Patents

Literature

75results about How to "Increasing concentration gradient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Interpenetrating network polymer type super porous aquogel, its prepn. method and application

InactiveCN1757662AOral administration is convenientHigh mechanical strengthPharmaceutical non-active ingredientsCarrier-bound/immobilised peptidesCross-linkFoaming agent

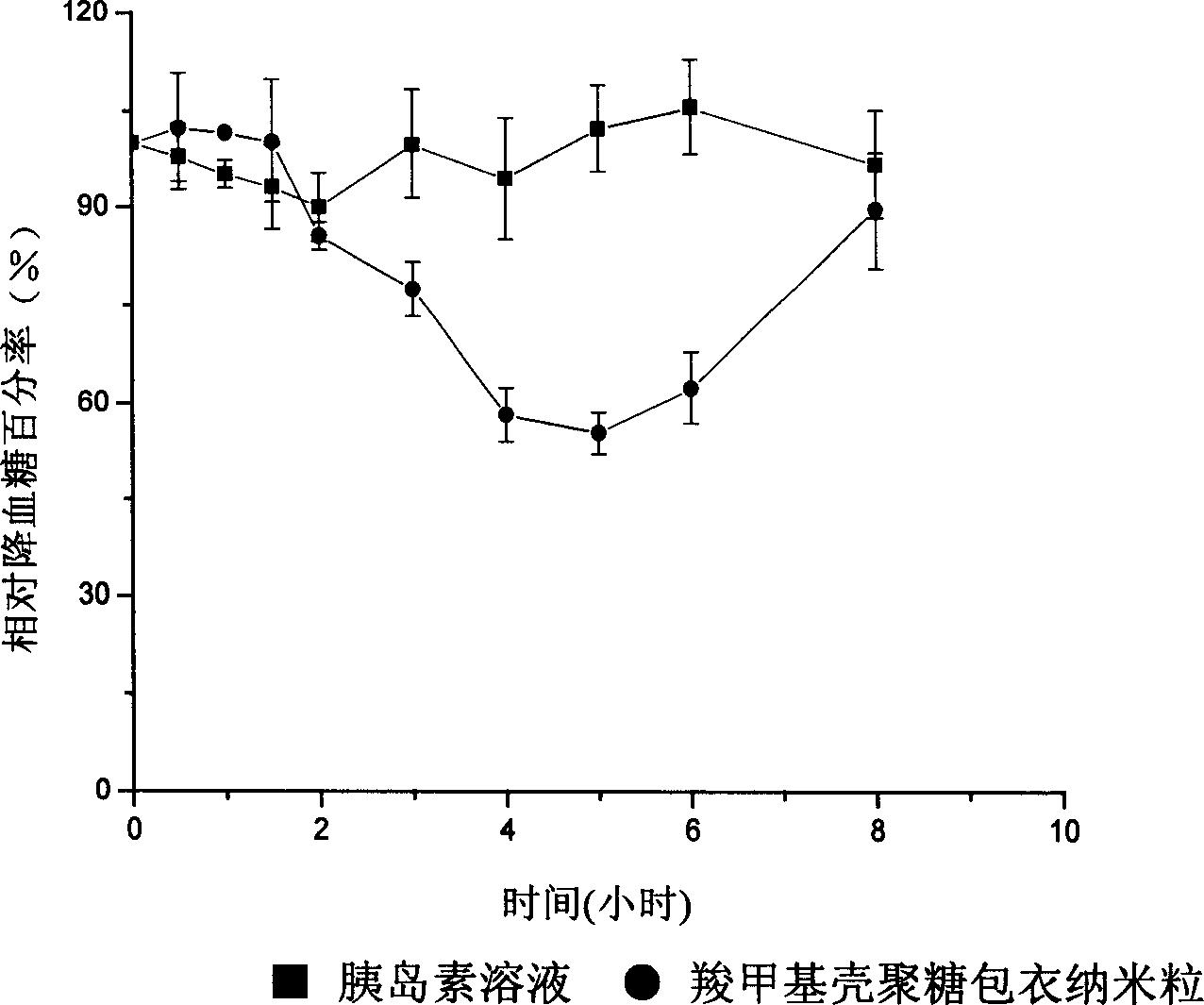

A super-porous aqueo-gel of an interpenetrating network polymer used for the orally applying system of protein polypeptide to suppress proteinase and break the close linking between epithelial cells contains two polymers: a cross-linked polymer and a cross-linked polyose polymer. Its preparing process includes such steps as mixing at least one unsaturated enylmonomer, at least one polyenyl cross-linking agent, a linear polyose polymer and a foaming agent to generate the super-porous aqueo-gel of semi-interpenetrating network polymer, and cross-linking with linear polyose.

Owner:FUDAN UNIV

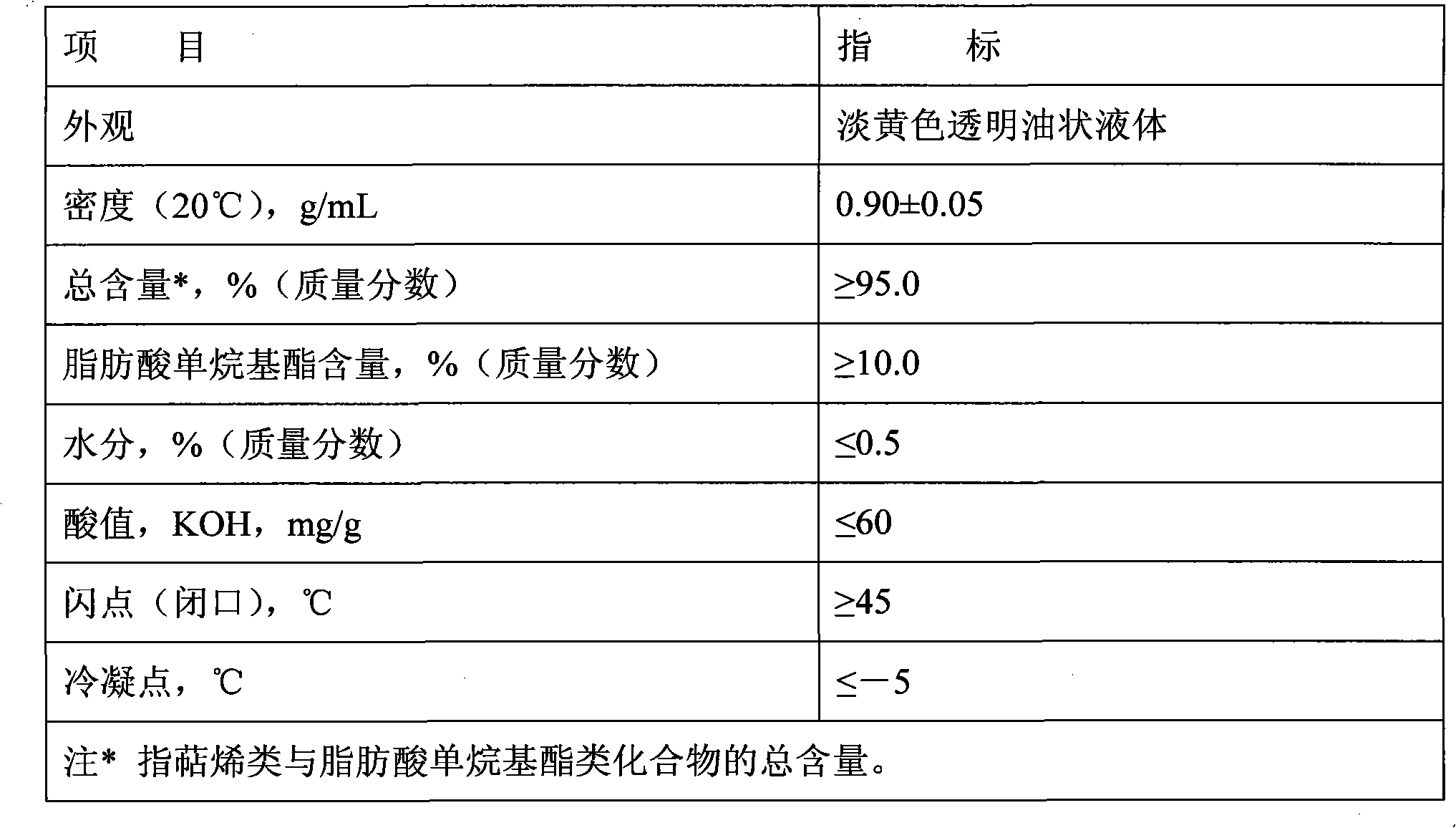

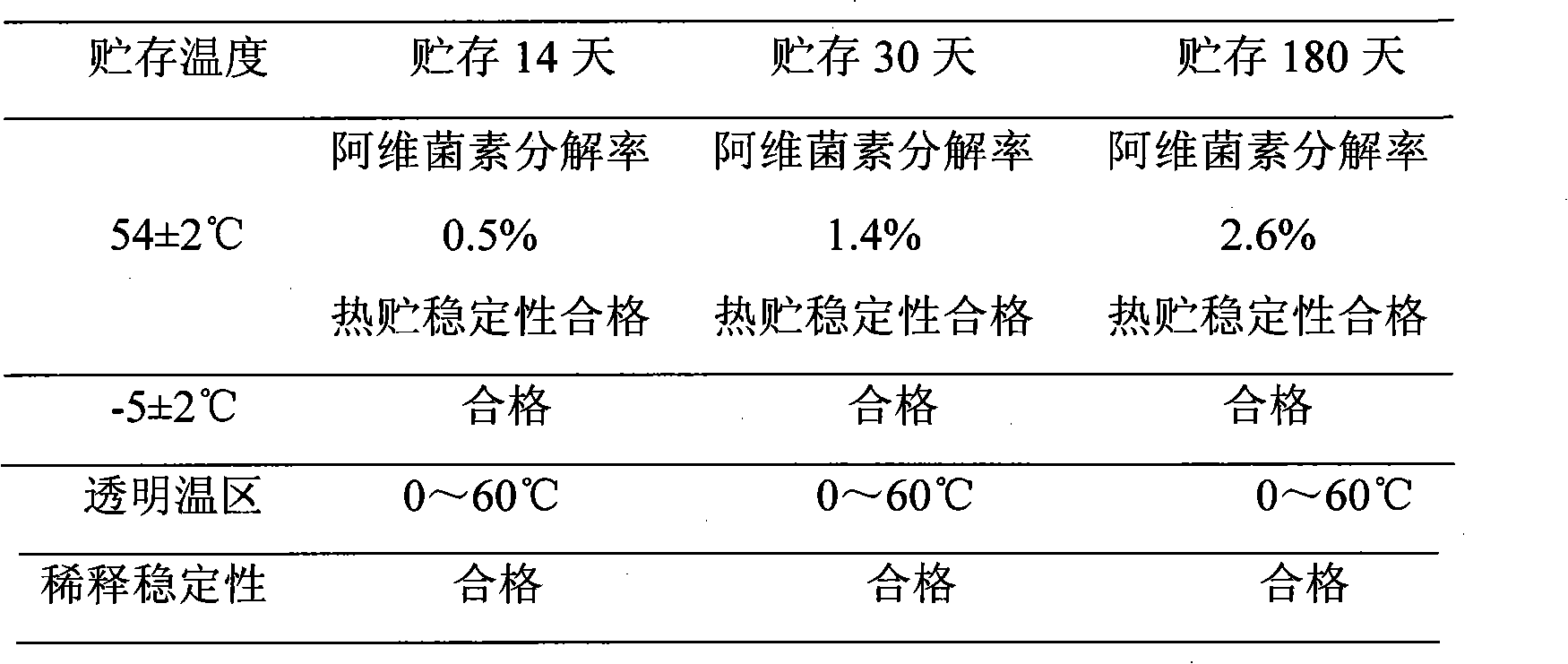

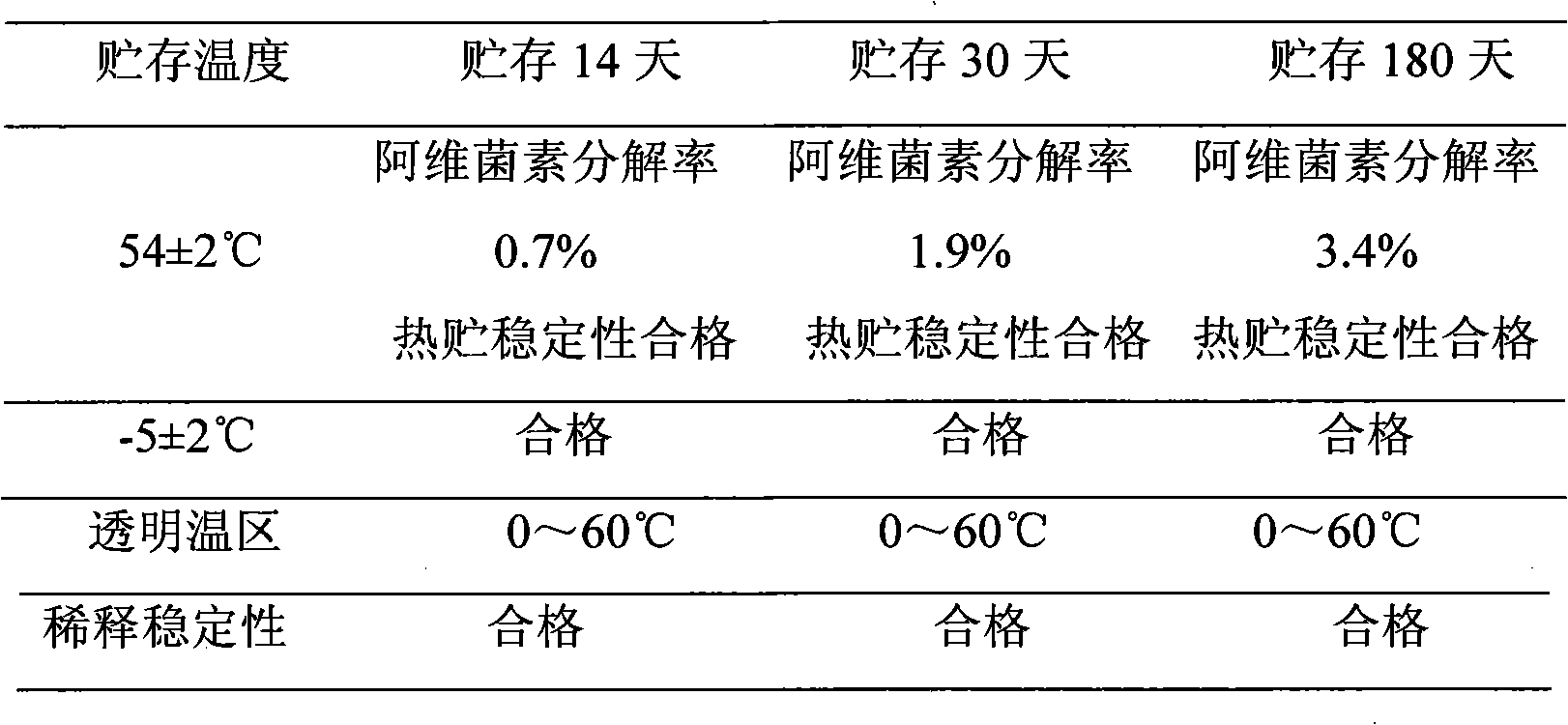

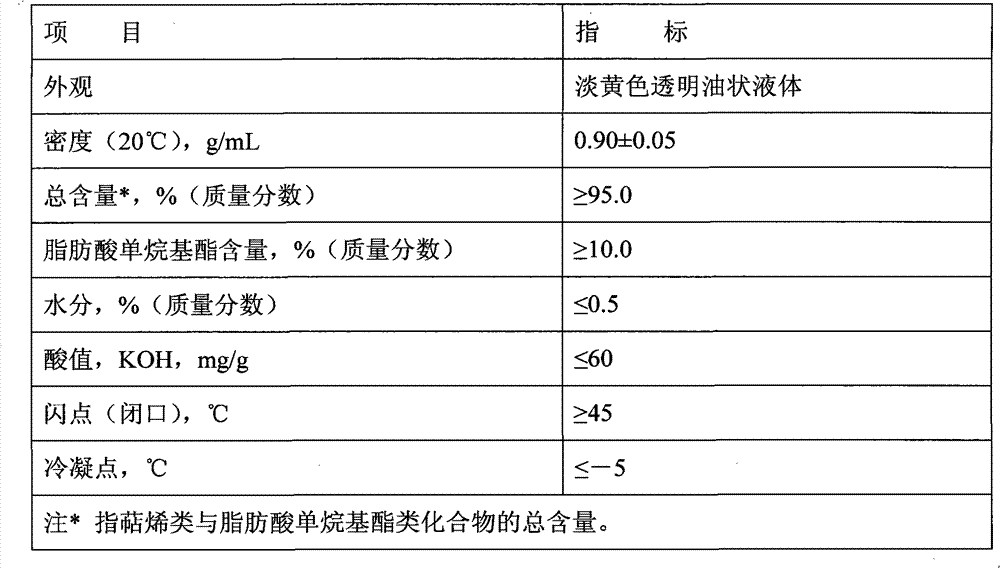

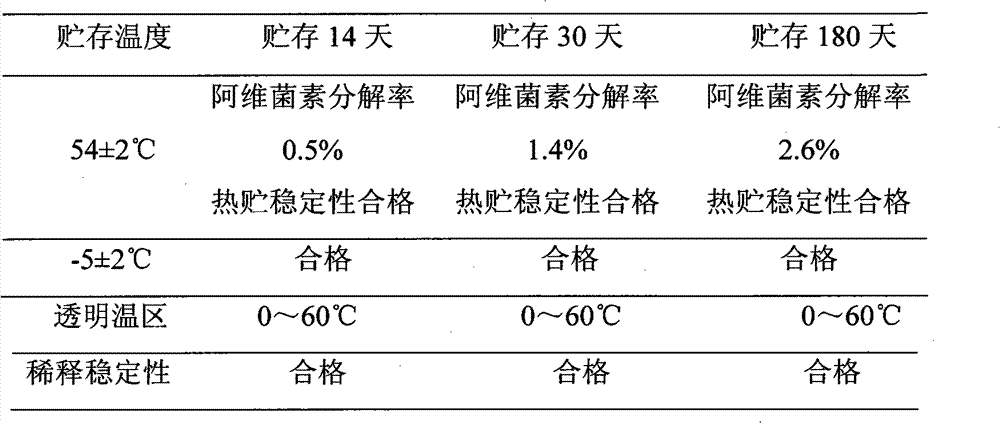

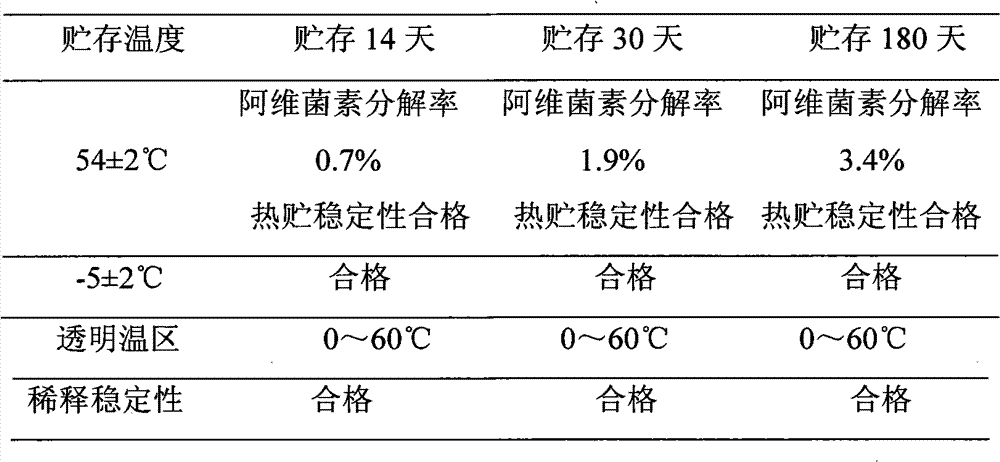

Microemulsion preparation taking rosin-based vegetable oil as solvent and preparation method thereof

The invention provides a microemulsion preparation taking rosin-based vegetable oil as a solvent and a preparation method thereof, and relates to a pesticide preparation. The microemulsion preparation consists of the following raw materials in percentage by mass: 0.5 to 30 percent of pesticide active ingredients, 55 to 20 percent of emulsifier, 0 to 8 percent of cosolvent, 0.1 to 0.3 percent of defoamer, 1 to 30 percent of rosin-based vegetable oil, and the balance of water. The preparation method comprises the following steps of: adding the pesticide active ingredients, the rosin-based vegetable oil, the cosolvent, emulsifier and the defoamer into a reaction kettle, performing cutting and uniform dispersion at 2,000 to 5,000 rpm / min, and adding the balance of water into the mixture for high-speed cutting to obtain the microemulsion preparation taking the rosin-based vegetable oil as the solvent.

Owner:FUJIAN NUODE BIOTECH

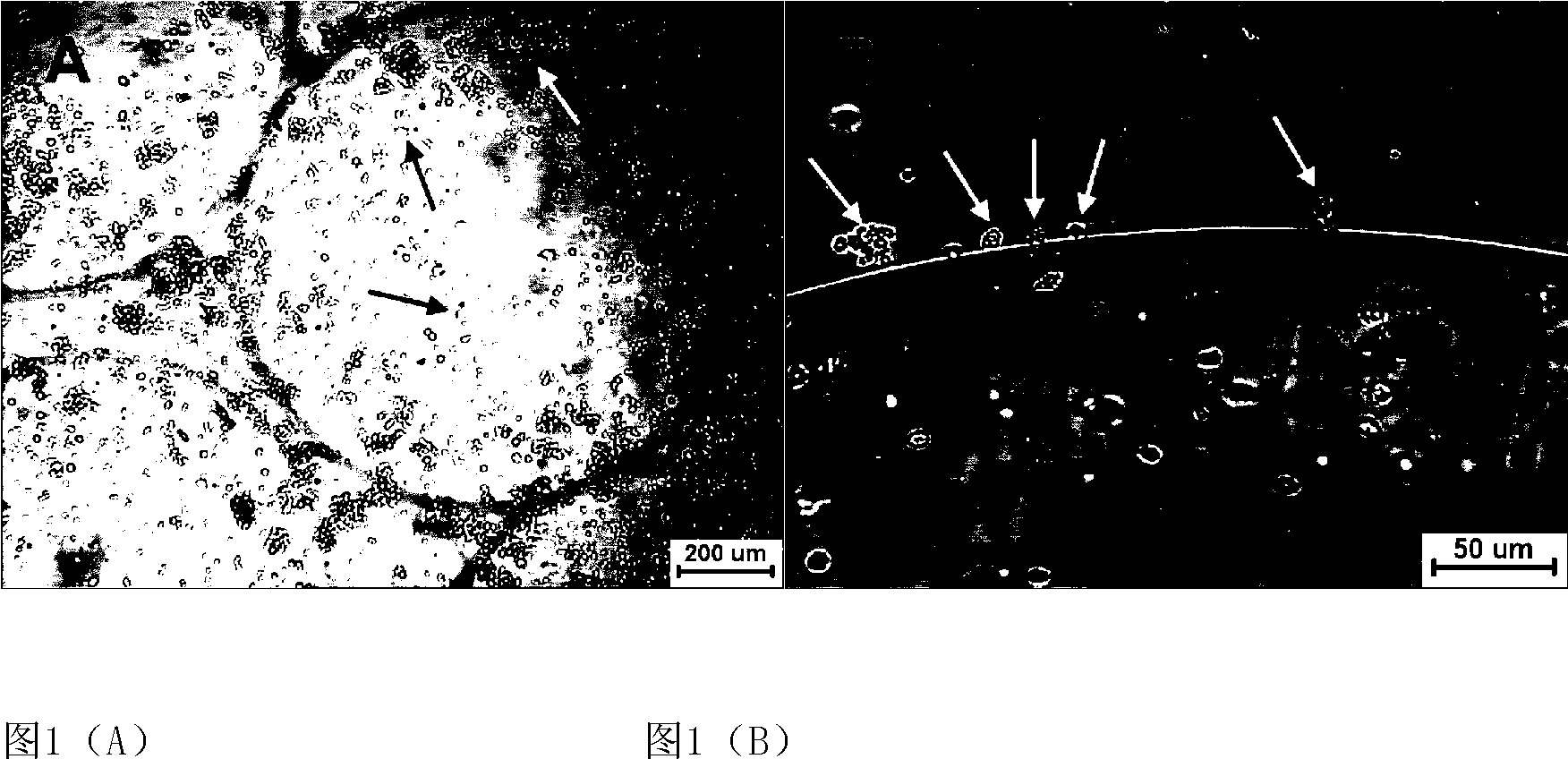

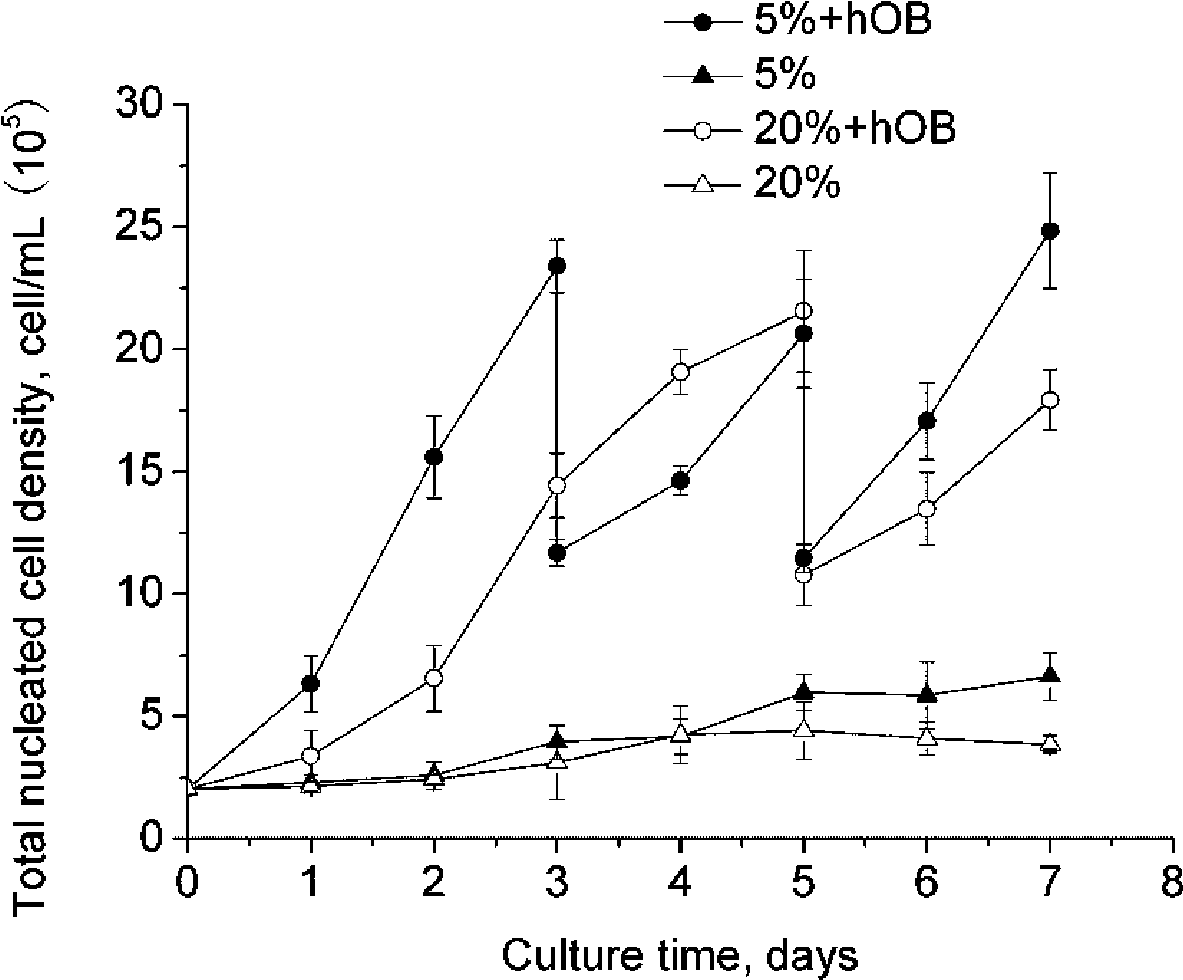

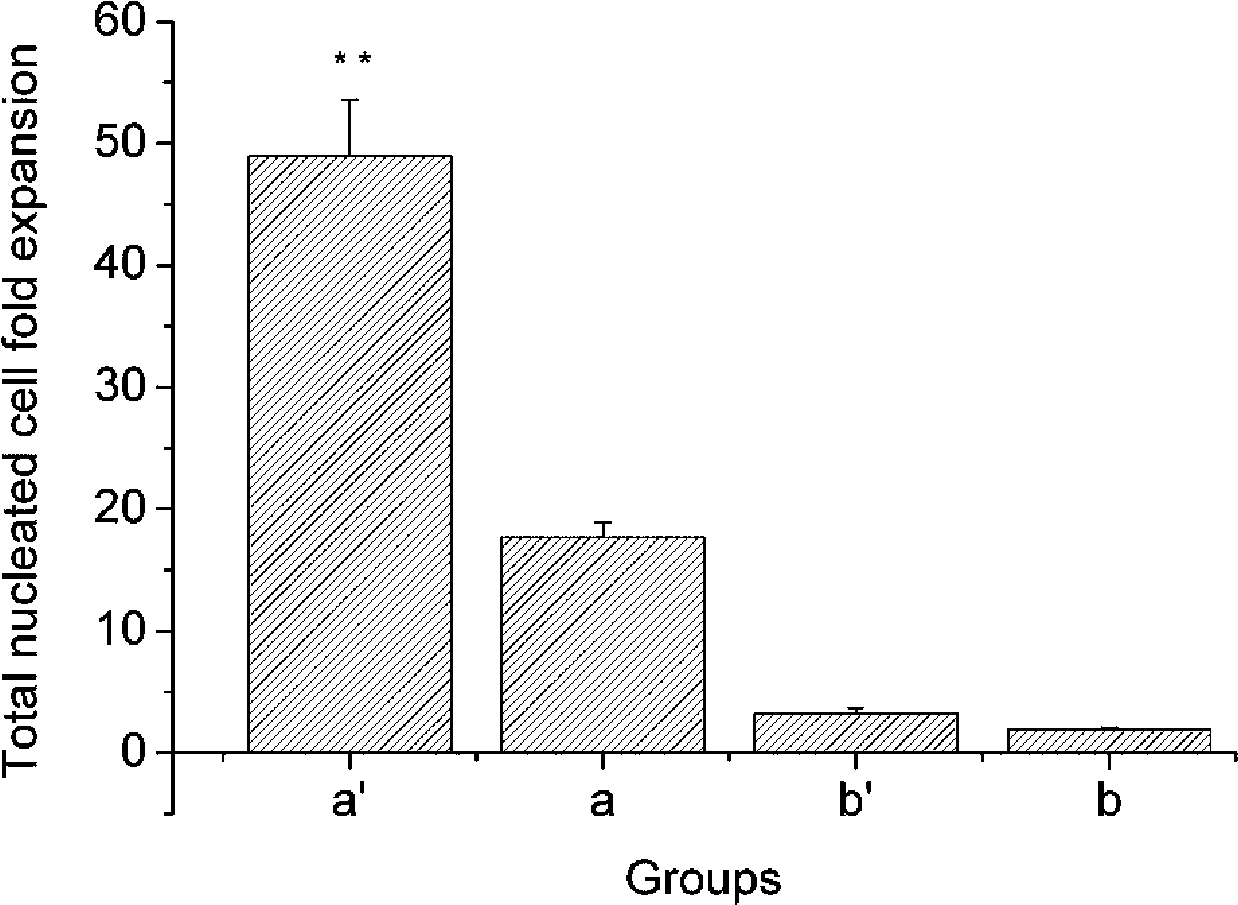

Method for supporting, regulating and controlling amplification of hematopoietic stem/progenitor cell in vitro with microencapsulation osteoblast in hypoxia condition

InactiveCN101508975AReach the appropriate concentration for amplificationReduce oxidative damageSkeletal/connective tissue cellsBlood/immune system cellsProgenitorCord blood stem cell

The invention discloses a method for encapsulated osteoblasts to support and regulate the in-vitro amplification of cord blood hematopoieticstem / progenitorcells (He) in the hypoxia condition, belonging to the fields of biotechnology and tissue TSPCS engineering. The method is characterized in that the human osteoblasts are embedded by gelatin-alginate-chitosan (GAC) microcapsule as matrix feeder cells and co-cultured with the cord blood HSPCs in the 5% hypoxia environment to obtain the HSPCs. The invention adopts GAC microcapsule to separate the human osteoblasts from the cord blood HSPCs to avoid the cell contamination and immunological rejection. Furthermore, the pore passages of the microcapsule are capable of causing hemopoietic growth factors secreted by the osteoblasts in the microcapsule to expand to the habitat of the HSPCs and play a role of stimulating the amplification of the hematopoietic stem / progenitor cells. Moreover, the material of the microcapsule has the slow release function to the expansion of the growth factors to increase the concentration gradient of the growth factors on the surface of the microcapsule, which is helpful for the long-term function of the growth factor. In addition, the microencapsulated osteoblasts form the 3D environment, which not only causes the culture system to contain more osteoblasts, but also causes the culture system to have bigger HSPCs-OBs action area compared with the co-culture pattern of the osteoblasts cultured by adherence. Besides, in the 5% hypoxia environment, the co-culture system is capable of better simulating the hematopoietic microenvironment iche of human bone marrow the osteoblasts have significant effects on the characteristic maintenance and number amplification of stem cells of the HSPCs.

Owner:DALIAN UNIV OF TECH

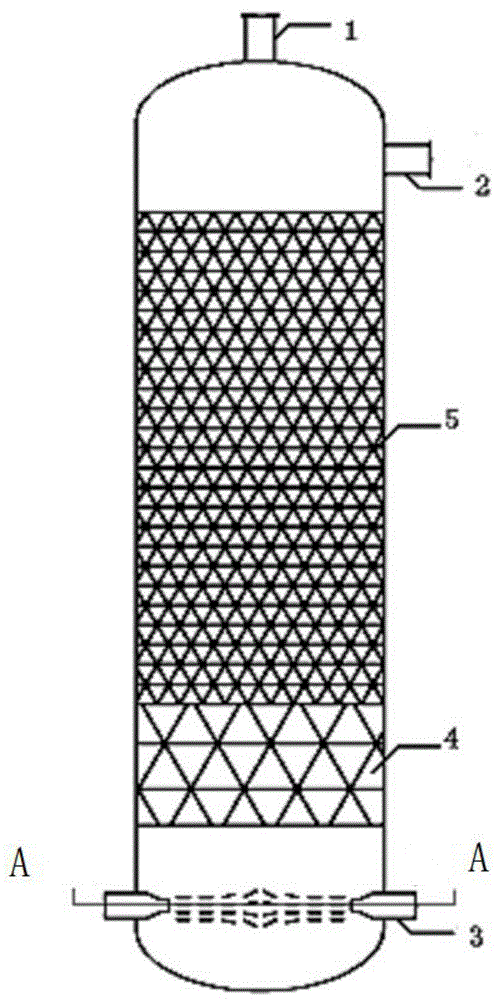

Reactor and method for preparing epoxypropane by reactor

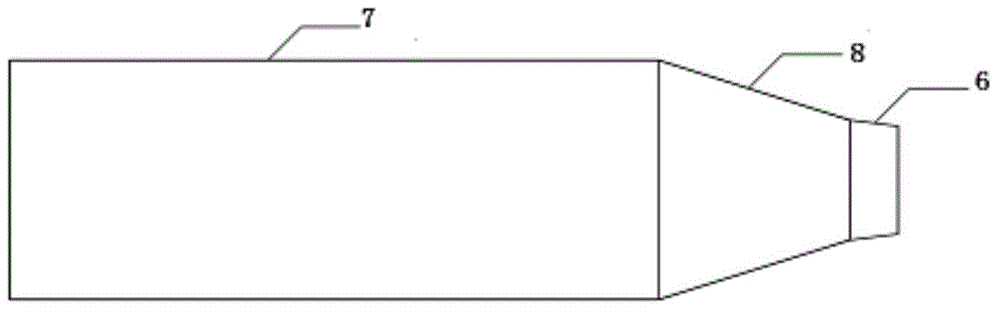

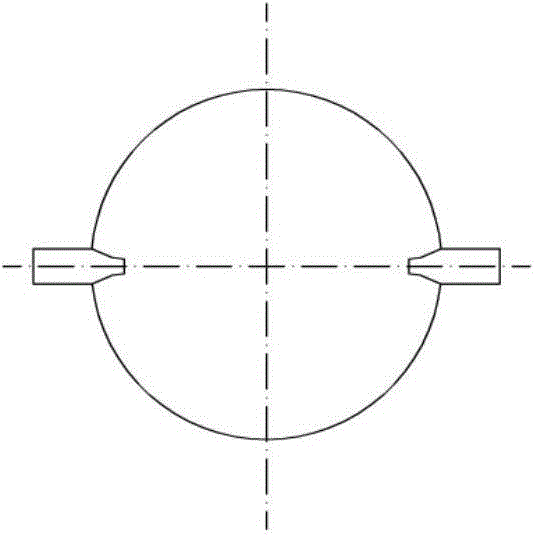

ActiveCN104907009AIntensified interphase mixingHigh selectivityOrganic chemistryChemical/physical processesSpray nozzleFixed bed

The invention discloses a reactor. The middle of the reactor is filled with an epoxidation catalyst, the top wall of the reactor is provided with a gas outlet, the upper side wall of the reactor is provided with a liquid outlet, the lower side wall of the reactor is provided with one or two groups of injectors, each group of the injectors comprises two injectors symmetrically distributed on the same plane, the injector comprises a jet pipe and a nozzle connected to the jet pipe, the nozzle is frustoconical, the diameter of one end of the nozzle connected to the jet pipe is greater than that of the other end, the nozzle stretches into a fixed bed reactor, the jet pipe comprises two sections, the section of the jet pipe far away from the nozzle is cylindrical, the other section is frustoconical, and the diameter of one end of the jet pipe far away from the nozzle is greater than the diameter of one end of the jet pipe connected to the nozzle. The invention discloses a method for preparing epoxypropane by the reactor and a reaction system composed of the reactors connected in series. The reactor realizes reactant high-speed clashing mixing, improves reactant mixing effects, improves heat and mass transfer effects and improves a cumene hydroperoxide conversion rate and epoxypropane selectivity.

Owner:HONGBAOLI GRP CO LTD +1

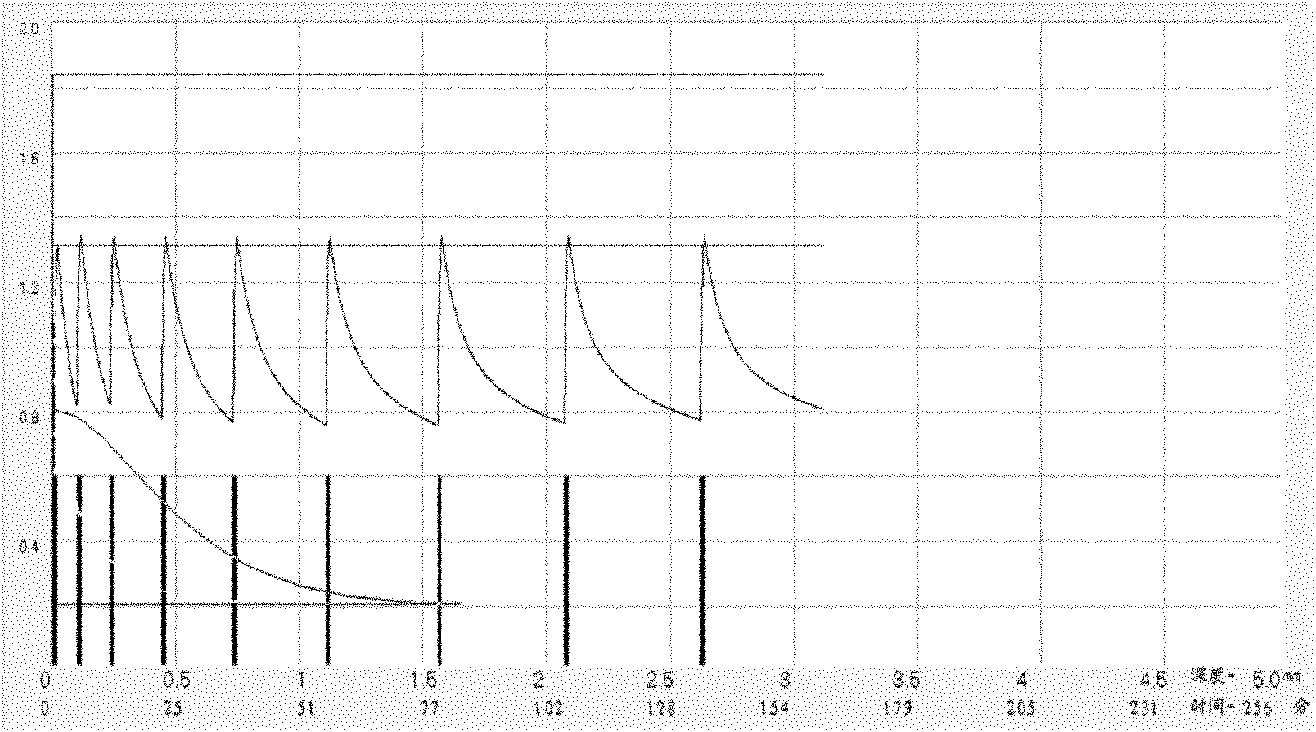

Control system of carbon intensity distribution of low-pressure carburized layer and control method thereof

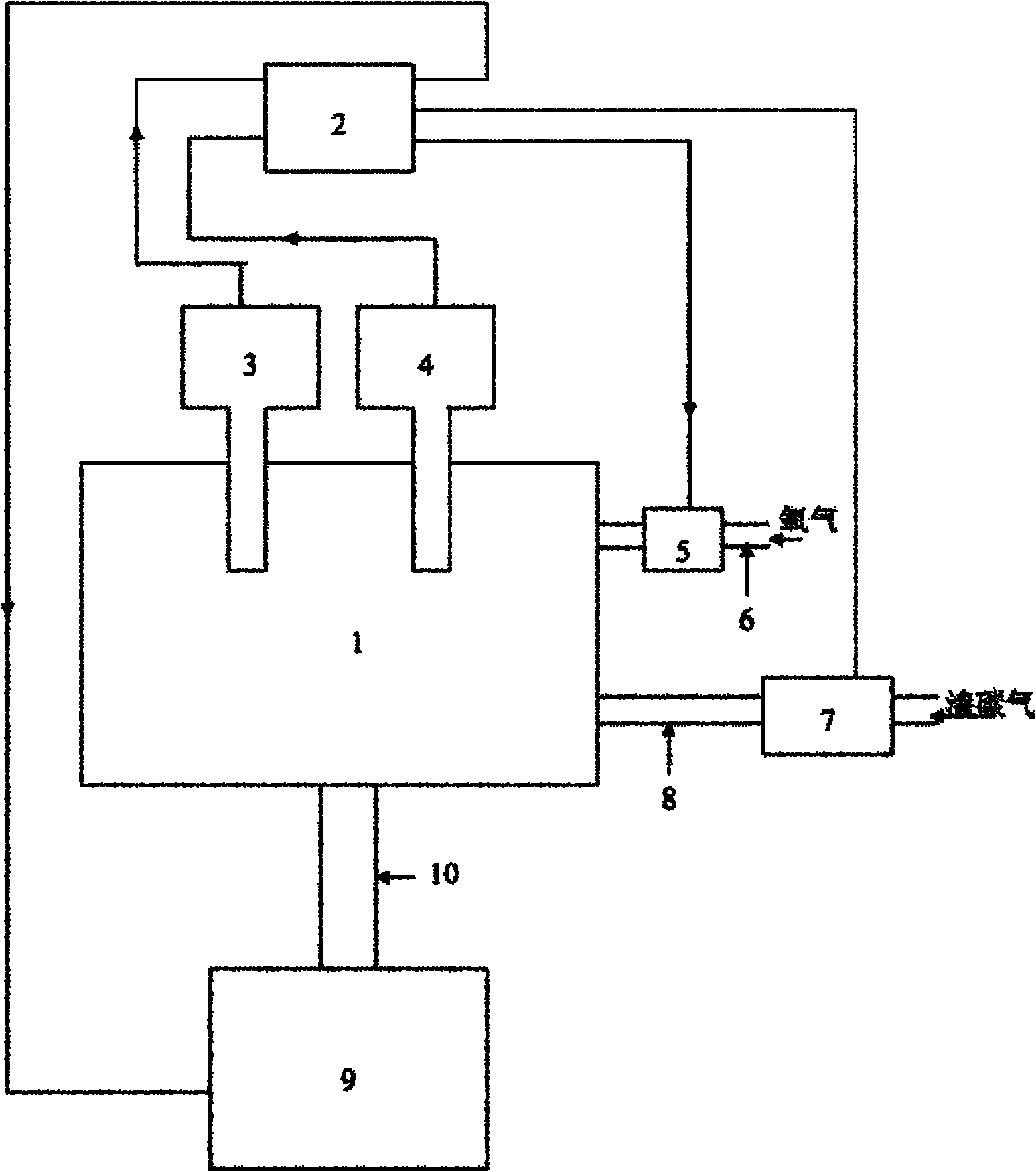

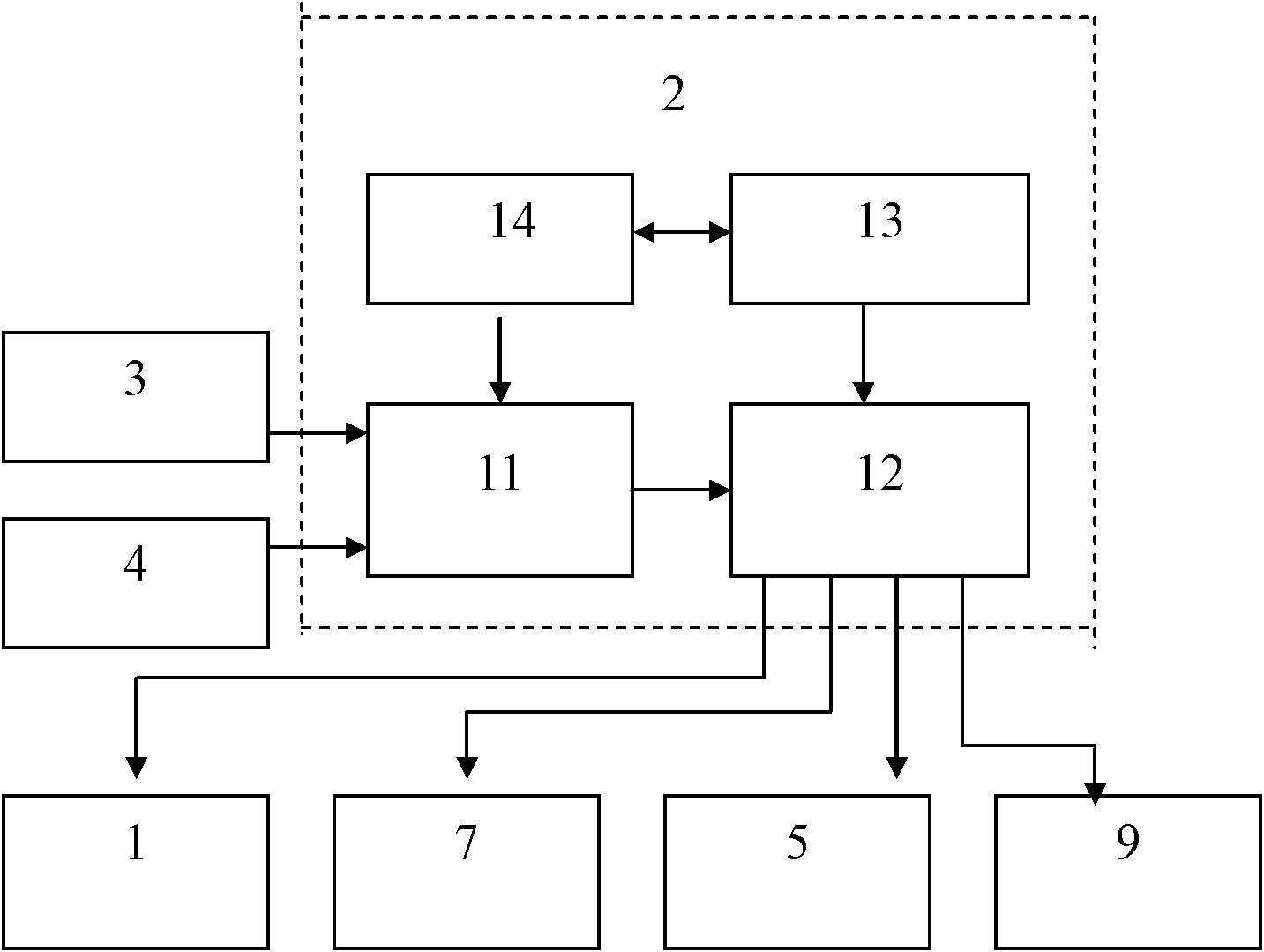

ActiveCN102063110AAvoid out-of-classOvercome the disadvantage of not being able to correctly carburize the carbon concentration distributionSolid state diffusion coatingTotal factory controlControl systemCarbide

The invention relates to a control system of the carbon intensity distribution of a low-pressure carburized layer and a control method thereof, belonging to the technical field of metal heat treatment. The control system comprises a low-pressure carburizing furnace, a controller, a pressure sensor, a thermoelectric couple, a nitrogen regulating valve, a nitrogen input pipe, a carburizing gas regulating valve, a carburizing gas input pipe, a vacuum system and a gas suction pipe. The invention simulates automatic optimized low-pressure pulse process parameters by using carburized layer concentration distribution values and realizes the control functions; the carburizing gas regulating valve executes on / off action according to an order of the controller to control carburizing section time and diffusing section time, therefore the accurate control of the intensity distribution of the carburized layer is realized; and in addition, the invention can keep high carburizing speed and prevent the tolerance of surface carbides, accurately controls the surface carbon intensity and the depth and the intensity distribution of the carburized layer, reduces the accumulated carbon black inside the low-pressure carburizing furnace, is free from depending on a gas component sensor and has the advantages of configuration simplification, easy implementation, high reliability and easy maintenance.

Owner:SHANGHAI JIAO TONG UNIV +1

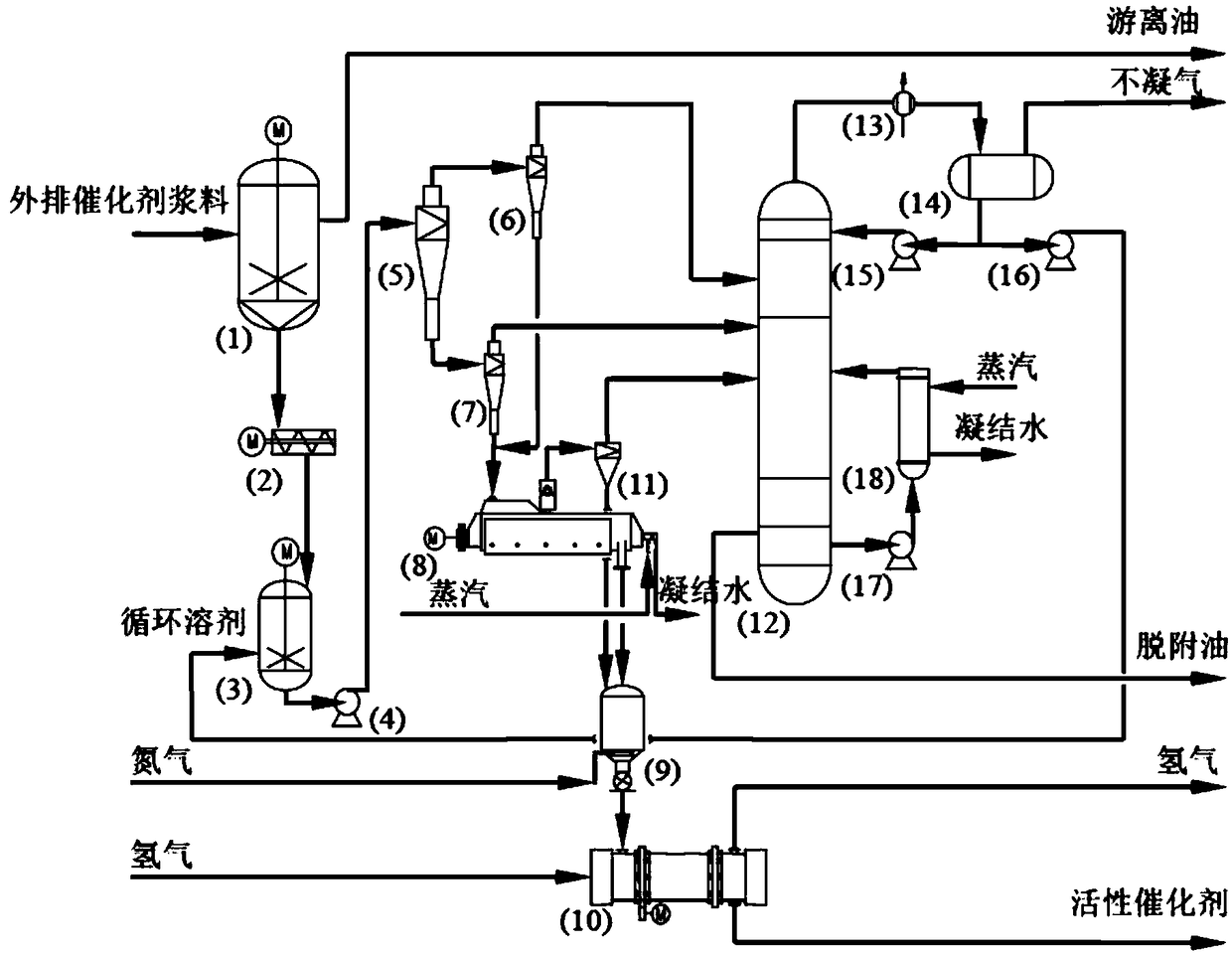

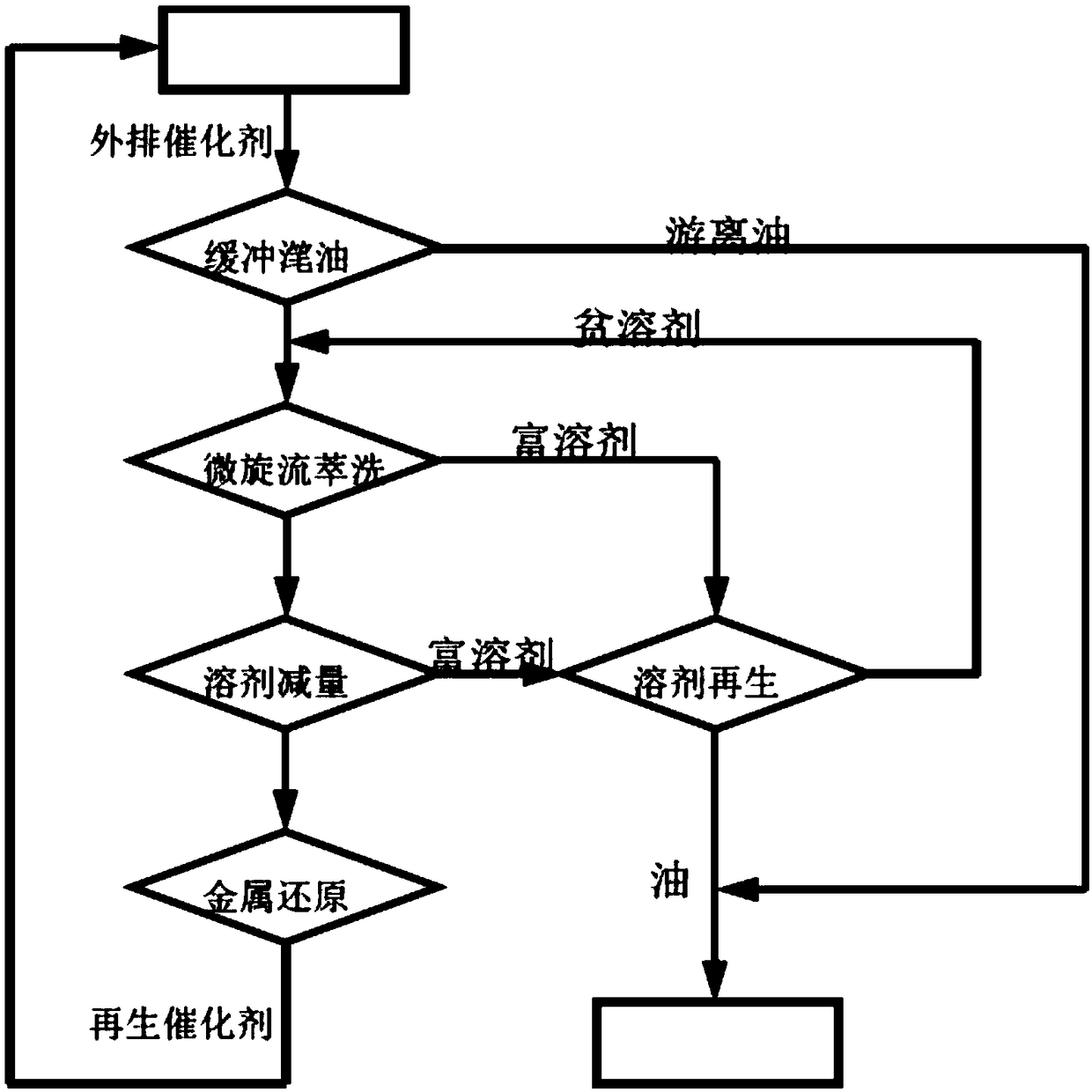

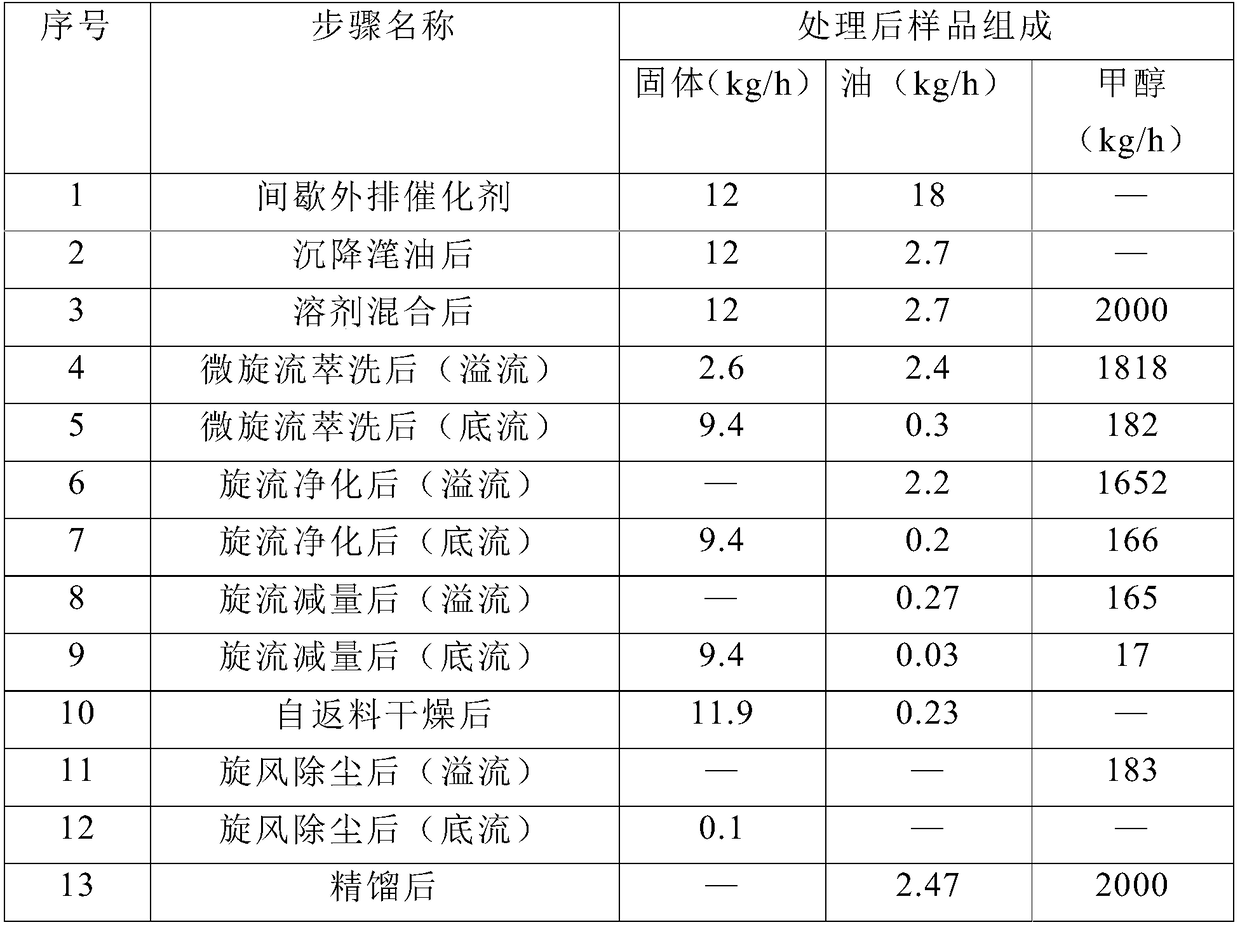

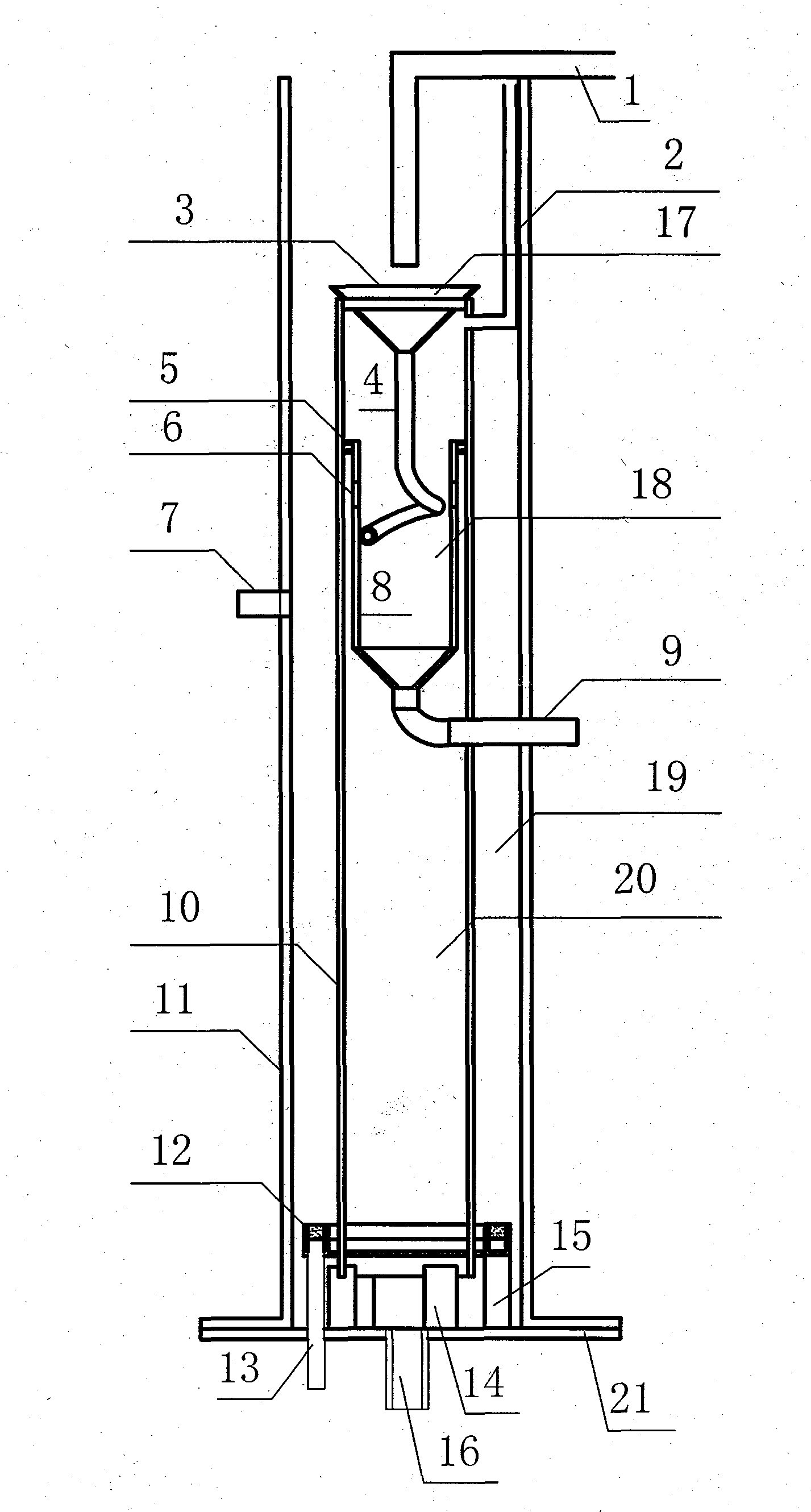

On-line deactivated catalyst regenerating method and on-line deactivated catalyst regenerating device for wood tar hydrogenation in fluidized bed

InactiveCN108704672AThe extraction efficiency is not highShort micro-swirl extraction and washing processCatalyst regeneration/reactivationHydrocarbon oils refiningFluidized bedTar

The invention relates to an on-line deactivated catalyst regenerating method and an on-line deactivated catalyst regenerating device for wood tar hydrogenation in a fluidized bed. The on-line deactivated catalyst regenerating method includes the following steps of (A) catalyst oil decanting; (B) mixing of catalyst and a lean solvent; (C) extracting and washing through tiny swirling flows; (D) solvent reducing; (E) solvent regenerating; (F) metallic reduction.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

After-finishing process of shrink-proof, anti-wrinkling, moisture absorption and quick-drying shirt collar support

The invention discloses an after-finishing process of a shrink-proof, anti-wrinkling, moisture absorption and quick-drying shirt collar support. The process comprises the following steps of: preparing a 30-40 g / l modifier of polyethylene siloxane serving as a quick-drying hygroscopic agent of an after-finishing agent, resin of a certain concentration and a Cat.D catalyst into a padding liquid of which the pH value is 4.5; and putting a fabric to be finished into the padding liquid, and performing pre-baking and baking steps when the padding rate is 80 percent. In the padding finishing liquid, the modifier of the polyethylene siloxane plays a role in absorbing moisture and drying quickly and is suitable for moisture absorption and quick-drying finishing of cotton, terylene and a blended fabric thereof, and the fabric is endowed with extremely good soft handfeel. The modifier of the polyethylene siloxane can be used separately with a padding method, and can be used together with initial condensation bodies such as a shrink-proof and anti-wrinkling agent, stiff resin and the like, so that the swelling ratio of a fiber pore canal is lowered, and better moisture absorption and quick-drying effects are achieved.

Owner:南通海盟实业股份有限公司

After-finishing process of shrink-proof, anti-wrinkling, moisture absorption and quick-drying shirt collar support

The invention discloses an after-finishing process of a shrink-proof, anti-wrinkling, moisture absorption and quick-drying shirt collar support. The process comprises the following steps of: preparing a 30-40 g / l modifier of polyethylene siloxane serving as a quick-drying hygroscopic agent of an after-finishing agent, resin of a certain concentration and a Cat.D catalyst into a padding liquid of which the pH value is 4.5; and putting a fabric to be finished into the padding liquid, and performing pre-baking and baking steps when the padding rate is 80 percent. In the padding finishing liquid, the modifier of the polyethylene siloxane plays a role in absorbing moisture and drying quickly and is suitable for moisture absorption and quick-drying finishing of cotton, terylene and a blended fabric thereof, and the fabric is endowed with extremely good soft handfeel. The modifier of the polyethylene siloxane can be used separately with a padding method, and can be used together with initial condensation bodies such as a shrink-proof and anti-wrinkling agent, stiff resin and the like, so that the swelling ratio of a fiber pore canal is lowered, and better moisture absorption and quick-drying effects are achieved.

Owner:南通海盟实业股份有限公司

All-solid-phase synthesis method for high-polymer materials with tumor site enzyme sensitive characteristics for constructing vesicae

InactiveCN106633084AHigh yieldAvoid lostMacromolecular non-active ingredientsLiposomal deliveryWater soluble drugSolid-phase synthesis

The invention relates to the field of synthesis of high-polymer materials, in particular to an all-solid-phase synthesis method for high-polymer materials with tumor site enzyme sensitive characteristics for constructing vesicae. The all-solid-phase synthesis method has the advantages that the high-polymer materials are synthesized by the aid of the all-solid-phase synthesis method, the all-solid-phase synthesis method is easy to implement, short in synthesis period and high in product yields, and only few byproducts can be generated; the high-polymer materials can be subjected to self-assembly to form the vesicae, water-soluble medicines are encapsulated in internal water phases and can be degraded by high-expression MMP-9 enzymes at tumor sites after being targeted to tumor tissues, accordingly, the vesicae can be broken, and antitumor medicines can be instantly released; the tumor tissue targeting ability of the medicines can be improved by vesica medicine delivery systems constructed by the aid of the high-polymer materials, the medicines can be released in a responsive manner, the concentration of the medicines at the tumor sites can be increased, and the toxicity of the antitumor medicines on normal tissues and cells can be reduced.

Owner:CHINA PHARM UNIV

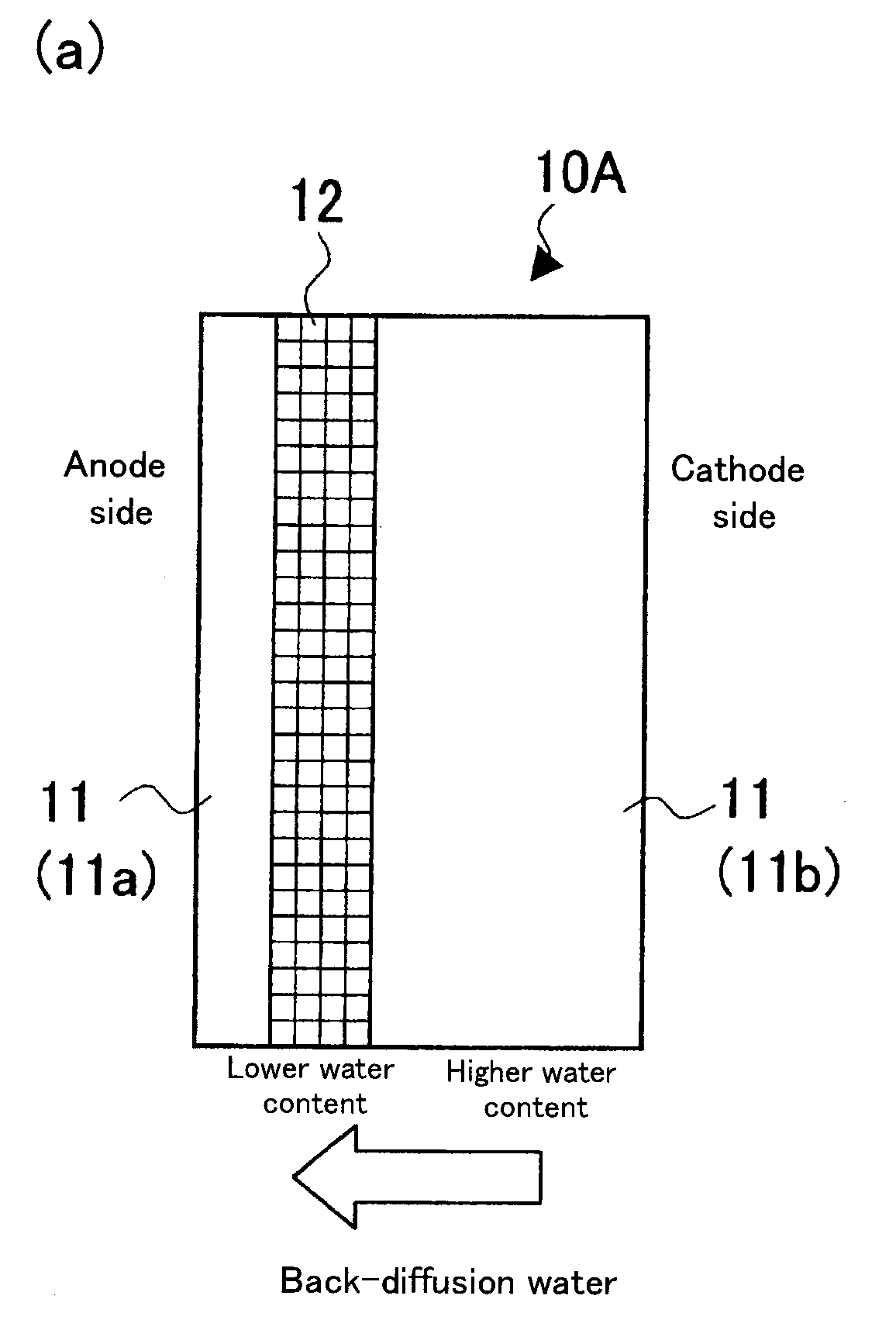

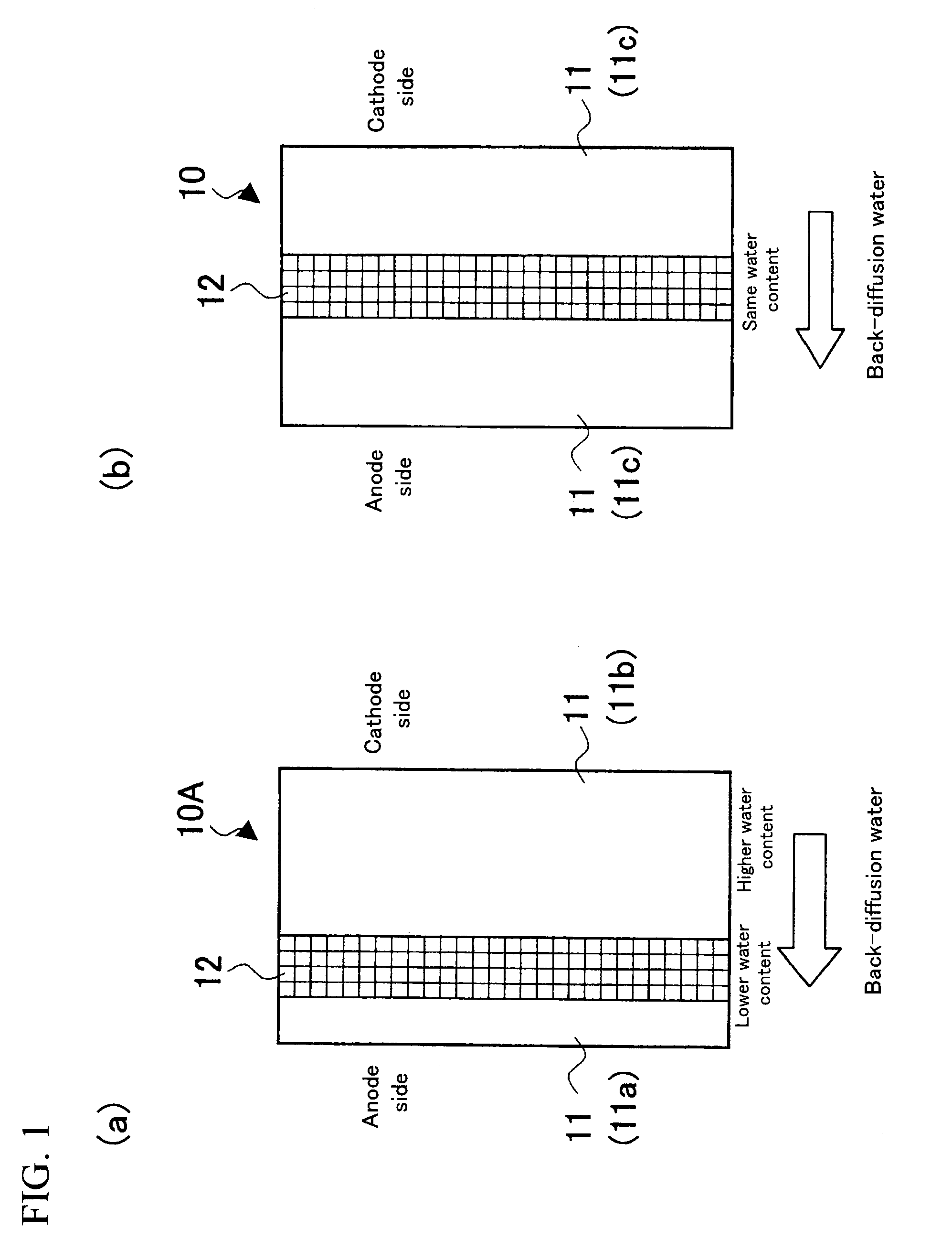

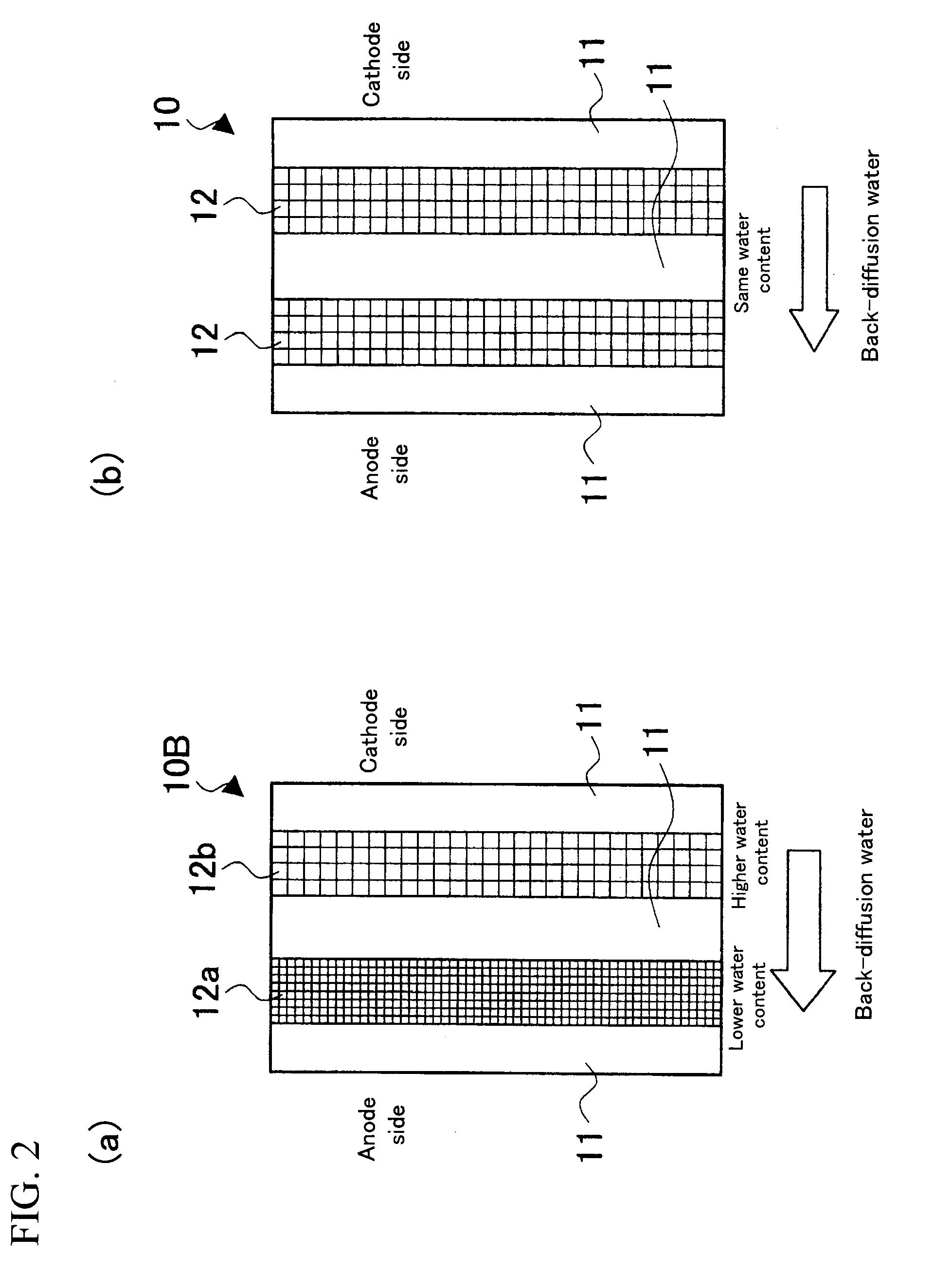

Electrolyte membrane and fuel cell using the same (as amended)

InactiveUS20100196787A1Increasing concentration gradientReduced operating requirementsSolid electrolytesSolid electrolyte fuel cellsFuel cellsPorous membrane

In a fuel cell 1 including a membrane electrode assembly 2 which includes a reinforcing-membrane-type electrolyte membrane 10A, a dry-up on the anode side is suppressed by actively forming a water content gradient in the electrolyte membrane to enhance water back-diffusion effect from the cathode side to the anode side. For that purpose, two sheets of expanded porous membranes 12a and 12b having different porosities are buried, as reinforcing membranes, in electrolyte resin 11 to obtain the reinforcing-membrane-type electrolyte membrane 10A. The reinforcing-membrane-type electrolyte membrane 10A is used to form the membrane electrode assembly 2, which is sandwiched by separators 20 and 30 such that the side of a reinforcing membrane 12b with a larger porosity becomes the cathode side, thus obtaining the fuel cell 1. When one sheet of the reinforcing membrane is buried, the reinforcing membrane is offset to the anode side to be buried in the electrolyte resin.

Owner:TOYOTA JIDOSHA KK

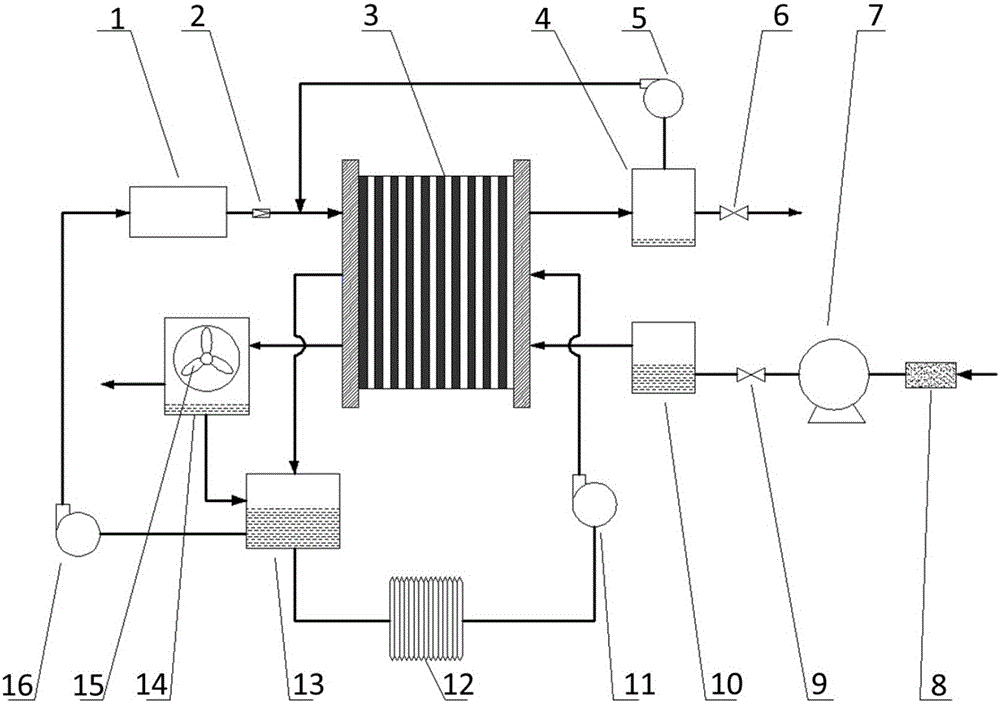

Fuel cell system capable of relieving cell water logging

InactiveCN106099143A"Flooding" MitigationIncrease powerFuel cellsElectrochemical responseGeneration process

The invention discloses a fuel cell system capable of relieving cell water logging. The system comprises an electric pile for producing electricity by using an electrochemical ration between oxygen-containing gas and hydrogen-containing gas, an air supply device for supplying the humidified oxygen-containing gas for the electric pile, a hydrogen supply device for supplying the hydrogen-containing gas for the electric pile and a cooling device for carrying out heat exchange between heat generated in the power generation process and guided cooling water on the electric pile, wherein the cooling device comprises a cooling water tank, a cooling water pump and a cooling flow passage arranged in the electric pile. The system also comprises a condensing device, for condensing air tail gas, which is arranged at an air outlet of the electric pile; a gas outlet of the condensing device is communicated with the outside; and a liquid water outlet of the condensing device is connected with the cooling water tank. According to the fuel cell system, the cell water logging can be relieved effectively, and the power of the electric pile is improved.

Owner:WUHAN UNIV OF TECH

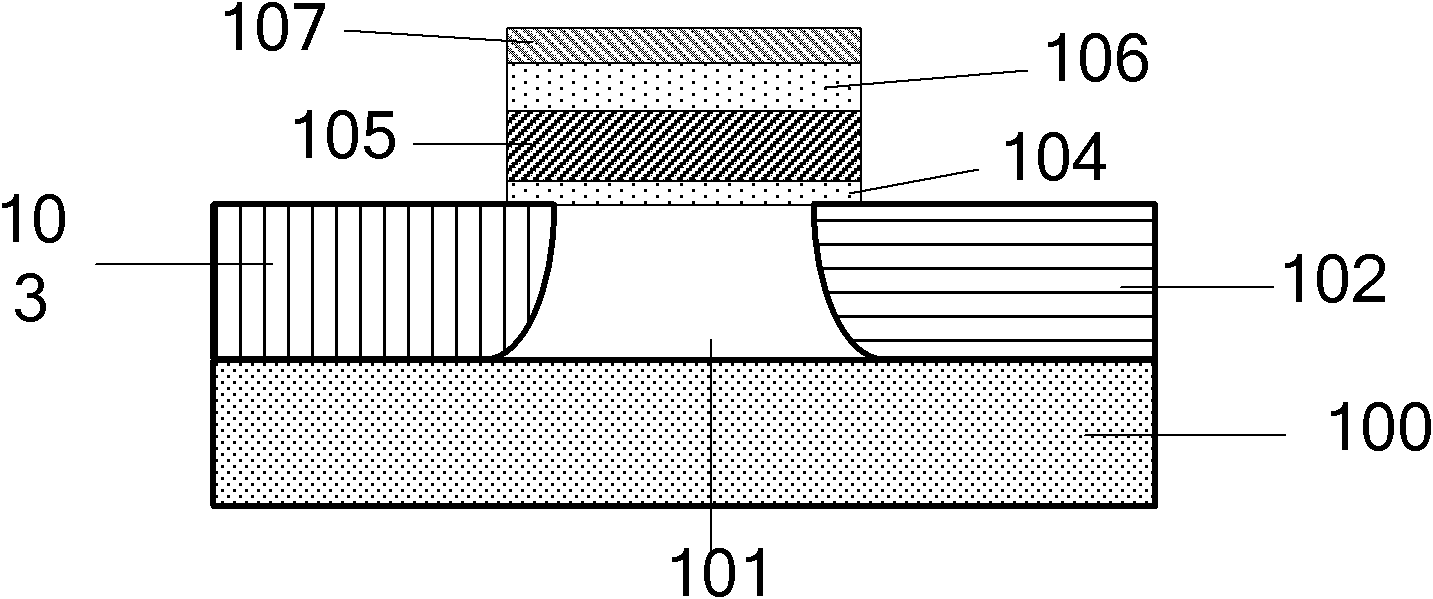

Flash memory and manufacturing method thereof

InactiveCN102738169ASuppression of punch-through effectImprove programming efficiencyTransistorSolid-state devicesGate stackEngineering

The invention discloses a flash memory and a manufacturing method thereof, belonging to the technology field of a semiconductor memory. The flash memory includes a buried oxide layer on which a source terminal, a channel and a drain terminal are arranged. The channel locates between the source terminal and the drain terminal. A tunnel oxide layer, a polysilicon floating gate, a barrier oxide layer and a polysilicon controlling gate are arranged on the channel in order. A thin silicon nitride layer is arranged between the source terminal and the channel. The manufacturing method comprises the following steps of: (1) providing an SOI silicon substrate with shallow trench isolation and forming an active area; (2) growing the tunnel oxide layer and a first polysilicon layer on the silicon substrate in order and preparing the polysilicon floating gate, and growing the barrier oxide layer and a second polysilicon layer and preparing the polysilicon controlling gate; (3) etching and forming a gate stacking structure; (4) preparing the drain terminal on one side of the gate stacking structure, etching a thin silicon film on the other side of the gate stacking structure, growing the thin silicon nitride layer, then backfilling a material of silicon, and preparing the source terminal. The flash memory and the method have the advantages of high programming efficiency, low power consumption, and capability of inhibiting a source-drain punch-through effect effectively.

Owner:PEKING UNIV

Supersonic lixiviating nimbin

InactiveCN1524858AEffective membrane rupturePromote dissolutionOrganic chemistrySupersonic wavesSolvent

A method for preparing nimbin through supersonic wave extraction which comprises the steps of, disintegrating the nim seeds after oil extraction, charging it into extraction solvent, carrying out leaching process by supersonic wave. The method for preparing nimbin by the invention realizes low cost, and increased nimbin extraction efficiency.

Owner:KUNMING UNIV OF SCI & TECH

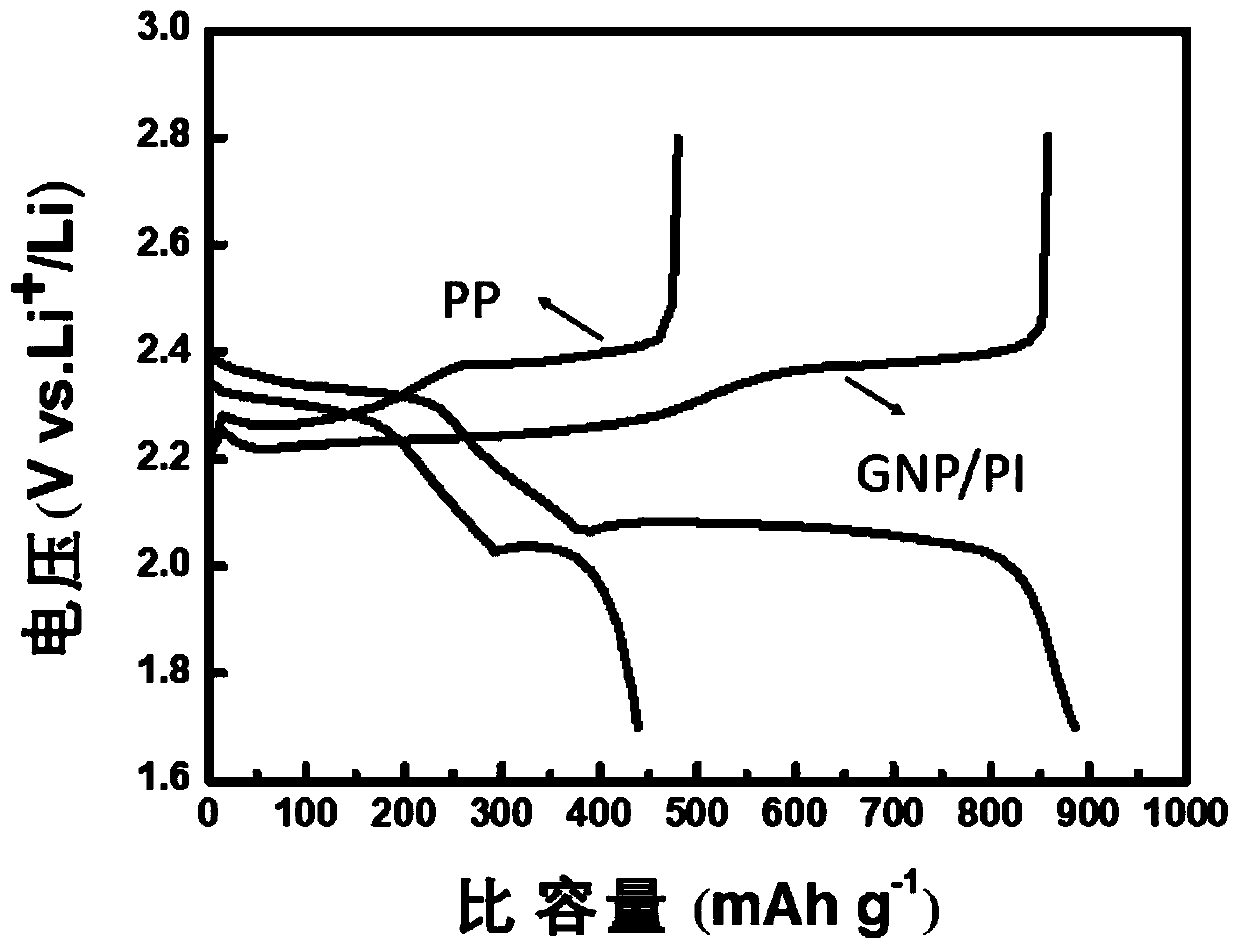

Method for preparing composite separator for lithium sulfur battery

ActiveCN110350128AImprove heat resistancePromote conversionCell seperators/membranes/diaphragms/spacersLi-accumulatorsInternal resistanceCarbonization

The present invention relates to the technology of lithium sulfur batteries, and aims to provide a method for preparing a composite separator for a lithium sulfur battery. The method comprises the following steps: a polyamide acid solution is obtained by reaction of diamine and dianhydride, which is used as a spinning solution for spinning film formation; polyimide spinning base film is obtained after thermal imidization treatment; the polyamic acid solution is mixed with small nitrogen-containing molecules and graphene oxide and then subjected to spinning film formation, and after thermal imidization and carbonization treatment, self-supporting reduced graphene oxide / nitrogen-doped carbon nanofiber is obtained; the polyimide spinning base film and the reduced graphene oxide / nitrogen-dopedcarbon nanofiber are taken; and the two layers are laminated and sliced to obtain the composite separator for assembling the lithium sulfur battery. The separator of the invention has good heat resistance and flame resistance, can greatly improve the safety performance of the lithium sulfur battery, reduces the internal resistance of the battery and enhances the electrochemical performance of thebattery. High charge and discharge specific capacity, high cyclicity and safety of the lithium sulfur battery are realized.

Owner:QUZHOU RES INST OF ZHEJIANG UNIV

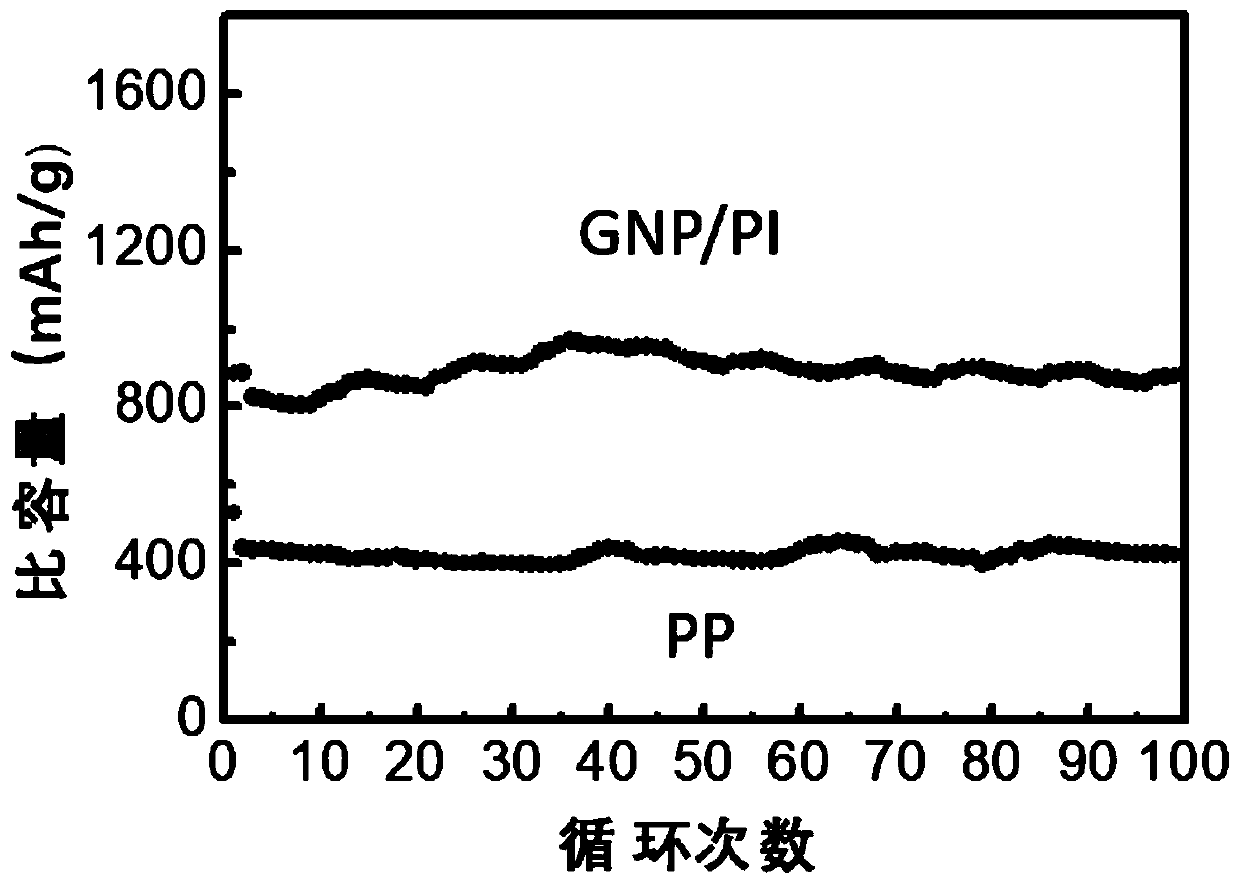

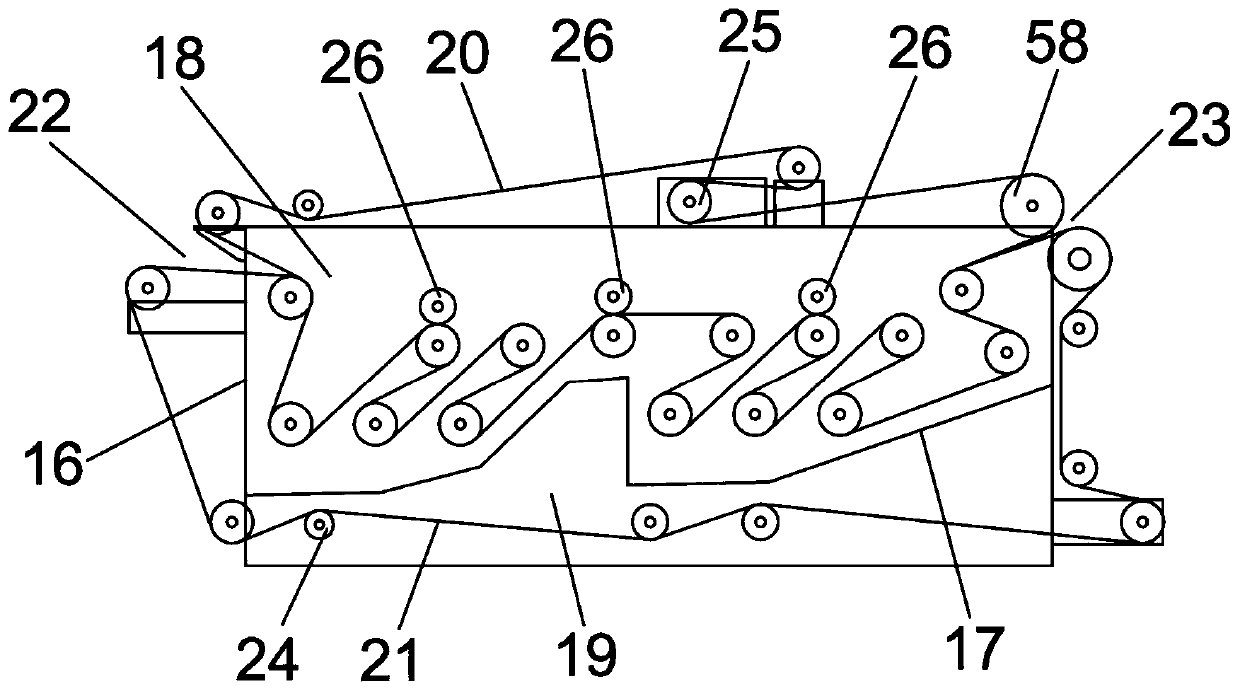

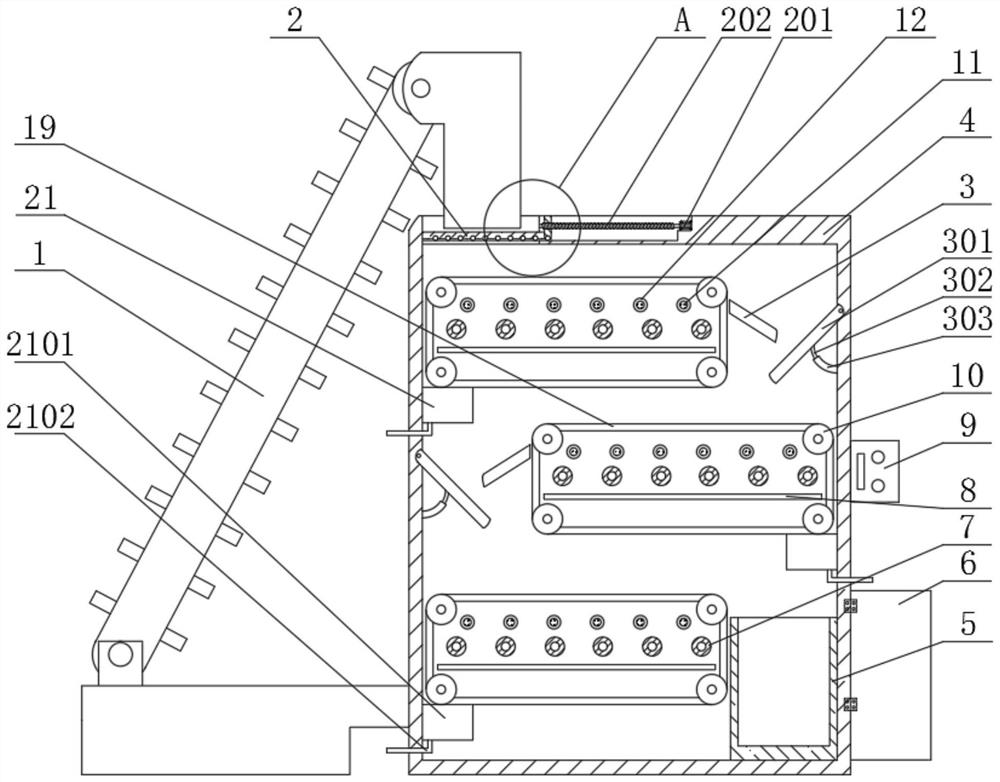

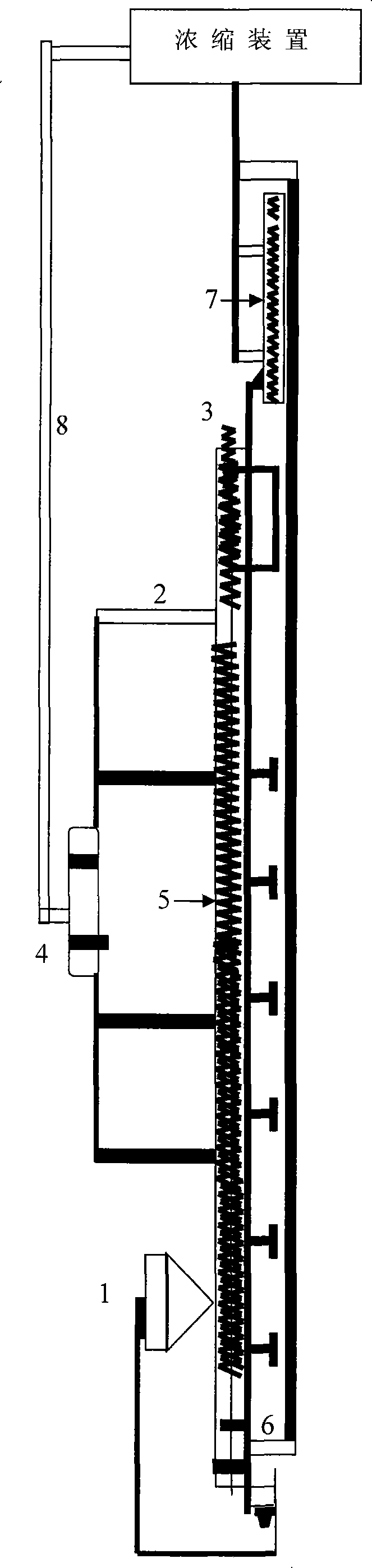

Miniature box-type leacher for special oil

InactiveCN104450171AImprove leaching production effectGuaranteed operabilityFatty-oils/fats productionEngineeringCirculating pump

The invention discloses a miniature box-type drag chain scraper flipover leacher. The miniature box-type drag chain scraper flipover leacher comprises a box-type leacher shell, wherein a plurality of driving chain wheels are arranged in the box-type leacher shell, and are sleeved by box chains; spaced push plates are fixedly arranged on the outer side of the box chains; material storage tanks, manholes and discharge holes are respectively formed in the upper end and the lower end of the box-type leacher; feeding augers are arranged below the material storage tanks; a plurality of push box lattices as leaching units are arranged in the box-type leacher; circulating mixed oil forms a soaking pond above each push box lattice; a plurality of oil buckets are formed in the bottom surface of the box-type leacher shell; and circulating pumps are arranged at oil inlets of the oil buckets. The miniature box-type drag chain scraper flipover leacher adopts a dual-layer multi-nozzle spray-type low material level, is suitable for a preform which is large in particle size and high in moisture content (5%-8%) and of which the normal moisture is not greater than 8%-10%; the equipment operation is controllable; the production operation is stable; blanking and meal discharging are stable; the residual meal discharge oil is not greater than 1.0%; the leaching time is controlled at about 90-120 minutes in general according to the oil variety; and the optimal effect of continuous production of the special oil is achieved.

Owner:DATUANJIE AGRI CO LTD

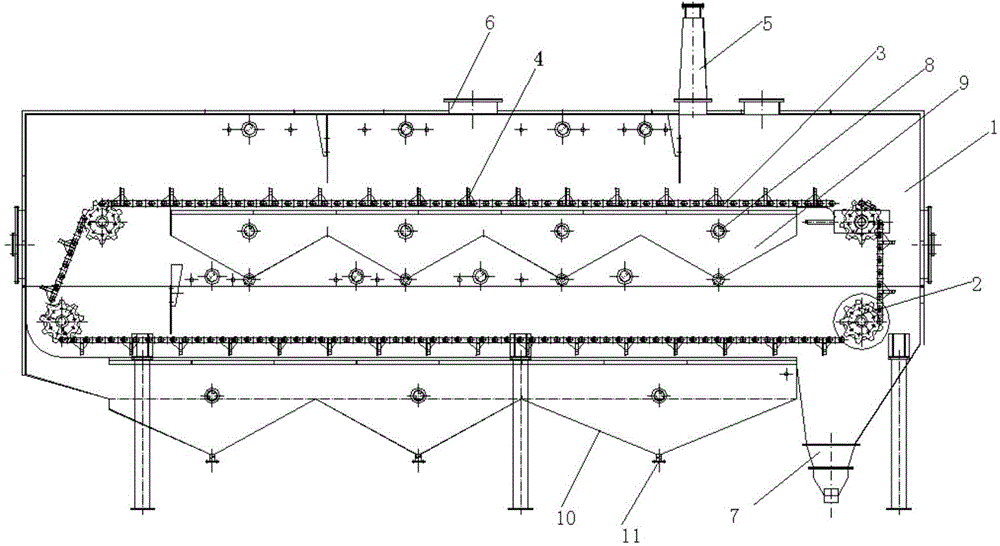

Treatment system and method of high-concentration ammonia nitrogen organic wastewater

InactiveCN105110571AEfficient killingImprove purification intensityWater contaminantsMultistage water/sewage treatmentHigh concentrationElectrolysis

The invention relates to the technical field of wastewater treatment and discloses a treatment system of high-concentration ammonia nitrogen organic wastewater. The system comprises a feed hopper (1), a homogenating tank (2), a methane tank (3), an upstream type anaerobic sludge bed reactor (4), a biological contact oxidation pond (5), a secondary sedimentation tank (11), a micro electrolytic reactor (10), a circular aeration biological filter (6) and an ozone disinfection tank (7), and the methane tank is connected with a sludge thickener (8). The invention further discloses a treatment method of the high-concentration ammonia nitrogen organic wastewater. The treatment method comprises anaerobic digestion treatment, activated sludge treatment, micro-electrolysis reaction, circular aeration biological filter biochemical treatment and ozone disinfection. The process is simple, the reaction process concentration gradient is large, and sludge is not prone to bulking; the capability to resist impact load is high, and the treatment effect is good; all working procedure time is controlled by adjusting the operation period, and at the same time, denitrification and phosphorus removal effects are remarkable.

Owner:徐雪祥

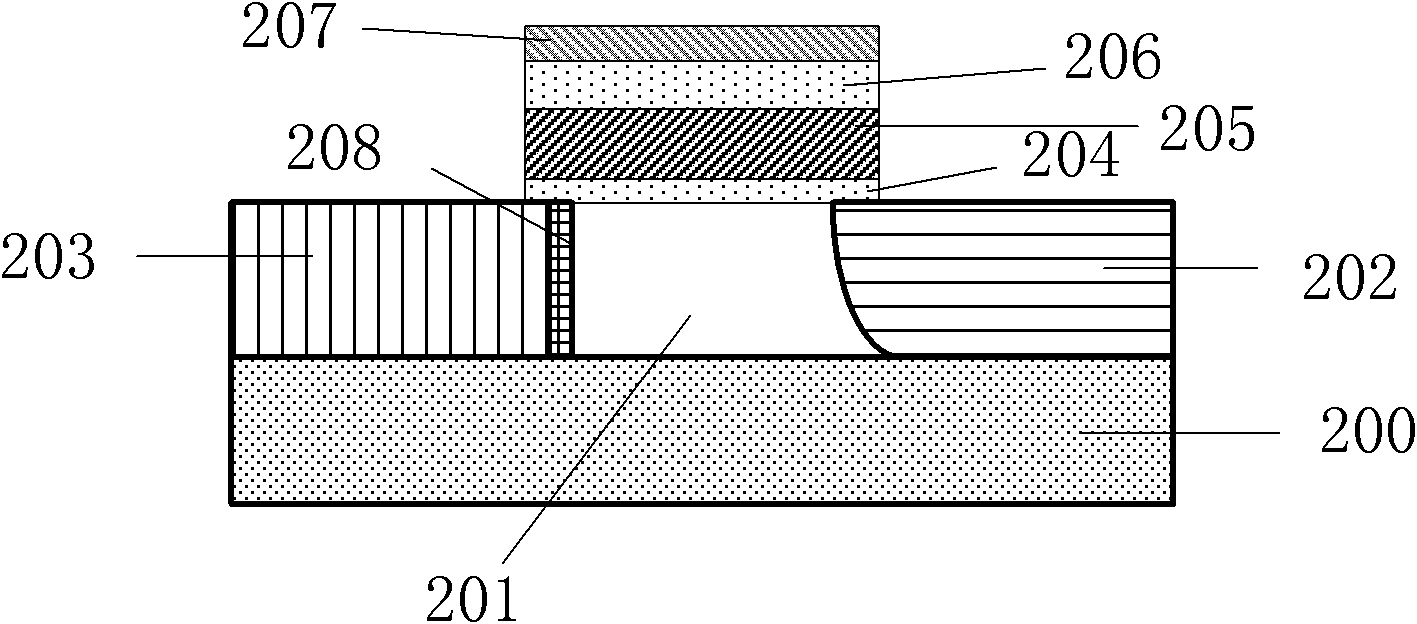

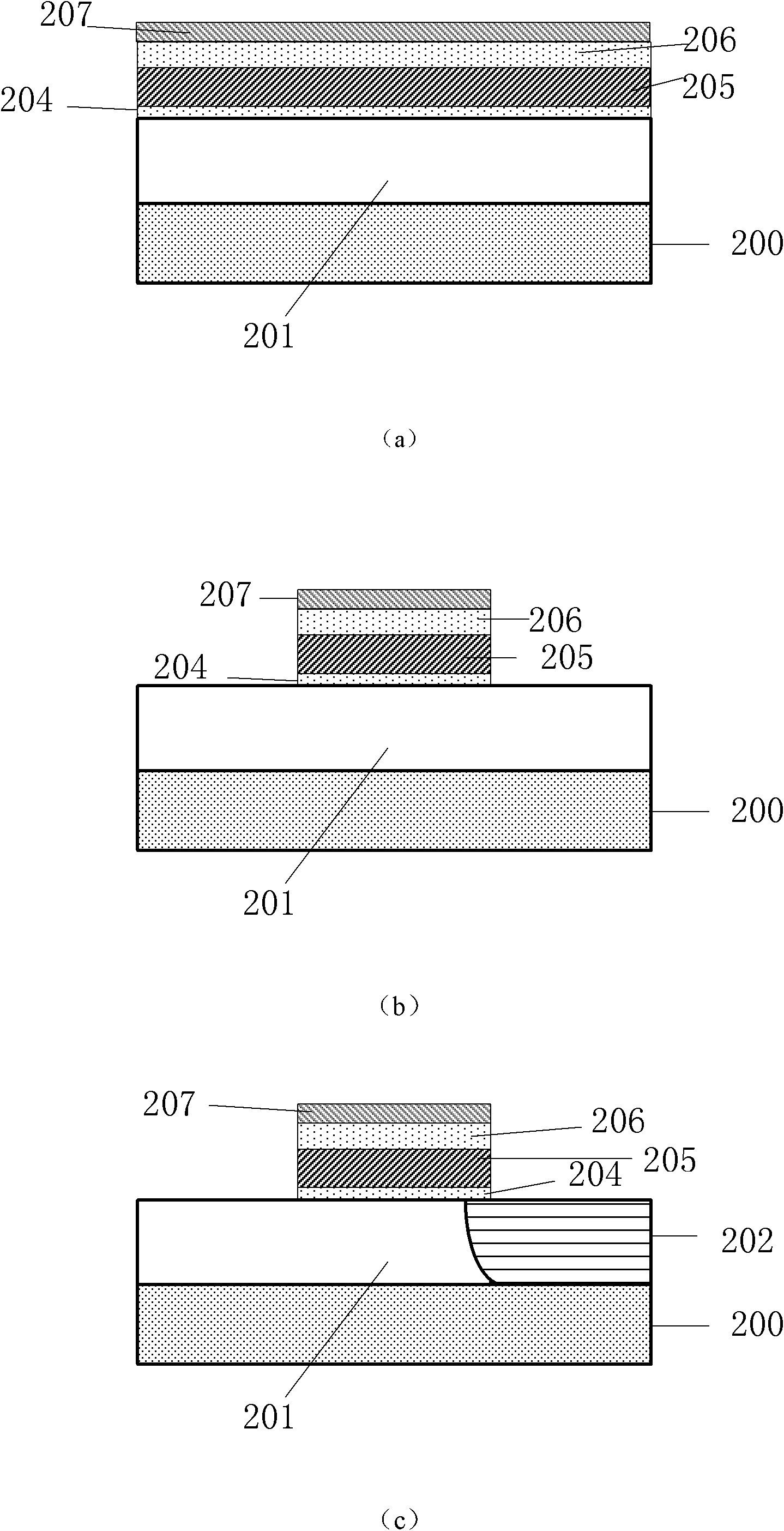

Selective etching method and preparation method of nano needle tip structure

InactiveCN110002393AHigh sharpnessIncrease the tilt angleSemi-permeable membranesVolume/mass flow by thermal effectsLinear relationshipNanometre

The invention provides a selective etching method and a preparation method of a nano needle tip structure. The selective etching method comprises the following steps that a first material layer and asecond material layer are sequentially formed on a substrate, the isotropic etching selection ratio of the first material layer to the second material layer is larger than 10, the first material layercontains doping elements, and the concentration of the doping elements is linearly increased in the thickness direction of the first material layer; and selective isotropic etching is performed on the first material layer, wherein the etching rate of the selective isotropic etching has a positive linear relationship with the concentration of the doping elements, so as to complete the etching of the outer wall of the first material layer. According to the invention, the positive linear relationship between the etching rate in the etching process and the concentration of the doping elements inthe to-be-etched material is utilized, so that sloped sidewalls opposite to the increasing direction of the concentration is obtained; by the adoption of the selective etching method, the nano needletip structure with high sharpness can be obtained, and the size, the shape and the angle of the needle tip structure can be flexibly adjusted.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Centella total-glycoside diacolation-extracting method from centella

InactiveCN101455693AHigh extraction rateEasy to operateNervous disorderDigestive systemGlycoside formationSolvent

The invention discloses a method for extracting asiaticoside from asiatic centella comprising the step of using asiatic centella as raw material, and water solution of ethanol or methanol as extraction solvent for extracting asiaticoside from asiatic centella in high efficiency by percolation method for achieving more than 93% extraction ratio for the asiaticoside. The method has high extraction ratio, small consumption of solvent, low production cost, and easy commercial process.

Owner:ZHEJIANG UNIV

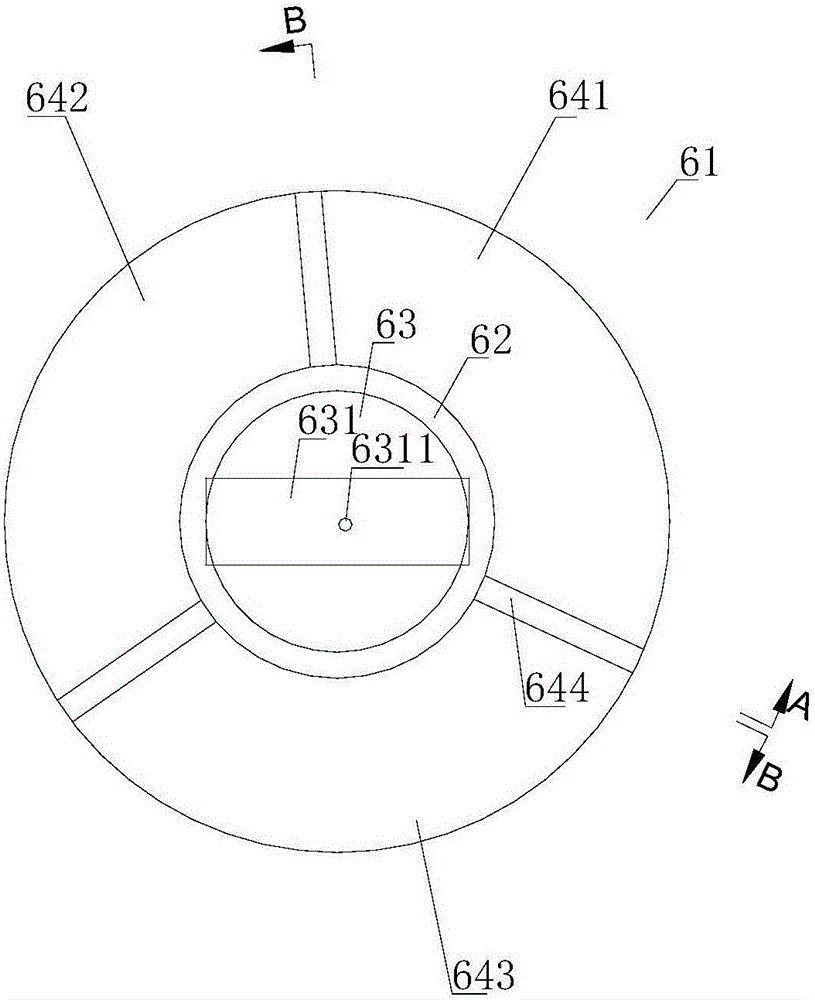

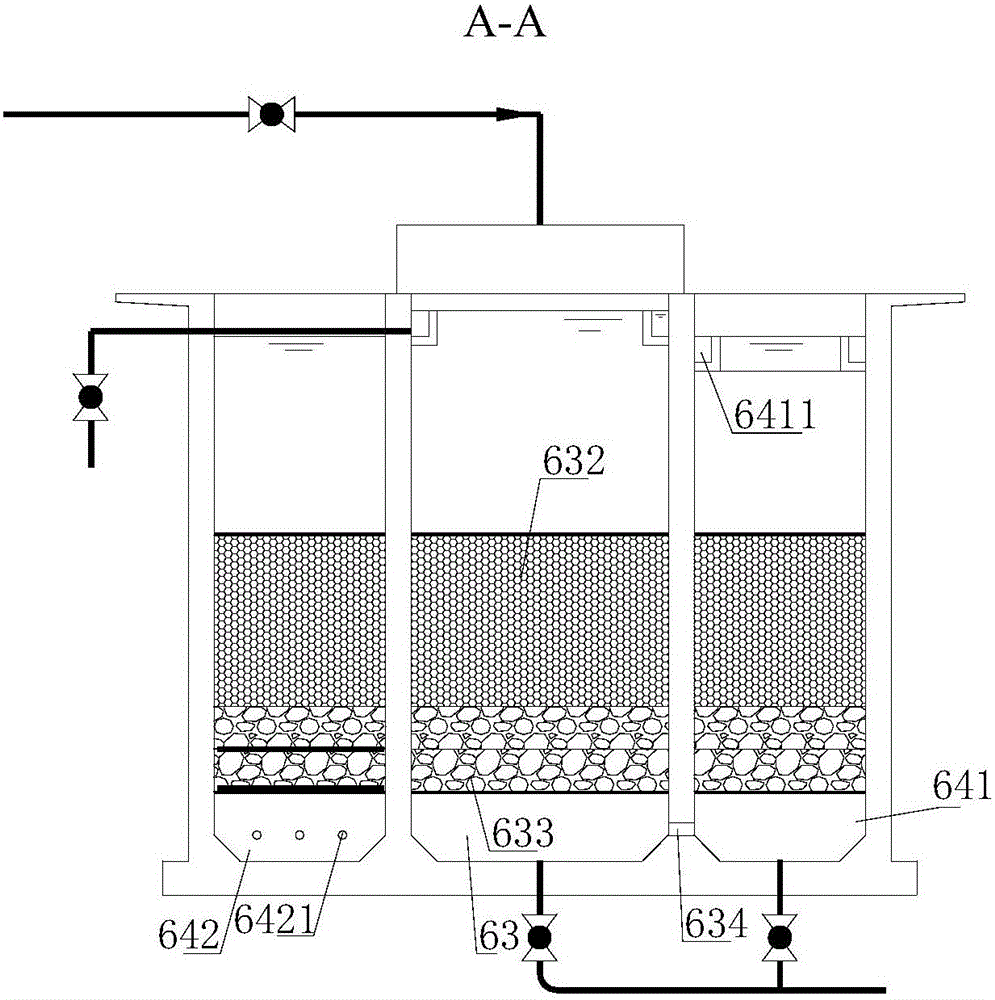

Granular sludge sewage treatment device capable of controlling diameter and density of granules

ActiveCN102153198ASmall particle sizeLow densityTreatment with aerobic and anaerobic processesSludgeWater quality

The invention discloses a granular sludge sewage treatment device capable of controlling diameter and density of granules. The device comprises an inner barrel and an outer barrel which are concentric; an aeration device is arranged in an annular space between the inner barrel and the outer barrel; the aeration device is fixed on a pedestal through a supporting pile of the aeration device; the inner barrel wall of the inner barrel is connected with a cylindrical cyclone cylinder; the lower end of the cyclone cylinder is connected with a wall through pipe, the wall through pipe passes through the walls of the inner barrel and the outer barrel, and the side wall of the cyclone cylinder is provided with an overflow hole; and a water inlet funnel is fixed at the upper barrel port of the inner barrel, the water inlet funnel is connected with a spiral thin bent pipe, and the outlet of the thin bent pipe is tightly attached to the inside wall of the cyclone cylinder. On the basis of ensuring good outlet water quality, the device successfully realizes human control and selection of the diameter and the density of the aerobic sludge granules, and realizes proper solid-liquid separation; in addition, through the device, the initial granule forming speed is high, and the sludge load is balanced; the oxygenation efficiency is improved by gas-liquid separation; and the device has the advantages of energy conservation and high efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

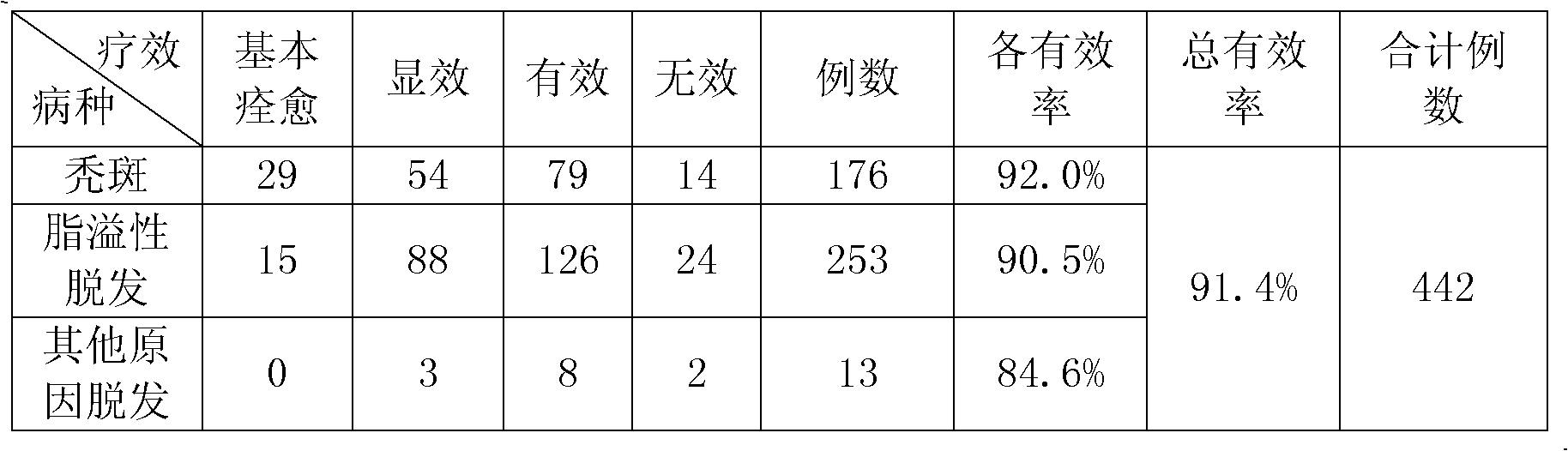

Main drug Ginseng-based compound externally-used liniment for treating hair loss and preparation method

ActiveCN102512539AReasonable compositionPromote blood circulationHydroxy compound active ingredientsDermatological disorderSide effectCastor oil

The invention relates to a traditional Chinese medicinal preparation, namely a compound containing Ginseng raw material externally-used liniment for treating hair loss and a preparation method. The compound externally-used liniment for treating hair loss is prepared by taking Ginseng as a main drug, compounding Ginseng with resorcinol, pepper, calcium pantothenate, castor oil and other medicines, and refining through a liquid-pan-extraction technology. The main drug Ginseng-based compound externally-used liniment for treating the hair loss has the effects of nourishing and growing hair, improving local blood circulation, nourishing hair follicles and promoting hair growth, is quick in curative effect, is easy, convenient and safe to use, and is free of any toxic side effect after a long-term use; and through clinical observation, the main drug Ginseng-based compound externally-used liniment for treating the hair loss has a significant effect on alopecia areata and seborrheic alopecia, with an effective rate of 91%.

Owner:吉林省集安益盛药业股份有限公司

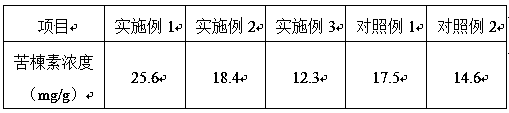

Extracting method for toosendanin

The invention provides an extracting method for toosendanin. The method comprises the following steps: firstly, washing and drying melia azedarach bark or melia azedarach seeds, smashing, and extracting by using cellulase and pectinase water solution; extracting filter residues by successively using buffer solution, wherein the pH value of the buffer solution is 2.0-3.0, 5.0-7.0 and 8.0-8.5, and performing the membrane separation to filter liquor after extracting by an organic solvent, reserving the solution, and concentrating in the low temperature to prepare the toosendanin. The extracting method is capable of separating and extracting toosendanin raw materials by creatively using a semi-bionic technology, the obtained toosendanin solution contains effective ingredients which can be highly absorbed by an animal body. A membrane separation reservation technology is combined to obtain a toosendanin product of which the molecular weight is less than or equal to 1000 Da. Under the synergistic effect of the semi-bionic technology and the membrane separation technology, the content of the effective ingredients of the finally obtained toosendanin product is higher.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

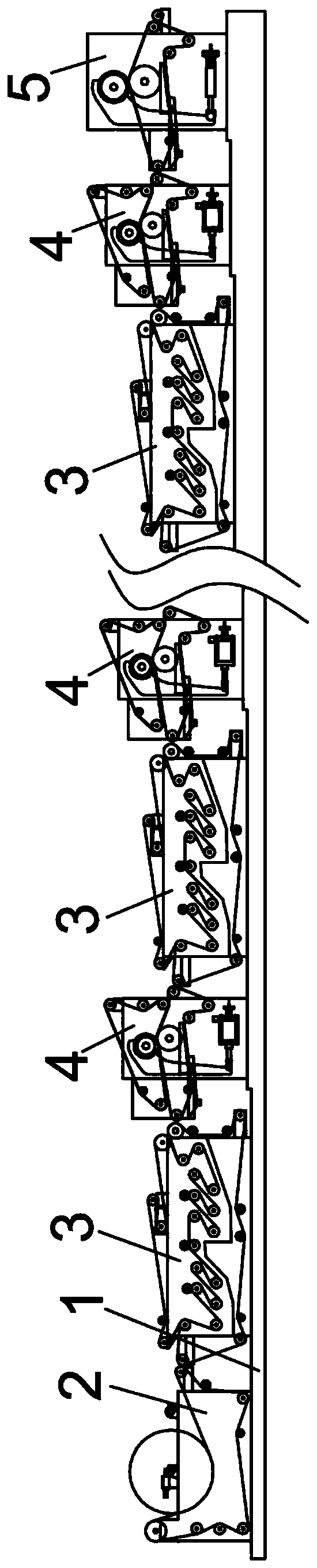

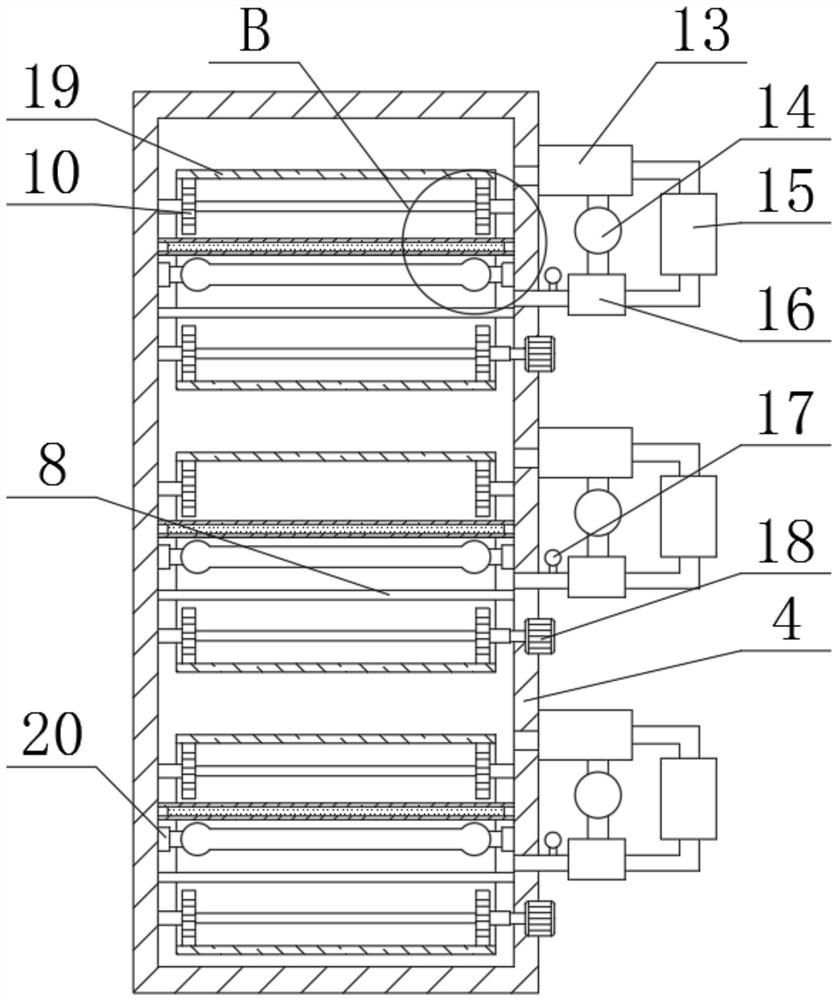

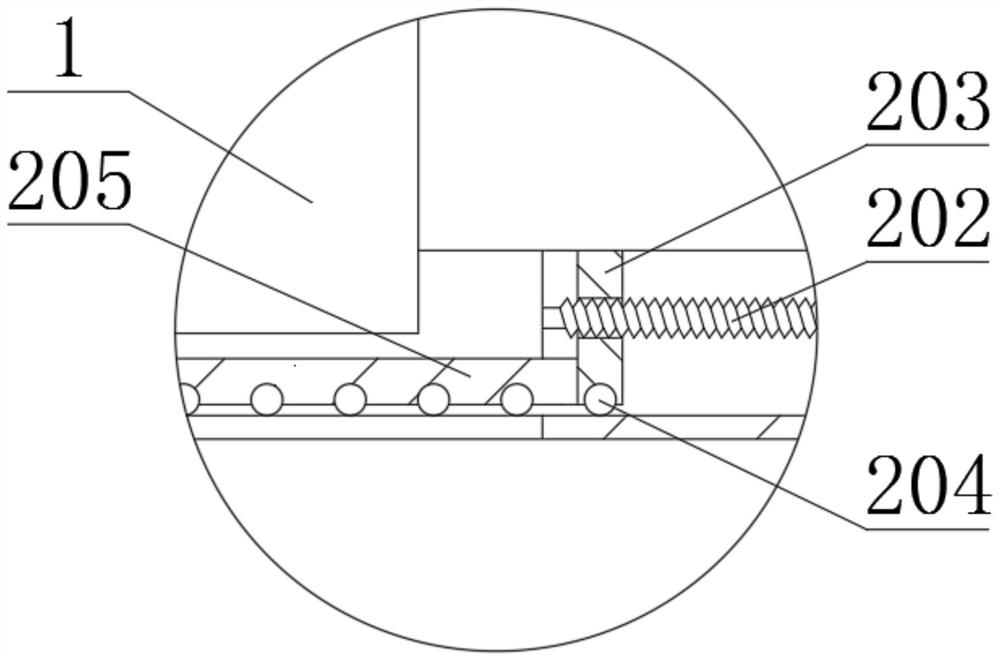

Loose fiber continuous washing and finishing machine

PendingCN109881402AIncrease profitQuick washLiquid/gas/vapor removal by squeezing rollersTextile treatment carriersWater sourceEngineering

The invention relates to a loose fiber continuous washing and finishing machine, and belongs to the technical field of loose fiber processing equipment. The equipment comprises a base, an unwinding device, multiple washing devices, multiple rolling devices and a squeezing device are arranged on the base in sequence in the processing direction of loose fiber; the washing devices and the rolling devices are arranged at intervals, washing tanks are filled with washing water, and a pipeline is connected between every two adjacent washing devices. Accordingly, by arranging the washing devices and the rolling devices which are arranged at intervals, a fiber layer is subjected to multiple times of cleaning and squeezing, residual chemical agents in the fiber layer are washed out rapidly conveniently, and cleaning is more sufficient; the adjacent two washing devices are connected through the pipelines, and the last washing device is connected with an external water source so as to supplement the washing water, the water in the external water source flows forwards step by step through the way of overflow, the utilization rate of the water is increased, and water consumption is greatly reduced.

Owner:新昌县艺力机械有限公司

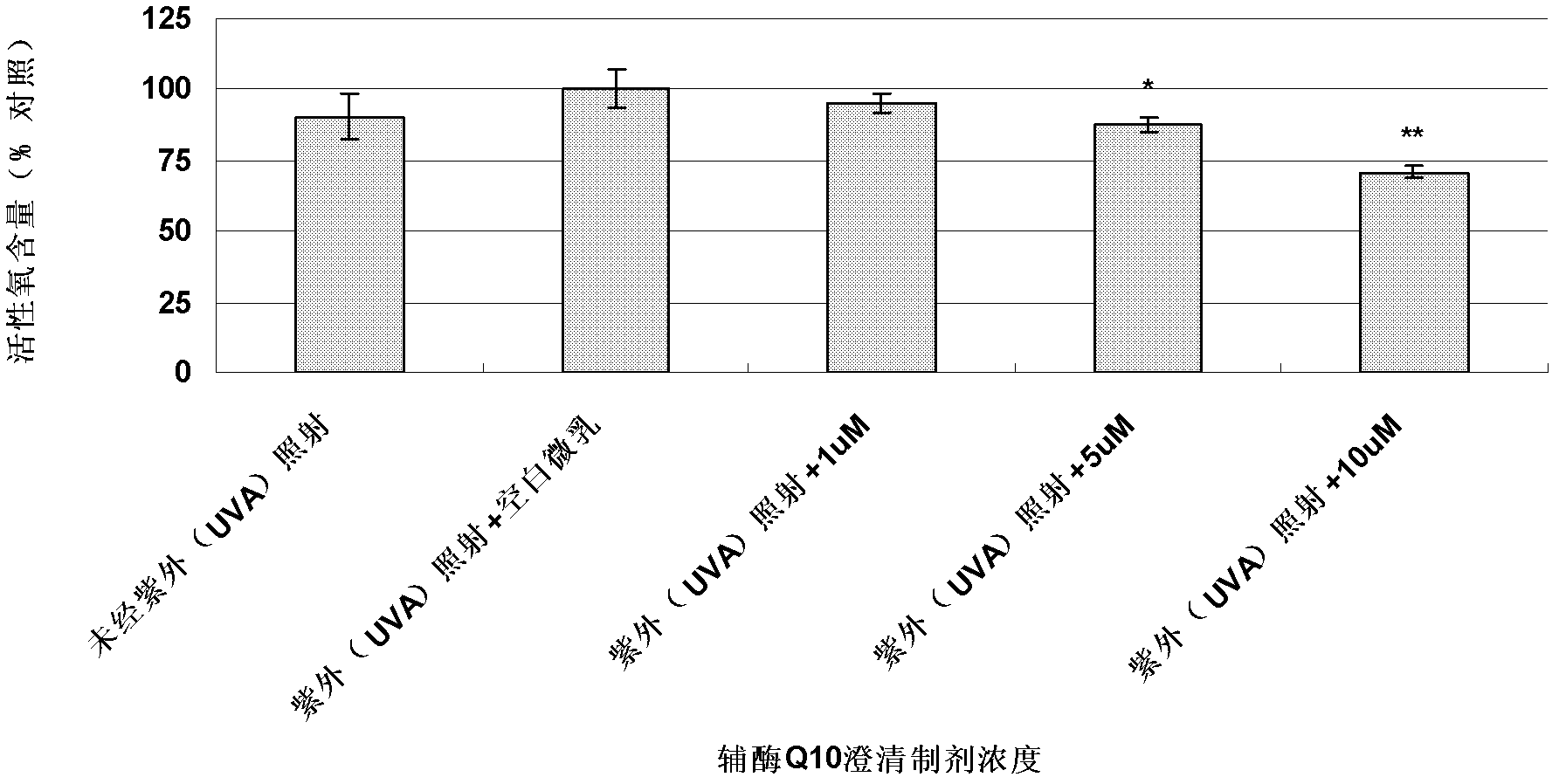

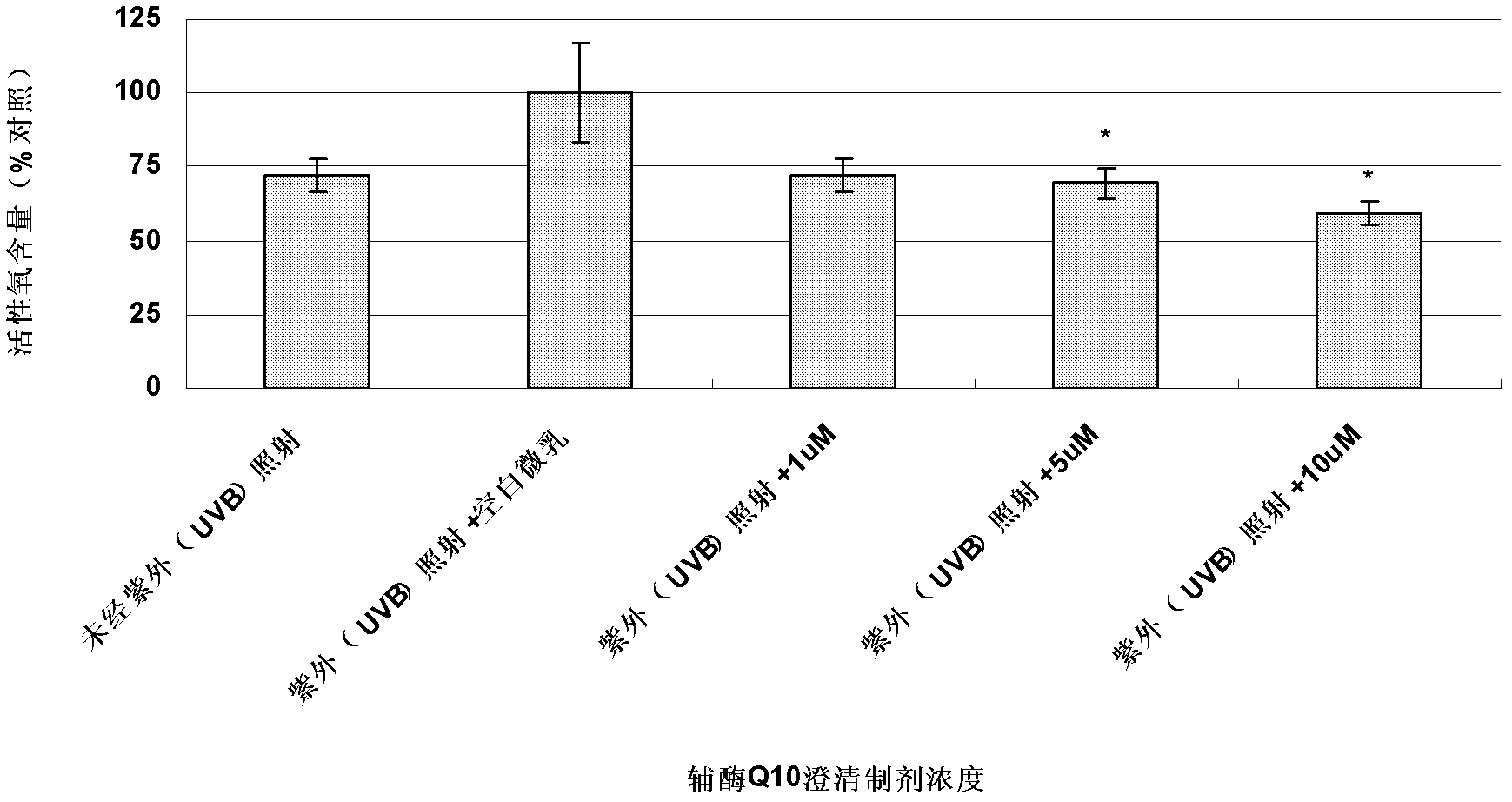

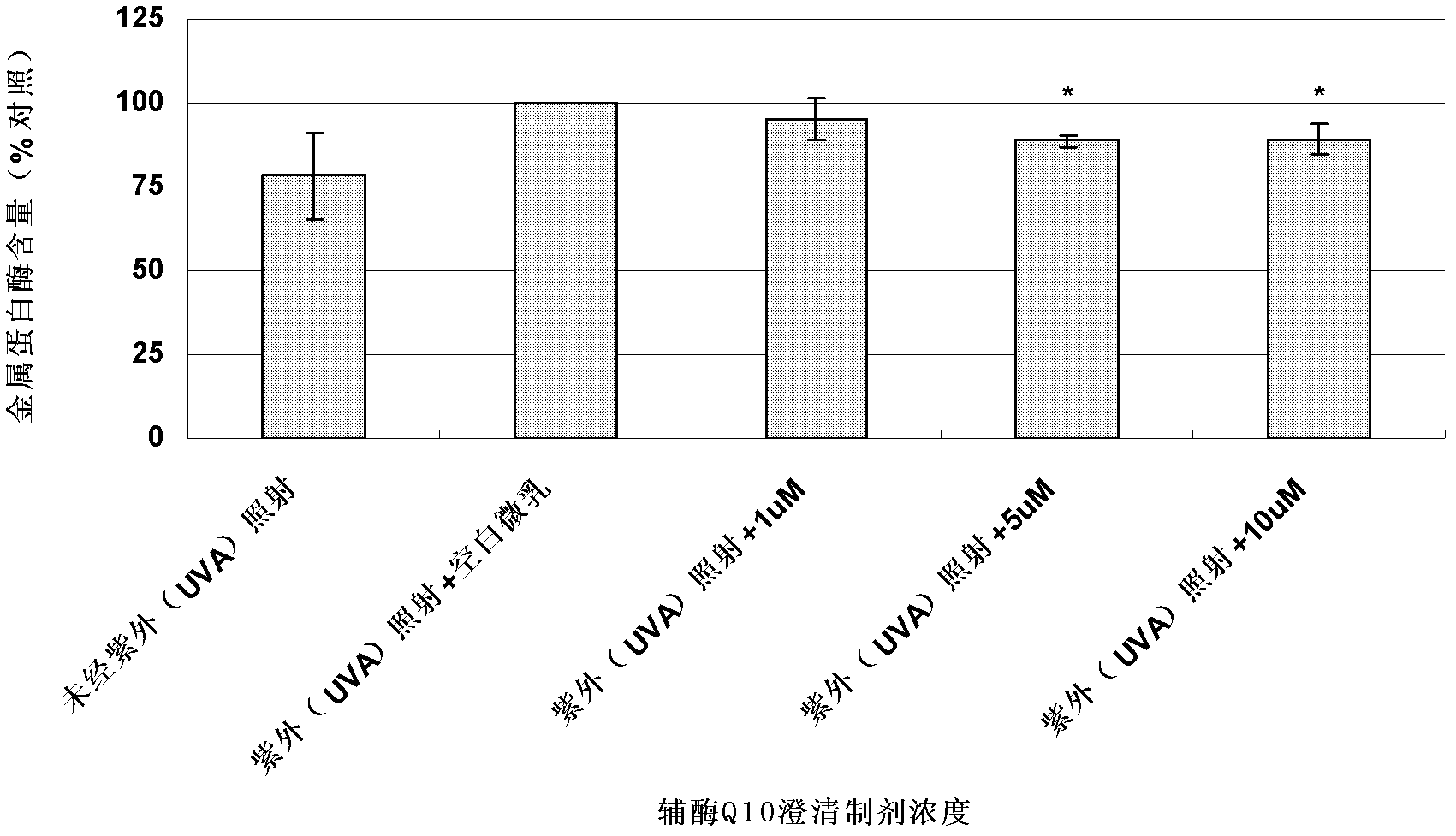

Coenzyme Q10 clear preparation being added into skin caring articles and preparation method thereof

InactiveCN102379829AHigh biological activityPromote transdermal absorptionCosmetic preparationsToilet preparationsSolubilityWater soluble

The present invention provides a coenzyme Q10 clear preparation which is added into skin caring articles and a preparation method thereof, and belongs to the technical field of personal caring article preparation. The coenzyme Q10 clear preparation comprises the following components: coenzyme Q10, emulsifier mixture, pH regulator, stabilizer and water. The particle size of microemulsion of the coenzyme Q10 is less than 150nm. The microemulsion solution is yellow clear water solution. Furthermore the coenzyme Q10 clear preparation has the following advantages: low viscosity, better fluidity, and high stability. The coenzyme Q10 clear microemulsion preparation prepared according to the invention overcomes the following defects in coenzyme Q10: low water solubility, low oil solubility, and high difficulty of being added into personal caring article. Simultaneously the preparation performs antioxidation and anti-aging biological activity on the skin. The process for preparing the personalnursing product which comprises the coenzyme Q10 is simplified. A novel dosage form is provided for the application of the coenzyme Q10 on the aspect of personal nursing product.

Owner:SHENZHOUSPACEBIOTECHGRP

Percolation extraction method for raffinose

ActiveCN101367846AReduce consumptionIncreasing concentration gradientLiquid solutions solvent extractionOligosaccharidesChemistryAqueous solution

The present invention discloses a percolation extraction method of raffinose. Utilizing extraction solvent for extraction, the method includes the following processes: degreased cotton seed meal is used as material, methanol aqueous solution or ethanol aqueous solution, the volume percentage concentration of which is 70 percent to 85 percent, is used as the extraction solvent, which is added into a percolation column containing the degreased cotton seed meal under the temperature of 50 DEG C to 70 DEG C, and after the degreased cotton seed meal is sufficiently swelled, the extraction solvent flows through the percolation column in order to collect percolated extract at an outlet. In the percolated extract, the extraction rate of the raffinose is more than 95 percent. The method has the advantages of high extraction rate, little solvent consumption, low production cost, easy industrialized production, and the like.

Owner:ZHEJIANG UNIV

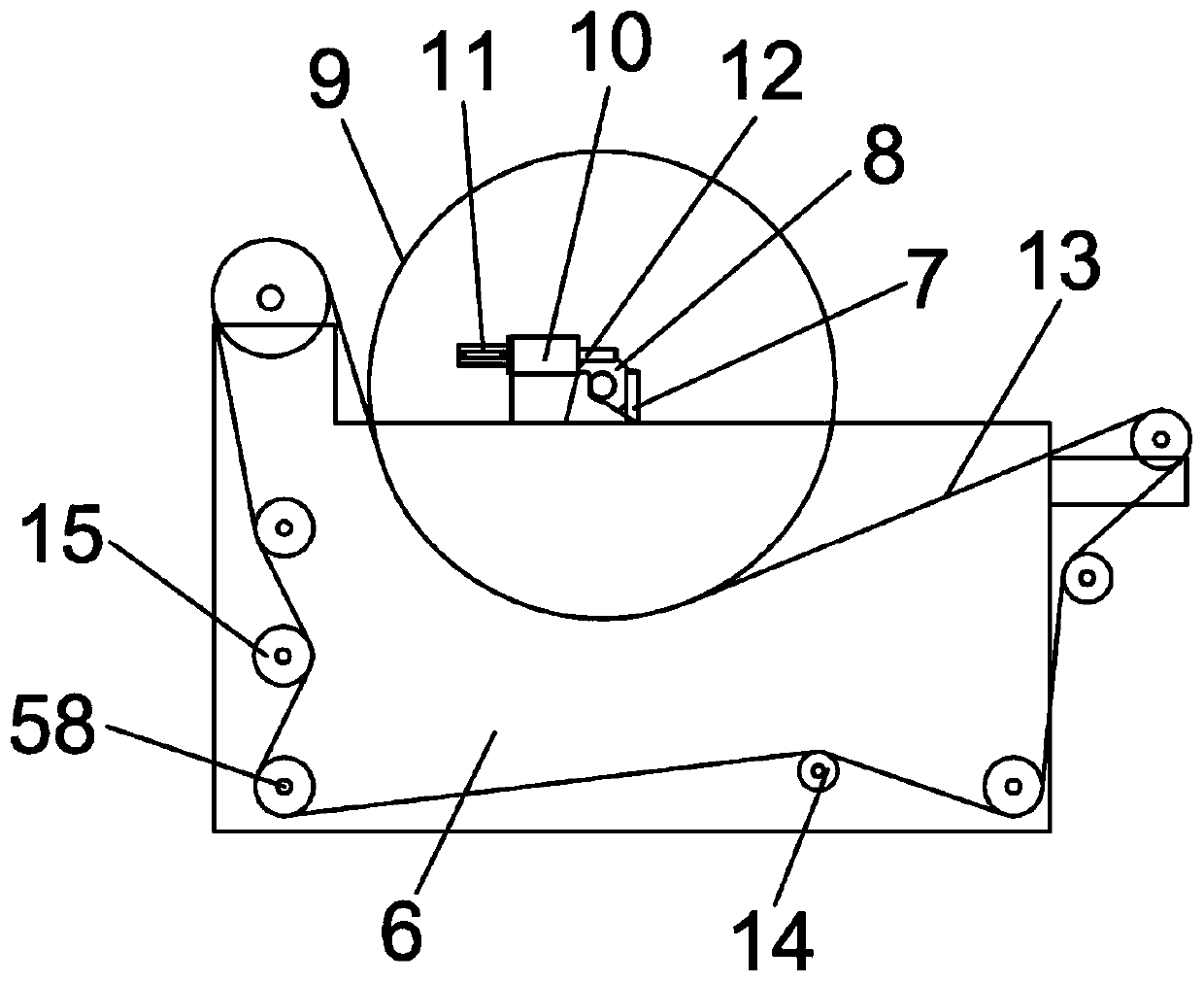

Ultrasonic wave and dry air combined production line drying equipment

PendingCN111707060AWill not affect normal feedingAvoid enteringDrying solid materials without heatDrying gas arrangementsProduction lineEngineering

The invention relates to the technical field of food washing, in particular to ultrasonic wave and dry air combined production line drying equipment. The ultrasonic wave and dry air combined production line drying equipment comprises an elevator and a drying shell; the drying shell is fixedly connected to the right end of the elevator; an anti-dust device is fixedly connected to the internal sideof the top end of the drying shell; a buffering device is fixedly connected to the internal side of the drying shell; a controller is fixedly connected to the right end of the drying shell; a door plate is rotationally connected to the right end of the drying shell through a hinge; a collection box is arranged at the bottom end of the drying shell; and a chain wheel is rotationally connected to the internal side of the drying shell. According to the ultrasonic wave and dry air combined production line drying equipment, by arranging a stainless steel water pipe, an insulation pipe, a condensingdehumidifier, a centrifugal fan, an air energy heat pump and a heating heat exchanger, the labor is saved through continuous conveying, and the labor intensity is reduced; and ultrasonic wave and static electricity are combined with dry air with a heat pump as a heat source, the product is sterilized and uniformly water-evaporated under the double effect of the ultrasonic wave and the static electricity at a lower temperature, and therefore, the drying time is shortened and is 1 / 4 of the common drying time.

Owner:福建一创机械设备有限公司

Microemulsion preparation taking rosin-based vegetable oil as solvent and preparation method thereof

ActiveCN101984808BLow toxicityReduce insecurityBiocideAnimal repellantsVegetable oilAdditive ingredient

The invention provides a microemulsion preparation taking rosin-based vegetable oil as a solvent and a preparation method thereof, and relates to a pesticide preparation. The microemulsion preparation consists of the following raw materials in percentage by mass: 0.5 to 30 percent of pesticide active ingredients, 55 to 20 percent of emulsifier, 0 to 8 percent of cosolvent, 0.1 to 0.3 percent of defoamer, 1 to 30 percent of rosin-based vegetable oil, and the balance of water. The preparation method comprises the following steps of: adding the pesticide active ingredients, the rosin-based vegetable oil, the cosolvent, emulsifier and the defoamer into a reaction kettle, performing cutting and uniform dispersion at 2,000 to 5,000 rpm / min, and adding the balance of water into the mixture for high-speed cutting to obtain the microemulsion preparation taking the rosin-based vegetable oil as the solvent.

Owner:FUJIAN NUODE BIOTECH

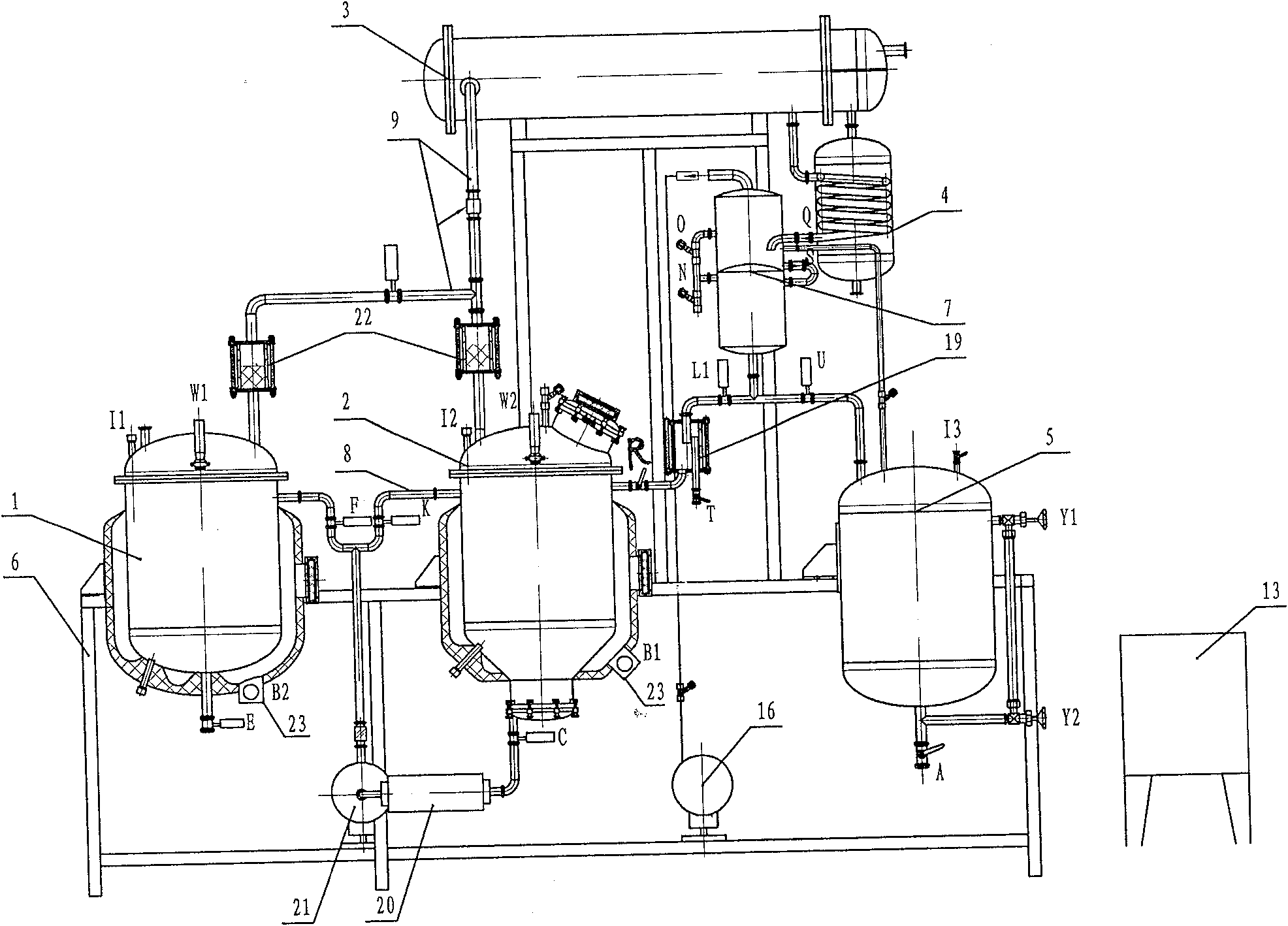

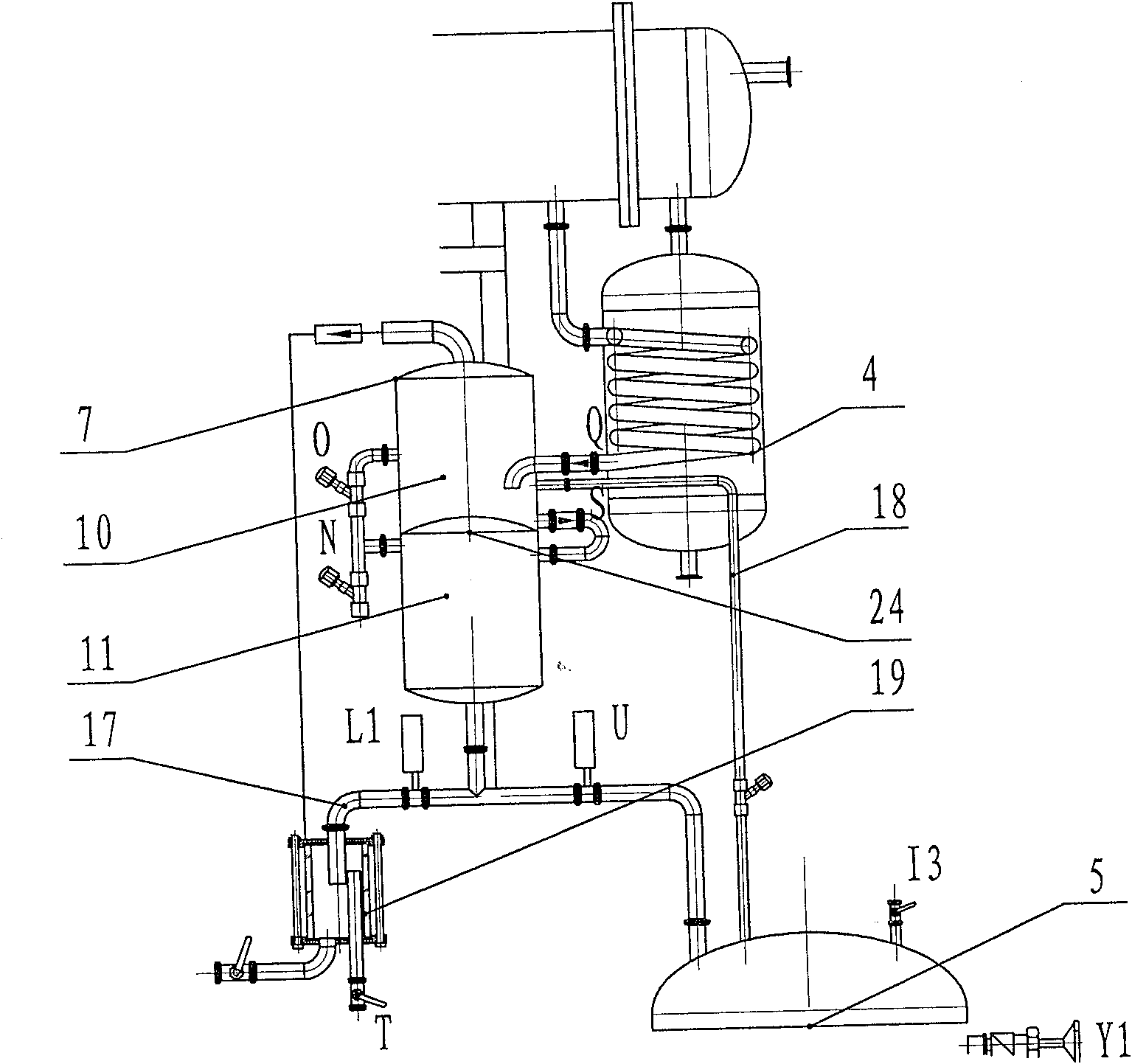

Miniaturized extracting concentrating machine set and formulation production technique thereof

ActiveCN100563769CLow boiling pointAvoid decompositionPharmaceutical product form changeSolid solvent extractionConvertersProcess engineering

Owner:ZHEJIANG SUNNY MACHINERY TECH

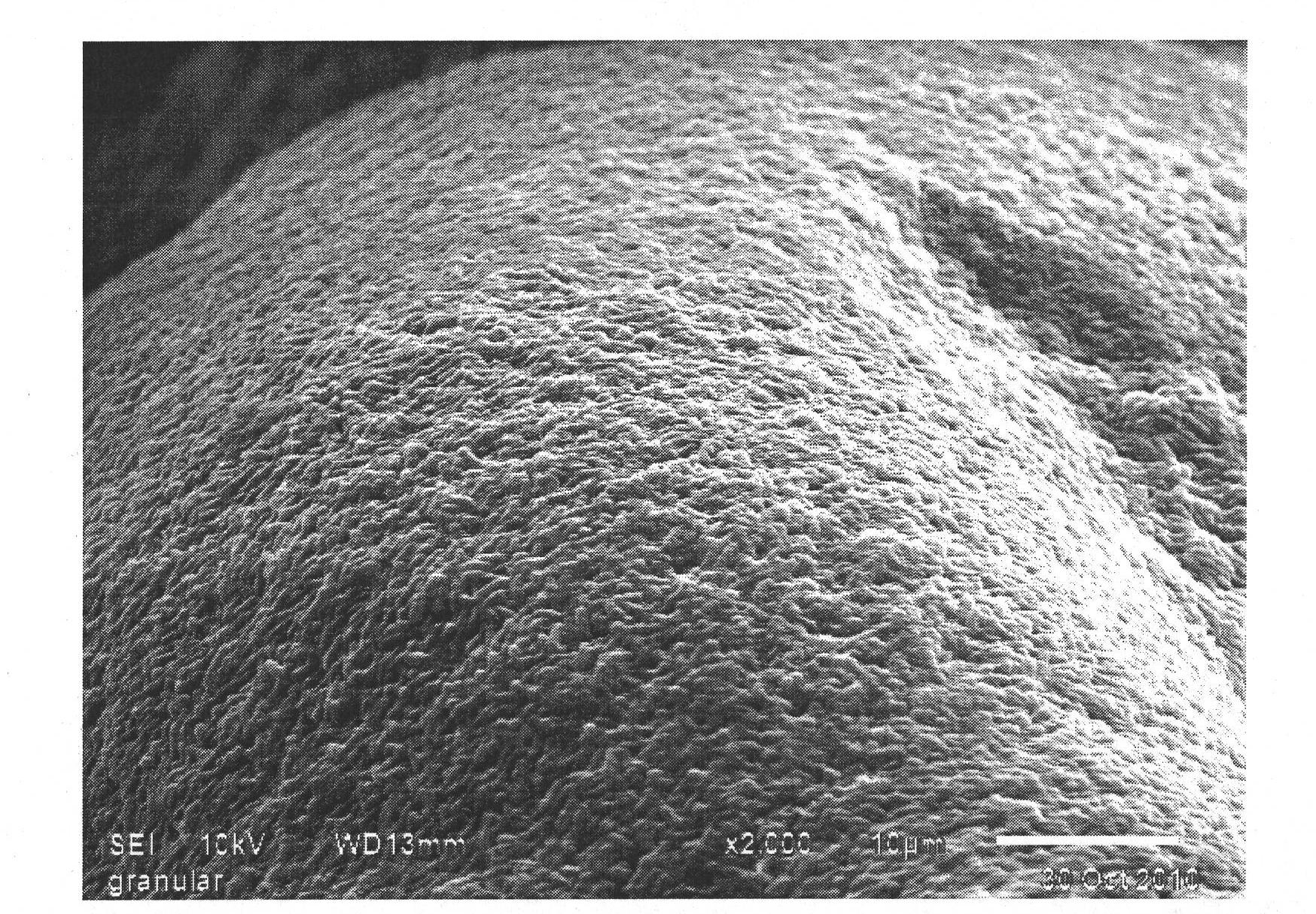

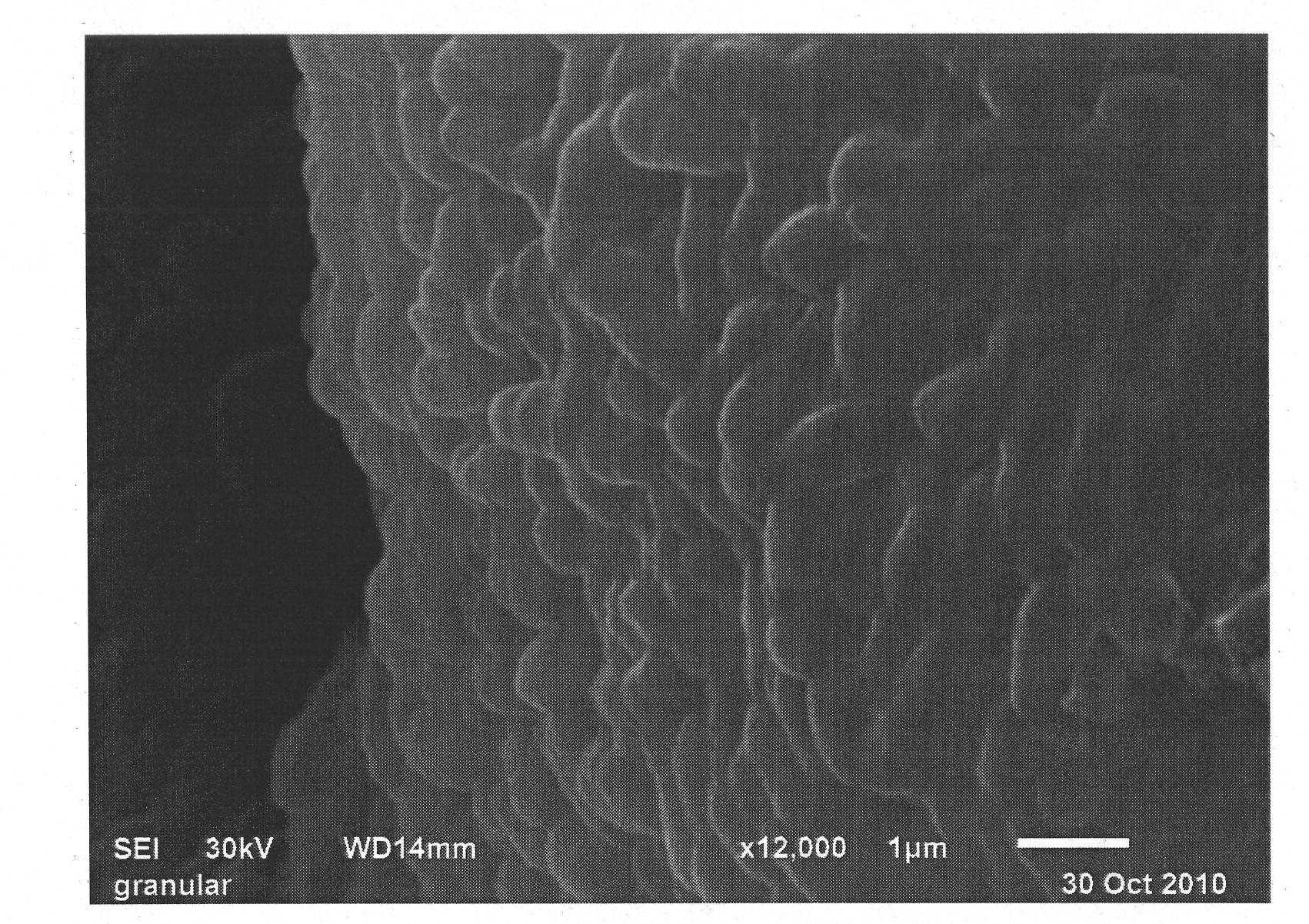

Process for extracting bacterial cell coenzyme Q10

InactiveCN101274884BIncreasing concentration gradientDiffusion thinQuinone separation/purificationBacteroidesMicroorganism

The invention relates to a technology for extracting coenzyme Q10 in bacterial cells, which pertains to the technical field of microbiology engineering. Thalli is automatically and quantitatively put into from the dog-house of a continuous countercurrent device under the control of a weigh-instrument, a solvent is injected from a solvent inlet under the control of a flowmeter and the leaching solution and the thalli form reverse continuous countercurrent leaching process under the push of a shovel-like thruster; the concentration gradient is large, relative movement exists between the solventand the thalli and the thalli moves from the left end to the right end of an extraction container continuously under the function of the shovel-like thruster while the solvent moves from the right end to the left end of the container under the action of pressure; a diffusion boundary layer is thin and fast to be updated and the coenzyme Q10 is extracted after 2 to 10 hours of reaction of the thalli which enters from the left end of the device after the contact of the solvent and the thalli; the thalli enters a rake type dryer from the right end of an extraction device by press treatment and residual organic solvent in the thalli is treated with drying treatment in the rake type dryer; the yield of the coenzyme Q10 reaches more than 90 percent.

Owner:SHENZHOUSPACEBIOTECHGRP +1

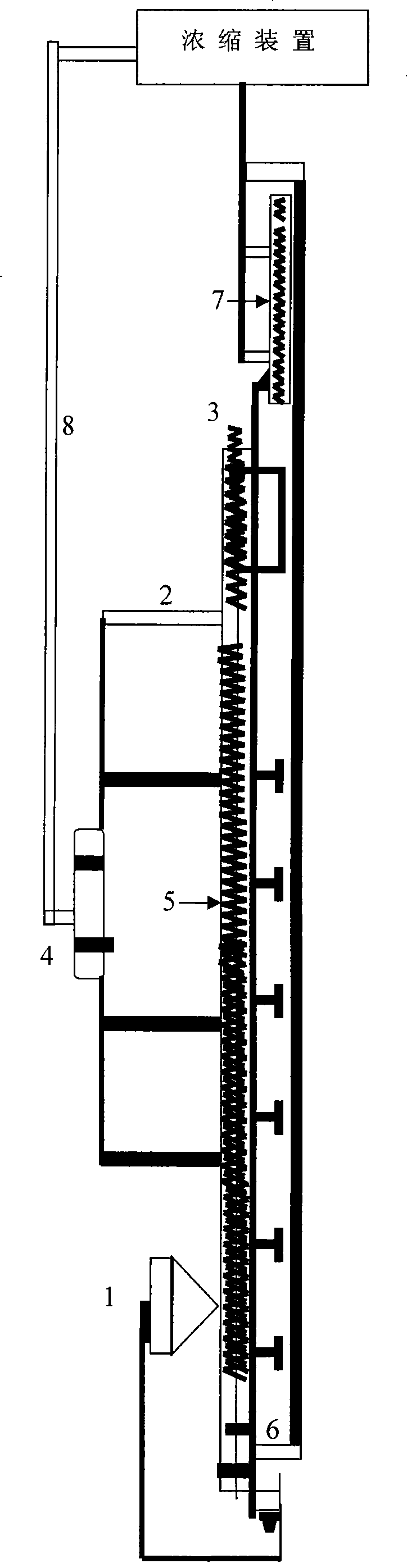

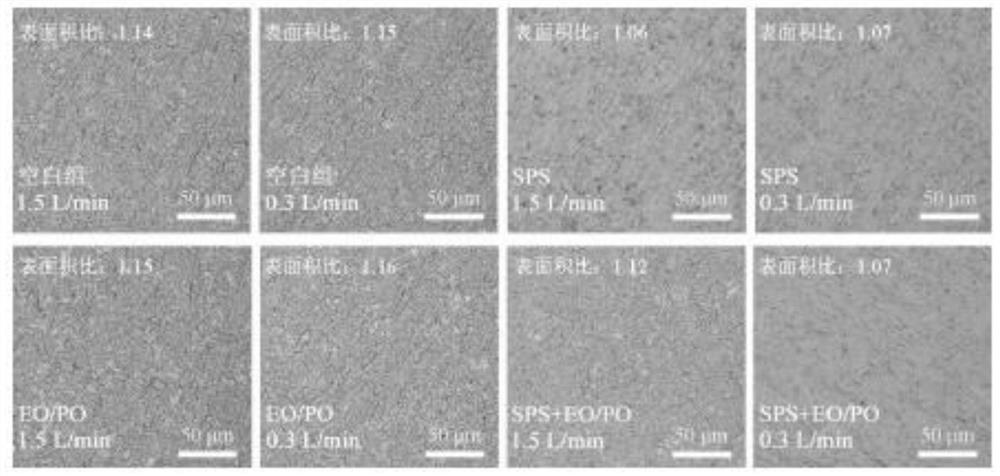

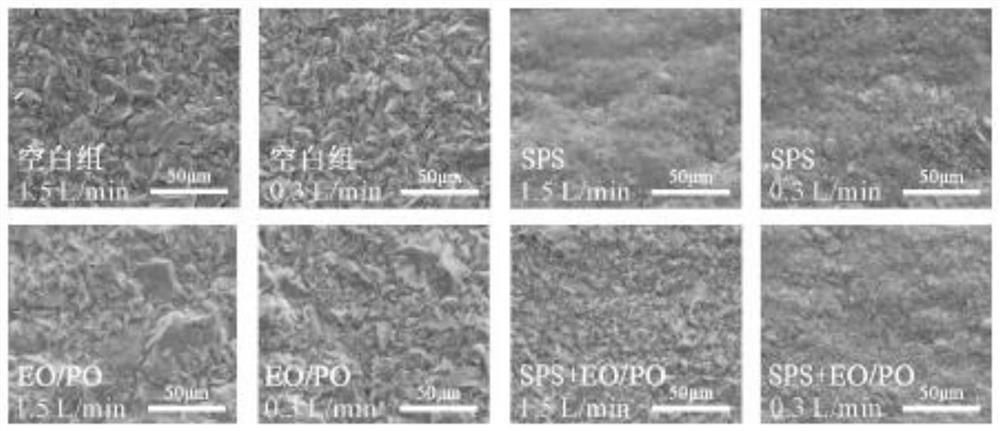

Damascus copper plating formula and electroplating process thereof

InactiveCN113388869AImproved ability to fill blind holesHigh molecular weightPrinted element electric connection formationPolypropyleneActive agent

The invention discloses a Damascus copper plating formula and an electroplating process thereof, and belongs to the technical field of chemical copper plating. The Damascus copper plating formula is prepared by adding water into the following raw materials in mass concentration: 8.0 to 15.0 g / L of copper sulfate pentahydrate, 25.0 to 40.0 g / L of disodium ethylene diamine tetraacetate, 9.0 to 15.0 g / L of glyoxylic acid, 55.0 to 65.0 mg / L of Cl-55.0 mg / L, 0.5 to 1.5 mg / L of ABA type bubble-free nonionic polymer surfactant containing polyethylene oxide (EO) and polypropylene oxide (PO), 0.3 to 4 mg / L of sodium dithiodipropane sulfonate (SPS), 0.5 to 1.5 mg / L of polyvinyl alcohol (PEG) PEG-4000 and 0.2 to 0.4 mg / L of Junagreen B (JGB), wherein the pH value is 12 to 13, and the temperature is 65 to 75 DEG C. According to the invention, a world mainstream level copper electroplating blind hole filling formula is obtained, and blind hole filling capability of the electroplating liquid is improved by more than 40%.

Owner:SHENZHEN CHUANGZHI SUCCESS TECH CO LTD

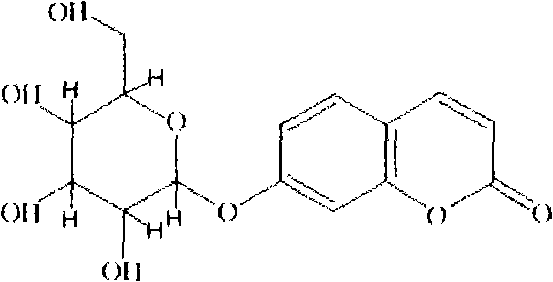

Preparation method of skimmin

InactiveCN102911224AAchieving Countercurrent ContactIncreasing concentration gradientSugar derivativesSugar derivatives preparationAcetic acidElution

The invention relates to a preparation method of skimmin. The method comprises technical steps of: creeping dichondra complete herb is subjected to tissue breaking and extraction 3 times by using acetone; an extraction liquid is subjected to reduced-pressure concentration, such that an extraction paste is obtained; multi-stage countercurrent extraction is carried out by using an ethyl acetate-methanol mixed solvent with a ratio of 10:1; extraction liquids are combined; the solvent is subjected to reduced-pressure recovery; the obtained material is processed by using a polyamide resin column; an obtained elution liquid is concentrated, such that a crude product is obtained; the product is fed into a medium-pressure chromatography column with silica gel of 200-300 meshes; a methanol-dichloromethane mixed solvent system is adopted; elution liquids at target component fragments are collected; the elution liquid is filtered and concentrated, and is subjected to low-temperature drying, such that skimmin is obtained. The skimmin preparation method provided by the invention has the advantages of high product purity and suitability for industrialized enlargement.

Owner:苏州宝泽堂医药科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com