Ultra-high performance concrete (UHPC) combined deck slab with formwork

A concrete deck, ultra-high performance technology, used in bridges, bridge parts, bridge construction and other directions, can solve the problems of easy cracking of ordinary concrete bridge decks, bridge deck pavement damage, fatigue cracking, etc., to solve fatigue cracking diseases, improve Local stiffness, low water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

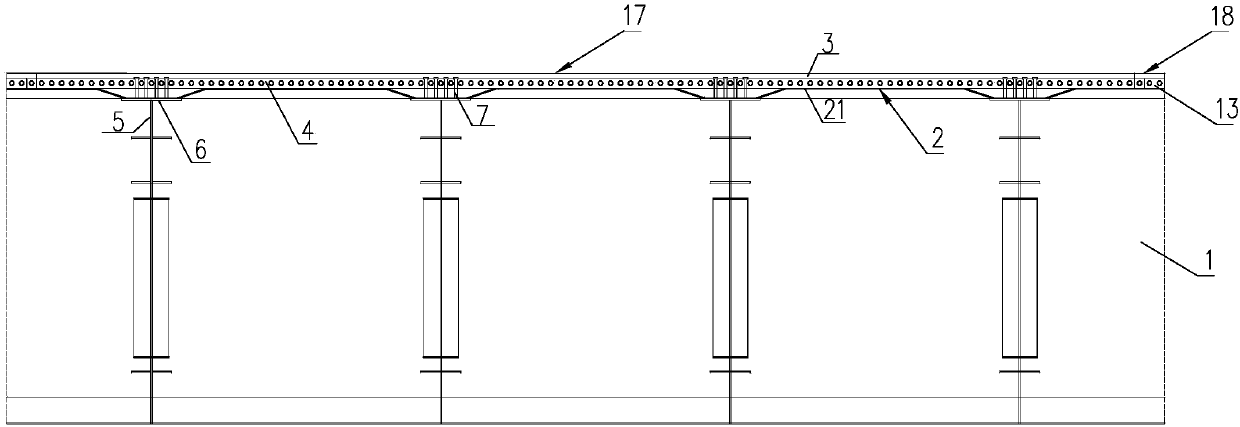

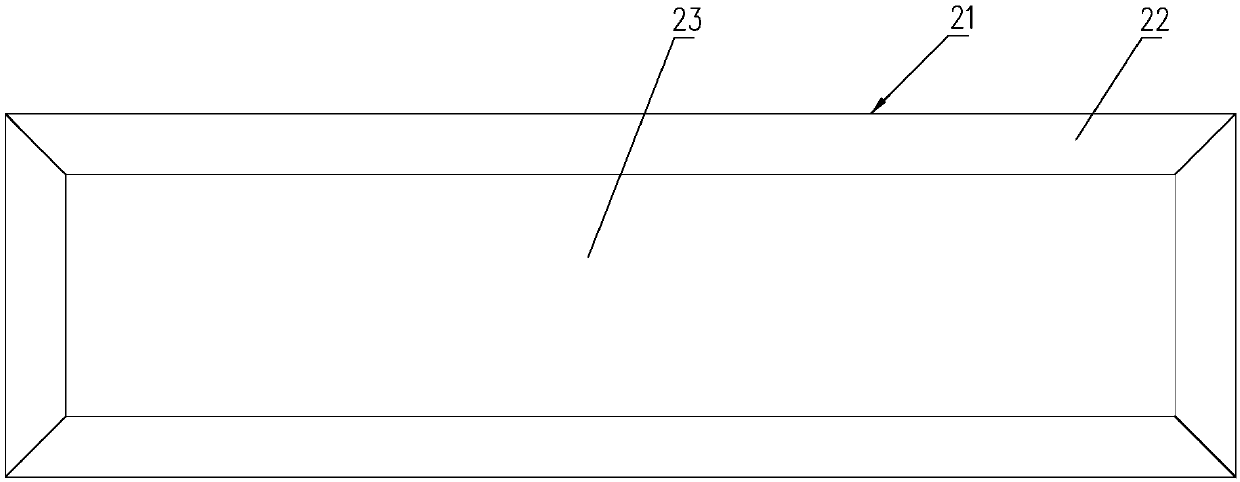

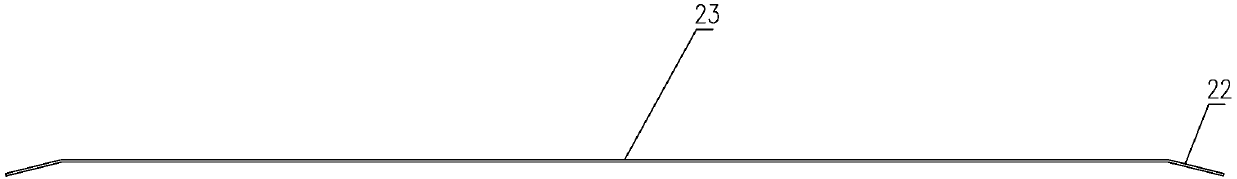

[0036] Such as Figure 1-7As shown, it is an ultra-high-performance concrete composite bridge deck with self-formwork of the present invention. The bridge deck is mainly formed by splicing several unit plates 2. The ultra-high performance concrete panel 3 is anchored with prestressed steel beams 14 in the ultra-high performance concrete panel 3 . The upper surface of the steel base plate 21 is welded with a shear connector for connecting the ultra-high performance concrete panel 3, and the shear connector is located in the ultra-high performance concrete panel 3. In this embodiment, the shear connector adopts PBL shear Force key 4, PBL shear key 4 is 80-180 mm high, 6-10 mm thick, PBL shear key 4 is arranged along the bridge direction and arranged side by side along the transverse bridge direction, and a PBL is welded every 350 mm to 500 mm The shear key 4 has a mounting hole 9 that runs through the PBL shear key 4 along the transverse direction of the PBL shear key 4. The mo...

Embodiment 2

[0045] Such as Figure 8 and 9 As shown, the difference between this embodiment and Embodiment 1 is that the shear connectors use shear nails 71 with a diameter of 10-22 mm, and the shear nails 71 are distributed in a matrix on the steel base plate 21, or arranged in a quincunx shape. , the distance between adjacent shear studs 71 is 150-300 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com