Highly efficient LED having current spread layer construction improved and manufacturing method thereof

A current spreading layer, light emitting diode technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems affecting current spreading, increase in mesh dislocation density, device reliability and stability, and improve reliability. and stability, forward voltage reduction, and extension efficiency enhancement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

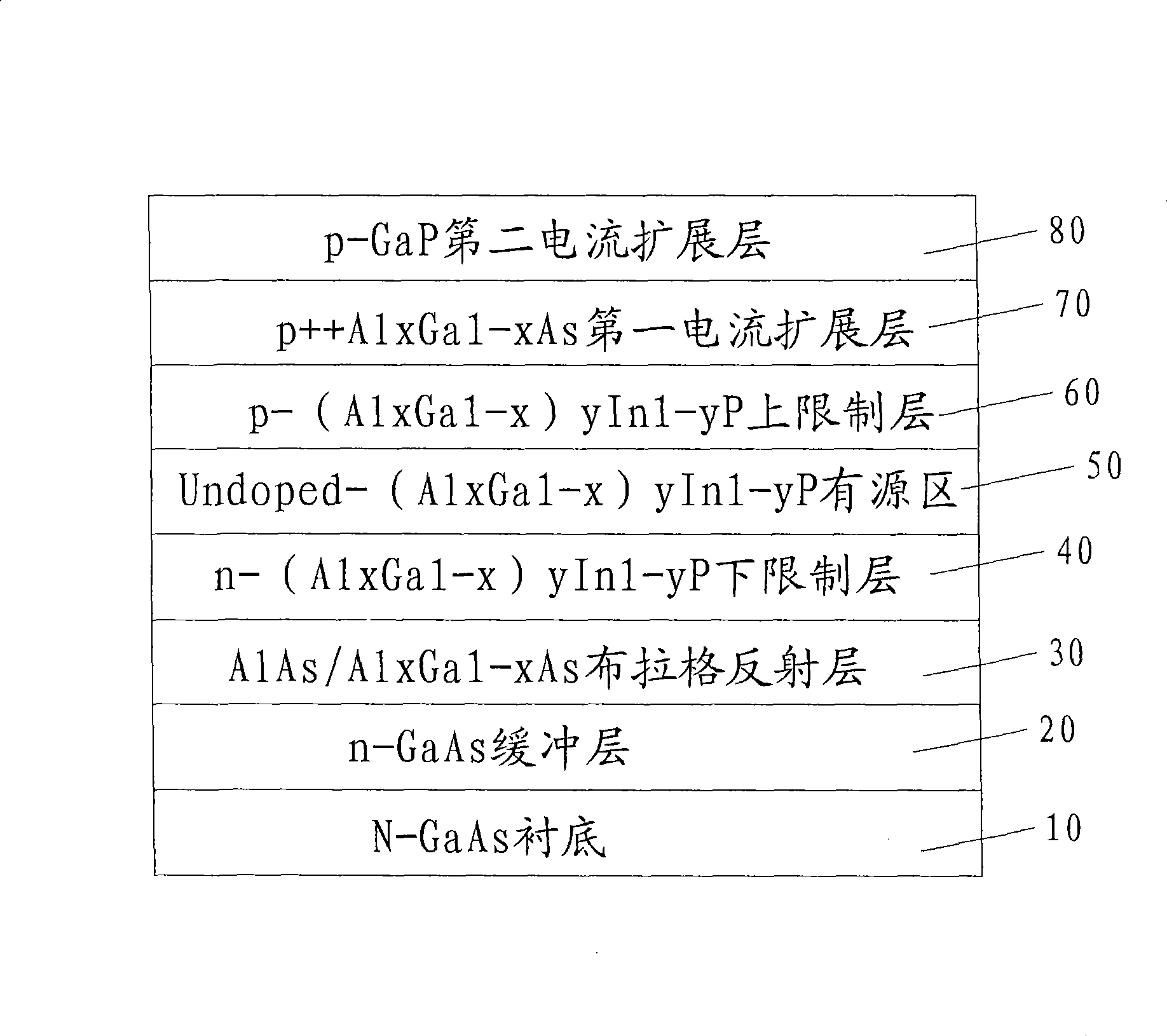

[0019] Such as figure 1 As shown, the AlGaInP light-emitting diode with the improved current spreading layer of the present invention is similar to the existing AlGaInP light-emitting diode in terms of epitaxial material structure. The epitaxial materials of the N-GaAs substrate 10 are: n-GaAs buffer layer 20, Bragg reflection layer 30, n-(Al x Ga 1-x ) y In 1-y P lower confinement layer 40, Undoped-(Al x Ga 1-x ) y In 1-y P active region 50, p-(Al x Ga 1-x ) y In 1-y Confinement layer 60 on P, p++Al x Ga 1-x As 70 and p-GaP 80 combined current spreading layer.

[0020] Wherein, the Bragg reflection layer 30 is AlAs / Al x Ga 1-x As or AlInP / (Al x Ga 1-x ) y In 1-y P, 0.35≤x≤0.7, period is 0~26, n-(Al x Ga 1-x ) y In 1-y In the P lower confinement layer 40, 0.6≤x≤1, 0.45≤y≤0.55, p-(Al x Ga 1-x ) y In 1-y In the P upper confinement layer 60, 0.6≤x≤1, 0.45≤y≤0.55, Undoped-(Al x Ga 1-x ) y In 1-yThe P active region 50 has an MQW (Multiple Quantum Hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com