Patents

Literature

179results about How to "Diffusion coefficient is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cast aluminum-silicon alloy for engine cylinder head and heat treatment process

InactiveCN102071341AImprove room temperature performanceHigh tensile strengthChemical compositionSilicon alloy

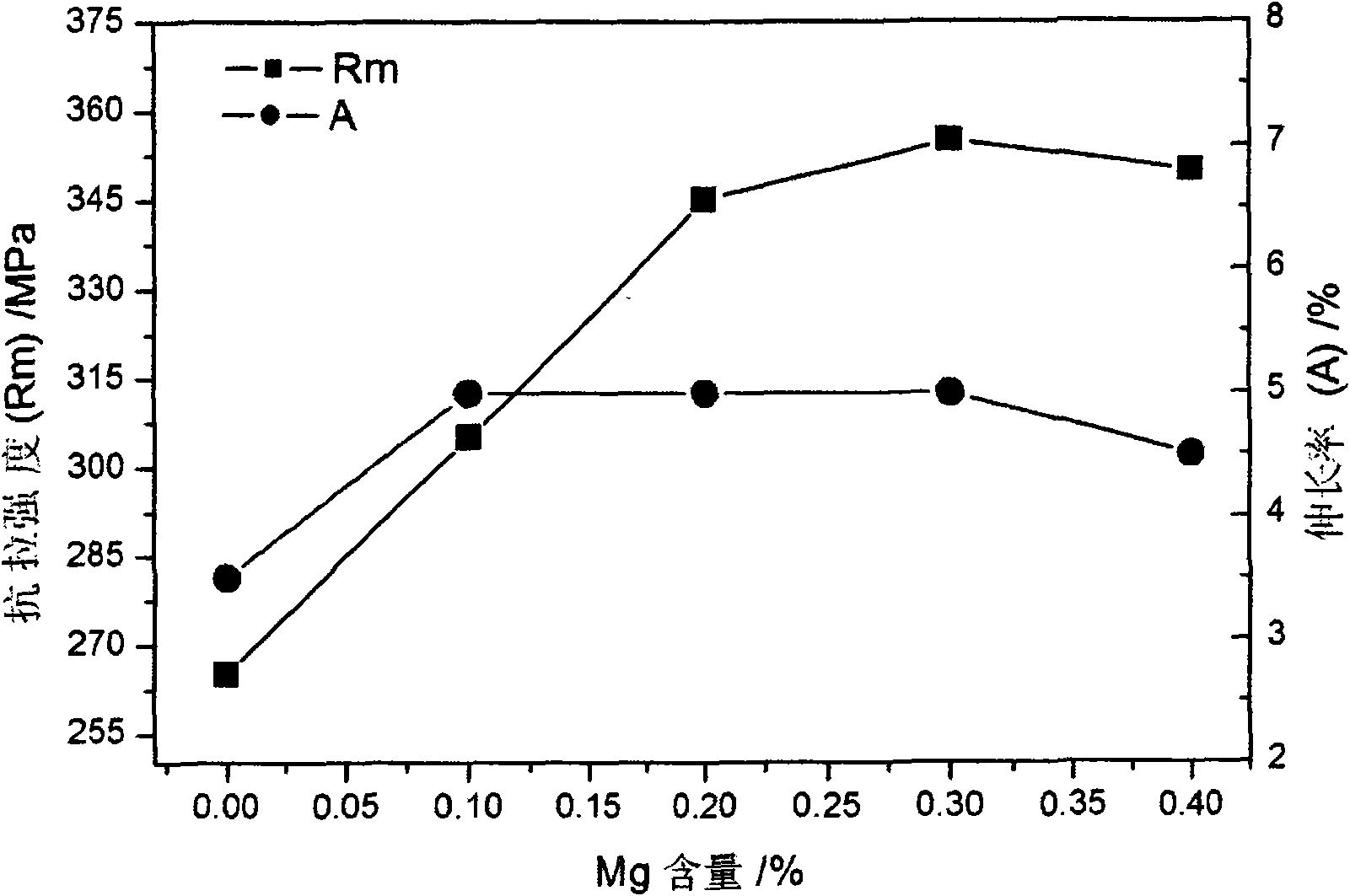

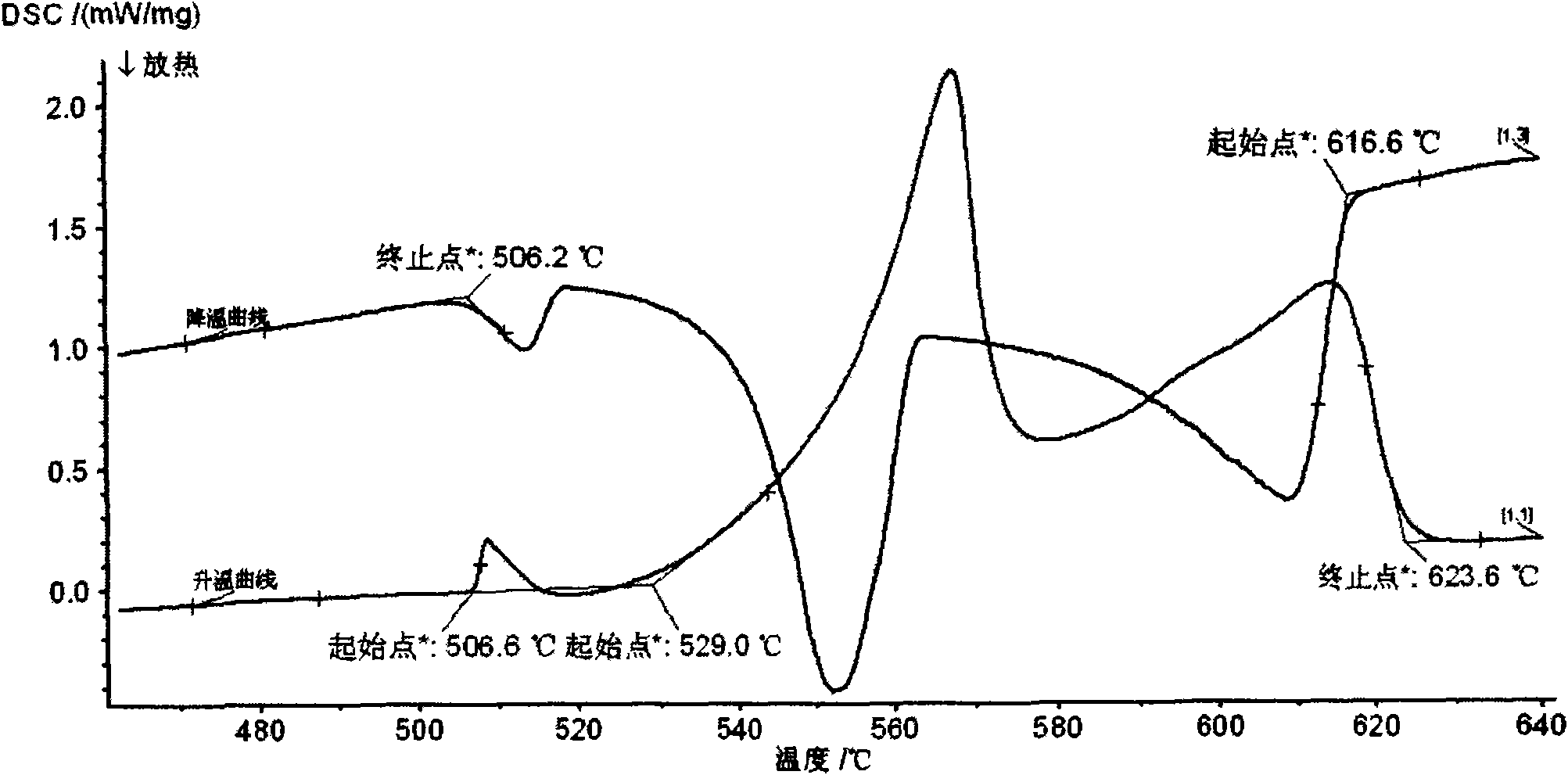

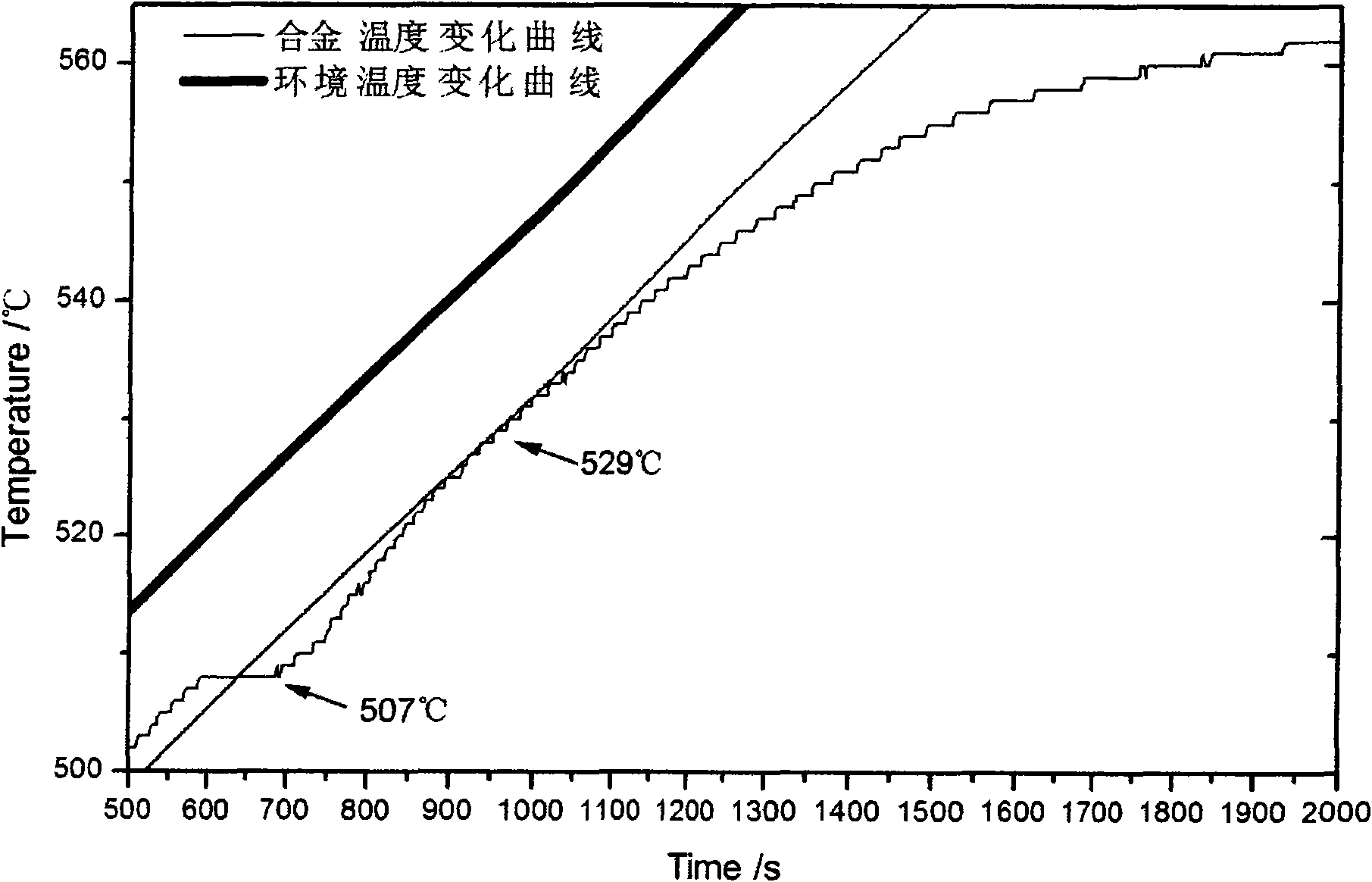

The invention relates to a cast aluminum-silicon alloy for an engine cylinder head and a heat treatment process. The alloy comprises the following chemical ingredients in percentage by weight: 5.0 to 7.0 percent of Si, 3.0 to 4.0 percent of Cu, 0.2 to 0.4 percent of Mg, 0.1 to 0.3 percent of Mn, 0.10 to 0.20 percent of Zr, 0.15 to 0.25 percent of Ti, 0.01 to 0.05 percent of B, 0.02 to 0.09 percent of Sr, 0.1 to 0.3 percent of rare earth (RE), less then 0.3 percent of Fe and the balance Al, wherein the rare earth (RE) adopts mixed rare earth. The heat treatment process comprises the following steps: carrying out primary solution at a temperature between 490 DEG C and 505 DEG C, and carrying out heat insulation for 4 to 6h; carrying out secondary solution at a temperature between 510 DEG C and 525 DEG C, carrying out heat insulation for 6 to 10h, and carrying out quenching by hot water of 60 to 80 DEG C; and carrying out aging treatment with parameters of the aging temperature being 155to 165 DEG C and the heat insulation time being 5 to 9h, and carrying out cooling in the air. All alloy elements of the cast aluminum-silicon alloy provided by the invention are reasonably matched, good mechanical performance is realized, at a normal temperature, the tensile strength reaches 325 to 355MPa, the tensile stretch is 2.5 to 5.5 percent, at a high temperature of 250 DEG C, the tensile strength reaches 240 to 270MPa, and the tensile stretch is 3.0 to 5.5 percent, after the heating processing technology, the heat resistance performance of the alloy is improved, and the casting defect is reduced.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

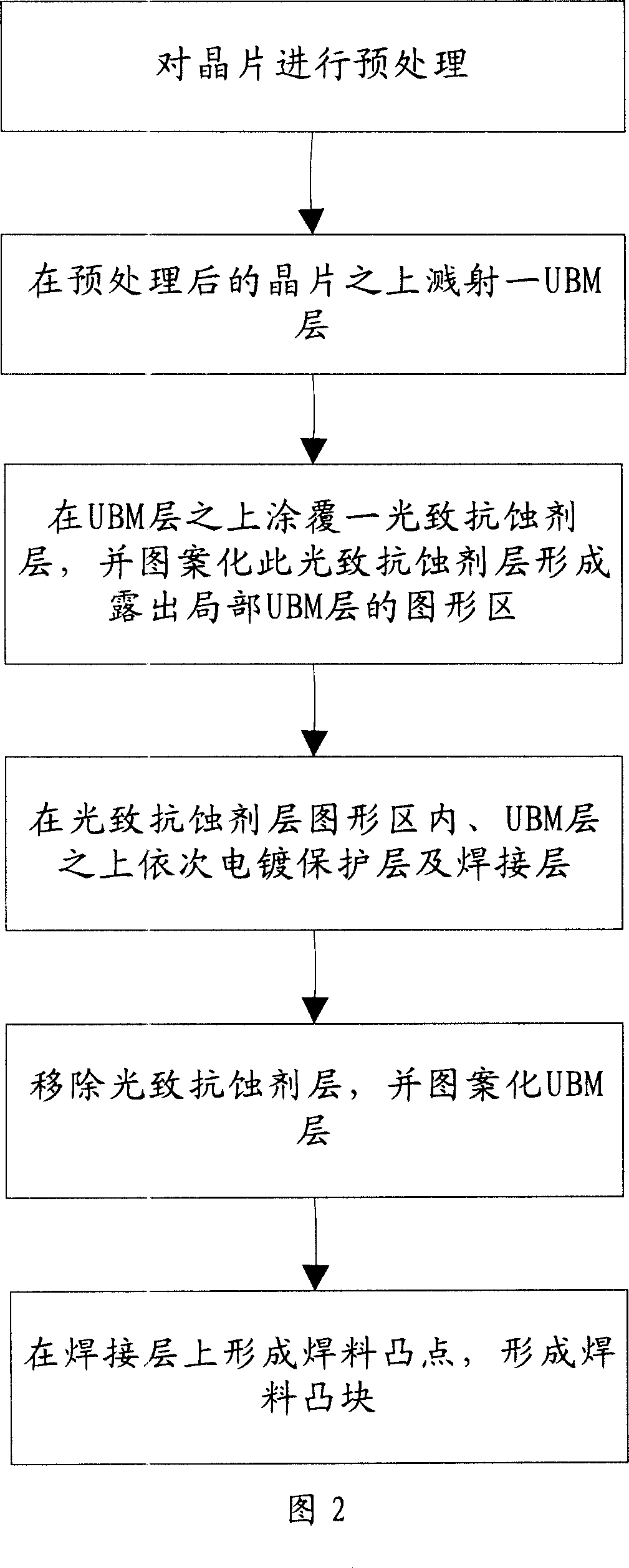

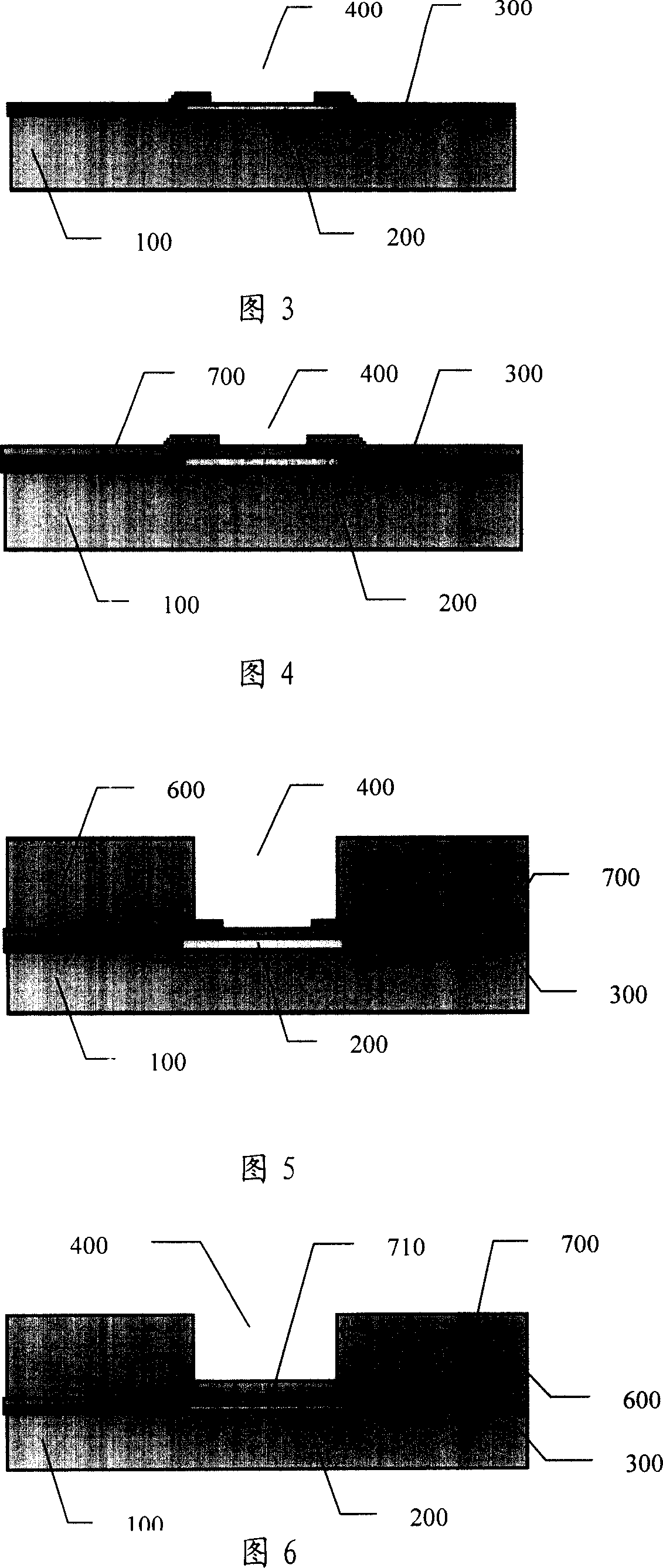

Solder lug and manufacturing method thereof

InactiveCN101090099AReduce volumeConvenient for miniaturization and portabilitySemiconductor/solid-state device detailsSolid-state devicesResistBlock layer

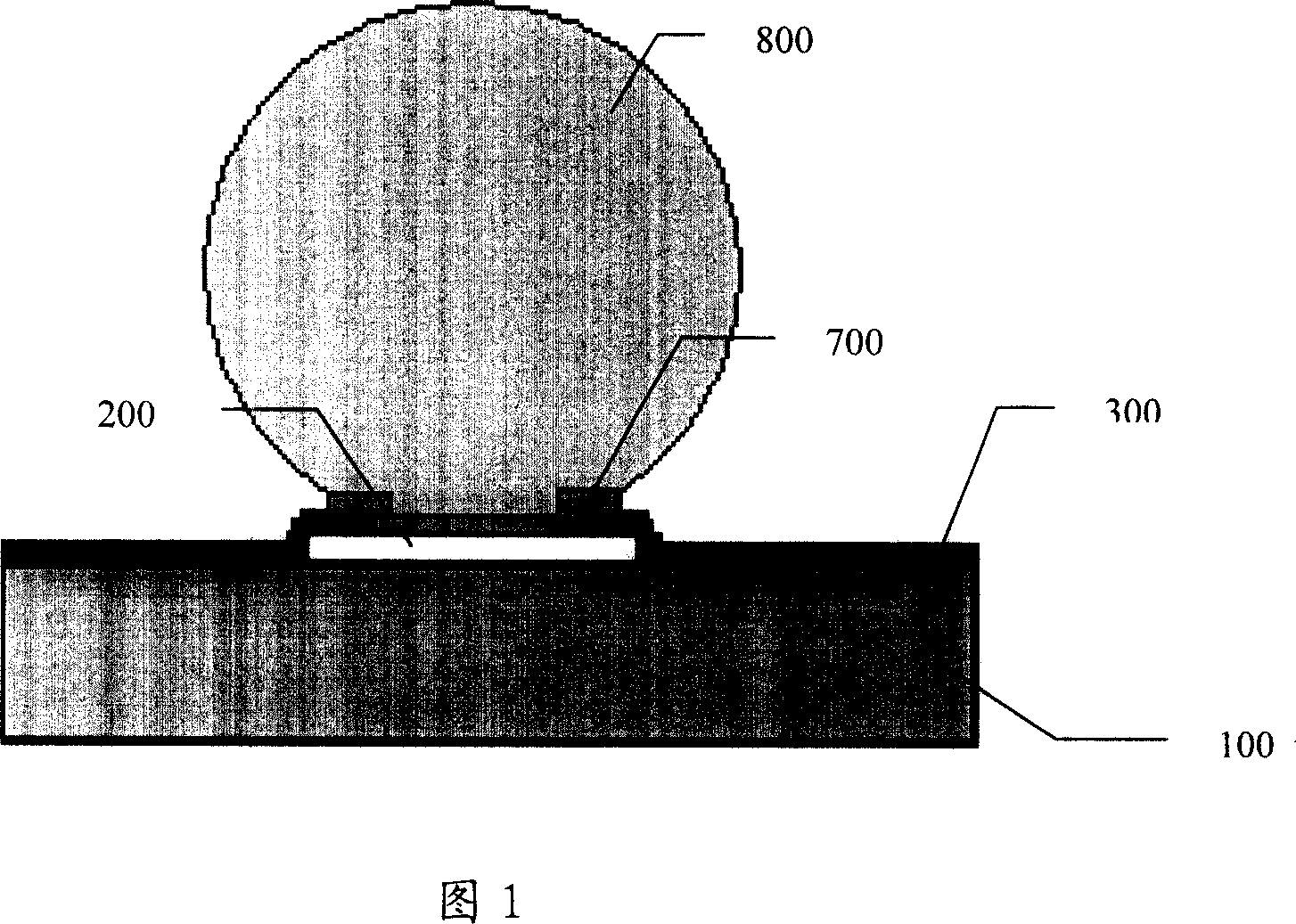

This inveention discloses a solder hump and its manufacturing method, which first of all coats a patttern photo resist layer on a wafer or UBM under salient points to form a figure area, in which, said UBM layer includes Cr / Cu, Cr / CrCu / Cu, Ti / Cu, TiW / Cu or Ta / Cu deposited layer by layer, then forms a Ni layer as the block layer in the figure, on the wafer or above the UBM layer and forms a Cu layer on the block layer as a welding layer and finally removes the photo resist layer on the un-figure region and etches the UBM layer covered by the un-figure region of the photo resist layer to form solder salient points on the welding layer to further realize connection of the wafer with outside by the welding way.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

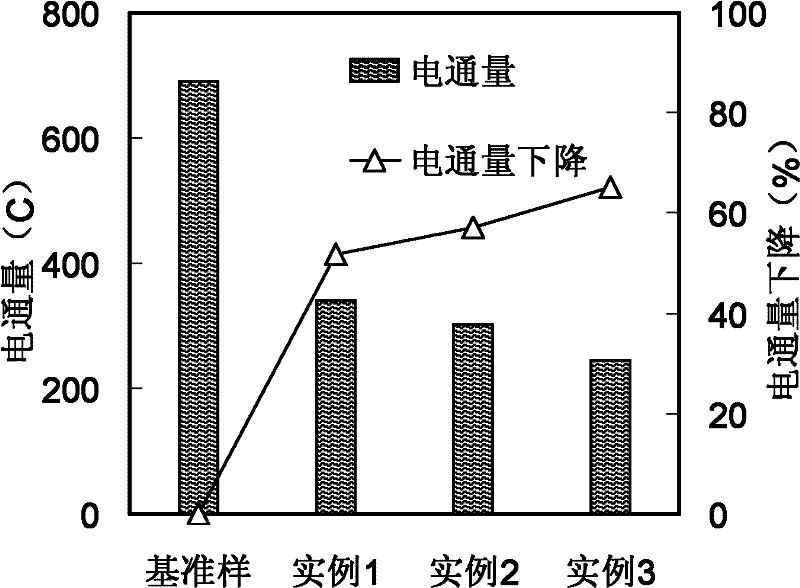

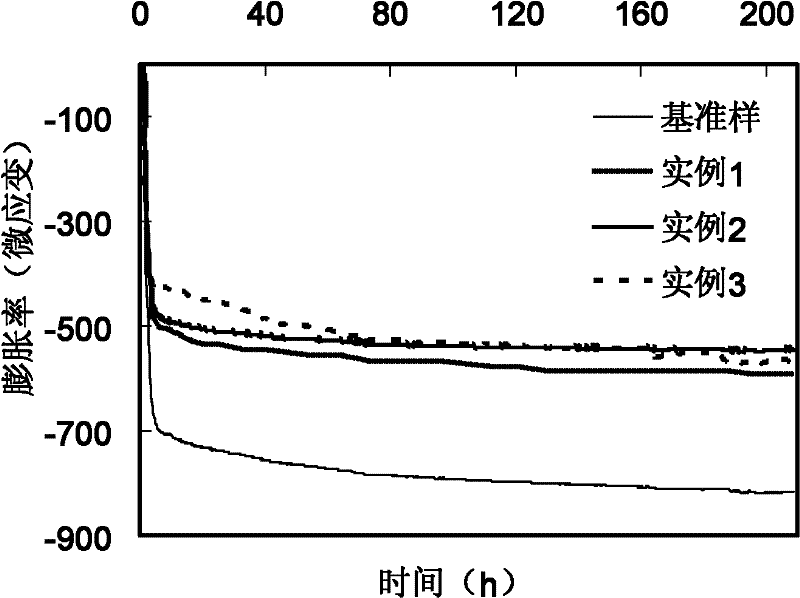

Modified metakaolin-based permeation-resistant and crack-resistant agent for concrete

The invention discloses a modified metakaolin-based permeation-resistant and crack-resistant agent for concrete. The modified metakaolin-based permeation-resistant and crack-resistant agent for concrete comprises: by mass, 10 to 75% of modified metakaolin, 5 to 40% of fine limestone powder, 4 to 40% of superfine coal ash, 1 to 20% of calcined hydrotalcite, 2 to 40% of fine quartz sand and 0.2 to 20% of solid silane powder. A preparation method of the modified metakaolin comprises the following steps of putting dry and washed kaolin into a bowl mill, carrying out grinding to obtain kaolin powder, carrying out calcination of the kaolin powder at a temperature of 500 to 1000 DEG C for 0.5 to 6.0 hours to obtain metakaolin, putting the metakaolin into a dispersion machine, adding an organic modifier of sulfamate or triethanolamine into the metakaolin, wherein a mass ratio of the metakaolin and the organic modifier is in a range of (5000: 1) to (100: 1), and carrying out dispersion to obtain the modified metakaolin having a contact angle of 50 to 100 degrees and a specific surface area of 8000 to 15000m<2> / kg. The modified metakaolin-based permeation-resistant and crack-resistant agentfor concrete can be utilized as a concrete additive, improves strength of concrete at different ages, does not produce obvious influences on concrete work performances, obviously improves anti-chloride ion penetration capability of concrete, reduces total shrinkage of concrete and improves crack resistance of concrete.

Owner:WUHAN UNIV OF TECH +1

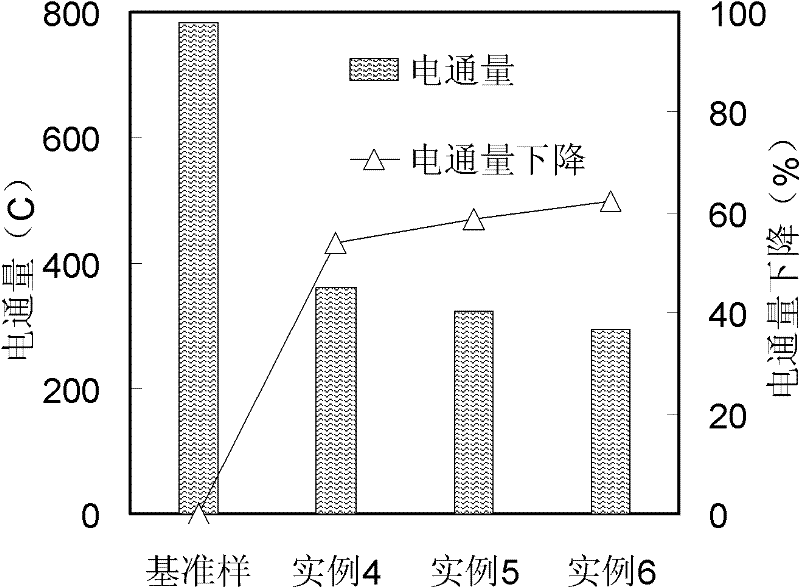

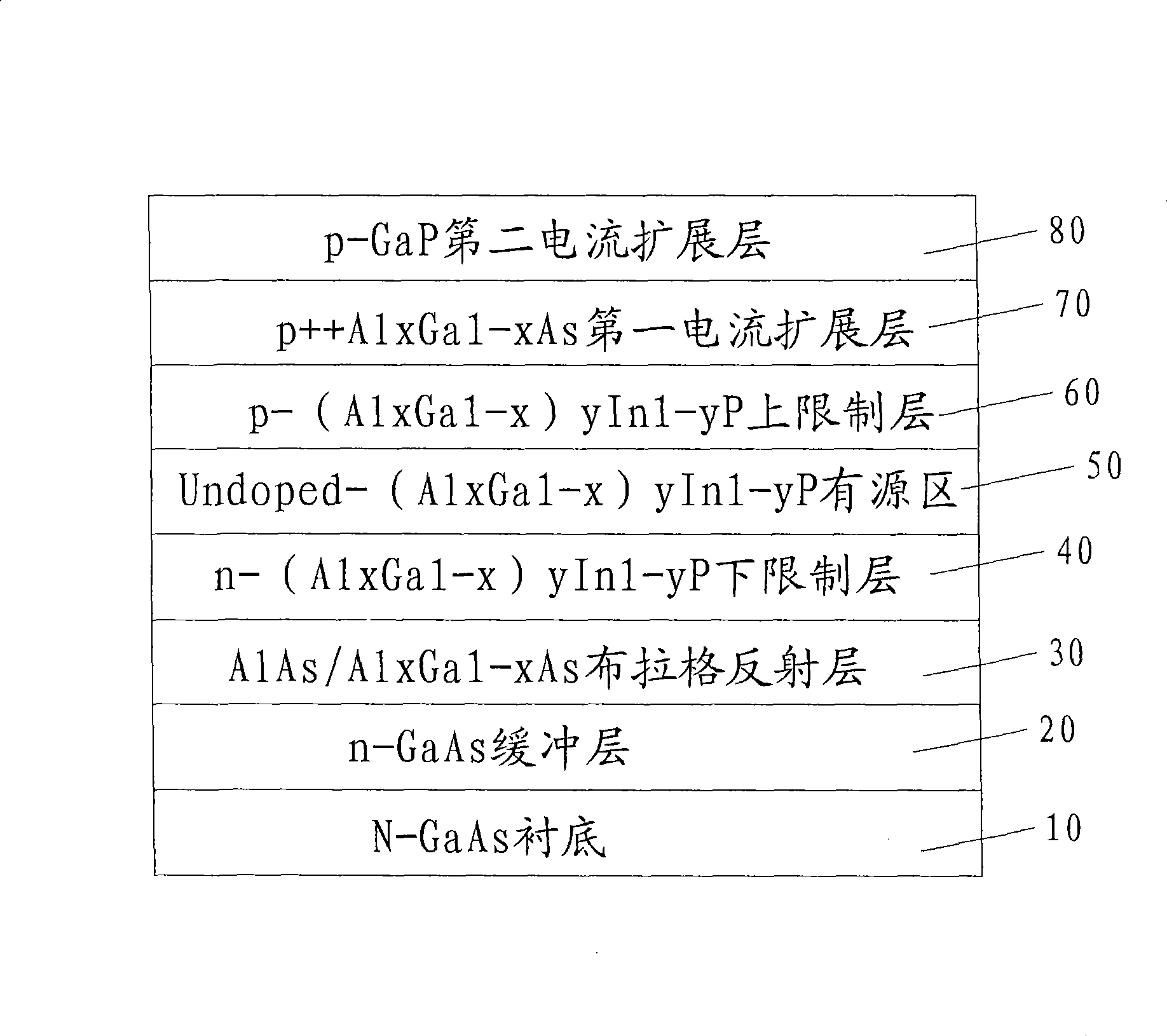

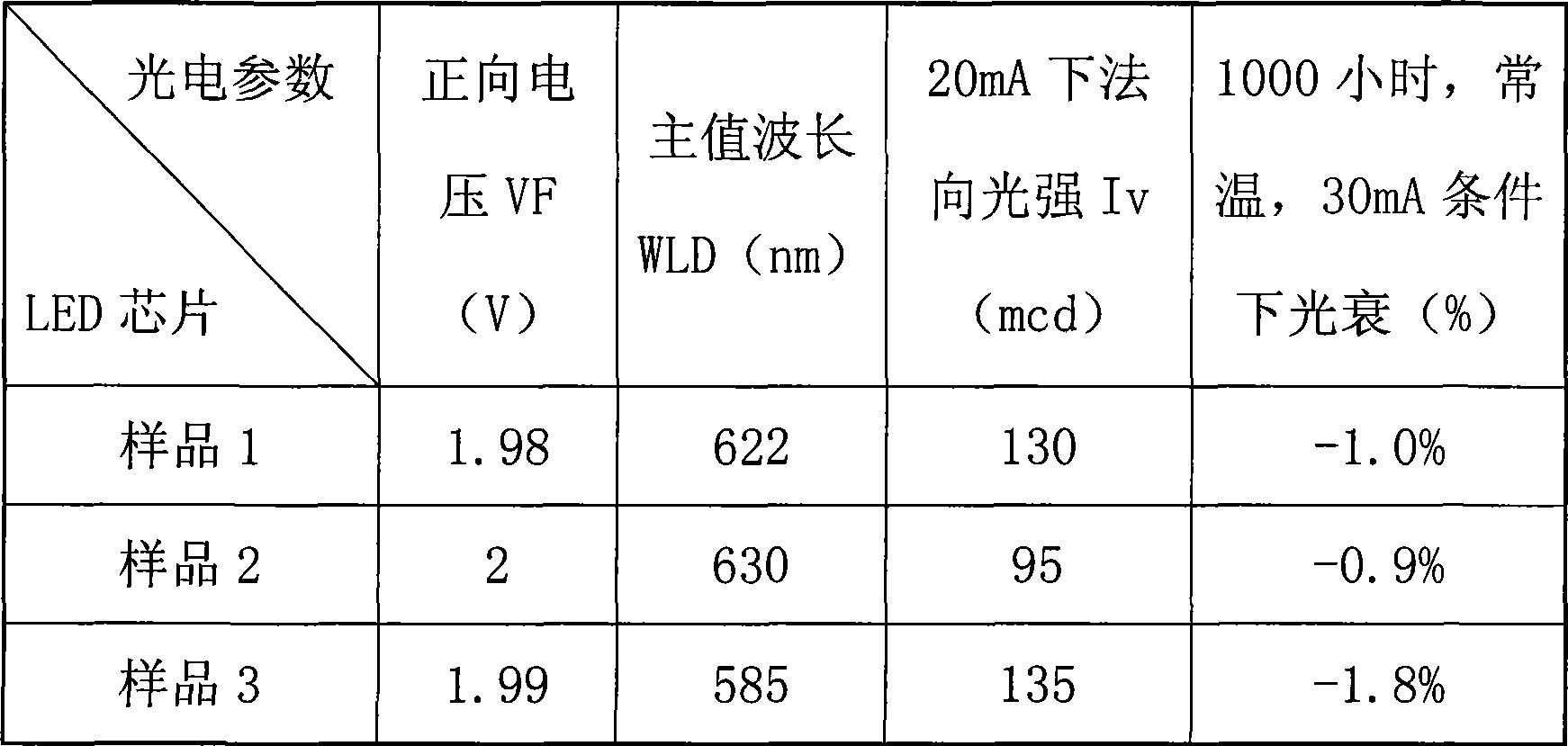

Highly efficient LED having current spread layer construction improved and manufacturing method thereof

ActiveCN101388430AImprove efficiencyLower forward voltageSemiconductor devicesEngineeringLight-emitting diode

The invention discloses a highly-effective light-emitting diode with an improved current spreading layer structure and a production method thereof. Material which is extended on an N-GaAs under-layer comprises an n-GaAs buffer layer, or an AlAs / AlxGal-xAs or AlInP / (A1x Ga1-x)yIn1-yP Bragg reflection layer, an n-(AlxGa1-x)yIn1-yP lower limiting layer, an Undoped-(AlxGa1-x)yIn1-yP active region, a p-(A1xGa1-x)yIn1-yP upper limiting layer, and a p++AlxGal-xAs and p-GaP combined current spreading layer, wherein the p++AlxGal-xAs is arranged on the lower surface as a first current spreading layer, and the p-GaP is arranged on the upper surface as a second current spreading layer. The structure integrates the advantages of GaP and A1xGal-xAs materials, avoids the oxidization of materials, and guarantees the reliability and the stability of the current spreading and apparatuses.

Owner:XIAMEN CHANGELIGHT CO LTD

Novel high-temperature alloy heat-resistant stainless steel bolt and production process thereof

ActiveCN103014551ADiffusion coefficient is smallImprove reinforcement stabilitySuperalloyUltimate tensile strength

The invention discloses a novel high-temperature alloy heat-resistant stainless steel bolt and a production process thereof. The bolt comprises the components of, by mass, no more than 0.08% of C, no more than 1.00% of Si, no more than 2.00% of Mn, no more than 0.035% of P, no more than 0.030% of S, 24.0-27.0% of Ni, 13.5-16.0% of Cr, 1.90-2.23% of Ti, no more than 0.35% of Al, no more than 0.10-1.50% of Mo, and balance of Fe and unavoidable impurities. The production process comprises that the raw materials are subjected to the steps of solid smelting, cold heading molding, re-crystallization and annealing, stress-removing tempering, hexagon-head cutting and wire rolling, washing, stabilization treatment, and aging treatment. With the process, the bolt has the advantages of high strength, high relaxation-resistance, low notch sensitivity, certain endurance strength, good oxidation resistance, and the like.

Owner:江苏新迅达不锈钢制品有限公司

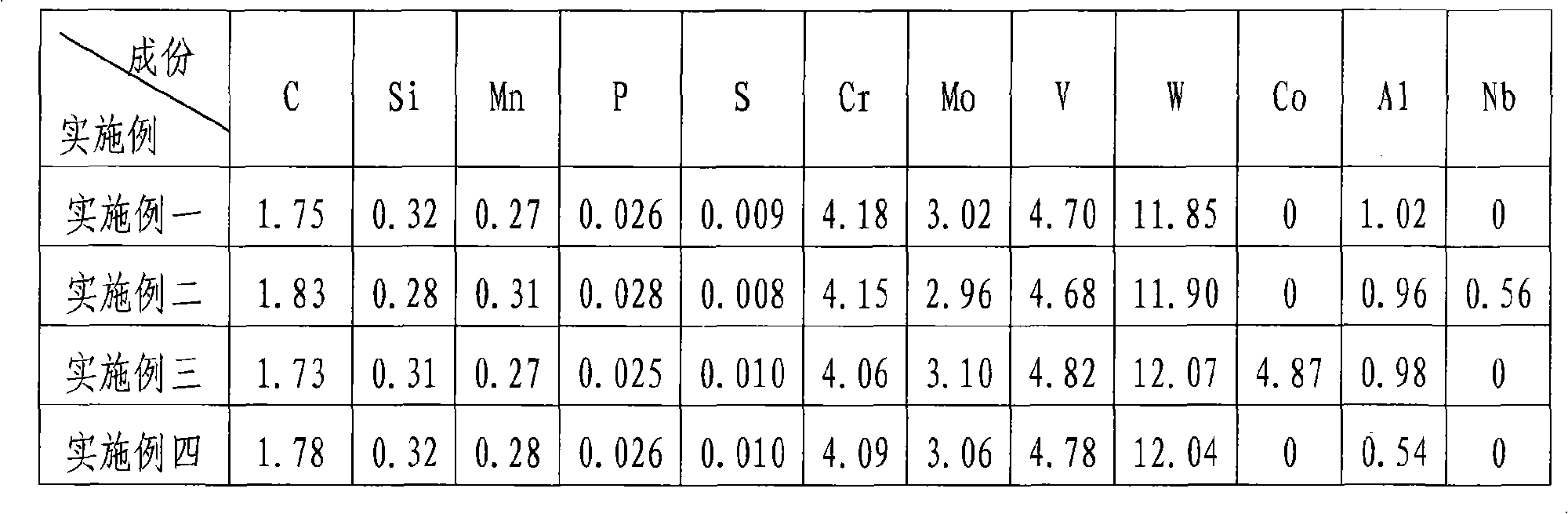

High-hardness high-wear-resistant powder metallurgy high-speed steel

The present invention relates to high-performance high-speed steel, and particularly to a high-hardness high-wear-resistant powder metallurgy high-speed steel which is manufactured according to a power metallurgy method and contains Al. The high-speed steel is composed of C, Si, Cr, Mo, V, W, Nb, Mn, Co, Al, Fe and impurities. The high-speed steel manufactured according to the technical solution has the following advantages: more than 67.5HRC of quenching-tempering hardness, better red hardness and wear resistance, stronger bending strength and lower cost.

Owner:HEYE SPECIAL STEEL

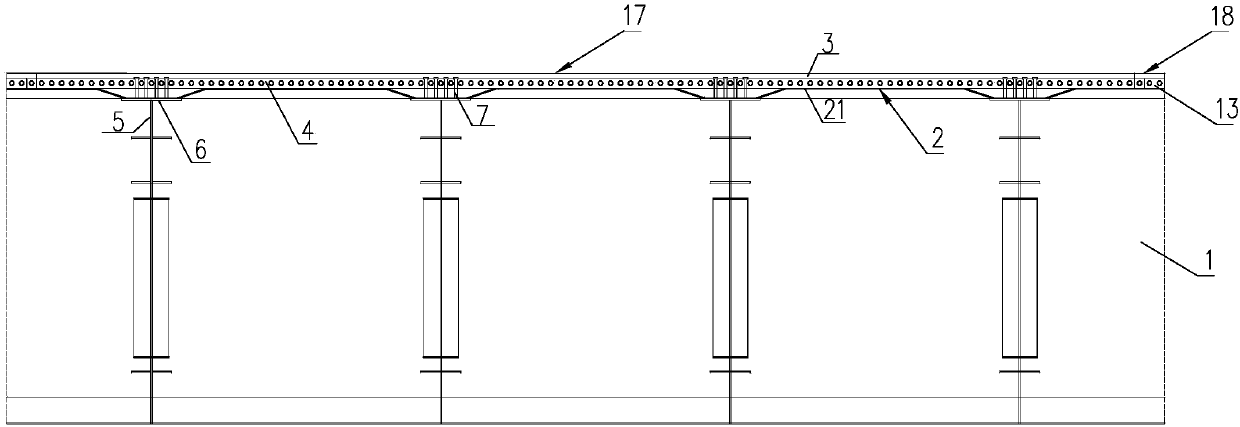

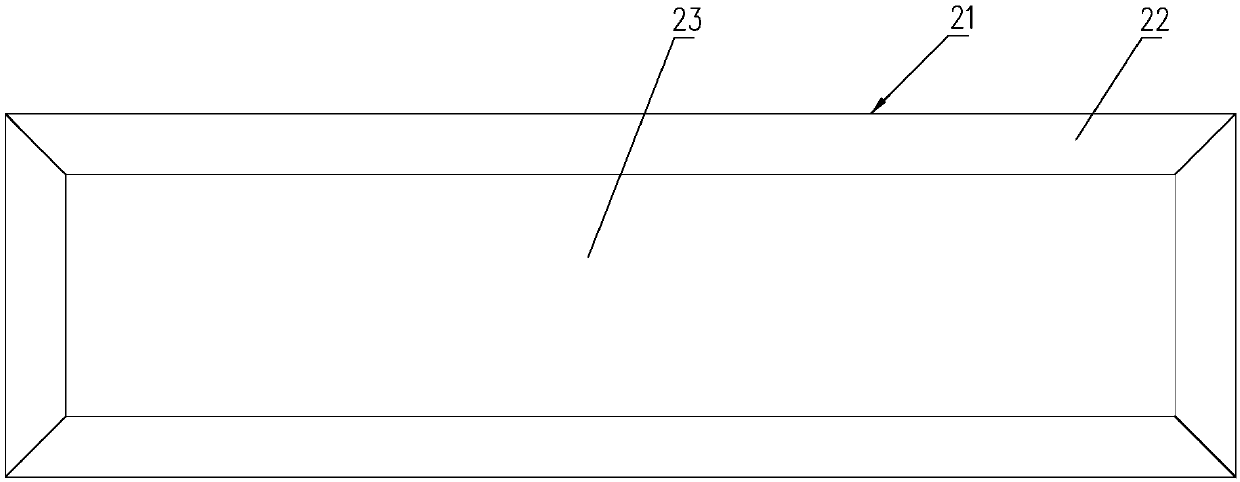

Ultra-high performance concrete (UHPC) combined deck slab with formwork

PendingCN107604815AHigh compressive strengthSmall water absorptionBridge structural detailsPrismRebar

The invention discloses an ultra-high performance concrete (UHPC) combined deck slab with a formwork. The UHPC combined deck slab is mainly formed by splicing of a plurality of unit plates. Each unitplate comprises a steel bottom plate and a UHPC slab body arranged on the steel bottom plate. Shear connecting pieces used for connecting the UHPC slab bodies are welded to the steel bottom plates. Each steel bottom plate is a flat thin-wall steel member in a quadrangular prism frustum shape. The adjacent steel bottom plates are connected with internal members of a main beam on the lower portionsof the deck slab, so that the steel bottom plates are connected into a whole. Steel bars connected into a whole are arranged on the upper portions of the shear connecting pieces in the forward direction of a bridge and the transverse direction of the bridge to form an upper edge force bearing steel net of the deck slab, the steel bottom plates and the shear connecting pieces become lower edge force bearing steel bars and shear steel bars of the deck slab correspondingly and serve as the bottom formwork jointly. The deck slab adopts UHPC so that the problems that in the prior art, cracking anddeck pavement damage are likely to occur can be effectively solved; and additionally the formwork engineering quantity can be reduced by a large margin, formwork mounting and demounting work is omitted, and thus the construction efficiency is improved.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

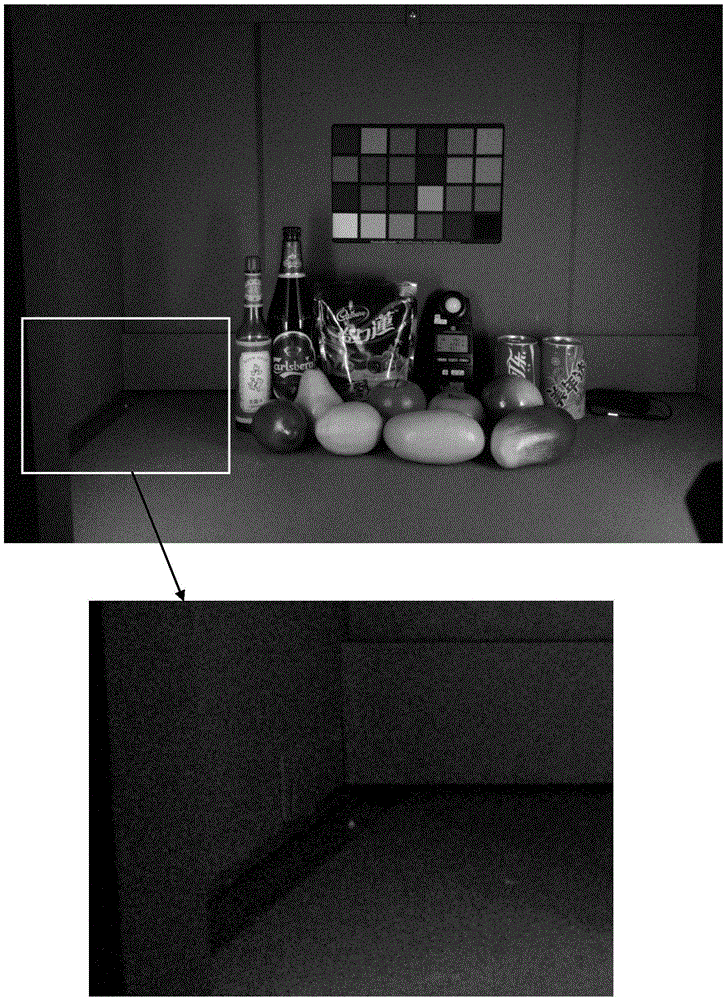

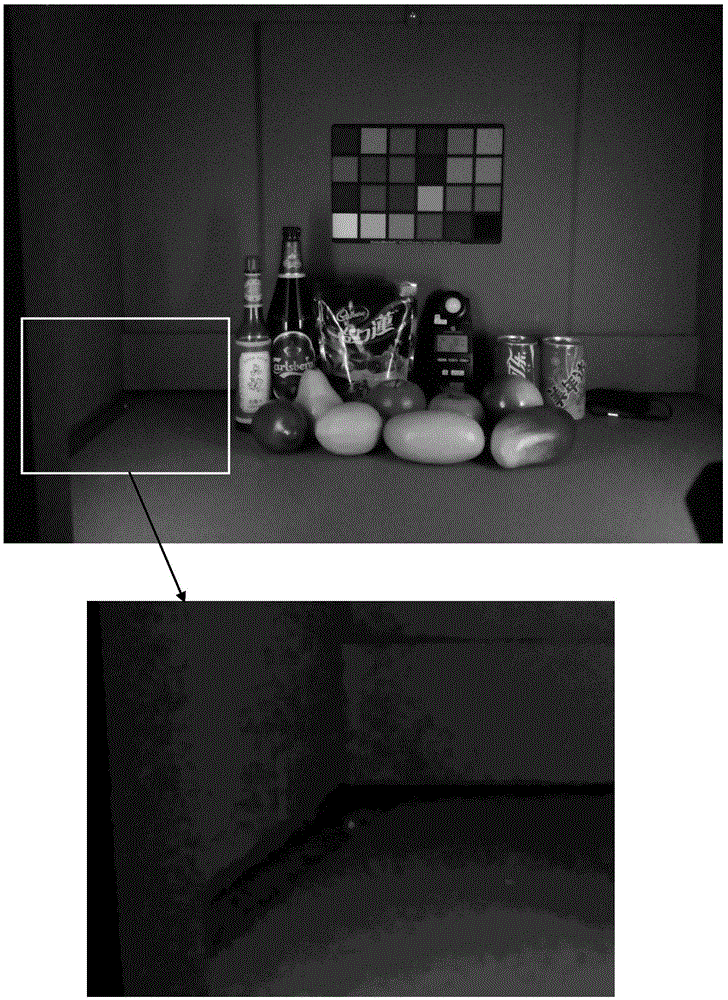

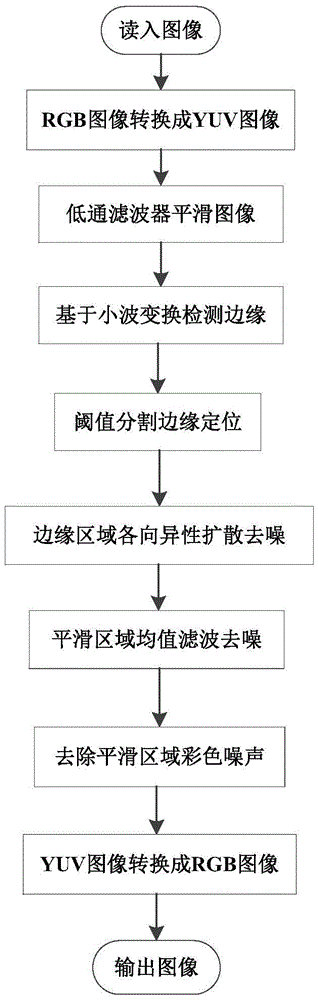

Mobile phone image denoising method based on wavelet transform edge detection

ActiveCN105654445AHigh precisionReduce misjudgmentImage enhancementImage analysisPattern recognitionImage denoising

The invention discloses a mobile phone image denoising method based on wavelet transform edge detection. The mobile phone image denoising method disclosed by the invention can be used for effectively smoothing noise, reserving image edge details and removing colour noise at the same time, so that an ideal denoising effect is obtained. The mobile phone image denoising method disclosed by the invention comprises the following steps: firstly, reading a colour noise image, and converting an input image into a YUV colour space from an RGB colour space; secondly, smoothing the image by adopting a Gaussian filter, and carrying out lowpass filtering on a Y channel image three times; thirdly, detecting the edge of the image by utilizing a wavelet transform algorithm; fourthly, obtaining a binary image of the edge by carrying out threshold segmentation; fifthly, smoothing noise by carrying out anisotropic diffusion at the edge region of the image; sixthly, carrying out mean filtering in a smooth region of the image for denoising; seventhly, further removing the colour noise from the image in the smooth region; and eighthly, converting the image into the RGB colour space from the YUV colour space to obtain a final denoised image.

Owner:SOUTHEAST UNIV

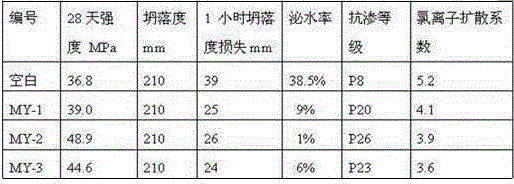

Chloridion-corrosion resistant concrete synergist and production technology thereof

The invention discloses a chloridion-corrosion resistant concrete synergist. The component percentage is anti-bleeding component : anti-permeability waterproof component : enhancing component : dispersing component : entraining component : coordinating component; the anti-bleeding component comprises polysaccharide and / or cellulose ether and / or polyacrylamide, the anti-permeability waterproof component comprises methyl sodium silicate and / or organosilicon waterproofing agent, the enhancing component comprises glycol monoisopropanolamine, composition of the glycol monoisopropanolamine and triethanolamine and triisopropanol, the dispersing component comprises MF and / or TCL and / or NNO, the entraining component comprises dodecyl benzene acid sodium and / or dodecyl benzene sodium sulfate, and the coordinating component comprises polymeric alcohol amine and polymeric polyhydric alcohol. The invention further provides a production technology for the chloridion-corrosion resistant concrete synergist. The chloridion-corrosion resistant concrete synergist is capable of improving the concrete strength, reducing the bleeding rate and reducing the slump loss.

Owner:株洲市中建新材料有限公司

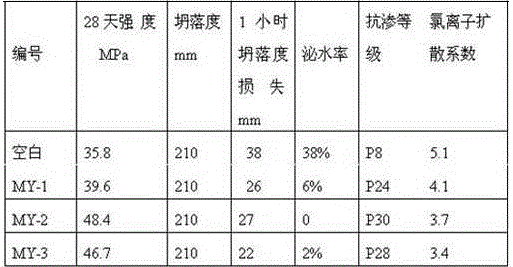

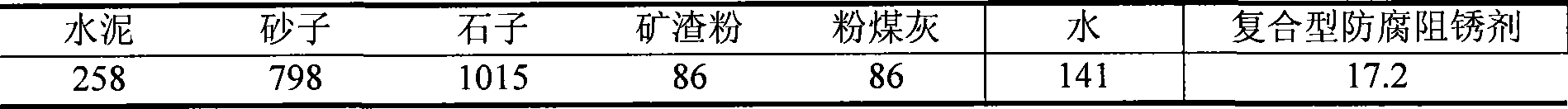

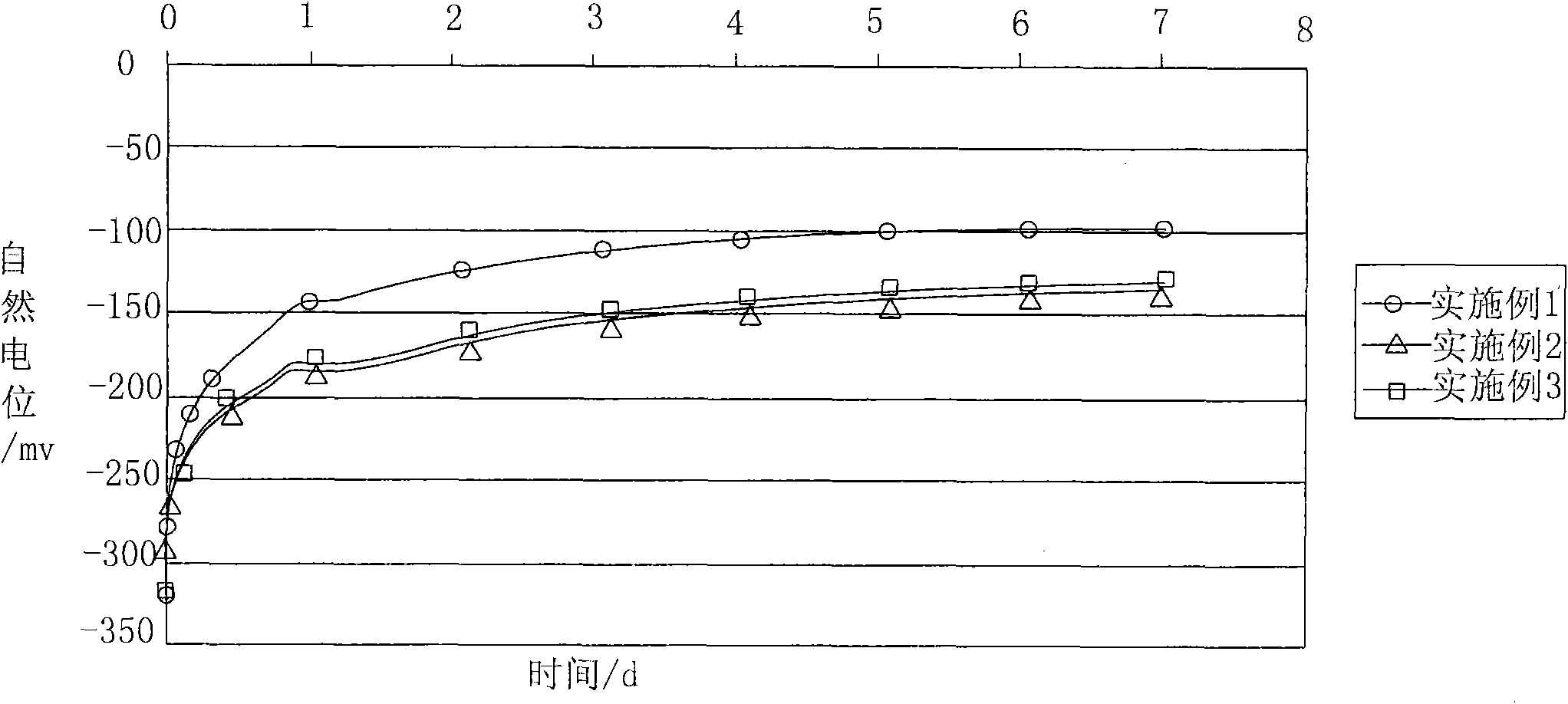

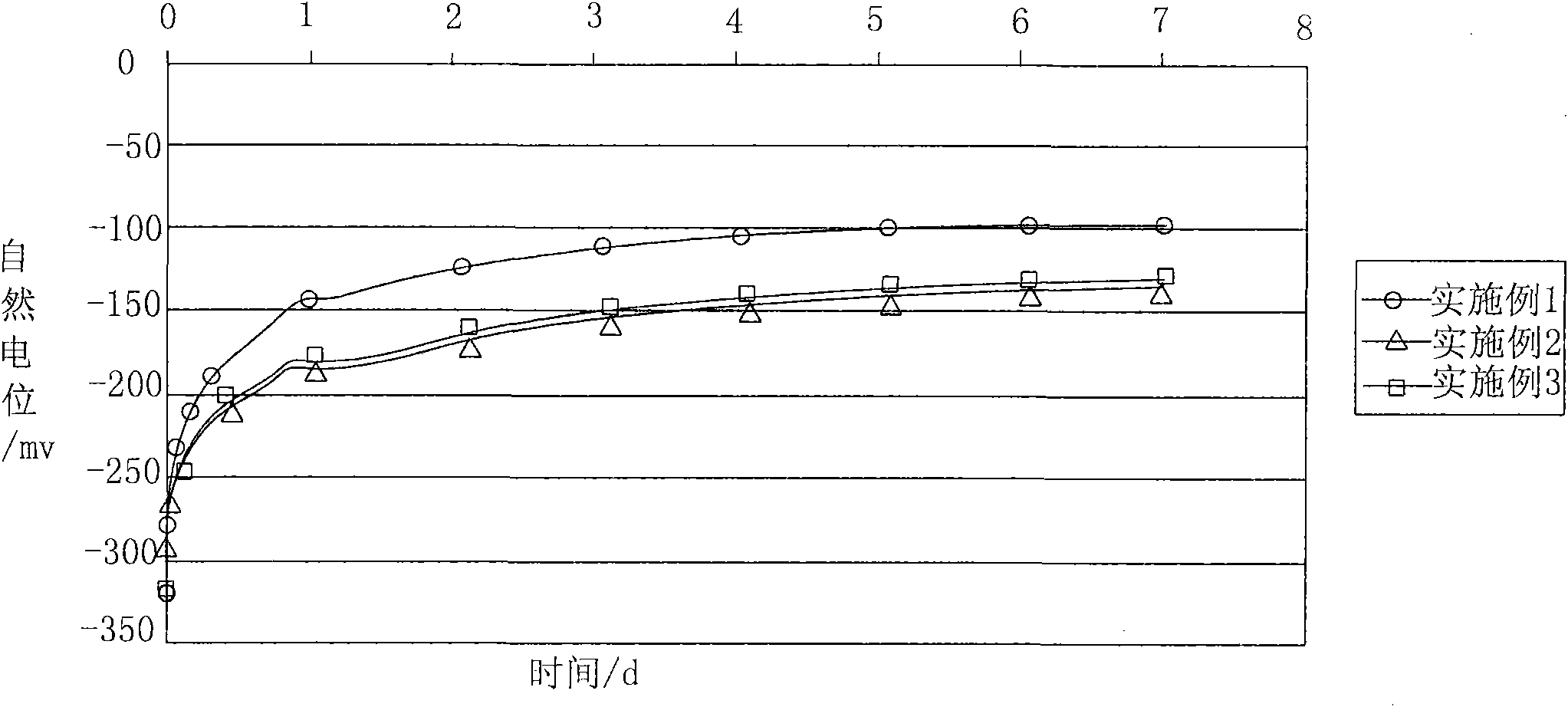

Composite anti-corrosive rust inhibitor for preparing high-durability concrete

The invention provides a composite anti-corrosion and anti-rust agent for preparing high-durability concrete, which comprises the following components in weight portion: 20 to 30 portions of anti-corrosion and anti-rust agent, 20 to 30 portions of super plasticizer, 1.0 to 3.0 portions of collapse protecting agent, 0.5 to 2.0 portions of adhesion promoter, 0.20 to 0.40 portion of air entraining agent, 0.05 to 0.20 portion of antifoaming agent, and 35 to 60 portions of water. The composite anti-corrosion and anti-rust agent has the advantages that the prepared concrete not only has anti-corrosion and anti-rust effects, but also can achieve good concrete fluidization, good cohesiveness, good collapse protecting property, small diffusion coefficient (Da) of concrete chloride ion, and good freezing-thawing resistant circulating property under the condition of low water to glue ratio.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION

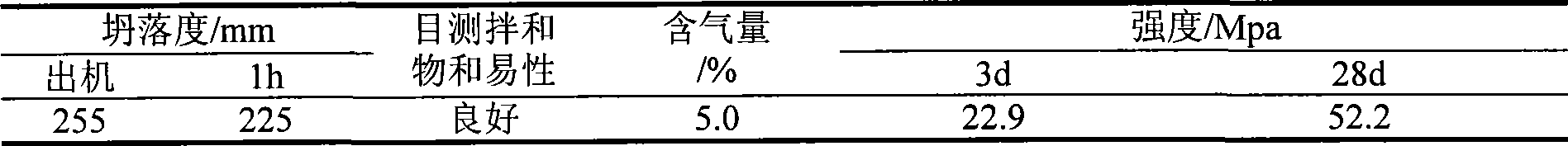

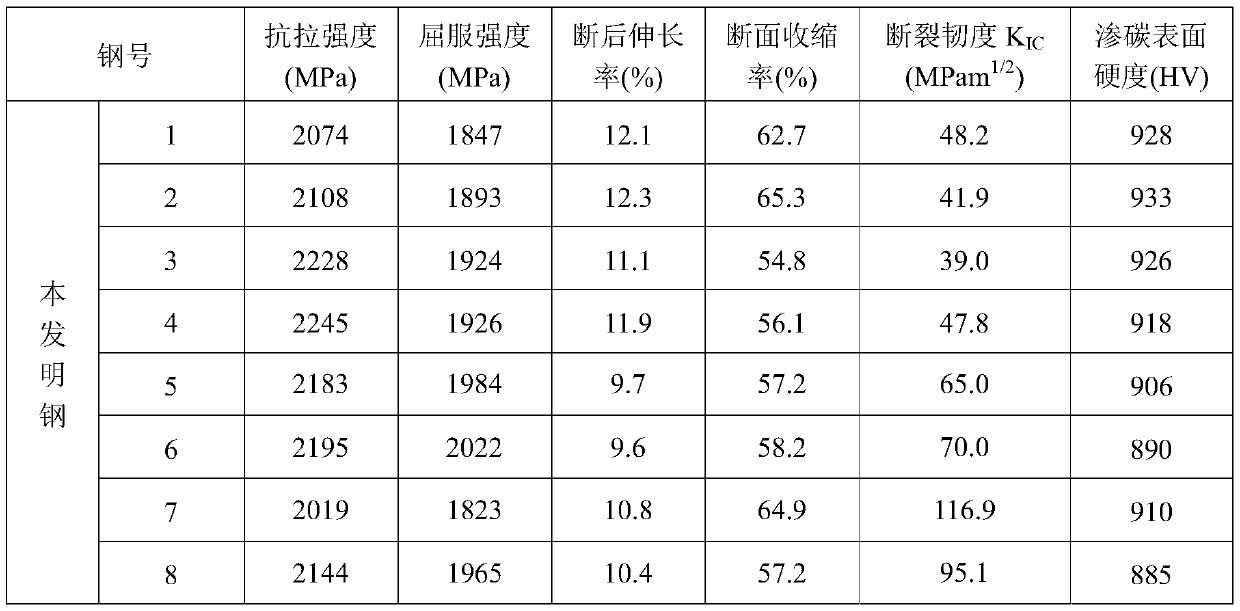

Ultra-high-strength heat-resistant gear bearing steel with ultra-hardened surface layer and preparation method thereof

ActiveCN110423955AHigh tensile strengthImprove plasticitySolid state diffusion coatingCarburizingVacuum arc remelting

The invention belongs to the technical field of materials, and relates to an ultra-high-strength heat-resistant gear bearing steel with ultra-hardened surface layer and a preparation method thereof. The chemical composition of the steel comprises the following chemical components of, in percentage by mass, 0.08-0.18% of C, 10.0-16.0% of Co, 3.0-8.0% of Ni, 3.0-7.0% of Cr, 3.0-6.0% of Mo, 0.5-2.0%of W, 0.2-1.0% of V, 0-0.1% of Nb, and the balance Fe and impurity elements. According to the method, vacuum induction melting, vacuum induction melting and vacuum arc remelting or vacuum induction melting and electroslag remelting are adopted for smelting. Steel ingots are diffusion annealed and forged into steel products. Steel samples are subjected to preliminary heat treatment, carburization and final heat treatment, the tensile strength of the steel is not less than 1900 MP a, the yield strength is not less than 1600 MP a, and the carburized surface hardness is not less than 850 HV (equivalent to 66 HRC). The method has the advantages that compared with the prior art, the method has higher tensile strength, yield strength and relatively good plasticity, toughness and heat resistance,has excellent surface carburization super-hardening performance and fatigue performance, and achieves good matching of the core super-toughening and surface super-hardening.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

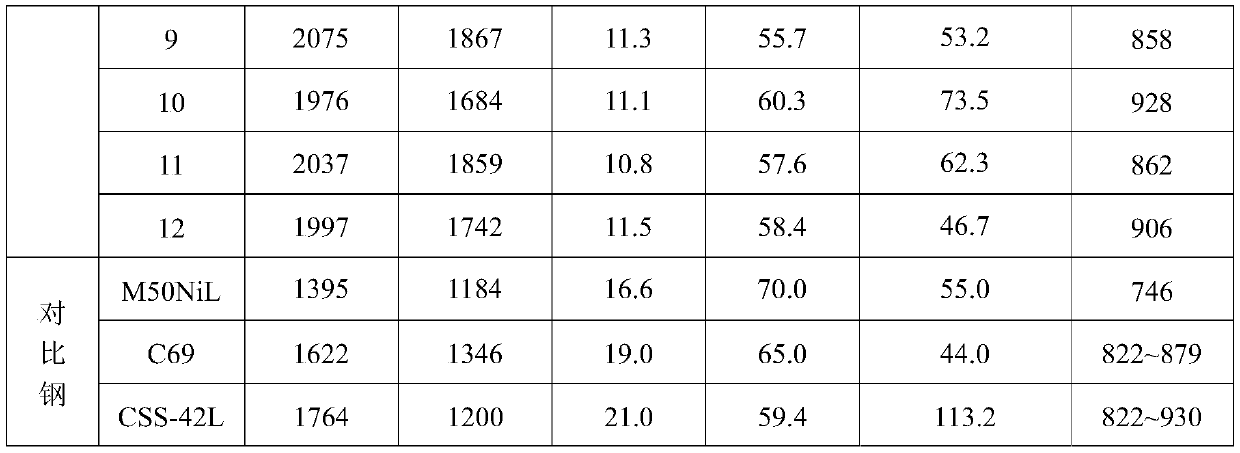

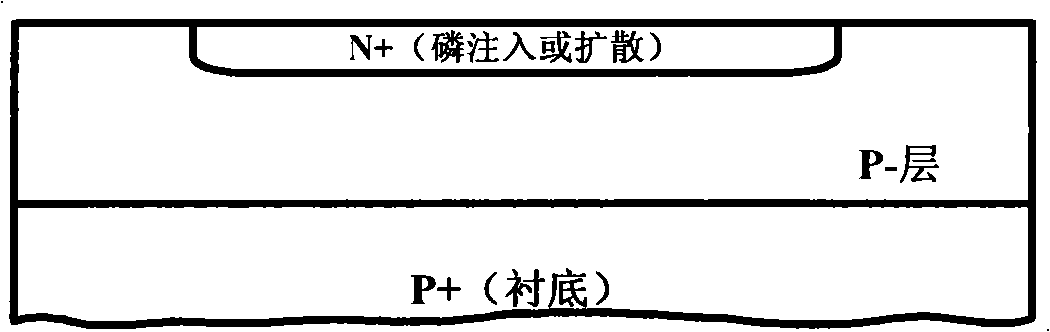

Preparation method of diode chip on P+ substrate and structure of diode chip

ActiveCN102142370AGuaranteed uniformityAvoid side penetrationSemiconductor/solid-state device manufacturingSemiconductor devicesRing deviceLow voltage

The invention discloses a preparation method of a diode chip on a P+ substrate and a structure of the diode chip. The method comprises the following steps of: directly forming a P- epitaxial layer on the P+ substrate through epitaxy; forming a P+ well through filling boron; annealing a P well; forming an N- ring region through photoetching and etching; annealing the N- ring; forming an N+ main junction region through photoetching and etching; annealing the N+ main junction region; evaporating or sputtering A1 as a positive electrode and the like. In the structure, special structures of the P-epitaxial layer, the P+ well and an N- voltage dividing ring device, and an N+ arsenic filling process are adopted to ensure that the N+ / P+ is broken down on a plane and to avoid lateral breakdown; the voltage of a diode formed on the P+ substrate is reduced to be lower than 5.1V, the lowest voltage can reach 2.0V, and leakage current is within 100uA, so that the uniformity of the voltage in the chip is ensured to be within 5%; and in fact the diode is a P-N junction formed by the P well and an N+ region. The structure is successfully applied to the fields of a low-voltage voltage-regulator diode and a low-voltage transient voltage suppressor diode.

Owner:CHENGDU SILAN SEMICON MFG

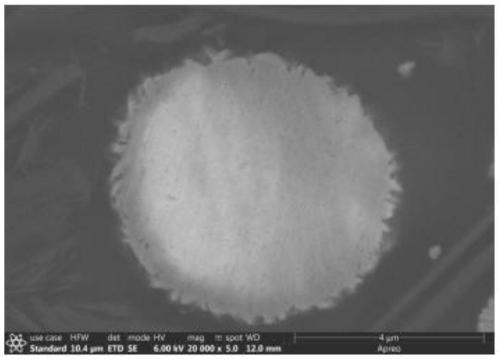

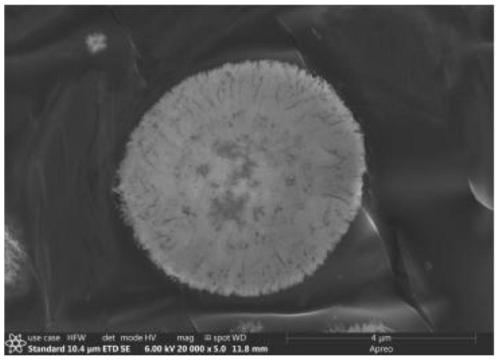

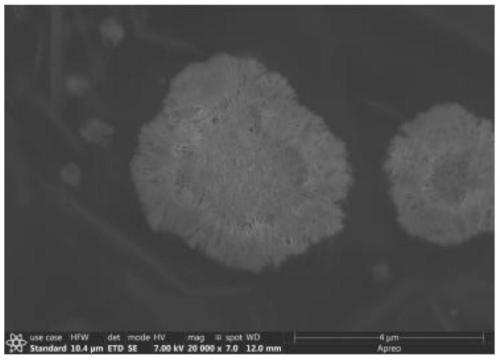

Metal vanadate compound co-doped high-nickel ternary precursor and preparation method thereof

ActiveCN111547780AAvoid shufflingHigh saturationSecondary cellsPositive electrodesMaterials scienceManganese

The invention provides a metal vanadate compound co-doped high-nickel ternary precursor and a preparation method thereof. A metal vanadate compound is doped in the coprecipitation reaction process, sothat one or two or more metals are synergistically doped to modify a nickel, cobalt and manganese or aluminum ternary precursor material; in the preparation process, a complexing agent solution and ametal solution are equally divided into an upper liquid inlet pipe and a lower liquid inlet pipe, and added into a reaction kettle; different regulation and control modes and growth process parameters are adopted in different stages of precursor growth; the ternary precursor with special primary particle morphology such as a flower sheet shape, a slender spindle shape, a thick and short rod shapeand the like or loose, porous, dense, hollow and other section morphology inside can be prepared, and the requirements of lithium batteries with different properties on precursors with different physical properties can be met.

Owner:ZHUJI PAWA NEW ENERGY

Extraction technology of perilla frutescens essential oil

The invention relates to an extraction technology of a perilla frutescens essential oil. The technology comprises: cleaning, wall breaking, freezing drying, crushing and screening, as well as cycling extraction. The invention adopts ultrasonic wall breaking so as to make the subsequent extraction faster and reduces production cost. Employment of a freezing sublimation drying technology can reserve all the components in plants to the utmost, and the vacuum state avoids the influence of oxidation on drug effect. Meanwhile, essential oil yield is obviously improved. Carbon dioxide is an optimal extracting agent for pure natural substance extraction. As carbon dioxide has low viscosity and high diffusion coefficient, so that the extraction efficiency and the product yield can be high. Carbon dioxide is easily available and inexpensive, and is recyclable during extraction, thus reducing cost. As carbon dioxide is incombustible and non combustion-supporting, production sites have no danger. The invention makes use of the supercritical temperature of carbon dioxide for low temperature extraction so as to exempt biologically active substances from thermal degradation and other undesired auxiliary reactions.

Owner:JIANGSU NATURAL FOOD

Narrow-hardenability pinion steel and preparation method thereof

ActiveCN102400052AImprove hardenabilityHardenability improved and stabilizedManufacturing convertersProcess efficiency improvementTemperature resistanceWear resistance

The invention provides a narrow-hardenability pinion steel which comprises the following components in percentage by weight: 0.18%-0.22% of C, 0.20%-0.30% of Si, 0.90%-1.15% of Mn, less than or equal to 0.030% of P, less than or equal to 0.030% of S, 1.00%-1.35% of Cr, 0.04%-0.08% of Ti, 0.004%-0.005% of B, 0.025%-0.038% of W, less than or equal to 11.5*10<-6> of [O], less than or equal to 1.5*10<-6> of [H], 35*10<-6>-45*10<-6> of [N] and the balance of Fe and inevitable impurities. The invention provides a preparation method of the narrow-hardenability pinion steel. The preparation method comprises the following steps: 1) primary smelting based on a top-bottom blowing converter; 2) ladle deoxidizing and alloying; 3) LF (ladle furnace) refining; 4) RH refining; and 5) continuous casting. Compared with the prior art, the narrow-hardenability pinion steel provided by the invention has the characteristics of better wear resistance and high temperature resistance, higher hardenability andnarrower jominy hardenability.

Owner:WANGUAN SMELTING MOLD CASTING

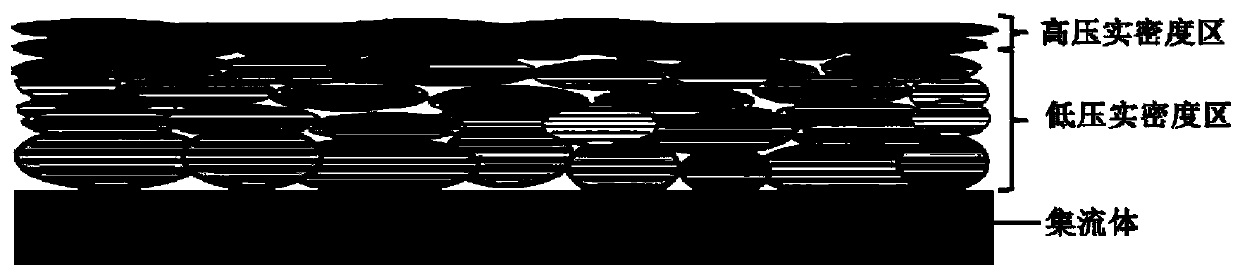

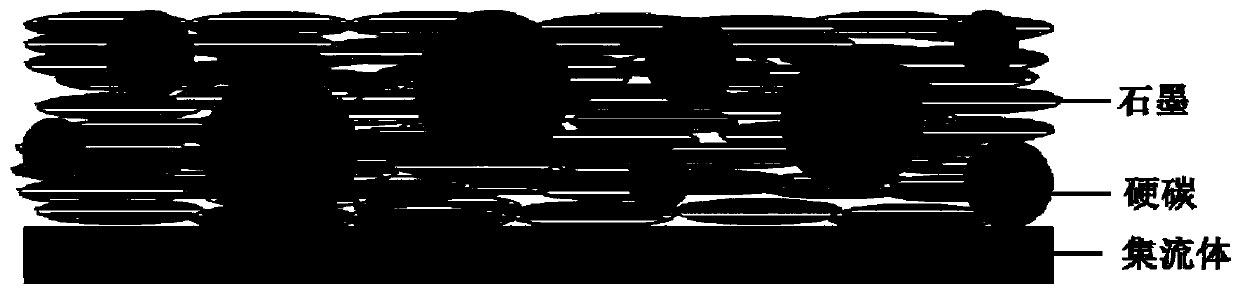

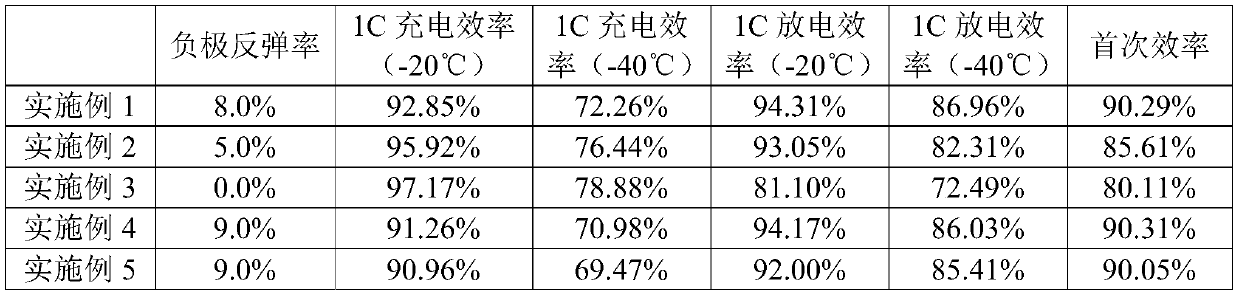

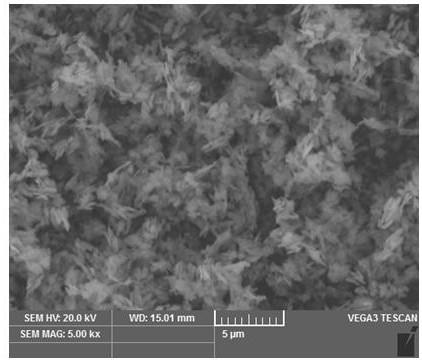

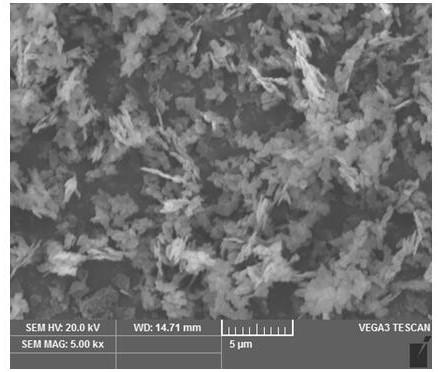

Anode material and preparation method thereof, prepared anode plate and lithium ion battery

ActiveCN110690436AImprove low temperature charging performanceSolve the problem of low charging capacity at low temperatureElectrode manufacturing processesSecondary cells servicing/maintenanceElectrical batteryNew energy

The invention discloses an anode material and a preparation method thereof, a prepared anode plate and a lithium ion battery. The anode material comprises graphite and hard carbon, and the particle size of the graphite is less than or equal to the particle size of the hard carbon and the mass content of the hard carbon in the anode material is less than or equal to the mass content of the graphite. According to the invention, hard carbon with a large particle size and graphite with a small particle size are compounded as the anode material, and the content relationship between hard carbon andgraphite in the anode material is controlled, so that the problem that the charging electric quantity of a power lithium ion battery for a new energy vehicle is far lower than the rated capacity at alow temperature of-40 DEG C is solved, the lithium precipitation resistance of the battery can be improved, and the charging and discharging safety of the battery under the low-temperature condition is improved. The module assembled by adopting the battery still can ensure the cruising ability of the electric vehicle without losing the self heating energy consumption, the system energy density ishigh, and the normal use requirements of the electric vehicle in winter in cold regions can be met.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

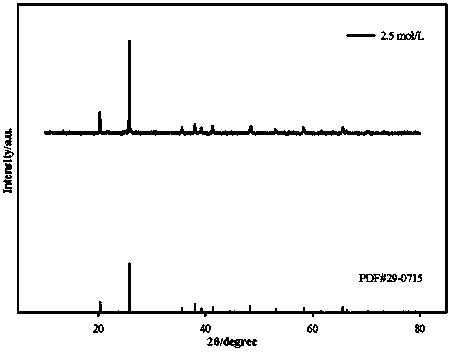

Preparation method for iron phosphate nanosheets

ActiveCN110294466AHigh purityAvoid interferenceMaterial nanotechnologyPhosphorus compoundsFiltrationPhosphate

The invention discloses a preparation method for iron phosphate nanosheets. The preparation method comprises the steps that iron black is slowly added to phosphoric acid with the concentration of 1.5-3.0 mol / L, stirring and heating are conducted for reacting, and after the reaction, the iron phosphate nanosheets are obtained through suction filtration, washing, drying, dewatering and other steps.The iron phosphate prepared by using the method has a nanosheet-shaped morphology, the thickness of the nanosheets is 70-80 nanometers, and the specific surface area is high. By optimizing the reaction conditions, in the reaction procsess, the pH value does not need to be adjusted, and no oxidizing agents are added; the interference with anionic and cationic impurities is effectively avoided, theiron phosphate obtained by using the method is free of impurity phases and high in purity. Besides, less water is used for washing iron phosphate precipitation, the iron phosphate synthesizing cost isreduced, and the pollution to the environment is reduced. The technology is simple, operation is convenient, industrial production is facilitated, and the preparation method is wide in application prospect.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

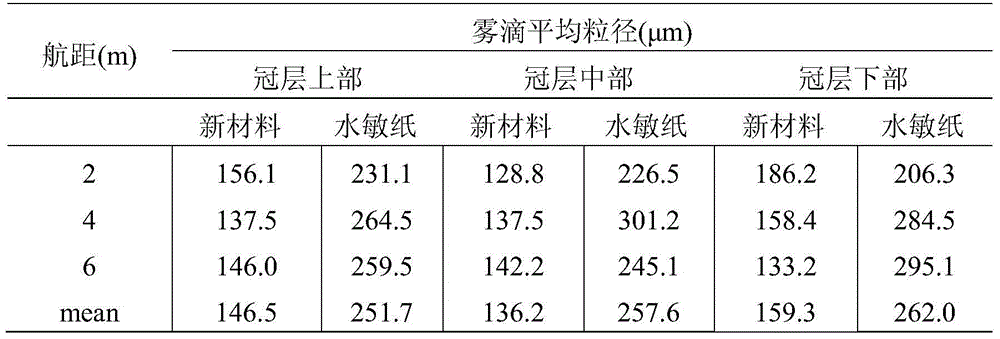

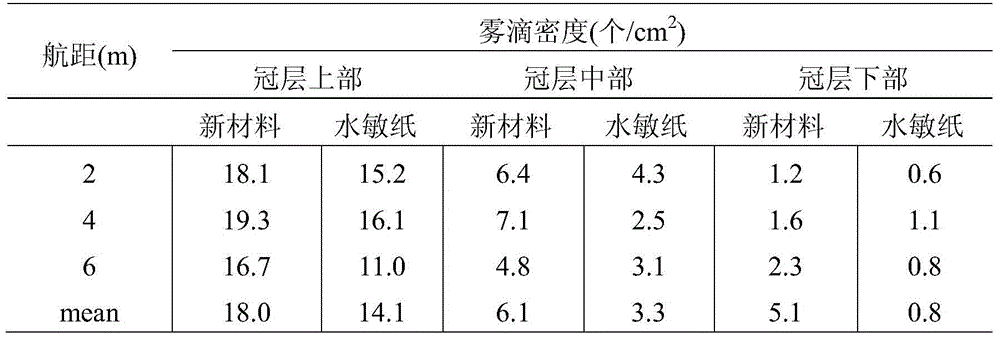

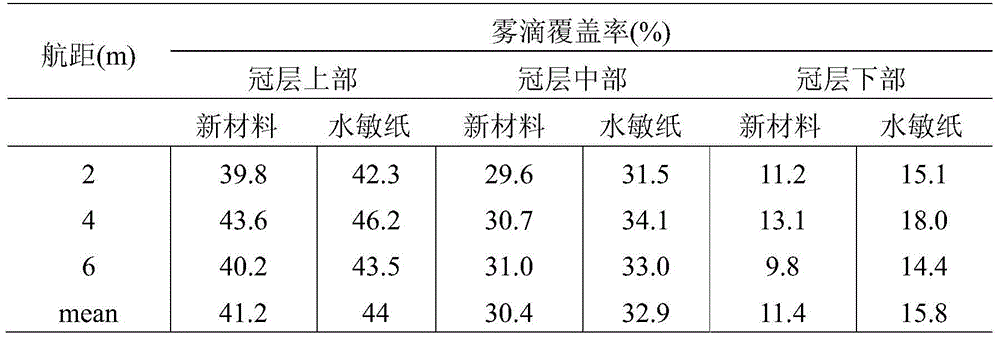

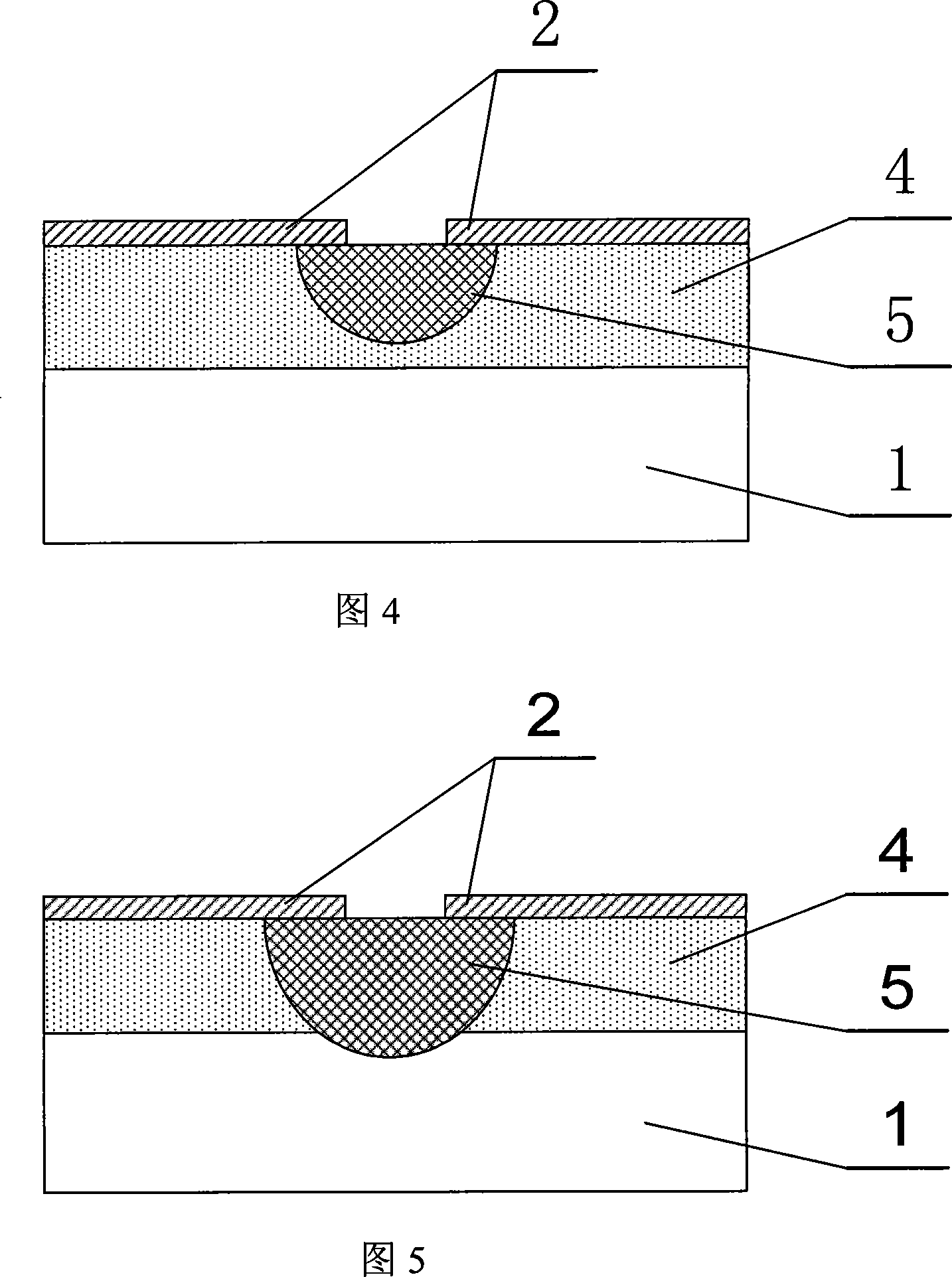

Humidity sensing ceramic, and preparation method and application thereof

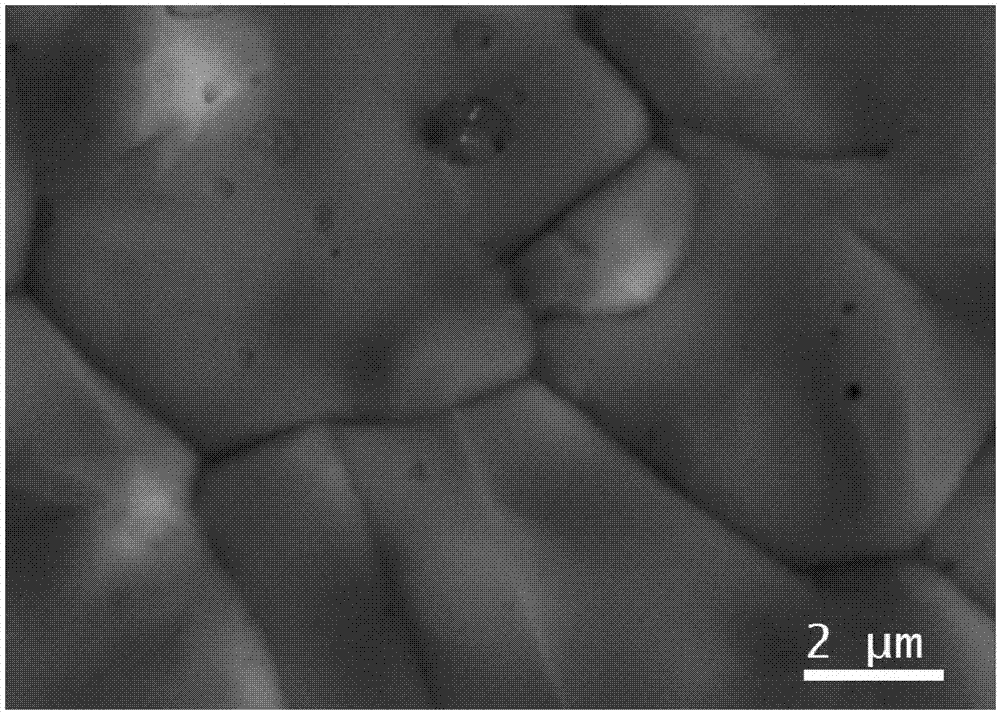

ActiveCN105753509AChange contact angleDiffusion coefficient is smallMaterial analysisElectrical resistance and conductanceCeramic substrate

The invention provides a humidity sensing ceramic and a preparation method thereof. An organosilane modification layer is arranged on the surface of a humidity sensing ceramic substrate, and the surface contact angle is 85 to 95 degrees. The organosilane is used for modifying the surface of the humidity sensing ceramic; the contact angle of fog drops deposited on the surface of the ceramic is changed; the diffusion coefficient of the fog drops on the surface of the humidity sensing ceramic is reduced. The invention also discloses a fog drop deposition sensor prepared by the humidity sensing ceramic and application of the fog drop deposition sensor to the unmanned aerial vehicle chemical spraying fog drop deposition characteristic detection. The fog drop deposition sensor provided by the invention has the advantages that information such as fog drop average particle diameter, fog drop density, fog drop covering rate and distribution uniformity can be accurately detected; meanwhile, a detection resistor reflects the relative humidity change; the fog drop deposition quantity comparison conditions of the chemical spraying specific regions can be obtained.

Owner:ZHEJIANG UNIV

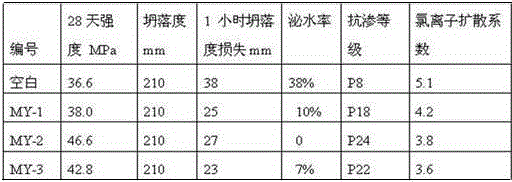

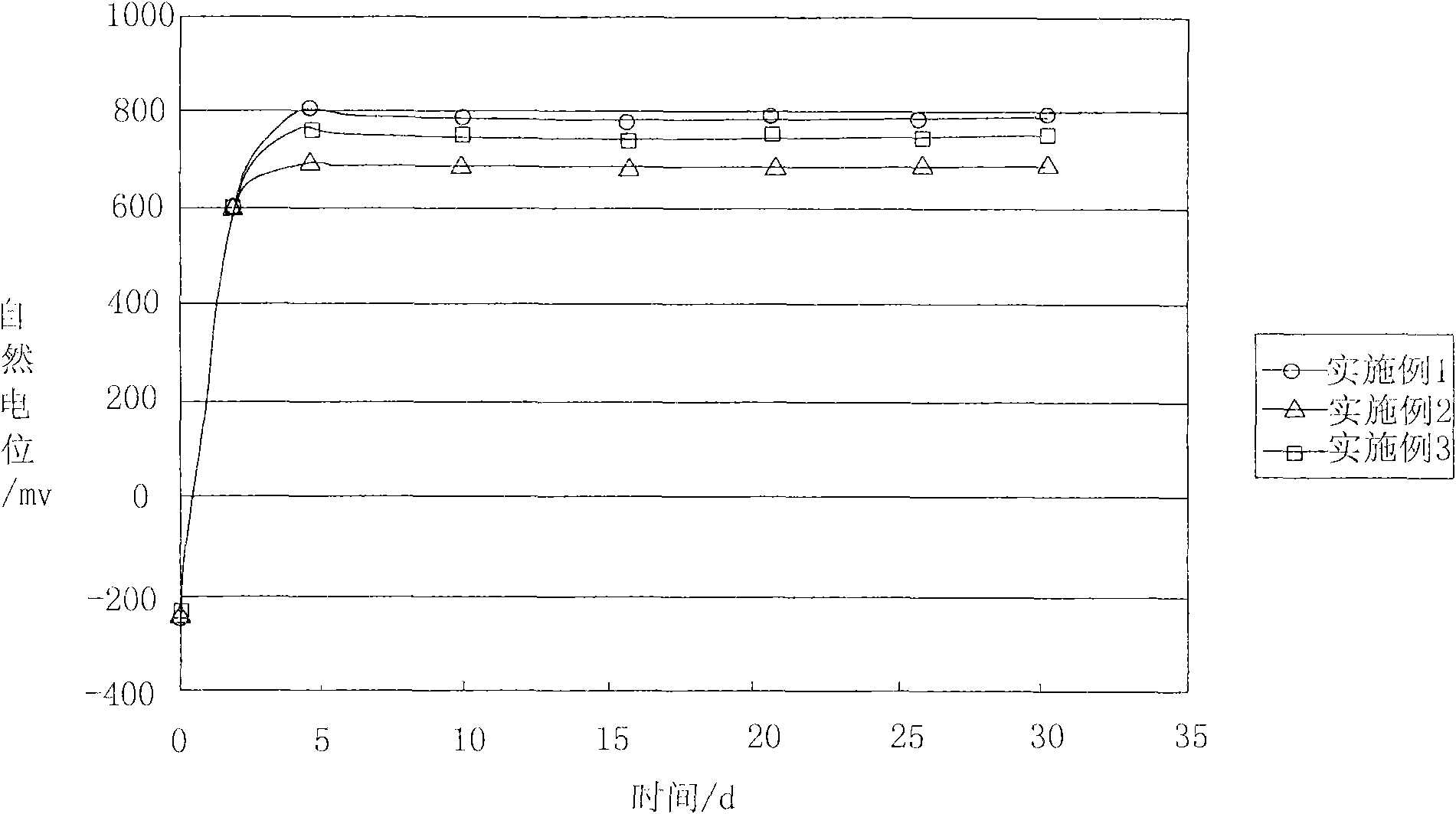

Composite type reinforced concrete rust inhibitor

The invention relates to a composite type reinforced concrete rust inhibitor. The composite type reinforced concrete rust inhibitor comprises the following components by weight percent: an anode type rust inhibitor adopts 20.0 to 30.0 percent of calcium nitrite and 10.0 to 15.0 percent of sodium benzoate; and a cathode type rust inhibitor adopts at least one of sodium hexametaphosphate and zinc oxide, wherein the cathode type rust inhibitor comprises 1.0 to 3.0 percent of sodium hexametaphosphate, 2.0 to 4.0 percent of zinc oxide, 0.001 to 0.005 percent of air entraining agent and the balance of volcanic ash. The rust inhibitor can effectively retard and prohibit the corrosion of reinforcing steel bars in reinforced concrete and can prohibit or delay the destruction of chlorine ions to a reinforced passivating film. The invention has the advantages of little use quantity, use quantity reduction of a single rust inhibitor and the like, is a high-efficiency concrete reinforcement rust inhibitor and can be widely applied to the fresh reinforced concrete structure of the engineering of seaports, railways, coastal buildings, civil buildings and the like.

Owner:浙江五龙新材股份有限公司

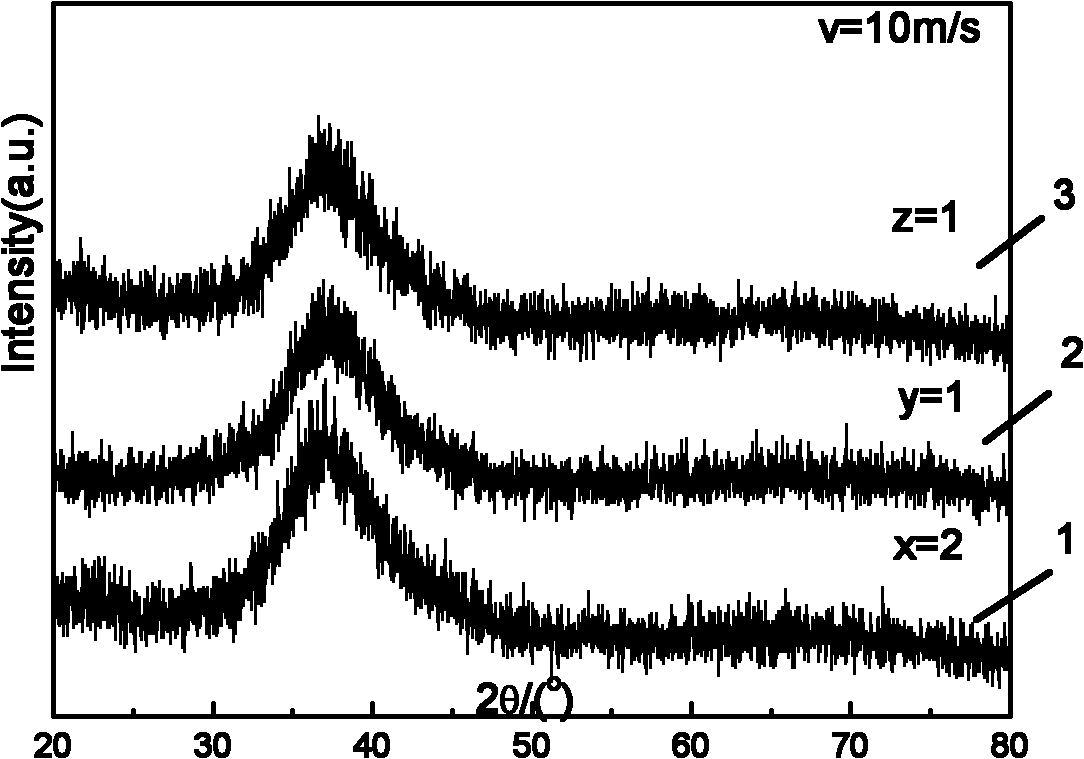

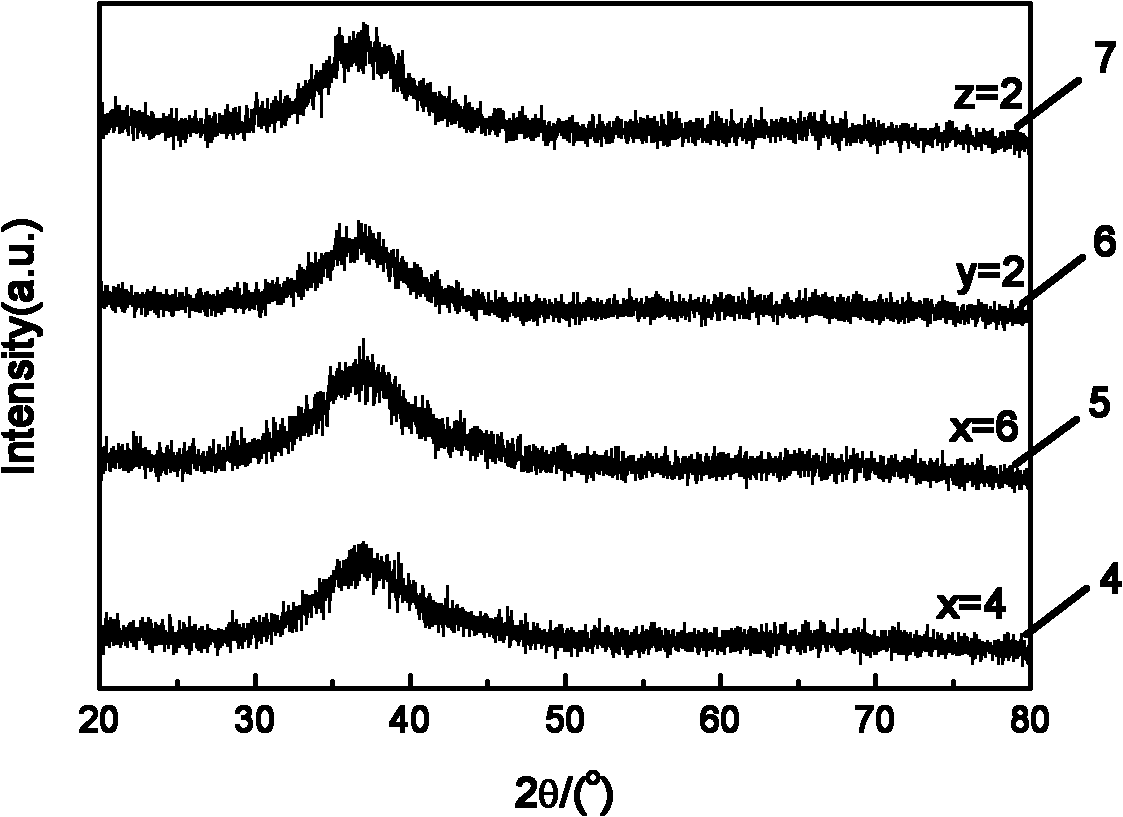

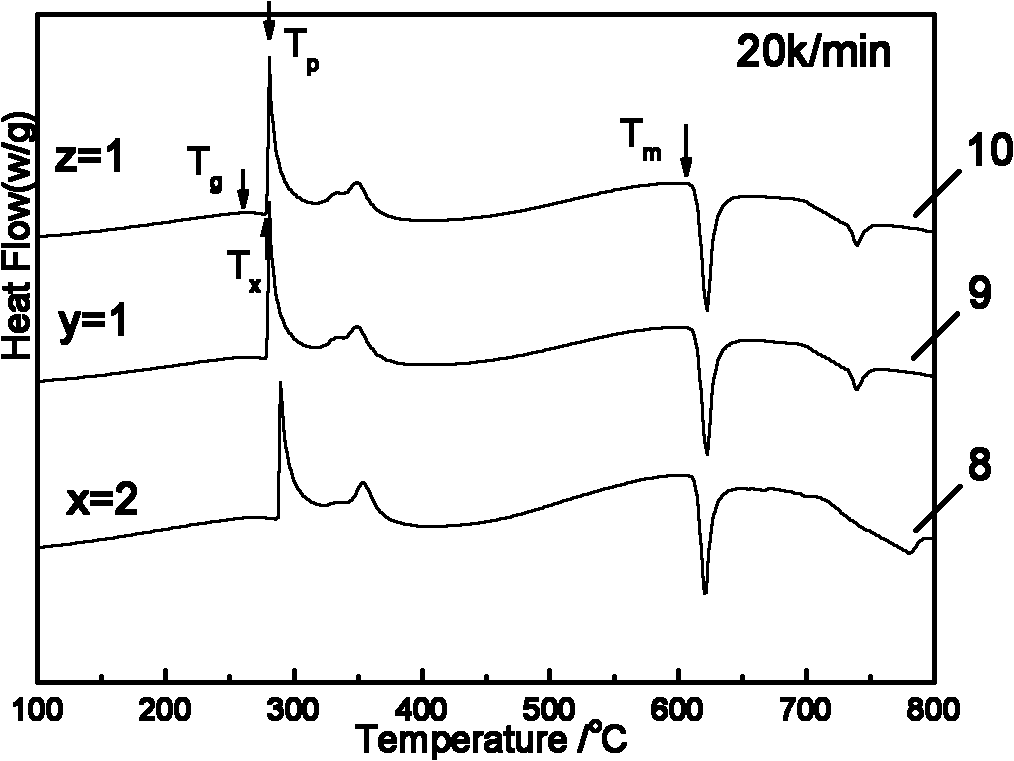

Al-Ni-Ce-La aluminum-based amorphous alloy and preparation method thereof

InactiveCN101838780AIncrease densityIncrease alloy viscosityVacuum induction meltingInjection pressure

The invention relates to an Al-Ni-Ce-La aluminum-based amorphous alloy which comprises the following components: Al84Ni10Ce(6-x)Lax(x=1 to 6, at.%), Al84Ni(10-y)Ce6Lay(y=1 to 3, at.%) and Al(84-z)Ni10Ce6Laz(z=1 to 3, at.%). A method for preparing the Al-Ni-Ce-La aluminum-based amorphous alloy comprises the following steps that: after preparing materials according to the nominal components of the alloy, under the protection of argon gas, a master alloy is prepared by vacuum arc melting or vacuum induction melting; and under the protection of Ar gas, an amorphous strip is prepared by spinning, the minimum linear speed of a copper roller when in spinning is 10m / s, the melt injection pressure is 0.07 to 0.08MPa, and the vacuum degree is 2 to 10-1Pa. The invention has the advantages of reasonable component ratio, strong amorphous forming capability, simple manufacturing method and low requirement on the vacuum degree.

Owner:CENT SOUTH UNIV

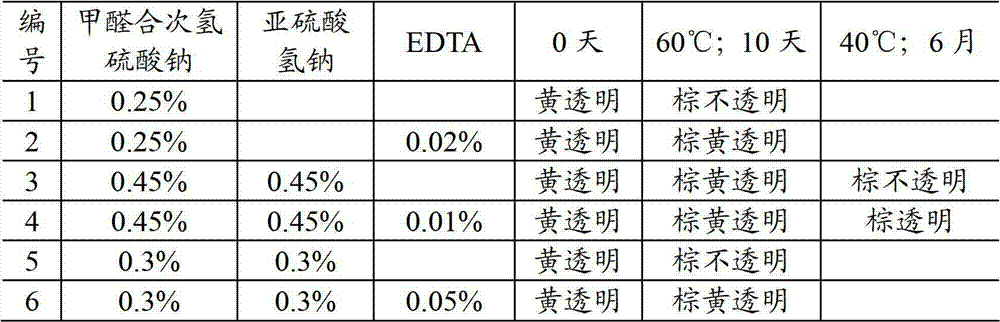

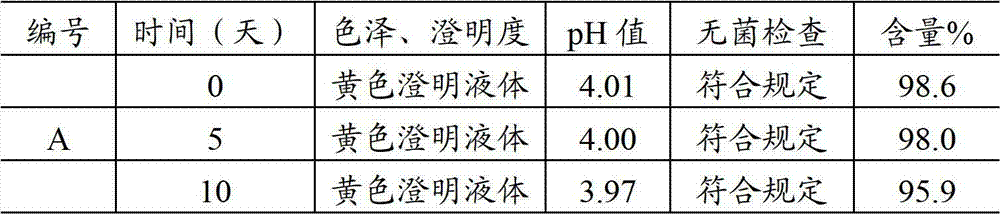

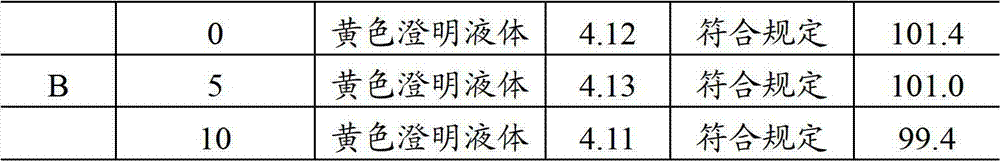

Doxycycline hydrochloride injection for animals and preparation method for doxycycline hydrochloride injection

ActiveCN102772360AImprove stabilityReduce releaseAntibacterial agentsTetracycline active ingredientsTreatment effectOrganic solvent

The invention relates to a doxycycline hydrochloride injection for animals and a preparation method for the doxycycline hydrochloride injection. The method comprises the following steps of: adding a proper amount of antioxygen and a proper amount of stabilizing agent into water for injection; then adding an aqueous solution into an organic solvent; adding doxycycline hydrochloride and a complexing agent; adjusting the pH; preserving the heat; then adding a metal ion chelant and partial antioxygen; and filtering, filling nitrogen and sterilizing to obtain the doxycycline hydrochloride injection for animals. The doxycycline hydrochloride injection prepared by the method is safe and stable; the half-life period is about 30 to 39 hours; the working time of the medicament in the body is prolonged, and the medicating frequency and the using amount are reduced; the treating effect and the treating efficiency are improved; and the doxycycline hydrochloride injection has a wide veterinary clinical application prospect.

Owner:CHINA INST OF VETERINARY DRUG CONTROL

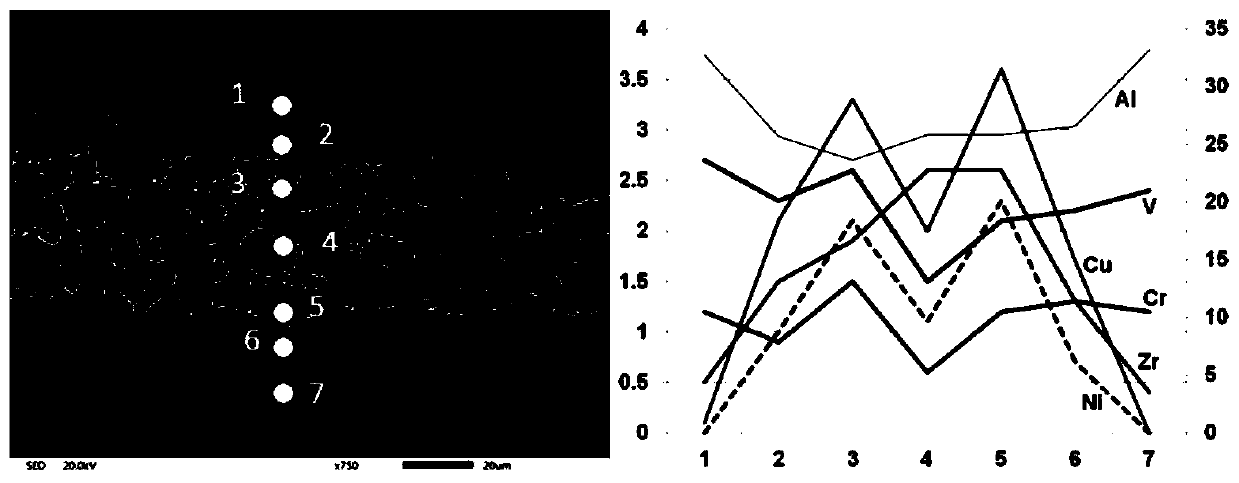

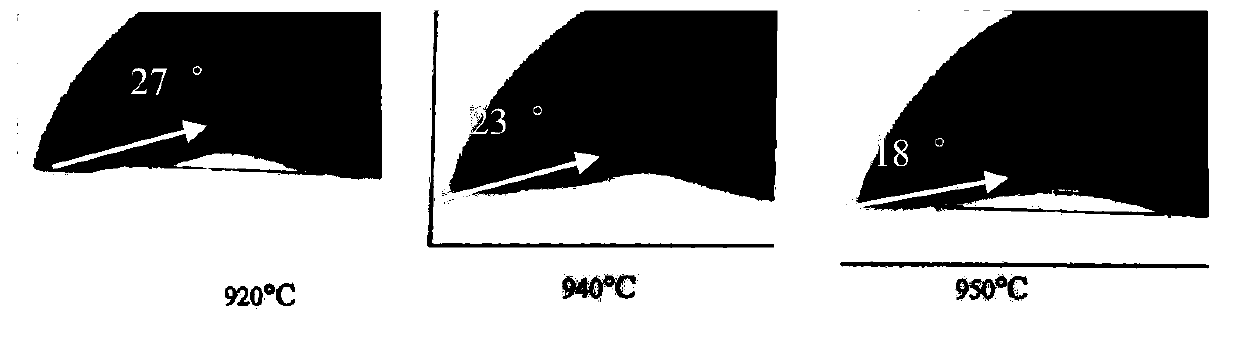

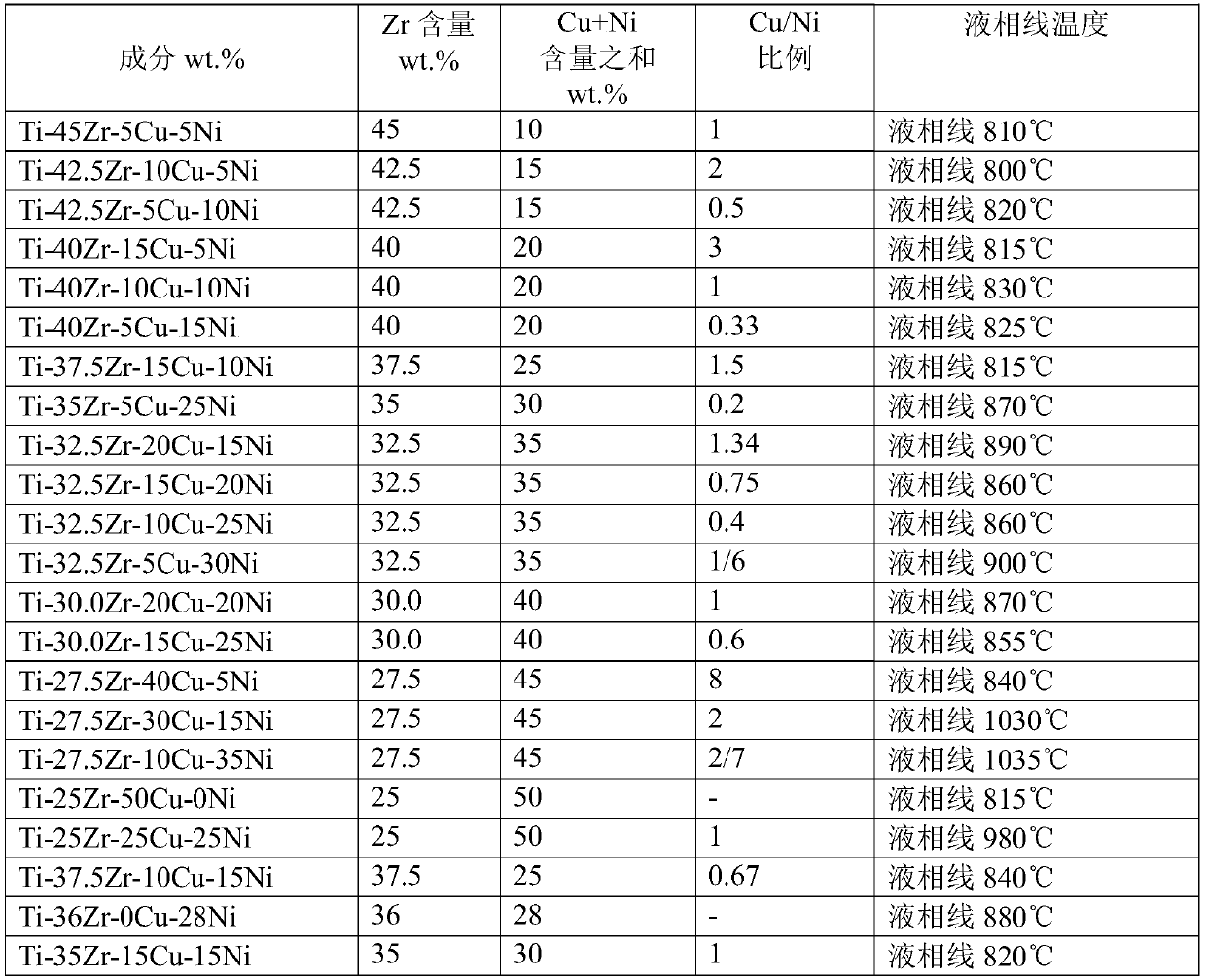

High-temperature-resistant solder capable of being used for welding gamma-tial alloy and welding process thereof

ActiveCN110355496ATake into account the temperatureTaking into account strengthWelding/cutting media/materialsWelding/soldering/cutting articlesRoom temperatureAlloy

The invention relates to a high-temperature-resistant solder capable of being used for welding gamma-TiAl alloy and a welding process thereof, and belongs to the technical field of welding manufacturing. Due to the fact that the gamma-TiAl alloy with the light and temperature-resistant structures is small in the moveable slippage coefficient, the plasticity of the material is low, the processing performance is poor, and at present, aiming at high-temperature-resistant welding of the gamma-TiAl alloy, the high-temperature-resistant solder and the welding process are lack. According to the high-temperature-resistant solder and the welding process, the Tti-Zr-Cu-Ni solder with both strength and toughness is designed, the welding of the gamma-TiAl alloy can be realized at the temperature rangeof 930-950 DEG c, the room temperature tensile strength of the joint reaches more than 90% of the strength of the matrix, namely 510-545 Mpa, the tensile strength of the joint at the temperature of 700-760 DEG c can maintain 70-82% of the strength level of the room-temperature joint, namely in the range of 389-445 Mpa; the welding temperature is lower than the heat treatment temperature and phasechange point of the matrix material, and the structure and the performance of the welded metal are not obviously influenced.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Hoop surface hot dip coating tin alloy process

InactiveCN105586557ALow melting pointImprove corrosion resistanceHot-dipping/immersion processesTinningMetal coating

The invention discloses a hoop surface hot dip coating tin alloy process. The hoop surface hot dip coating tin alloy process comprises the steps of sanding, alkali wash oil removal, acid pickling, plating assisting, preheating, hot dip coating and analysis and detection. According to the hoop surface hot dip coating tin alloy process, no harmful heavy metal ion or phosphorus or sediment exists, heating is not needed, the treatment time is short, the number of treatment steps is small, a surface adjusting procedure can be omitted, hot drip coating can be reused, and the adhesive force of a metal coating to a substrate is effectively improved.

Owner:大连新锋钢管厂

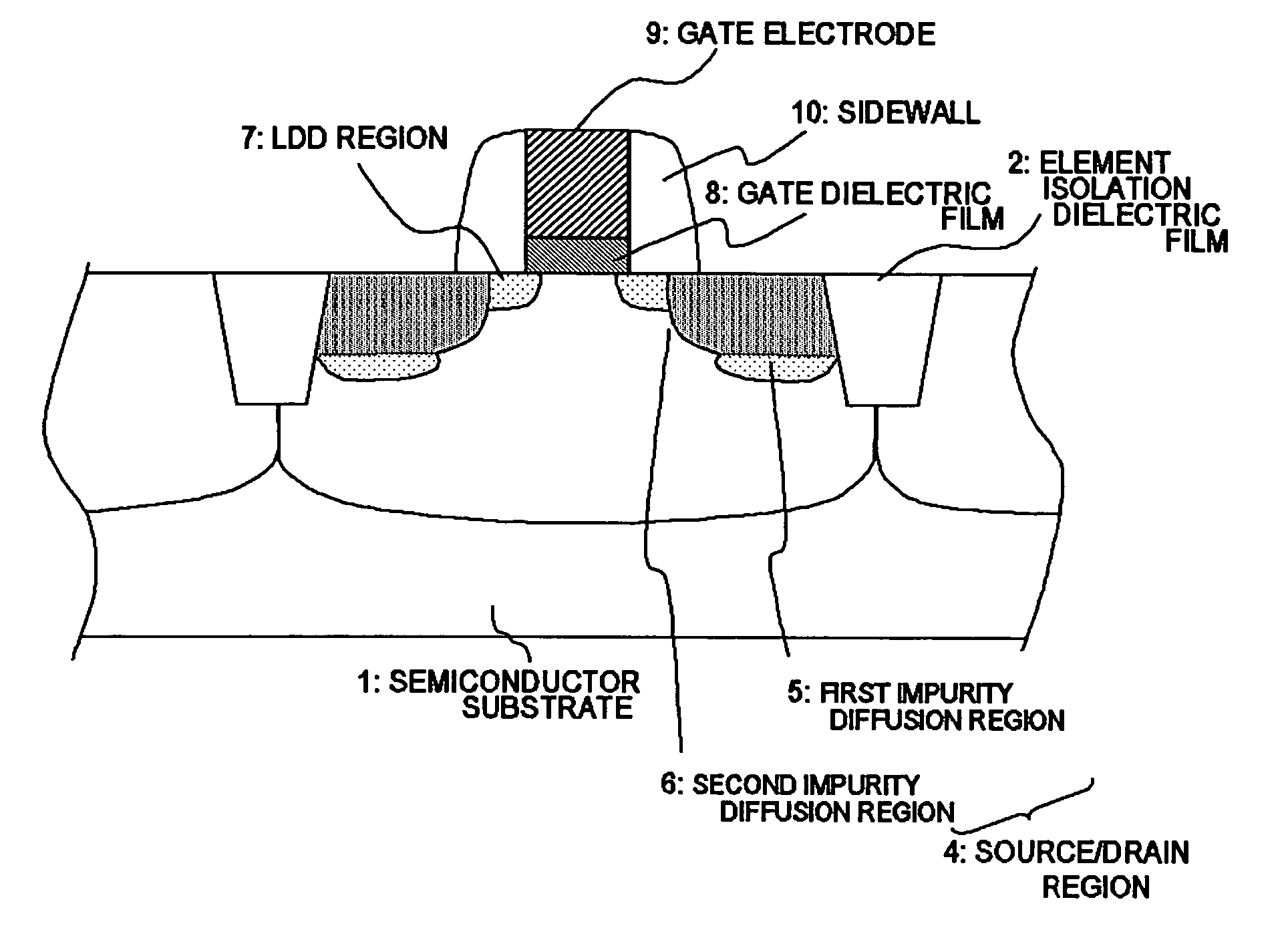

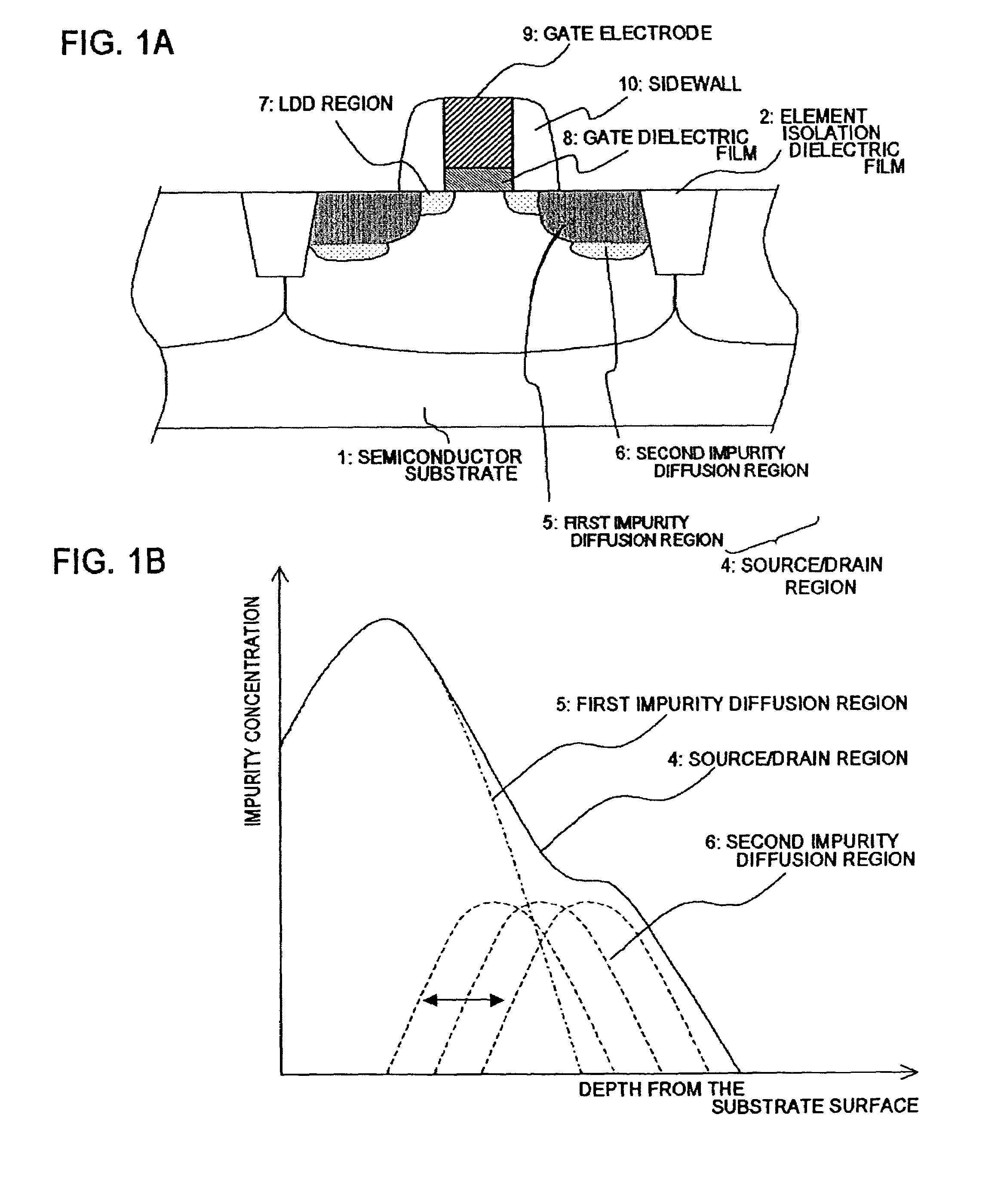

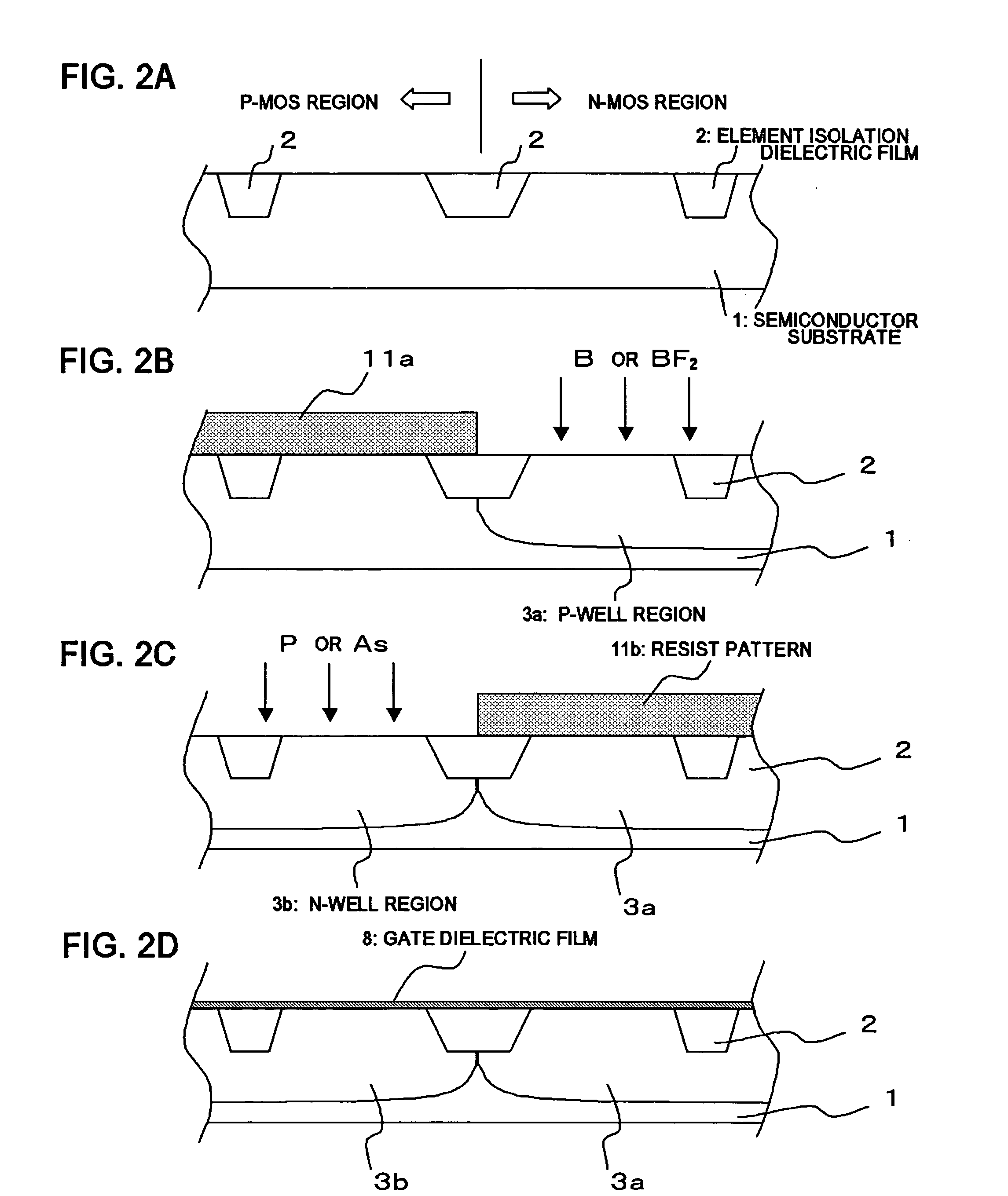

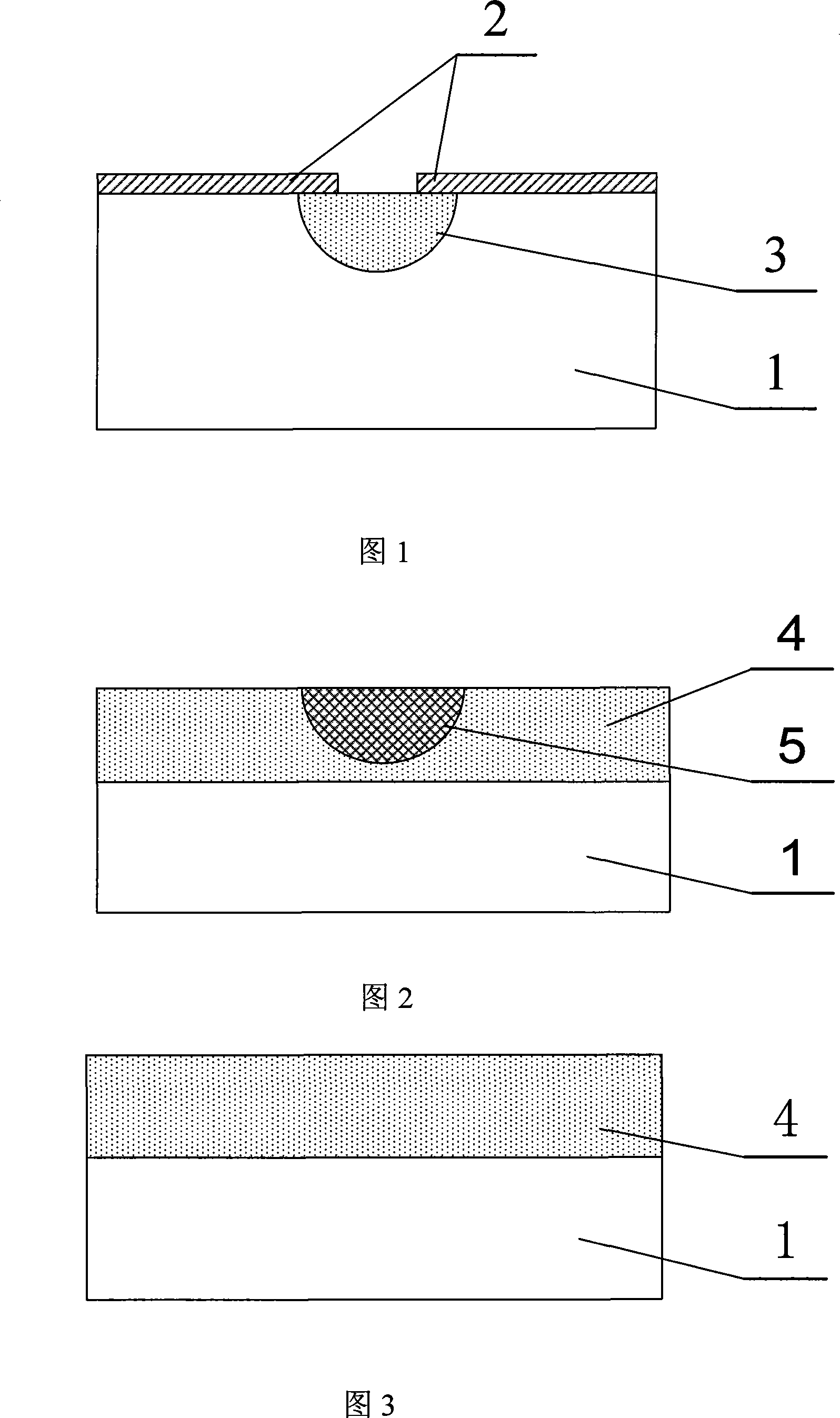

Semiconductor device and method of manufacturing the same

InactiveUS7030464B2Prevent junction leakageReduced short channel restraining effectTransistorSolid-state devicesJunction leakageImpurity diffusion

A technology of restraining junction leakage in a semiconductor device is to be provided. There is provided a semiconductor device provided with a semiconductor substrate, a gate electrode 9 formed on the semiconductor substrate, and a source / drain region formed beside the gate electrode, wherein the source / drain region 4 comprises a first impurity diffusion region including a first P-type impurity and located in the proximity of a surface of the semiconductor substrate, and a second P-type impurity diffusion region located below the first impurity diffusion region and including a second P-type impurity having a smaller diffusion coefficient in the semiconductor substrate than the first P-type impurity.

Owner:RENESAS ELECTRONICS CORP

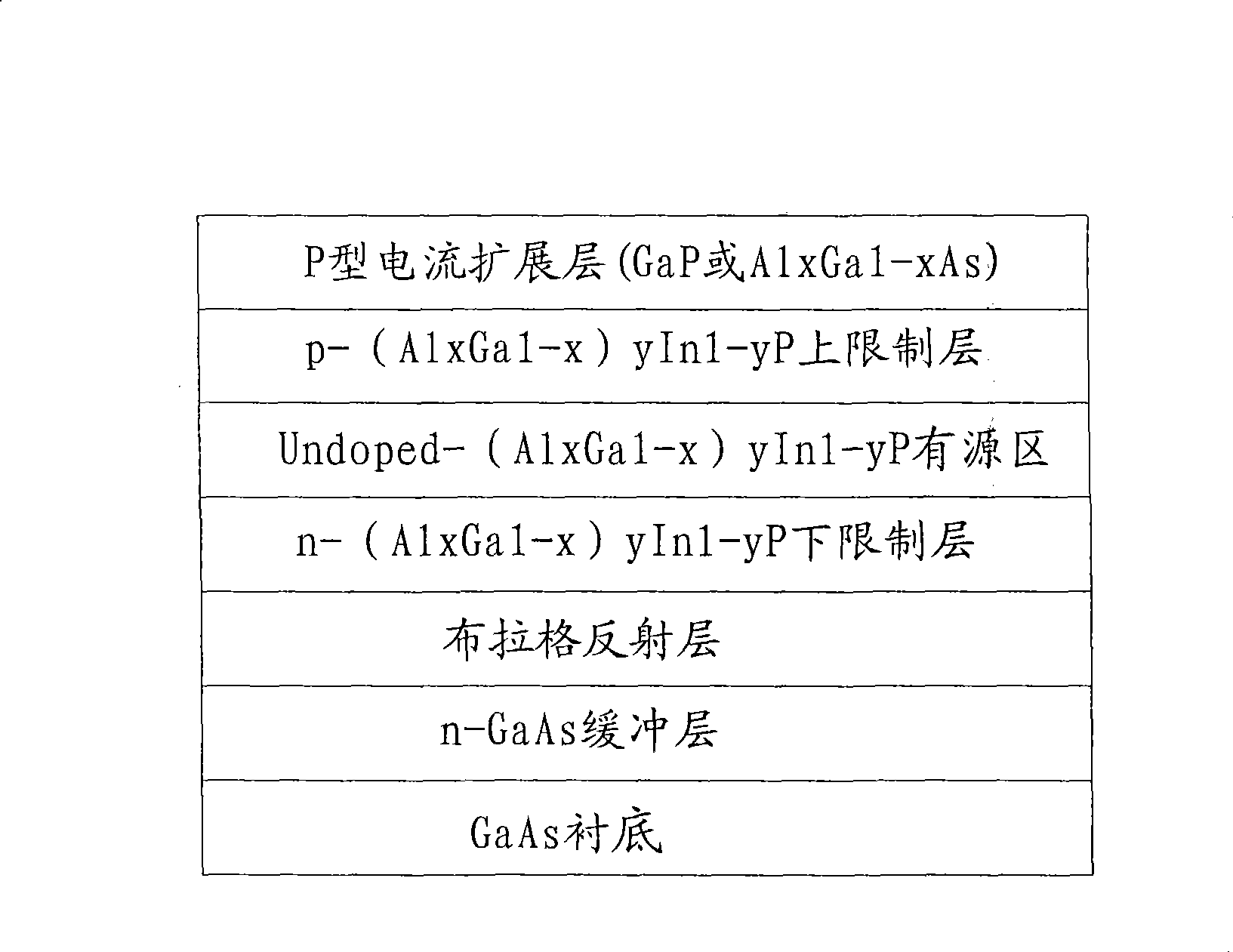

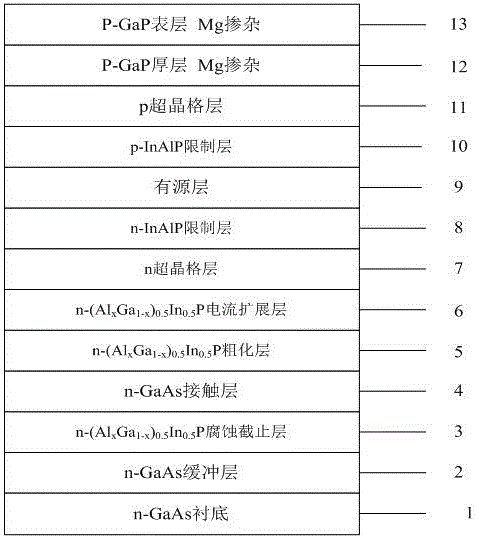

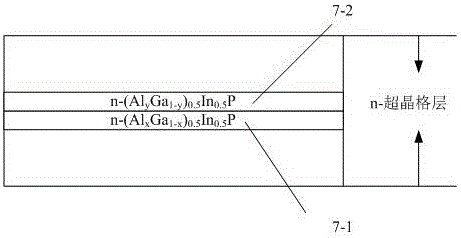

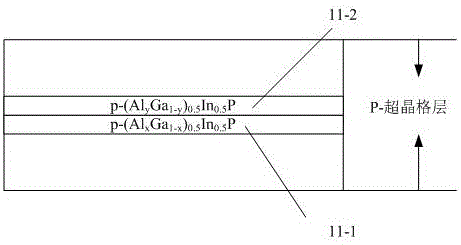

Epitaxial wafer for inverted LED chip and fabrication method of epitaxial wafer

InactiveCN106129196AImprove current spreading effectImprove luminous efficiencySemiconductor devicesPotential wellLight-emitting diode

The invention relates to an epitaxial wafer for an inverted LED chip and a fabrication method of the epitaxial wafer, belongs to the technical field of epitaxy of a light emitting diode. An n-(Al<x>Ga<1-x>)<0.5>In<0.5>P potential well layer and an n-(Al<y>Ga<1-y>)<0.5>In<0.5>P barrier layer are periodically, alternatively and epitaxially grown during growth of an n-type superlattice, and a p-(Al<x>Ga<1-x>)<0.5>In<0.5>P potential well layer and a p-(Al<y>Ga<1-y>)<0.5>In<0.5>P barrier layer are periodically, alternatively and epitaxially grown during growth of a p-type superlattice. The fabrication process is simple and reasonable, the transverse motion of an electron in an n-(Al<x>Ga<1-x>)<0.5>In<0.5>P current extension layer can be effectively improved by the n-type superlattice, and the luminous efficiency of an AlGaInP epitaxial structure is further improved. With the product fabricated by the method, the luminous efficiency, the photoelectric property and the yield of an AlGaInP-based inverted LED epitaxial wafer can be effective enhanced.

Owner:YANGZHOU CHANGELIGHT

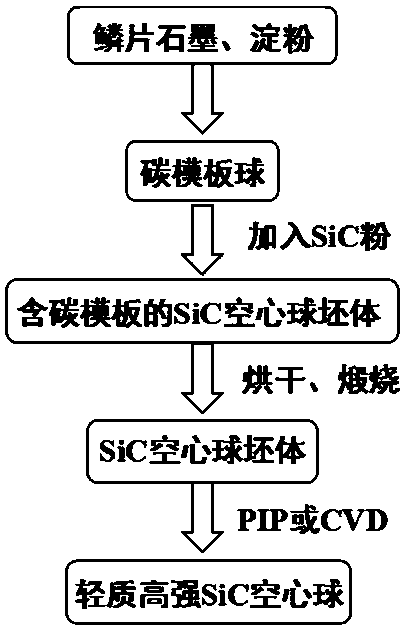

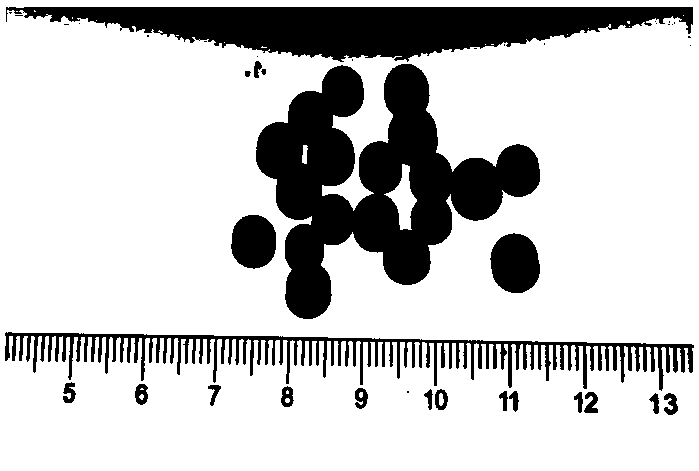

SiC hollow sphere and preparation method of same

The invention discloses a SiC hollow sphere and a preparation method of same. The preparation method includes the steps of: 1) mixing raw materials, including flake graphite, starch and water, and forming carbon template spheres in a pelletizing machine, placing the carbon template spheres in a roll-forming machine, adding SiC powder, in several batches, into the roll-forming machine to form a SiChollow sphere green body internally coated with the carbon template sphere, and drying and calcining the green body to remove the carbon template sphere to obtain a SiC hollow sphere green body; 2) compacting the surfaces of the SiC hollow sphere green body in the step 1) through a precursor vacuum impregnation pyrolysis process or a chemical vapor deposition process. The light-weight and high-strength SiC hollow sphere has high density and high compression resistance, has uniform and controllable size and smooth and compact surface, can reach 10-50 MPa in compression resistance, and can be widely applied to light packing, catalysis materials, heat preservation and insulation materials, fire-proofing and water-proofing materials, anti-radiation materials, etc.

Owner:NAT UNIV OF DEFENSE TECH

Optical waveguide containing Cu ion

InactiveCN101251621AAffect corrosionAffect high temperature resistanceOptical waveguide light guideDiffusionRefractive index

The invention discloses an optical waveguide with Cu ions. An upper surface of a glass substrate is provided with a flat shape Cu ion diffusion zone which is provided with a strip shape high polarizability ion diffusion zone which is used as a core layer of the optical waveguide and has a refractive index higher than that of the glass substrate and also higher than that of the flat shape Cu ion diffusion zone. Because the strip shape high polarizability ion diffusion zone is formed based on the flat shape Cu ion diffusion zone, an ion-exchange optical waveguide has a characteristic of blue-green luminescence of the Cu ions. Meanwhile, the optical waveguide avoids a process that an ion exchange of Cu and salt forms the ion exchange of strip shape optical waveguide under a high temperature condition in the manufacturing process, has a low requirement to a mask, thereby having a lower cost.

Owner:ZHEJIANG UNIV

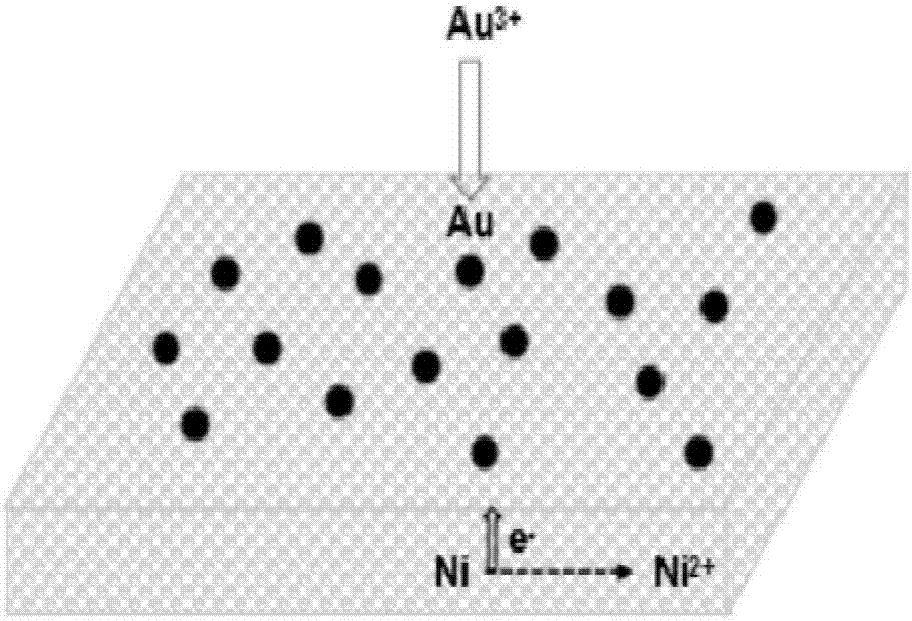

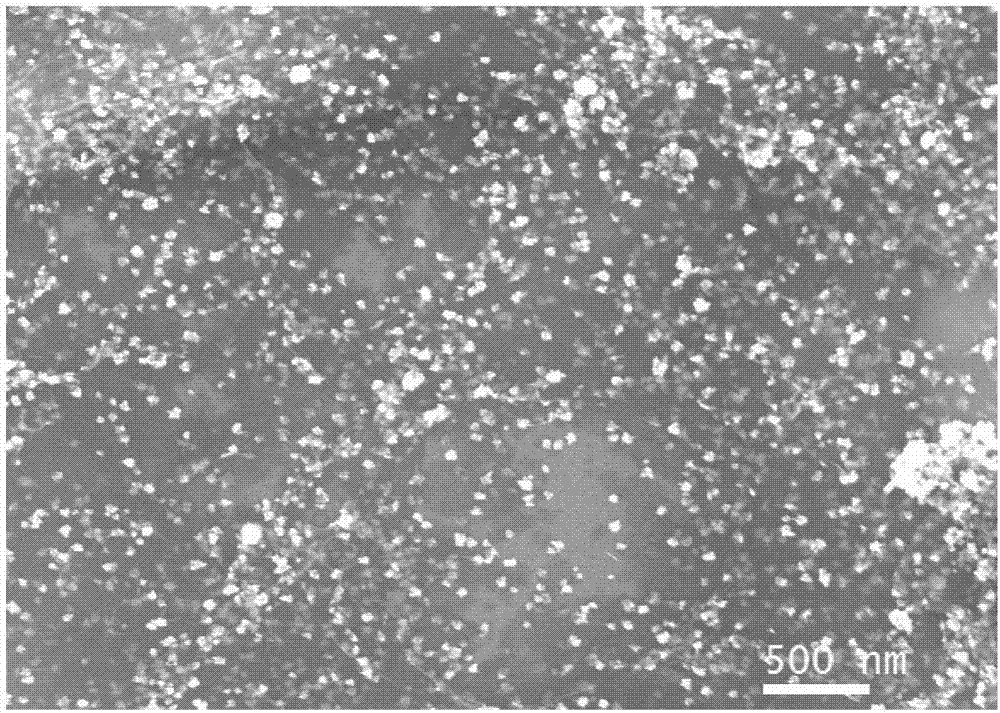

Preparation method of gold-reduced graphene oxide-foamed nickel composite

ActiveCN107354336AReduce dosageWith strengthTransportation and packagingMetal-working apparatusWater bathsAqueous solution

The invention provides a preparation method of a gold-reduced graphene oxide-foamed nickel composite. The preparation method of the gold-reduced graphene oxide-foamed nickel composite mainly comprises the following technological steps that firstly, graphene oxide is prepared, and a graphene oxide aqueous solution of a certain concentration is prepared; secondly, the foamed nickel is dipped in the prepared graphene oxide aqueous solution, after dipping is full, the foamed nickel is taken out and dried, and graphene oxide-foamed nickel is obtained after repetition conducted for many times; thirdly, the graphene oxide-foamed nickel is dipped in a newly-prepared ascorbic acid aqueous solution, the ascorbic acid aqueous solution is placed in a water bath kettle at the temperature of 60-90 DEG C, the temperature is kept for 20-40 min, the graphene oxide-foamed nickel is taken out, rinsed and dried, and then reduced graphene oxide-foamed nickel is obtained; and fourthly, the reduced graphene oxide-foamed nickel is placed in a chloroauric acid solution, under the ultrasonic condition, an reaction is performed for 1-5 min, and after drying, the gold-reduced graphene oxide-foamed nickel material uniform in gold nanometer particle distribution can be obtained.

Owner:SOUTHEAST UNIV

Method for compositely plating Ni/CrAl/Y2O3 gradient plated layer on T91 steel surface

InactiveCN103343379AStrong combinationExcellent high temperature oxidation resistanceElectrolytic coatingsMicro nanoOxidation resistant

The invention relates to a method for compositely plating Ni / CrAl / Y2O3 gradient plated layer on a T91 steel surface. The method comprises the steps of preparing CrAl / Y2O3 powder, carrying out T91 steel surface treatment and compositely plating. CrAl / Y2O3 micro nano spherical powder is obtained by controlling a high-speed milling process; an appropriate amount of CrAl / Y2O3 micro nano powder is added into a Watts plating liquid, and the Ni / CrAl / Y2O3 gradient plated layer which has excellent corrosion resistance and oxidation resistance is prepared through composite plating. The Ni / CrAl / Y2O3 gradient plated layer provided by the invention is good in bonding force with a base material, low in porosity, free of crack and unlikely to peel off, the CrAl / Y2O3 content of the plated layer from the inner layer to the outer layer changes in a linear gradient manner, and the plated layer has excellent corrosion resistance and oxidation resistance, and has the advantages of low cost and simplicity in operation and industrialization is easy to realize.

Owner:NANCHANG HANGKONG UNIVERSITY

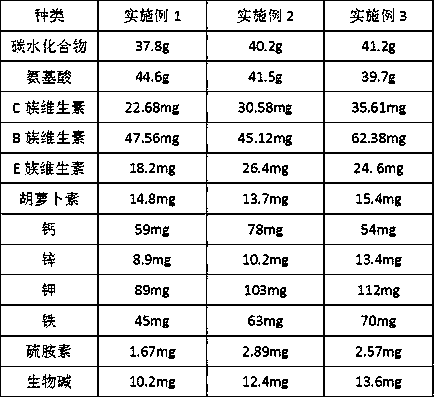

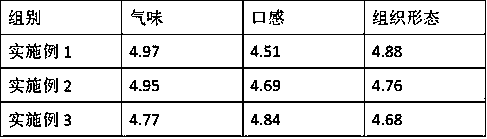

Nutritive edible bird's nest thick soup and making method thereof

InactiveCN108433104AImprove sleepingEnhance physical fitnessNatural extract food ingredientsFood ingredient as mouthfeel improving agentBiotechnologyNutrition

The invention relates to nutritive edible bird's nest thick soup and a making method thereof, and belongs to the field of health-care foods. The nutritive edible bird's nest thick soup consists of thefollowing raw materials in parts by mass of 15-20 parts of edible bird's nests, 5-8 parts of lily bulbs, 3-5 parts of lotus seeds, 4-6 parts of white fungi, 6-8 parts of red jujubes, 10-12 parts of black Chinese wolfberries, 3-5 parts of chrysanthemum flowers and 3-5 parts of rose flowers. The edible bird's nest thick soup is comprehensive and balanced in nutrients, nutrient loss during preparation is low, components are synergic in action, effective components are high in digestibility, the product stability is good, and the nutritive edible bird's nest thick soup has the efficacy of well improving sleep, strengthening constitutions, nourishing the kidney, boosting essence, nourishing blood, maintaining beauty, whitening skin and dispelling acnes.

Owner:李涛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com