Damascus copper plating formula and electroplating process thereof

A formula and copper plating technology, applied in electrical components, printed circuits, printed circuit manufacturing, etc., can solve the problems of reducing the width of copper interconnection lines and difficulty in electroplating copper filling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

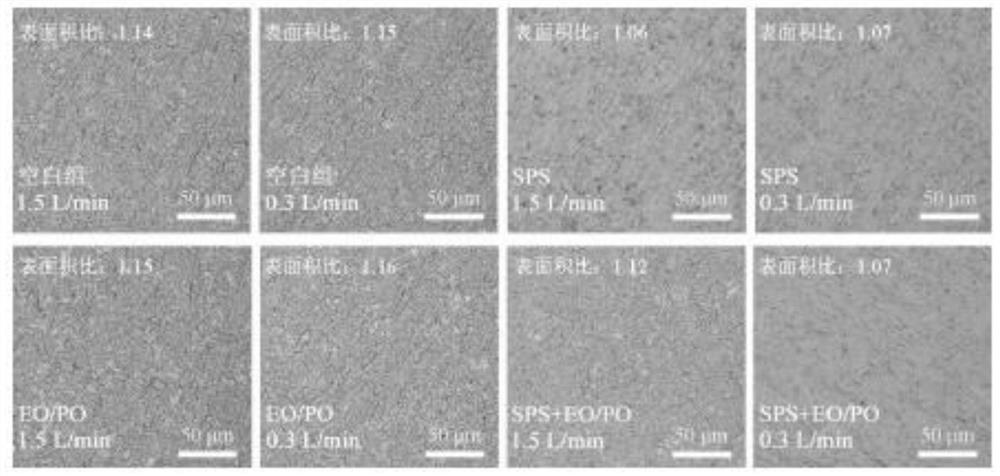

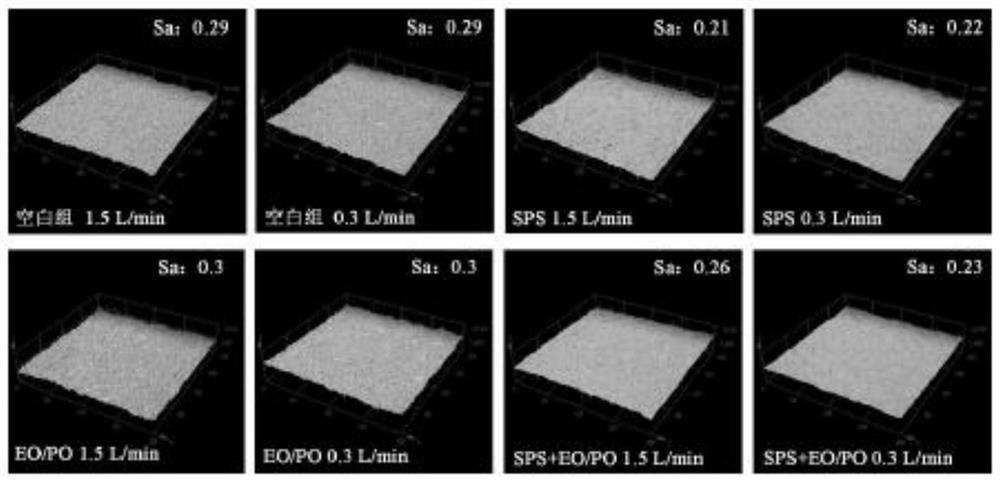

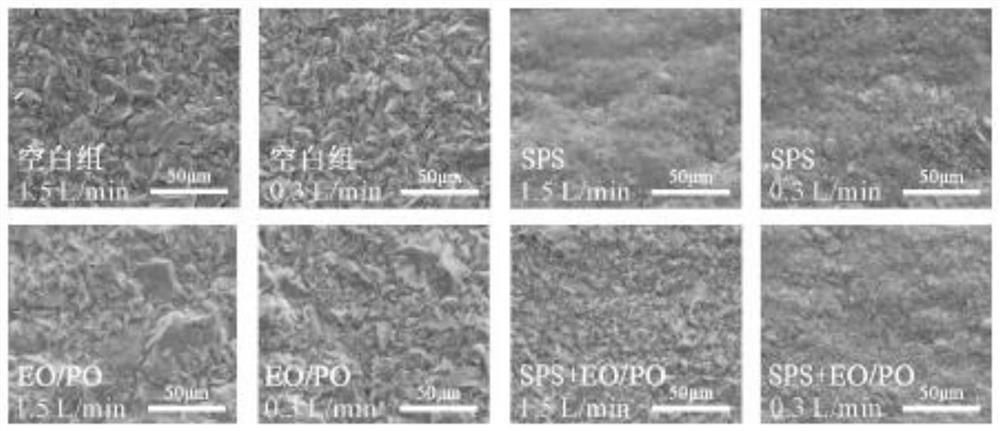

[0030] In order to better understand the purpose, structure and function of the present invention, a Damascus copper plating formulation of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] Experimental process of electroless copper plating:

[0032] (1) Sample preparation

[0033] The simulated silicon wafer used was provided by Applied Materials, USA, with a 5nm-thick copper seed layer on the surface. Before use, cut off a silicon wafer from the whole chip with a glass cutter (containing a channel with a width from 80nm to 500nm above), and set it aside for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com