Extraction technology of perilla frutescens essential oil

A technology of perilla essential oil and extraction process, which is applied to seeds as raw materials, which can solve the problems of affecting purity and quality, low extraction yield, and affecting application, and achieve the effects of fast extraction time, high extraction efficiency, and reduced drug efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

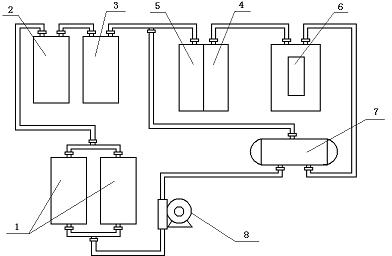

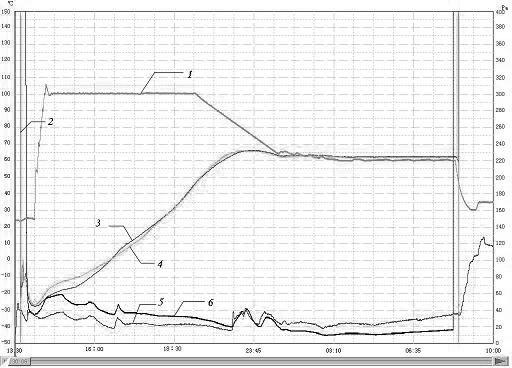

[0027] Embodiment one: see attached figure 1 , 4 , a kind of extraction process of perilla essential oil, comprises the following steps:

[0028] (1) Clean the broken wall: Put the perilla stem and seeds into the ultrasonic cleaning machine to clean the broken wall, the ultrasonic frequency is 20KHz, and the time is 10min;

[0029] (2) Freeze-drying: After the wall is broken, the raw materials are put into the quick-freezing tunnel to freeze, the freezing temperature is -20°C, and the freezing time is 6 hours; enter the vacuum drying chamber, and when the vacuum degree is 60Pa, start the heating programmer and set the drying curve of the heating programmer : 1. 20°C uniformly rises to 100°C for 45 minutes; 2. 100°C maintains for 360 minutes; 3. 100°C uniformly drops to 65°C for 210 minutes; 4. 65°C uniformly drops to 60°C for 150 minutes; 5. Keep at 60°C for 300 minutes;

[0030] (3) crushing and sieving: the perilla stem and seeds after freeze-drying are pulverized with a...

Embodiment 2

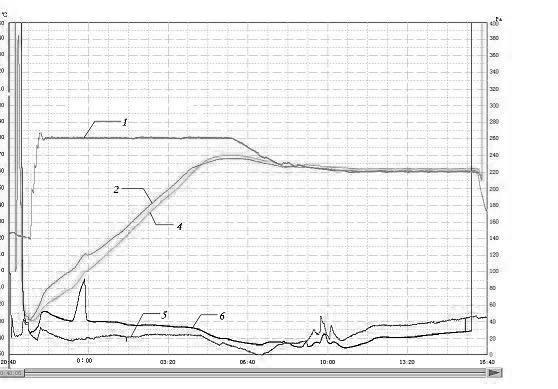

[0032] Embodiment two: see appendix figure 2 , 4 , a kind of extraction process of perilla essential oil, comprises the following steps:

[0033] (1) Clean the broken wall: Put the perilla stem and seeds into the ultrasonic cleaning machine to clean the broken wall, the ultrasonic frequency is 23KHz, and the time is 15min;

[0034] (2) Freeze-drying: After the wall is broken, the raw materials are put into the quick-freezing tunnel to freeze, the freezing temperature is -22°C, and the freezing time is 7h; enter the vacuum drying chamber, and the heating programmer is started at a vacuum degree of 80Pa, and the drying curve of the heating programmer is set. : 1. Rise from 20°C to 80°C evenly for 45 minutes; 2. Keep at 80°C for 450 minutes; 3. Fall from 80°C to 65°C evenly for 150 minutes; 4. Fall from 65°C to 60°C evenly for 150 minutes; 5. Keep at 60°C for 300 minutes;

[0035] (3) Pulverize and sieve: pulverize the perilla stem and seeds after freeze-drying with a unive...

Embodiment 3

[0037] Embodiment three: see attached image 3 , 4 , a kind of extraction process of perilla essential oil, comprises the following steps:

[0038] (1) Clean the broken wall: put the perilla stem and seeds into the ultrasonic cleaning machine to clean the broken wall, the ultrasonic frequency is 25KHz, and the time is 20min;

[0039] (2) Freeze-drying: After the wall is broken, the raw materials are put into the quick-freezing tunnel to freeze, the freezing temperature is -25°C, and the freezing time is 8 hours; enter the vacuum drying chamber, and when the vacuum degree is 100Pa, start the heating programmer and set the drying curve of the heating programmer : 1. Rise from 20°C to 100°C evenly for 45 minutes; 2. Keep at 100°C for 330 minutes; 3. Fall from 100°C to 65°C evenly for 210 minutes; 4. Keep at 65°C for 405m;

[0040] (3) Pulverize and sieve: pulverize the perilla stem and seeds after freeze-drying with a universal pulverizer, and pass through a sieve with a specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com