Patents

Literature

130results about How to "Improve local stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

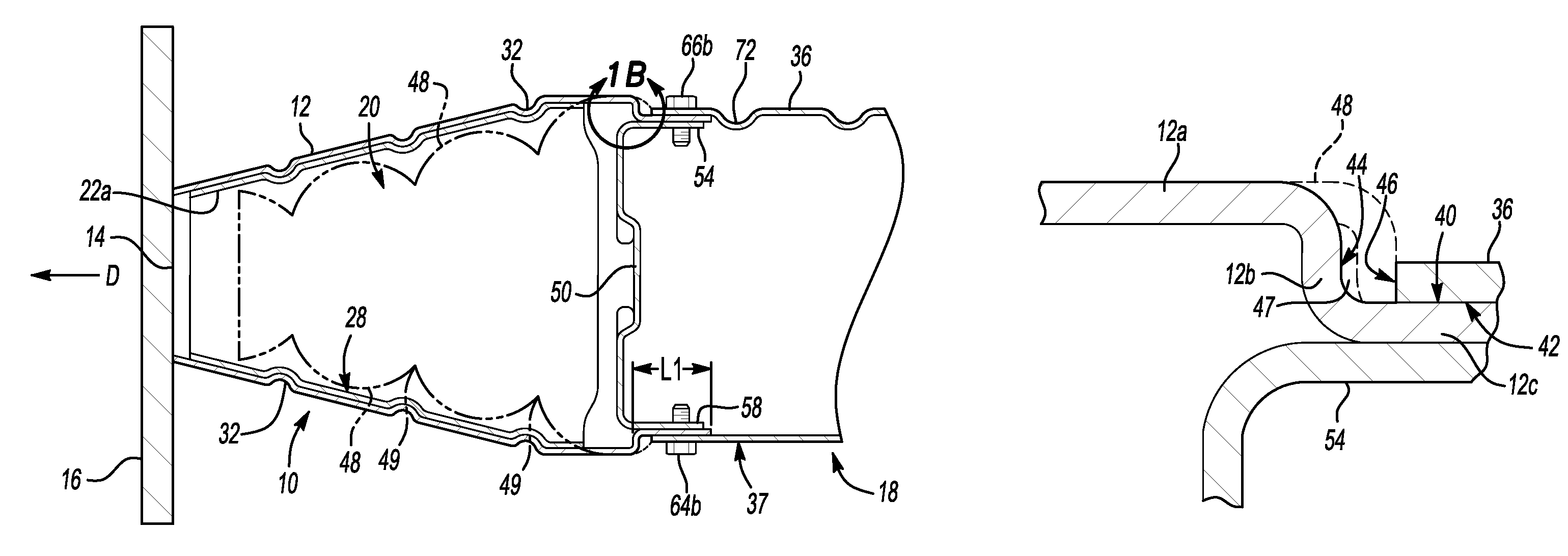

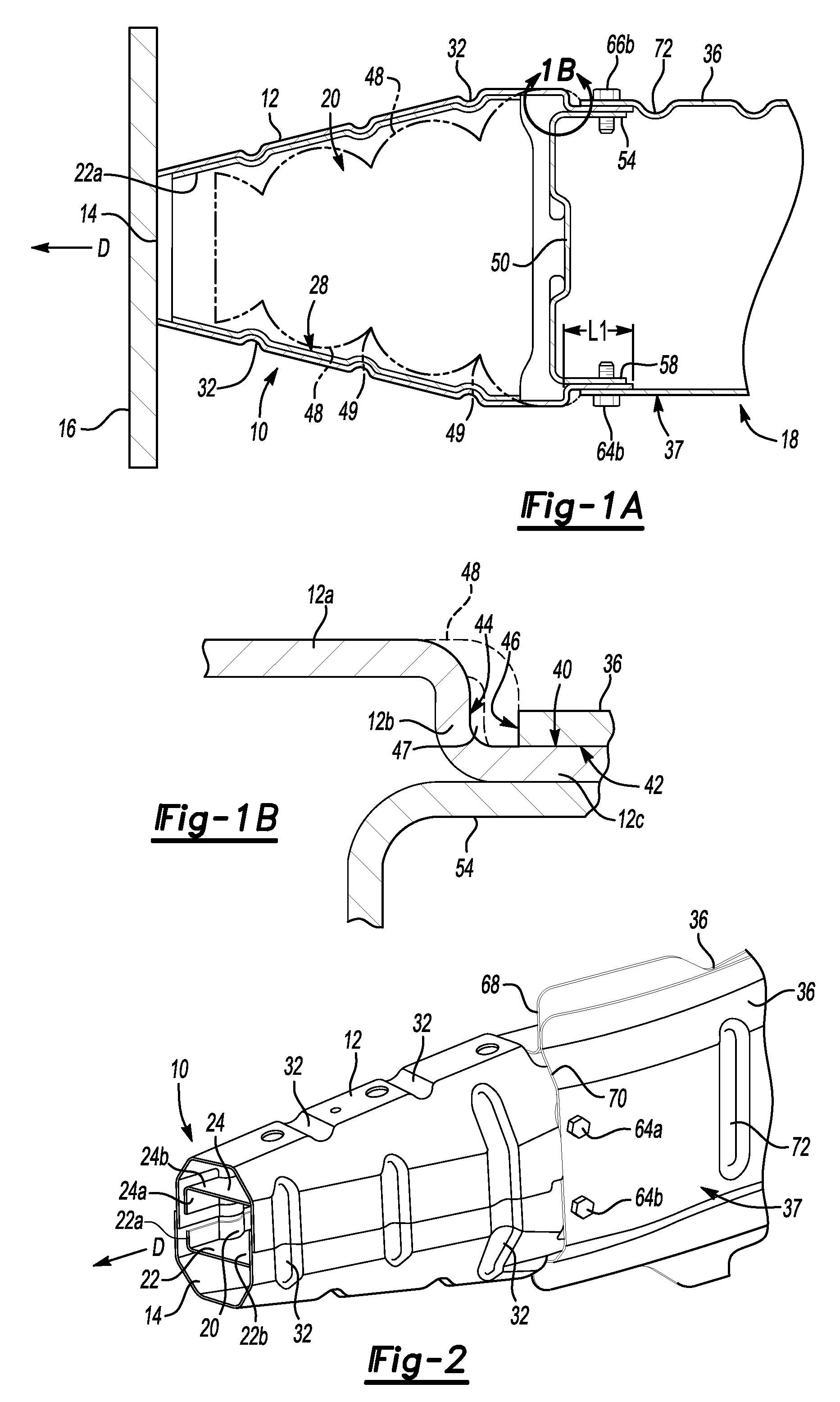

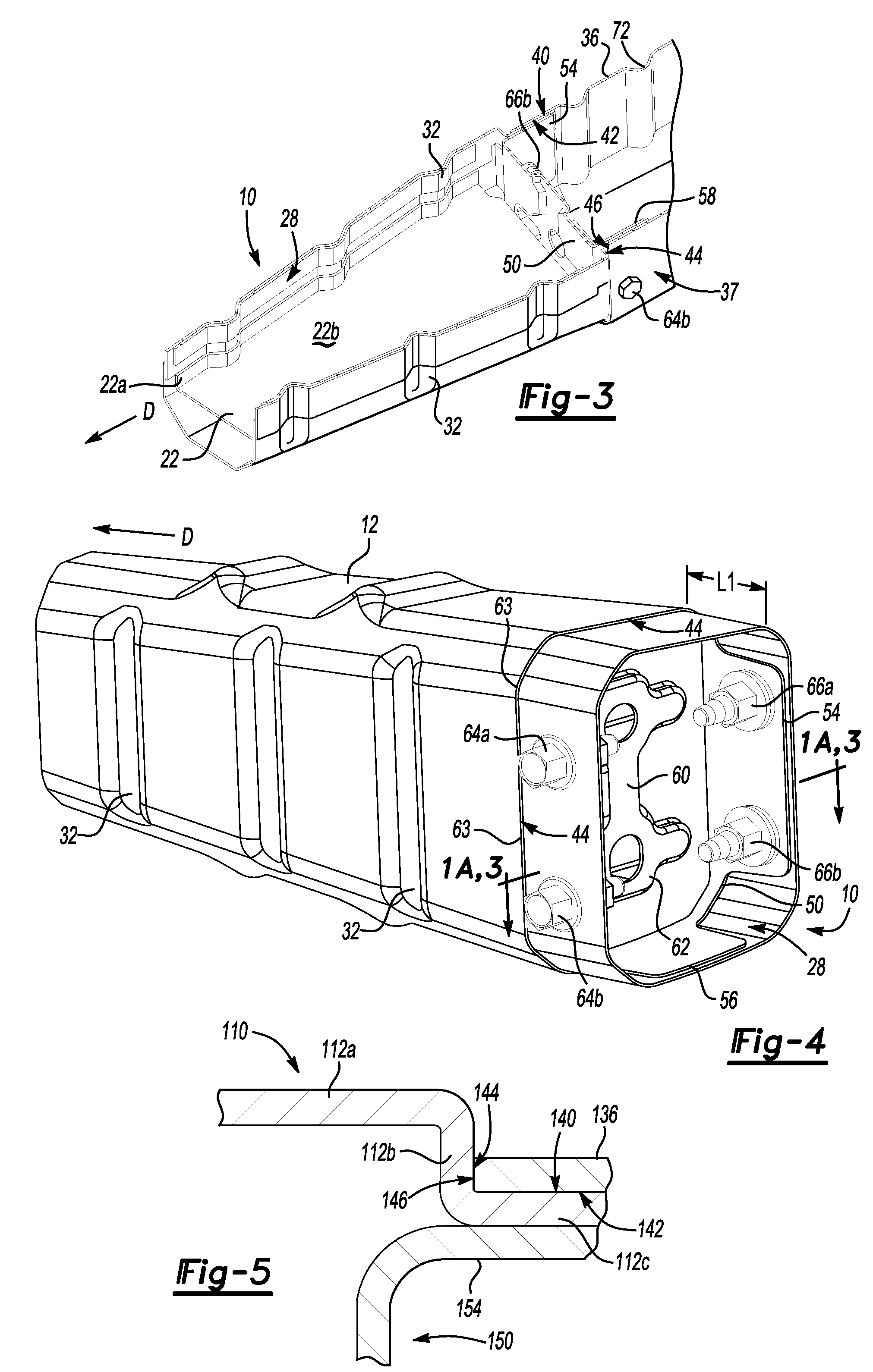

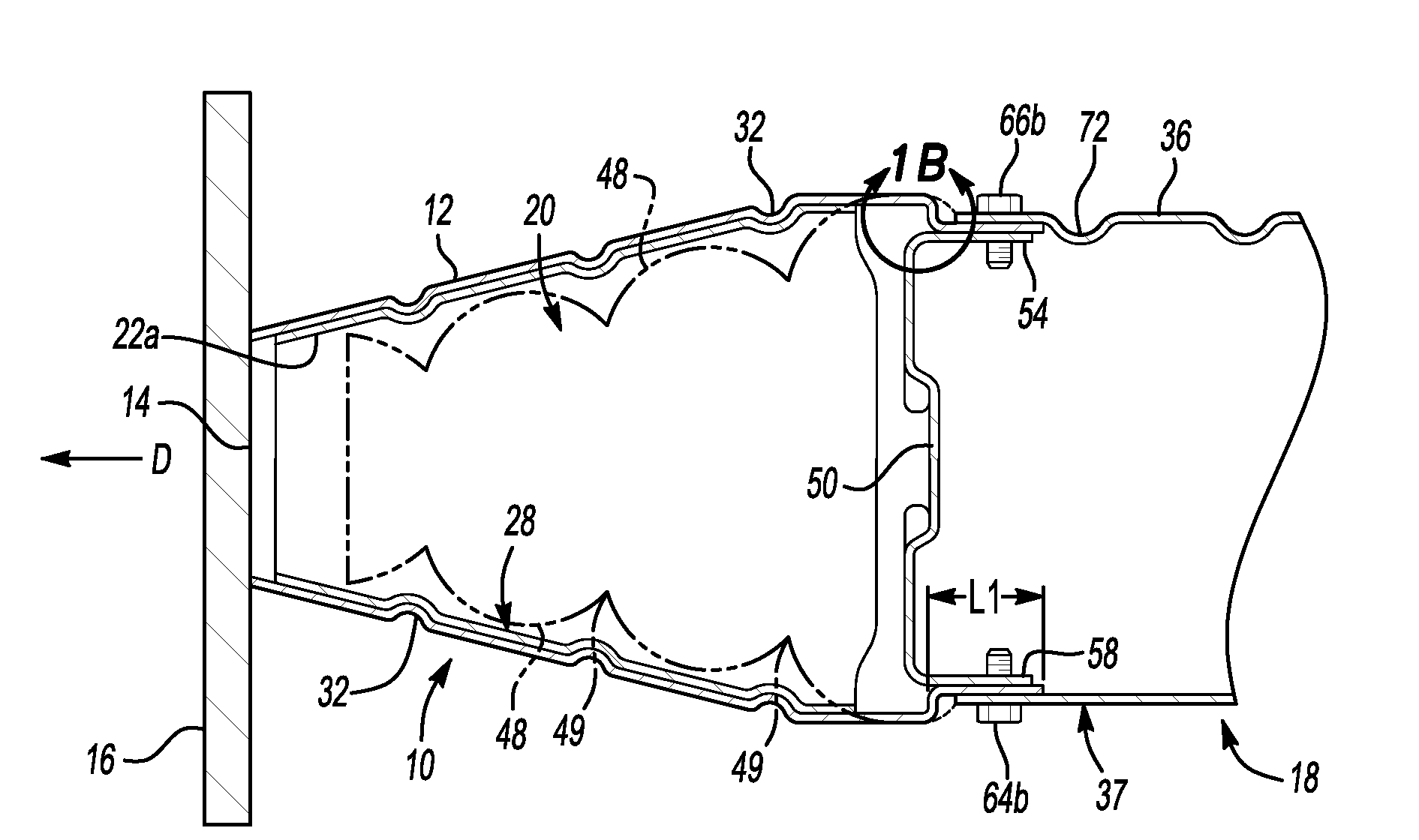

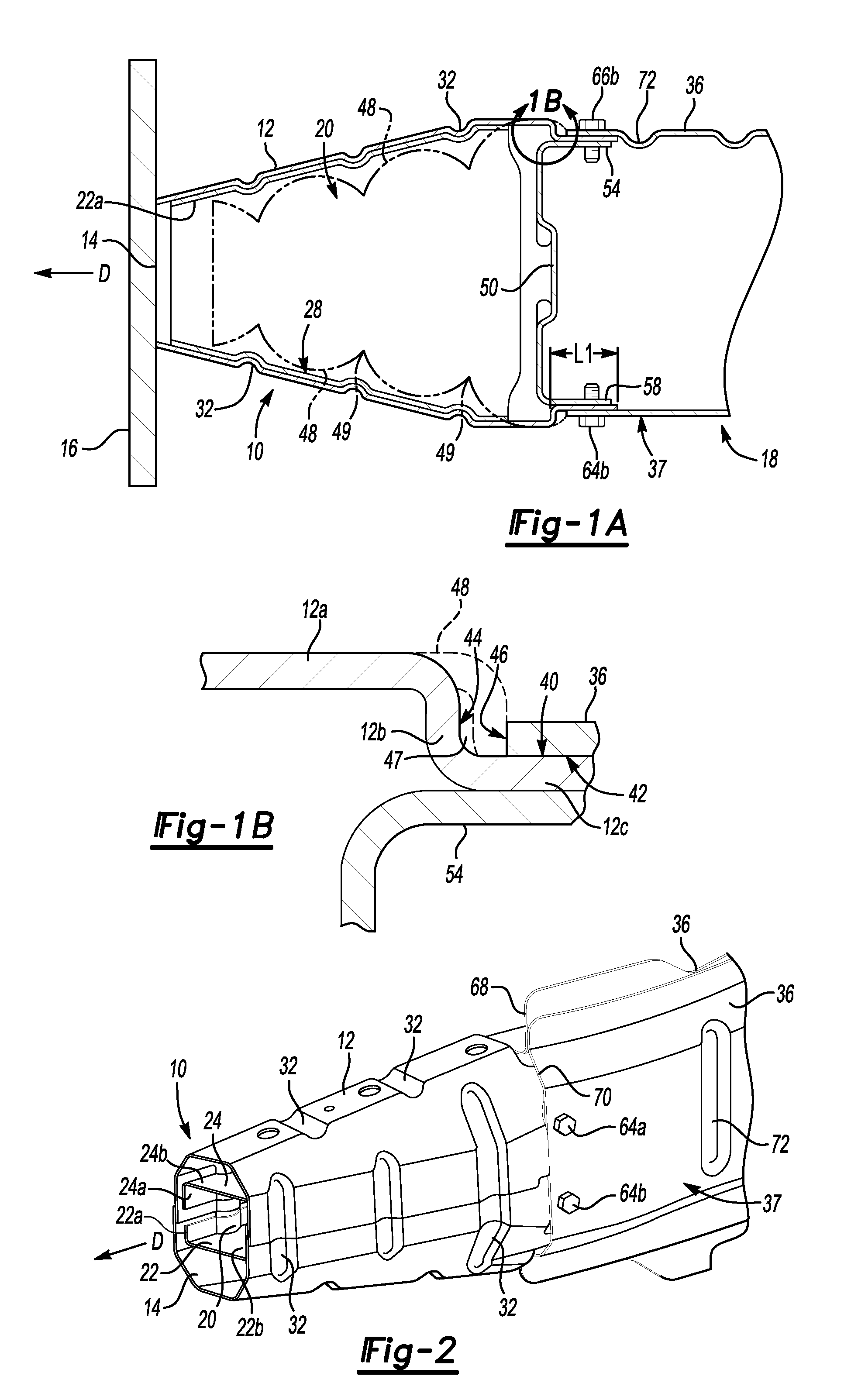

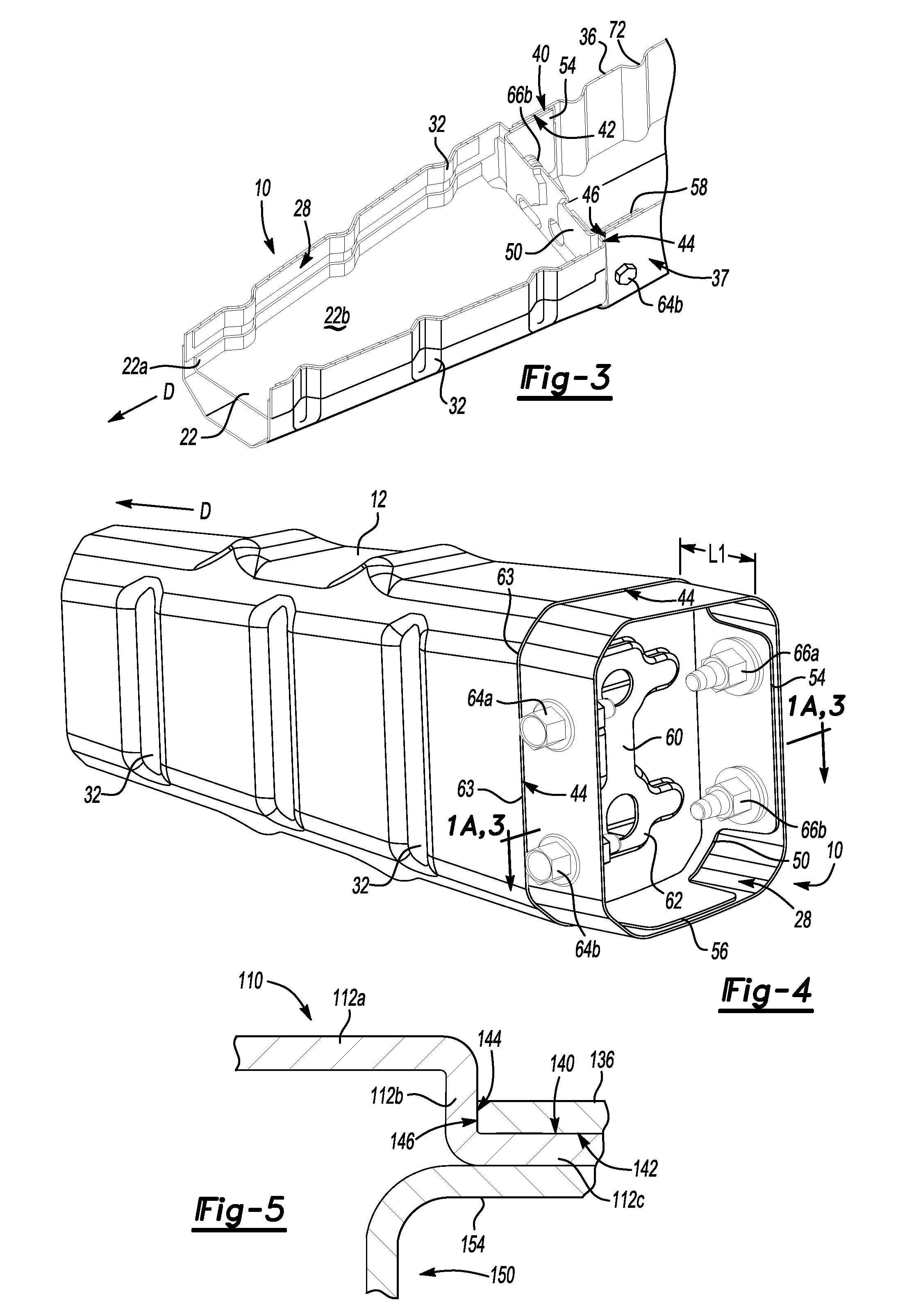

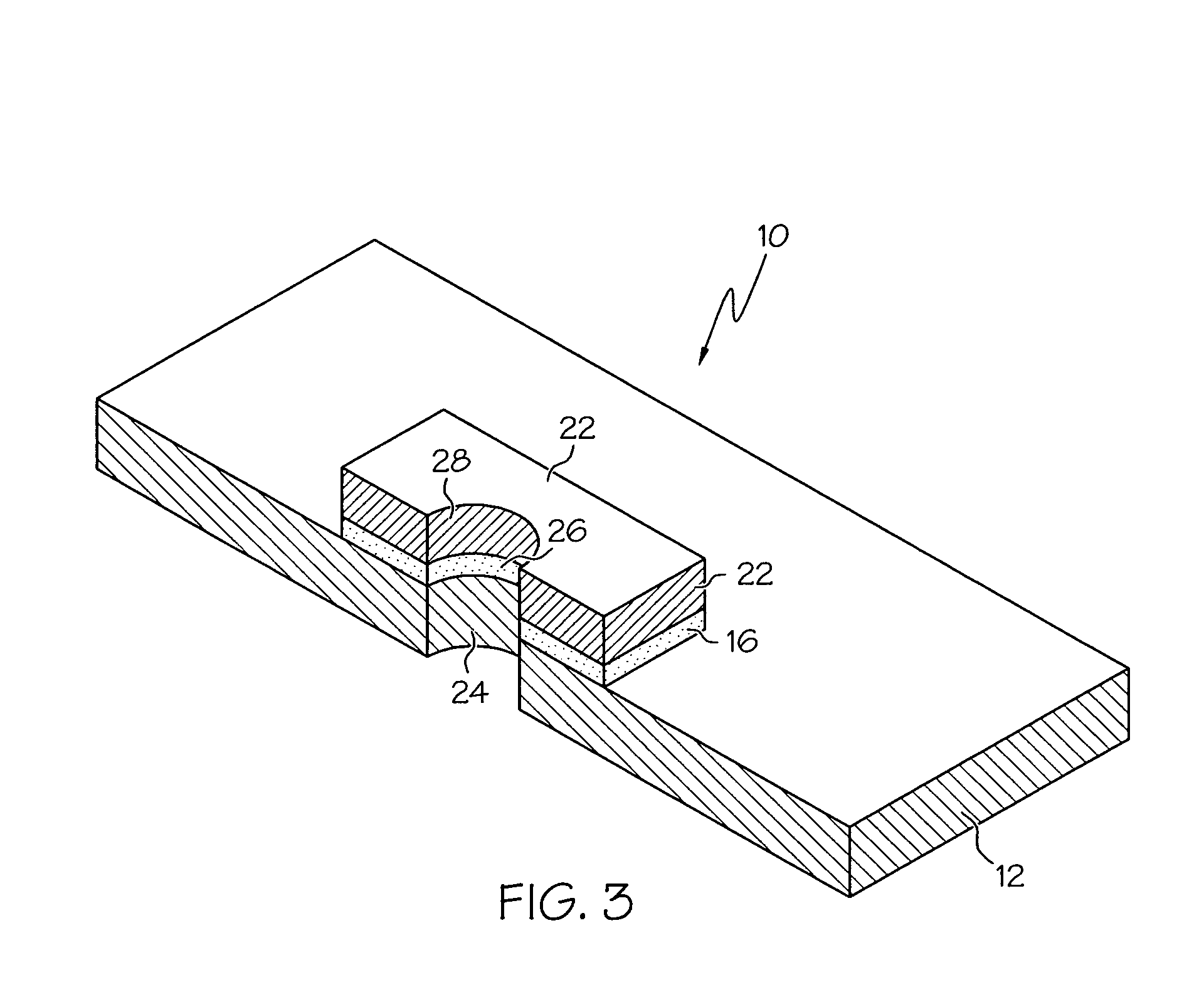

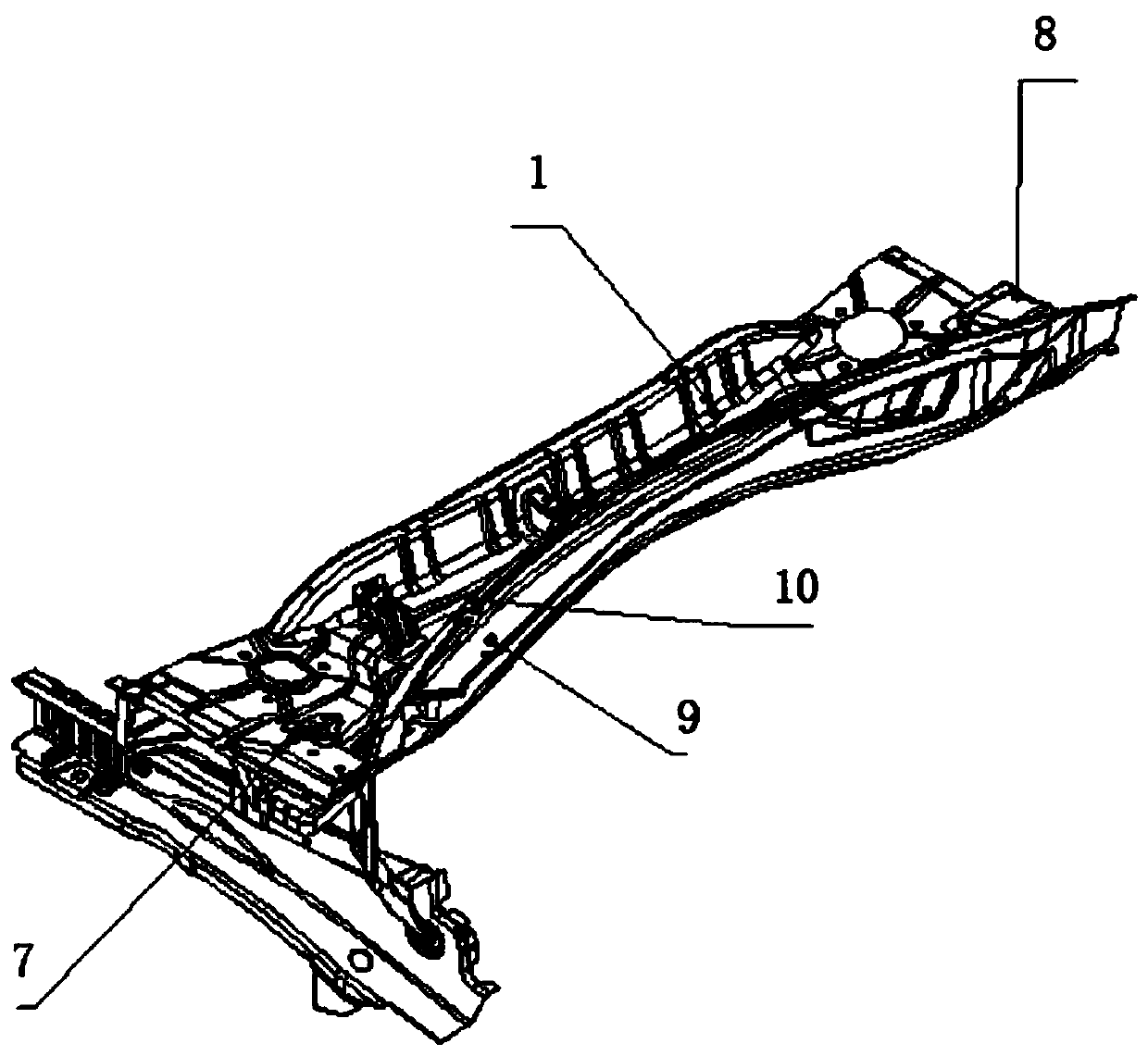

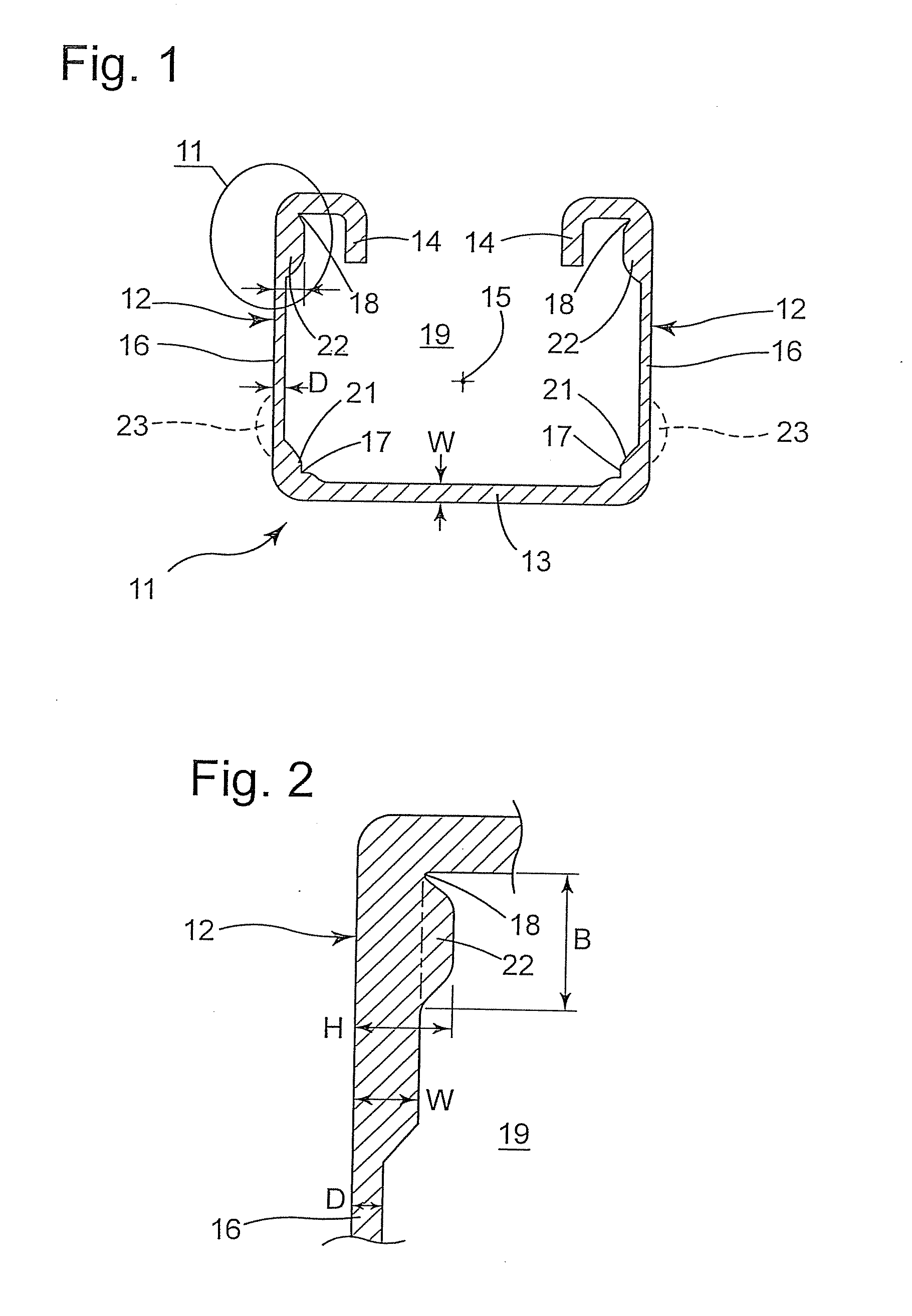

Efficient joint for vehicle energy-absorbing device

A vehicle having an energy-absorbing device mountable to a bumper of the vehicle is provided. The energy-absorbing device is attached to a vehicle rail having an inner rail surface and an edge surface. The energy-absorbing device defines a first crush surface interfacing with the inner rail surface. In a first embodiment, the energy-absorbing device defines a second crush surface positioned to directly interface with the edge surface of the vehicle rail in the event of an impact. The energy-absorbing device is configured to transmit load received from the impact directly to the edge surface of the vehicle rail through the second crush surface. This results in an efficient joint for the energy-absorbing device.

Owner:GM GLOBAL TECH OPERATIONS LLC

Efficient joint for vehicle energy-absorbing device

A vehicle having an energy-absorbing device mountable to a bumper of the vehicle is provided. The energy-absorbing device is attached to a vehicle rail having an inner rail surface and an edge surface. The energy-absorbing device defines a first crush surface interfacing with the inner rail surface. In a first embodiment, the energy-absorbing device defines a second crush surface positioned to directly interface with the edge surface of the vehicle rail in the event of an impact. The energy-absorbing device is configured to transmit load received from the impact directly to the edge surface of the vehicle rail through the second crush surface. This results in an efficient joint for the energy-absorbing device.

Owner:GM GLOBAL TECH OPERATIONS LLC

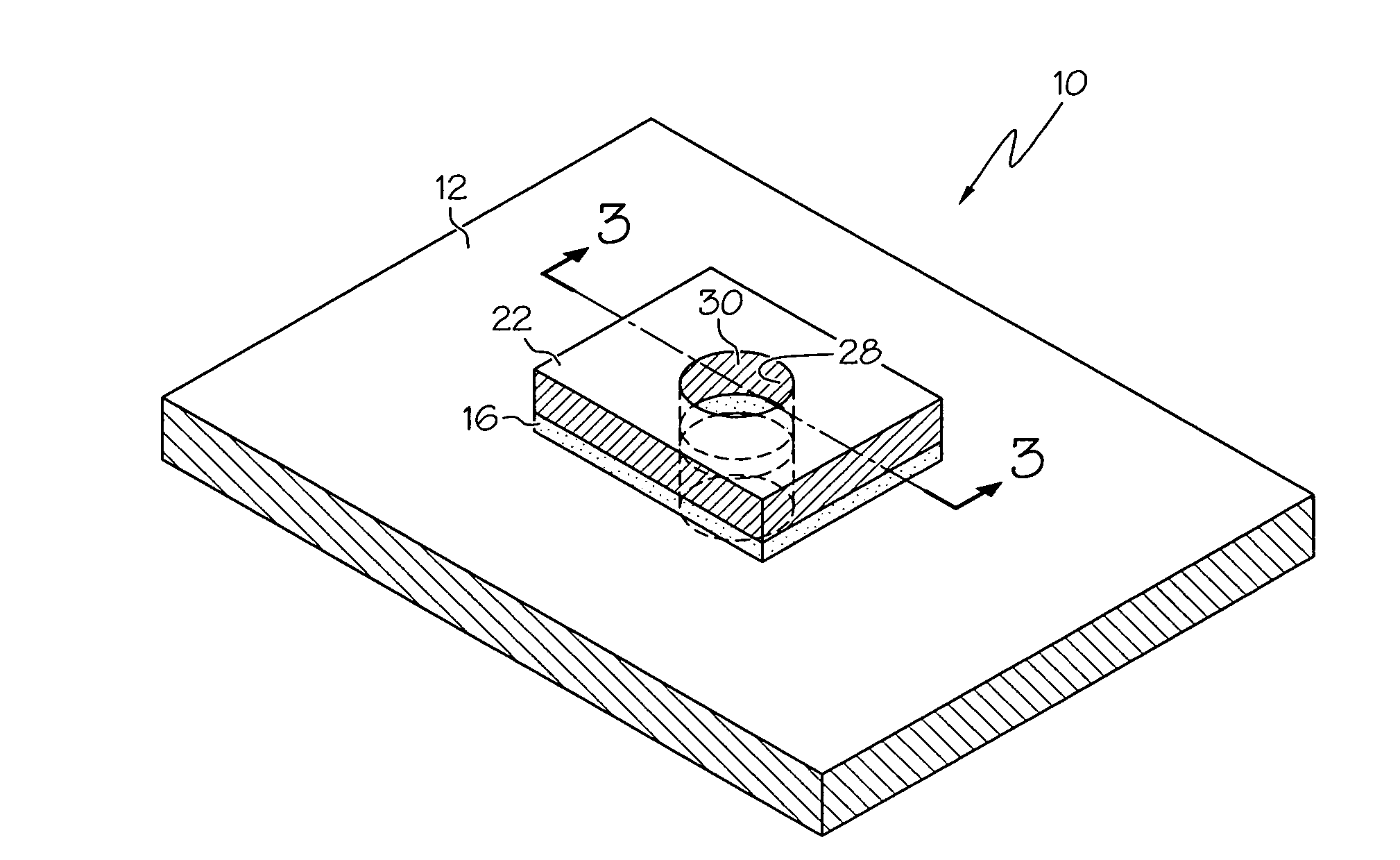

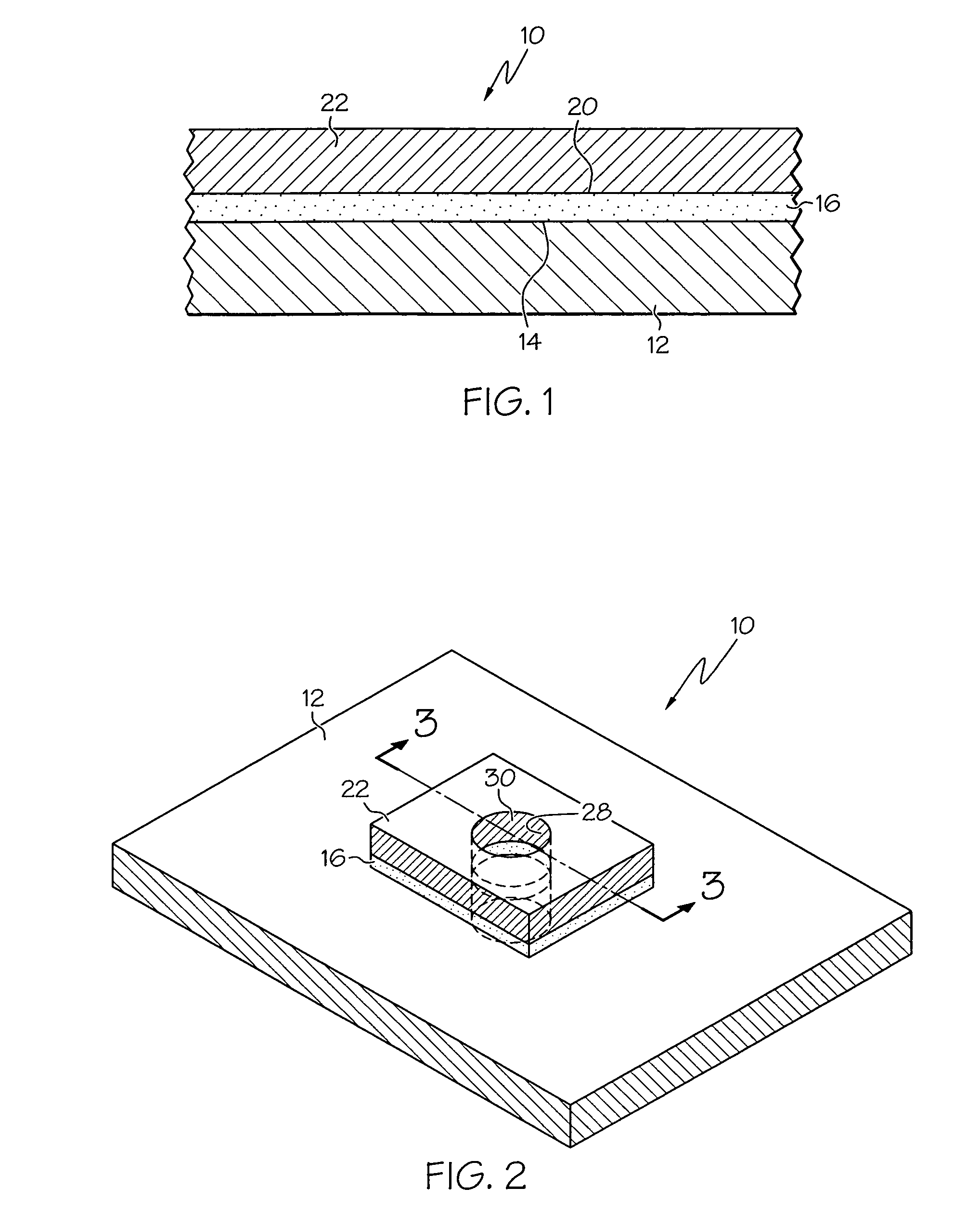

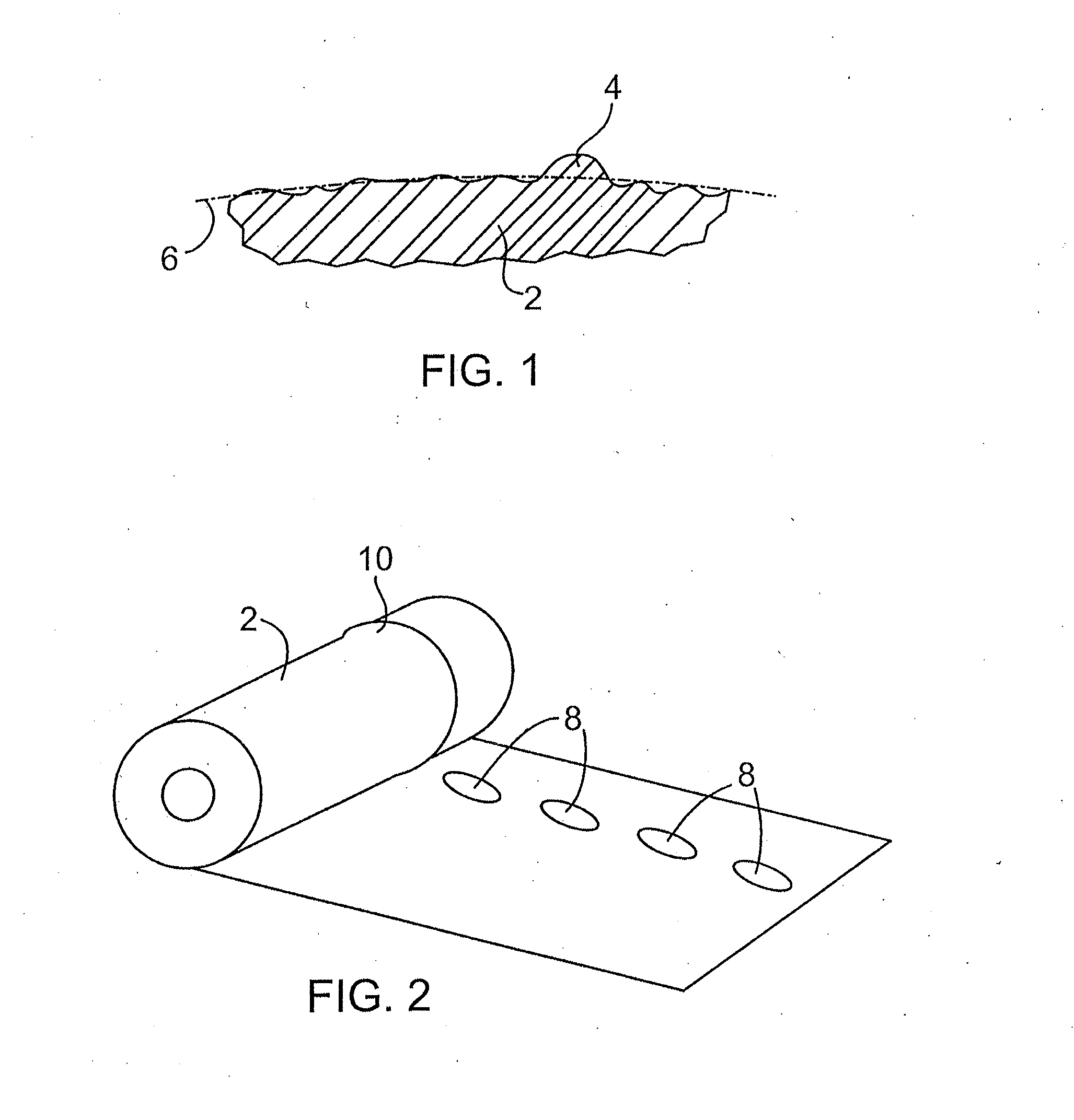

Body panel having improved stiffness and method of making

InactiveUS7748184B1Improve local stiffnessSynthetic resin layered productsBuilding componentsSteering columnEngineering

A damping system includes a base substrate, a constraining substrate and a non-foam damping layer between them. The base substrate has greater lateral dimensions than the constraining substrate. Consequently, the damping system is provided in a localized region of the base substrate. The damping system can be provided, for example, at a region of the base substrate where a longitudinal projection or moving linkage extends through an opening in the base substrate, such as a steering column through a dashboard panel. In this embodiment, a composite opening is provided through the damping system to accommodate the extending projection or linkage, and the damping system is effective to provide localized damping against vibrations due to the through-the-panel linkage. The damping system provides these benefits without increasing the overall thickness of the body part, and without providing damping and constraining layers across its entire lateral expanse, saving cost and weight. Methods of making such a damping system are also provided.

Owner:INTPROP HLDG

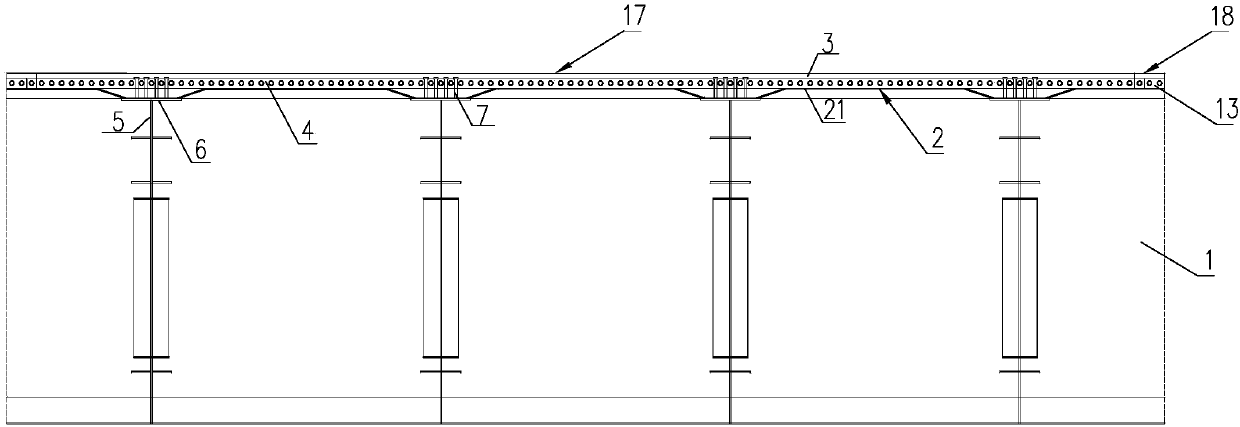

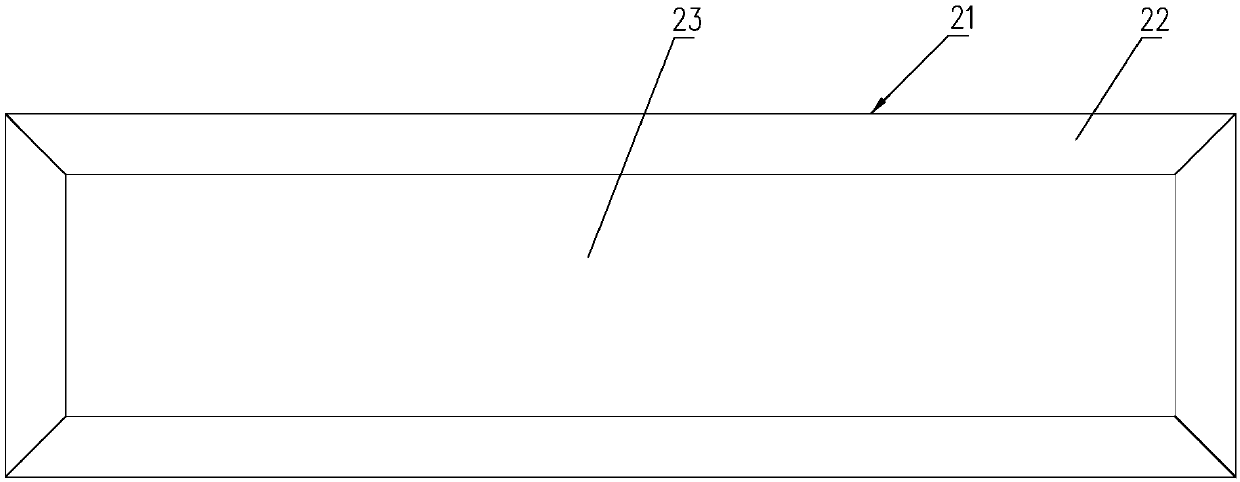

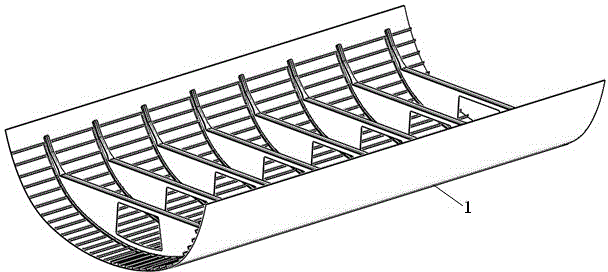

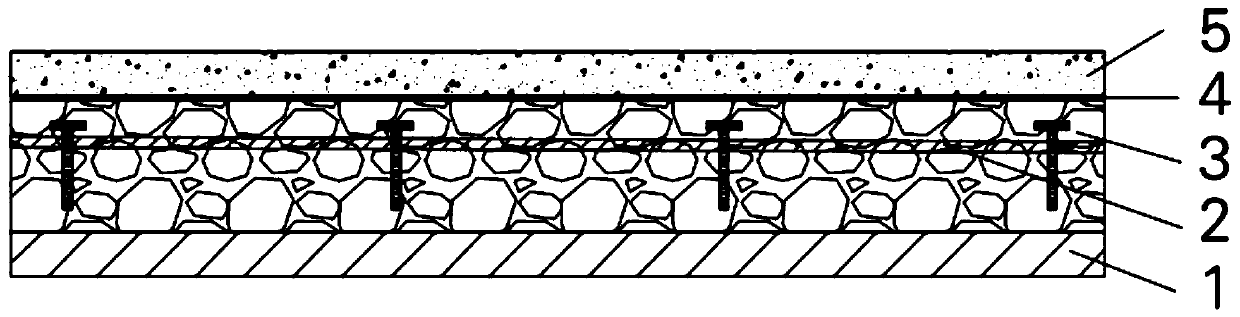

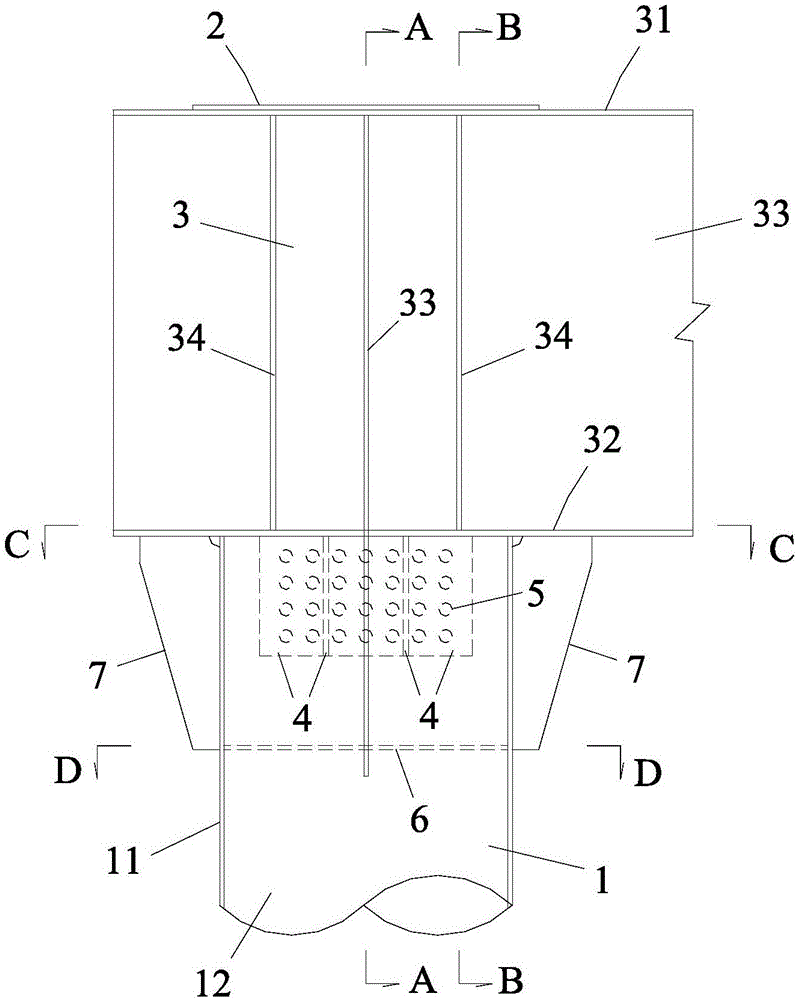

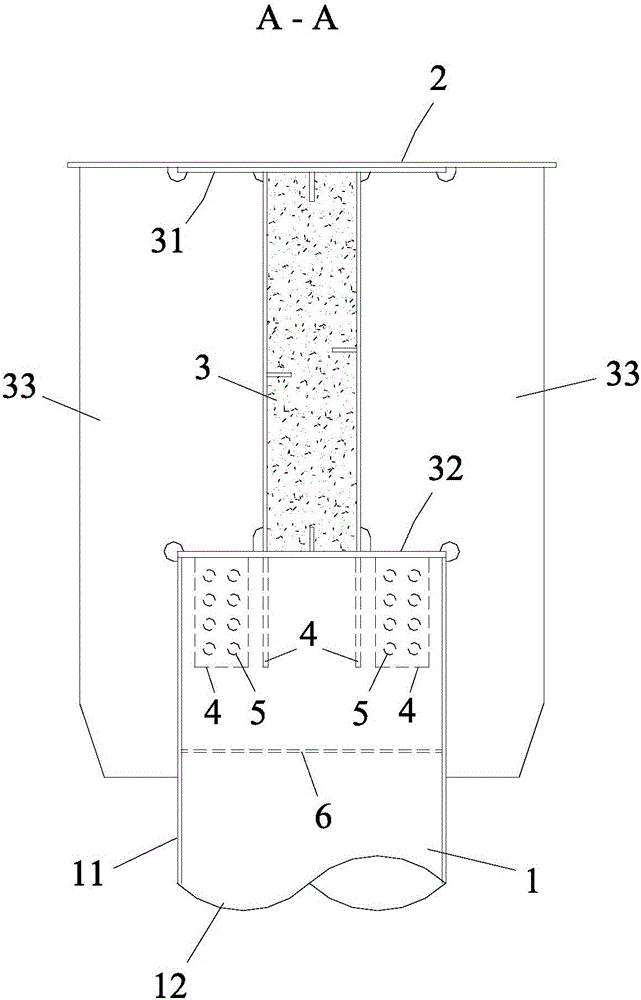

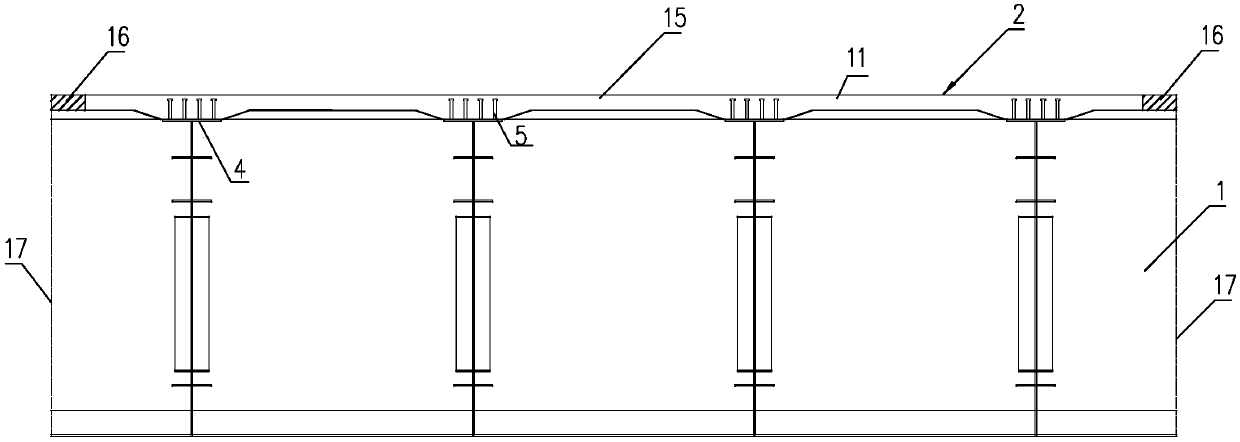

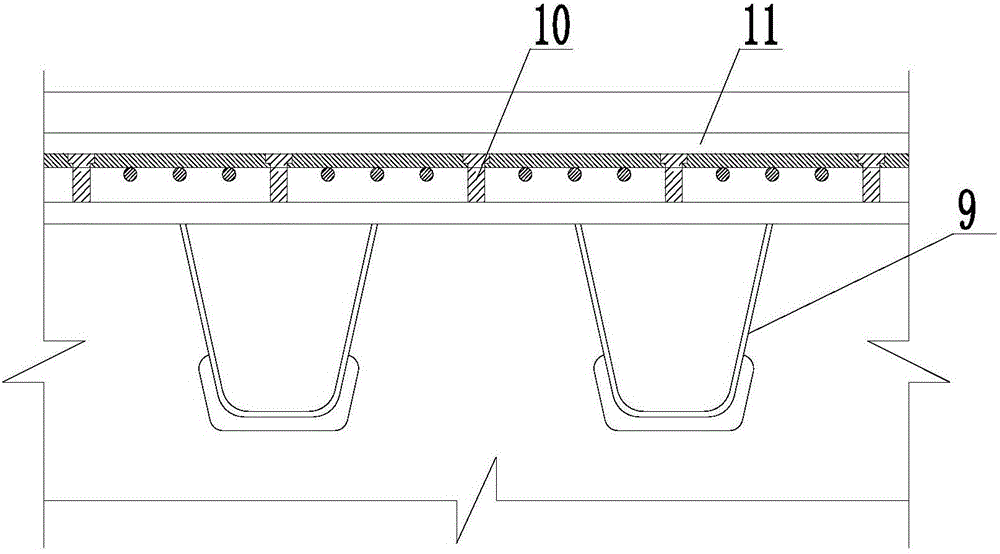

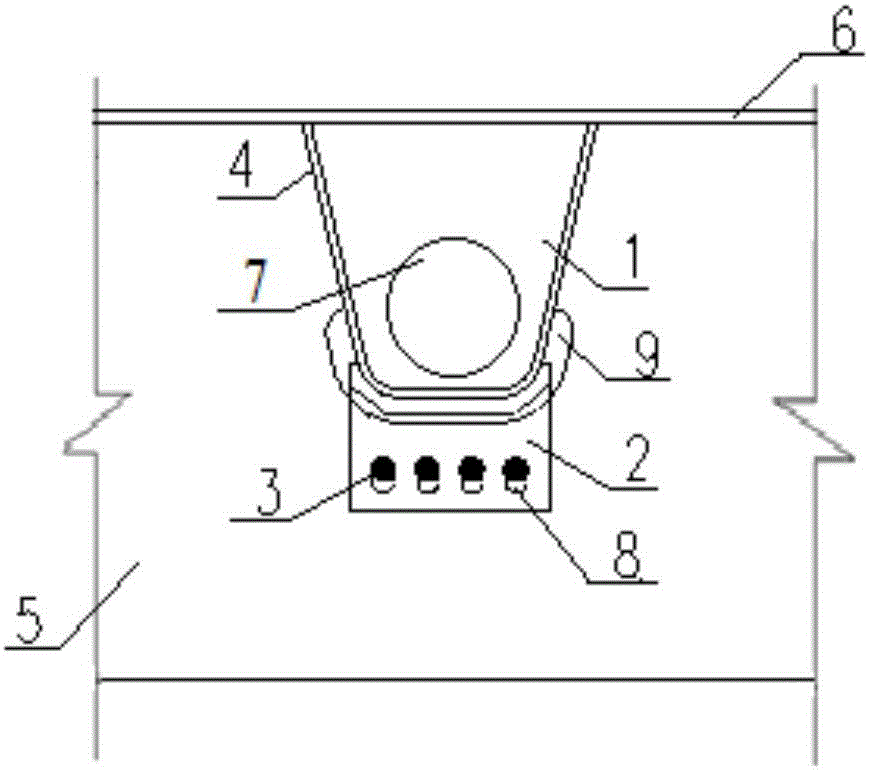

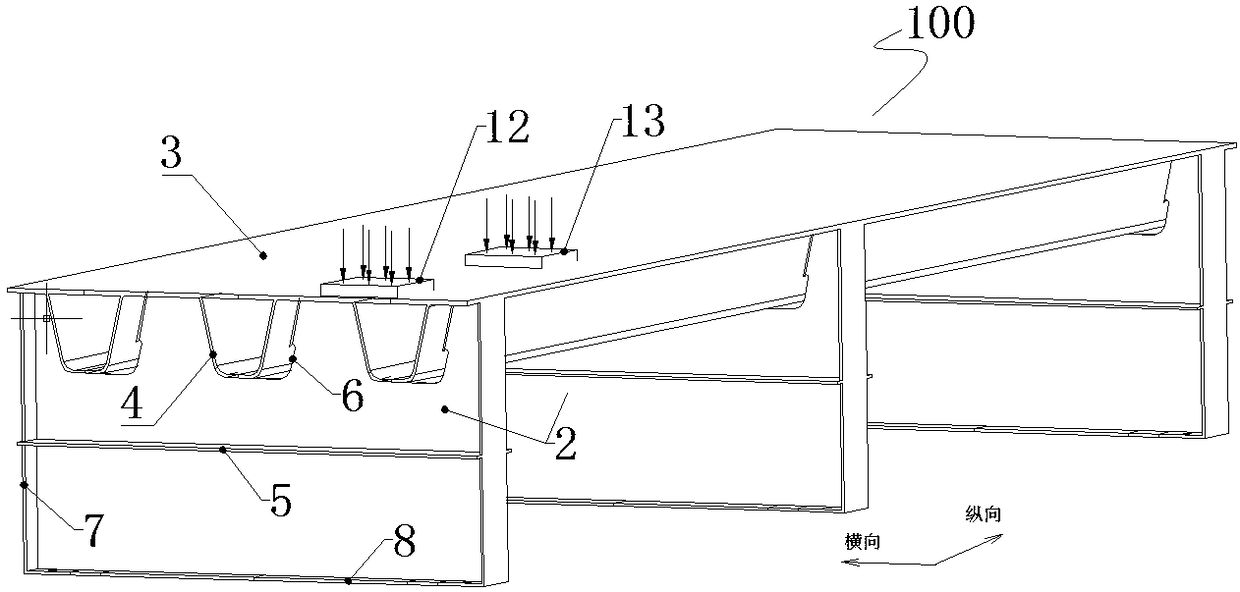

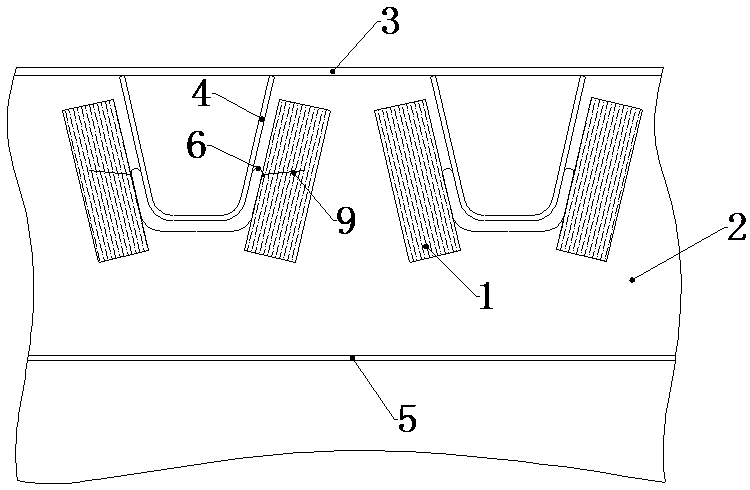

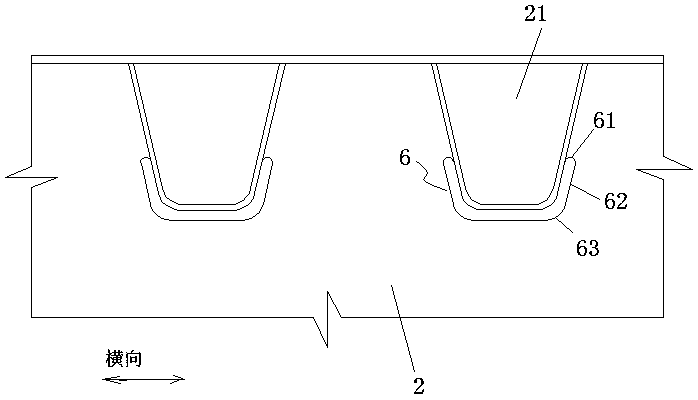

Ultra-high performance concrete (UHPC) combined deck slab with formwork

PendingCN107604815AHigh compressive strengthSmall water absorptionBridge structural detailsPrismRebar

The invention discloses an ultra-high performance concrete (UHPC) combined deck slab with a formwork. The UHPC combined deck slab is mainly formed by splicing of a plurality of unit plates. Each unitplate comprises a steel bottom plate and a UHPC slab body arranged on the steel bottom plate. Shear connecting pieces used for connecting the UHPC slab bodies are welded to the steel bottom plates. Each steel bottom plate is a flat thin-wall steel member in a quadrangular prism frustum shape. The adjacent steel bottom plates are connected with internal members of a main beam on the lower portionsof the deck slab, so that the steel bottom plates are connected into a whole. Steel bars connected into a whole are arranged on the upper portions of the shear connecting pieces in the forward direction of a bridge and the transverse direction of the bridge to form an upper edge force bearing steel net of the deck slab, the steel bottom plates and the shear connecting pieces become lower edge force bearing steel bars and shear steel bars of the deck slab correspondingly and serve as the bottom formwork jointly. The deck slab adopts UHPC so that the problems that in the prior art, cracking anddeck pavement damage are likely to occur can be effectively solved; and additionally the formwork engineering quantity can be reduced by a large margin, formwork mounting and demounting work is omitted, and thus the construction efficiency is improved.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

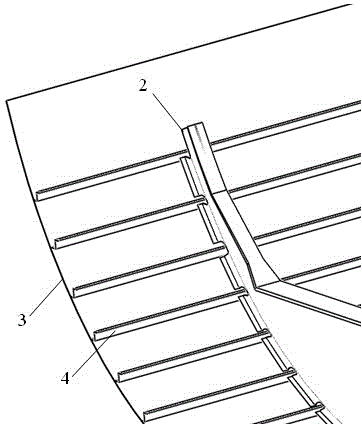

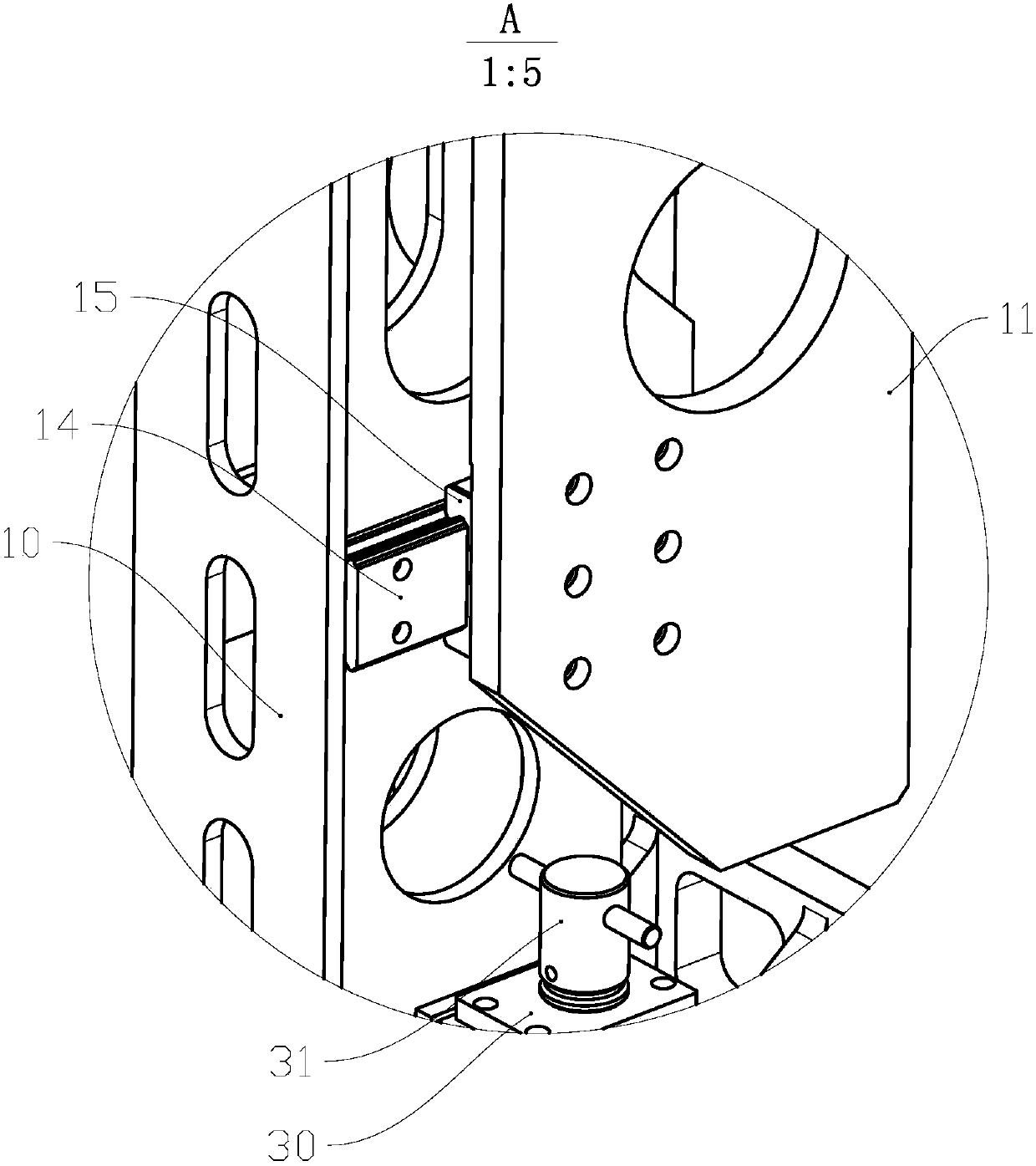

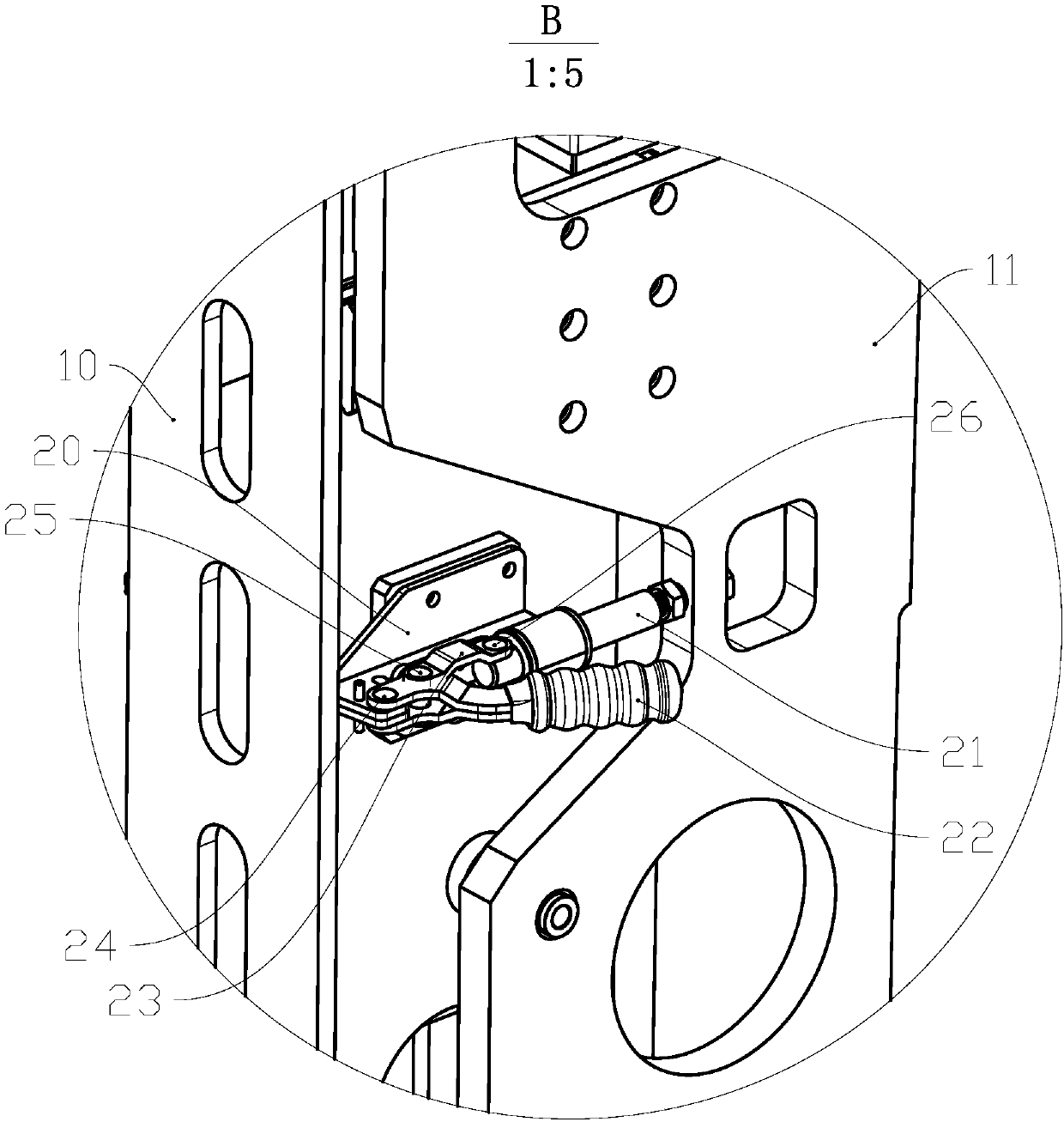

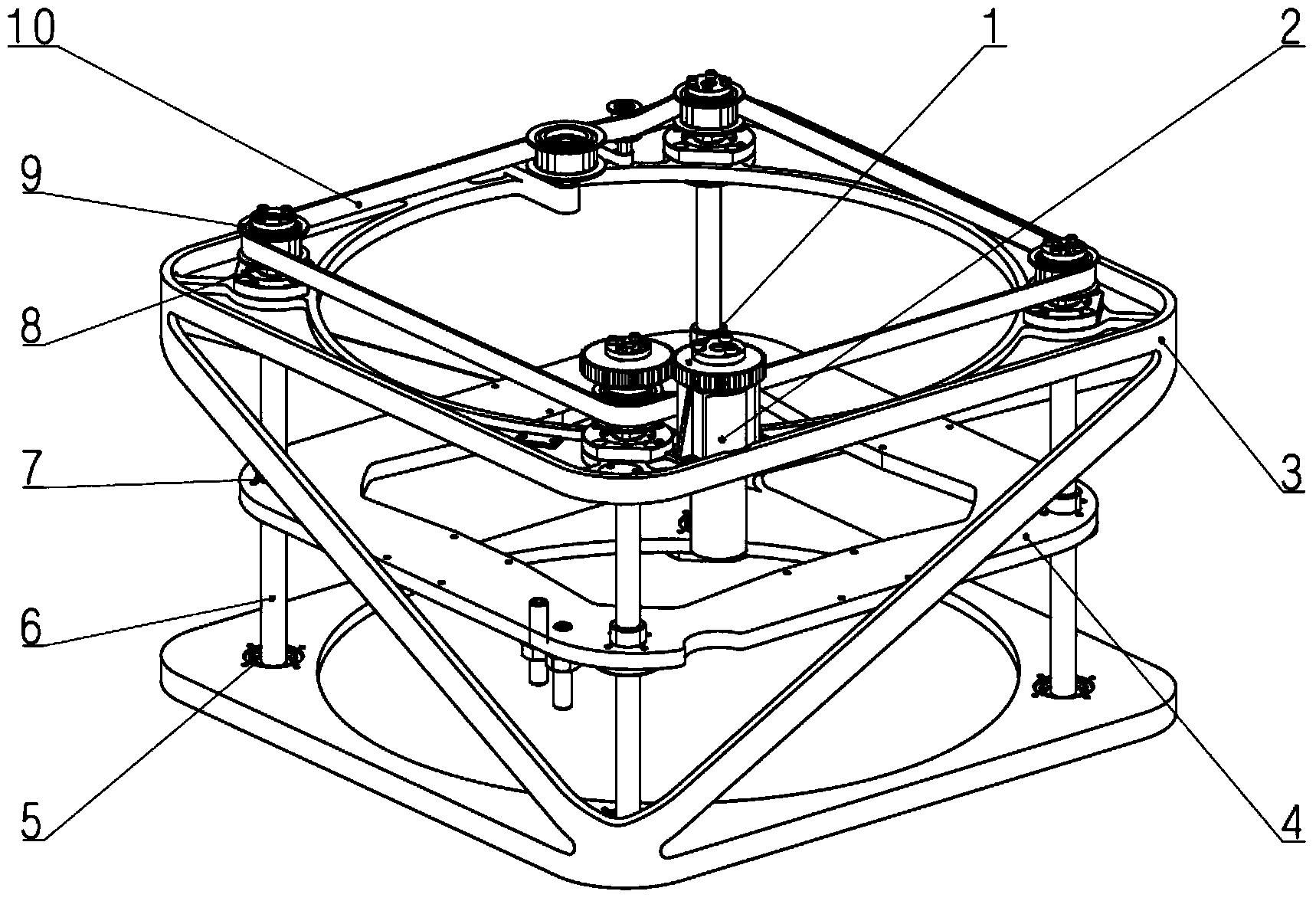

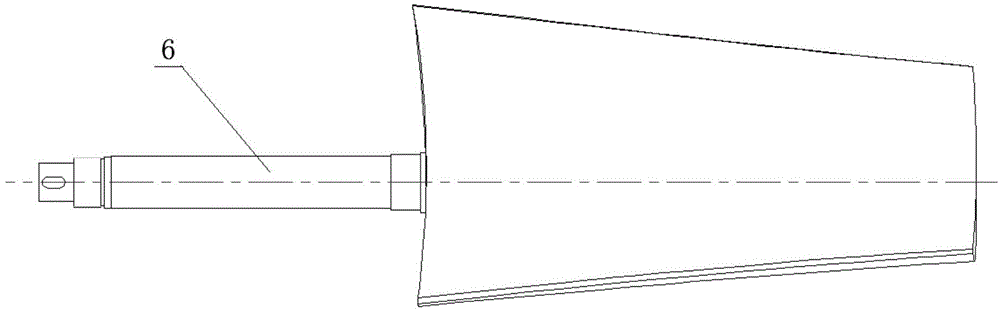

Large plane panel deformation control and restoration method based on local rigidity enhancement

InactiveCN102745339AAvoid deformationImprove local stiffnessAircraft assemblyDatabase machineControl system

The invention discloses a large plane panel deformation control and restoration method based on local rigidity enhancement. The method includes the following steps that: (1) process connectors are mounted to enhance the local rigidity of a large plane panel and inhibit the deformation of the large plane panel; (2) process ball head centre measurement data are recorded in a database computer, and the large plane panel is then taken down and hoisted away; (3) each axis of numerically controlled positioners and settling devices are controlled to settle and support the large plane panel, and the current positions of the numerically controlled positioners are uploaded to an integrated management system computer; (4) according to the restoration data sent by the integrated management system computer, a control system computer instructs the numerically controlled positioners to move to restore the large plane panel. The method has the following advantages that: (1) by mounting the process connectors, the local rigidity of the large plane panel is enhanced and the deformation of the large plane panel is inhibited; (2) the numerically controlled positioners move to restore the large plane panel; (3) toolings become equipment, and the system is easy and reliable to operate; (4) the positioning efficiency is increased by multiple times.

Owner:ZHEJIANG UNIV +1

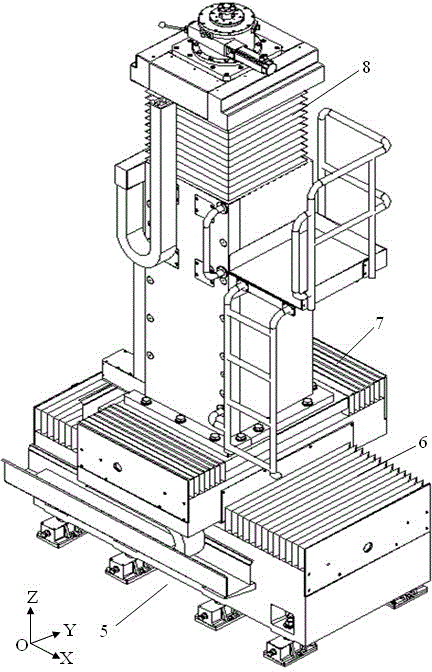

Conformal compressing tool of wing wallboard

ActiveCN107719692AImprove installation efficiencyQuality improvementAircraft assemblyEngineeringAircraft manufacturing

The invention discloses a conformal compressing tool of a wing wallboard, and belongs to the technical field of digital aircraft assembly. The conformal compressing tool comprises a conformal frame, the conformal frame comprises a supporting frame, wallboard connecting parts and a wallboard compressing part, wherein the wallboard connecting part and the wallboard compressing part are installed onthe supporting frame, the face, where the wallboard compressing part exerts pressure, of a wallboard is a curved face adaptive to the face of a pressure bearing plate of the wallboard; the two or morewallboard connecting parts are arrayed in the wallboard heading at intervals; a pushing and pressing mechanism is arranged between the wallboard compressing part and the supporting frame and used forforcing the wallboard compressing part to move relative to the supporting frame and compressing the wallboard. The conformal tool is connected with the wallboard, not only wallboard rigidity can be improved, the wallboard and a wing rib skeleton can be compressed to improve the wallboard installing efficiency and quality, and the conformal compressing tool can be widely applied to the aircraft manufacturing field.

Owner:ZHEJIANG UNIV

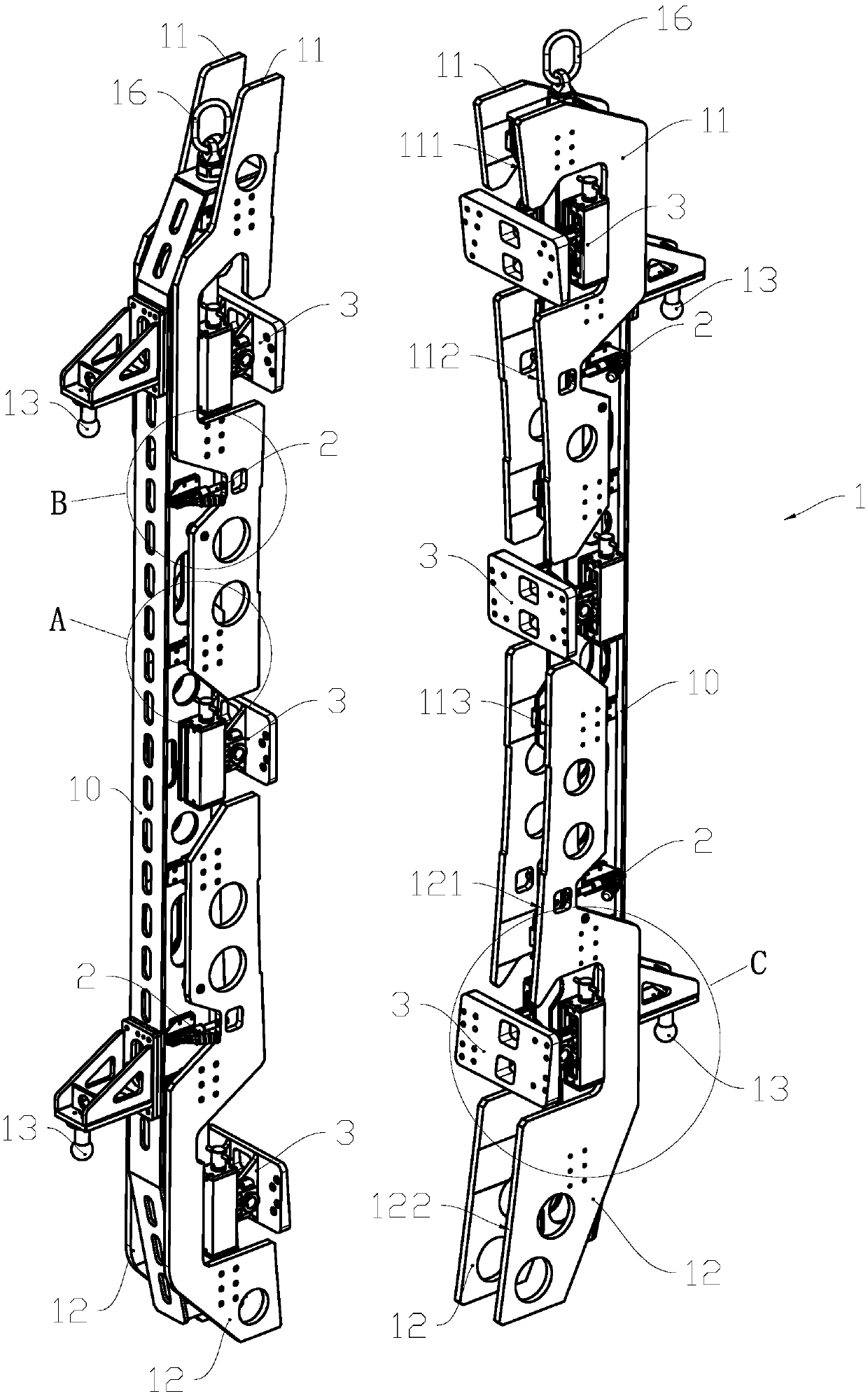

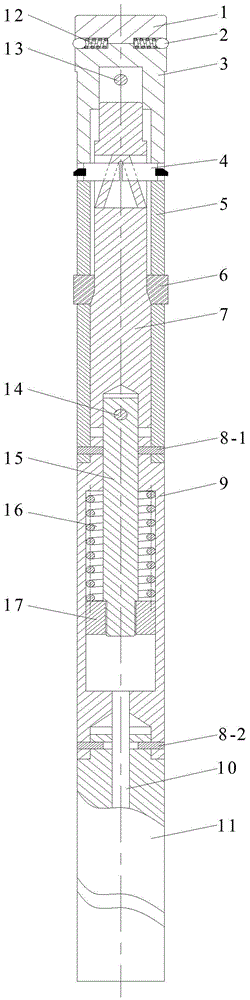

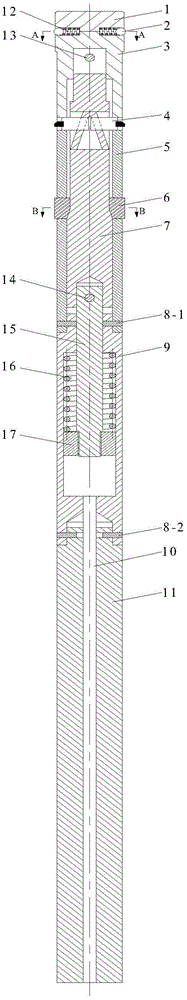

Lifting device for onboard optoelectronic platform

InactiveCN104044749APlay the role of orientationAvoid deformationAircraft componentsAviationGear drive

The invention provides a lifting device for an onboard optoelectronic platform, belongs to the technical field of aviation optoelectronics, and solves the problems of unstable structure and poor rigid connectivity of the existing lifting device for the onboard optoelectronic platform. The device comprises a gear bank, a motor, a substrate, a lifting plate, four screws, four toothed belt wheels and a toothed synchronous belt, wherein the gear bank comprises a driving gear and a driven gear; the lifting plate is connected with the four screws; upper and lower ends of the four screws are connected with the substrate; the motor is installed on the substrate; the driving gear is arranged on the motor; the driven gear is connected with one of the four screws; the toothed belt wheels are connected with the upper ends of the screws; the toothed synchronous belt is wound on the four toothed belt wheels; when the motor is operated, the driven gear drives one of the four screws to rotate, then the toothed synchronous belt drives the four toothed belt wheels to rotate synchronously, and the rotation movement of the four screws is changed into up-and-down movement of the lifting plate. The lifting device disclosed by the invention is compact in structure, easy to install and stable.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

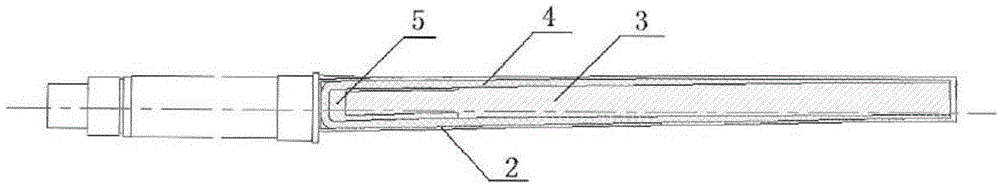

Boring bar special for machining deep hole and inner groove

InactiveCN105642929AIncrease stiffnessImprove local stiffnessBoring barsHydraulic cylinderTangential force

The invention discloses a segmented type boring bar with a guide support part and special for machining a deep and long hole and an inner groove. The boring bar comprises the guide support part, a tool bit part, a feeding and retracting mechanism, a rod body part and a hydraulic drive part. The guide support part comprises a guide head and an auxiliary support part. The guide head is divided into a front guide head body and a rear guide head body which are connected through a screw. The rear guide head body is connected with the front end of a sleeve through a pin, a hydraulic cylinder is connected with the rear end of the sleeve through a pin, and a cutter bar is connected with the bottom of the hydraulic cylinder through a pin. When the inner groove is bored, the guide support part has a supporting effect, and the local static rigidity of the tool bit part can be improved. By means of the feeding and retracting mechanism, the axial positioning and the feeding and retracting movement of the tool can be achieved. The segmented type special tool with the guide support part is suitable for machining the multi-layer inner groove and can also be used for boring the inner wall of the deep and long hole; a blade is symmetrically arranged, so radial force and tangential force counteract, the rigidity of the cutter bar is greatly improved, and machining conditions are remarkably improved.

Owner:NANJING UNIV OF SCI & TECH

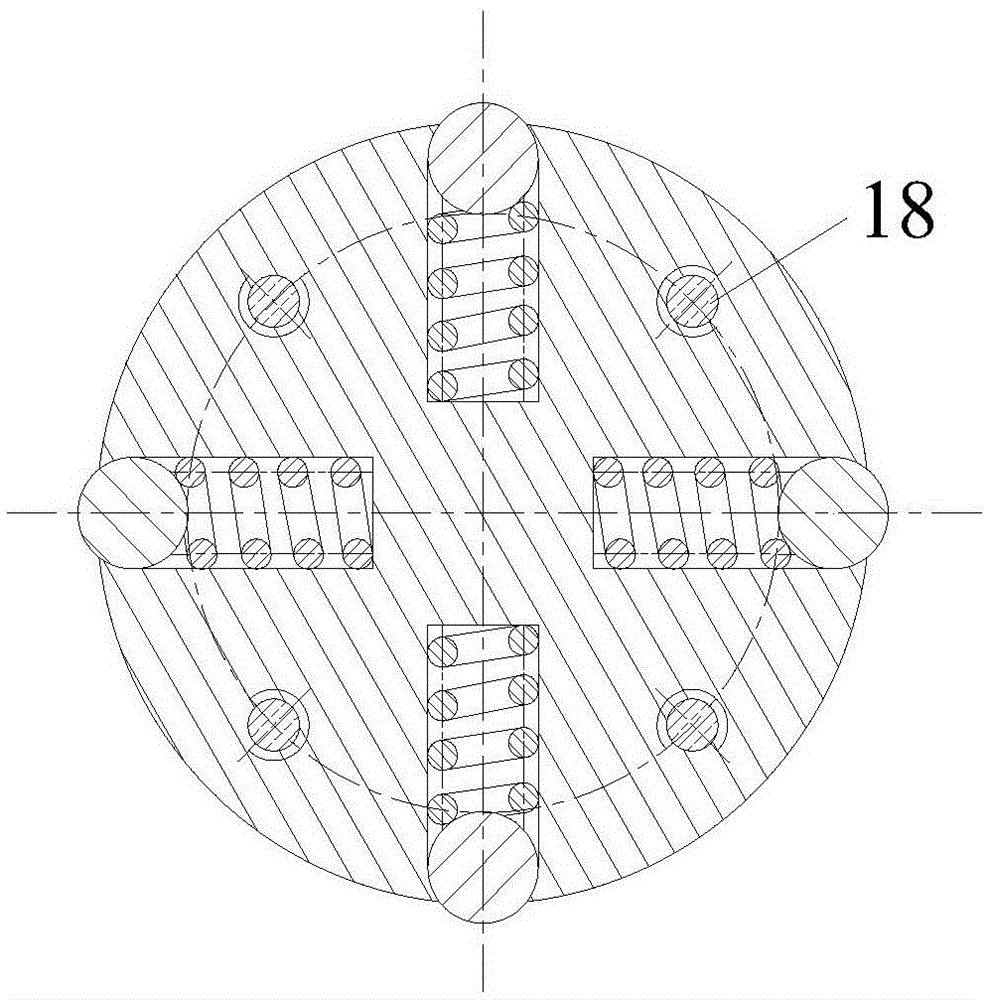

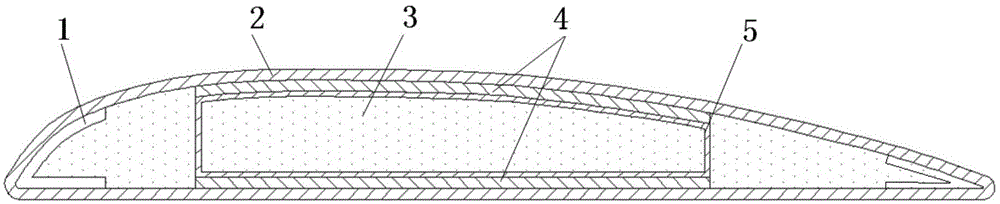

Composite material blade for wind tunnel

ActiveCN103982463AStrong resistance to deformationReduce weightPump componentsPumpsEngineeringFront edge

The invention provides a composite material blade for a wind tunnel. The composite material blade for the wind tunnel comprises a covering skin, a front edge reinforcement area, a rear edge reinforcement area, foam core materials, a main bearing beam and a metal blade handle, wherein the metal blade handle comprises a blade portion in square frame shape and a shaft portion in long rod shape, the blade portion is stretched into a central area in the covering skin in blade shape, the front edge reinforcement area and the rear edge reinforcement area are respectively arranged at the front end and the rear end of the interior of the covering skin, the covering skin and the blade portion are filled with the foam core materials, the square main bearing beam is embedded between the covering skin and the blade portion, the thickness of the main bearing beam is varied and decreases progressively in ladder mode from one side of the shaft portion, and the width of the main bearing beam is varied and decreases progressively in ladder mode from the side of the shaft portion. The composite material blade for the wind tunnel is made of carbon fiber composite material, and thereby is light and strong. Furthermore, the foam core materials have an effective supporting function for a wing-shaped profile surface of the composite material blade for the wind tunnel, and the main bearing beam bears a majority of loads on the composite material blade for the wind tunnel.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

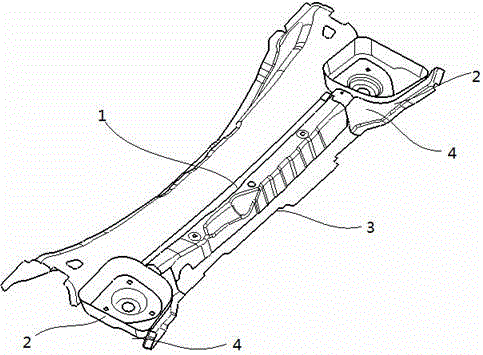

Auxiliary frame mounting point structure

The invention aims at providing an auxiliary frame mounting point structure. The auxiliary frame mounting point structure can realize drop in a collision process and reduce harm on a passenger in a passenger compartment. The auxiliary frame mounting point structure comprises an auxiliary frame provided with a mounting support and a longitudinal beam. The auxiliary frame mounting point structure is characterized inthat an internal screw thread sleeve with the bottom end open is fixed on the longitudinal beam; the mounting support is composed of a tubular support body with the two ends open and a cap body fixedly arranged at the top end of the support body, gaps corresponding in position are formed in the front end of the cap body and the front end of the upper part of the support body, a guide slot connected with the gaps is formed in the cap body, and the guide slot extends along the length direction of an automobile; and the auxiliary frame is fixedly connected with the longitudinal beam by utilizing a bolt which penetrates through the support body and the cap body and is screwed into the internal screw thread sleeve, and an anti-drop part with the diameter larger than the width of the guide slot is arranged at the bottom end of the bolt. The auxiliary frame mounting point structure has the advantages that the auxiliary frame can drop in the collision process and harm done to a passenger can be reduced.

Owner:CHERY AUTOMOBILE CO LTD

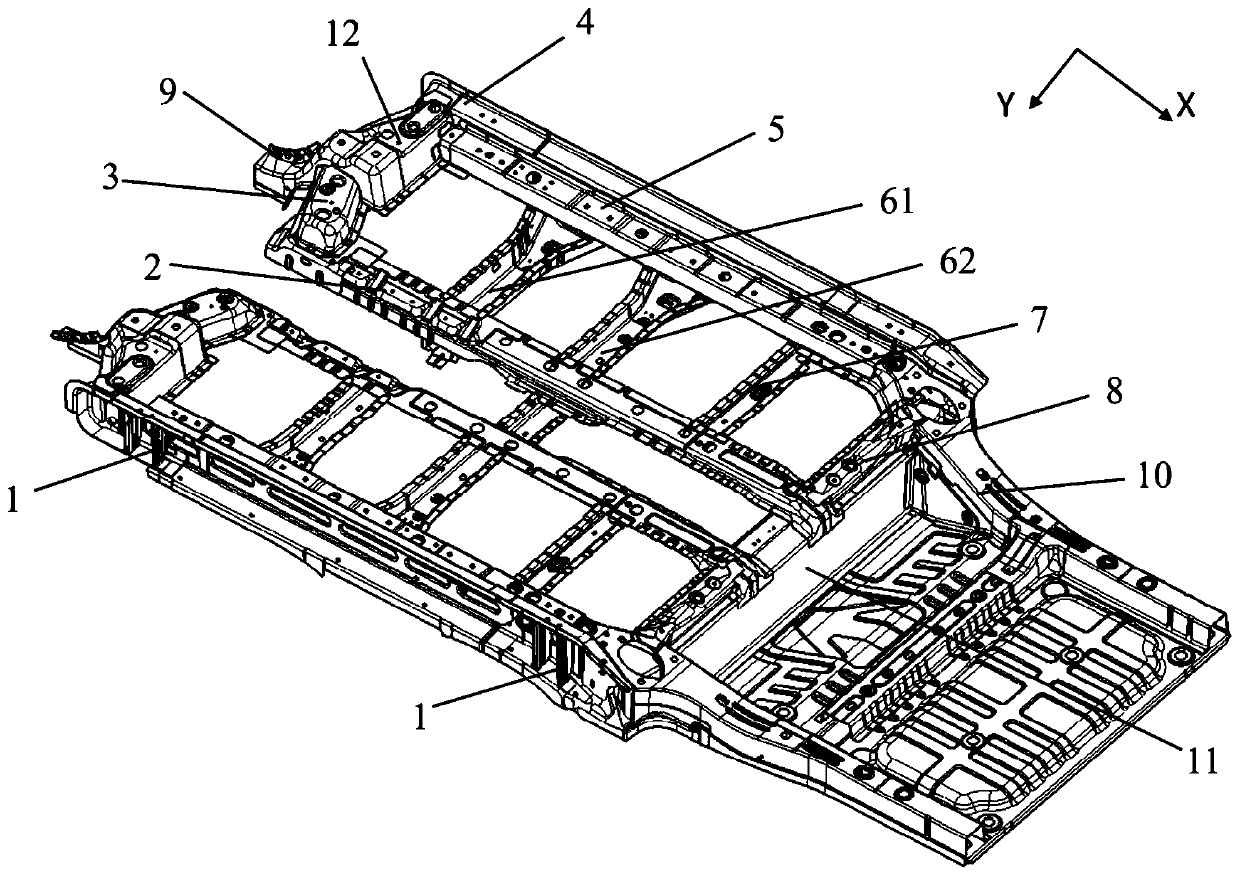

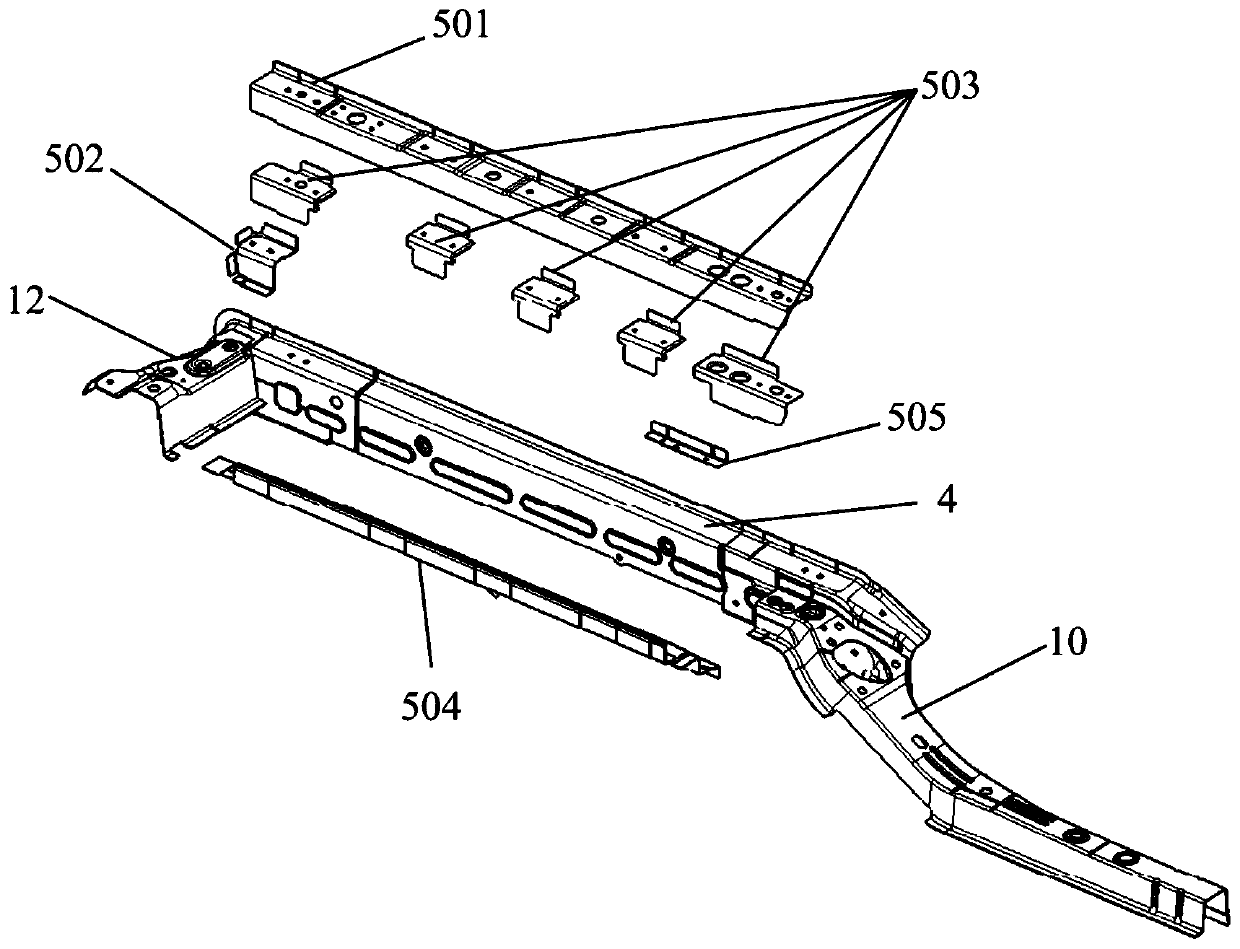

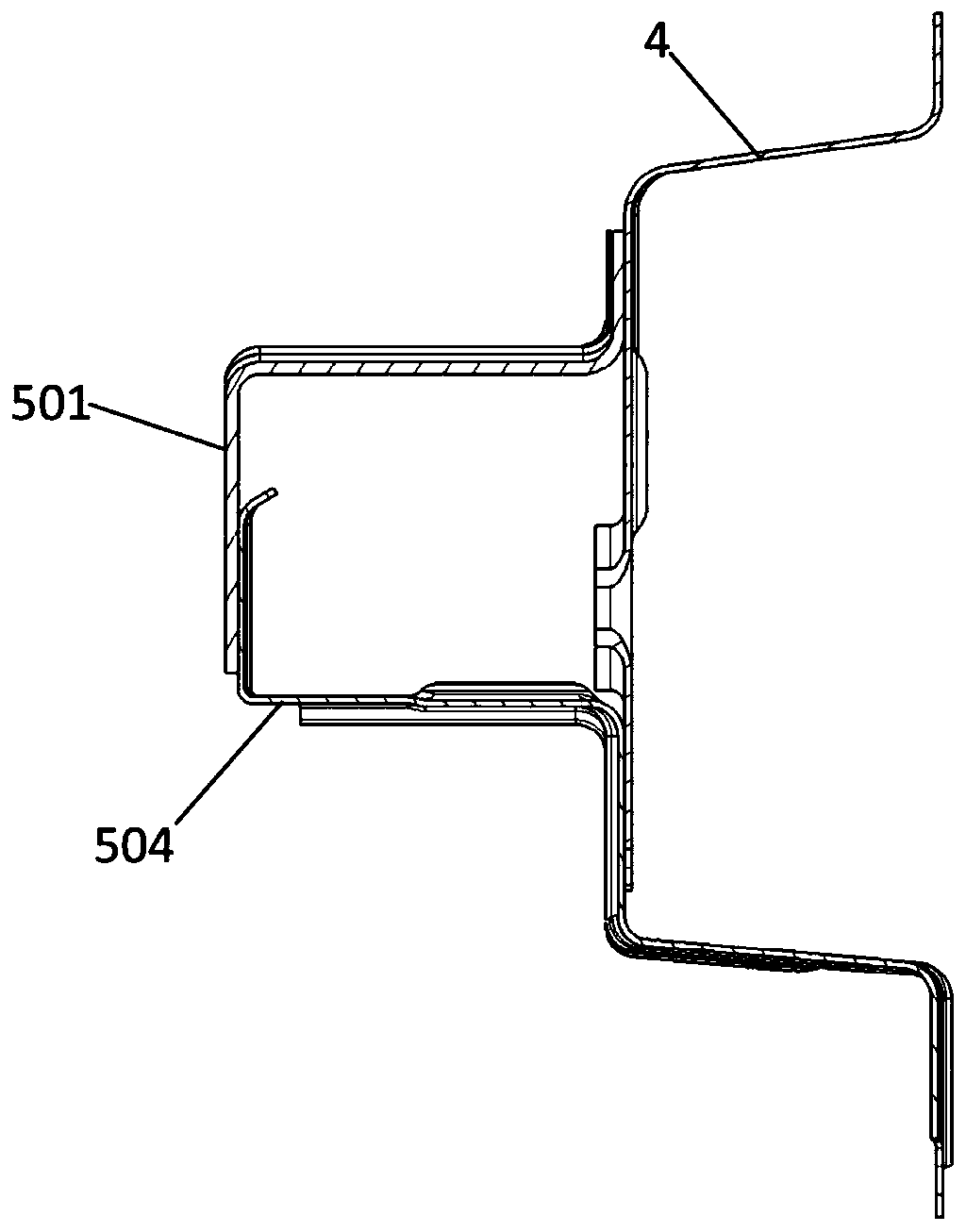

Vehicle body structure for battery-replaceable electric vehicle

ActiveCN111186492AHigh strengthIncrease stiffnessCharging stationsElectric propulsion mountingLap jointElectric cars

The invention provides a vehicle body structure for a battery-replaceable electric vehicle, and belongs to the field of vehicles. The vehicle body structure is of a bilateral symmetry structure. The vehicle body structure comprises a plurality of longitudinal beams and a plurality of cross beams. The longitudinal beams extend along the longitudinal direction of the vehicle, the plurality of longitudinal beams at least comprise two doorsill beams and two battery replacing longitudinal beams which are positioned on the left side and the right side of the vehicle, and middle channel side reinforcing beams which are positioned on the left side and the right side of a middle channel of the vehicle, each battery replacing longitudinal beam is connected with the corresponding doorsill beam, and the battery replacing longitudinal beams are used for mounting a battery pack. The multiple cross beams extend in the transverse direction of the vehicle and are in lap joint among the multiple longitudinal beams, and at least one cross beam is through in the transverse direction of the vehicle. According to the vehicle body structure, the battery pack can be protected from being extruded, and theproblem that the precision of a battery replacing plane is poor due to the fact that the battery replacing beam bodies are directly connected with other components through a welding process is solved.

Owner:ZHEJIANG JIZHI NEW ENERGY AUTOMOBILE TECH CO LTD +1

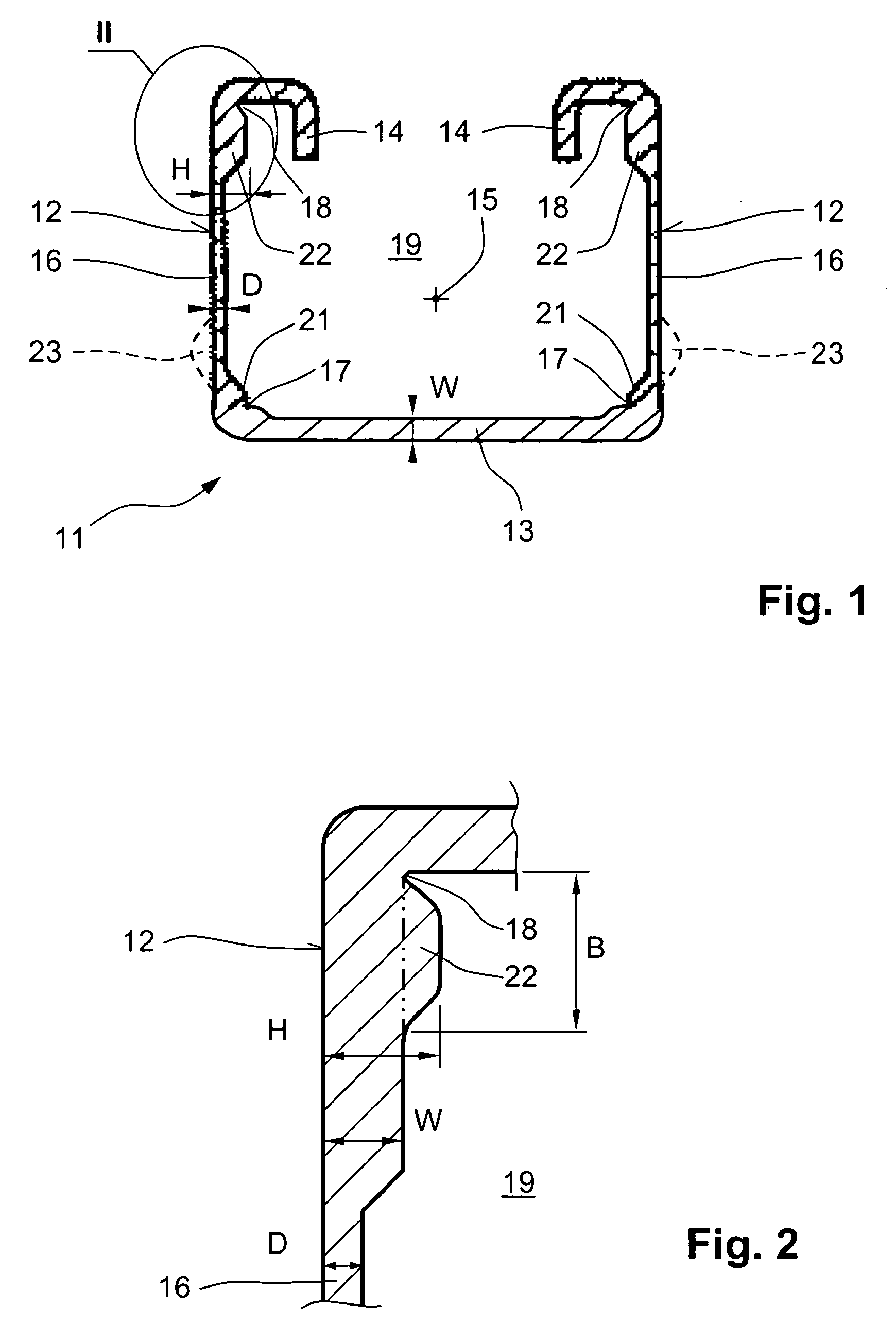

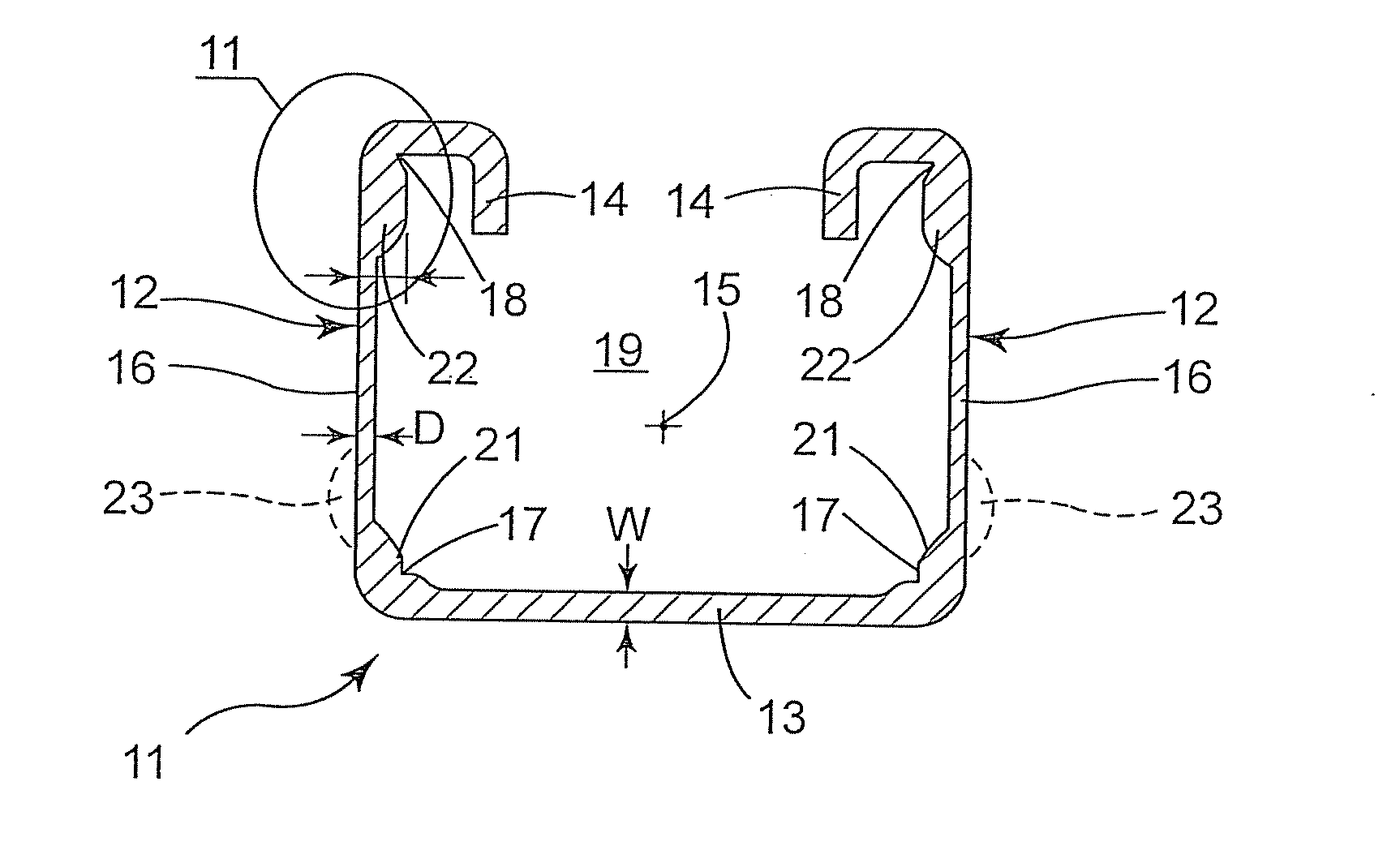

Profile

InactiveUS20090133460A1Increase stiffnessImprove local stiffnessGirdersJoistsMechanical engineeringEngineering

Owner:HILTI AG

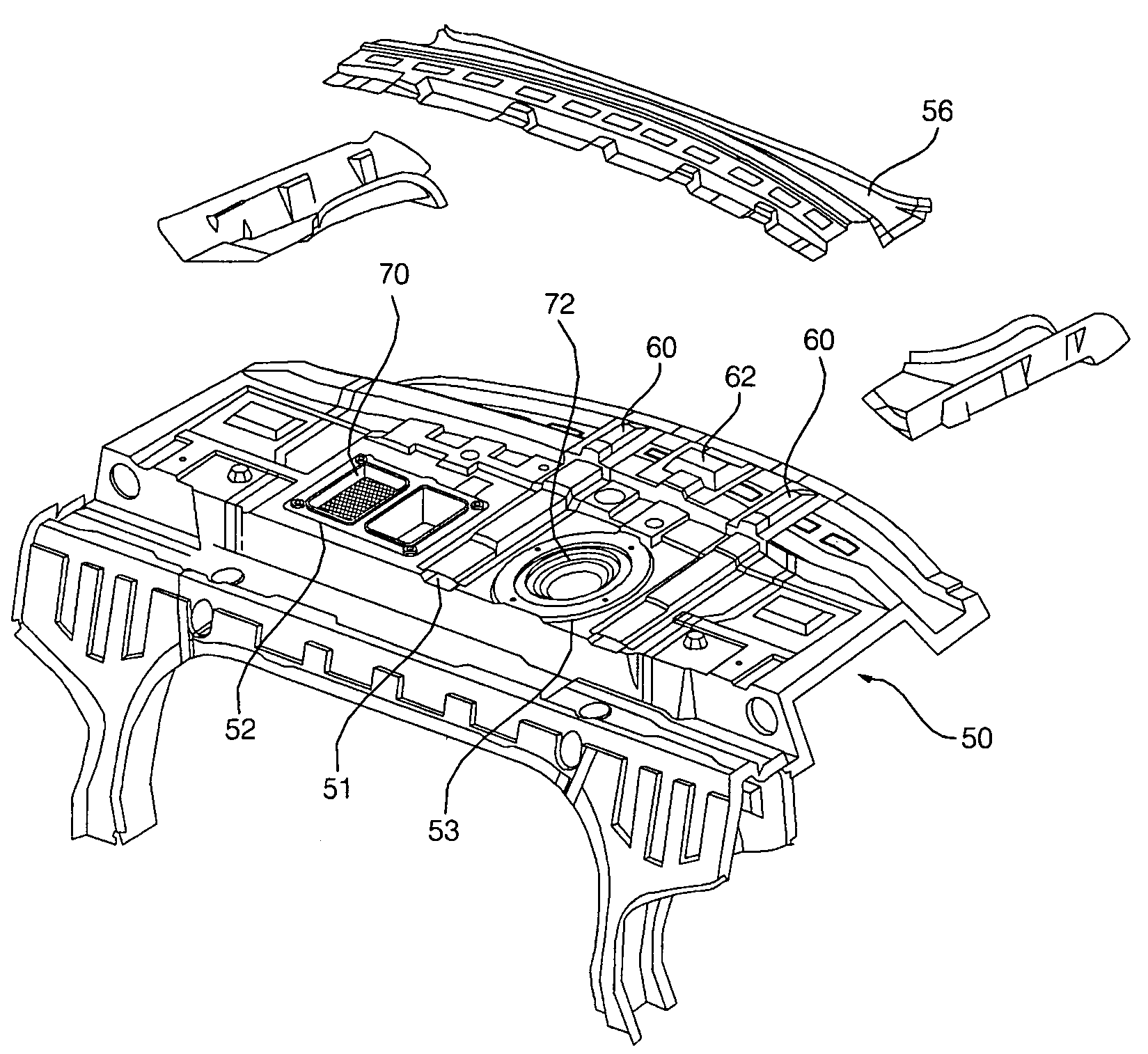

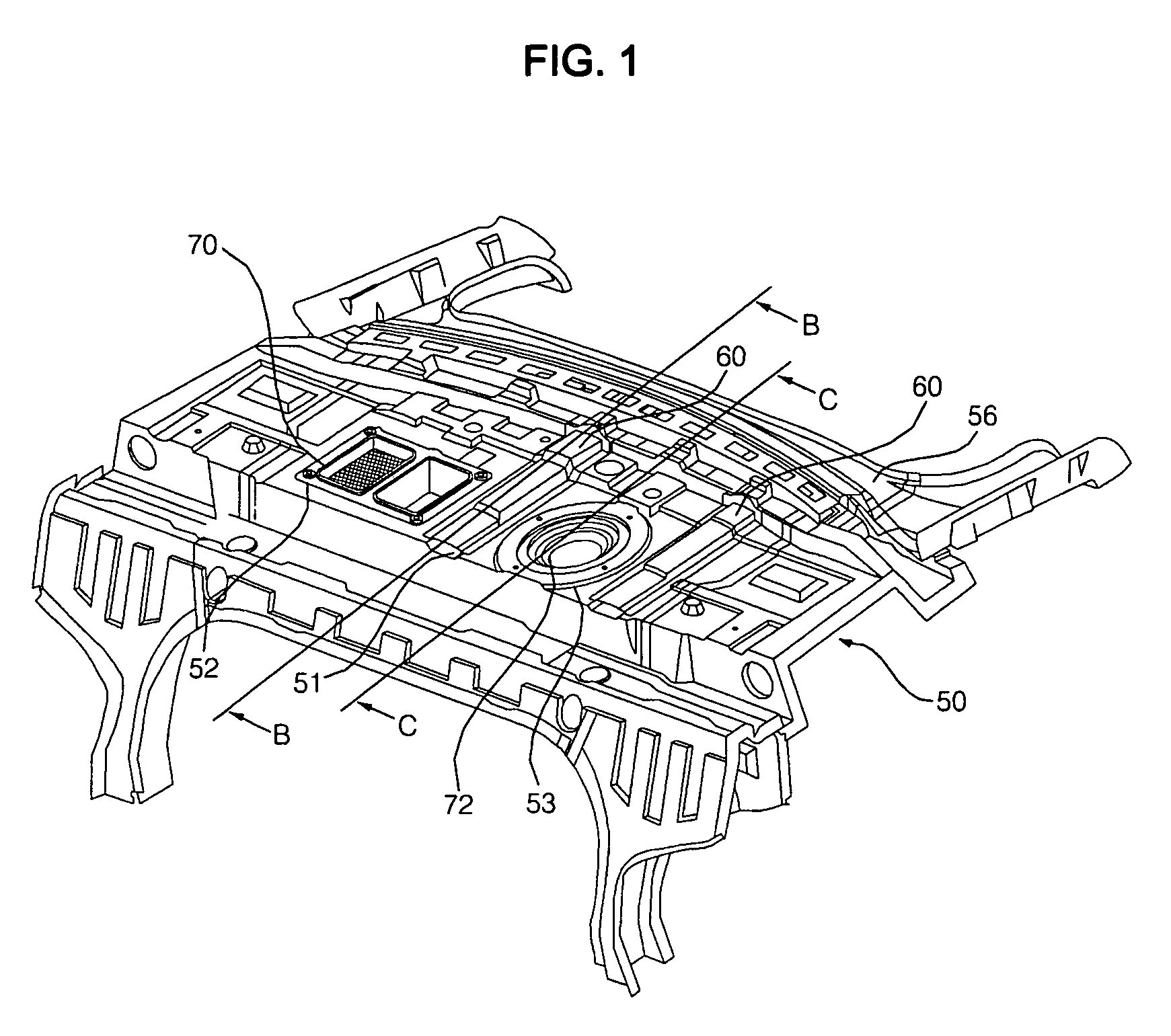

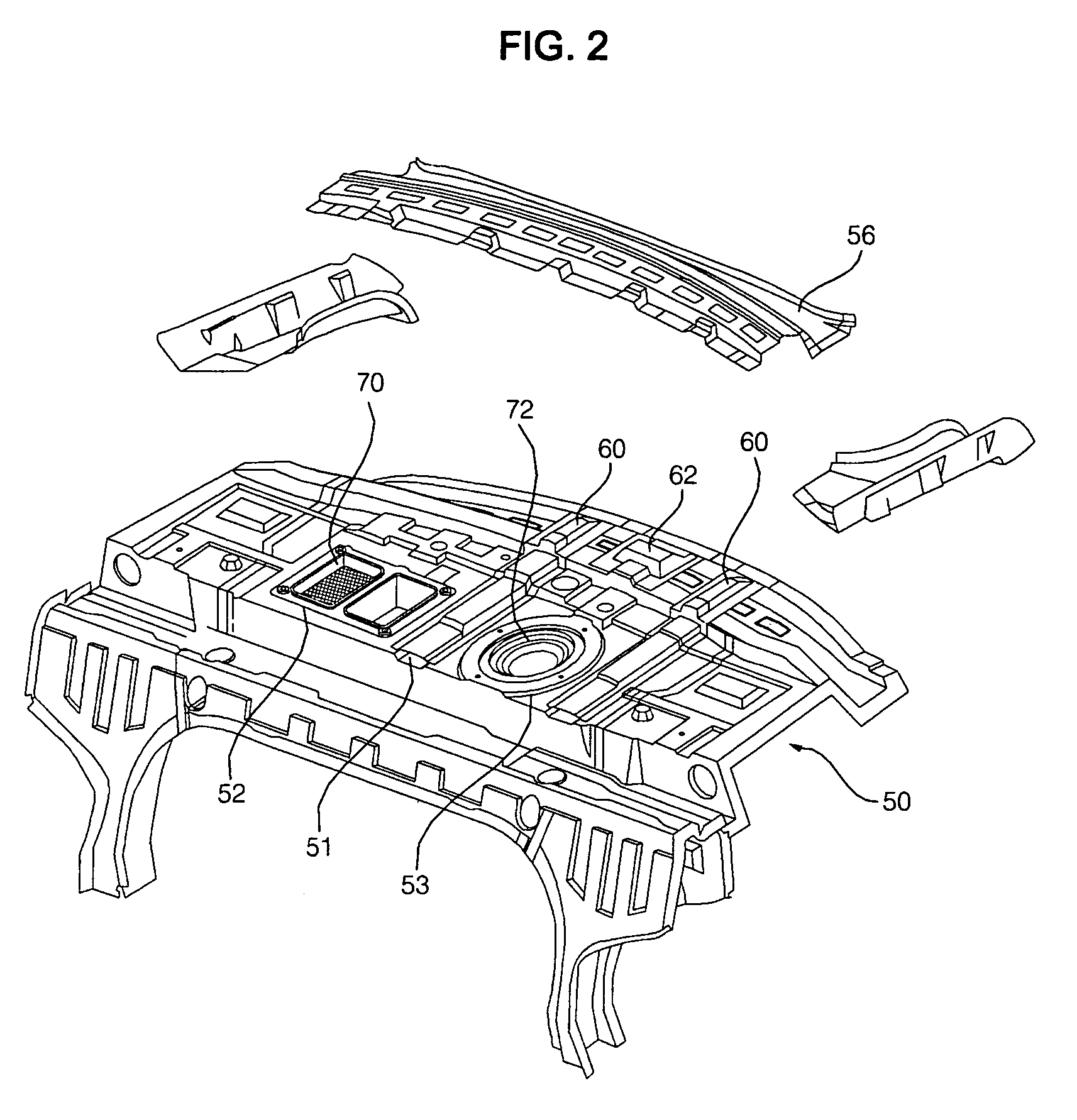

Package tray of vehicles and reinforcing structure thereof

InactiveUS7410208B2Improve local stiffnessSimple structureVehicle seatsDashboardsEngineeringAcoustic wave

Owner:HYUNDAI MOTOR CO LTD

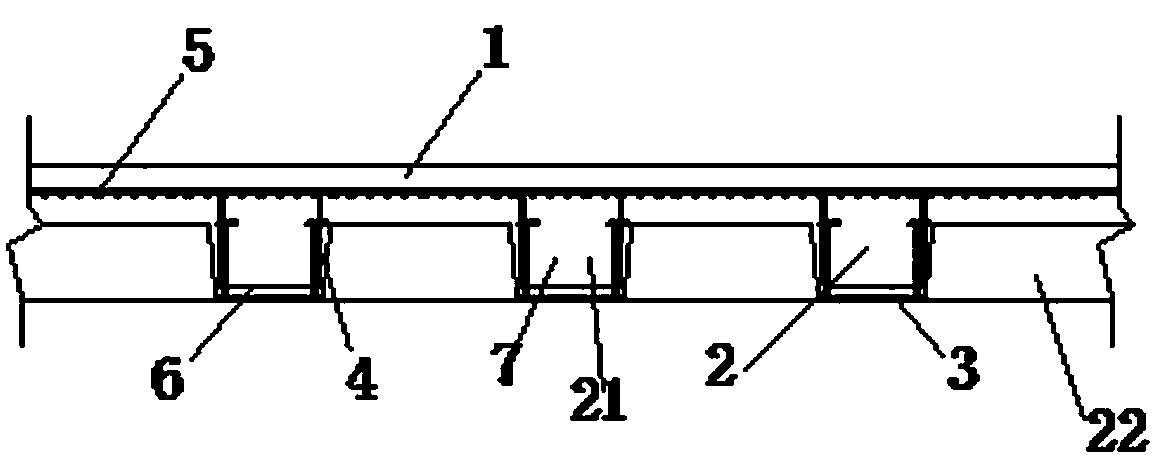

Steel bridge light pavement layer structure and paving method

InactiveCN110080087AReduce fatigue stressImprove local stiffnessBridge structural detailsBridge erection/assemblyBridge deckThin layer

The invention provides a steel bridge light pavement layer structure and a paving method and relates to the technical field of steel bridge paving. The fatigue stress of a bridge deck steel structurecan be effectively reduced, the local rigidity of a bridge deck system can be greatly enhanced, and the fatigue life of a steel bridge deck can be prolonged. The steel bridge light pavement layer structure comprises the steel bridge deck, a cement concrete layer, an adhesive layer and a multifunctional thin layer in sequence from bottom to top; the two adjacent layers are connected with each other; a reinforcement mesh is arranged in the cement concrete layer; the reinforcement mesh is fixedly connected with the steel bridge deck through a plurality of short bolt nails; the multifunctional thin layer is an open-graded or cut-off graded asphalt concrete thin layer; and the thickness of the multifunctional thin layer is 10-25 mm. The steel bridge light pavement layer structure provided by the technical scheme of the invention is suitable for steel bridge paving processes of new construction and bridge deck large and medium-sized repairing.

Owner:BEIJING ZHIHUATONG TECH CO LTD

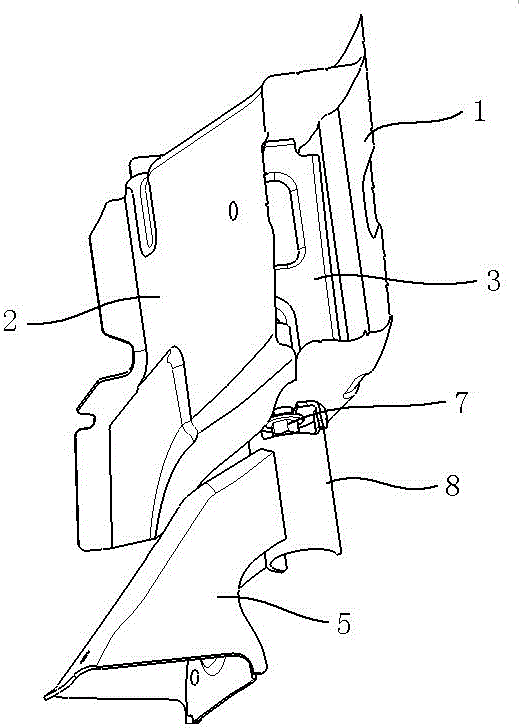

Reinforcing device for rear body of vehicle

ActiveCN105523088AImprove local stiffnessIncrease stiffnessSuperstructure subunitsEngineeringMechanical engineering

The invention discloses a reinforcing device for a rear body of a vehicle. The rear body of the vehicle comprises a drain channel member, wherein the drain channel member is fixedly connected with a rear shelf component, a side-frame outer panel component and a tail light base plate component of the rear body. The reinforcing device comprises a substantially L-shaped reinforcing plate, wherein the front end of the reinforcing plate is fixedly connected with both a C-pillar inner panel and a side connecting plate of a rear shelf component, which is at the front part of the reinforcing plate; the middle part of the reinforcing plate is fixedly connected with the drain channel member; the rear part of the reinforcing plate is fixedly connected with the tail light base plate component; and the rear end of the reinforcing plate is connected with a rear end panel assembly. Therefore, the rear shelf component and the rear end panel assembly are connected by the reinforcing plate to form a complete annular structure.

Owner:PEZHO SITROEN AUTOMOBILS SA

Pier and beam transitional connecting structure

ActiveCN105926427ASimple connection structureEasy to operateBridge structural detailsEngineeringShear force

The invention relates to a pier and beam transitional connecting structure which comprises a pier column and a cover beam. The pier column comprises a steel pipe and concrete arranged in the steel pipe. The cover beam comprises a cover beam top board and a cover beam bottom board. The lower surface of the cover beam bottom board is connected with multiple anchor boards. Each anchor board is provided with multiple holes. The cover beam bottom board is fixed to the top of the steel pipe of the pier column. The anchor boards are embedded in the concrete in the steel pipe. By the adoption of the pier and beam transitional connecting structure, the multiple anchor boards are arranged on the cover beam bottom board of the cover beam, and each anchor board is provided with the multiple holes, so that when the cover beam and the pier column are connected with each other, the anchor boards are directly inserted in the steel pipe of the pier column, the anchor boards are embedded in the concrete in a sleeved manner when the concrete in the steel pipe is poured, the holes in the anchor boards serve as shearing force holes to interact with the concrete, and anchoring connection between the pier column and the cover beam is achieved. The pier and beam transitional connecting structure is simple, convenient to operate, short in construction period and more stable and effective in connection.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

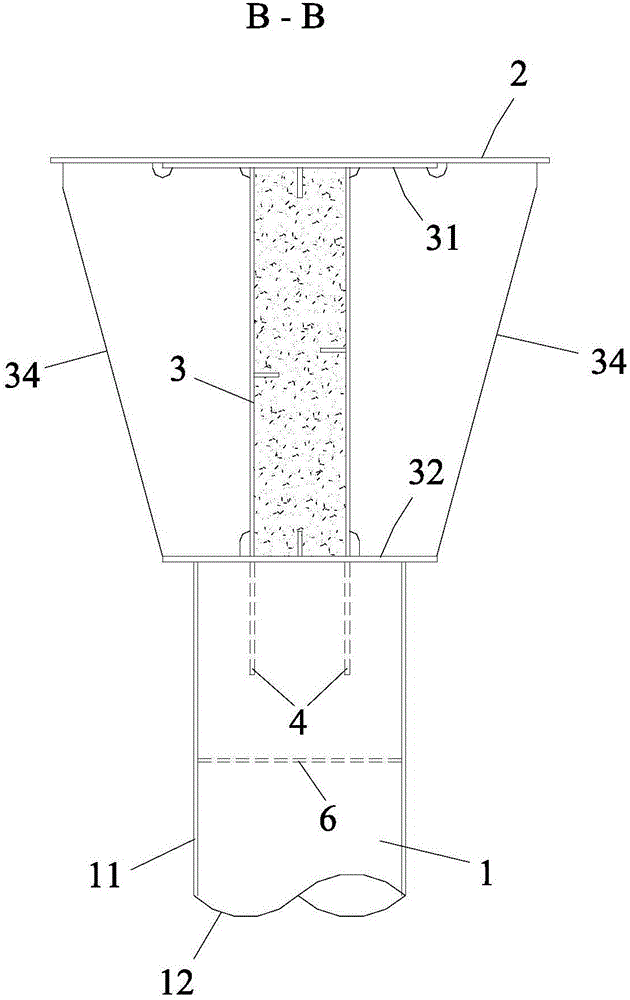

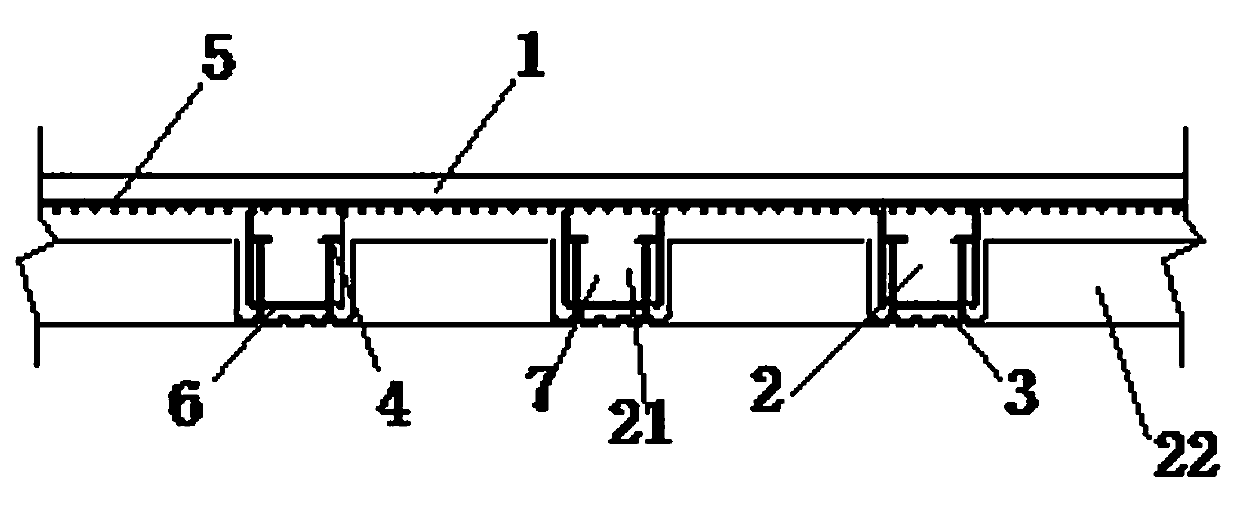

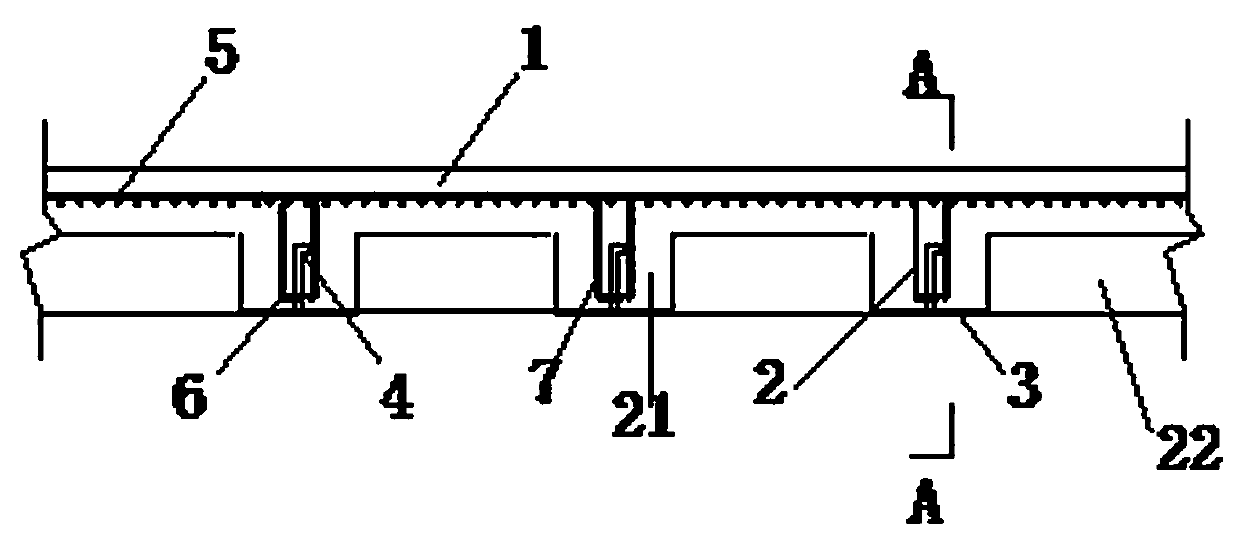

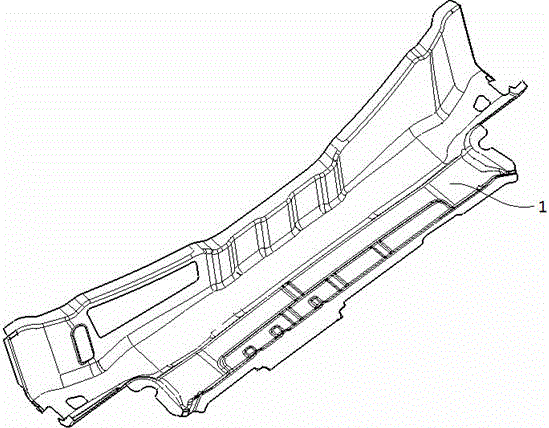

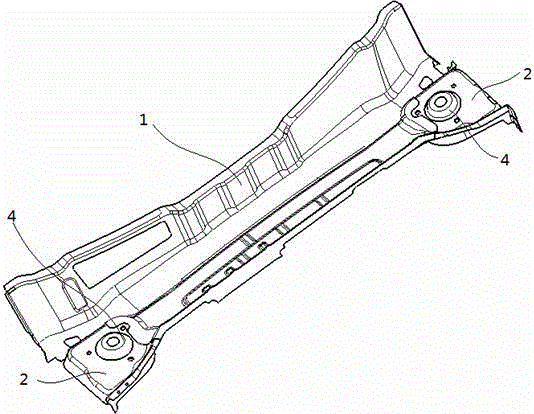

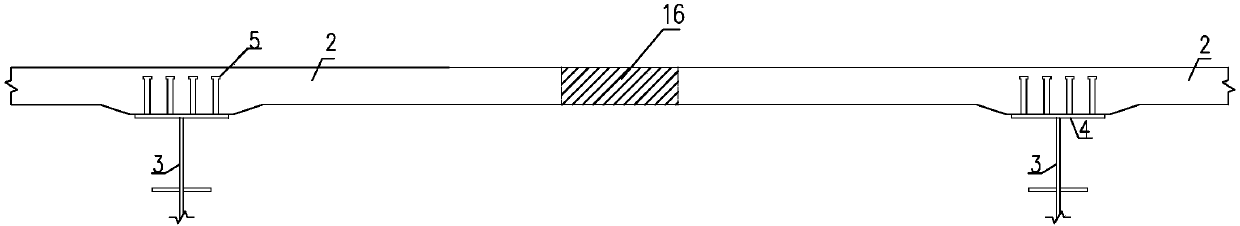

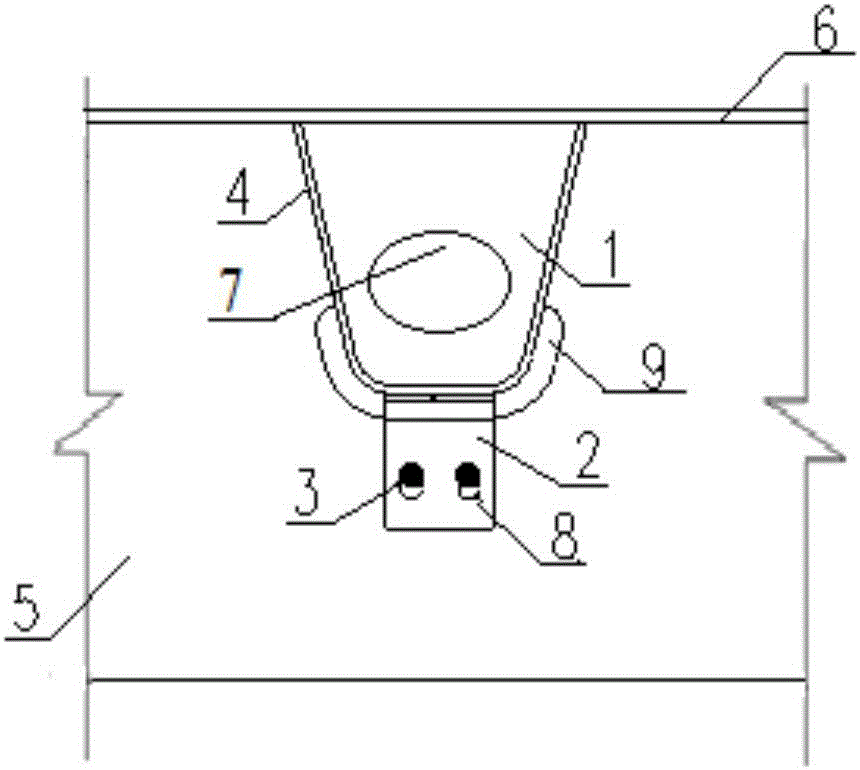

Ultra high performance concrete rib plate with rib bottom steel plate and machining method thereof

PendingCN109577189AGive full play to the tensile strengthImprove crack resistanceCeramic shaping apparatusBridge structural detailsSheet steelWhole body

The invention provides an ultra high performance concrete rib plate with a rib bottom steel plate and a machining method thereof. The ultra high performance concrete rib plate with the rib bottom steel plate is mainly to solve technical problems, such as easy fatigue cracking, poorer tensile and compressive performance, low section utilization efficiency and high cost, of an existing ultra high performance concrete rib plate. The key point of the technical scheme is that more than three plate ribs (2) are arranged at the bottom of a panel (1) to be connected with the panel (1) to form a wholebody; a reinforcing mesh (5) is arranged in the panel (1); the rib bottom steel plate (3) is arranged at the bottom of a rib body (7); a shear connector (4) is arranged on the upper surface of the ribbottom steel plate (3); a hoop (6) is arranged at the lower part of the reinforcing mesh (5); the hoop (6) is fixedly connected with the shear connector (4) so that the reinforcing mesh (5) is connected with the hoop (6) and the shear connector (4) to form an integral reinforcement structure; and ultra high performance concrete is poured outside the reinforcing mesh (5), the hoop (6) and the shear connector (4) to form the panel (1) and the plate ribs (2) which are connected to form a whole body.

Owner:HUNAN UNIV +1

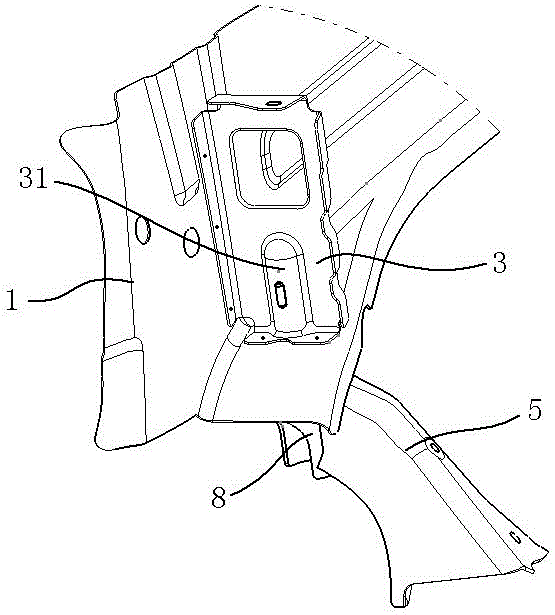

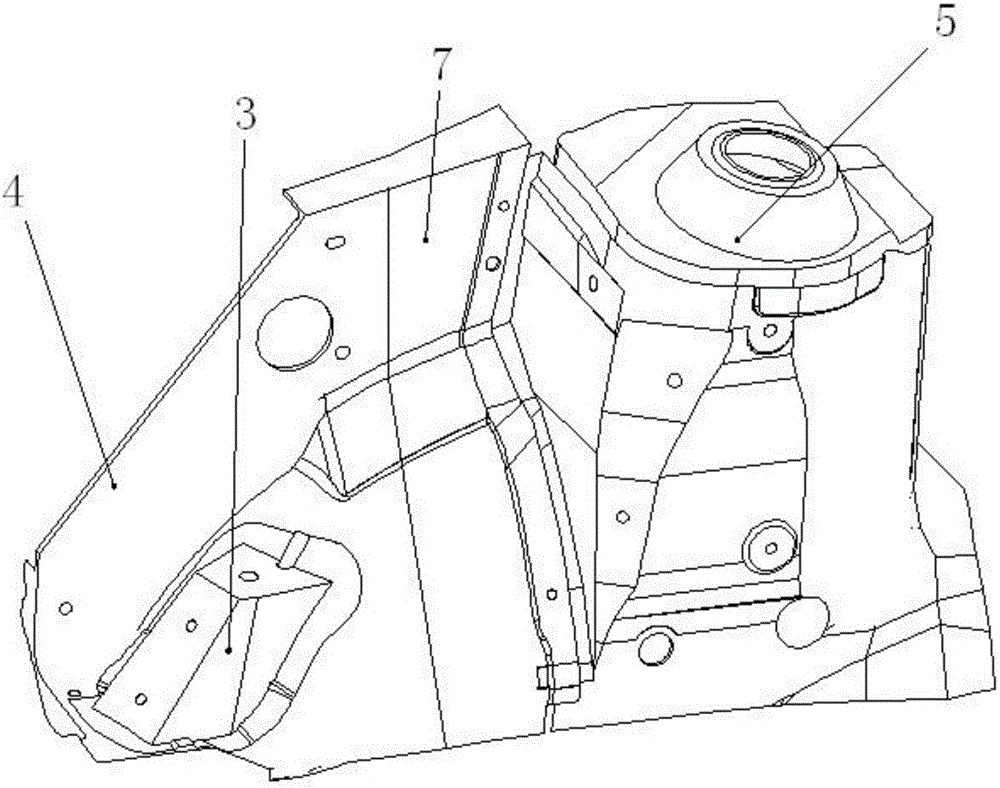

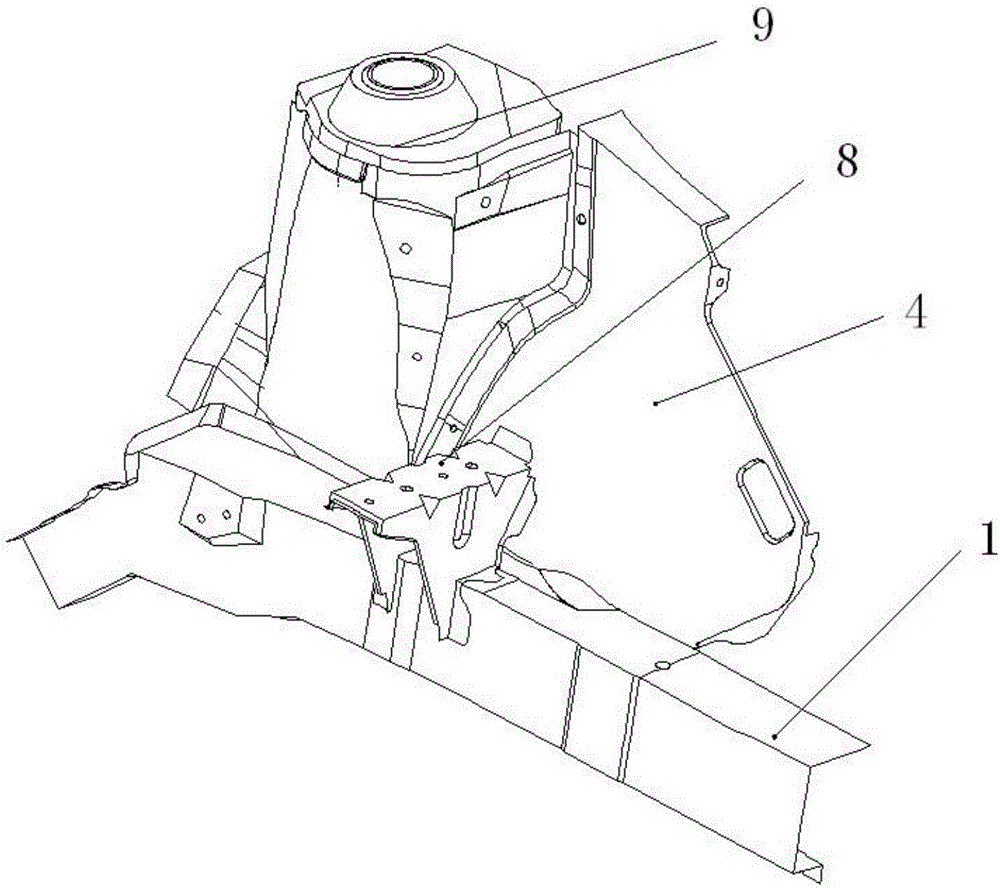

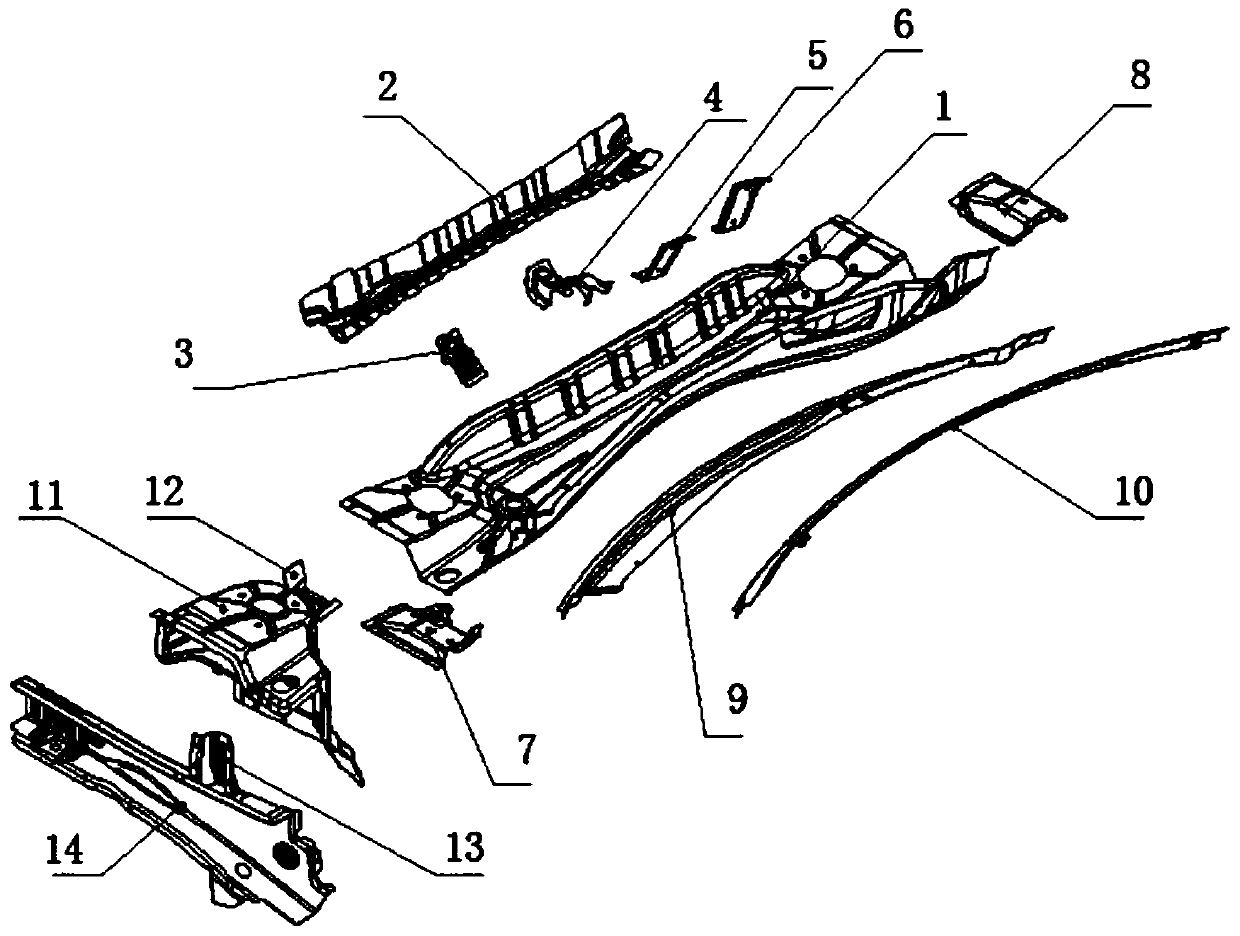

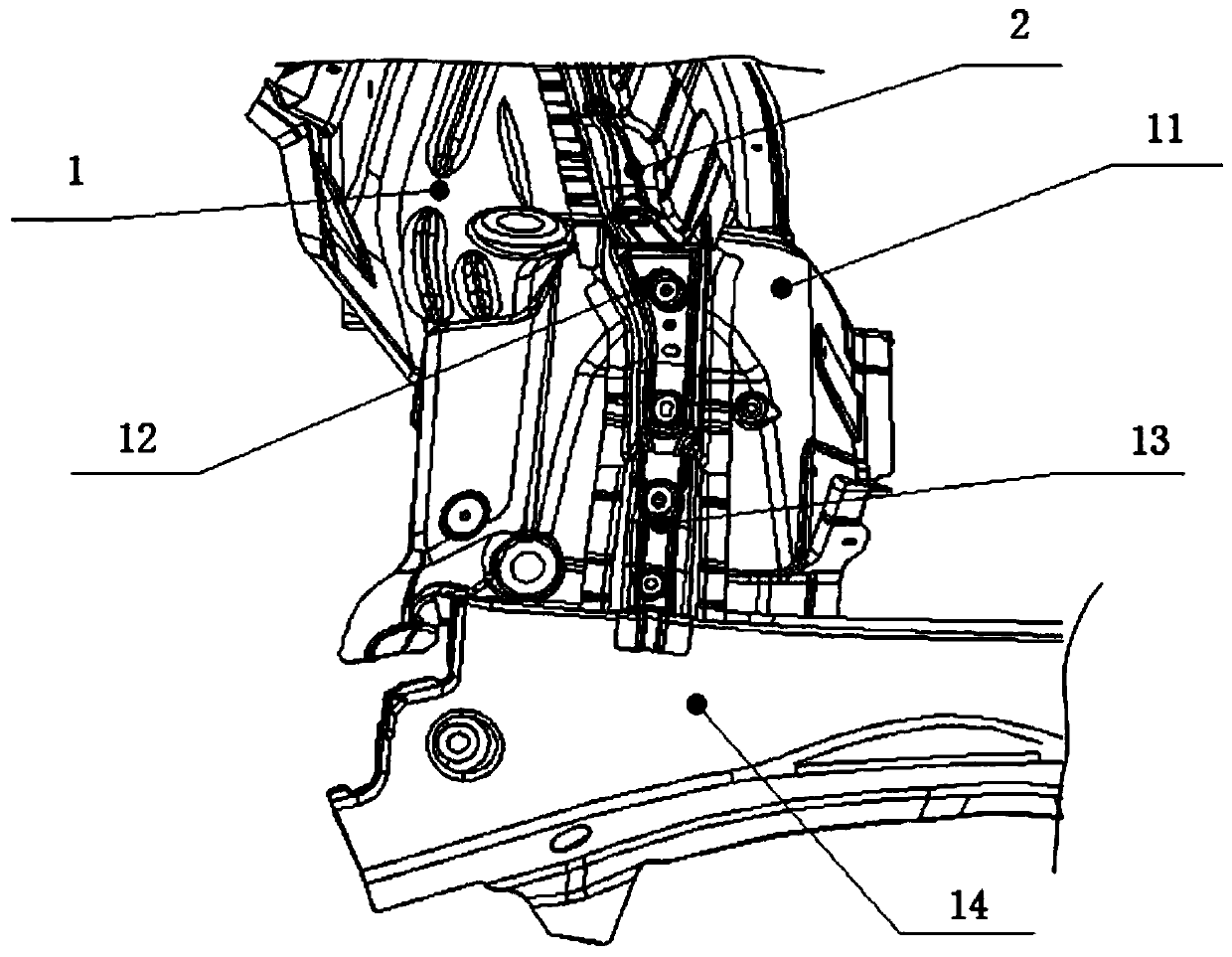

Structure for improving gutter channel modality and lateral rigidity of shock absorber support

InactiveCN106671893ABoost local modalReduce vibrationResilient suspensionsDiagnostic Radiology ModalityEngineering

The invention discloses a structure for improving gutter channel modality and lateral rigidity of a shock absorber support. The structure comprises a gutter channel body and a shock absorber installing support and further comprises a reinforcing beam with a certain depth. The reinforcing beam is fixedly connected with the bottom of the gutter channel body, the shock absorber installing support comprises a mounting base body and a body reinforcing plate, the two ends of the gutter channel body each are provided with a notch, and the notch position is connected with the mounting base body. The reinforcing beam and the gutter channel body form a sealed section; a left side shock absorber installing support and a right side shock absorber installing support are connected with the sealed section formed by the gutter channel body and the reinforcing beam, the local modality of the front end of the gutter channel can be improved, vibration of the gutter channel body is reduced, and the lateral rigidity of the shock absorber support is improved. Preferably, the invention provides a vehicle body front structure comprising the gutter channel body, the shock absorber installing support and the reinforcing beam.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

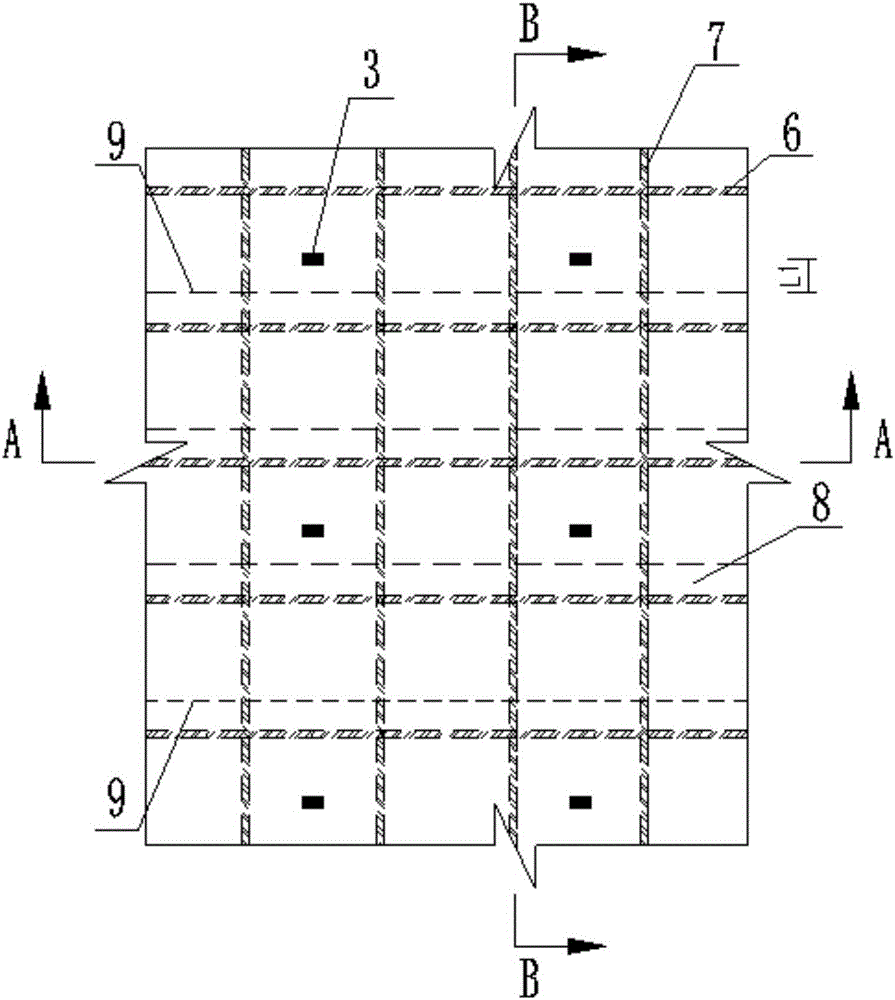

Ultrahigh-performance concrete bridge deck

PendingCN107587424AImprove local stiffnessImprove adhesionBridge structural detailsBridge deckEngineering

The invention discloses an ultrahigh-performance concrete bridge deck. The ultrahigh-performance concrete bridge deck is formed in the manner that ultrahigh-performance concrete slabs arranged in an array are connected into a whole. The bottom face of each ultrahigh-performance concrete slab is in a groove shape. Each groove is in a flat quadrangular pyramid frustum shape which becomes wider gradually from top to bottom. Reinforcing meshes formed in the manner that steel reinforcing bars arranged in the two stress main directions are connected into a whole are arranged in the ultrahigh-performance concrete slabs. The connection section between every two adjacent ultrahigh-performance concrete slabs is an ultrahigh-performance concrete slab connection section. All or a part of the ultrahigh-performance concrete slab connection sections are connected with inner components of a main beam below the bridge deck. By the adoption of the ultrahigh-performance concrete bridge deck, the local rigidity of the bridge deck is improved, and the fatigue cracking problem caused by an orthotropic steel bridge deck is solved; the adhesive performance and mutual coordination deformation between UHPCand bituminous concrete are good, the risks that adhesion between the orthotropic steel bridge deck and a pitch wearing layer is prone to ineffectiveness and a pitching pavement layer is prone to damage are solved, and bridge deck pavement can adopt conventional bituminous concrete.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

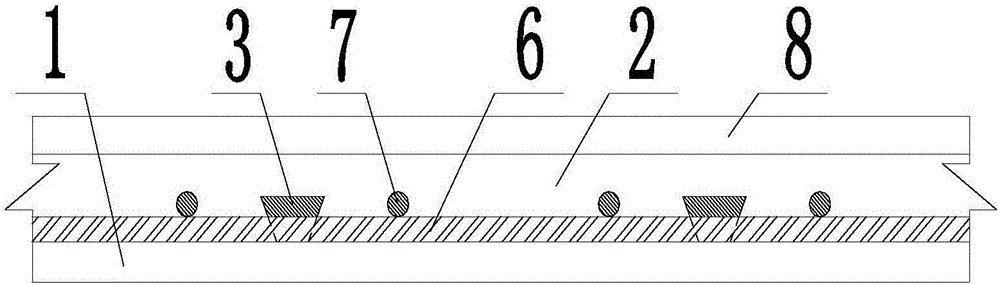

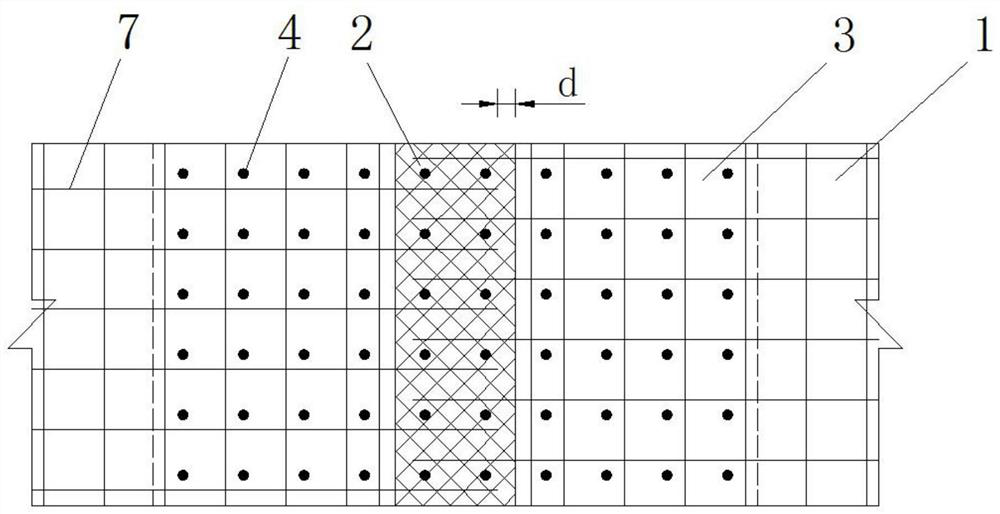

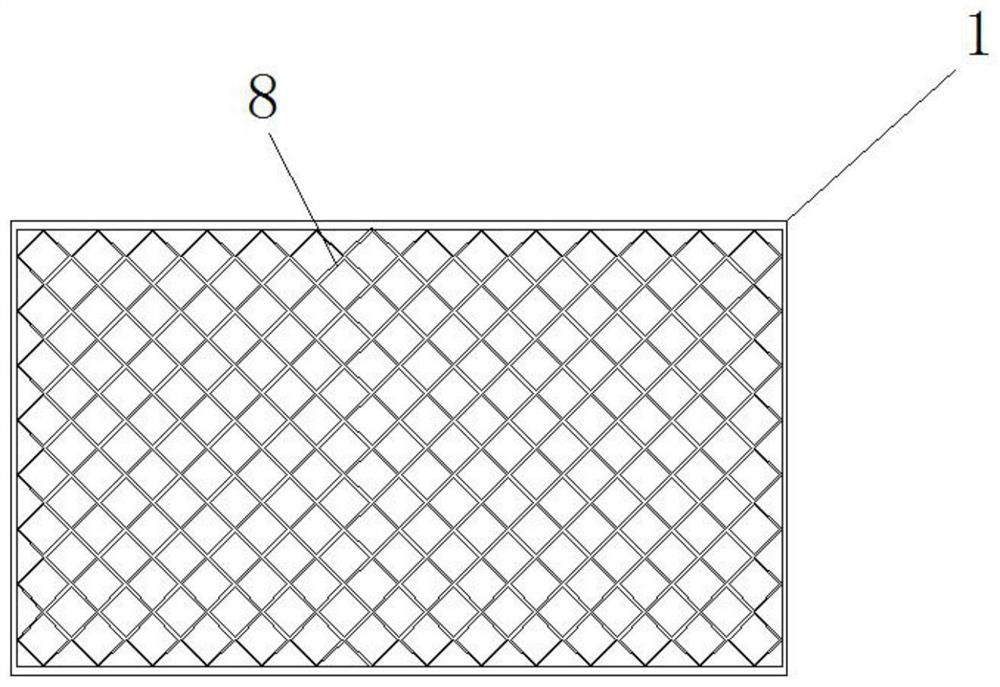

Steel-ultrahigh performance concrete combined bridge deck structure with short-steel-bar anti-shear structures and construction method thereof

ActiveCN106638306ALow construction heightIncreased shear strengthBridge structural detailsBridge materialsRebarHigh performance concrete

The invention discloses a steel-ultrahigh performance concrete combined bridge deck structure with short-steel-bar anti-shear structures and a construction method thereof. The combined bridge deck structure comprises a steel bridge deck layer (1) and an ultrahigh performance concrete layer (2) poured on the steel bridge deck layer (1). The steel bridge deck layer (1) is fixedly connected with the short-steel-bar anti-shear structures, each short-steel-bar anti-shear structure comprises a plurality of short steel bars (3) fixedly connected to the upper surface of the steel bridge deck layer (1), wherein the short steel bars (3) are horizontally arranged in the longitudinal bridge direction. The short-steel-bar anti-shear structures are wrapped in the ultrahigh performance concrete layer (2). According to the steel-ultrahigh performance concrete combined bridge deck structure with the short-steel-bar anti-shear structures, the thickness of the ultrahigh performance concrete layer can be reduced, the weight of a bridge deck can be lowered, the shear key structure is small in size and simple in construction process, and the steel-ultrahigh performance concrete combined bridge deck structure is especially suitable for large-span flexible bridges which are sensitive in bridge weight.

Owner:HUNAN UNIV

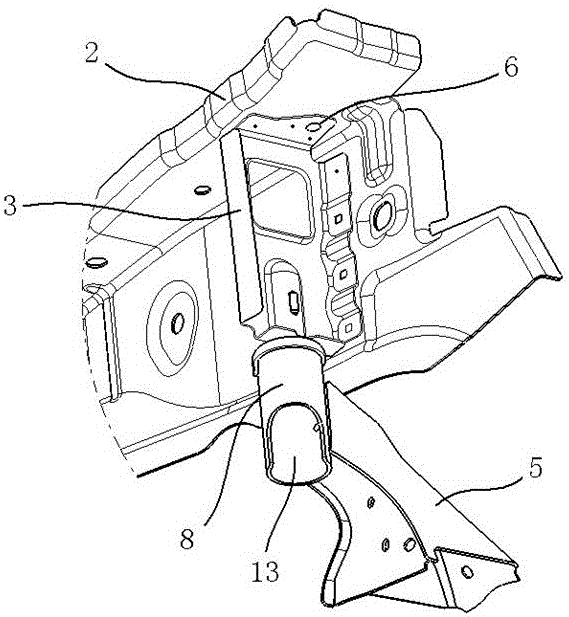

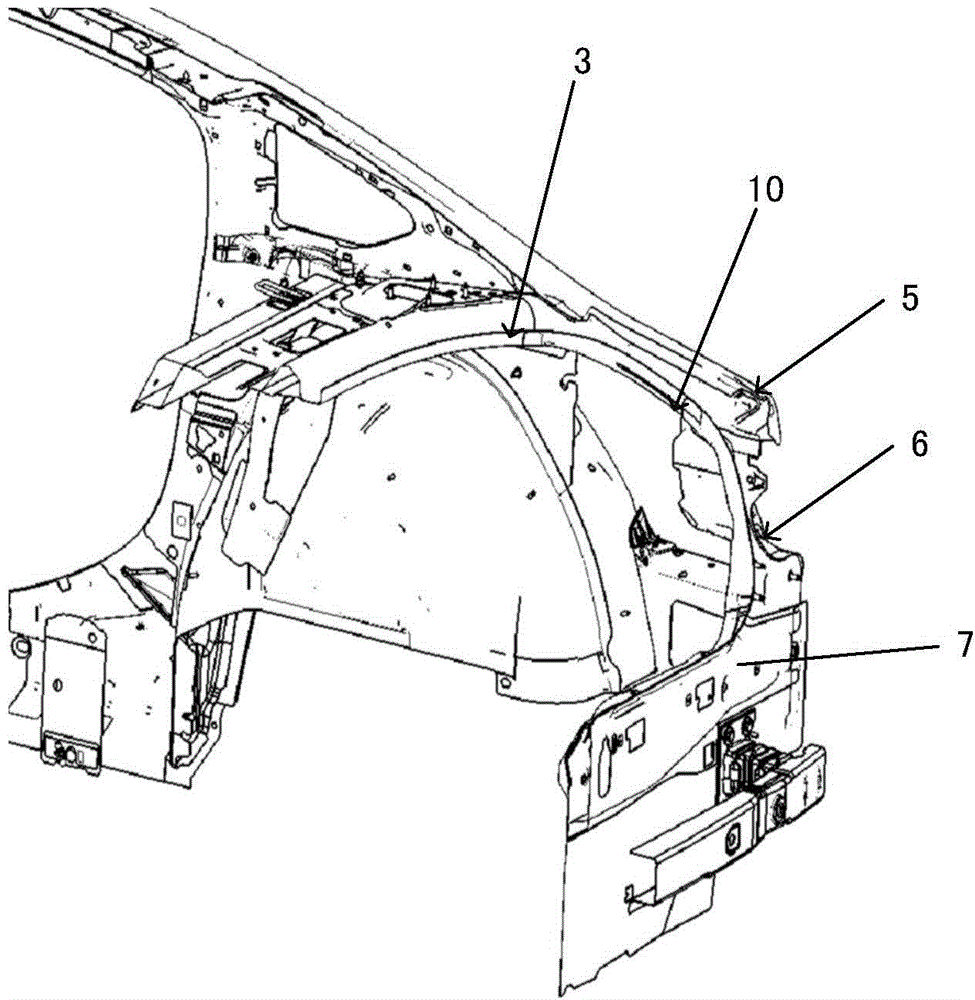

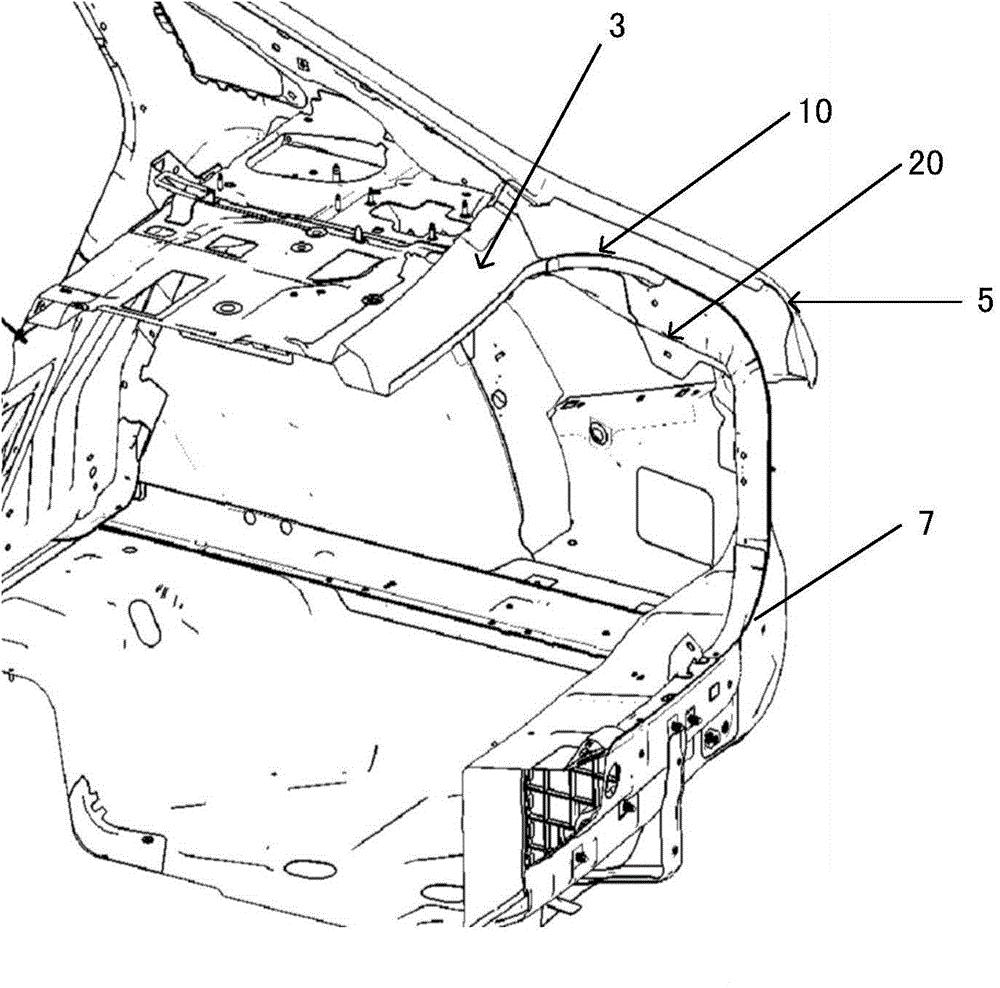

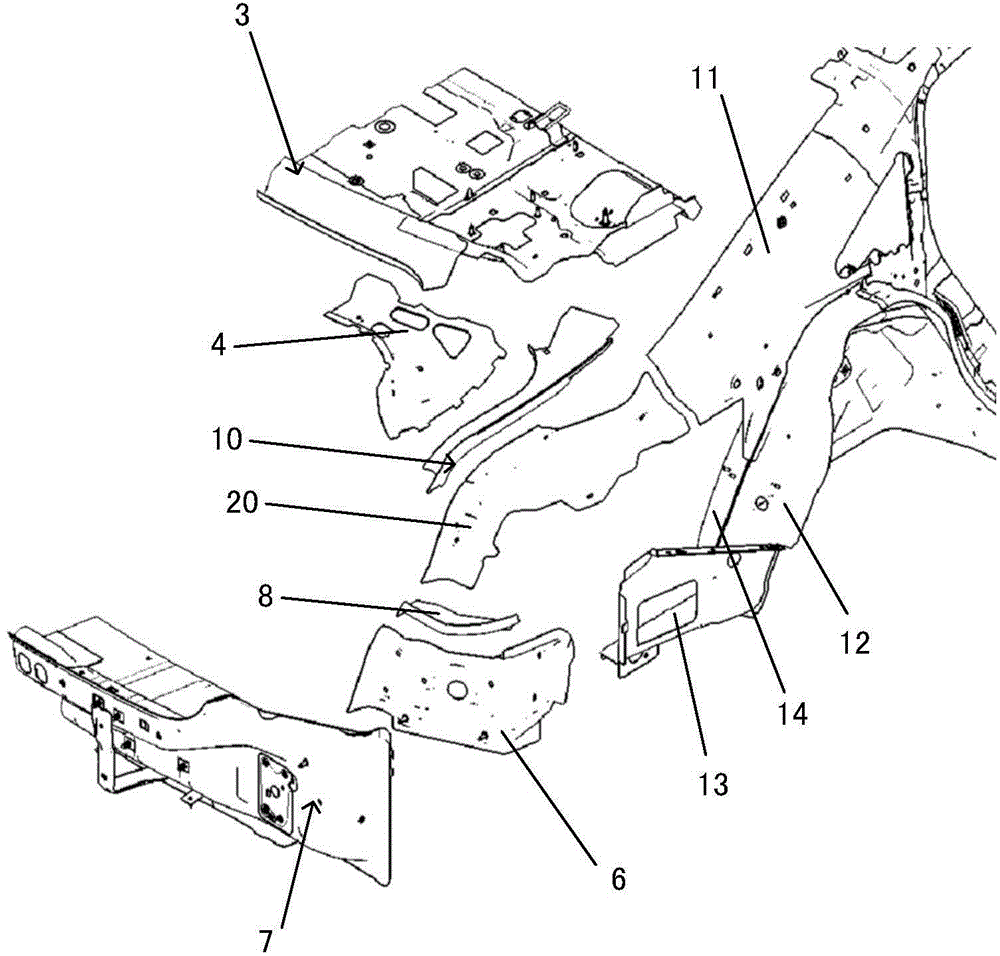

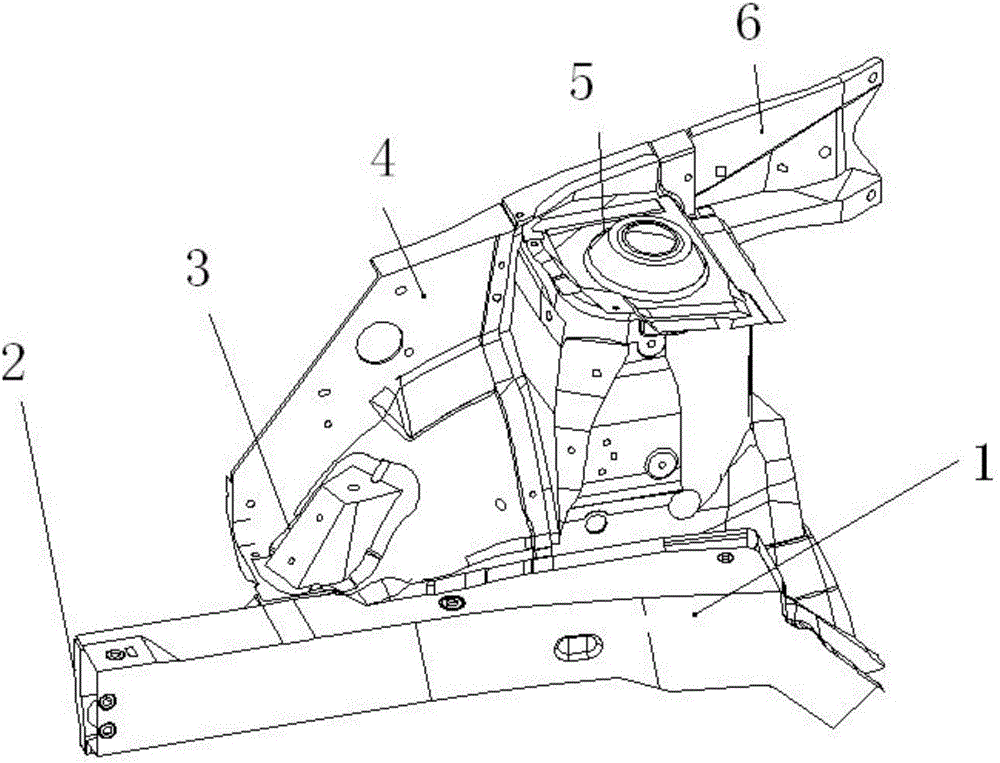

Car body side structure for increasing engine suspension Y-direction dynamic stiffness

ActiveCN105905161AIncrease Y-stiffnessImprove local stiffnessUnderstructuresJet propulsion mountingDynamic stiffnessAutomotive engineering

The invention provides a car body side structure for increasing engine suspension Y-direction dynamic stiffness. The car body side structure comprises a suspension right side car body structure, a suspension left side car body structure and a longitudinal beam connecting plate. The suspension right side car body structure comprises a longitudinal beam web B, a right side suspension support, a fender guard, a right side wheel cover plate and a vertical plate. The suspension left side car body structure comprises a longitudinal beam web A, a fender guard, a left side suspension support and a left side wheel cover plate. The suspension right side car body structure and the suspension left side car body structure are each provided with a wheel cover reinforcing plate used for reinforcing connection rigidity. One wheel cover reinforcing plate is arranged between one fender guard and the right side wheel cover plate, and the other wheel cover reinforcing plate is arranged between the other fender guard and the left side wheel cover plate.

Owner:CHINA AUTOMOTIVE ENG RES INST

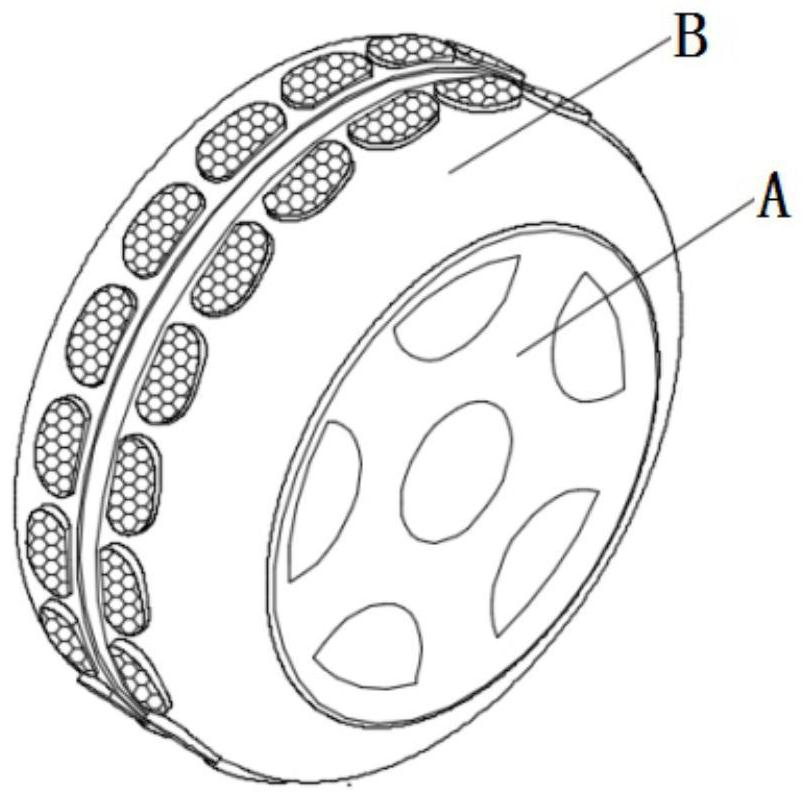

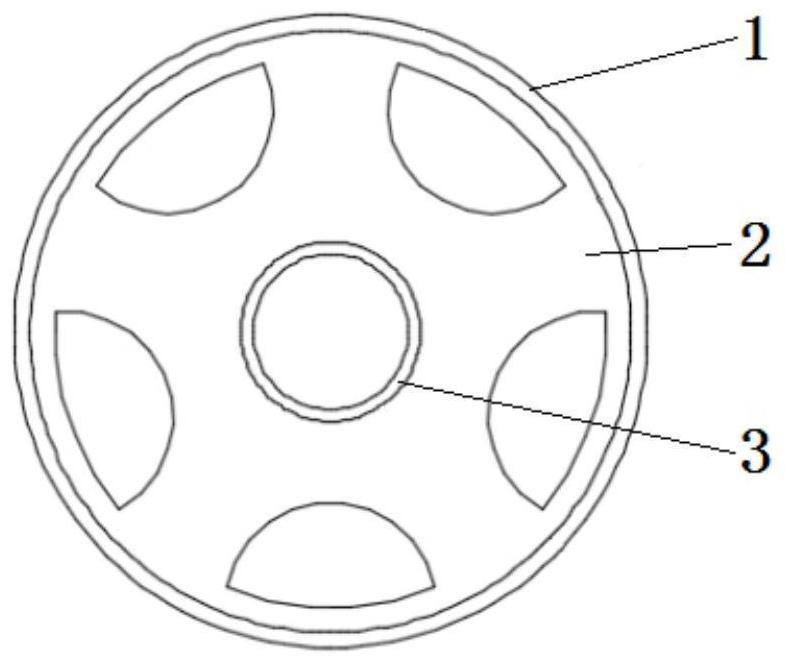

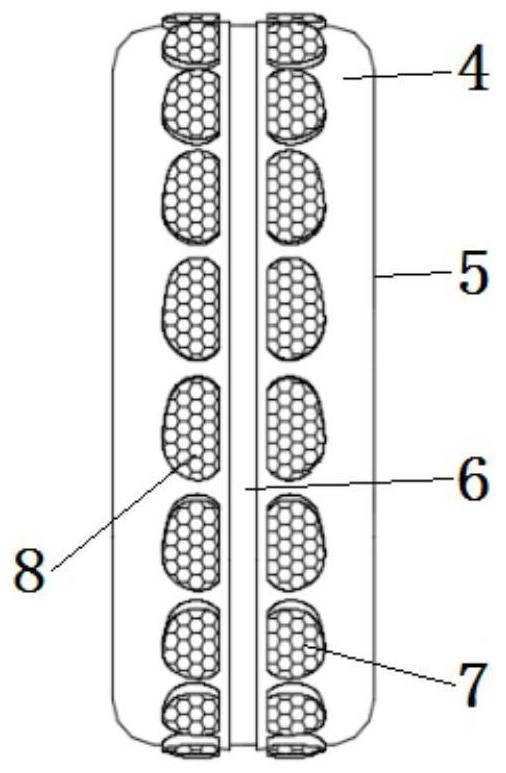

All-region bionic wheel of off-road vehicle

PendingCN113043795AGood envelopmentImprove local stiffnessTyre tread bands/patternsControl theoryTread

An all-terrain bionic wheel for off-road vehicles belongs to the technical field of tire tread pattern structure design, and is characterized in that 30-36 pattern blocks in each of two pattern block groups are uniformly distributed on the circumference of a wheel surface and are symmetrically arranged on the left and right sides of a groove; regular hexagonal column structures which are uniformly distributed are arranged in the peripheral contour line of the single pattern block, and the bottom structure L2 of the pattern block is 10-15mm; the side length L4 of the regular hexagon ranges from 15 mm to 20 mm; and the height L5 of the regular hexagonal column is 10-13 mm. And along with the change of the tire pressure, the distance between the adjacent regular hexagons is 0-5mm. According to the invention, a camel toe structure and a tree frog foot biological structure are used for reference, and a pattern structure suitable for various ground environments is formed by changing the distance between the pattern blocks, so that the adhesion capability of the tire on low-adhesion roads such as soft, muddy, frozen and slippery roads can be improved.

Owner:JILIN UNIV

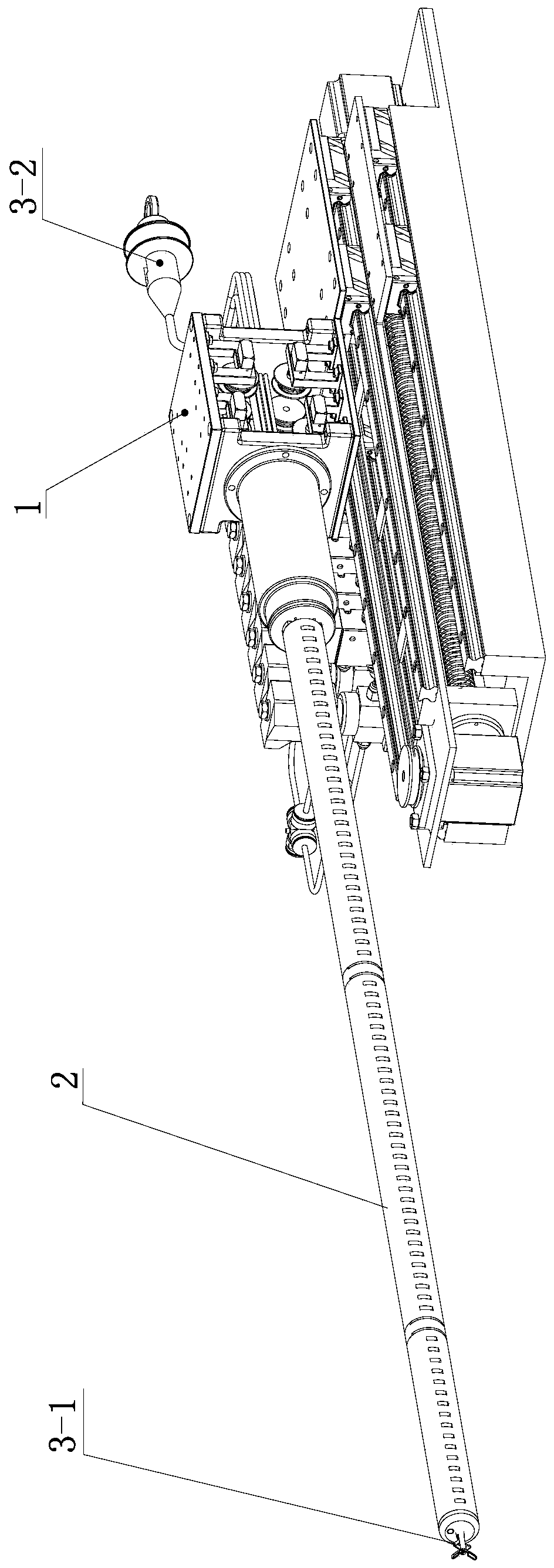

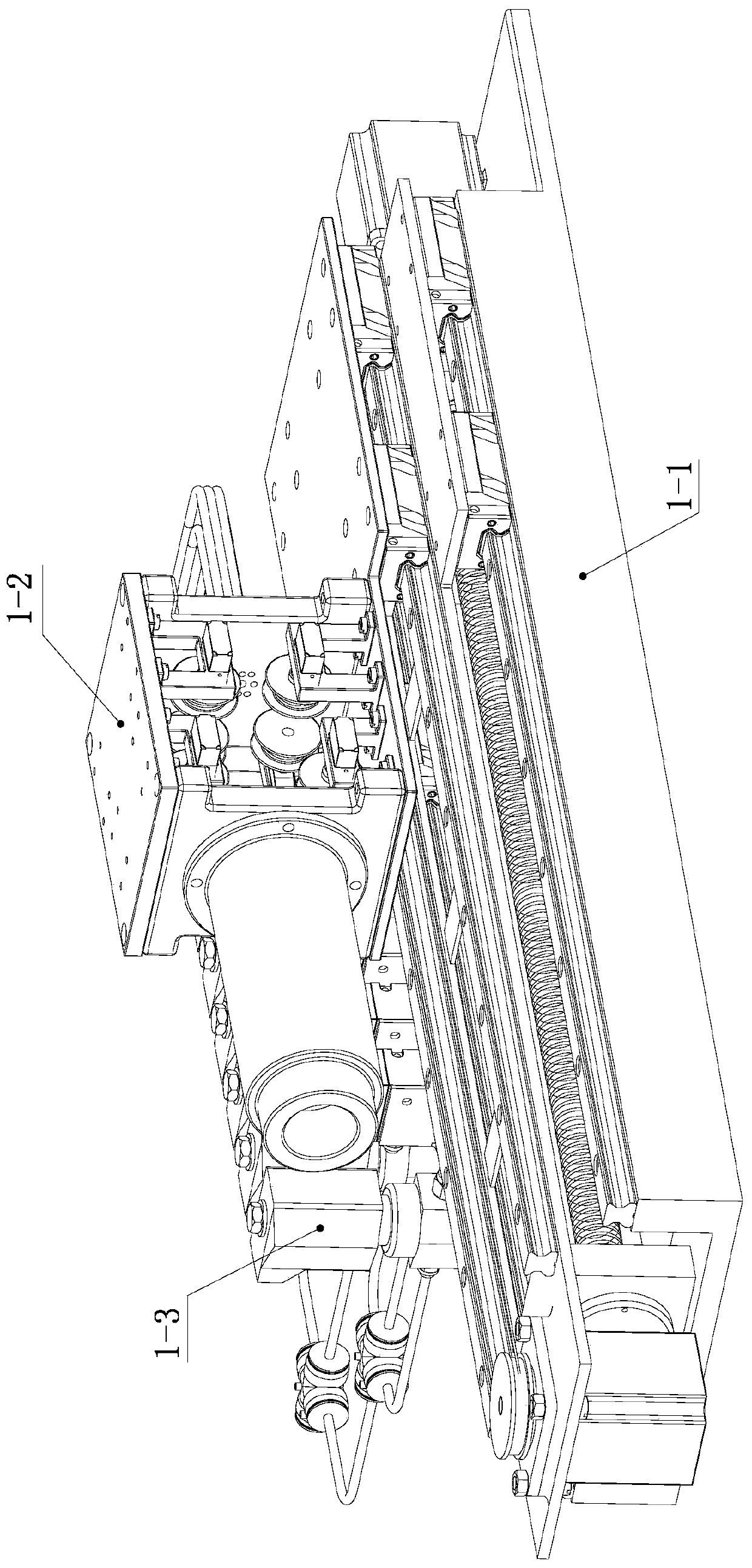

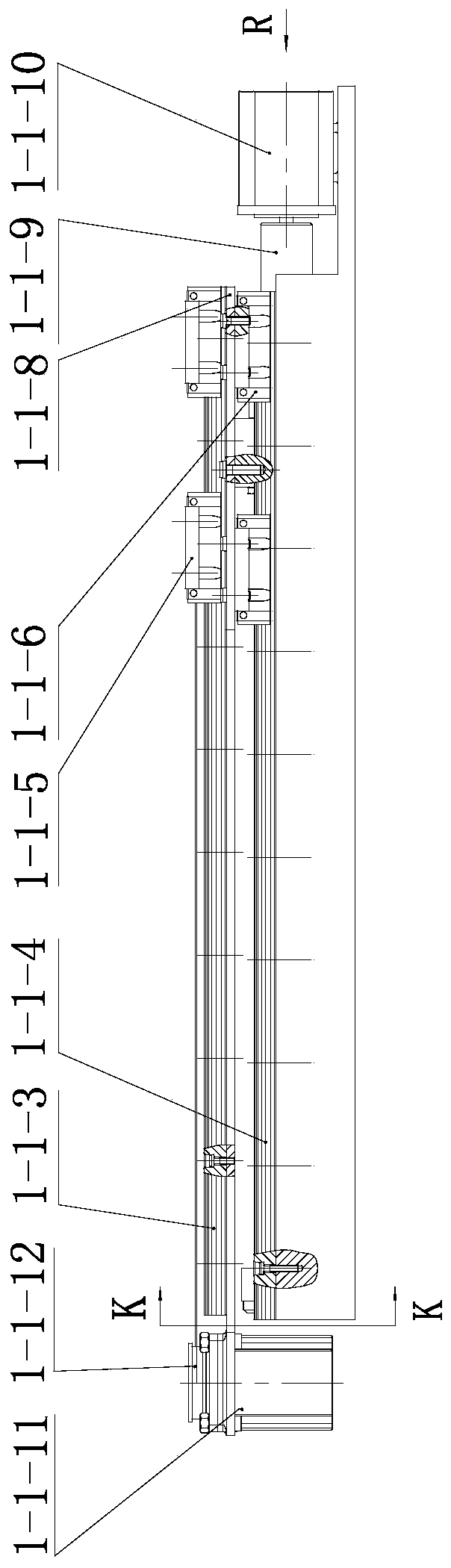

Flexible robot for abdominal cavity minimally invasive surgery

ActiveCN110464466ARealize complex deformationCause some damagesSurgical manipulatorsSurgical robotsVariable stiffnessMedical equipment

The invention relates to a flexible robot for abdominal cavity minimally invasive surgery, and relates to the technical field of medical equipment for abdominal cavity minimally invasive surgery. Theflexible robot comprises a driving system, a flexible robot main body and an end surgical forceps mechanism; the driving system comprises a linear feed system, a cable-driven system and a gas-driven system; the cable-driven system is connected with the linear feed system, and the flexible robot main body is arranged on the cable-driven system; the gas-driven system supplies gas to the flexible robot main body through a gas pipe passing through the cable-driven system, a front-end gripper of the end surgical forceps mechanism is arranged at the front end of the flexible robot main body, the endhand-held handle of the end surgical forceps mechanism is arranged on the cable-driven system, and a front-end gripper is connected with the end hand-held handle through a steel wire rope penetratingthe cable-driven system and the flexible robot main body. The flexible robot has the advantages of compact structure, adopts a flexible material, can realize polymorphic change and self variable stiffness effect with multi-module design, improves the spatial movement ability of the robot, and has the functions of realizing visual detection and biological tissue sampling.

Owner:JILIN UNIV

Anti-fatigue strengthening structure of steel bridge deck for reducing fatigue stress

InactiveCN106677055AReduce stressReduce stress levelsBridge structural detailsBridge deckEngineering

The invention discloses an anti-fatigue strengthening structure of a steel bridge deck for reducing fatigue stress comprising a top plate, a U-shaped rib and a transverse division plate which are respectively welded to the top plate, wherein the anti-fatigue strengthening structure is characterized in that an inner division plate is arranged inside the U-shaped rib; and a support plate is arranged under the U-shaped rib and is fixed on the transverse division plate. The anti-fatigue strengthening structure of the steel bridge deck for reducing fatigue stress has the advantages of simple structure and low cost, and can greatly reduce the stress of the main fatigue cracking details of the steel bridge deck, thereby effectively alleviating or solving the fatigue stress problem of the steel bridge. The anti-fatigue strengthening structure of the steel bridge deck for reducing fatigue stress has significant scientific research value and economic effect.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +3

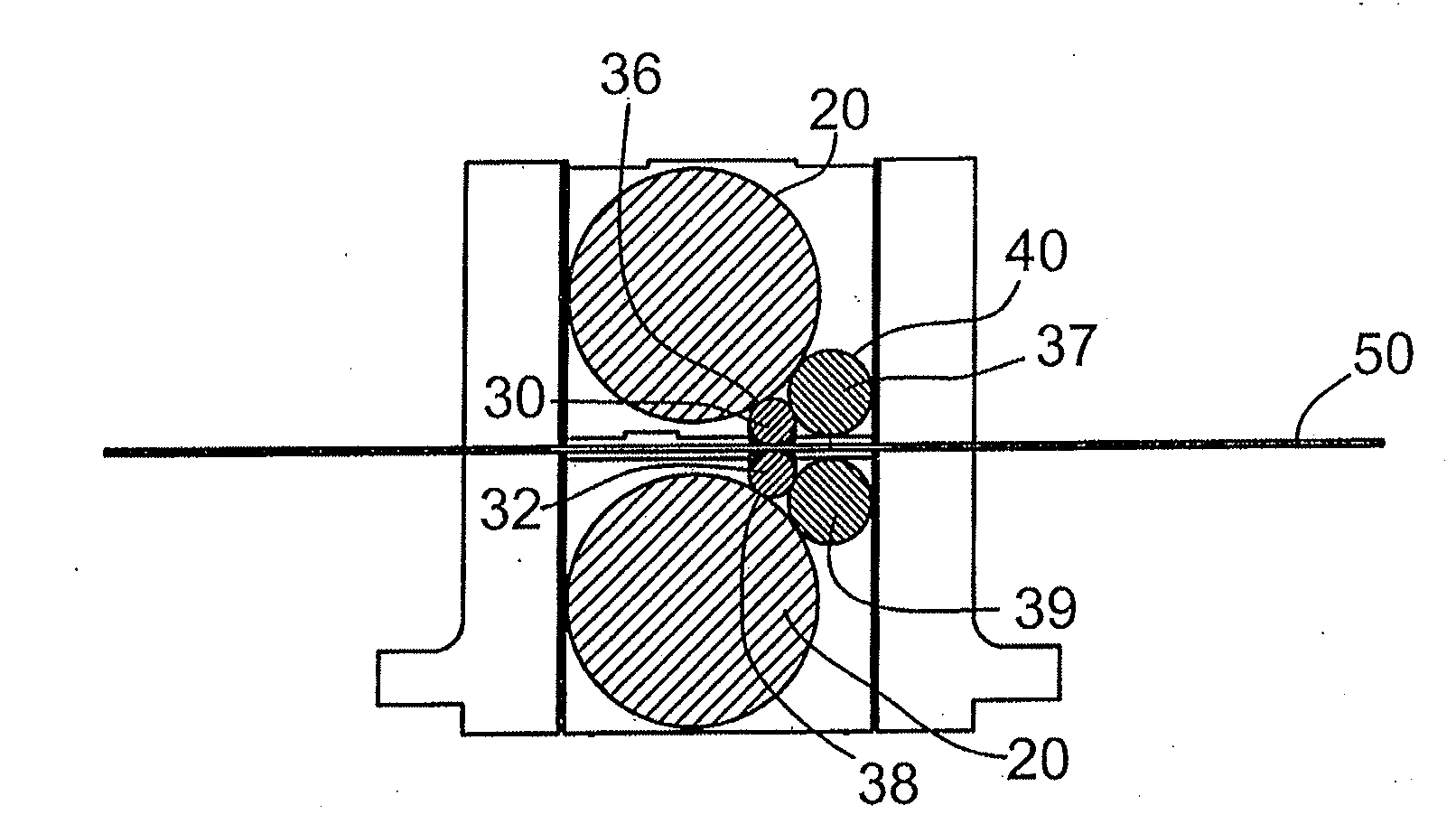

Methods for reducing ridge buckles and annealing stickers in cold rolled strip and ridge-flattening skin pass mill

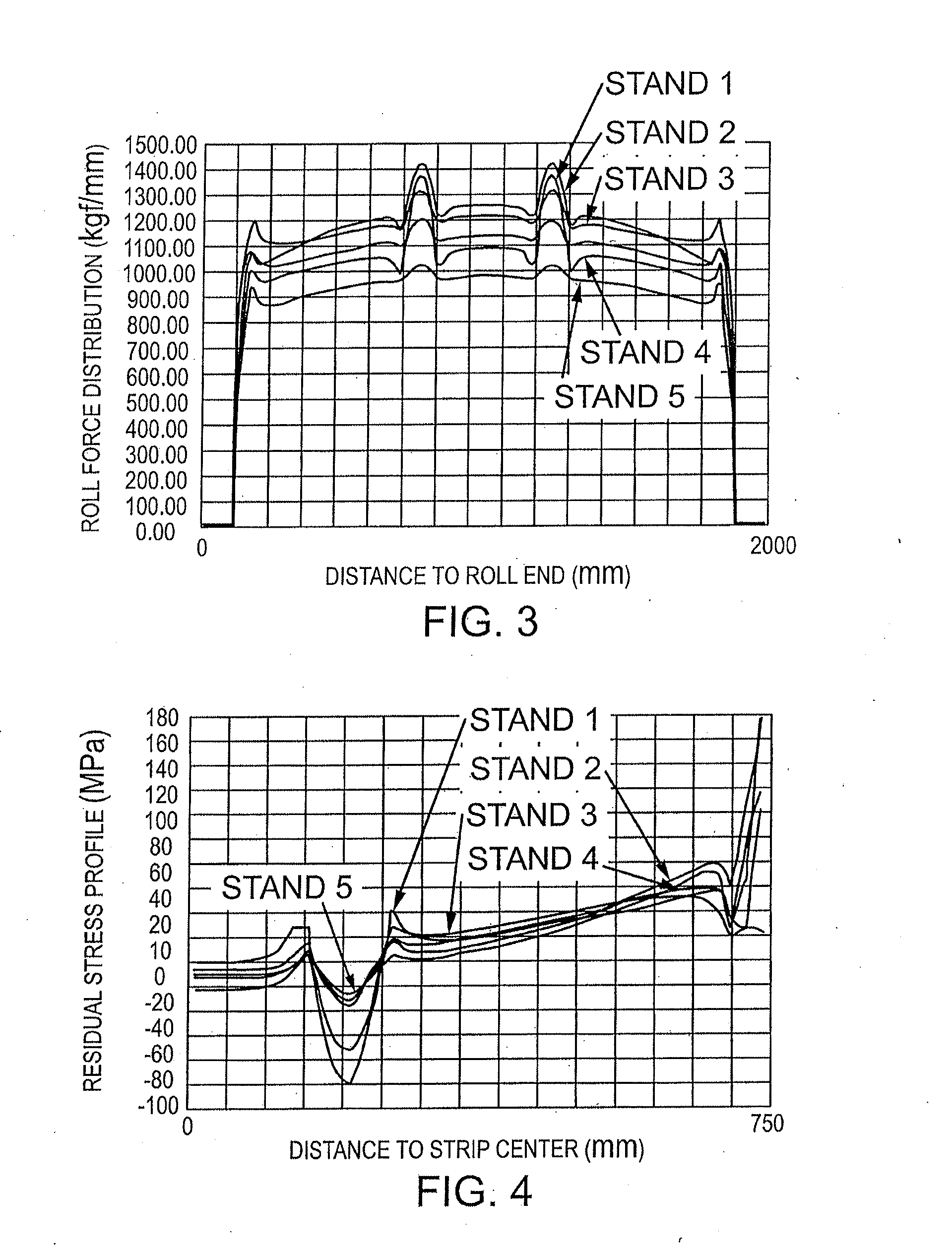

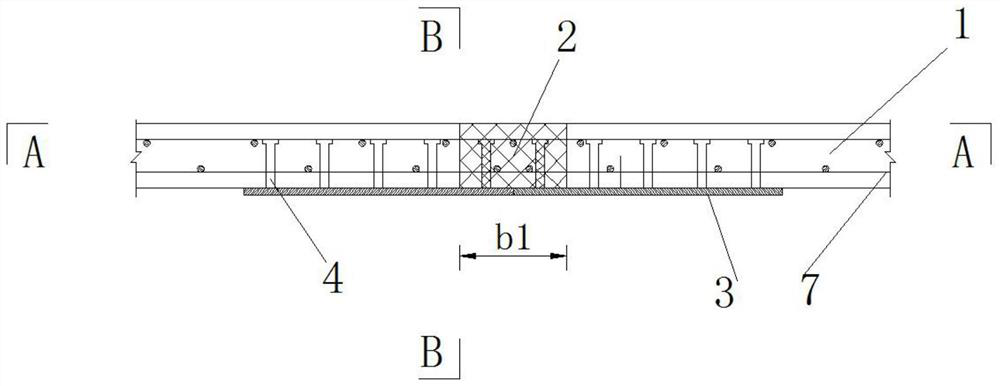

InactiveUS20110113848A1Improve local stiffnessGood control resultRoll force/gap control deviceMetal rolling stand detailsBackup rollSteel belt

A method for flattening steel strip by cold rolling the strip by passing it through at least two cold rolling mill stands each having work rolls. A first of the mill stands has work rolls having local rigidity K significantly different from a second mill stand, wherein the local rigidity K is calculated in Kgf / mm / mm accordance with an equation. Also a six high mill for flattening steel strip has an entry side where the strip enters the mill and an exit side where the strip exits the mill. The mill comprises a pair of driven backup rolls disposed on the entry side of the mill, a pair of horizontal support rolls disposed on the exit side of the mill and a pair of small diameter work rolls, the work rolls having an entry side face and an exit side face. The work rolls are disposed between the pair of backup rolls and the pair of support rolls. The entry side face of the work rolls is in engagement with the backup rolls during operation and the exit side face of the work rolls is in engagement with the support rolls during operation.

Owner:QUAD ENG

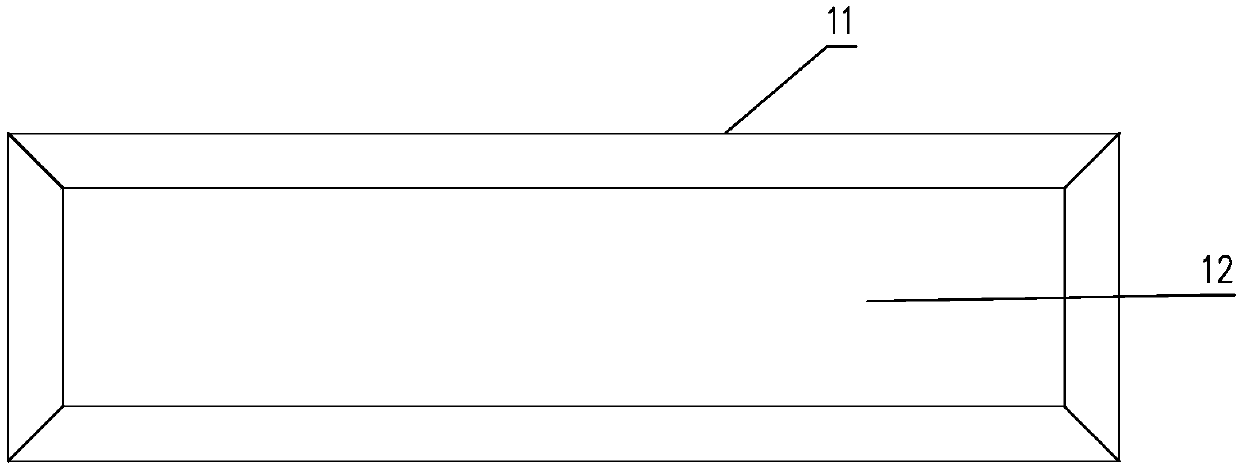

Cast-in-place joint structure of UHPC beam plate with embedded reinforcing steel components and construction method thereof

ActiveCN111705650AImprove local stiffnessGive full play to the tensile strengthBridge structural detailsBridge erection/assemblyBridge deckStructural engineering

The invention discloses a cast-in-place joint structure of a UHPC beam plate with embedded reinforcing steel components. The structure comprises a pair of adjacently-arranged prefabricated UHPC beam plates and a cast-in-place UHPC joint cast in place between the pair of prefabricated UHPC beam plates, wherein the bottom of each prefabricated UHPC beam plate is fixedly provided with an embedded reinforcing steel component extending to the cast-in-place UHPC joint, and the end parts of the adjacent embedded reinforcing steel components are fixedly connected; and the side wall of the end part ofthe prefabricated UHPC beam plate is provided with a latticed groove. The invention further provides a construction method of the cast-in-place joint structure of the UHPC beam plate with the embeddedreinforcing steel components. According to the invention, through the mutual synergistic effect of the latticed grooves and the embedded reinforced steel components, the latticed grooves and the embedded reinforced steel components are mutually matched, so that the problem of weak stress of the UHPC bridge deck wet joint connection can be effectively solved, the stress performance of the new andold UHPC interfaces is remarkably improved, the interfaces cannot crack under the action of service load, and the durability and the service performance of the structure are improved.

Owner:HUNAN UNIV

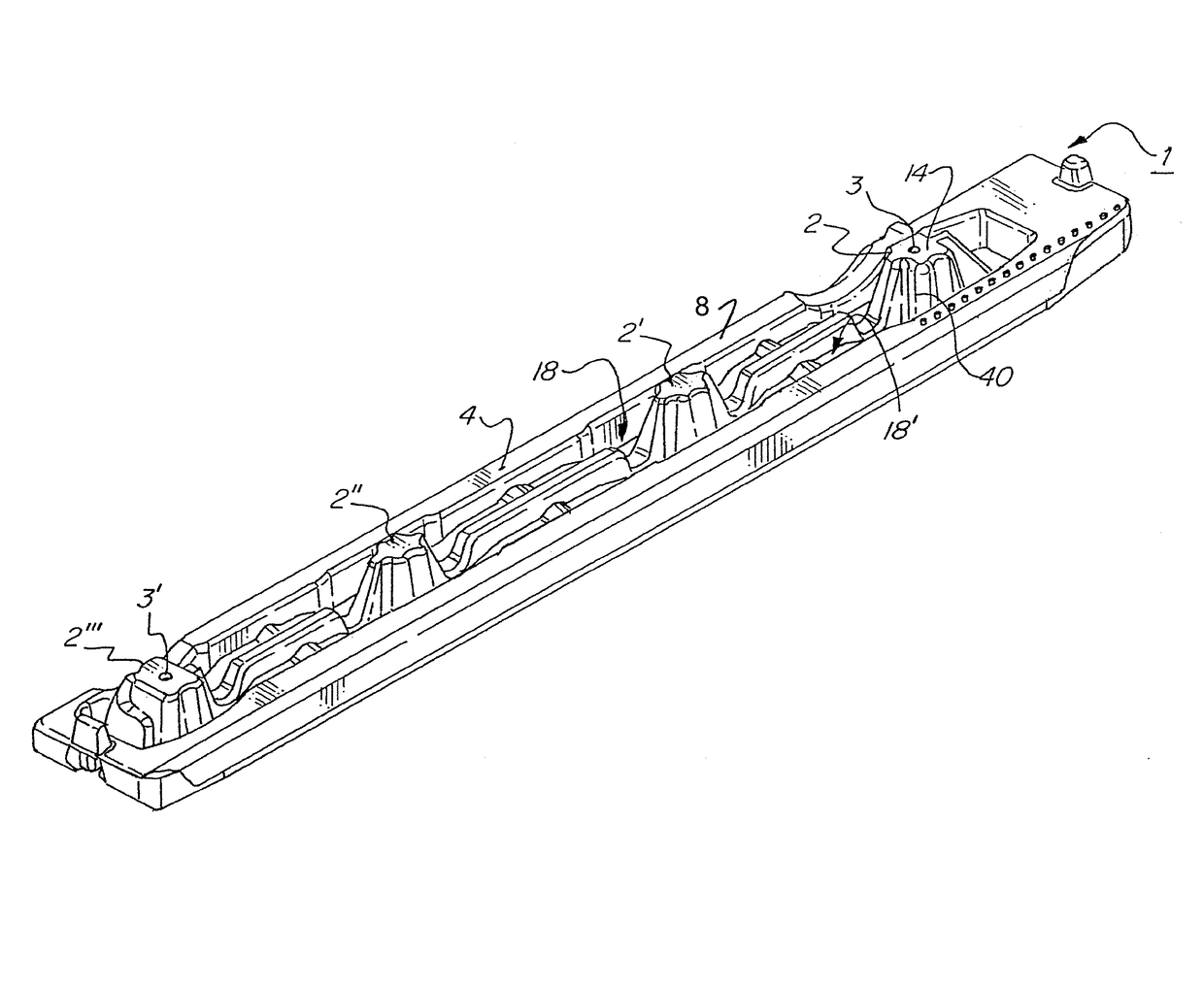

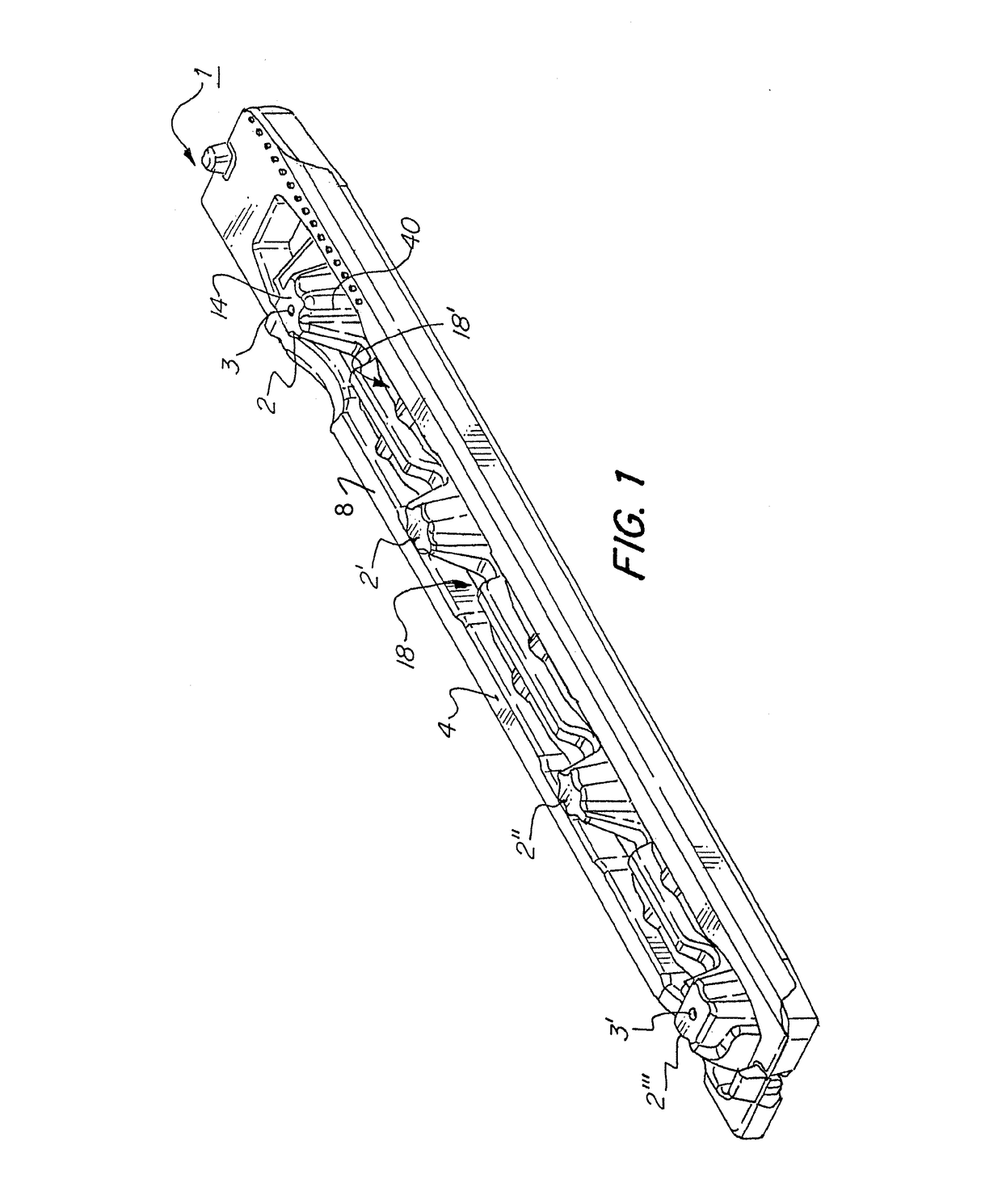

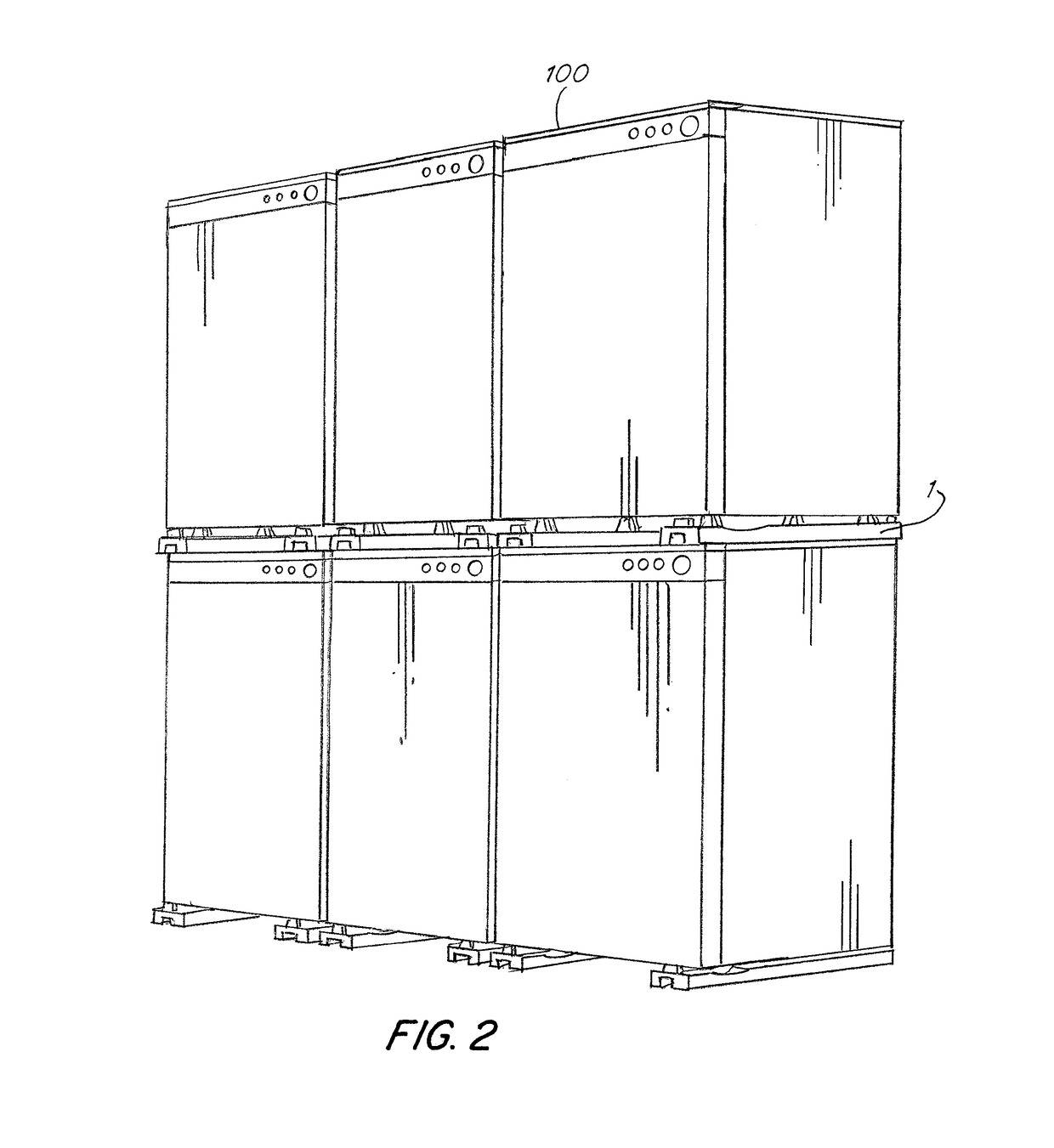

Appliance Shipping Runner

ActiveUS20170082238A1Increase stiffnessRigid enoughPackaging vehiclesContainers for machinesDouble wallEngineering

A blow molded runner having a bottom wall and a top wall forming a double wall blow molded configuration, at least one compressed double wall structure defined by fusion an inner surface of the bottom wall to an inner surface of the top wall. At least two columns spaced apart at a distance wherein each of the at least two columns defines one of the at least one compressed double wall structure and has a top surface and the compressed double wall structure corresponding to each of the at least two columns extends from the top surface to a bottom surface of the runner at the at least two columns wherein the bottom surface is defined by an outer surface of the bottom wall. A width of the runner varies along a length thereof.

Owner:CUSTOM PAK

Vehicle cabin cutter channel assembly and vehicle with the same

The invention relates to a vehicle cabin cutter channel assembly and a vehicle. The vehicle cabin cutter channel assembly comprises a gutter channel body. One end of the gutter channel body is provided with a cover left hinge installing plate. The other end of the gutter channel body is provided with a cover right hinge installing plate. Gaps are reserved between the cover left hinge installing plate and the gutter channel body and between the cover right hinge installing plate and the gutter channel body. A gutter channel reinforcing beam is connected with one side face of the gutter channelbody. A front air window lower beam is installed on the other side face of the gutter channel body and fixed to the gutter channel body through a front air window lower beam connecting plate. The gutter channel body is connected with a front damper installing base through welding. The gutter channel reinforcing beam is connected with a front wheel cover middle section upper reinforcing piece. Thefront wheel cover middle section upper reinforcing piece is connected with a front wheel cover middle section lower reinforcing piece through welding. The vehicle cabin cutter channel assembly has theadvantages of being high in water conductivity, capable of improving rigidity and high in stability.

Owner:力帆科技(集团)股份有限公司

Steel box girder reinforcing structure and method

PendingCN108103966AImprove tip stress stateInhibit expansionBridge erection/assemblyBridge strengtheningStructural engineeringEngineering

The invention discloses a steel box girder reinforcing structure and method. The steel box girder reinforcing structure comprises a box girder body. The box girder body comprises transverse partitionplates arranged at intervals and groove openings running through the transverse partition plates. Arc-shaped notches are formed in the two lateral sides in each groove opening. Each arc-shaped notch has an area with fatigue cracking risks or even fatigue cracks. Reinforcing plates are arranged on the side faces of each transverse partition plate. By reinforcing the areas with fatigue cracking risks or even fatigue cracks of the transverse partition plates, the local rigidity of the arc-shaped notches of the transverse partition plates is remarkably improved, the production of the fatigue cracks can be restrained or delayed or the expansion of the cracks can be effectively restrained, and the fatigue service life is greatly prolonged. Moreover, by means of the reinforcing method, no new damage is caused to the original structure of the transverse partition plates, the structure is simple, and construction is convenient.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

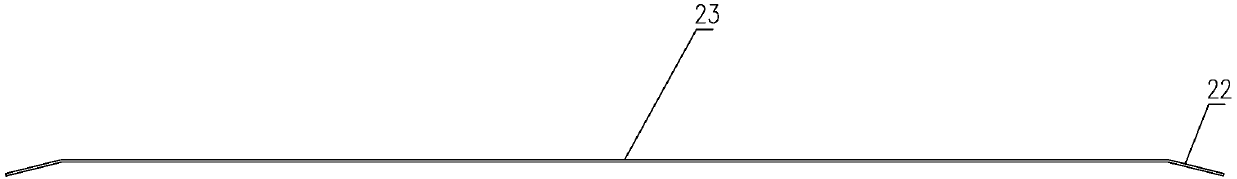

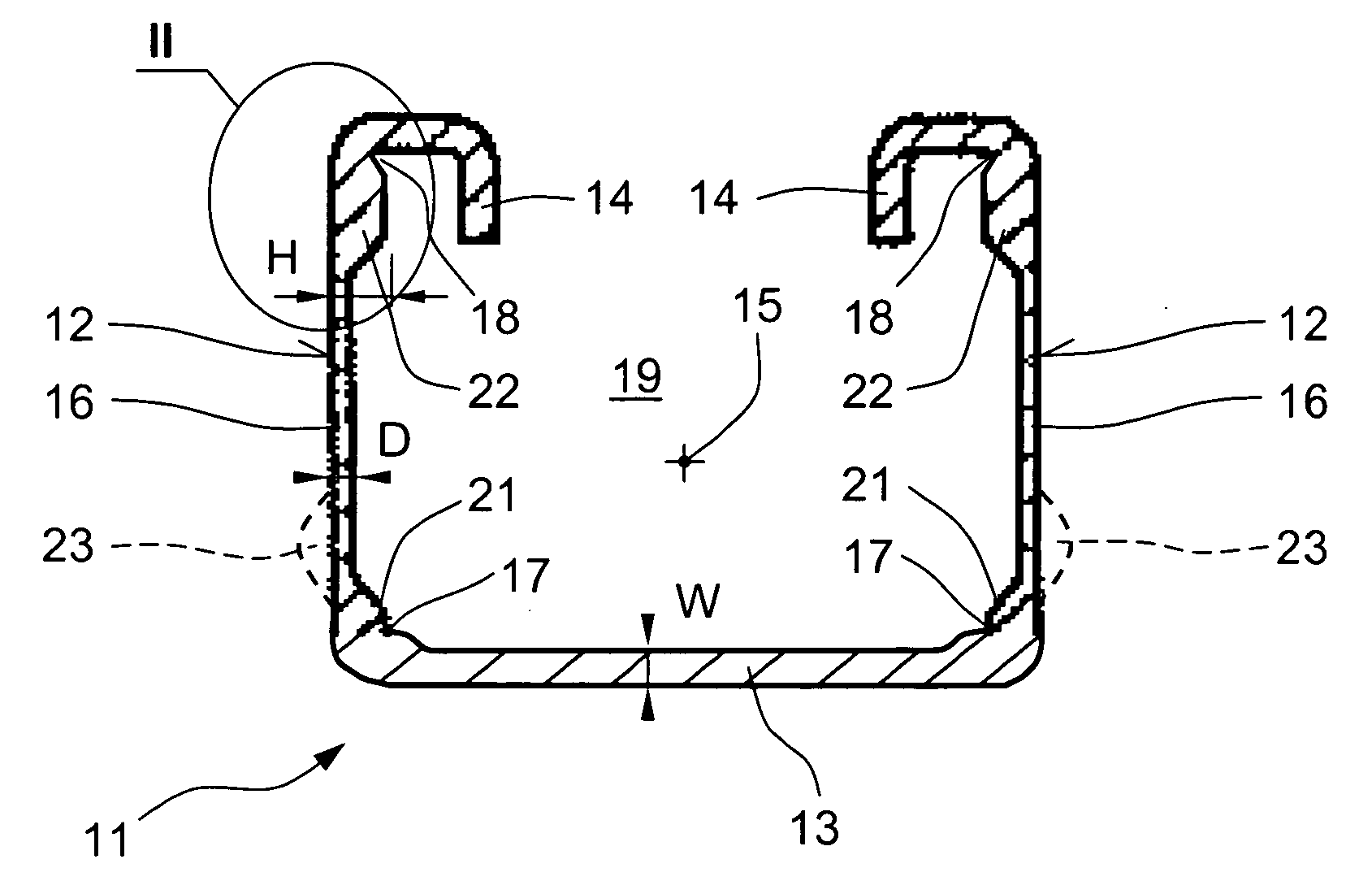

Profile and method of forming same

A cold-rolling method of forming a profile formed of a strip-shaped rolling stock and having thickness-reduced section (16) and at least one thickened region (21, 22) provided in a region of at least one bend (17, 18) of the profile, includes deforming a strip-shaped rolled metal stock in at least one region for forming the thickness-reduced section, with simultaneous accumulation of the initial material in a region adjacent to the thickness-reduced section so that a thickened region is formed adjacent to the thickness-reduced section, and bending the deformed rolled metal stock section into the profile.

Owner:HERMANN FRITZ +6

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com