Steel-ultrahigh performance concrete combined bridge deck structure with short-steel-bar anti-shear structures and construction method thereof

A technology of ultra-high performance and combined bridge deck, which is applied in the direction of bridges, bridge parts, bridge materials, etc., and can solve the problems that are difficult to meet the application requirements of thin ultra-high performance concrete layers, difficult to realize thin ultra-high performance concrete layers, and shear key structures Large size and other issues, to achieve the effect of good operability and economy, strong flexibility and adaptability, and high shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

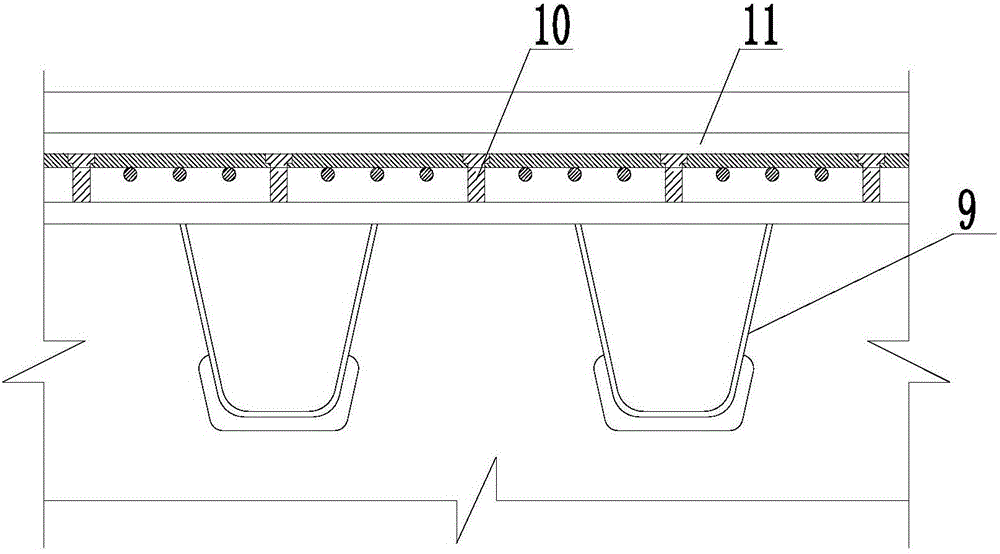

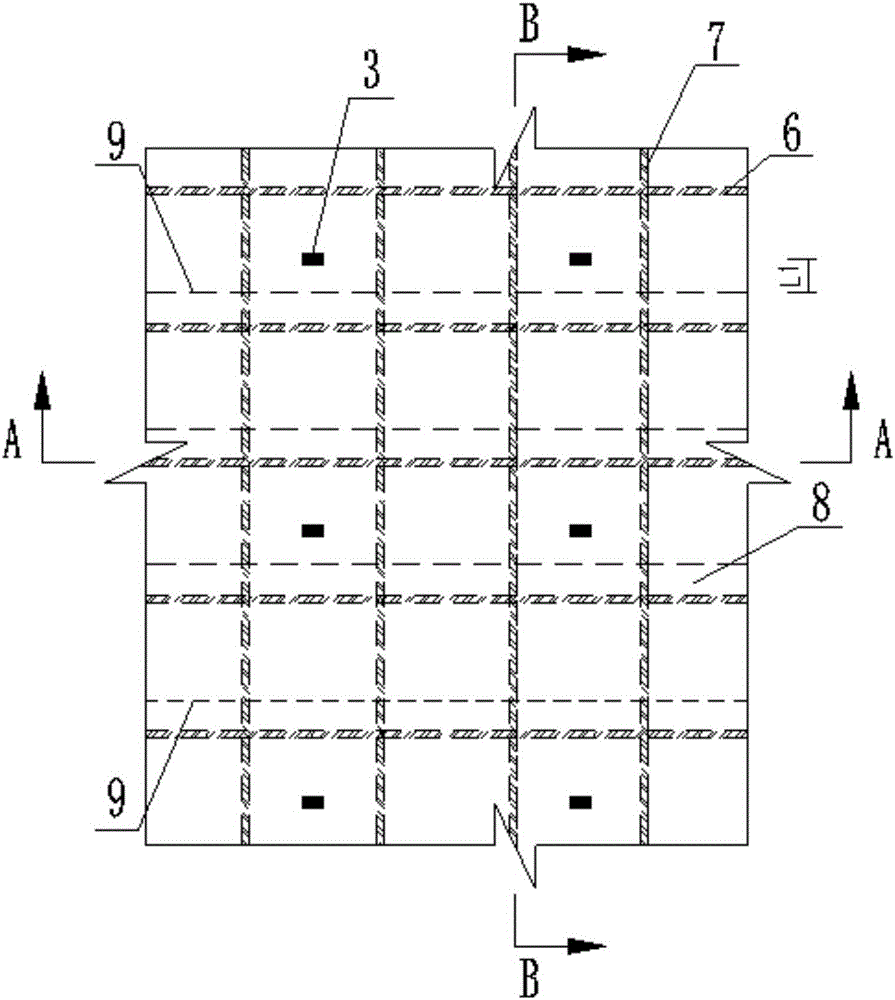

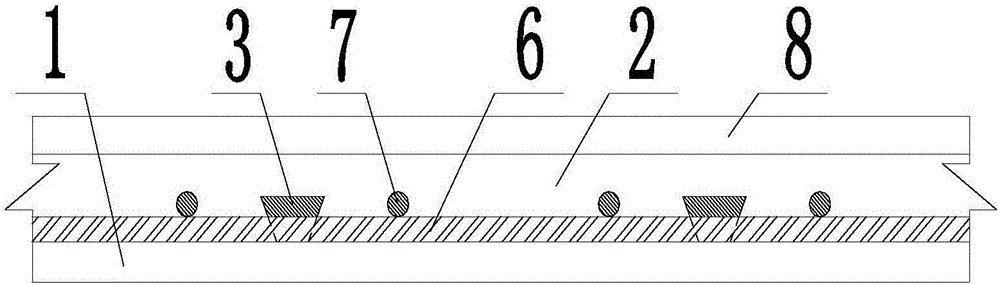

[0048] like figure 2 , image 3 and Figure 4 Shown, a kind of steel-ultra-high-performance concrete composite bridge deck structure with short steel bar shear structure of the present invention, this composite bridge deck structure comprises steel bridge deck layer 1 and pours the ultra-high performance bridge deck layer above steel bridge deck layer 1 Concrete layer 2. A longitudinal rib web 9 is arranged on the lower part of the steel bridge deck layer 1, and a short steel bar shear structure is welded on the steel bridge deck layer 1 and a steel mesh tensile structure is arranged. Both the shear structure of the short steel bar and the tensile structure of the steel mesh are embedded in the ultra-high performance concrete layer 2 . A plurality of short shear-resistant steel bars 3 are arranged in a matrix along the longitudinal bridge direction and welded on the deck layer 1 of the steel bridge to form a shear-resistant structure of short steel bars. The short steel b...

Embodiment 2

[0056] like Figure 5 , Image 6 and Figure 7 Shown, a kind of steel-ultra-high-performance concrete composite bridge deck structure with short steel bar shear structure of the present invention, this composite bridge deck structure comprises steel bridge deck layer 1 and pours the ultra-high performance bridge deck layer above steel bridge deck layer 1 Concrete layer 2. A longitudinal rib web 9 is arranged on the lower part of the steel bridge deck layer 1, and a short steel bar shear structure is welded on the steel bridge deck layer 1 and a steel mesh tensile structure is arranged. Both the shear structure of the short steel bar and the tensile structure of the steel mesh are embedded in the ultra-high performance concrete layer 2 . A plurality of short shear-resistant steel bars 3 are arranged in a matrix along the longitudinal bridge direction and welded on the deck layer 1 of the steel bridge to form a shear-resistant structure of short steel bars. The short steel b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com