Processing method of low yield ratio high strength titanium coiled plate for heat exchanger

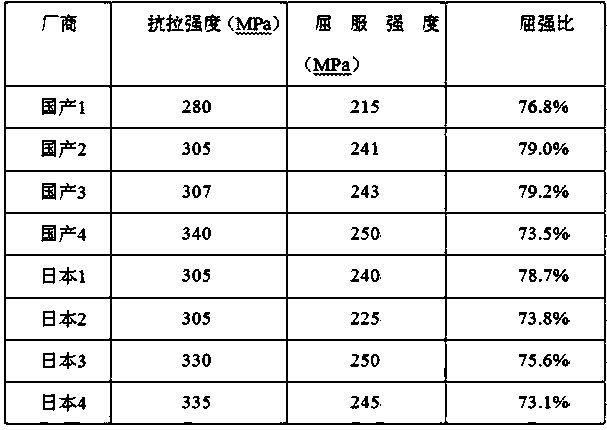

A processing method and low yield-strength ratio technology, which are applied in the field of processing titanium coils for high-strength heat exchangers, can solve the problems of tensile strength not higher than 340MPa, low yield-strength ratio, etc., and achieve excellent deep-drawing performance and yield strength. The effect of lower ratio and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

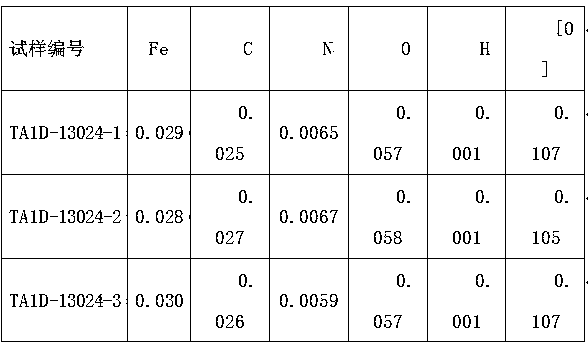

[0036] 1) Slab preparation: Grade 1 sponge titanium with a Brinell hardness of 105HB is selected. The test results of the sponge titanium composition are Fe=0.034%, C=0.02%, O=0.05%, N=0.007%, and oxygen equivalent [O]=0.05 %+0.5×0.034%+0.7×0.02%+2.5×0.007%≌0.099%. According to the experience of smelting pure titanium ingots in an electron beam cooling bed, the oxygen content of ingots is about 0.01% higher than that of sponge titanium, and the content of Fe, C, and N impurity elements will basically not increase during the smelting process. The composition of the smelted titanium ingots meets: the O content is 0.05-0.08%, the Fe content is not more than 0.05%, the C content is not more than 0.03%, the N content is not more than 0.01%, and the oxygen equivalent is between 0.10-0.13%. Smelting ingot according to [004]~[016] section described in patent document 1, 500mm from the head and tail of the ingot and sampling test in the middle of the ingot, the chemical composition tes...

Embodiment 2

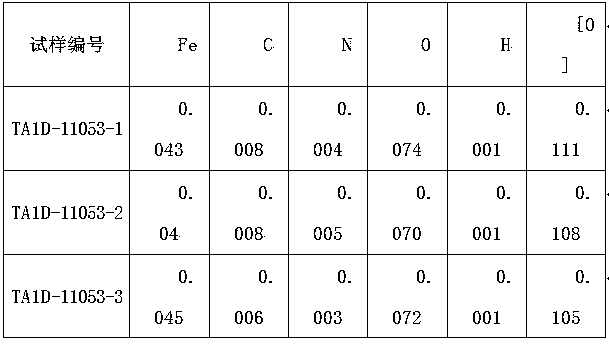

[0045] 1) Slab preparation: Grade 0 sponge titanium with a Brinell hardness of 98HB is selected. The test results of the sponge titanium composition are Fe=0.04%, C=0.008%, O=0.042%, N=0.004%, and oxygen equivalent [O]=0.042 %+0.5×0.04%+0.7×0.008%+2.5×0.004%≌0.078%. According to the experience of smelting pure titanium ingots in electron beam cooling bed, the oxygen content of cast ingots is about 0.01% higher than that of sponge titanium, and the content of Fe, C, and N impurity elements will basically not increase during the smelting process. The composition of titanium ingots after smelting must meet: O The content is 0.05-0.08%, the oxygen equivalent is between 0.10-0.13%, and titanium dioxide needs to be added. The oxygen equivalent is designed according to the target value of 0.115, and the added oxygen value of titanium dioxide is 0.115%-0.01%-0.078%=0.027%. After calculation, the weight of titanium dioxide added to 100 kg of titanium sponge is m=0.027÷0.45×1000=60g. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com