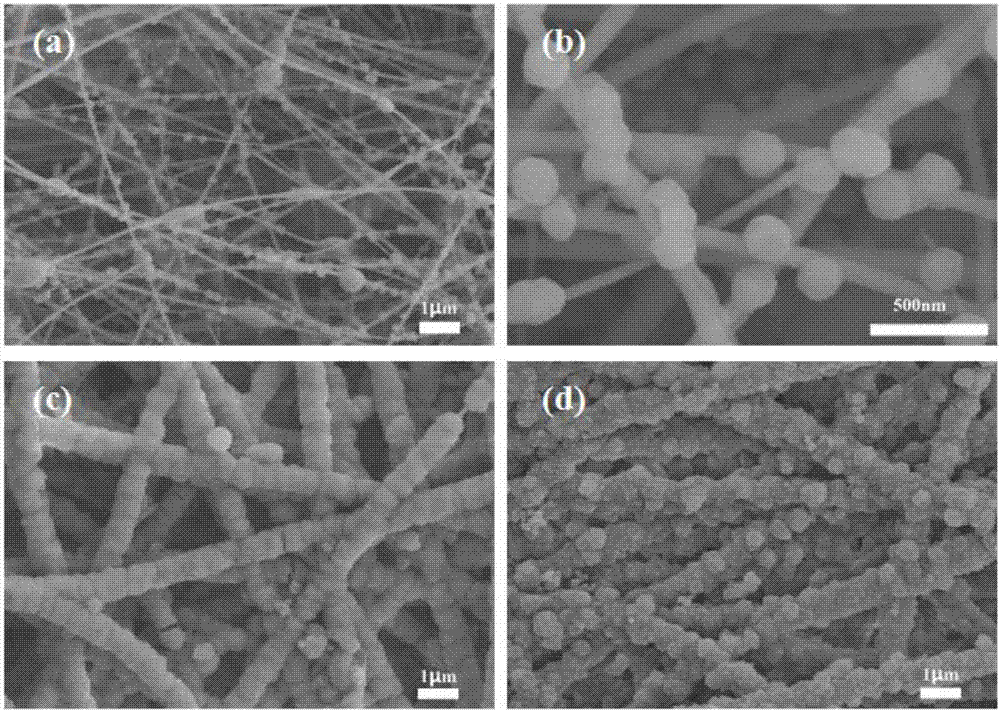

Method for preparing metal organic framework film

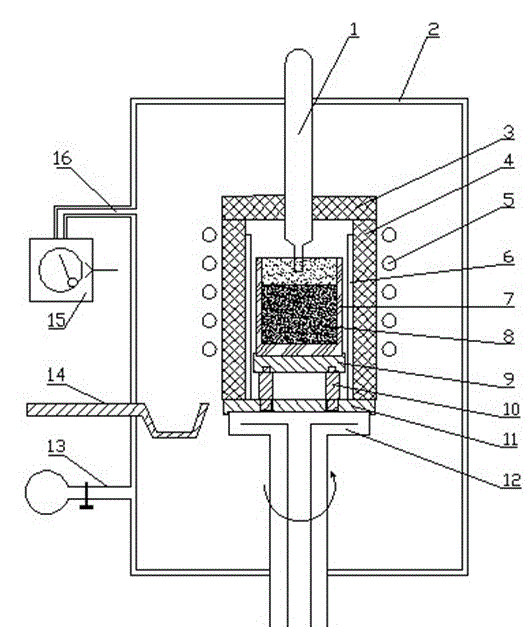

InactiveCN101693168AEasy to operateWide applicabilitySemi-permeable membranesDiffusionMetal framework

The invention belongs to the technical field of new material, and relates to a method for preparing a novel metal organic framework (MOFs) film and the potential application prospect thereof, in particular to the MOFs film which is continuous, compact, firm and crackles and is prepared on the surface of a porous carrier by a back diffusion method. The invention is characterized in that metal precursor of a synthetic membrane and organic ligand nutrient solution are respectively supplied from the two sides of a carrier tube (as shown); the diffusion of metal precursor nutrient solution is promoted to facilitate metal organic framework compound to crystallize and grow on the surface of the carrier; and finally, the MOFs separating film which is continuous, compact, firm and crackles and hasselective permeability for molecular mixture is obtained. The invention has the effect and advantage of solving the difficulty that the binding force between metal framework organic matter and the carrier is weak, so that the continuous and compact film is hardly formed; furthermore, the invention provides the method which is used for preparing the MOFs film as well as simple in operation and easy in control, thus initiating the precedent of preparing the MOFs film with high performance on the tubular carrier.

Owner:DALIAN UNIV OF TECH

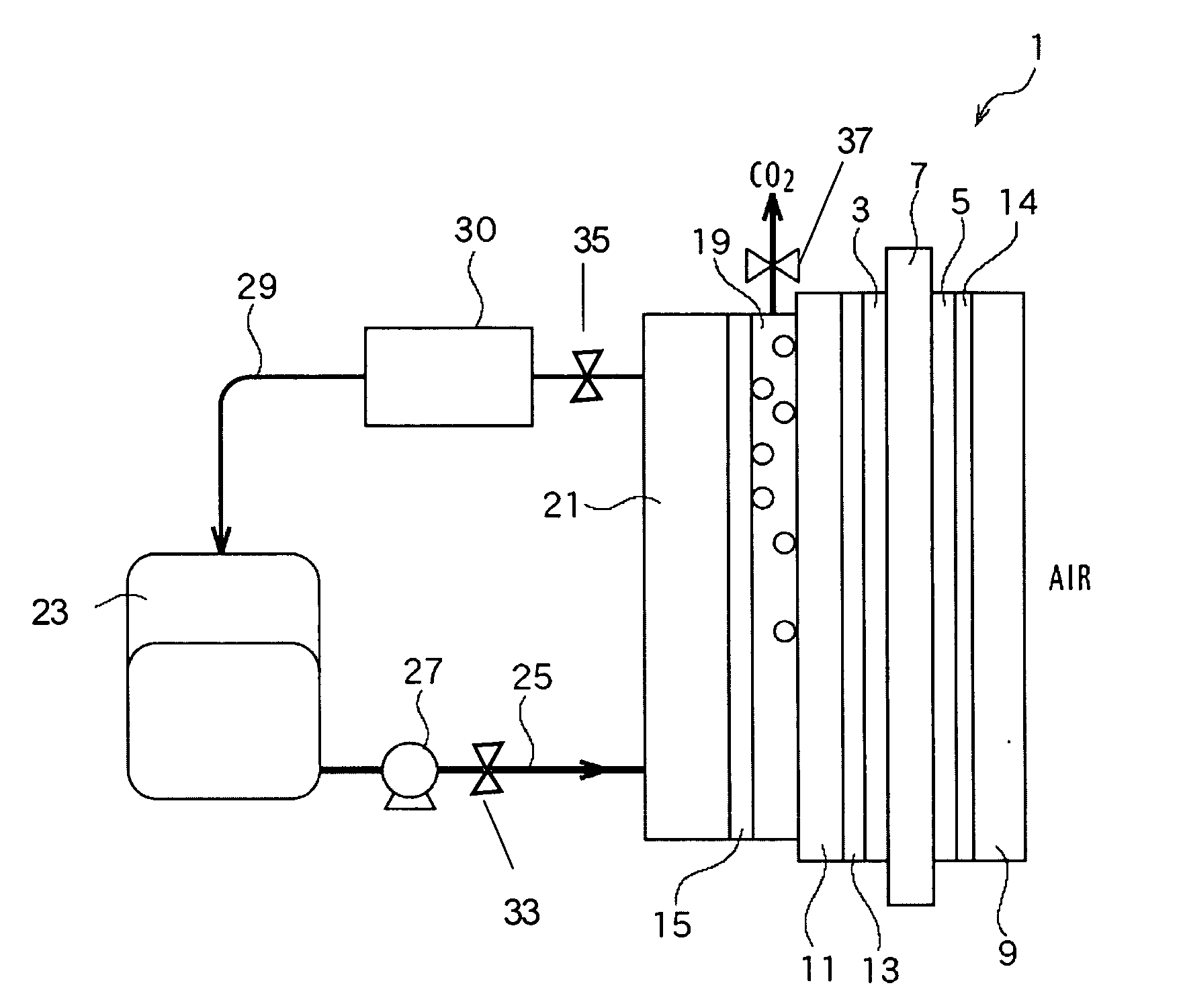

Methods to control water flow and distribution in direct methanol fuel cells

InactiveUS20060134487A1Good cell performanceGood fuel efficiency performanceWater management in fuel cellsSolid electrolyte fuel cellsFuel efficiencyAir cathode

A direct methanol fuel cell unit is provided with a fuel cell including an anode, a cathode with a hydrophobic microporous layer, an electrolyte membrane put in-between, and a fuel supply path supplying fuel to the anode. The fuel supply path is provided with an upwind water barrier preventing back-diffusion of water and a gas flow path channeling gas generated at the anode and disposed between the barrier and the anode. A water-rich zone is formed between the water barrier and the cathode microporous layer. Water loss from either side of this zone is eliminated or minimized, thereby permitting direct use of highly concentrated methanol in the fuel flow path with good fuel efficiency and power performance. The cell unit can be applied equally well to both an active circulating air cathode and an air-breathing cathode.

Owner:EC POWER LLC +1

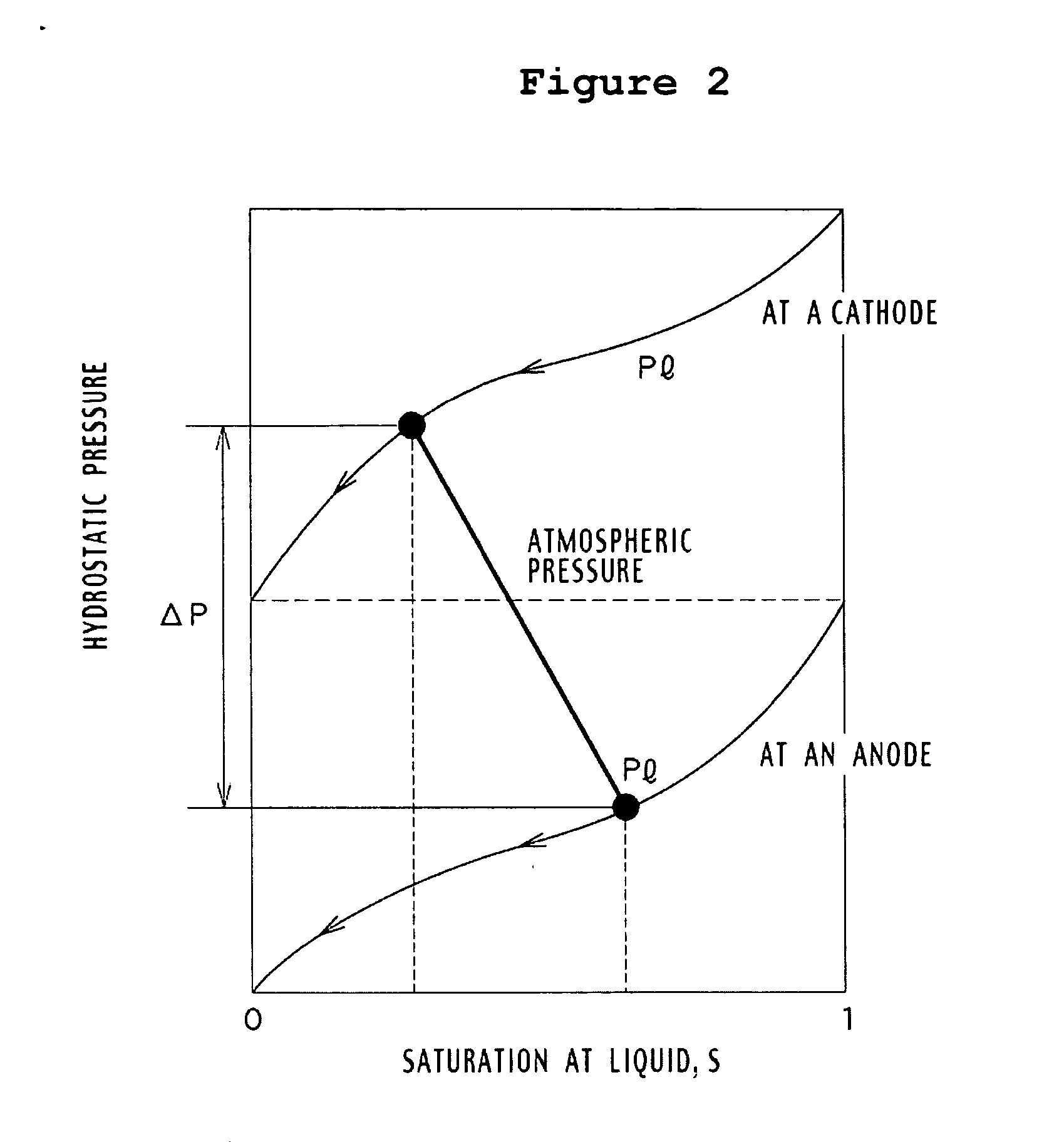

Optical diffusion membrane

The invention discloses an optical diffusion membrane, which comprises a base material, and a main diffusion layer and a back diffusion layer which are formed on two surfaces of the base material. The parts are structurally characterized in that: the main diffusion layer is formed by coating and setting coating fluid containing optical dispersant, adhesive and cross linker on any one surface of the base material; the back diffusion layer is formed by coating and setting coating fluid containing optical dispersant, adhesive, an antistatic agent and cross linker on the other surface of the base material; the optical dispersant is spherical high polymer microspheres; the optical dispersant of the main diffusion layer comprises large granular optical dispersant and small granular optical dispersant, and the weight ratio of the large granular optical dispersant to the small granular optical dispersant is 11:1 to 7:1; and the grain diameter of the optical dispersant of the back diffusion layer is 1 to 5 microns. The optical diffusion membrane has sufficient optical diffusivity, and has good transmittance, good fog degree coordination, good scratch resistance and antistatic property.

Owner:CHINA LUCKY FILM CORP +2

Back diffusion suppression structures

ActiveUS8436398B2Avoid disadvantagesSemiconductor/solid-state device manufacturingSemiconductor devicesDiffusion barrierBack diffusion

An enhancement-mode GaN transistor, the transistor having a substrate, transition layers, a buffer layer comprised of a III Nitride material, a barrier layer comprised of a III Nitride material, drain and source contacts, a gate containing acceptor type dopant elements, and a diffusion barrier comprised of a III Nitride material between the gate and the buffer layer.

Owner:EFFICIENT POWER CONVERSION CORP

Method of preparing perm-selective porous membrane and method of separating gases using porous membrane prepared thereby

ActiveUS20180272288A1Improve stabilityImprove thermal stabilitySemi-permeable membranesMembranesSeparation factorDiffusion methods

The present invention relates to a method of preparing a perm-selective porous membrane and a method of separating gases using the prepared porous membrane. According to the present invention, a membrane is synthesized using a hierarchically structured alumina porous support by a counter diffusion method. During this synthesis, the diffusion rate of metal ions loaded on the porous support is controlled by controlling the pore size of the porous support, and the position at which the membrane is synthesized is controlled by synthesizing the membrane inside the support. This can increase the physical stability of the membrane and make the membrane thicker so as to ensure higher H2 / CO2 separation factors.

Owner:KOREA UNIV RES & BUSINESS FOUND

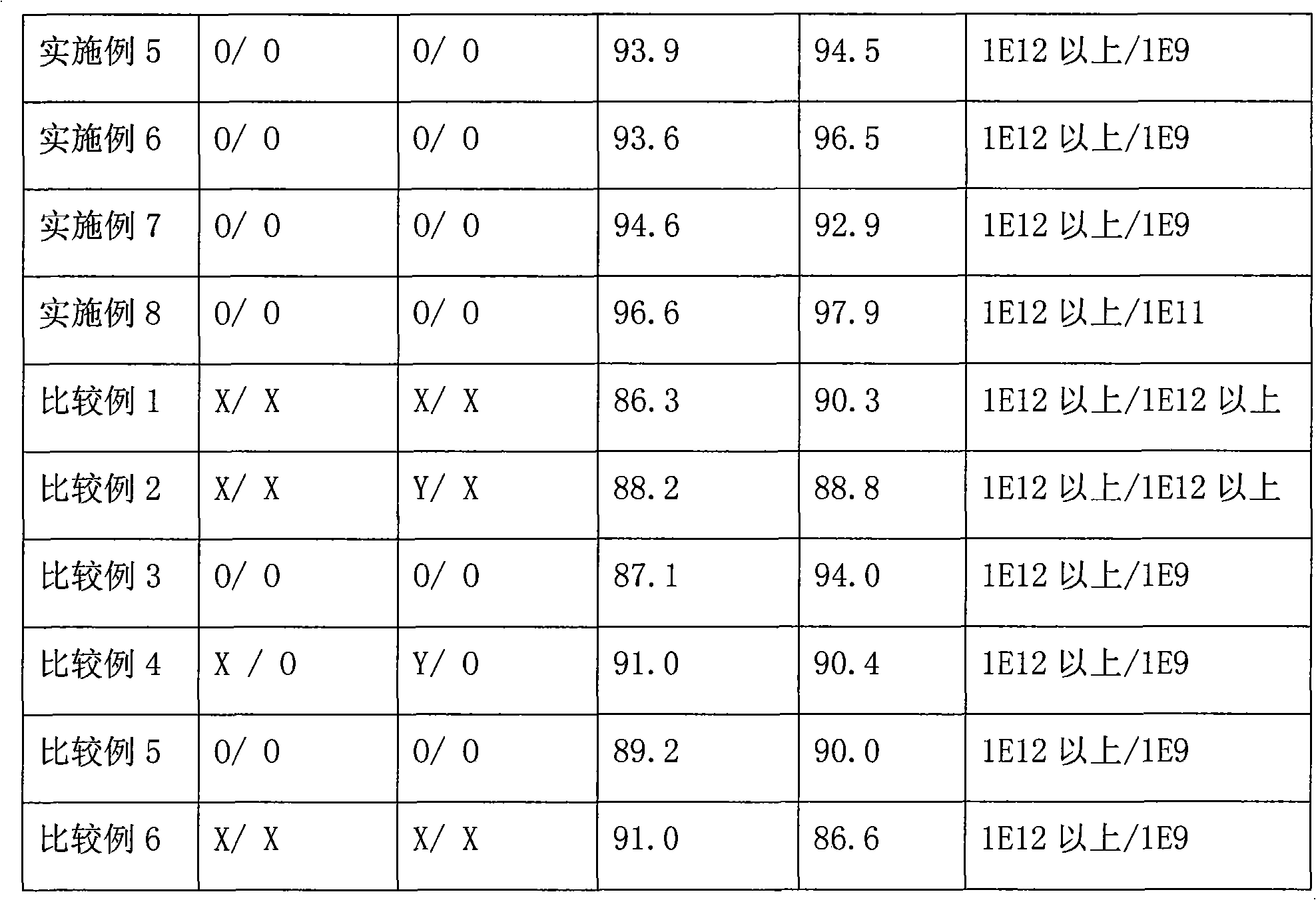

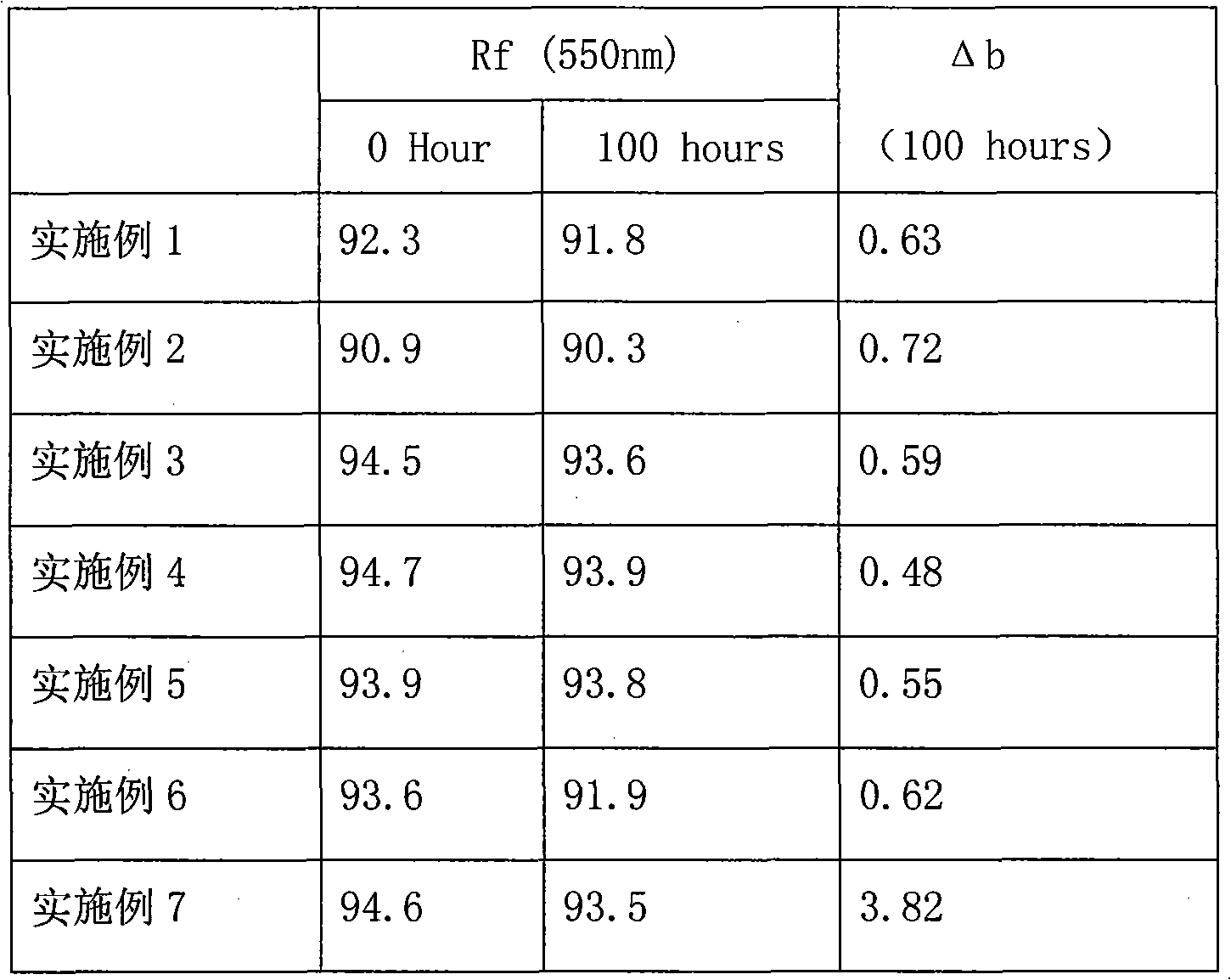

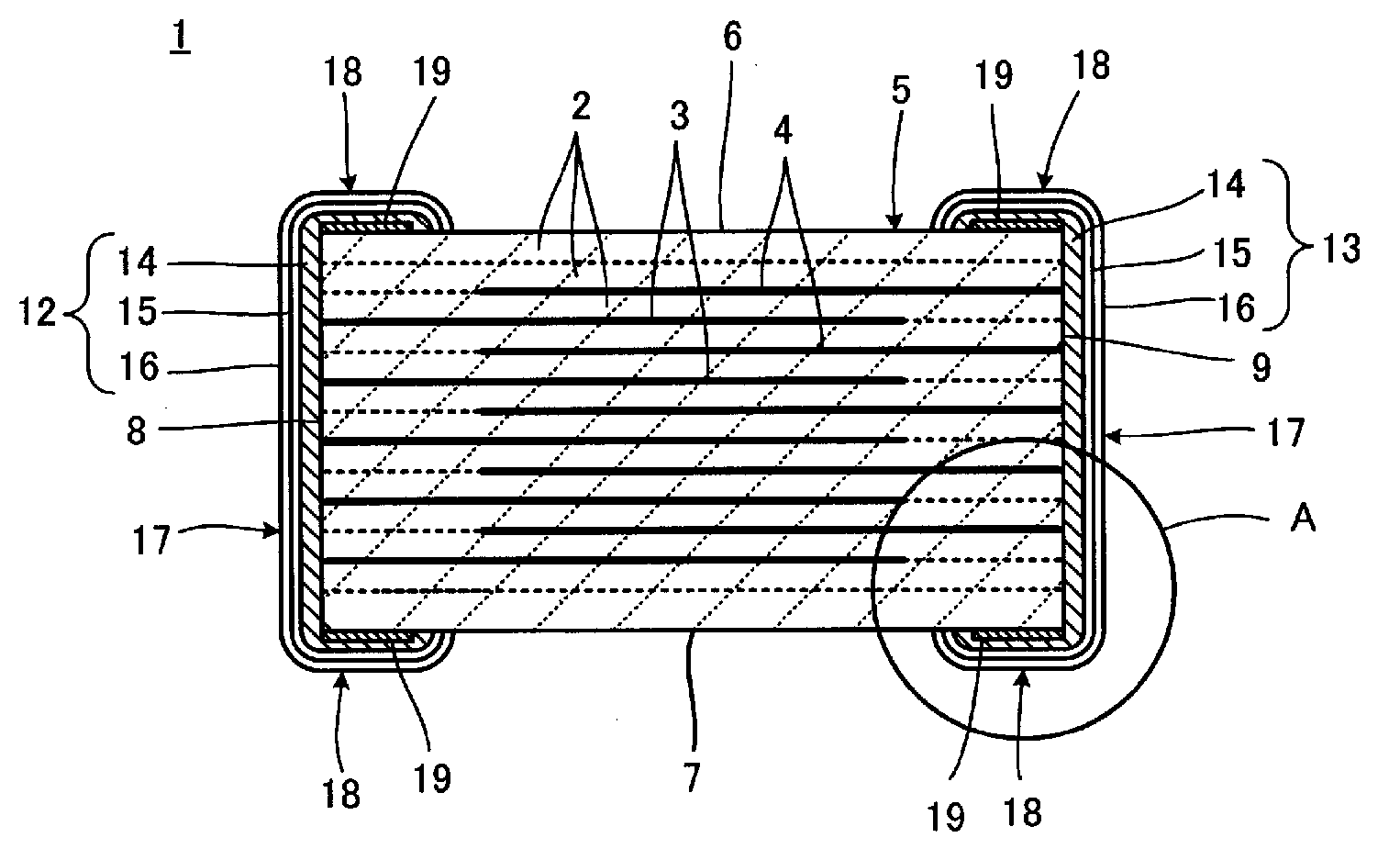

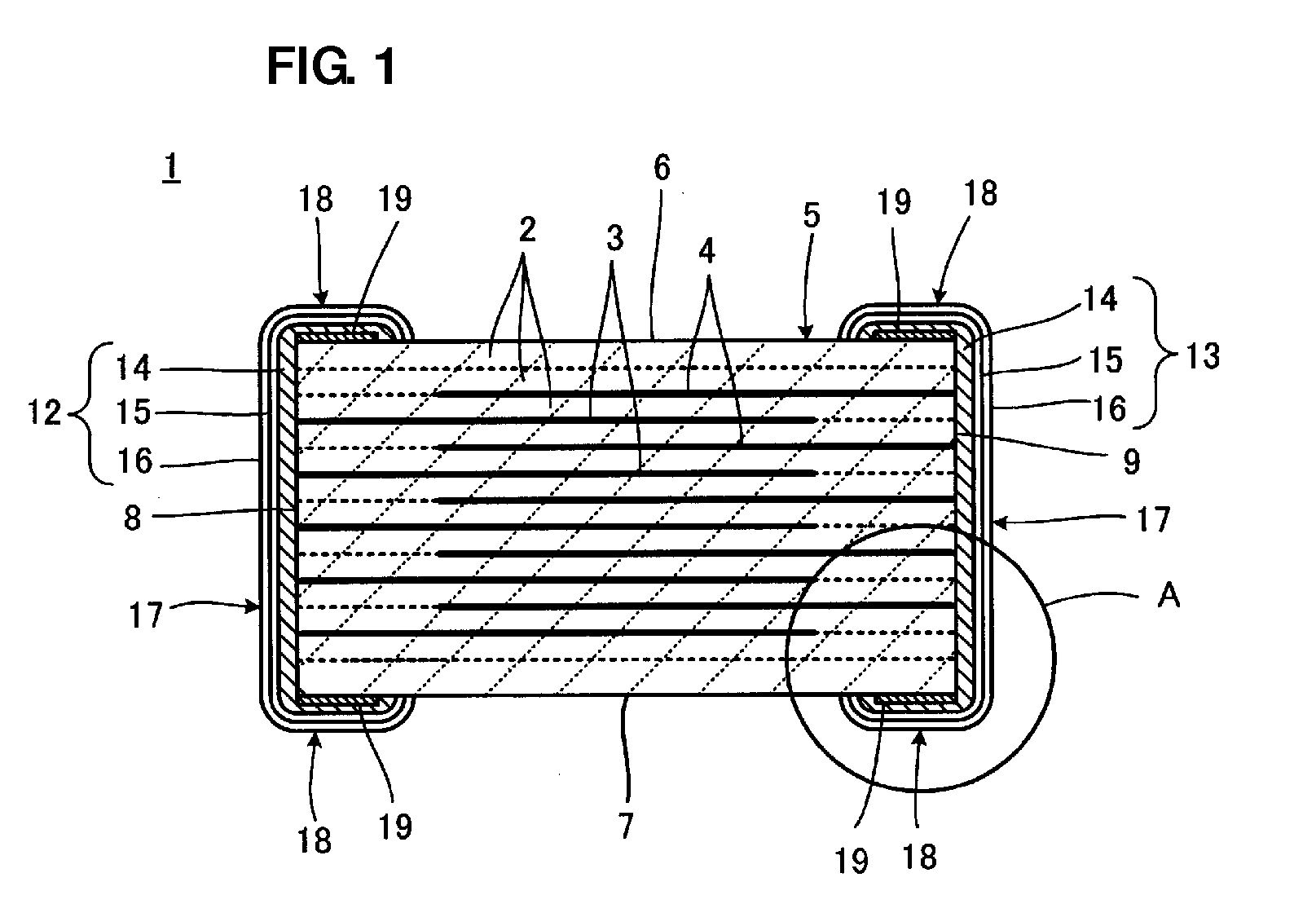

Laminated ceramic electronic component and manufacturing method thereof

ActiveUS20100128412A1Improving moisture load resistant propertyAdhesive strengthFixed capacitor electrodesFixed capacitor dielectricElectronic componentBack diffusion

In a laminated ceramic electronic component in which, by directly carrying out a plating process on an outer surface of a component main body, an external electrode is formed thereon, an attempt is made to improve the adhesion strength between a plated film forming the external electrode and the component main body. A brazing material containing Ti is applied to at least one portion of a surface on which external electrodes of a component main body is formed, and by baking this brazing material, a metal layer containing Ti is formed. Moreover, the external electrodes are formed by a plating process so as to coat at least the metal layer, and a heating process is then carried out so as to cause counter diffusion between the metal layer and the plated film that is to form the external electrodes.

Owner:MURATA MFG CO LTD

Solar cell manufacturing process for blocking back diffusion by using mask

InactiveCN101894888AEliminate the problem of short circuitPlay a passivation roleFinal product manufactureSemiconductor devicesCell damageSilicon chip

The invention belongs to the field of solar cell manufacturing processes, in particular relates to a solar cell manufacturing process for blocking back diffusion by using a mask. Before a silicon chip is diffused, a silicon dioxide or silicon nitride mask is prepared on the back side of the silicon chip, and a back side mask before diffusion prevents the formation of PN junctions on the back side in a silicon chip diffusion process, so that the problem of short circuits of upper and lower electrodes of the silicon chip can be solved directly, and edge and back side etching processes after diffusion can be eliminated. Therefore, losses such as cell damage, efficiency reduction and the like caused by edge etching are avoided. Moreover, passivation effect can be acted on the back side of the silicon chip when the back side of the silicon chip is masked, so that the photoelectric efficiency of a solar cell can be improved effectively, and the process is suitable for industrial production.

Owner:山东力诺太阳能电力股份有限公司

Preparation method and preparation technology of efficient PERC crystalline silicon solar cell

InactiveCN106328765AImprove efficiencyReduce compoundingFinal product manufactureSemiconductor/solid-state device manufacturingScreen printingSilicon solar cell

The invention discloses a preparation method and a preparation technology of an efficient PERC crystalline silicon solar cell. The preparation method sequentially comprises the steps of texturing, diffusing, etching, Al2O3 plating, back SiNx plating, front SiNx plating, silk-screen printing and sintering. The characteristics lie in that acid polishing or alkaline polishing is further performed between the steps of texturing and diffusing, the step of diffusing comprises double-side diffusion and single-side diffusion, and laser grooving or tapping is performed between the steps of back SiNx plating and front SiNx plating. Transition metal impurities are gettered through double-side diffusion phosphorus gettering, electronics effects of a defect are cut down, and recombination of minority carriers is reduced, so that the minority carrier lifetime is prolonged, the conversion efficiency is further improved, and double-side diffusion is enabled to be well matched with acid polishing or alkaline polishing. Meanwhile, a problem of coating uniformity after etching of the solar cell is solved through back diffusion junction preparation, so that the appearance of back coating is improved, and substantial improvement in PERC cell efficiency is realized in a cost controllable range.

Owner:JINENG CLEAN ENERGY TECH LTD

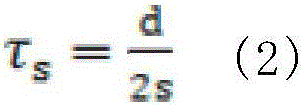

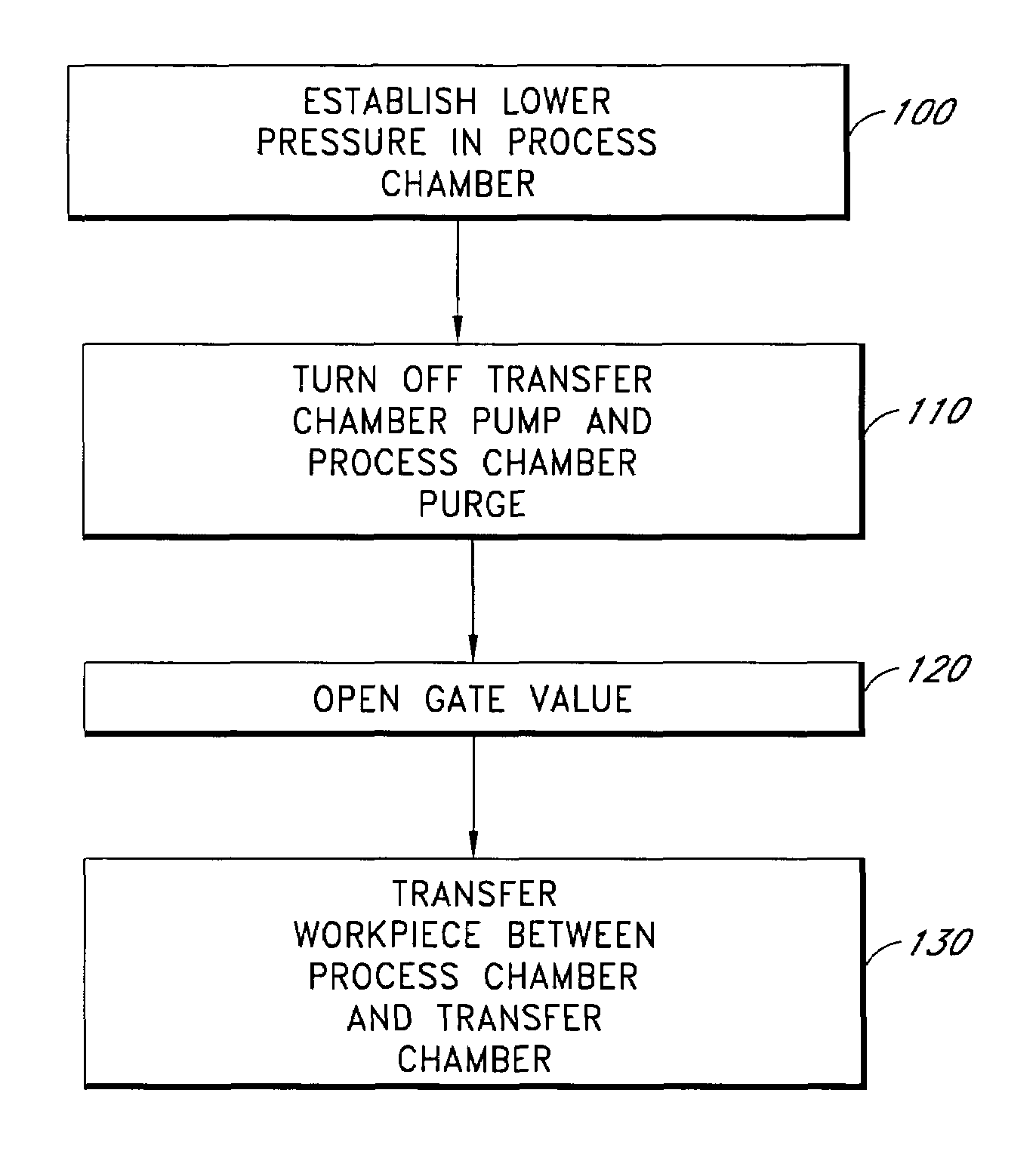

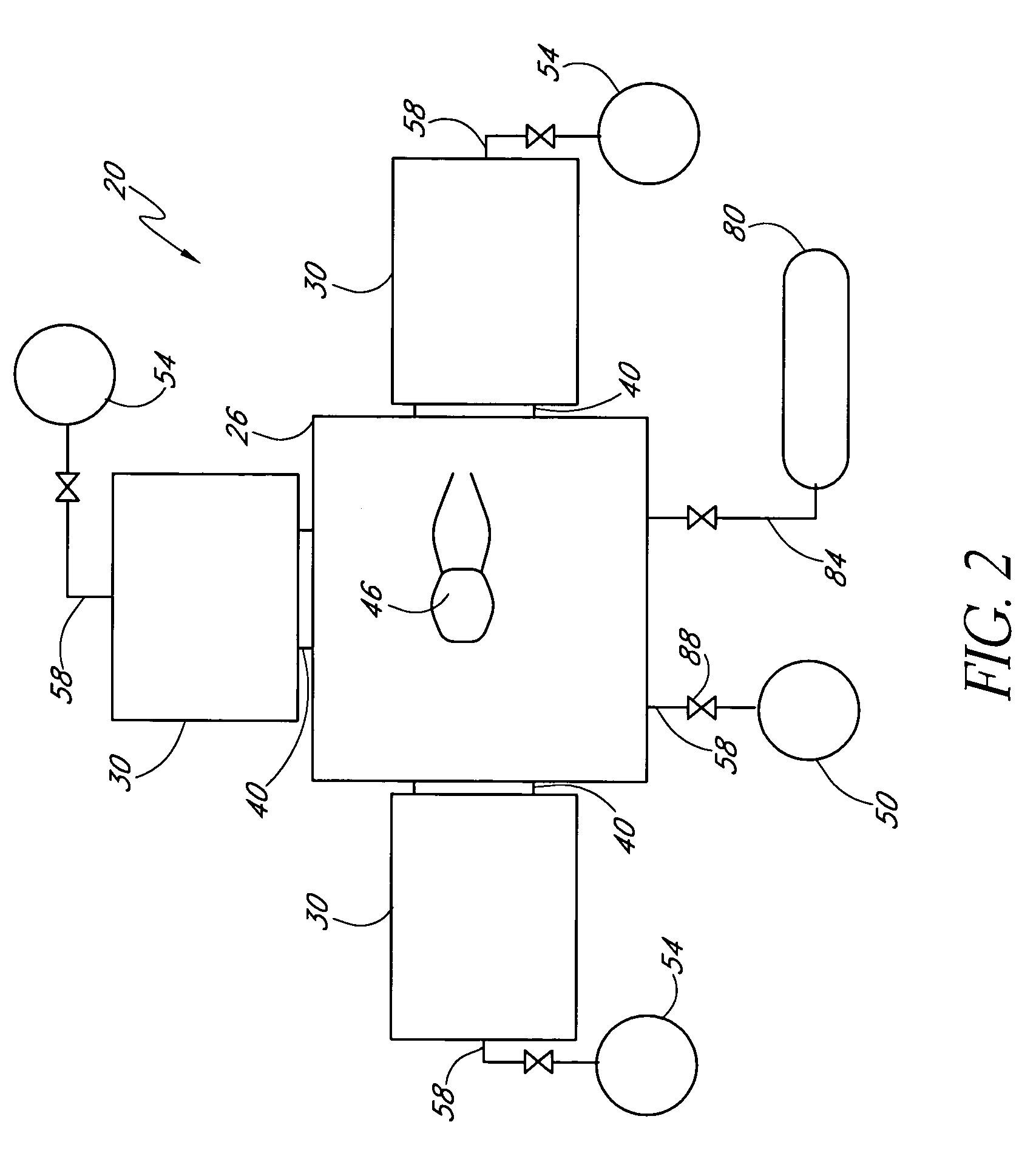

Reduced cross-contamination between chambers in a semiconductor processing tool

ActiveUS7022613B2Semiconductor/solid-state device manufacturingCharge manipulationVacuum pumpingEngineering

In accordance with one aspect of the present invention, a method is provided for transporting a workpiece in a semiconductor processing apparatus comprising a transfer chamber, a process chamber, and a gate valve between the transfer chamber and the process chamber. The method comprises vacuum pumping the transfer chamber to achieve a first pressure in the transfer chamber and vacuum pumping the process chamber to achieve a second pressure in the process chamber. An inert gas is flowed into the transfer chamber and shut off in the process chamber. The transfer chamber is isolated from pumping, but pumping continues from the process chamber. The gate valve is opened after isolating the transfer chamber from pumping. The workpiece is then transferred between the transfer chamber and the process chamber. A definitive flow direction from transfer chamber to process chamber is thereby achieved, minimizing risk of back-diffusion.

Owner:ASM IP HLDG BV

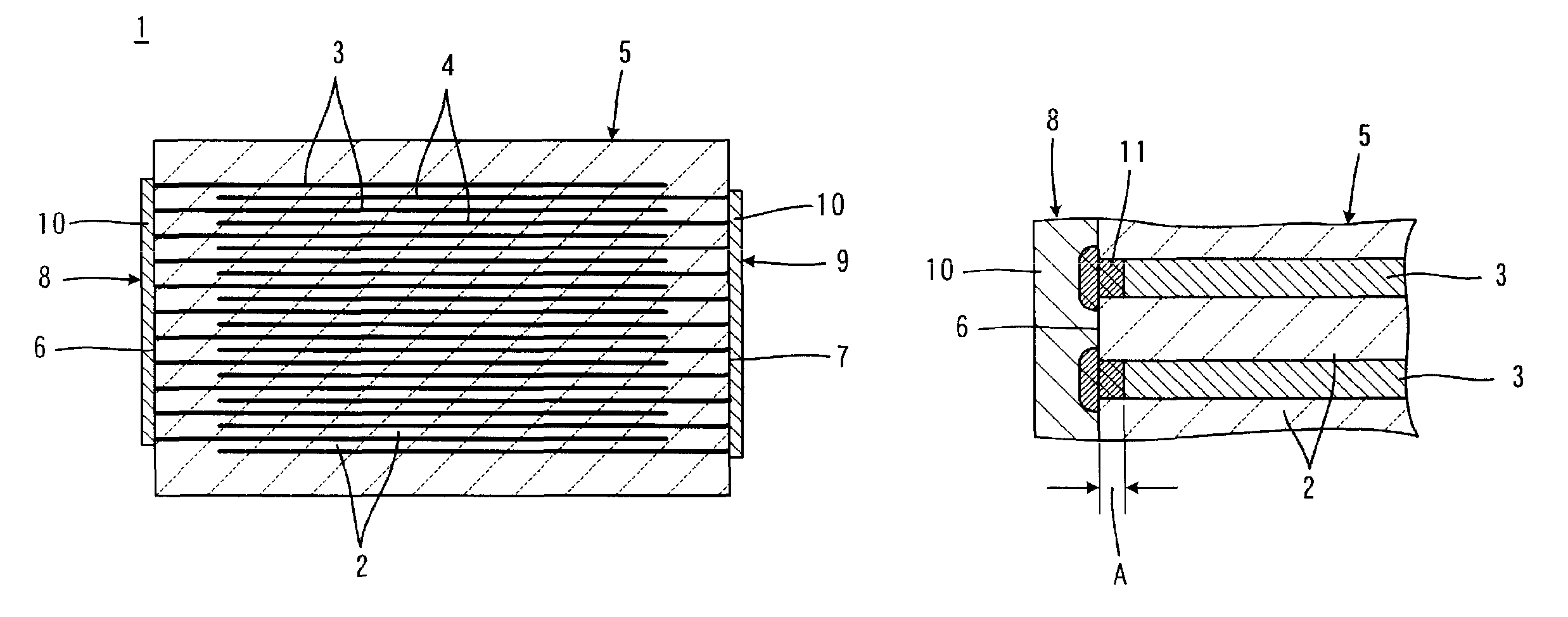

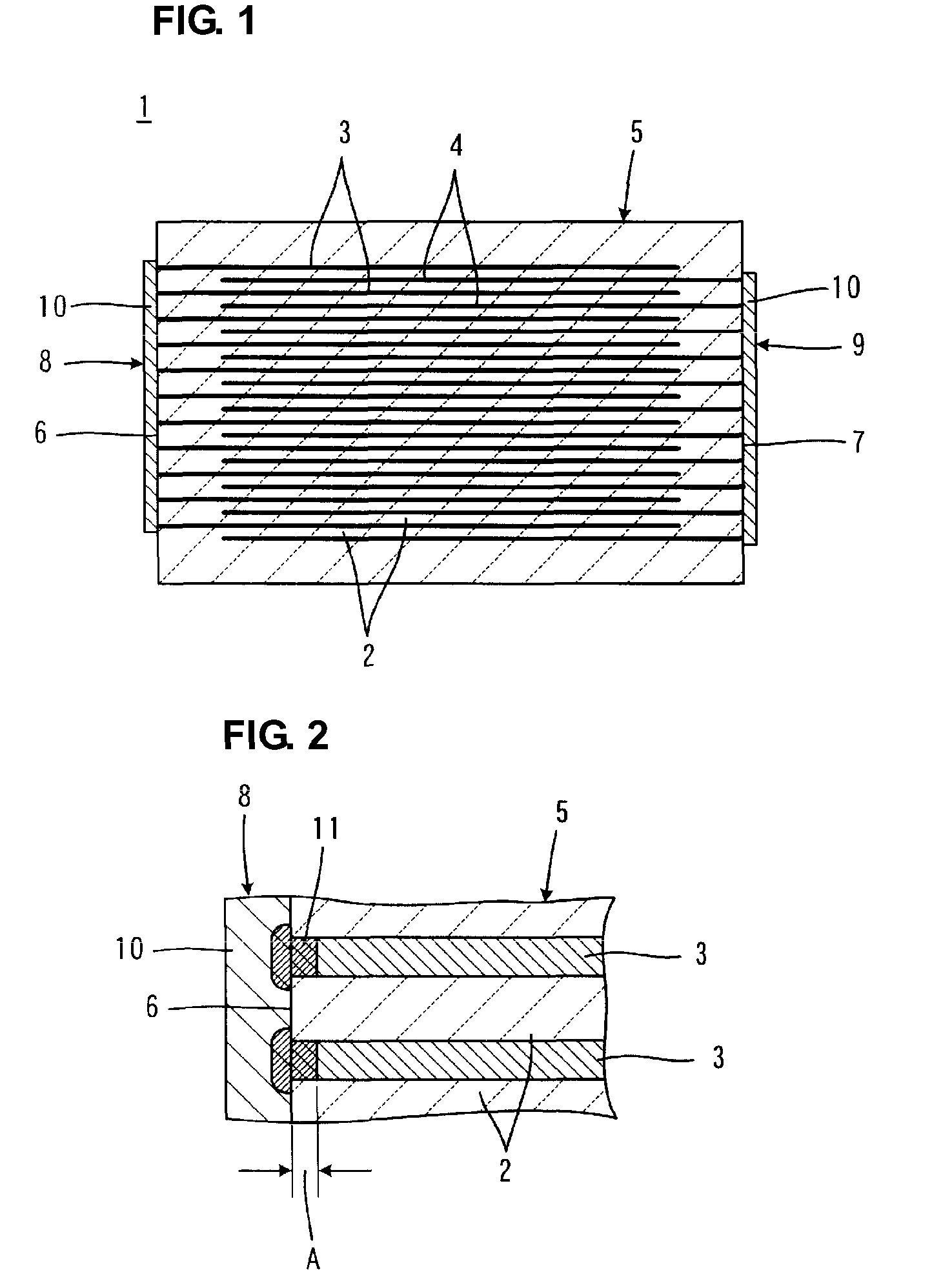

Multilayer electronic component including a counter diffusion layer

ActiveUS8184424B2Reduction in lifeFixed capacitor electrodesStacked capacitorsEngineeringElectronic component

A multilayer electronic component includes a laminate including insulating layers that are laminated to each other and internal electrodes provided along interfaces between the insulating layers, edges of the internal electrodes being exposed at a predetermined surface of the laminate and an external electrode provided on the predetermined surface. The external electrode includes a plated film which is directly provided on the predetermined surface of the laminate so as to electrically connect edges of the internal electrodes exposed at the predetermined surface of the laminate, and at a boundary portion between each of the internal electrodes and the plated film, a counter diffusion layer is provided, in which a metal component in the plated film and a metal component in the internal electrodes are both detectable, and extend to both sides of the internal electrodes and the plated film, and, at a side of the internal electrodes.

Owner:MURATA MFG CO LTD

Preparation method of solar cell for reutilizing diffusion oxide layer

InactiveCN102364698AQuick removalShorten manufacturing timeFinal product manufactureSemiconductor devicesHydrofluoric acidSilicate glass

The invention relates to a preparation method of a solar cell for reutilizing a diffusion oxide layer. The method comprises the following steps of: not removing a silicon oxide layer (such as BSG (Boron Silicate Glass) and PSG (Phosphosilicate Glass)) formed by diffusion on a front face immediately but plating a layer of film on the oxide layer after a diffusion process is completed to form a double-layer film for serving as a mask for quickly removing back face junctions subsequently and for use in a procedure for making a back face electric field by back diffusion; and removing the film and the silicon oxide layer on the front face, and a silicon oxide layer on the back face together with hydrofluoric acid in a post cleaning procedure. Due to the adoption of the method, back junctions formed by diffusion can be removed quickly, the production process flow is optimized, the cell producing and manufacturing time is shortened greatly, and mass production is available.

Owner:TRINASOLAR CO LTD

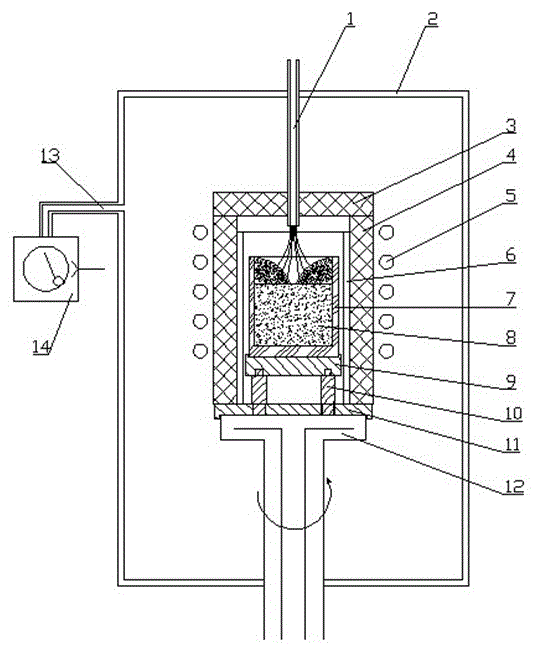

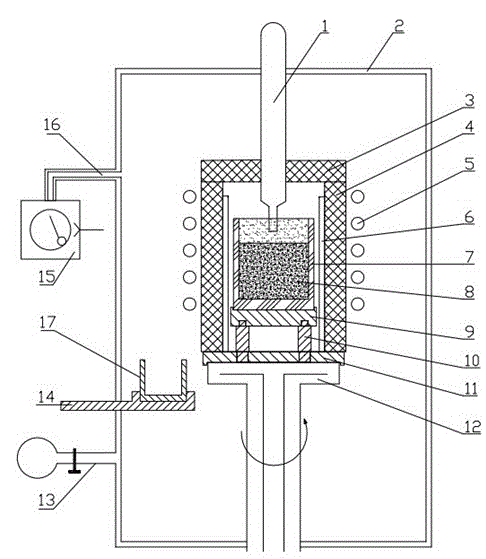

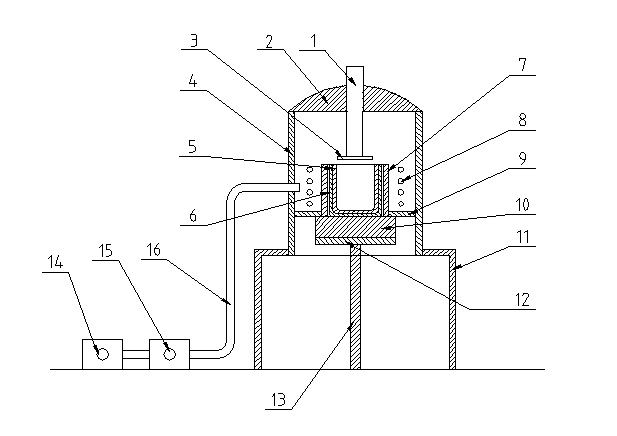

Method and apparatus for purifying polycrystalline silicon through rotation and blow induced inversion solidification

The invention belongs to the technical field of metallurgical purification, and especially relates to a method and an apparatus of induced inversion solidification. The method comprises the following steps of: in the vacuum environment, heating the cleaned silicon material until the silicon material is completely melted and directionally solidified; when 80-90% of solidification is completed, rotating the crucible so that the silicon melt of the upper layer is gathered towards the sidewalls of the crucible under the action of the centrifugal force, and simultaneously blowing an inert gas to the center of the top of the left silicon melt of the upper layer so that the left silicon melt of the upper layer is gathered towards the sidewalls from the center of the crucible under the action of the gas flow and quickly solidified inversely, and is completely solidified at the sidewalls of the crucible; after the whole silicon ingot is cooled, removing the cast ingot of the upper layer obtained through solidification on the sidewalls of the crucible, so as to obtain the left cast ingot as the high-purity silicon cast ingot. The apparatus provided by the invention is added with the functions of crucible rotation and blowing on the basis of the previous solidification apparatus. The method and the apparatus provided by the invention have the advantages that back-diffusion of impurities is reduced, the yield of the cast ingot is improved, the process links are reduced and the energy consumption is reduced; the equipment is convenient to reform and mount; the impurities enriched at the tail part of the cast ingot are effectively removed; and the production cycle and the production cost are saved.

Owner:DALIAN UNIV OF TECH QINGDAO NEW ENERGY MATERIALS TECH RES INST CO LTD

Method and equipment for rapid collection and purification of polycrystalline silicon through directional solidification of tailing

The invention belongs to the technical field of metallurgy purification, and particularly relates to a method and equipment for directional solidification and purification of polycrystalline silicon through taking tailing. According to the method, under the inert gas shielding environment, abluent silicon is heated to be fully melted so as to carry out directional solidification; ingot pulling is stopped when solidification is completed by 85-90%, a graphite bent pipe is stretched into surplus unset silicon at the upper layer, then the other end of the graphite bent pipe is vacuumed through a vacuum unit, so that the surplus unset silicon at the upper layer enters the graphite bent pipe under the action of pressure difference and enters a water cooling collection box through the guide of the graphite bent pipe; heating is stopped after all the surplus unset silicon at the upper layer enters the water cooling collection box, and cast ingot solidified in a crucible is silicon cast ingot of high purity. Due to the method, back-diffusion of impurity is prevented, technology processes are reduced, and the yield of cast ingot is improved. The equipment is convenient to improve and install, and a tailing collection device can be used repeatedly, can collect more tailings, and is safe and reliable.

Owner:QINGDAO NEW ENERGY SOLUTIONS

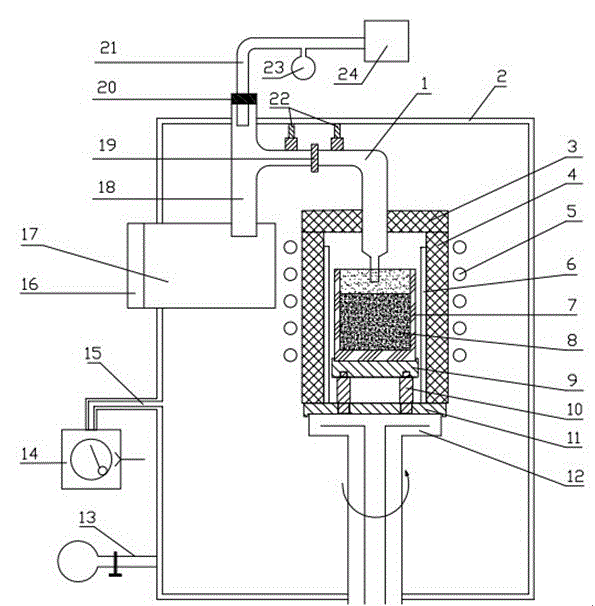

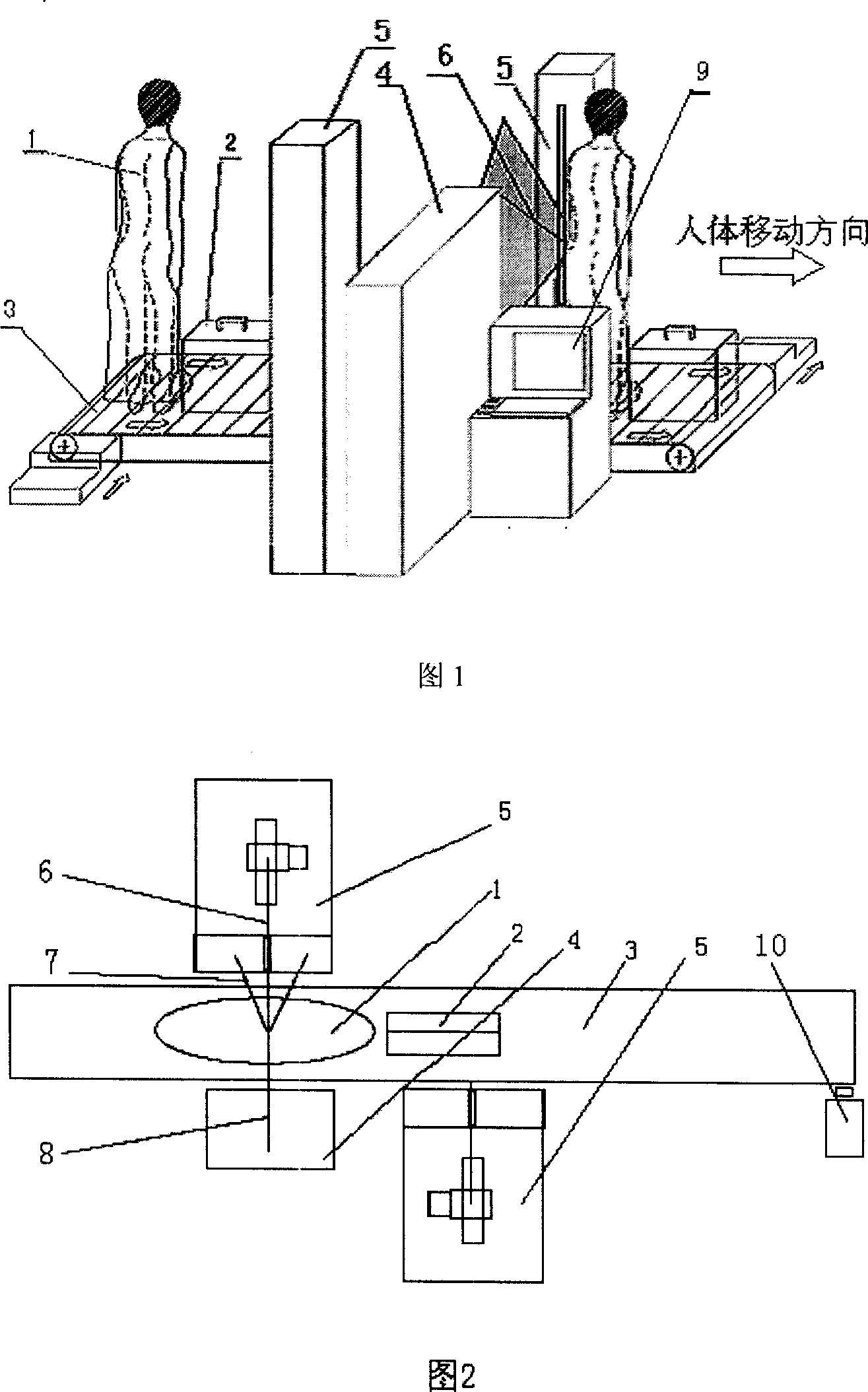

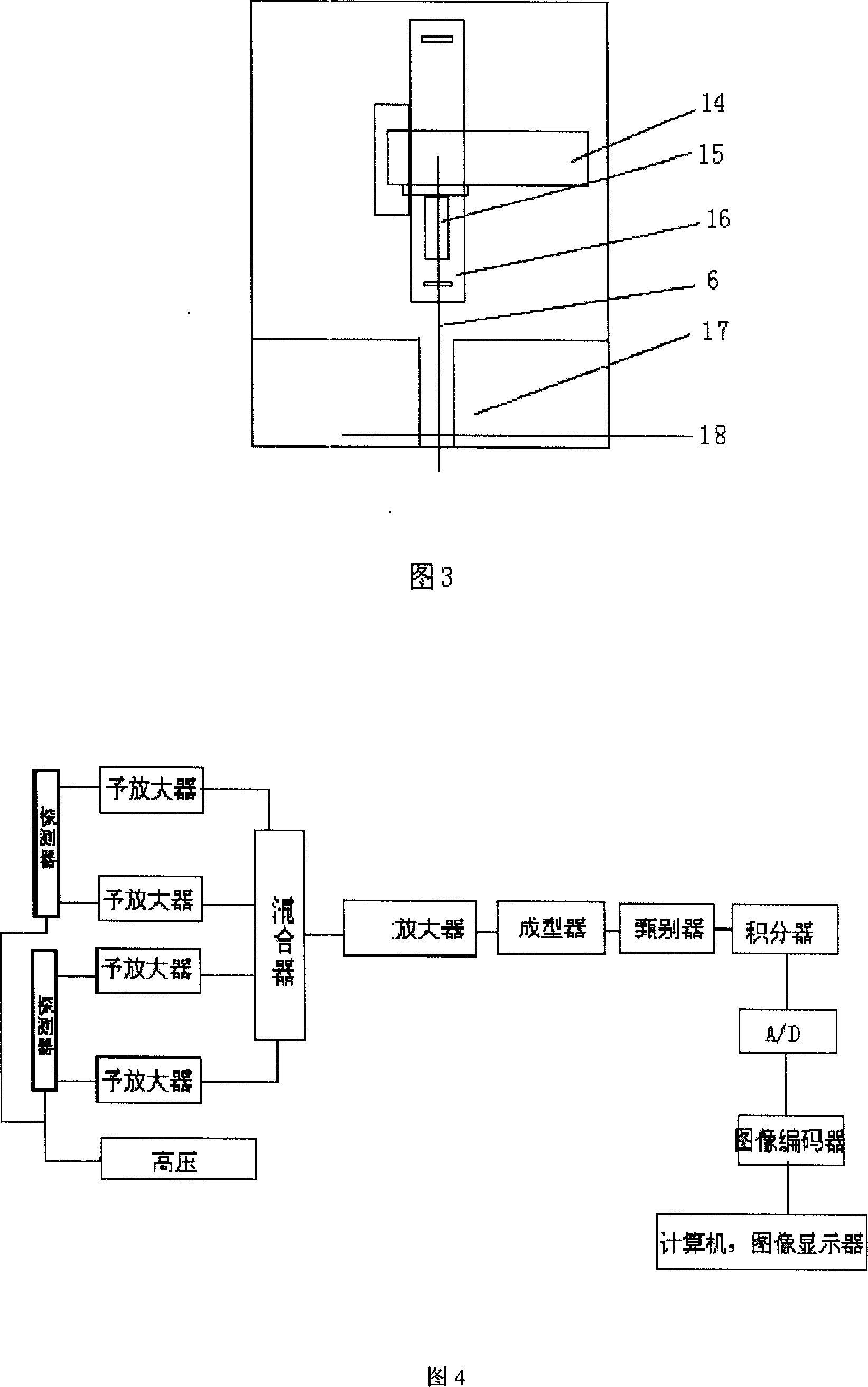

Humanized human body and portable case detector

InactiveCN1995992AFriendly treatmentReduce radiation doseMaterial analysis by transmitting radiationHuman bodyX-ray

The human friendly human body and hand carry suitcase inspection equipment particularly uses the flying spot scanning and back diffusion scanning X ray safety inspection. It comprises two reflective X ray inspection device, one transmission X ray detector, information image handling system, conveyer belt and extraction belt mechanism. It can provide safe, friendly and reliable safety inspection of human body and suitcase, with high sensitivity. It also enjoys low radiation and scanning point, with less harm to human body.

Owner:SHENFA SCI & TECH

Method and equipment for directional solidification and purification of polycrystalline silicon through taking tailing by quartz tube

The invention belongs to the technical field of metallurgy purification, and particularly relates to a method and equipment for directional solidification and purification of polycrystalline silicon through taking tailing by a quartz tube. According to the method, under inert gas environment, silicon is melt and then is cooled to pull ingot; when solidification is completed by 85-90%, the quartz tube is stretched into the surplus melt silicon, vacuumizing is stopped, inert gas is led in, the surplus melt silicon enters the quartz tube under the action of pressure difference, ingot pulling is continuously carried out, after the upper end of a crucible leaves a heating area, a tailing collection box is stretched below the quartz tube with a point; the power is cut off so as to stop heating, melt silicon in the quartz tube expands, then the quartz tube cracks and falls into the tailing collection box, and cast ingot of high purity in the crucible is obtained. Due to the method, back-diffusion of impurity is prevented, technology processes are reduced, and the yield of cast ingot is improved. The equipment is convenient to improve and install, is simple to operate, can effectively remove impurities accumulated at the tail of the cast ingot, save production period and cost, and is applicable to industrial production.

Owner:QINGDAO NEW ENERGY SOLUTIONS

Microchip and Method for Detecting Molecules and Molecular Interactions

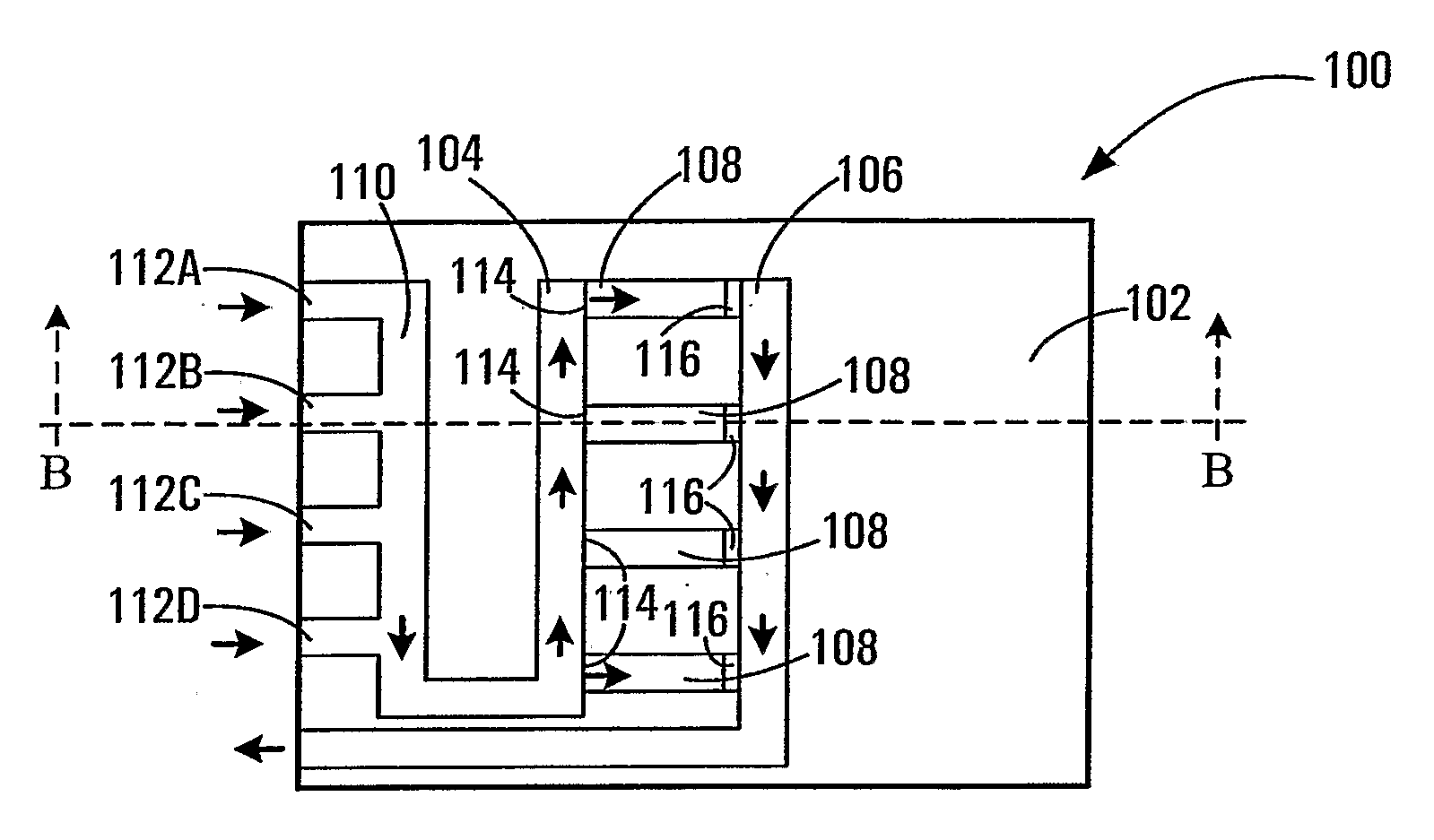

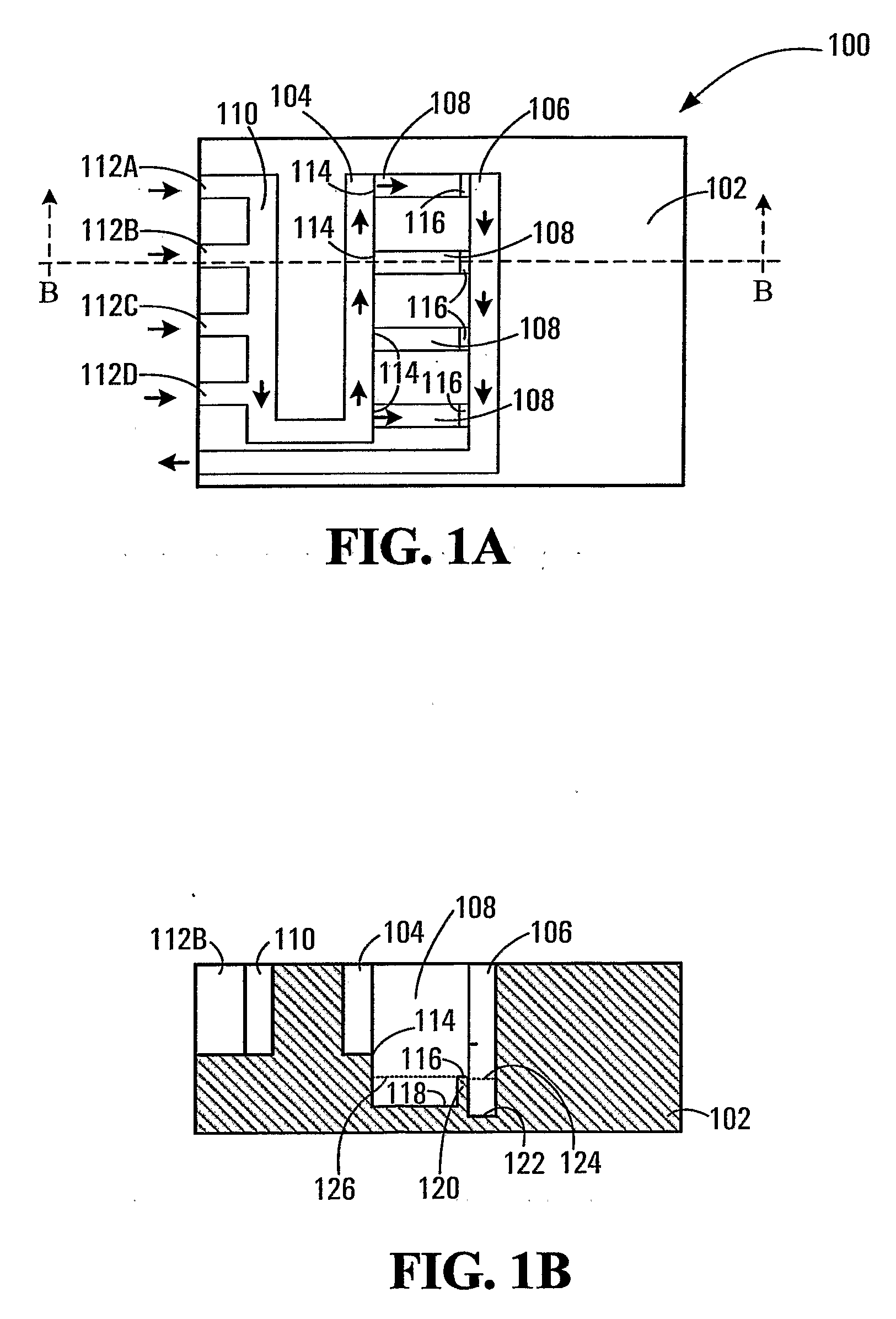

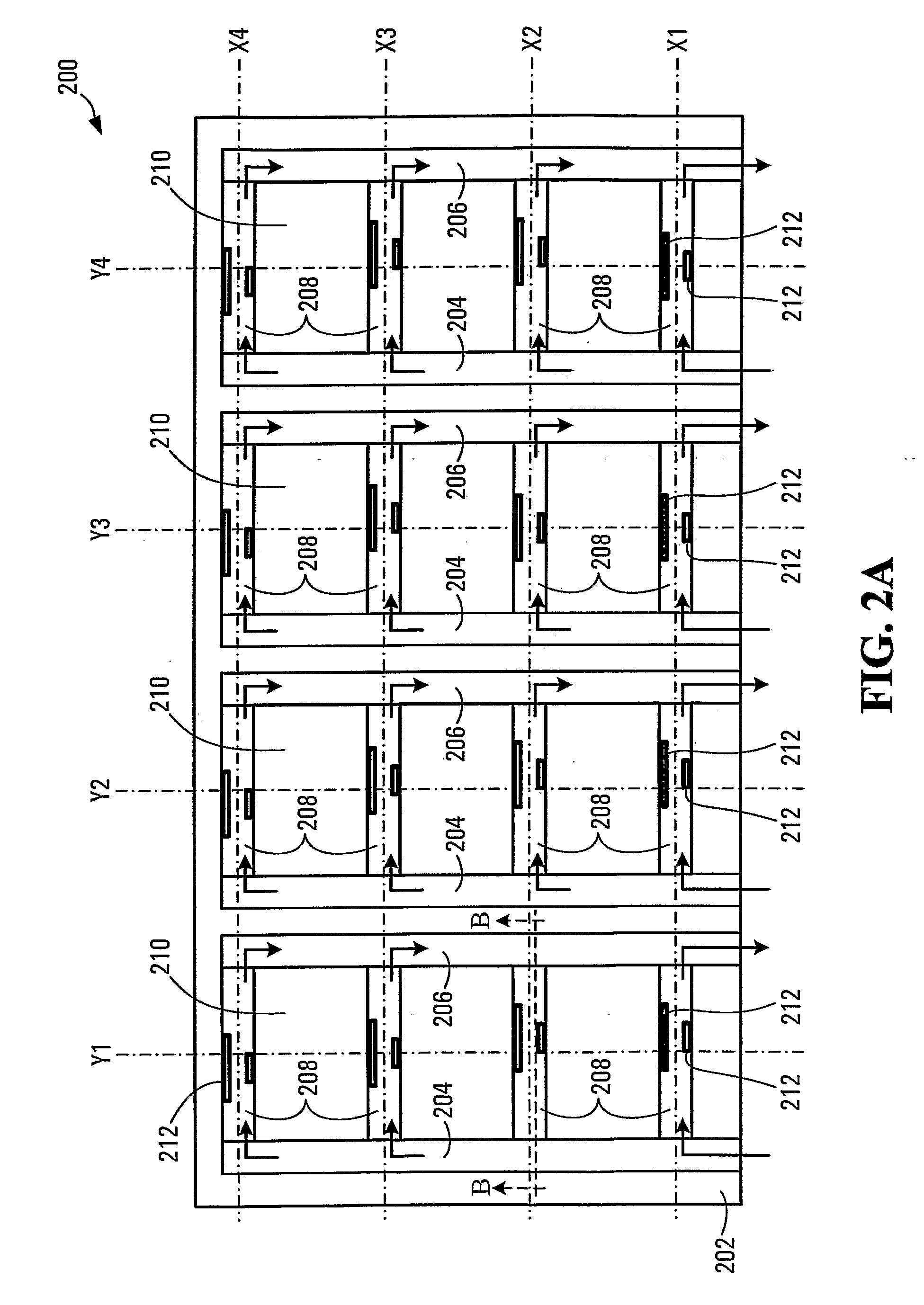

ActiveUS20080108095A1Inhibited DiffusionReduce and eliminate cross-interferenceMicrobiological testing/measurementLaboratory glasswaresInlet channelHigh density

A microchip with flow-through inlet (104) and outlet (106) channels and test channels (108). The test channels (108) are in fluid communication with the inlet (104) and outlet (106) channels, through inlets (114) and outlets (116) respectively. Each test channel (108) has one test site therein for detection of specific molecules or molecular interactions. The inlet (114) in a test channel (108) is elevated from the outlet (116) of the test channel (108) and the outlet (116) is elevated from a fluid level (124) in the outlet channel (106). Back diffusion from outlet channel (106) to the test channels (108) and from the test channels (108) to the inlet channel (104) can thus be inhibited to reduce or eliminate cross-interference between different test sites. The microchip can be useful as a flow-through high density enzyme immunoassay array device with high-throughput.

Owner:NANYANG TECH UNIV

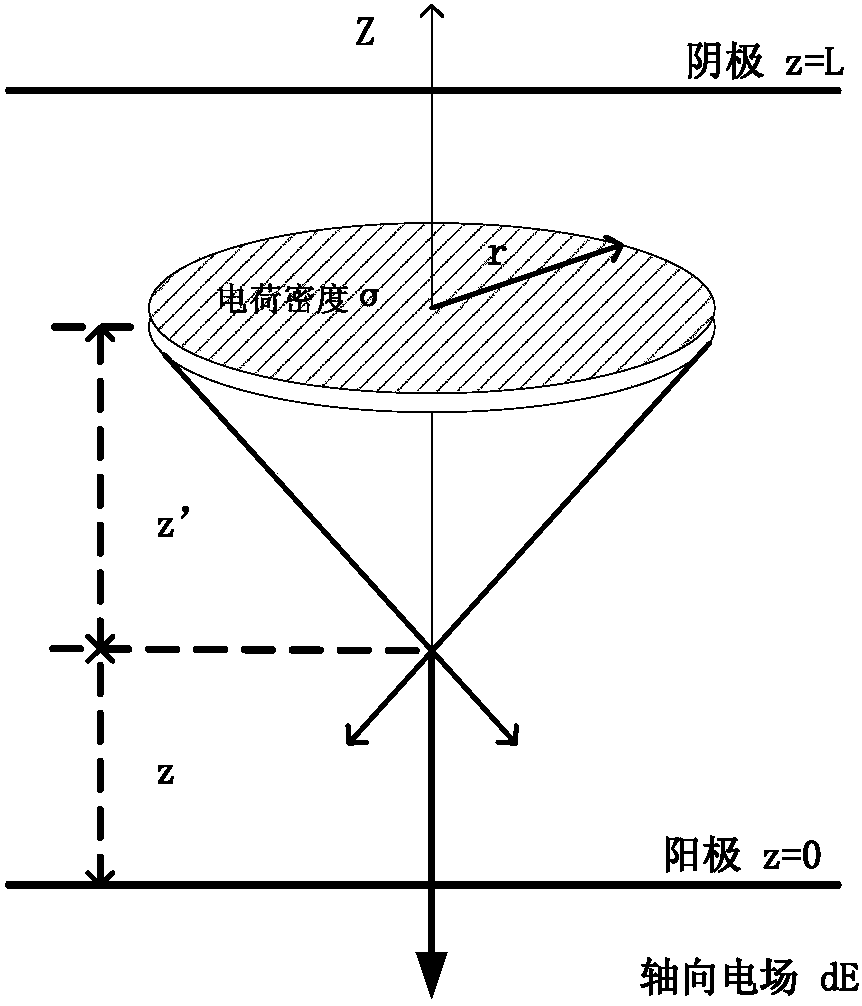

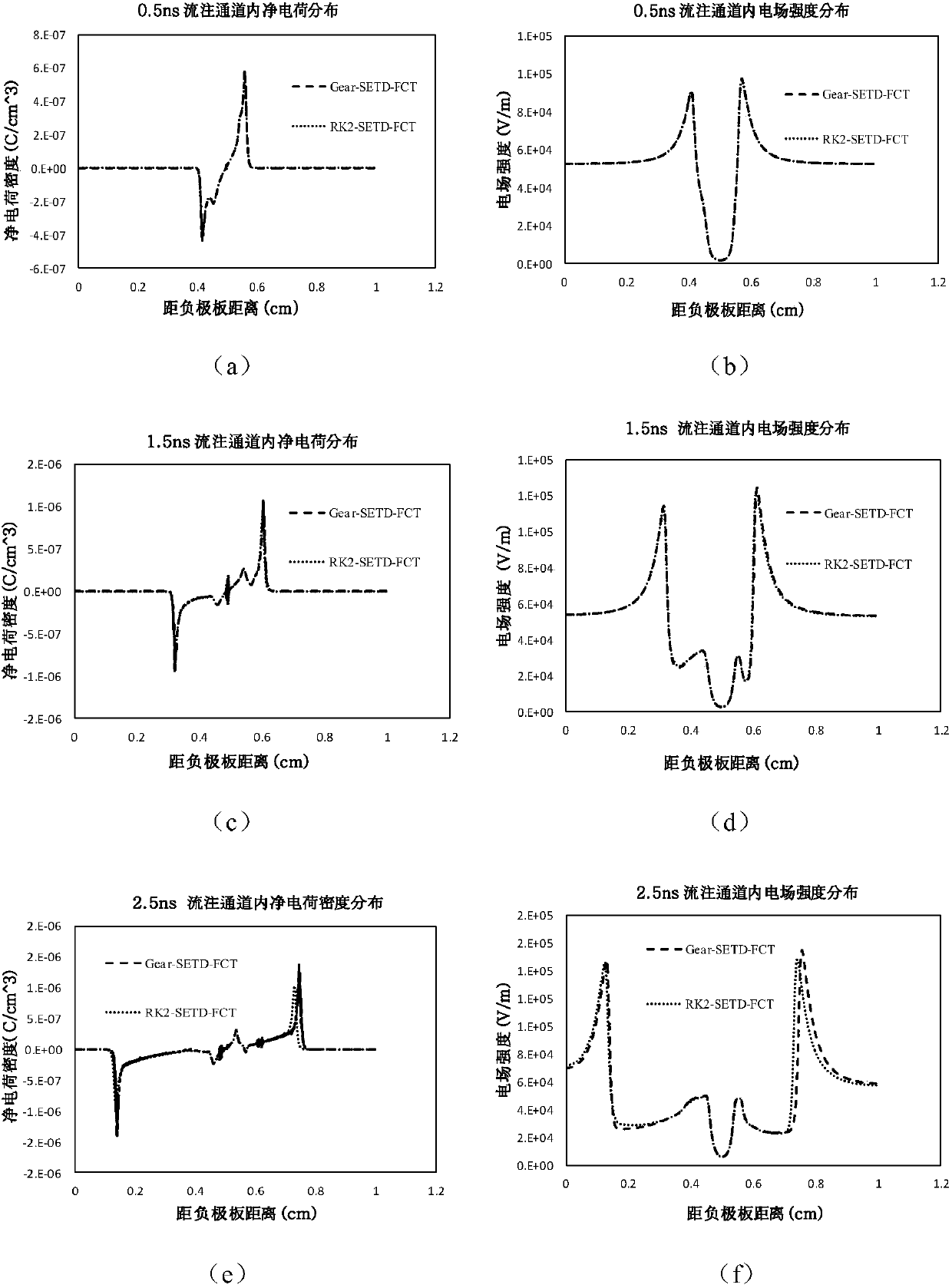

Short gap gas discharge numerical simulation method based on time-domain spectral element method

ActiveCN107729608AIncrease time stepReduced simulation timeDesign optimisation/simulationSpecial data processing applicationsElectron densityDiscretization

The invention discloses a short gap gas discharge numerical simulation method based on a time-domain spectral element method. The method comprises the following steps of establishing a structure modelof short gap gas, and conducting discretization to obtain the structural information of the model; using a GLL basis function based on the spectral element method for discretization, conducting a Galerkin test, and obtaining an expression of a high-order scheme; for a stiffness matrix, eliminating negative elements outside diagonal lines to obtain an expression of a lower-order scheme; conductingsubtraction on the expressions of the high-order and low-order schemes to obtain original back-diffusion flux and prelimit the original back-diffusion flux; calculating correction factors, obtaininglimited back-diffusion flux at last, adding the limited back-diffusion flux to the expression of the lower-order scheme, conducting time discretization in a multi-step backward difference format, using Newton iteration in each time step for solution, obtaining the electron density and ion density of the gas, calculating an electric field, and updating transport parameters. By means of the method,unconditional stability in time can be achieved, the calculation precision is high, and the simulation effect is good.

Owner:NANJING UNIV OF SCI & TECH

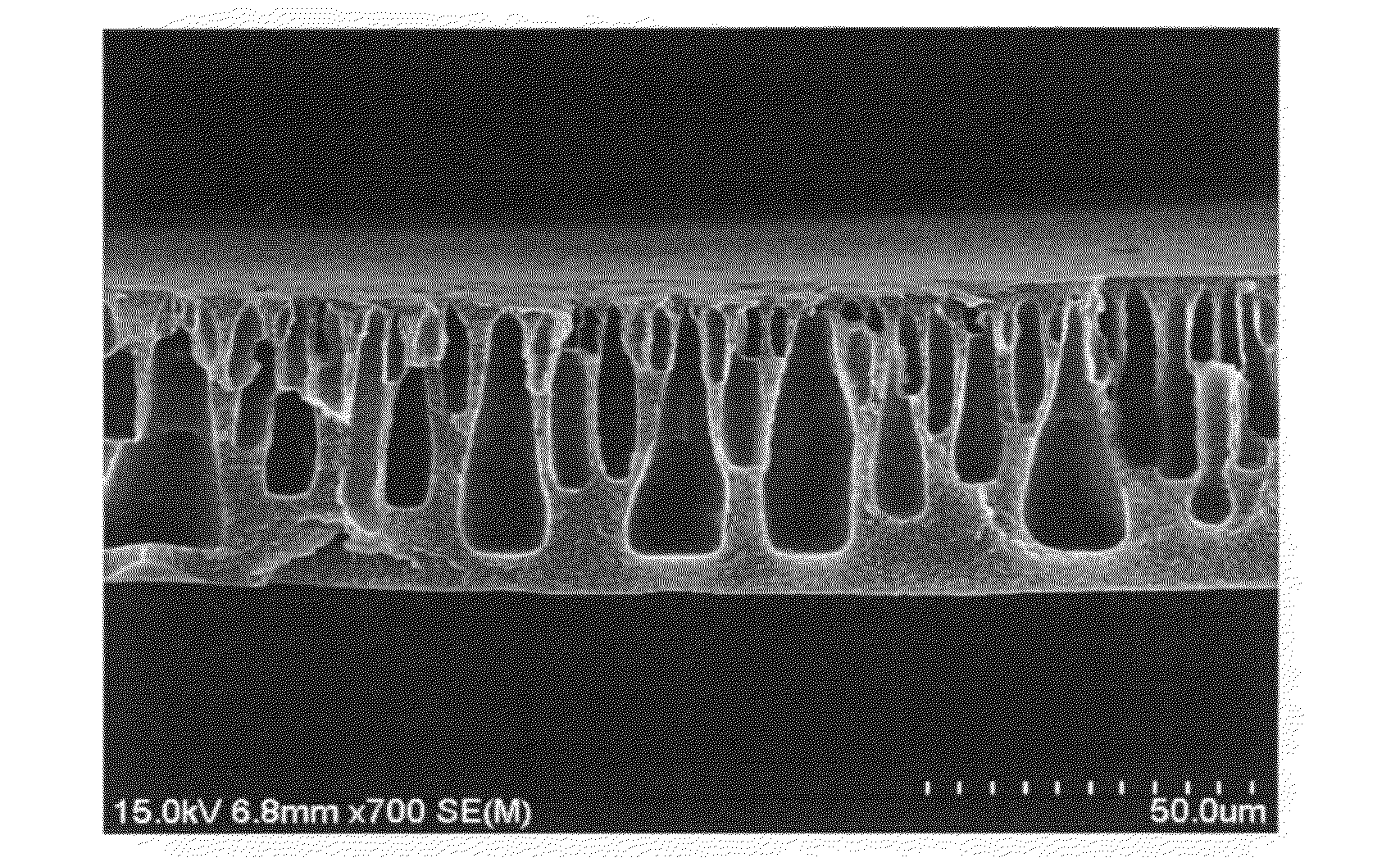

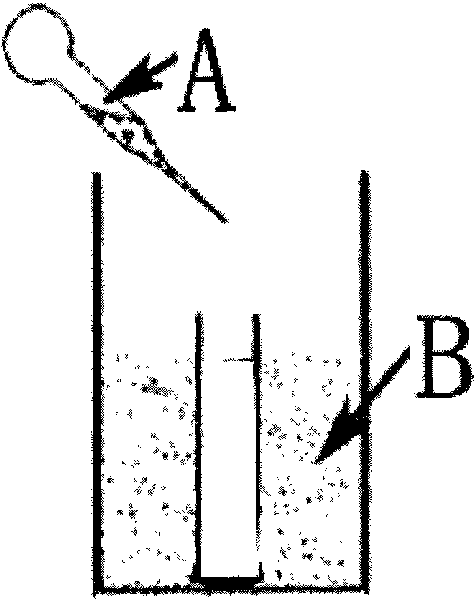

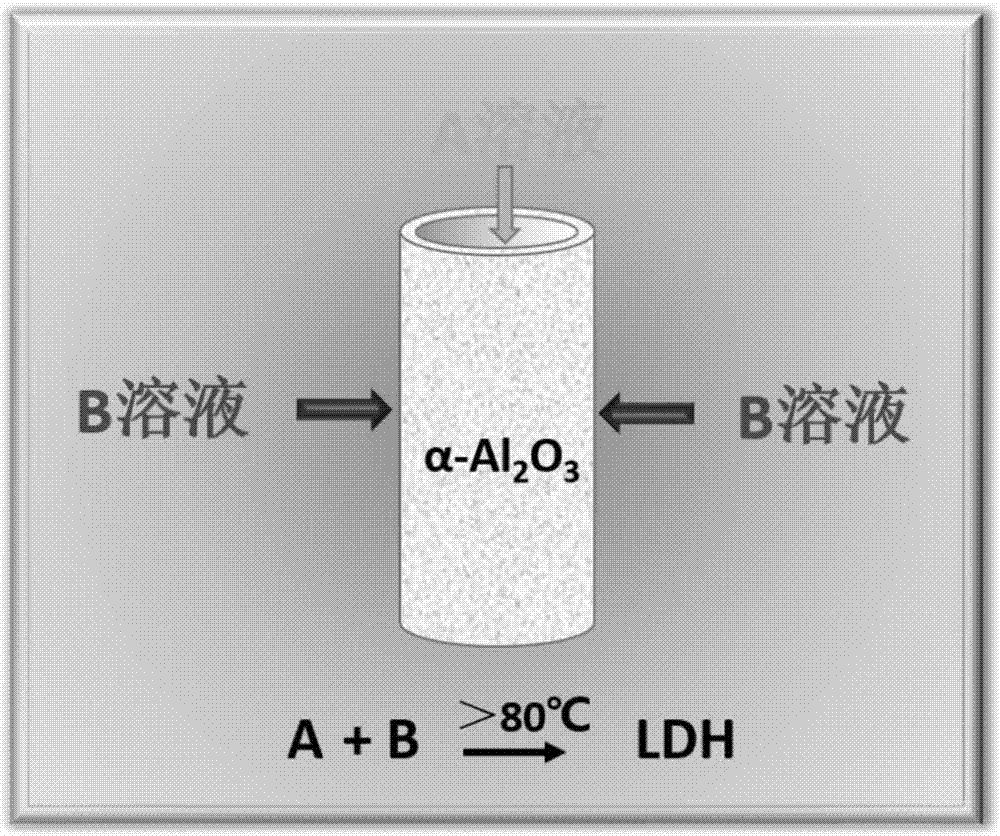

Method for preparing hydrotalcite composite film by back diffusion technology

InactiveCN106914144AImprove running stabilityImprove bindingDistillationPorous substrateComposite film

The invention relates to a method for preparing a hydrotalcite composite film by a back diffusion technology, which belongs to the technical field of membrane separation. The method comprises the following steps: a porous substrate is pre-treated, two metal ion solutions for synthesis of hydrotalcite are respectively placed at two sides of a base film, through regulation and control of two metal ionic mol ratio, precursor concentration, synthesis temperature and reaction time, the solutions containing the metal ions are diffused in a porous structure of the base film, and are subjected to a reaction to generate hydrotalcite, and then the material is dried. The method can realize uniform growth and uniform size of hydrotalcite on the substrate surface and inner part, and can effectively overcome the problem of difficult nucleation of many inorganic materials on a substrate.

Owner:BEIJING UNIV OF TECH

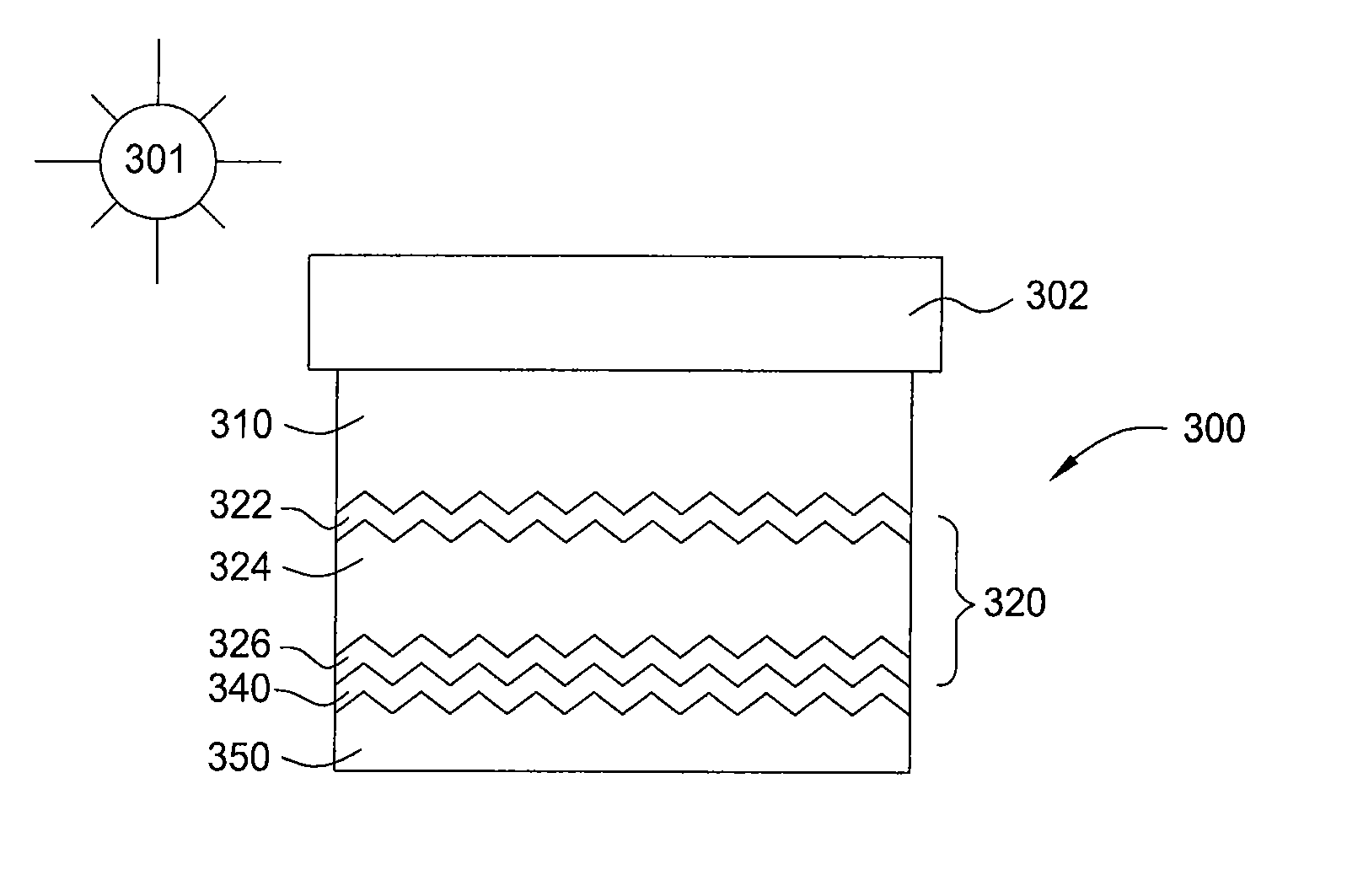

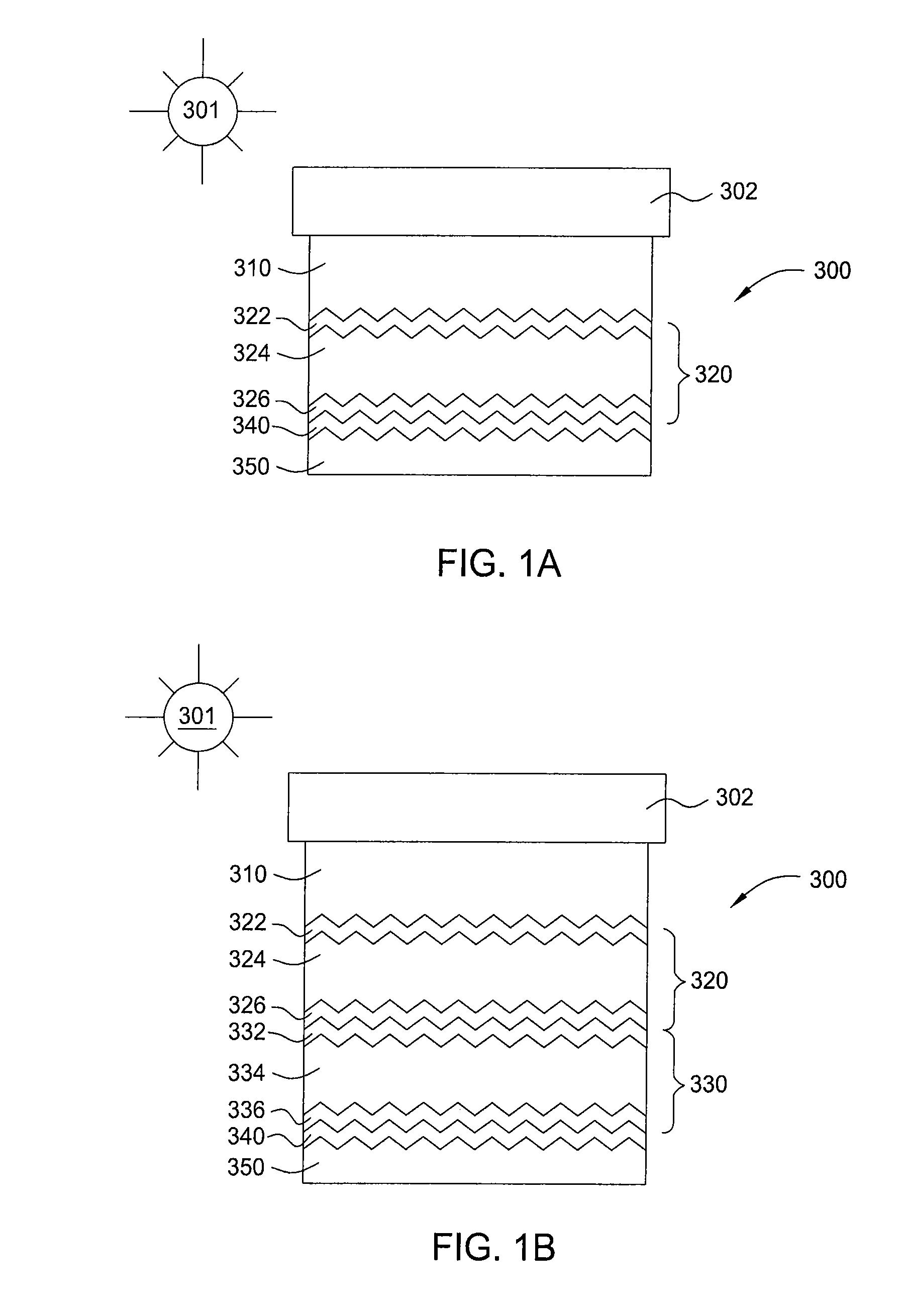

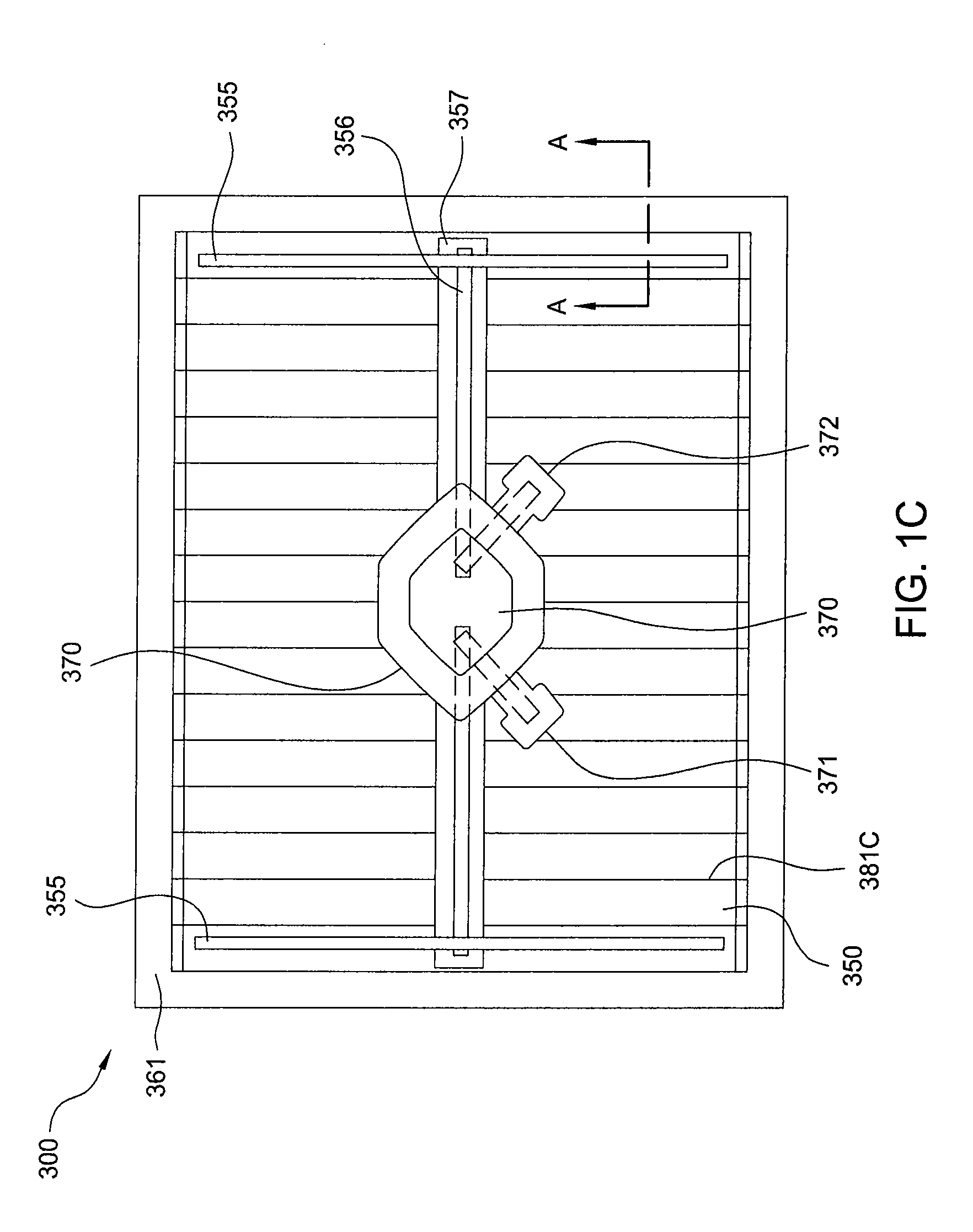

Gas mixing method realized by back diffusion in a pecvd system with showerhead

InactiveUS20110053356A1Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringMicrocrystalline silicon

Embodiments of the present invention generally relate to methods of forming a microcrystalline silicon layer on a substrate in a deposition chamber. In, one embodiment, the method includes flowing a processing gas into a diffuser region between a backing plate and a showerhead of the deposition chamber, flowing the processing gas through a plurality of holes in the showerhead and into a process volume between the showerhead and a substrate support in the deposition chamber, igniting a plasma in the process volume, back-flowing gas ions formed in the plasma through the plurality of holes in the showerhead and into the diffuser region, mixing the gas ions and the processing gas in the diffuser region, re-flowing the gas ions and processing gas through the plurality of holes in the showerhead and into the process volume, and depositing a microcrystalline silicon layer on the substrate.

Owner:APPLIED MATERIALS INC

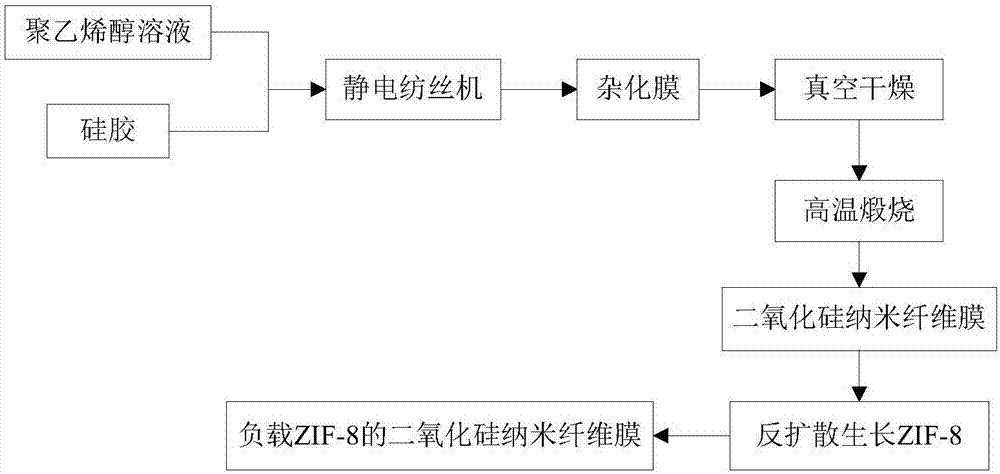

Silicon dioxide nanofiber membrane loaded with ZIF-8 and used for purifying air

ActiveCN107503044AEfficient killingExtended service lifeNon-woven fabricsPolyvinyl alcoholSilica gel

The invention discloses a preparation method of a silicon dioxide nanofiber membrane loaded with a zeolite imidazate framework structural material (ZIF-8) and used for purifying air, a blend spinning solution is prepared by a polyving akohol solution and silica gel, and the silicon dioxide nanofiber membrane is prepared through electrostatic spinning, vacuum drying and high-temperature calcination; a methanol solution of zinc nitrate hexahydrate and a methanol solution of 2-methylimidazole are subjected to back-diffusion on the two sides of the silicon dioxide membrane respectively, and the silicon dioxide nanofiber membrane loaded with the zeolite imidazate framework structural material (ZIF-8) is obtained. According to the silicon dioxide nanofiber membrane loaded with the ZIF-8 and used for purifying the air, the cost is low, the technology is simple and practical, and the PM 2.5 is efficiently gathered in the air purification process by the aid of the high specific surface area of the zeolite imidazate framework structural material (ZIF-8).

Owner:NANJING UNIV OF TECH

Method and equipment for controlled directional solidification and purification of polycrystalline silicon through taking tailing by graphite tube

The invention belongs to the technical field of metallurgy purification, and particularly relates to a method and equipment for directional solidification and purification of polycrystalline silicon through taking tailing. According to the method, under the inert gas shielding environment, abluent silicon is melted so as to carry out directional solidification; ingot pulling is stopped when solidification is completed by 85-90%, a graphite tube is stretched into surplus melt silicon, then inert gas is led into a vacuum chamber, so that the surplus melt silicon enters the graphite pipe under the action of pressure difference and ingot pulling is continuously carried out, after the upper end of a crucible leaves a heating area, the water cooled crucible is stretched below the graphite tube, inert gas is stopped being led into the vacuum chamber, the vacuum chamber is vacuumed, the surplus melt silicon in the graphite tube falls into the water cooled crucible to be cooled and solidified; the power is cut off so as to stop heating, and cast ingot solidified in a crucible is silicon cast ingot of high purity. Due to the method, back-diffusion of impurity is prevented, technology processes are reduced, and the yield of cast ingot is improved. The equipment is convenient to improve and install, is easy to operate, can effectively remove impurities accumulated at the tail of the cast ingot, saves production period and cost, and is applicable to industrial production.

Owner:QINGDAO NEW ENERGY SOLUTIONS

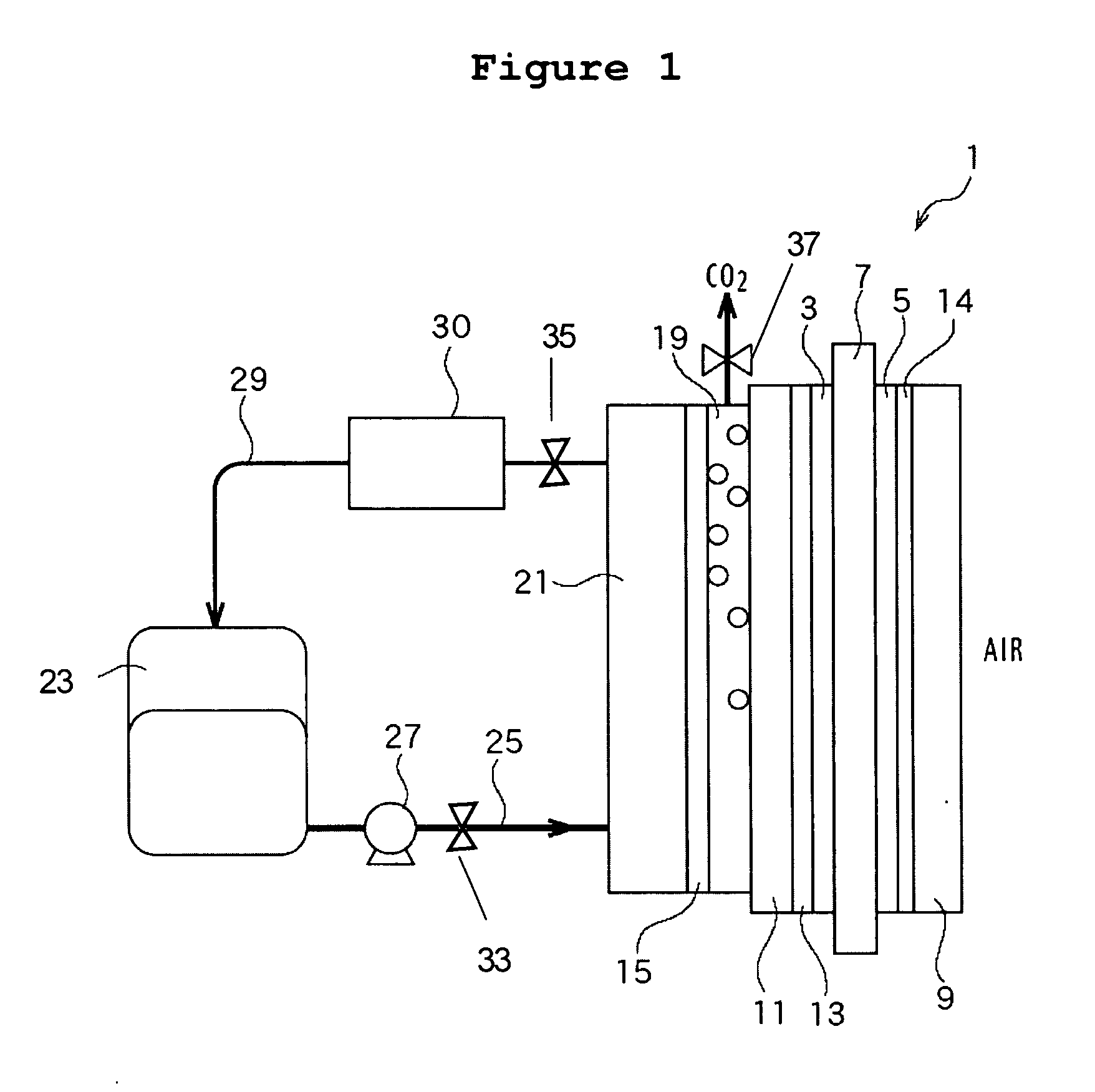

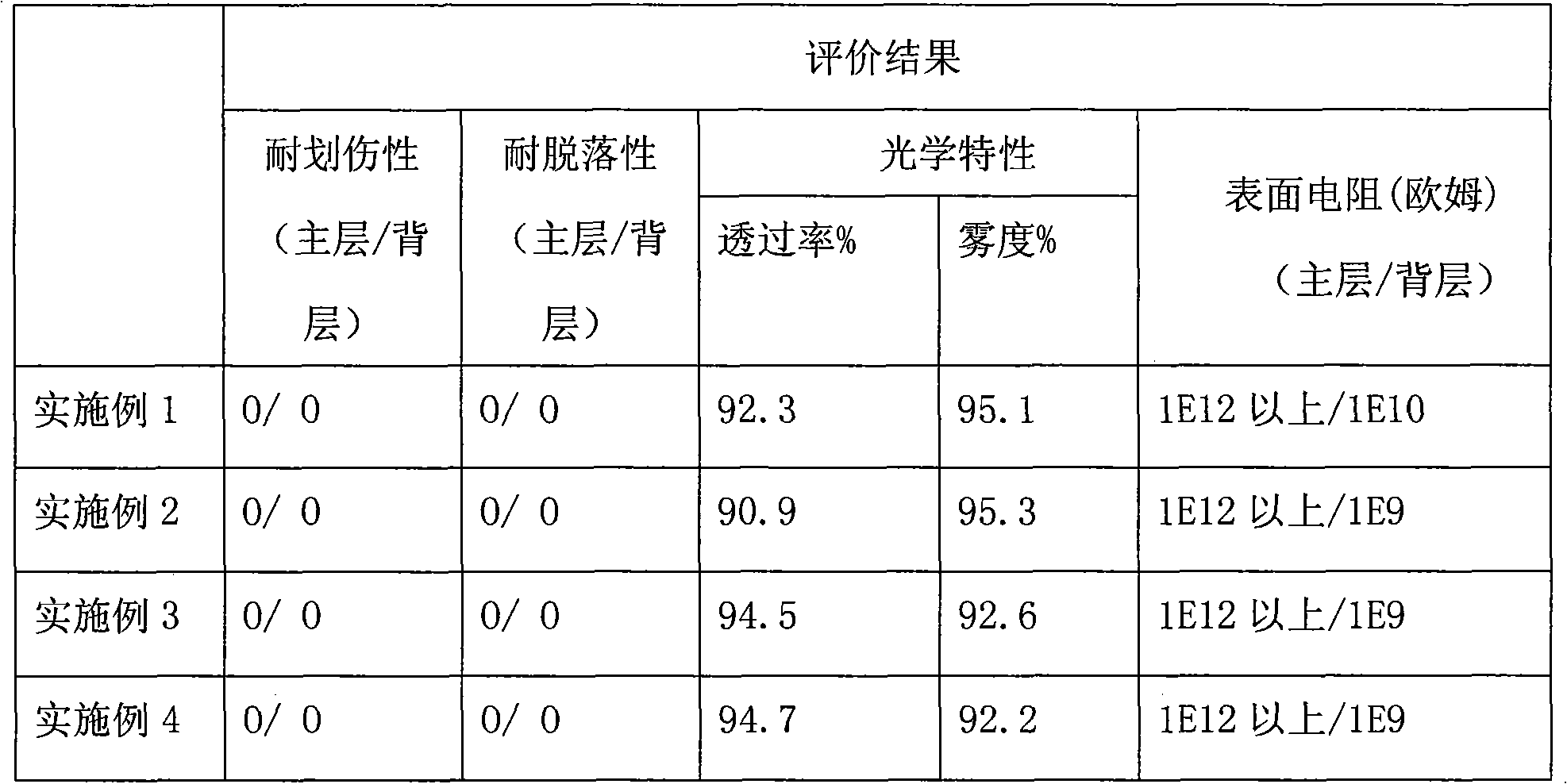

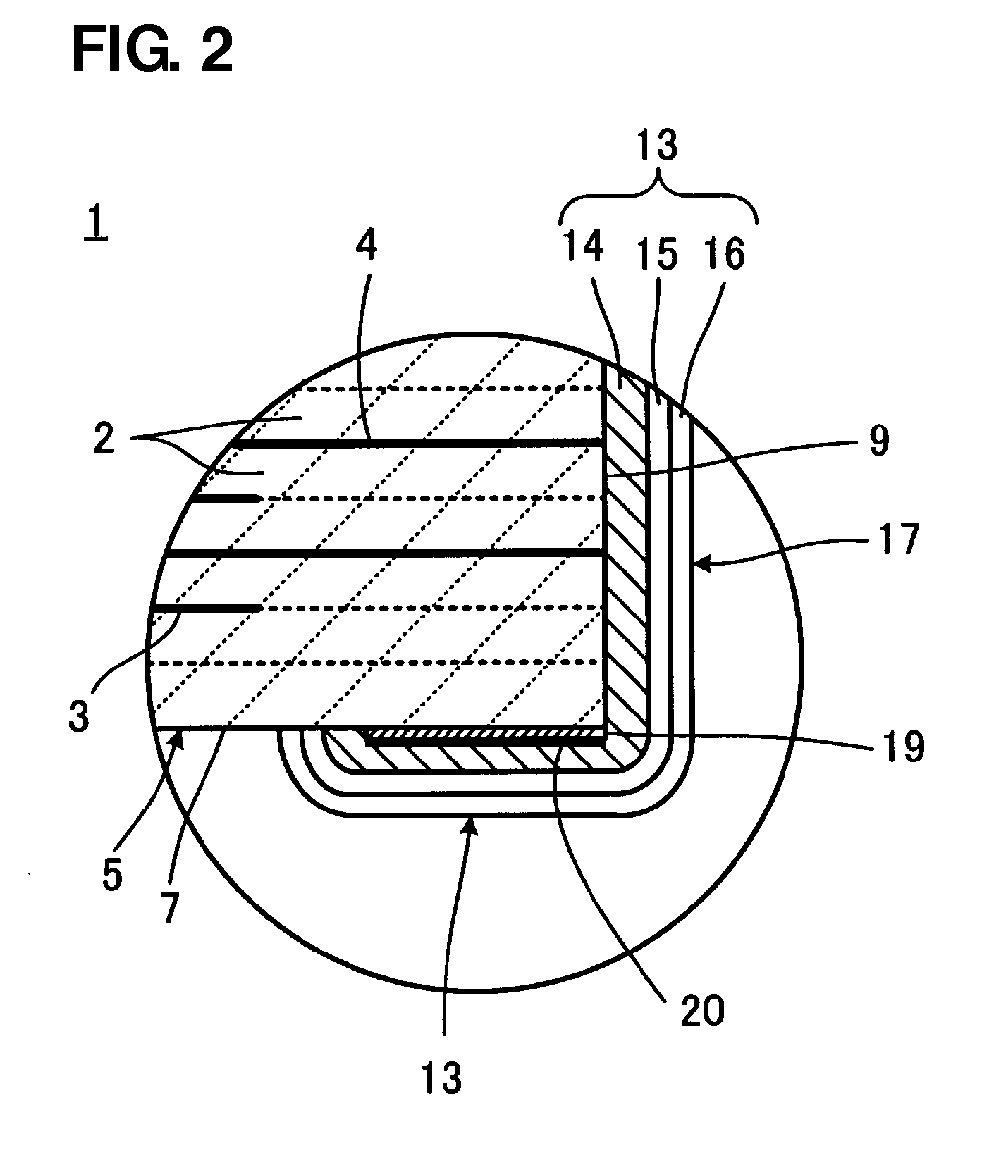

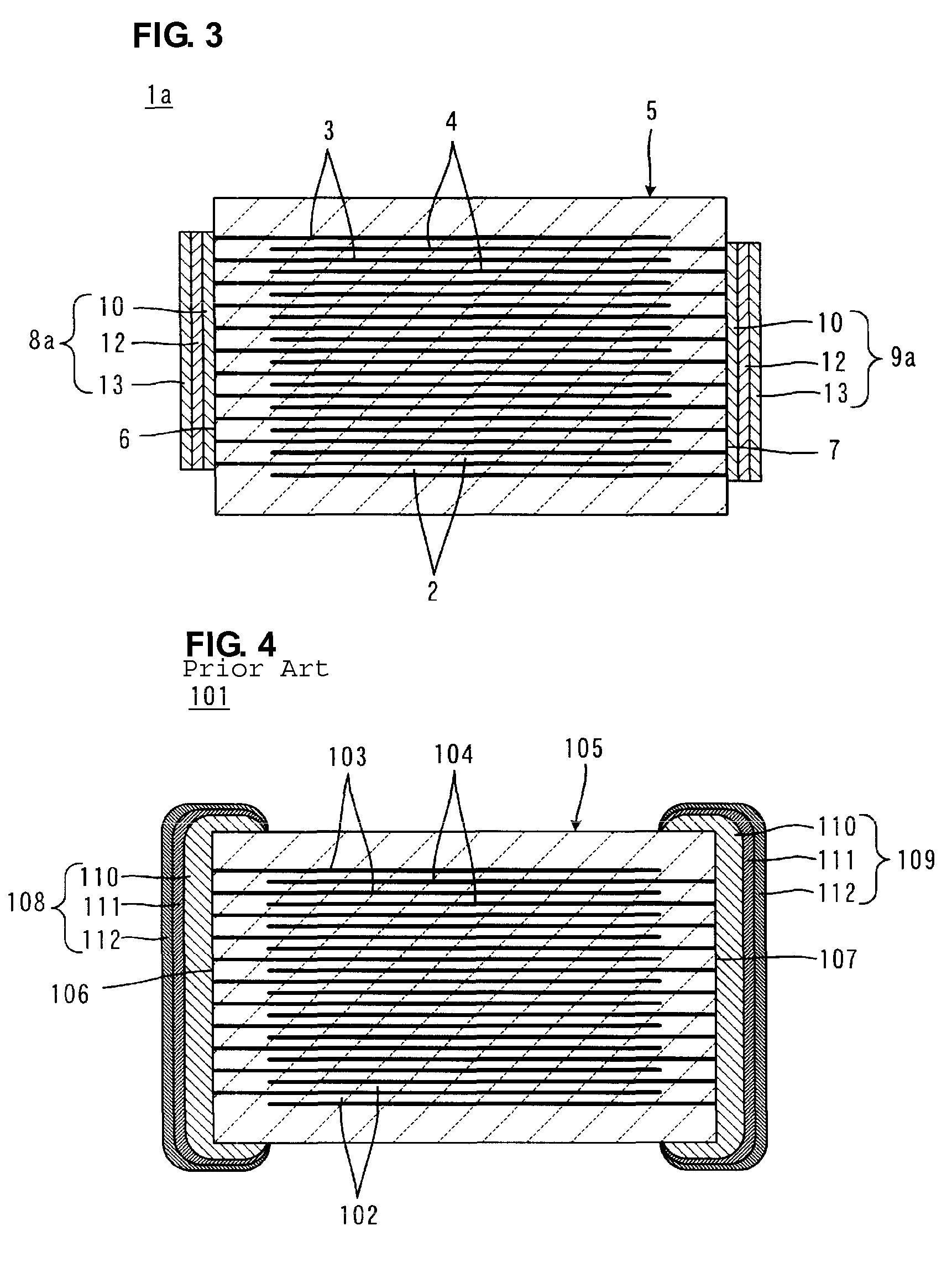

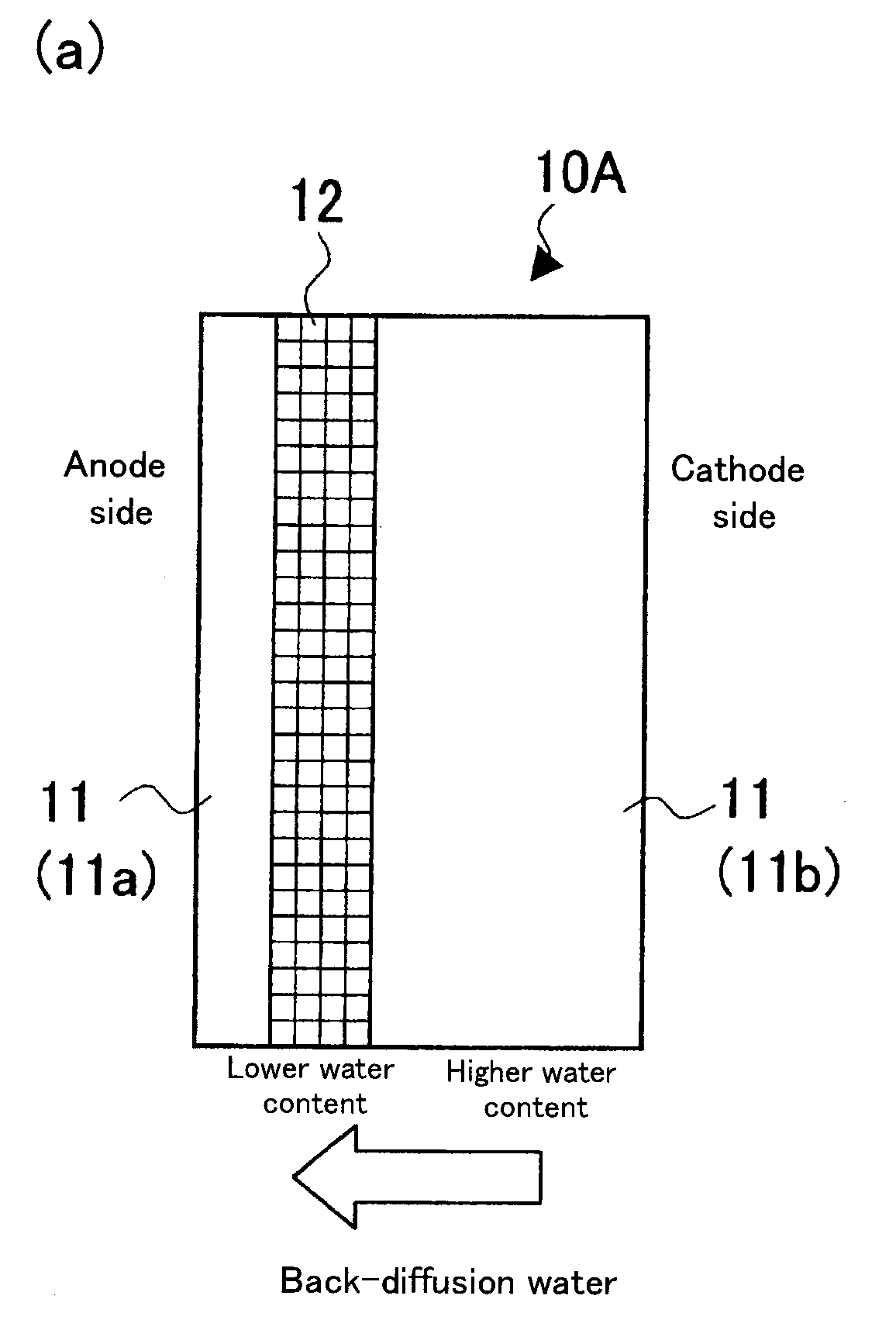

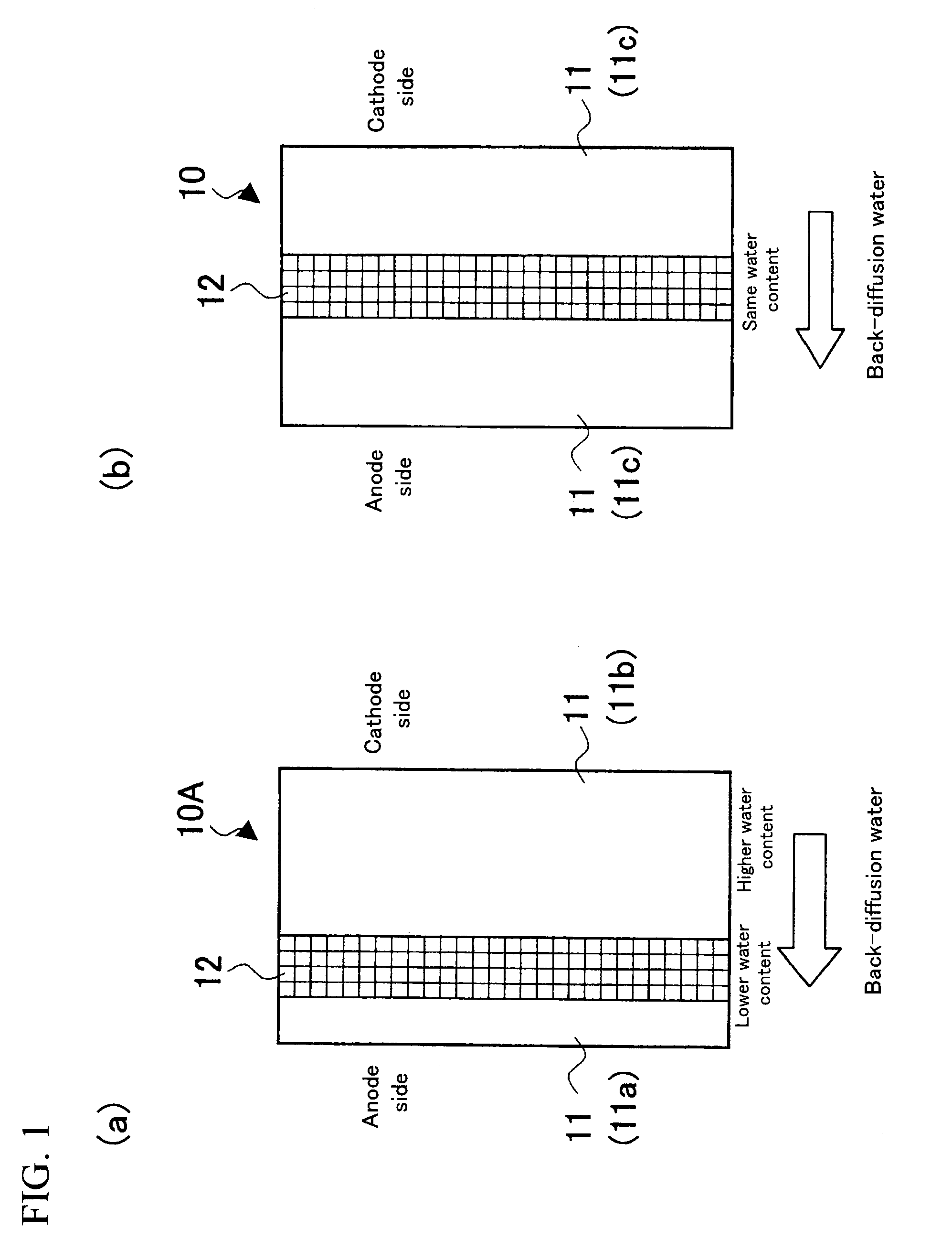

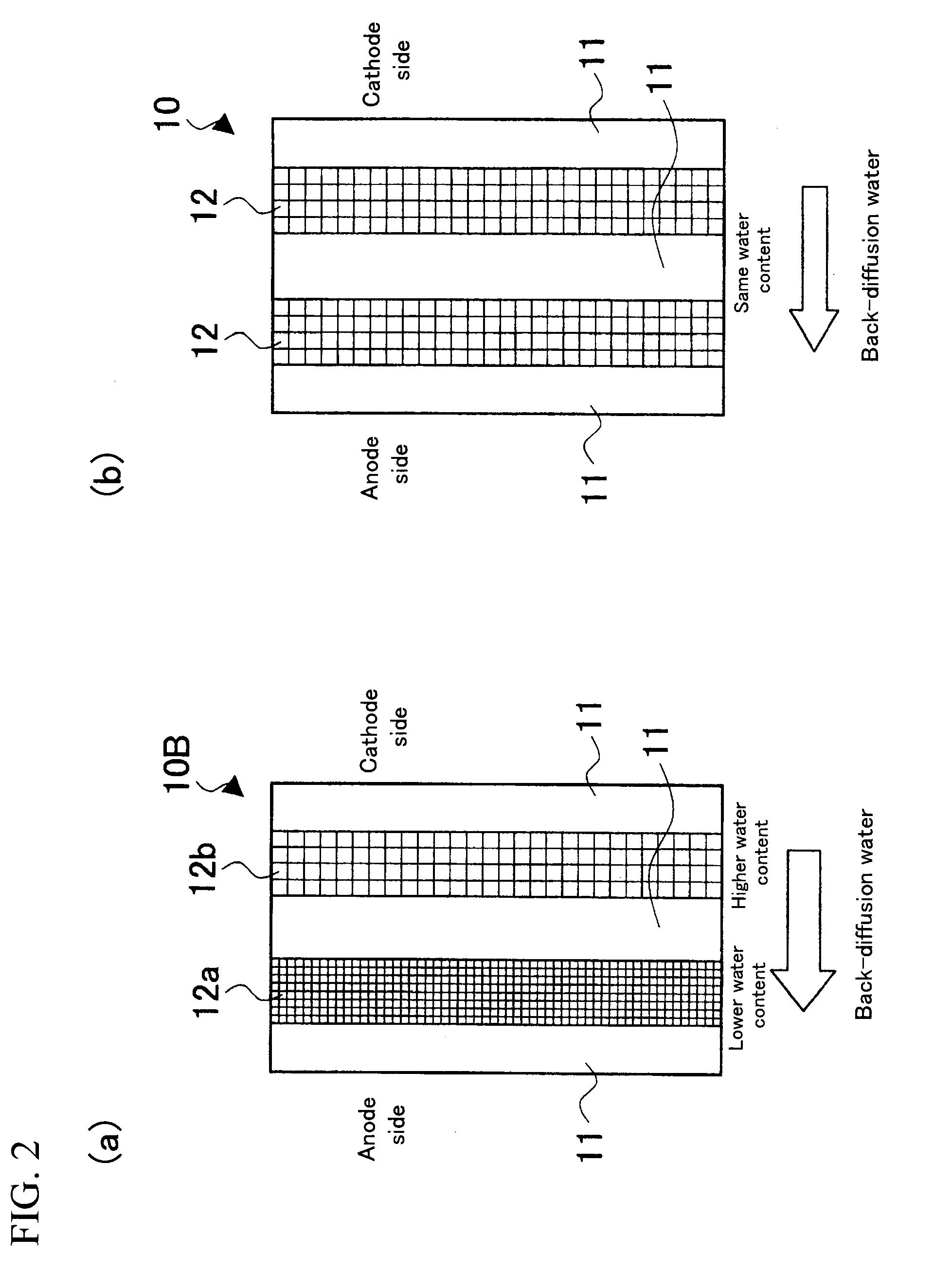

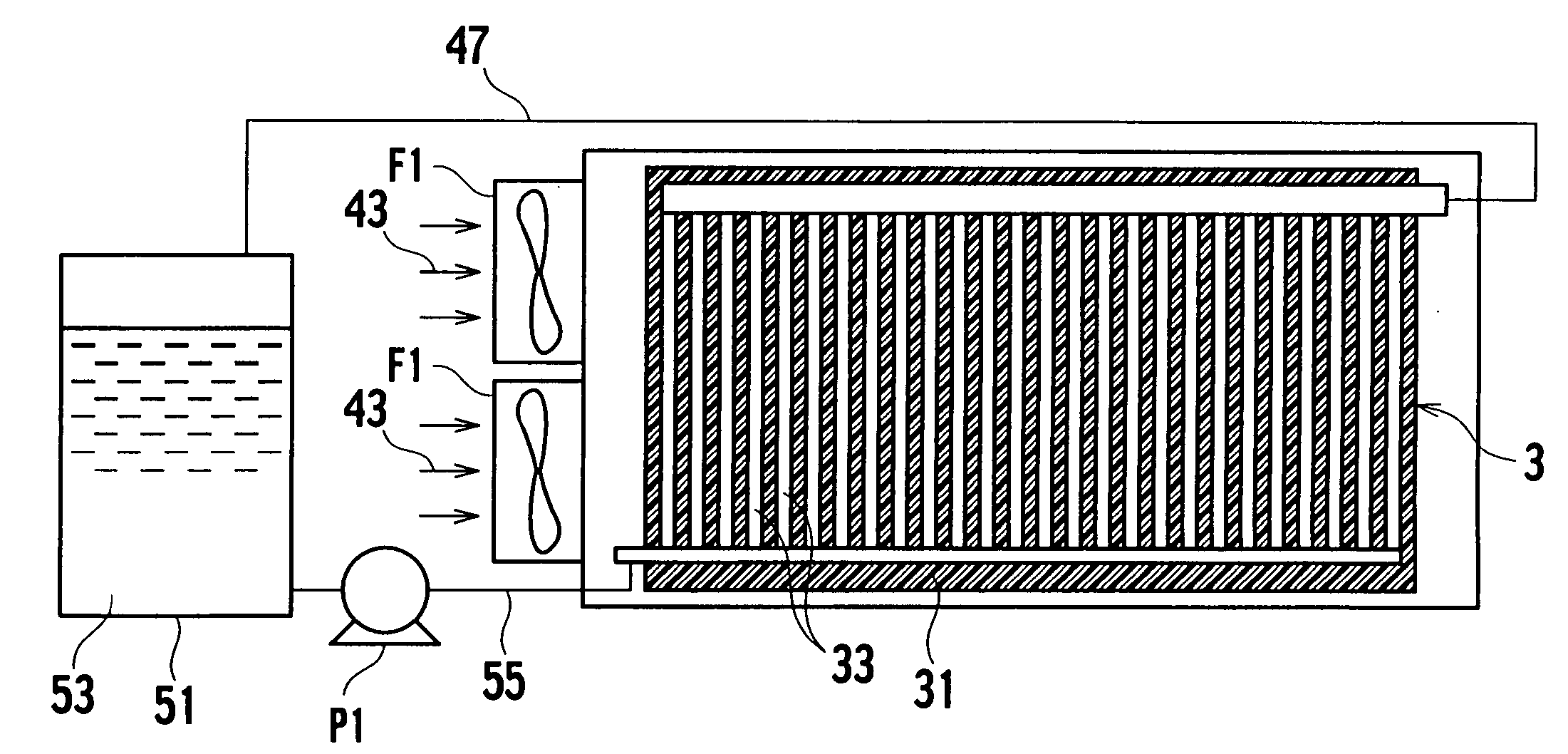

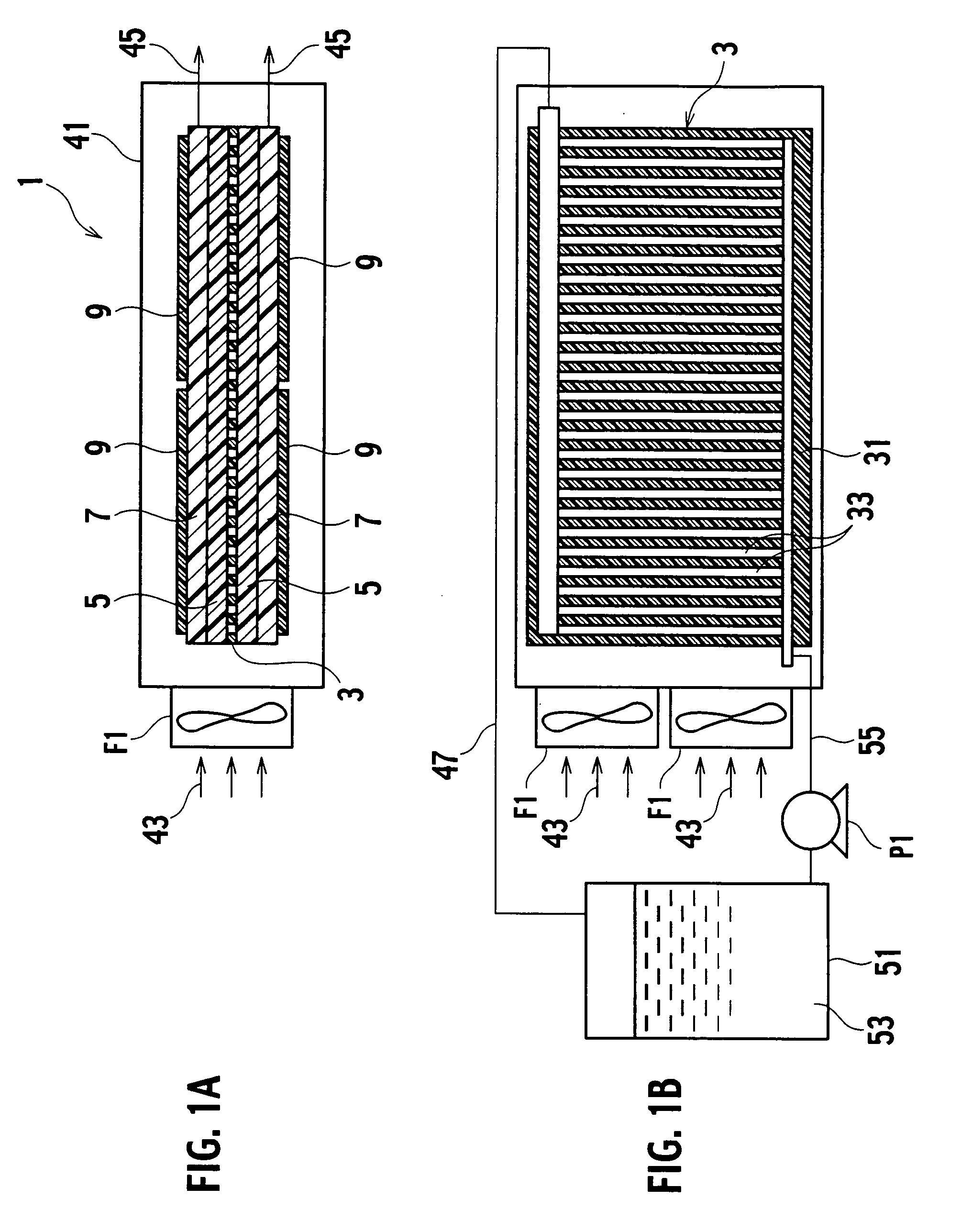

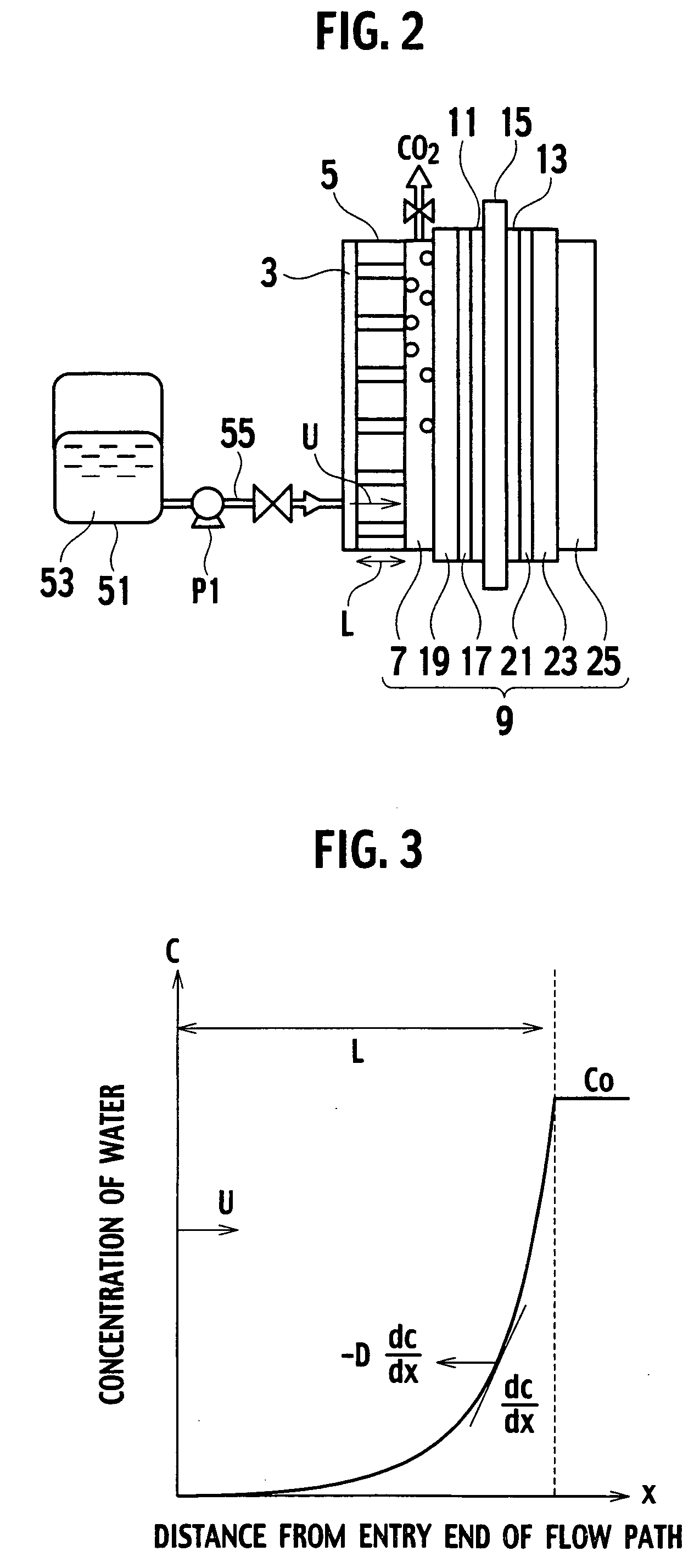

Electrolyte membrane and fuel cell using the same (as amended)

InactiveUS20100196787A1Increasing concentration gradientReduced operating requirementsSolid electrolytesSolid electrolyte fuel cellsFuel cellsPorous membrane

In a fuel cell 1 including a membrane electrode assembly 2 which includes a reinforcing-membrane-type electrolyte membrane 10A, a dry-up on the anode side is suppressed by actively forming a water content gradient in the electrolyte membrane to enhance water back-diffusion effect from the cathode side to the anode side. For that purpose, two sheets of expanded porous membranes 12a and 12b having different porosities are buried, as reinforcing membranes, in electrolyte resin 11 to obtain the reinforcing-membrane-type electrolyte membrane 10A. The reinforcing-membrane-type electrolyte membrane 10A is used to form the membrane electrode assembly 2, which is sandwiched by separators 20 and 30 such that the side of a reinforcing membrane 12b with a larger porosity becomes the cathode side, thus obtaining the fuel cell 1. When one sheet of the reinforcing membrane is buried, the reinforcing membrane is offset to the anode side to be buried in the electrolyte resin.

Owner:TOYOTA JIDOSHA KK

Fuel Cell

InactiveUS20060222926A1Inhibited DiffusionFuel cell auxillariesSolid electrolyte fuel cellsFuel cellsProton

A fuel cell is provided with: a membrane electrode assembly including an anode, a cathode and a proton-permeation membrane provided between the anode and the cathode; and a fuel supply path to supply a fuel including any of water-soluble organic matters to the anode, the fuel supply path including a back-diffusion barrier to prevent water from diffusion in a direction reverse to supply of the fuel.

Owner:KK TOSHIBA

Polycrystalline silicon ingoting process for shortening corner crystal growth time

InactiveCN103469302APrevent back proliferationQuality improvementPolycrystalline material growthAfter-treatment detailsVacuum pumpingMetallurgy

The invention belongs to the field of polycrystalline silicon ingoting, and particularly relates to a polycrystalline silicon ingoting process for shortening corner crystal growth time. The process comprises the following steps: loading, vacuum-pumping, preheating, melting and heat-insulating, crystal growth, annealing, temperature reduction and squaring, wherein the step of crystal growth comprises a central crystal growth stage and a corner crystal growth stage. The polycrystalline silicon ingoting process is characterized in that the next step of annealing stage can be performed after 1 / 4-1 / 6 of the corner crystal growth stage is completed. The ingoting process has the advantages as follows: 1, through shortening the time of the corner crystal growth stage, the annealing stage comes in advance, and the whole process time is effectively shortened by 2-3 h, and moreover, back diffusion of impurities at the ingoting top can be effectively prevented so as to improve the polycrystalline silicon ingoting quality; 2, as the process time is shortened, the expenditure on electric power and manual labour is reduced, and as a result, the cost of the whole ingoting process is reduced by 5 percent.

Owner:青岛隆盛晶硅科技有限公司

Power device for improving morphology of diffusion region and manufacture method thereof

ActiveCN103811545AGood lookingIncrease concentrationTransistorSemiconductor/solid-state device manufacturingGate dielectricEngineering

The invention provides a power device for improving morphology of a diffusion region and a manufacture method thereof. The power device comprises a substrate, an epitaxial layer, a buried layer, and a source region. The buried layer between the source region and the epitaxial layer is a conducting channel region. A prediffusion region is formed in the epitaxial layer close to the conducting channel region. The power device further comprises a gate dielectric layer, a gate electrode, a dielectric layer, a front metal layer, a back diffusion region, and a back metal layer. According to the power device for improving morphology of the diffusion region, the prediffusion region enables the buried layer to be smoothly expanded towards the epitaxial layer so as to improve the morphology of the diffusion region at the edge of the channel, and optimize the electric field distribution of the power device under high temperature and high voltage. Therefore, the electric leakage level of the power device under high temperature and high voltage is reduced; and the thermal reliability of power devices such as MOSFET, IGBT, and the like can be substantially improved. The power device satisfies operating requirements in high temperature and large power environments. The manufacturing process of the power device is completely compatible with that of a conventional power device. The power device is simple in structure, convenient in manufacture, and has improved production efficiency and rate of finished products.

Owner:BYD SEMICON CO LTD +1

Solid-liquid separation method and device for polycrystalline silicon ingot

InactiveCN103266351AEasy to separateHigh yieldPolycrystalline material growthSingle crystal growth detailsIngotBack diffusion

The invention provides a solid-liquid separation method and device for a polycrystalline silicon ingot. The solid-liquid separation method comprises the following steps of: fusing a silicon material into a fused silicon material in a container, when carrying out ingot pulling until the quantity of silicon liquid in the fused silicon material is 10-20%, applying pressure to the fused silicon material by utilizing a press plate matched with the cross section of the container, and extruding the silicon liquid from the fused silicon material onto the press plate along a gap between the container and the press plate under the action of pressure; stopping applying pressure to the fused silicon material after the silicon liquid is completely extruded onto the press plate; and forming a high-purity ingot below the press plate. The invention further discloses the device for realizing the solid-liquid separation method for the polycrystalline silicon ingot. According to the solid-liquid separation method and the solid-liquid separation device, lots of disadvantages in the prior art are overcome; and when the separation between the enriched impurity melts and the high-purity ingot is guaranteed, the back diffusion is restrained, and the primary product yield in the polycrystalline silicon production is improved.

Owner:DALIAN UNIV OF TECH

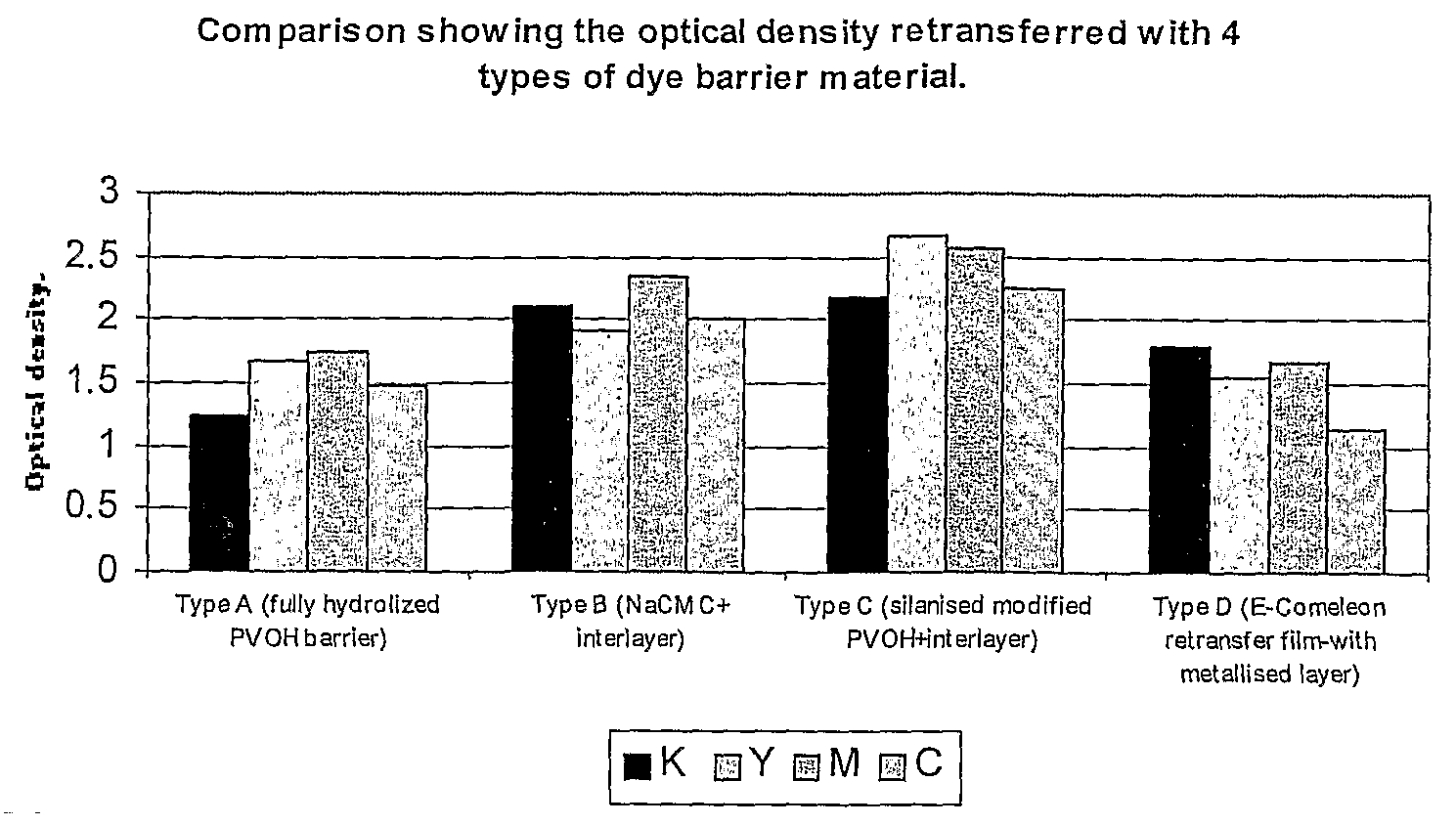

Thermal transfer printing

InactiveUS20100119739A1Improve adhesionAvoid lostDecorative surface effectsElectrography/magnetographyPolyvinyl alcoholEngineering

A retransfer intermediate sheet for receiving an image to be printed onto an article by thermal retransfer comprises a substrate; and an image-receiving coating on one side of the substrate for receiving an image by printing of dye-containing ink, the coating comprising a fluid-absorbing layer and a superposed dye management layer comprising functionalised polyvinyl alcohol and / or an ionic polymer. The dye management layer functions to reduce back diffusion and to increase dye transfer efficiency, resulting in production of printed images of improved optical density. The sheet can be heat-deformable, and finds particular use in printing on 3D articles, e.g. being heated and vacuum formed to conform to an article. The invention also covers a method of printing and an article bearing a printed image.

Owner:AKZO NOBEL COATINGS INT BV

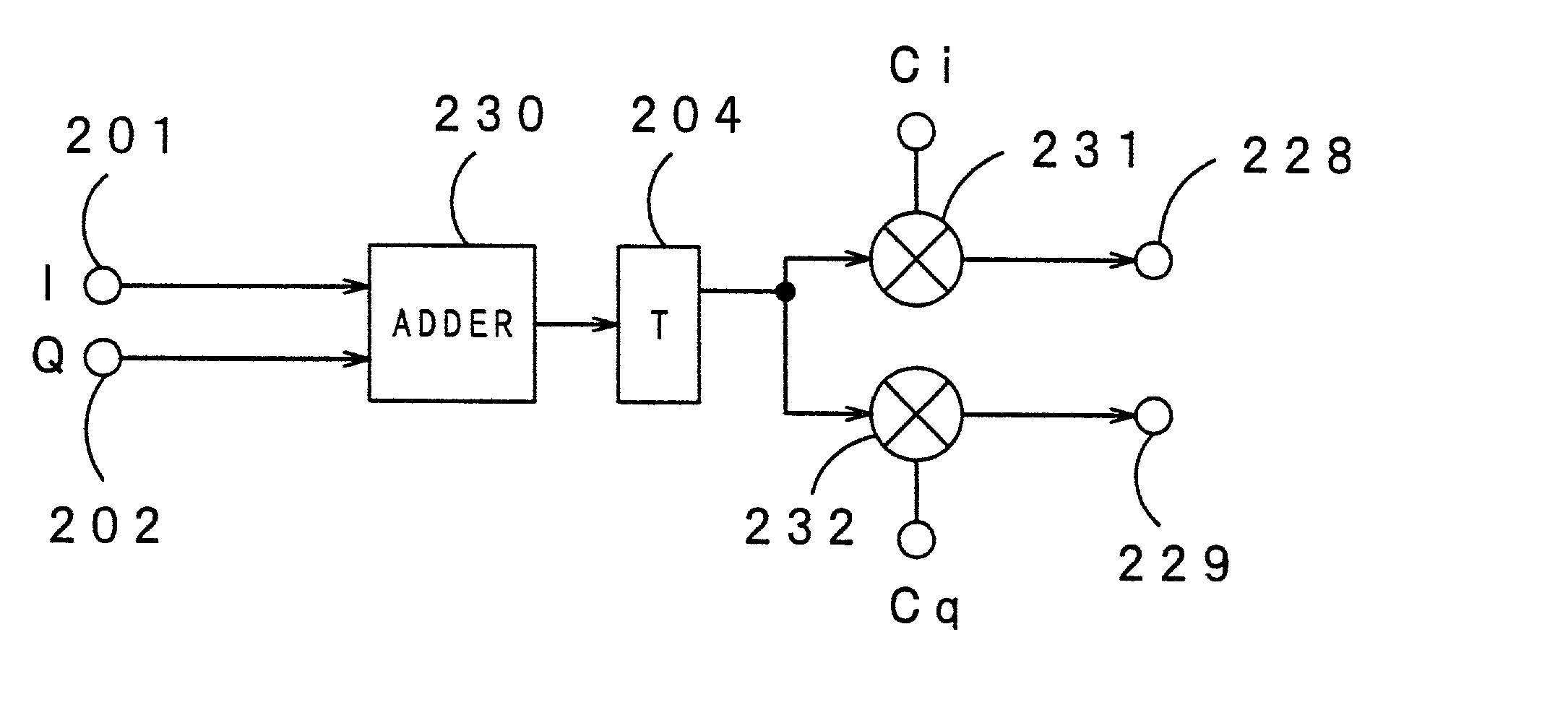

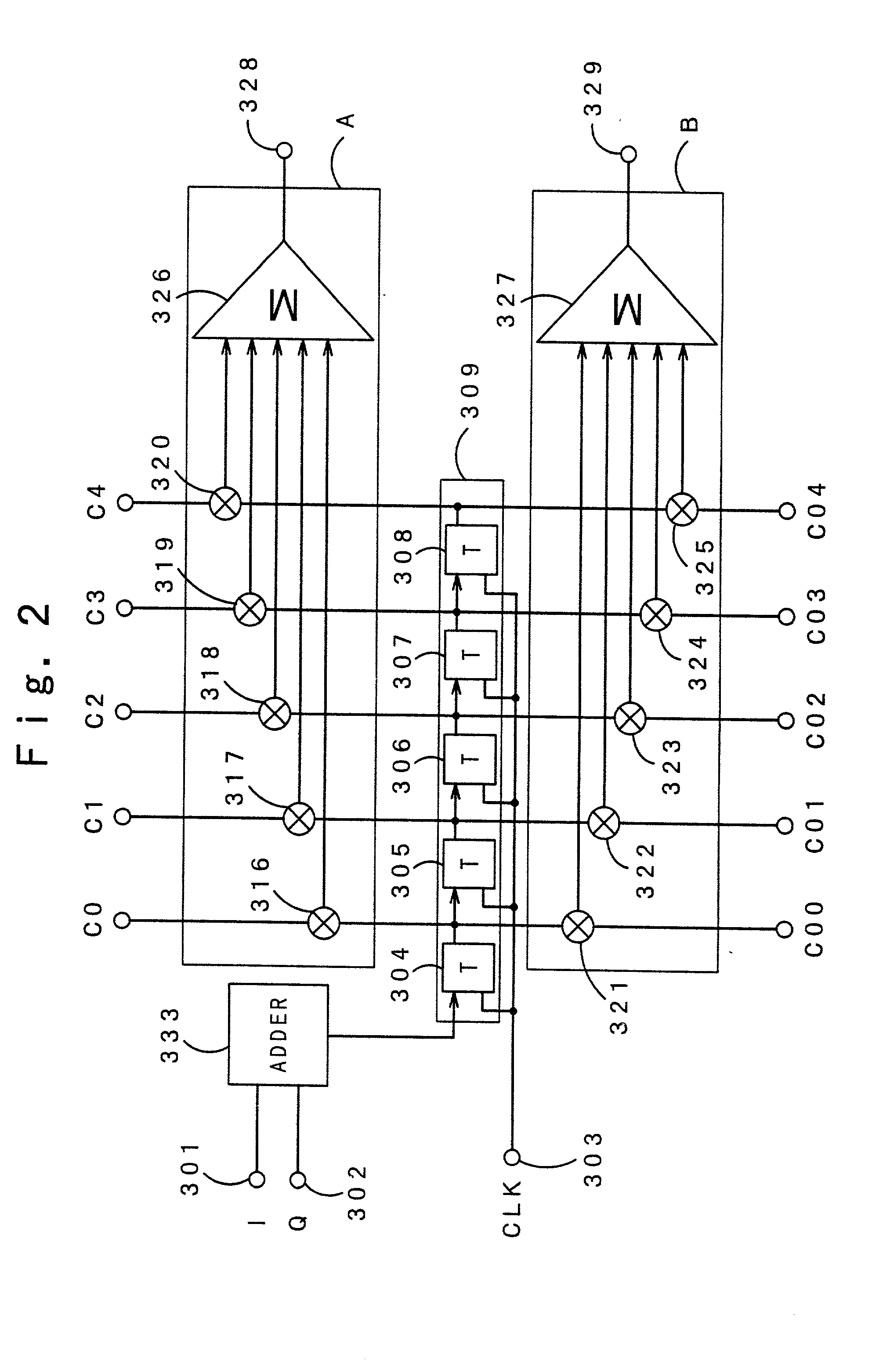

Correlation detecting method and matched filter unit

InactiveUS20020027965A1Digital technique networkAmplitude-modulated carrier systemsMiniaturizationBack diffusion

The matched filter unit of the present invention is used for finding a value of correlation between each of a plurality of digital signals synchronized with a clock and each of a plurality of digital code strings consisting of M (M: plural) digital codes respectively. The matched filter unit comprises a circuit for multiplexing a plurality of the digital signals, a storage circuit composed of delay circuits disposed in M stages and used for entering a signal output from the signal multiplexing circuit to the first stage delay circuit, then shifting the signal to the subsequent delay circuits sequentially in synchronization with the clock, and a plurality of computing devices for finding a value of correlation between each of the digital signals and a digital code string respectively using a signal output from each of the delay circuits disposed in M stages. Each of a plurality of the computing devices is composed of M multipliers (M: plural) for multiplying a signal output from each of the delay circuits by each digital code of a digital code string and an adder for adding results of multiplication from the M multipliers to find a value of the correlation. According to this configuration of the matched filter unit, a plurality of the digital signals that are diffusion-modulated with different code values are not correlative with each other. Those non-correlative digital signals are multiplexed by a signal multiplexing circuit, then the multiplexed signal is computed for back-diffusion in the storage circuit, the multipliers, and the adder using different digital code strings, thereby to detect a value of correlation between digital signals entered from a plurality of channels using the same storage circuit. It is thus possible to provide a matched filter unit that can be reduced significantly in circuitry size, thereby to satisfy the miniaturizing, lower manufacturing cost, and power saving prerequisites.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com