Patents

Literature

53results about How to "Reduce design thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

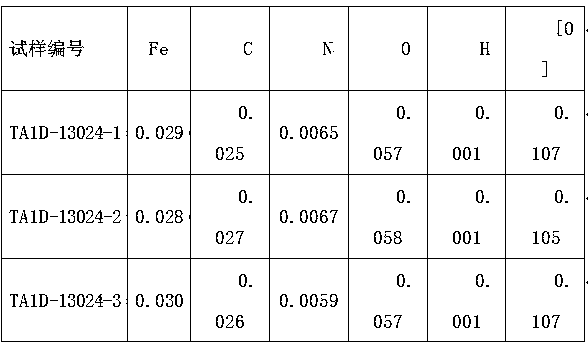

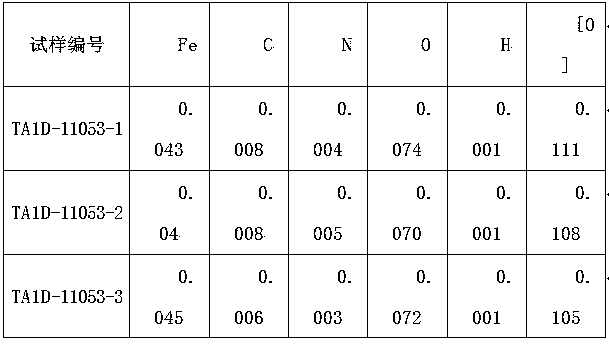

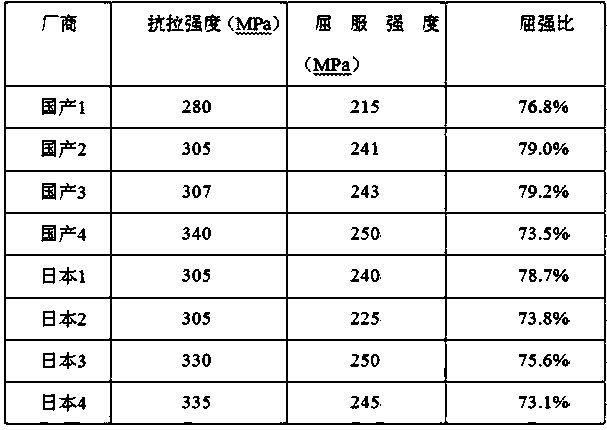

Processing method of low yield ratio high strength titanium coiled plate for heat exchanger

The invention provides a processing method of a low yield ratio high strength titanium coiled plate for a heat exchanger. The processing method of the titanium coiled plate comprises the following steps of: preparing a plate blank; rolling a hot coil; annealing the hot coil; performing surface treatment on the hot coil; cold rolling; degreasing; and annealing to obtain the low yield-ratio high titanium coiled plate for the heat exchanger. According to the processing method, the content of a titanium cast ingot is controlled, and the processing technology of a titanium tape is utilized, so that the tensile strength of a titanium plate is about 385+ / -15MPa, and the yield ratio is not greater than 70%; and with the improvement of the tensile strength of the titanium plate for the heat exchanger, the design thickness of the titanium plate can be reduced by more than 10%, and therefore, the titanium plate being 0.5 to 1.2mm in thickness can be prepared for the heat exchanger. Compared with the titanium coiled plate in the prior art, the titanium coiled plate processed by the method provided by the invention has high strength, low yield ratio and high deep drawing performance, and the production cost is also greatly decreased.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

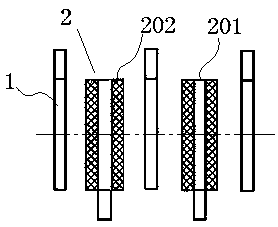

Composite component of meridian tyre cord fabric layer and air barrier and preparation technology

ActiveCN101612867ASimple production processIncrease productivitySpecial tyresPneumatic tyre reinforcementsRadial tireEngineering

The invention discloses a composite component of meridian tyre cord fabric layer and air barrier and a preparation technology. Base material rubber, an aging-proof system, a reinforcing system, a vulcanization system and a radiosensitizer are mixed at a ratio to form a mixture; the rubber mixture is mixed to smelt in an internal mixer to be prepared into a tyre body cord fabric layer component and a lining air barrier component respectively according to the production technology of the tyre body cord fabric layer and the lining air barrier component; then the tyre body cord fabric layer component and the lining air barrier component are compounded into an integral composite component on a compound machine; an electron accelcrator is used for radiating the composite component; under the condition of limited-oxygen radiation, radiation prevulcanization is carried on the composite component of the tyre cord fabric layer and the lining air barrier. The composite component of the tyre cord fabric layer and the air barrier, which is radiated by the invention, has high Green strength, stable structure size and performance, saves raw material, has small radiation dose and high production efficiency and is favourable for environment protection.

Owner:BEIJING RADIATION APPL RES CENT

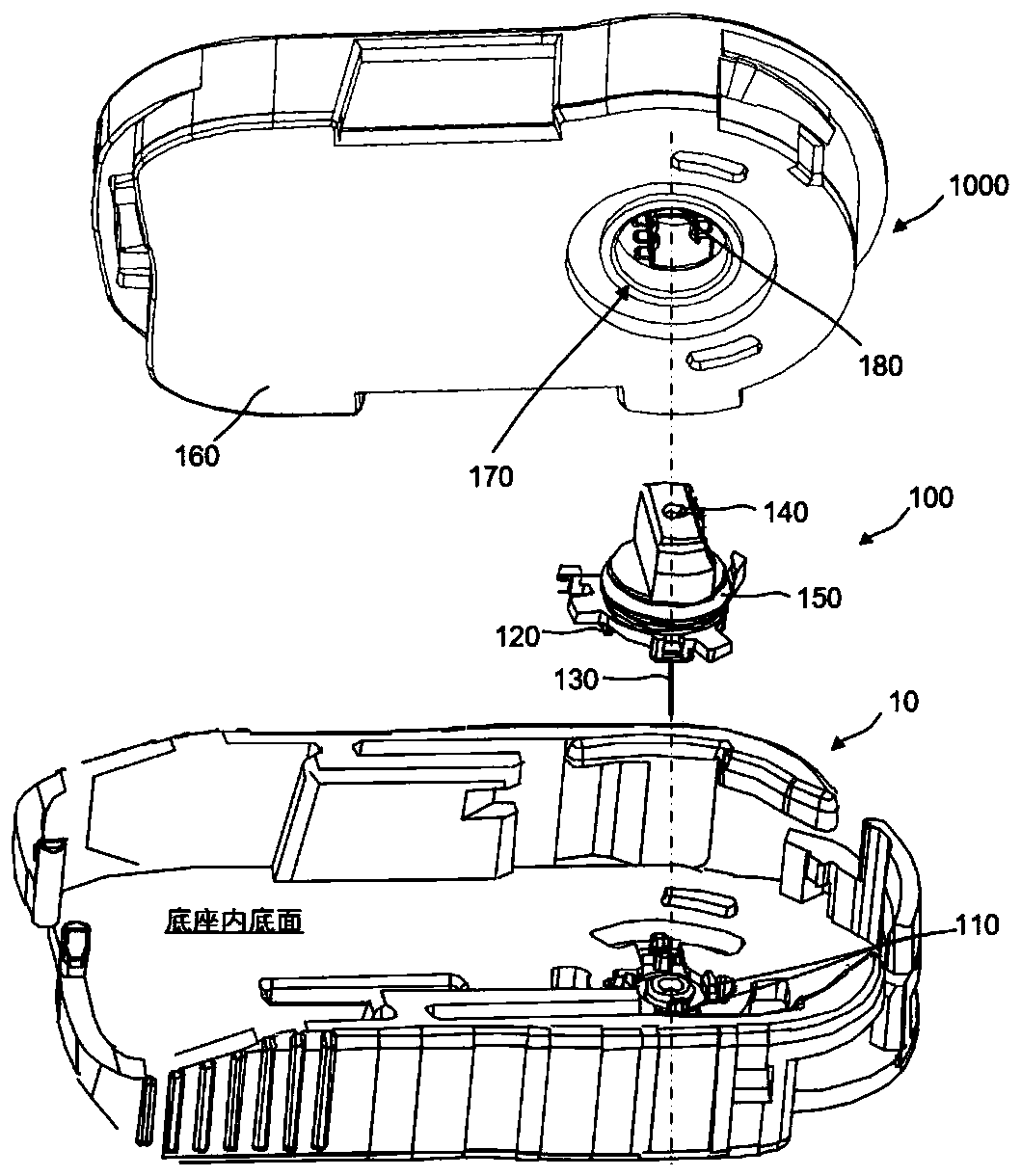

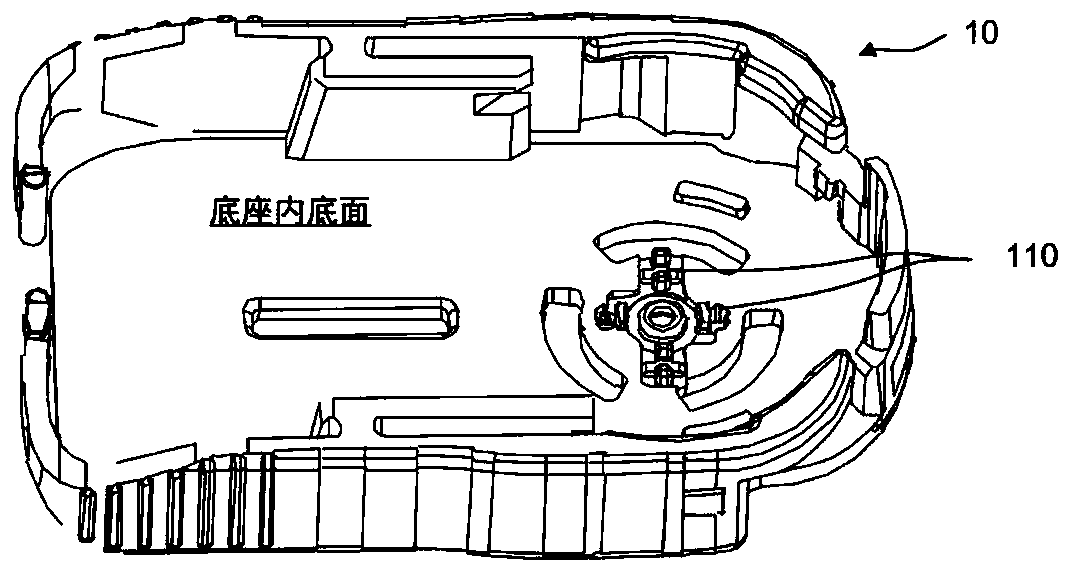

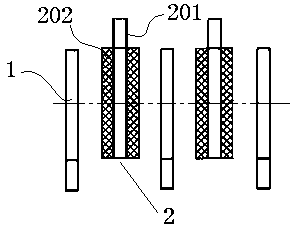

Sensing device

InactiveCN110584676AReduced Thickness DimensionsReduce complexitySensorsBlood characterising devicesAnalyteBody fluid

The invention discloses a sensing device, and the device comprises the following parts: a pedestal which is provided with a first clamping part; a probe structure which comprises a second clamping part capable of being clamped with the first clamping part, a probe used for detecting body fluid analyte parameters and a connecting area electrically connected with the probe, wherein the second clamping part is arranged at one end of the probe structure, and the second clamping part and the first clamping part are clamped with each other so that the probe structure can be installed on the pedestal; and a transmitter structure, which comprises an emitter shell and an emitter arranged in the emitter shell, wherein the emitter shell is provided with a connecting hole, the connecting hole is matched with the probe structure in shape and structure, when the emitter structure is installed on the pedestal, the probe structure is located in the connecting hole, and the emitter is electrically connected with the connecting area so as to receive signals generated by the probe. Due to the design, the thickness of the sensing device is reduced, and the user experience is enhanced.

Owner:MEDTRUM TECH

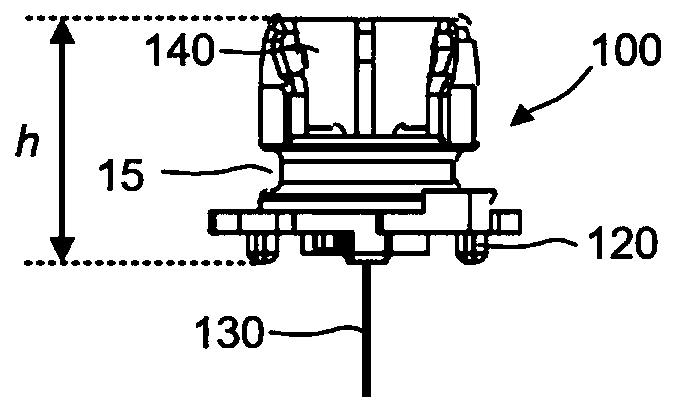

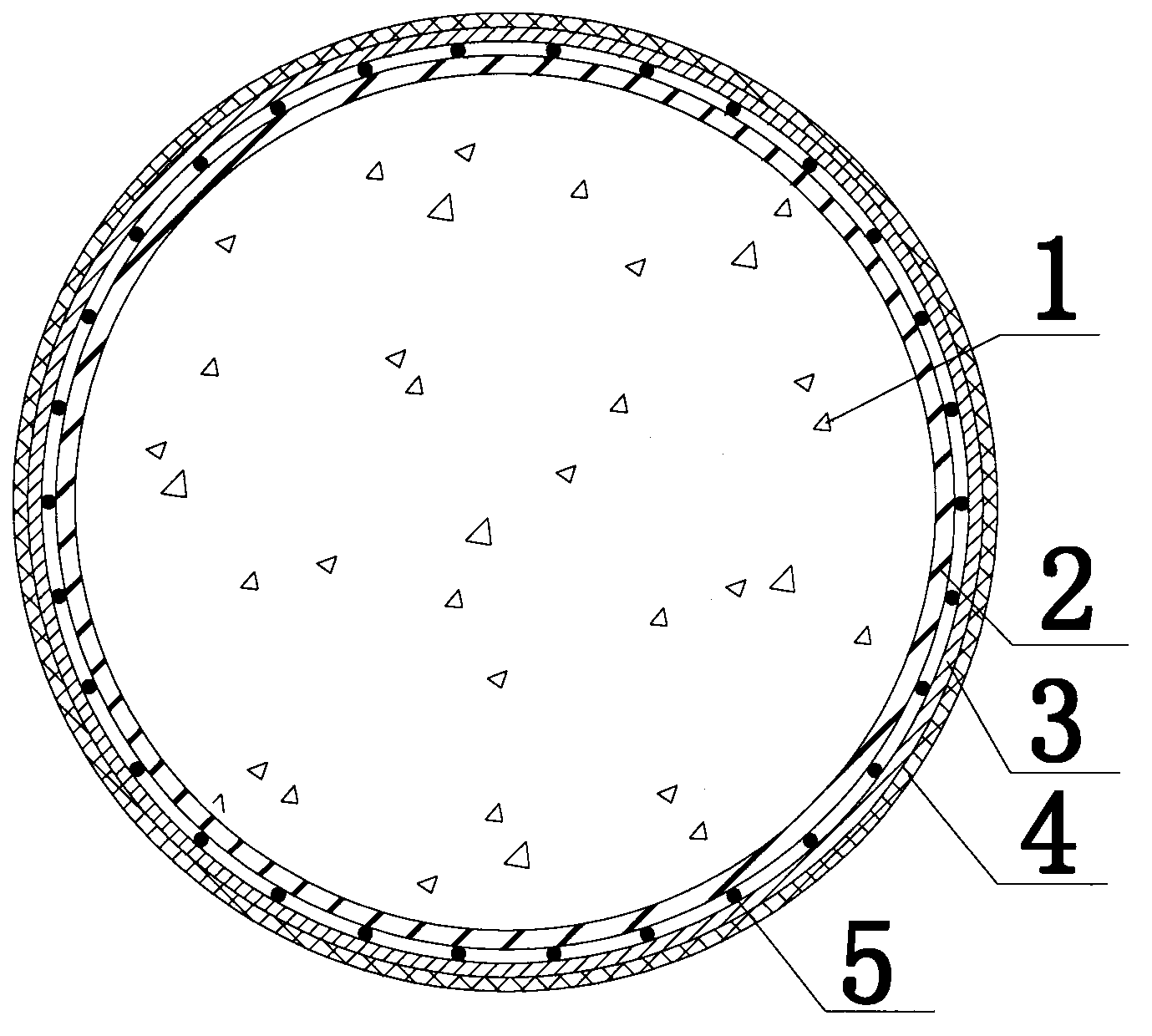

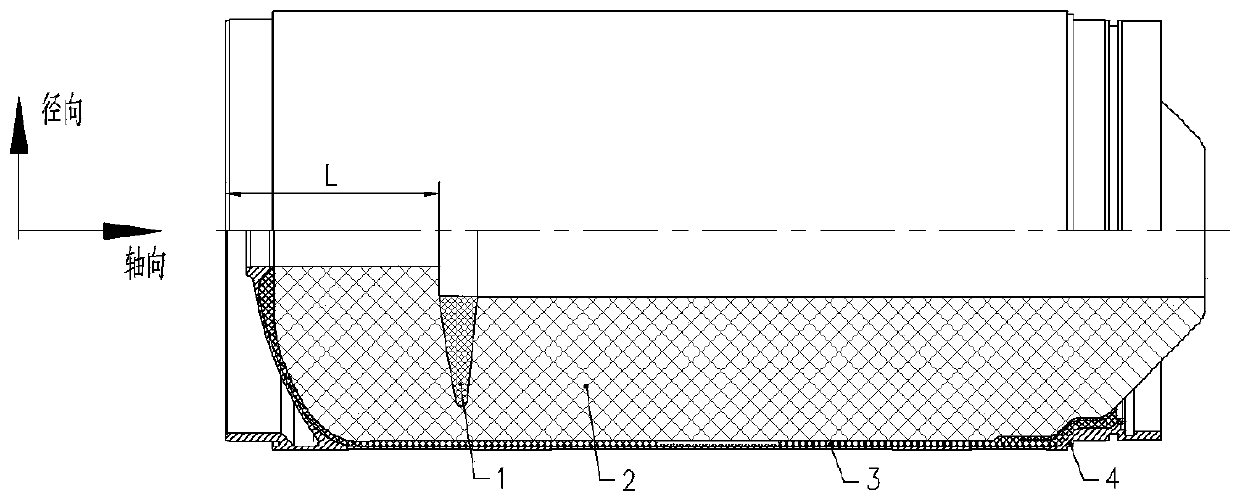

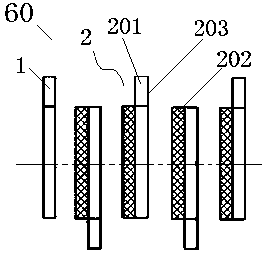

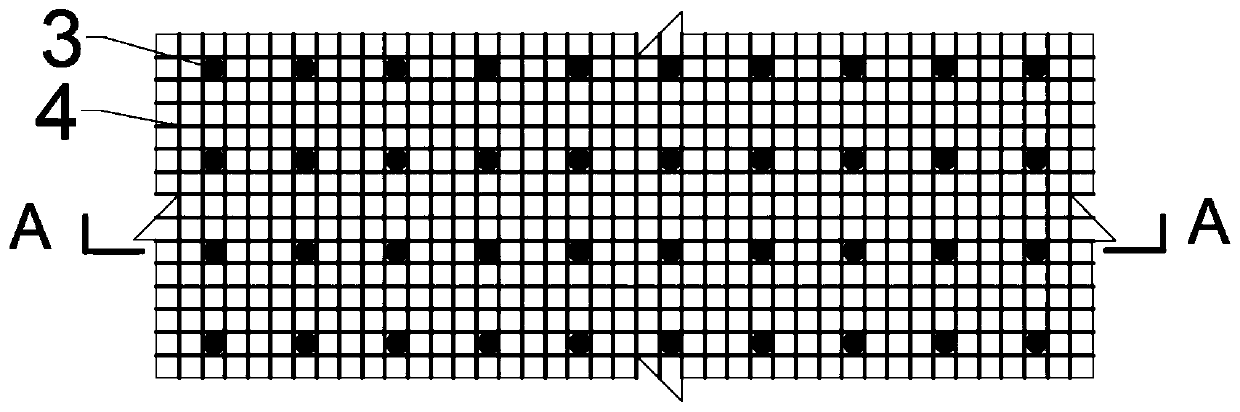

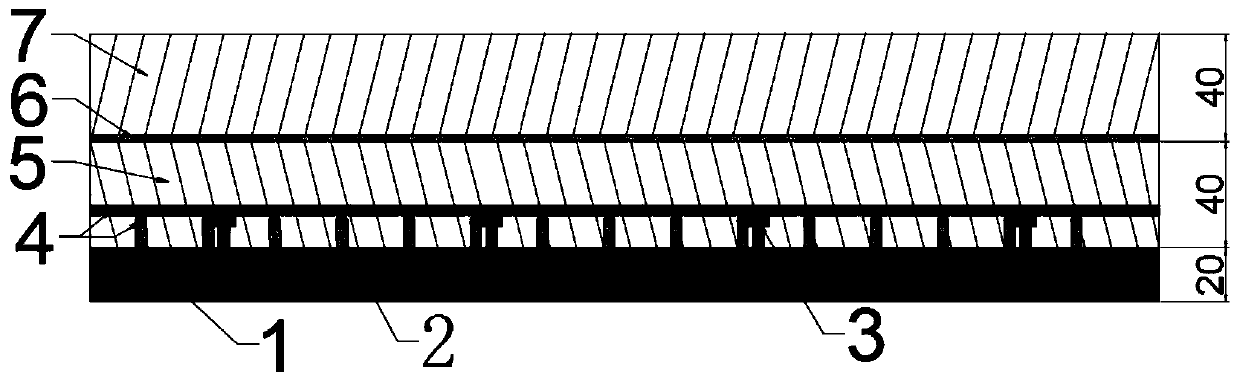

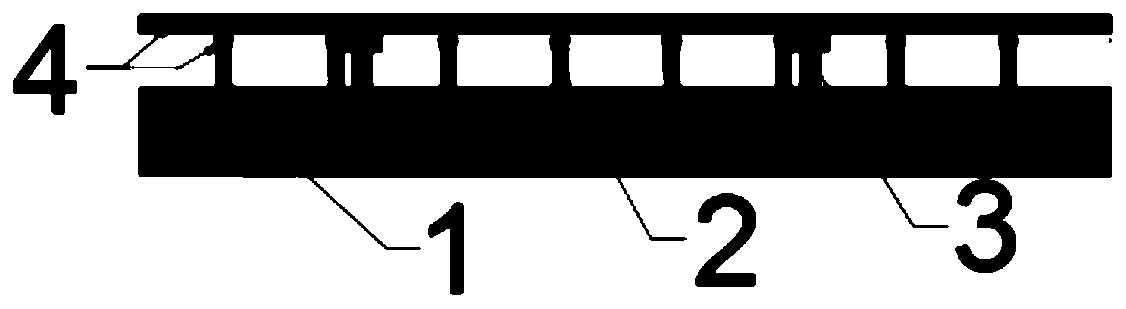

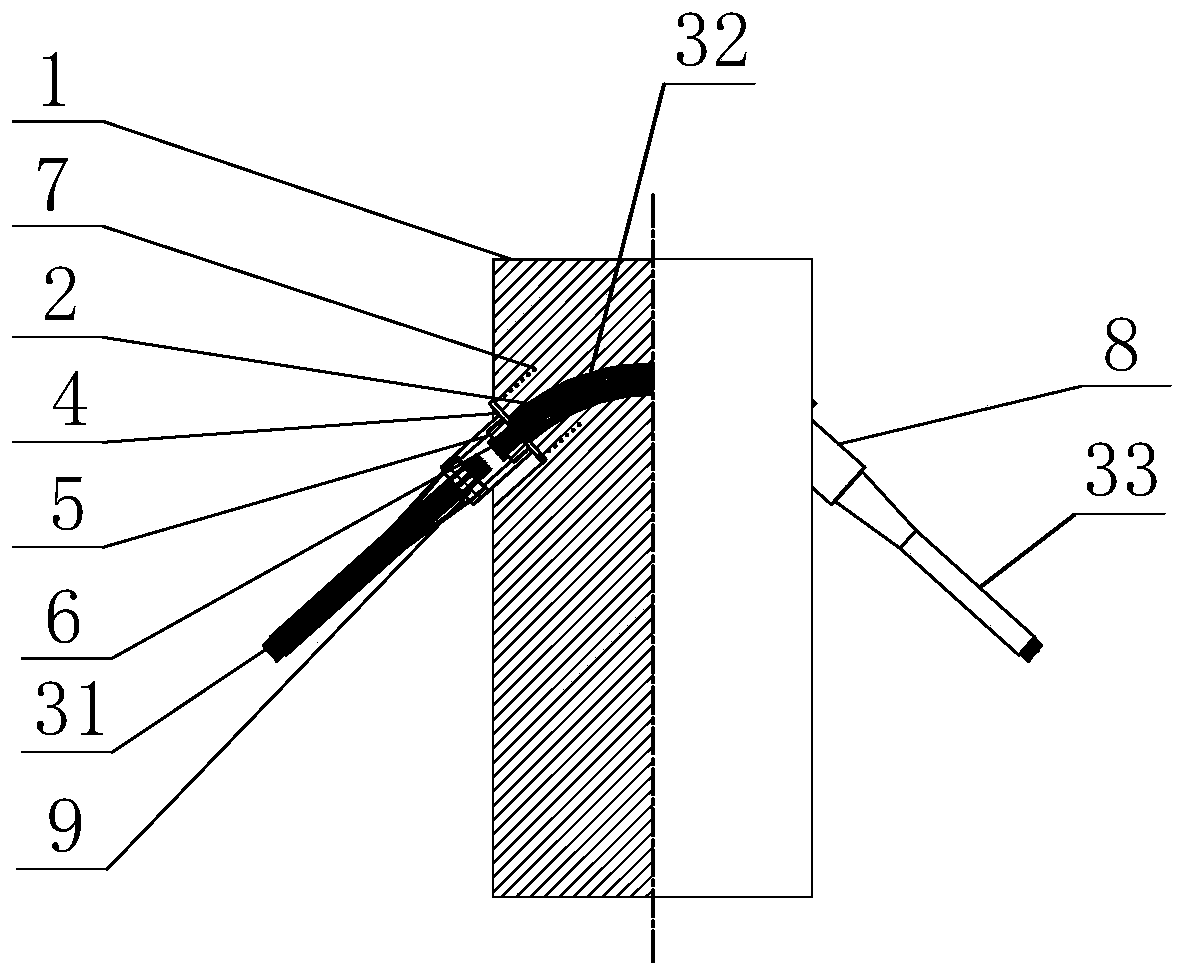

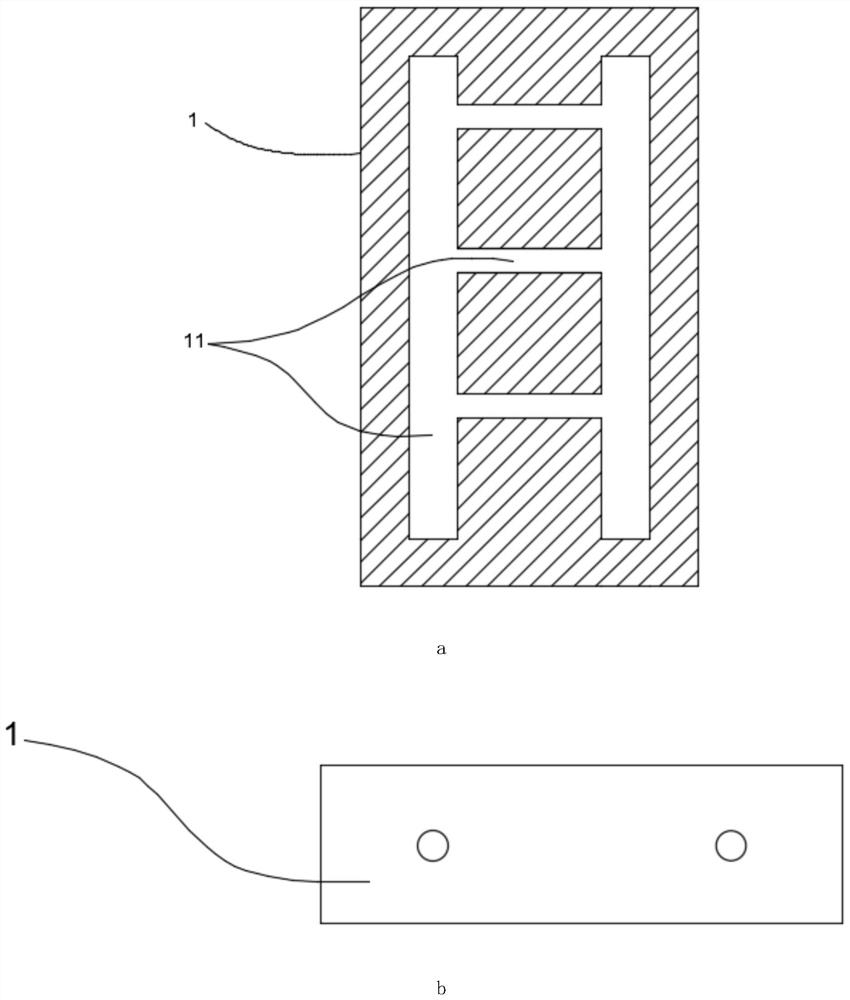

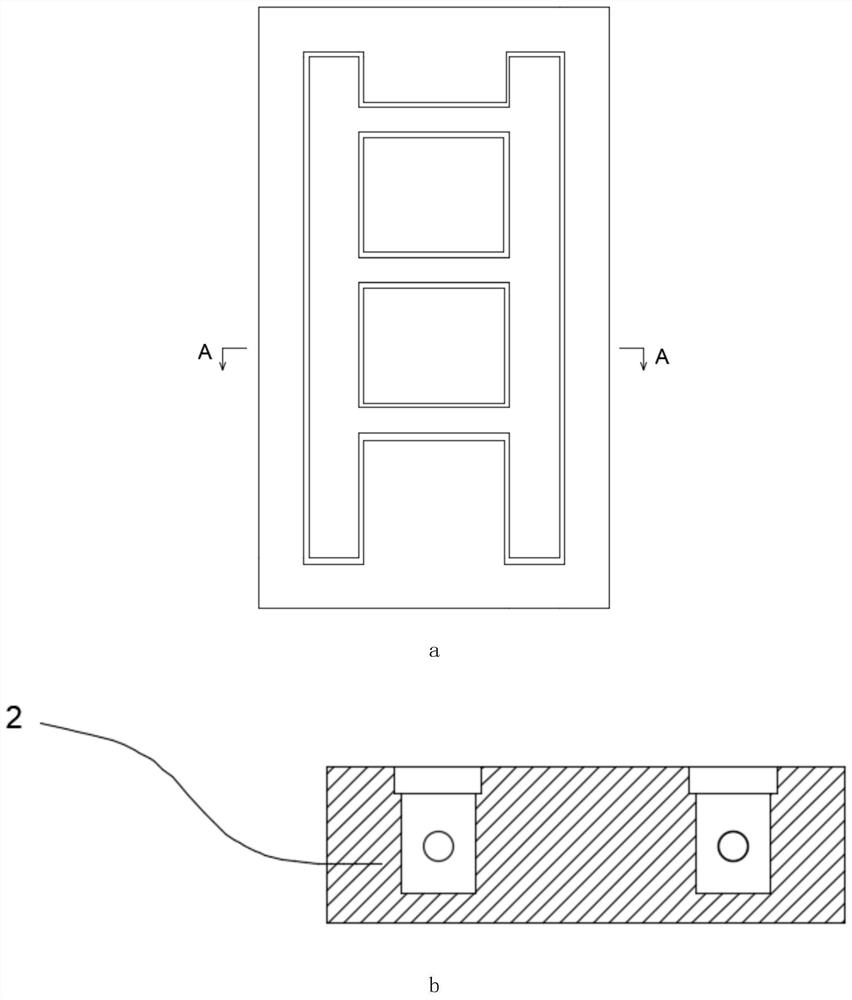

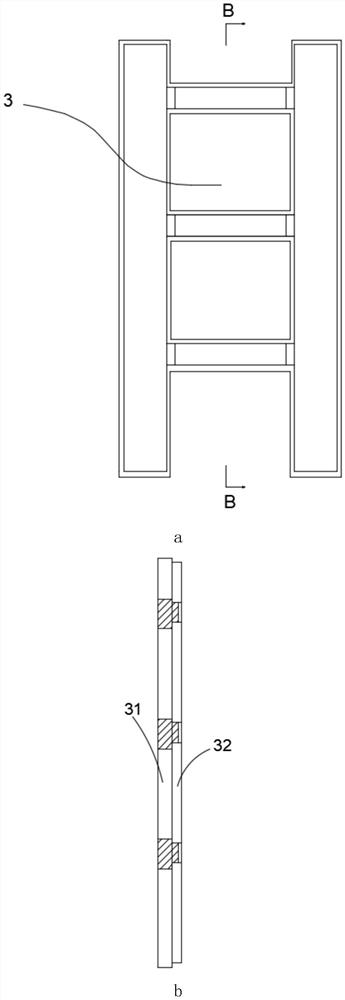

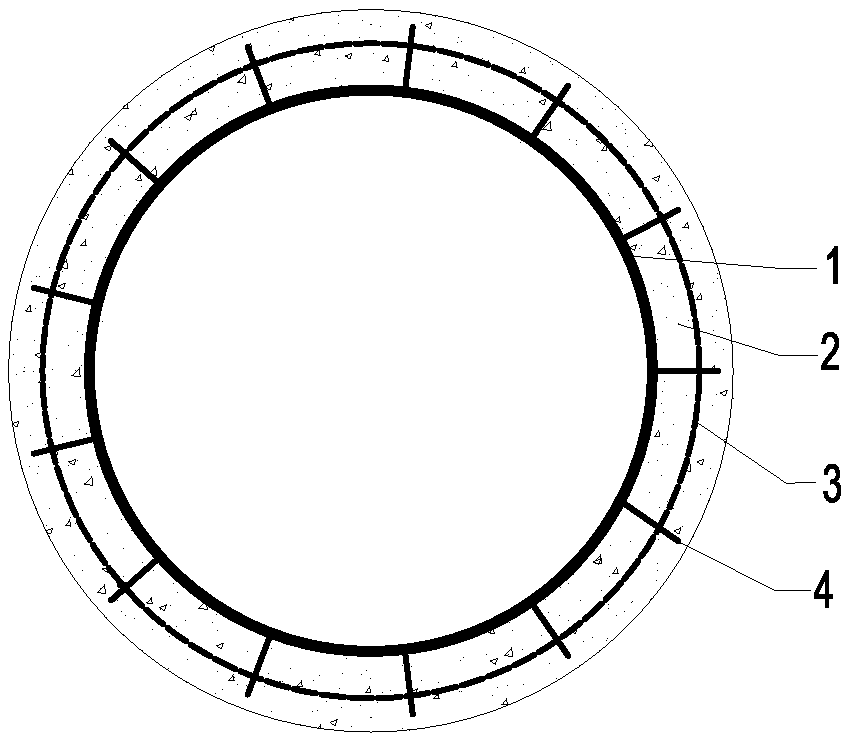

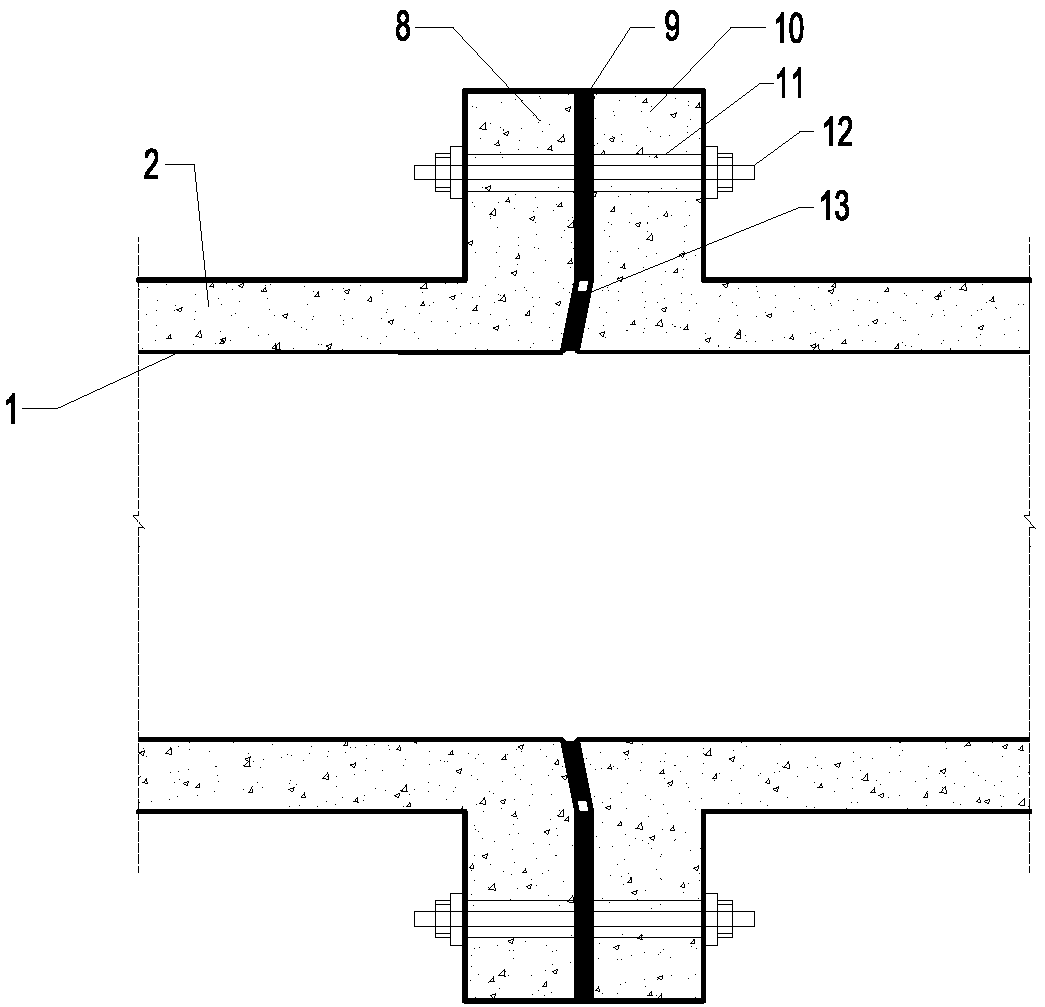

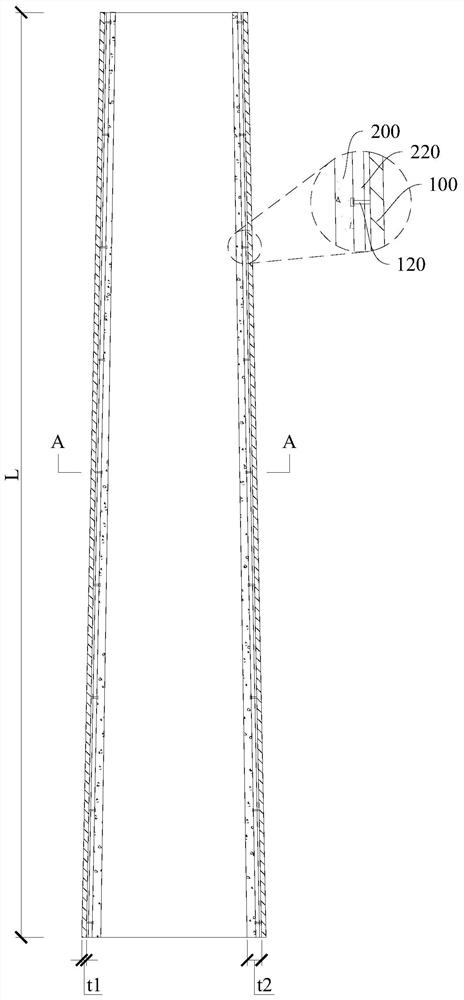

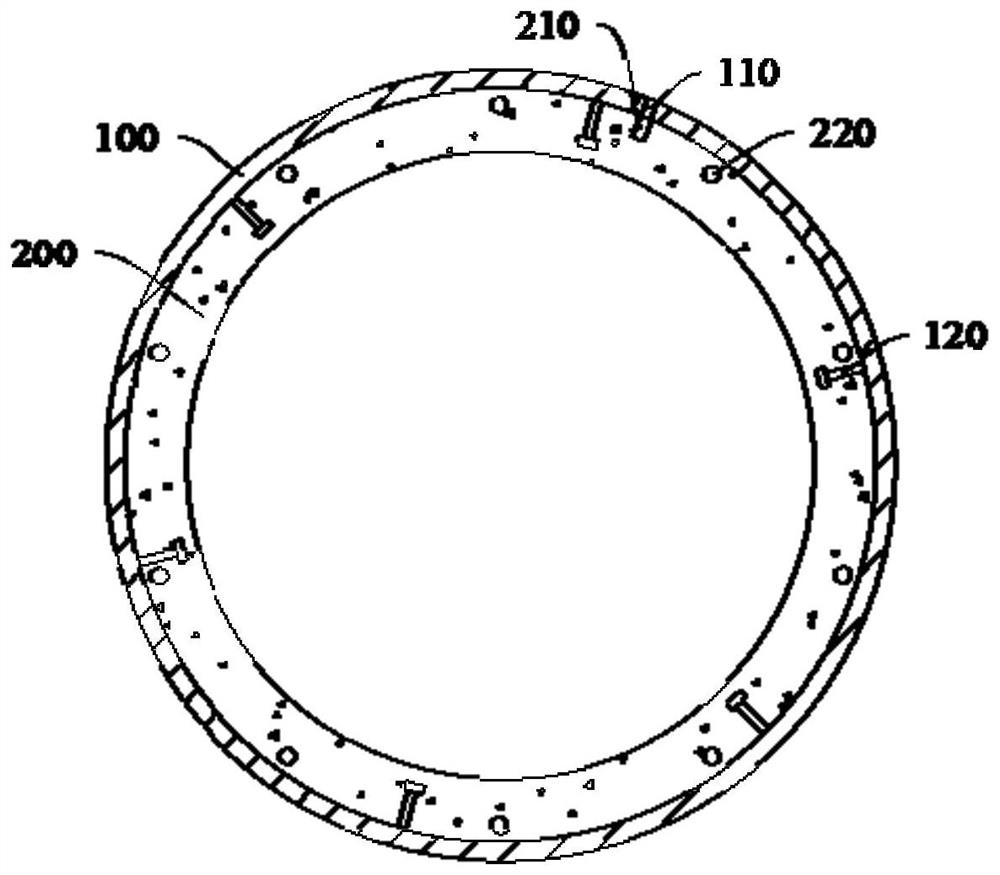

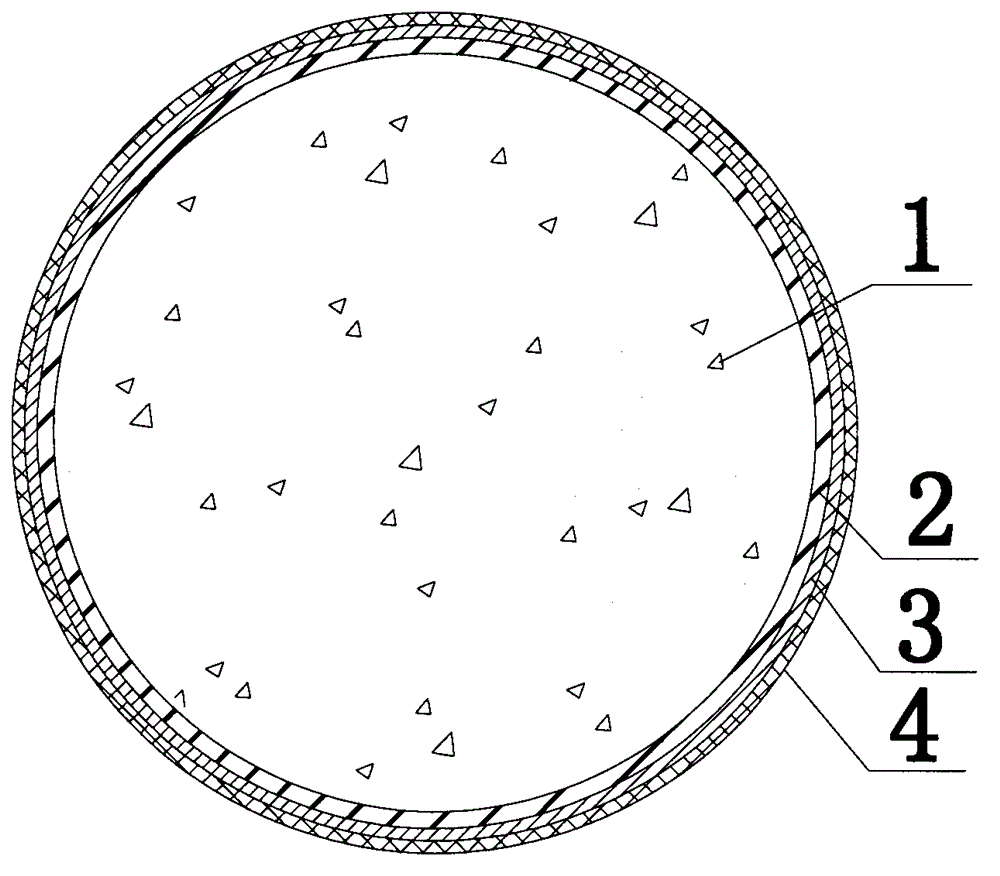

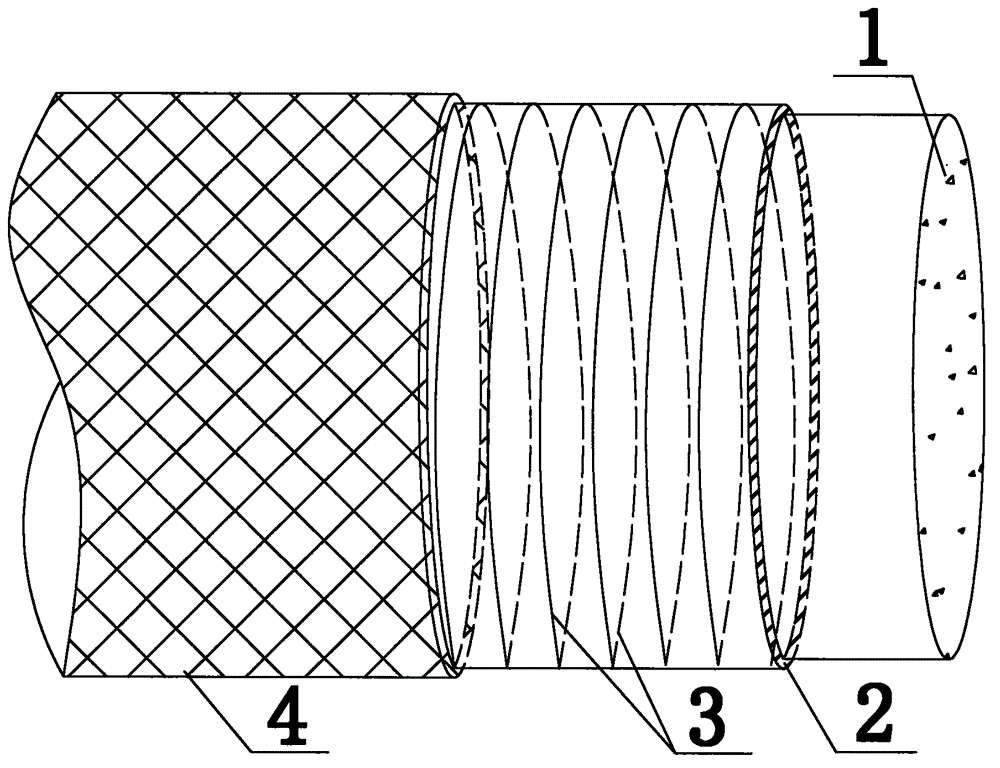

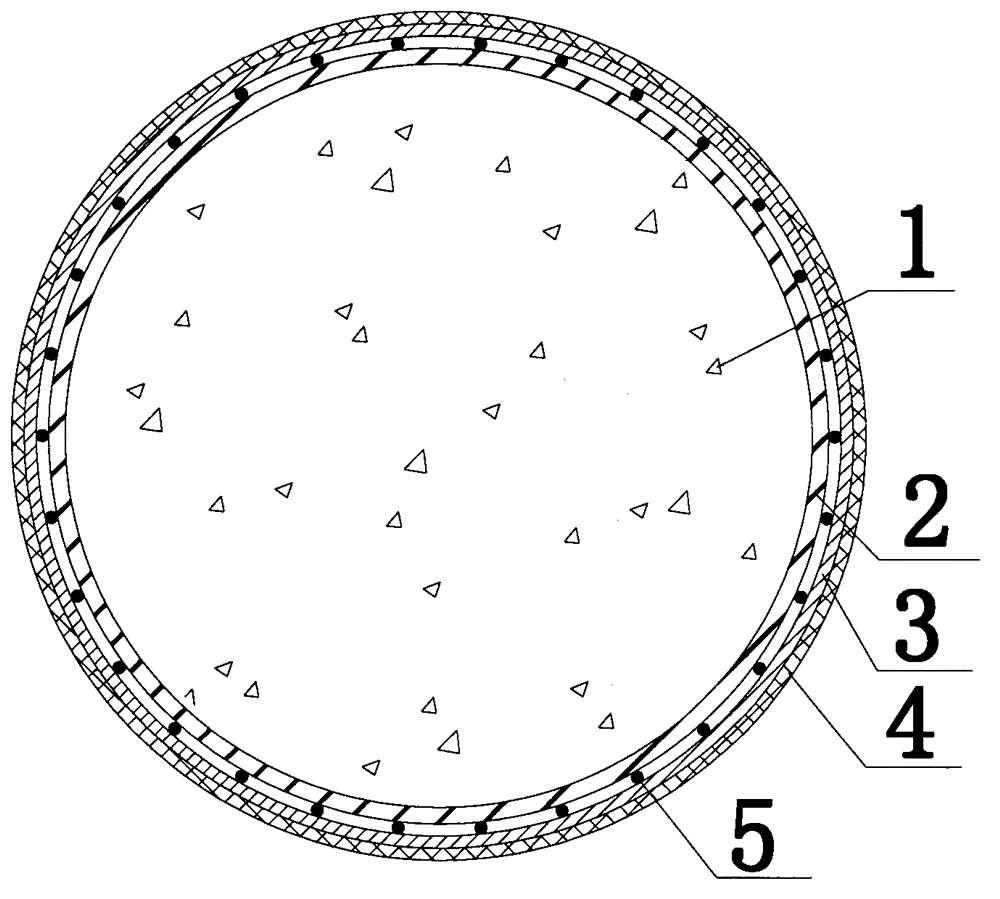

Composite pipe concrete composite structure

The invention relates to a composite pipe concrete composite structure which is characterized in that the structure comprises internal concrete (1), a steel pipe (2), transverse pre-stressed steel wires (3), and a fiber-reinforced plastic material (4). According to the invention, through applying pre-stress to the steel wires, the pre-stressed steel wires (3) are transversally continuously and uniformly wound on the outer wall of the steel pipe (2). The fiber-reinforced plastic material (4) is adhered to the outer surface of the transverse pre-stressed steel wires (3) on the outer layer. The internal concrete (1) is filled in the steel pipe (2). The winding pitches between the transverse pre-stressed steel wires (3) are no larger than 40mm. With the structure provided by the invention, defects of commonly known steel pipe concrete and FRP-steel composite pipe concrete structures are overcome, and advantages such as high yield load, large bearing capacity storage, good ductility, moderate failure mode, good durability, and the like are provided. Especially, the structure has stable and continuous decline stage and low cost. The structure provide by the invention is suitable to be used in piles, columns, bridge piers, and arch ribs in newly built structures, and can be used in reinforcement of mainly compressed members in existing reinforced concrete structures and steel pipe concrete structures.

Owner:NANJING FORESTRY UNIV +2

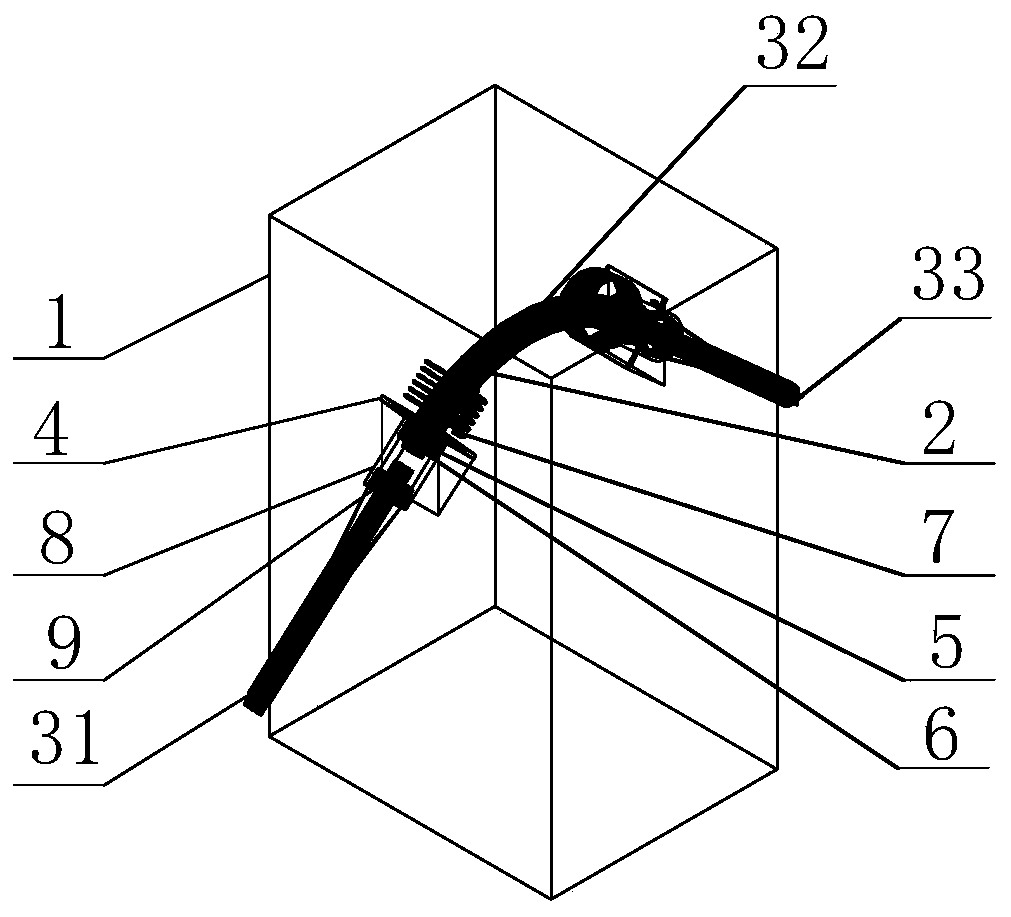

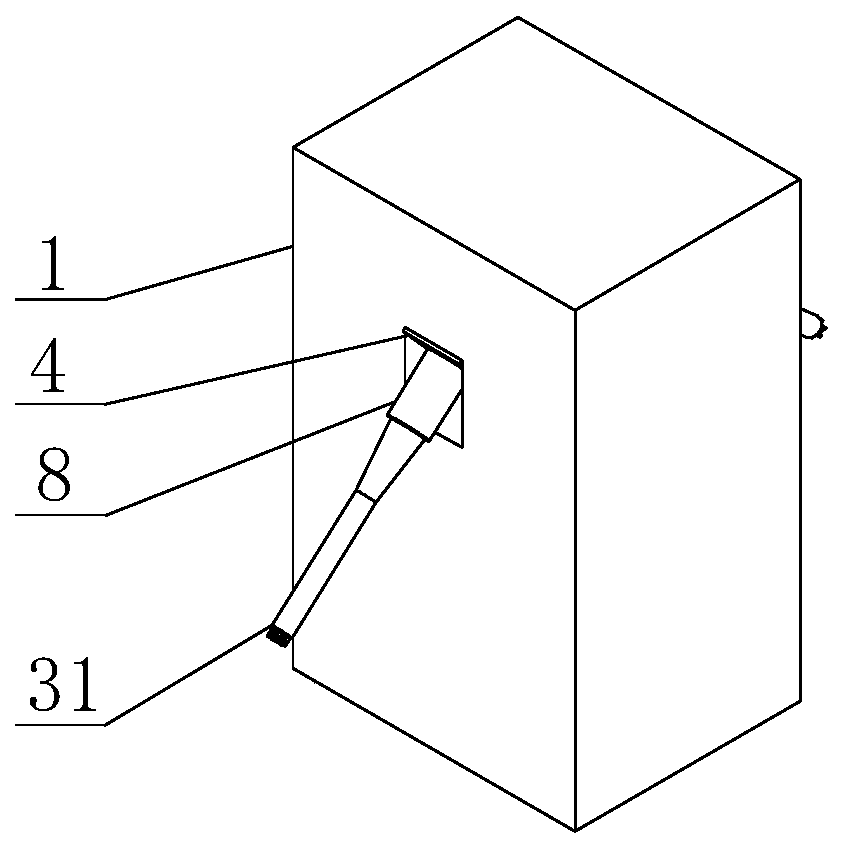

Tubular inner-hole charge structure with inner cavity partition and used for solid rocket engine, and method

ActiveCN110145411AImprove surface increaseReduce maximum pressureRocket engine plantsCombustion chamberWorking pressure

The invention discloses a tubular inner-hole charge structure with an inner cavity partition and used for a solid rocket engine. The inner cavity partition is arranged in the combustion chamber chargestructure of the solid engine, and the inner cavity partition is made from a polyurethane foam material. The tubular inner-hole charge structure with the inner cavity partition and used for the solidrocket engine has the beneficial effects of being capable of effectively improving the progressive performance of the solid rocket engine in a working process, reducing the maximum working pressure of the engine, reducing the design thickness of a shell body, reducing the passive mass of the missile engine, and increasing the missile range.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

6-series aluminum alloy profile suitable for aluminum template and preparation method thereof

The invention discloses a 6-series aluminum alloy profile suitable for an aluminum template and a preparation method thereof. By adjusting the alloy components of an aluminum alloy ingot and a heat treatment process, the average main cylinder pressure of the 6-series aluminum alloy profile suitable for the aluminum template in the extrusion process is effectively reduced, and the finally prepared aluminum template profile has more excellent tensile strength and yield strength. The adjusted alloy components are prepared from the following components in percentage by weight: 0.65-0.75% of Si, less than or equal to 0.25% of Fe, 0.05-0.10% of Cu, 0.05-0.10% of Mn, 0.55-0.65% of Mg, less than or equal to 0.10% of Cr, 0.20-0.30% of Zn, 0.05-0.10% of Sn, less than or equal to 0.05% of Ti, less than or equal to 0.05% of single impurity, less than or equal to 0.15% of total impurities and the balance Al. The aluminum template profile is prepared by the steps of ingot casting, homogenization treatment, surface brush rod or peeling treatment, extrusion forming, quenching cooling and artificial aging of the prepared alloy components.

Owner:FOSHAN AOMEI ALUMINUM IND

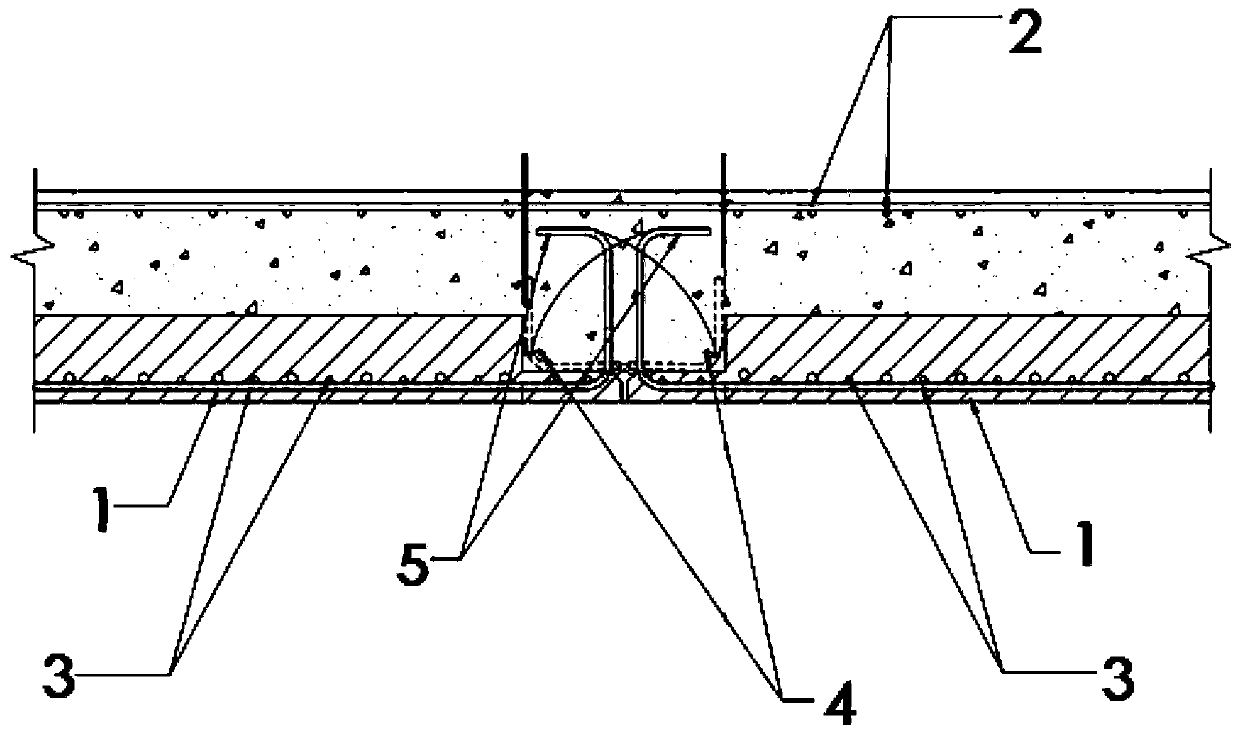

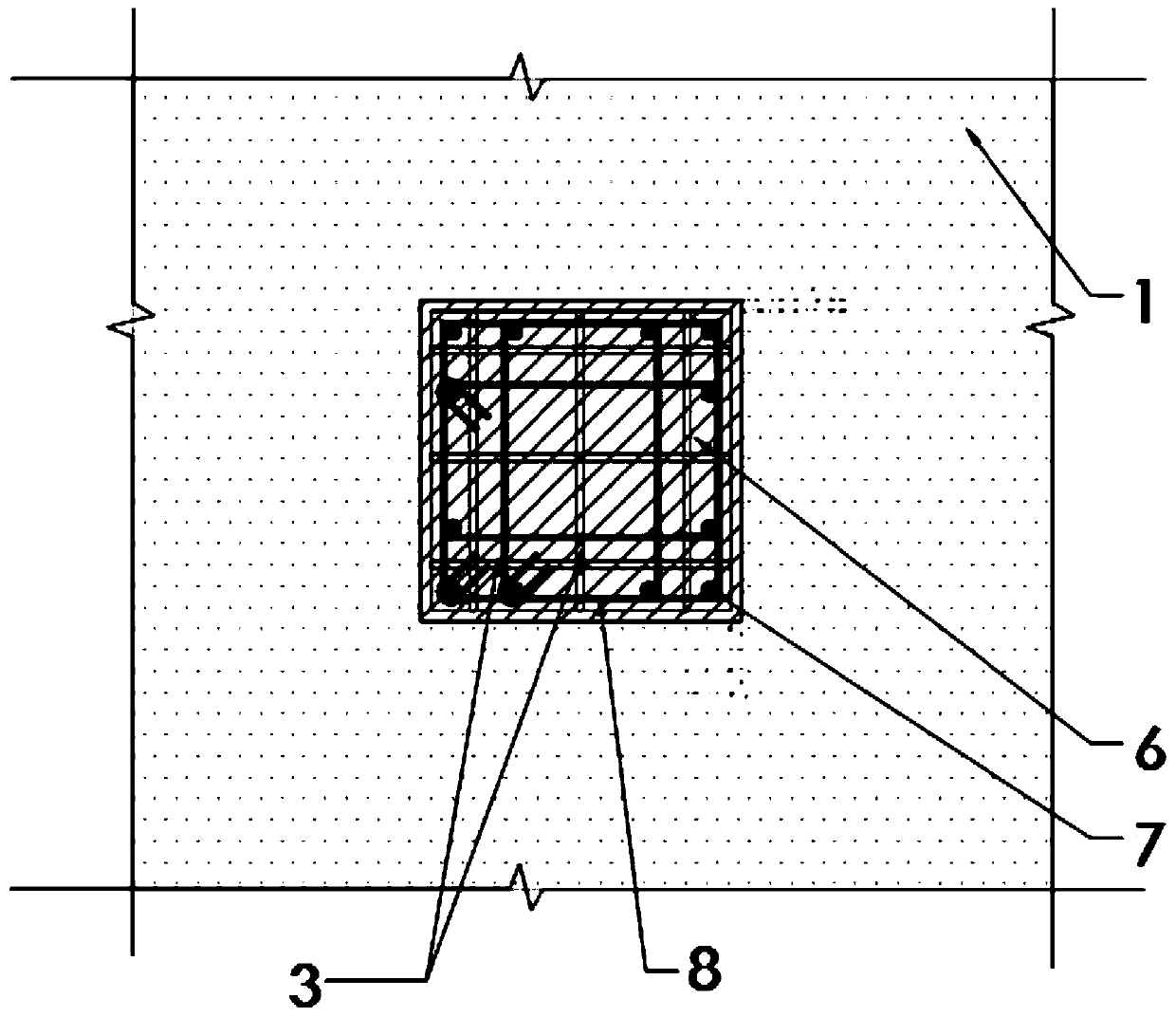

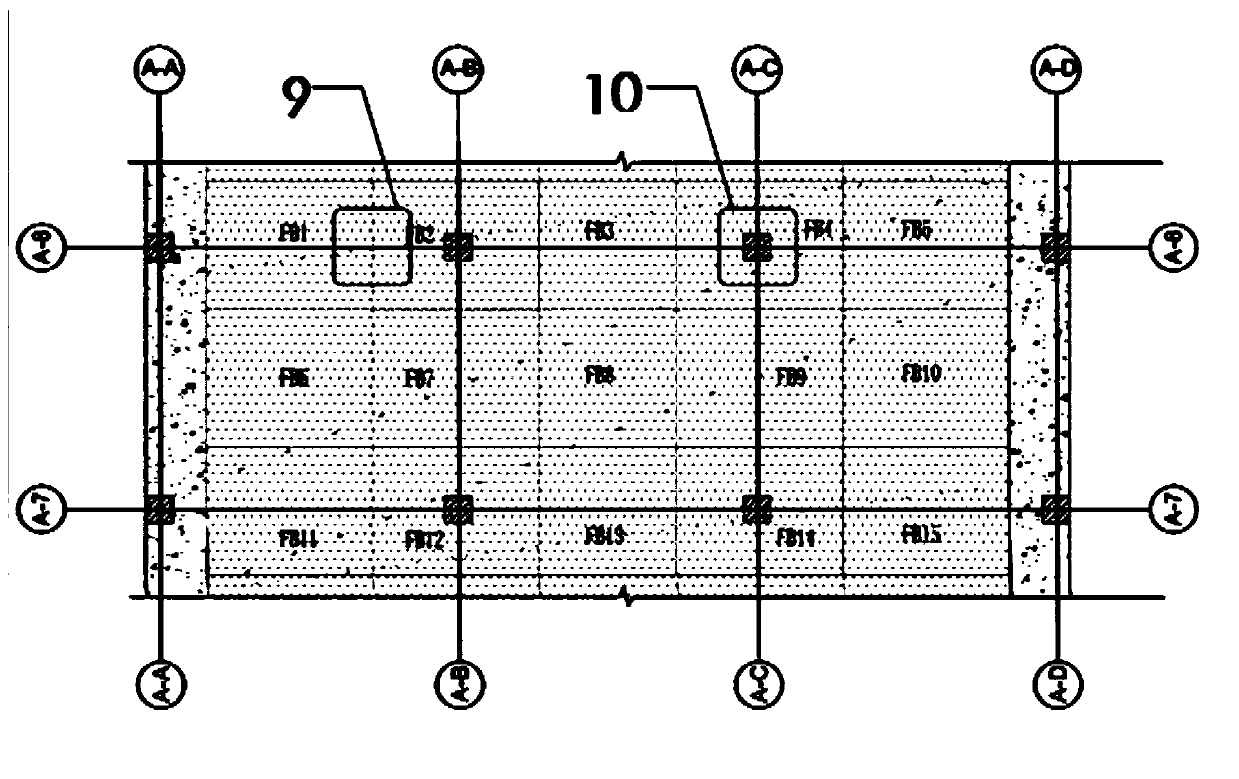

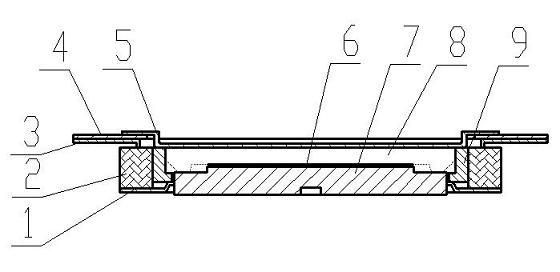

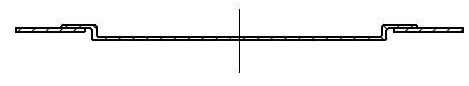

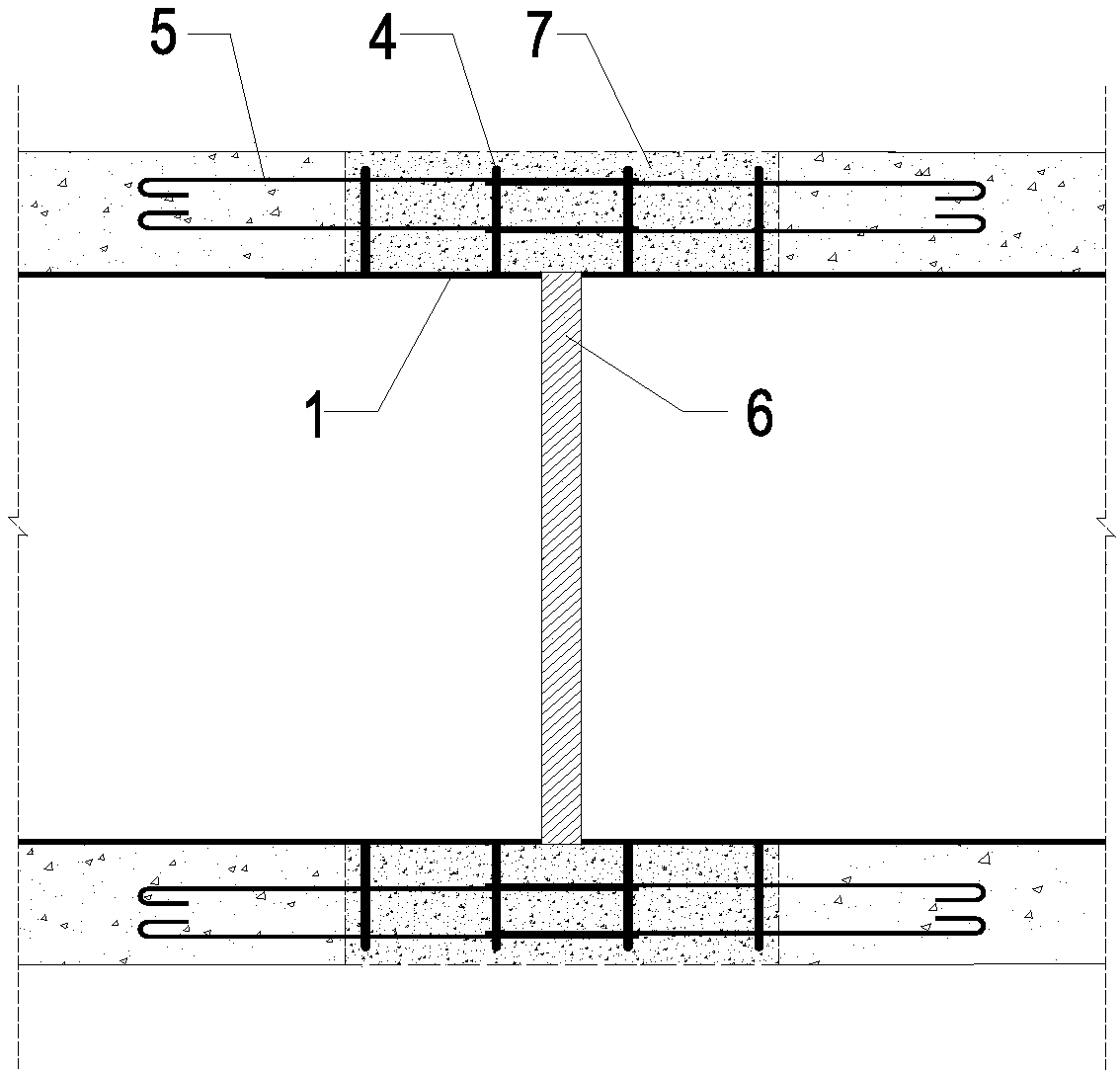

Prefabricated beamless floor composite slab based on stress and disassembly method thereof

InactiveCN110644662AReduce difficulty and errorsImprove efficiencyFloorsBuilding reinforcementsRebarFloor slab

The invention provides a prefabricated beamless floor composite slab based on stress and a disassembly method thereof. The prefabricated beamless floor composite slab comprises a prefabricated composite floor, a prefabricated column connection node and a prefabricated composite slab connection node, and the prefabricated composite floor and prefabricated column connection node comprise entering the prefabricated composite floor into a prefabricated column protection layer to keep steel bar continuous with a prefabricated column; a prefabricated column stirrup is bound, and the prefabricated composite floor connection node comprises a cast-in-situ layer and a prefabricated composite floor layer. The connection node of the prefabricated composite slab of the invention can realize the support-free formwork of the floor, and promote construction efficiency, and the overlap requirements of the steel bar at the connection node can be ensured; the continuity kept with the steel bar of the composite floor can ensure the stress in a prefabricated column concentrated stress area well; in addition, the disassembly point of the prefabricated composite slab has a small bending moment or closes to 0, the reasonable stress design disassembly can reduce the design thickness of the floor and the usage of the steel bar, so the disassembly is more convenient.

Owner:佛山建装建筑科技有限公司

Ultrathin tube shell

ActiveCN102074512AEliminate high voltage dischargeImprove ductilitySemiconductor/solid-state device detailsSolid-state devicesMetal sheetEngineering

The invention discloses an ultrathin tube shell, comprising an upper cover, a location member, a base and a circular thick sliver sheet, wherein the upper cover comprises an external ring sheet and a disc-shaped non-oxygenic copper plate; the external ring sheet is connected to the edge of the non-oxygenic copper plate; the base comprises an annular metal sheet, a cylindrical shell, an annular edge and a bottom block; the edge is fixed at the top end of the shell; the upper surface of one end of the annular metal sheet is welded with the shell, and the other end of the annular metal sheet is sleeved and fixed at the lower part of the side wall of the bottom block; the thick sliver sheet is disposed on the bulge of the bottom block; the location member is an annular location ring; the bottom of the location ring is provided with an eave layer shaped ring projected inwardly; the outer wall of the location ring is fitted with the inner wall of the shell in an embedding manner; the inner side of the eave layer shaped ring is contacted with the upper part of the side wall of the bottom block; the outer ring sheet is welded with the edge in a sealing manner. In the invention, the part structure and assembling manner are improved on the original basis; the tube shell is compared with the traditional tube shell for packaging tube cores of the same type, the thickness is reduced about 66%, and the weight is reduced about 73%.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

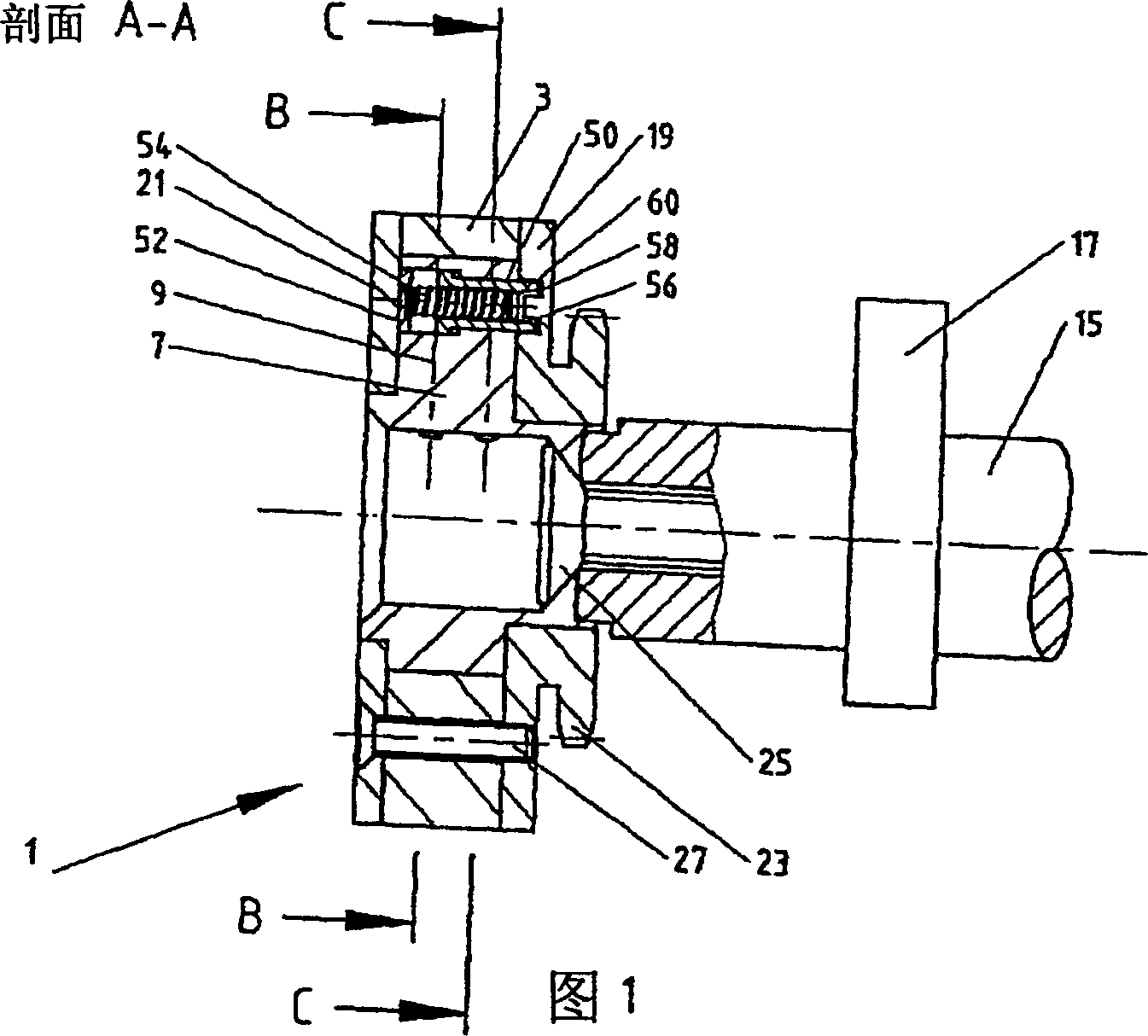

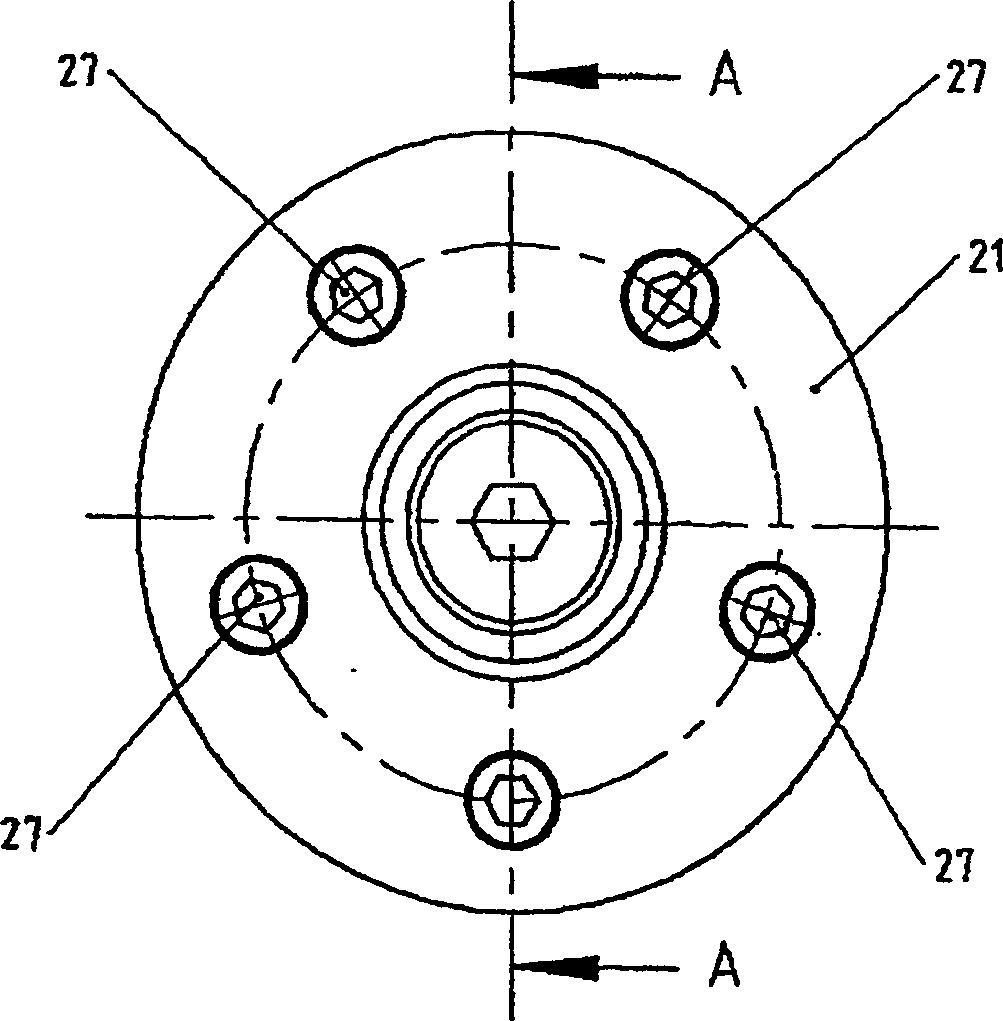

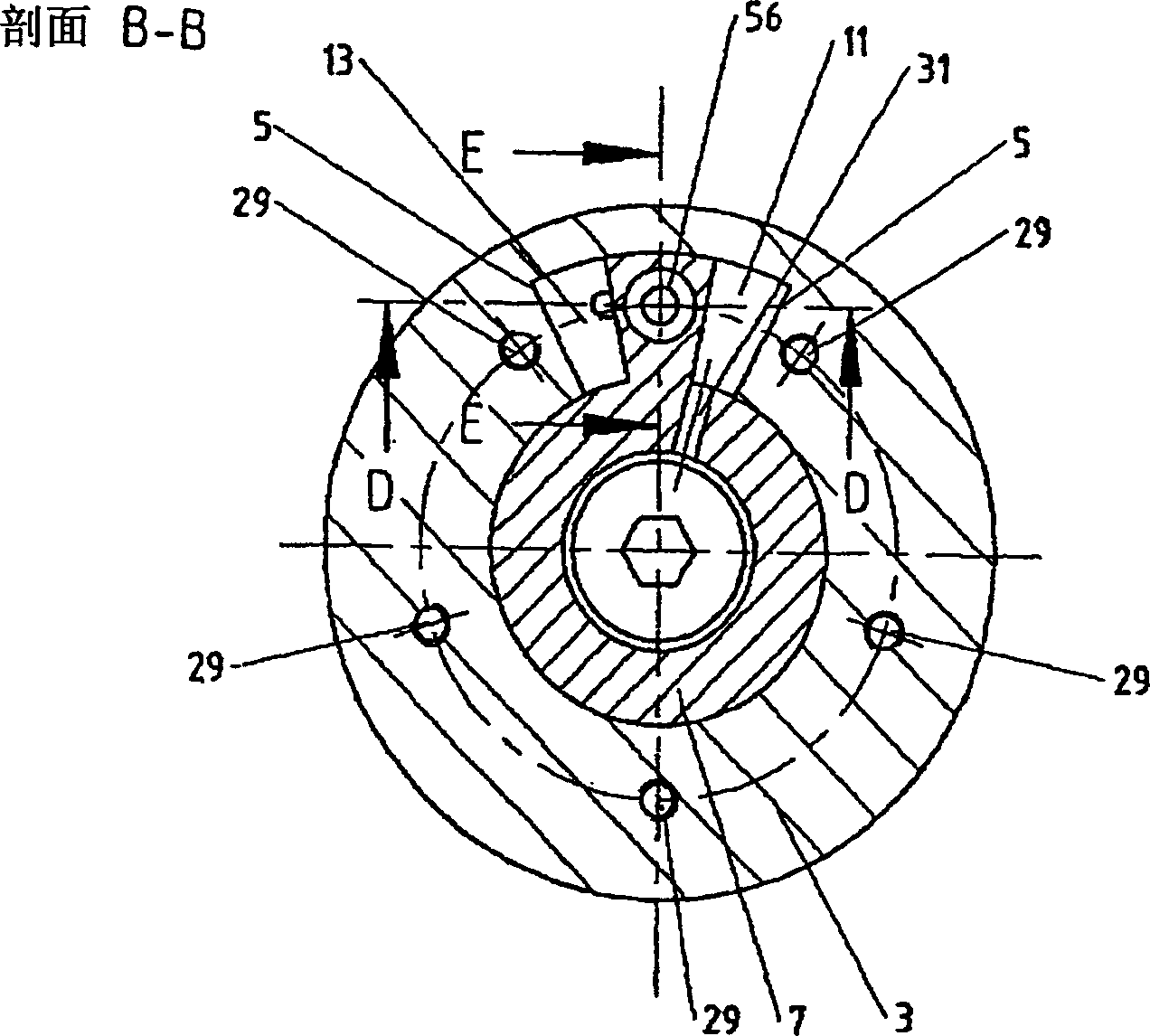

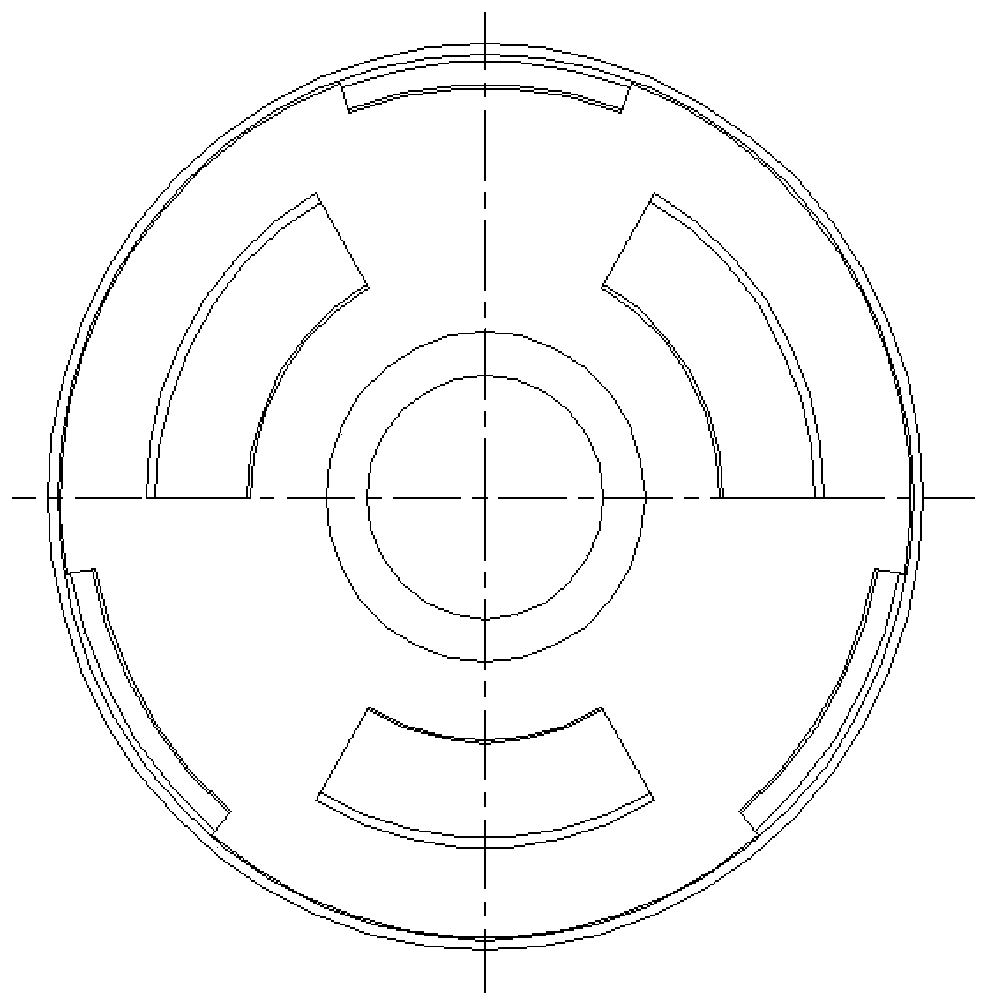

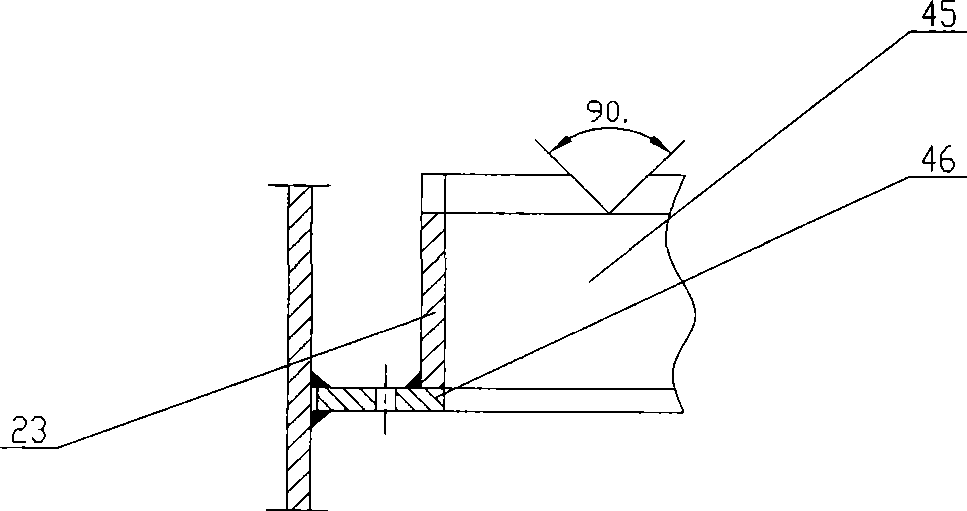

Camshaft adjuster with play-free locking

Camshaft adjusters according to the swivel motor principle may be provided with a bar which arrests the rotor in a position relative to the stator. A bar according to the invention is provided with two portions, between which a change of power transmission takes place during the arresting process.

Owner:HAIDER RUN CO LTD

Friction pair system of double clutch

PendingCN107830077AImprove heat dissipationAvoid high temperature failureFriction clutchesClutchEngineering

The invention discloses a friction pair system of a double clutch. The friction pair system is characterized in that a friction material is adhered onto one surface of the steel disc bracket of each of friction plates, and the other surface of the steel disc bracket of each of the friction plates is a smooth surface; the friction plates are arranged and mounted on one side of a dual disc in sequence; all the surfaces, where the friction materials are mounted, of the friction plates directly face one side of the dual disc; and the steel disc bracket of a previous friction plate is in contact with the friction material of the last friction plate, and heat generated by friction among the components is dissipated. According to the friction pair system of the double clutch, the heat dissipationeffect of the clutch is effectively optimized, and the clutch is prevented from losing effectiveness due to the excessive temperature; meanwhile, the heat dissipation burden on the dual disc, the friction plates and the steel disc brackets is reduced, the design thickness of the friction pair system is reduced correspondingly, the axial length of the clutch is reduced, and the arrangeability of the clutch is obviously improved.

Owner:GETRAG JIANGXI TRANSMISSION

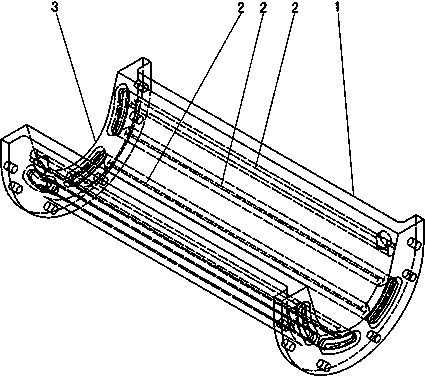

Machining method of metallurgical furnace launder

Provided is a machining method of a metallurgical furnace launder. A mode that plate blank forging and machining are combined is used for machining. The method comprises the following steps that forged plate blanks are forged and pressed into a metallurgical furnace launder semi-finished product with an arc face; and a metallurgical furnace launder component semi-finished product is subjected to finish machining to form a metallurgical furnace launder finished product. The machined metallurgical furnace launder finished product comprises a launder body. The launder is formed in the top of the launder body. A plurality of cooling water channels are arranged in the launder body. The cooling water channels are communicated with each other in an end-to-tail mode. At least one water inlet and one water outlet are formed. A forming technology is changed into the mode that forging, pressing and machining are combined, so that body materials are compact, grain refining is achieved, mechanical property is good, heat conductivity is high, composite holes are used as the cooling water channels, the cooling performance of the cooling water channels is further improved, the improvements are combined so that the thickness of the launder body can be greatly reduced, a producer can know that the launder with good performance can be obtained with low cost increased, frequent maintaining or replacing is of no need, influence on normal production can be greatly reduced, and production efficiency is greatly improved.

Owner:SHANTOU HUAXING METALLURGICAL EQUIP CO LTD

Steel-ultra-high performance concrete combined bridge deck structure with shearing resisting structure and construction method thereof

ActiveCN102943436BEasy to get materialsEasy to processBridge structural detailsBridge erection/assemblyArchitectural engineeringMesh reinforcement

The invention discloses a steel-ultra-high performance concrete combined bridge deck structure with a shearing resisting structure and a construction method thereof. The structure comprises a steel bridge deck layer and an ultra-high performance concrete layer, wherein a shearing-resisting reinforcing mesh structure is fixedly connected with the steel bridge deck layer; and the shearing-resisting reinforcing mesh structure is embedded in the ultra-high performance concrete layer. The construction method comprises the following steps of: firstly, erecting a steel beam so as to obtain the steel bridge deck layer; secondly, constructing and welding a reinforcing mesh, wherein the reinforcing mesh can adopt the mode that a lower longitudinal rib distributed layer is combined with an upper transverse rib distributed layer, or a mode that a lower transverse spacing rib distributed layer, a longitudinal rib distributed layer and the upper transverse rib distributed layer are combined, and longitudinal reinforcing ribs and transverse reinforcing ribs can be arranged among shearing-resisting longitudinal ribs and shearing-resisting transverse ribs; subsequently casting the ultra-high performance concrete layer so as to embed the shearing-resisting reinforcing mesh structure into the ultra-high performance concrete layer; and finally paving a wearing layer so as to accomplish the construction. The steel-ultra-high performance concrete combined bridge deck structure has the advantages of being small in building height, large in partial rigid, reliable in shearing-resisting connection between combined layers, good in fatigue resistance, convenient to construct and the like.

Owner:HUNAN UNIV

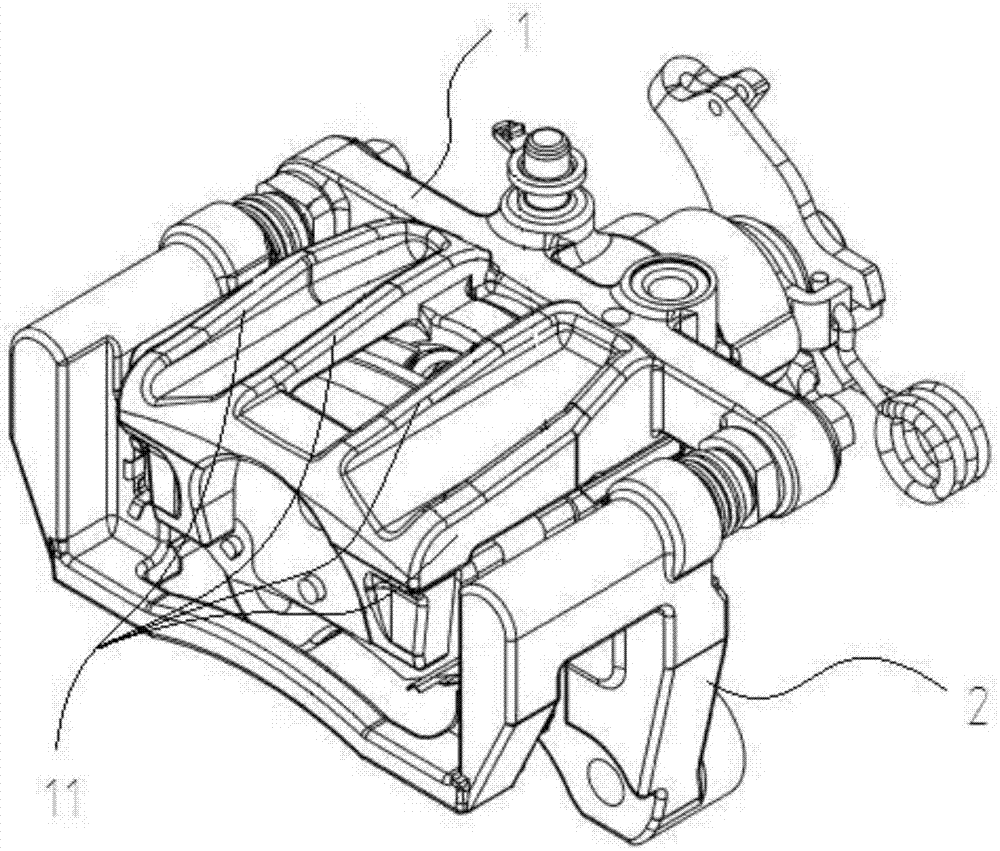

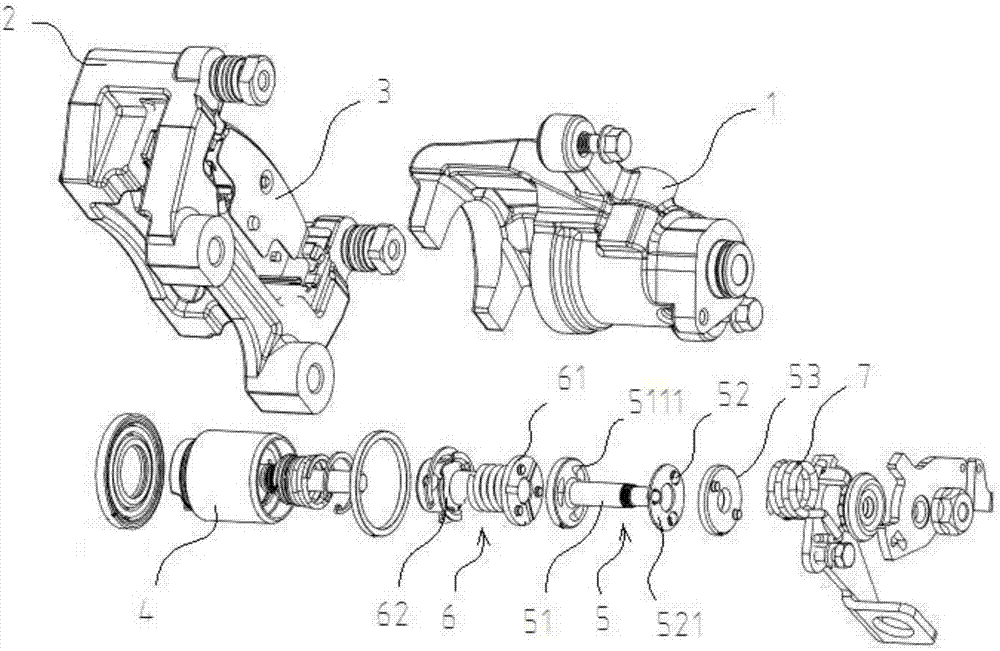

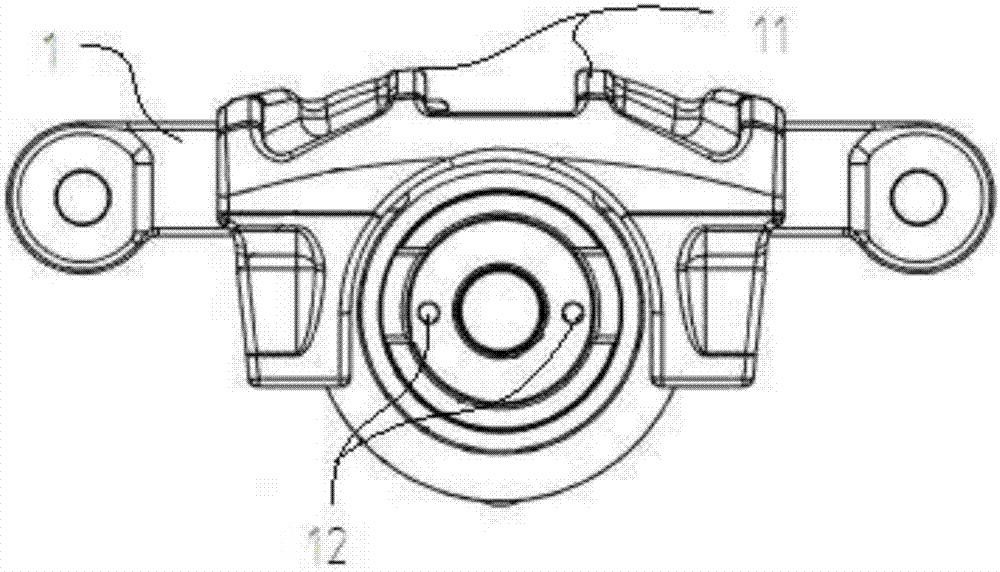

Integrated brake caliper

ActiveCN107956822APrevent rotationIncrease rotation speedNoise/vibration controlBrake actuating mechanismsControl theoryPiston

The invention provides an integrated brake caliper, and belongs to the technical field of vehicle braking. The integrated brake caliper comprises a brake support assembly provided with a friction plate structure and a brake shell connected with the brake support assembly; and a thrust assembly, an adjusting assembly and a piston are arranged in the brake shell. According to the integrated brake caliper, a limiting convex point and a limiting groove are arranged between the thrust assembly and the brake shell, and a connecting convex point and a connecting concave point are embedded and connected between the thrust assembly and the adjusting assembly, so that the layout space is reduced, the fit clearance is small, the parking endurance abrasion is small, the durability is better; meanwhile, a ball ramp structure and a multiple thread structure are adopted, so that the ejection effect of the piston is further improved, the mechanical transmission gap is shortened, and the braking performance is improved; the brake shell is a cast aluminum piece with reinforcing ribs, so that the weight is lighter; and the surface material of a silencing piece with a friction plate structure adoptsa rubber cloth ripple silencing piece so that the friction coefficient can be increased, the piston can be prevented from rotating, the parking performance is further improved, and the market competitiveness is improved.

Owner:WANXIANG QIANCHAO SHANGHAI AUTOMOTIVE SYST

Steel-PVA fiber toughness concrete combined bridge deck structure and construction method thereof

PendingCN110106785AInsufficient control stiffnessCoordinated Control Method for Structural DeformationBridge structural detailsFiberSurface layer

The invention discloses a steel-PVA fiber toughness concrete combined bridge deck structure and a construction method thereof. The combined bridge deck structure comprises a steel bridge panel layer,a PVA fiber toughness concrete layer, a bonding layer and an asphalt concrete surface layer; a plurality of shear bolt nails are fixed to the steel bridge panel layer; and the PVA fiber toughness concrete layer is laid on the steel bridge panel layer, and internally provided with longitudinal and transverse double-layer reinforcing meshes and chloroprene rubber cushion blocks which are laid out onthe steel bridge panel layer and used for supporting the longitudinal and transverse double-layer reinforcing meshes. The combined bridge deck structure has the advantages that the building height issmall, the light weight and high strength are achieved, bonding performance between all the combined layers is good, cooperative bearing of all the combined layers is uniform, deformation compatibility is easy to control, durability is good, anti-fatigue performance is good, and the impact effect of vehicles is small, and is particularly suitable for bridge deck pavement of large-span bridges.

Owner:ZHEJIANG UNIV OF TECH

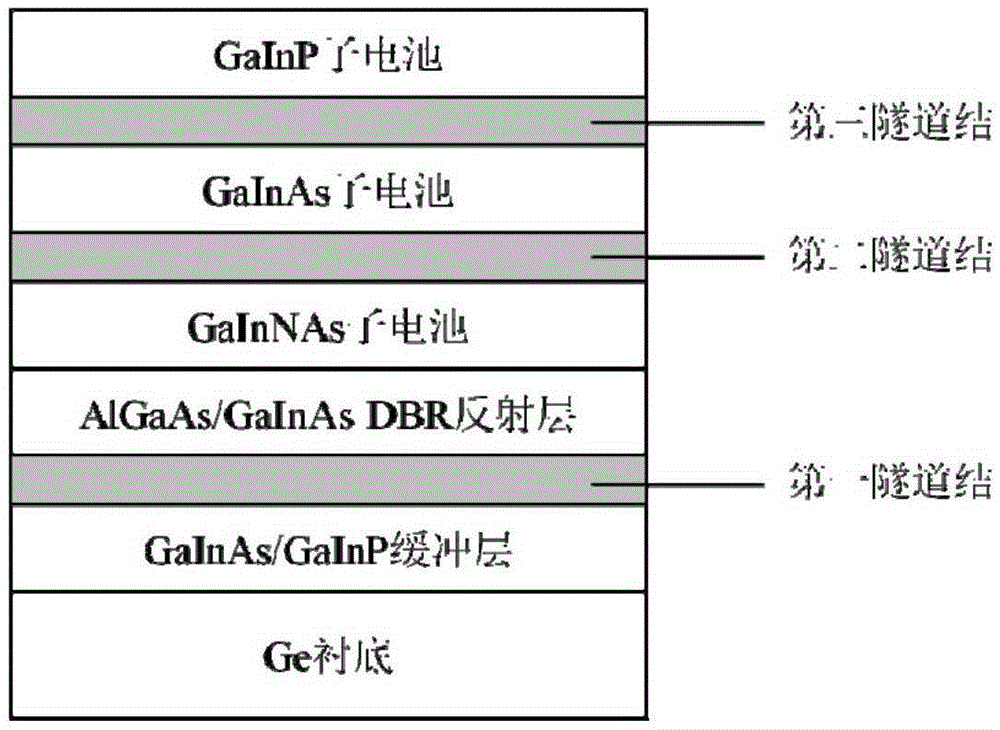

Four-junction solar energy cell having reflection layer

InactiveCN105355669AIncrease currentImprove photoelectric conversion efficiencyPhotovoltaic energy generationSemiconductor devicesSingle crystalOptoelectronics

The invention discloses a four-junction solar energy cell having a reflection layer and can be applied to the focusing photovoltaic power generation system. According to the four-junction solar energy cell, a Ge single crystal slice is taken as a substrate, the Ge substrate is sequentially provided with a GaInAs / GaInP buffer layer, an AlGaAs / GaInAs DBR reflection layer, a GaInNAs sub cell, a GaInAs sub cell and a GaInP sub cell, wherein the AlGaAs / GaInAs DBR reflection layer is used for reflecting long-wave photons to make the long-wave photons be absorbed by the GaInNAs sub cell. Through the four-junction solar energy cell, thickness of the GaInNAs sub cell can be reduced, cell collection efficiency is improved, and photoelectric conversion efficiency of the four-junction solar energy cell is improved.

Owner:ZHONGSHAN DEHUA CHIP TECH CO LTD

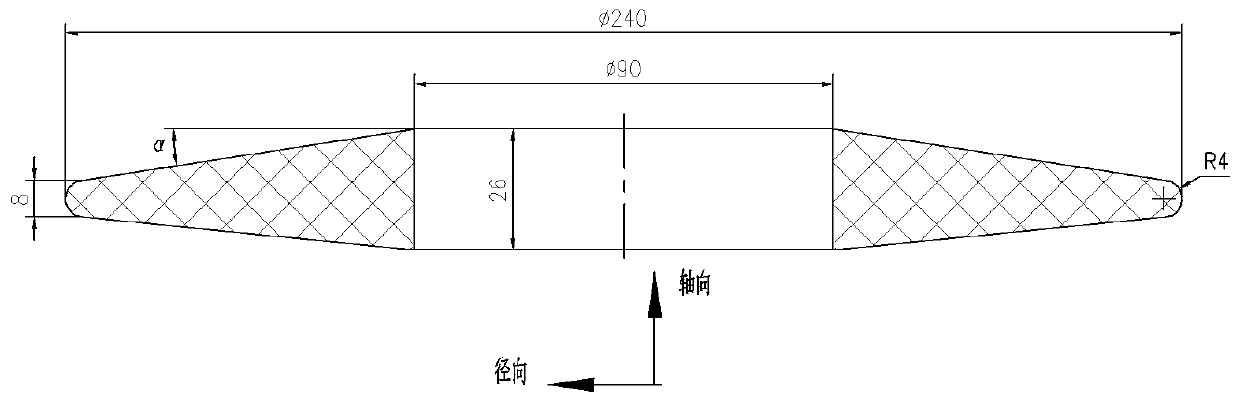

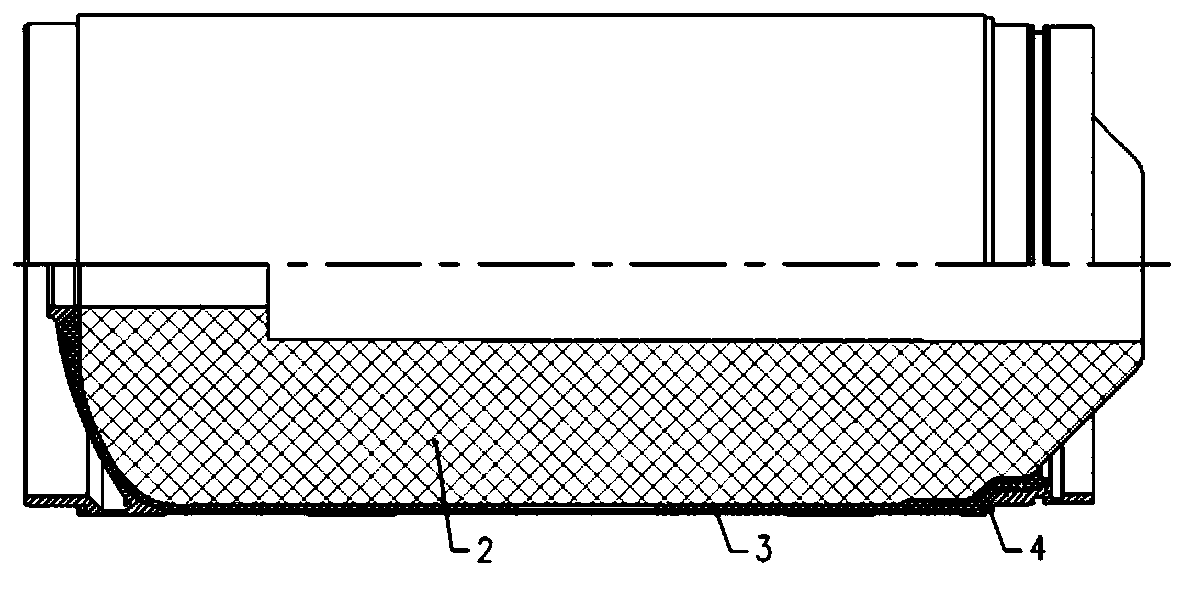

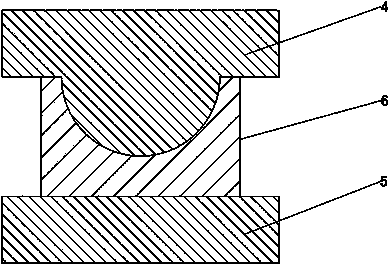

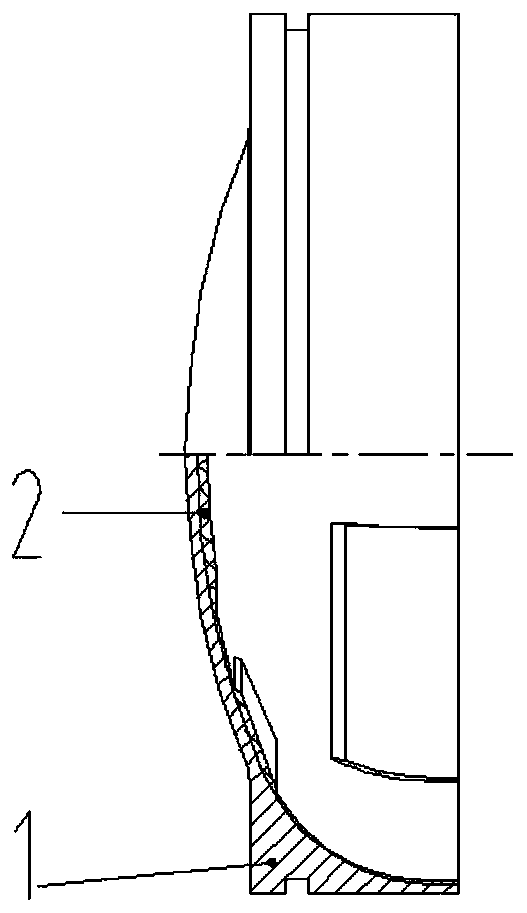

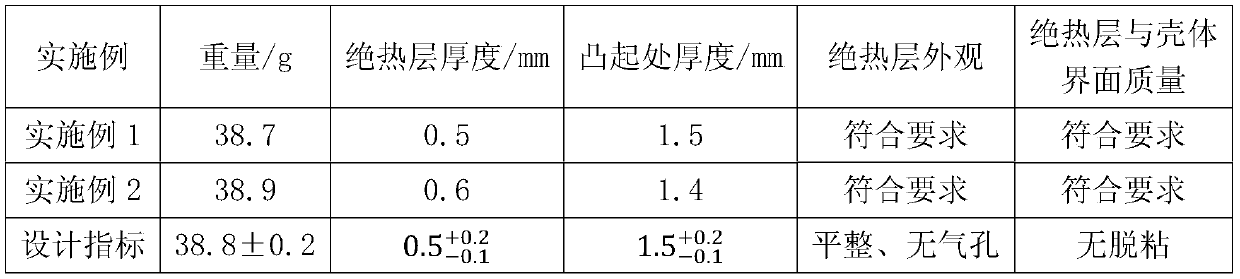

Inner heat insulation layer of front seal head of solid rocket engine and forming method of inner heat insulation layer

ActiveCN110792529AReduce design thicknessReduce negative qualityCoatingsRocket engine plantsInsulation layerSand blasting

The invention discloses an inner heat insulation layer structure of a front seal head of a solid rocket engine and a forming method of the inner heat insulation layer structure. A multi-step structureof an inner profile surface of the inner heat insulation layer is realized. The forming method of the inner heat insulation layer comprises the step 1 of manufacturing a mold according to an inner heat insulation layer structure, the step 2 of sandblasting the inner wall surface of the front seal head, the step 3 of preparing a liquid heat insulation layer, the step 4 of pouring the liquid heat insulation layer with the set mass into the front seal head, the step 5 of assembling the mold and the front seal head to a set position to ensure the designed thickness of the heat insulation layer, the step 6 of putting the product into an oven for curing, and the step 7 of taking out the product after the curing time is met, cooling the product to normal temperature, taking out the mold, and shaping and cutting the heat insulation layer to obtain the designed heat insulation layer. The heat insulation layer is high in size control precision, good in quality consistency and simple in process,and the forming method can meet the forming requirements of inner heat insulation layers in various irregular shapes.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

Cable-stayed bridge sectional cable system with prestressed cable saddle structure and fabrication and installation method thereof

PendingCN110468709AStress Relief AmplitudeReduce fatigue damageBridge structural detailsBridge erection/assemblyFatigue damagePre stress

The invention comprises a cable-stayed bridge sectional cable system with a prestressed cable saddle structure. The sectional cable system comprises a first-section cable, a second-section cable, a third-section cable and an arc-shaped profile steel cable saddle. The second-section cable passes through the profile steel cable saddle and is anchored on both sides of a cable tower through cable saddle cable anchor devices after being pre-tensioned. The profile steel cable saddle, the second-section cable, the cable saddle cable anchor devices and a spiral reinforcement jointly constitute the prestressed cable saddle structure. The number of the cable saddle cable anchor devices is two, and the two cable saddle cable anchor devices are arranged at both ends of the profile steel cable saddle correspondingly. Each cable saddle cable anchor device comprises an anchor base plate, an anchor plate with external threads and a clamping piece. Prestressed reinforcements of the second-section cableare anchored on the anchor plates; and the first-section cable with an anchor device at one end and the third-section cable with an anchor device at one end are correspondingly connected with both sides of the second-section cable through connecting devices. The sectional cable system can eliminate the stress amplitude in the second-section cable, reduce the fatigue damage of the cable, and fundamentally solve the problem of cable breakage caused by the insufficient fatigue strength of cable saddle cable with the small bending radius.

Owner:LIUZHOU OVM MASCH CO LTD

A large-scale liquid-cooled pipe network and its welding method

ActiveCN112207414BReduce thicknessImprove carrying capacityNon-electric welding apparatusStructural engineeringPipe

The invention discloses a large-scale liquid-cooled pipe network and a welding method thereof, belonging to the technical field of large-scale liquid-cooled pipe network welding, including a liquid-cooled shell and a stepped cover plate, and the stepped cover plate includes a welded stepped cover plate and a reinforced stepped cover The reinforced stepped cover plate includes a plurality of steps corresponding to the pipelines at various levels, and each step is integrally formed with the welded stepped cover plate. In the present invention, the cover plate is designed as a stepped cover plate, and a design model based on bearing capacity is established. On the premise of ensuring that the pressure bearing capacity of the cover plate does not decrease, the thickness of the cover plate required for welding is greatly reduced, so that the welding process can be used Smaller stirring tools greatly reduce welding heat input and welding deformation; the welding thickness of the designed stepped cover plate is greatly reduced, which causes changes in the physical space design on both sides of the weld, because the width of one side of the weld is equal to the welding thickness, so the weld The physical space on both sides of the seam is greatly reduced, which improves the integration of large liquid cooling pipe networks and reduces the weight of the system.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST +1

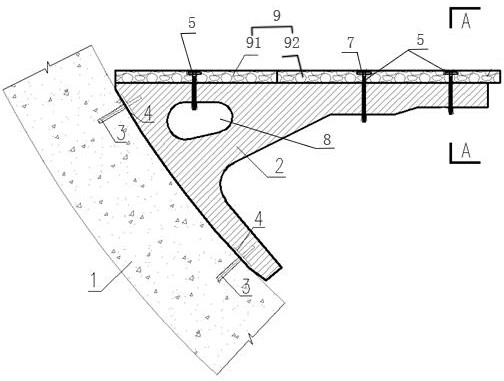

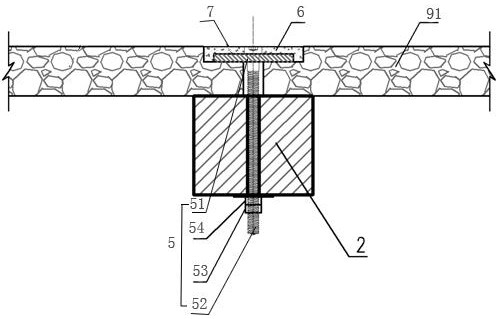

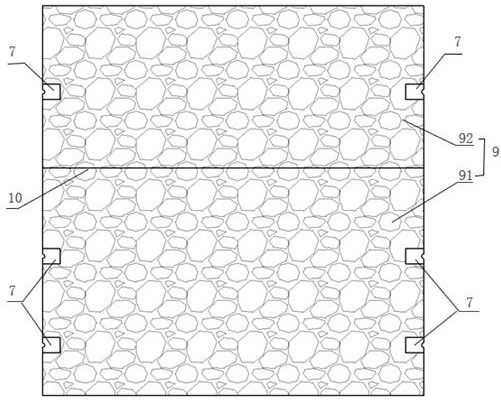

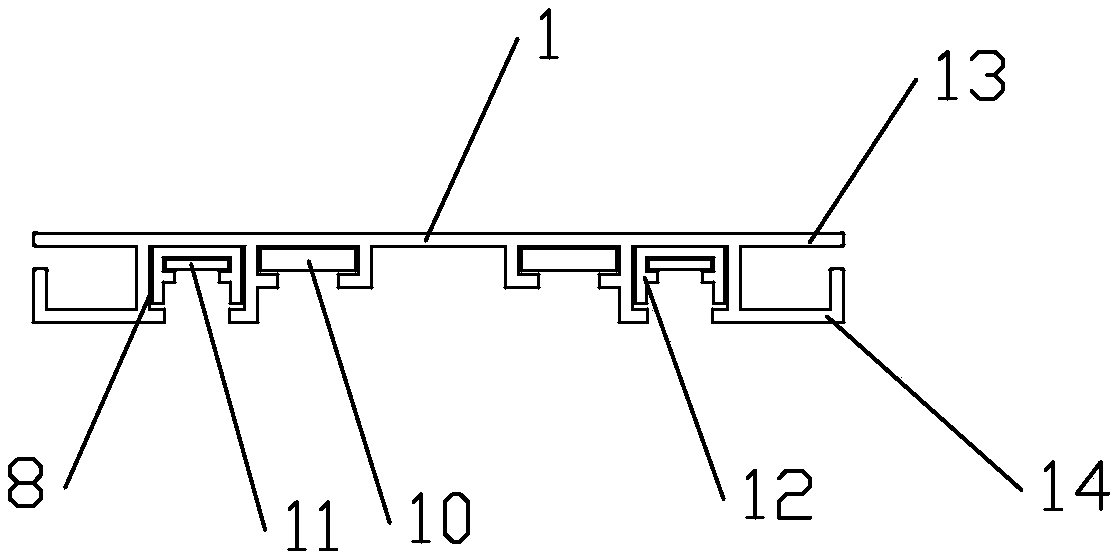

A rail transit evacuation platform that can resist high wind pressure

ActiveCN111605566BImprove anti-corrosion performanceDurableUnderground chambersRailway componentsButtressArchitectural engineering

The invention discloses the technical field of rail transit facilities, and in particular relates to a rail transit evacuation platform that can resist high wind pressure. The rail transit evacuation platform includes a support pier and a platform plate installed on the support pier. It is a concrete composite material, the platform slab includes a standard block and an adjustment block, and the standard block and the adjustment block are spliced to form a platform slab, and both the standard block and the adjustment block are connected to the pier through a wind pressure resistant bolt assembly The detachable connection, the evacuation platform is made of concrete composite material, which reduces the workload of maintenance, maintenance and replacement in the later operation process, and reduces the maintenance cost. In the technology, the heavy weight of the monolithic platform slab leads to the difficulty of installation. Both the standard block and the adjustment block are detachably connected to the pier through wind-resistant bolt components, which solves the problem that cannot be solved in the prior art. Solve or only rely on increasing the thickness of the platform slab to resist high wind pressure, which will increase the load of the pier and affect the bearing performance.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

UHPC-SS (Ultra High Performance Concrete) composite pipeline and manufacturing method thereof

PendingCN108426103AIncrease stiffnessImprove thermal insulation performanceThermal insulationGeneral water supply conservationFiberFrost

The invention discloses an UHPC-SS (Ultra High Performance Concrete) composite pipeline and a manufacturing method thereof. The UHPC-SS composite pipeline consists of a stainless steel tube, wherein casting the outer side of the stainless steel with an UHPC concrete layer; a reinforced steel network is arranged in the UHPC concrete layer; the UHPC concrete layer is prepared from the following rawmaterials in percentage by mass: 25 to 30 percent of cement, 5 to 15 percent of silicon powder, 3.5 to 13.5 percent of quartz powder, 30 to 50 percent of fine sand being 1.6 to 3.7mm in particle size,3 to 9 percent of steel fiber being 8mm in length and 3.4 to 9.4 percent of water; the raw materials are stirred and cast on the outer surface of a stainless steel inner tube; compaction is performedby adopting a compaction platform after casting; then, hot water maintenance is performed on the UHPC-SS composite pipeline in water of 80 DEG C for 3 days. Three connection manners are adopted for pipeline joints. The inner tube is made of stainless steel, and the outer tube is made of UHPC, so that the problems concerned with tendency to corrosion, poor frost resistance, poor durability and high manufacturing cost in the existing pipelines for transporting crude oil, natural gas and dangerous chemicals are solved.

Owner:周敉

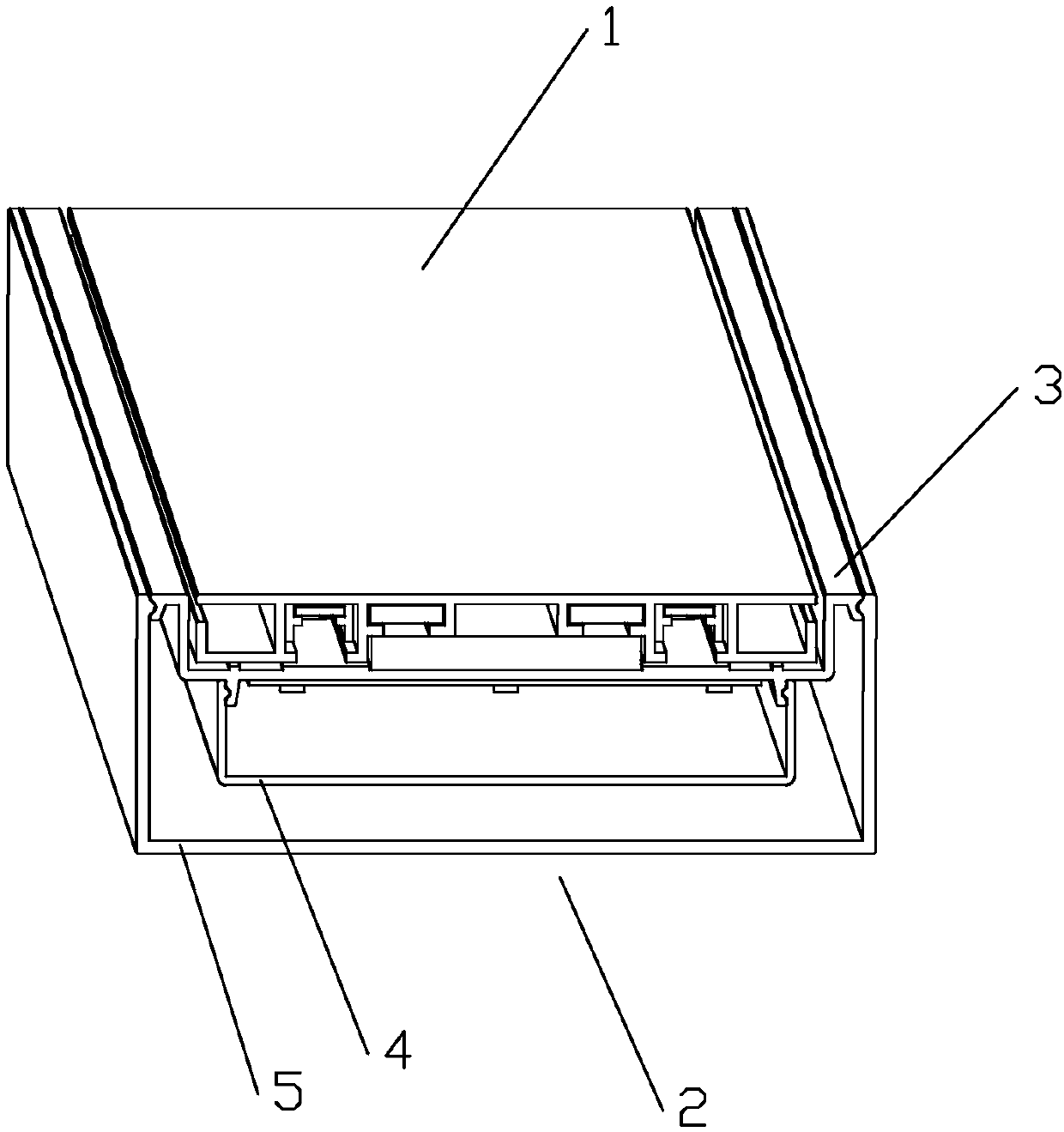

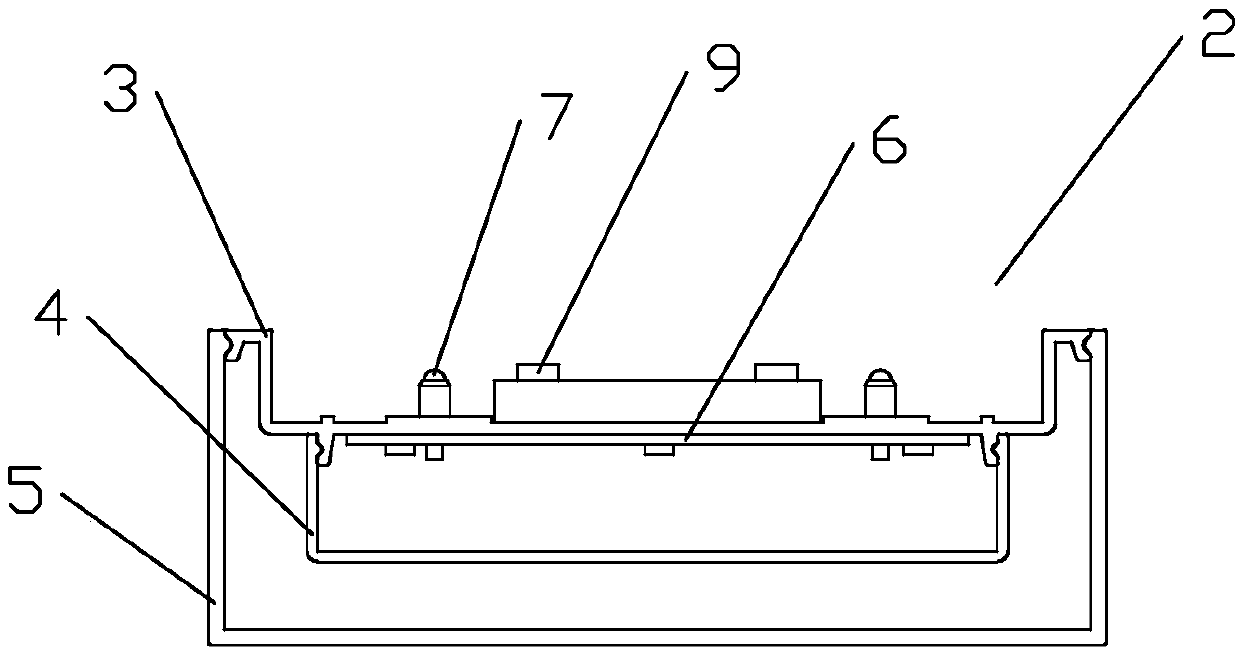

Ultrathin magnetic suction lamp bank

PendingCN107859924ASolve the spot problemReduce design thicknessLighting support devicesElectric circuit arrangementsElectricityChannel power

The invention discloses an ultrathin magnetic suction lamp bank. The ultrathin magnetic suction lamp bank comprises a lamp support. The lamp support is formed by splicing multiple mounting rails. Eachmounting rail is provided with multiple lamp modules. Each lamp module comprises a base and a lamp shade. Each lamp shade comprises a first diffusion housing and a second diffusion housing, wherein each first diffusion housing and the corresponding second diffusion housing are sequentially mounted. Each base is provided with a lamp strip and multiple electric connection contacts, wherein each lamp strip is mounted inside the corresponding first diffusion housing, and the multiple electric connection contacts are connected with the corresponding lamp strip. Each mounting rail is provided withmetal channels, wherein the metal channels are in contact with the electric connection contacts to be powered on. According to the ultrathin magnetic suction lamp bank, the design of the double layersof diffusion housings which are arranged internally and externally is adopted, so that the design thickness of each lamp module is greatly reduced; the lamp bank is embedded into a wall body to be mounted without forming grooves, and the requirement that the surface of each lamp module is attached to the wall surface in a smooth manner can be met; the lamp bank is easy to mount; all the lamp modules can be spliced in a seamless manner; meanwhile, the problem that a lamp module of the ultrathin generates light spots is solved; a lamp can emit uniform and gentle light; and the use comfortable sensation of a user is improved.

Owner:JIANGMEN INTEVISION TECH CO LTD

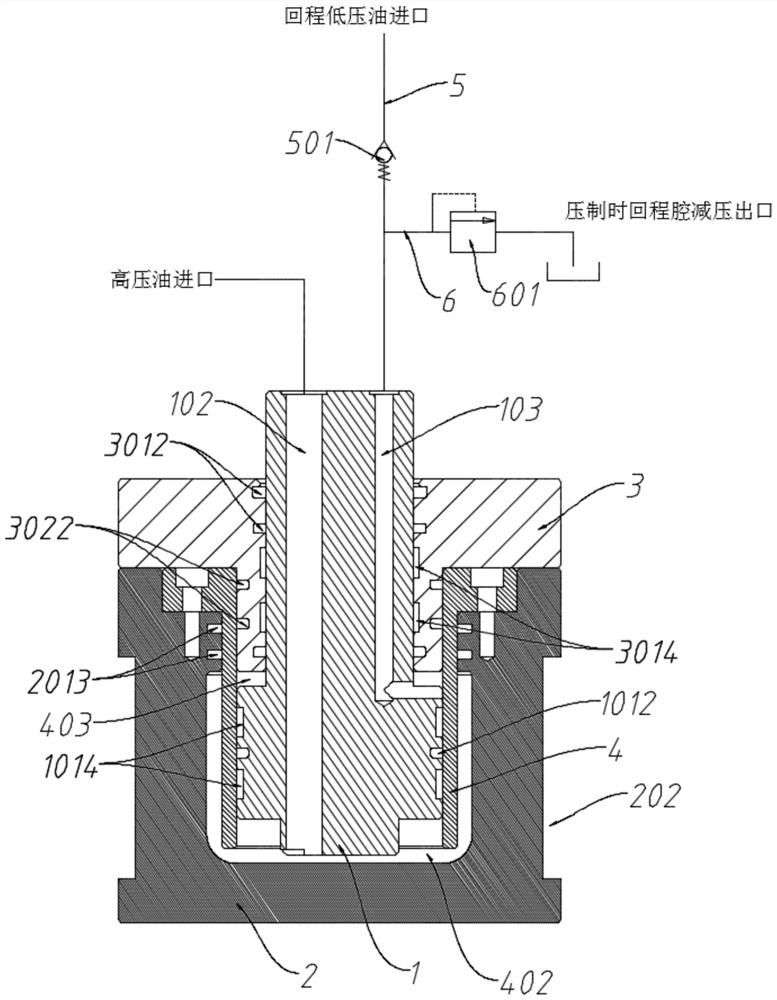

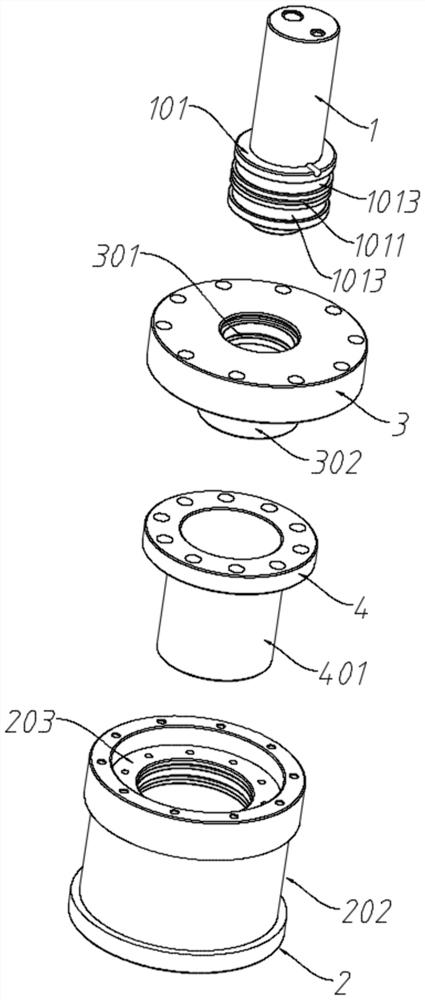

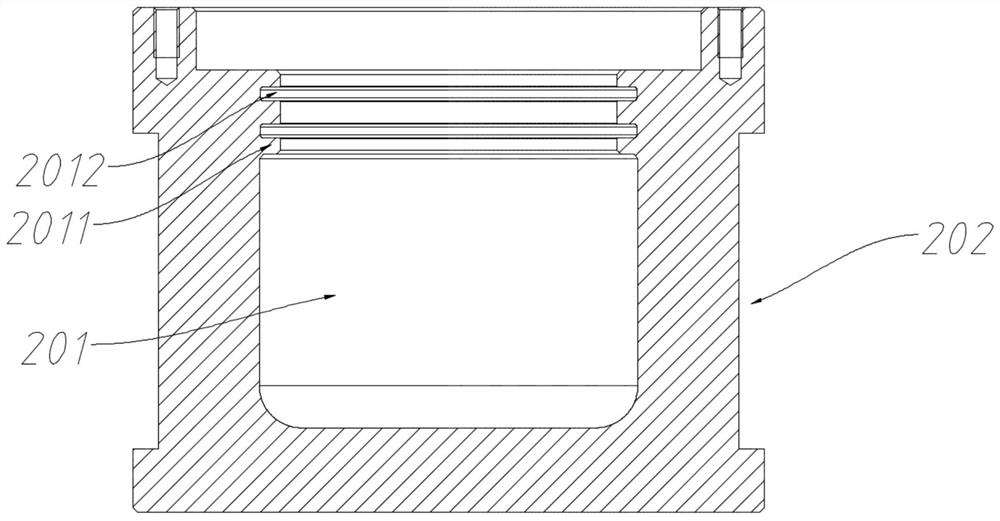

High-pressure leak-proof hydraulic cylinder

InactiveCN111852987ASmall working gapImprove sealingFluid-pressure actuatorsHydraulic cylinderCylinder block

The invention provides a high-pressure leak-proof hydraulic cylinder. The high-pressure leak-proof hydraulic cylinder comprises a piston rod provided with a piston block, a cylinder body provided witha cavity and a cylinder sleeve comprising an end cover and a sliding wall, wherein the cylinder sleeve is fixed into the cavity, and the end cover is fixed to the upper end of the cylinder body; theupper end of the inner wall of the cavity is hermetically connected to the upper end of the outer wall of the sliding wall, and a spacing is arranged between the middle and the lower part of the outerwall and the inner wall of the cavity; the piston rod penetrates through the end cover and is arranged in the cylinder sleeve and can move up and down in the cylinder sleeve, the piston block is hermetically connected to the cylinder sleeve to divide the cylinder sleeve into a working high-pressure cavity and a low-pressure backflow cavity which are isolated from each other, and the piston rod ishermetically connected to the end cover; and a first channel communicating with the working high-pressure cavity and a second channel communicating with the low-pressure backflow cavity are arrangedon the piston rod. The high-pressure leak-proof hydraulic cylinder can solve a problem of poor sealing performance of the hydraulic cylinder, which is caused by the changes in a piston gap due to highpressure.

Owner:佛山宇仁智能科技有限公司

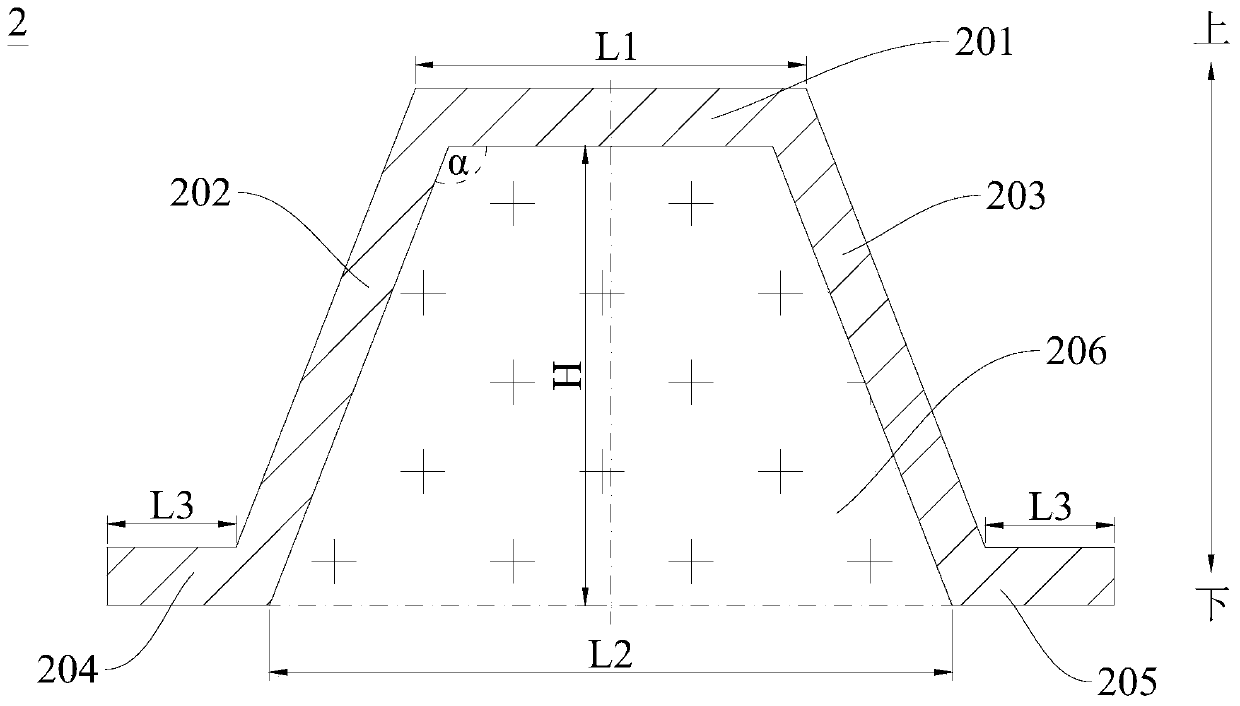

Ribs for battery pack lower case, battery pack and vehicle

ActiveCN106450054BReduce weightHigh strengthSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringMechanical engineering

The invention discloses a reinforcing rib for the lower casing of the battery pack, a battery pack and a vehicle. The reinforcing rib is suitable for being fixed on the lower casing body of the lower casing of the battery pack. The reinforcing rib includes a top wall and a first side wall. and the second side wall, the first side wall and the second side wall extend downwards from the two side edges of the top wall respectively, the lower end of the first side wall and the lower end of the second side wall are respectively provided with a first side wall flanging and a The second side wall flanging, the first side wall flanging and the second side wall flanging respectively extend in a direction away from each other, and a filling space is defined between the first side wall, the second side wall and the top wall, and the filling space Filled with thermosetting resin. According to the reinforcing rib of the embodiment of the present invention, the design thickness of the lower case of the battery pack can be reduced while ensuring high strength of the lower case of the battery pack, thereby reducing the weight of the battery pack and further reducing the weight of the entire vehicle.

Owner:BEIJING ELECTRIC VEHICLE

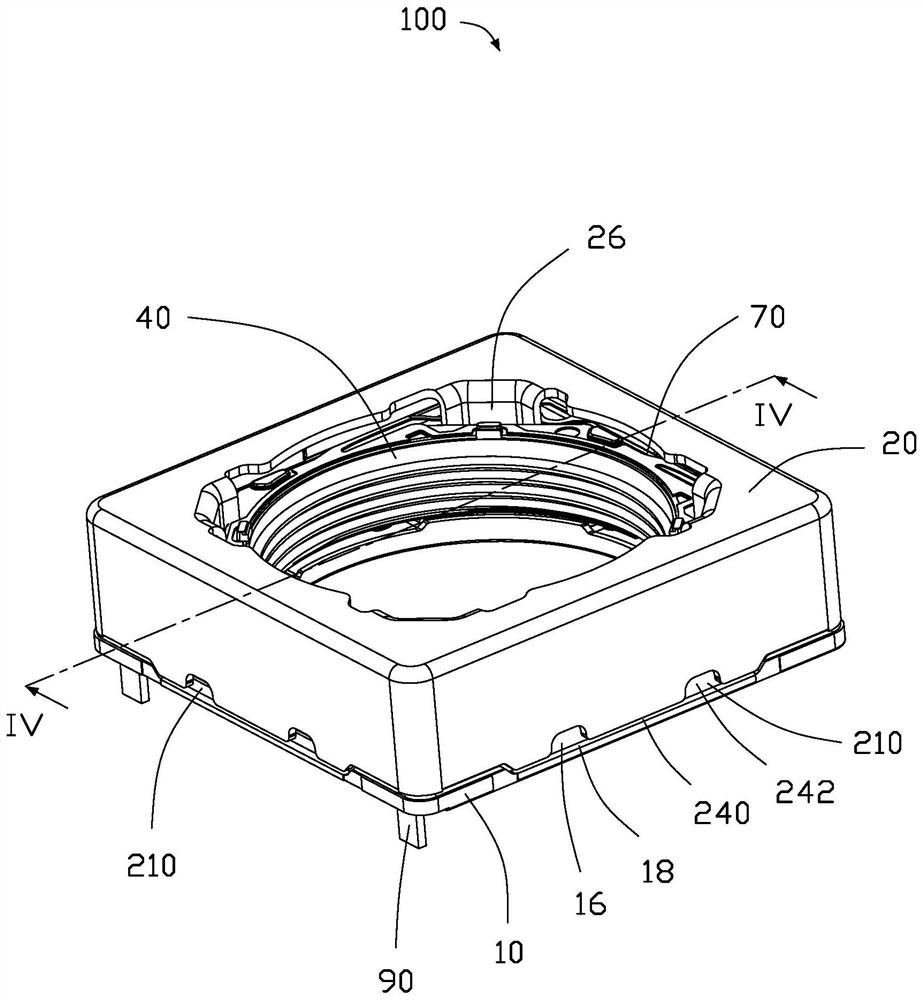

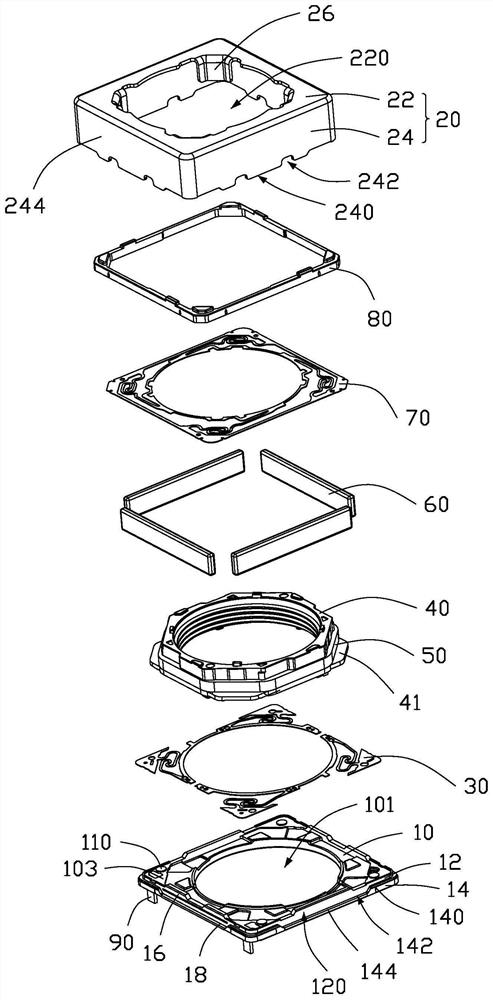

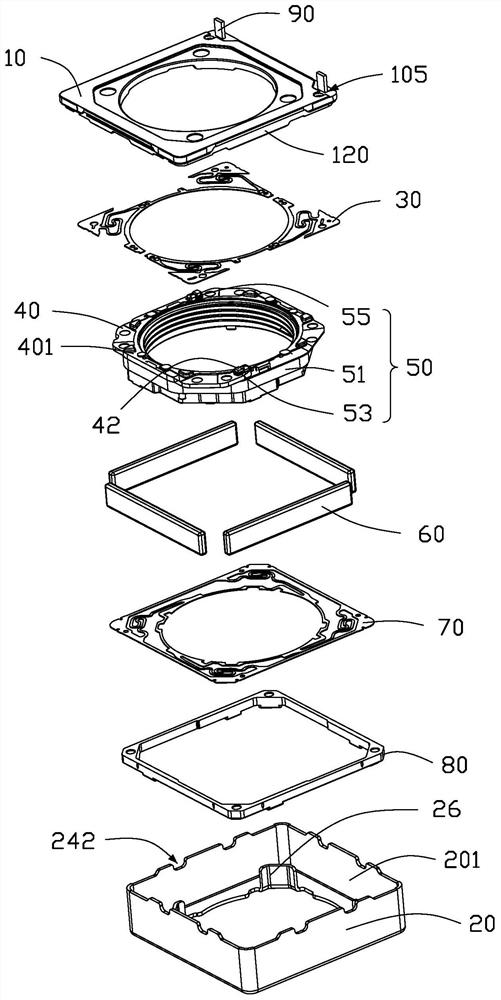

Voice coil motor and manufacturing method thereof

ActiveCN110829785BCheap manufacturingTorque stabilizationProjector focusing arrangementCamera focusing arrangementEngineeringMechanical engineering

The present invention proposes a voice coil motor, including a base, a casing, a lower elastic piece, a lens holder, a coil, a magnet, an upper elastic piece, an upper cover pressing plate and pins, the lower elastic piece, the lens holder, the coil, and the magnet , the upper elastic piece and the upper cover pressing plate are sequentially arranged between the base and the shell, the stitches are arranged on the base, the lens holder and the coil are integrally formed, and the coil is wound around on the outer side of the lens holder. The invention also proposes a manufacturing method of the voice coil motor.

Owner:TRIPLE WIN TECHSHENZHEN CO LTD +1

Prestressed stainless steel tube ultra-high performance concrete composite electric pole and preparation method thereof

InactiveCN112267745AImprove corrosion resistanceImprove mechanical propertiesShaping reinforcementsTowersPre stressEngineering

The invention relates to the technical field of electric poles, and discloses a prestressed stainless steel tube ultra-high performance concrete composite electric pole and preparation method thereof.The prestressed stainless steel tube ultra-high performance concrete composite electric pole comprises a stainless steel tube and an ultra-high performance concrete layer poured on the inner wall ofthe stainless steel tube, and a prestressed steel reinforcement framework is planted in the ultra-high performance concrete layer. According to the prestressed stainless steel tube ultra-high performance concrete composite electric pole and preparation method thereof, the composite hollow structure is mainly formed by centrifugal forming of the stainless steel tube and ultra-high-performance concrete, the characteristics of good mechanical property and good corrosion resistance of the stainless steel tube and the ultra-high-performance concrete are brought into full play, the overall performance of the structure is improved, and compared with a traditional composite electric pole structure, the composite electric pole structure is easy to form, high in bearing capacity, large in rigidity,good in impact resistance, good in anti-collision and anti-collapse performance, high in corrosion resistance and good in corrosion resistance to atmosphere, water, acid, alkali, salt and various solvents with general concentrations. According to the prestressed stainless steel tube ultra-high performance concrete composite electric pole and preparation method thereof, the problems that the priortraditional concrete electric pole is insufficient in bending moment and poor in frost resistance, and the steel tube pole is poor in corrosion resistance and high in manufacturing cost are solved.

Owner:惠州富盈新材料科技有限公司

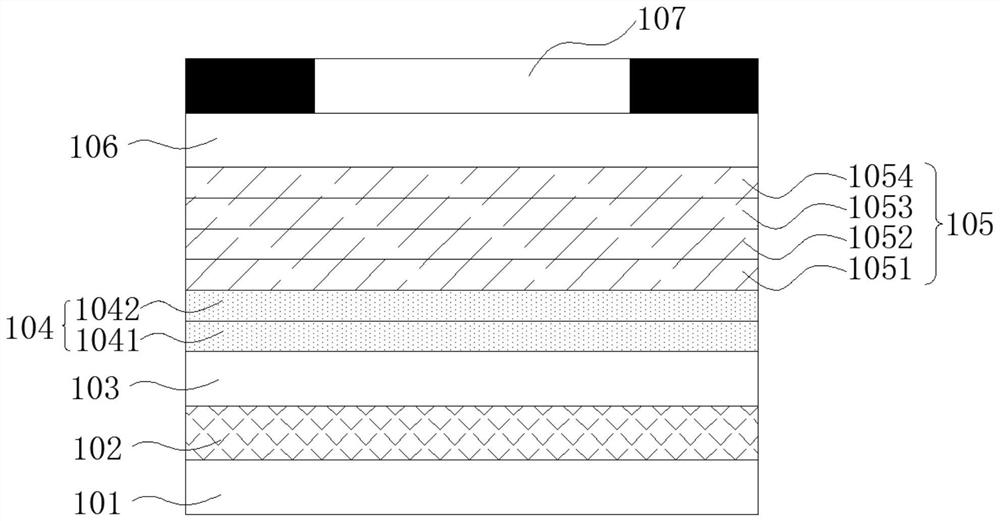

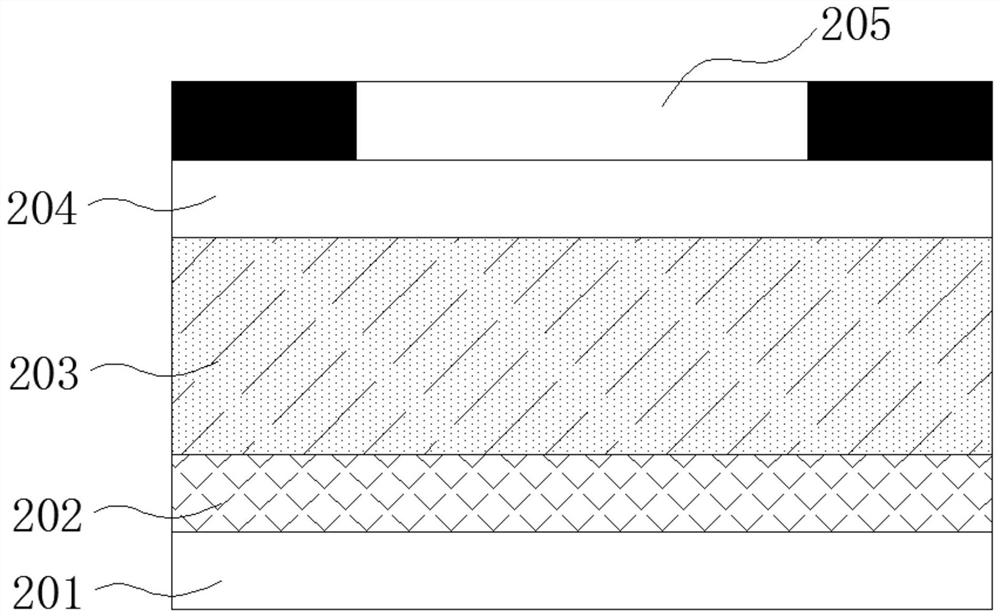

Folding display panel and preparation method of folding display panel

InactiveCN111768696AReduce design thicknessIncreased upper layer hardnessInput/output processes for data processingIdentification meansMaterials sciencePhysics

The invention discloses a folding display panel and a preparation method of the folding display panel. The folding display panel comprises a first substrate; the second substrate arranged opposite tothe first substrate; a display layer arranged on the surface of one side of the first substrate; and a composite functional layer and an optical adhesive layer which are arranged between the display layer and the second substrate, wherein the composite functional layer comprises at least one protective layer and a touch electrode layer, and the touch electrode layer is arranged on the surface of one side of the protective layer. Compared with an existing folding display panel, a polarizing layer and a touch layer are integrated into the composite functional layer in the folding display panel,the touch electrode layer is arranged on the surface of the protective layer, a layer of stacked optical adhesive layer is omitted, the hardness of the upper layer of the stacked structure can be improved, the overall stacking design thickness is reduced, the bending radius can be reduced, the laminating process is reduced, and the process flow is simplified.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

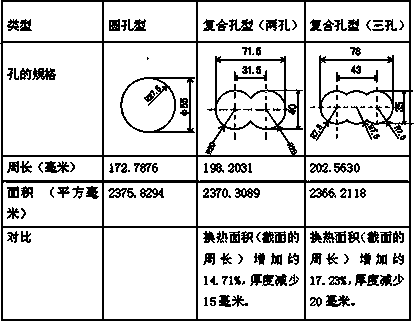

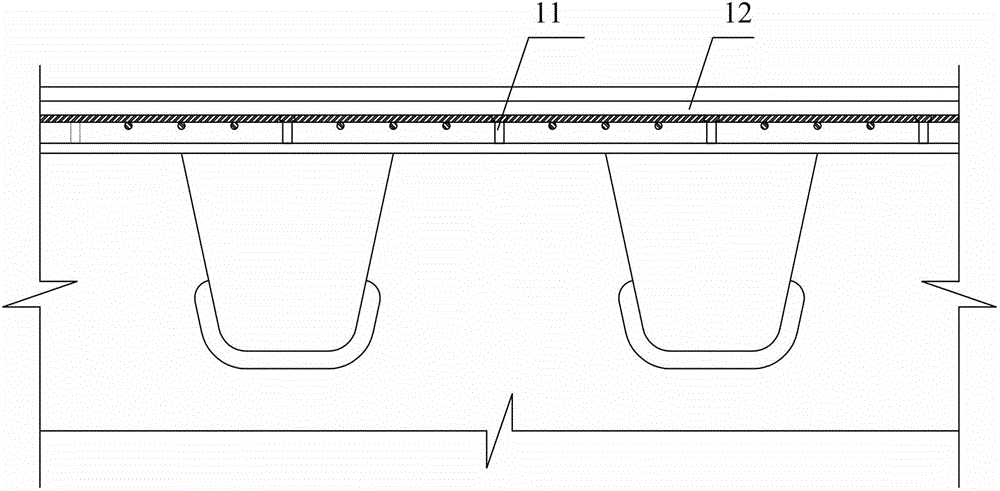

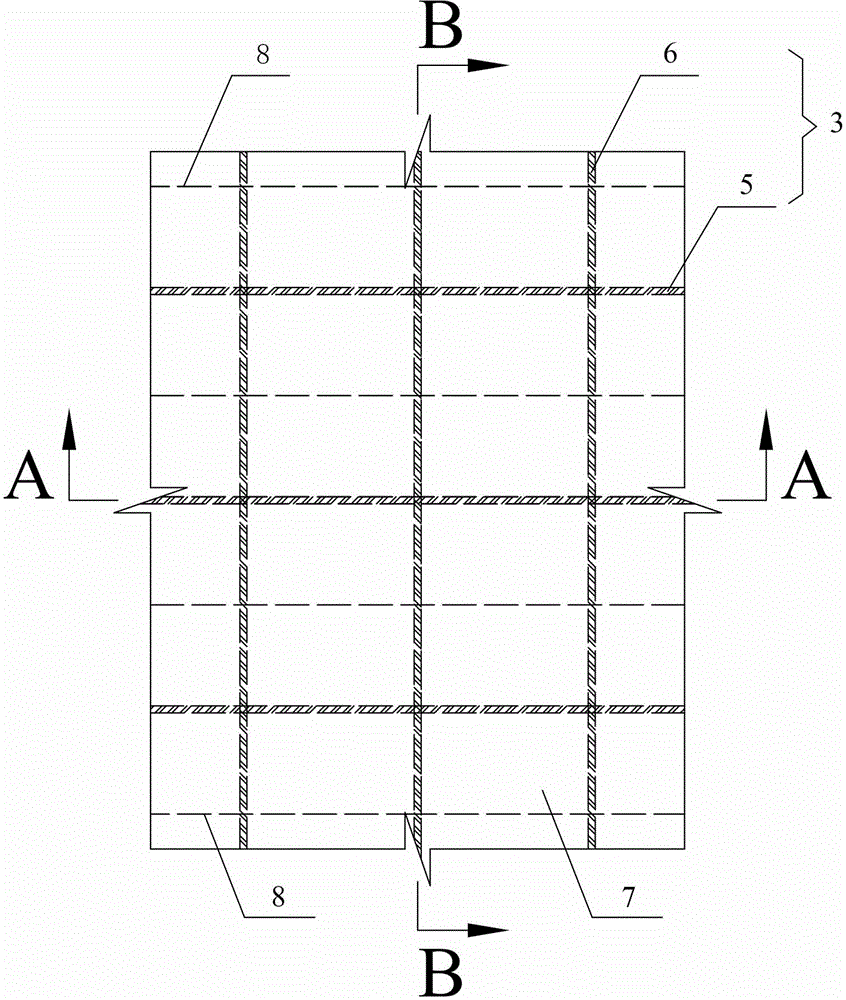

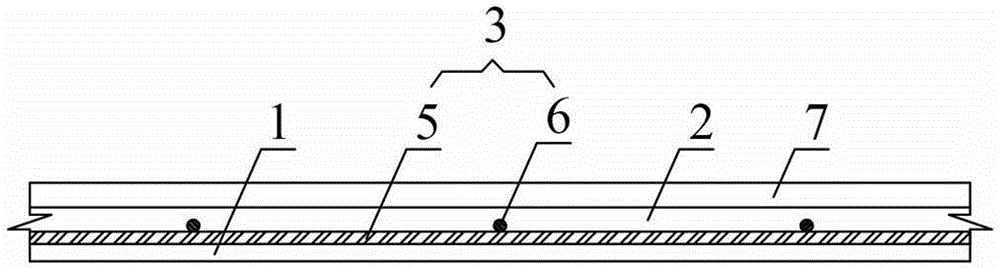

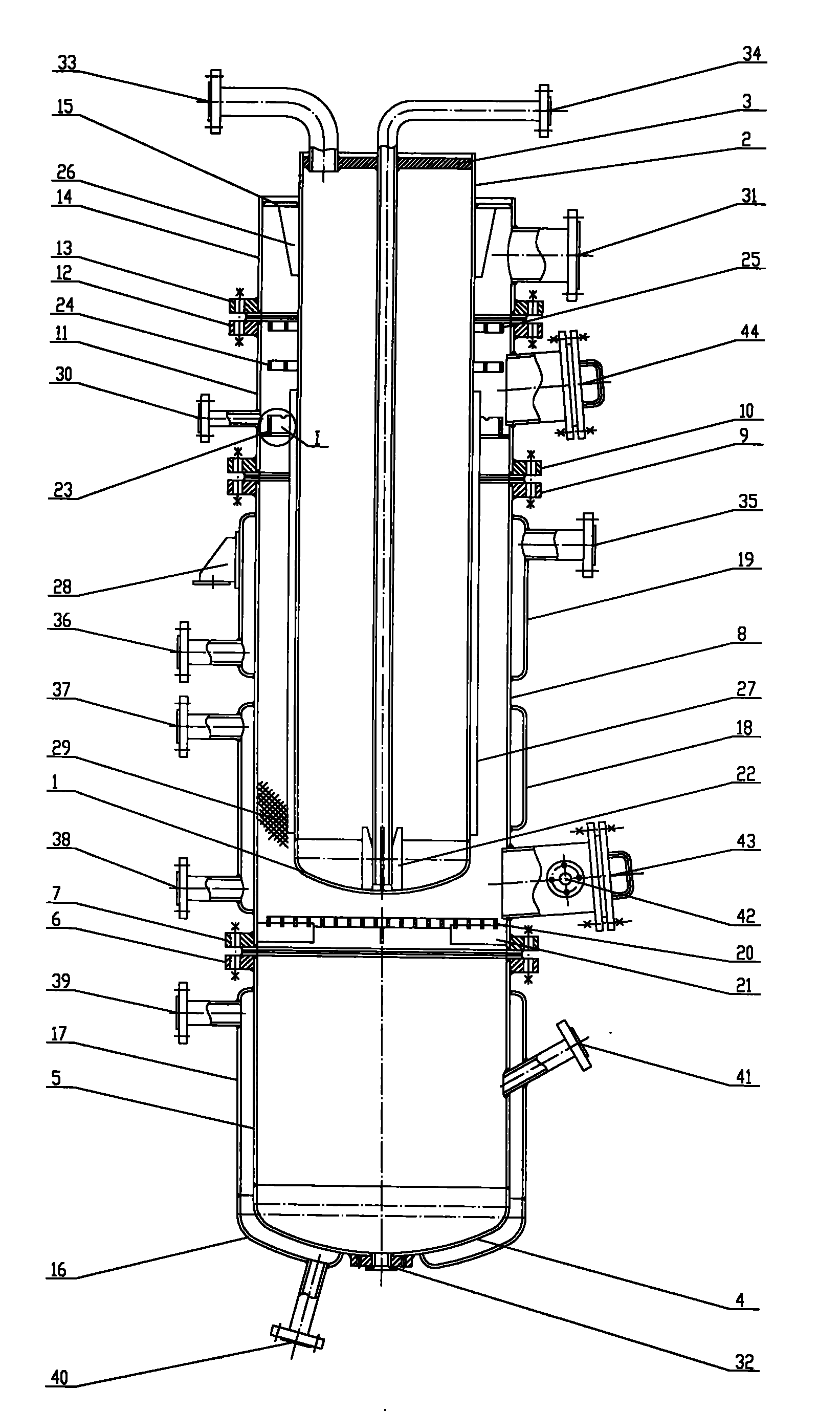

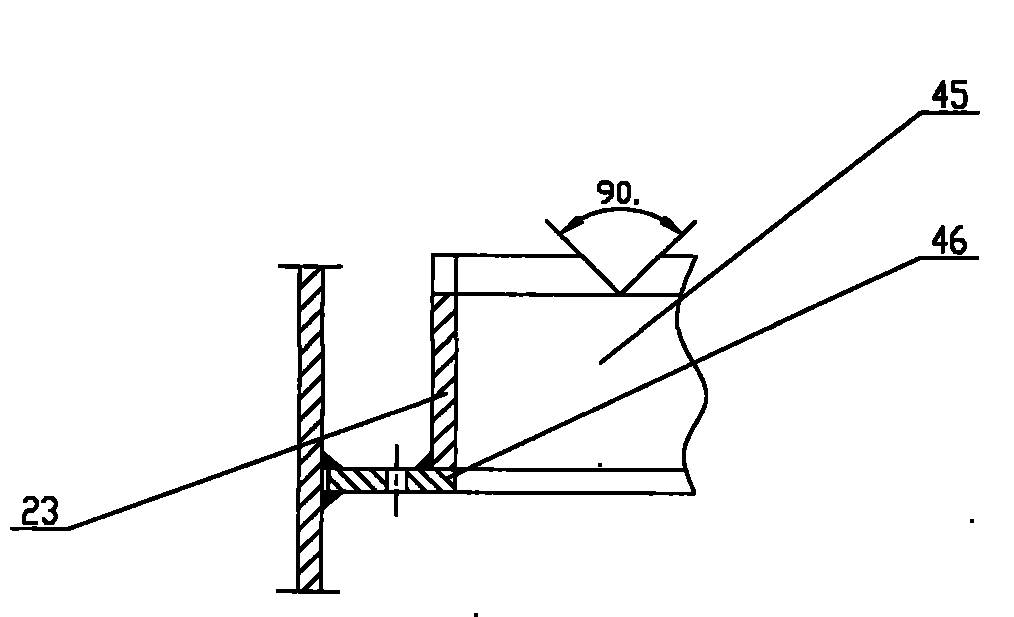

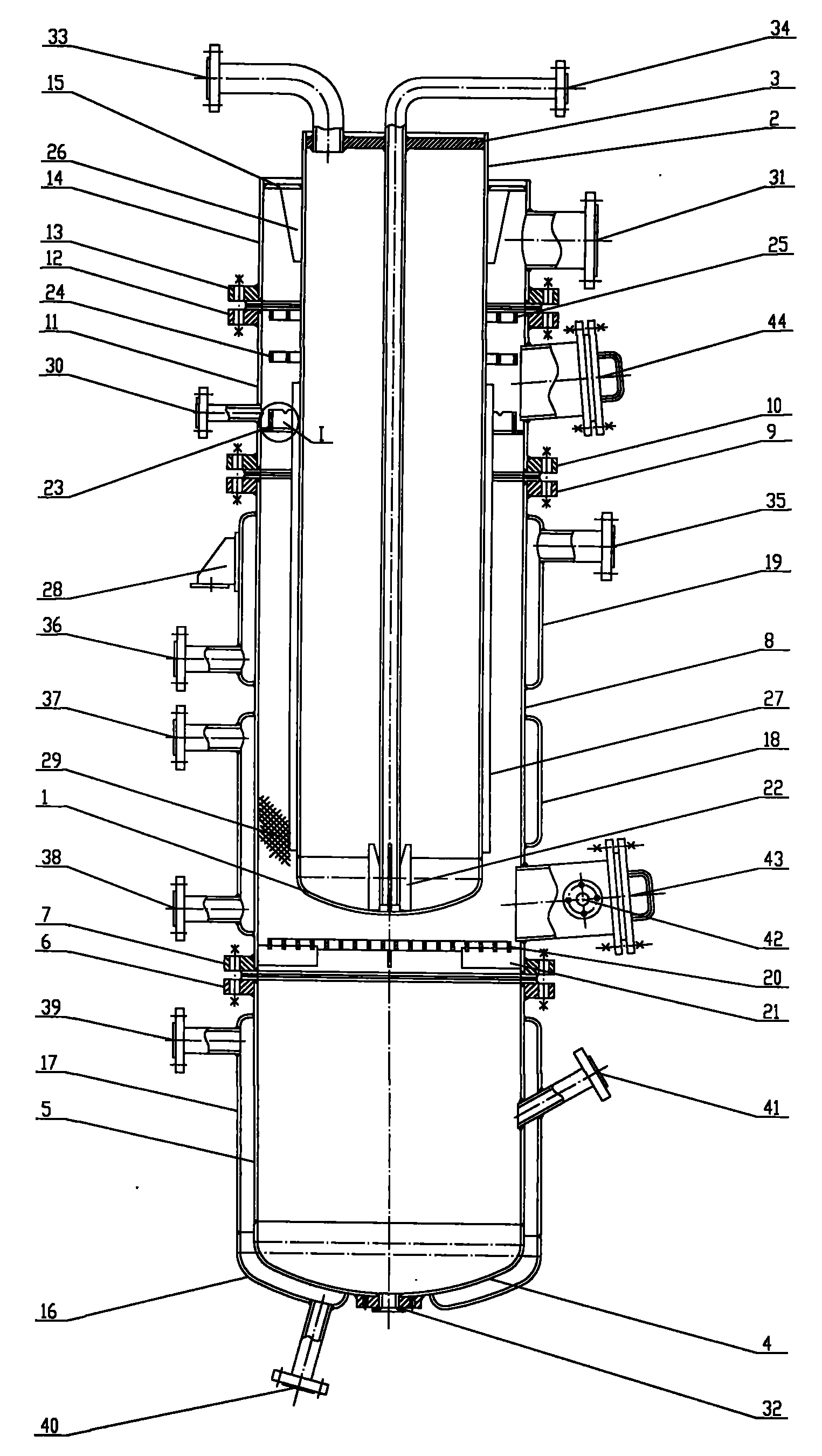

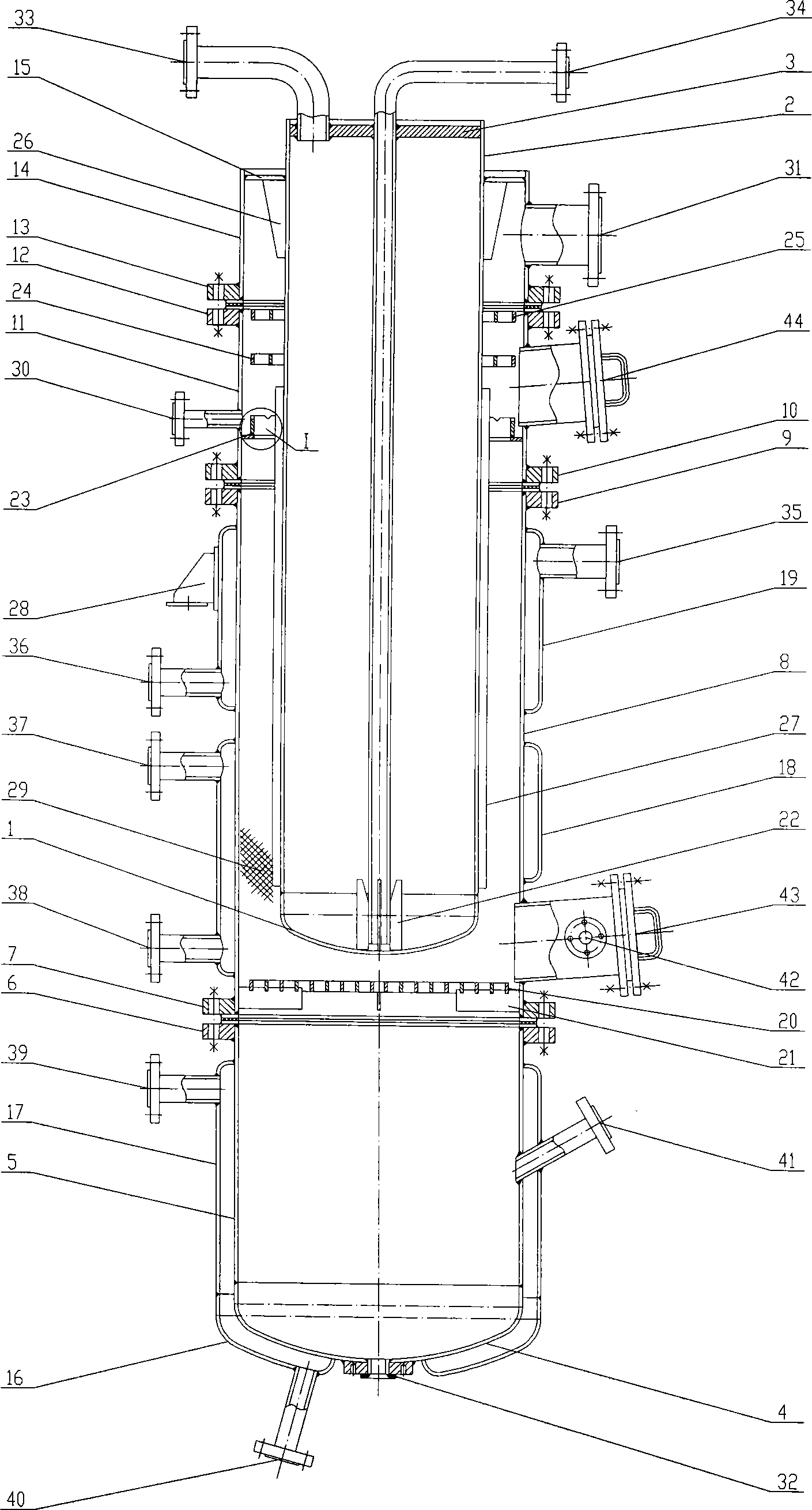

Hydrogen fluoride heater

ActiveCN101444714BImprove heat transfer effectIncrease cooling areaEvaporationChemical/physical/physico-chemical processesHydrofluoric acidHydrogen fluoride

The invention relates to a hydrogen fluoride heater. The technical proposal is as follows: a sealing end of an inner cylinder is connected with a cylinder body of the inner cylinder, the cylinder body of the inner cylinder is connected with a flat cover, a fixed stiffened plate is arranged in the sealing end of the inner cylinder, a condensate outlet pipe is extended out of the inner cylinder, a steam inlet is arranged on the flat cover, and a supporting stiffened plate, a strengthening stiffened plate and a grid are arranged out of the cylinder body of the inner cylinder; the sealing end of a container is connected with the cylinder body of the container, the cylinder body of the container is connected by a flange, and the cylinder body of the container is connected with an annular plate; the sealing end is provided with a hydrofluoric acid outlet, and the cylinder body of the container is provided with a temperature measuring port, a hand hole, a liquid inlet and a hydrogen fluoride gas outlet; the inner cylinder and the container are connected with the supporting stiffened plate by the annular plate; the supporting stiffened plate is arranged in the cylinder body of the container, a packing supporting ring is arranged on the supporting stiffened plate, a packing Raschig ring is filled between the cylinder body of the container and the cylinder body of the inner cylinder on the packing supporting ring, and a distributor is arranged on the inner wall of the cylinder body of the container; the sealing end of a jacket is connected with the cylinder body of the jacket, the cylinder body of the jacket is connected with the cylinder of the container, and the steam inlet and a steam outlet are arranged on the cylinder body of the jacket. The hydrogen fluoride heater has low cost and good heat exchange effect.

Owner:沈阳东方钛业股份有限公司

Composite pipe concrete composite structure

InactiveCN102936941BReduce design thicknessHigh yield loadStrutsPillarsReinforced concretePre stress

The invention relates to a composite pipe concrete composite structure which is characterized in that the structure comprises internal concrete (1), a steel pipe (2), transverse pre-stressed steel wires (3), and a fiber-reinforced plastic material (4). According to the invention, through applying pre-stress to the steel wires, the pre-stressed steel wires (3) are transversally continuously and uniformly wound on the outer wall of the steel pipe (2). The fiber-reinforced plastic material (4) is adhered to the outer surface of the transverse pre-stressed steel wires (3) on the outer layer. The internal concrete (1) is filled in the steel pipe (2). The winding pitches between the transverse pre-stressed steel wires (3) are no larger than 40mm. With the structure provided by the invention, defects of commonly known steel pipe concrete and FRP-steel composite pipe concrete structures are overcome, and advantages such as high yield load, large bearing capacity storage, good ductility, moderate failure mode, good durability, and the like are provided. Especially, the structure has stable and continuous decline stage and low cost. The structure provide by the invention is suitable to be used in piles, columns, bridge piers, and arch ribs in newly built structures, and can be used in reinforcement of mainly compressed members in existing reinforced concrete structures and steel pipe concrete structures.

Owner:NANJING FORESTRY UNIV +2

Hydrogen fluoride heater

ActiveCN101444714AImprove heat transfer effectIncrease cooling areaEvaporationChemical/physical/physico-chemical processesHydrofluoric acidHydrogen fluoride

The invention relates to a hydrogen fluoride heater. The technical proposal is as follows: a sealing end of an inner cylinder is connected with a cylinder body of the inner cylinder, the cylinder body of the inner cylinder is connected with a flat cover, a fixed stiffened plate is arranged in the sealing end of the inner cylinder, a condensate outlet pipe is extended out of the inner cylinder, a steam inlet is arranged on the flat cover, and a supporting stiffened plate, a strengthening stiffened plate and a grid are arranged out of the cylinder body of the inner cylinder; the sealing end of a container is connected with the cylinder body of the container, the cylinder body of the container is connected by a flange, and the cylinder body of the container is connected with an annular plate; the sealing end is provided with a hydrofluoric acid outlet, and the cylinder body of the container is provided with a temperature measuring port, a hand hole, a liquid inlet and a hydrogen fluoride gas outlet; the inner cylinder and the container are connected with the supporting stiffened plate by the annular plate; the supporting stiffened plate is arranged in the cylinder body of the container, a packing supporting ring is arranged on the supporting stiffened plate, a packing Raschig ring is filled between the cylinder body of the container and the cylinder body of the inner cylinder on the packing supporting ring, and a distributor is arranged on the inner wall of the cylinder body of the container; the sealing end of a jacket is connected with the cylinder body of the jacket, the cylinder body of the jacket is connected with the cylinder of the container, and the steam inlet and a steam outlet are arranged on the cylinder body of the jacket. The hydrogen fluoride heater has low cost and good heat exchange effect.

Owner:沈阳东方钛业股份有限公司

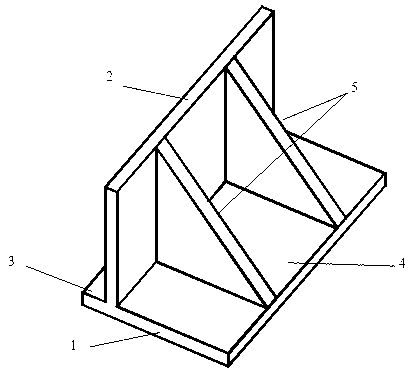

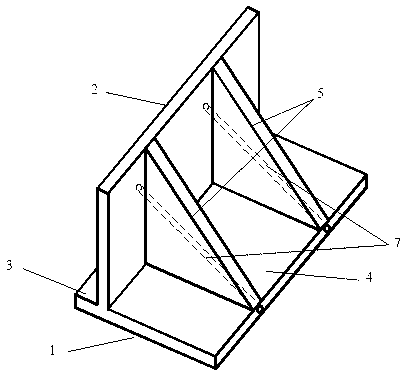

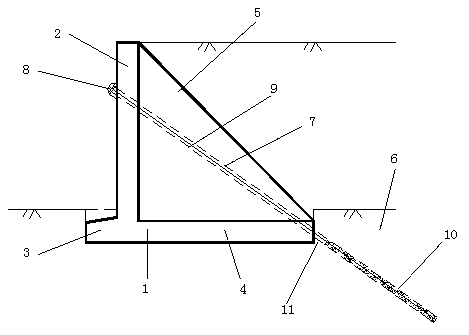

Prestress anchor cable buttress-type parapet suitable for rock substrate

ActiveCN102304927BImprove anti-overturn performanceShorten design lengthArtificial islandsUnderwater structuresButtressPre stress

The invention discloses a prestress anchor cable buttress-type parapet suitable for a rock substrate, comprising a parapet base, a parapet panel and a buttress plate, wherein the parapet panel and the buttress plate are arranged on the parapet base; the buttress plate is arranged on the inner side of the parapet panel; an inclined duct is arranged in the buttress plate; the steel strand of the prestress anchor cable passes through a PVC (Polyvinyl Chloride) pipe in the inclined duct; an included angle between the inclined duct and a horizontal plane is 15-45 degrees; one end of the steel strand is connected with the anchor head of the prestress anchor cable on the outer side of the parapet panel; the anchor head is fixed on the outer side of the parapet panel by an anchor head mad pillar; and the other end of an anchor cable steel strand extends into a rock foundation drilling hole below the rear side of a parapet heel slab. In the prestress anchor cable buttress-type parapet, the prestress anchor cable is effectively combined with the buttress-type parapet, and the prestress anchor cable built in the buttress plate can be used for increasing the strength of the buttress plate. In addition, the parapet base, the parapet panel, the parapet plate and the rock substrate are tightly combined, and the limit skidding resistance force and topple resistance performance of the buttress-type parapet are improved.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com